Method for preparing polyimide fibers

A technology of polyimide fiber and polyamic acid, which is applied in the direction of fiber chemical characteristics, single-component synthetic polymer rayon, textiles and papermaking, can solve the problems of poor movement ability of rigid macromolecules and unfavorable fiber properties, etc. Achieve the effects of improving mechanical properties, less environmental pollution, and increasing crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

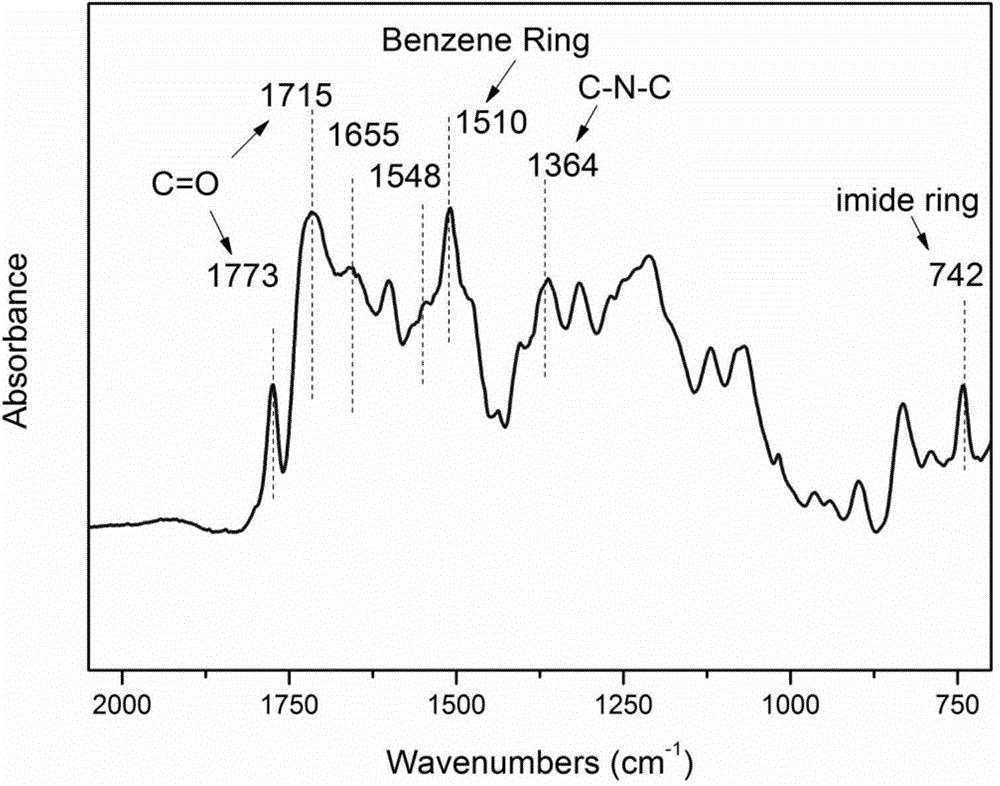

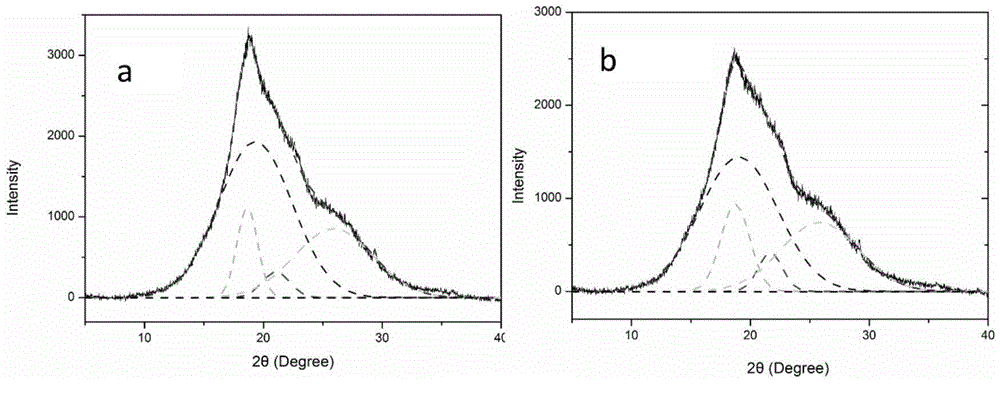

[0047] Synthesis of polyamic acid solution: according to the molar ratio of BPDA: ODPA: p-PDA = 7:3:10, put the diamine p-PDA into a three-necked flask, and add a measured amount of solvent N,N-dimethyl Acetamide (DMAc) was stirred under nitrogen to fully dissolve it, then BPDA and ODPA were mixed evenly and then added in batches and stirred so that the solid content of the solution was 15%. Stirring for 3 hours under the condition of nitrogen protection, the polyamic acid spinning solution with a certain viscosity was obtained, and its intrinsic viscosity was 2.86dL / g.

[0048] Synthesis of partially imidized polyamic acid solution: According to the ratio of 0.6:1 molar ratio of acetic anhydride and diamine, mix acetic anhydride and pyridine (molar ratio is 2:1) and add to the above polyamic acid In the solution, react for 3 hours to obtain a partially imidized polyamic acid solution with an intrinsic viscosity of 2.03 dL / g.

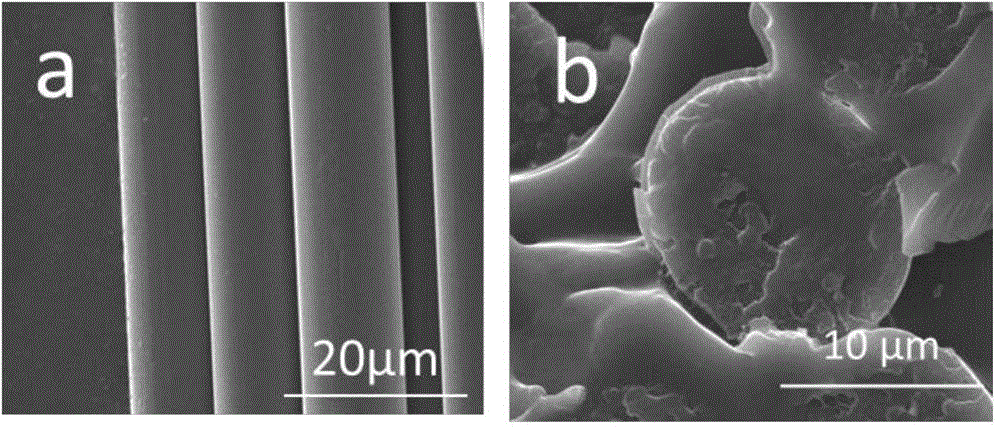

[0049] Preparation of polyamic acid fiber: filte...

Embodiment 2

[0055]Synthesis of polyamic acid solution: according to the molar ratio of BPDA:p-PDA=1:1, put the diamine p-PDA into a three-necked flask, and add a measured amount of solvent N,N-dimethylformamide (DMF ), stirred under nitrogen conditions to fully dissolve, then added BPDA in batches and stirred so that the solid content of the solution was 10%. Stirring for 5 hours under the condition of nitrogen protection, the polyamic acid spinning solution with certain viscosity was obtained, and its intrinsic viscosity was 2.56dL / g.

[0056] Synthesis of partially imidized polyamic acid solution: According to the molar ratio of acetic anhydride and diamine is 0.4:1, mix acetic anhydride and triethylamine (molar ratio is 1:1) and add to the above polyamic acid In the amic acid solution, react for 4 hours to obtain a partially imidized polyamic acid solution with an intrinsic viscosity of 1.95 dL / g.

[0057] Preparation of polyamic acid fiber: filter and defoam the polyamic acid solutio...

Embodiment 3

[0061] Synthesis of polyamic acid solution: according to the molar ratio of BPDA:p-PDA:ODA=10:5:5, put the diamine p-PDA and ODA into a three-necked flask, and add a measured amount of solvent dimethyl sulfoxide (DMSO), stirred under the condition of nitrogen to make it fully dissolved, then added BPDA in batches and stirred, so that the solid content of the solution was 20%. The mixture was stirred for 4 hours under the protection of nitrogen to obtain a polyamic acid spinning solution with a certain viscosity, and its intrinsic viscosity was 2.77dL / g.

[0062] Synthesis of partially imidized polyamic acid solution: According to the ratio of 0.8:1 molar ratio of acetic anhydride and diamine, mix acetic anhydride and pyridine (molar ratio is 4:1) and add to the above polyamic acid In the solution, react for 2.5 hours to obtain a partially imidized polyamic acid solution with an intrinsic viscosity of 2.15 dL / g.

[0063] Preparation of polyamic acid fiber: filter and defoam th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com