Ultraviolet-curable extinction resin and preparation method thereof

A technology of matting resin and ultraviolet light, which is applied in coatings, polyurea/polyurethane coatings, etc., can solve problems such as uneven gloss, decreased coating film hardness, and excessive viscosity of the system, achieving good matting effect and good antifouling performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

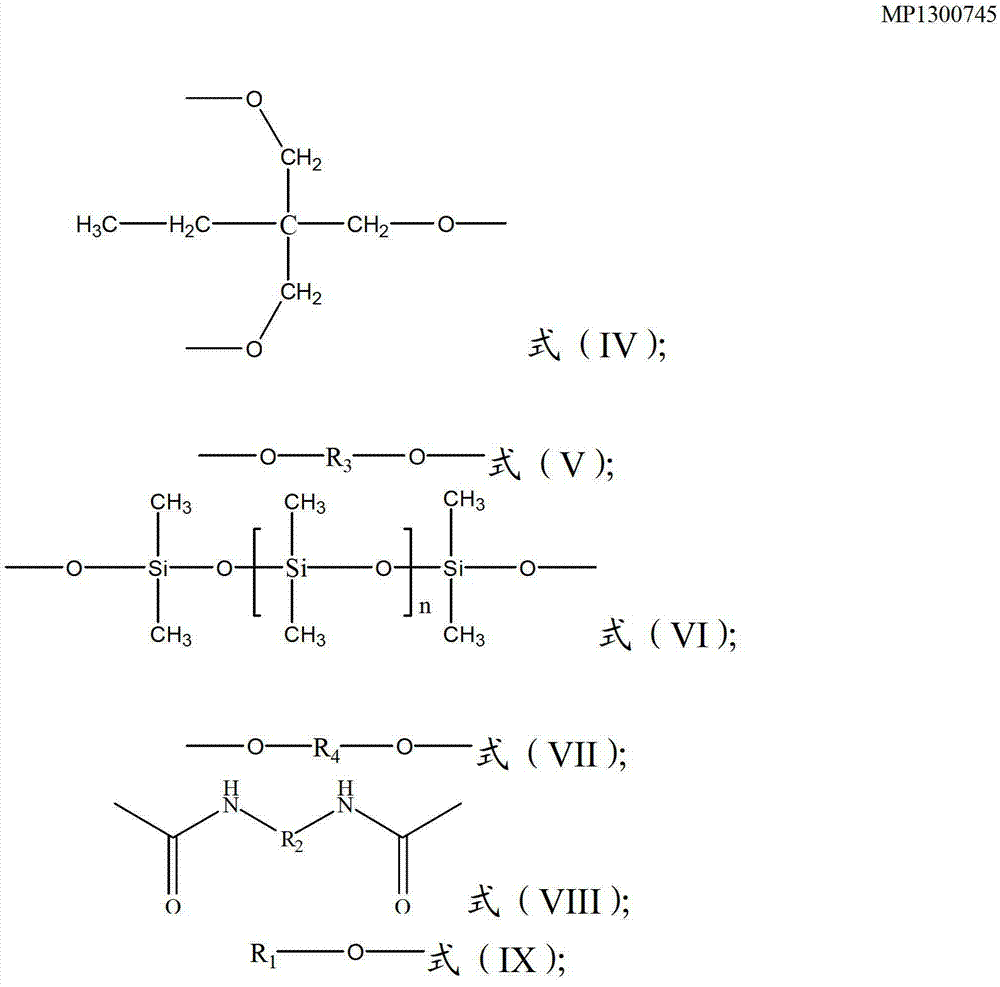

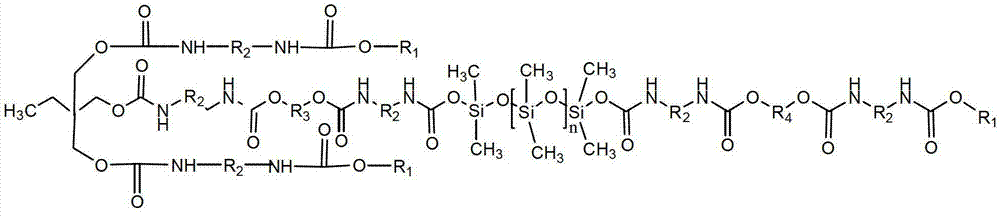

[0042] The present invention also provides a preparation method of ultraviolet light-cured matting resin, comprising:

[0043] A) removing water from poly(1,4-butylene adipate) diol and trimethylolpropane, and reacting with diisocyanate to obtain the first intermediate;

[0044] B) reacting the first intermediate with hydroxy silicone oil, hydroxyphenyl sulfide and hydroxy-terminated acrylate under the action of a catalyst and a polymerization inhibitor to obtain a UV-curable matting resin.

[0045] The present invention first removes water from polyadipate-1,4-butylene glycol and trimethylolpropane, and the number average molecular weight of the polyadipate-1,4-butylene glycol is preferably 1000~3500 Daltons; the present invention has no limitation on the dewatering method, the dewatering method well known to those skilled in the art is enough, preferably 105°C~115°C, vacuum distillation 1~1.5h; the present invention is for The sources of the poly-1,4-butylene adipate diol a...

Embodiment 1

[0058] Mix 252 g of polyadipate-1,4-butylene glycol ester diol with a number average molecular weight of 1000 Daltons and 128 g of trimethylolpropane in a three-necked flask, heat up to 110° C., and depressurize for 1 hour; Under the protection of nitrogen, the temperature of the reaction system was lowered to 75° C., and 160 g of 2,4-toluene diisocyanate was added dropwise at a speed of 10 mL / min. After the dropwise addition was completed, the mixture was reacted for 2.5 hours to obtain the first intermediate.

[0059] Add 380g of hydroxysilicone oil (n=30), 58g of 4,4'-dihydroxydiphenyl sulfide, 0.32g of dibutyltin dilaurate and 0.61g of p-hydroxyanisole to the first intermediate, and react The temperature of the system was lowered to 80° C., and 165 g of hydroxyethyl acrylate was added dropwise at a rate of 10 mL / min. After the dropwise addition was completed, the reaction was carried out for 1.5 hours to obtain a UV-curable resin.

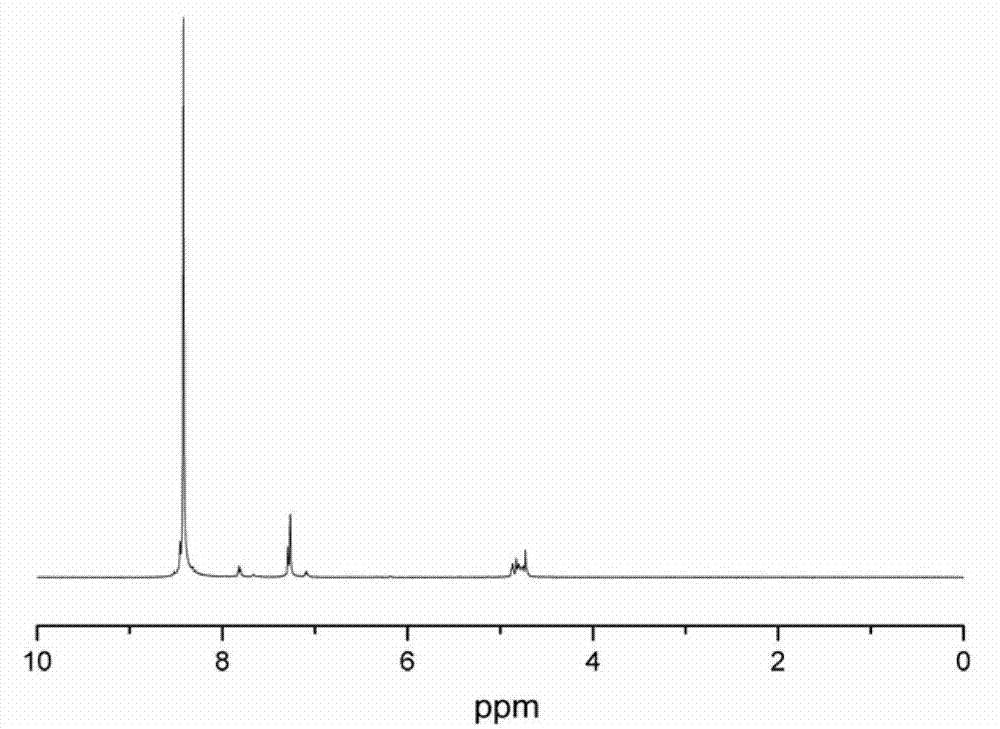

[0060] Carry out nuclear magnetic resona...

Embodiment 2

[0065] Mix 320 g of poly(1,4-butylene adipate) diol with a number average molecular weight of 3,500 Daltons and 145 g of trimethylolpropane in a three-necked flask, raise the temperature to 110° C., and depressurize for 1.5 hours; Under nitrogen protection, the temperature of the reaction system was lowered to 75° C., and 226 g of diphenylmethane-4,4′-diisocyanate was added dropwise at a rate of 13 mL / min. After the dropwise addition was completed, the mixture was reacted for 4 hours to obtain the first intermediate.

[0066] Add 448g of hydroxysilicone oil (n=50), 92g of 3,3'-dihydroxydiphenyl disulfide, 0.55g of dibutyltin dilaurate and 1.15g of p-hydroxyanisole to the first intermediate. The temperature of the reaction system was lowered to 80° C., and 284 g of dipentaerythritol pentaacrylate was added dropwise at a rate of 13 mL / min. After the dropwise addition was completed, the mixture was reacted for 2 hours to obtain a UV-curable resin.

[0067] The above-mentioned pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com