Patents

Literature

40results about How to "Excellent tensile strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pinprick material and manufacturing method thereof

ActiveCN101984178AExcellent tensile strengthFunction increaseNeedling machinesTemperature resistanceToxicity

The invention belongs to the non-woven weaving industry, in particular relating to a composite multifunctional pinprick material and a manufacturing method thereof. The technical scheme adopted by the invention is as follows: the pinprick materal with the thickness of 3.0-3.5cm is mainly prepared from the following raw materials by weight percent through a pinprick process: 90-95% of superfine glass fiber chopped yarns and 5-10% of high grade glass fiber chopped yarns; and the method for manufacturing the pinprick material has the steps of selecting, opening, mixing, carding, lapping, clamping and pressurizing, feeding and prickling the raw materials. The invention has the following beneficial effects: the pinprick material provided by the invention has the characteristics of radiation resistance, high temperature resistance, corrosion resistance, electric insulation, shock absorption, sound absorption, noise reduction, no toxicity, safety and the like, has small pore diameter, superior sound absorption due to high porosity up to 70-80% and wide application range, and can be widely used in multiple fields.

Owner:SHANDONG XINLI ENVIRONMENTAL PROTECTION MATERIAL

Bi and Nd composite reinforced high-strength cast magnesium alloy and preparation method thereof

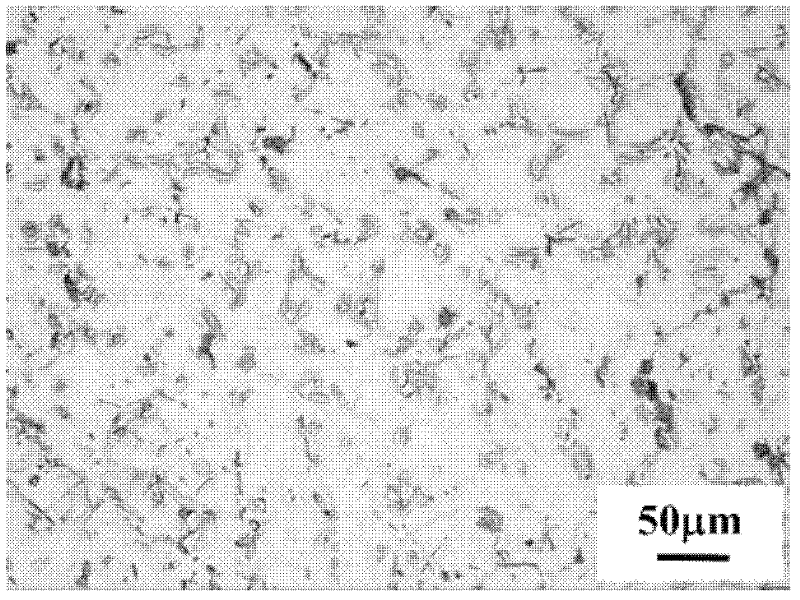

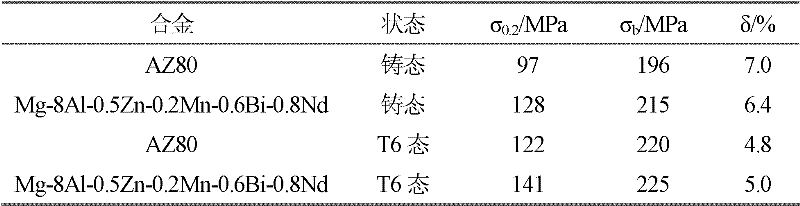

The invention relates to the field of metal material magnesium alloys, in particular to a Bi and Nd composite reinforced high-strength cast magnesium alloy. The alloy comprises the following components in percentage by parts: 3.0-10.0% of Al, 0.01-1.0% of Zn, 0.01-1.0% of Mn, 0.01-3.0% of Bi, 0.01-3.0% of Nd, less than 0.005% of impurity Fe, less than 0.015% of Cu, less than 0.002% of Ni and the balance of Mg. Mg3Bi2, Al2Nd and Al11Nd3 composite reinforced magnesium alloys are simultaneously prepared by adding Bi and Nd, and a Mg-Al-Zn-Mn-Bi-Nd alloy with excellent performances of a cast state and a thermal treatment state is obtained in a separation reinforcement and fine grain reinforcement manner. The Bi and Nd composite reinforced high-strength cast magnesium alloy disclosed by the invention has better yield strength and tensile strength compared with a traditional AZ-system magnesium alloy under the cast state and a T6 state. Taking Mg-8Al-0.5Zn-0.2Mn-0.6Bi-0.8Nd for example, the yield strength rho 0.2 reaches 128MPa at the cast state, and the tensile strength rhob reaches 215MPa. Compared with the AZ 80 alloy under the same condition, the Bi and Nd composite reinforced high-strength cast magnesium alloy disclosed by the invention has the yield strength increased by 32% and the tensile strength increased by 10%. The yield strength rho 0.2 of the alloy reaches 141MPa and the tensile strength rhob thereof reaches 225MPa at the T6 state. Compared with the AZ 80 alloy under the same condition, the Bi and Nd composite reinforced high-strength cast magnesium alloy disclosed by the invention has the yield strength increased by16% and the tensile strength increased a little.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

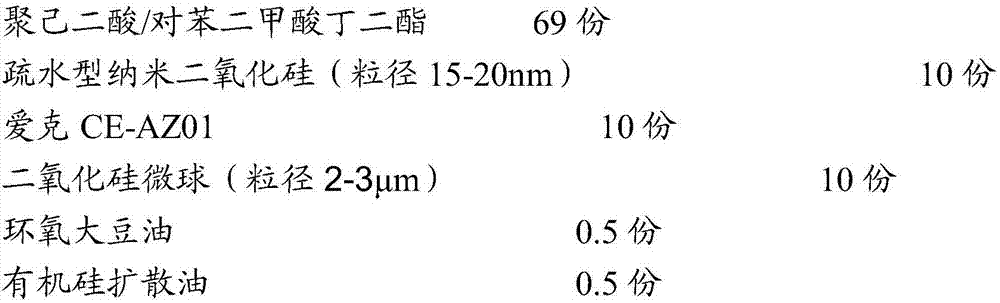

Ultrathin ultra-transparent full-biodegrade film blowing level material and preparation method thereof

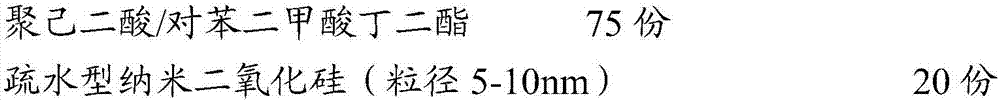

The invention belongs to the field of a biodegrade high polymer material and especially relates to an ultrathin ultra-transparent full-biodegrade film blowing level material and a preparation method thereof. The material is prepared from the following raw materials: poly-adipic acid / butylene terephthalate, polylactic acid and special reinforced and toughened anti-reflection master batch. The preparation method of the film blowing level material is simple and is easy in operation; an ultrathin film in the thickness below 6um can be directly blown; the acquired film is stable under normal temperature, can be stored for 12 months in dark place, has excellent mechanical properties and can be widely applied to the fields, such as, film packaging, shopping bag, agricultural plastic mulching film and garbage classification backfilling compost treatment.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

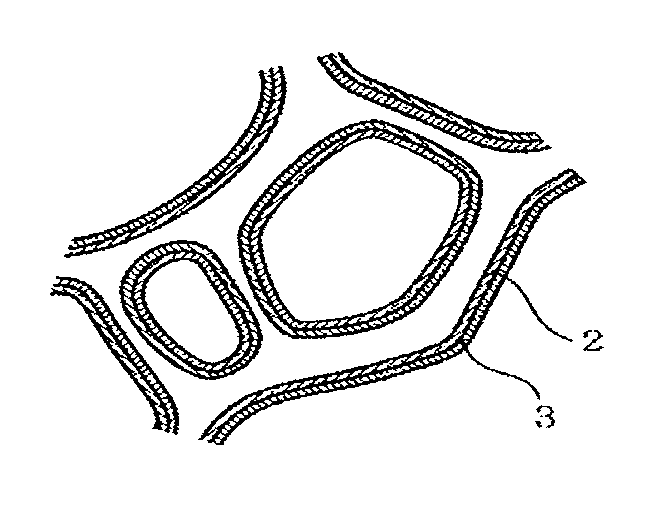

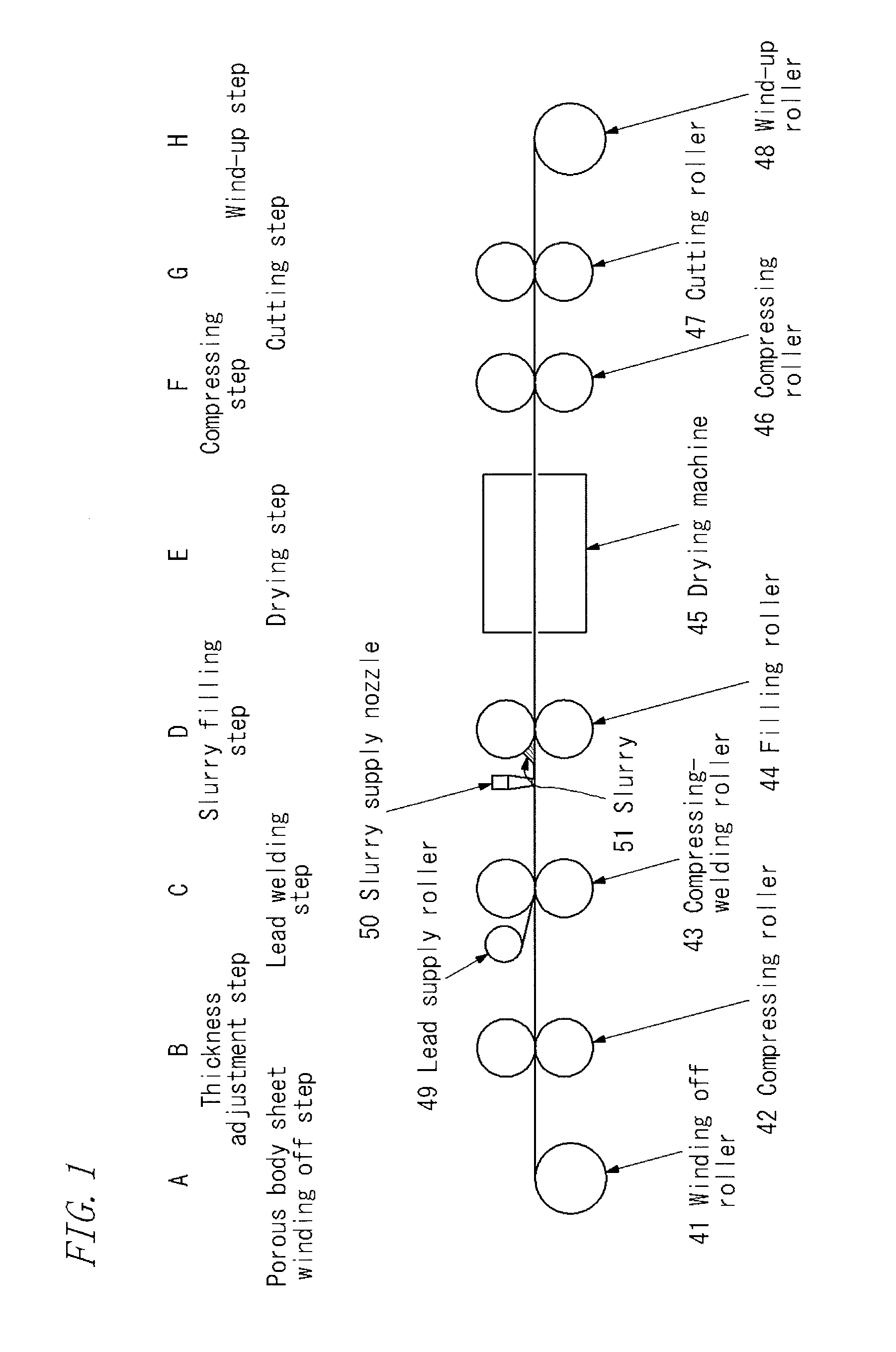

Three-dimensional network aluminum porous body, electrode using the aluminum porous body, and nonaqueous electrolyte battery, capacitor and lithium-ion capacitor with nonaqueous electrolytic solution, each using the electrode

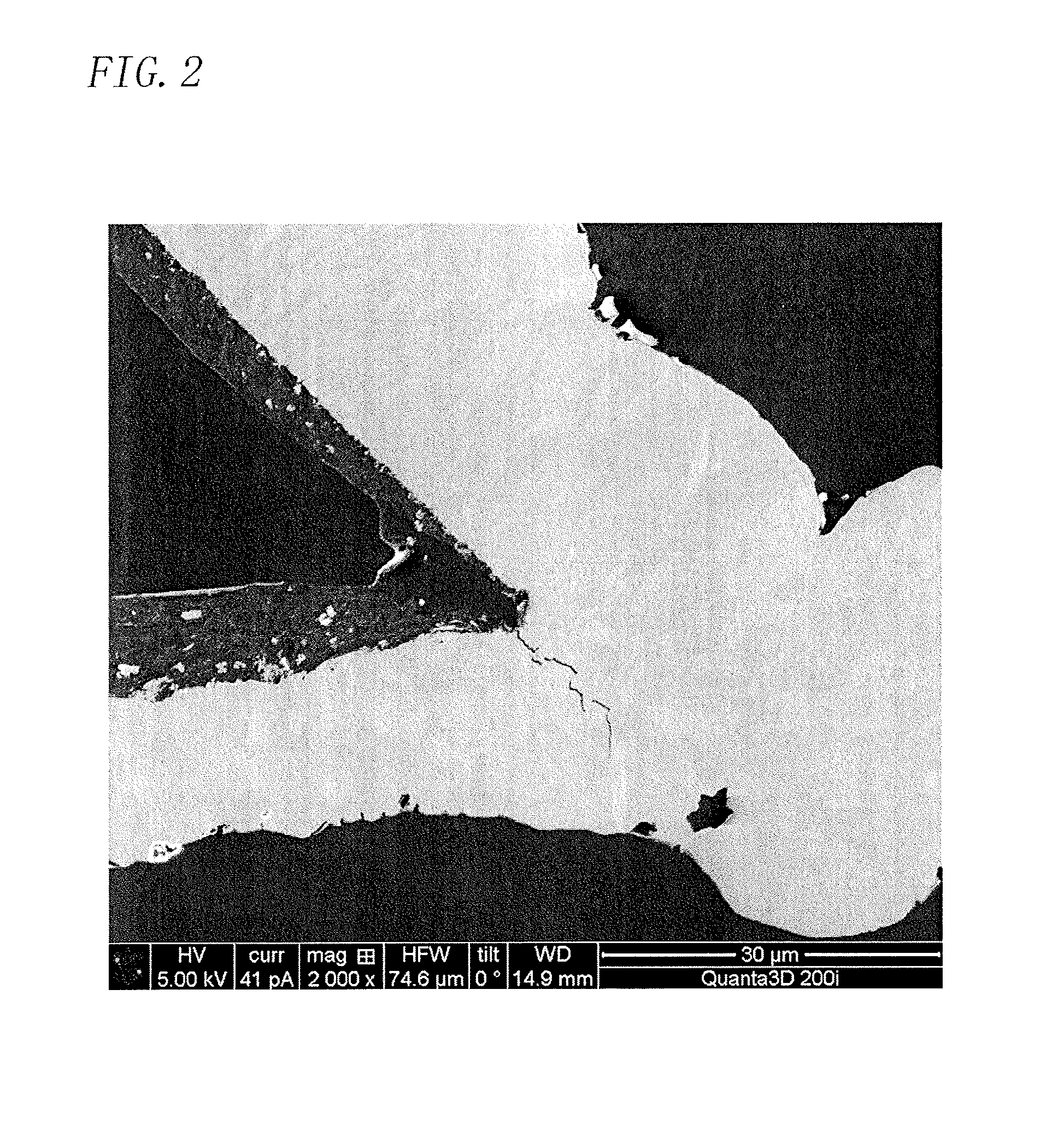

ActiveUS20120328957A1Cost reductionExcellent tensile strengthContact member manufacturingElectrode manufacturing processesLithium-ion capacitorAluminium

It is an object of the present invention to provide a three-dimensional network aluminum porous body which enables to produce an electrode continuously, an electrode using the aluminum porous body, and a method for producing the electrode. The present invention provides a long sheet-shaped three-dimensional network aluminum porous body to be used as a base material in a method for producing an electrode including at least winding off, a thickness adjustment step, a lead welding step, an active material filling step, a drying step, a compressing step, a cutting step and winding-up, wherein the three-dimensional network aluminum porous body has a tensile strength of 0.2 MPa or more and 5 MPa or less.

Owner:SUMITOMO ELECTRIC IND LTD +1

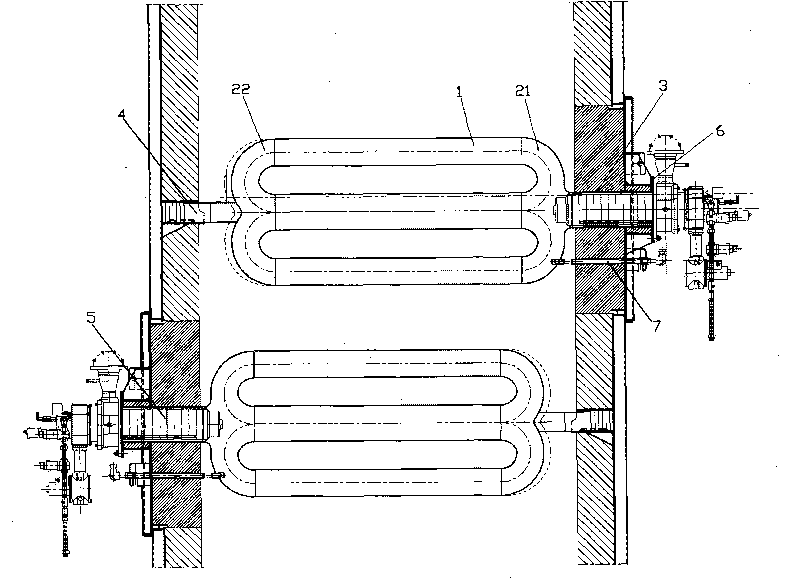

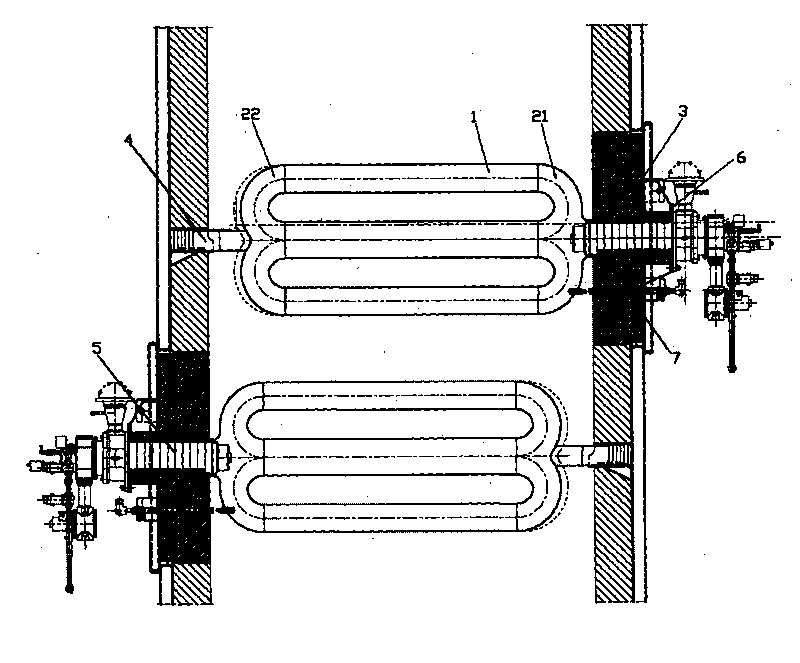

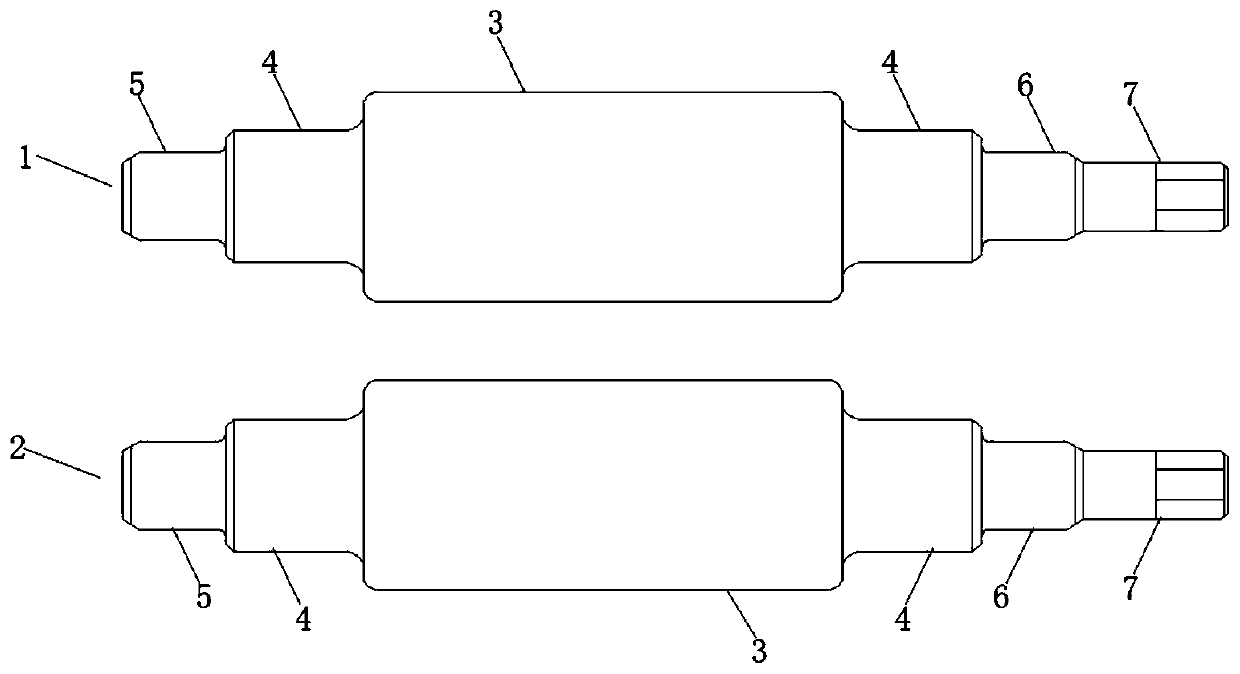

Double-P type radiant tube and manufacture method thereof

ActiveCN101724744ALighten the loadReduce design weightFurnace typesHeat treatment furnacesStraight tubeEngineering

The invention relates to a double-P type radiant tube. The double-P type radiant tube is arranged in a heat treatment furnace and comprises three parallel arrayed straight tubes, and both ends of each straight tube are symmetrically welded with two bent tubes, wherein the middle of one bent tube is provided with an air inlet tube coaxially arranged with the middle straight tube, while the other bent tube is welded with one end of a supporting tube coaxial to the middle straight tube. The manufacture method of the double-P type radiant tube comprises the following steps of: (1) calculating the manufacture size of the double-P type radiant tube; (2) cutting a plate, rolling the plate and welding the plate into the straight tubes; (3) punching and forming a plate into half bent tubes and welding the half bent tubes into the bent tubes; and (4) argon arc welding the manufactured straight tubes and the bent tubes and welding the supporting tube.

Owner:JIANGSU KUSUN SPECIAL STEEL PROD

Preparation method for decorative base paper

InactiveCN105862502APromote absorptionOvercoming the disadvantage of poor absorptionCoatings with pigmentsSpecial paperState of artMicrocrystalline cellulose

The invention relates to a preparation method for decorative base paper. The preparation method comprises the following steps: base paper preparation, coating preparation and surface coating. According to the invention, in the process of coating preparation, nanometer calcium carbonate microcapsules and microcrystalline cellulose are added, so glue liquid absorption performance of paper and strength of the paper are increased, and the disadvantage of poor absorptivity in the prior art is overcome. With a technical scheme provided by the invention, extensive application prospects are obtained.

Owner:宜城成雄织造有限公司

Graphite steel roller used by ribbon steel reversible roughing mill and manufacturing process thereof

PendingCN110218944AImprove wear resistanceLubricant, anti-oxidation, anti-thermal cracking performanceFurnace typesRollsStrip steelGraphite

The invention relates to the technical field of rollers, in particular to a graphite steel roller used by a ribbon steel reversible roughing mill and a manufacturing process thereof. The defect that the use requirement cannot be met in the prior art is overcome; the graphite steel roller includes an upper roller and a lower roller, the upper roller and the lower roller are symmetrically arranged and each comprise a roller body, bearing guards are fixedly arranged on the both sides of each roller body, the other sides of the bearing guards are fixedly provided with first roller necks and secondroller necks, and the other side of each second roller neck is fixedly provided with a transmission part. According to the graphite steel roller used by the ribbon steel reversible roughing mill, molten steel is spheroidized and inoculated by a spheroidizing agent and an inoculant correspondingly, an electromagnetic vibration centrifugal casting manner is used in cooperation, the microstructure of solidification crystallization of the steel industry can be improved, the structure loose area is eliminated, when the roller is used for rolling weathering resistant steel class strip steel, the rolling amount is 1-2 times that of a traditional roller, and the graphite steel roller very popular with users.

Owner:常州市中宇合金轧辊厂

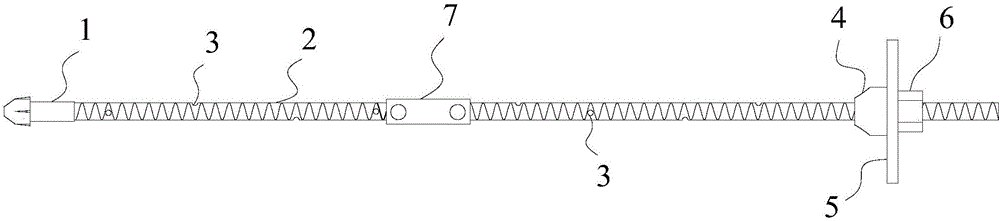

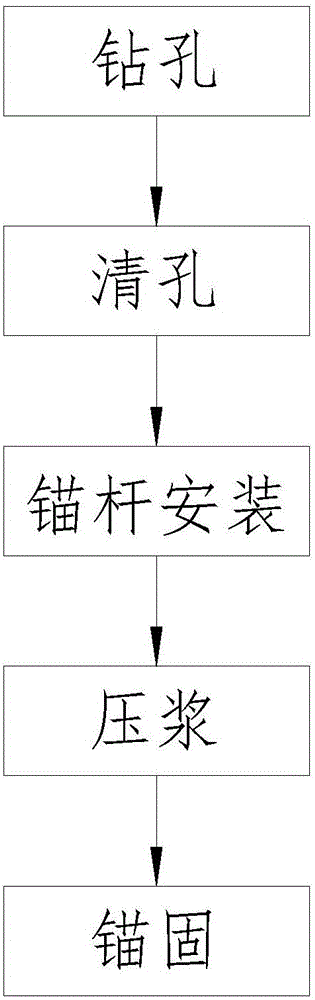

Glass fiber anchor rod and construction method

InactiveCN106523006AExcellent carrying capacityExcellent tensile strengthAnchoring boltsGlass fiberArchitectural engineering

The invention discloses a glass fiber anchor rod and a construction method. The glass fiber anchor rod comprises an anchor head, a rod body, a stop-grouting plug and an anchor accessory, wherein one end of the rod body is connected with the anchor head, and the other end of the rod body is in sliding connection with the stop-grouting plug and the anchor accessory; the stop-grouting plug is located between the anchor head and the anchor accessory; the rod body is of a hollow structure and is made of glass fibers; and the rod body is provided with a plurality of openings, and the openings communicate with the hollow structure of the rod body. The method comprises the steps of drilling, hole cleaning, installation of the anchor rod, grouting, anchorage and the like. By the adoption of the glass fiber anchor rod and the construction method, the bearing capacity and the tensile capacity of the rod body can be improved advantageously, the construction cost is reduced, a whole installation hole and surrounding cracks can easily be densely filled, and overall strength is improved. By the adoption of the method, the filling effect of grout to surrounding rock cracks can be improved, the grouting compaction degree is increased, the probability of corrosion to the rod body is lowered, the service life is prolonged, construction efficiency is improved, and construction safety is improved.

Owner:CHINA RAILWAY 23RD BUREAU GRP NO 1 ENG

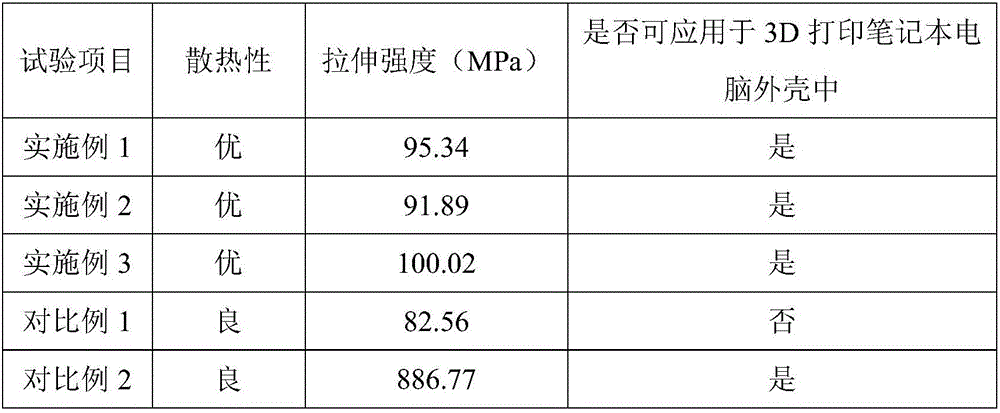

Graphene-modified shell material and preparation method thereof

InactiveCN106751597AExcellent heat dissipationExcellent tensile strengthAdditive manufacturing apparatusPolytetramethylene terephthalateFiber

The invention discloses a graphene-modified shell material and a preparation method thereof. Graphene-modified environment-friendly wear-resistant plastic material is prepared from graphene, a PET (polyethylene terephthalate) resin, tri(2,4-di-tert-butylphenyl)phosphite, polylactic acid, potassium tripolyphosphate, chloropropyl styrene, maleic anhydride graft polypropylene, hydroxymethyl cellulose sodium, Kevelar fibers, polybutylene terephthalate fibers, a surfactant, a regulator, propellant, a crosslinking agent, a compatilizer, a bridging agent, a catalyst, a plasticizer, a dispersing agent, a tackifier, a curing agent, an antioxidant, a stabilizer, an antiaging agent and a flame retardant. The preparation method comprises the following steps: pulverizing, activating, mixing, extruding and the like. The heat dissipation property and tensile strength of the graphene-modified shell material are obviously higher than those of the composite materials in the prior art. Meanwhile, the composite material is applicable to 3D printing notebook computer shells.

Owner:广西丰达三维科技有限公司

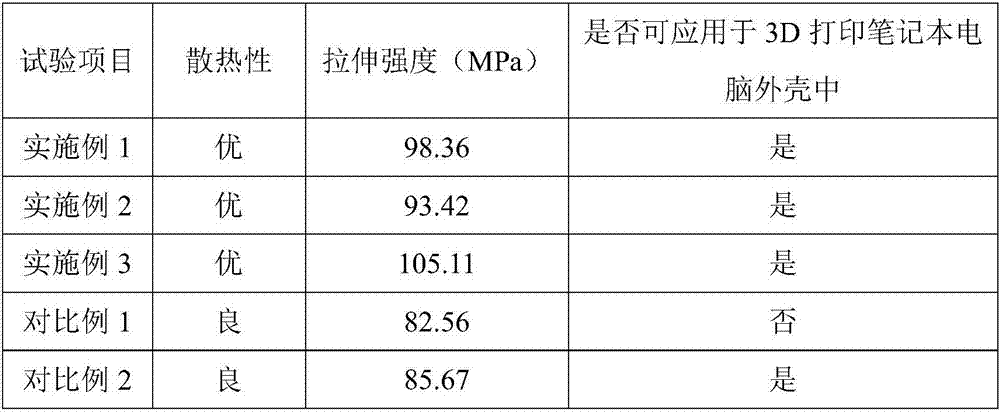

Graphene modified radiating consuming material for printing and application thereof

InactiveCN106928666AExcellent heat dissipationExcellent tensile strengthAdditive manufacturing apparatusDigital processing power distributionCross-linkPolytetramethylene terephthalate

The invention discloses a graphene-modified printing heat-dissipating consumable and its application. The graphene-modified printing heat-dissipating consumable includes the following raw materials: graphene, PET resin, glycol ether acetate, polylactic acid, three Sodium polyphosphate, chloropropyl styrene, maleic anhydride grafted polypropylene, sodium hydroxymethyl cellulose, Kevlar fiber, polybutylene terephthalate fiber, surfactant, conditioner, generator , cross-linking agent, compatibilizer, bridging agent, catalyst, plasticizer, dispersant, tackifier, curing agent, antioxidant, stabilizer, anti-aging agent, flame retardant, the graphene modified The thermal consumables for printing are made through crushing, activation, mixing, extrusion and other steps. The heat dissipation and tensile strength of the graphene-modified printing heat-dissipating consumables prepared by the invention are obviously better than the composite materials in the prior art; at the same time, the composite materials of the invention can be applied to 3D printing notebook computer shells.

Owner:广西丰达三维科技有限公司

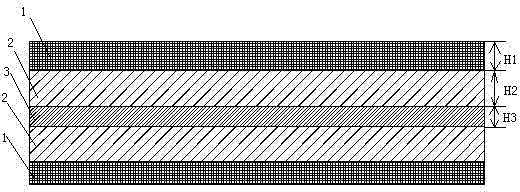

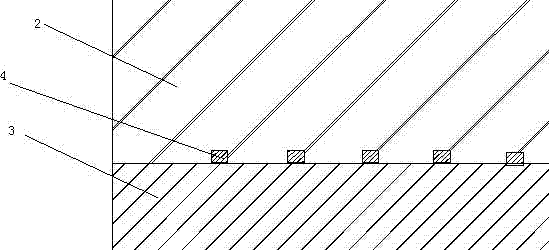

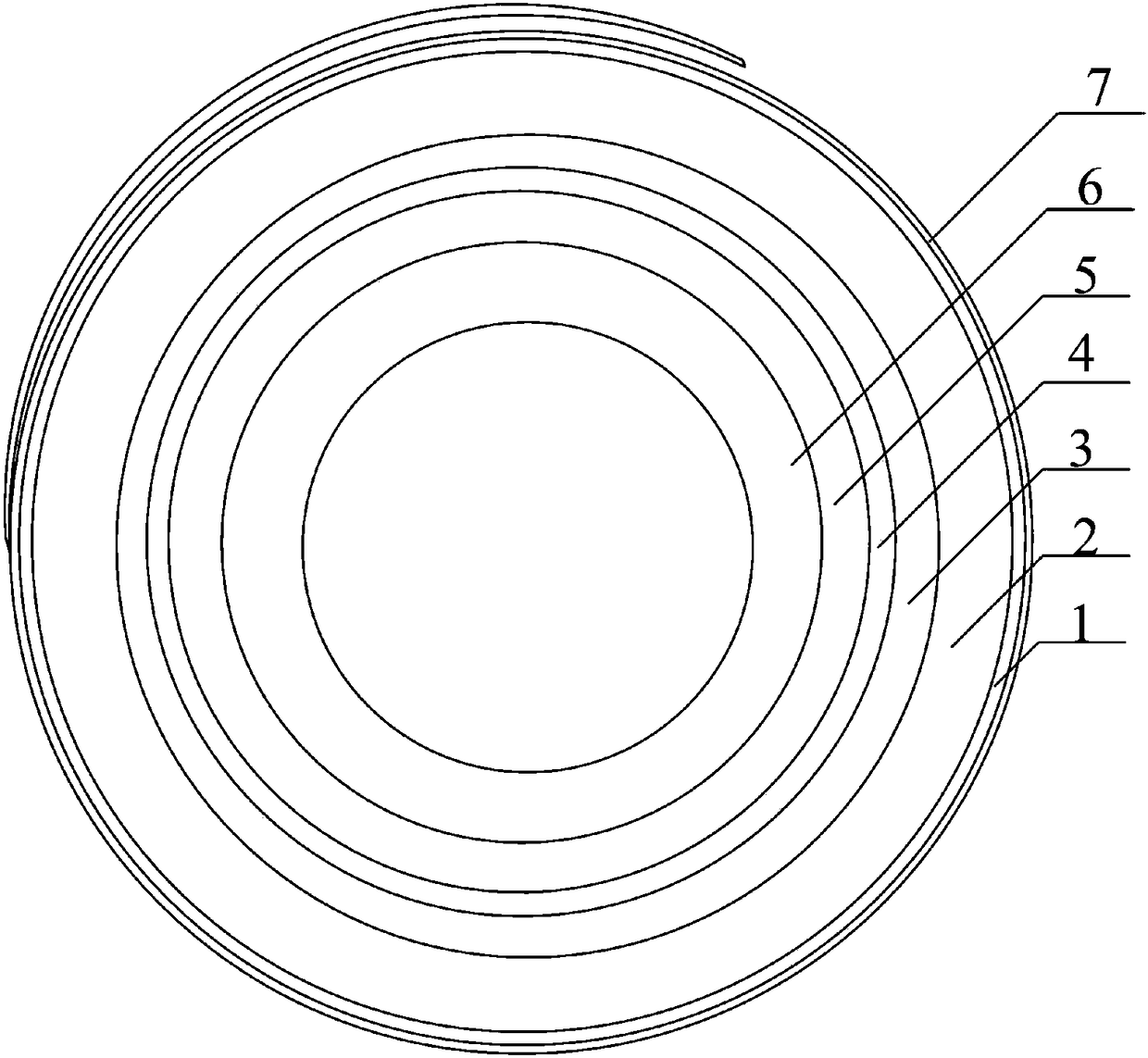

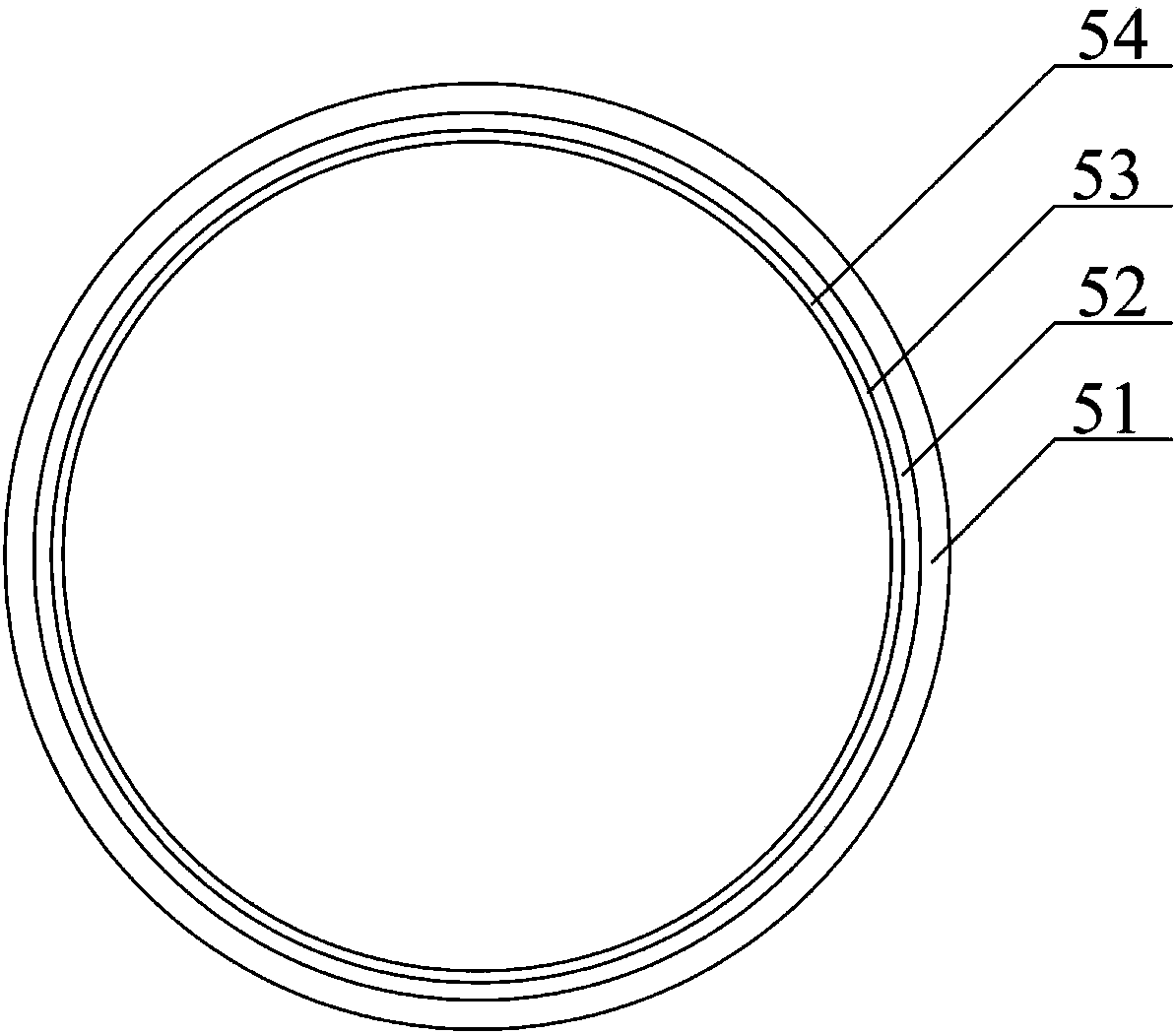

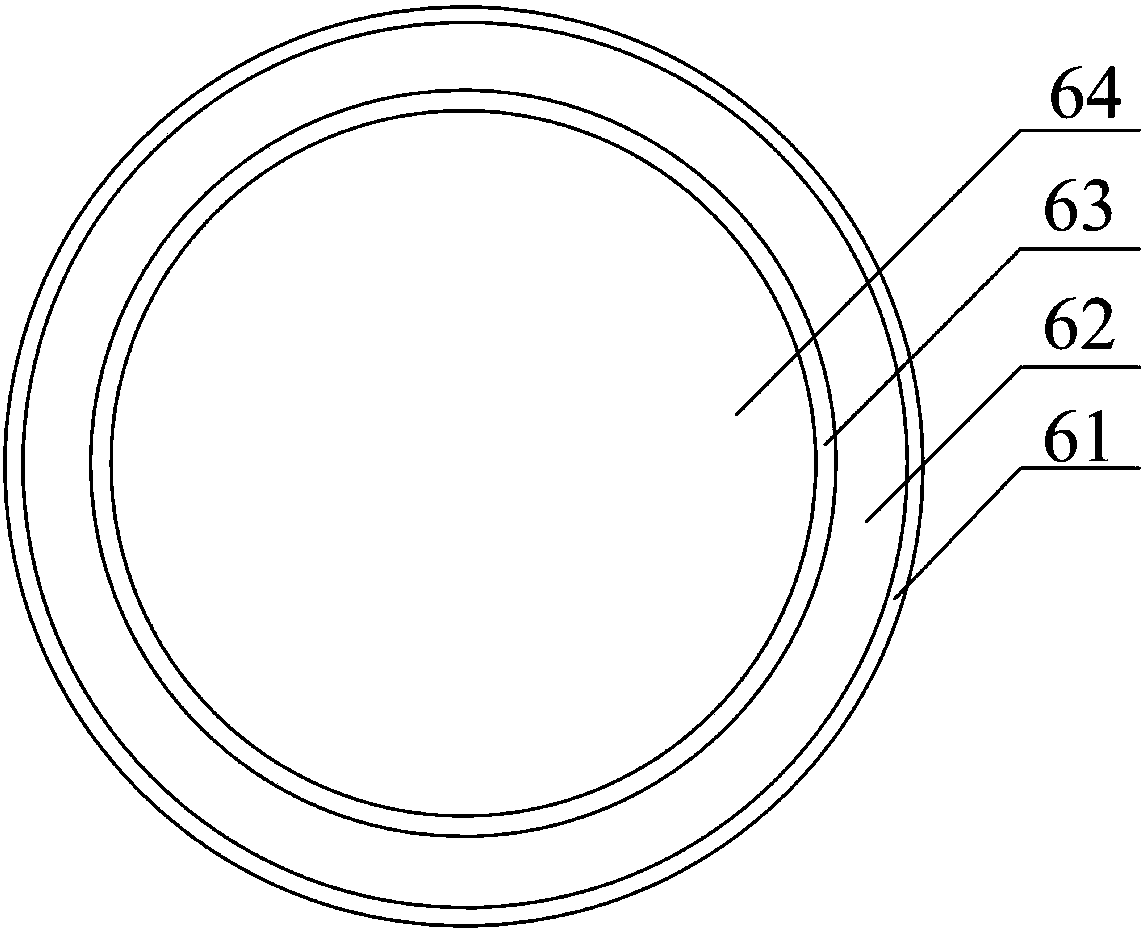

Polytetrafluoroethylene sealing belt

The invention discloses a polytetrafluoroethylene sealing belt. A belt body is composed of a surface layer, an elastic layer and a fiber layer from outside to inside, the surface layer is made of expanded polytetrafluoroethylene in a machined mode, and the elastic layer is made of rubber in a composite mode. The fiber layer is made of carbon fibers and formed by at least three layers of carbon fibers in a tight press-fitting mode, the connection position of the fiber layer and the elastic layer is filled with carbon fiber particles in a distributed mode, the size of the carbon fiber particles is 55 micrometers to 95 micrometers, and the ratio of the thickness H1 of the surface layer to the thickness H2 of the elastic layer to the thickness H3 of the fiber layer is 4:5:3. Through the layer-by-layer function of the surface layer, the elastic layer and the fiber layer, the toughness, the retraction elasticity, the tensile strength and the compressive strength of the polytetrafluoroethylene sealing belt can be greatly improved, and the use performance of the polytetrafluoroethylene sealing belt can be greatly improved.

Owner:镇江春环密封件集团有限公司

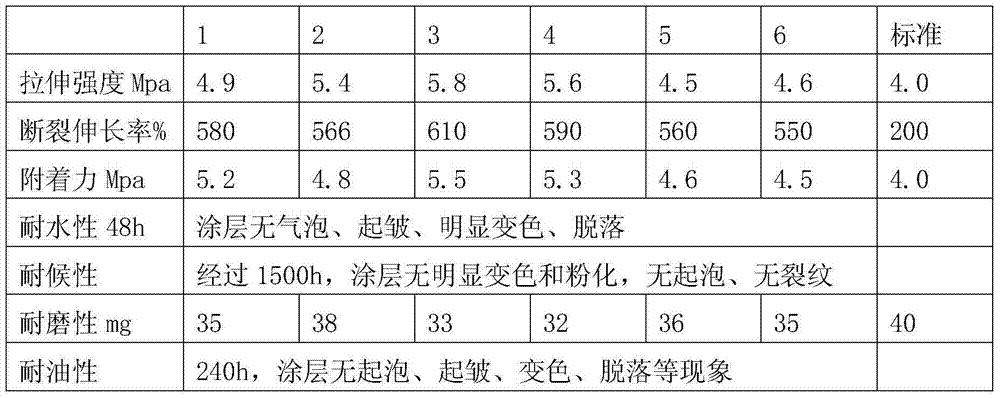

Special waterproof material for high-speed rail and preparation method thereof

ActiveCN103540121AExcellent tensile strengthExcellent elongation at breakPolyvinyl alcoholRare earth

The invention discloses a special waterproof material for high-speed rail and a preparation method thereof. The special waterproof material comprises the following components in parts by weight: 15-30 parts of amino acetal ester, 30-35 parts of carbon black, 30-40 parts of polypropylene, 25-40 parts of polyurethane, 10-15 parts of polyvinyl alcohol, 0.5-1 part of aluminum sulfate, 3-5 parts of chlorinated paraffin, 2-5 parts of trichloroethyl phosphate, 1-3 parts of talcum powder, 3-8 parts of polypropylene wax, 5-8 parts of PVC (polyvinyl chloride) binder, 0.5-1.5 parts of rare earth composition and 1-2 parts of BYK969. The tensile strength, the elongation at break and other parameters of the special waterproof material disclosed by the invention are better than those of the prior art, and the special waterproof material further has low-temperature resistance and can keep excellent properties in an environment with temperature being lower than -45 DEG C.

Owner:句容市睿远科技有限公司

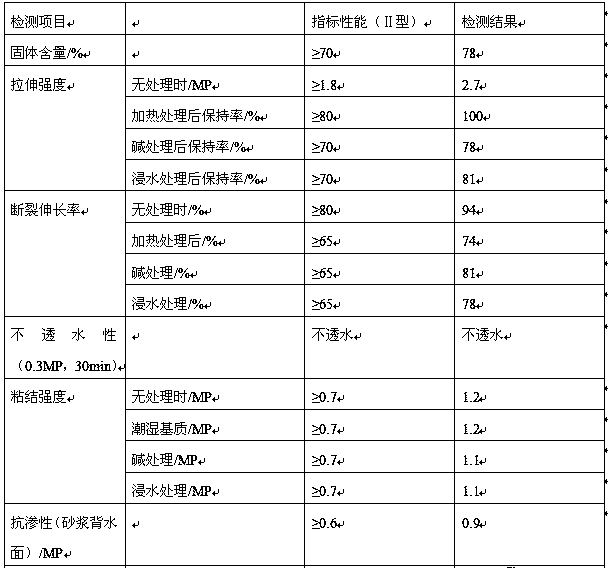

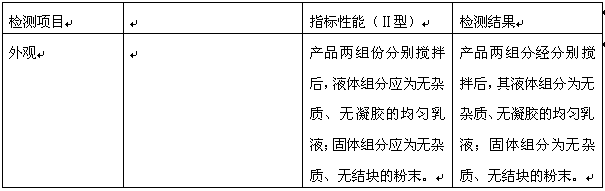

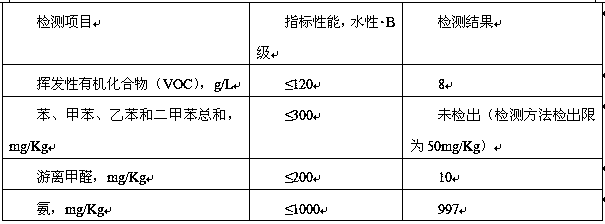

II-type polymer cement waterproof coating and preparation method thereof

InactiveCN108409262AExcellent tensile strengthExcellent elongation at break indexEmulsionNational standard

The invention discloses an II-type polymer cement waterproof coating and a preparation method thereof. The coating comprises mixed liquid and mixed powder according to the weight part ratio of 90-110:140-160, the mixed liquid comprises the following raw materials in parts by weight: elastic waterproof emulsion, water, a defoamer and a sterilizing agent according to the weight ratio of 90-110: 8-18: 0.15-0.25: 0.08-0.16; and the mixed powder comprises the following raw materials in parts by weight: 32.5 cement, 800-mesh ground calcium carbonate, 40-120-mesh silica sand and a water reducing agent according to the weight part ratio of 90-110: 90-110: 90-110: 0.8-2. Fifteen physical and mechanical properties of a polymer cement waterproof coating as claimed in an embodiment of the invention totally pass all stipulations of GB / T23445-2009, and are much higher than the national standard, and after the II-type polymer cement waterproof coating is soaked in water, heated and subjected to alkali treatment, the tensile strength, the index of elongation at break, bonding force and anti-permeability actual measurement index are much higher than those of the product in the prior art.

Owner:马官友

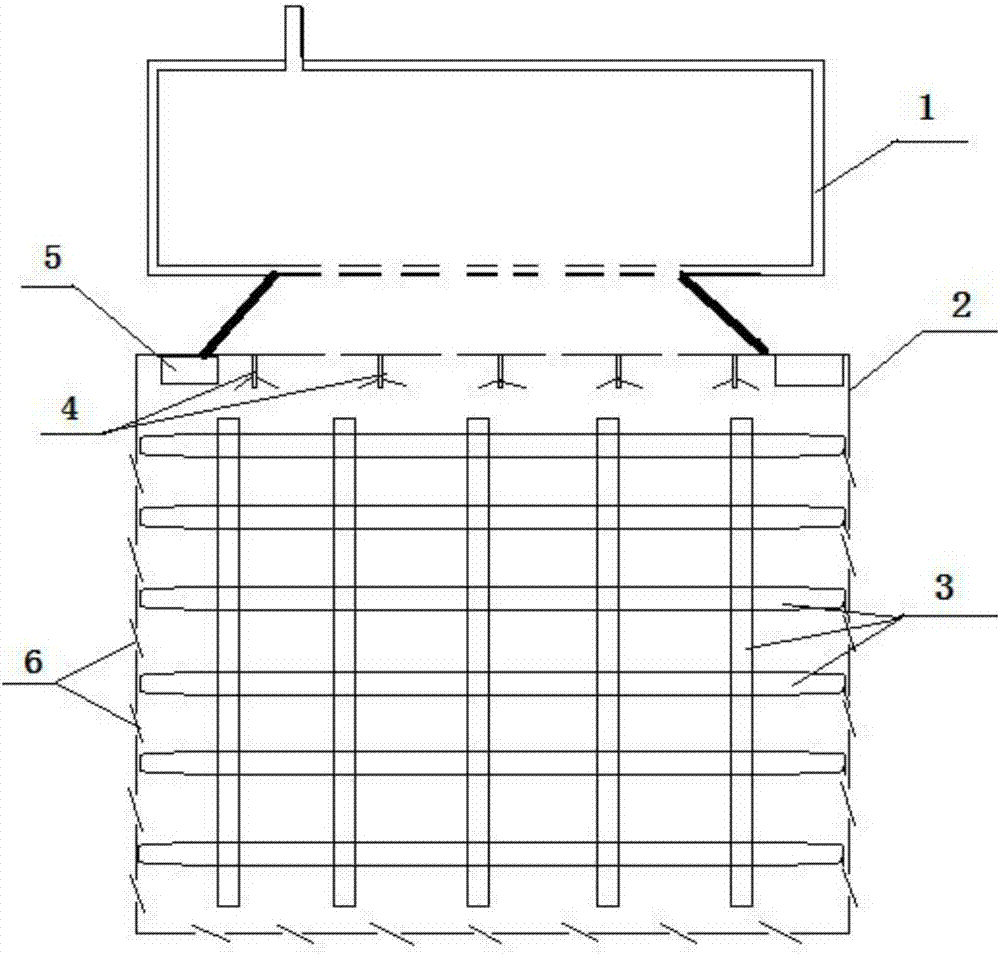

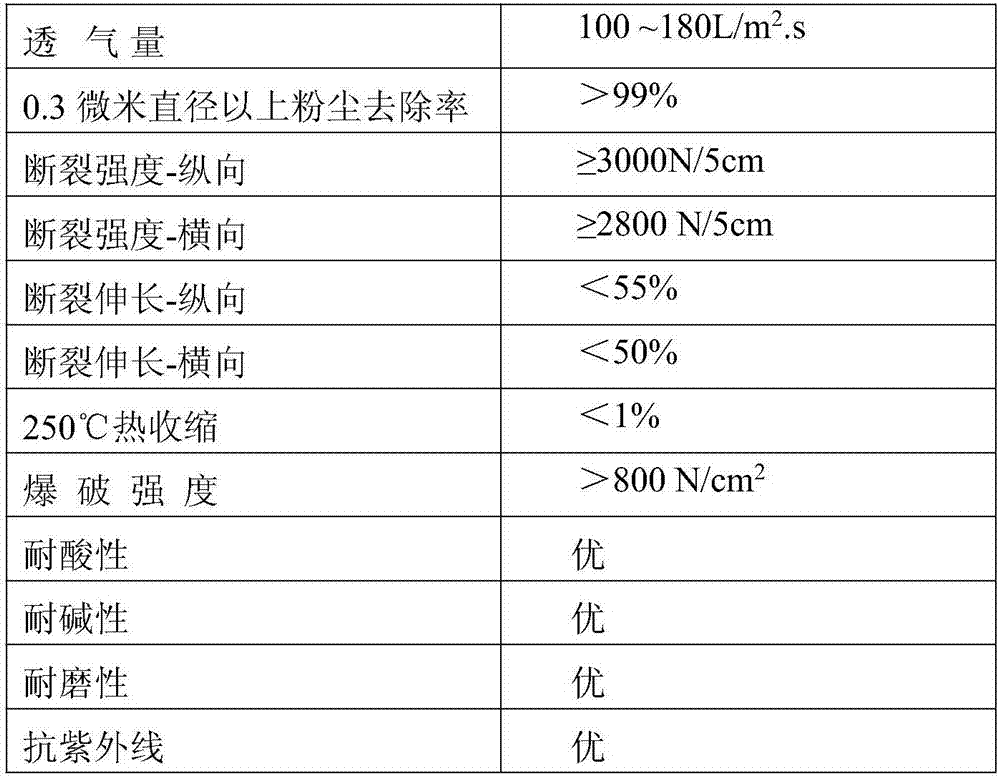

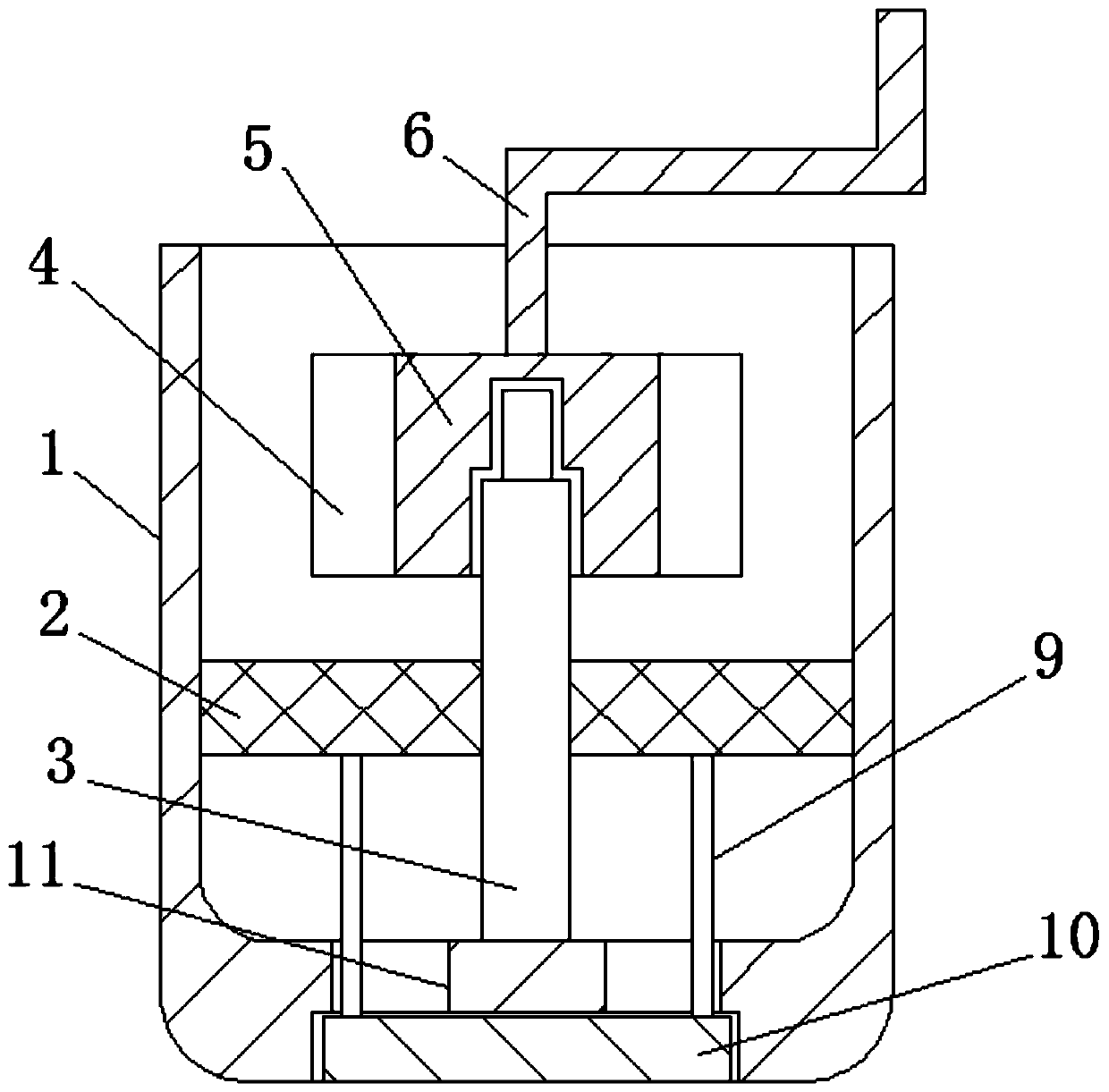

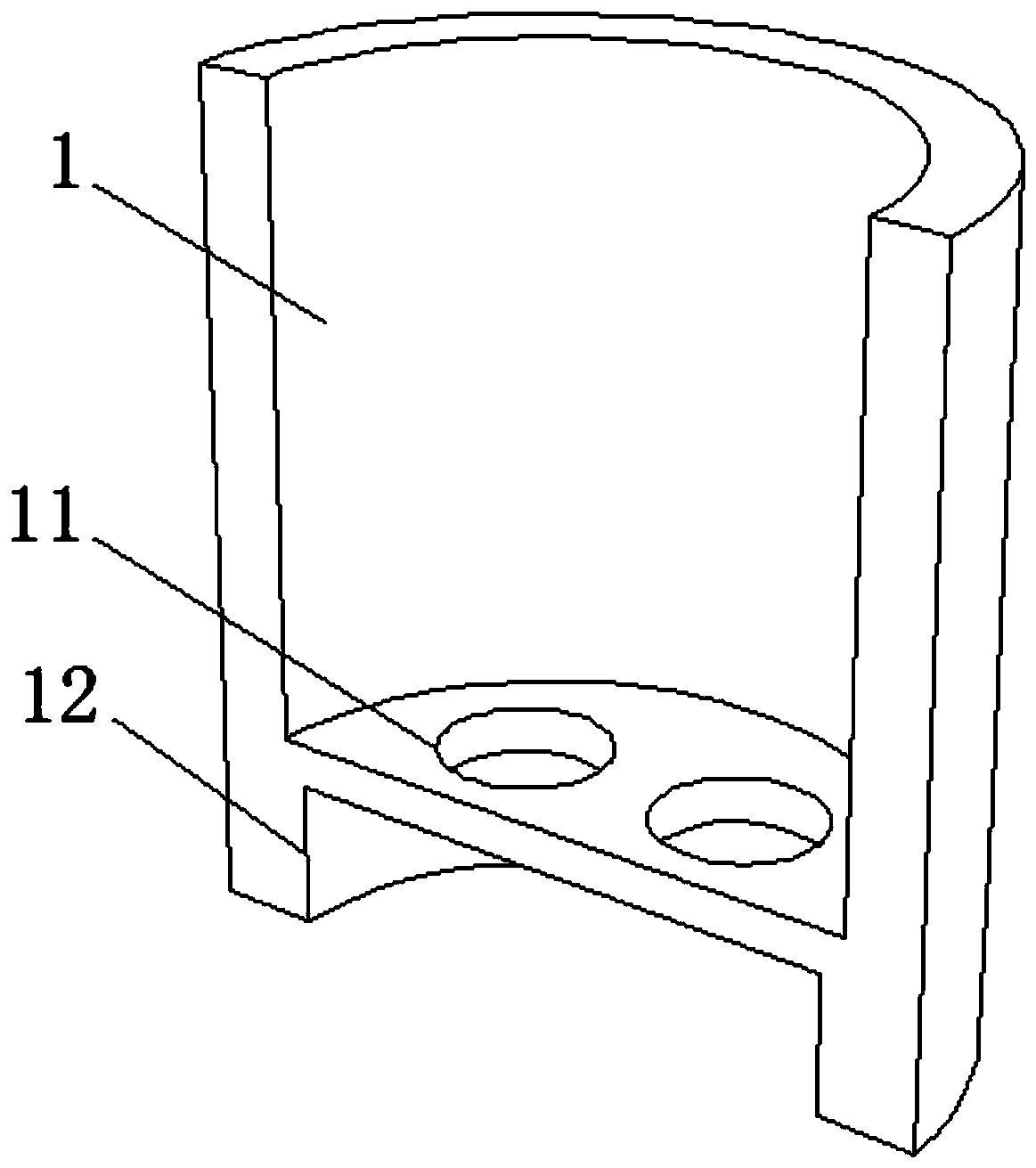

High-temperature-resistant and corrosion-resistant washable industrial dust removal device

ActiveCN107081015AAvoid cloggingImprove filtering effectGas treatmentDispersed particle filtrationEngineeringTemperature resistance

The invention discloses a high-temperature-resistant and corrosion-resistant washable industrial dust removal device, which comprises a dust removal box (1), a suction device (2) connected with the top of the dust removal box (1), and a filter element (3) arranged in the dust removal box (1), wherein the filter element (3) is arranged in the dust removal box (1) in a crossed manner; a pressure sensor and a temperature sensor are arranged in the filter element (3) and are connected with a PLC; a water spray cleaning device (4) and an infrared heating device (5) are arranged at the top of the dust removal box (1); and a motor, the suction device (2), the water spray cleaning device (4) and the infrared heating device (5) all are connected with the PLC. The high-temperature-resistant and corrosion-resistant washable industrial dust removal device is high in environmental protection property, reasonable in structural design, excellent in dust removal and filter properties, higher in filter precision and low in cost, can be cleaned regularly and can be repeatedly used; the filter element has excellent mechanical properties, such as high temperature resistance, corrosion resistance and tensile resistance, and is long in service life and wide in application range.

Owner:JIANGSU LVDI ENVIRONMENTAL PROTECTION FILTER

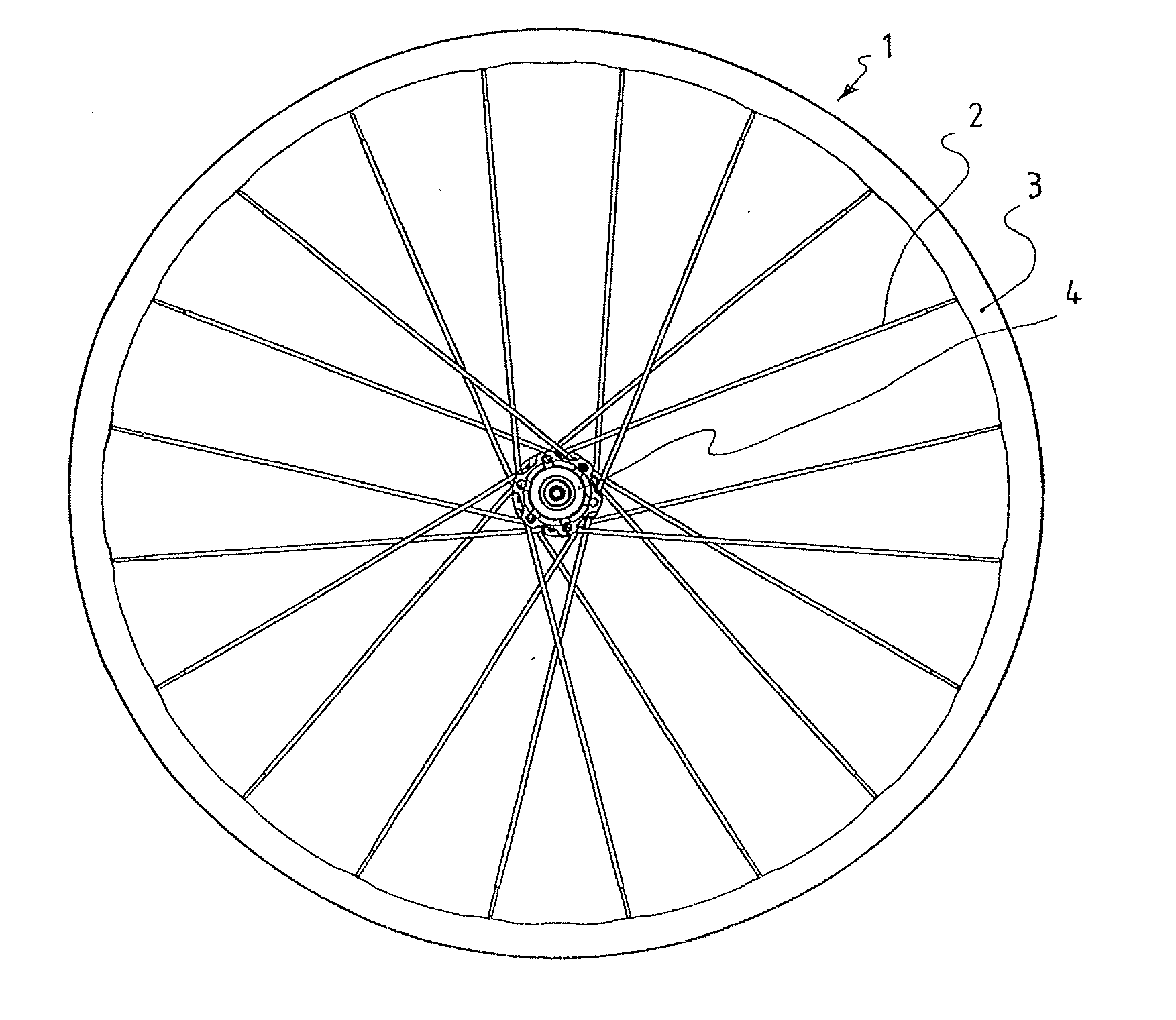

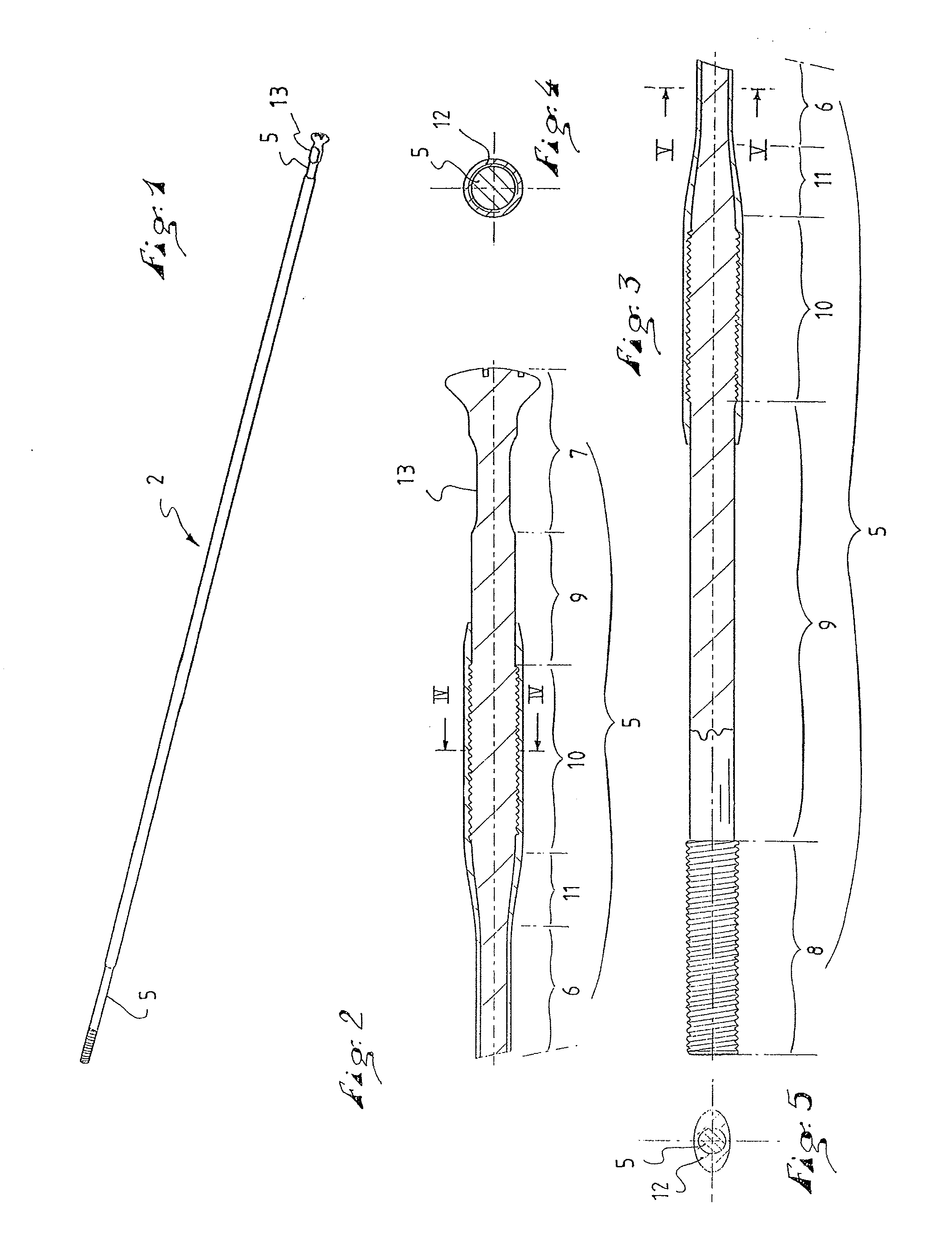

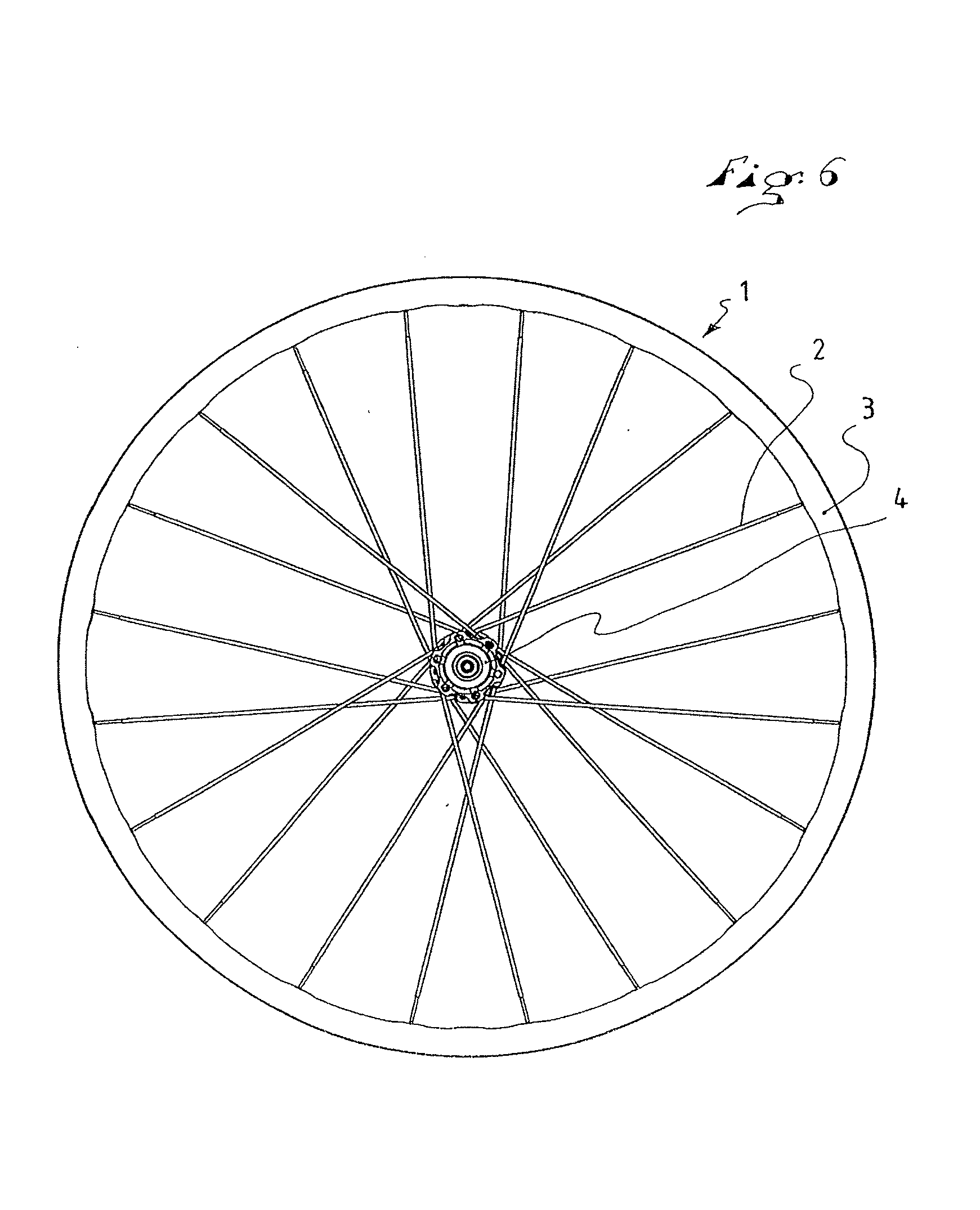

Cycle wheel spoke and cycle wheel comprising such a spoke

InactiveUS20130285436A1Excellent tensile strengthCertain degreeMetal-working apparatusNon-metallic wheel bodyEngineeringSpoke

A spoke including a metallic core covered, at least in its central portion, with a sheath of composite material comprised of an assembly of fibers embedded in a matrix, the core including an end portion adapted to be attached to the rim or the hub of a wheel, and a main body whose cross-sectional surface area is between 30% and 50% or, in a particular embodiment, between 35% and 45%, of the cross-sectional surface area of the aforementioned end portion. Furthermore, in the area of the main body, the sheath has a cross section between 150% and 500% or, in a particular embodiment, between 150% and 350%, of the cross section of the metallic core in the same area. The metal core includes two mechanical anchoring zones, positioned in the vicinity of its ends, on both sides of the main body.

Owner:MAVIC SA

Polyamide composition and preparation method thereof

The invention provides a polyamide composition and a preparation method thereof. The polyamide composition comprises the following components in parts by weight: 100 parts of polyamide 56, 10-30 partsof long-carbon-chain polyamide and 5-50 parts of an auxiliary agent, wherein the long-carbon-chain polyamide is polyamide of which the methylene number between adjacent amide groups on a main chain is greater than or equal to 10; and the auxiliary agent at least comprises a mineral filler. The polyamide composition provided by the invention has the advantages of low water absorption, high dimensional stability, high tensile strength and high impact strength through reasonable configuration of the components.

Owner:CATHAY R&D CENT CO LTD +1

Biodegradable plastic product material

The invention relates to a biodegradable plastic product material being composed of, by weight, 30-60% of a biodegradable material and 50-70% of polypropylene plastic, wherein the biodegradable material includes soya bean protein and starch according to the ratio of 1:3. Compared with a conventional synthetic plastic product, the biodegradable synthetic material is better than the common synthetic plastic products in light transmittance, oxygen permeability, heat resistance, toughness, softness, elasticity, tensile strength and anti-aging property. In addition the biomass synthetic plastic is greatly reduced in production cost. The biodegradable plastic product material needs 5-8 months for being completely decomposed in soil into high-quality organic fertilizers.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

Anti-aging geocell material and preparation method thereof

The invention discloses an anti-aging geocell material. The high-density polyethylene material is prepared from the following raw materials in parts by weight: 70 to 85 parts of high-density polyethylene, 7 to 16 parts of ethylene-vinyl acetate copolymer, 2 to 6 parts of basalt fiber, 3 to 8 parts of nano zinc oxide, 0.2 to 1 part of ultraviolet absorbent, 0.3 to 1 part of antioxidant, 2 to 6 parts of interfacial compatibilizer and 0.3 to 1 part of processing aid. The ultraviolet absorbent is at least one of a hindered amine ultraviolet absorbent, benzotriazole UVP and dihydroxy benzophenone UV531; the antioxidant is a mixture of a hindered phenol main antioxidant and a phosphite ester auxiliary antioxidant, and the mass ratio of the hindered phenol main antioxidant to the phosphite esterauxiliary antioxidant is 1:(0.2-0.4). The aging-resistant geocell material disclosed by the invention is long in oxidation induction time and excellent in aging resistance; the tensile strength is high and the mechanical property is good. The geocell material is high in cantilever beam notch impact strength and good in impact resistance, is high in the bending modulus and has good comprehensive mechanical property.

Owner:哈尔滨金蜂巢工程材料开发有限公司

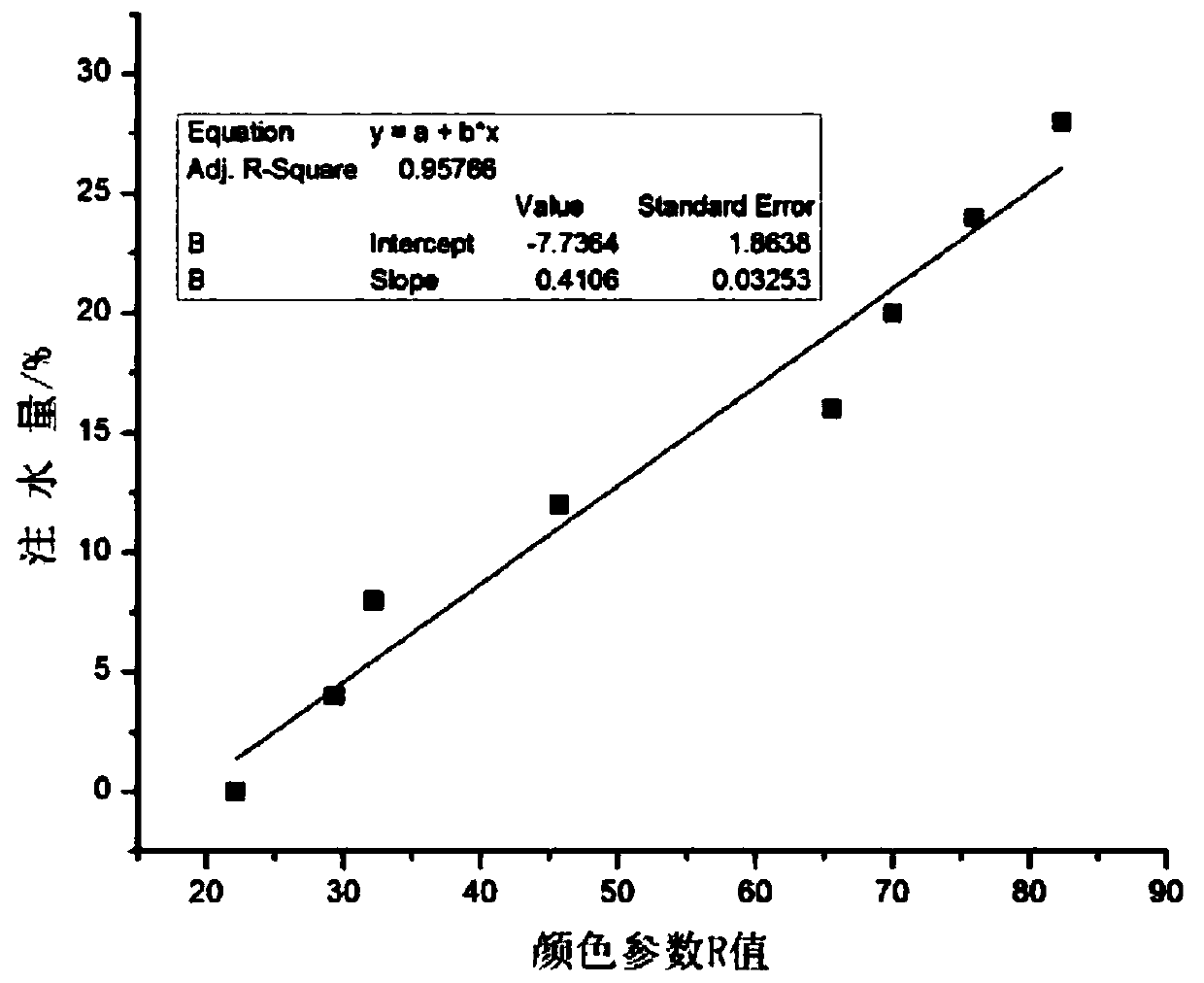

Paper-based/silica sol/polyvinyl alcohol (PVA) color-changing composite film for detecting water-injected meat, preparation method and application thereof

InactiveCN110093810AExcellent tensile strengthGood liquid absorption performanceCoatings with pigmentsMaterial analysis by observing effect on chemical indicatorChemistryPolyvinyl alcohol

The invention discloses a paper base / silica sol / polyvinyl alcohol (PVA) color-changing composite film for detecting water-injected meat, a preparation method and application thereof, belonging to thefield of meat quality detection. A paper base selected by the composite film is dust-free paper which is a non-woven mixed structure composed of 55% cellulose and 45% polyester fiber and has excellenttensile strength, excellent liquid absorption performance and anti-dissolution performance. A composite coating composed of silica sol and PVA has the characteristics of good film-forming property and strong water absorption. The film has excellent mechanical properties, good stability and long service life. The paper base / silica sol / polyvinyl alcohol (PVA) color-changing composite film is less affected by moisture in the environment and is convenient to store. The used color-changing composite film can be put into an oven with 100 DEG C for re-drying to realize recycling. According to the method, a mixed liquid containing a color-changing reagent and the dust-free paper are combined to detect the water injection quantity of the water injected meat, the water injection quantity can be judged not only by the color change of the composite film but also by a wet area of the composite film. The preparation method is simple and does not need special instruments and equipment. All the reagents used are low in price, the preparation method can effectively reduce the cost of the composite film and is beneficial to realizing industrialization.

Owner:JILIN UNIV

Anti-corrosion, anti-stretching, and direct burial water-blocking medium-voltage cable

InactiveCN108461196AAvoid scrappingAvoid it happening againInsulated cablesInsulated conductorsElectrical conductorWater block

The invention provides an anti-corrosion, anti-stretching, and direct burial water-blocking medium-voltage cable. The cable comprises a semi-conductive graphite coating layer, an HDPE outer sheath layer, an aluminum alloy wire armored layer, an MDPE isolation sleeve, a multi-layer shielding protection structure, a conductor insulating water-blocking layer and a cable connecting and fixing band structure; the outer side of the HDPE outer sheath layer is coated with the semi-conductive graphite coating layer; the HDPE outer sheath layer is arranged on the outer side of the aluminum alloy wire armored layer in an extrusion manner; the aluminum alloy wire armored layer is wound around the outer side of the multi-layer shielding protection structure; and the multi-layer shielding protection structure is arranged on the outer side of the conductor insulating water-blocking layer in an extrusion or coating manner. By adding a water-blocking material in the conductive wire core and by adoptingthe lead alloy sheath, the cable has the longitudinal water blocking and radial sealing and dampproof anti-corrosion effects; and through the metal armored material and by adopting the aluminum alloywires, the tensile property and tensile strength of the cable are ensured, and thermal runaway fault caused by heating due to eddy current loss can be effectively eliminated.

Owner:山东森联能源科技有限公司

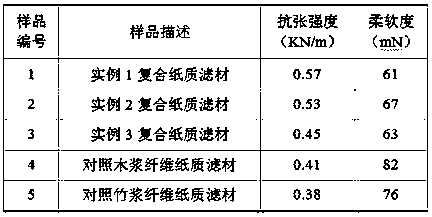

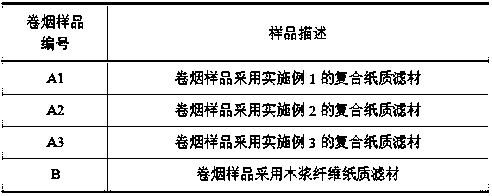

Wingceltis skin and bagasse fiber composite paper filter material and preparation method and application thereof

ActiveCN108158035AImprove the defect of poor tasteExcellent tensile strengthTobacco smoke filtersFiberSmoked Plum

The invention relates to a wingceltis skin and bagasse fiber composite paper filter material and a preparation method and application thereof. The preparation method comprises the following steps of step (1) preparation of paper base; step (2) preparation of coating liquid; and step (3) preparation of paper filter material. According to the wingceltis skin and bagasse fiber composite paper filtermaterial and the preparation method and application thereof, wingceltis skin long staples and bagasse short staples are reasonably matched, the paper base with good tensile strength and flexibility isobtained, an extractive of smoked plum and liquorice used for the paper base is developed at the same time, and the problem that sensory quality is reduced caused by the traditional paper filter material. The novel plant fiber composite paper filter material can provide sweet and fresh gas fume after is used for cigarette filter, the woodsiness offensive odor, irritation and dry sensation are allreduced somewhat, the residue is small, and the remaining taste is sour and sweet.

Owner:CHINA TOBACCO YUNNAN IND

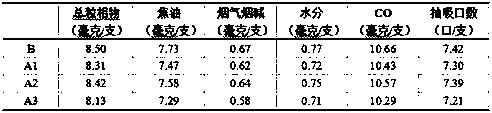

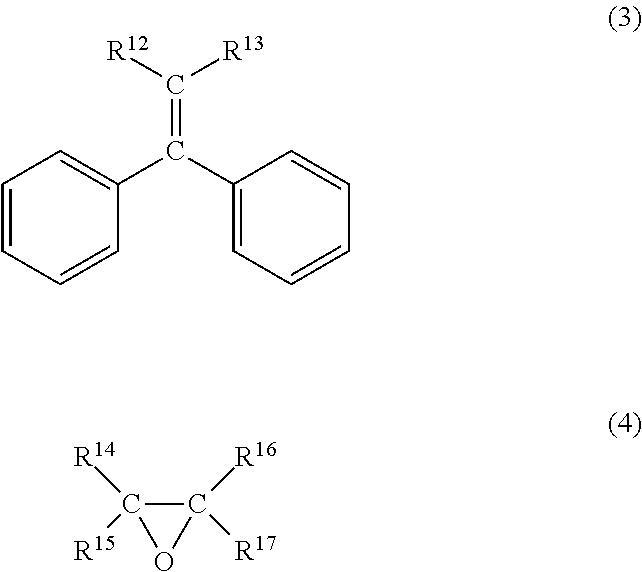

Method of production of modified conjugated diene rubber

ActiveUS20180016362A1Good processabilityExcellent tensile strengthSpecial tyresTyre tread bands/patternsHalogenConjugated diene

A method of production of modified conjugated diene rubber includes causing an aromatic compound having three or more carbon atoms directly bonded to an aromatic ring in one molecule to react with an alkali metal atom so as to obtain an alkali metal-reacted aromatic compound; polymerizing a monomer at least containing a conjugated diene compound by using the alkali metal-reacted aromatic compound so as to obtain a conjugated diene rubber having an active end; causing the active end of the conjugated diene rubber having an active end to react with an activity control agent so as to obtain a conjugated diene rubber reacted with an activity control agent; and causing the active end of the conjugated diene rubber reacted with an activity control agent to react with a modifier having an alkoxy group and a halogen atom-containing group so as to obtain a modified conjugated diene rubber.

Owner:ZEON CORP

Fruit-protecting bag and its making method

InactiveCN1141013CImprove shadingWeatherproofPaper/cardboardPlant protective coveringsFiberEngineering

A fruit-protecting bag for protecting growth of fruits is made up from paper pulp through digestion, bleaching, filtering, mixing it with durable non-toxic or low-toxin antibacterial chemical, stirring, making paper, baking and making the fruit-protecting bags. Its advantages include no need of spraying agricultural chemical, and high light shielding, wind and rain resistance, hydrophobicity and air permeability.

Owner:蔡秒水 +1

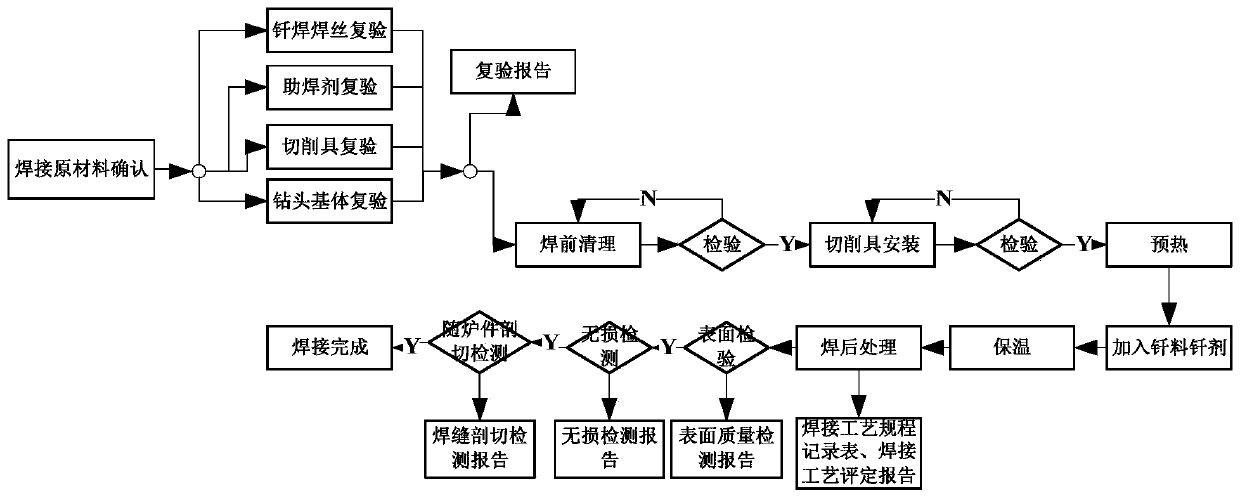

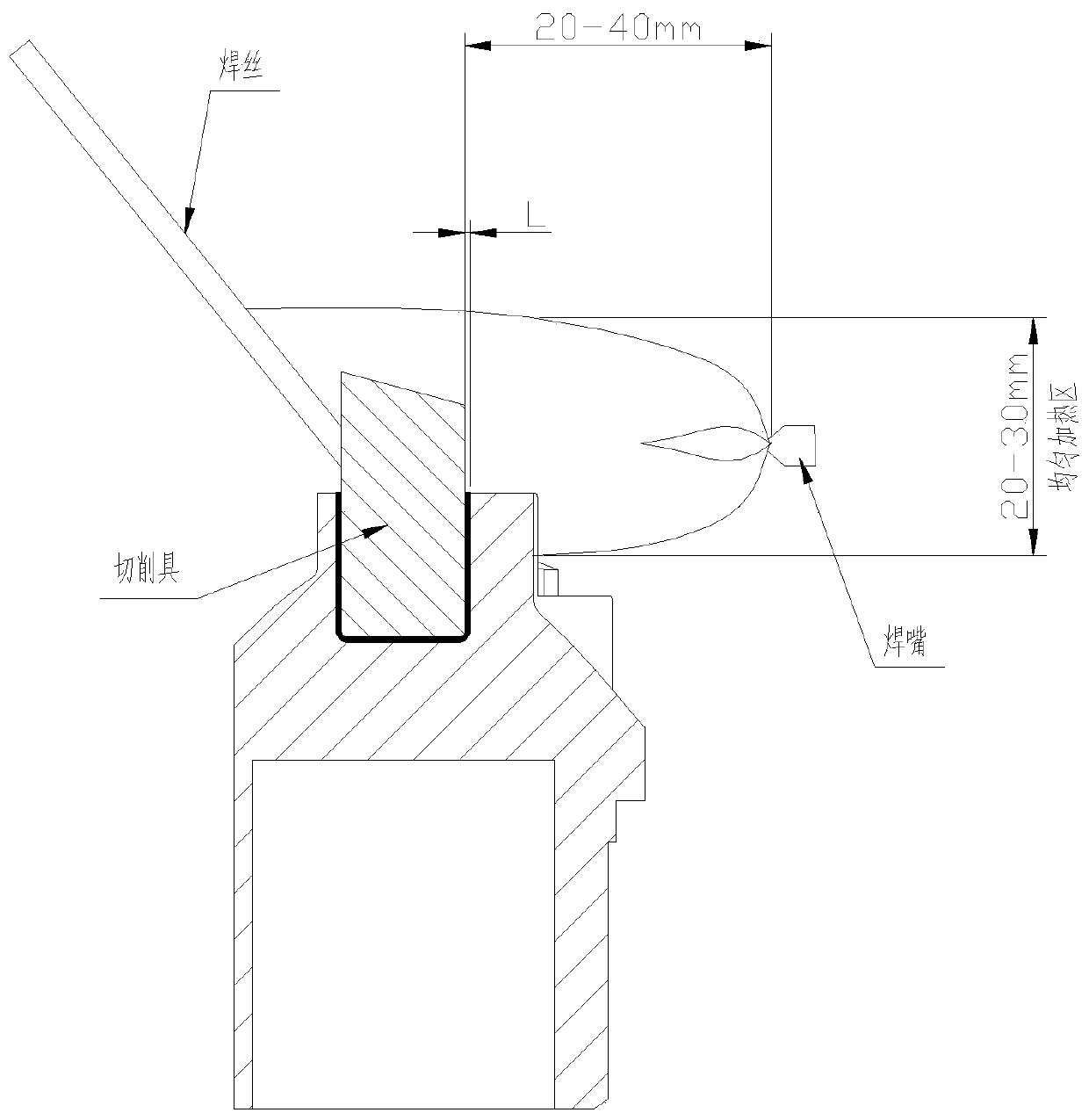

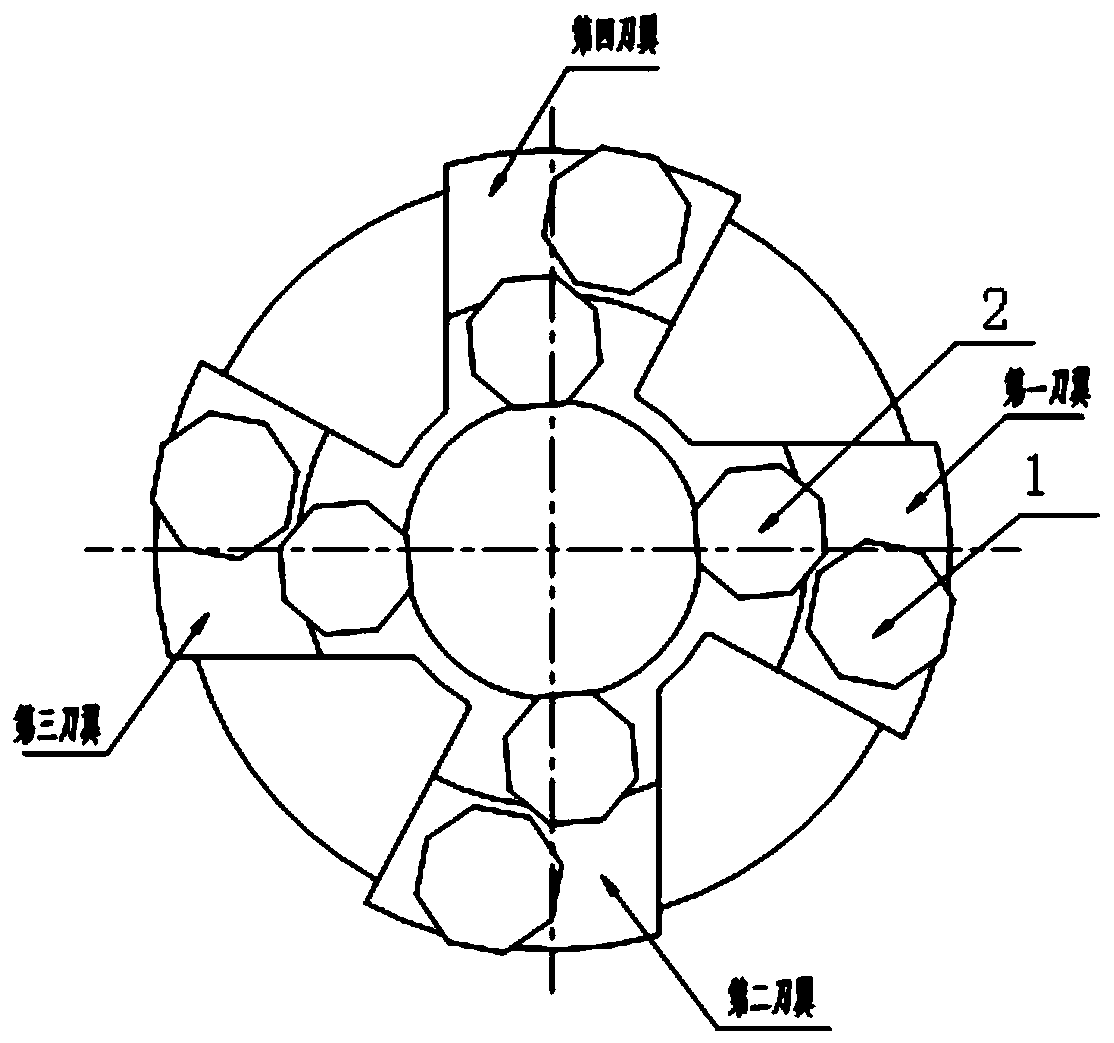

Brazing and nondestructive detecting method of drill bit for lunar soil drilling

ActiveCN109773295AExcellent tensile strengthExcellent shear strengthSoldering apparatusMaterial analysis by transmitting radiationLunar soilNondestructive testing

The invention discloses a brazing and nondestructive detecting method of a drill bit for lunar soil drilling. The method comprises the following steps: (1) a drill bit basal body, a cutter, a weldingwire and a flux are prepared; (2) sand is blasted to the drill bit basal body and the cutter; and then, the welding wire, the drill bit basal body and the cutter are cleaned by using anhydrous ethanol; (3) the cutter and the drill bit basal body are assembled; (4) welding nozzle parameters for brass brazing are set to obtain brazing flame; (5) the drill bit basal body and the cutter assembled in the step (3) are preheated according to the brazing flame in the step (4); (6) the cutter and the drill bit basal body preheated in the step (5) are welded; (7) the cutter and the drill bit basal bodywelded in the step (6) are insulated; and (8) the nondestructive detection is performed on the cutter and the drill bit basal body insulated in the step (7). Key process parameters are strictly controlled, and the welding line quality is detected, so that the welding reliability of the drill bit is high.

Owner:BEIJING SATELLITE MFG FACTORY

Graphene modified plastic printing consuming material and preparation method thereof

InactiveCN106928742AWide variety of sourcesLow priceAdditive manufacturing apparatusFootwearCross-linkPolymer science

The invention discloses a graphene modified plastic printing consuming material and a preparation method thereof. The graphene modified plastic printing consuming material is prepared from the following raw materials: graphene, abandoned plastics, maleic anhydride grafted ethylene propylene terpolymer, polylactic acid, sodium tripolyphosphate, 2-hydroxy-4-octyl diphenylbutanone, butenyl distearamide, glycol monostearate, tributoxy ethyl phosphate, tri(2,4-ditert-butylphenyl) phosphite ester, surface active agent, modifier, generating agent, cross-linking agent, compatilizer, bridging agent, catalyst, plasticizer, dispersing agent, tackifier, curing agent, antioxidant, stabilizer, anti-aging agent, fire retardant and smoke inhibitor. The graphene modified plastic printing consuming material is prepared according to the following steps: cleaning, drying, crushing, activating, mixing and extruding. The abrasive resistance and the tensile strength of the graphene modified plastic printing consuming material prepared according to the invention are obviously better than the abrasive resistance and the tensile strength of the plastic material in the prior art.

Owner:广西丰达三维科技有限公司

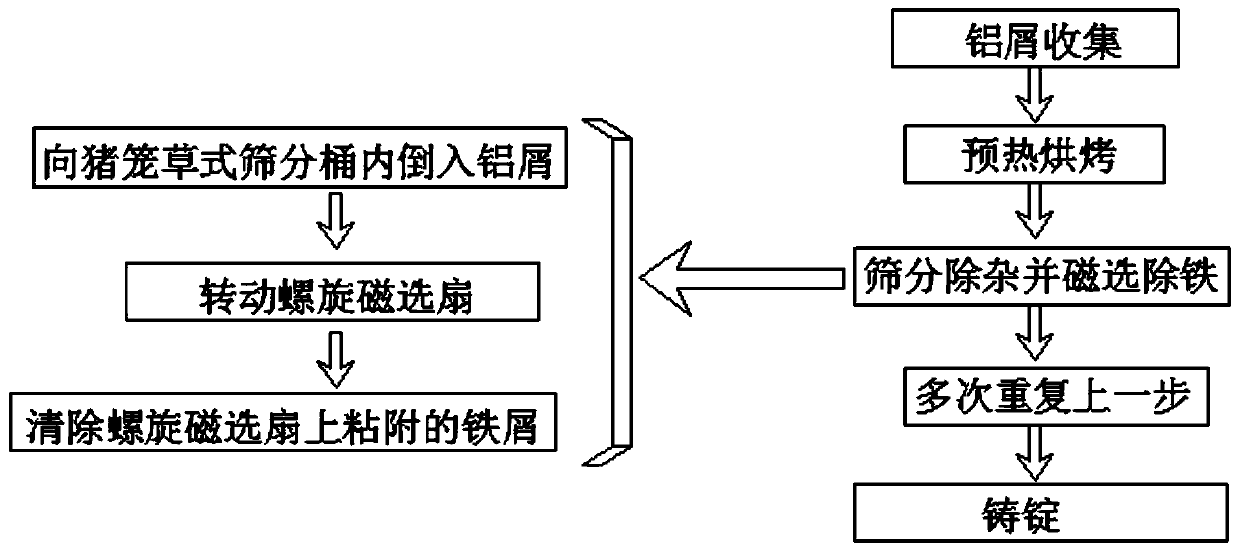

Nepenthes type aluminum scrap recycling treatment process

The invention discloses a nepenthes type aluminum scrap recycling treatment process, and belongs to the field of metal waste recovery. The nepenthes type aluminum scrap recycling treatment process hasthe beneficial effects that the two steps of screening and impurity removal, and magnetic separation and iron removal are combined in one step through the use of a nepenthes type screening barrel, sothat the aluminum scrap recovery process is simplified, and the time of the aluminum scrap recycling treatment is saved to a great extent, and the efficiency of the aluminum scrap recycling treatmentis remarkably improved; meanwhile, nepenthes type special-shaped sleeve pipes in screening holes are used so as to enable the probability that aluminum scraps are gotten stuck in the screening holesto be reduced, and the service life of a screen is prolonged; and meanwhile, nano-scale micropores of the nepenthes type special-shaped sleeve pipes and lubricating oil inside the nepenthes type special-shaped sleeve pipes are used, so that the aluminum scraps gotten stuck in the screening holes are just like insects preyed by nepenthes and are very difficult to stay in the screening holes; and even if the aluminum scraps are gotten stuck, when the aluminum scraps are taken out, the screen can be effectively protected due to the reduction of the friction, so that the probability that the screen is damaged by the aluminum scraps is reduced, and the cost investment of the aluminum scrap treatment is reduced.

Owner:宁波锦锐能源科技有限公司

High-weather-resistance aluminum alloy sectional material

InactiveCN108149094AImprove securityExcellent tensile strengthAnodisationWeather resistanceCorrosion resistant

The invention discloses a production method for a high-weather-resistance aluminum alloy sectional material. The production method comprises the following steps: preparing materials and smelting, specifically, preparing materials in percentage by mass: 7%-8.8% of Zn, 0.8%-1.5% of Cu, 1%-4% of Fe, 2%-3% of Mn, 2%-3% of Mg, 0.2%-0.5% of Si, 0.2%-0.8% of Cr, 0.08% of Ni, 0.03% of Ti and the balance Al, and smelting at a high temperature for 6h to 8h to obtain an aluminum alloy melt; casting; annealing; carrying out two-step heat treatment; extruding the treated aluminum alloy cast ingot through an aluminum alloy sectional material die to obtain the aluminum alloy sectional material; carrying out double-stage aging and air-cooling on the aluminum alloy sectional material; and finally carryingout oxidation treatment. According to the process disclosed by the invention, the super-weather-resistant and corrosion-resistant aluminum alloy sectional material can be prepared without the need ofadditional spraying, and the process is energy-saving and environment-friendly, and high in safety.

Owner:黄发金

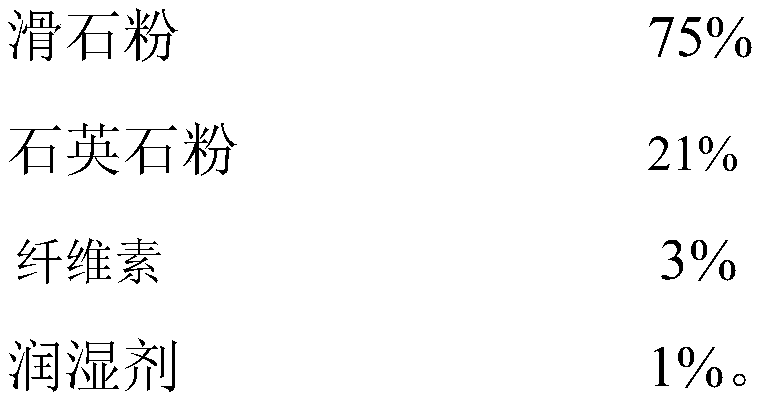

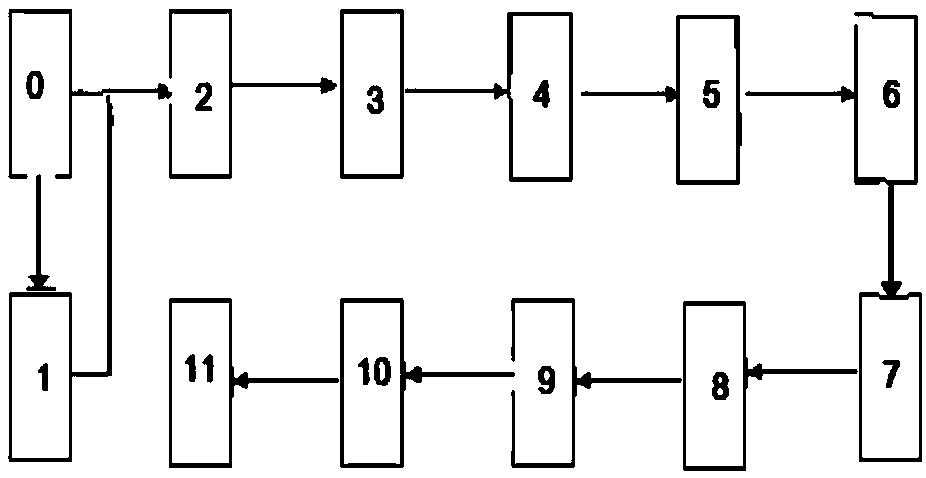

3D printing powder and preparation method thereof

InactiveCN109553331ARich sourcesThe preparation conditions are easy to achieveAdditive manufacturing apparatusCelluloseUltimate tensile strength

The invention provides 3D printing powder and a preparation method thereof, wherein the 3D printing powder comprises, by mass, 50-80% of talc powder, 15-45% of quartz stone powder, 3-5% of cellulose,and 0.8-1.3% of a wetting agent, wherein the particle sizes of the talc powder and the quartz stone powder are 150-800 mesh. According to the present invention, the 3D printing powder has characteristics of low cost, good toughness, high strength and excellent marketing value.

Owner:TIANHE COLLEGE GUANGDONG POLYTECHNIC NORMAL UNIV

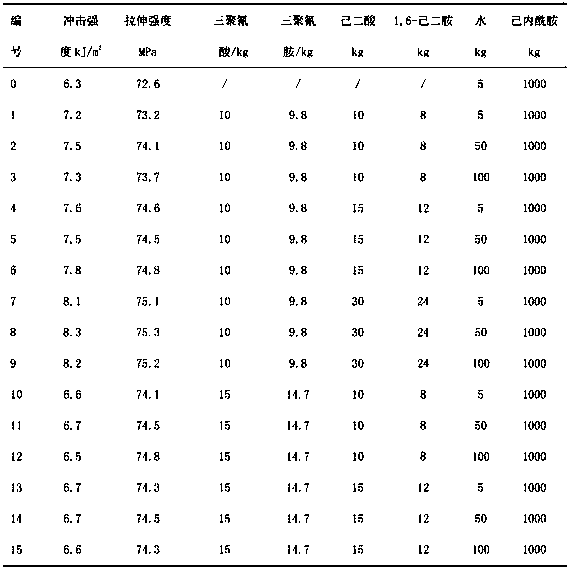

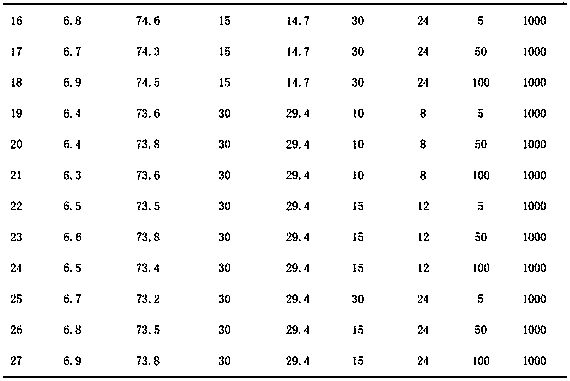

Delustering agent, and delustering nylon 6 material and preparation method thereof

The invention discloses a delustering agent, and a delustering nylon 6 material and a preparation method thereof, wherein the delustering agent comprises a melamine cyanurate generated by a reaction of a melamine compound and a cyanuric acid compound. The method for preparing a fiber-grade delustering nylon 6 material by adopting the delustering agent comprises: adding a melamine compound, a cyanuric acid compound, dicarboxylic acid, a binary primary amine and water into a molten caprolactam liquid, and carrying out shearing dispersing to obtain a dispersion liquid; and feeding the dispersionliquid and molten caprolactam liquid into a polymerization system, and carrying out ring-opening polymerization to obtain the delustering nylon 6 material. According to the invention, the delusteringagent has advantages of low cost, intersolubility with caprolactam, stable dispersion and good delustering performance, and the prepared polycaprolactam has good mechanical properties, such as excellent impact strength, excellent tensile strength and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

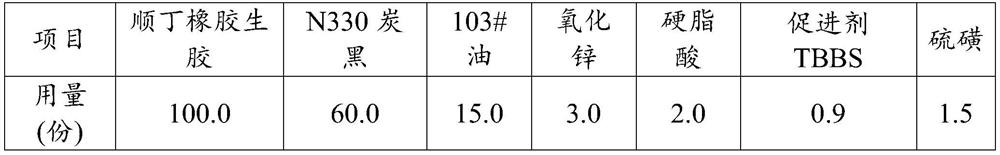

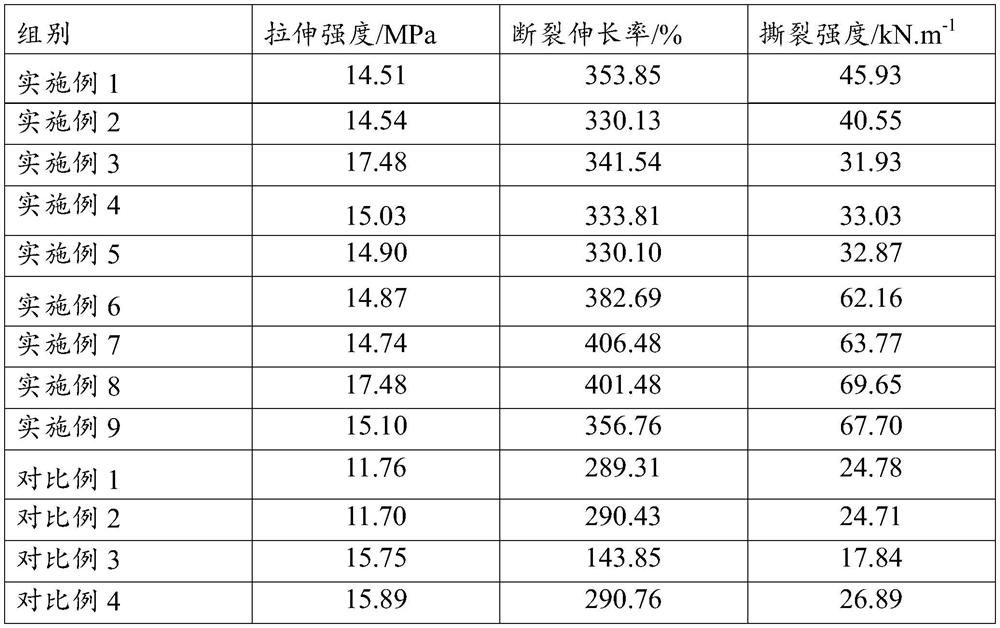

Raw butadiene rubber rubber and preparation method thereof

ActiveCN114031698AHigh tensile strengthHigh tear strengthRolling resistance optimizationPolymer sciencePtru catalyst

The invention relates to the technical field of raw rubber, and particularly discloses raw butadiene rubber and a preparation method thereof. The method comprises the following steps: S1, mixing a refined butadiene monomer, a solvent and a catalyst, and carrying out a polymerization reaction to obtain a rubber solution; S2, mixing the rubber solution prepared in the step S1 with a terminating agent and an anti-aging agent, and carrying out a termination reaction to obtain a mixed solution; S3, at the temperature of 70-98 DEG C, mixing and stirring the mixed solution obtained in the step S2 and a dispersing agent, carrying out condensation reaction, condensing out rubber particles, and removing the solvent and unreacted butadiene monomer; and S4, washing the rubber particles with a rubber washing solution, and after the rubber particles are washed, carrying out extrusion dehydration, drying, briquetting and packaging to obtain the raw butadiene rubber. According to the method, the tensile strength and the tearing strength of the raw butadiene rubber are improved in the rubber washing process stage in the raw butadiene rubber production process, the existing process does not need to be greatly changed, and the technical improvement investment is relatively low.

Owner:CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com