High-damage-threshold laser film process technical method

A technology of high damage threshold and laser thin film, which is applied in metal material coating technology, optics, optical components, etc., can solve the problem of low anti-laser damage threshold, achieve high linear and nonlinear optical performance, good fastness performance, Effect of Broad Spectral Transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

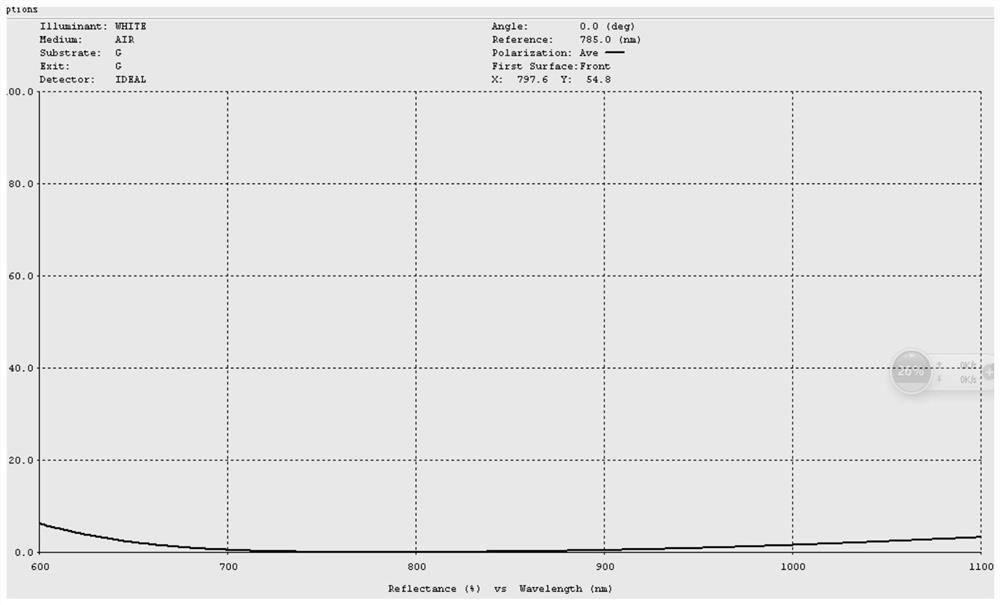

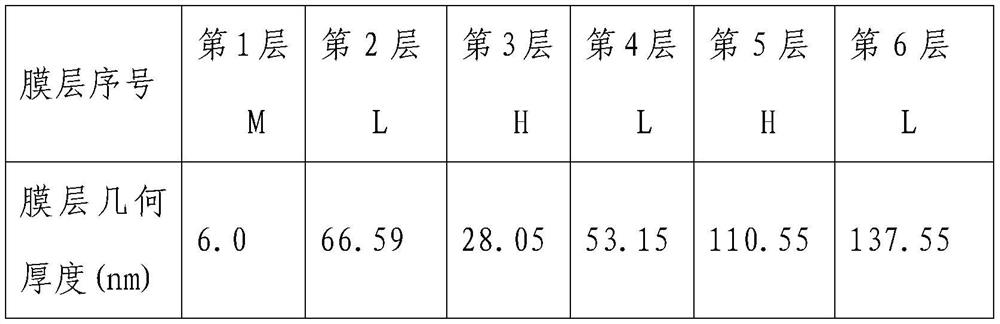

[0053] The design curve of the anti-laser anti-reflection coating system designed with the quartz substrate as sample 1 is figure 1 , and the geometric thicknesses are listed in Table 1. Using quartz as the optical substrate material, an optimized anti-reflection film system meeting the technical index requirements of the present invention is designed by using an optical thin film design software (TFCalc). The optically processed quartz substrate is coated on its surface. The film thickness calculation module uses the TFC film system design software to design the quartz as the substrate, M is Al 2 o 3 As substrate film material, H is HfO 2 High refractive index film material, L is SiO 2 Low-refractive-index film material (the above M, H, and L are granular film materials with a purity of 99.99%). Calculate the geometric thickness value of each layer of the film system based on the quartz substrate and arrange the geometric thickness in order as follows:

[0054] Table 1 ...

Embodiment 2

[0073] The design of the anti-laser anti-reflection film system using the K9 substrate as sample 2 includes the following steps.

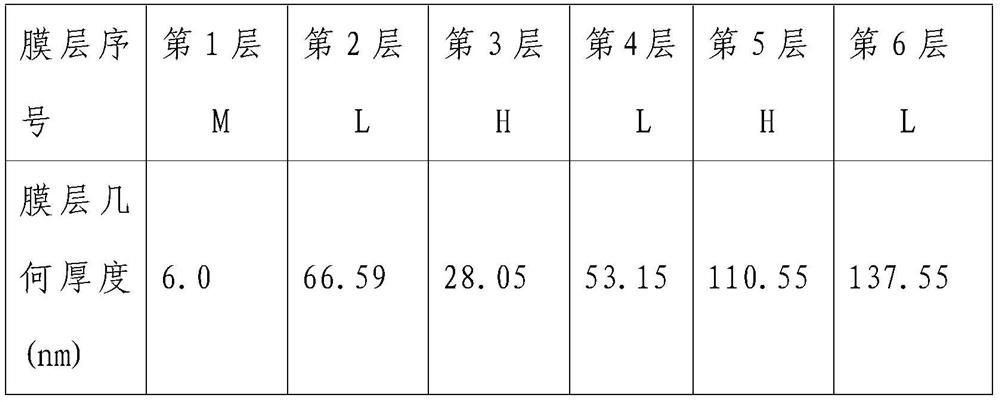

[0074] (1) take K9 as base material, utilize optical thin film design software (TFCalc) to design the optimization anti-reflection film system that meets the technical index requirement of the present invention, the K9 substrate through optical processing is coated on its surface, calculate each with film system design formula The geometric thickness values of the layers are listed in order. Based on K9, M is Al 2 o 3 As substrate film material, H is HfO High refractive index film material, L is SiO Low refractive index film material, (above M, H, L are the granular film material of purity 99.99%). The experimental records of the film geometric thickness of the K9 substrate are listed as follows:

[0075] Table 2

[0076]

[0077] (2) process step (2) is repeated in embodiment 1; Just fixed cleaning time is as follows: A: cleaning solution...

Embodiment 3

[0083] The design of the anti-laser anti-reflection film system based on quartz and K9 as sample 3 includes the following steps.

[0084] (1) take K9 as base material, utilize optical thin film design software (TFCalc) to design the optimization anti-reflection film system that meets the technical index requirement of the present invention, the K9 substrate through optical processing is coated on its surface, calculate each with film system design formula The geometric thickness values of the layers are listed in order. Based on K9, M is Al 2 o 3 As substrate film material, H is HfO 2 High refractive index film material, L is SiO 2 Low-refractive-index film material (the above M, H, and L are granular film materials with a purity of 99.99%). The experimental records of the film geometric thickness of the quartz and K9 substrates are listed as follows:

[0085] table 3

[0086]

[0087] (2) Repeat process step (2) in embodiment 1; Just fix cleaning time as follows: A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com