Nitrogen laser cutting machining device for saw blade base body

A technology of laser cutting and processing equipment, which is applied in the manufacture of cutting tools of sawing machines, metal sawing equipment, laser welding equipment, etc., and can solve the problems of easy burns of tooth tips and tooth seats, increased grinding allowance, and distortion of mounting holes, etc. problems, to achieve the effect of strong product consistency, small grinding allowance, and improved matrix quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

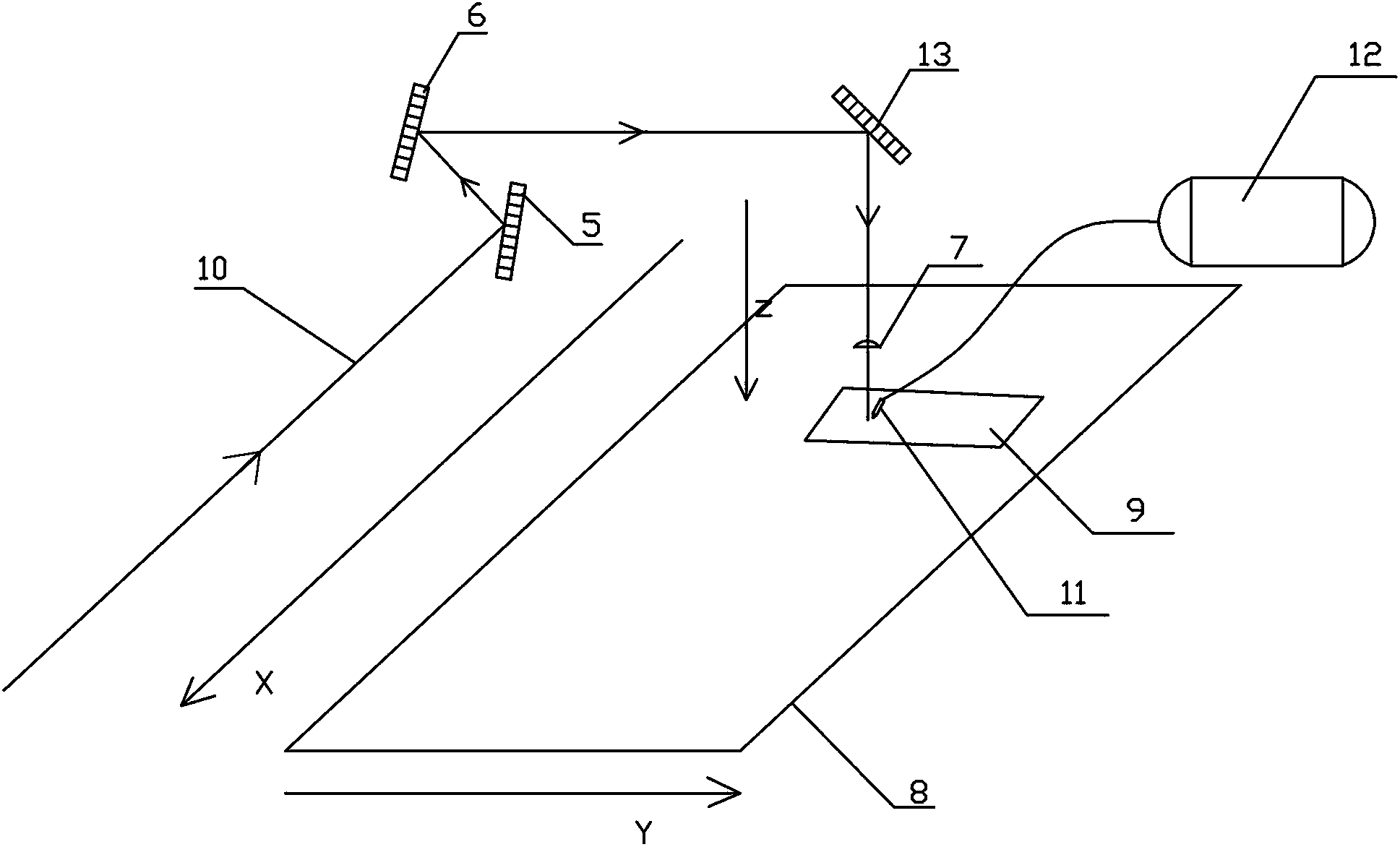

[0024] Such as figure 1 Among them, a saw blade substrate nitrogen laser cutting processing device, including a laser cutting machine, the laser beam 10 acts on the workpiece to be cut after passing through the first copper reflector 5, copper polarizer 6, second copper reflector 13 and focusing mirror 7 9; A nitrogen nozzle 11 is provided on one side of the workpiece 9 to be cut, and the nitrogen nozzle 11 is connected to a nitrogen supply device 12 .

[0025] The air pressure in the nitrogen supply device 12 is 12-18 bar, that is, the inlet pressure is 12-18 bar. The nitrogen purity in the nitrogen supply device 12 is ≥99.8%. The nozzle model is a single layer, and the diameter of the gas outlet of the nitrogen nozzle 11 is 1.5-2.5 mm. The distance between the nitrogen nozzle 11 and the workpiece to be cut is 0.5-1.5 mm.

[0026] The laser output power of the laser cutting machine is ≥2000W, and the mode of the laser beam 10 is TEM00 or TEM01. The laser beam 10 adopts a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com