Special waterproof material for high-speed rail and preparation method thereof

A technology of waterproof material and high-speed iron, applied in the field of waterproof material and its preparation, can solve the problems of low tensile strength and elongation at break, low temperature resistance, low solid content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

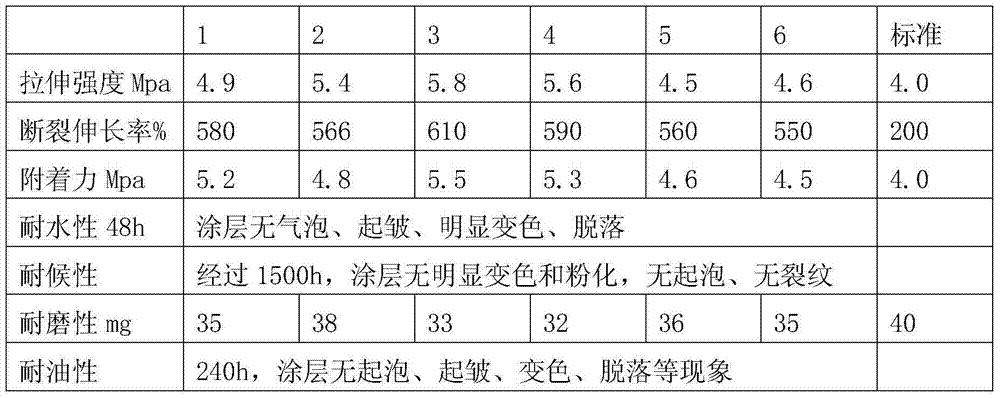

Examples

Embodiment 1

[0016] A special waterproof material for high-speed rail, which is composed of the following components in parts by weight: amino acetal ester 15, carbon black 31, polypropylene 30, polyurethane 40, polyvinyl alcohol 15, aluminum sulfate 0.5, chloride Paraffin wax 5, trichloroethyl phosphate 2, talcum powder 3, polypropylene wax 3, PVC adhesive 8, rare earth composition 1, BYK9692, said rare earth composition is composed of cerium oxide, praseodymium sulfate, neodymium oxide and lanthanum sulfate Composition by weight ratio 1:2:1:1.5.

[0017] The preparation method of the above-mentioned special waterproof material for high-speed rail comprises the following steps:

[0018] Step 1: Prepare each component according to the above-mentioned ratio of raw materials, and mix them uniformly to obtain a mixture;

[0019] Step 2: Melt and extrude the above mixture to obtain a composite material, wherein the temperature of the first zone is 310°C, the temperature of the second zone is ...

Embodiment 2

[0021] A special waterproof material for high-speed rail, which is composed of the following components in parts by weight: amino acetal ester 25, carbon black 33, polypropylene 33, polyurethane 35, polyvinyl alcohol 13, aluminum sulfate 0.9, chloride Paraffin wax 4, trichloroethyl phosphate 4, talcum powder 2, polypropylene wax 6, PVC adhesive 6, rare earth composition 0.8, BYK9691.4, said rare earth composition is composed of cerium oxide, praseodymium sulfate, neodymium oxide and sulfuric acid Lanthanum is composed of 1:2:1:1.5 by weight

[0022] The preparation method of the above-mentioned special waterproof material for high-speed rail comprises the following steps:

[0023] Step 1: Prepare each component according to the above-mentioned ratio of raw materials, and mix them uniformly to obtain a mixture;

[0024] Step 2: Melt and extrude the above mixture to obtain a composite material, wherein the temperature of the first zone is 315°C, the temperature of the second zo...

Embodiment 3

[0026] A special waterproof material for high-speed rail, which consists of the following components in parts by weight:

[0027] Amino acetal 20, carbon black 30, polypropylene 35, polyurethane 30, polyvinyl alcohol 12, aluminum sulfate 0.8, chlorinated paraffin 4, trichloroethyl phosphate 4, talcum powder 2, polypropylene wax 5 , PVC adhesive 6, rare earth composition 1.0, BYK9691.5.

[0028] The preparation method of the above-mentioned special waterproof material for high-speed rail comprises the following steps:

[0029] Step 1: Prepare each component according to the above-mentioned ratio of raw materials, and mix them uniformly to obtain a mixture;

[0030] Step 2: Melt and extrude the above mixture to obtain a composite material, wherein the temperature of the first zone is 320 degrees, the temperature of the second zone is 330 degrees, the temperature of the third zone is 330 degrees, the temperature of the fourth zone is 315 degrees, the temperature of the head is 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com