Transmission type pulse compression grating device and preparation method thereof

A pulse compression and transmission technology, applied in diffraction grating and other directions, can solve the problems of large deformation of the substrate, affecting the output laser aberration, substrate deformation, etc., to improve the utilization rate of laser light energy and improve the laser damage threshold.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

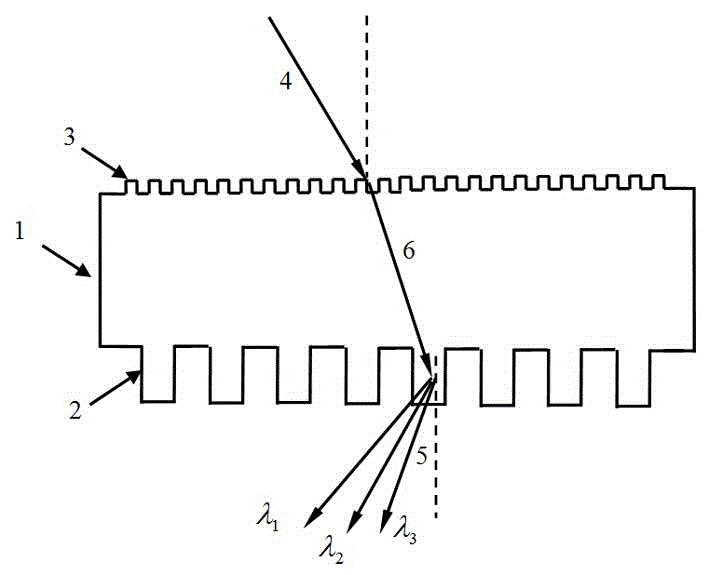

[0025] Embodiment one: see attached figure 2 As shown, a transmission pulse compression grating device includes a fused silica substrate 1, a transmission pulse compression grating microstructure 2 is arranged on one optical surface of the fused silica substrate 1, and on the other side of the fused silica substrate 1 A high-frequency anti-reflection grating microstructure 3 is arranged on an opposite optical surface. Its electron microscope photograph sees appendix Figure 5 And attached Image 6 shown.

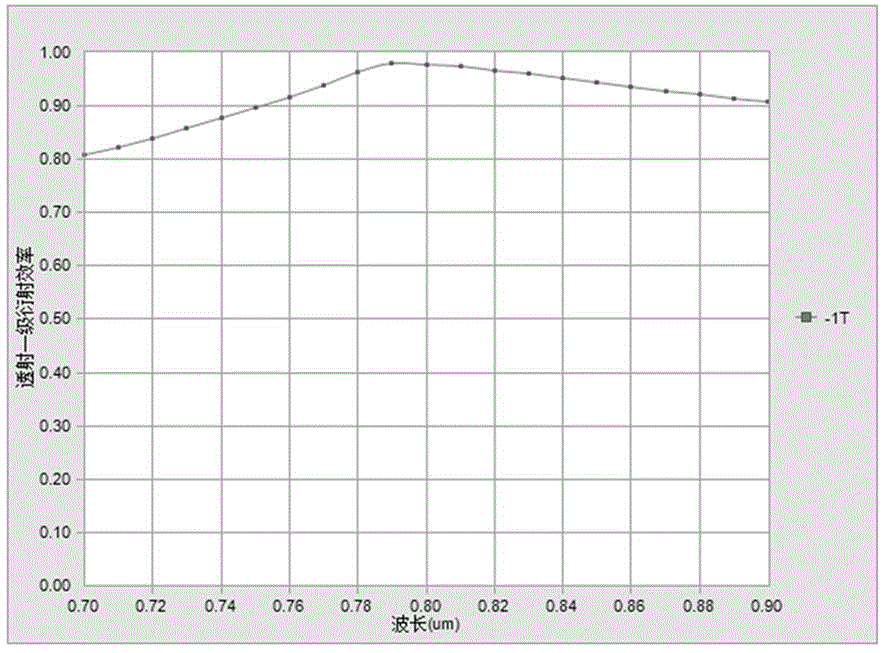

[0026] In this embodiment, the wavelength range of the pulse compression grating is 700nm-900nm, TE polarization, the center wavelength is 800nm, the incident angle of the beam is 30 degrees, the spatial frequency of the pulse compression grating is 1250line / mm, and the grating material is fused silica.

[0027] Such as figure 2 As shown, the incident laser beam 4 undergoes first-order dispersion transmission at the transmissive pulse compression grating 1 , and the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com