A kind of preparation method of acetylated distarch adipate starch

A technology for acetylating distarch and adipate, applied in the field of starch production, can solve the problems of poor stability, inability to accurately determine the addition amount and effective amount, toxicity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

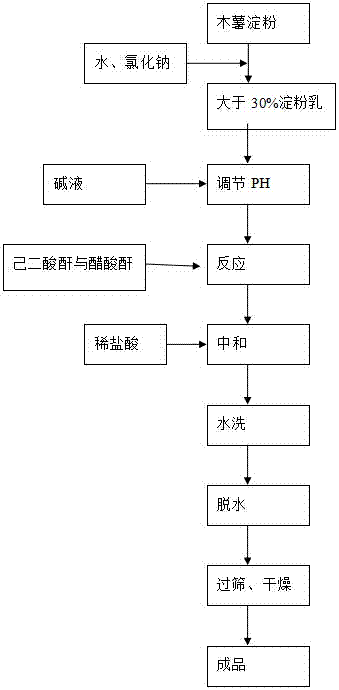

[0017] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0018] Such as figure 1 Shown, a kind of preparation method of acetylated distarch adipate starch comprises the following steps:

[0019] Step 1, put 1000 units of cassava starch into a reaction tank, add water and stir to prepare starch milk with a concentration greater than 30%. Too much reaction medium will dilute the reagent and reduce the reaction rate. If there is too little reaction medium, the starch milk will not stir. Easy to precipitate, and the reaction is uneven after the reagent is added;

[0020] Step 2, when the tapioca starch is mixed with water, 50 to 80 units of mass sodium chloride can be added, which is mainly used to improve the gelatinization temperature of the starch, and can also inhibit the swelling of the starch granules;

[0021] Step 2: Stir the starch milk. During the stirring process, lye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com