Compound quartz glass optical fiber device

A technology of quartz glass and optical fiber devices, applied in the field of laser medicine, can solve the problems of the clinical effect of composite optical fiber devices, uneven distribution of laser moxibustion energy, and enlarged laser spot of laser needle, etc., and achieves good therapeutic effect, small laser spot, The effect of uniform energy distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

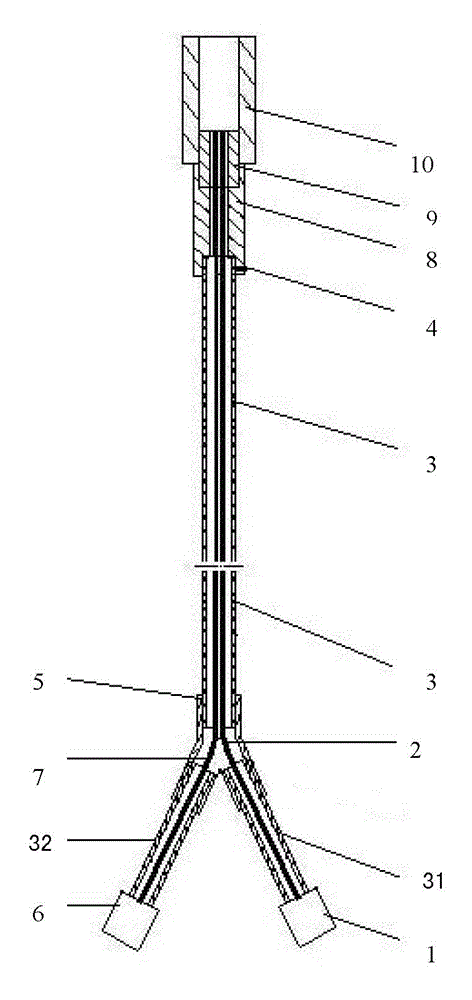

[0043] Such as Figure 1 to Figure 2 As shown, an optical fiber connector 1 is installed on the input end of the silica glass optical fiber 2 with a small numerical aperture, and the two ends of the secondary metal hose 31 are respectively connected with the optical fiber connector 1 and Y of the silica glass optical fiber 2 with a small numerical aperture by threaded connections. Shaped bracket 5 is connected. An optical fiber connector 6 is installed on the input end of the quartz glass optical fiber 7 with a large numerical aperture, and the two ends of the secondary metal hose 32 are respectively connected with the optical fiber connector 6 and the Y-shaped support 5 of the quartz glass optical fiber 7 with a large numerical aperture through threaded connections. connected. The quartz glass optical fiber 2 with a small numerical aperture and the quartz glass optical fiber 7 with a large numerical aperture are assembled in the Y-shaped bracket 5 and placed in the main meta...

Embodiment 2

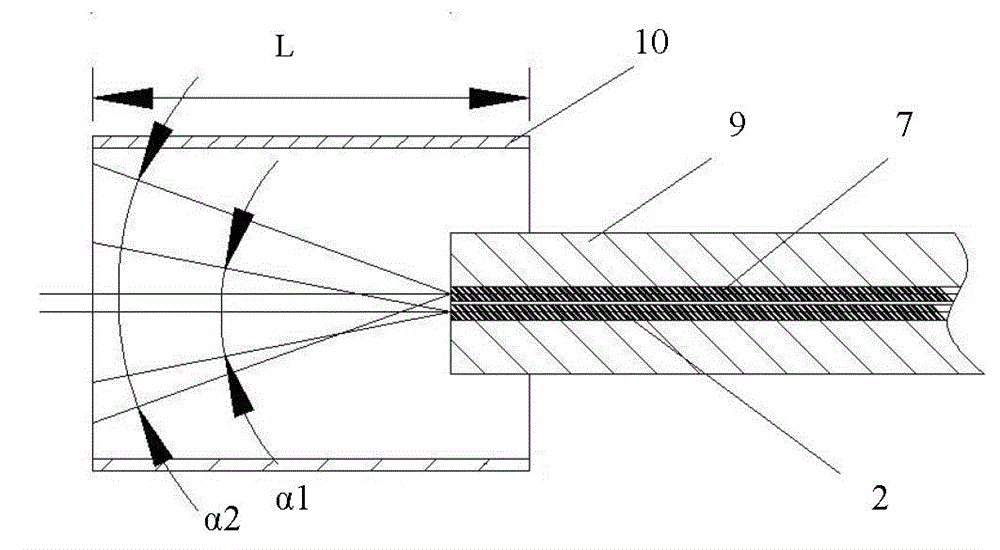

[0045] In the composite optical fiber head 9 composed of the silica glass optical fiber 2 with a small numerical aperture and the silica glass optical fiber 7 with a large numerical aperture, the two optical fibers are parallel and close to each other. In Example 2, the numerical value of the silica glass optical fiber 2 with a small numerical aperture is The aperture is 0.2, the divergence angle α1=22°, and the diameter is φ0.2mm; the numerical aperture of the quartz glass fiber 7 with large numerical aperture is 0.36, the divergence angle α2=40°, and the diameter is φ0.4mm. According to the calculation, detection and clinical test, at the position L=18mm of the length of the positioner 10, the light spot output by the quartz glass fiber 7 will completely cover the light spot of the quartz glass fiber 2, realizing the compounding of the two lasers.

Embodiment 3

[0047] Although not shown in the figure, it is also possible to connect a 2×1 silica glass fiber coupler to the optical fiber connector 1 of the silica glass optical fiber 2 with a small numerical aperture in the composite silica glass optical fiber device of Example 2, so that the numerical aperture A small silica glass fiber 2 is extended with two inputs. Thus the composite silica glass optical fiber device of the present invention can be formed to have three input ports so that laser light of three different wavelengths can be transmitted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com