Testing instrument for dynamic virtual power of spindle

A virtual power and tester technology, applied in the direction of instruments, power metering, measuring devices, etc., can solve the problems of low precision, large system error, large drift, etc., achieve high degree of automation and efficiency, excellent bearing capacity and vibration resistance , the effect of high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions in the embodiments of the present invention will be further described below in conjunction with the drawings in the embodiments of the present invention.

[0031] The invention provides a dynamic virtual power tester for a spindle to meet the needs of just, scientific and accurate evaluation of the energy consumption of the spindle, objective evaluation of the energy-saving performance of the spindle, and dynamic testing of the dynamic power curve of the spindle.

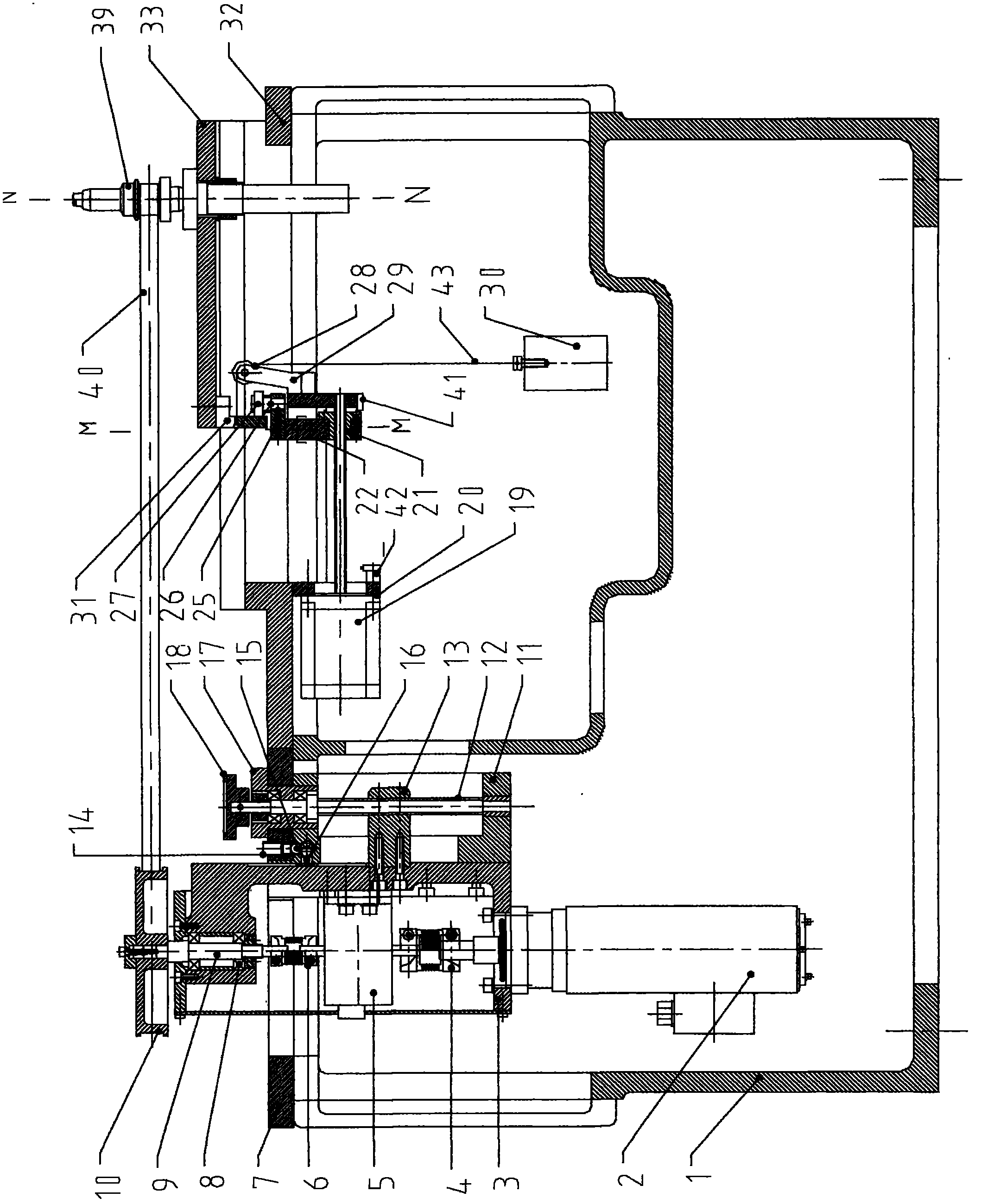

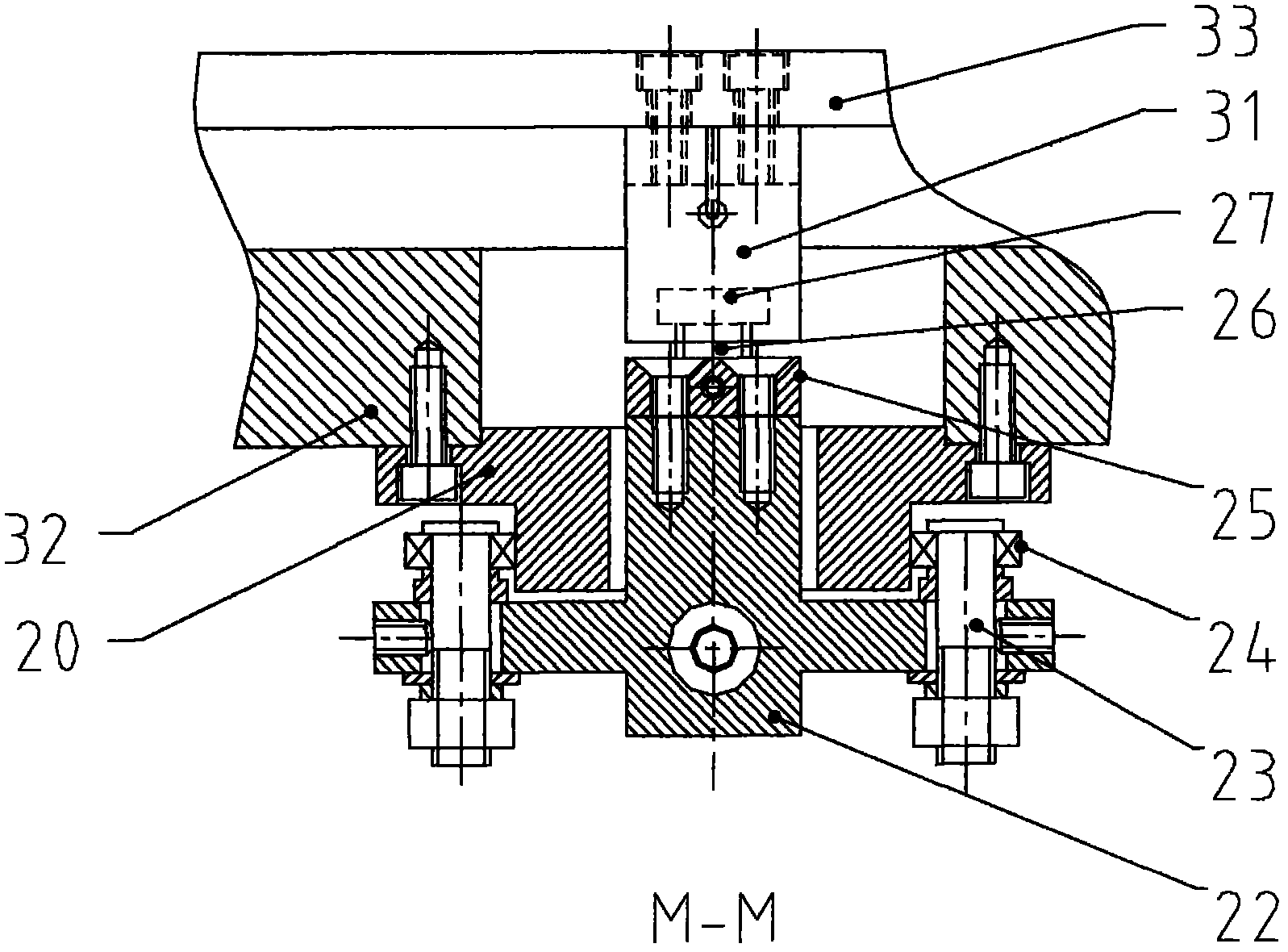

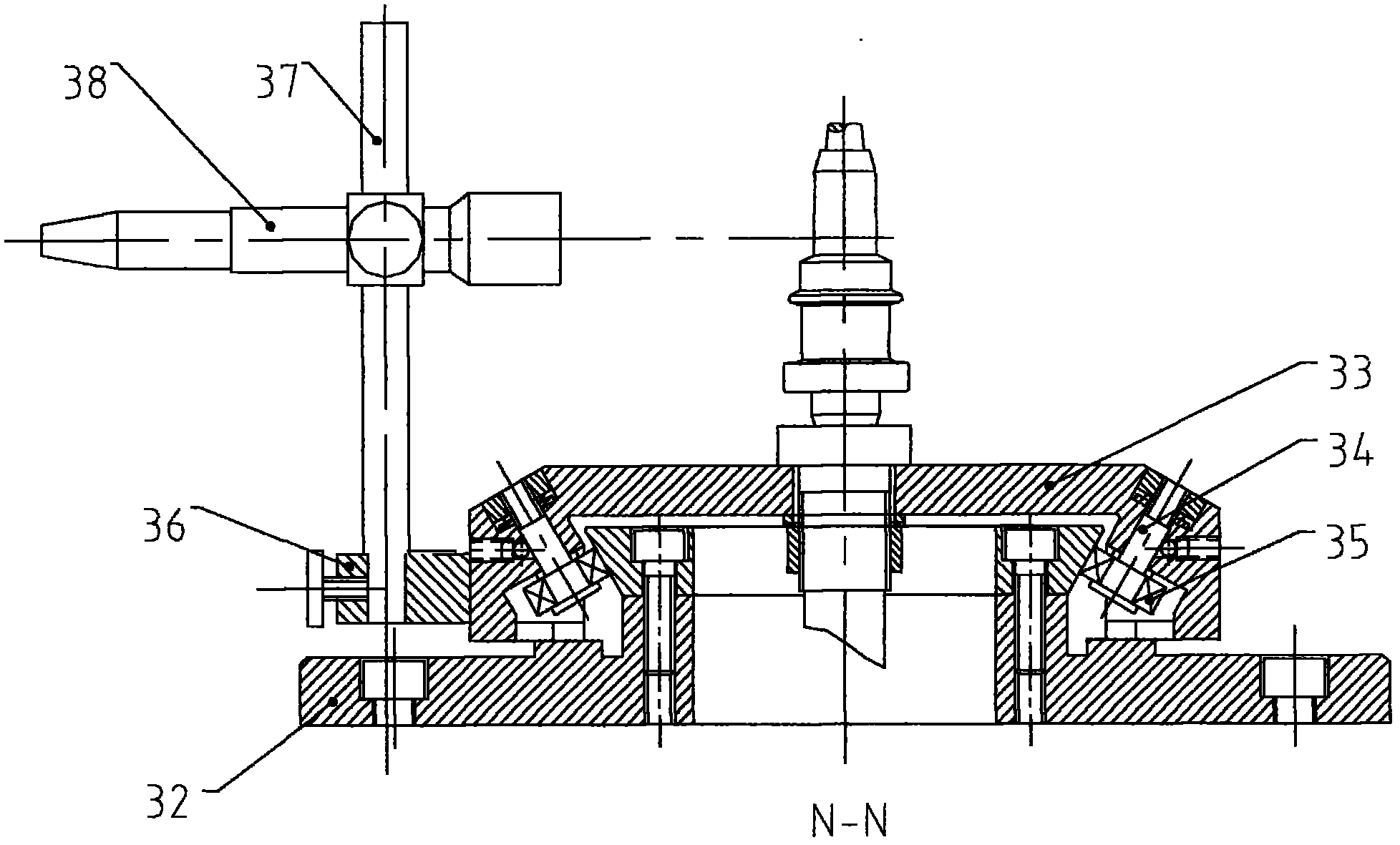

[0032] figure 1 The assembly diagram of a dynamic virtual power tester for spindles is shown in , and the following descriptions are given according to the components, including:

[0033] Frequency conversion motor drive lifting mechanism, frequency conversion motor drive mechanism, dynamic torque sensor, spindle installation movement mechanism, stepper motor loading and unloading mechanism, laser speed sensor speed measurement mechanism, of which:

[0034] The frequency conversion mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com