Patents

Literature

158results about How to "No burns" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-adhesive polymer modified bituminous polyester fiber waterproof sheet material and preparation technology thereof

InactiveCN101644094AImprove construction efficiencyImprove flexibilityRoadwaysUnderground chambersSolventPetroleum

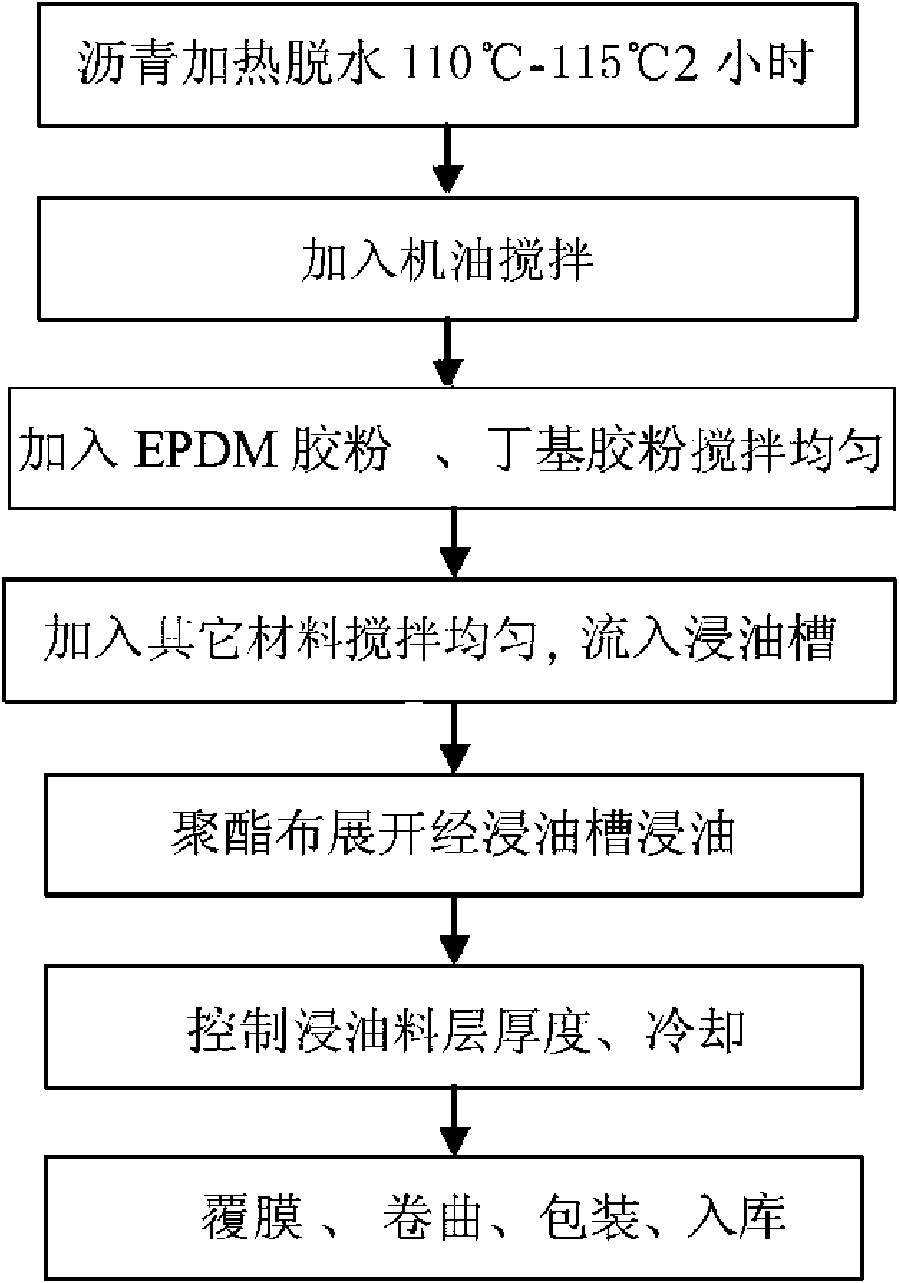

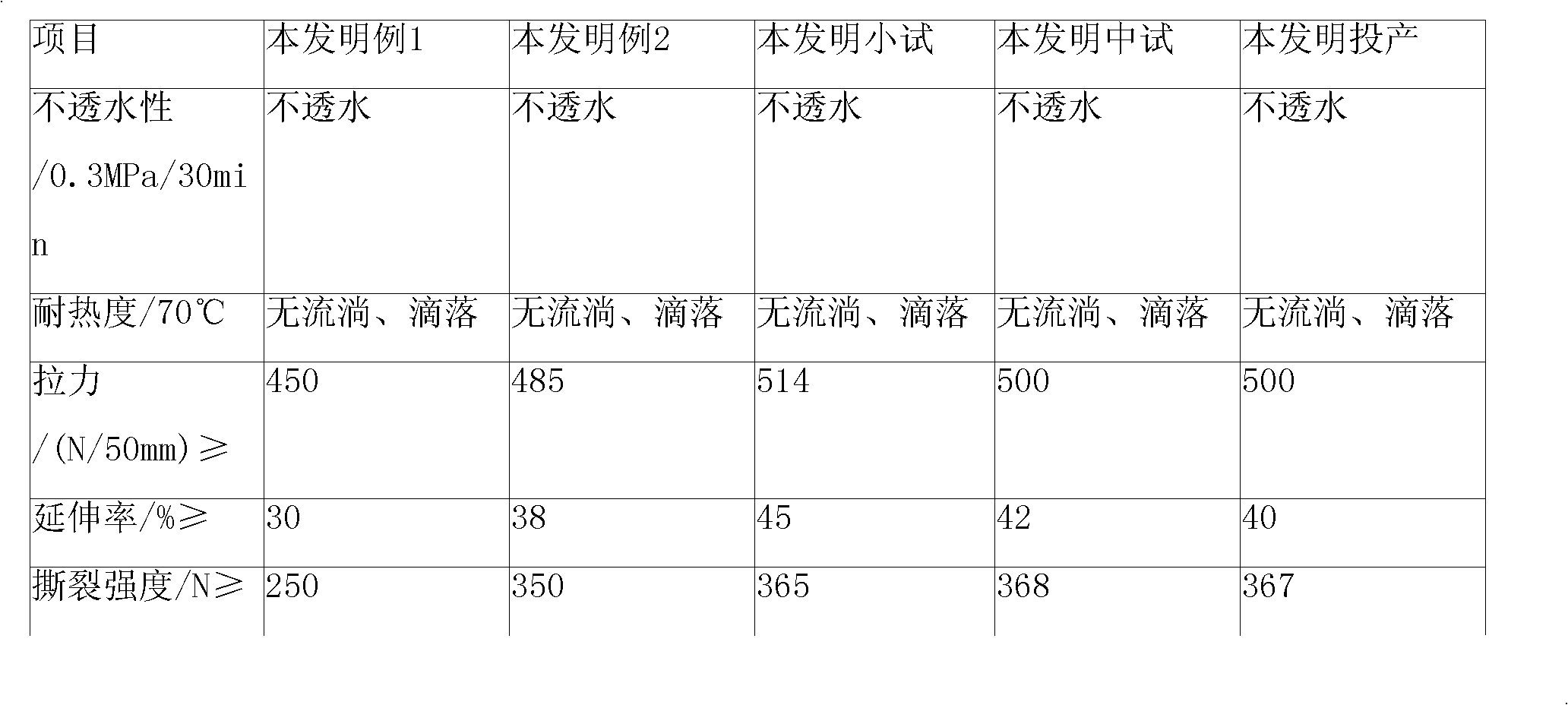

The invention provides a self-adhesive polymer modified bituminous polyester fiber waterproof sheet material and preparation technology thereof. The waterproof sheet material comprises polyester cloths, an immersion oil coating layer and a film-mulching layer. The immersion oil comprises the following materials in parts by mass: 37-47 parts of bitumen, 8-18 parts of machine oil, 5-10 parts of SBSrubber, 2-12 parts of SBR rubber, 2-12 parts of EPDM rubber powder, 2-7 parts of butyl rubber powder, 25-35 parts of talc powder and 1-10 parts of petroleum resins. The bitumen is 90# one. The invention has the effects as follows: the waterproof sheet material uses the EPDM modified bitumen as the base material and polyester cloths as the matrices; the back of the adhesive side is covered by the reinforced self-adhesive waterproof sheet material of abherent, thus achieving the effect of sticking while adhering and improving the construction efficiency; the waterproof sheet material is characterized by solvent-free construction, safety and no scald; the waterproof sheet material has shining surface and good elasticity, and the properties of the waterproof sheet material are not obviously changed after aging through laboratory test.

Owner:北京立高科技股份有限公司 +1

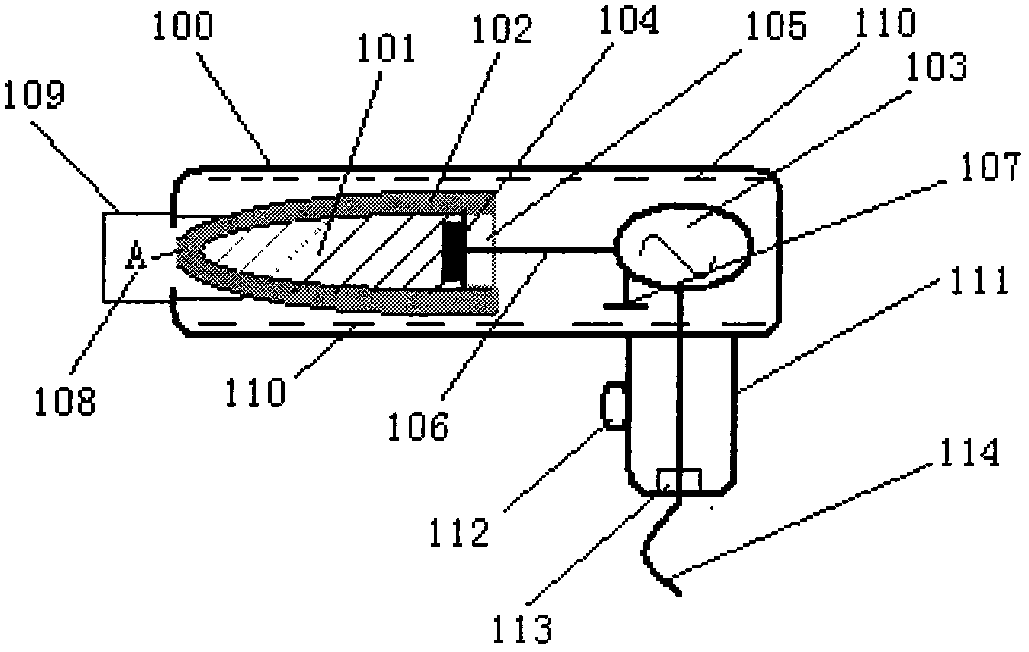

Cold plasma discharger

The invention discloses a cold plasma discharger. The cold plasma discharger is characterized by comprising a hand-held housing, the housing is provided with a control switch, the inner wall of the housing is provided with a metal shield net layer, the housing is internally provided with a power supply and an electrode (hereafter referred to wrapped electrode for short) wrapped by an insulation medium, the wrapped electrode is installed at one end portion of the housing, and the other end of the housing is provided with a power supply lead wire plug. When human skin approaches or contacts the wrapped electrode at the end portion of the housing, cold plasma discharge is generation between the human skin and the wrapped electrode. The cold plasma discharger has the effects of sterilization and disinfection for human skin surface.

Owner:王守国

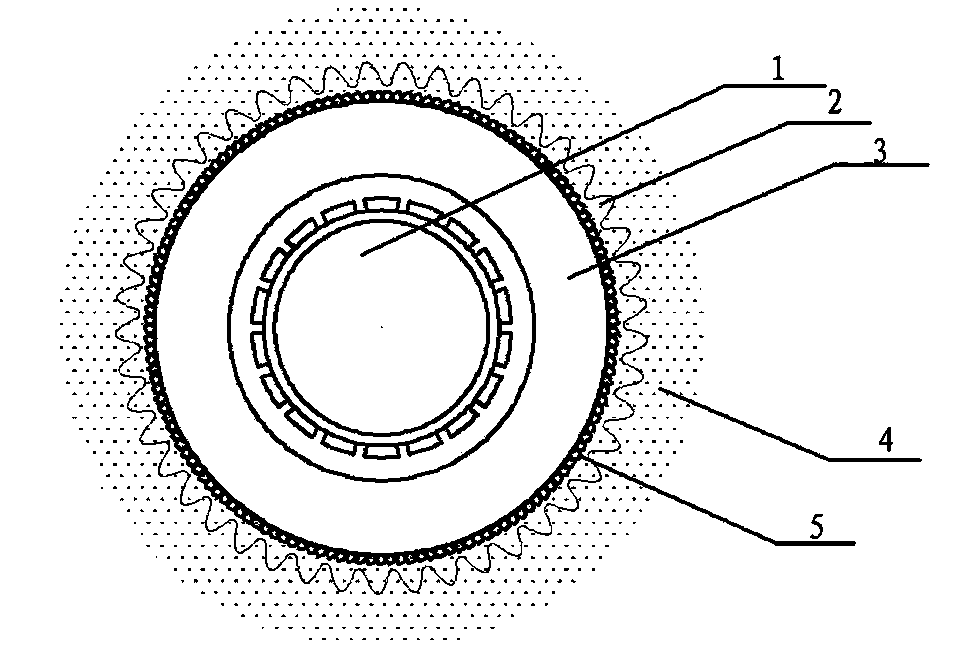

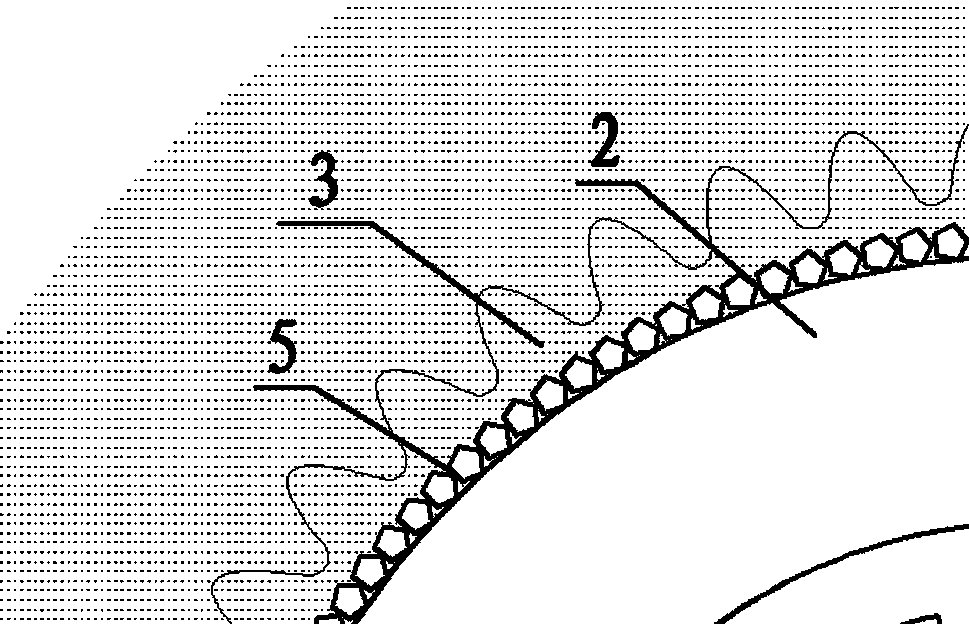

Abrasive feeding method for electroplate grinding wheel

The invention discloses an abrasive feeding method for an electroplate grinding wheel. The method comprises (1) a step of surface treatment of an abrasive; (2) a step of abrasive distribution, wherein the abrasive after being treated and a magnetic fluid containing a plating solution are mixed uniformly to form a suspension liquid, and then the magnetic fluid carrying the abrasive is controlled by magnetic field changes to motion on the surface of an electroplate grinding wheel matrix, thus completing distribution of the abrasive on the surface of an electroplate grinding wheel matrix; and (3) a step of abrasive fixation. The electroplate grinding wheel matrix is a steel matrix, a copper matrix, a bronze matrix, an aluminum matrix, an aluminum alloy matrix or a cemented carbide matrix. According to the method, the precision of abrasive distribution is improved and the strength between the abrasive and the matrix is enhanced. The grinding wheel prepared by the method has a good heat dissipation effect and a long service lifetime, and causes no surface burns of workpieces during machining processes.

Owner:赛尔科技(如东)有限公司

Blade part efficient and precise grinding microcrystal ceramic corundum grinding wheel and machining method thereof

InactiveCN104015131AIncreased durabilityExtended service lifeAbrasion apparatusGrinding devicesMaterials preparationAdhesive

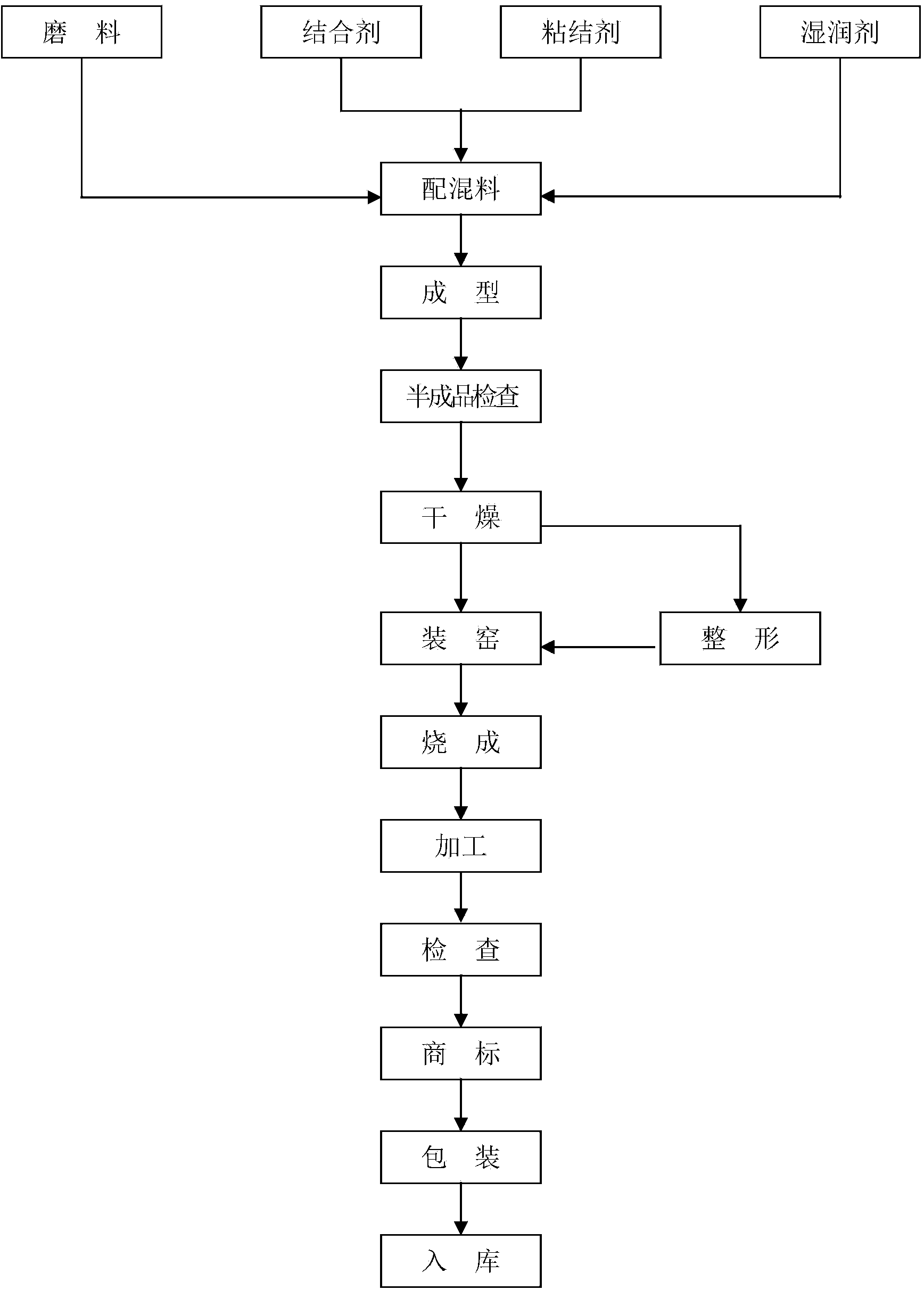

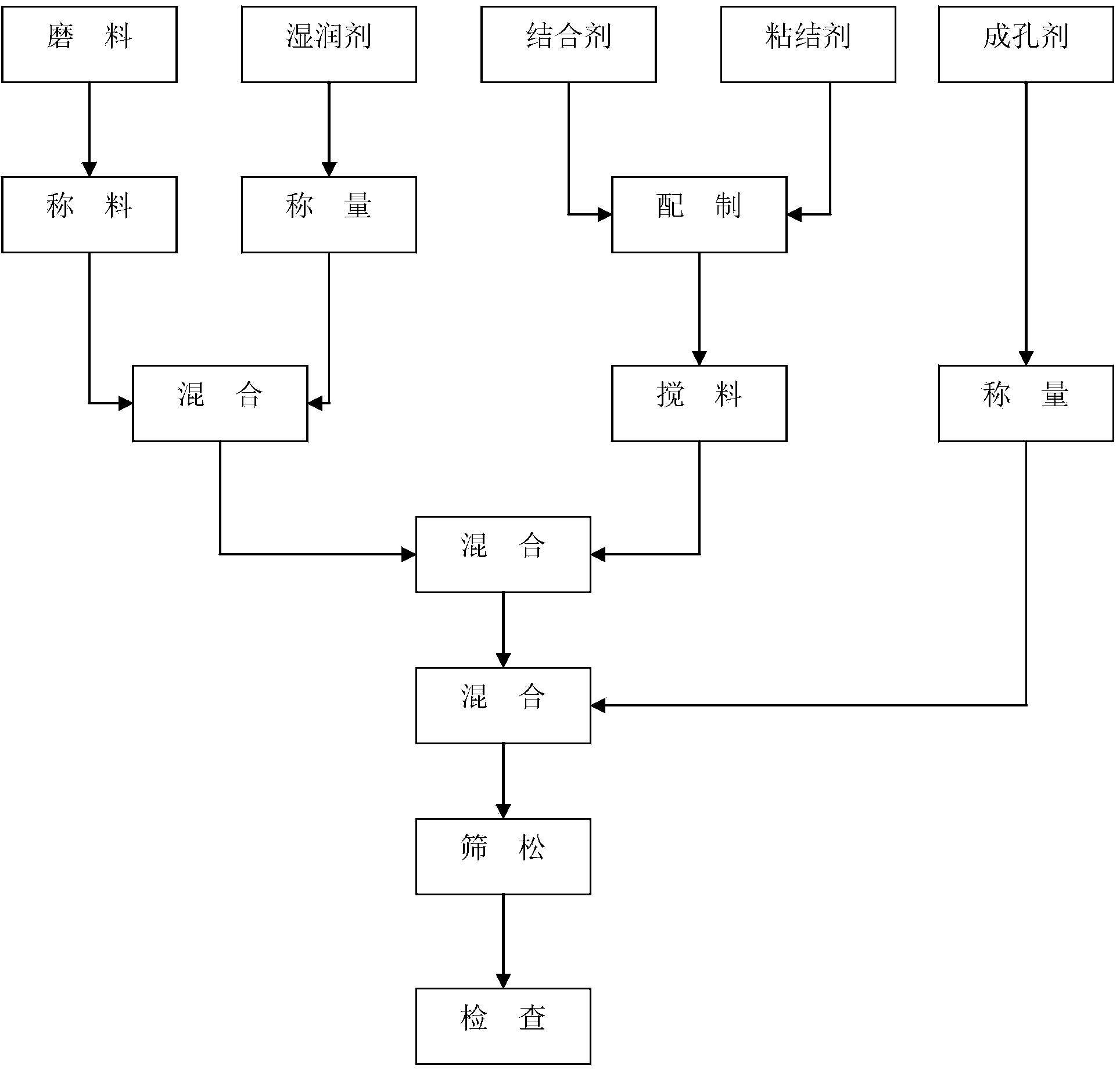

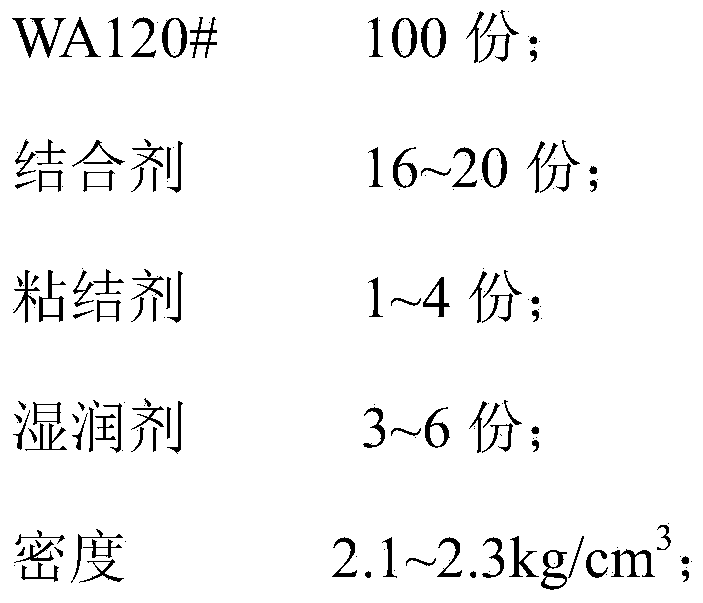

The invention particularly relates to a high-precision blade part efficient and precise grinding microcrystal ceramic corundum grinding wheel and a machining method of the grinding wheel. The grinding wheel comprises a non-grinding layer part and a grinding layer part, and is characterized in that the non-grinding layer part comprises 100 parts of WA No.120, 16-20 parts of binding agents, one to four parts of adhesives and three to six parts of wetting agents; the grinding layer part comprises 50 parts of CA No.60-120, 50 parts of WA No.60-120, 8-14 parts of bonding agents, one to four parts of wetting agents and 6-15 parts of pore-forming agents. The machining method of the grinding wheel is characterized by comprising the following steps of (1), material preparation and mixing, (2), forming, (3), drying and (4), firing. The grinding wheel has the advantages of having the deep cutting performance, large feeding performance, heavy load performance and efficient grinding performance, being high in durability, long in service life, good in self-sharpening performance, free of blocking, low in cost and good in grinding stability and the like.

Owner:LUXIN VENTURE CAPITAL GRP

Zirconium corundum heavy load strong abrasive band

ActiveCN101134300AImprove toughnessImprove grinding effectAbrasion apparatusHeavy loadMaterials science

The present invention relates to abrasive belt, and is especially one kind of powerful zirconia corundum supported abrasive belt comprising cloth base, adhesive and grinding material zirconia corundum adhered onto the cloth base. It features the adhesive comprising thermosetting phonetic resin 28-36 wt%, diphenol propane type epoxy resin 4-8 wt%, melamine resin 1-4 wt%, boron 0.2-0.6 wt%, dispersant 0.1-0.3 wt%, coupling agent 0.1-0.3 wt%, diluent 3-6 wt%, fluoride salt 45-60 wt%, fluoride of inert gas 0.5-1 wt%. The abrasive belt has high heat resistance high adhesion strength at high temperature, capacity of softening metal surface and lowering surface hardness, no damage to metal surface and high grinding efficiency.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

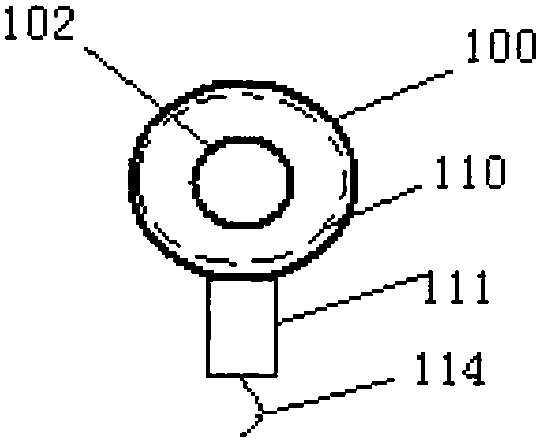

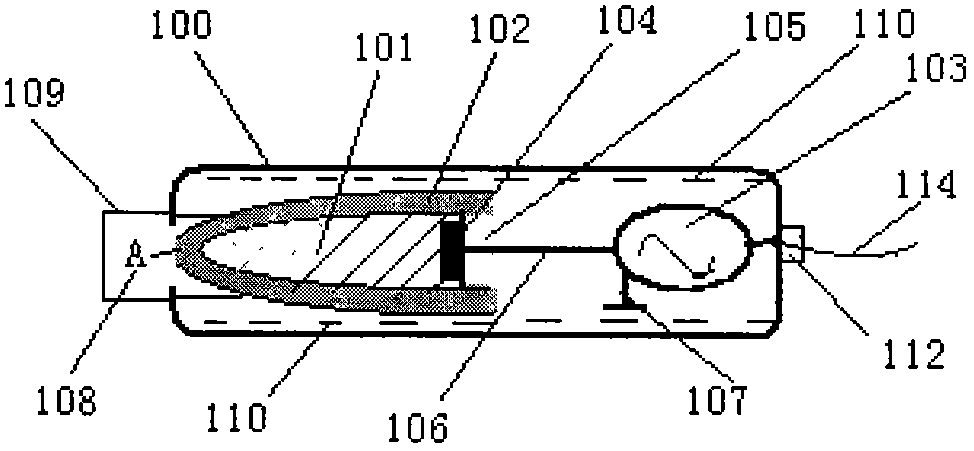

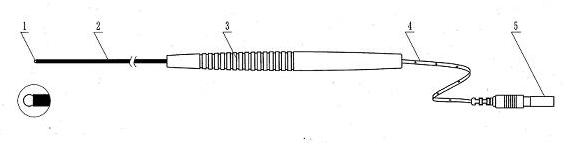

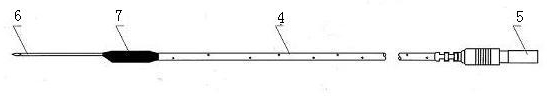

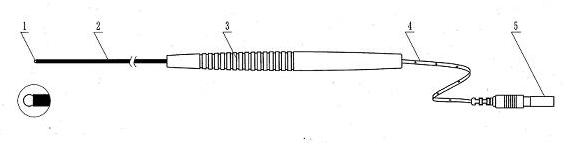

Electrode for nerve electrophysiology monitoring in high field intensity magnetic resonance compatible technology

ActiveCN102626309AEasy to operateSmall influence of high field strength magnetic fieldDiagnostic recording/measuringSensorsSpherical probeHigh field

The invention belongs to the field of medical instruments and auxiliary devices, and in particular relates to an electrode for nerve electrophysiology monitoring in high field intensity magnetic resonance compatible technology. The electrode comprises a probe electrode and a pin electrode, wherein the probe electrode is a spherical probe electrode, and the pin electrode is a pin-shaped electrode. The spherical probe electrode is composed of a head portion, an electrode rod, a handle, a wire and a plug. The pin type electrode is composed of a pin-shaped head portion, a handle, a wire and a plug. The wire penetrates through the handle to be welded with the head portion through silver, and the other end of the wire is rivet joint with the plug. A high field intensity magnetic field has small influence on the electrode for monitoring, and a heat effect and a displacement effect are small. The electrode for monitoring does not generate extra current and tissue burn, and can be safely applied in a high field intensity environment without interfering magnetic resonance imaging. A recording electrode does not need to be removed when nerve electrophysiology monitoring is performed, image analysis is not influenced, and operation is convenient, simple and standard.

Owner:XIAN FRIENDSHIP MEDICAL ELECTRONICS CO LTD +1

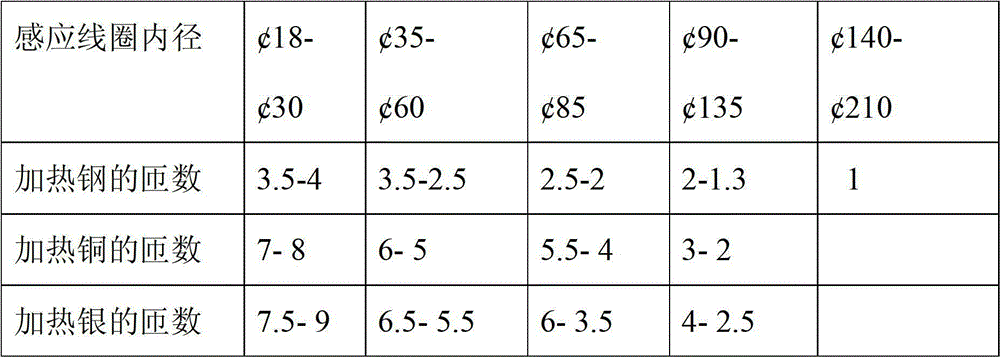

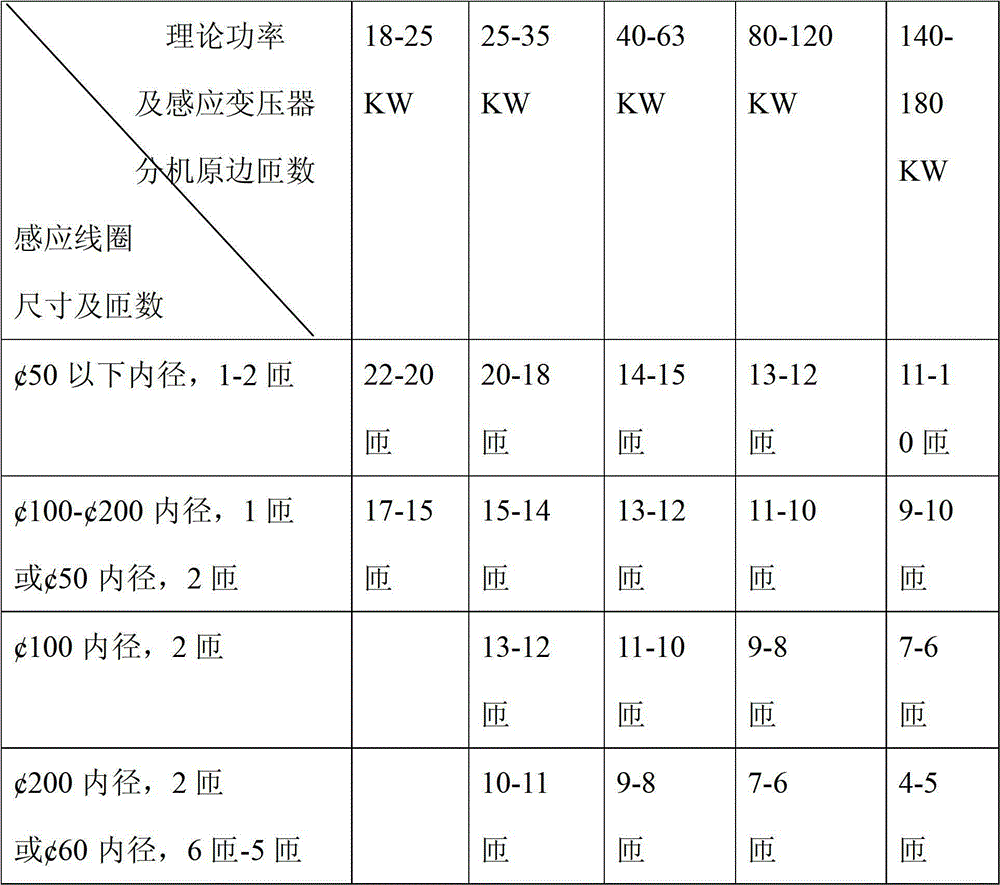

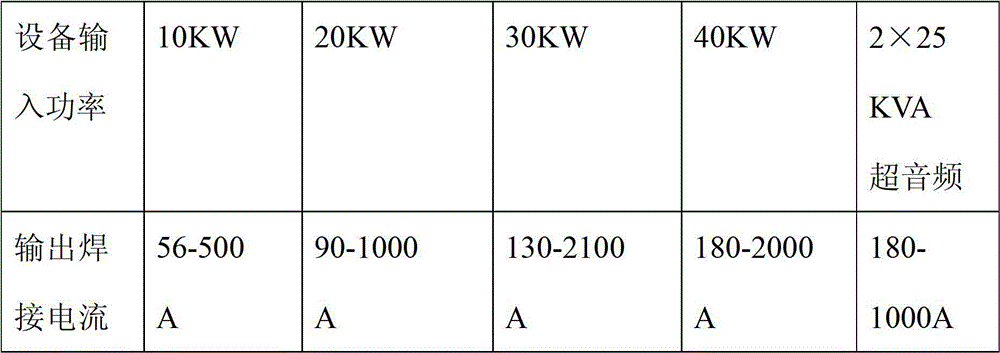

Induction brazing welding method for metal part

The invention discloses an induction brazing welding method for a metal part. The method utilizes induction brazing welding equipment and then is implemented according to the following steps of: a step 1 of selecting the induction brazing welding equipment and determining related parameters; a step 2 of carrying out weldment surface processing, i.e. roughening the welding surface of a weldment, processing the metal-plated surface of the weldment, carrying out matched selection between the weldment and a soldering flux, a brazing filler metal, a welding temperature and a brazing clearance and selecting each process parameter of induction brazing; a step 3 of assembling and fixing the weldment; and a step 4 of implementing welding. According to the induction brazing welding method disclosed by the invention, the induction welding and the induction brazing welding of structures of different materials, pipe fittings, sheets, tube plates and the like are implemented, the sealing performance of a weld joint is improved, the intensity of the weld joint is reduced, the electrical conductivity is obviously improved, and the weld joint has a reliable quality.

Owner:ZHEJIANG CHINT ELECTRIC CO LTD

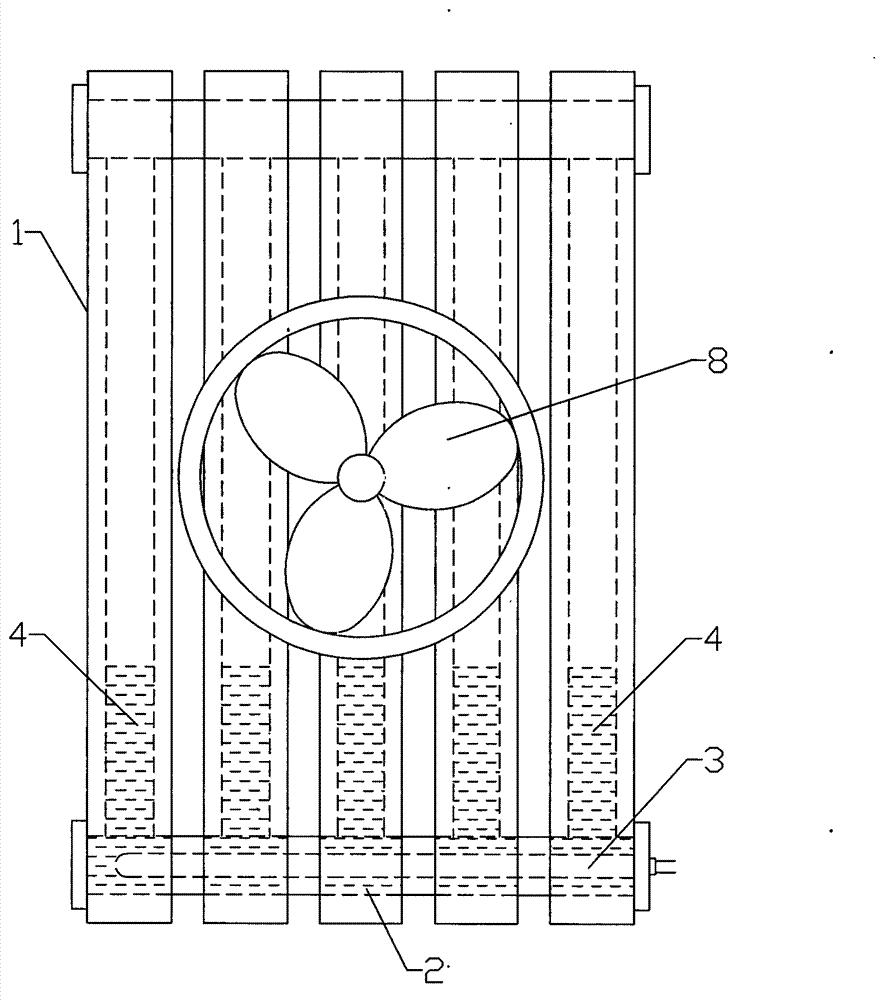

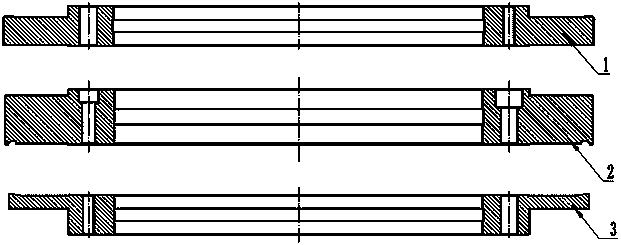

Drying closet

InactiveCN102493159AQuick drying and settingImprove energy savingTextiles and paperLaundry driersCold airThermodynamics

The invention discloses a drying closet comprising a closet door and a closed closet body, wherein a baffle plate is arranged in the closet body so as to divide the closet body into a hot chamber and a cold chamber; hot air and cold air circulate between the hot chamber and the cold chamber; and a condensed water receiver or a condensed water outlet is arranged at the bottom of the closet body. The drying closet works in such a manner that moisture on clothes placed in the hot chamber can be taken away by hot air conveniently, and the hot air containing the moisture is condensed and dewatered after passing through the cold chamber and is changed into relatively dry air which enters into the hot chamber for circulation again, so that the invention has the advantages that the clothes are dried, the efficiency is high, the energy is saved, the environment pollution is eliminated, the temperature is uniform, the quantity of discharged moist hot air is small, the low-temperature operation is safe and reliable, and the surface temperature on a heater is not higher than 75 DEG C generally. Therefore, the clothes cannot be damaged or scalded; and accidents such as explosion, fire and the like are avoided.

Owner:镇江市金舟船舶设备有限公司

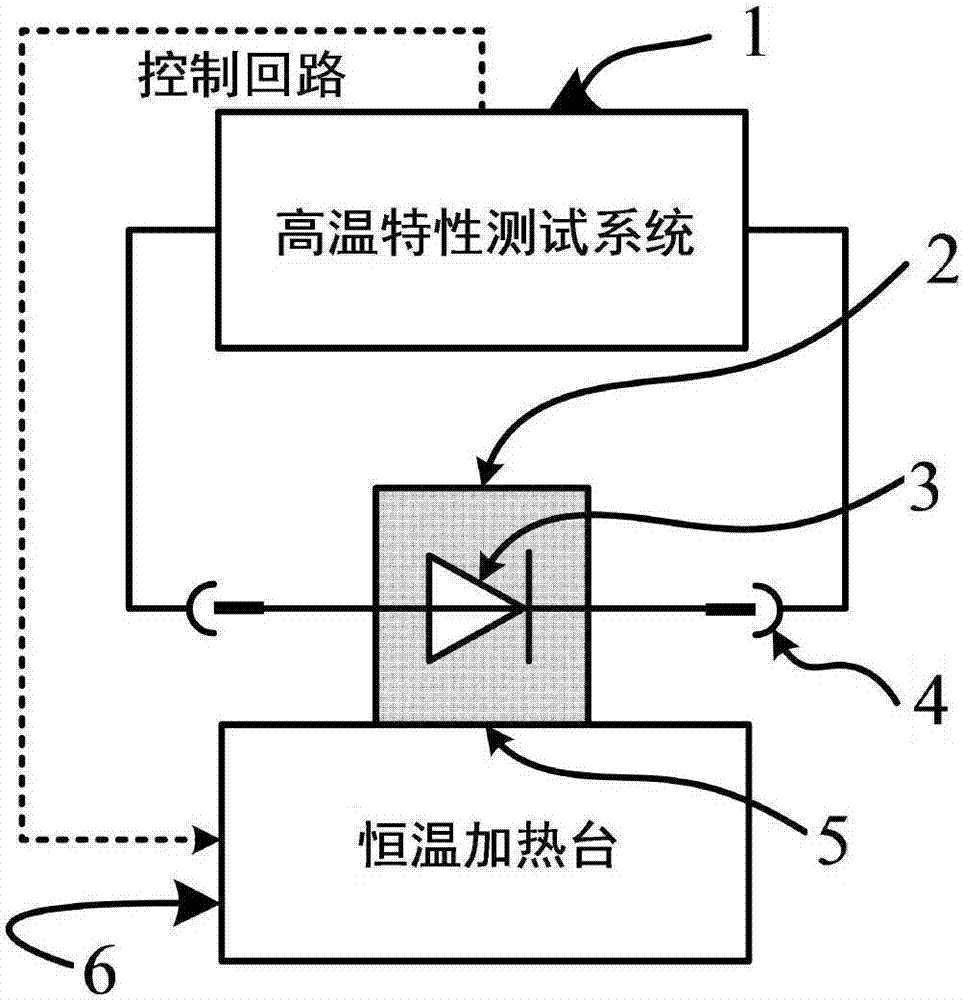

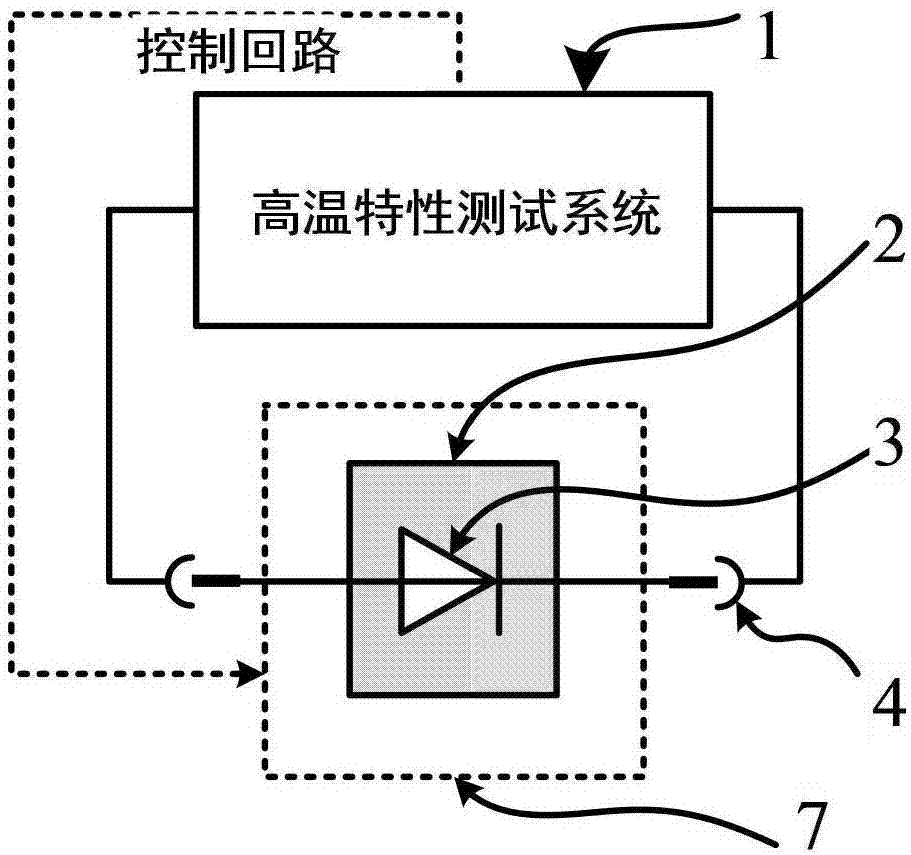

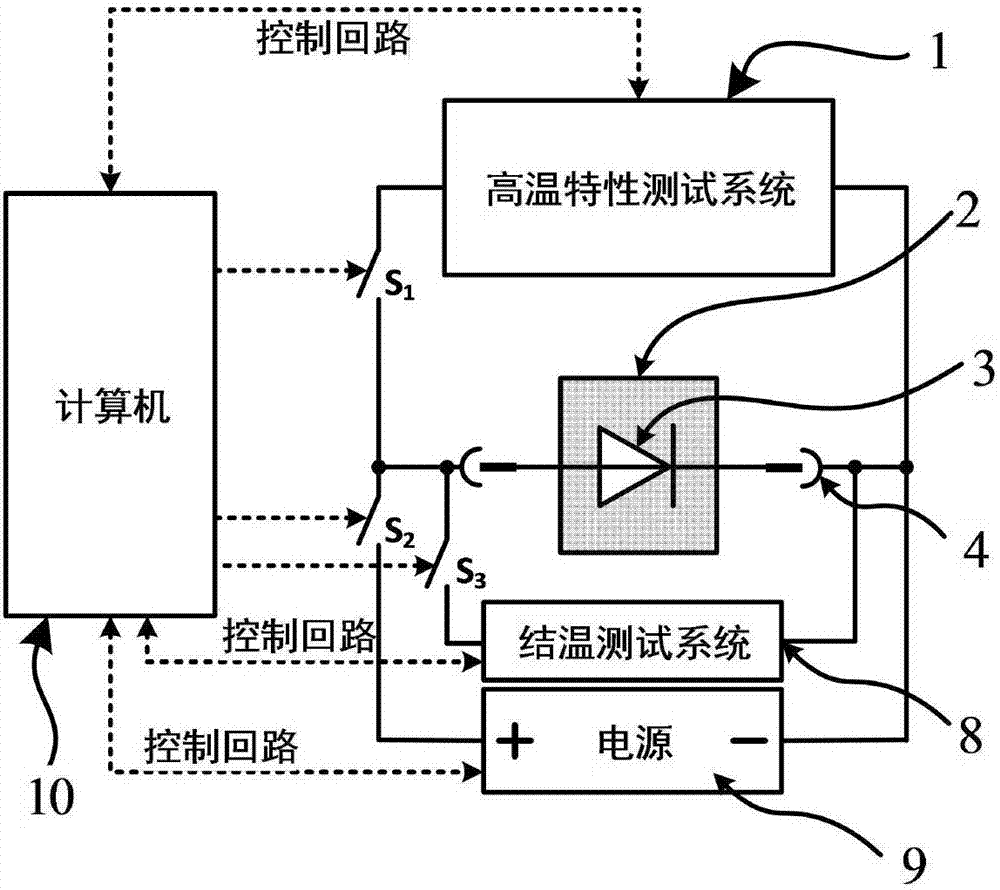

High temperature characteristic test method and device for semiconductor device heated by current

ActiveCN107271878AReduce temperature riseFast heatingIndividual semiconductor device testingElectricityPower semiconductor device

The invention relates to a high temperature characteristic test method and a device for a semiconductor device heated by current. When the circuit formed when a power supply and a to-be-tested semiconductor device are electrically connected is conducted, conduction current exists in the to-be-tested semiconductor device, loss of the semiconductor device itself can be used to heat a semiconductor chip, and the heating speed is quick; during the heating process, a TSP parameter of the semiconductor device is monitored timely, the TSP parameter is used to calculate the junction temperature of the to-be-tested semiconductor device, once the junction temperature is enough close to the test target temperature Tj-test, the high temperature characteristic test system is used to realize a high temperature characteristic test on the to-be-tested semiconductor device. The time consumed for test is little, the efficiency is high, and the method and the device are extremely suitable for test on a large number of samples; the test precision is high; and no scalding possibility exists during the operation process, and the test safety is improved.

Owner:山东阅芯电子科技有限公司

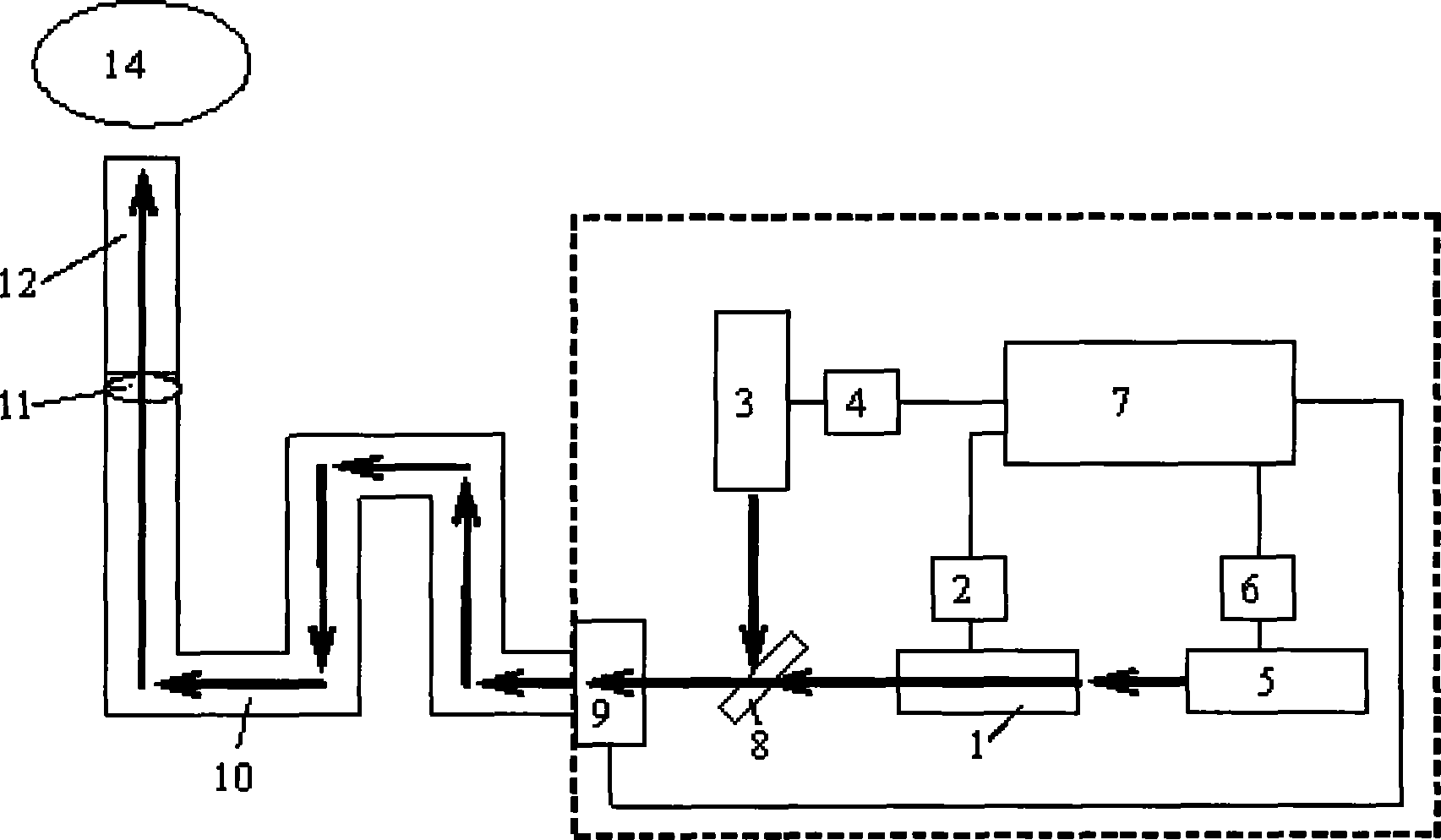

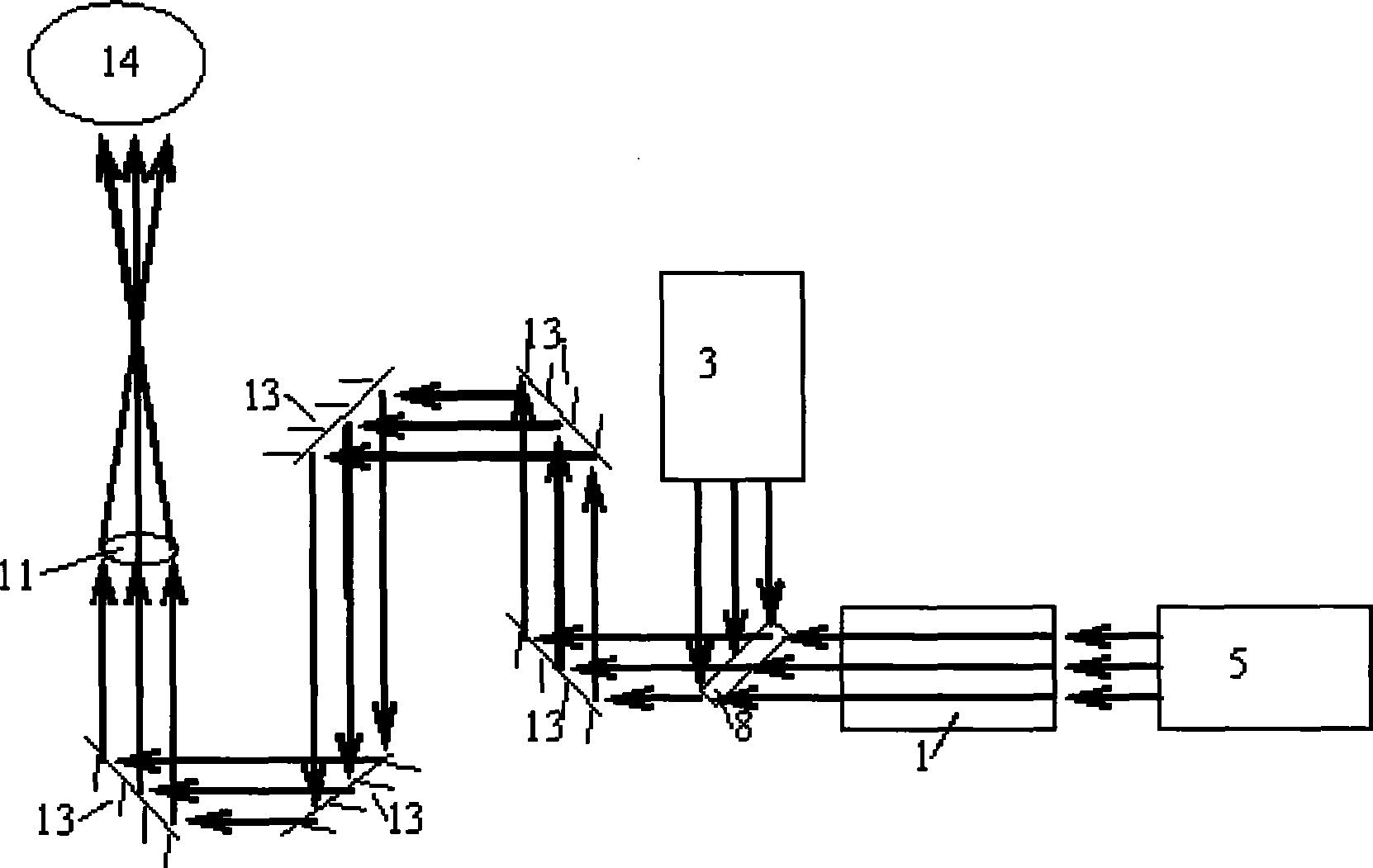

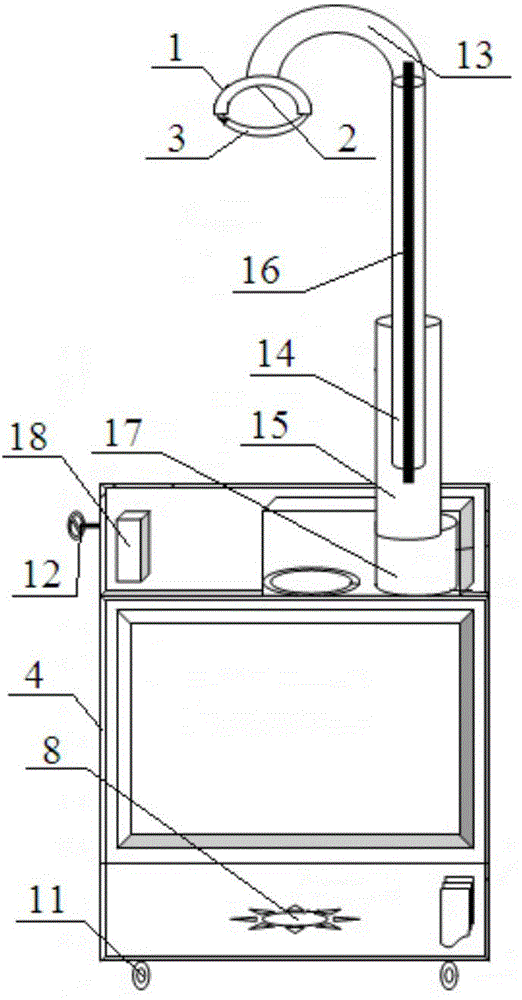

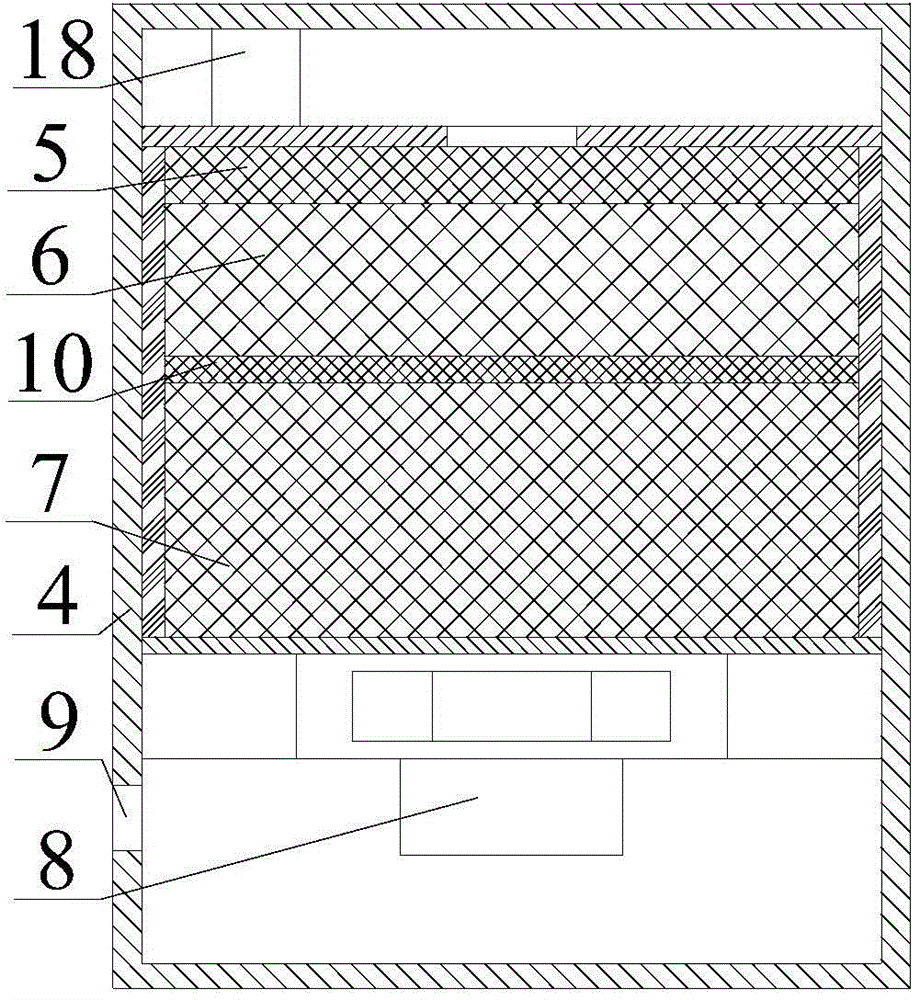

Laser mixubustion treatment instrument based on traditional moxibustion infrared-spectrum

ActiveCN101507683ANo burnsPulse frequency adjustableRadiation therapyPhysical therapy involving specific reflex pointsMedical equipmentControl power

The invention belongs to the field of medical equipment, and in particular discloses a laser moxibustion instrument based on traditional moxibustion infrared spectrum. The laser moxibustion instrument is a composite laser acupuncture point treatment instrument stimulating moxa mild moxibustion and indirect moxibustion; the laser moxibustion instrument consists of laser with the range from 2 to 4 mu m and from 9 to 11 mu m, a laser power supply, a visible indicating light laser and a control power supply thereof, a circuit controller, a co-light path device, a joint-type light guide arm, and the like. The composite laser moxibustion instrument realizes dual treatment functions of moxa strip mild moxibustion and indirect moxibustion and simultaneously realizes security and smokelessness of moxibustion.

Owner:SHANGHAI UNIV OF T C M +1

Multifunctional resin grinding wheel and production method thereof

ActiveCN106002666AGood cutting performanceGood sharpnessBonded abrasive wheelsGrinding devicesMulti materialCeramic tiles

The invention relates to the technical field of grinding wheels and particularly relates to a multifunctional resin grinding wheel and a production method thereof. The grinding wheel comprises the following components in percentage by weight: 20-30% of silicon carbide, 20-30% of white fused alumina, 20-30% of brown fused alumina, 15-20% of a binding agent and 10-15% of cryolite, wherein the binding agent is phenolic resin liquid or powder. The grinding wheel can be used for cutting various materials and has better cutting performance; the grinding wheel has lower unit weight than a conventional product with the same specification, and every grinding wheel can save the molding material by 10-20g; and the grinding wheel is good in sharpness, incapable of generating a burn injury phenomenon when being used for cutting stone, ceramic tiles, iron, aluminum, stainless steel and the like, and meanwhile, the cutting efficiency is also greatly increased.

Owner:菊龙(天津)磨具有限公司

Stainless steel cleaning passivator and application thereof

PendingCN111926338AAchieve recyclingReduce sludge dischargeMetallic material coating processesOrganic acidActive agent

The invention relates to a stainless steel cleaning passivator and application thereof. The stainless steel cleaning passivator is prepared from the following components of, in percentage by mass, based on the total weight of the stainless steel cleaning passivator, 10%-40% of organic acid, 5%-10% of organic acid salt, 1%-5% of surfactant, 1%-5% of chelating agent, 1%-3% of passivating oxidation auxiliary and the balance water; and the passivating oxidation auxiliary agent is alkali metal salt. Acid of the stainless steel cleaning passivator is organic acid, acid mist and waste acid are not generated in the acid pickling process, and the stainless steel cleaning passivator is suitable for rinsing stainless steel through a microelectrolysis oxidation method subsequently, environment-friendly and high in safety.

Owner:绿水新材料科技(苏州)有限公司

Strong acid metal surface phosphor passivation and anti-rust agent and its production method

InactiveCN101086062ADeduction consumptionNo three wastes pollutionMetallic material coating processesPhosphateSoft water

The invention relates to a kind of strong acidic phosphorous passive antirust agent for metal surface and the preparation method. The comprised raw material and their weigt proportion are as follows: phosphate 22- 66 uints, additive 8- 12 units, acidc ferric manganese phosphate 15- 45 uints, metal salt such as zinc nitrate, aluminum nitrate, nickel nitrate or nickel sulfate, calcium sulphate or calcium sulphate, silica dioxide, 12- 22 uints, OP or cleaning agent 2- 3 uits, clean water 14- 60 untis. The method comprises following steps: (1) feeding distilled water or soft water into autoclave; (2) adding ferric manganese phosphate into autoclave, stirring and adding zinc nitrate, nickel nitrate or nickel sulfate, silica dioxide and calcium chloride into it, reacting and getting semi- solid pasty; (3) dropping phosphate, adding additive, OP or cleaning agent, getting finished product when the liquid is clear. The invention is characterized in that it is smelless during immersion, spraying and coating below 120 Deg. C or at normal temperature, the binding force is the first grade, saves energy consumption by more than 80%, cost is reduced above 70%, no three waste discharge and non toxic, and the product is widely used.

Owner:陈历泽

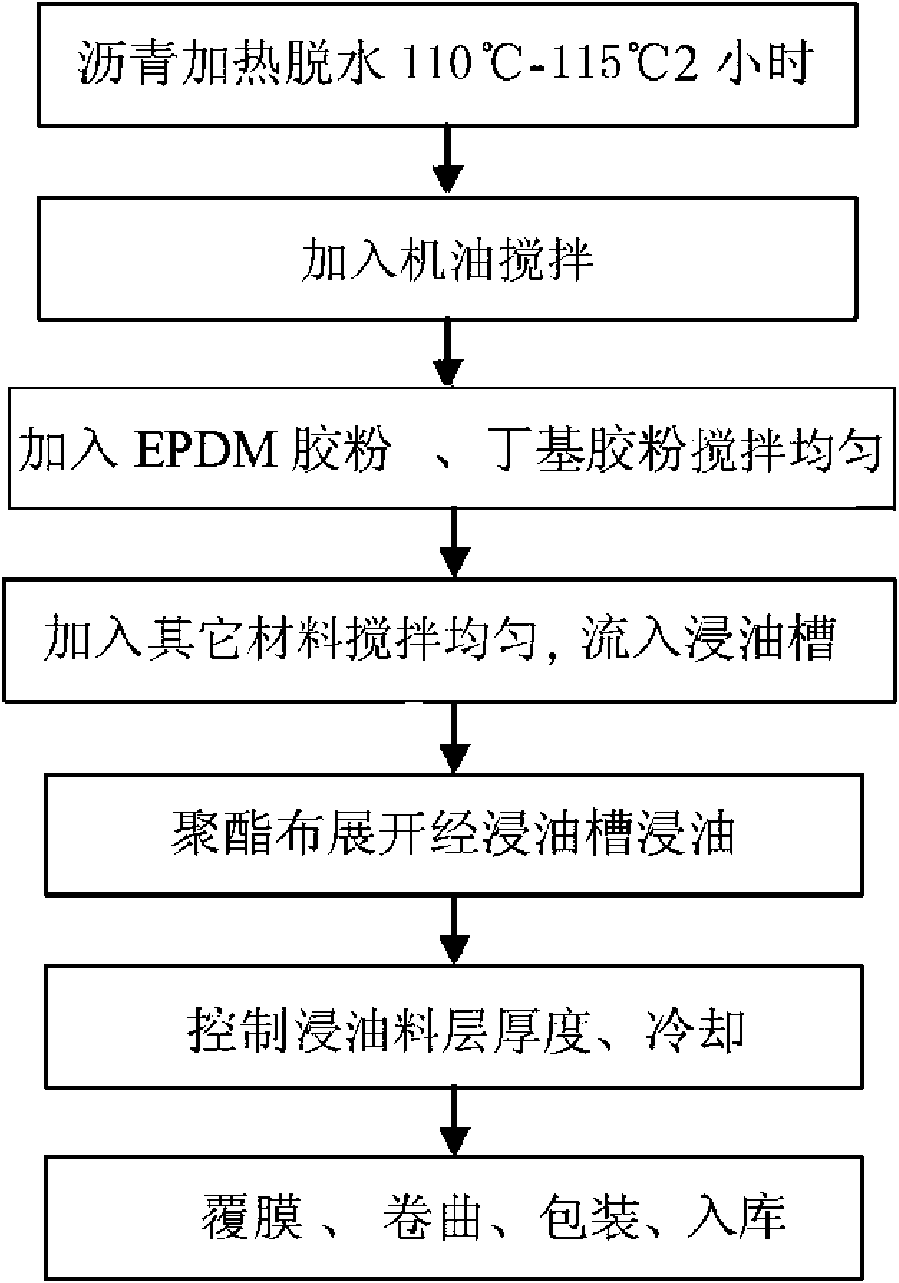

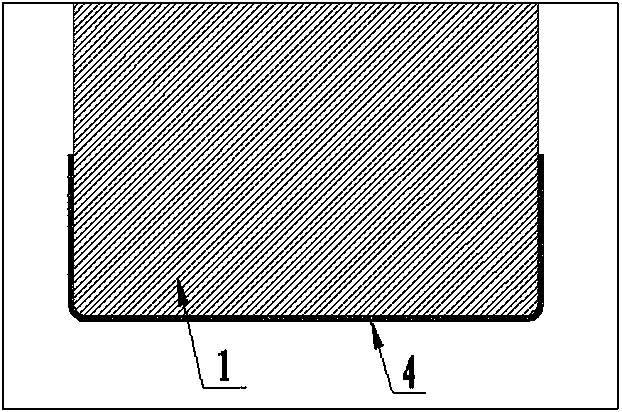

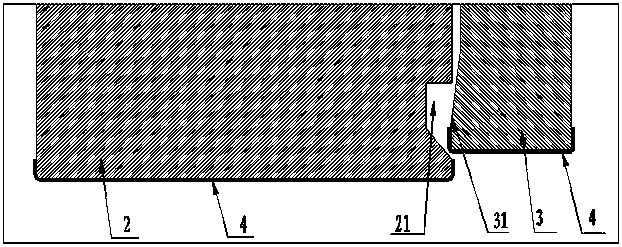

Self-adhesive rubber bituminous waterproof sheet material and preparation technology thereof

InactiveCN101644096AImprove construction efficiencyGood flexibilityRoadwaysUnderground chambersPolyesterBituminous waterproofing

The invention provides a self-adhesive rubber bituminous waterproof sheet material and preparation technology thereof. The waterproof sheet material comprises polyester cloths, an immersion oil coating layer and a film-mulching layer. The immersion oil comprises the following materials in parts by mass: 43-52 parts of bitumen, 5-15 parts of machine oil, 3-13 parts of SBS rubber, 3-13 parts of SBRrubber, 3-13 parts of EPDM rubber powder, 3-8 parts of butyl rubber powder, 15-25 parts of talc powder and 1-10 parts of petroleum resins. The bitumen is 90# one. The invention has the effects as follows: the waterproof sheet material can achieve the effect of sticking while adhering and improve the construction efficiency obviously; the waterproof sheet material is characterized by solvent-free construction, safety and no scald; the waterproof sheet material has shining surface and good elasticity, and the properties of the waterproof sheet material are not obviously changed after aging through laboratory test. The waterproof sheet material is suitable for waterproofing works of basements of industrial and civil buildings, subways, accumulated water in tunnels and the like, is also suitable for waterproofing of roofing of non-exposed buildings and is especially suitable for works which are characterized in that solvents and open fire are not allowed on the construction site.

Owner:北京立高科技股份有限公司 +1

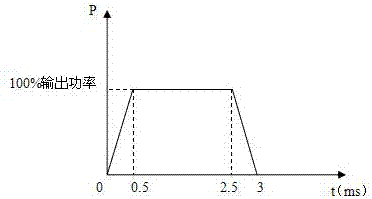

Welding method for stainless steel plates with thickness being smaller than 0.3 mm

ActiveCN106938384AReduce wasteNo missing weldingLaser beam welding apparatusBreaking strengthHeat-affected zone

The invention provides a welding method for stainless steel plates with the thickness being smaller than 0.3 mm. The welding method for the stainless steel plates with the thickness being smaller than 0.3 mm comprises the following steps that the stainless steel plates are cut according to requirements, cut openings are made smooth, and burrs are removed; and the two to-be-welded plates are fixedly mounted on clamps correspondingly, and weld openings of the two to-be-welded plates are aligned; a YAG pulse laser welding machine is adopted, laser beams are kept irradiating the corresponding weld openings of the two plates, and energy is output in the trapezoidal pulse form; and the moving speed of the plates is kept being matched with the frequency and pulse width of laser pulses, so that two adjacent welding spots are made to be in lap joint. By adoption of the welding method for the stainless steel plates with the thickness being smaller than 0.3 mm, small-width stainless steel plates with the same thickness can be combined through laser welding, welding omission, seams, holes, flow and burning damage of a heat affected zone are avoided; the welding spots are continuous, the edges of the welding spots are in lap joint, the overlapping degree of the welding spots is not smaller than half of the diameter of the welding spots, airtightness is guaranteed, and holes are voided; and the strength of welding lines is higher than that of base metal, and high yield strength and tensile breaking strength are achieved.

Owner:天津滨海雷克斯激光科技发展有限公司

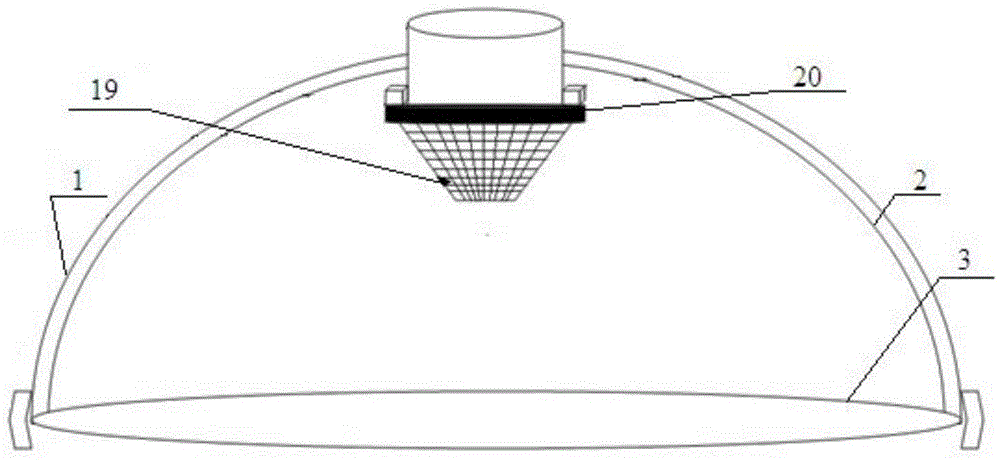

Biophysical warm-tonification medicinal moxibustion instrument adopting traditional Chinese medicine

InactiveCN104666072AEffective preservationSolve the problem of unclear acupoint recognitionDevices for heating/cooling reflex pointsDispersed particle filtrationInsulation layerMedicine

A biophysical warm-tonification medicinal moxibustion instrument adopting traditional Chinese medicine comprises a lead-in device, a medicine reaction chamber, a telescopic device and a smoke purification device. The lead-in device comprises a semispherical cover with the open side down, a reflection board is arranged on the inner side of the cover, an ash isolation net is arranged at the bottom end of the cover and fixedly clamped to the cover, a cavity formed between the ash isolation net and the reflection board serves as a medicine reaction chamber, and a bag filled with traditional Chinese medicine is put in the medicine reaction chamber. The top end of the medicine reaction chamber is provided with a smoke outlet which is communicated with a smoke inlet of the telescopic device, a smoke outlet of the telescopic device is communicated with a smoke inlet of the smoke purification device, and the bottom of the smoke purification device is provided with an air outlet. The instrument is characterized in that a heat insulation layer is arranged between the cover and the reflection board. The biophysical warm-tonification medicinal moxibustion instrument adopting the traditional Chinese medicine has the advantages that the instrument is flexible in use and convenient to operate, heat generated by burning of the bag filled with the traditional Chinese medicine is less prone to dispersion and can act on acupoints for a long time, and curative effects are multiplied due to concentrated lasting fire power.

Owner:刘瑜

Heat dissipation type photovoltaic terminal box

ActiveCN102593216AAvoid burnsNo burnsPhotovoltaicsPhotovoltaic energy generationEngineeringMaterials science

The invention discloses a heat dissipation type photovoltaic terminal box which comprises a photovoltaic terminal box base and a photovoltaic terminal box upper cover which are covered mutually, wherein the photovoltaic terminal box base is internally provided with terminal assemblies, support pieces and diodes, the support pieces are connected with the terminal assemblies, the terminal assemblies which are connected with the support pieces are arranged in the photovoltaic terminal box base and are connected with the photovoltaic terminal box base through the support pieces, and the diodes are arranged among the terminal assemblies. According to the heat dissipation type photovoltaic terminal box, the terminal assemblies are not directly contacted with the photovoltaic terminal box base, so that the photovoltaic terminal box base can be prevented from being burned by the heat of the terminal assemblies; through holes are arranged at positions of the terminal assemblies, which are close to the installing surface so as to form convection; a U-shaped slot leading to an upper space is arranged at the front part of each terminal assembly so as to form convection; and therefore, the convection space is effectively enlarged, the heat dissipation is fast, the photovoltaic terminal box base cannot be burned, and the reliability is high. In addition, a pasting plate is arranged between each diode and the photovoltaic terminal box upper cover, so that the photovoltaic terminal box upper cover can be prevented from being burned by the heat of the diodes.

Owner:浙江正泰鑫辉光伏有限公司

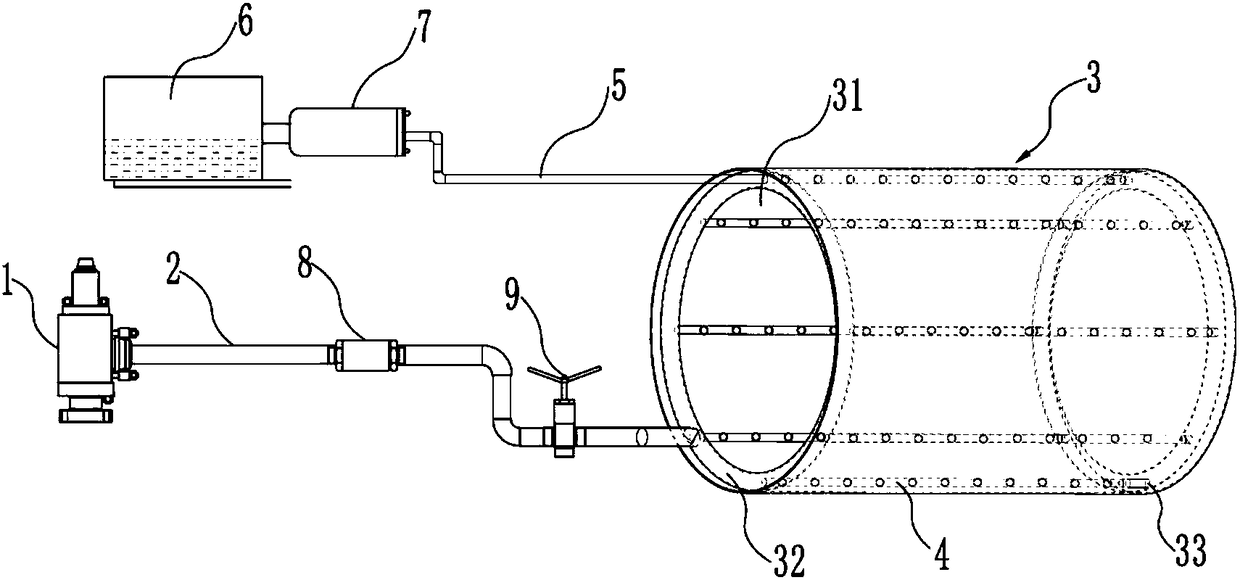

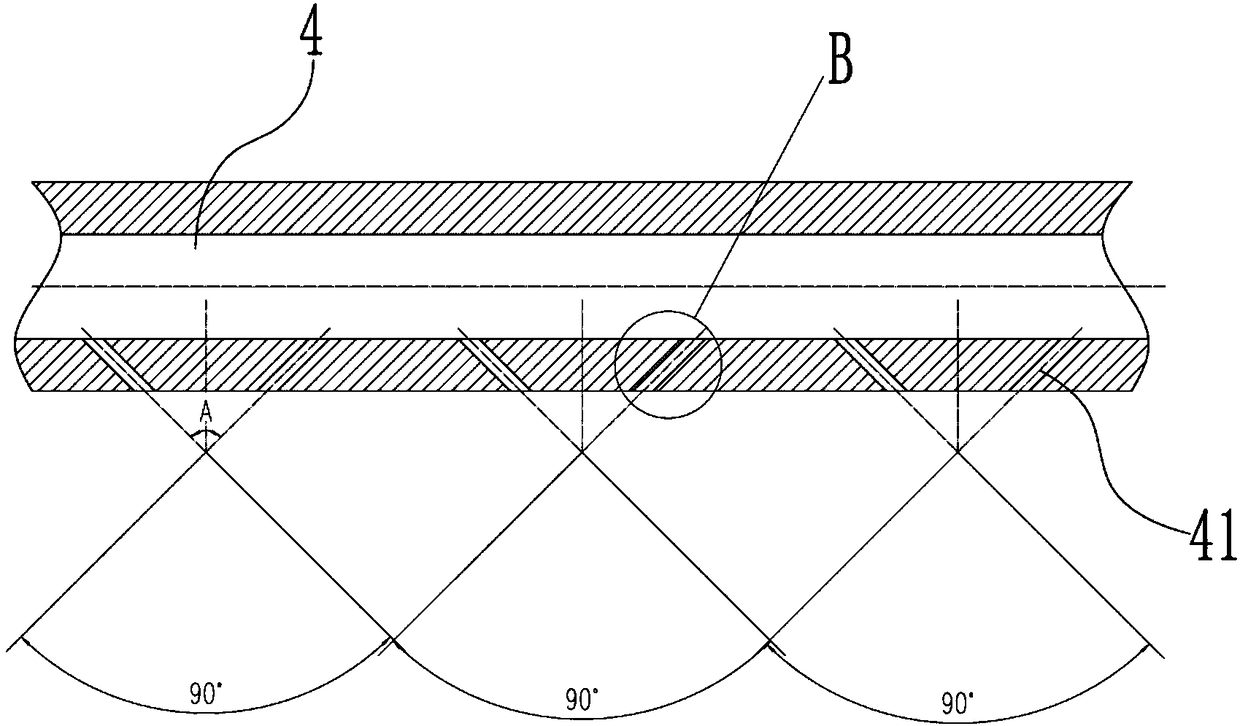

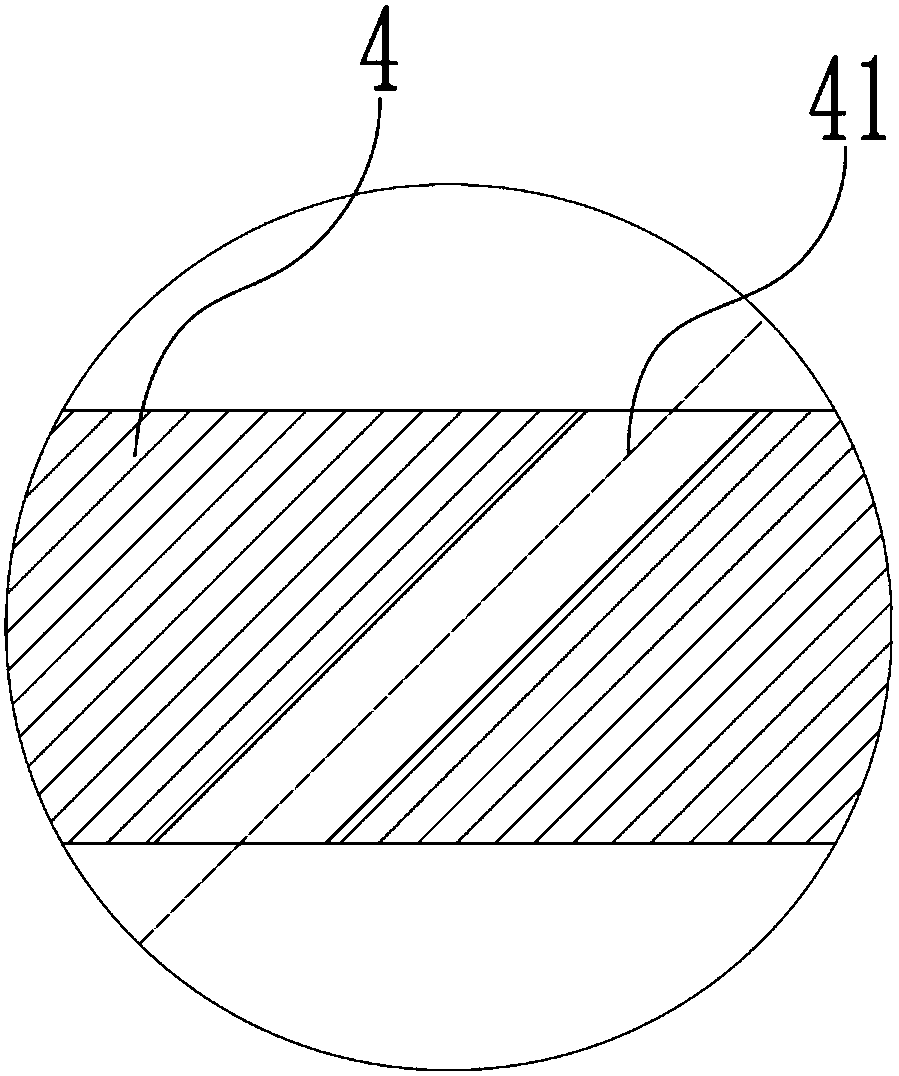

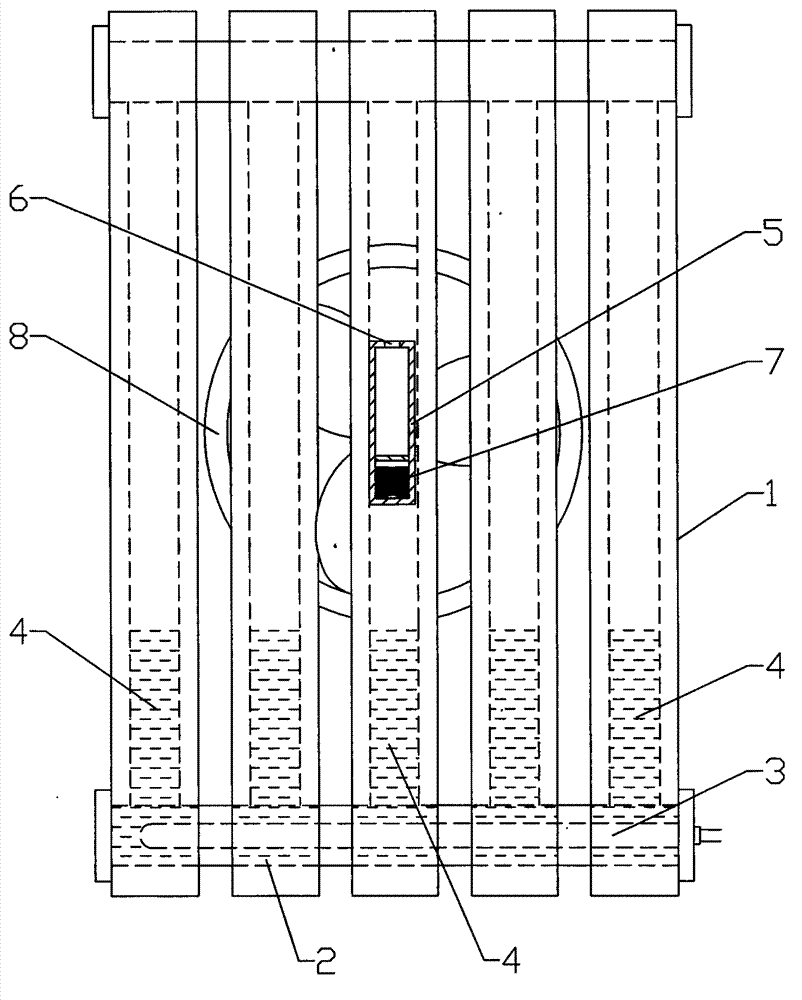

Array self-impact type water-mist cooling device

ActiveCN108518290AWill not deformEliminate injection blind spotsRocket engine plantsEngineeringStructural engineering

The invention belongs to the technical field of ground experiments for liquid propellant rocket engines and discloses an array self-impact type water-mist cooling device with the aim of resolving theproblem in the prior art of incomplete cooling of a cooling device. The device comprises a fire hydrant, a main liquid supply pipeline and a drainage drum. The drainage drum comprises a drum body andannular liquid collection cavities arranged at two ends of the drum body. One end of the main liquid supply pipeline communicates with the fire hydrant and the other end thereof communicates with oneof the annular liquid collection cavities. At least four injection pipes are arranged between the two annular liquid collection cavities and fixed on the inner wall of the drum body along the axial direction and extend from one end of the drum body to the other end thereof. Lines of main injection holes are arranged along the length directions of the injection pipes. The main injection holes are slant hole passages communicating with the injection pipes. The center lines of two adjacent slant hole passages intersect at one point. After the point of intersection departs from the inner wall of the drum body, two main injection holes firstly intersecting with each other become a pair. Center lines of the main injection holes intersect to form an included angle A. The angular bisector of the included angle A is vertical to pipe walls of the injection pipes.

Owner:SHAANXI AEROSPACE ELECTROMECHANICAL ENVIRONMENTAL ENG DESIGNING INST CO LTD

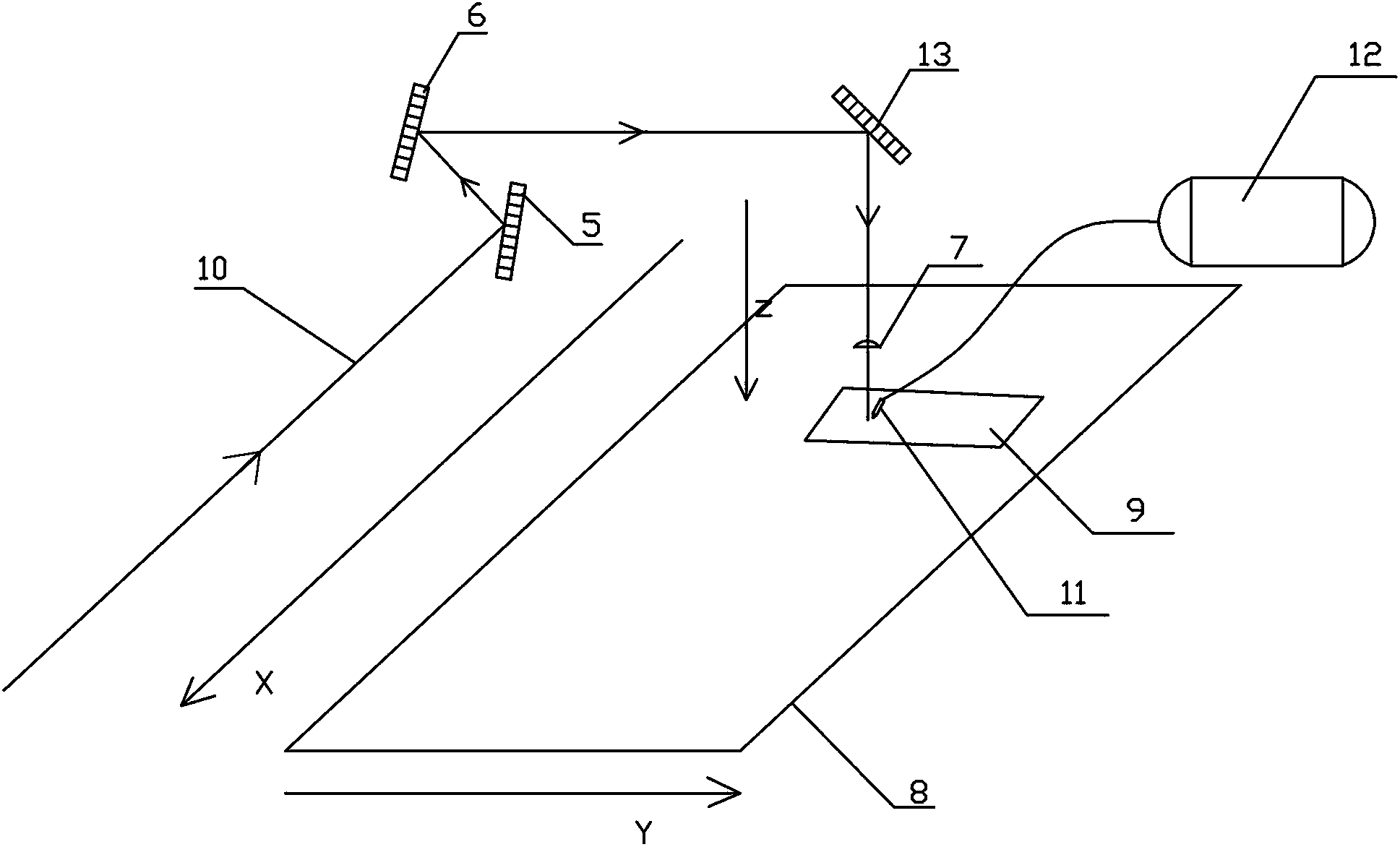

Nitrogen laser cutting machining device for saw blade base body

InactiveCN103658996AAvoid chemical reactionsReduce the temperatureMetal sawing tool makingLaser beam welding apparatusGear grindingChemical reaction

A nitrogen laser cutting machining device for a saw blade base body comprises a laser cutting machine, and a laser beam passes a first copper reflector, a copper polarizer, a second copper reflector and a focus lens to act on a workpiece to be cut. One side of the workpiece to be cut is provided with a nitrogen nozzle which is connected with a nitrogen supplying device. The nitrogen laser cutting machining device has the following advantages that materials are melted completely through the laser energy during nitrogen cutting, the nitrogen blows molten slag in a cutting gap out, and inappropriate chemical reaction is avoided. The temperature of a melting point area is relatively low, and due to the fact that the nitrogen has the functions of cooling and protecting, the thermal deformation is small, the reaction is stable and even, and the cutting quality is high. The fracture surface is fine and smooth, the surface roughness is low, and an oxidation layer does not exist. The precision of the saw blade base body cut by the nitrogen laser is high, an installing hole does not deforme, the tooth part is not burned, the gear grinding allowance before a welding cutting head is small or gear grinding does not exist, and the quality of the base body is obviously improved. A cutter is not abraded in the process of machining, and the consistency of products is high during the batch processing.

Owner:HEIXUANFENG SAW IND

Special PE-coated paper and preparation method thereof

InactiveCN104149413ANo stratificationNo color lossSynthetic resin layered productsMetal layered productsLow-density polyethylenePolymer science

The invention discloses special PE-coated paper and a preparation method thereof. The PE-coated paper adopts kraft paper as a base and adopts low-density polyethylene as a bonding medium, and an aluminum laminated film and the kraft paper are bonded together; the preparation method comprises the following steps: arranging the aluminum laminated film at a front station, arranging the kraft paper at a rear station, and arranging the low-density polyethylene at a middle station, melting at 175-330 DEG C in a machine barrel, filtering by a filter, casting a PE film through a high-temperature casting manner of a die head at 310-330 DEG C, bonding the aluminum laminated film and the kraft paper by the cast PE film, and pressing, carrying out knurling and shaping instantly by a refrigerating knurling roll and a refrigerating silicone rubber roll. When the prepared special PE-coated is slightly torn in different environments of 0-35 DEG C, no layering phenomenon occurs to an aluminum layer, a color layer, a PE layer, a film layer and a kraft paper layer, the film surface color is permanent, the problems of obvious color blackspot and color fading due to high temperature are avoided, and the finished product has no color loss when being wiped by solution.

Owner:GUANGZHOU HENGRUI NON WOVEN FABRIC

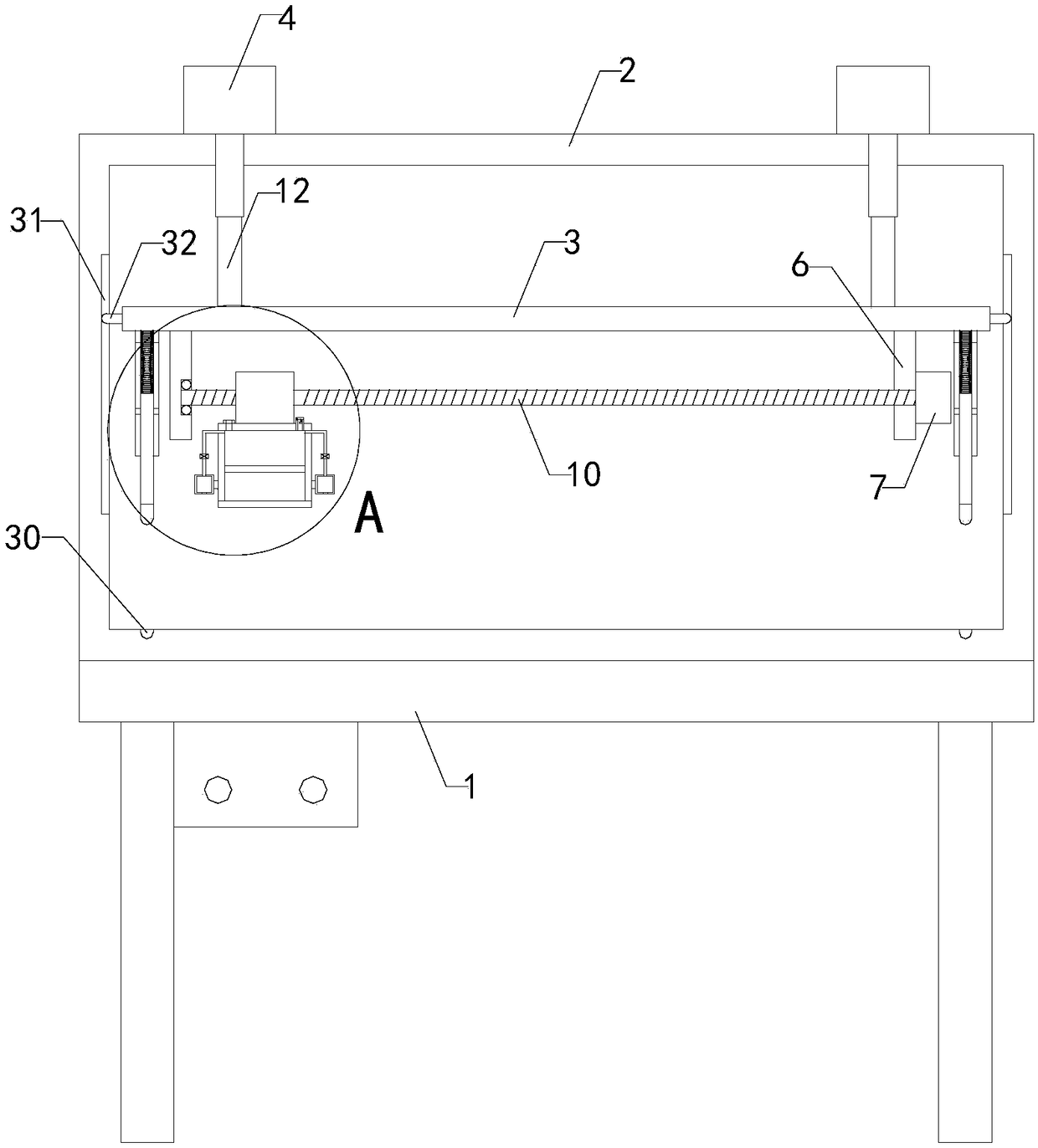

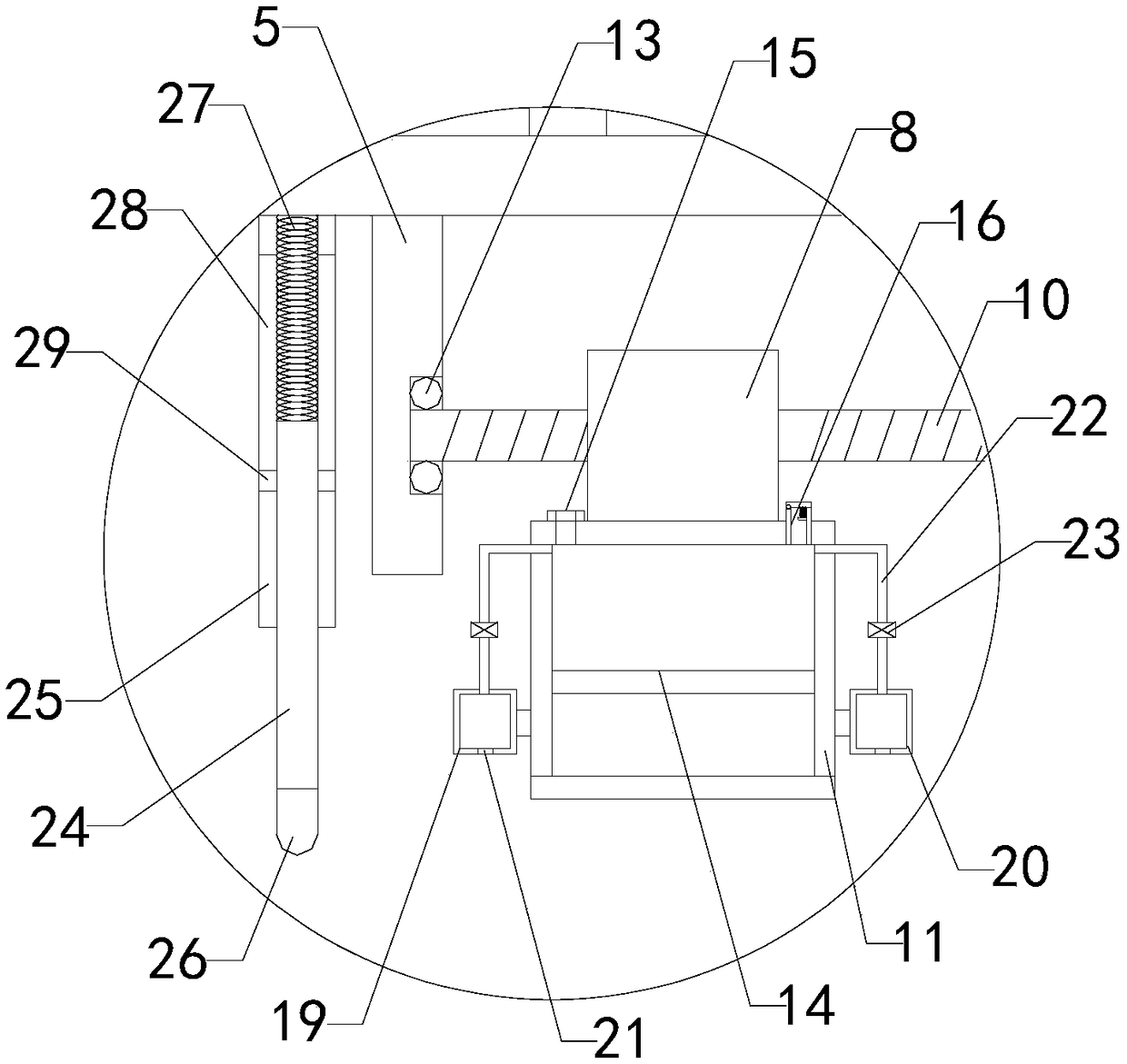

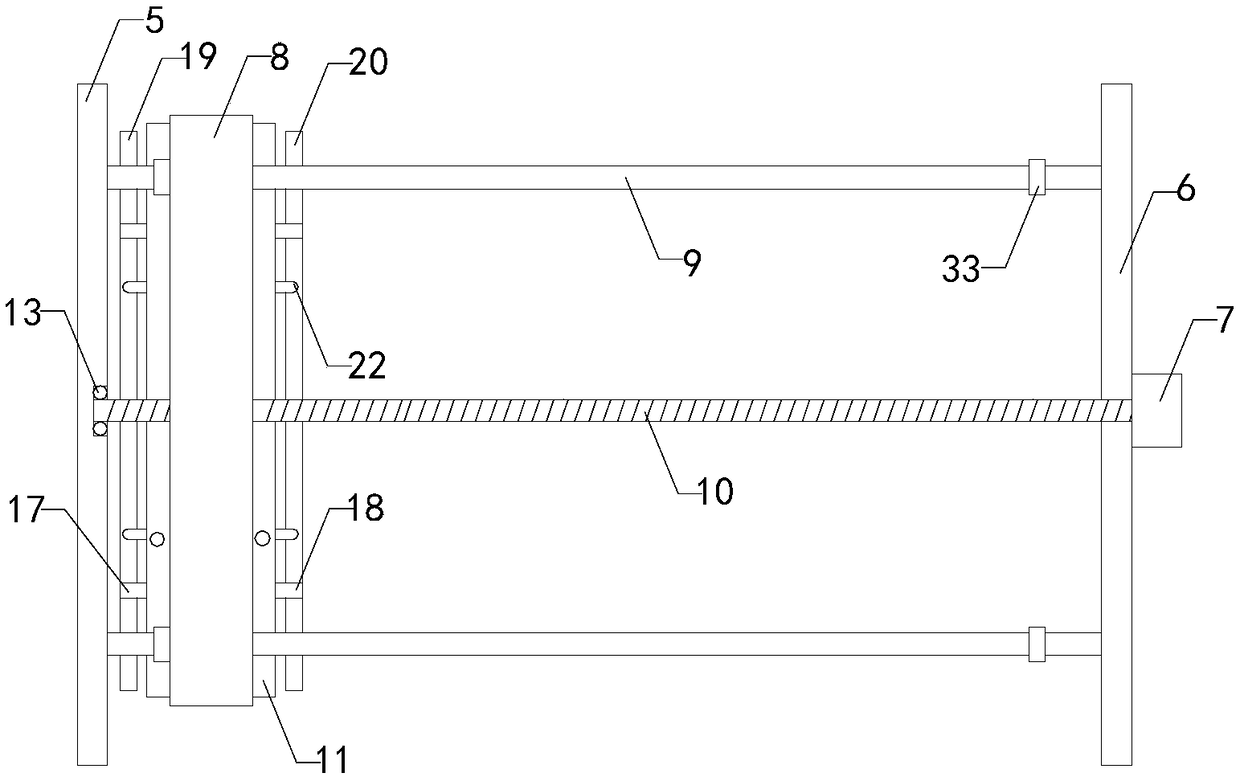

Fabric ironing device for garment processing

InactiveCN109371646ANo burnsImprove ironing effectIroning machinesTextile treatment by spraying/projectingExhaust valveBall bearing

The invention relates to the technical field of garment processing affiliated devices, in particular to a fabric ironing device for garment processing. The device has the advantages that the automation degree is high, labor force is saved, labor cost is reduced, the practicability is improved, the working efficiency is improved, production demands are met, potential safety hazards are reduced, andthe using reliability is improved. The device comprises a rack, a box body, a lifting and lowering platform, an air cylinder group, a left supporting plate, a right supporting plate, a driving motor,a sliding plate, two groups of limiting rods, a lead screw, a heating box, a piston rod, a rolling bead bearing and a heating bar, openings are formed in front and rear ends of the box body, the topof the heating box is provided with a water adding port and a gas discharging port, the water adding port and the gas discharging port are provided with a cover plate and a gas discharging valve respectively, two groups of left fixing rods, two groups of right fixing rods, a left spraying pipe, a right spraying pipe, a spraying hole and two groups of steam pipes are included, the two groups of steam pipes are communicated with a placing cavity, and electromagnetic valves are arranged on the two groups of the steam pipes.

Owner:YANCHENG DIJIANI CLOTHING

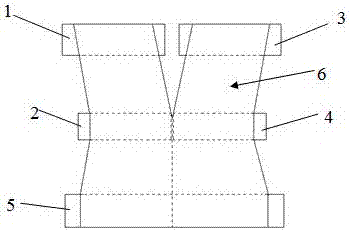

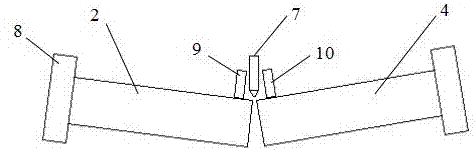

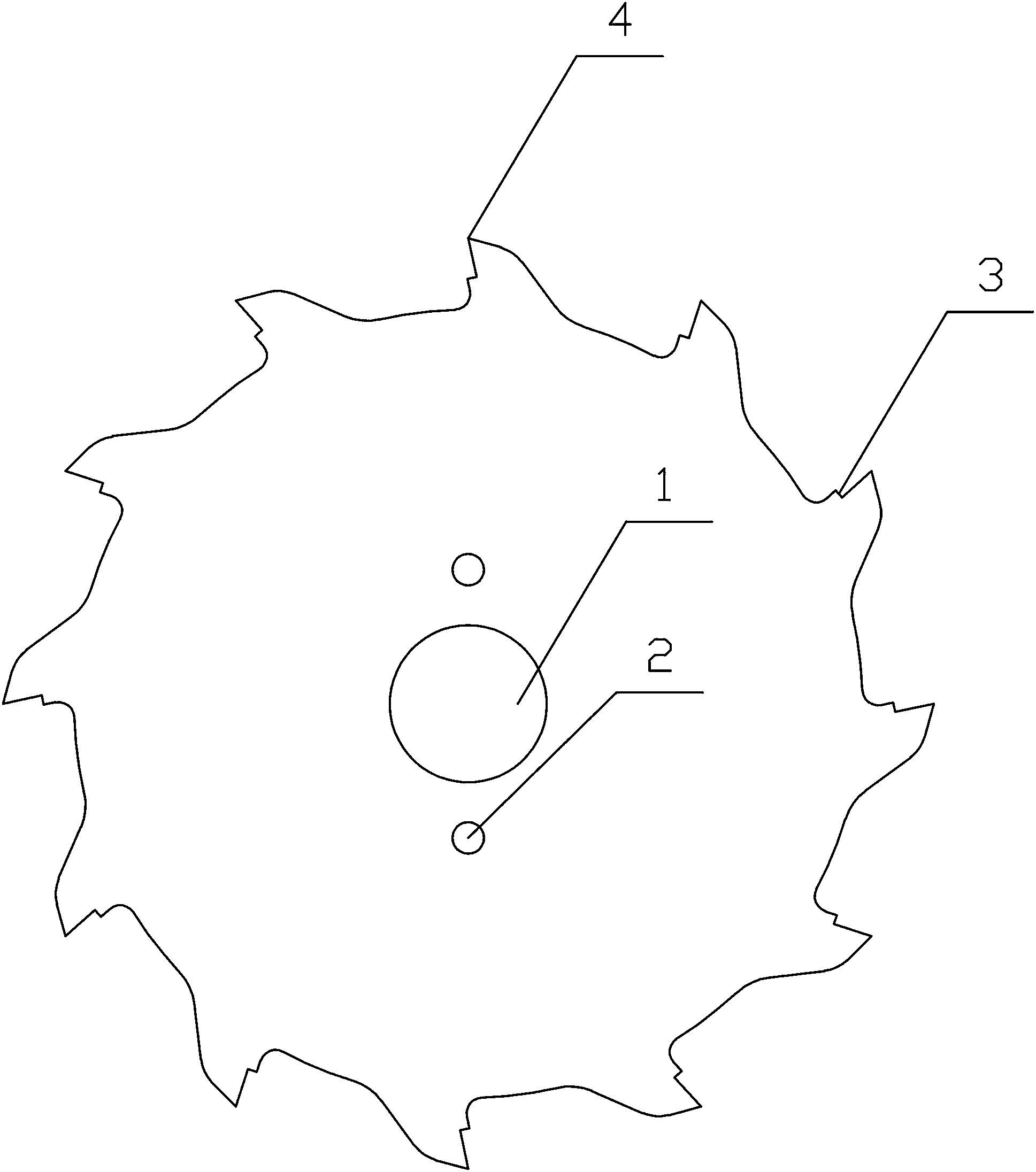

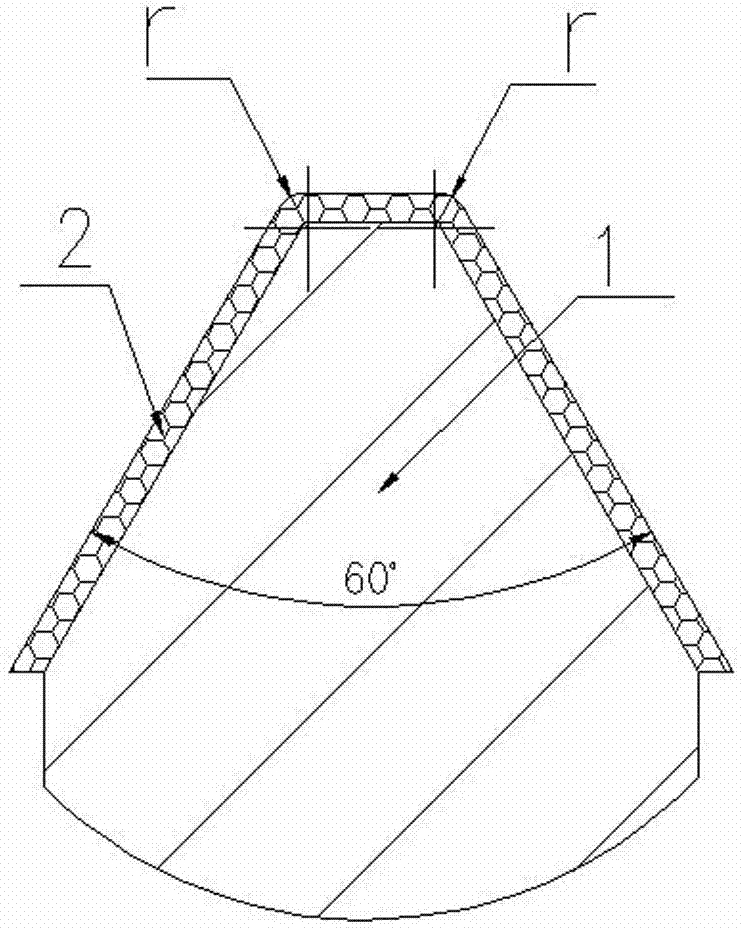

Electroplating CBN grinding wheel for efficient and precise gear profile grinding and manufacturing method of electroplating CBN grinding wheel for efficient and precise gear profile grinding

ActiveCN103878705AImprove mass distributionIncrease limit speedBonded abrasive wheelsIsosceles trapezoidAdsorptive membrane

The invention relates to an electroplating CBN grinding wheel for efficient and precise gear profile grinding. The electroplating CBN grinding wheel comprises a dish-shaped base body and a material grinding area at the edge of the dish-shaped base body, the mass of the material grinding area is 4%-15% of the total mass of the base body, the cross-section of a material grinding layer on the material grinding area is in an isosceles trapezoid shape, and the upper bottom and the two lateral edges are chamfered. A manufacturing method of the electroplating CBN grinding wheel includes the steps of firstly machining the base body of the grinding wheel, and then sequentially conducting negative and positive pole alternative electrochemistry oil removing, clamp and electrostatic adsorption film insulation assembling, negative and positive pole alternative electrolytic treatment, ballistic method preplating, grinding material assembling, thickening and grinding wheel electroplating on the base body of the grinding wheel. The using linear velocity of the electroplating CBN grinding wheel can achieve 250 m / s, and the grinding feeding amount achieves 4 m / min-10 m / min and is much higher than that of a common grinding wheel. The roughness Ra can achieve 0.4 micrometers, the surface quality requirement of a workpiece can be met, and gear efficient and precise gear profile grinding can be successfully achieved.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Composite chitosan dressing

InactiveCN103536955ANo burnsStorage conditions without any restrictionsAdhesive dressingsAbsorbent padsDressing changeLamellar structure

The invention relates to a composite chitosan dressing, and belongs to the technical field of hemostatic materials. The composite chitosan dressing is of a layered structure with a functional layer, wherein the functional layer is formed by compounding a chitosan recovery promoting layer and a chitosan hemostasis layer; the functional components of the functional layer contain no other components except for chitosan. The composite dressing plays the role by directly contacting with red blood cells and blood platelets without depending on in-vivo hemostasis mechanisms, moreover no irritability is caused, no heat is released, and the role can come into play under the condition of low body temperature. The composite chitosan dressing provided by the invention is applicable to gynaecology and obstetrics surgery, endoscope minimally invasive surgery, general surgery department surgery, open type wound of orthopaedics departments, plastic and aesthetic surgery, outpatient service and emergency treatment trauma, superficial skin ulcer and the like, and can be applicable to wound fixation, nursing and dressing change of various puncture, conduits and cathetering, and to nursing and dressing change of wound and wound surfaces of individual bruise, contusion, knife wound, small-area burn and the like. The composite chitosan dressing has the effects of hemostasis, heal prompting, analgesia, antibiosis and scar generation prevention.

Owner:UNION MEDICAL SUPPLIES

Multifunctional electric heater

InactiveCN102927611AHeating fastRapid expansionLighting and heating apparatusElectric heating systemWater storageRoom temperature

The invention relates to a multifunctional electric heater which comprises a radiating main body, wherein a heating cavity is arranged in the radiating main body, electric heating elements and heating media are arranged in the heating cavity, and a humidifying device is arranged on the outer surface of the radiating main body. The humidifying device comprises a water storage box arranged on the radiating main body and a water outlet arranged on the water storage box, wherein an electric vibrator opposite to the water outlet is arranged in the water storage box, and an auxiliary element used for fastening heat circulation is further arranged on the outer surface of the radiating main body. The heating media in the heating cavity are heated through the electric heating elements and gradually diffuse in the whole peripheral space with heated air serving as heat transfer medium to form hot air circulation. Water in the water storage box is changed to vapor and escapes from the water outlet position. The vapor temperature at the time is room temperature so that the phenomena of scalding and water dropping are avoided during use, and the multifunctional electric heater is good in humidifying effect.

Owner:QINGZHOU SHENGHONG IND & TRADE

Hot compress dressing and preparation method thereof

InactiveCN109674574AFast heatingLong time feverTherapeutic coolingTherapeutic heatingActivated carbonHeating time

The invention discloses a hot compress dressing and a preparation method thereof. The hot compress dressing is prepared from the following raw materials in parts by weight: 2-4 parts of vermiculite, 2-3 parts of activated carbon, 1-2 parts of sodium chloride, 45-48 parts of iron powder and 22-28 parts of water. Raw material components and proportion are specifically adjusted, so that heating rateof dressing is higher, heating time is longer and hot compress effect is better. A method for repeatedly adding sodium chloride solution into mixture is adopted for restraining the oxidation reactionrate in dressing, so that the heating time of dressing is longer, the hot compress effect is better, scald caused by high temperature can be avoided and use is safer.

Owner:山西康宁医药科技有限公司

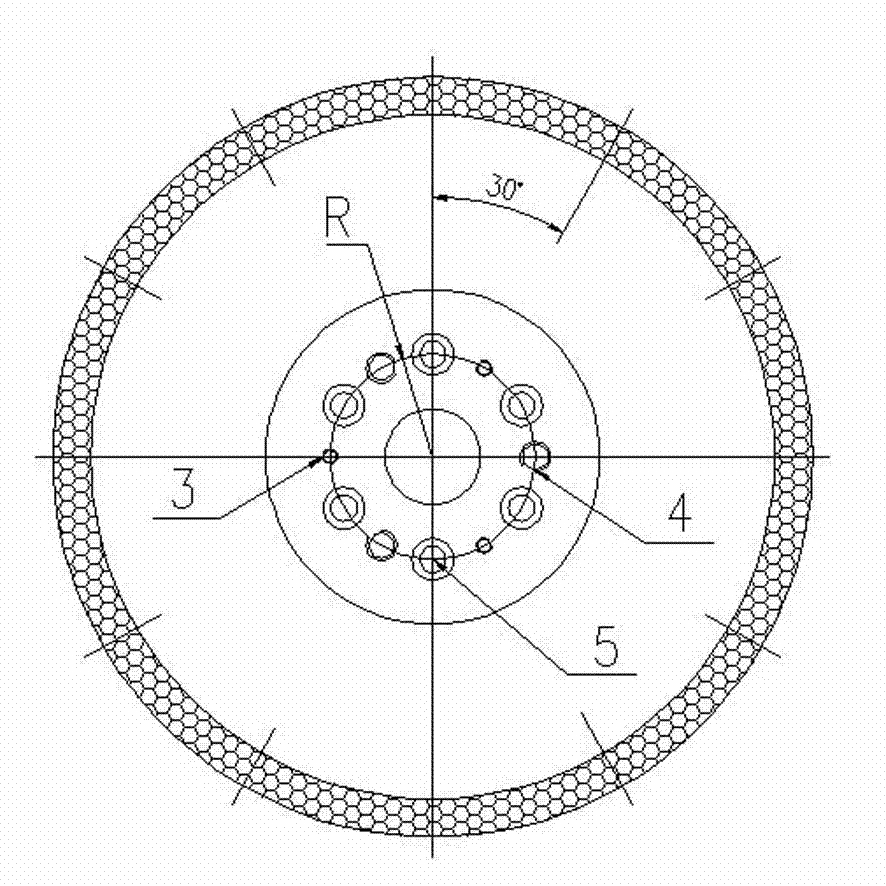

Combined plating CBN grinding wheel for camshaft grinding and manufacturing method thereof

ActiveCN109551383AMeet surface quality requirementsNo burnsBonded abrasive wheelsGrinding devicesSurface roughnessEngineering

The invention discloses a combined plating CBN grinding wheel for camshaft grinding and a manufacturing method thereof, belonging to the technical field of design and manufacture of abrasive grindingtools. The combined plating CBN grinding wheel for camshaft grinding comprises a camshaft and a combined plating CBN grinding wheel sleeving a main shaft for grinding different parts of the camshaft;one side, far away from the combined plating CBN grinding wheel, of the camshaft is abutted against a guide wheel; the combined plating CBN grinding wheel comprises a grinding wheel for grinding big end excircle and end face, a grinding wheel for grinding big end excircle journal and a plurality of grinding wheels for grinding excircle journal; and the molded surfaces of the grinding wheel for grinding big end excircle and end face and the grinding wheel for grinding big end excircle journal are matched. The invention is suitable for one-time grinding of a plurality of excircle journals of thecamshaft, can process a plurality of journals and big end of the camshaft at a time, improves the processing efficiency and ensures the surface roughness of the processed workpiece being smaller thanRz 10.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Mongolian medicine Garixi and preparation method thereof

InactiveCN106994173AGood treatment effectQuick effectPowder deliveryDigestive systemSide effectMedicine

The invention discloses a Mongolian medicine Garixi and a preparation method thereof. The Mongolian medicine Garixi is prepared from 250g of dry dung of wild boar, 100g of round cardamom fruit, 50g of ox bile powder, 125g of fructus forsythiae, 50g of fruit cluster of long pepper, 200g of pomegranate fruit, 125g of semen momordicae, 75g of halite, 250g of fructus chebulae, 22.5g of cortex cinnamomi, 50g of radix inulae racemosae, 200g of rhizome of Chinese rhubarb, 100g of rhizoma kaempferiae, 250g of north gypsum rubrum (calcined) and 300g of tronae; the preparation method comprises the steps of weighing the ingredients according to weight proportion, crushing the ingredients into fine powder, screening and mixing, thus obtaining the Mongolian medicine Garixi. The Mongolian medicine Garixi and the preparation method thereof have the advantages that the curative effect on digestive system disease is remarkable, the Mongolian medicine Garixi and the preparation method thereof are economical and reasonable, a technology is simple, and side effects are avoided.

Owner:巴音郭楞蒙古自治州第二人民医院

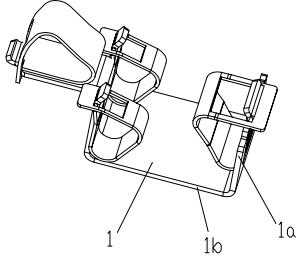

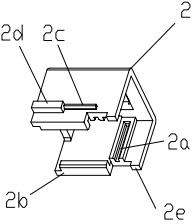

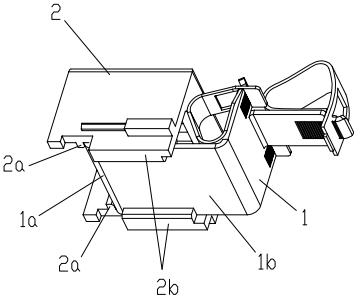

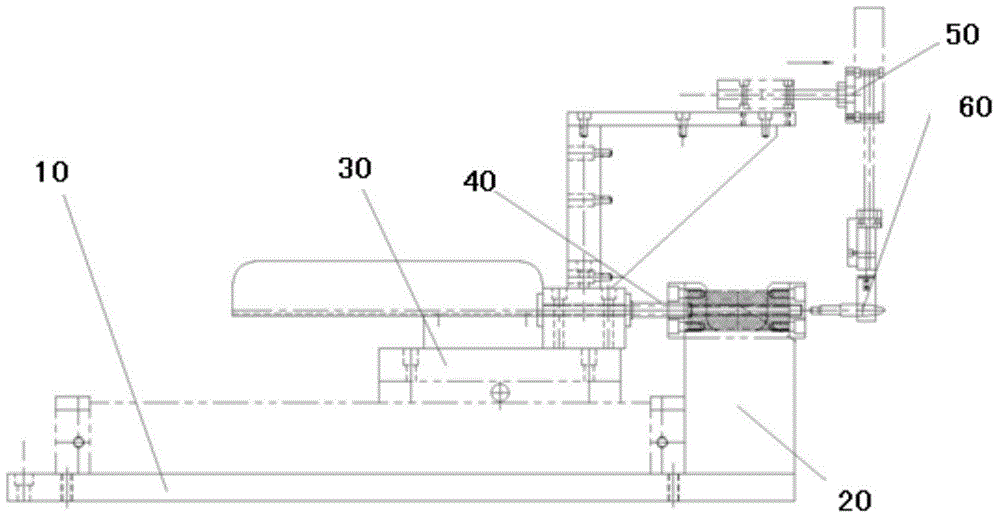

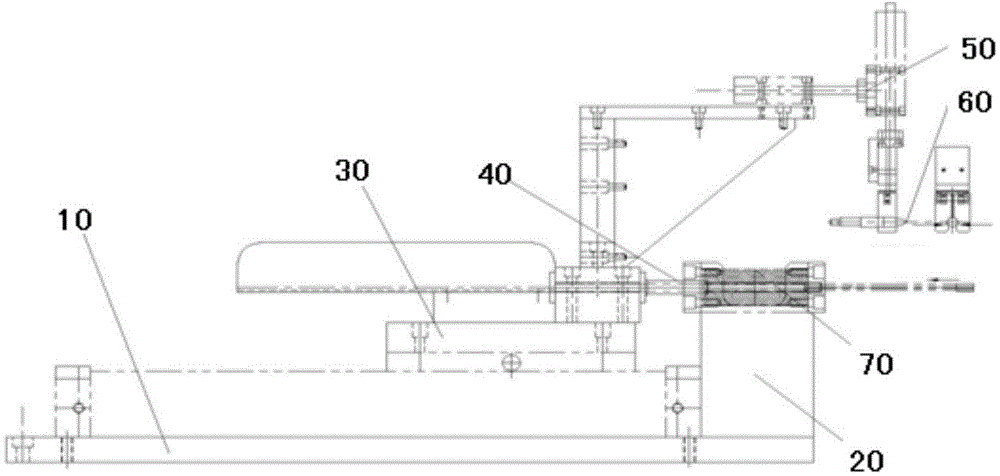

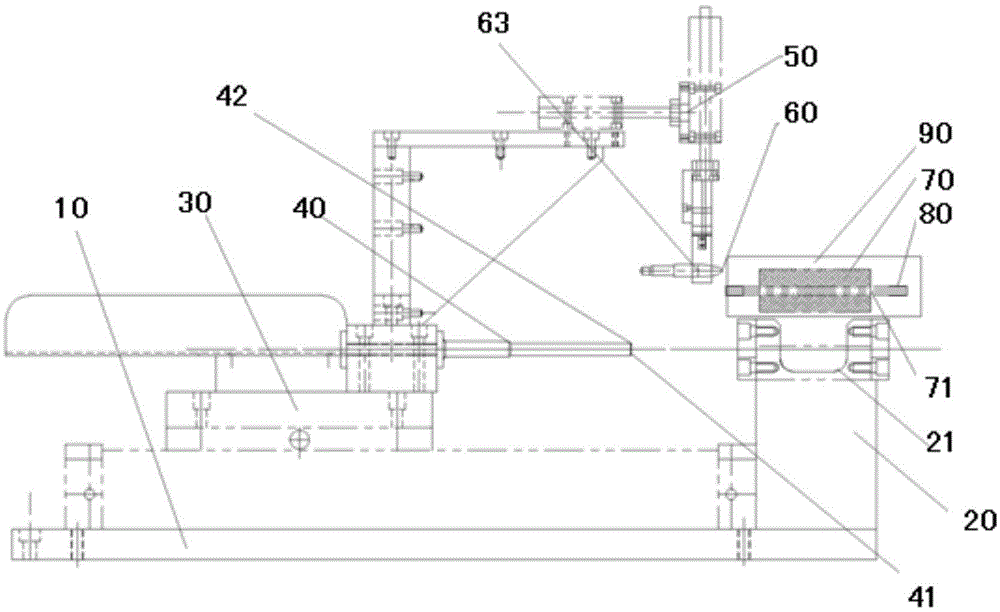

Penetrating and mounting machine of elastic part and penetrating and mounting method thereof

InactiveCN104972288AOvercome shortcomings such as insufficient rigidityOvercome the disadvantage of high noise in air pressure dressingMetal working apparatusPush pullEngineering

The invention discloses a penetrating and mounting machine of an elastic part and a penetrating and mounting method thereof. The penetrating and mounting machine of the elastic part comprises an engine base, a clamping seat, a push-pull mechanism and a mechanical arm, wherein the clamping seat is arranged on the engine base, the push-pull device is arranged on the engine base, the push-pull device and the clamping seat are symmetrically arranged, the mechanical arm is arranged on the engine base, the clamping seat is provided with a cavity which is used to clamp an elastic part, a guide piece is driven by the push-pull mechanism to go forward and retreat, the mechanical arm is used to detachably mount a guide head onto the guide piece to face to the end portion of the elastic part, the guide head comprises a joint end and a guide end, the joint end is arranged on the end portion of the guide piece, and is used to connect the guide piece and the guide head together, the guide end plays the role of expansion and guidance when being inserted into an interference assembly hole of the elastic part, the guide end is of a bullet-shaped structure which is gradually bigger from a tip along an axial direction, the biggest position of the outer diameter of the guide end is same to the outer diameter of the guide piece, the joint end is of a step shaft shape, and further comprises a joint segment, and the outer diameter of the biggest cross section of the joint segment is same to the inner diameter of the guide piece, thereby being capable of conveniently mounting the guide head and the guide piece. The penetrating and mounting machine of the elastic part and the penetrating and mounting method thereof guarantee mounting quality and improve yield at the same time, also can be lightly penetrated and mounted, improve efficiency, reduce labor strength, do not have noise during production process, do not have scald, and are environmentally friendly and safe.

Owner:DURA GANXIANG AUTOMOTIVE SYST SHANGHAI

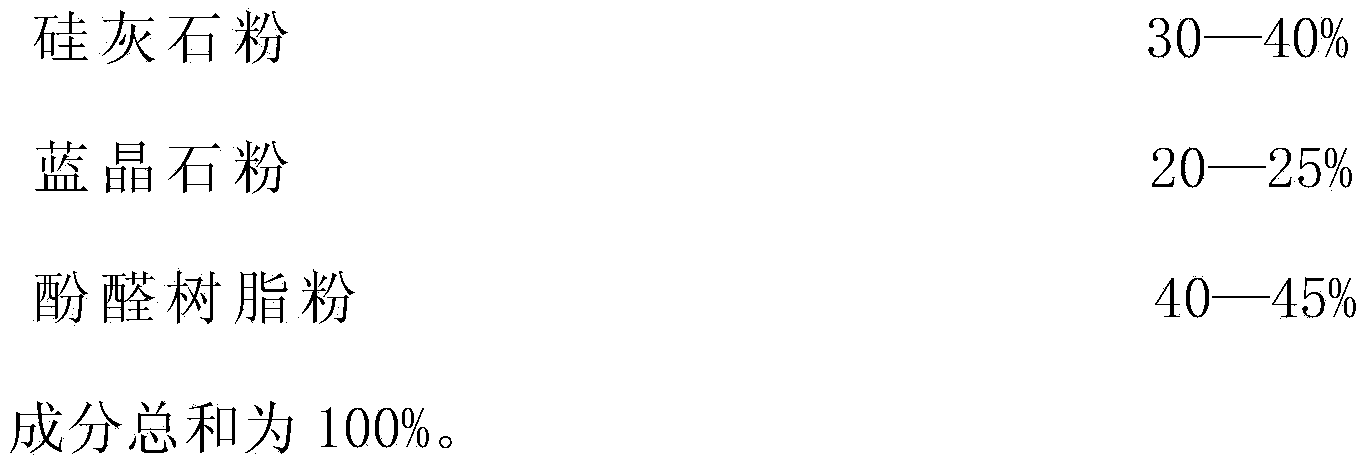

Steel rail grinding wheel allowing less grinding smoke and dust and production method thereof

ActiveCN103406838AImprove grinding sharpnessAvoid burnsAbrasion apparatusGrinding devicesSulfur containingSmoke

The invention discloses a steel rail grinding wheel allowing less grinding smoke and dust and a production method thereof. According to the production method of the steel rail grinding wheel allowing the less grinding smoke and dust, cyanite powders and wollastonite powders are used to replace the ferrous sulfide mineral powder filler of an original grinding wheel; the cyanite powders and the wollastonite powders are served as the filler to be uniformly combined together to form into the binding agent which guarantees the intensity of grinding wheel; sulfur-containing harmful gases are not generated during the grinding process and the intensity of the grinding wheel is greatly improved due to the fact that the cyanite powders and the wollastonite powders are served as the filler of the grinding wheel; the grinding sharpness of the grinding wheel is remarkably improved, steel rail surface burn caused by grinding is effectively avoided, and the operation of the production method is convenient due to the fact that a small amount of white corundum and fused zirconia alumina are mixed to be used.

Owner:江苏新砺河磨具科技有限公司

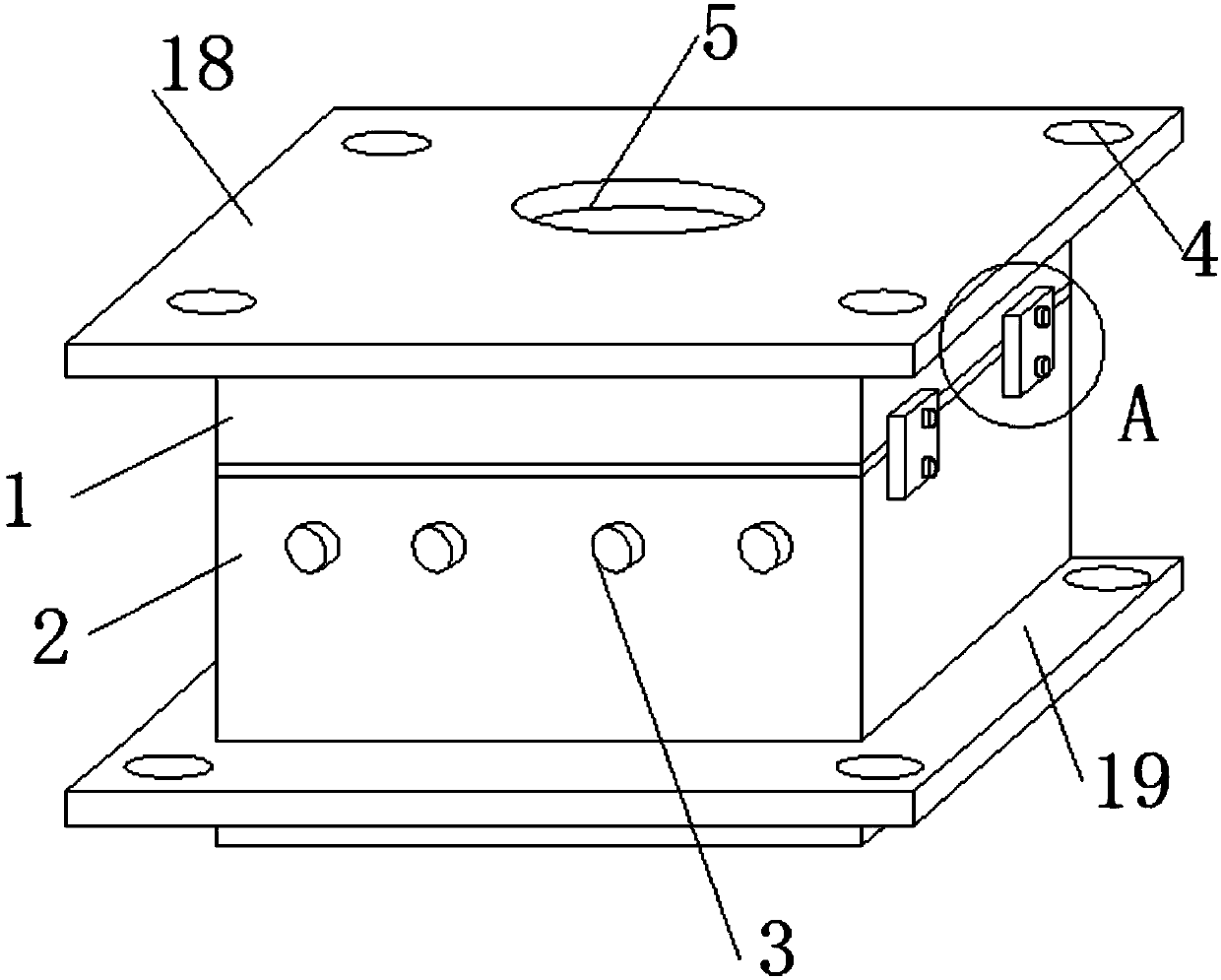

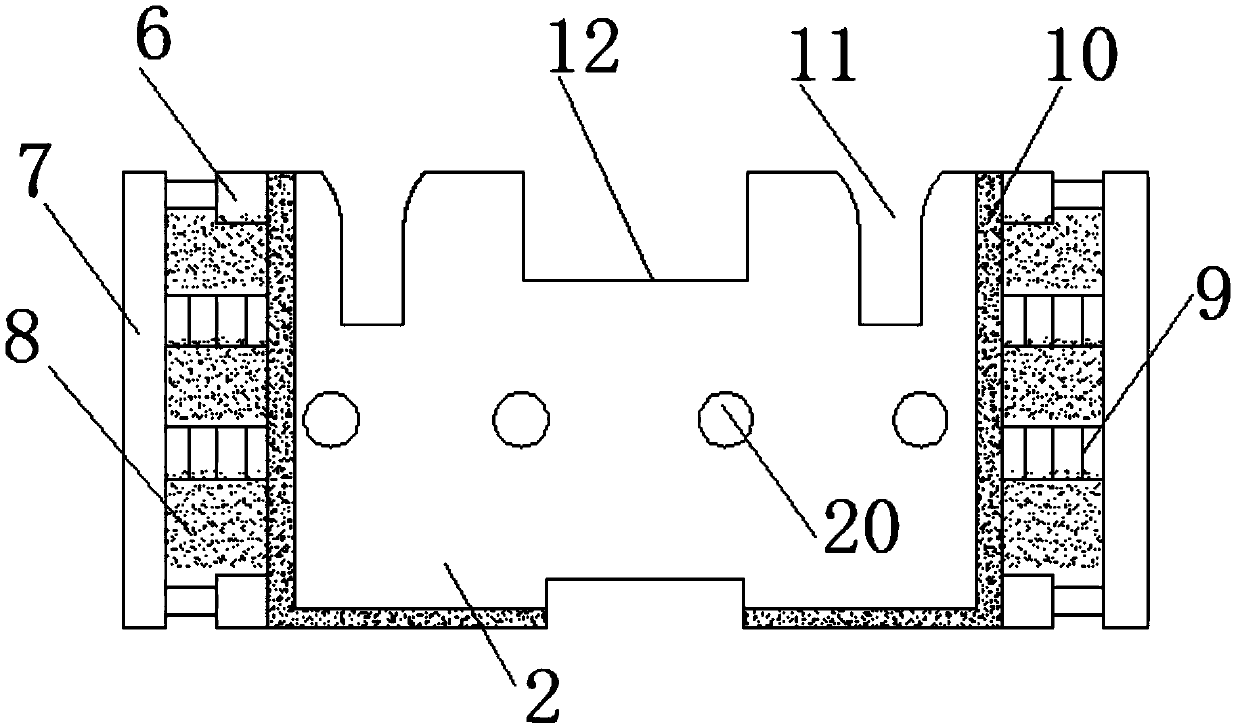

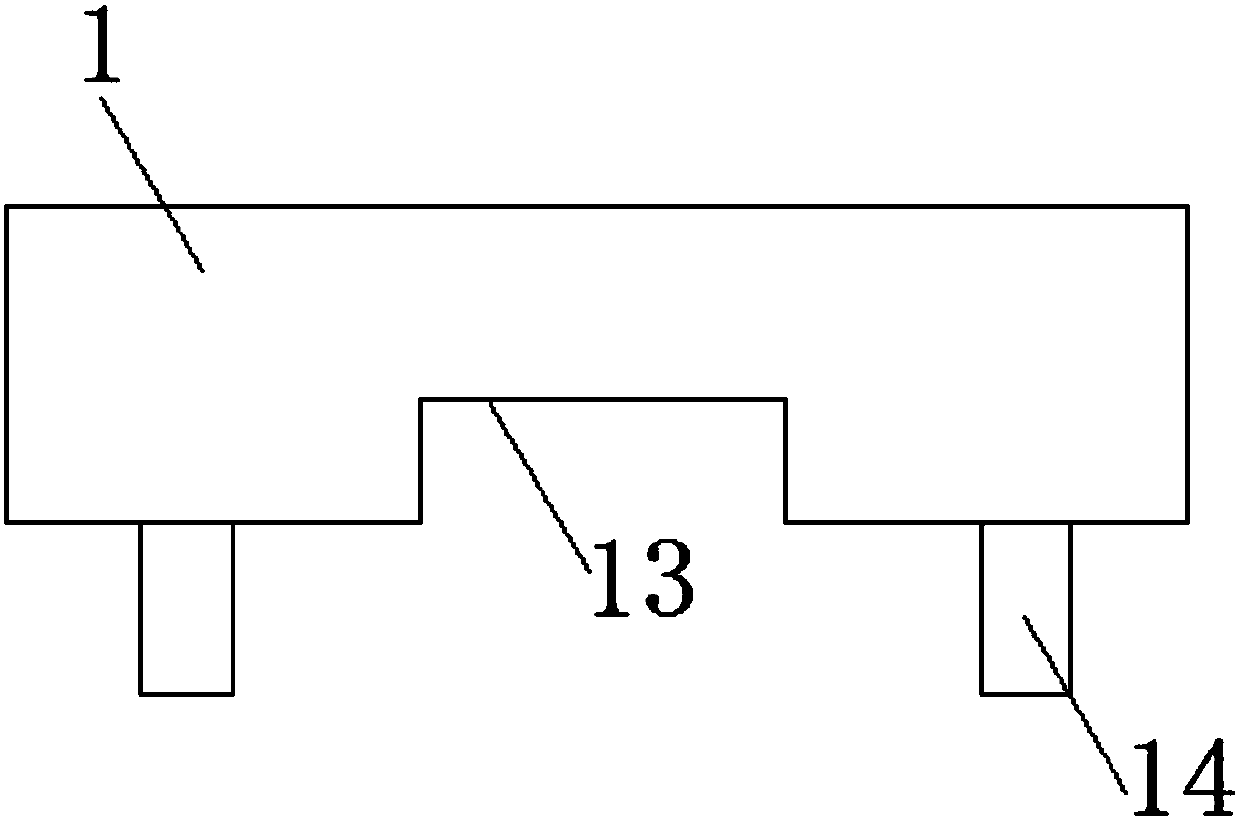

Precision injection mold

The invention discloses a precision injection mold, which comprises an upper mold, a lower mold, a heating rod, a bolt hole, a positioning hole, a telescopic column, a baffle, a buffer layer, a damping spring, an asbestos layer, perforations, a lower mold cavity, and an upper mold Cavities, limit posts, coil springs, fastening bolts, connecting plates, top plates, bottom plates and mounting holes. The beneficial effects of the present invention are: by connecting the baffles on both sides of the upper mold and the lower mold, and filling the elastic buffer material between the two mold bodies and the baffles, and installing shock-absorbing springs and telescopic columns, the working baffles The two phantoms can be protected from damage. During transportation or handling, when the mold collides or is squeezed, the two mold bodies and the mold cavity inside are not easily damaged and deformed, ensuring that the mold can work safely and efficiently without easily affecting its precision. The injection mold is convenient and quick to install, saves energy, and has high work safety performance and precision performance.

Owner:惠州市利尔康精密五金有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com