Patents

Literature

39results about How to "Reduce stray light interference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

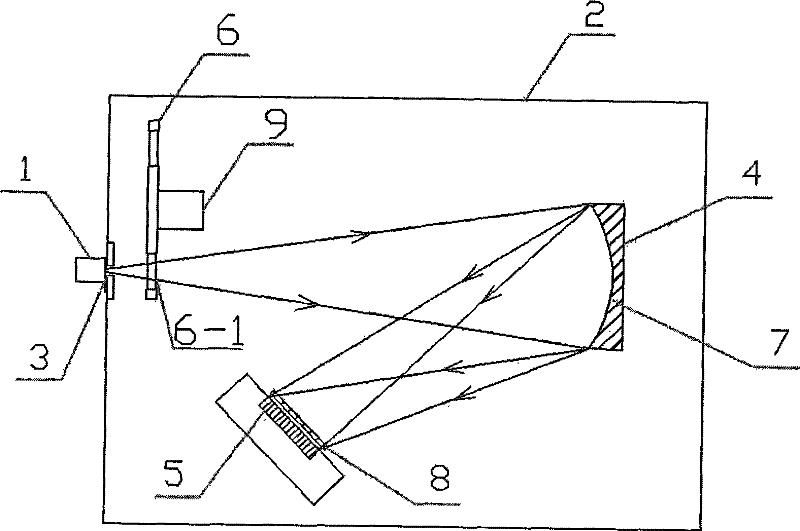

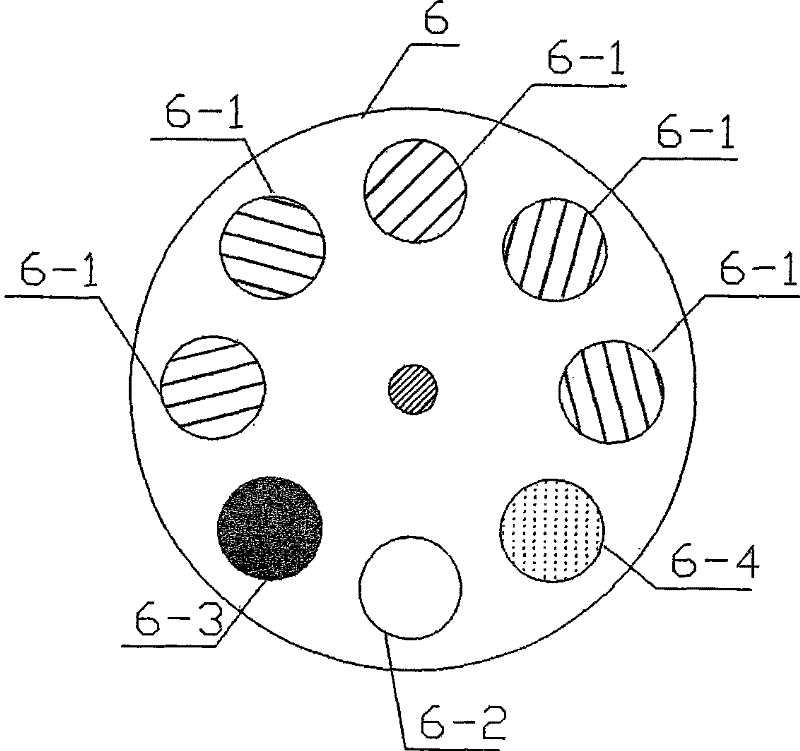

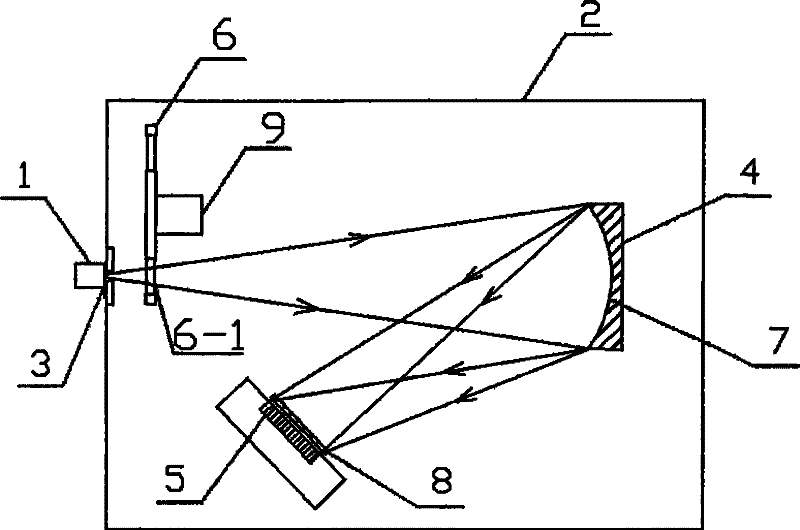

Low stray light rapid spectrometer and measurement method thereof

ActiveCN101324468AOvercome limitationsReduce stray light interferenceRadiation pyrometrySpectrum generationSpectrographLight beam

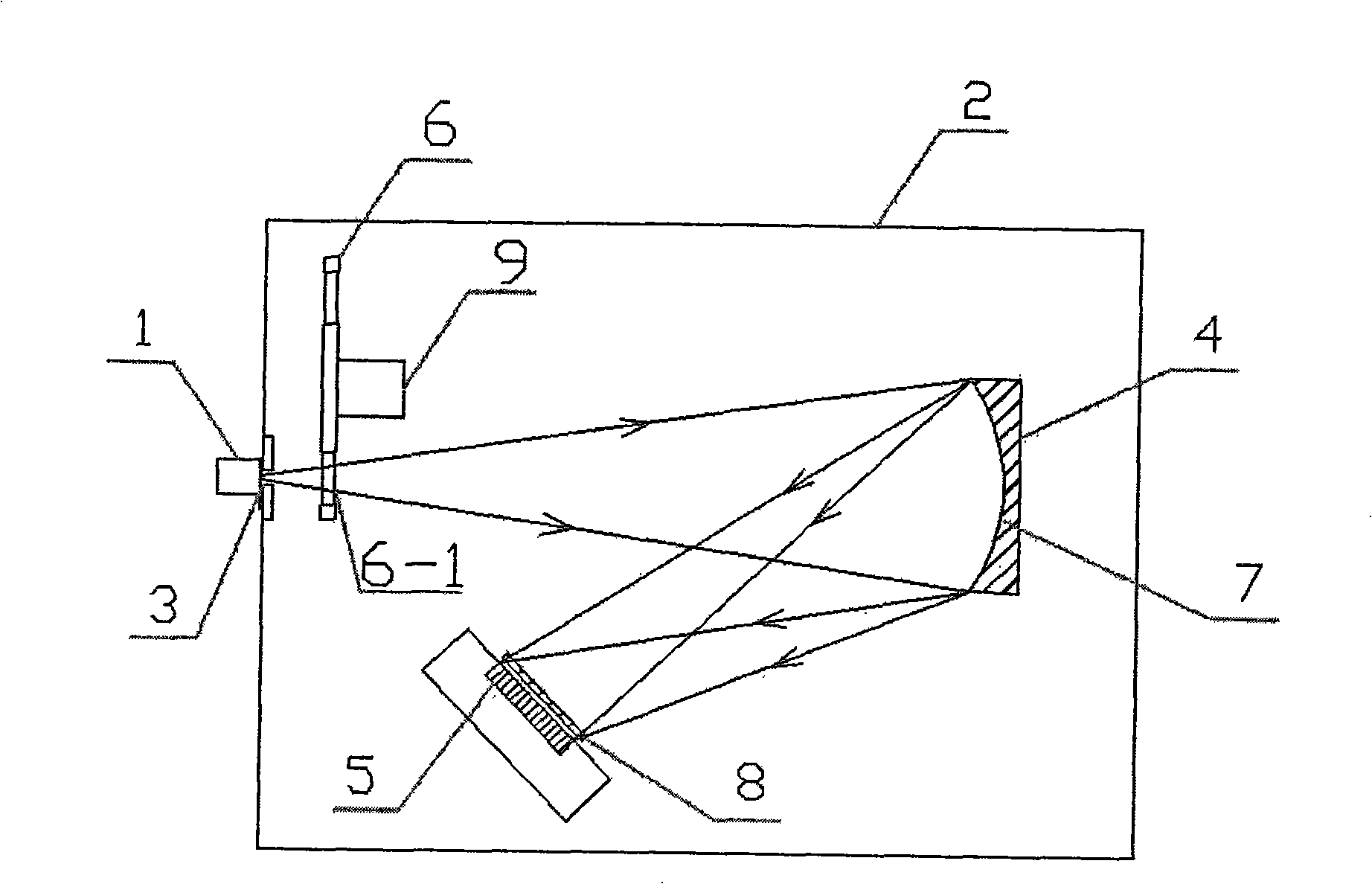

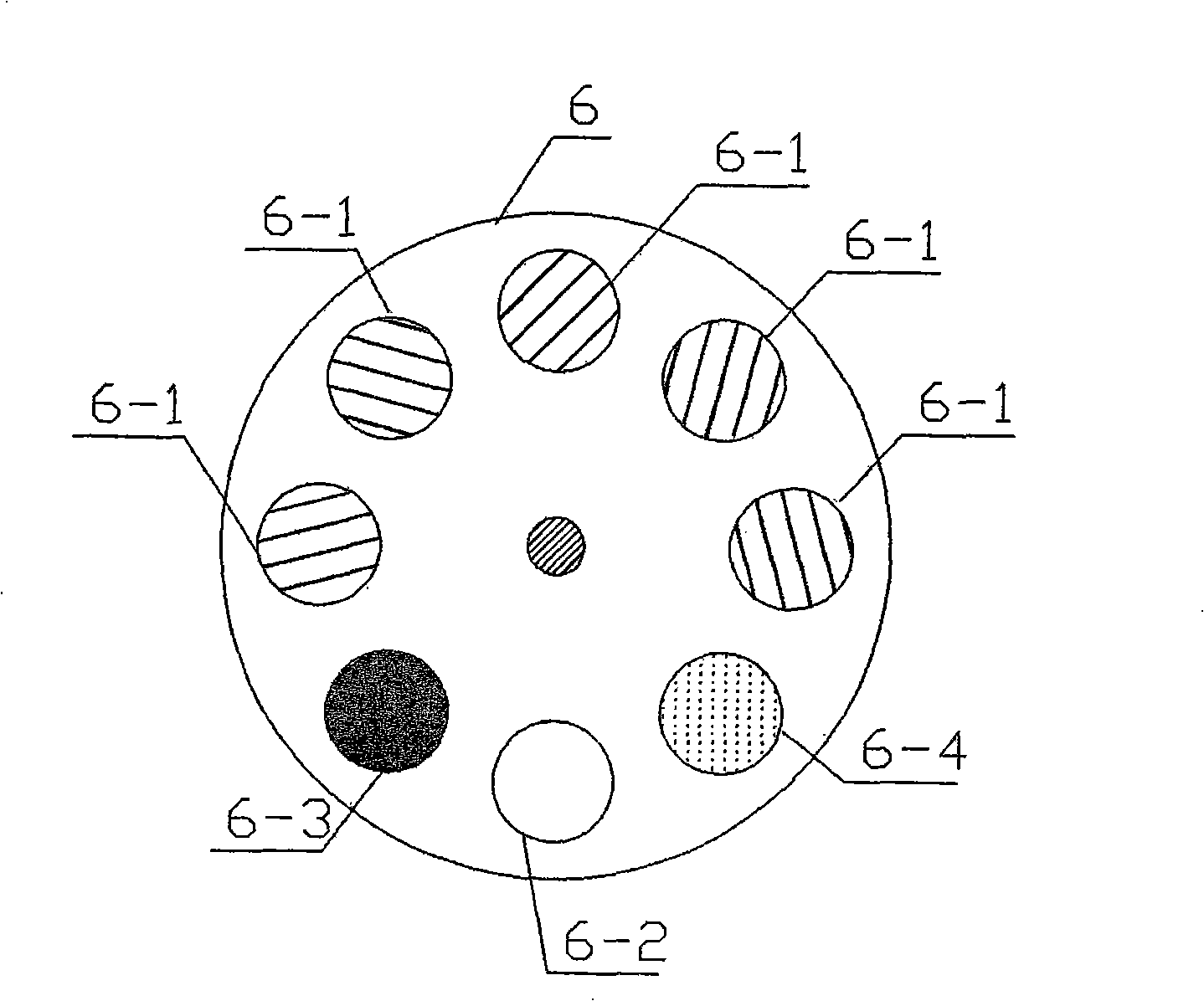

The invention discloses a low-stray-light fast spectrometer and a measurement method thereof. The spectrometer includes a light signal collection mechanism and an optical platform and is characterized in that the optical platform includes a bandpass color wheel; a group of bandpass color filters and via-holes are arranged on the bandpass color wheel; and an incident light reaches a dispersive element through the bandpass color filters or the via-holes, is split and then received by an array detector. Through rotation of the bandpass color wheel, the incident light scans the bandpass color filters one by one, and the spectrometer accurately detects a sample to be detected segment by segment to correspond to a response function. When a similar sample with similar spectral characteristics is measured, the sample is accurately detected segment by segment and is subjected to full-spectrum fast detection through the via-holes, the stray light correction factor can be calculated according to the two measurement results, and the similar sample is subjected to the full-spectrum fast detection and is corrected by the stray light correction factor to achieve fast accurate detection. The method can effectively reduce the measurement stray light of the fast spectrometer and fast accurately measure the spectrum curves and related spectroradiometric parameters of the sample with similar spectral characteristics.

Owner:HANGZHOU EVERFINE PHOTO E INFO

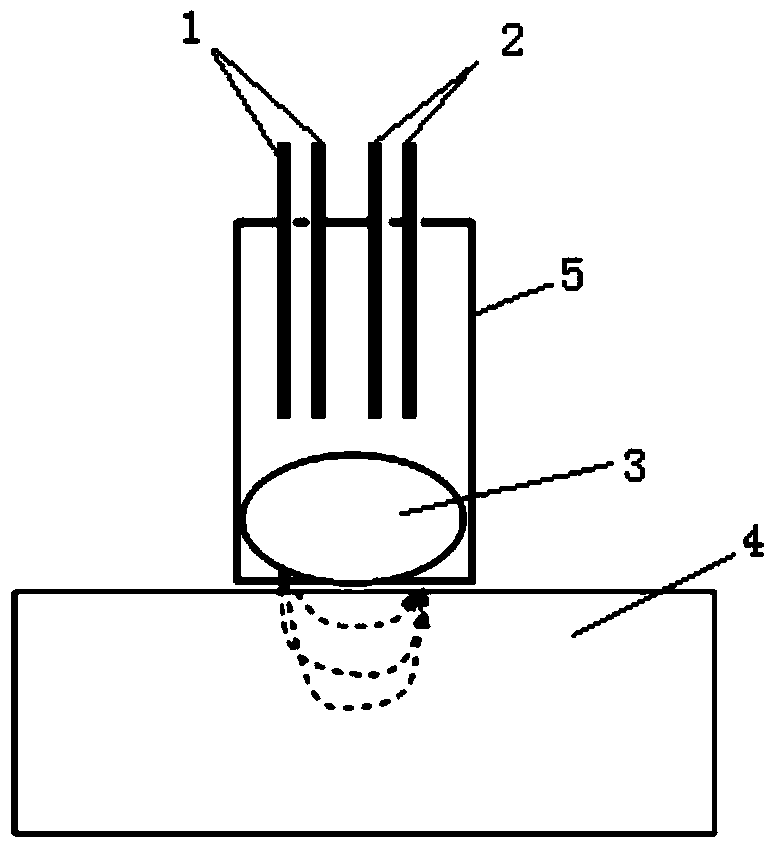

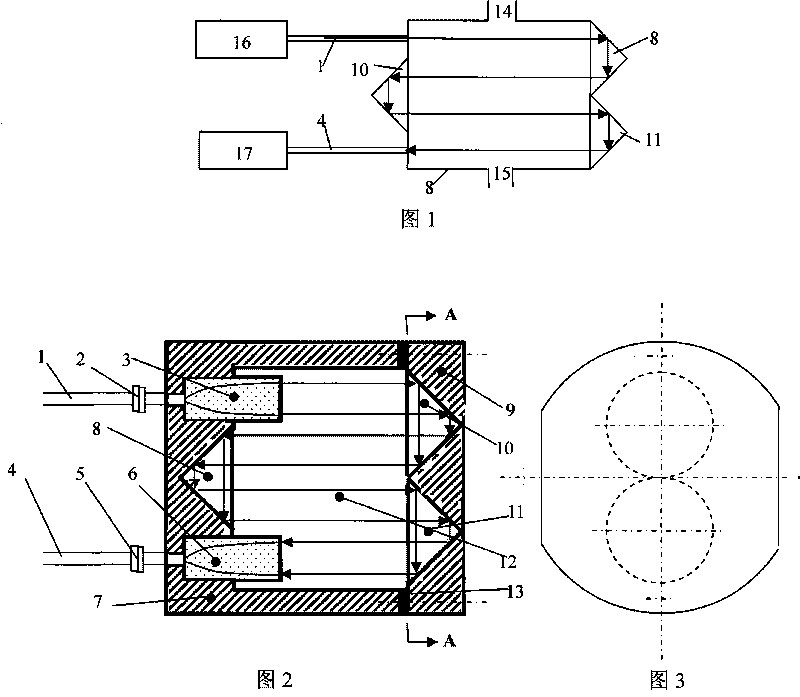

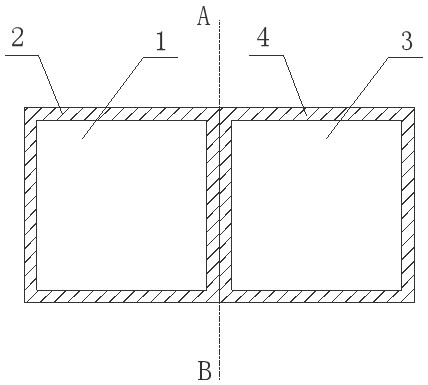

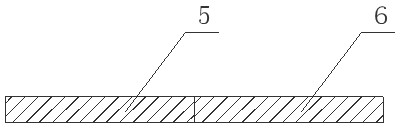

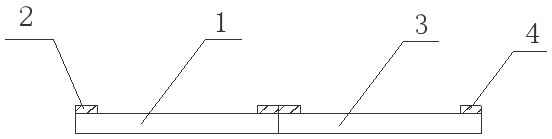

Fluorescent pool for atmosphere Hox free radical real-time measurement

InactiveCN103674911ARealize online monitoringAcquisition stableFluorescence/phosphorescenceFluorescenceShielding gas

The invention discloses a fluorescent pool for atmosphere Hox free radical real-time measurement. The fluorescent pool comprises a gas flow tube, a laser tube, and a fluorescence detection tube. A vacuum pump is used to extract the gas to be detected into the gas flow tube through a pinhole-shaped molecular beam splitter; an N2 shielding gas inlet is formed in the side of the gas inlet of the gas flow tube to ensure the sampling stability and low loss. 308 nm laser emitted and tuned by a laser is guided in the laser tube, and OH free radicals in the gas to be detected in the center of the fluorescent pool is excited to generate fluorescence; a plurality of diaphragms are mounted in the laser tube to reduce influence of laser stray light; a lens assembly and a reflector collect the excited fluorescent signals; the fluorescent signals pass through an optical filter and are detected through a photomultiplier; NO gas is introduced in the gas flow tube through an NO annular intake tube; the HO2 free radicals are converted to OH free radicals, and then the HO2 free radicals are compared and measured. The fluorescent pool can respectively measure the concentration of the OH free radicals and the HO2 free radicals, and can be applied to measurement and study of the concentration of HOx which is an important radical for the atmosphere oxidability.

Owner:ANHUI INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

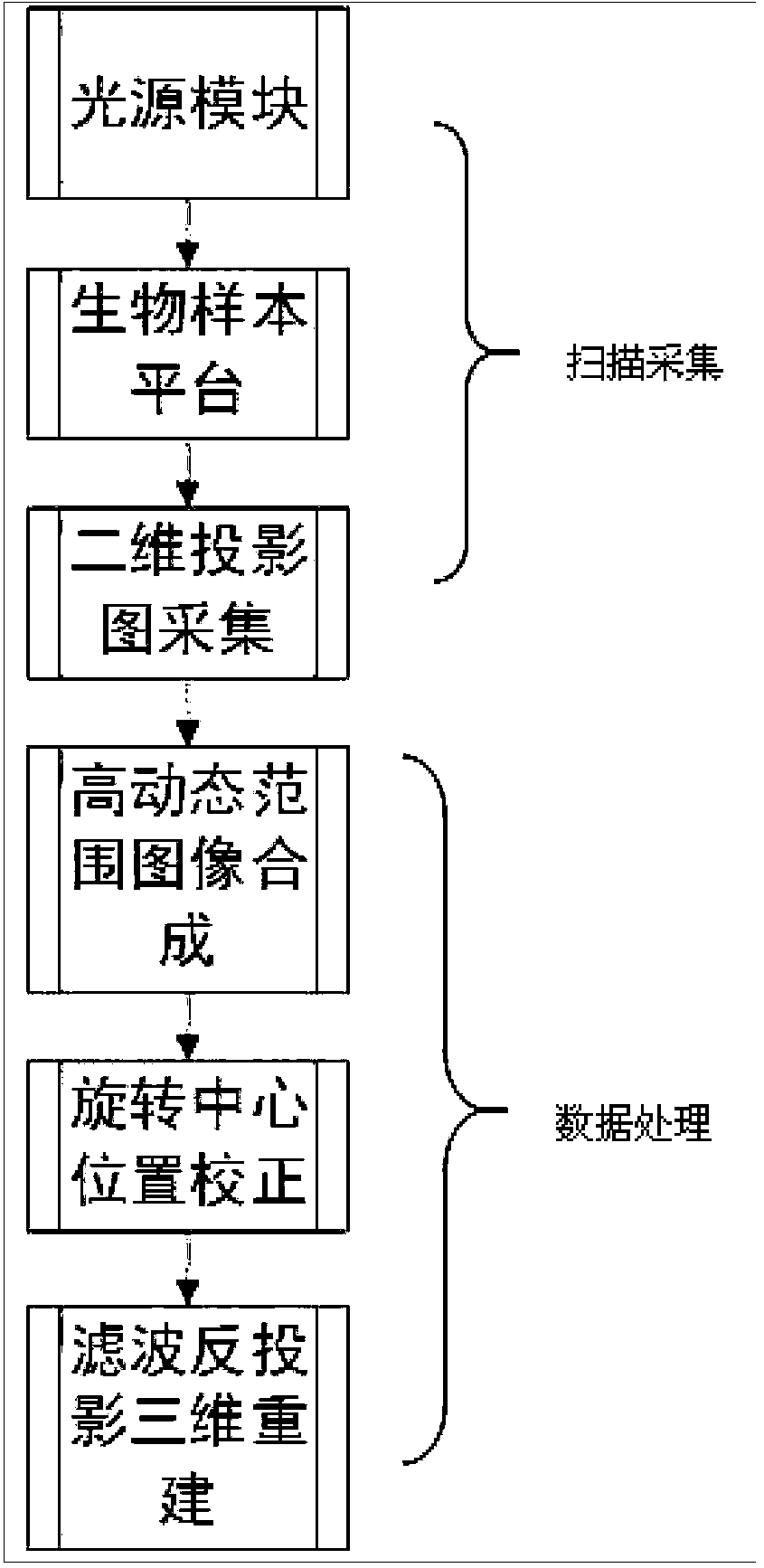

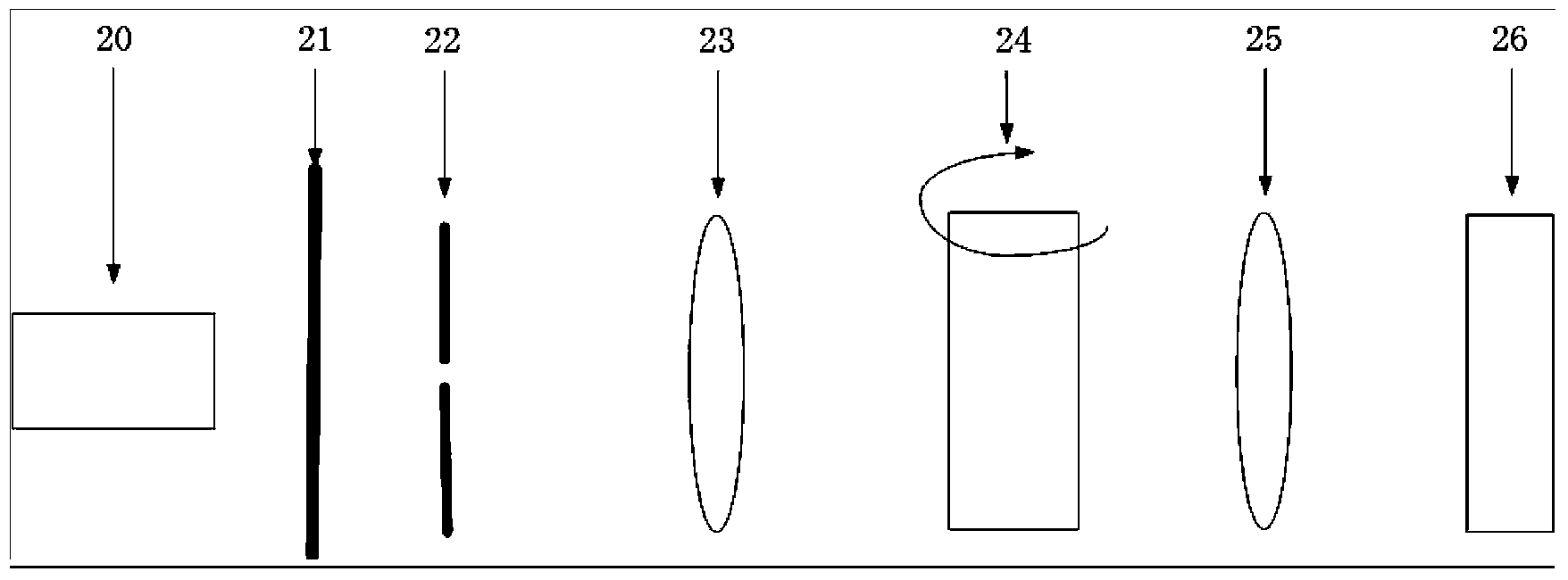

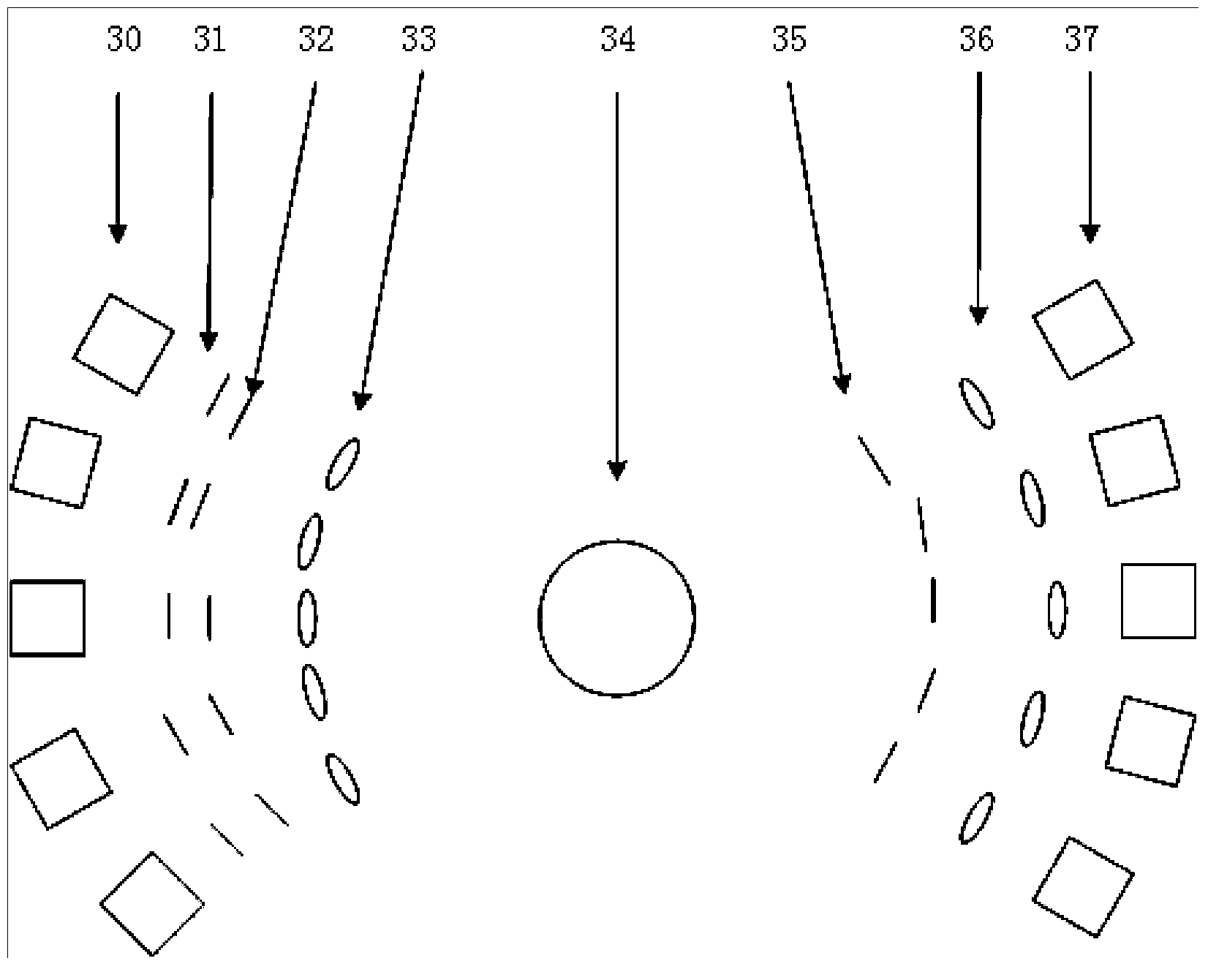

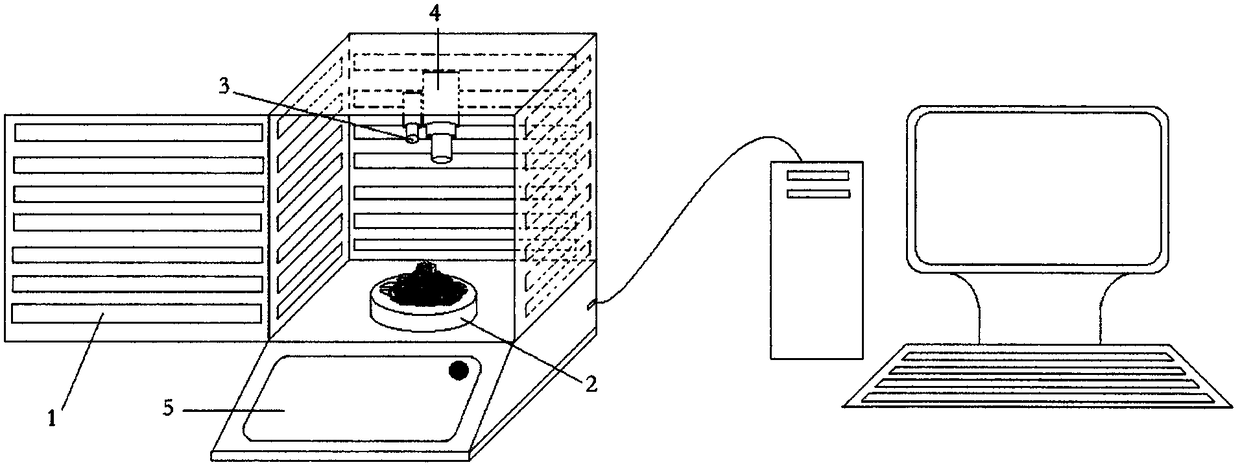

Optical projection tomography device and method based on camera array

InactiveCN104224127AClear detailsReduce stray light interferenceDiagnostic recording/measuringSensorsHigh-dynamic-range imagingOptical projection tomography

The invention provides an optical projection tomography device and a method based on a camera array. A light source array and the camera array are utilized to realize two-dimensional projection images of different exposures of an organism, and high-quality reconstruction of a three-dimensional image of a biological sample is realized through a high dynamic range imaging technique and a filter back projection algorithm. According to the optical projection tomography device and the method based on the camera array, an imaging module mainly comprises a scanning acquisition module and a data processing module, wherein the scanning acquisition module mainly comprises: (1) a light source module formed by the light source array, an optical lens, a beam expander and a polarizer; (2) a biological sample platform formed by a stepping motor rotating platform and a sample clamping device; (3) a two-dimensional projection image acquisition module formed by a microscope, the camera array, a polarization analyzer and a filter plate; the data processing module mainly comprises: (1) high dynamic range image synthesis; (2) rotary center position correction; (3) filter back projection three-dimensional reconstruction.

Owner:XIDIAN UNIV

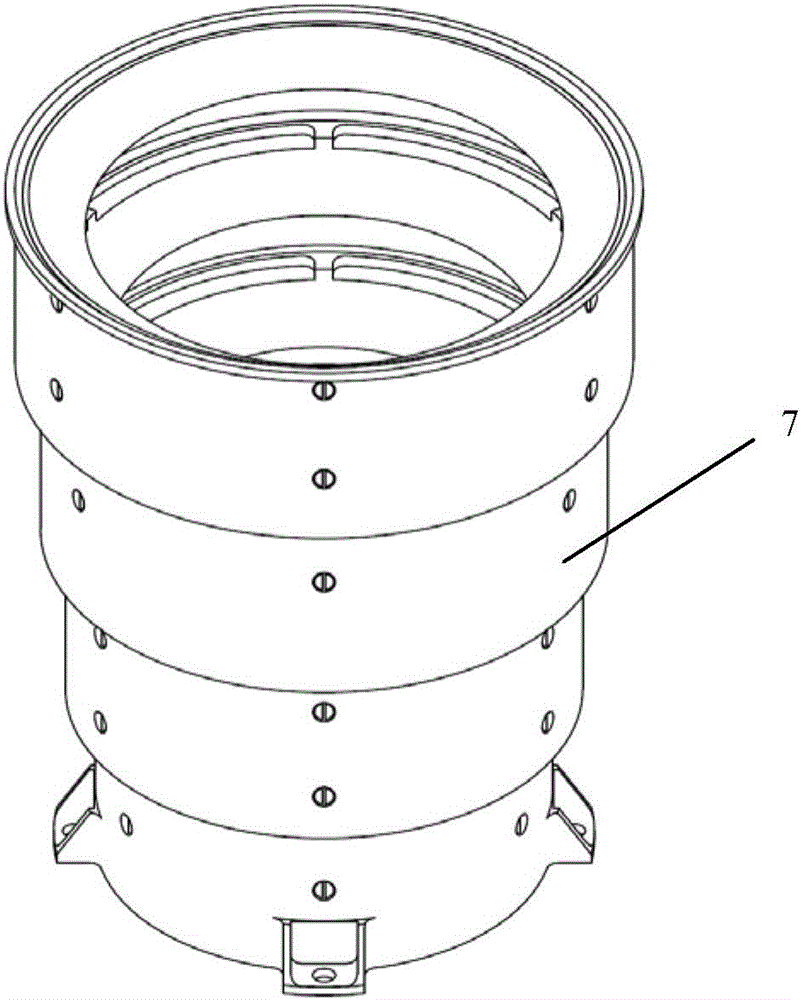

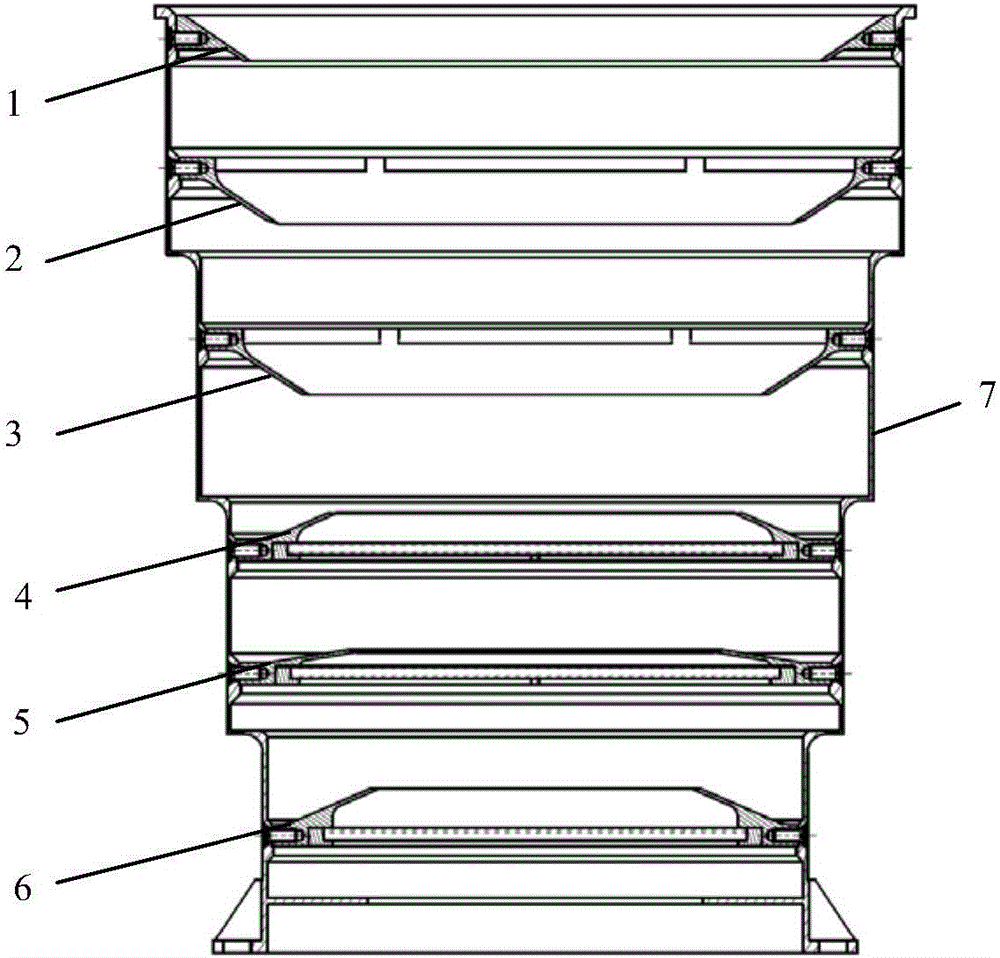

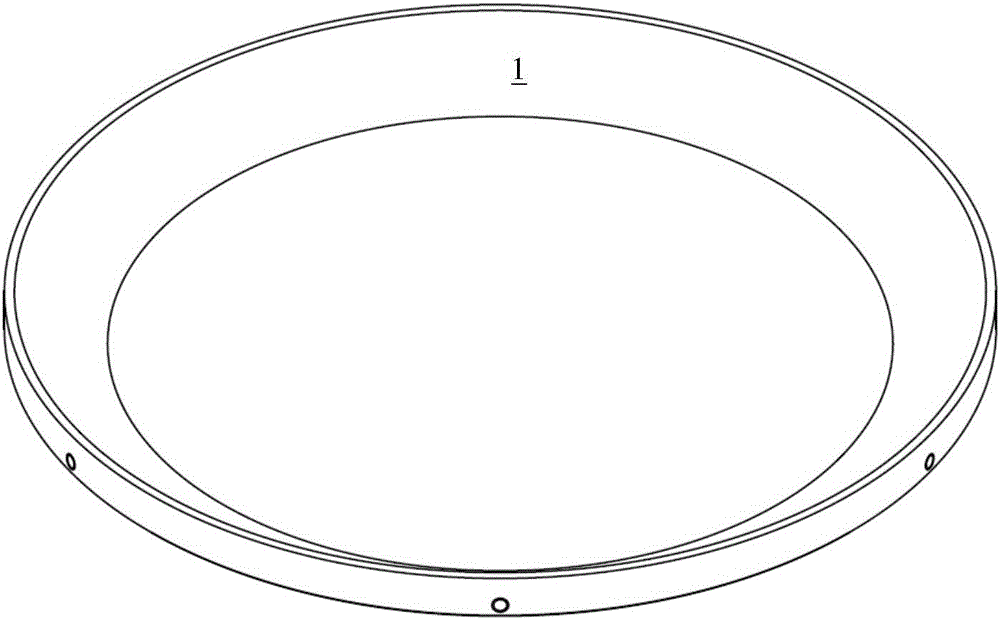

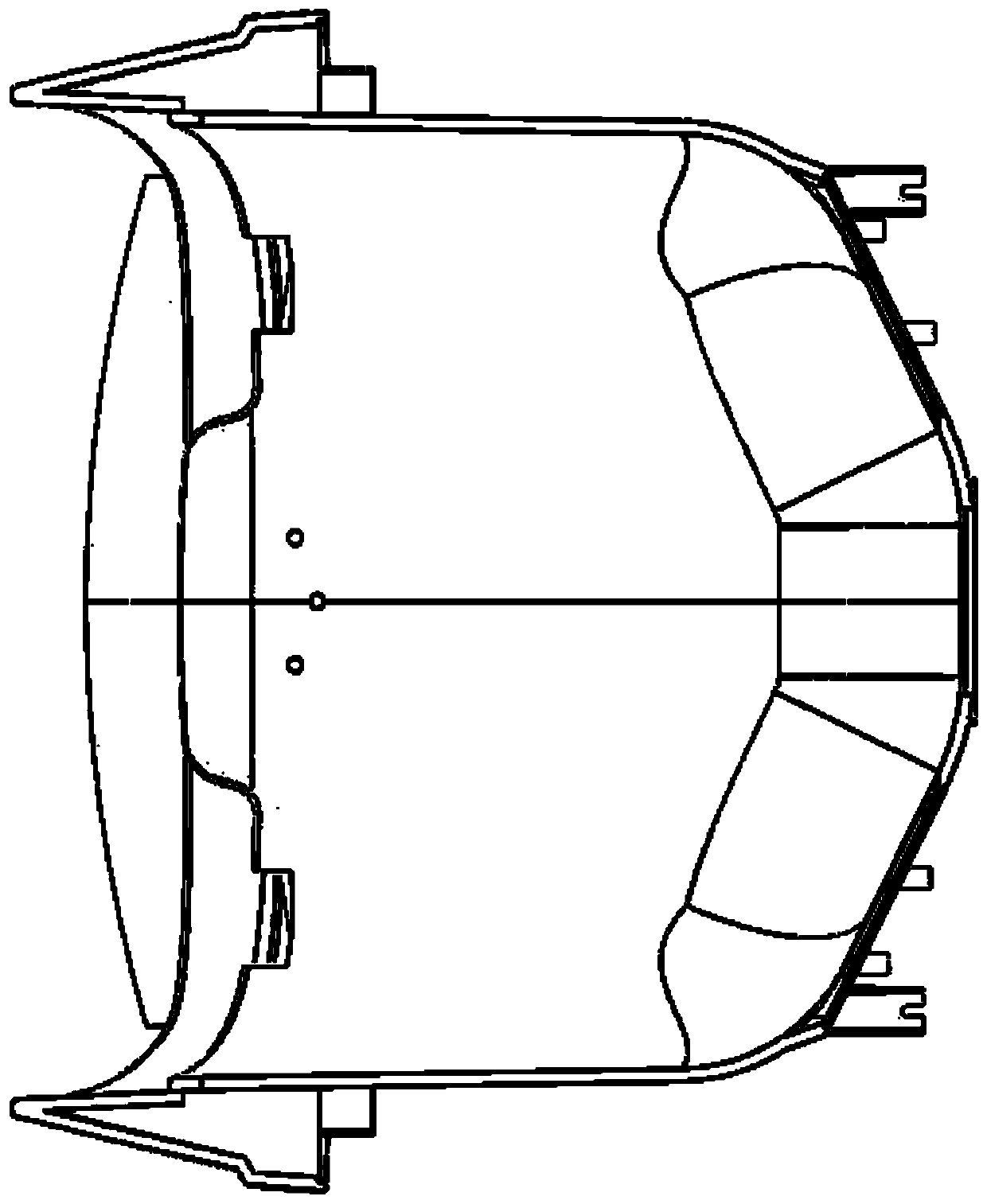

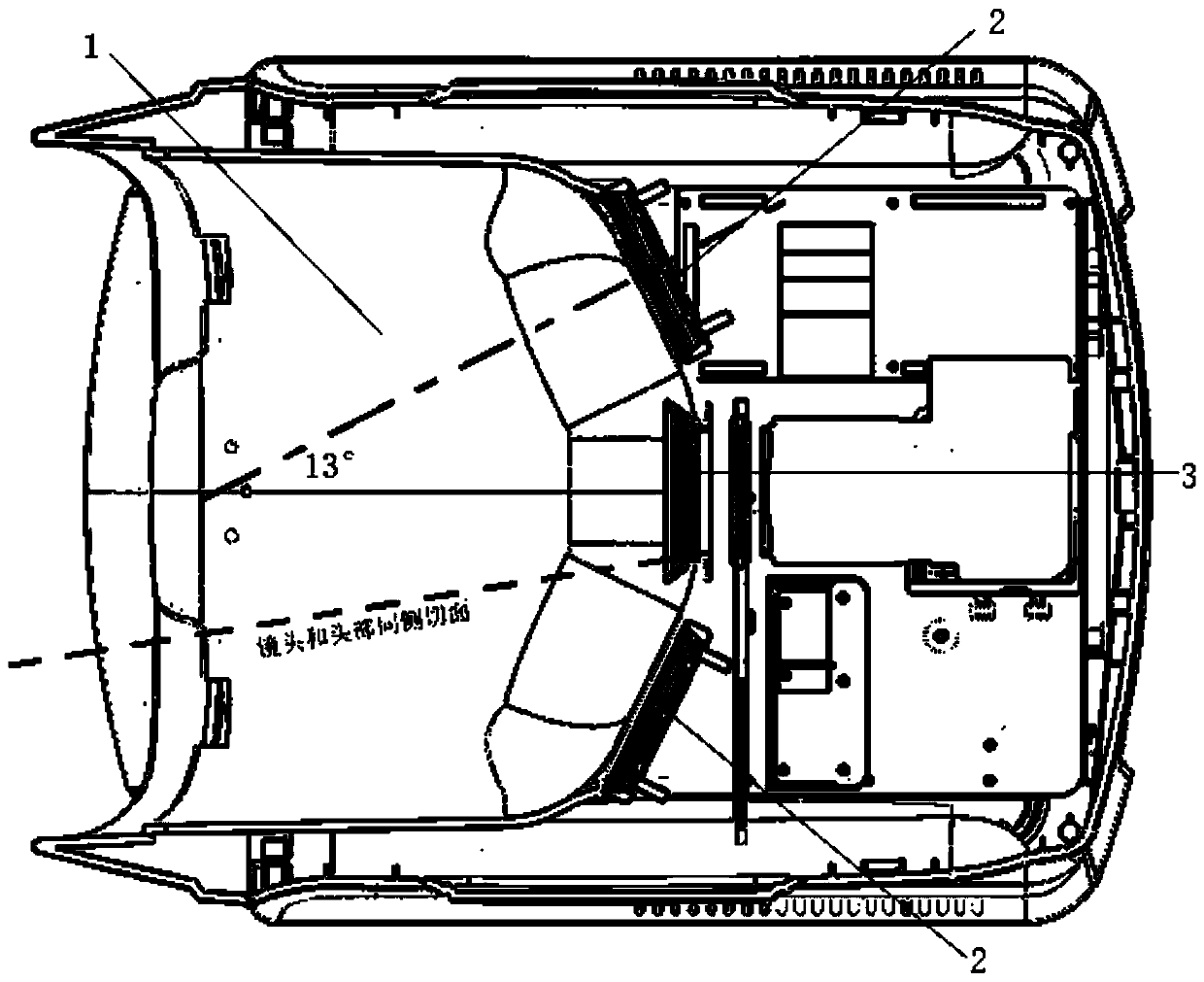

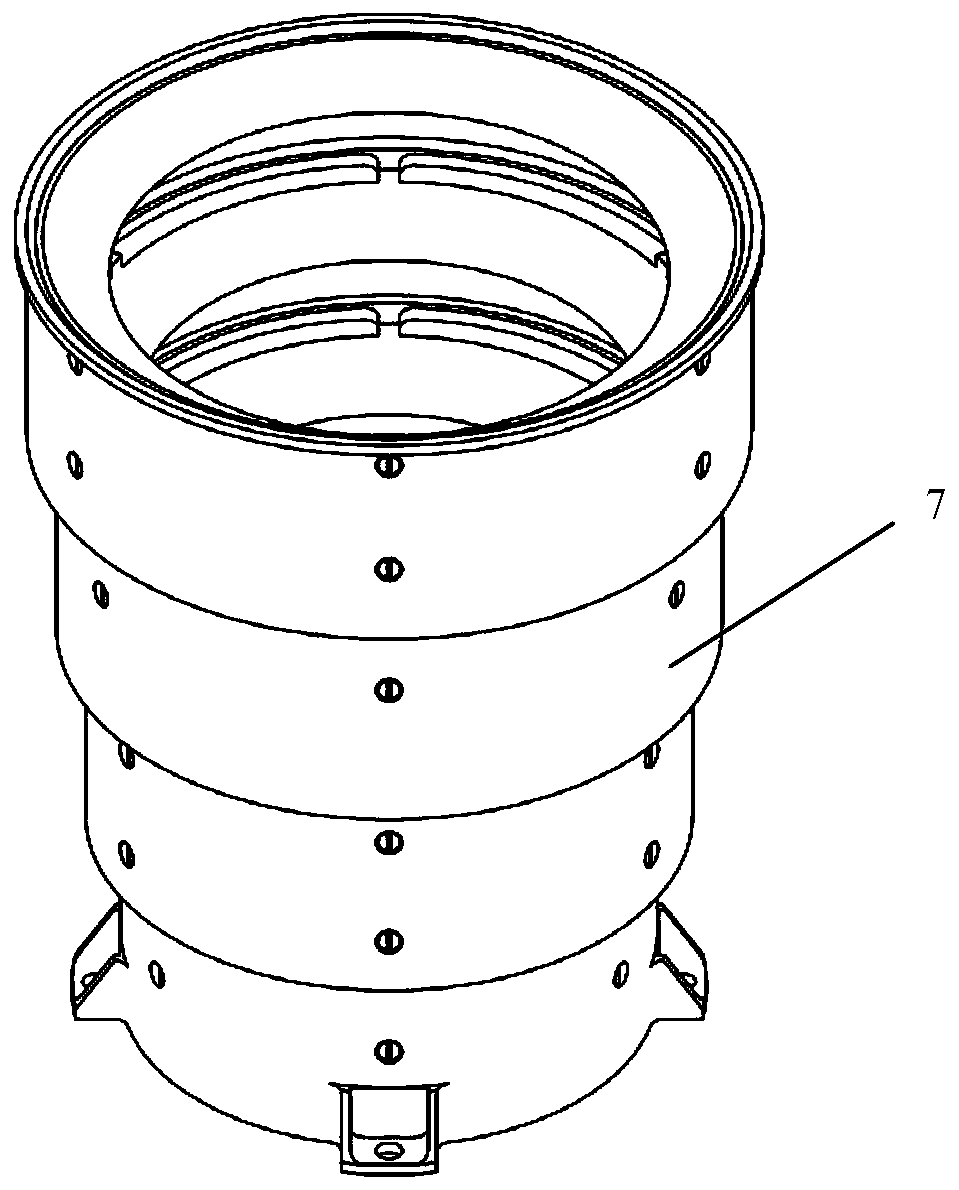

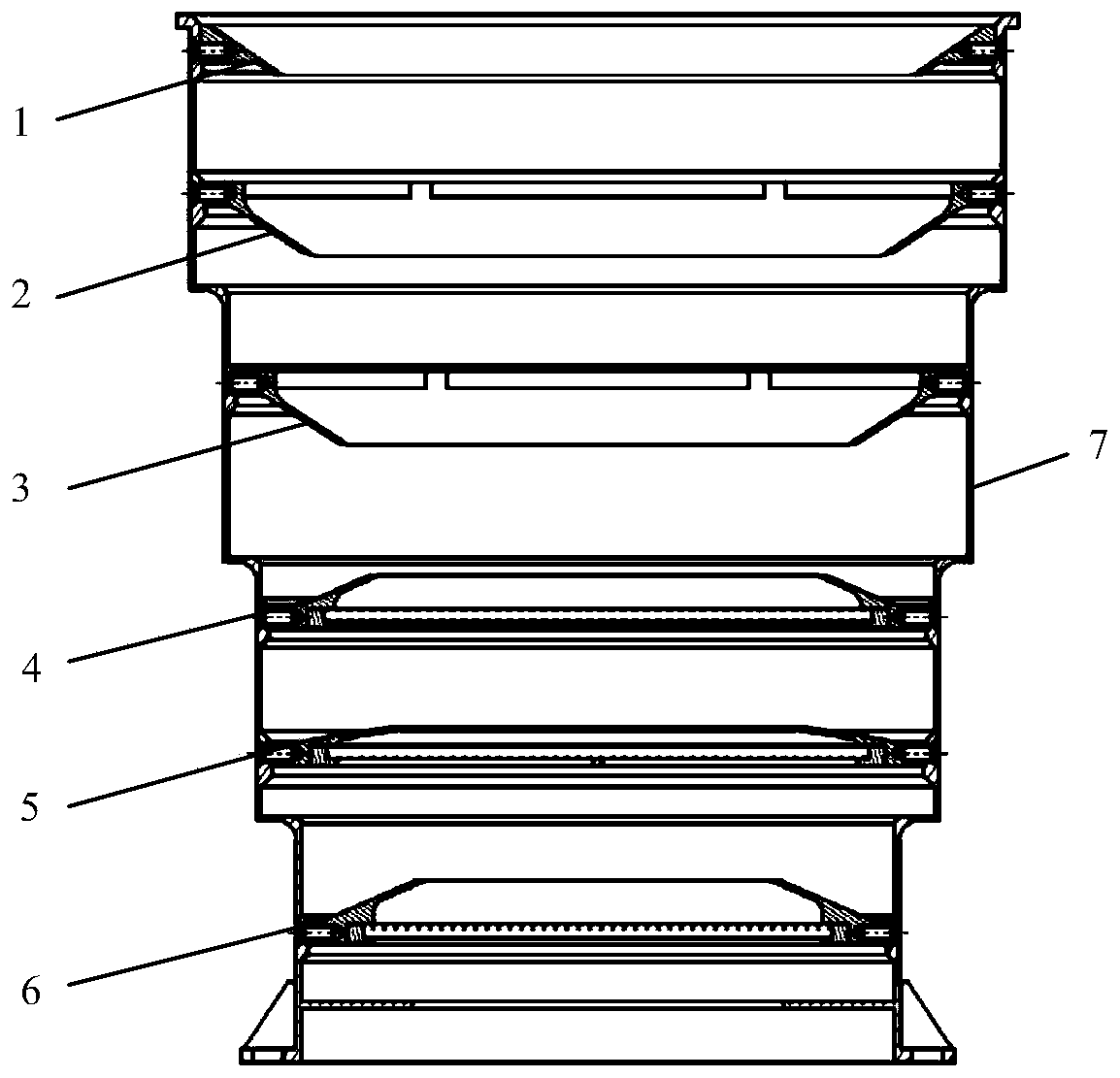

Space filtering based light shield of star sensor

ActiveCN106383427ARealize the spectral filtering functionReduce stray light interferenceCamera filtersExit pupilLens hood

The invention discloses a space filtering based light shield of a star sensor. The light shield comprises a cover casing and first to sixth shading rings, and the first to sixth shading rings are arranged from an entrance pupil position to the exit pupil position sequentially and mounted in the cover casing; the first shading ring and the sixth shading ring are arranged at the two ends of the cover casing opposite to each other, and a connecting line between cutting edges of the first shading ring and the sixth shading ring and a center line of the cover casing form an included angle of 16 degree; and the middle portions of the fourth, fifth and sixth shading rings are provided with optical filters in a rotational installation manner respectively. The light shield has the advantages that the cover casing, the shading rings and the optical filters form an optical-mechanical assembly of the light shield, and it is ensured that the star sensor can output effective attitude data when a sun shielding angle is greater than 20 degree; a non-imaging spectrum of the sun shielding angle greater than 20 degree can reach the entrance pupil position of an optical system via at least twice absorptive scattering; and the light shield has a high light shielding performance, and is capable of spectrum filtering.

Owner:SHANGHAI AEROSPACE CONTROL TECH INST

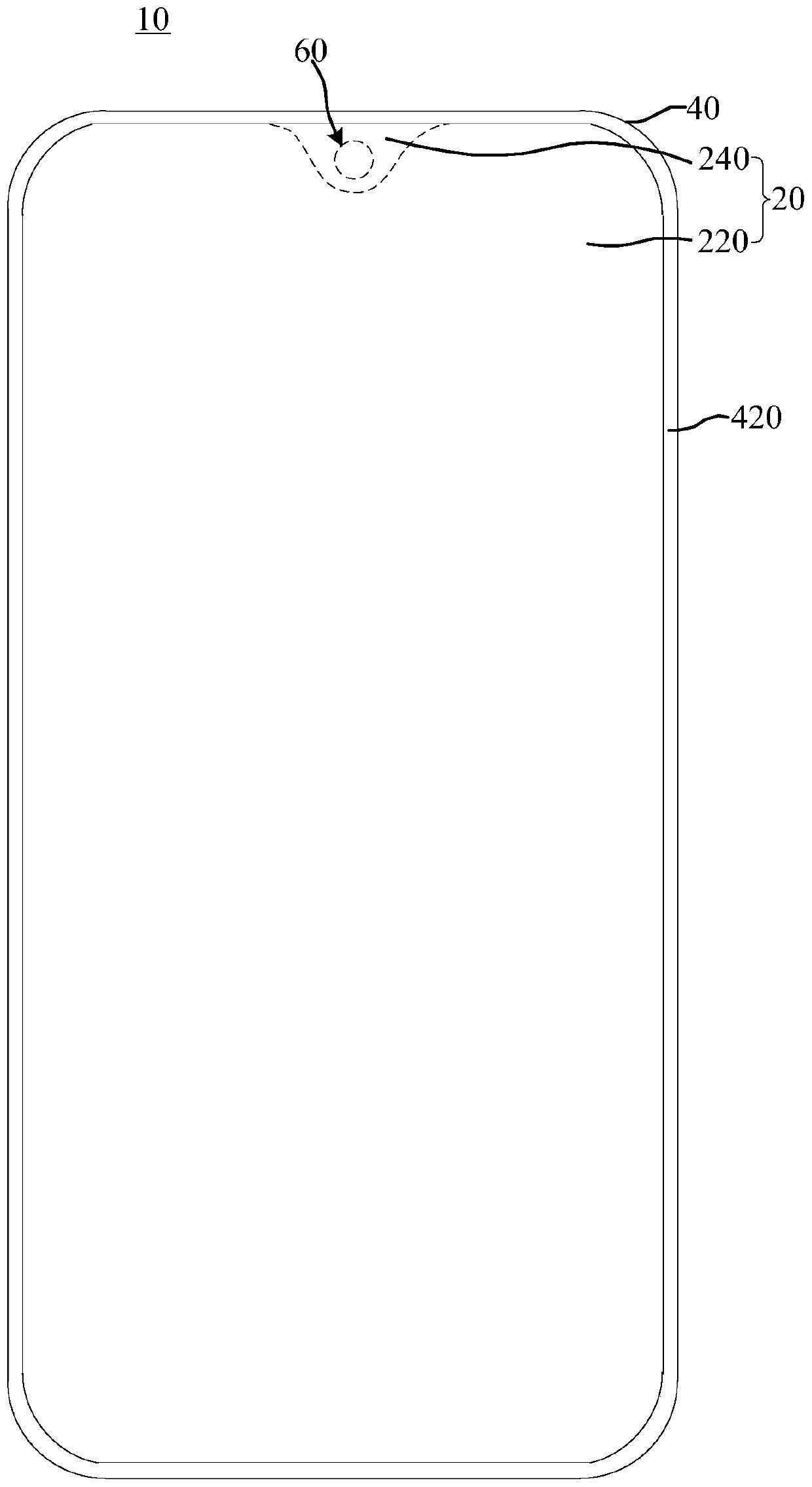

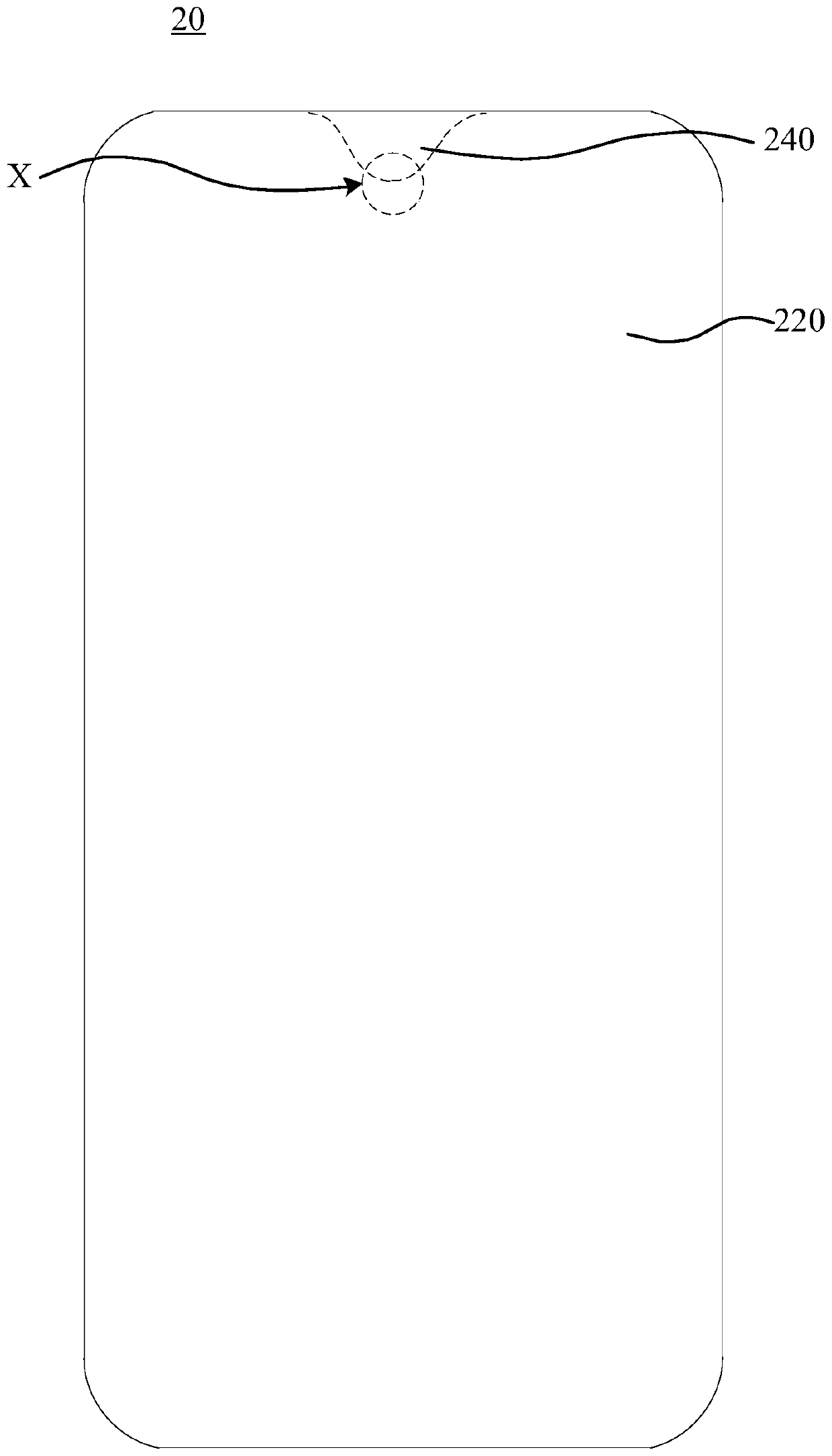

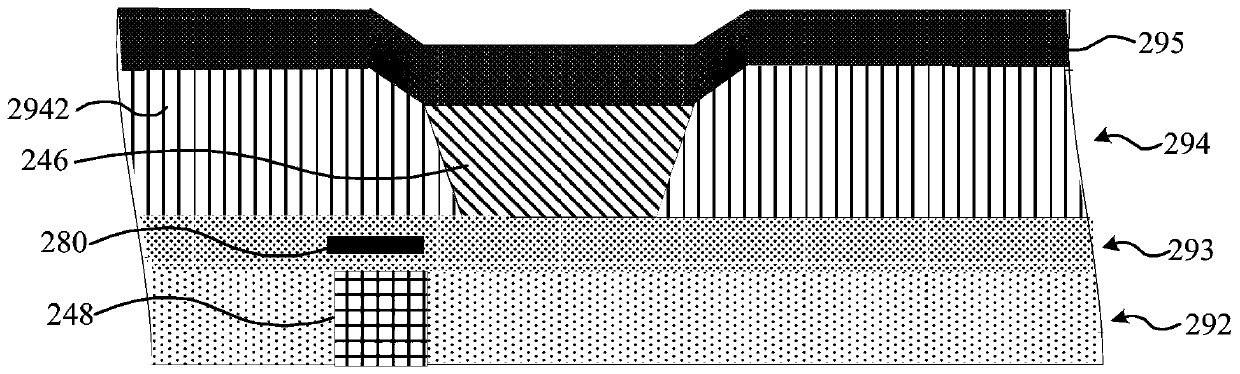

Display device and electronic equipment

PendingCN110767729AIncrease the screen ratioThe display area is completeSolid-state devicesTelephone set constructionsDisplay deviceHemt circuits

The embodiment of the invention provides a display device and electronic equipment. The display device comprises a first display area and a second display area, and the light transmittance of the first display area is greater than that of the second display area. The first display area comprises a driving circuit layer, an anode layer, a light emitting layer and a common electrode layer which arearranged in a stacked mode, and the driving circuit layer, the anode layer and the common electrode layer work together to drive the light emitting layer. A shading block is arranged between the lightemitting layer and the driving circuit layer. The driving circuit layer comprises a first driving unit, the first driving unit and the shading block are at least partially and oppositely arranged, and the shading block is used for shading an external optical signal irradiated to the first driving unit. The shading block can be used for shading an external light signal irradiated to the first driving unit of the driving circuit layer, so that the problem of stray light interference caused by reflection and refraction of the first driving unit is reduced.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

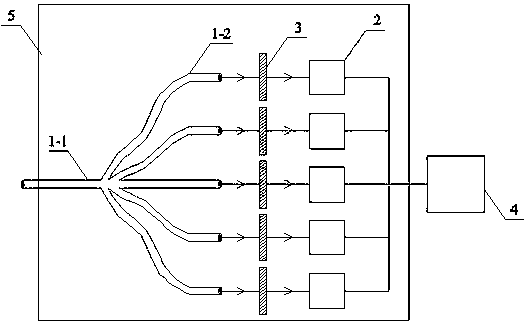

Spectrograph

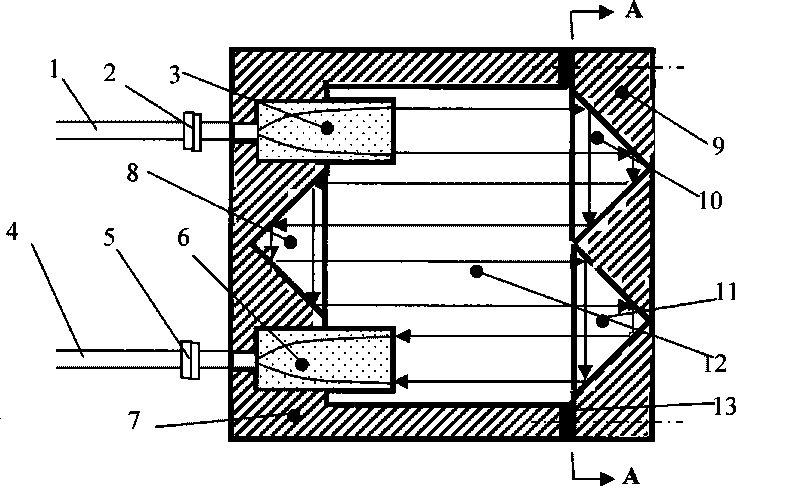

InactiveCN103134588AFast measurementHigh wavelength subdivisionSpectrum investigationSpectrum generation using diffraction elementsBeam splitterLight beam

The invention discloses a spectrograph which comprises a beam splitter and a plurality of array spectrographs. To-be-detected light is divided into a plurality of beams by the beam splitter, each wave band is measured accurately by measuring each array spectrograph, wherein the array spectrographs are connected end to end in scope and cover the whole to-be-detected wave bands, and spectral power distribution of the whole to-be-detected wave bands is obtained accurately only by one measurement. The spectrograph has the advantages of being fast in measuring speed, high in measuring accuracy, high in fine division of wavelength, high in energy utilization rate, convenient to operate and the like.

Owner:HANGZHOU EVERFINE PHOTO E INFO

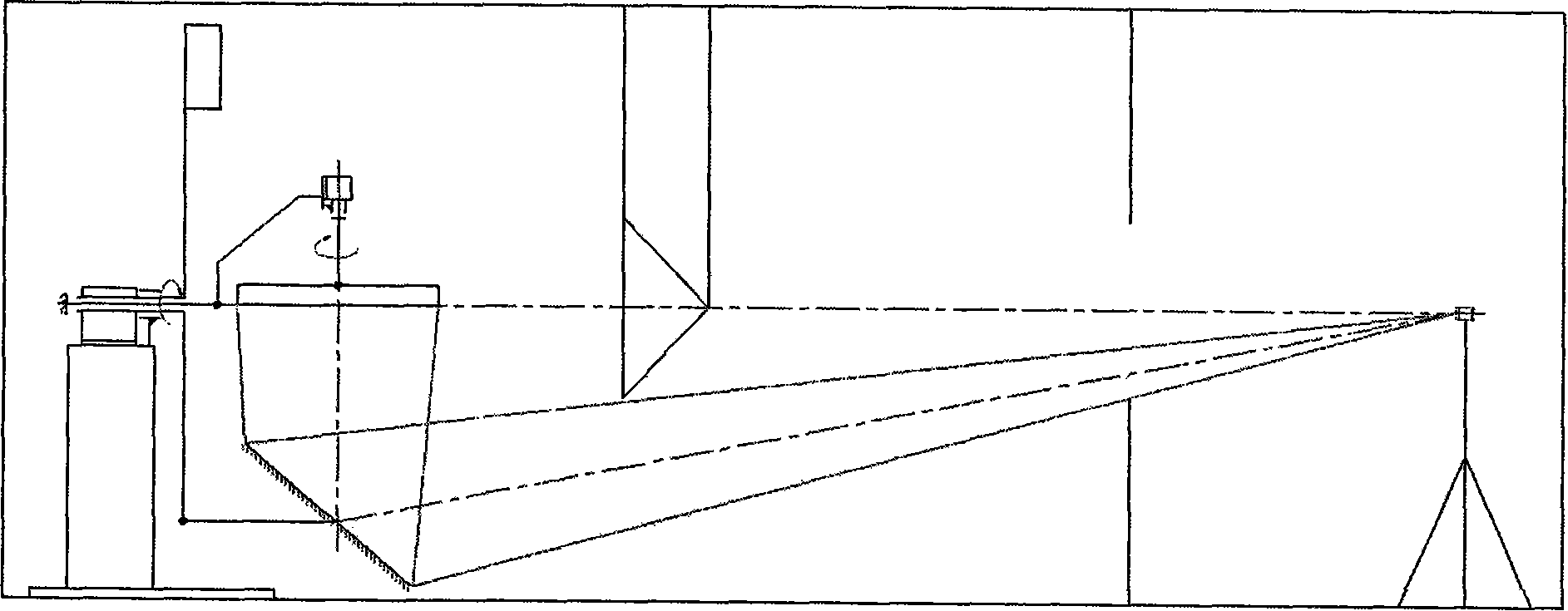

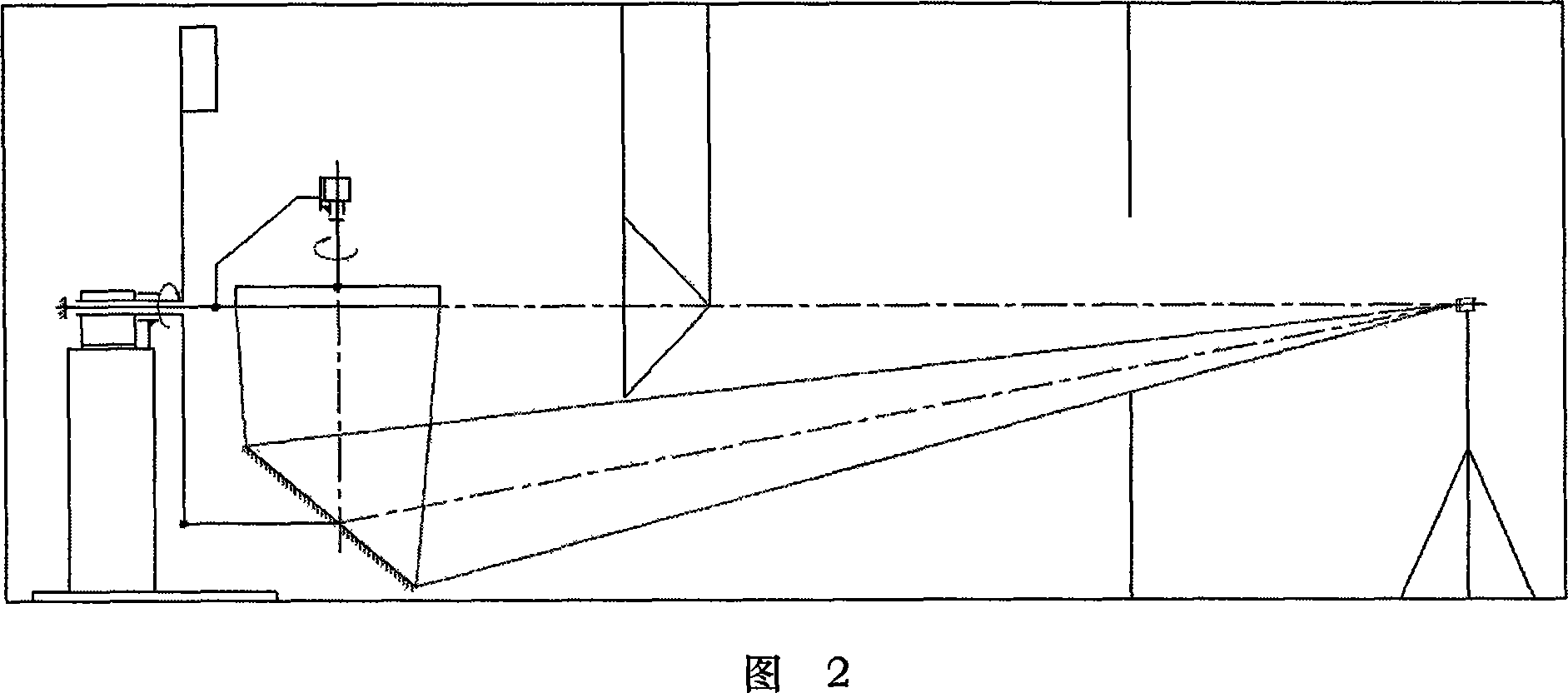

Distribution photometer

InactiveCN101158600ASmall footprintStable ignitionColor measuring devicesPhotometryOptical reflectionShortest distance

The invention discloses a distributing photometer including two independent bases, a rotary arm which rotates around a horizontal rotary central line arranged on a first base, an ellipse circumrotate plane optical reflector, a first optical detector, a second optical detector and a second laser ejector are arranged on the rotary arm and rotates around the tested lighting source with the rotary arm, the tested lighting source can rotate around the own vertical axis, a vertical round or ellipse plane optical reflector is arranged on the second base; a lighting beam from the tested lighting source is reflected to the vertical optical reflector by rotating the optical reflector, normal incidence of the lighting beam on the first optical detector is reflected by the vertical optical reflector, tests of large and medium lamps and lanterns can be implemented with long distance; the second optical detector aims at the tested lighting source directly, thus implementing tests of small lamps and lanterns of short distance. The testing chamber of the invention occupies less space with high testing precision, no extra calibration or adjusting instrument is needed in implementing tests of diverse testing arm length (testing distance) by adopting different optical detectors.

Owner:HANGZHOU EVERFINE PHOTO E INFO

Phototoxicity experiment detection device

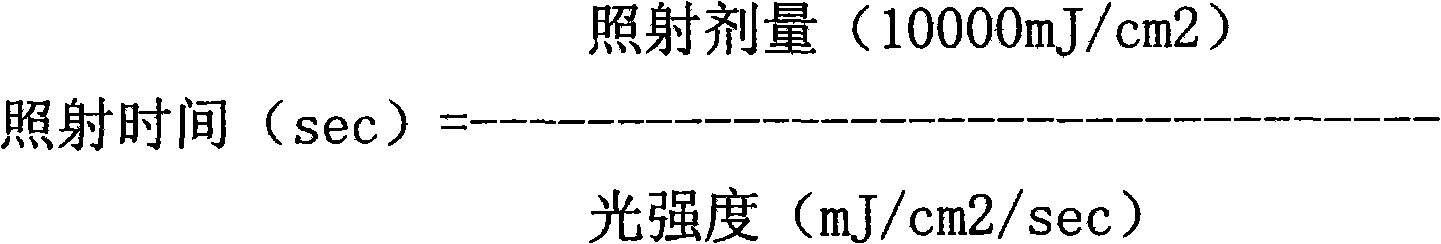

InactiveCN101554340AControllable light intensityControllable exposure timeDiagnosticsSurgeryHuman exposureUltraviolet

The invention provides a phototoxicity experiment detection device which comprises a lightproof experimental bin body. The lightproof experimental bin body is internally provided with a plurality of uviol lamps with UVA of single wavelength of 365nm as an experimental light source and a plurality of small animals fixing brackets. The front face of the experimental bin body is provided with movable observation windows on which glass capable of filtering ultraviolet waves is arranged. A sterilizer, a ventilation installation and a temperature and humidity controller are arranged in the experimental bin body to enable the environment in the bin body to meet experiment requirement. The experimental bin body is internally provided with an ultraviolet irradiation detector for detecting the intensity of the experiment light source. With the computer control of the experimental process, experimental data can be stored in a computer or experiment reports are printed through a printer. The invention has the advantages that the injury reaction of chemical substances to a human body exposed in ultraviolet irradiation is detected; the light intensity and irradiation time can be controlled, the interference of stray light is less, the experimental efficiency is high, the experimental environment is safe, and the experimental data is accurate.

Owner:范维林

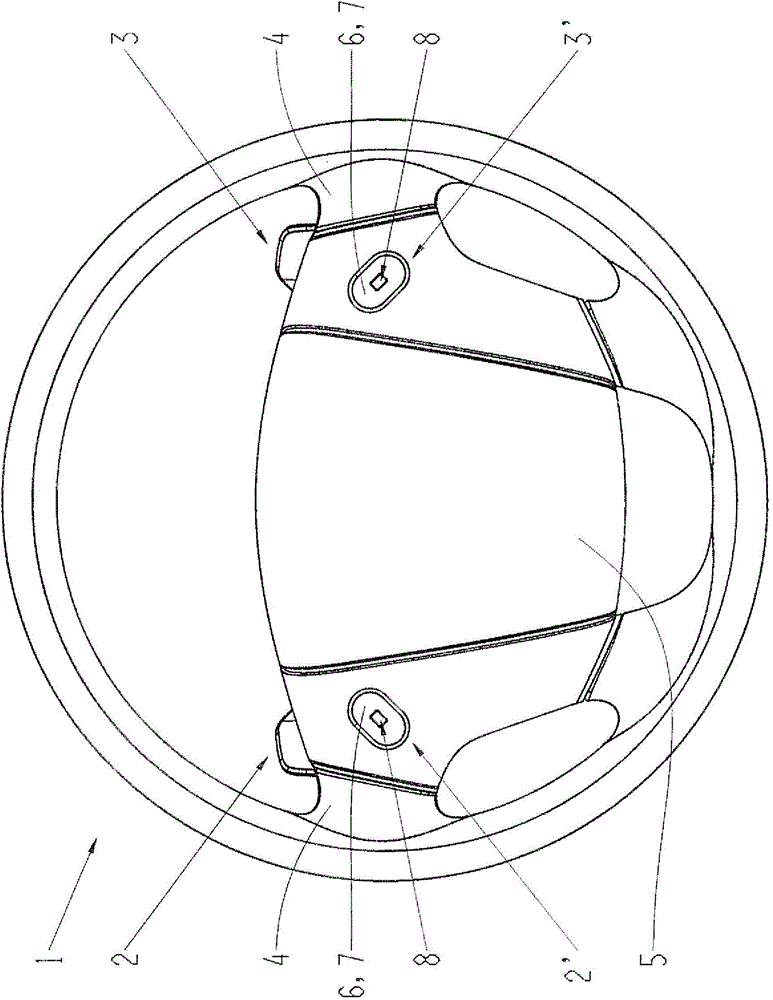

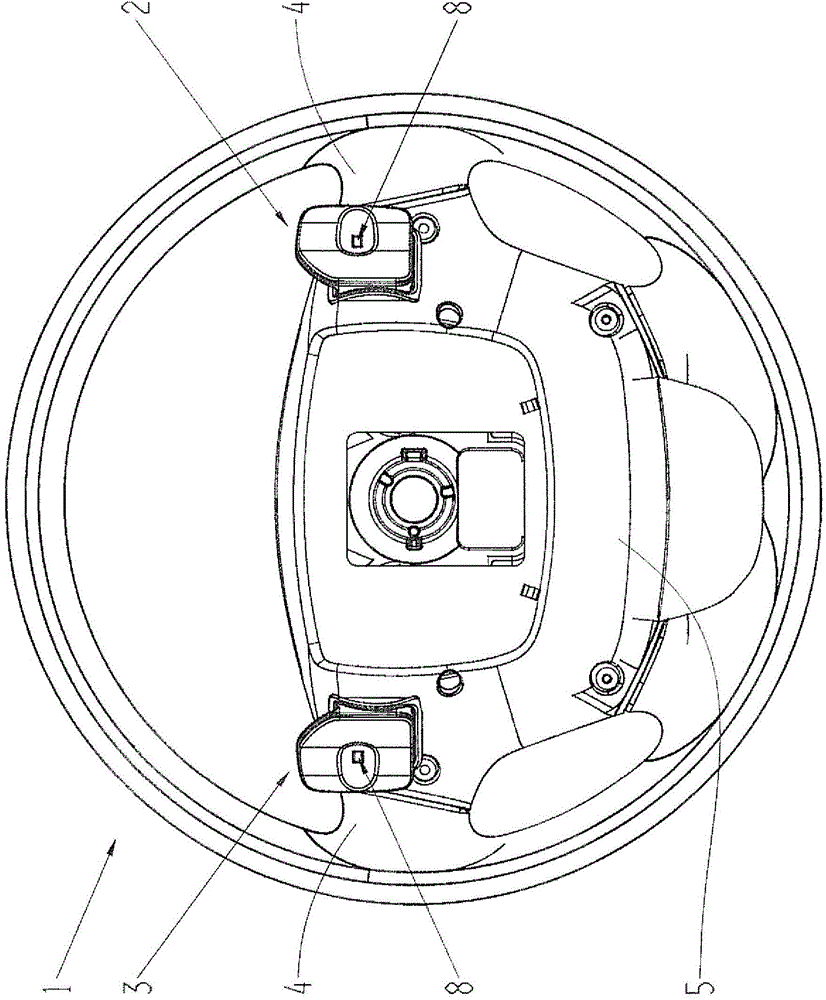

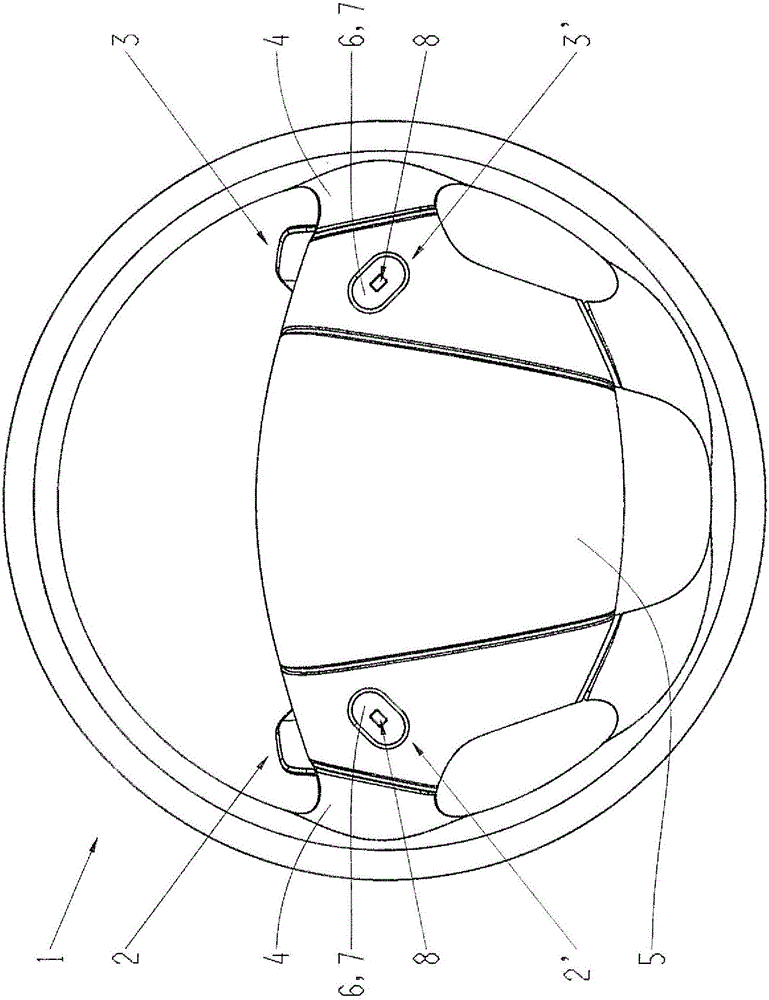

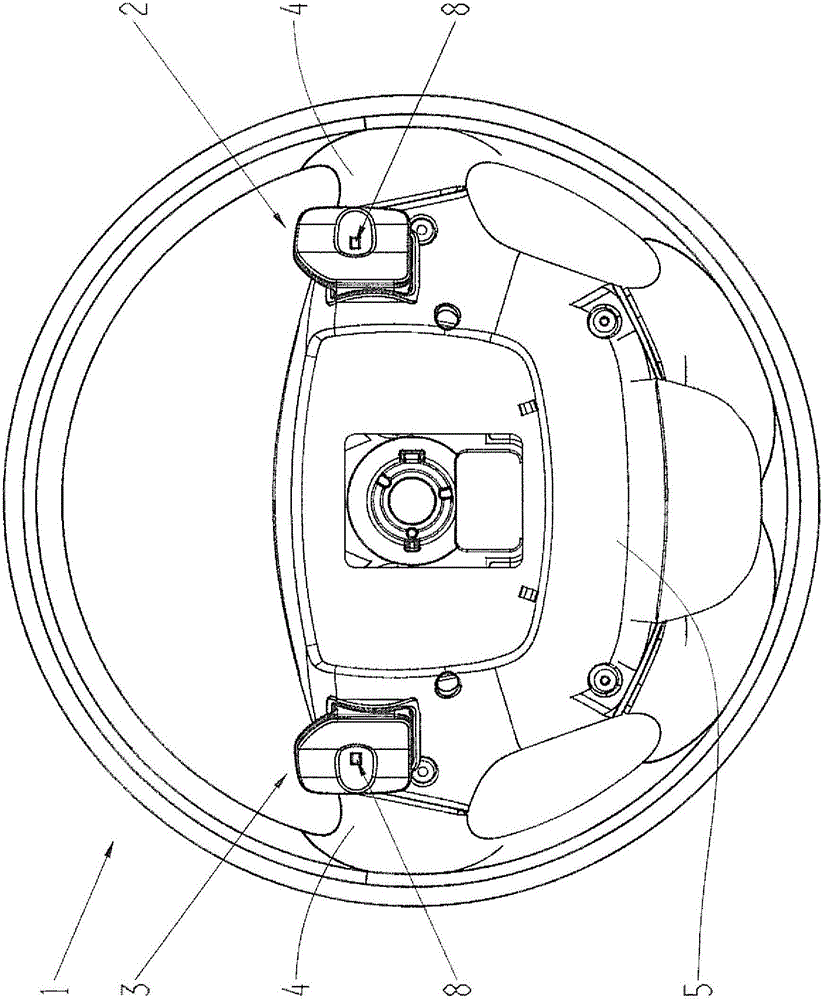

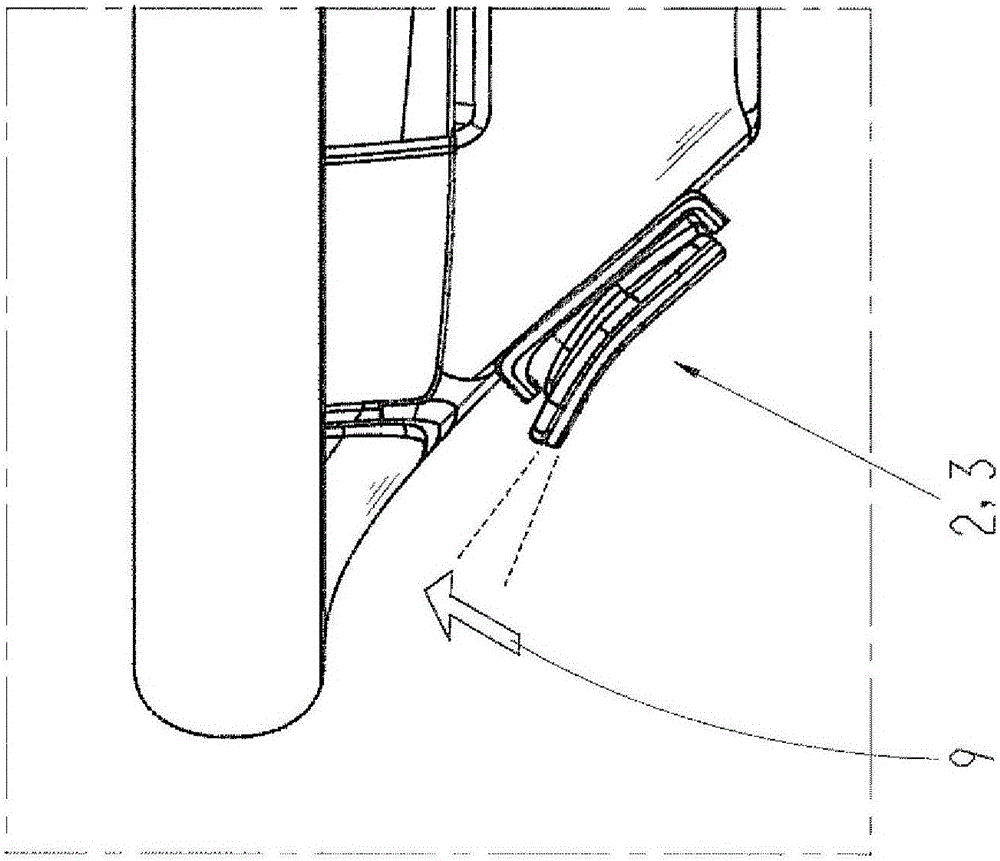

Detection of vital parameters by means of an optical sensor on the steering wheel

InactiveCN103957796AReduce consumptionEasy to measureDiagnostics using lightHand wheelsSteering wheelElectrocardiography

The invention relates to a detection device for detecting at least one vital parameter of a person in a motor vehicle with a steering wheel (1). The detection device comprises a finger sensor device (2, 3) with an optical sensor device (8), the finger sensor device (2, 3) being arranged on the steering wheel (1) in the transition region between a steering wheel spoke (4) and the steering wheel body (5). In a preferred embodiment, the sensor surface area is formed by the actuation surface of a push-button switch. The push-button switch can, in particular, be a shifting paddle for a gearshift transmission. The sensor surface area can have an electrically conductive surface for generating an electrocardiogram (ECG).

Owner:ZF FRIEDRICHSHAFEN AG

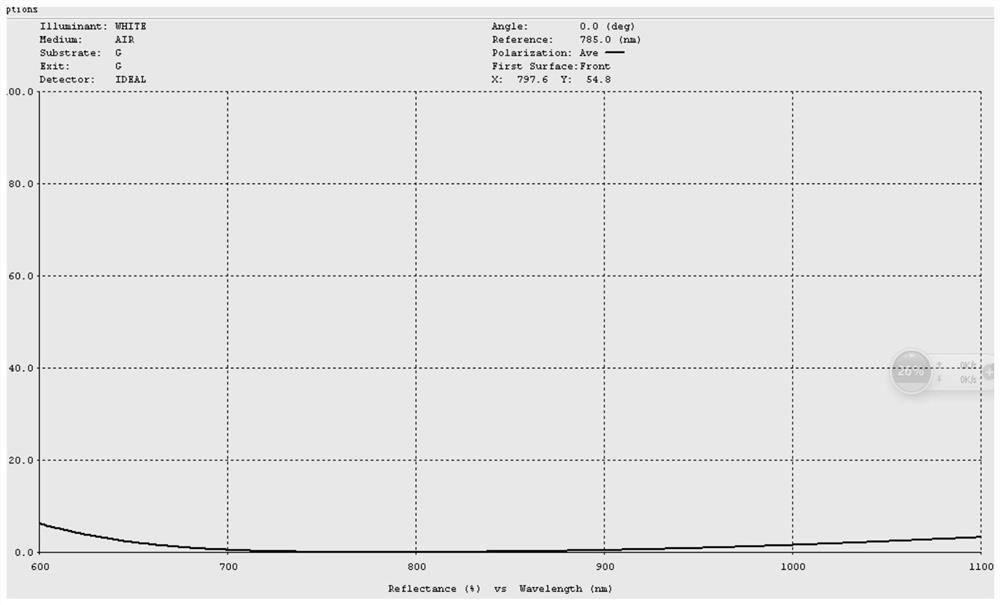

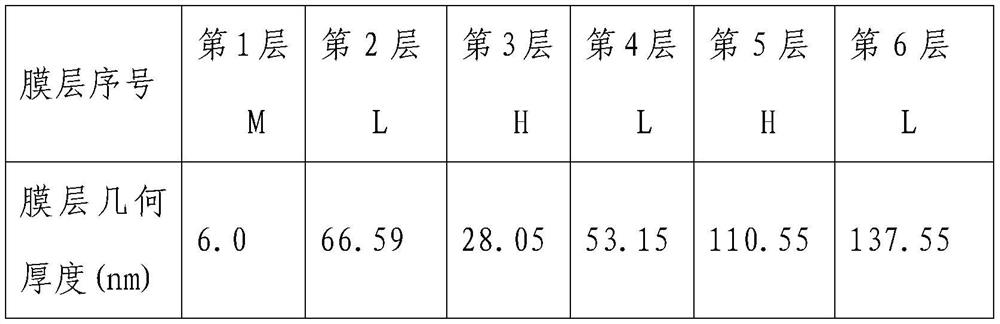

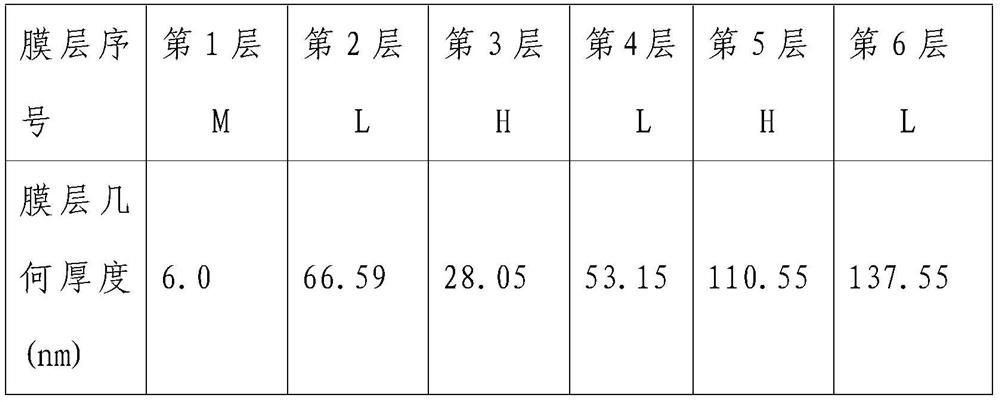

High-damage-threshold laser film process technical method

InactiveCN111679347AExcellent resistance to laser damageImprove permeabilityVacuum evaporation coatingSputtering coatingRefractive indexOptical thin film

The invention relates to a high-damage-threshold laser film technological method, and belongs to the field of optical film plating. The invention aims to overcome the defect that the laser damage resistance threshold of a laser film plated in visible light and near-infrared bands by a conventional laser film plating technology is relatively low. Quartz or K9 is used as a coating substrate, sapphire is used as a substrate film material M, HfO2 is used as a high-refractive-index film material H, SiO2 is used as a low-refractive-index film material L, and TFC is used for giving geometric thicknesses and film system sequence calculation results of all layers of film systems; ultrasonic cleaning and heating baking are carried out on the coating substrate; in an optical film layer bonding bottoming process and a stress matching process, three film materials are sequentially put into an electronic gun evaporation source crucible boat, and then a coating process is completed according to the geometric thickness of each layer of film system and the sequence of the film systems; and the coating substrate is bombarded by using an ion source before coating and in the coating process. The filmlayer is hard, firm, excellent in laser damage resistance and good in permeability, and can be used for a long time in a severe field environment.

Owner:SOUTH WEST INST OF TECHN PHYSICS +1

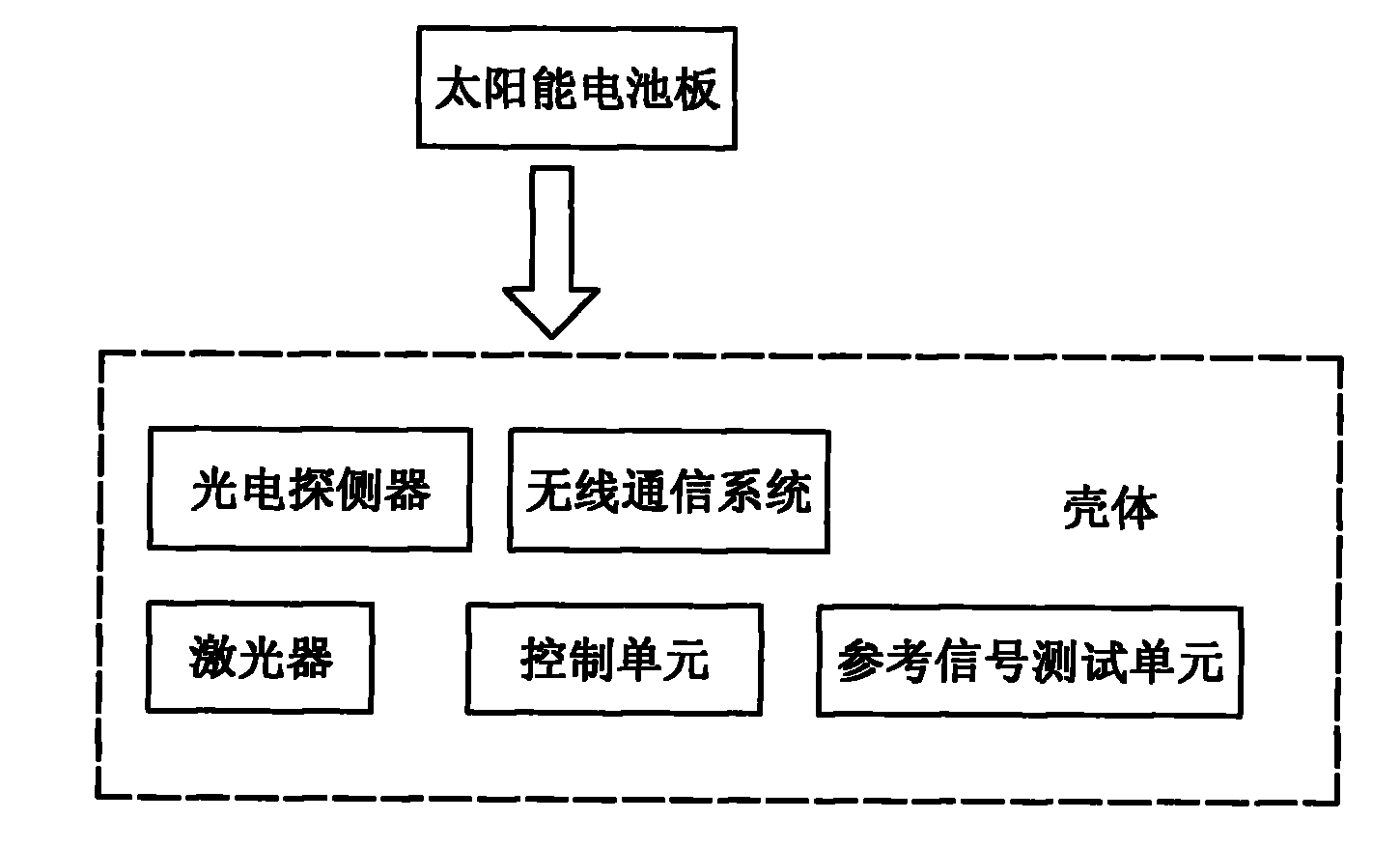

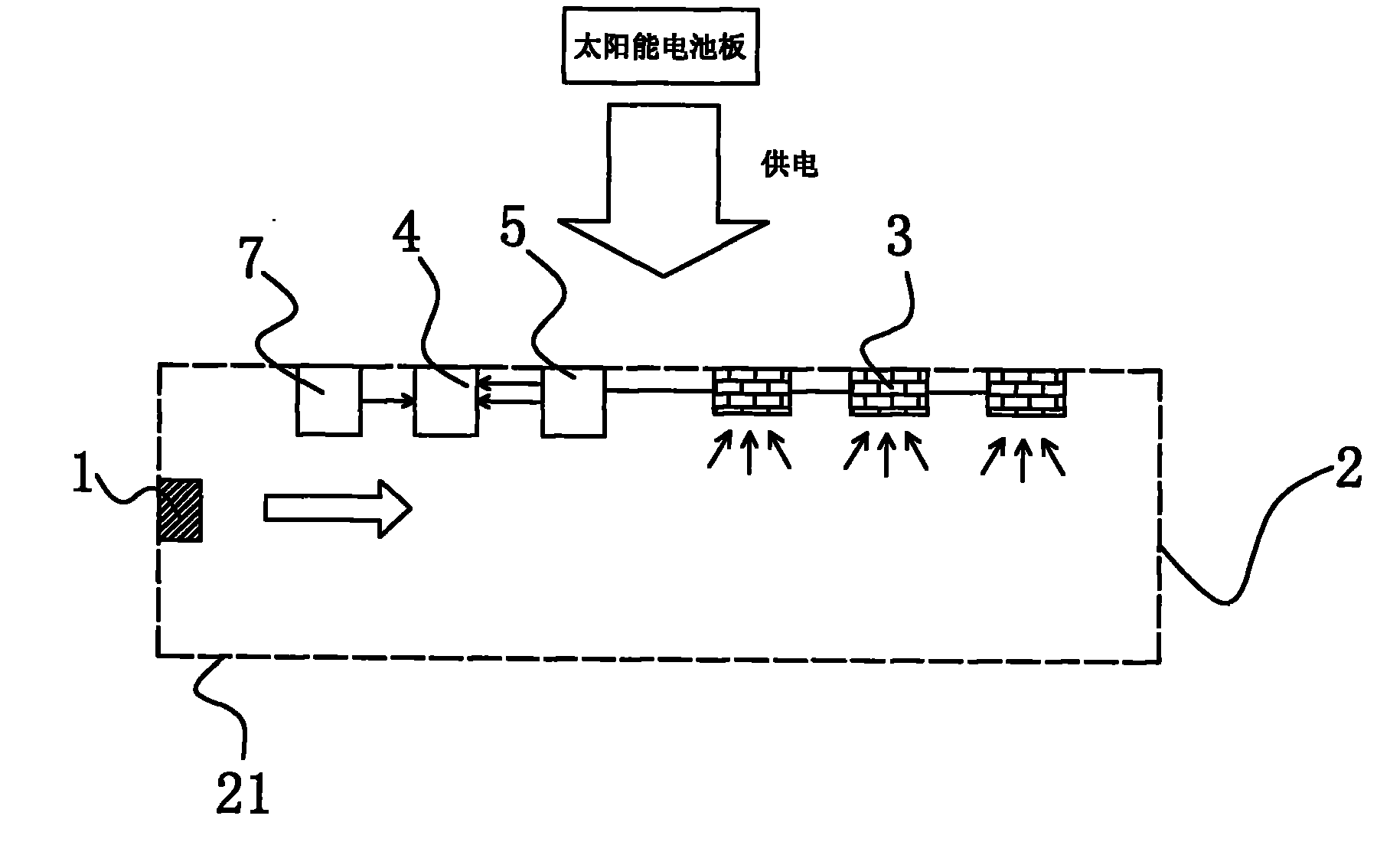

Mist zone visibility detection method and equipment

InactiveCN101995394ALow costExpand the scope of useScattering properties measurementsScattered lightPhotovoltaic detectors

The invention discloses a mist zone visibility detection method and mist zone visibility detection equipment. By measuring scattering strength of mist on light, an extinction coefficient is acquired and a visibility value is finally acquired. Laser is adopted as a detection light source, and a photoelectric detector is used for receiving the light. Mist with different visibility values brings different scattering receiving results; when the visibility is high, light scattering is low and an output value on the photoelectric detector is low; and when the mist visibility is low, a receiving value of the photoelectric detector is increased. By analyzing and calculating scattered light receiving data, the mist visibility value is acquired, and through multipoint arranged photoelectric receivers and the correction of environmental temperature and humidity, the measurement accuracy can be effectively improved. A wireless communication module is arranged inside an instrument, and remote signal transmission can be realized. The instrument is convenient to use, overcomes the defect that the conventional related products have high cost, and is convenient to monitor environment in foggy weather.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI +1

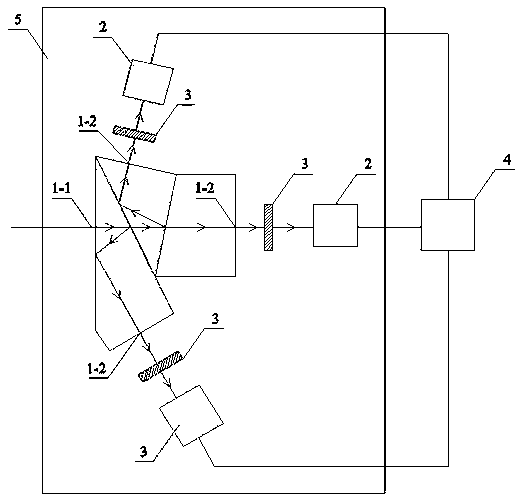

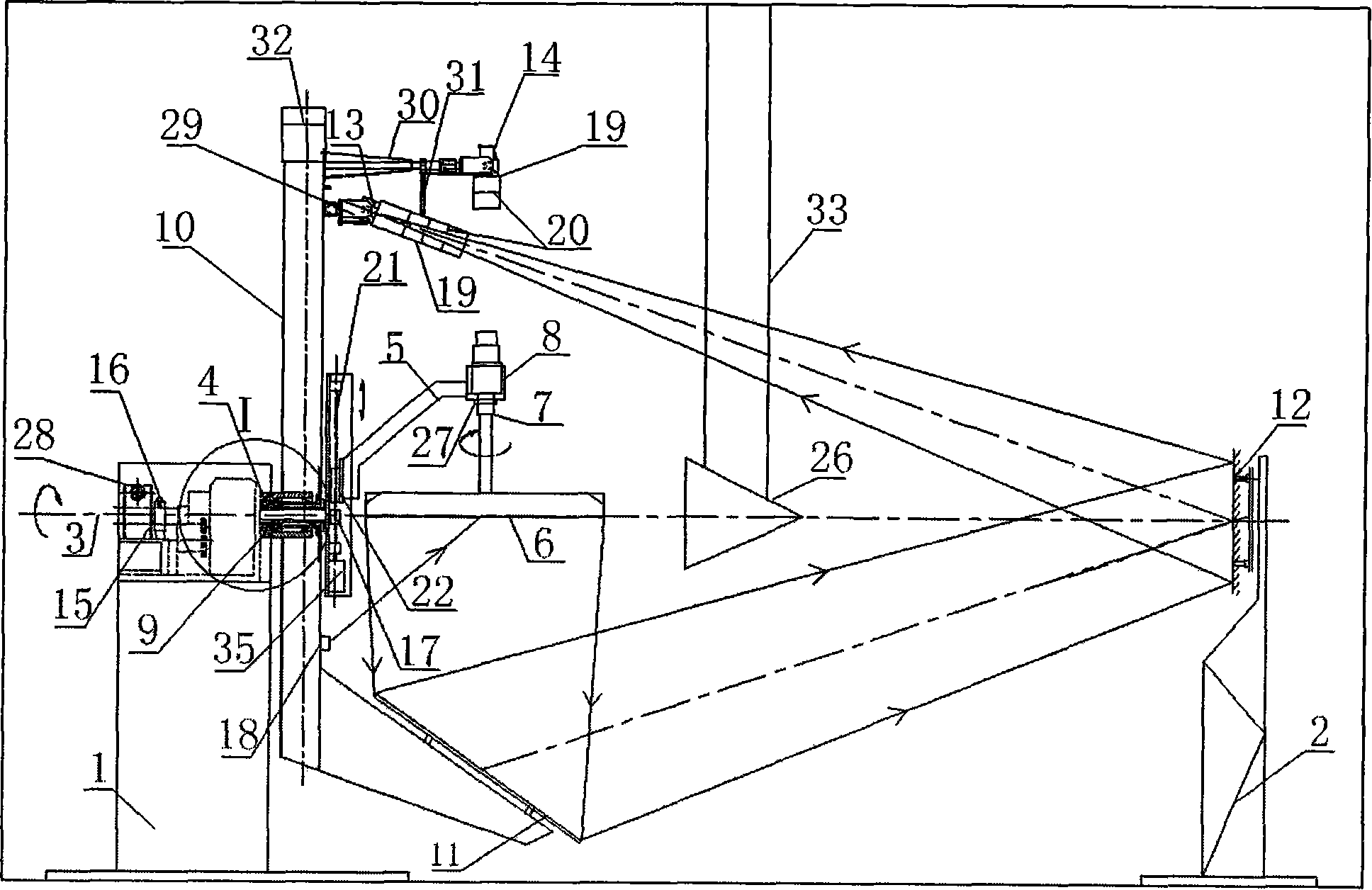

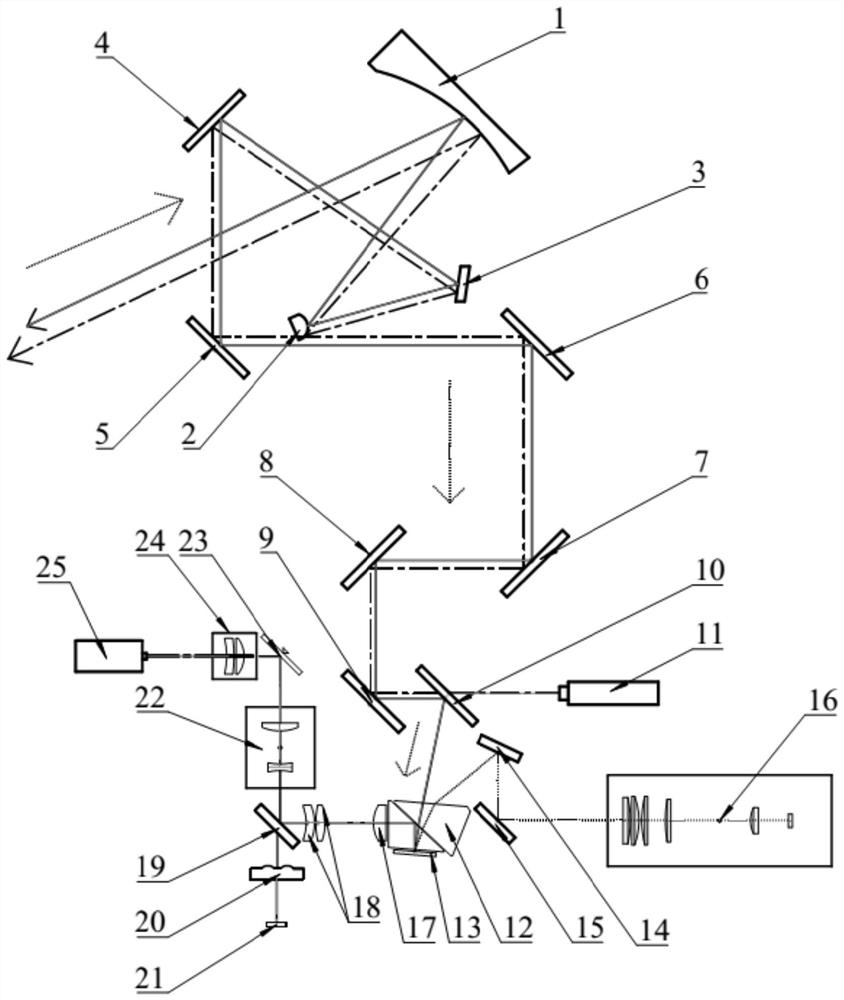

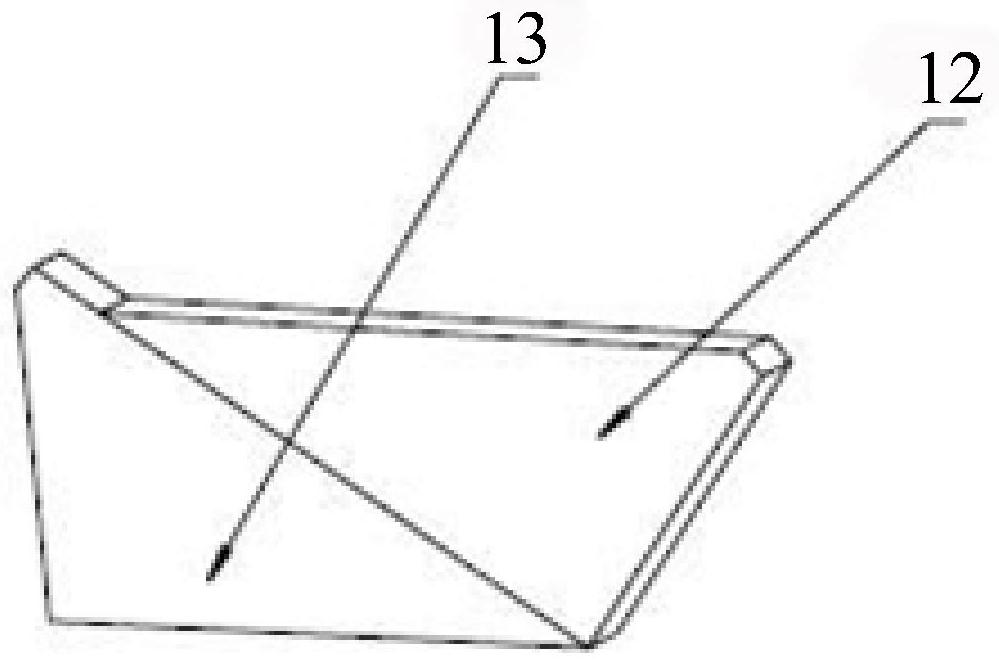

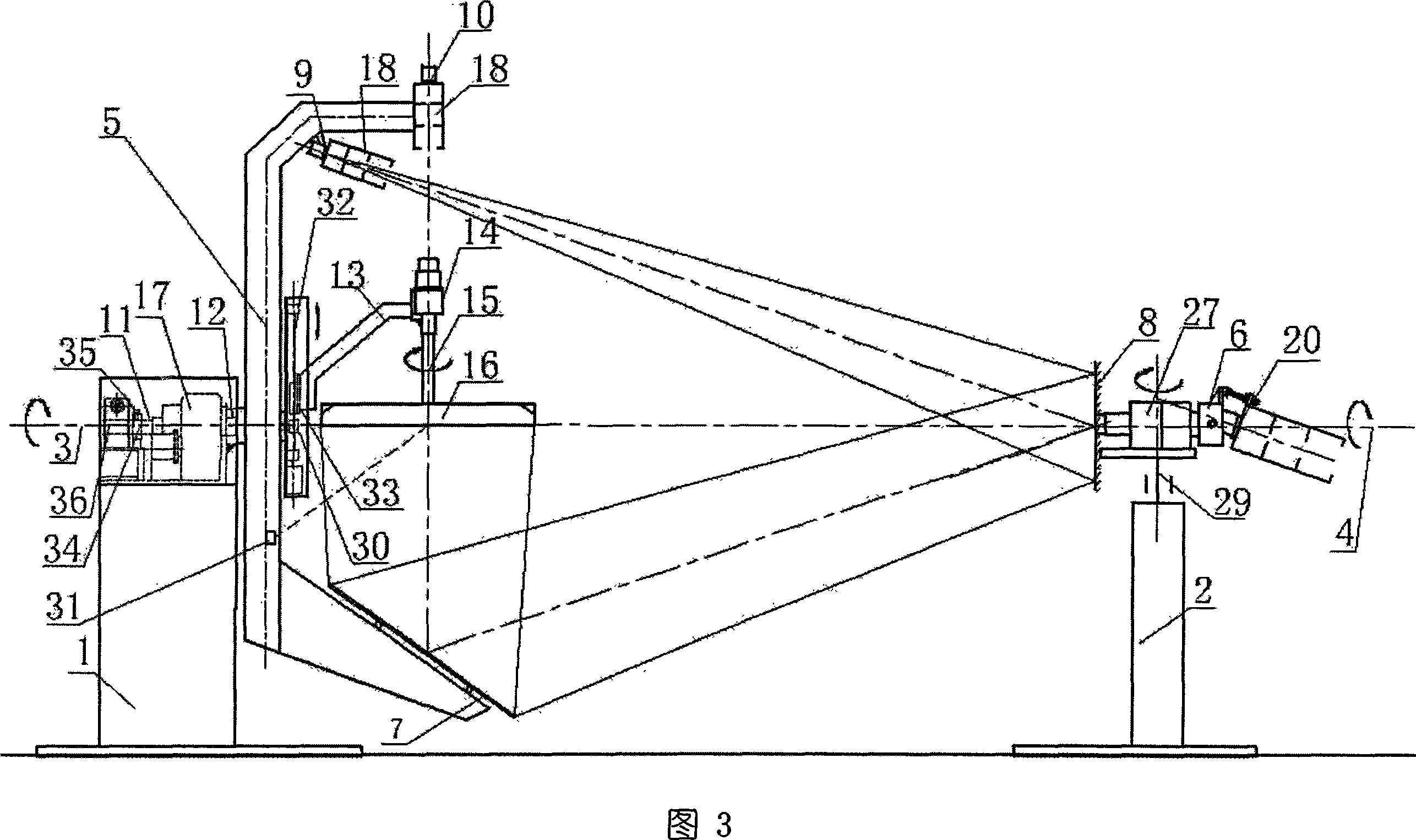

Light path system for photoelectric tracking active tomography illumination

ActiveCN112596230AReduce stray light interferenceReduce volumeWave based measurement systemsTelescopesPhysicsTomography

The invention discloses a light path system for photoelectric tracking active tomography illumination. The system comprises a transmitting telescope, a fast reflecting mirror, a plurality of Coude mirrors, a spectroscope, a transmitting laser, an illumination pulse laser, a short-wave optical imaging system, a TIR prism, a relay DLP chip imaging optical system, an illumination laser optical axis calibration optical system, an illumination laser beam shrinking system, an illumination laser collimating lens, a Coude optical path formed by the plurality of Coude mirrors and the like. The system has the advantages of being capable of detecting and imaging an ultra-long-distance target around the clock, reducing stray light interference, achieving detection and imaging of the target in a complex environment, reducing the size of the photoelectric tracking and pointing device and the like.

Owner:AEROSPACE SCI & IND MICROELECTRONICS SYST INST CO LTD

Laser device

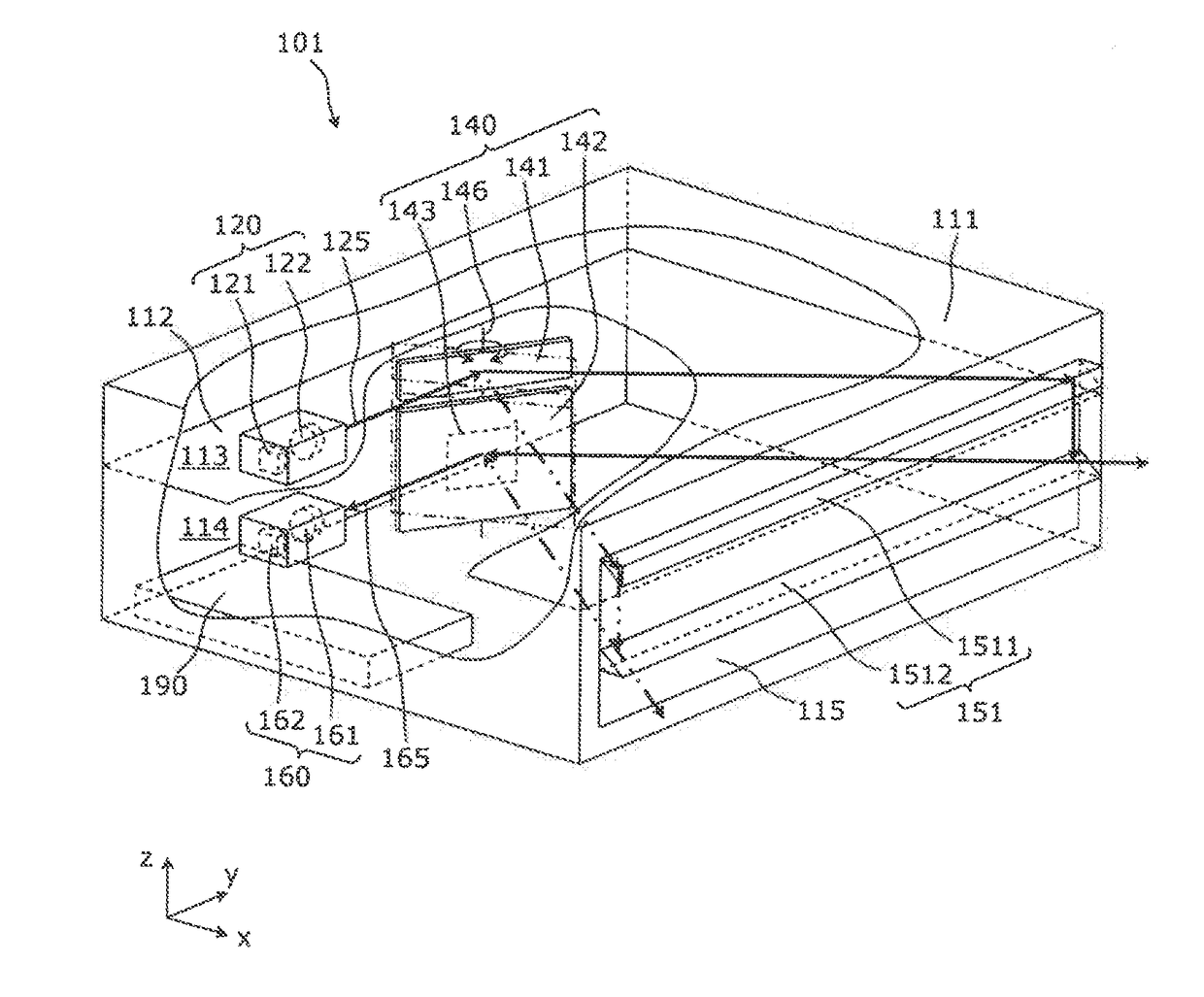

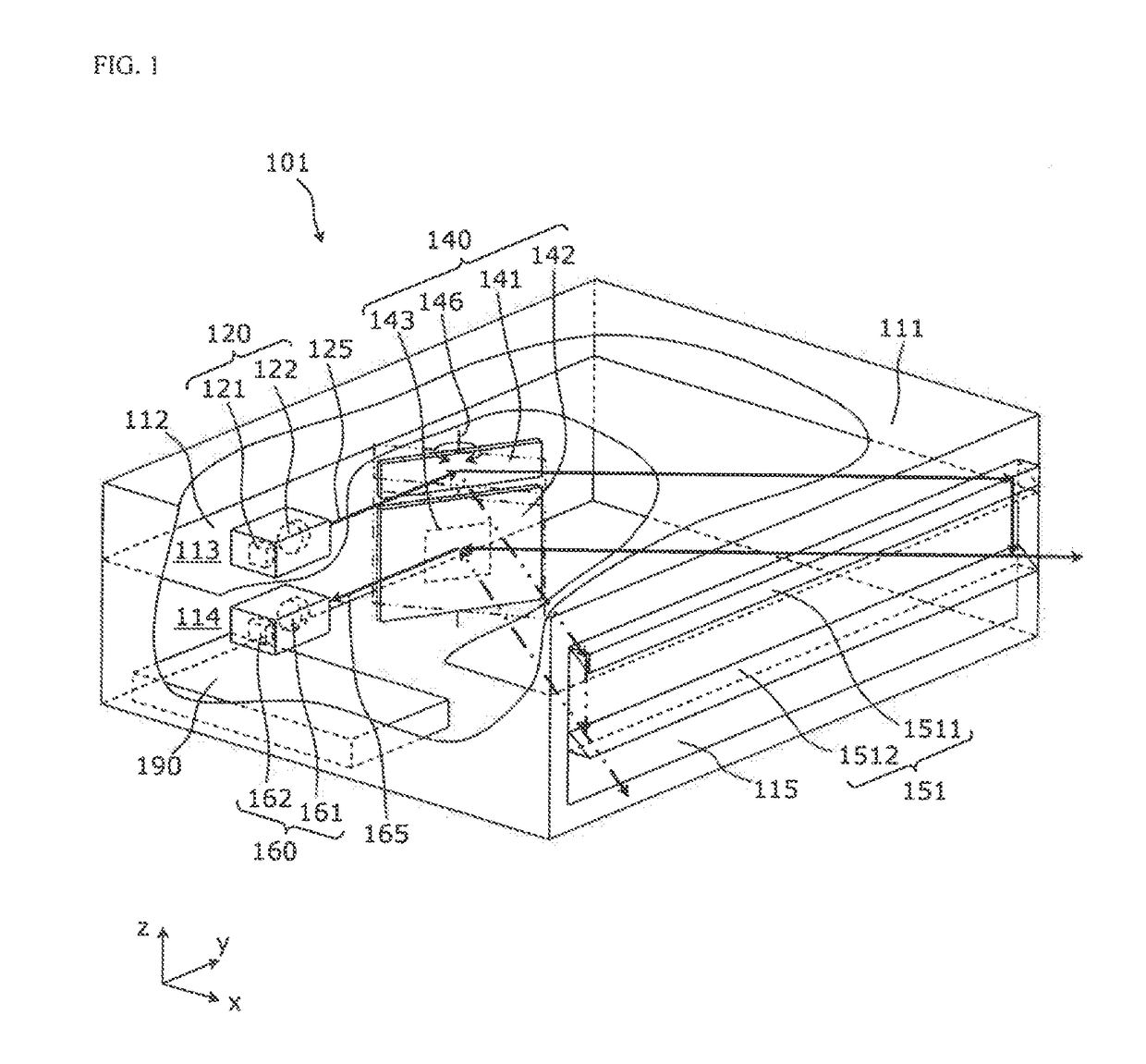

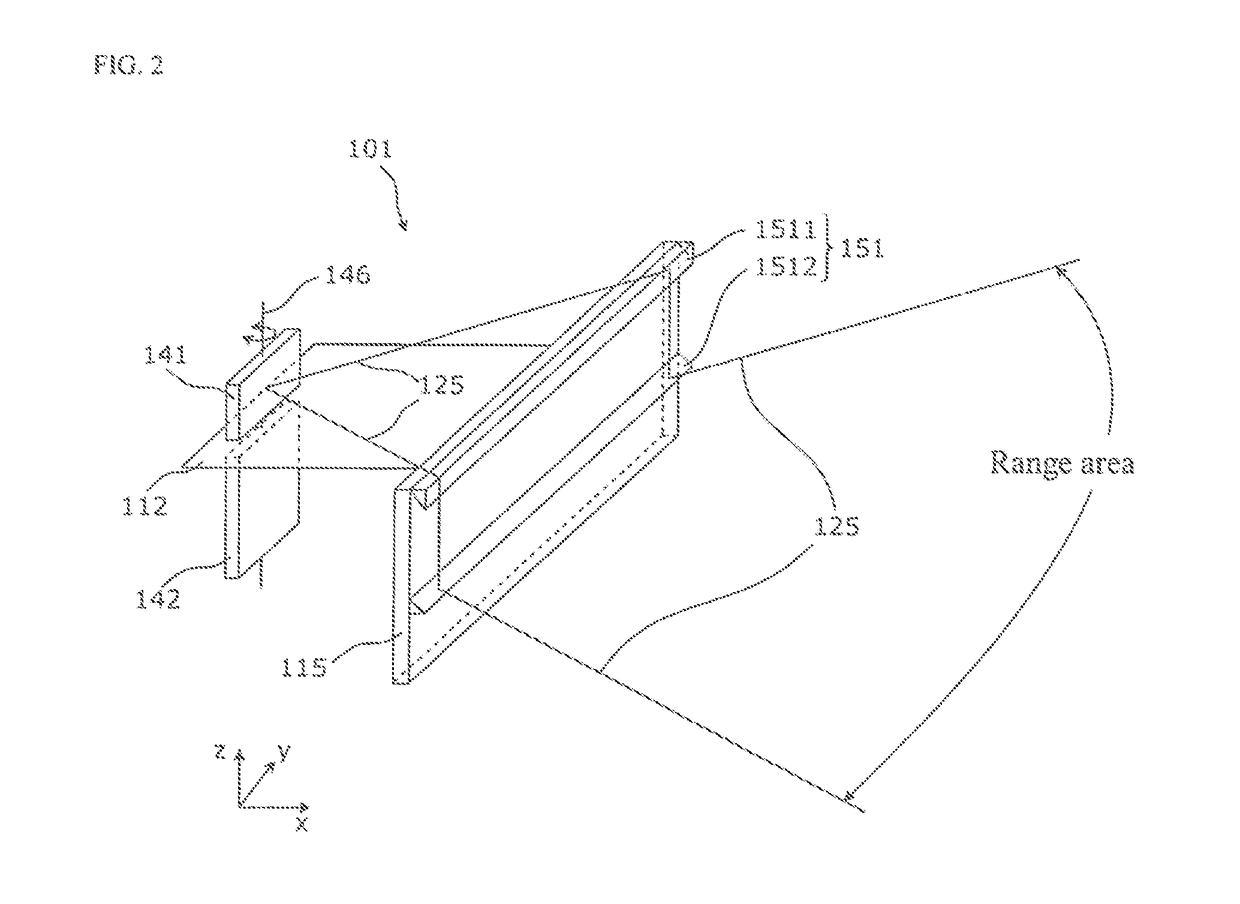

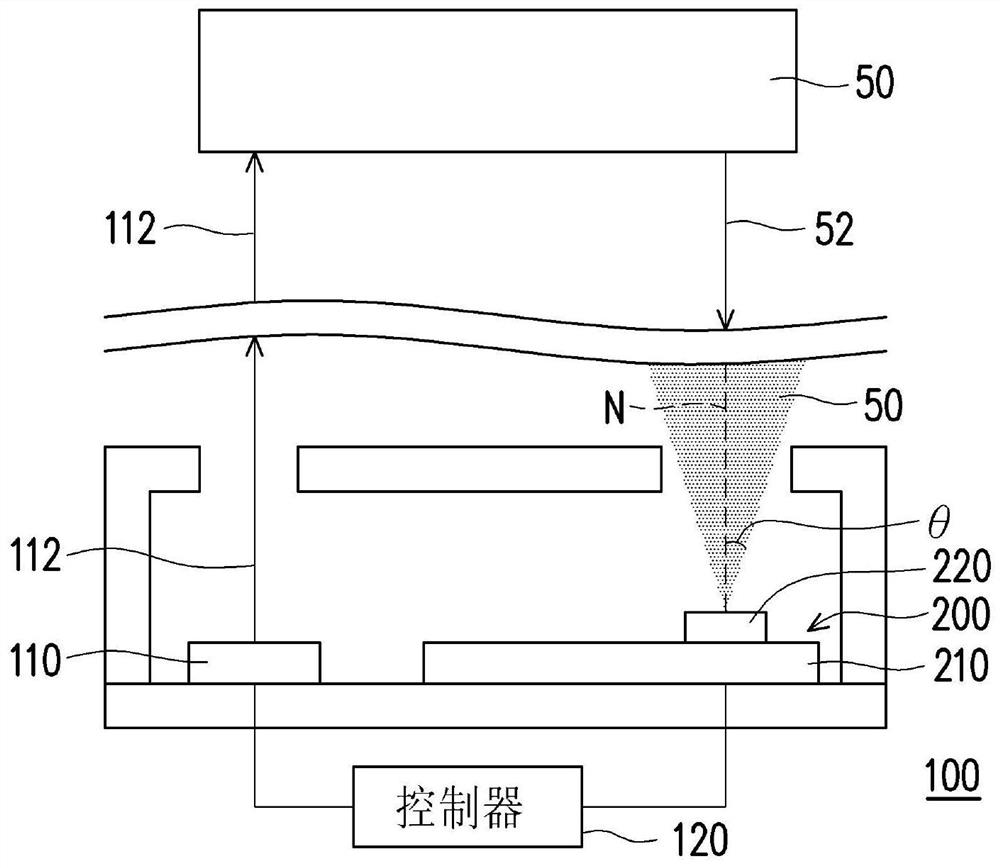

ActiveUS20170131386A1Reduce parallaxReduce stray light interferenceElectromagnetic wave reradiationOptoelectronicsTransmitter

A laser device includes a transmitter that emits a light, a first reflector that pivotally reflects the light by a shaft, a light receiver provided apart from the transmitter in a first direction parallel to the shaft, a guide part that receives the light from the first reflector and changes a direction of the light in the first direction, and a second reflector that reflects a returning light from an object and pivots in sync with the first reflector.

Owner:FUNAI ELECTRIC CO LTD

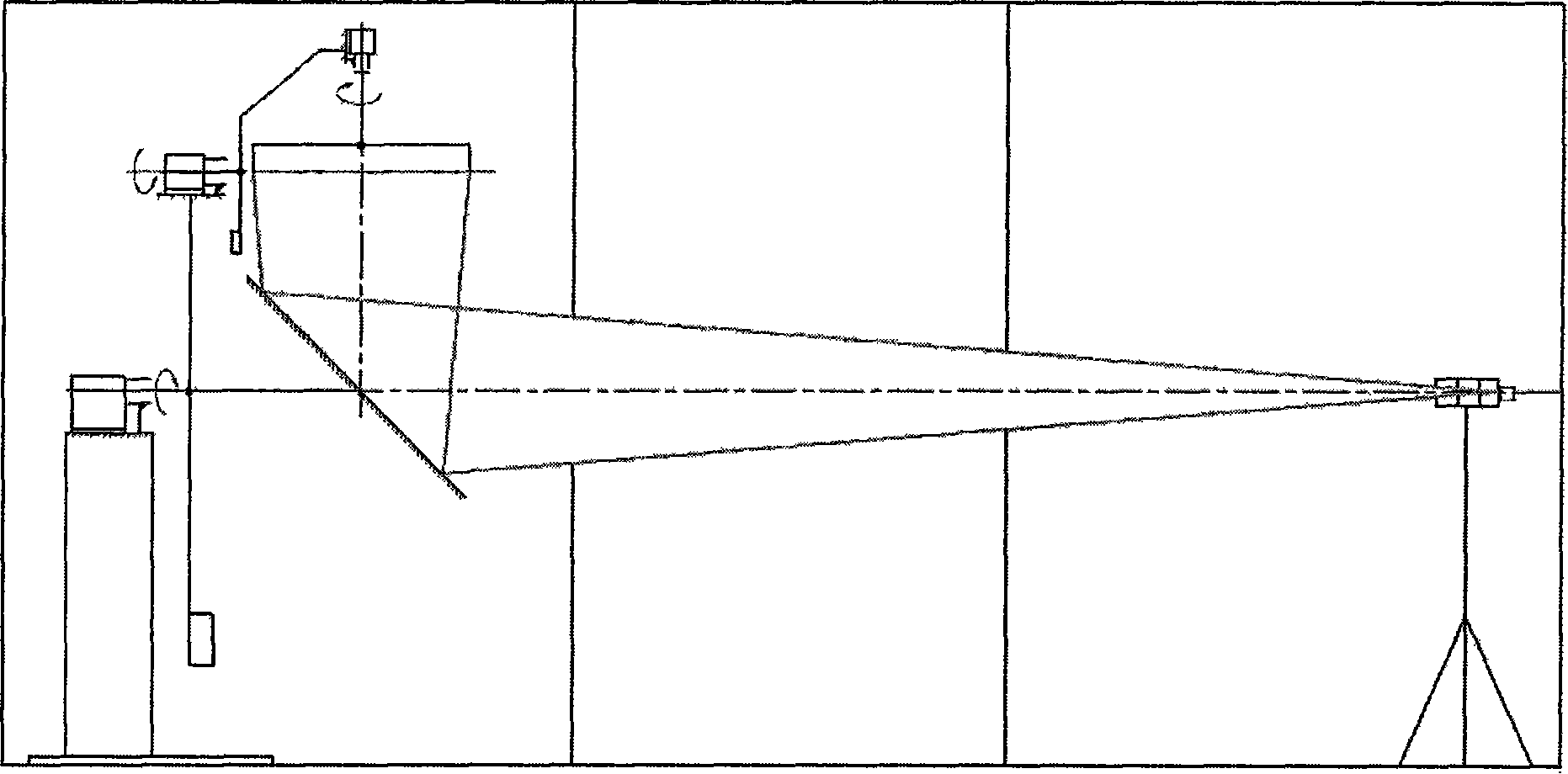

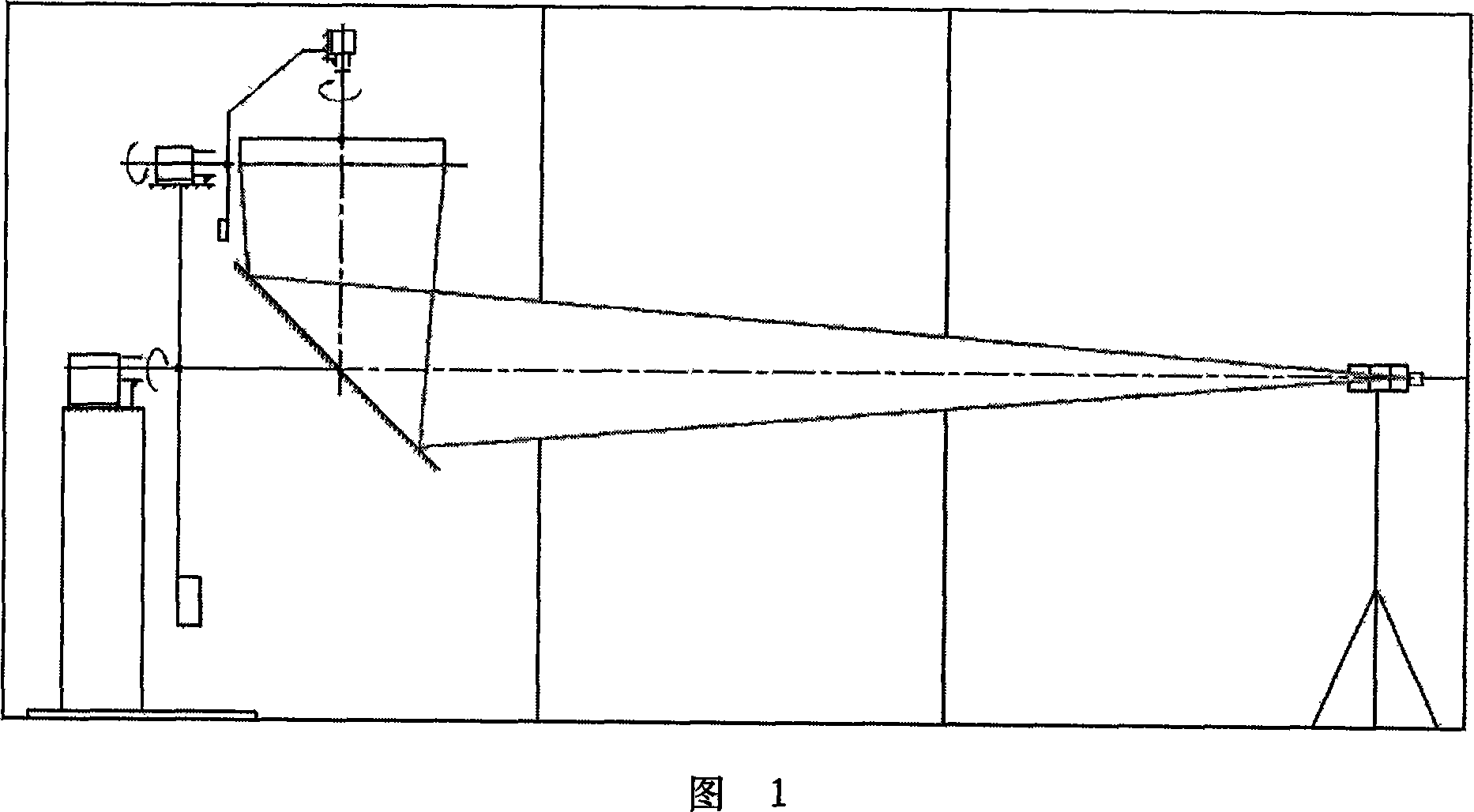

Synchronous reflection distribution photometer

ActiveCN101059369AEasy to installEasy to adjustPhotometryTesting optical propertiesObservational errorOptical reflection

The invention discloses a synchronous reflective distribution photometer, comprising two independent bases, wherein a first pivoted arm is connected with the first base to rotate around a first rotary central line, a first optical mirror is mounted on the first pivoted arm, a second optical mirror is connected with the second base or a second pivoted arm connected with the second base, the second pivoted arm can synchronously rotate coaxially with the first pivoted arm, an optical receiver is mounted on the pivoted arm, an object light source via a lamp arm is connected with the first base to rotate around itself shaft. The invention utilizes synchronous reflection and receiving, to effectively utilize the space of dark room, reduce measurement error, while the invention arranges optical receiver at different positions to select measuring arm length easily, which effectively resolve the defects of prior arm as large area of dark room, high measuring error, and hard range adjustment or the like.

Owner:HANGZHOU EVERFINE PHOTO E INFO

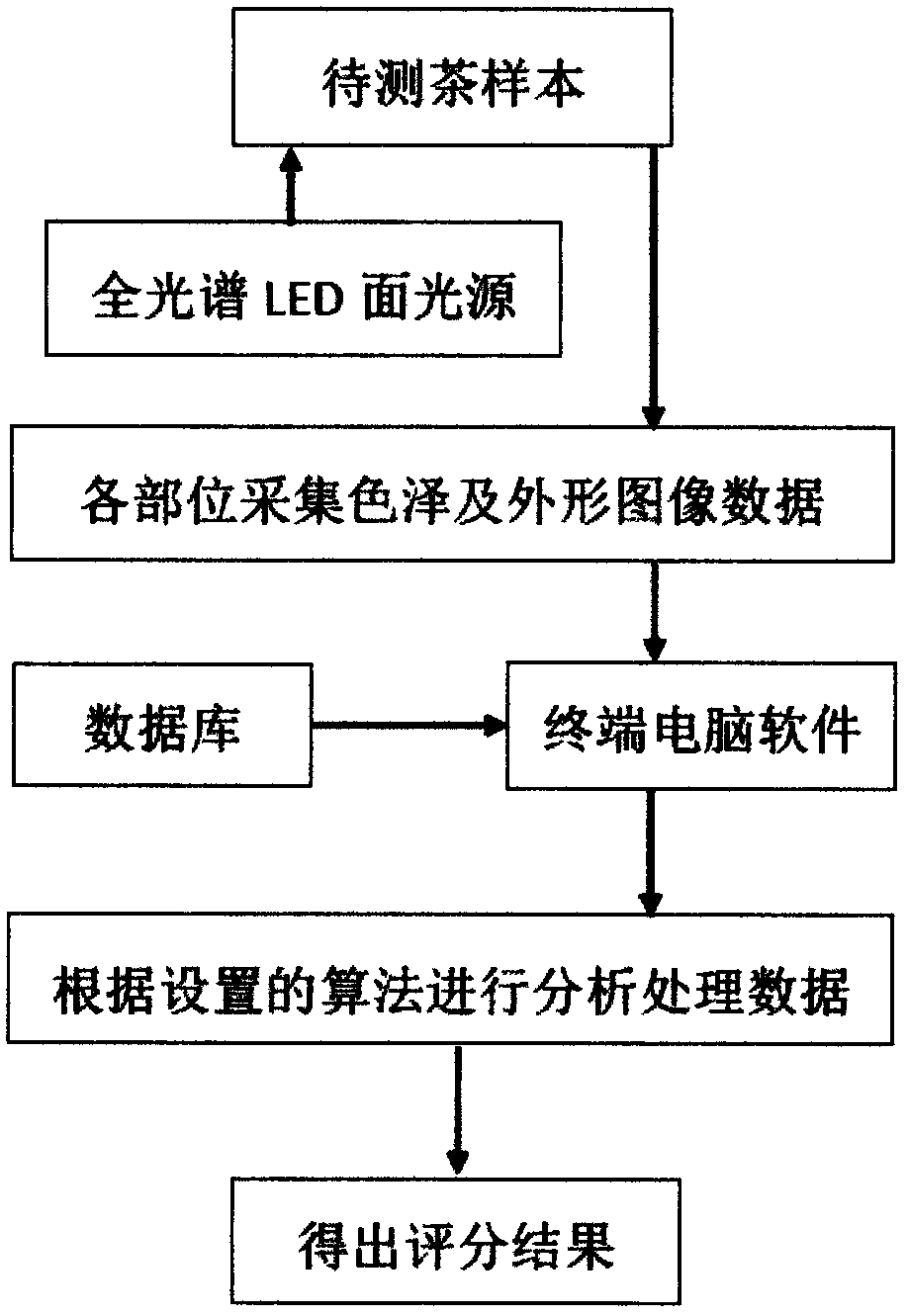

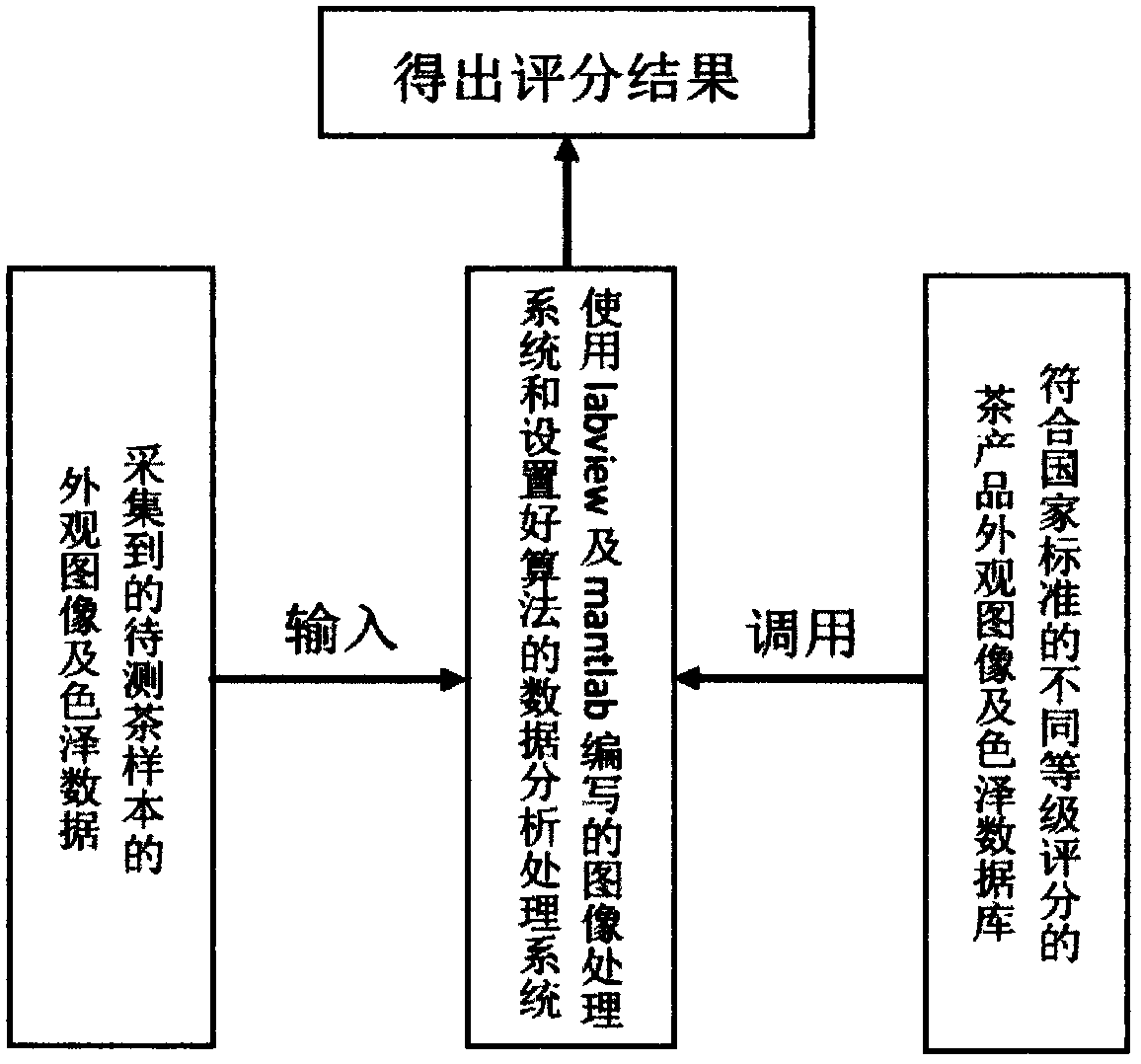

Intelligent sensory tea quality evaluation method and system

InactiveCN108287161AAvoid defectsReduce uncertaintyMaterial analysis by optical meansPattern recognitionHigh definition

The invention discloses an intelligent sensory tea quality evaluation method and system and belongs to the technical field of artificial intelligence and image recognition. The evaluation device is composed of a full spectrum LED area source, a high-definition camera, a color sensor, an objective table and an LCD touch screen. According to the intelligent sensory tea quality evaluation method andsystem disclosed by the invention, the artificial intelligence bionic device color sensor and the image recognition technology replace artificial sense organs for comprehensively identifying appearance quality of tea products from two aspects of dry tea, tea soup and bottom such as color and appearance. The system performs comparison calculation on acquired sample data and standard data in a database by a set algorithm, and a standard core corresponding to a central value of standard deviation can serve as a quality score of the sample. By utilizing forefront analysis and recognition technology design, many defect problems existing in the traditional artificial sensory evaluation are solved, and the intelligent sensory tea quality evaluation method is efficient and rapid in identificationprocess, high in result accuracy, clean, environmentally friendly, and material- and labor-saving and can provide guidance for the tea product identification process.

Owner:CHINA JILIANG UNIV

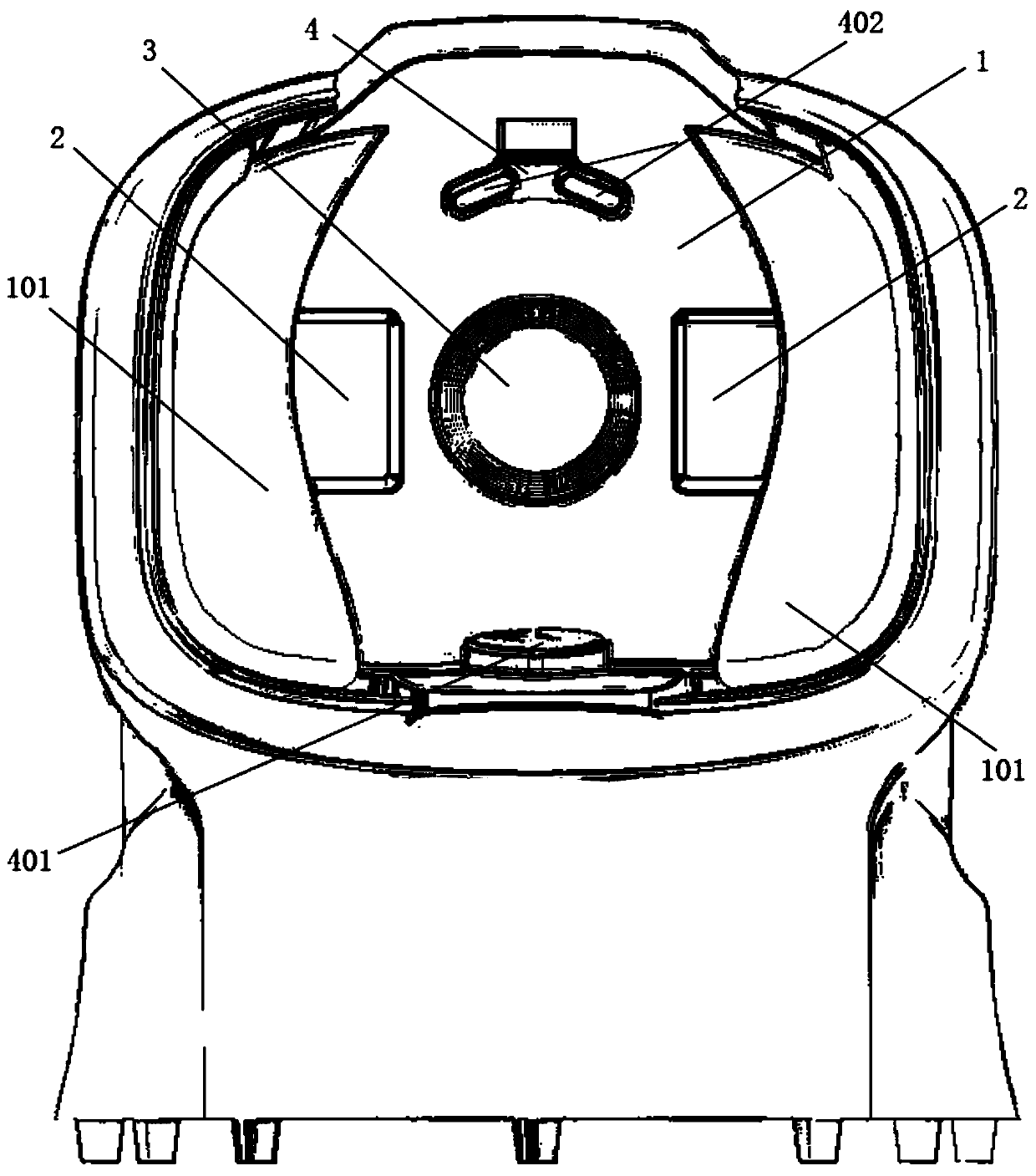

Facial image acquisition device for skin analysis

InactiveCN109893096AOptimize shape designReduce ambient stray light interferenceDiagnostic recording/measuringSensorsCamera lensPhysics

The invention discloses a facial image acquisition device for skin analysis. The device comprises a photomask, light sources, an imaging lens and a locator, wherein the photomask is symmetric about avertical plane and gradually narrows from the opening to the bottom; the imaging lens is arranged in the center of the bottom of the photomask and used for acquiring a facial image of a user; the light sources are arranged at the bottom of the photomask and symmetric about the imaging lens; the locator is arranged at the opening of the photomask and used for fixing the head of the user, so that points of the face of the user can fall in the focal plane of the imaging lens as many as possible. A proper imaging light path is designed by simulation of heads of Asian people, so that imaging conditions are almost consistent when facial images of users are shot each time, consistency of acquired images is improved during facial acquisition of different users or repeated facial acquisition of thesame user, and skin analysis of different groups or skin condition analysis of tracked unified users is facilitated.

Owner:武汉嫦娥医学抗衰机器人股份有限公司

Low stray light rapid spectrometer and measurement method thereof

ActiveCN101324468BHigh precisionSlow measurementRadiation pyrometrySpectrum generationLight beamOptical table

The invention discloses a low-stray-light fast spectrometer and a measurement method thereof. The spectrometer includes a light signal collection mechanism and an optical platform and is characterized in that the optical platform includes a bandpass color wheel; a group of bandpass color filters and via-holes are arranged on the bandpass color wheel; and an incident light reaches a dispersive element through the bandpass color filters or the via-holes, is split and then received by an array detector. Through rotation of the bandpass color wheel, the incident light scans the bandpass color filters one by one, and the spectrometer accurately detects a sample to be detected segment by segment to correspond to a response function. When a similar sample with similar spectral characteristics ismeasured, the sample is accurately detected segment by segment and is subjected to full-spectrum fast detection through the via-holes, the stray light correction factor can be calculated according tothe two measurement results, and the similar sample is subjected to the full-spectrum fast detection and is corrected by the stray light correction factor to achieve fast accurate detection. The method can effectively reduce the measurement stray light of the fast spectrometer and fast accurately measure the spectrum curves and related spectroradiometric parameters of the sample with similar spectral characteristics.

Owner:HANGZHOU EVERFINE PHOTO E INFO

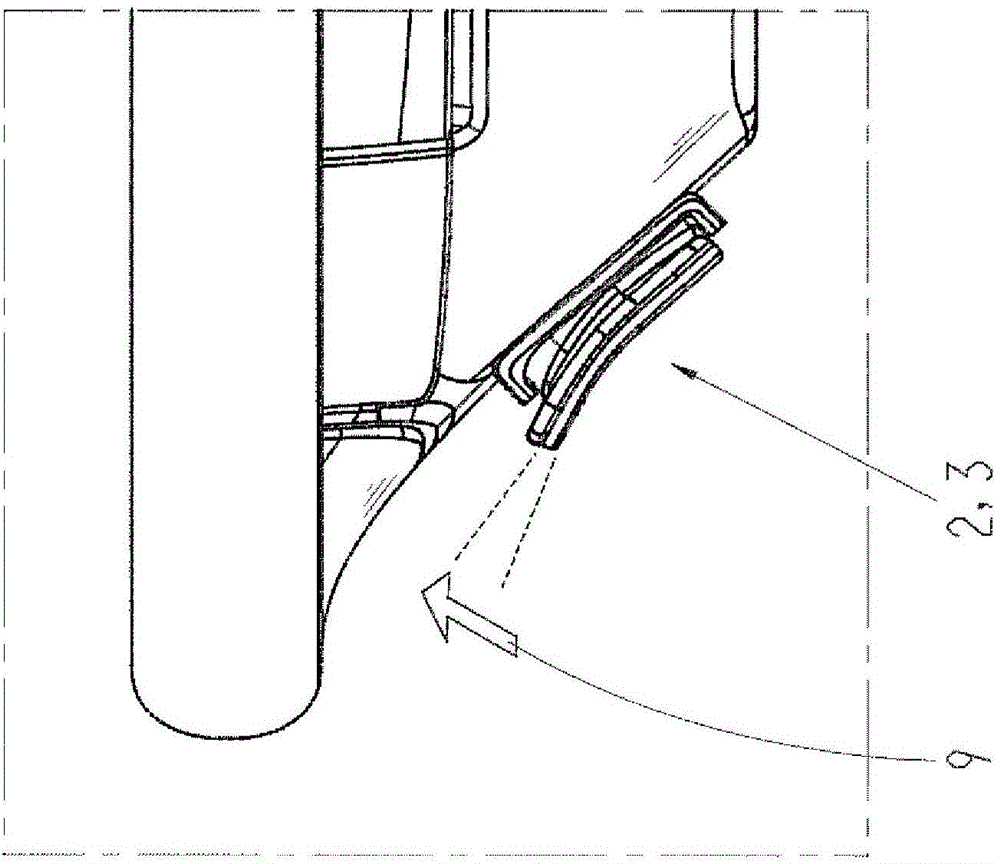

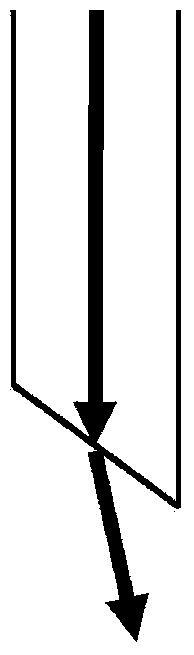

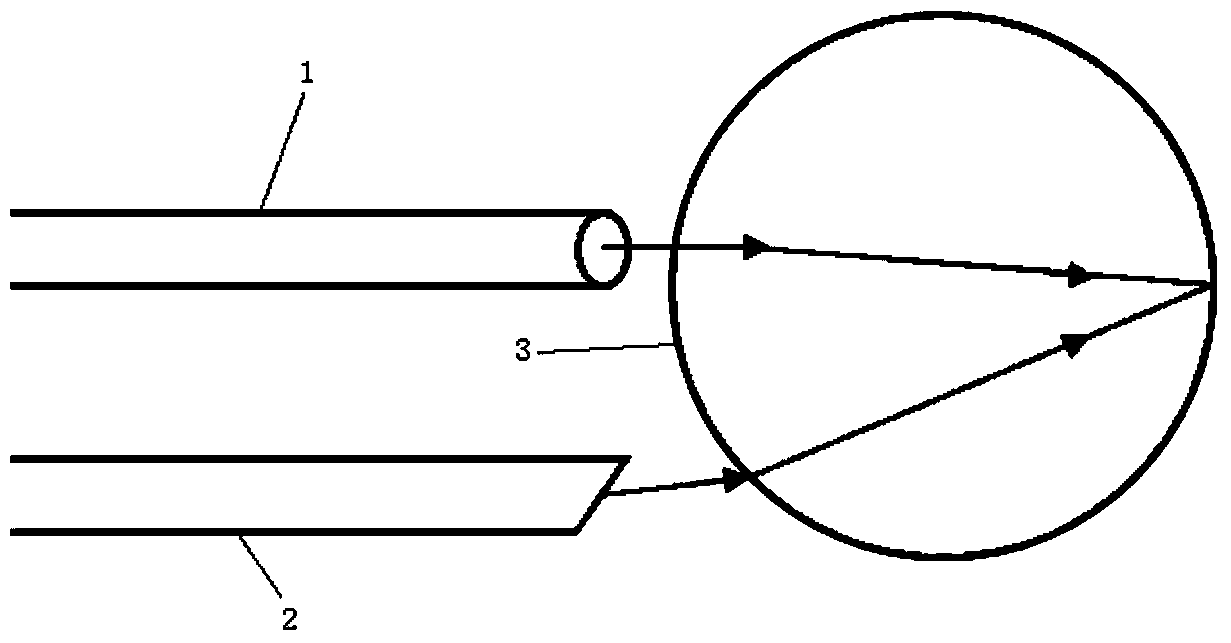

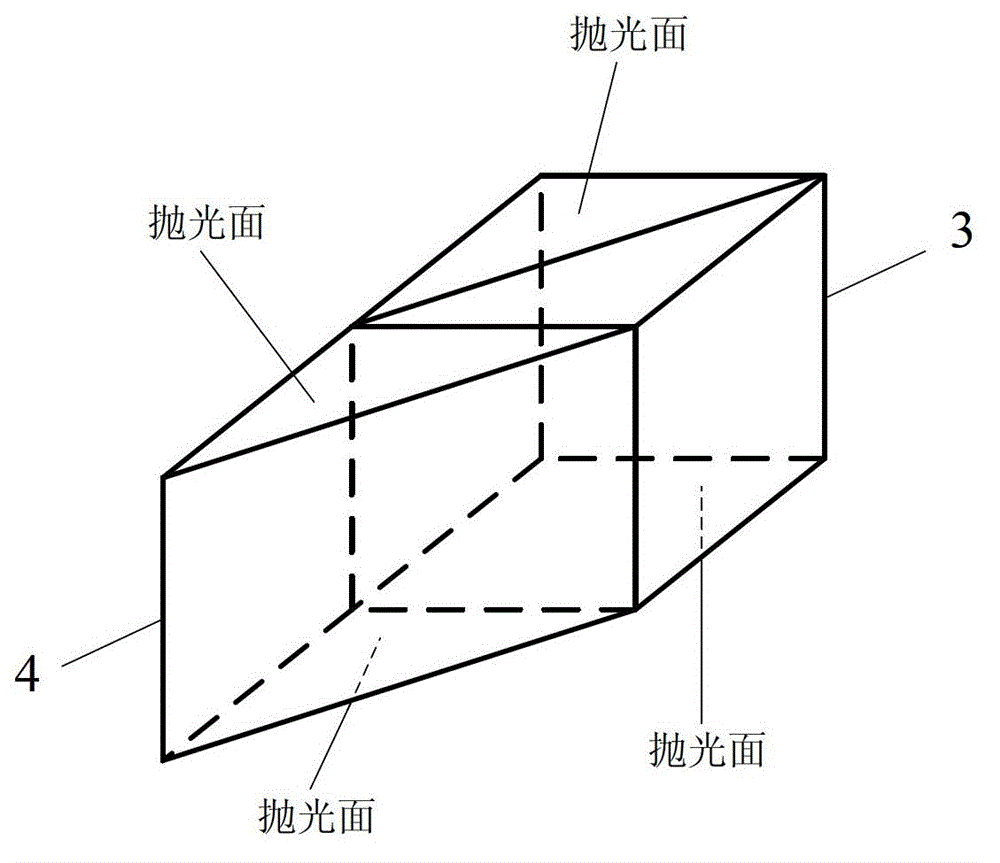

Super-shallow detecting spectrum probe

ActiveCN103411907AAvoid interferenceReduce stray light interferenceColor/spectral properties measurementsPenetration depthLight beam

The invention discloses a super-shallow detecting spectrum probe. The super-shallow detecting spectrum probe comprises an illumination optical fiber, a collection optical fiber, a coupling lens and a shell; the illumination optical fiber is used for leading the light emitted from a light source into the coupling lens to form an illumination spot on a to-be-detected object through the irradiation of the coupling lens; the light ray irradiated on the to-be-detected object is capable of entering into the collection optical fiber through the refraction of the coupling lens and can be guided to a check instrument through the collection optical fiber; the tail end surfaces of the collection optical fiber and the illumination optical fiber are polished as inclined planes, the inclined plane is used for enabling the light beam to deflect to an symmetry axis of the probe. By using the coupling lens and in matching with the bevel polishing of the end surfaces of the illumination optical fiber and the collection optical fiber, the superposed spots with high convergence, small diameter and large angle crossing are produced at the tail end of the spectrum probe through the illumination optical fiber and the collection optical fiber so as to obtain the short penetration depth. The pickup to the shallow signal is high in sensitivity and the interference from the deep signal is effectively avoided.

Owner:SOUTHWEST UNIVERSITY

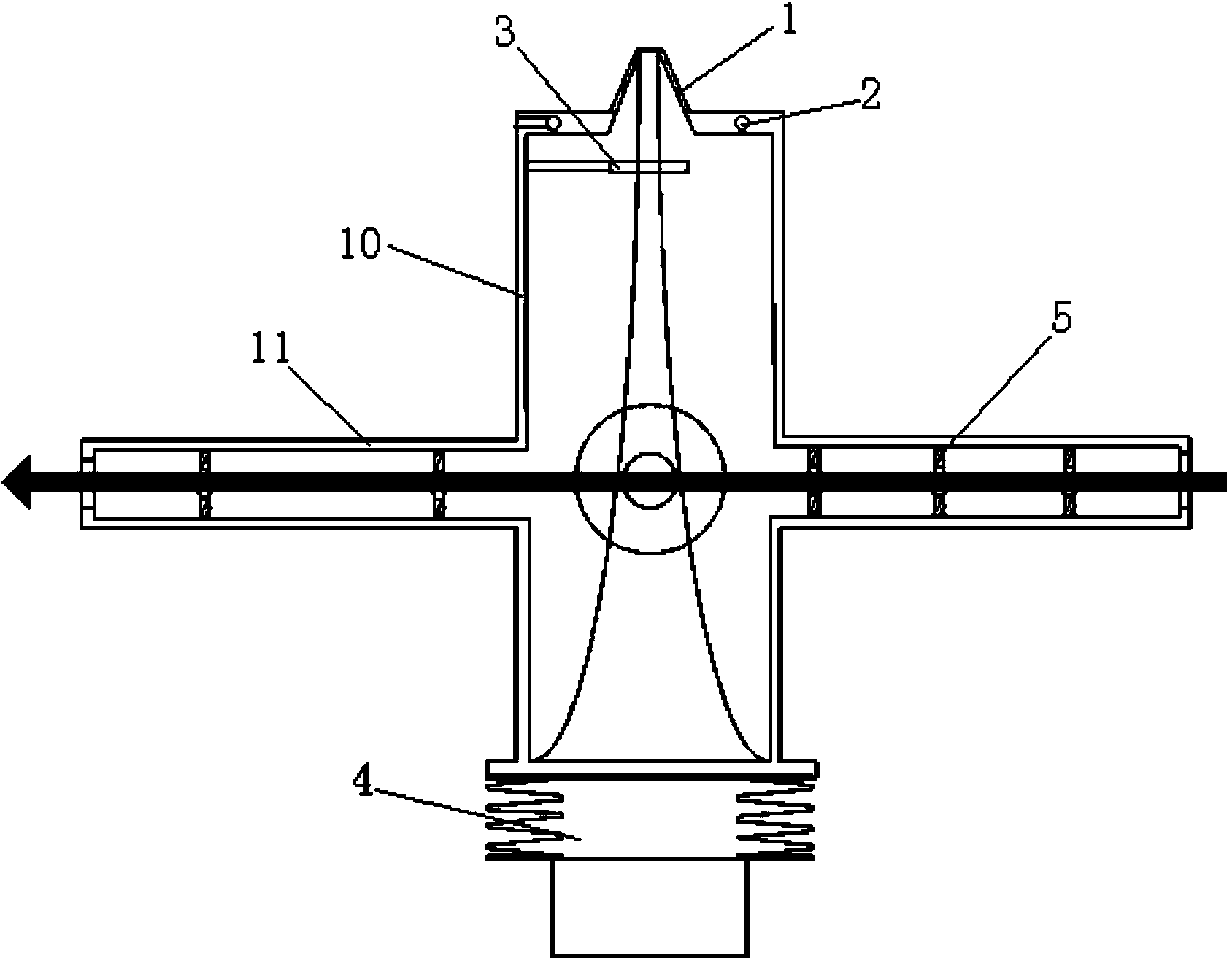

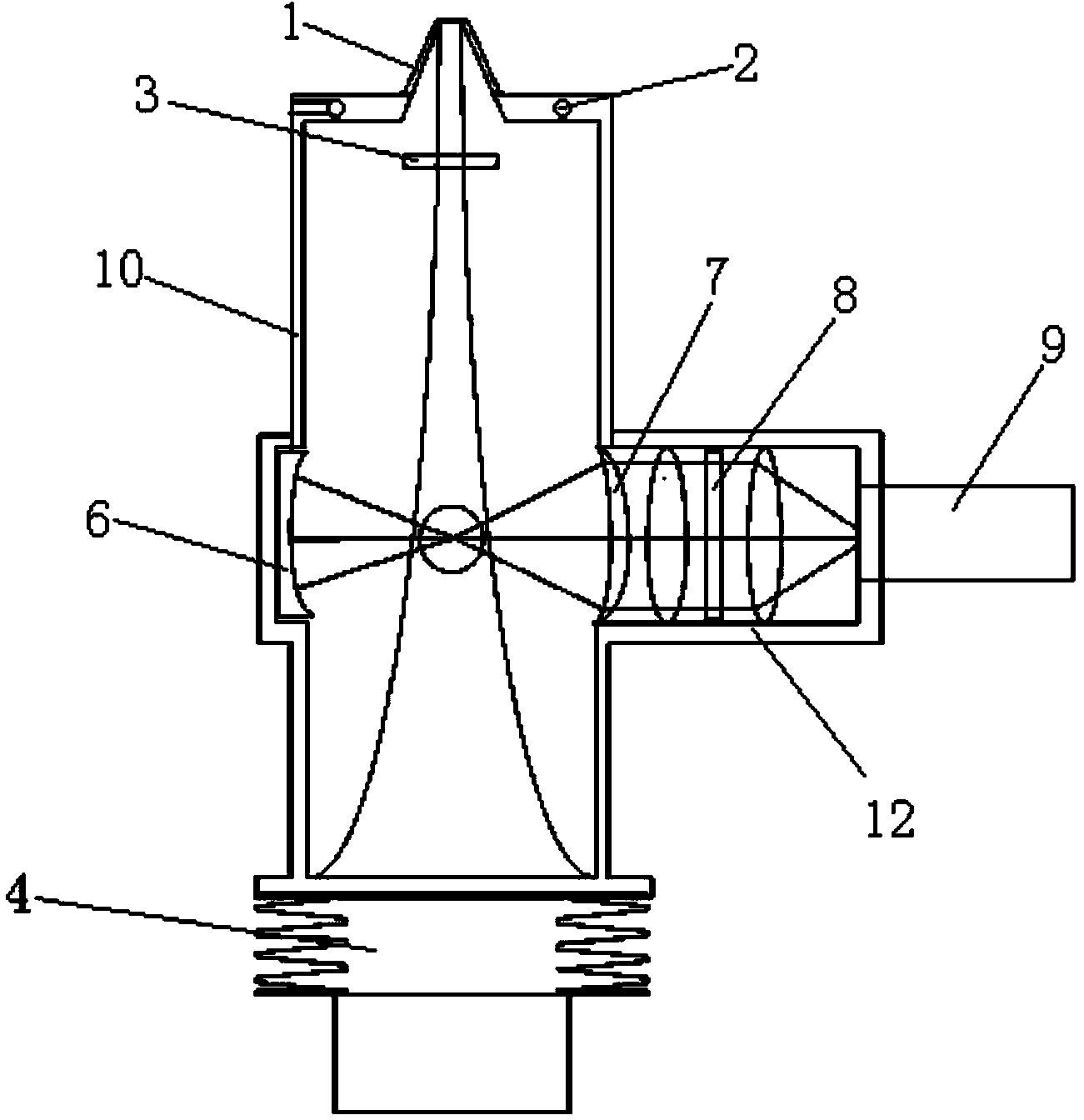

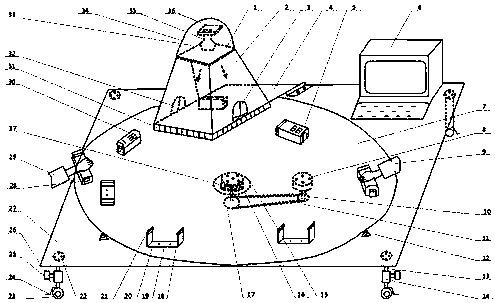

Rotating disc type animal phototoxicity rapid tester

PendingCN107928834AReduce stray light interferenceImprove experimental efficiencyAnimal fetteringAutomatic controlAstigmatism

The invention provides a rotating disc type animal phototoxicity rapid tester which includes an illumination cabin and a rotating disc which are installed on a fixed platform provided with a movable supporting component. A plurality of spring supports are positioned on the rotating disc with the rotating speed controlled by a stepping motor and can fix a tested mouse cage containing an experimental animal. When the tested mouse cage moves to the illumination cabin, a cabin inlet movable door and a cabin outlet movable door can be automatically switched on and switched off, a UV light source module in the illumination cabin sends out a UVA light source of 365 nm with a single wavelength and a suitable intensity to perform phototoxic irradiation experiments on experimental animals. Soft sunblinds are mounted around the bottom of the illumination cabin to ensure UVA light source purity during the experiments and light intensity accuracy, and in the experiments, a computer controller controls and records the process of each experiment, results and other parameters or the parameters are output to a printer to print a lab report. The rotating disc type animal phototoxicity rapid testerhas the advantages that the the phototoxicity irradiation experiment of small animals can be quickly and automatically completed. Light intensity and irradiation time required for the experiments canbe automatically controlled, the stray light interference is small, the experimental efficiency is improved, and experimental data is accurate and reliable.

Owner:TIANJIN HOPE IND & TRADE

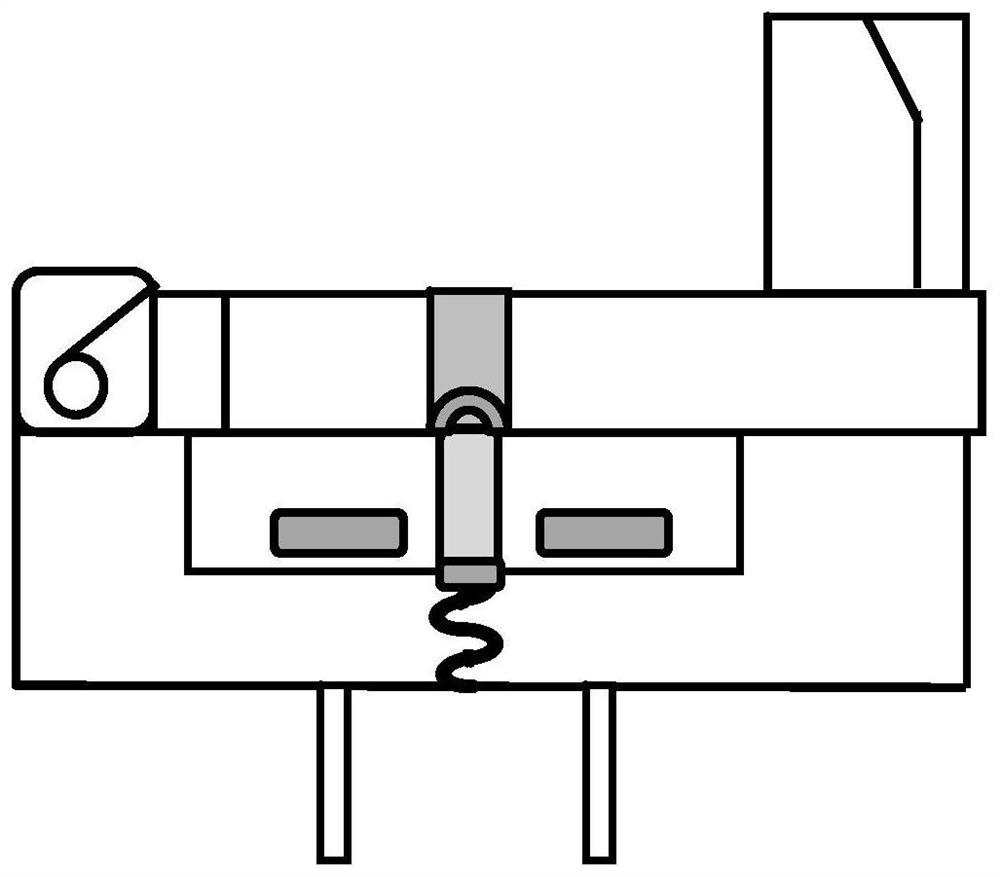

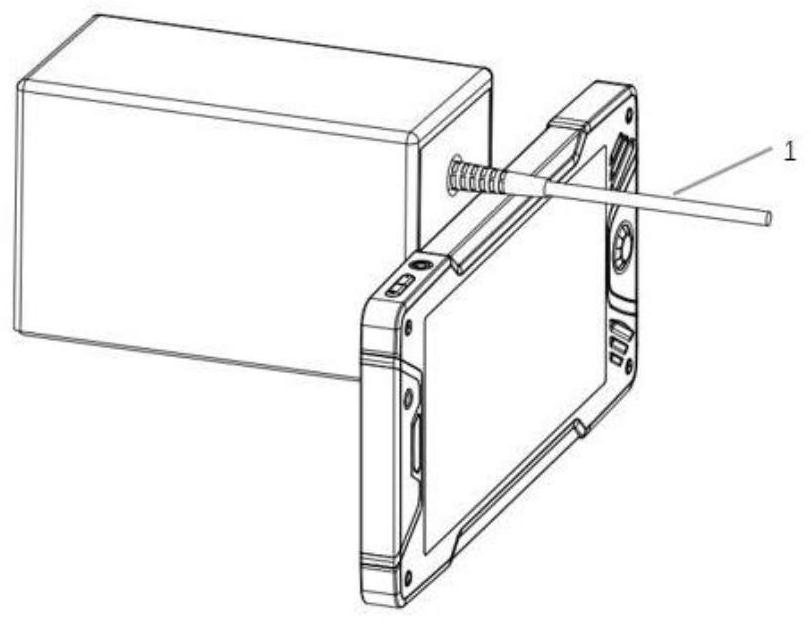

Photoelectric device test conversion clamp

PendingCN114487499AReduce the risk of injuryImprove stabilityMeasurement instrument housingEngineeringMechanical engineering

The invention discloses a test conversion clamp for a photoelectric device. The test conversion clamp comprises clamp pins, a lower bottom plate, a middle interface plate, a spring piece and an upper cover plate, the middle interface plate is fixedly installed on the lower bottom plate, the middle interface plate is provided with a groove used for installing a device to be tested, the spring piece is fixed at the bottom of the groove, one end of the clamp pin is connected with the spring piece, and the other end of the clamp pin extends to the outside of the lower bottom plate; one end of the upper cover plate is rotatably connected with the middle interface plate, a to-be-tested device is arranged in a groove formed in the middle interface plate, the upper cover plate presses the to-be-tested device, meanwhile, the leading-out end of the to-be-tested device presses the spring piece, the to-be-tested device is connected with the clamp pin through the spring piece, and the cover plate is provided with a light window corresponding to the to-be-tested device. Light emitted by the light source reaches the to-be-tested device through the light window. The switching clamp is simple in structure, rapid to install, convenient to disassemble, wide in applicability, capable of effectively improving the testing efficiency, high in stability and capable of effectively improving the testing yield.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

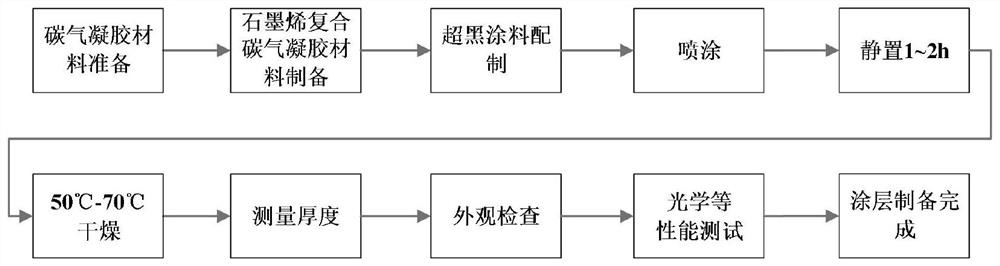

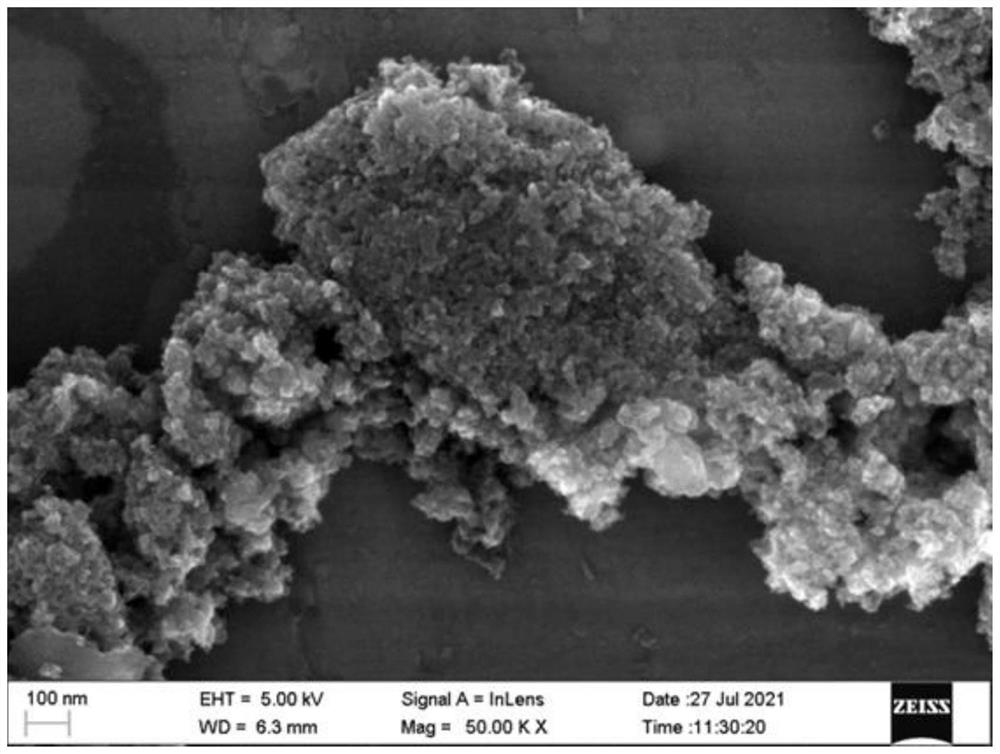

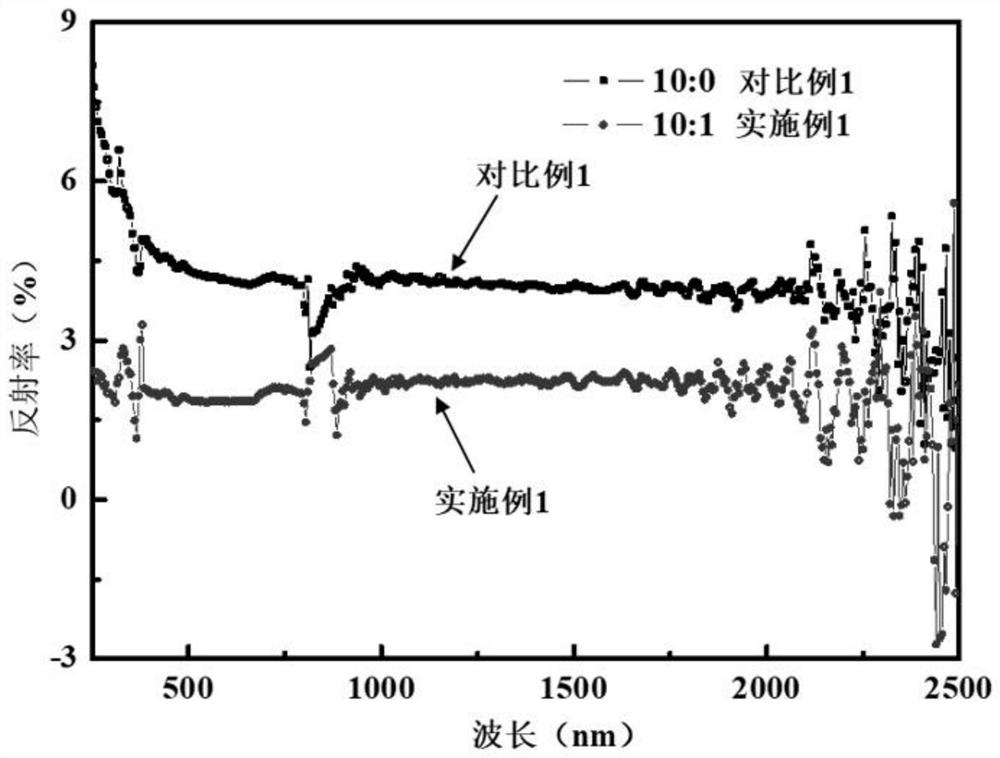

Carbon-based ultra-black stray light-eliminating nano-composite coating and preparation method thereof

ActiveCN114479659AMean free path reductionReduce the amplitudeCarbon compoundsCoatingsSupercritical dryingOrganic solvent

The invention provides a carbon-based ultra-black stray light-eliminating nano composite coating and a preparation method thereof. The preparation method comprises the following steps: (1) preparing aerogel through a sol-gel method; sequentially carrying out supercritical drying, carbonization and activation on the aerogel to obtain a graded porous carbon aerogel material; (2) mechanically mixing the carbon aerogel obtained in the step (1) and graphene to obtain a graphene composite carbon aerogel filler; and (3) adding the graphene composite carbon aerogel filler obtained in the step (2) into a resin binder, mixing and stirring, adding an organic solvent, mixing, ultrasonically stirring uniformly to obtain a carbon-based ultra-black stray light-eliminating nano-coating, then spraying the carbon-based ultra-black stray light-eliminating nano-coating on the surface of a pretreated matrix, and curing to obtain the carbon-based ultra-black stray light-eliminating nano-composite coating. The carbon-based ultra-black stray light eliminating nano-composite coating can reduce stray light interference of an optical load of a spacecraft in a special environment, guarantee the reliability of spacecraft operation and meet the requirement of the optical load for stray light suppression.

Owner:SHANGHAI INST OF SATELLITE EQUIP

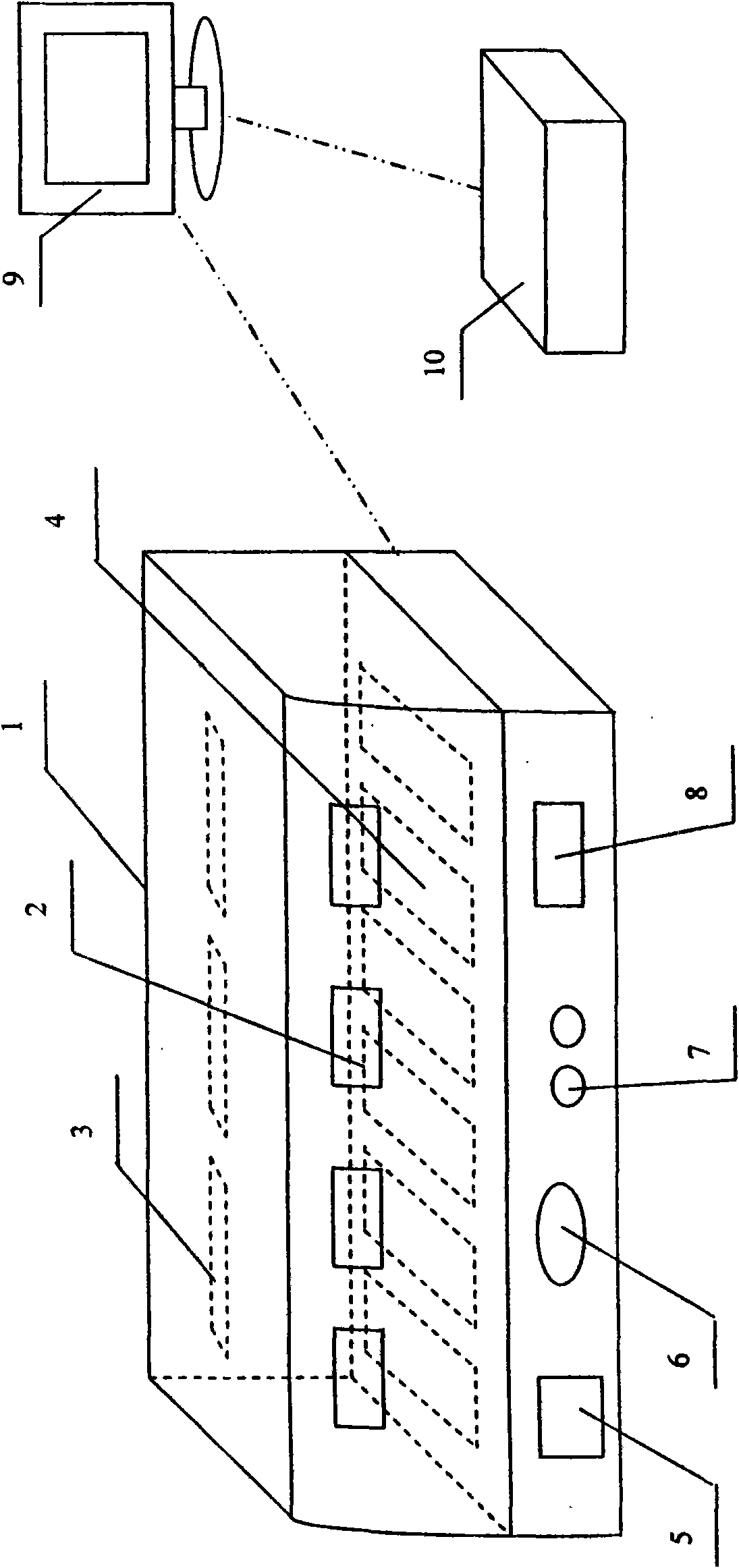

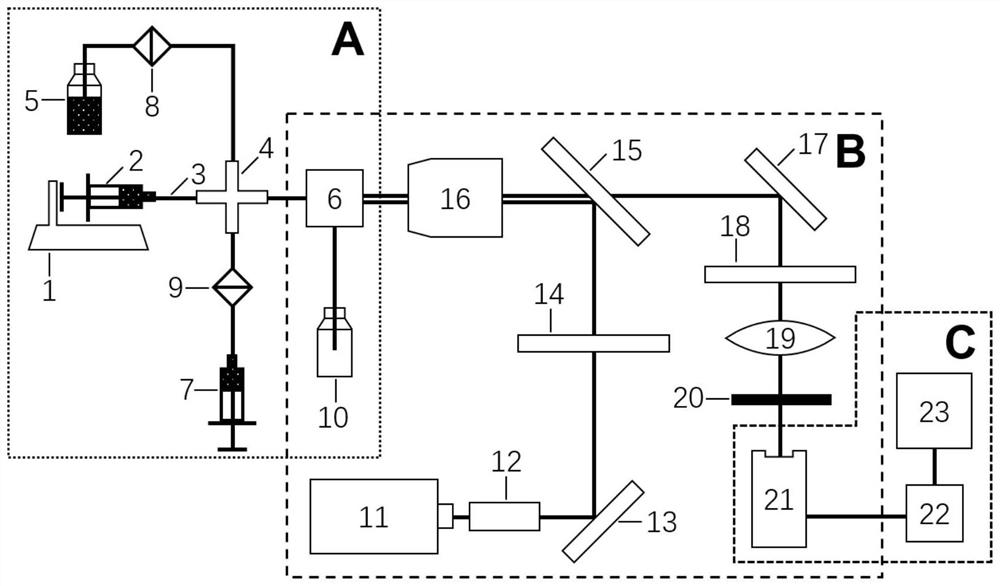

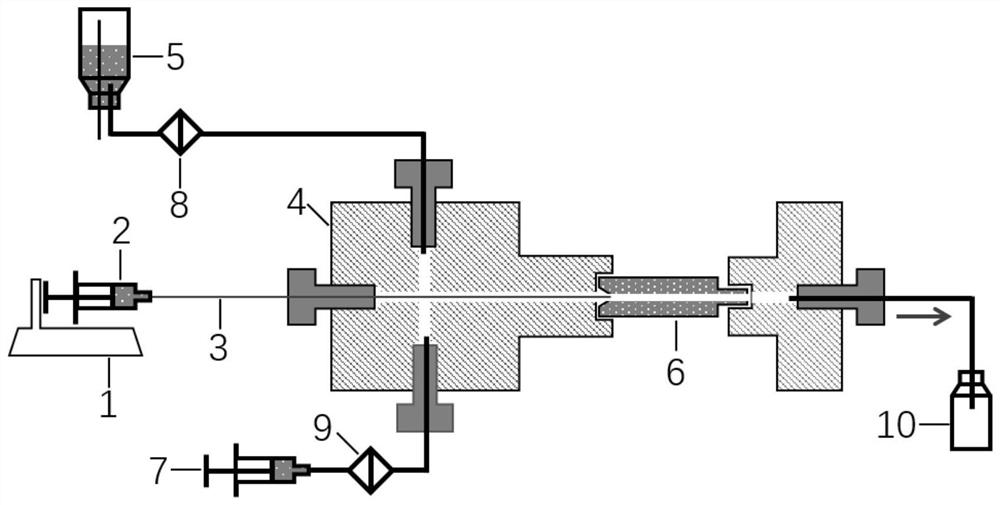

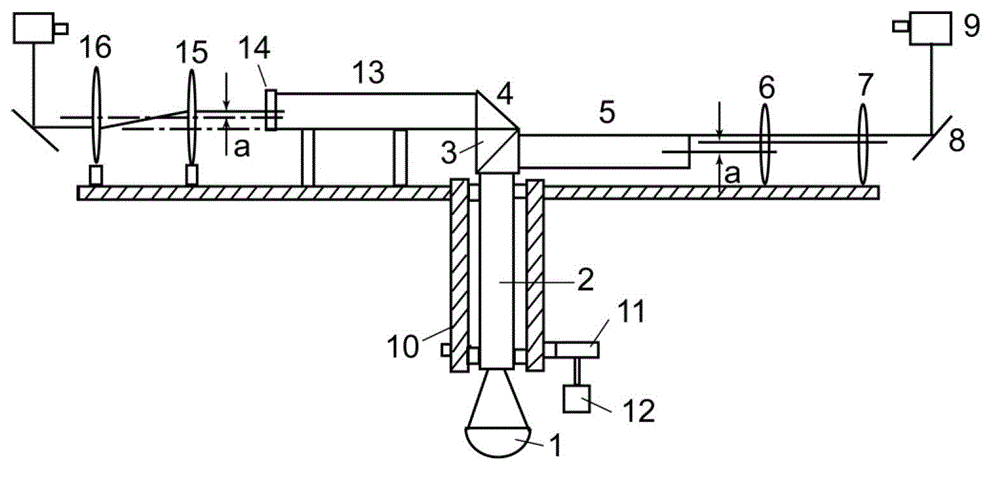

Flow cytometer based on confocal light path design

PendingCN114705611AReduce the difficulty of focusingReduce stray light interferenceIndividual particle analysisPhotovoltaic detectorsFlow cell

The invention discloses a flow cytometer based on confocal light path design, and belongs to the technical field of life analysis scientific detection equipment. The flow cytometer comprises a liquid flow system, an optical system and a detection system, the liquid flow system comprises an injection pipeline and a sheath fluid pipeline which are respectively communicated with the quartz flow cell, the injection pipeline injects a cell sample into a central sheath fluid channel of the quartz flow cell, and the cell sample is wrapped and extruded by sheath fluid injected into the central sheath fluid channel of the quartz flow cell by the sheath fluid pipeline to form single cell flow; the optical system comprises an excitation light path and a fluorescence collection light path, a laser beam of the excitation light path is focused on a central sheath flow channel of the quartz flow cell and is used for exciting a cell sample in the central sheath flow channel of the quartz flow cell to generate fluorescence, and the fluorescence is collected through the fluorescence collection light path; the detection system comprises a photoelectric detector, a data acquisition card and an upper computer which are connected in sequence. The flow cytometer is compact in structure, simple and efficient in light path focusing and convenient to use.

Owner:NORTHEASTERN UNIV

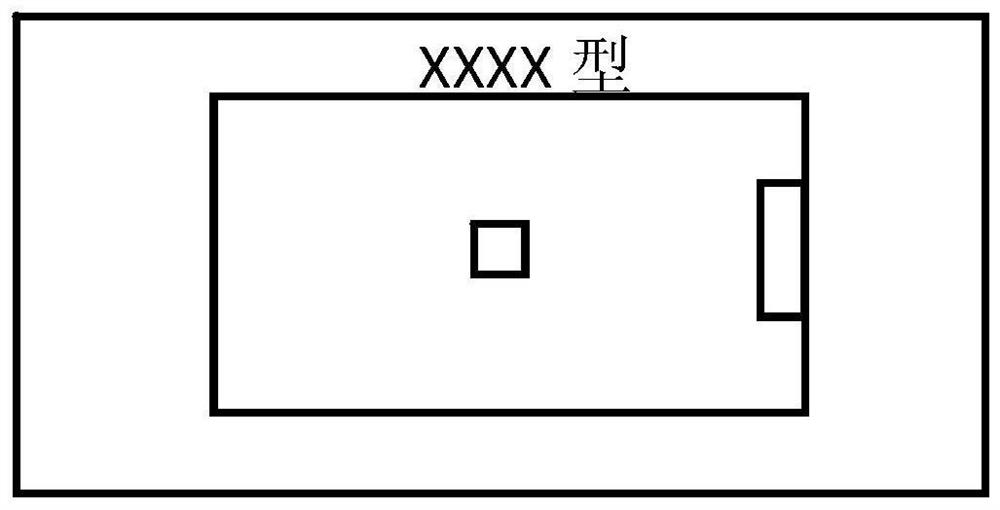

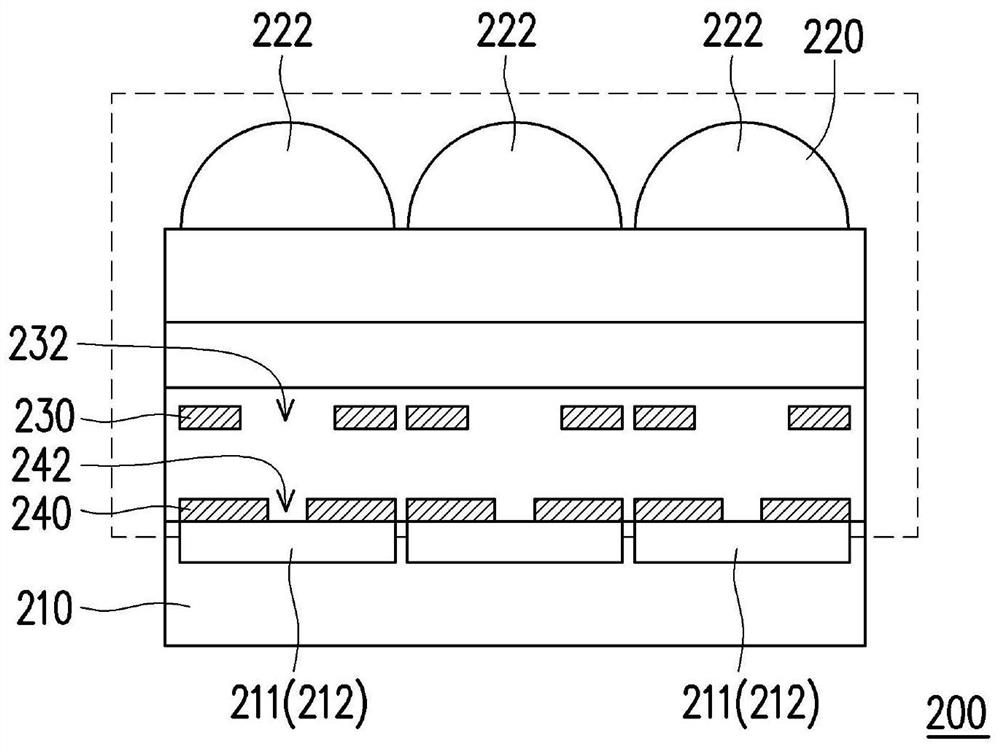

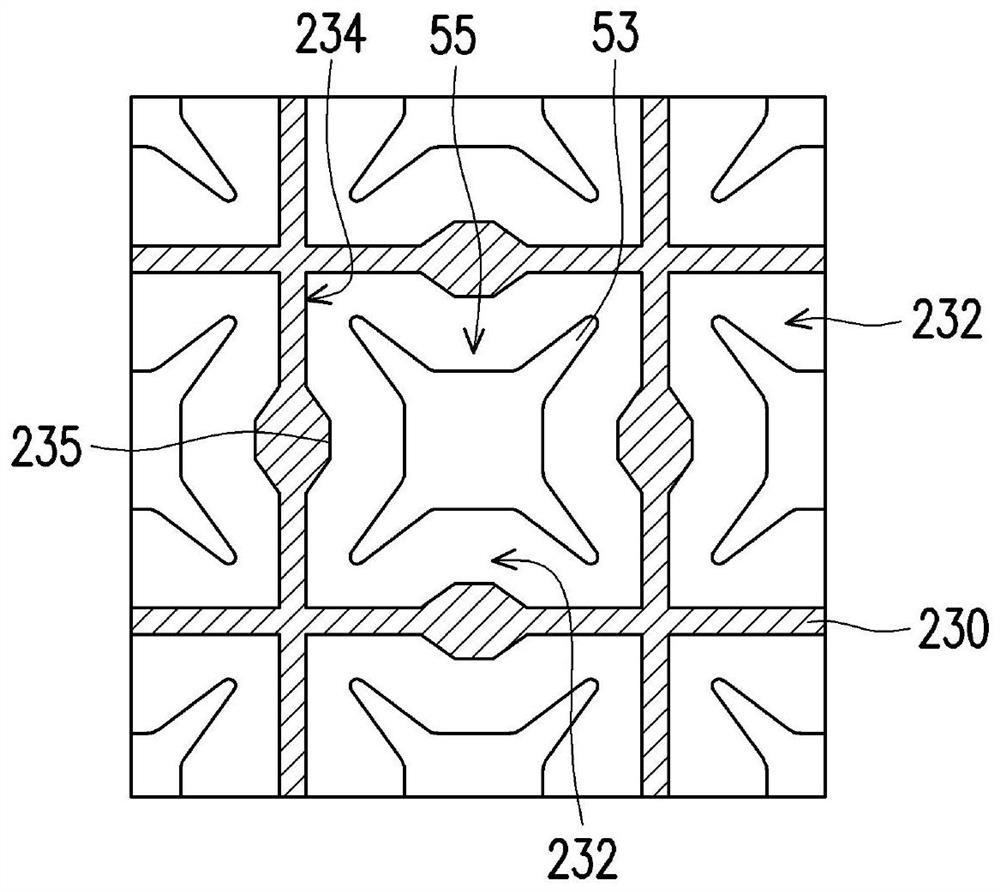

Light sensing array module and light transmitting and receiving device

PendingCN113809109AImprove quantum efficiencyReduce stray light interferenceSolid-state devicesRadiation controlled devicesLight sensingAngle of incidence

The invention provides a light sensing array module and a light transmitting and receiving device. The light sensing array module comprises a light sensing array substrate, a lens array and a light shielding layer. The light sensing array substrate includes a plurality of pixels arranged in an array. The lens array is arranged above the light sensing array substrate and comprises a plurality of micro lenses which are respectively arranged above the pixels. The light shielding layer is arranged between the light sensing array substrate and the lens array and comprises a plurality of light passing openings. The light-passing openings are respectively arranged between the micro-lenses and the pixels, and light of which the incident angle of the incident lens array is at least within 14 degrees can be transmitted to the pixels through the light-passing openings and cannot be shielded by the light shielding layer.

Owner:EGIS TECH

Ultraviolet spectrophotometer detecting head

InactiveCN101514920BImprove anti-interference abilityCompact structureRadiation pyrometryPhotometryUltravioletPlug and produce

Owner:XIAMEN UNIV

Detection of vital parameters using optical sensors on the steering wheel

InactiveCN103957796BReduce consumptionEasy to measureElectrocardiographyDiagnostics using lightMeasurement deviceSteering wheel

The invention concerns a measurement device to capture at least one vital parameter of a person in a motor vehicle with a steering wheel. The measurement device includes a finger sensor device with an optical sensor device, where the finger sensor device is attached to the steering wheel in the transition zone between a steering wheel spoke and the hub of the steering wheel.

Owner:ZF FRIEDRICHSHAFEN AG

A camera switching module and its manufacturing method

ActiveCN110955098BImprove day and night switching effectReduce stray light interferenceCamera filtersCamera body detailsInfraredFull-spectrum light

The invention provides a camera switching module and its manufacturing method. The infrared cut-off filter and the full-spectrum optical glass are separated to form independent light-transmitting regions through the light-shielding layers arranged on both sides of the separation line, which reduces mutual interference. Stray light interference improves the day and night switching effect of the camera.

Owner:HANGZHOU MDK OPTO ELECTRONICS CO LTD

Conduction-type polarizing and beam-splitting synchronized lighting device

ActiveCN102929088BReduce stray light interferenceShorten the light transmission distanceProjectorsOptical light guidesCamera lensLight guide

The invention provides a conduction-type polarizing and beam-splitting synchronized lighting device. The lighting device comprises a light source, a light guide stick, a polarizing and beam-splitting prism, a first lens, a polarized light conversion unit and a second lens, wherein light emitted by the light source is focused on the light guide stick; the incident face of the polarizing and beam-splitting prism is bonded with the exit face of the light guide stick; the polarizing and beam-splitting prism divides incident light into a first linearly polarized light and a second linearly polarized light; the first lens projects the first linearly polarized light to one of a plurality of first projectors; the polarized light conversion unit converts the polarization direction of the second linearly polarized light to be the same as that of the first linearly polarized light; and the second lens projects the second linearly polarized light of which the polarization direction is converted to one of a plurality of second projectors. The lighting device adopts the polarizing and beam-splitting prism to divide natural light of the light source into two paths of linearly polarized light, converts natural light into linearly polarized light while achieving beam-splitting, improves the light efficiency and lowers interference of parasitic light in the projectors.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

A Star Sensor Shade Based on Spatial Filtering

ActiveCN106383427BRealize the spectral filtering functionReduce stray light interferenceCamera filtersExit pupilLens hood

The invention discloses a space filtering based light shield of a star sensor. The light shield comprises a cover casing and first to sixth shading rings, and the first to sixth shading rings are arranged from an entrance pupil position to the exit pupil position sequentially and mounted in the cover casing; the first shading ring and the sixth shading ring are arranged at the two ends of the cover casing opposite to each other, and a connecting line between cutting edges of the first shading ring and the sixth shading ring and a center line of the cover casing form an included angle of 16 degree; and the middle portions of the fourth, fifth and sixth shading rings are provided with optical filters in a rotational installation manner respectively. The light shield has the advantages that the cover casing, the shading rings and the optical filters form an optical-mechanical assembly of the light shield, and it is ensured that the star sensor can output effective attitude data when a sun shielding angle is greater than 20 degree; a non-imaging spectrum of the sun shielding angle greater than 20 degree can reach the entrance pupil position of an optical system via at least twice absorptive scattering; and the light shield has a high light shielding performance, and is capable of spectrum filtering.

Owner:SHANGHAI AEROSPACE CONTROL TECH INST

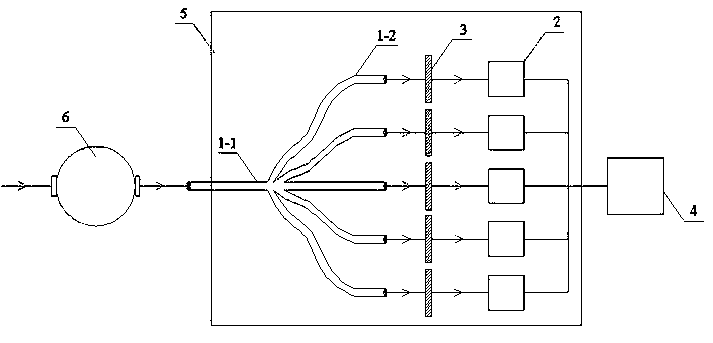

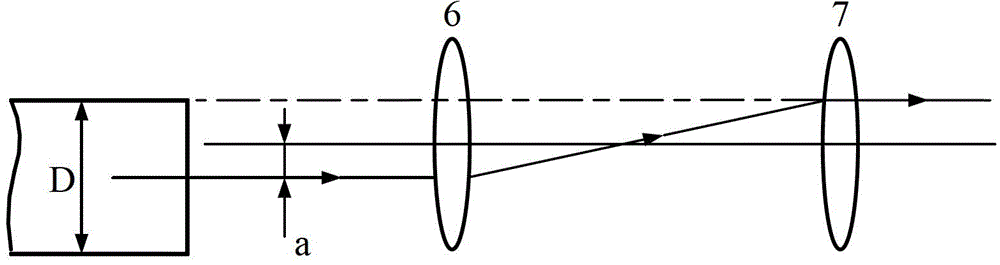

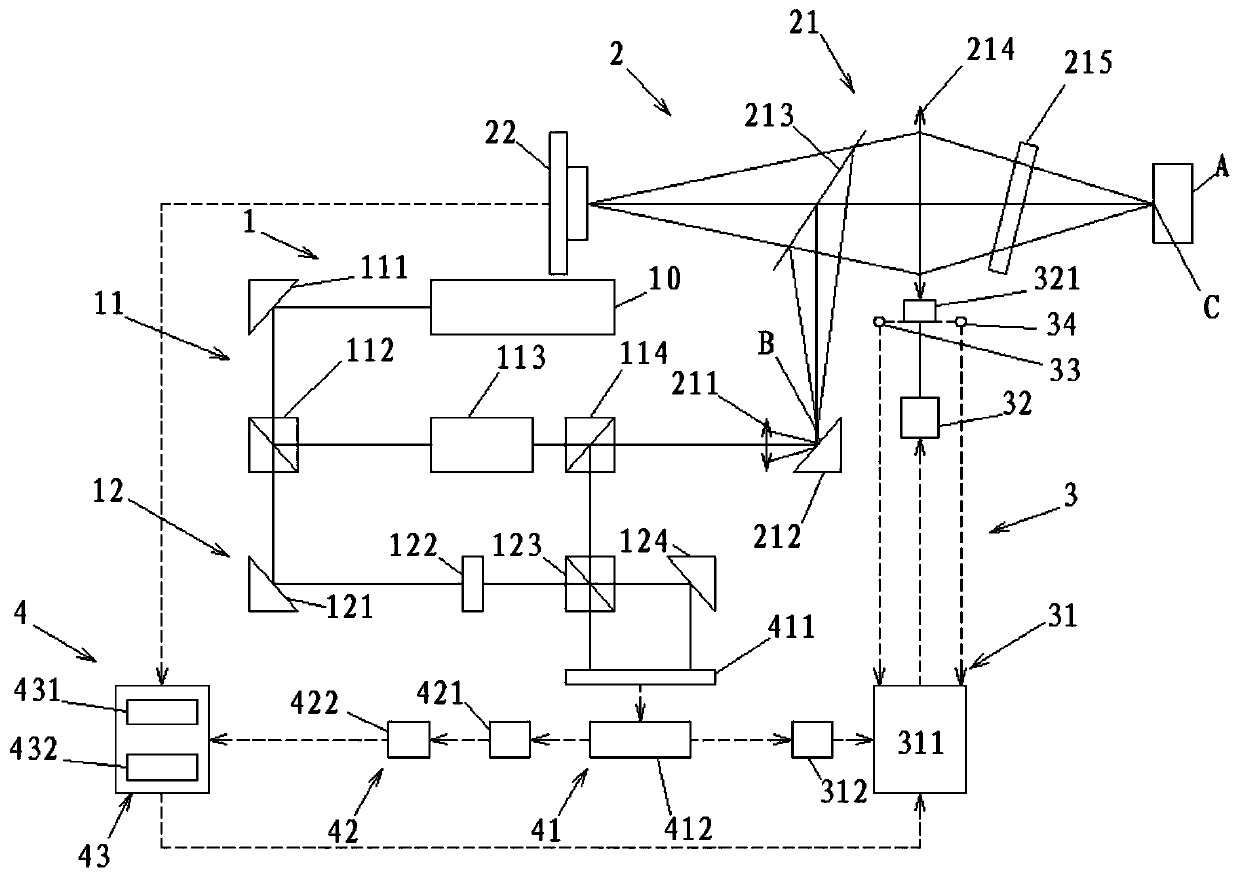

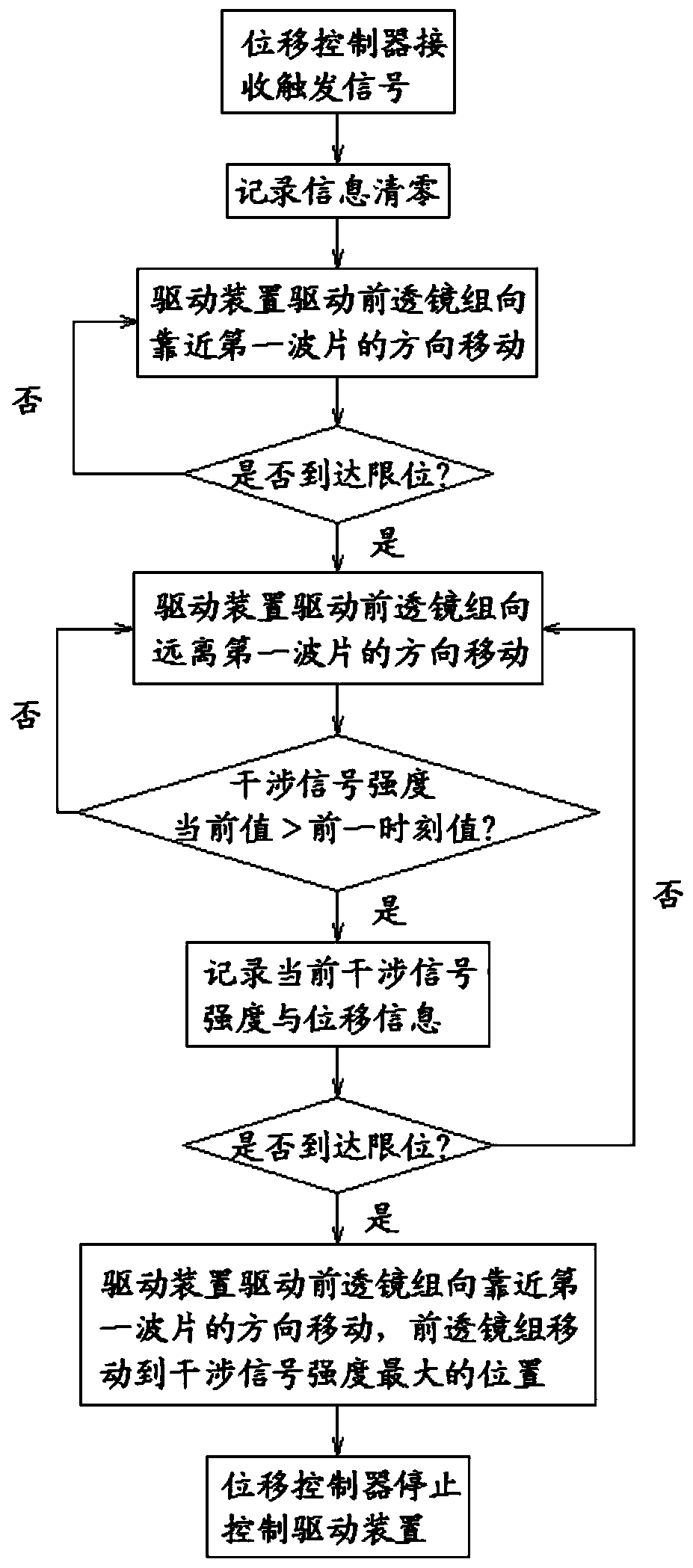

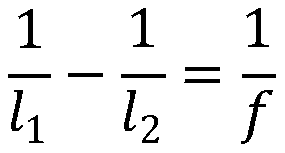

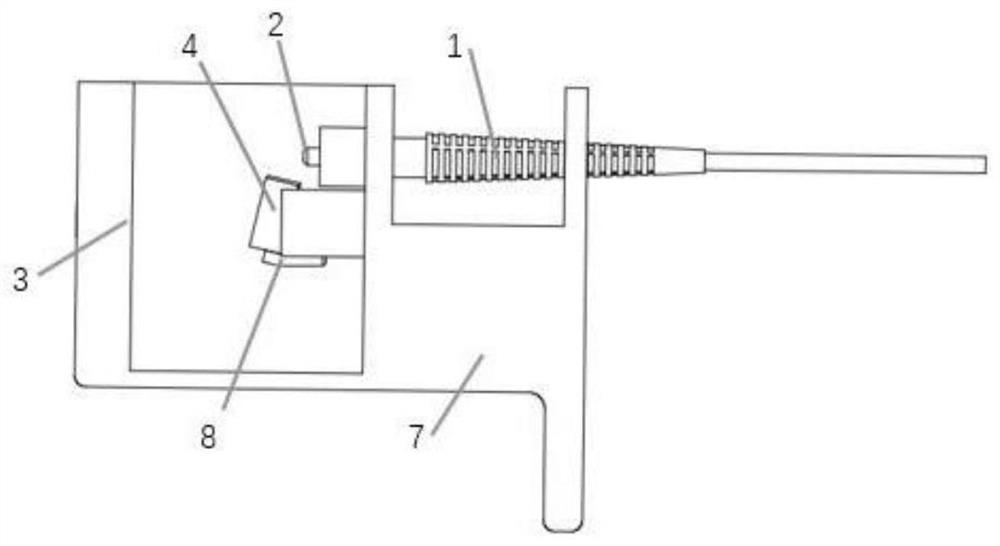

A Laser Vibration Measurement System

ActiveCN108225539BImprove securityHigh measurement accuracySubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansVibration measurementControl cell

The invention relates to a laser vibration measurement system which comprises a laser unit (1), a focus imaging unit (2), a focusing unit (3) and a control unit (4), wherein the focus imaging unit (2)is connected with the laser unit (1); the focusing unit (3) is connected with the focus imaging unit (2), wherein the control unit (4) is connected with the focus imaging unit (2) and the focusing unit (3). The laser vibration measurement system provided by the invention can automatically complete the identification and the vibration measurement of an object, so that the manual operation processis reduced. Meanwhile, as laser is adopted for the vibration measurement, manual focusing, identification and other processes are not required in the whole process, so that the injury to an operator is avoided, and the safety of the whole measurement system is improved. The measurement system provided by the invention realizes the coaxial synchronization of laser focusing and image acquisition during the laser vibration measurement, so that the measurement accuracy and the measurement efficiency of the whole measurement system are improved.

Owner:NINGBO SUNNY INTELLIGENT TECH CO LTD +1

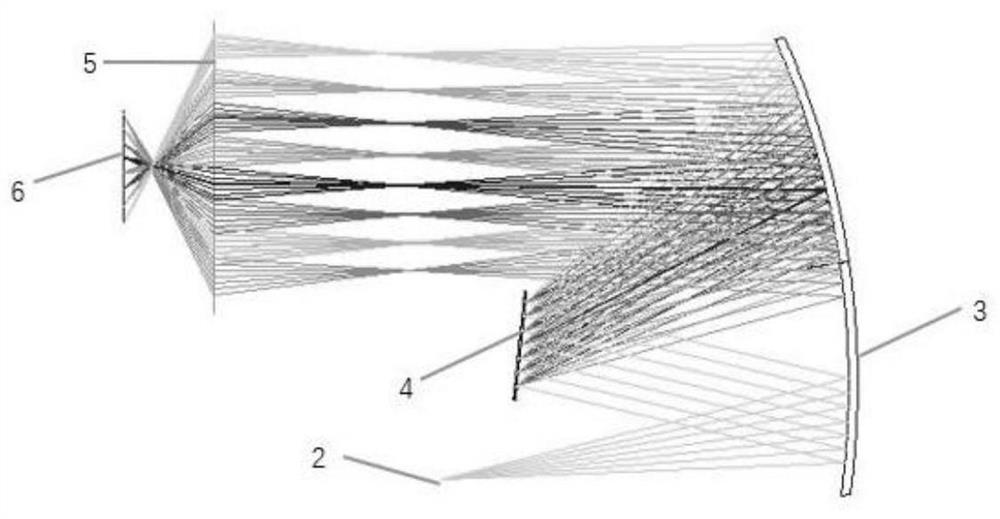

Miniature diffuse reflection spectrum measurement system based on smart phone

PendingCN114062304ACompact structureMiniaturizationSpectrum generation using diffraction elementsScattering properties measurementsMathematical modelSpectrograph

The invention designs a miniature diffuse reflection spectral measurement system based on a smart phone, and belongs to the field of spectral analysis. According to the invention, a small-caliber concave spherical reflector is adopted to realize a collimation imaging system of a traditional micro spectrometer, a miniaturized structure and higher resolution are realized, and a light source, the spectrometer and data processing equipment are integrated into a portable system. The spectrograph is composed of an optical fiber, a slit, a concave spherical reflector and a diffraction grating, and a spectral image formed by the spectrograph is shot by the smart phone. The detection range of the spectrograph is 400 nm to 1100 nm, and the resolution of the central wavelength reaches 0.3 nm. Based on the system, a matched mobile phone APP comprises an image processing program and a spectral analysis program, and different mathematical models can be used for analyzing contents, concentrations and the like of different components. According to the invention, the defects of low resolution, narrow spectral range, multiple elements, large volume and the like of the existing mobile phone spectrometer technology are overcome, and the mobile phone spectrometer is a practical portable spectral analysis solution.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com