Water-based fireproof coating and preparation method thereof

A fire-resistant coating, water-based technology, applied in the direction of fire-resistant coatings, coatings, etc., can solve problems such as poor waterproof ability of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

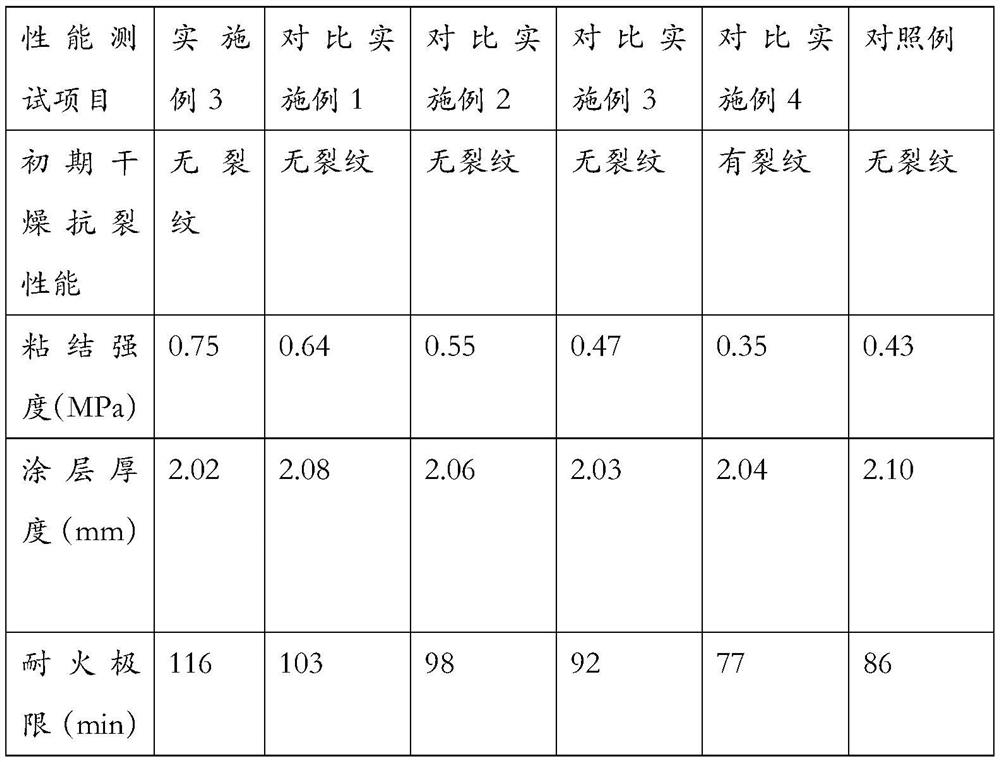

Examples

Embodiment 1

[0025] A water-based fireproof coating, comprising the following substances in corresponding parts by weight: 25 parts of vinegar-acrylic emulsion, 6 parts of silicone resin, 4 parts of alumina fiber, 2 parts of thickener, 0.5 part of defoamer, 1 part of silane coupling agent , 3 parts of ammonium polyphosphate, 2 parts of potassium tripolyphosphate, 1 part of paraformaldehyde, 7 parts of compound modified filler, 80 parts of deionized water.

[0026] The thickener is microcrystalline cellulose; the defoamer is mineral oil; and the silane coupling agent is silane coupling agent kh550.

[0027] The preparation method of described composite modified filler comprises the steps:

[0028] 1) Put the diatomite into the calciner for calcining treatment, and take it out after 1.5h;

[0029] 2) Put the diatomite into the irradiation box for irradiation treatment, and take it out after 25 minutes;

[0030] 3) Mix diatomaceous earth, zinc acetate dihydrate, sodium hydroxide solution, n...

Embodiment 2

[0038] A water-based fireproof coating, comprising the following substances in corresponding parts by weight: 28 parts of vinegar-acrylic emulsion, 8 parts of silicone resin, 6 parts of alumina fiber, 3 parts of thickener, 0.8 part of defoamer, 2 parts of silane coupling agent , 4 parts of ammonium polyphosphate, 4 parts of potassium tripolyphosphate, 3 parts of paraformaldehyde, 8 parts of compound modified filler, 83 parts of deionized water.

[0039] The thickener is microcrystalline cellulose; the defoamer is mineral oil; and the silane coupling agent is silane coupling agent kh570.

[0040] The preparation method of described composite modified filler comprises the steps:

[0041] 1) put the diatomite into the calciner for calcining treatment, and take it out after 1.8h;

[0042] 2) Put the diatomite into the irradiation box for irradiation treatment, and take it out after 30 minutes;

[0043] 3) Mix diatomaceous earth, zinc acetate dihydrate, sodium hydroxide solution,...

Embodiment 3

[0051]A water-based fireproof coating, comprising the following substances in corresponding parts by weight: 30 parts of vinegar-acrylic emulsion, 10 parts of silicone resin, 7 parts of alumina fiber, 4 parts of thickener, 1 part of defoamer, 3 parts of silane coupling agent , 5 parts of ammonium polyphosphate, 5 parts of potassium tripolyphosphate, 4 parts of paraformaldehyde, 10 parts of compound modified filler, 85 parts of deionized water.

[0052] The thickener is microcrystalline cellulose; the defoamer is mineral oil; and the silane coupling agent is silane coupling agent kh570.

[0053] The preparation method of described composite modified filler comprises the steps:

[0054] 1) Put the diatomite into the calciner for calcining treatment, and take it out after 2 hours;

[0055] 2) Put the diatomite into the irradiation box for irradiation treatment, and take it out after 35 minutes;

[0056] 3) Mix diatomaceous earth, zinc acetate dihydrate, sodium hydroxide solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com