Patents

Literature

98 results about "Trichloroethyl Phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High temperature resistant conveyor belt

ActiveCN102275712AImprove adhesionGood burning resistanceConveyorsNatural rubber adhesivesEthylene-propylene-diene-monomerMetallic materials

The invention provides a high-temperature resistant conveyer belt which comprises a framework layer and a covering glue layer which covers the surface of the framework layer, wherein the framework layer is made of a metal material; the covering glue layer is mainly made of ethylene propylene diene monomer rubber and chloroprene rubber and is added with a fire retardant agent, trichloroethyl phosphate, a binding agent and a binding improver apart from a main cross-linking agent, an auxiliary cross-linking agent, an activating agent, an anti-aging agent, a reinforcing agent, a dispersing agent and a softening agent, wherein the binding agent comprises phenolic resin and hexakis(methoxymethyl)melamine; and the binding improver comprises maleic anhydride complexing butadiene and liquid natural rubber. The high-temperature resistant conveyer belt provided by the invention can be used at a temperature of 300 DEG C and has good firing bonding performance and firing resistant performance.

Owner:YANKUANG GRP CO LTD +1

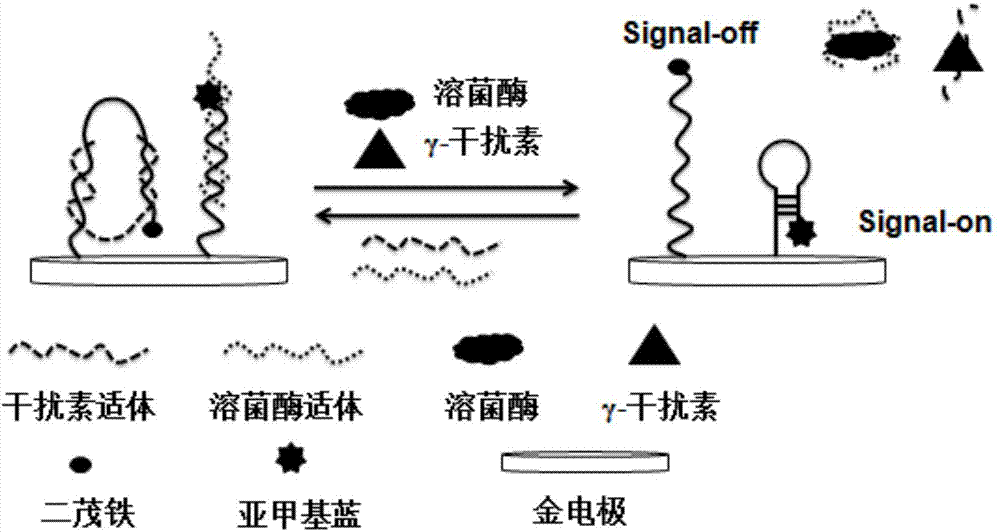

Preparation method and application of electrochemical sensor capable of simultaneously detecting two acute leukemia markers

ActiveCN103940872AAchieving High Sensitivity DetectionHigh selectivityMaterial electrochemical variablesTear lysozymeAcute leukemia

The invention discloses a preparation method of an electrochemical sensor capable of simultaneously detecting two acute leukemia markers. The method comprises the following steps: respectively standing a lysozyme report probe and a gamma-interferon report probe in a liquid containing trichloroethyl phosphate (TCEP), so as to open a disulfide bond and respectively form a double-chain structure together with a lysozyme aptamer and a gamma-interferon aptamer; preprocessing a gold electrode, and immersing the processed gold electrode into the pre-processed mixed liquid of lysozyme report probe-aptamer double chains and gamma-interferon report probe-aptamer double chains; standing at room temperature over the night, and then cleaning by using secondary distilled water and a cleanout fluid; immersing the electrode into the liquid containing MCH to seal the electrode, and then cleaning the secondary distilled water and the cleanout fluid; and taking the electrode processed by the above steps as a work electrode to be connected on a chemical work station together with a reference electrode and a counter electrode, so as to obtain the electrochemical sensor. The electrochemical sensor can be applied to simultaneous detection of two acute leukemia markers, namely lysozyme and gamma-interferon.

Owner:QINGDAO UNIV

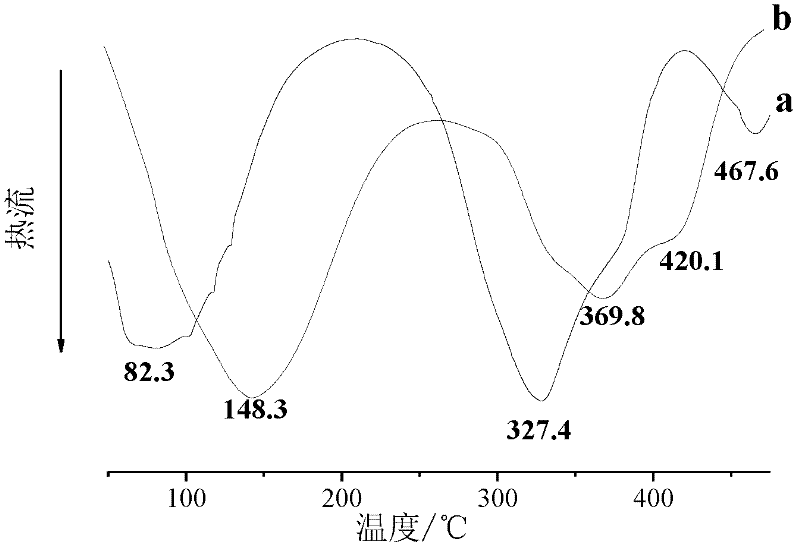

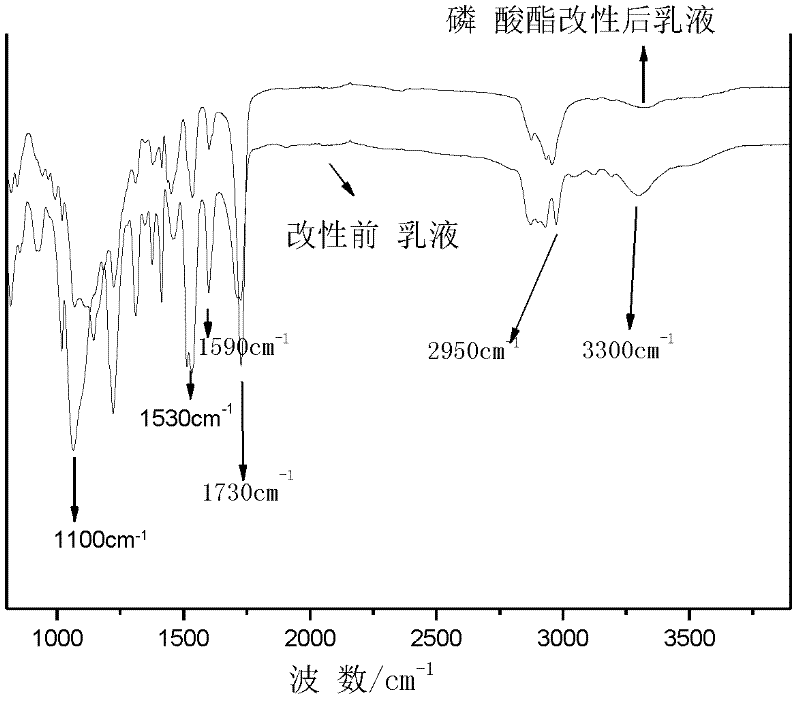

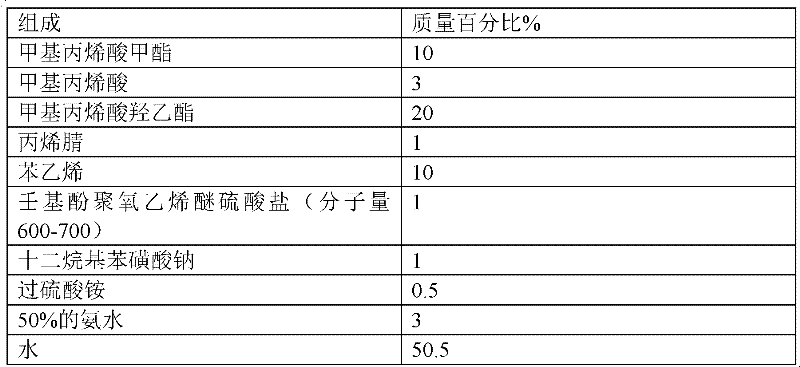

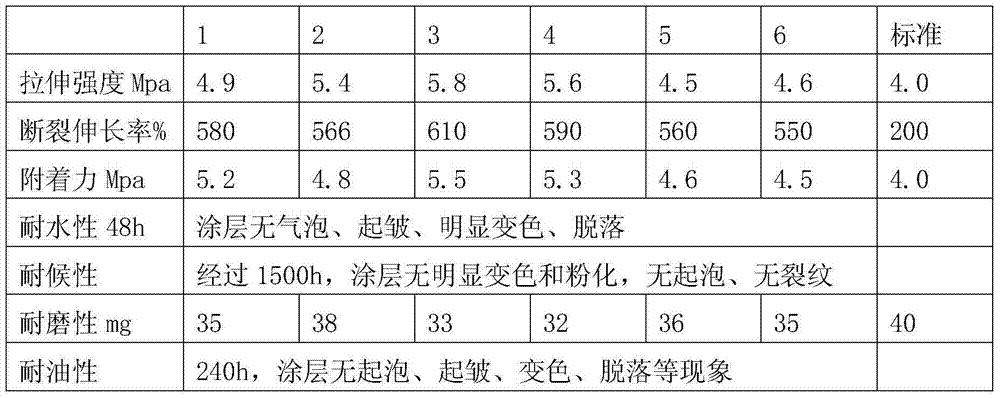

Preparation method of phosphate modified acrylate emulsion

The invention relates to a preparation method of phosphate modified acrylate emulsion. The preparation method not only has relatively low cost, but also can effectively improve the flame retardation property of polyacrylate emulsion. The preparation method of phosphate modified acrylate emulsion comprises the following steps of: (1) primary polymerization: pre-emulsifying 10-20 parts of methyl methacrylate, 2-3 parts of methacrylic acid, 1-2 parts of acrylonitrile and 10-15 parts of styrene, then performing primary emulsion polymerization, and adjusting the pH value to obtain the primary polymerized emulsion; and (2) secondary polymerization: pre-emulsifying 30-45 parts of hydroxyl methacrylate substance, then adding the pre-emulsified product and 5-10 parts of phosphate monomer into the primary polymerized solution, and performing secondary emulsion polymerization to obtain the phosphate modified acrylate emulsion with a core-shell structure, wherein the phosphate monomer is trichloroethyl phosphate, trichloropropyl phosphate or n-ethyl phosphate; the molecular weight of polymer in the obtained phosphate modified acrylate emulsion is 2000-3000; and the particle size is 0.2-0.6 mum.

Owner:JIANGSU SOBUTE NEW MATERIALS

Expansive fire-retardant paint

InactiveCN103122173AStrong weather resistanceStrong light resistanceFireproof paintsCelluloseParaffin wax

The invention provides expansive fire-retardant paint which comprises the following raw materials in parts by weight: 21.0 parts of ammonium polyphosphate, 11.5 parts of pentaerythritol, 11.5 parts of melamine, 4.7 parts of titanium white, 1.0 part of 10% sodium hexametaphosphate, 3.7 parts of 3% hexamethyl cellulose, 11.2 parts of chlorinated paraffin wax, 18.2 parts of water and 7.2 parts of trichloroethyl phosphate toughened polyvinyl acetate emulsion. The paint provided by the invention is non-toxic and harmless, has zero radioactivity, is high in weather resistance and light fastness and favorable in environment-friendly adsorption capacity, and can not be decolorized when being used for a long time.

Owner:王娟

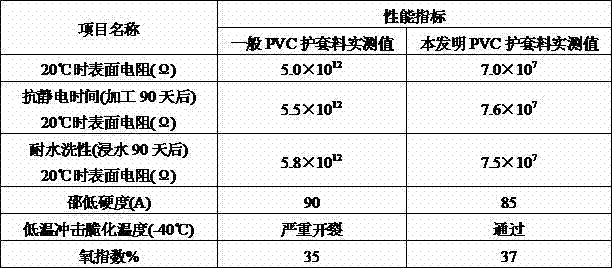

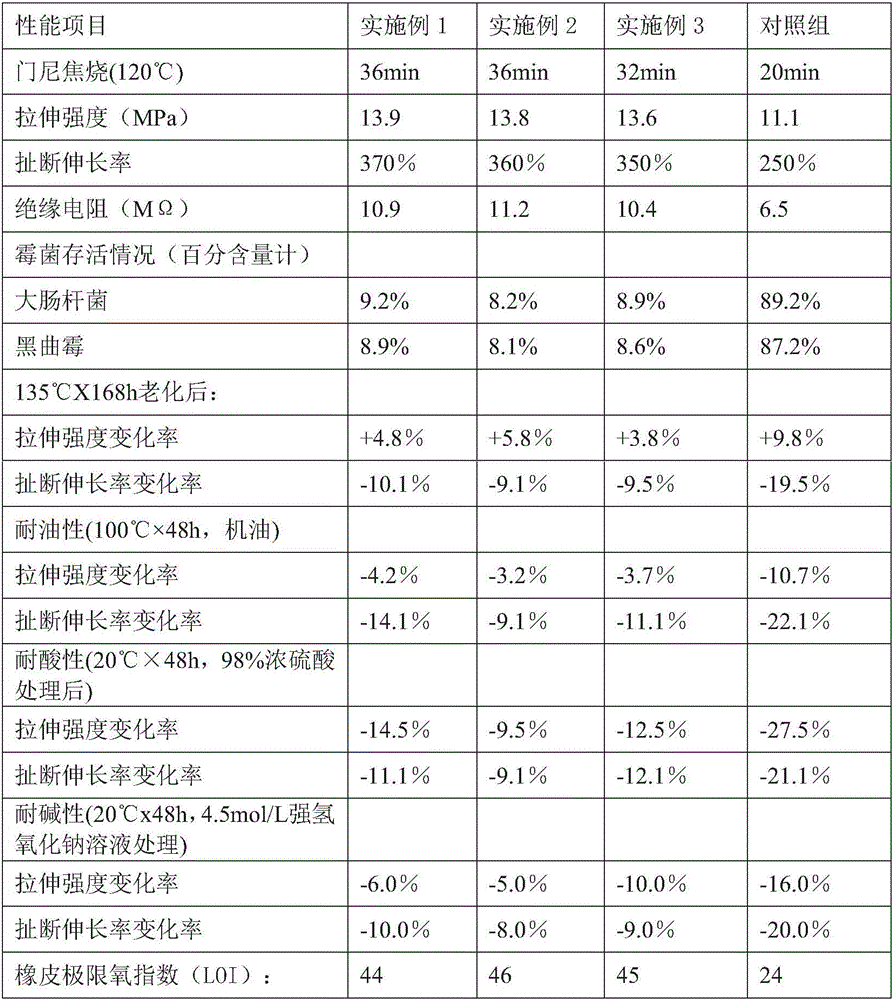

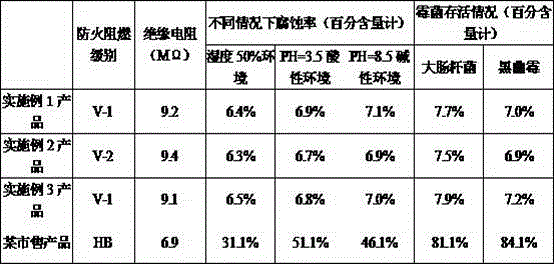

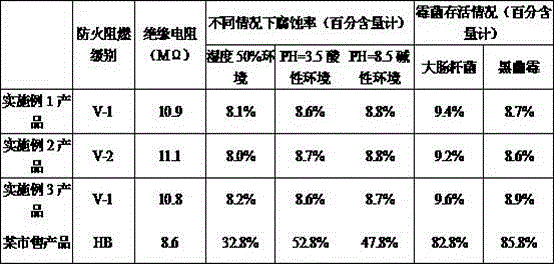

Cold-resistant flame-retardant anti-static polyvinyl chloride sheathing material for coal mine cable

ActiveCN103113692ALower surface resistance valueImprove antistatic performanceInsulated cablesInsulated conductorsPhosphatePolyvinyl chloride

The invention discloses a cold-resistance flame-retardant anti-static polyvinyl chloride sheathing material for coal mine cable; the sheathing material is characterized by consisting of the following raw materials: polyvinyl chloride resin SG3, tri(2-chloroethyl) phosphate, an anti-static agent, dioctyl sebacate, dioctyl phthalate, tricresyl phosphate, antimonous oxide, zinc borate, tribasic lead sulfate, bibasic lead sulfate, light calcium carbonate, bisphenol A, 2-mercapto benzimidazole, vinyl tri(beta-methoxyl ethyoxyl) silane, accelerant TMTD and modified asbestos powder; the polyvinyl chloride sheathing cable material provided by the invention has the following characteristics of being low in surface resistance value and high in anti-static property; by adopting the compound high-concentration anti-static agent consisting of TCEP (trichloroethyl phosphate), quaternary ammonium salt cationic surface active agent and nonionic surface active agent, the excellent anti-static synergistic effect can be brought; the surface resistance value of the sheathing material is no higher than 108ohms, and thus the sheathing material has excellent anti-static property.

Owner:安徽龙庵电缆集团有限公司

High-strength and high-flame retardation polyurethane composite heat insulation plate

InactiveCN105924942AHigh strengthImprove heat resistanceSynthetic resin layered productsEpoxyInsulation layer

The invention discloses a high-strength and high-flame retardation polyurethane composite heat insulation plate. The high-strength and high-flame retardation polyurethane composite heat insulation plate comprises two backing layers and a polyurethane heat insulation layer positioned between the two backing layers, the polyurethane heat insulation layer is made of a high-performance polyurethane foam material, and raw materials of the high-performance polyurethane foam material comprise a component A and a component B according to a weight ratio of 2:1.2-2.3; raw materials of the component A comprise polyether polyol, pentamethyldiethylenetriamine, trimethylolpropane, pentaerythritol, polyethylene glycol, an organic bismuth catalyst, cyclohexane, water, an organosilicon foaming stabilizer, amino modified carbon nanotubes, expanded perlite, hollow glass micro-beads, silicon whiskers, nanometer aluminum hydroxide, trichloroethyl phosphate, piperazine pyrophosphate, a phosphamide fire retardant, epoxy resin and polyvinyl chloride; and raw materials of the component B comprise diphenylmethane diisocyanate and hexamethylene diisocyanate.

Owner:ANHUI GUANGYAN NEW MATERIAL TECH

High performance aging resistant cable sheath material

ActiveCN103897272AGood heat resistance and flame retardant performanceExcellent ozone resistanceInsulated cablesInsulatorsSilanesLead salt

The invention discloses a high performance aging resistant cable sheath material which comprises the following raw materials in parts by weight: 30-40 parts of chlorinated polyethylene 135B, 15-20 parts of chlorinated polyethylene, 1.5-3 parts of magnesium oxide, 4-6 parts of dioctyl phthalate, 5-8 parts of dioctyl phthalate, 20-30 parts of white carbon black, 0.5-1 part of rare earth stabilizer, 0.3-0.6 part of a lead salt composite stabilizer, 2-5 parts of antimonous oxide, 8-12 parts of zinc borate, 2-4 parts of trichloroethyl phosphate, 8-12 parts of carbon black N770, 15-20 parts of calcium carbonate, 0.7-0.9 part of a surfactant gamma-mercaptopropyl triethoxyl silane, 0.5-1.3 parts of avulcanizing agent dicumyl peroxide and 0.5-1 part of a co-vulcanizing agent triallyl isocyanurate. The high performance aging resistant cable sheath material disclosed by the invention is excellent in heat resistant and flame retardant effect, good in ozone resistance and oil resistance, excellent in physical and mechanical properties and long in service life.

Owner:江苏鑫海腾线缆有限公司

Anti-aging oil tube rubber material and preparation method thereof

InactiveCN106519462AImprove high temperature resistanceImprove aging resistanceRubber materialButylated hydroxytoluene

The invention discloses an anti-aging oil tube rubber material and a preparation method thereof. The anti-aging oil tube rubber material is prepared from the following raw materials in parts by weight: 23-40 parts of carboxy nitrile rubber, 20-50 parts of ethylene propylene diene monomer rubber, 10-22 parts of vinyl silicone resin, 6-16 parts of magnesium stearate, 4-9 parts of zinc di-n-butyl dithiocarbamate, 1-5 parts of accelerator, 1.5-5 parts of styrenated phenol, 6-14 parts of ammonium polyphosphate, 7-15 parts of tetrabutyl titanate, 4-8 parts of paraffin, 10-18 parts of ultramicro hollow microbead, 5-11 parts of trichloroethyl phosphate, 2-6 parts of plasticizer, 5-11 parts of butylated hydroxytoluene, 3-7 parts of barium stearate, 0.8-2.3 parts of stabilizer, 1-5 parts of flame retardant, 4-9 parts of carbon black and 2-8 parts of vulcanizing agent. Compared with the prior art, the oil tube rubber material disclosed by the invention has the advantages of favorable high-temperature resistance, favorable aging resistance and long service life.

Owner:安徽微威环保科技有限公司

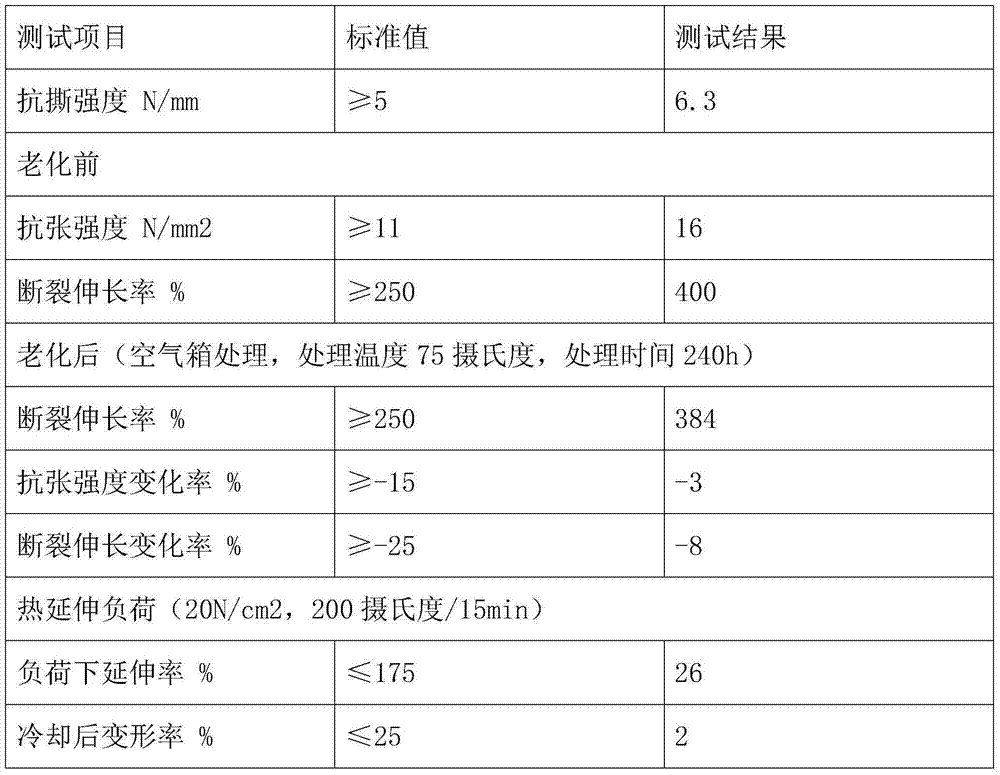

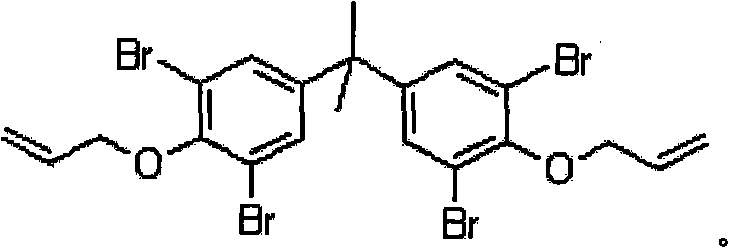

Flame retardant polyurethane composition, flame retardant polyurethane foam material and method for preparing same

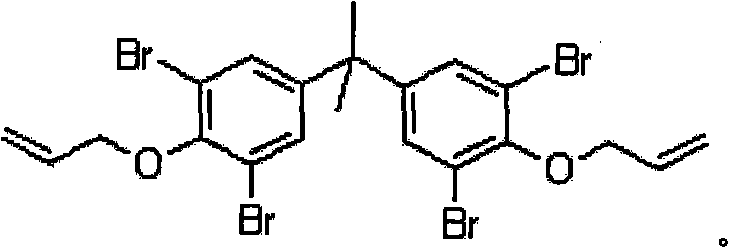

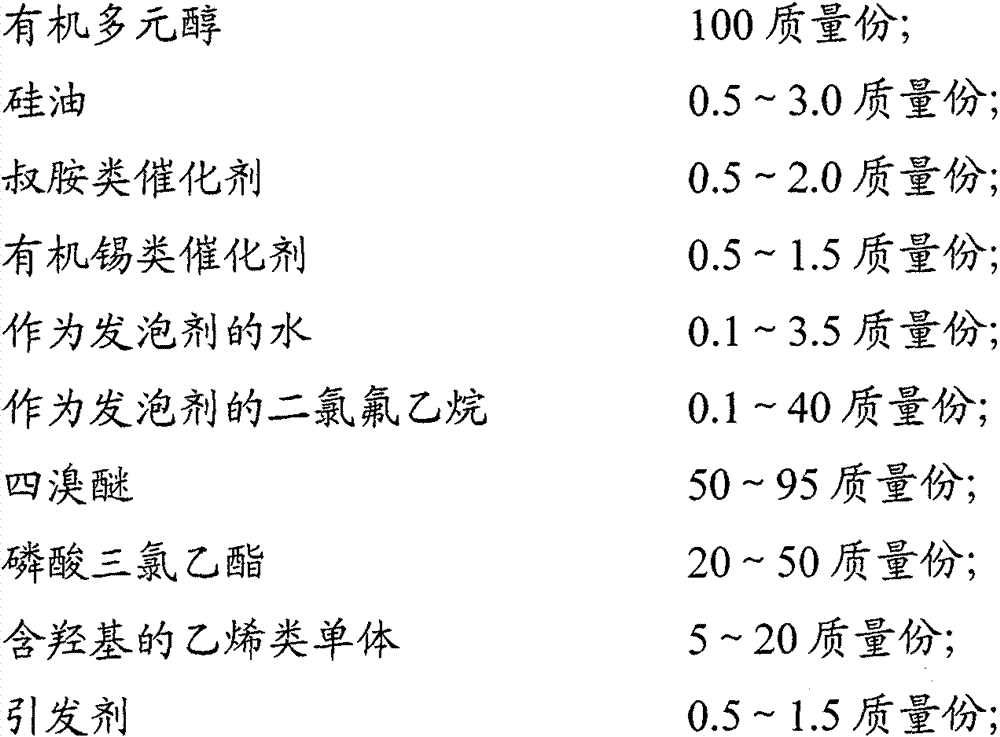

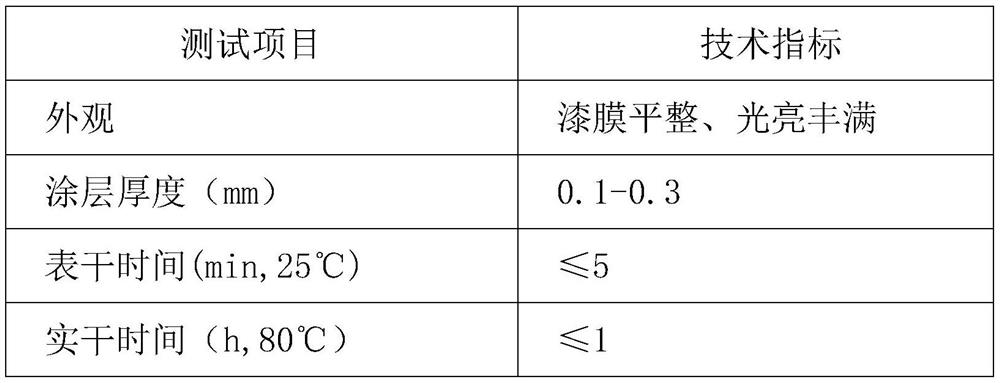

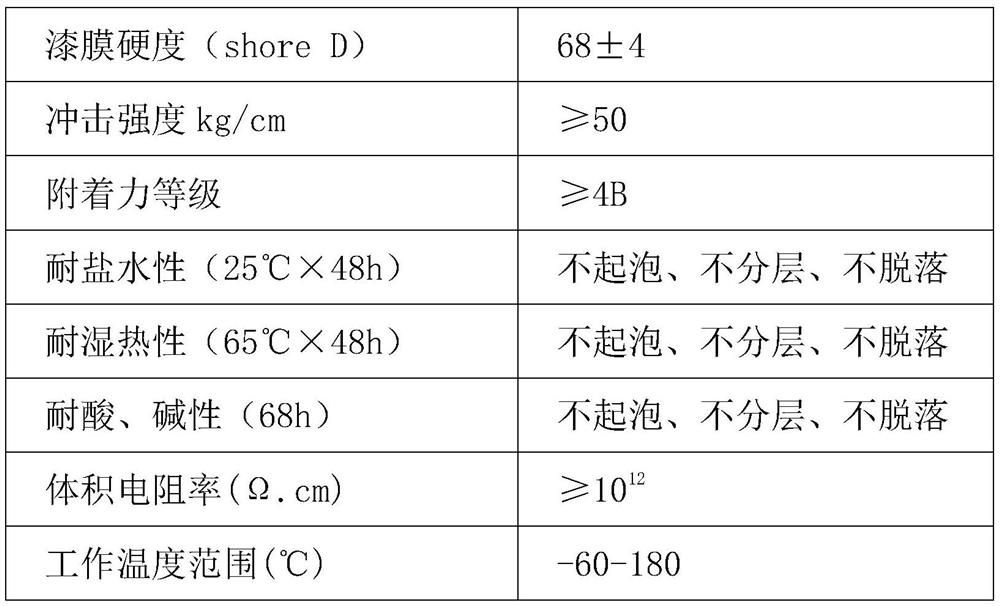

The invention provides a flame retardant polyurethane composition, a flame retardant polyurethane foam material and a method for preparing the same. The flame retardant polyurethane composition comprises a first component and a second component, wherein the first component comprises organic polyhydric alcohols, silicone oil, foaming agent, catalyst, ethylene monomer which contains hydroxyl, initiator, 2,2',6,6'-tetrabromobisphenol A diallyl ether and trichloroethyl phosphate; and the second component comprises polyisocyanates. Because the ethylene monomer which contains hydroxyl and the initiator are added in the flame retardant polyurethane composition, during the foaming process, the hydroxyl of the ethylene monomer which contains hydroxyl and isocyanate group are reacted with each other to form carbamate bond, meanwhile, the ethylene unsaturated bond and the unsaturated end group of the 2,2',6,6'-tetrabromobisphenol A diallyl ether are subjected to free radical polymerization under the action of the initiator, finally, the 2,2',6,6'-tetrabromobisphenol A diallyl ether is connected into the polyurethane cross-linked network structure in a chemical bond mode, so in the final flame retardant polyurethane foam material, the 2,2',6,6'-tetrabromobisphenol A diallyl ether plays the role of reactive flame retardant, and the obtained foam material has a better flame-retardant effect.

Owner:嘉纳尔科技(北京)有限公司

Low corresion fire retardant polyurethane composition material and its manufacturing method

The low corrosion fire retardant heat insulating polyurethane composition material includes two components, component A and component B. The component A consists of polyether polyol, cyclohexane, silicone oil, potassium acetate, dimethylethanolamine, 2, 4, 6-tri(dimethylaminomethyl) phenol, water, monofluoro trichloroethanone, trichloroethyl phosphate and silicate hydrate; and the component B is isocyanate. When the composition material is used, the component A and the component B are mixed to form the foamed heat insulating polyurethane material with low corrosion, high fire retarding performance and simple production process. The foamed heat insulating polyurethane material is used for oil and gas pipeline.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Cable insulating material for ocean vessel and preparation method of cable insulating material

InactiveCN105885128AAntioxidant is goodImprove corrosion resistanceRubber insulatorsFiberCalcium silicate

The invention discloses cable insulating material for an ocean vessel and a preparation method of the cable insulating material. The cable insulating material comprises, by weight, 30-50 parts of natural rubber, 10-15 parts of nanoscale silicon dioxide, 5-15 parts of organosilicon crosslinking agent, 10-15 parts of nano modified resin, 8-15 parts of toughening agent, 7-15 parts of ascharite, 8-15 parts of dicumyl peroxide, 10-20 parts of methyl silicone oil, 10-20 parts of reinforced fibers, 20-30 parts of methacrylic acid modified nano silicon nitride, 15-25 parts of active calcium silicate, 7-16 parts of trichloroethyl phosphate, 10-15 parts of phenolic resin, 7-12 parts of silane coupling agent, 4-10 parts of white carbon black and 2-9 parts of plasticizer. The cable insulating material has the advantages that the preparation process is simple, environmentally friendly and free of pollution, the prepared cable insulating material for the ocean vessel is good in oxidization resistance, corrosion resistance, humidity resistance and flame retardance, and the service life of a cable for the ocean vessel is prolonged.

Owner:李文军

Environment-friendly flame-retardant impact-resistant polycarbonate composite material and preparation method thereof

The invention discloses an environment-friendly flame-retardant impact-resistant polycarbonate composite material and a preparation method thereof. The environment-friendly flame-retardant impact-resistant polycarbonate composite material is prepared from a bisphenol A polycarbonate resin, polyetheretherketone, zinc stearate, magnesium stearate, polytetrafluoroethylene micropowder, aluminum metaphosphate, trichloroethyl phosphate, nano titanium carbide, tributyl citrate, antimony glance powder, hydrated magnesium silicate micropowder, pentaerythritol tetra[beta-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate], nano calcium carbonate, attapulgite, graphene, 2,2'-dihydroxy-4,4'-dimethoxy diphenyl ketone, ethylene bis stearamide and the like. The nano calcium carbonate, nano titanium carbide, hydrated magnesium silicate micropowder and the like are sufficiently dispersed in the plastic resin to enhance the weather resistance, mechanical properties and other properties of the material. The antimony glance powder, aluminum metaphosphate, polyetheretherketone, trichloroethyl phosphate and other reinforcing fillers and modifying materials are added to enhance the flame retardancy, impact resistance and other properties of the material.

Owner:陈可创

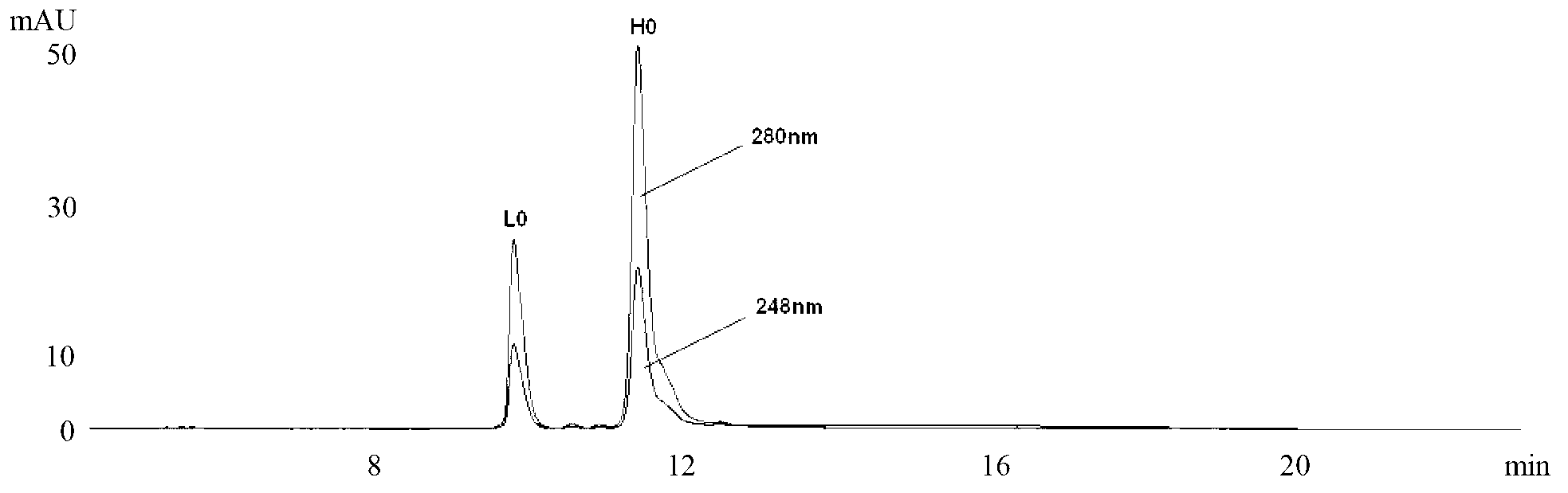

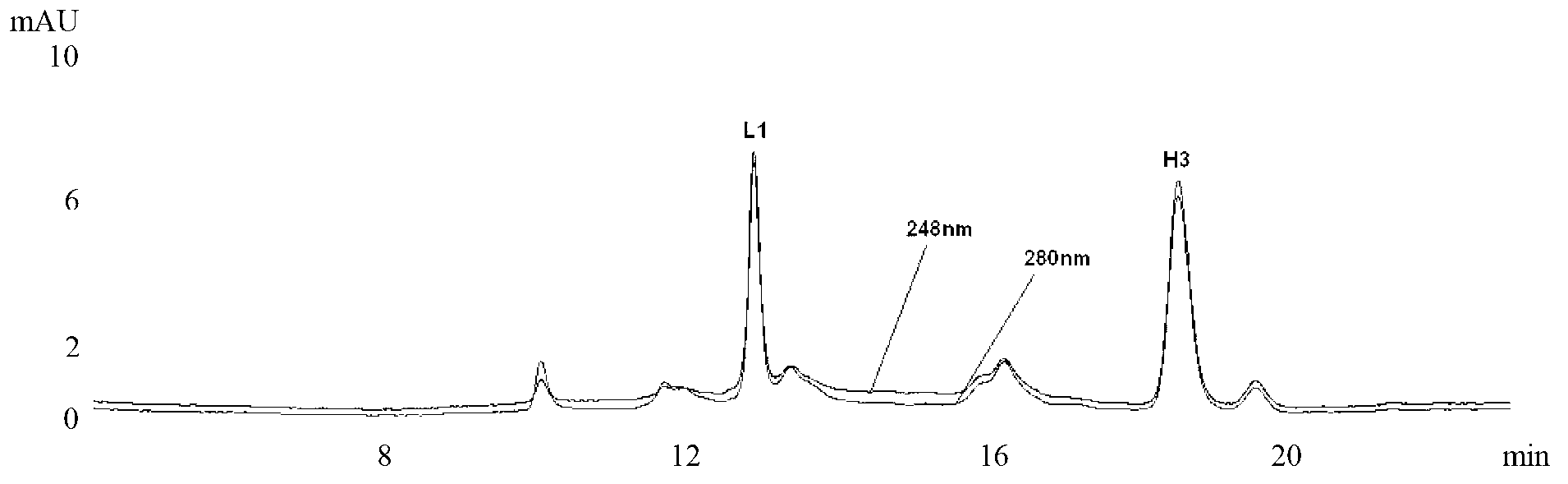

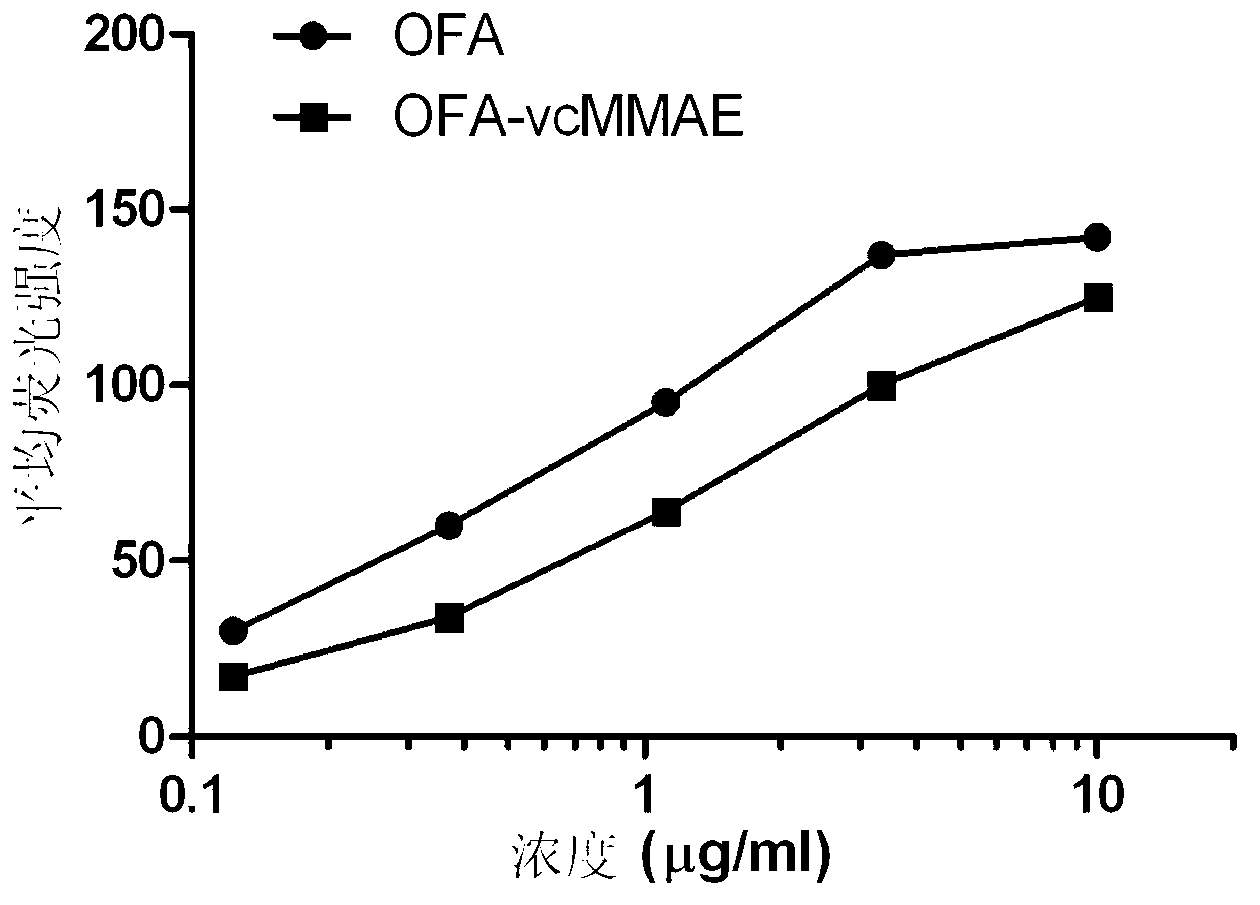

Anti-CD20 monoclonal antibody-aplysiatoxin conjugate as well as preparation method and application thereof

ActiveCN103254317AHas a biological functionCapable of killingTetrapeptide ingredientsPeptide preparation methodsTumor targetSide effect

The invention discloses an anti-CD20 monoclonal antibody-aplysiatoxin conjugate as well as a preparation method and application thereof. The preparation method comprises the steps of dissolving the anti-CD20 monoclonal antibody into a buffer solution, adding trichloroethyl phosphate to carry out reduction reaction; mixing restored anti-CD20 monoclonal antibody with aplysiatoxin having a connecting arm to carry out coupled reaction; and separating and purifying to obtain the anti-CD20 monoclonal antibody-aplysiatoxin conjugate after reaction is finished. Compared with the prior art, 8 aplysiatoxin molecules are coupled in the conjugate disclosed by the invention at most; the anti-CD20 monoclonal antibody-aplysiatoxin conjugate has the biological functions of the anti-CD20 monoclonal antibody and MMAE, has strong tumor targeting property, can kill CD20 positive tumor cells, and also reduces the toxic and side effects caused by independent dosing of the MMAE; and the anti-tumor effect is obviously reinforced.

Owner:ZHEJIANG UNIV

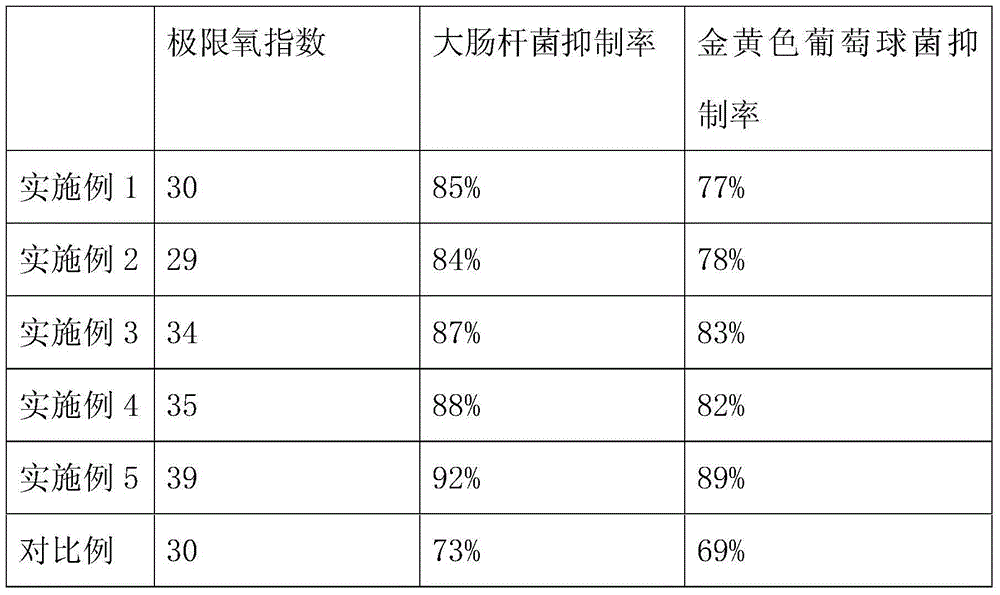

Preparation method of novel flame-retardant antibacterial acrylic fabric

ActiveCN104452280AIncreased flame retardant strengthImprove performanceFibre typesPhosphateRoom temperature

The invention discloses a preparation method of a novel flame-retardant antibacterial acrylic fabric. The preparation method comprises the following steps: (1) weighing triaryl phosphate, trichloroethyl phosphate, Tween-65, glycerin and water, and heating and uniformly stirring the five components; (2) completely immersing an acrylic fabric in flame-retardant treatment liquid prepared in the step (1), standing at the room temperature for 1.5 hours, immersing and rolling twice until the liquid detention rate is 60%, and drying at 95 DEG C; (3) weighing ammonium dihydrogen phosphate, chitosan and 20wt% ethanol water extract of herba lycopi, dissolving the components in water, and uniformly stirring after the dissolving; and (4) after the uniform stirring, completely dipping the acrylic fabric treated in the step (2) into antibacterial treatment liquid prepared in the step (3), standing at the room temperature for 2 hours, immersing and rolling twice until the liquid detention rate is 80%, and drying at 95 DEG C so as to obtain the flame-retardant antibacterial acrylic fabric.

Owner:佛山市顺德区丽轩纺织实业有限公司

ABS flame retardant alloy

The invention discloses an ABS flame retardant alloy, which comprises the following materials by weight: 1-2 parts of PE ester, 2-8 parts of zinc borate, 1-9 parts of an acetylacetonate salt, 10-30 parts of PBT, 30-40 parts of ABS, 20-30 parts of styrene, 10-18 parts of montmorillonite, 1-9 parts of an antioxidant, 1-7 parts of a flame retardant APP (ammonium polyphosphate), 1-8 parts of a flame retardant PER (pentaerythritol), 3-9 parts of trichloroethyl phosphate, and 2-9 parts of a halogen-free intumescent flame retardant. By utilizing the synergistic effect of the montmorillonite and the halogen-free flame retardant, the ABS flame retardant alloy disclosed in the invention abandons the traditional flame retardant system, has excellent flame retardant performance and mechanical properties, is harmless to the environment and human health, thus belonging to an environmental protection product. Moreover, the use of montmorillonite reduces the flame retardant dosage, so that the mechanical properties and heat resistance of flame retardant materials are improved to a large extent. More importantly, the production cost is greatly reduced.

Owner:青岛永卓真塑料制品有限公司

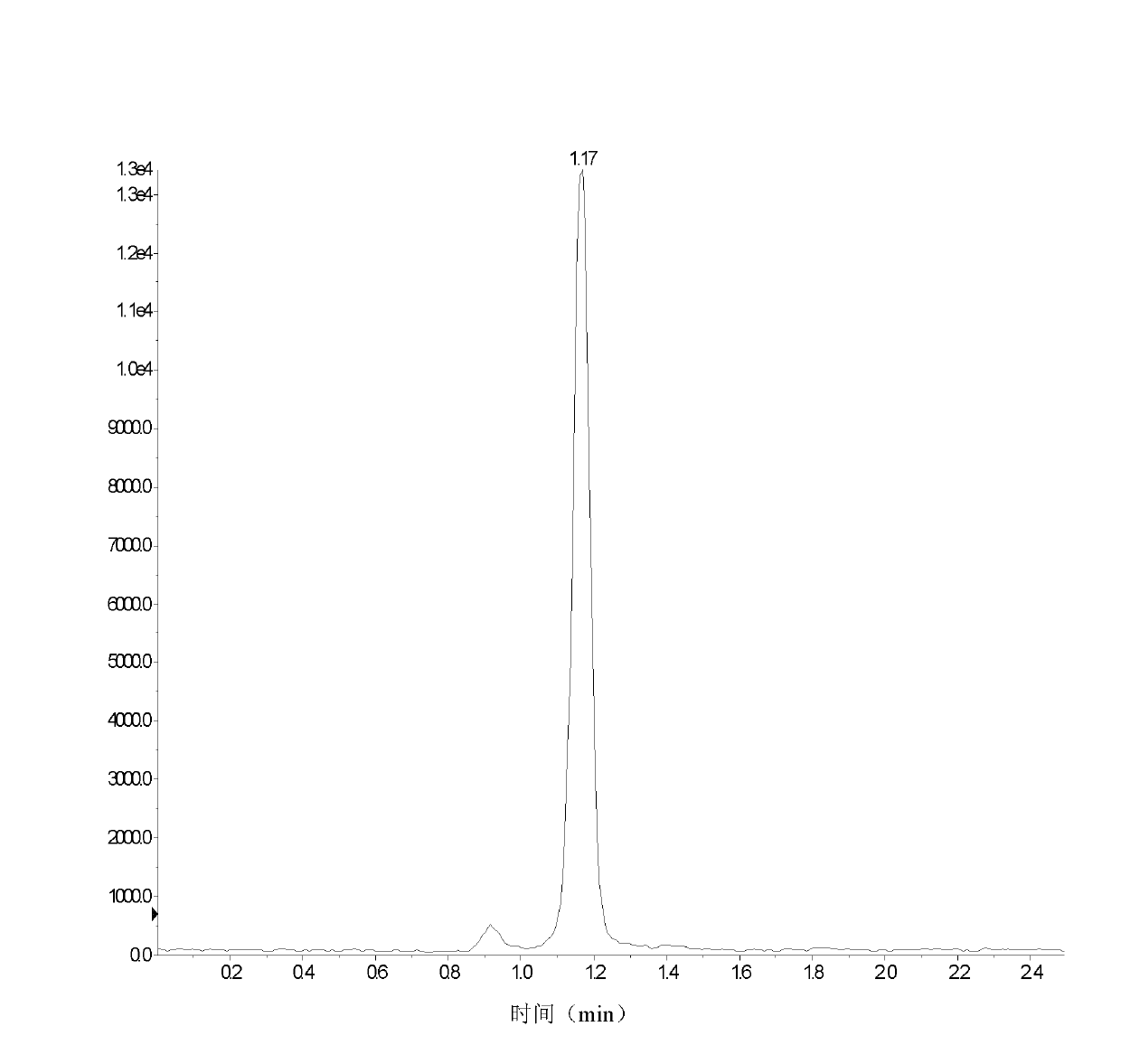

Method for detecting content of homocysteine in blood or urine

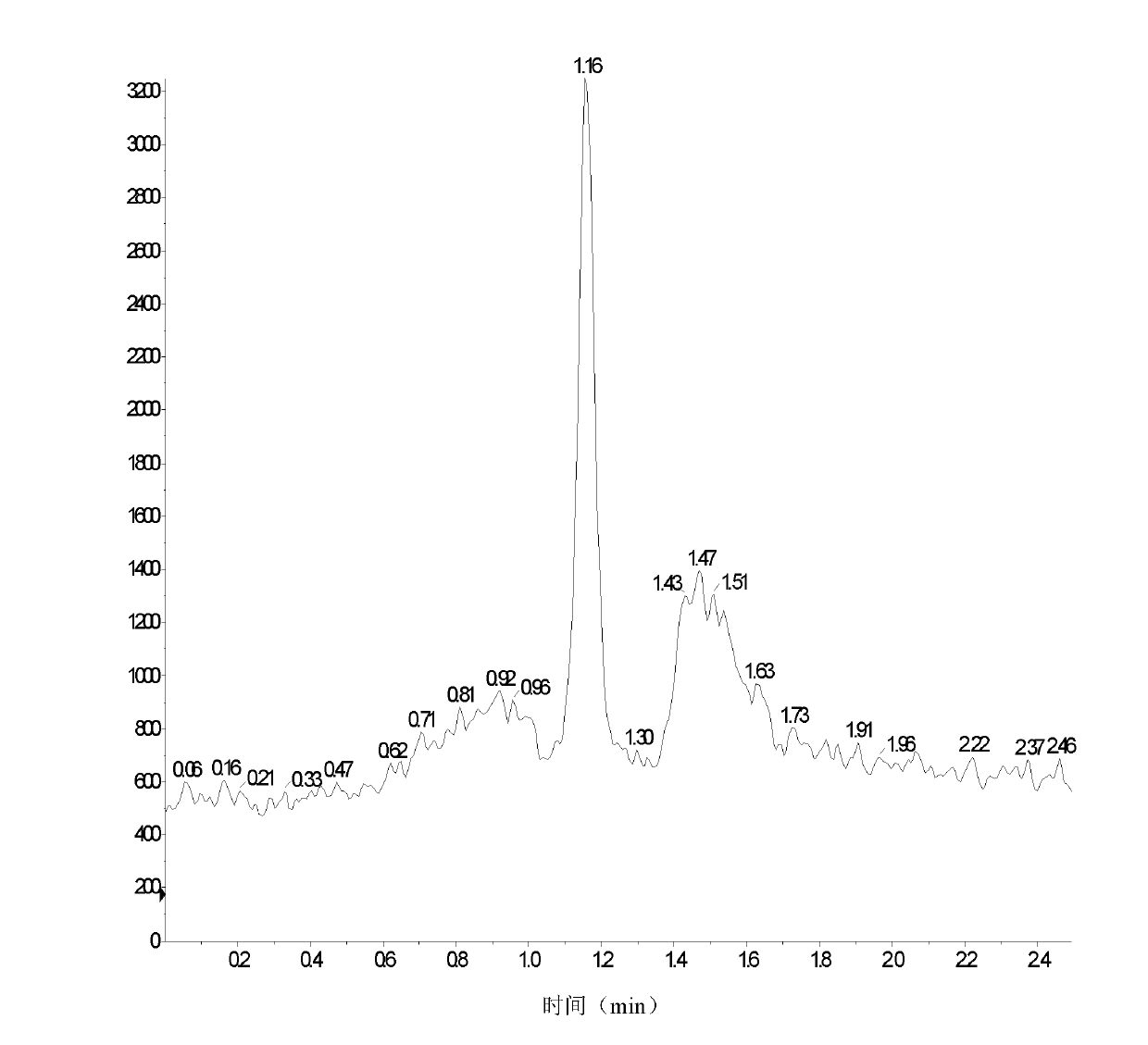

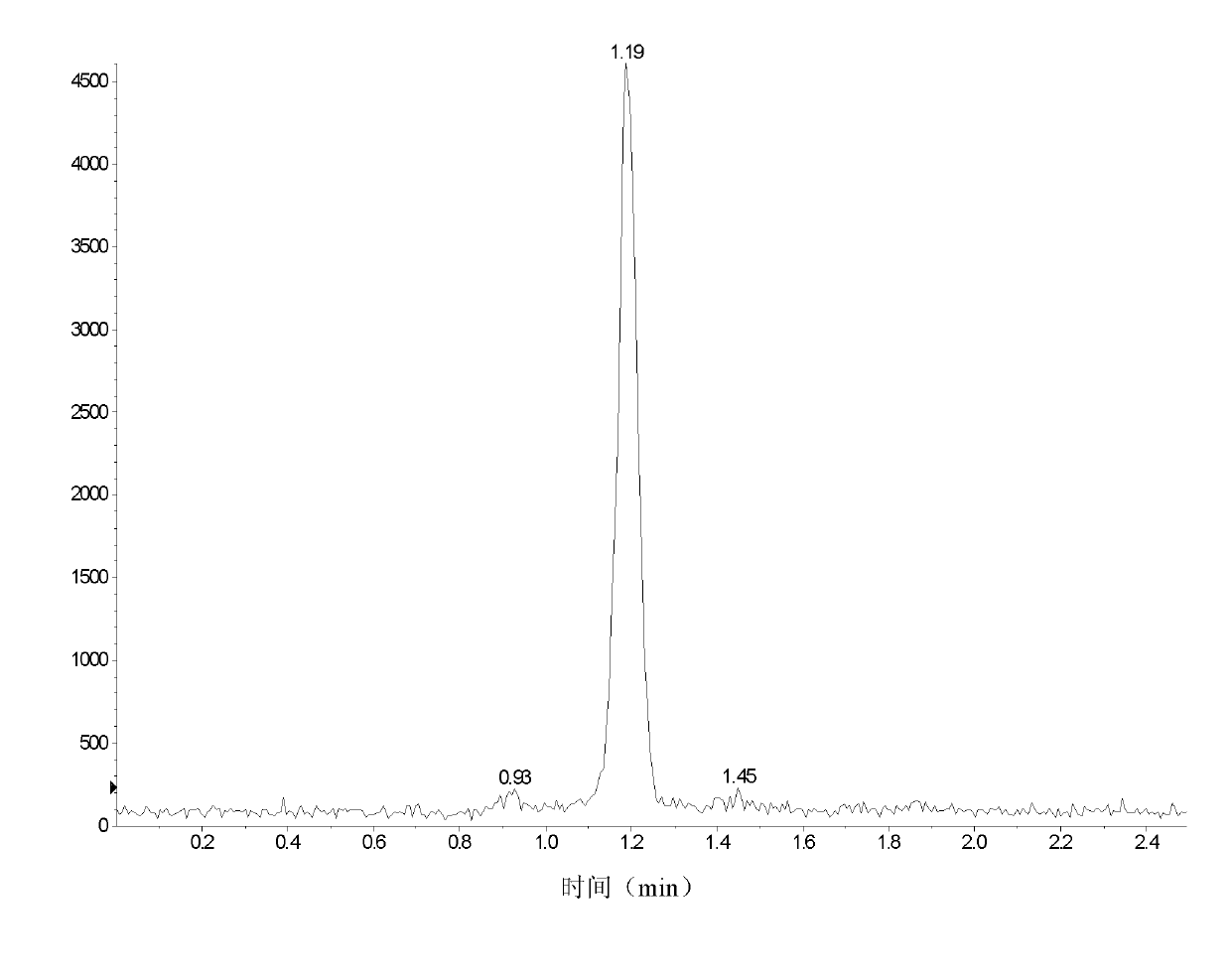

ActiveCN102565252AHigh recovery rateAccurate identificationComponent separationMatrix solutionChromatography column

The invention discloses a method for detecting the content of homocysteine in blood or urine. The method comprises the following steps: 1, respectively mixing a standard substance and a sample to be tested with an internal standard solution, adding a matrix solution, and uniformly mixing; 2, adding mercaptoethanol, dithiothreitol or TCEP (trichloroethyl phosphate), uniformly mixing, and allowing the obtained solutions to stand for 10min; 3, adding trichloroacetic acid with the mass percentage of 10%, centrifuging at a high speed, taking the obtained supernatants, diluting the supernatants by deionized water, carrying out liquid phase-mass spectrometry by respectively allowing the diluted supernatants and a mobile phase to flow through a chromatographic column, and finally determining the content of the homocysteine in the blood or the urine. The method for detecting the content of the homocysteine in the blood or the urine of the invention has the advantages of simplicity, rapidness and sensitivity, can be applied to the screening of a large amount of samples, and makes accurate quantification and strong specificity be realized.

Owner:郑州和合医学检验实验室有限公司

Anticorrosive multifunctional cable for civil building construction

InactiveCN105924912ASoft textureExcellent flame retardantPlastic/resin/waxes insulatorsInsulated cablesPhosphateCobalt

The invention relates to an anticorrosive multifunctional cable for civil building construction. The cable comprises a plurality of copper alloy leads and lags, the copper alloy leads are arranged in parallel, every copper alloy lead is coated with one lag, and the lag comprises poly(butylene succinate), polyketone resin, bimaleimide resin, dimethyl formamide, cottonseed oil, phosphate ester, phenylmethyl silicone oil, 2-mercaptobenzothiazole, benzalkonium chloride, dodecyl dimethyl benzyl ammonium chloride, didecyldimethylammonium chloride, phenyltriethoxysilane, lithium phosphate powder, zeolite powder, barium sulfate powder, molybdenum disulfide powder, fly ash, antimony oxide powder, dolomite powder, nanometer zinc oxide, trichloroethyl phosphate, polybenzimidazole imide, nanometer magnesium hydroxide, alkyl glycoside, ethylene glycol dimethacrylate, aluminum distearate, alkyl benzene sulfonic acid, sodium lauryl sulfate, petroleum sulfonate and cobalt isooctoate. The use performances of the cable are improved in the invention.

Owner:虞永华

Flame-retardant impact-resistant ultrafine fiber polyurethane synthetic leather for automobile interior trim and preparation method of synthetic leather

InactiveCN105507005AEasy to processHigh mechanical strengthFibre treatmentPolyesterSODIUM DODECYL BENZENE SULFONATE

The invention discloses flame-retardant impact-resistant ultrafine fiber polyurethane synthetic leather for automobile interior trim. The flame-retardant impact-resistant ultrafine fiber polyurethane synthetic leather is characterized by being prepared from, by weight, 75-77 parts of polyamide-6, 25-26 parts of alkali-soluble polyester chips, an appropriate amount of a sodium hydroxide solution with the concentration of 20%, 50-53 parts of waterborne polyurethane, 5-6 parts of nano-magnesium hydroxide, 3-4 parts of ammonium polyphosphate, 5-6 parts of sodium dodecyl benzene sulfonate, 3-4 parts of rutile titanium white paste, an appropriate amount of water, 0.7-0.8 part of cocoanut fatty acid diethanolamide, 5-6 parts of expanded graphite, 2-3 parts of trichloroethyl phosphate, 1-1.2 parts of castor oil, 2-3 parts of phenolic resin emulsion, 0.8-1 part of cardanol and 2-3 parts of plastic clay. The prepared synthetic leather has the advantages that the touch sense is soft and comfortable, the impact resistance is achieved, postprocessing is easy, environment-friendly raw materials are adopted in the whole technological process, no harm is generated to the environment and human bodies, and the requirements of customers for the leather for automobile interior parts are met.

Owner:WUHU HUANRUI AUTO INTERIOR DECORATION

High-strength fire resisting wooden door and production method thereof

InactiveCN107118581AImprove mechanical properties and strengthNot easy to damageFireproof doorsWar-like protectionAdhesiveEthylene thiourea

The invention discloses a high-strength fire-proof wooden door and a production method thereof. The high-strength fire resisting wooden door comprises a core board, wherein the core board is prepared from the following raw materials: pine sawdust, aluminum oxide, magnesium sulfate, polyurethane, silicon carbide fibers, zirconium diboride, ammonium molybdate, bamboo powder, inositol, an ethylene-vinyl alcohol copolymer, tourmaline powder, trichloroethyl phosphate, starch adhesive, 1,2-ethylene thiourea, magnesia powder, organosilicon waterproofing agent powder, a flame retardant, a foaming agent and a foam stabilizing agent. The production method of the high-strength fire-proof wooden door comprises the following steps: dissolving the magnesium sulfate into a magnesium sulfate solution, and adding other raw materials into the magnesium sulfate solution and uniformly mixing to obtain slurry; then carrying out standing, solidifying, curing and the like on the slurry to obtain the core board of the fire resisting door; finally, carrying out assembling. The production method of the fire resisting wooden door, disclosed by the invention, has the advantages of simplicity and convenience, low energy consumption and less pollution; the fire resisting wooden door also has the characteristics of low possibilities of absorbing water, generating pulverization and argillization phenomena, high strength, excellent fire-proof performance and a broad market prospect.

Owner:HEFEI YIZHI DOORS & WINDOWS CO LTD

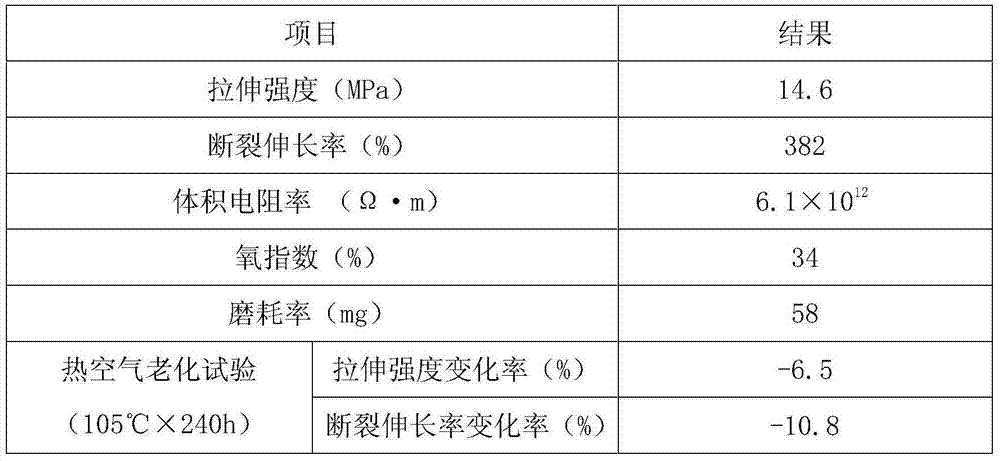

Special waterproof material for high-speed rail and preparation method thereof

ActiveCN103540121AExcellent tensile strengthExcellent elongation at breakPolyvinyl alcoholRare earth

The invention discloses a special waterproof material for high-speed rail and a preparation method thereof. The special waterproof material comprises the following components in parts by weight: 15-30 parts of amino acetal ester, 30-35 parts of carbon black, 30-40 parts of polypropylene, 25-40 parts of polyurethane, 10-15 parts of polyvinyl alcohol, 0.5-1 part of aluminum sulfate, 3-5 parts of chlorinated paraffin, 2-5 parts of trichloroethyl phosphate, 1-3 parts of talcum powder, 3-8 parts of polypropylene wax, 5-8 parts of PVC (polyvinyl chloride) binder, 0.5-1.5 parts of rare earth composition and 1-2 parts of BYK969. The tensile strength, the elongation at break and other parameters of the special waterproof material disclosed by the invention are better than those of the prior art, and the special waterproof material further has low-temperature resistance and can keep excellent properties in an environment with temperature being lower than -45 DEG C.

Owner:句容市睿远科技有限公司

Preparation method of environment-friendly mildew-proof plastic-wooden composite plate

The invention discloses a preparation method of an environment-friendly mildew-proof plastic-wooden composite plate. The method comprises the following steps: weighing the following raw materials in parts by weight: 80 to 90 parts of PVC, 60 to 80 parts of a rice straw powder, 20 to 25 parts of terpene resin, 5 to 8 parts of trichloroethyl phosphate, 3 to 7 parts of Vaseline, 6 to 11 parts of phenol, 15 to 20 parts of sa-hao seed gum, 3 to 5 parts of carbon nano tubes, 4 to 8 parts of an antioxidant 264, 15 to 22 parts of butylated melamine formaldehyde resin, 4 to 8 parts of nanosilicon dioxide, 10 to 20 parts of glass beads, and 4 to 8 parts of dithiocarbamate molybdenum formate; then performing extrusion pelleting, mechanical stirring, melt blending and extrusion molding in an extruder, so that the environment-friendly mildew-proof plastic-wooden composite plate is obtained through a flat opening die. The environment-friendly mildew-proof plastic-wooden composite plate is convenient to produce and manufacture, low in cost, environmentally friendly, anti-mildew and long in service life, cannot be mildewed or rotted during use, and can be widely applied to various occasions, such as decoration, municipal gardens and docks.

Owner:苏州仲勉装饰有限公司

Flame retardant polyurethane composition, flame retardant polyurethane foam material and method for preparing same

The invention provides a flame retardant polyurethane composition, a flame retardant polyurethane foam material and a method for preparing the same. The flame retardant polyurethane composition comprises a first component and a second component, wherein the first component comprises organic polyhydric alcohols, silicone oil, foaming agent, catalyst, ethylene monomer which contains hydroxyl, initiator, 2,2',6,6'-tetrabromobisphenol A diallyl ether and trichloroethyl phosphate; and the second component comprises polyisocyanates. Because the ethylene monomer which contains hydroxyl and the initiator are added in the flame retardant polyurethane composition, during the foaming process, the hydroxyl of the ethylene monomer which contains hydroxyl and isocyanate group are reacted with each other to form carbamate bond, meanwhile, the ethylene unsaturated bond and the unsaturated end group of the 2,2',6,6'-tetrabromobisphenol A diallyl ether are subjected to free radical polymerization under the action of the initiator, finally, the 2,2',6,6'-tetrabromobisphenol A diallyl ether is connected into the polyurethane cross-linked network structure in a chemical bond mode, so in the final flame retardant polyurethane foam material, the 2,2',6,6'-tetrabromobisphenol A diallyl ether plays the role of reactive flame retardant, and the obtained foam material has a better flame-retardant effect.

Owner:嘉纳尔科技(北京)有限公司

Alloy material for automobile fuel pipes

The invention discloses an alloy material for automobile fuel pipes. The alloy material comprises the following substances in parts by weight: 50-90 parts of ABS (acrylonitrile butadiene styrene) resin powder, 10-20 parts of trichloroethyl phosphate, 20-30 parts of trichloropropyl phosphate, 14-25 parts of talcum powder, 10-25 parts of liquid gedanite, 25-30 parts of antistatic agent, 11-24 parts of plasticized starch, 14-21 parts of PP (polypropylene), 10-20 parts of PE (polyethylene), 1-10 parts of mixed solvent, 14-25 parts of inorganic thickener, 25-30 parts of toughening agent, 10-20 parts of flame retardant, 1-5 parts of carbon black, 1-8 parts of plasticizer and 1-5 parts of thinner. The alloy material conforms to the regulations in the automobile industry, is non-toxic and harmless to the environment and simultaneously improves the heat and glycerin resistance and other properties of rubber materials.

Owner:QINGDAO WENSHENG AUTOMOBILE COMPONENTS & PARTS

Nylon cable protective sleeve based on bentonite modification and preparation method thereof

InactiveCN106700510AImprove mechanical propertiesImprove corrosion resistancePlastic/resin/waxes insulatorsFiberCarbon fibers

The invention discloses a nylon cable protective sleeve based on bentonite modification and a preparation method of the nylon cable protective sleeve based on the bentonite modification. The preparation method comprises the following steps: 1) calcining bentonite, then placing a calcined product in a modified solution to be soaked, and finally filtering to obtain a filter cake so as to prepare the modified bentonite; and 2) mixing and molding nylon, polyethylene oxide, polyisobutylene, mica powder, barium sulfate, antimony trioxide, dolomite powder, trichloroethyl phosphate, slag cotton and paraffin emulsion with the modified bentonite to obtain the nylon cable protective sleeve based on the bentonite modification, wherein the modified solution comprises water, hydrochloric acid, ethylene glycol butanediether, carbon fibers and lauric acid diethanolamide. The nylon cable protective sleeve prepared through the preparation method has high mechanical properties and corrosion resistance, and the preparation method further has the advantages of simple process and convenient operation.

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

Waterproof material

The invention discloses a waterproof material which is prepared from the following raw materials in parts by weight: 10-20 parts of acrylate, 30-50 parts of quartz sand, 10-20 parts of petroleum resin, 5-10 parts of synthetic rubber, 3-5 parts of chlorinated paraffin, 2-5 parts of trichloroethyl phosphate, 1-3 parts of talcum powder, 30-55 parts of asphalt, 10-20 parts of Portland cement, 10-20 parts of hydroxide, 1-10 parts of p-phenylenediamine, 5-12 parts of styrene, 15-30 parts of polyamide and 1-5 parts of elastic fiber. The waterproof material can be directly applied to the surface of a building, does not need to make any waterproof protective layer, is convenient for construction, has the advantages of cost saving and wide application range, and is suitable for large-scale production.

Owner:QINGDAO JUNZE SHENGTAI INTELLIGENT TECH

Flame-retardant conformal coating for printed circuit board and preparation method thereof

InactiveCN111662621AImprove surface activityLow viscosityFireproof paintsAnti-corrosive paintsXylyleneBenzoic acid

The invention discloses a flame-retardant conformal coating for a printed circuit board. The conformal coating comprises 45-52 parts of a main material and 2-4 parts of an auxiliary agent, wherein themain material is prepared from 30 to 35 parts of short-oil alkyd resin, 6-9 parts of dioctyl phthalate, 10-12 parts of polyvinyl acetate, 8-10 parts of xylene, 10-12 parts of ethyl acetate, 6-9 partsof trimellitic anhydride, 2-3 parts of 600-mesh transparent powder, 1-2 parts of a titanate coupling agent, 1-2 parts of cobalt naphthenate, 1-2 parts of butanone oxime, 2-4 parts of trichloroethyl phosphate and 4-5 parts of isocyanate; and the auxiliary agent comprises 2-4 parts of sepiolite fabric, 1-2 parts of isopropanolamine, 4-6 parts of diethylene glycol dibenzoate, 2-4 parts of propyleneglycol monomethyl ether, 1-3 parts of wool palmitic acid, 12-15 parts of boiled tung oil, 1-2 parts of oleic acid diethanolamide, 0.1-0.2 part of mustard oil, 9-12 parts of dimethyl carbonate and 1-2parts of polydimethylsiloxane. According to the flame-retardant conformal coating for the printed circuit board and the preparation method of the conformal coating, the environmental tolerance of theconformal coating is improved, a line of the circuit board is prevented from heating and catching fire especially in a high-heat environment, and the use safety of equipment is improved.

Owner:金宝电子(铜陵)有限公司

Art design packaging film material

InactiveCN106519713AExcellent flame retardantGood acid and alkali resistanceFlexible coversWrappersROSIN POWDERChromium trioxide

The present invention relates to an art design packaging film material, which comprises rosin pentaerythritol ester, an ethylene-vinyl acetate copolymer, an epichlorohydrin rubber, isobutyl propionate, epichlorohydrin, butyl acetate, glyceryl monostearate, diethanolamine, dimethyl fumarate, bromohexadecane, imidazoline, ammonium fluorosilicate, diantimony trioxide powder, chromium trioxide powder, quick lime powder, limestone powder, asbestos fiber, graphite fiber, disodium octaborate tetrahydrate, rosin powder, hexabromocyclododecane, triphenyl phosphate, sodium stannate, trichloroethyl phosphate, sodium methylenebisnaphthalenesulphonate, tert-butyl peroxybenzoate, benzoyl peroxide, oxidized polyethylene, polyvinyl formal-acetal, and n-oxydiethylidene-2-benzothiazole sulfamide. The product of the present invention has advantages of excellent fire retardation, excellent acid resistance, excellent alkali resistance, excellent anti-mildew property, excellent antibacterial property, and product performance improving.

Owner:安陆市万众创新智能科技有限公司

Art design packaging film material

InactiveCN106280042AExcellent flame retardantGood acid and alkali resistancePolymer scienceManganese oxide

The invention relates to an art design packaging film material consisting of the following components: chlorinated polyethylene, chlorosulfonated polyethylene resin, epichlorohydrin rubber, diethyl ethanephosphonate, trimethyl phosphate, trichloroethyl phosphate, potassium titanate whisker enhanceosome, garlic oil, tea polyphenol, dodecyl benzyl dimethyl ammonium chloride, pyrithione zinc, 10-10'- oxybisphenoxarsine, chimney ash, calcium oxide powder, cobalt oxide powder, manganese oxide powder, tin oxide powder, luminous powder, sodium stearate, ethylenediamine tetramethylene phosphonic acid, isobutyltriethoxysilane, dimethylformamide, cottonseed oil, aniline, phenyl glycidyl ether, phenoxyethanol, propylene glycol monomethyl ether, N,N-dimethylaminoethyl acrylate, sodium acryloyldimethyl taurate / acrylamide / VP copolymer and pentaerythritol. The product has excellent flame retardant, acid and alkali resistance, anti-mildew and antibacterial properties, and the performance of the product is improved.

Owner:XIAOGAN QISIMIAOXIANG CULTURAL MEDIA

Flame retardant containing flame-retardant synergistic composition and preparation method thereof

The invention discloses a flame retardant containing a flame-retardant synergistic composition and a preparation method thereof. The flame retardant comprises the following raw materials by weight: 10-30 parts of organic silicon, 3-6 parts of melamine, 5-8 parts of triethyl phosphate, 10-13 parts of triphenyl phosphate, 6-9 parts of trichloroethyl phosphate, 1-4 parts of tributyl phosphate, 7-10 parts of hydroxyl polysiloxane, 4-7 parts of sodium methoxide, 70-100 parts of water, 5-20 parts of strong base, 3-6 parts of dibutyltin dilaurate, 10-30 parts of a flame-retardant synergistic composition, 5-20 parts of 2, 2-dihydroxymethyl-3-nitro-1-propanol, and 5-8 parts of an acid binding agent. The preparation method comprises the following steps: S1, raw material weighing: weighing the aboveraw materials through an electronic scale for standby use; and S2, mixed reaction: reacting the triethyl phosphate, triphenyl phosphate, trichloroethyl phosphate, tributyl phosphate, hydroxyl polysiloxane and water prepared in S1. The prepared flame retardant containing phosphorus and nitrogen is wide in application, and the flame retardant properties of the flame retardant can be improved throughthe flame-retardant synergistic composition.

Owner:JIAXING UNIV

Wear-resisting nitrile rubber thermoplastic elastomer power line jacket material as well as preparation method thereof

InactiveCN103539978AGood flexibilityIncrease elasticityRubber insulatorsInsulated cablesCalcitePolyvinyl chloride

The invention discloses a wear-resisting nitrile rubber thermoplastic elastomer power line jacket material as well as a preparation method thereof. The wear-resisting nitrile rubber thermoplastic elastomer power line jacket material is prepared from the following substances in parts by weight: 60-70 parts of nitrile rubber (N41), 15-25 parts of XS-2 type PVC (Polyvinyl Chloride) resin, 10-15 parts of POM (Polyoxymethylene) resin, 5-10 parts of terpene resin, 8-12 parts of trichloroethyl phosphate, 5-10 parts of dioctyl phthalate, 1-2 parts of a calcium and zinc composite stabilizer, 2-3 parts of active zinc oxide, 1-2 parts of stearic acid, 3-5 parts of white mineral oil, 20-25 parts of carbon black N339, 10-15 parts of brucite flour, 8-12 parts of gangue flour, 5-10 parts of nano calcite, 1-2 parts of an anti-aging agent NBC (Nickelous N, N-dibutyldithiocarbamate), 0.5-1 part of an anti-aging agent MB (2-Mercaptobenzimidazole) and 3-5 parts of composite filler. The jacket material disclosed by the invention is good in flexibility and elasticity, and has excellent scratch and wear resistances. The scratching number of the jacket material on scratch-resisting detection equipment is greater than 500 times. The jacket material has excellent performances such as tensile strength, oil resistivity, heat resistance and ageing resistance, can fully satisfy the demand on various power line jackets, and has a good market prospect.

Owner:天长市富达电子科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com