Preparation method of phosphate modified acrylate emulsion

The technology of acrylate and methyl methacrylate is applied in the field of preparation of phosphate-modified acrylate emulsion, can solve problems such as high price, and achieve the effects of low product cost, friendly corrosive environment and improved thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

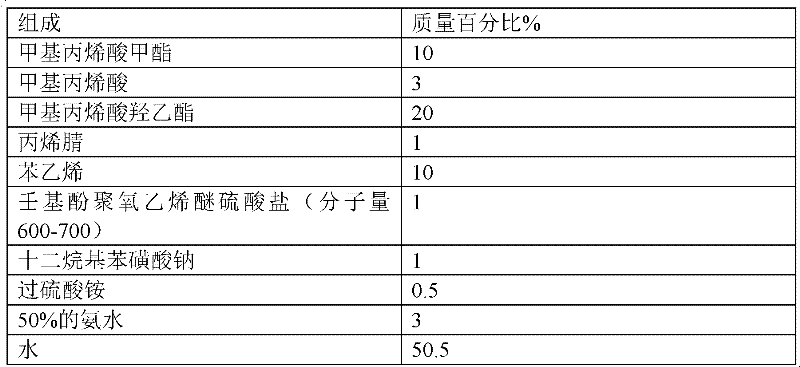

[0047] The component formula is composed as follows:

[0048]

[0049] The synthesis steps are as follows:

[0050] (1) One aggregation

[0051] Add 20% of the total amount of water, 30% emulsifier and all methyl methacrylate, styrene, methacrylic acid, acrylonitrile, and dodecanethiol into a four-necked flask, and stir at a high speed at 50°C to prepare a Polymerized pre-emulsion, cooled for later use;

[0052] Primary polymerization process: Add 50% of the total amount of water to the four-necked bottle, add the primary polymerization pre-emulsion to the four-necked bottle, heat to 60°C, add 40% FeSO 4 ·7H 2 O, then add dropwise the solution formed by dissolving 70% tert-butyl hydroperoxide in 2% water, and then add dropwise the solution formed by dissolving carving white powder in 5% water, and react for 30 minutes. Then add 50% ammonia solution with a mass fraction of 50%. The molecular weight of the primary polymerized emulsion is 2000, and the particle size is 0....

Embodiment 2

[0065] The component formula is composed as follows:

[0066]

[0067] The synthesis steps are as follows:

[0068] (1) One aggregation

[0069] Add 20% of the total amount of water, 30% emulsifier and all methyl methacrylate, styrene, methacrylic acid, acrylonitrile, and dodecanethiol into a four-necked flask, and stir at a high speed at 50°C to prepare a Polymerized pre-emulsion, cooled for later use;

[0070] Primary polymerization process: Add 50% of the total amount of water to the four-necked bottle, add the primary polymerization pre-emulsion to the four-necked bottle, heat to 60°C, add 40% FeSO 4 ·7H 2 O, then add dropwise the solution formed by dissolving 70% tert-butyl hydroperoxide in 2% water, and then add dropwise the solution formed by dissolving carving white powder in 5% water, and react for 30 minutes. Then add 50% ammonia solution with a mass fraction of 50%. The molecular weight of the primary polymerized emulsion is 2200, and the particle size is 0....

Embodiment 3

[0083] The component formula is composed as follows:

[0084]

[0085] The synthesis steps are as follows:

[0086] (1) One aggregation

[0087] Add 20% of the total amount of water, 30% emulsifier and all methyl methacrylate, styrene, methacrylic acid, acrylonitrile, and dodecanethiol into a four-necked flask, and stir at a high speed at 50°C to prepare a Polymerized pre-emulsion, cooled for later use;

[0088] Primary polymerization process: Add 50% of the total amount of water to the four-necked bottle, add the primary polymerization pre-emulsion to the four-necked bottle, heat to 60°C, add 40% FeSO 4 ·7H 2 O, then add dropwise the solution formed by dissolving 70% tert-butyl hydroperoxide in 2% water, and then add dropwise the solution formed by dissolving carving white powder in 5% water, and react for 30 minutes. Then add 50% ammonia solution with a mass fraction of 50%. The molecular weight of the primary polymerized emulsion is 3000, and the particle size is 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com