Alignment light source apparatus

A technology of light source device and alignment mark, which is applied in the direction of exposure device, optics and optical components of photoengraving process, can solve the problems of stray light generated by integrated circuit graphics, high requirements of signal amplification system, and reduced signal-to-noise ratio, etc. Improve the utilization rate of laser light energy, reduce the laser spot, and reduce the effect of stray light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0039] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

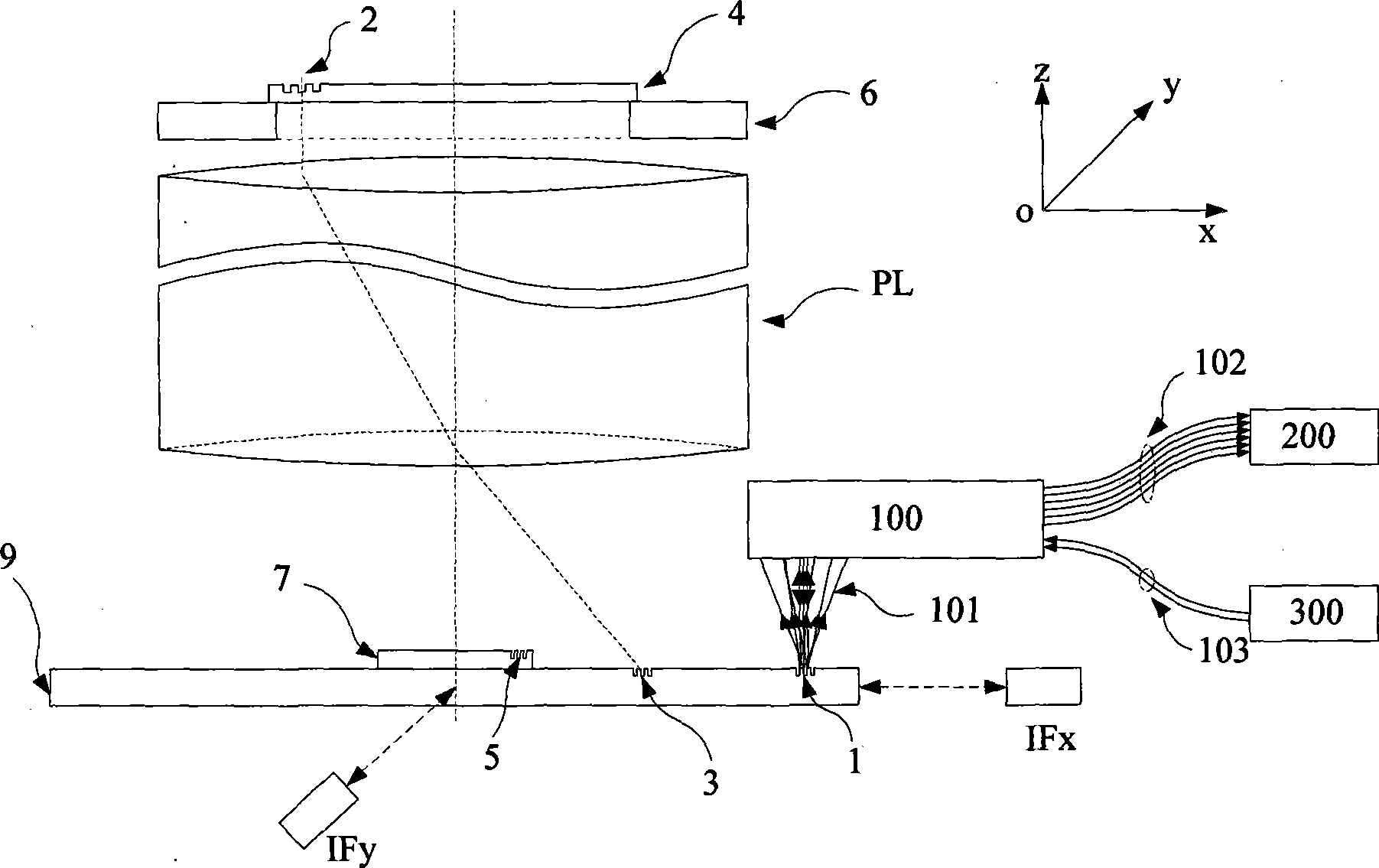

[0040] An alignment light source device of the present invention is used in a lithography alignment system, please refer to figure 1 , figure 1 Schematic diagram of the alignment system for the lithography equipment. The main structure includes: an alignment light source device 300 , an optical module 100 , alignment marks 1 , 2 , 3 , 5 , and a signal processing module 200 . Peripheral components include: mask plate 4 , mask stage 6 , projection objective lens PL, substrate 7 , substrate stage 9 , and transmission fibers 102 and 103 . The composition and functions of each structural module are described below.

[0041] The optical module 100 mainly includes a 4f system, an aperture, a reference grating, an optical path turning prism, and a detection fiber. Among them, the 4f system is mainly used to coherently image the diffracted ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com