Glass fiber anchor rod and construction method

A glass fiber and construction method technology, which is applied in the installation of bolts, earth-moving drilling, mining equipment, etc., can solve the problems of poor grouting and poor support, and reduce working strength, service life and damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

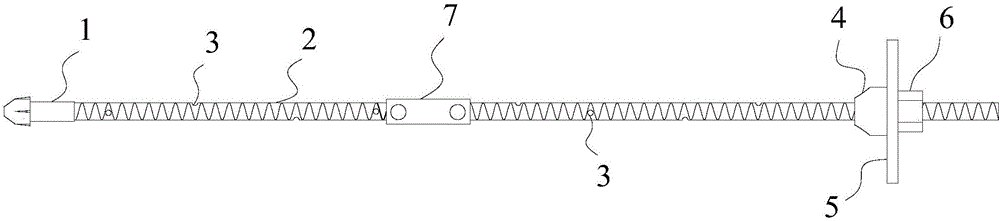

[0044] Such as figure 1 As shown, a glass fiber anchor rod according to the present invention includes an anchor head 1, two rod bodies 2, a grout plug 4, a backing plate 5 and a nut 6, wherein one end of one rod body 2 is connected to the anchor head 1 One end of the other rod body 2 is connected to the grout stopper 4 and the anchor fitting, and the two rod bodies 2 are connected by a coupling sleeve 7, and the grout stopper 4 is located between the coupling sleeve 7 and the anchor fitting Between, the anchor fittings are a backing plate 5 and a nut 6, the rod body 2 is a hollow structure, the materials of the rod body 2, the grout stopper 4, the backing plate 5 and the nut 6 are all glass fibers, and the rod body 2 The outer wall is a threaded structure, and the rod body 2 is provided with several openings 3, all the openings 3 are evenly distributed on the entire rod body 2, in a quincunx shape, and all the openings 3 are circular in shape and size , and the diameter is 5...

Embodiment 2

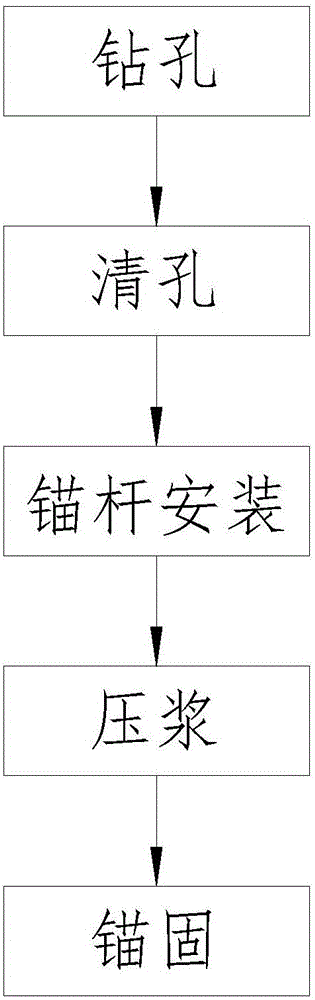

[0046] The construction method of a kind of glass fiber anchor rod of the present invention comprises using a kind of glass fiber anchor rod as in embodiment 1, as figure 2 , its construction method includes the following steps:

[0047] Step 1, drilling, drilling on the construction work surface according to the construction plan and measurement setting;

[0048] Step 2: Clear the hole, carry out pressure air cleaning on the drilled hole, and remove cuttings;

[0049] Step 3, install the anchor rod, install the anchor head 1 on one end of the rod body 2, install the grout stopper 4 on the other end and insert it into the hole, so that the rod body 2 is located at the center of the hole;

[0050] Step 4, grouting, using a grouting machine to grout the inside of the rod body 2 until the grouting in the hole is full;

[0051] Step 5, anchoring. After the grouted grout reaches the required strength, install the anchoring accessories.

[0052] First, according to the construct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com