Polytetrafluoroethylene sealing belt

A polytetrafluoroethylene and sealing tape technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of not fully meeting the requirements of sealing surface sealing, insufficient tensile strength, etc., and achieve enhanced compressive performance, The effect of improving strength and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

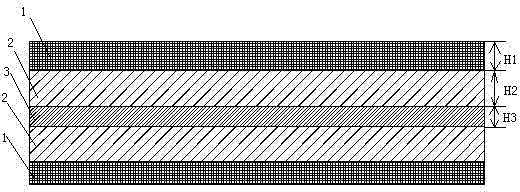

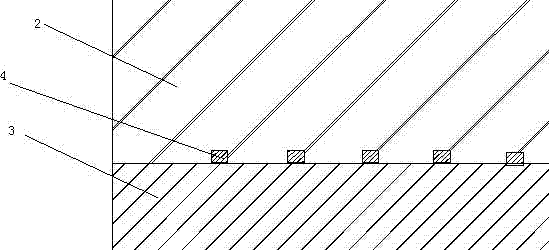

[0016] As shown in the figure, a polytetrafluoroethylene sealing tape of the present invention includes a tape body, wherein, the tape body is respectively a surface layer 1 processed from expanded polytetrafluoroethylene from the outside to the inside, and is made of rubber compound The elastic layer 2 and the fiber layer 3 are composed; the fiber layer 3 is composed of carbon fibers; the fiber layer 3 is formed by tightly pressing at least 3 layers of carbon fibers, and the fiber layer 3 and the elastic The joints of the layer 2 are filled with carbon fiber particles 4, and the particle size of the carbon fiber particles 4 is 55-95 microns; the ratio of the thickness H1 of the surface layer 1, the thickness H2 of the elastic layer 2 to the thickness H3 of the fiber layer 3 is 4:5: 3. The elastic layer 2 can be composed of one or more kinds of rubber, such as: nitrile rubb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com