Delustering agent, and delustering nylon 6 material and preparation method thereof

A matting agent and nylon technology, which is applied in the field of matting agent, matting nylon 6 material and matting nylon 6 material, can solve the problems of increasing the processing cost of polycaprolactam, affecting the performance of polycaprolactam, and uneven dispersion, and increasing the difficulty of type selection. , Excellent impact strength and tensile strength, good dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

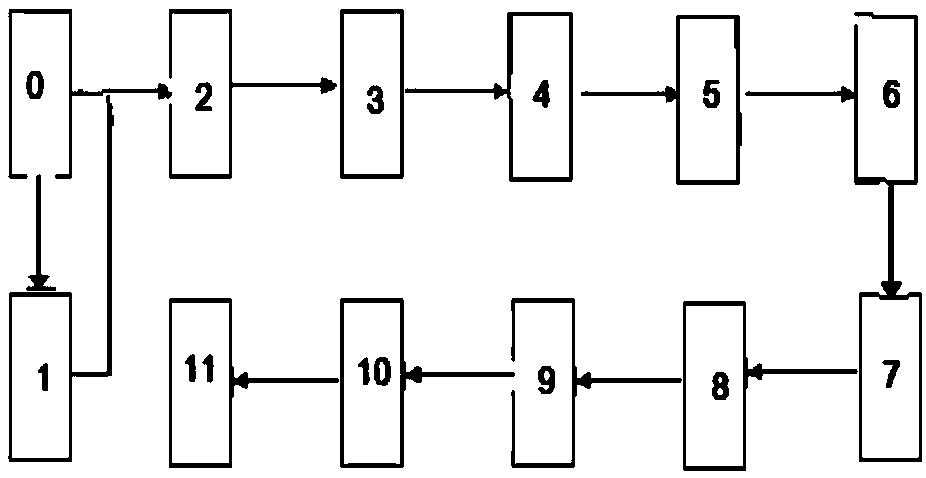

Image

Examples

Embodiment 1

[0039] 10kg of cyanuric acid, 9.8kg of melamine, 10kg of adipic acid, 8kg of 1,6-hexamethylenediamine, 5kg of deionized water, and 100kg of molten caprolactam from No. 0 storage tank were added to the dispersion tank 1 with stirring for 30 Minutes, then enter into the storage tank 2 together with the 900kkg caprolactam from No. 0 storage tank, then enter the pre-poly tower 6, the post-poly tower 7 and the pelletizer through the fine filter 3, preheater 4, static mixer 5 After being pelletized by machine 8, it enters pre-extraction tower 9, then enters extraction tower 10 for extraction, and finally enters drying tower 11 for drying, and then packs to obtain the fiber-grade matte nylon 6 of the present invention. The properties of the obtained matte nylon product are shown in Table 1.

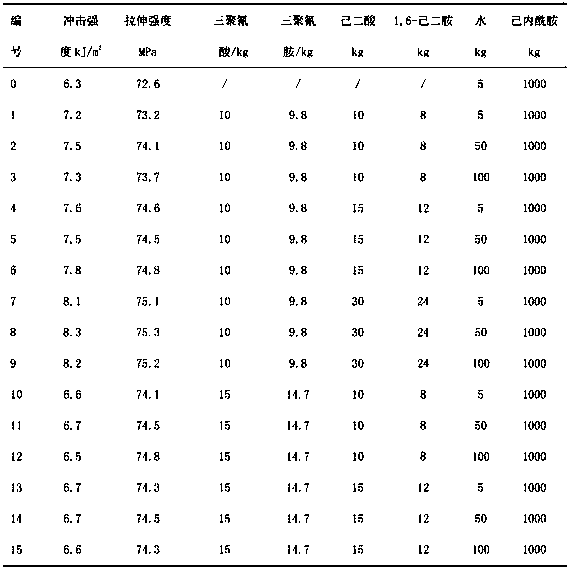

[0040] In Table 1: No. 0 is the comparative test with 0.6% titanium dioxide matting agent added.

[0041] Numbers 1 to 27 are examples 1 to 27 respectively; they are matting nylon products prep...

Embodiment 2

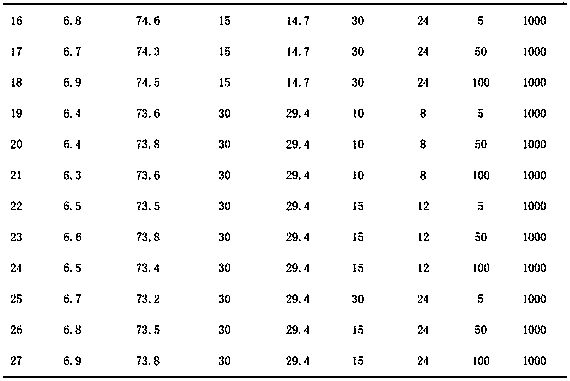

[0046] Numbers 28 to 37 are examples 28 to 37 respectively, listing the matting agents formed by the reaction of cyanuric acid and melamine with different substituted alkyl groups (the content accounts for 3.0% of the mass of caprolactam, the same below) and different binary The matt nylon product prepared by the combination of primary amine and dicarboxylic acid (1.5%), the impact and tensile properties of the matt nylon material prepared by the same operation method as described in Example 1 were compared with the experimental results data.

[0047] The meanings of the letters in Table 2 are as follows:

[0048] AM1: 1-methyl-substituted melamine; AM2: 2,2-dimethyl-substituted melamine. CA1: 1-methyl substituted cyanuric acid; CA2: 2,2-dimethyl substituted cyanuric acid;

[0049] AB: Propylenediamine; AD: Butylenediamine; AW: Pentylenediamine; AP: p-phenylenediamine; AI: m-phenylenediamine

[0050] CB: malonic acid; CD: succinic acid; CW: glutaric acid; CP: terephthalic ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com