Preparation technology of acetylated distarch adipate

A technology for acetylated distarch and adipate, which is applied in the field of preparation of acetylated distarch adipate, can solve the problems of starch thermal paste stability, difference in viscosity, etc., and achieves enhanced shear resistance and improved Shear resistance, the effect of improving cross-linking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

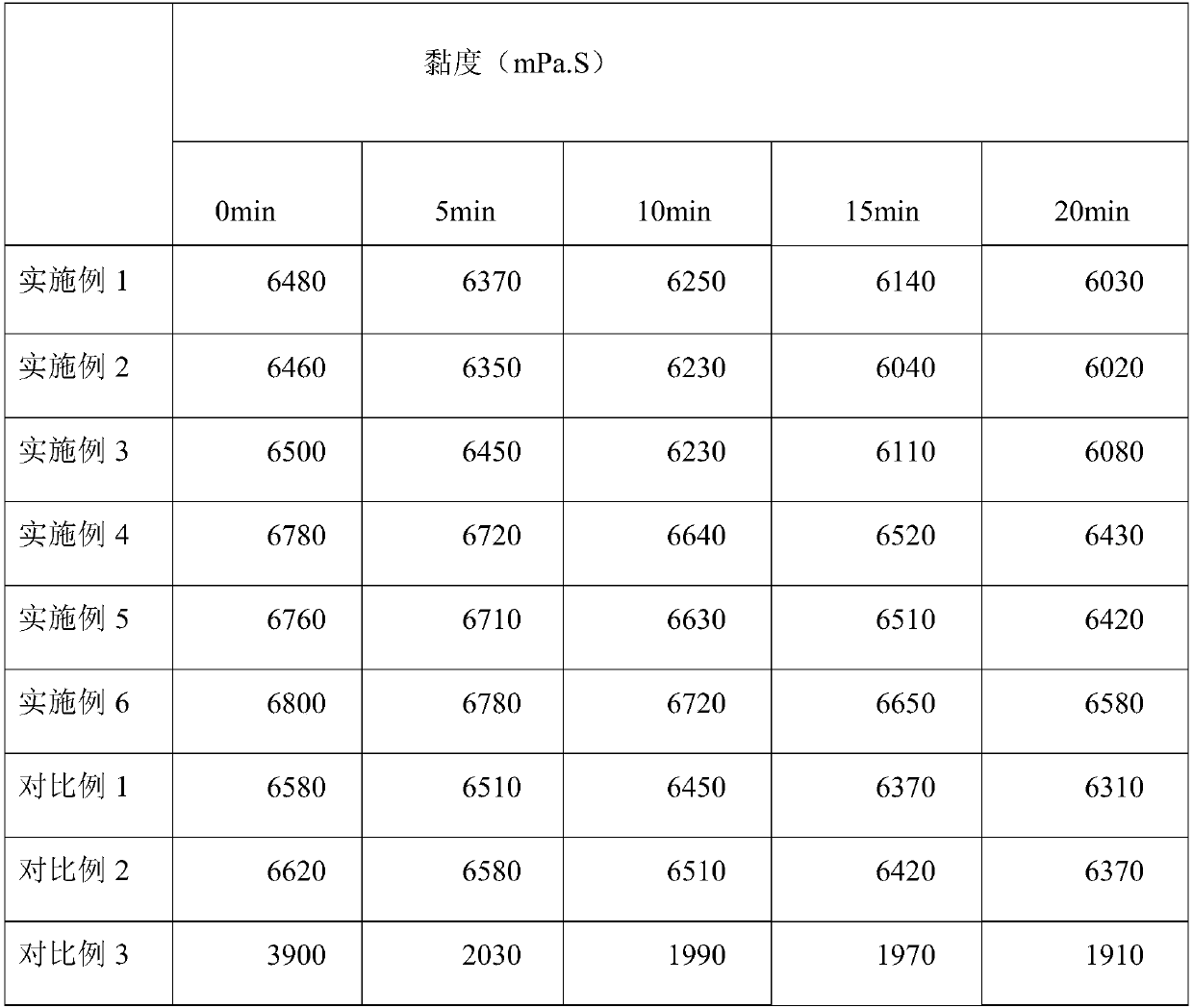

Examples

Embodiment 1

[0024] A kind of preparation technology of acetylated distarch adipate, comprises the following steps:

[0025] Inject the process water into the feeding tank, put in the original starch, adjust the concentration of the starch milk to 18 degrees Baume, beat the adjusted starch slurry into the reaction tank; adjust the pH value to 7.8 with a dilute alkali solution, and add no more than the mass fraction of starch on a dry basis 0.12% adipic acid is reacted with acetic anhydride not exceeding 8% of starch dry basis mass fraction, and the addition rate of acetic anhydride is 200L / h. Washing in a disc centrifuge, the conductivity of the starch milk after washing is ≤3000μs / cm, then dehydrating with a scraper, and then drying in an airflow dryer, the drying tail air temperature is 55°C, the moisture content of the dried product is <18%, and then sieved to Fineness ≥ 99.0%, then package the finished product, the net weight of the finished product is 25kg, and then put it into storag...

Embodiment 2

[0027] A kind of preparation technology of acetylated distarch adipate, comprises the following steps:

[0028] Pour the process water into the feeding tank, put in the original starch, adjust the concentration of the starch milk to 27 degrees Baume, beat the adjusted starch slurry into the reaction tank; adjust the pH value to 9.5 with a dilute alkali solution, and add no more than the starch dry basis mass fraction 0.12% adipic acid is reacted with acetic anhydride not exceeding 8% of starch dry basis mass fraction, and the addition rate of acetic anhydride is 350L / h. Washing in a disc centrifuge, the conductivity of the starch milk after washing is ≤3000μs / cm, then dehydrating with a scraper, and then drying in an airflow dryer, the drying tail air temperature is 55°C, the moisture content of the dried product is <18%, and then sieved to Fineness ≥ 99.0%, then package the finished product, the net weight of the finished product is 25kg, and then put it into storage.

Embodiment 3

[0030] A kind of preparation technology of acetylated distarch adipate, comprises the following steps:

[0031] Inject the process water into the feeding tank, put in the original starch, adjust the concentration of the starch milk to 22.5 degrees Baume, beat the adjusted starch slurry into the reaction tank; adjust the pH value to 8.7 with a dilute alkali solution, and add no more than the starch dry basis mass fraction 0.12% adipic acid is reacted with acetic anhydride not exceeding 8% of starch dry basis mass fraction, and the addition rate of acetic anhydride is 275L / h. Washing in a disc centrifuge, the conductivity of the starch milk after washing is ≤3000μs / cm, then dehydrating with a scraper, and then drying in an airflow dryer, the drying tail air temperature is 55°C, the moisture content of the dried product is <18%, and then sieved to Fineness ≥ 99.0%, then package the finished product, the net weight of the finished product is 25kg, and then put it into storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com