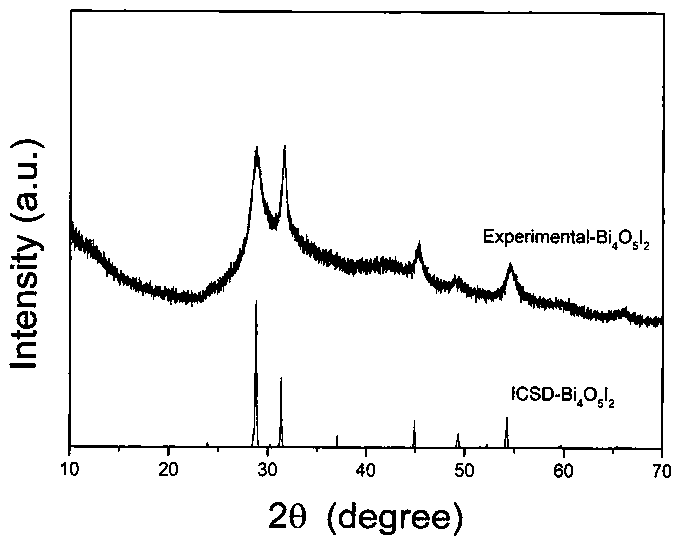

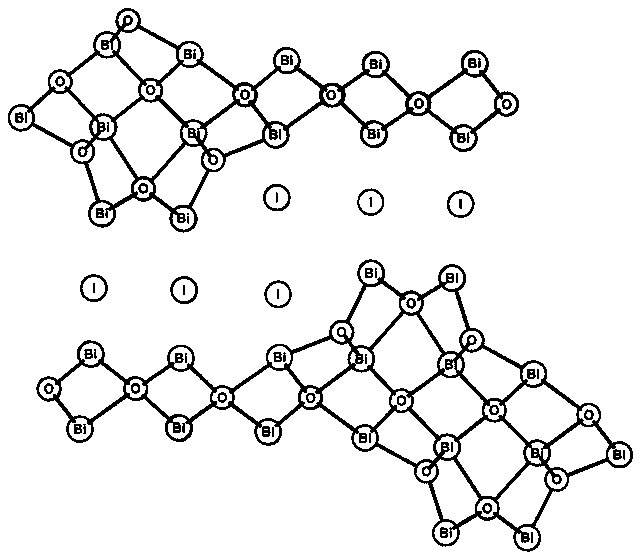

Preparation method and application of bismuth oxyiodide non-linear optical crystal

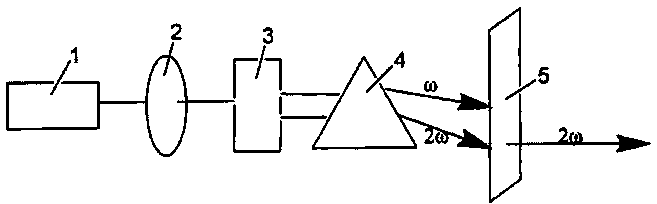

A nonlinear optics, bismuth oxyiodide technology, applied in nonlinear optics, chemical instruments and methods, optics, etc., can solve problems such as few nonlinear optical properties of oxyhalide, achieve a large laser damage threshold, low cost, The effect of the large octave effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] a, 0.002mol bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) Dissolve in 10mL of ethylene glycol, and simultaneously dissolve 0.002mol of potassium iodide (KI) in 10mL of ethylene glycol, stir magnetically for 40min until fully dissolved, and mark solution A and solution B respectively;

[0026] b. Add the B solution obtained in step a dropwise into the A solution, and after magnetically stirring for 30 minutes, mark it as C solution;

[0027] c. Pour the C solution obtained in step b into a 50mL reaction kettle, raise the temperature to 150°C, keep it warm for 16h, cool down to room temperature naturally, separate the powder with a filter, and rinse with deionized water and alcohol three times respectively to remove impurities;

[0028] d. After drying the filtered powder in a drying oven at a temperature of 60°C for 5 hours, take it out and collect it after grinding to obtain a mixture;

[0029] e. Take 0.3 g of the mixture obtained in step d, dissolve it in 100...

Embodiment 2

[0031] a, 0.002mol bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 (2) Dissolve in 10mL ethylene glycol), and simultaneously dissolve 0.002mol of sodium iodide (NaI) in 10mL ethylene glycol, stir magnetically for 40min until fully dissolved, and mark as A solution and B solution respectively;

[0032] b. Add the B solution obtained in step a dropwise into the A solution, and after magnetically stirring for 40 minutes, mark it as C solution;

[0033] c. Pour the C solution obtained in step b into a 50mL reaction kettle, raise the temperature to 160°C, keep it warm for 17h, cool down to room temperature naturally, separate the powder with a filter, and rinse it with deionized water and alcohol three times respectively to remove impurities;

[0034] d. After drying the filtered powder in a drying oven at a temperature of 80°C for 6 hours, take it out and collect it after grinding to obtain a mixture;

[0035] e. Take 0.3 g of the mixture obtained in step d and dissolve it in ...

Embodiment 3

[0037] a, 0.002mol bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) be dissolved in 10mL ethylene glycol, simultaneously dissolve the sodium iodide (NaI) of 0.002mol in 10mL ethylene glycol, stir magnetically for 60min, mark as A solution and B solution respectively;

[0038] b. Add the B solution obtained in step a dropwise into the A solution, and after magnetically stirring for 60 minutes, mark it as C solution;

[0039] c. Pour the C solution obtained in step b into a 50mL reaction kettle, raise the temperature to 170°C, keep it warm for 18h, cool down to room temperature naturally, separate the powder with a filter, and rinse it with deionized water and alcohol three times respectively to remove impurities;

[0040] d. After drying the filtered powder in a drying oven at a temperature of 90°C for 8 hours, take it out and collect it after grinding to obtain a mixture;

[0041] e. Take 0.3 g of the mixture obtained in step d, dissolve it in 100 mL of deionized water, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com