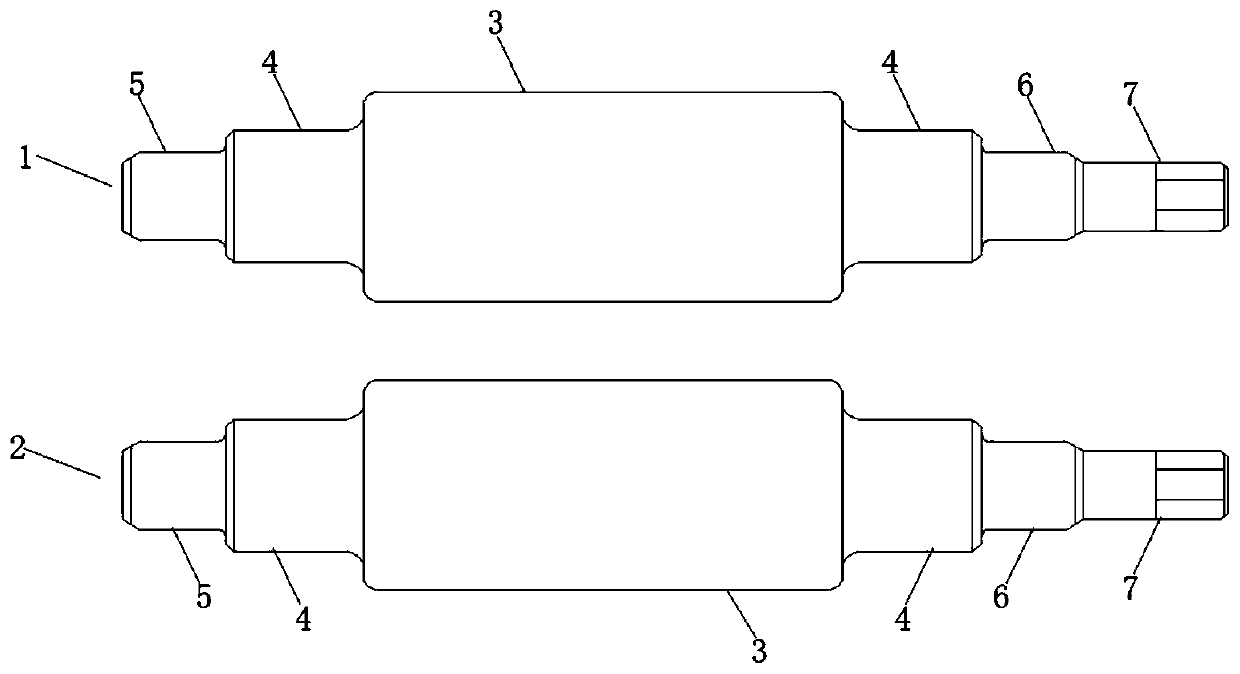

Graphite steel roller used by ribbon steel reversible roughing mill and manufacturing process thereof

A processing technology and rough rolling mill technology, applied in the direction of rolls, metal processing equipment, metal rolling, etc., can solve problems such as inability to meet the needs of use, and achieve the effect of eliminating loose tissue areas, reducing production costs, and improving microstructures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment one, a kind of processing technology of the graphite steel roll that narrow-strip reversible roughing mill uses, comprises the following steps:

[0029] S1. Determine the chemical composition: the chemical composition of the upper roll and the lower roll is C: 1.85%; Si: 1.00%; Mn: 0.80%; Cr: 1.50%; Ni: 1.50%; Mo: 0.40%; V: 0.20 %; Nb: 0.10%; P: 0.010%; S: 0.010%;

[0030] S2. Smelting: Melt primary molten steel in an intermediate frequency induction furnace, add slagging material at 1450°C for slagging (the slagging material is made of a mixture of quartz sand, block lime and fluorite powder), remove slag at 1520°C, and the temperature reaches Add high melting point alloy at 1580°C, then add 2 kg of yttrium-based heavy rare earth modifier per ton, add 0.03% aluminum by inserting method, tap after 5 minutes of calming in the furnace, and add 0.05% CaSi balls after tapping Add 0.45% CaBa inoculant, and then complete stirring with an electromagnetic stirrer fo...

Embodiment 2

[0034] Embodiment two, a kind of processing technology of the graphite steel roll that narrow-strip reversible roughing mill uses, comprises the following steps:

[0035] S1. Determine the chemical composition: the chemical composition of the upper roll and the lower roll is C: 1.95%; Si: 1.20%; Mn: 0.90%; Cr: 2.00%; Ni: 2.00%; Mo: 0.60%; V: 0.30 %; Nb: 0.20%; P: 0.020%; S: 0.020%;

[0036] S2. Smelting: Melt primary molten steel in an intermediate frequency induction furnace, add slagging material at 1460°C for slagging (the slagging material is made of a mixture of quartz sand, block lime and fluorite powder), remove slag at 1520°C, and the temperature reaches Add high melting point alloy at 1600°C, then add 3 kg of yttrium-based heavy rare earth modifier per ton, add 0.03% aluminum by inserting method, tap after 7 minutes of calming in the furnace, and add 0.60% CaSi balls after tapping Add 0.50% CaBa inoculant, and then complete stirring with an electromagnetic stirrer fo...

Embodiment 3

[0040] Embodiment three, a kind of processing technology of the graphite steel roll that narrow-strip reversible roughing mill uses, comprises the following steps:

[0041] S1. Determine the chemical composition: the chemical composition of the upper roll and the lower roll is C: 2.05%; Si: 1.50%; Mn: 1.00%; Cr: 2.50%; Ni: 2.50%; Mo: 0.80%; V: 0.40 %; Nb: 0.30%; P: 0.030%; S: 0.025%;

[0042] S2. Smelting: Melt the primary molten steel in an intermediate frequency induction furnace, add slagging material at 1480°C for slagging (the slagging material is made of a mixture of quartz sand, block lime and fluorite powder), remove slag at 1520°C, and the temperature reaches Add high melting point alloy at 1620 ℃, then add 4 kg of yttrium-based heavy rare earth modifier per ton, add 0.03% aluminum by inserting method, tap after 8 minutes of calming in the furnace, and add 0.80% CaSi balls after tapping Add 0.60% CaBa inoculant, and then complete stirring with an electromagnetic stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com