High performance aging resistant cable sheath material

A cable sheathing and resistant technology, used in insulated cables, cables, circuits, etc., can solve problems such as a large amount of smoke and hydrogen halide gas, secondary disasters, etc., achieve slow aging degradation, excellent heat and flame retardant effect, and oil resistance. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

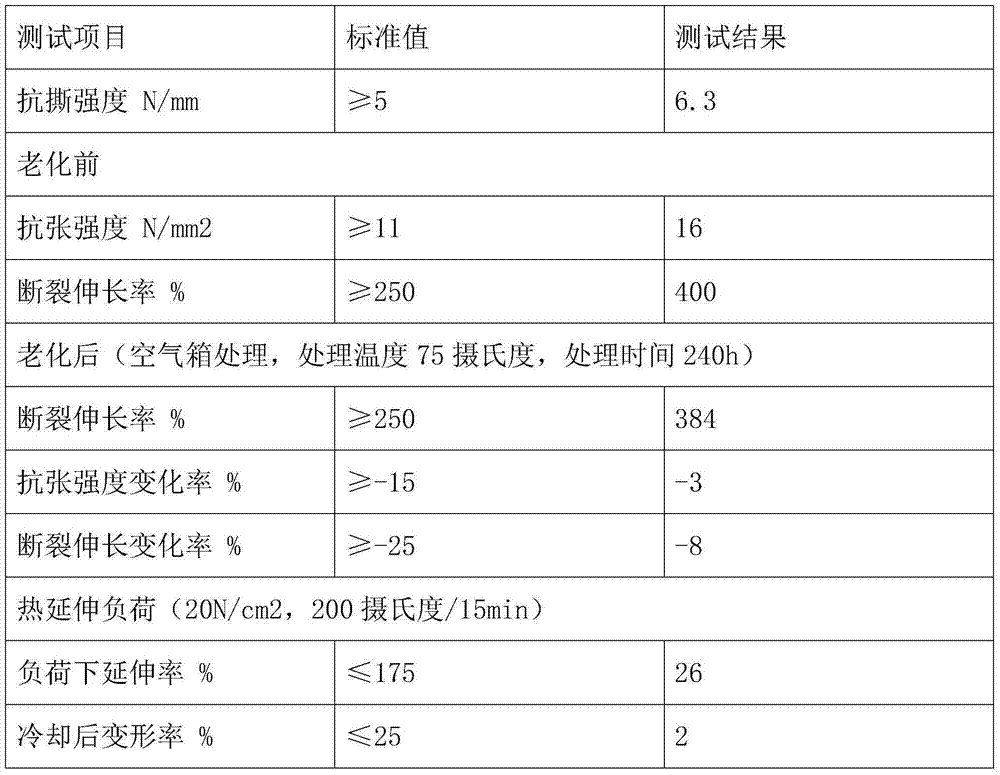

Examples

Embodiment 1

[0013] In this embodiment, the raw materials of a high-performance aging-resistant cable sheath material include by weight:

[0014] 40 parts of chlorinated polyethylene 135B, 19 parts of chlorosulfonated polyethylene, 2.3 parts of magnesium oxide, 5.5 parts of dioctyl phthalate, 7 parts of chlorinated paraffin, 25 parts of white carbon black, 0.8 parts of rare earth stabilizer, lead salt 0.55 parts of composite stabilizer, 2.5 parts of antimony trioxide, 11 parts of zinc borate, 3.6 parts of trichloroethyl phosphate, 9 parts of carbon black N7709, 19 parts of calcium carbonate, surfactant γ-mercaptopropyltriethoxysilane 0.85 parts, vulcanizing agent dicumyl peroxide 1.25 parts, co-curing agent triallyl isocyanurate 0.9 parts; Mooney viscosity (ML1+40100°C) of chlorosulfonated polyethylene is 72, chlorine content is 26.2%, and the sulfur content is 1.32%.

Embodiment 2

[0016] In this embodiment, the raw materials of a high-performance aging-resistant cable sheath material include by weight:

[0017] 33 parts of chlorinated polyethylene 135B, 18 parts of chlorosulfonated polyethylene, 1.8 parts of magnesium oxide, 5.2 parts of dioctyl phthalate, 7.2 parts of chlorinated paraffin, 24 parts of white carbon black, 0.85 parts of rare earth stabilizer, lead salt 0.52 parts of composite stabilizer, 4.5 parts of antimony trioxide, 10.6 parts of zinc borate, 3.5 parts of trichloroethyl phosphate, 11 parts of carbon black N7701, 18 parts of calcium carbonate, surfactant γ-mercaptopropyltriethoxysilane 0.85 parts, vulcanizing agent dicumyl peroxide 1.25 parts, co-curing agent triallyl isocyanurate 0.62 parts; Mooney viscosity (ML1+40100°C) of chlorosulfonated polyethylene is 72, chlorine content is 25.5%, and the sulfur content is 1.32%.

Embodiment 3

[0019] In this embodiment, the raw materials of a high-performance aging-resistant cable sheath material include by weight:

[0020] 37 parts of chlorinated polyethylene 135B, 16 parts of chlorosulfonated polyethylene, 2.6 parts of magnesium oxide, 5 parts of dioctyl phthalate, 7 parts of chlorinated paraffin, 28 parts of white carbon black, 0.65 parts of rare earth stabilizer, lead salt 0.42 parts of composite stabilizer, 4.7 parts of antimony trioxide, 9.5 parts of zinc borate, 3.3 parts of trichloroethyl phosphate, 10.5 parts of carbon black N770, 18.5 parts of calcium carbonate, surfactant γ-mercaptopropyl triethoxy 0.85 parts of base silane, 1.25 parts of dicumyl peroxide as a vulcanizing agent, and 0.72 parts of triallyl isocyanurate as a vulcanizing agent; the Mooney viscosity (ML1+40100°C) of chlorosulfonated polyethylene is 72, The chlorine content is 26.4% and the sulfur content is 1.35%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com