Acquisition and energy-saving control method of power consumption of CNC machine tool spindle rotation acceleration

A technology of rotational acceleration power and spindle speed, applied in the direction of digital control, electrical program control, etc., can solve problems such as the inability to use machine tools for energy-saving control, few researches on the power of the main drive system, complex experiments and data analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

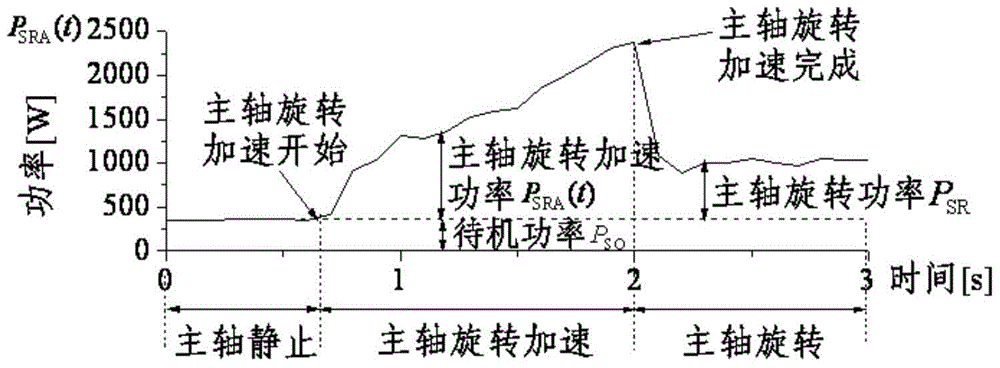

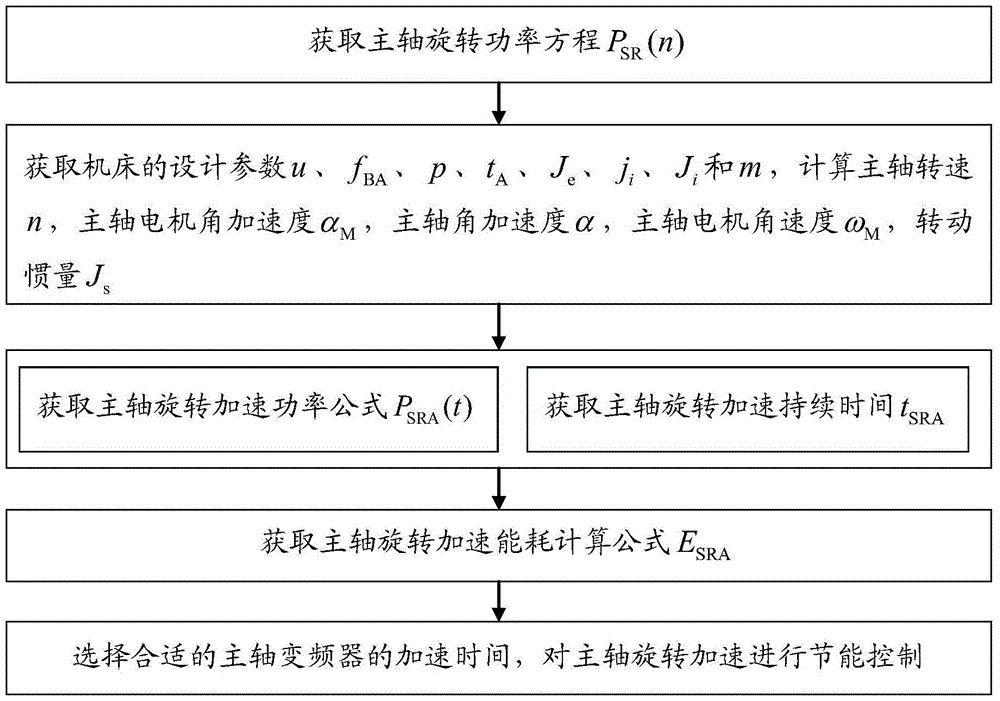

[0051] Now, with reference to the accompanying drawings and embodiments, taking the spindle rotation process of a numerically controlled machine tool as an example, the methods for obtaining the spindle rotation acceleration power and energy consumption will be described in detail.

[0052] The machine tool selected in the current embodiment of the present invention is the CK6153i CNC machine tool of Jinan No. 1 Machine Tool Factory. Its spindle box includes four gears. Taking the AH gear as an example, the spindle rotation acceleration power and energy consumption are obtained, and then the CNC machine tool is energy-saving. design.

[0053] Such as figure 1 Shown, the step of the inventive method is as follows:

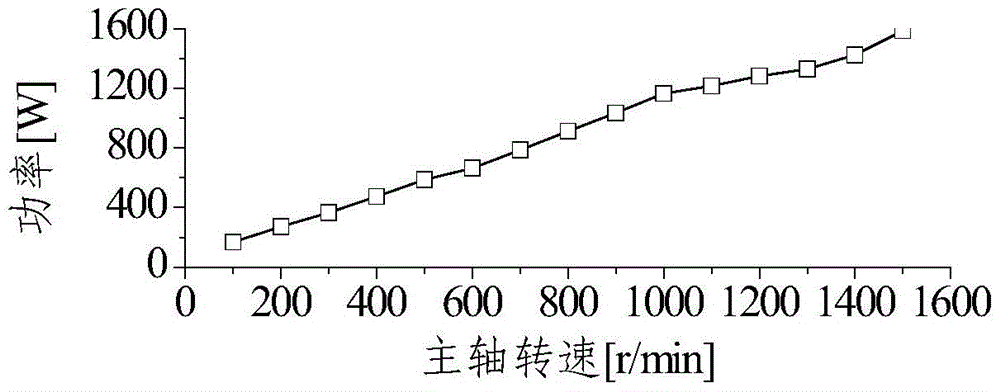

[0054] Step 1, set the maximum spindle speed, control the spindle rotation and obtain the spindle rotation power equation P SR (n), where n is the spindle speed.

[0055] Step 1-1, measure the standby power P of the machine tool when the spindle is stationary SO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com