Patents

Literature

131results about How to "Density is accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

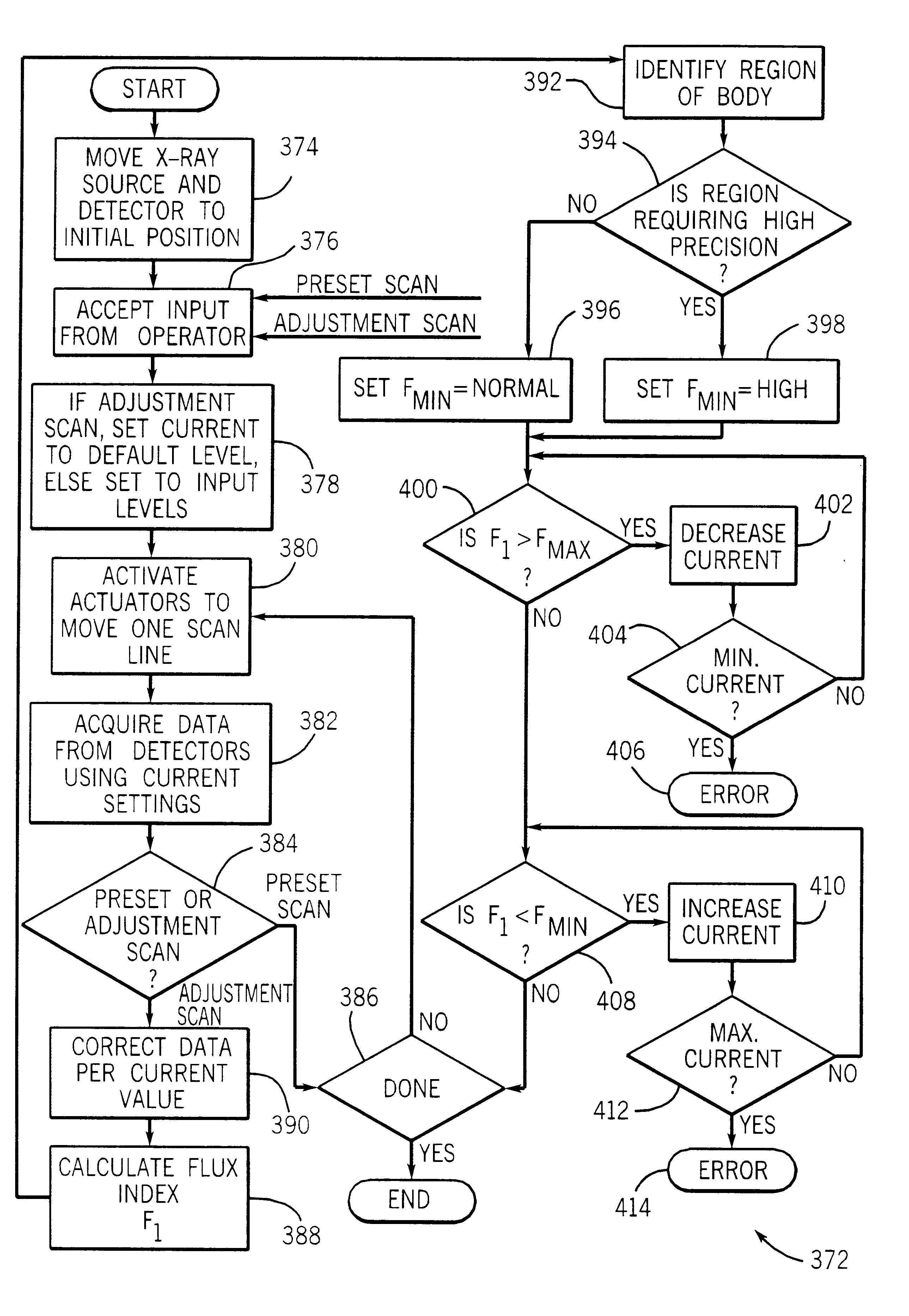

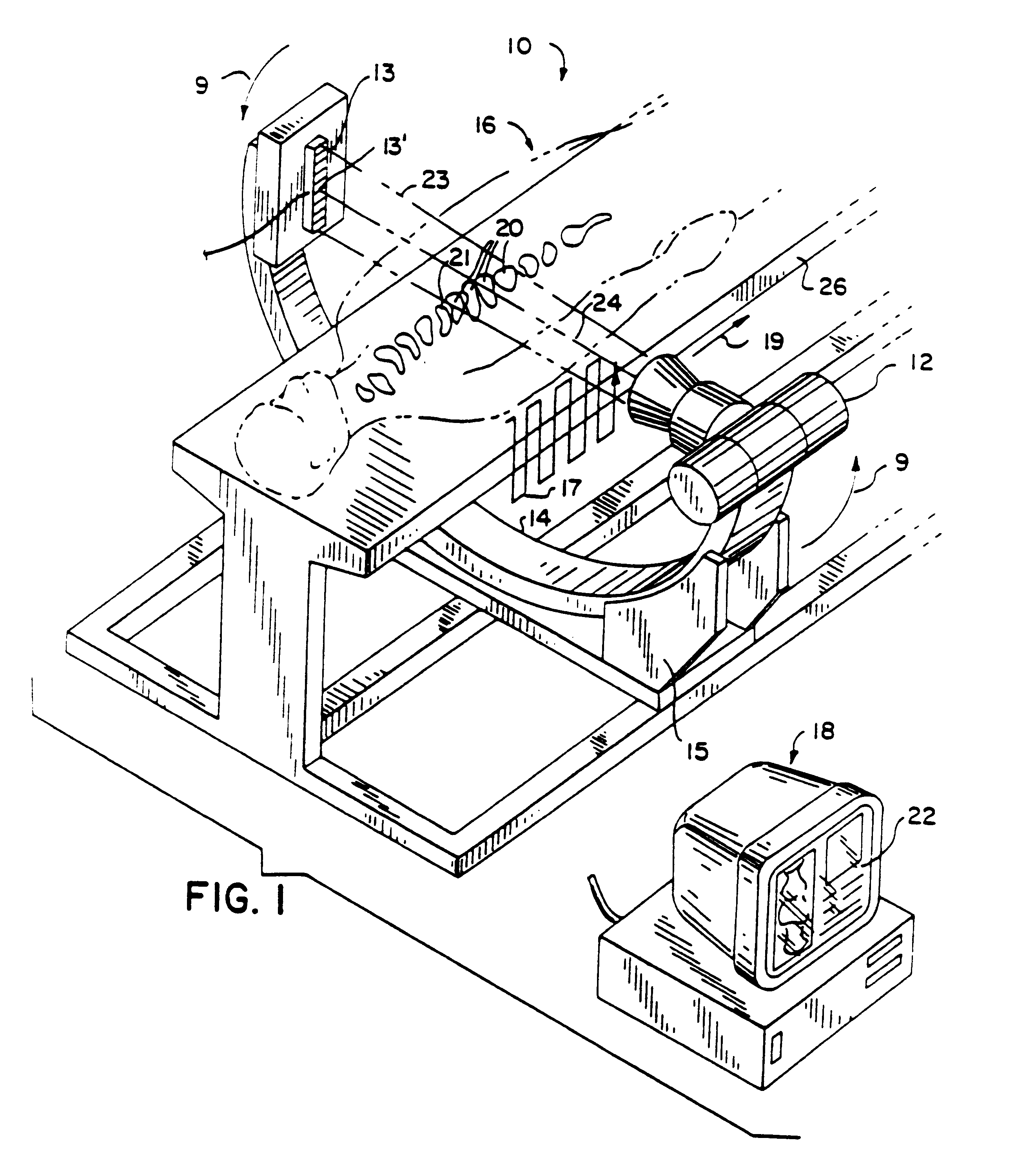

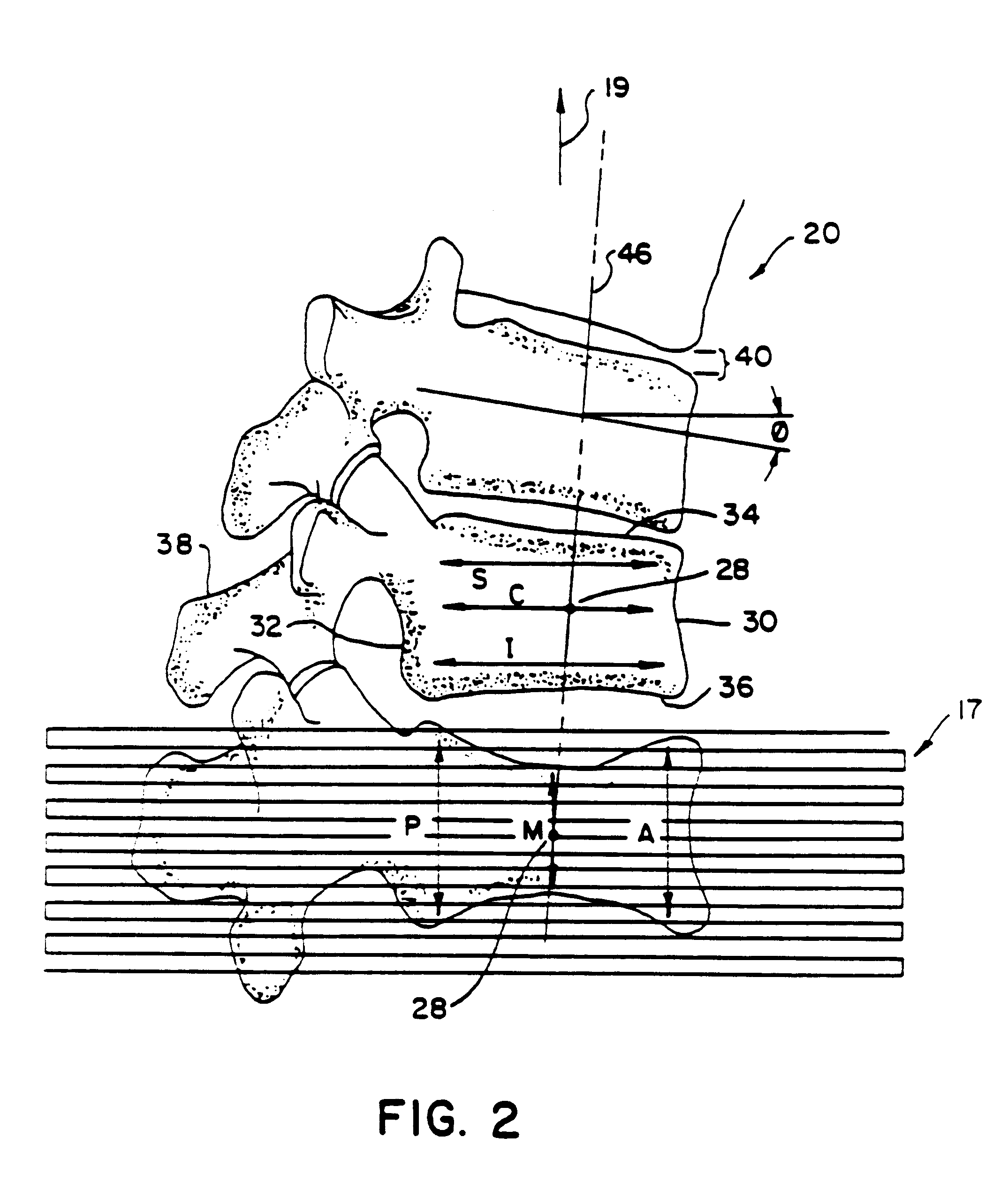

Scanning densitometry system with adjustable X-ray tube current

InactiveUS6438201B1Effectively continuous adjustmentEffective regulationImage enhancementImage analysisBone densityX-Ray Tube Current

A dual energy scanning densitometry system for imaging and measuring bone density maintains acceptable flux by adjusting the x-ray current or scan speed according to preceding scan line data. The amount of acceptable flux is maintained within limits modified by information about the region of the body being scanned so that different precisions may be maintained for different body regions. Scan speed and current may be controlled so that scan speed is maximized within the current limits. Essentially continuous flux control can be achieved.

Owner:LUNAR CORP

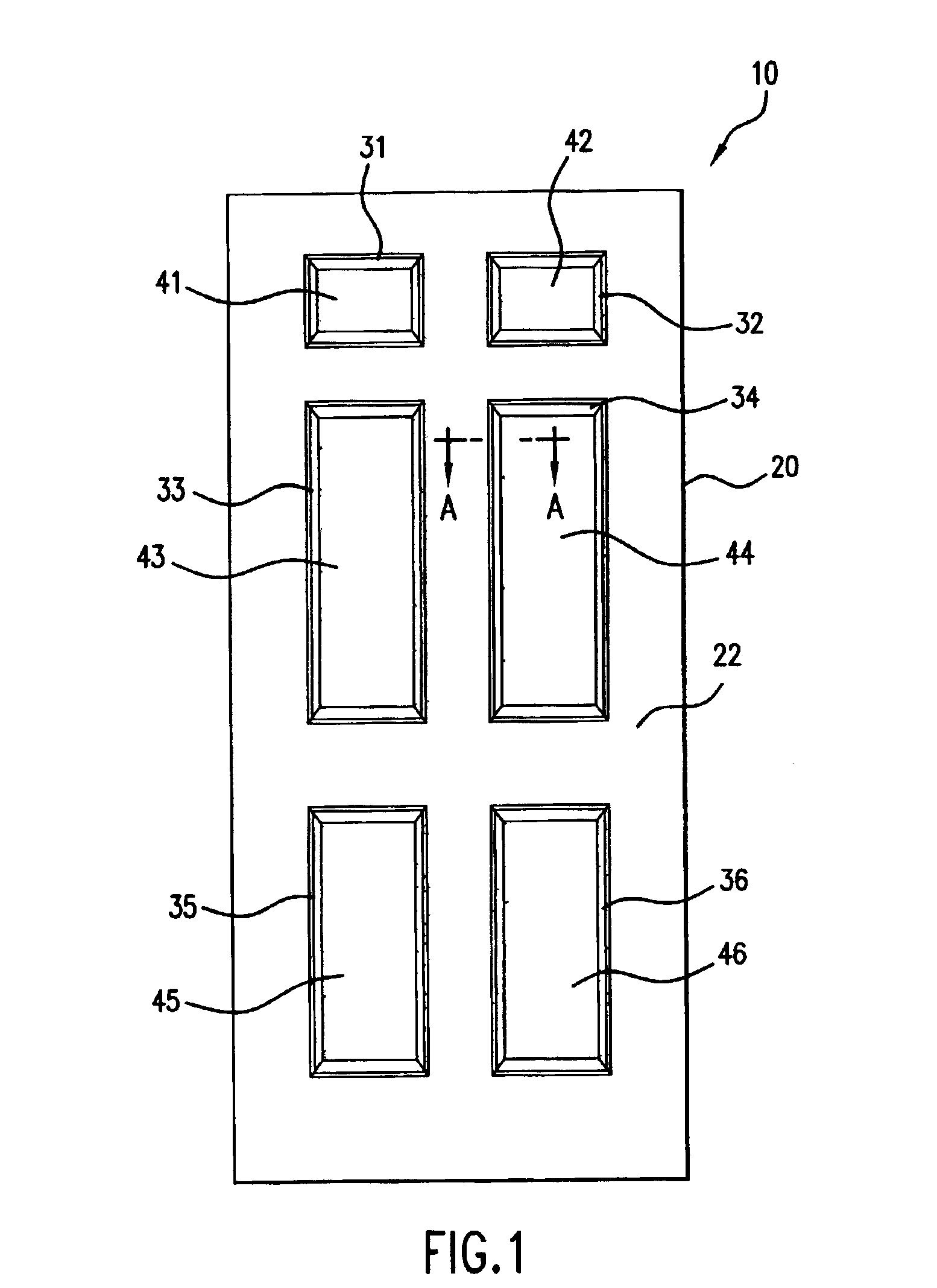

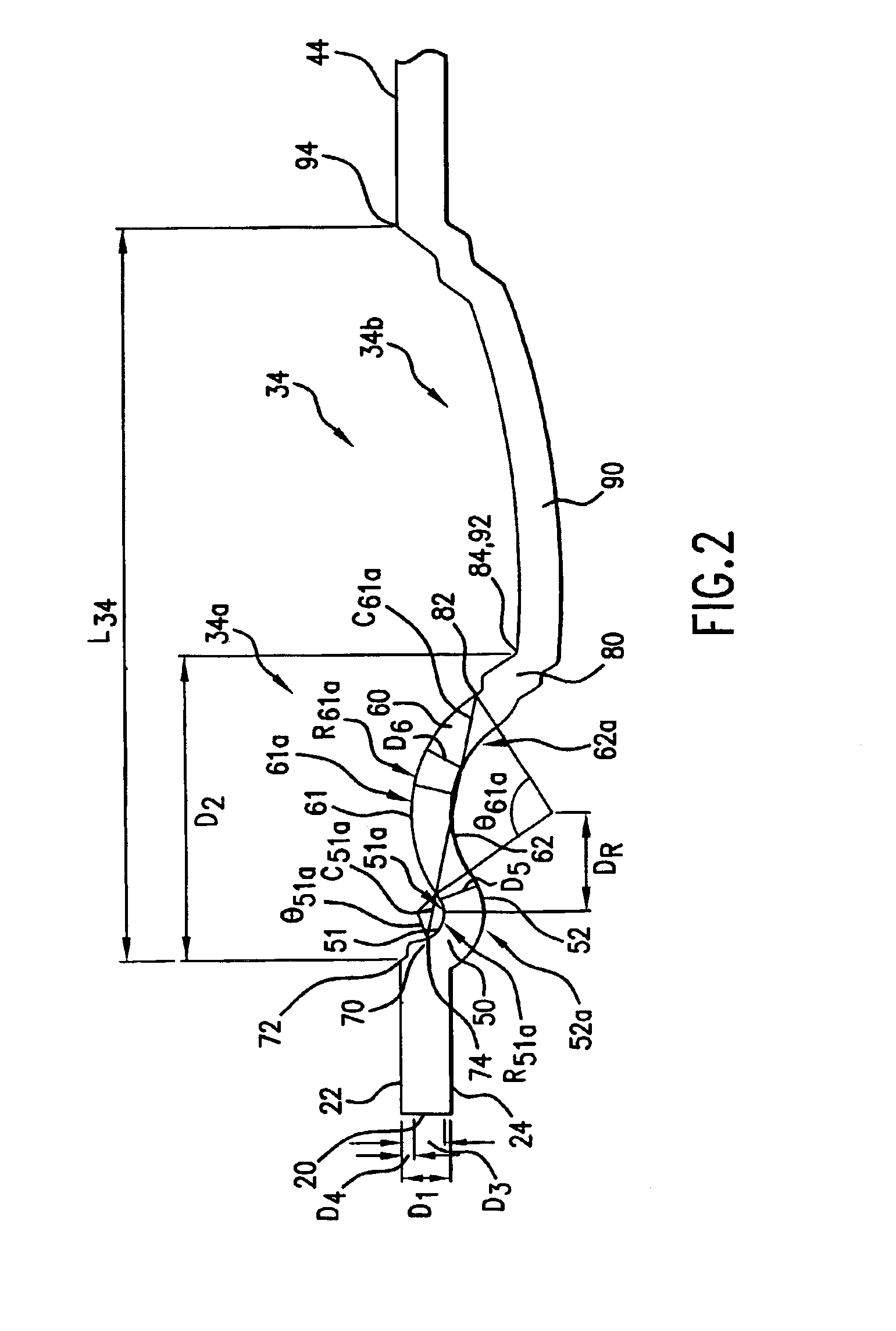

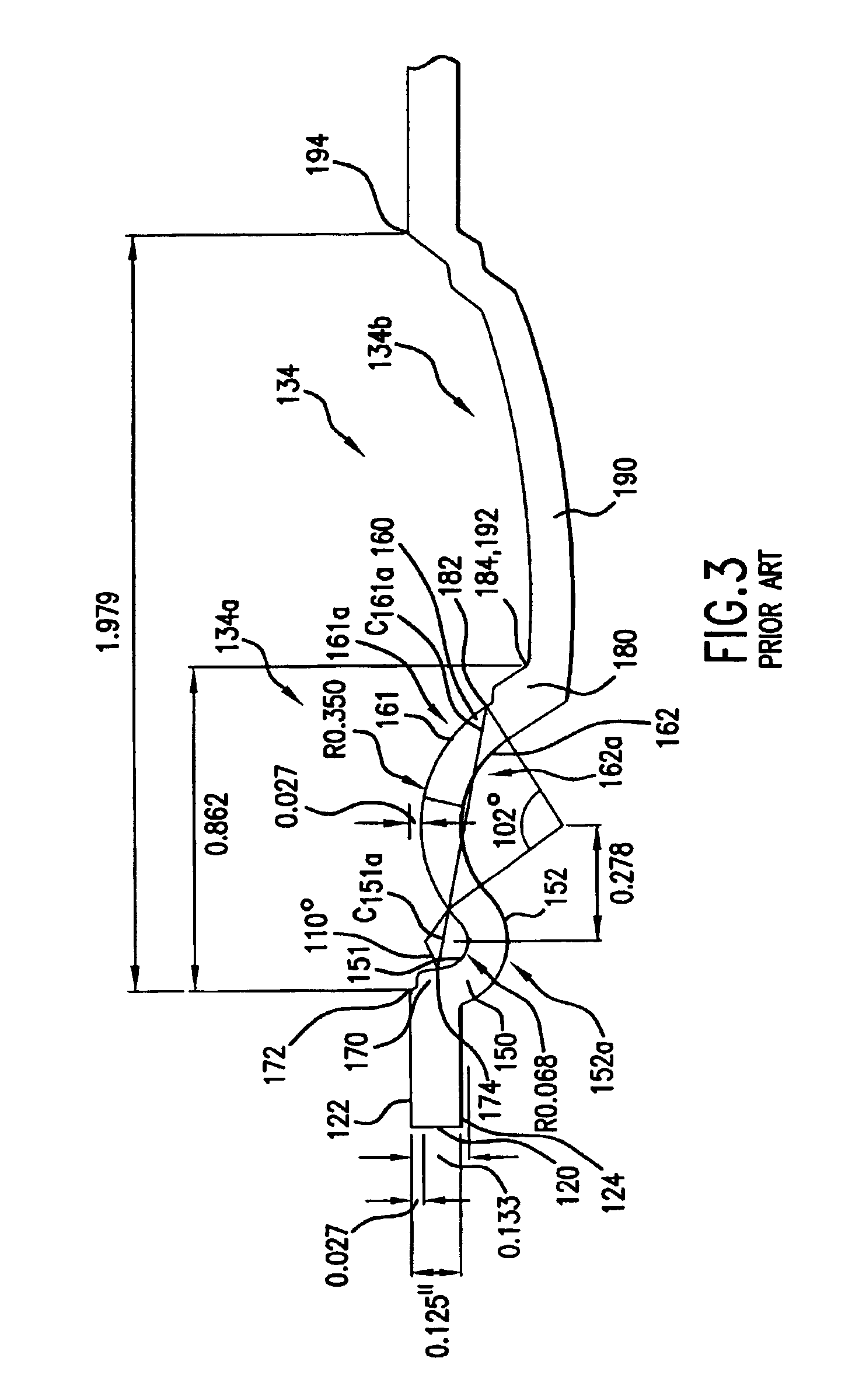

Molded skin with curvature

InactiveUS7022414B2Density is accurateUniform appearanceCeramic shaping apparatusWood layered productsEngineeringSheet material

Molded skins and methods of making molded skins are disclosed. An embodiment of a skin includes a sheet having first and second surfaces, a first arcuate portion integral with the sheet, and a second arcuate portion integral with the sheet and adjacent to the first arcuate portion. The sheet includes a cellulosic material. The first arcuate portion includes a first surface and a second surface, each having an arc. The second arcuate portion includes a first surface and a second surface, each having an arc. An angle forming the arc of the first surface of the first arcuate portion is greater than 110 degrees and an angle forming the arc of the first surface of the second arcuate portion is less than 102 degrees.

Owner:JELD-WEN

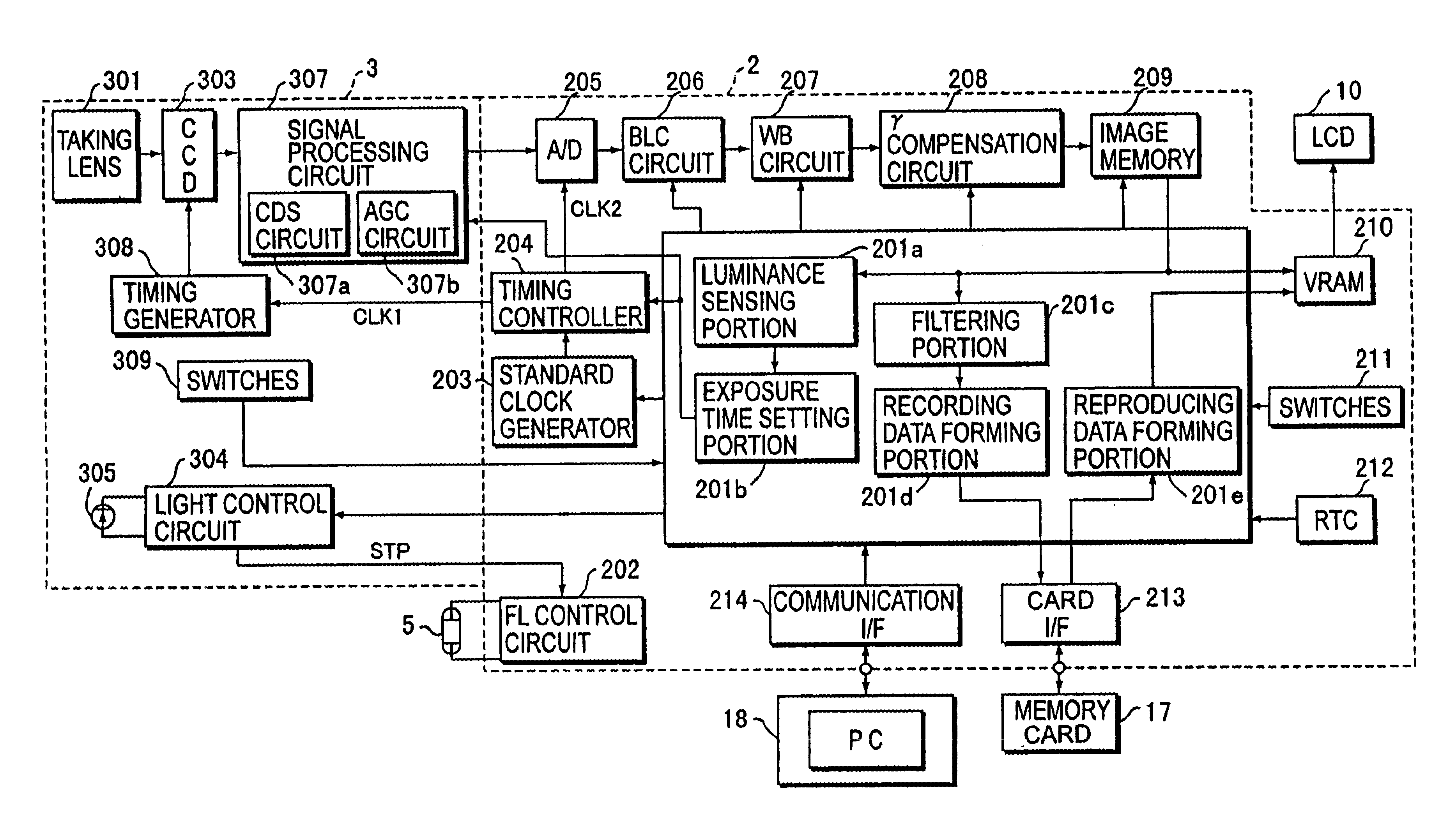

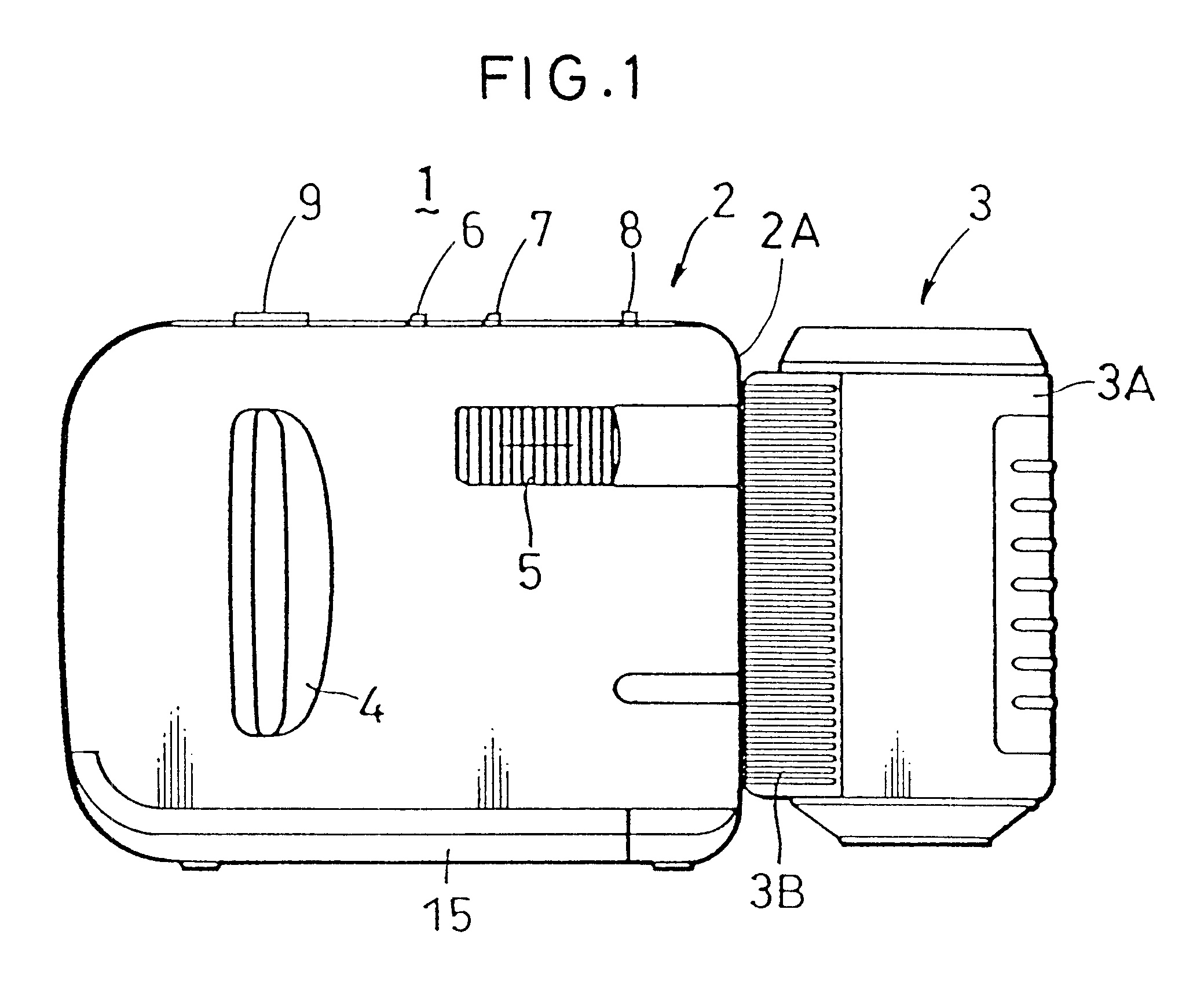

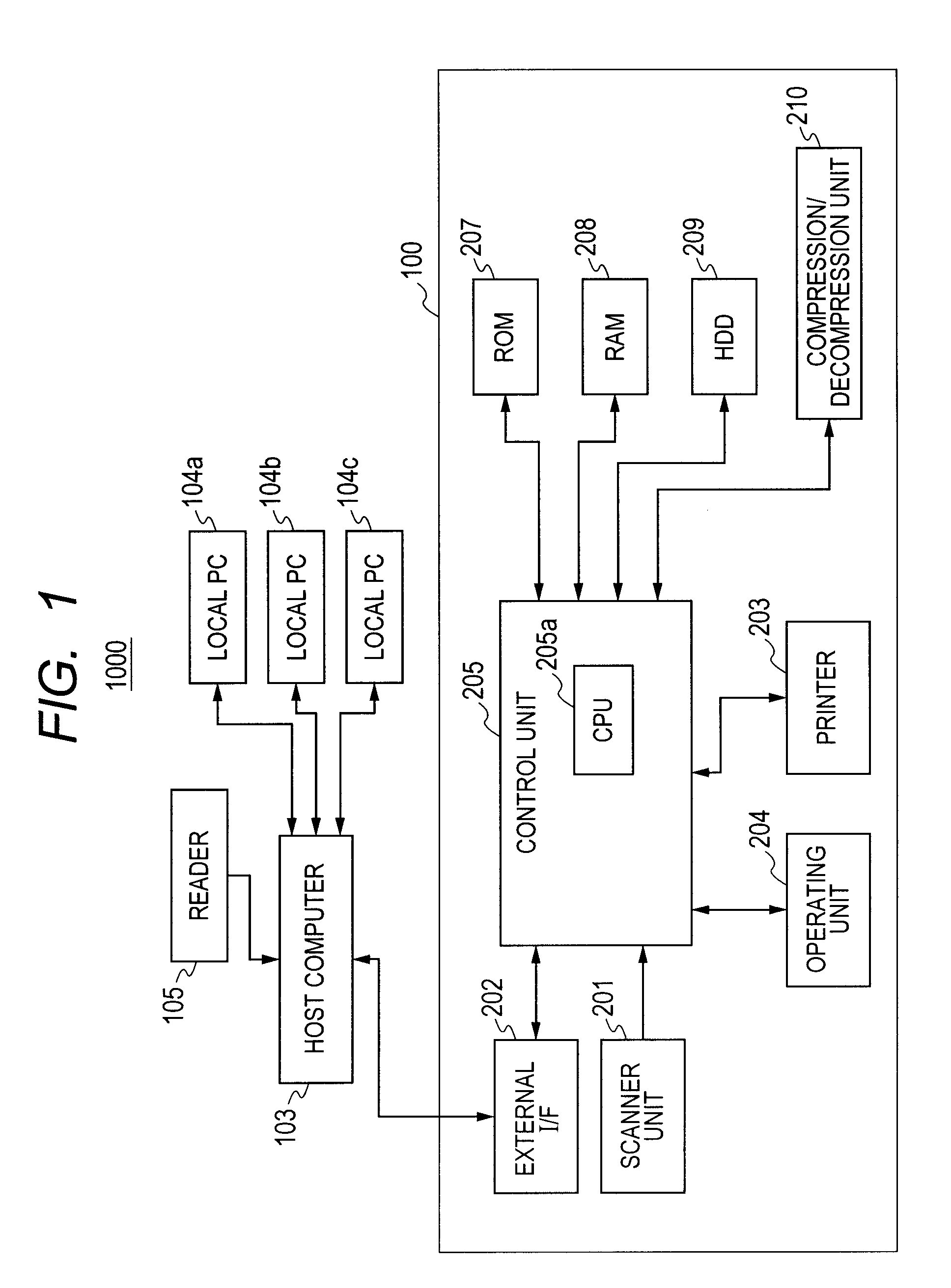

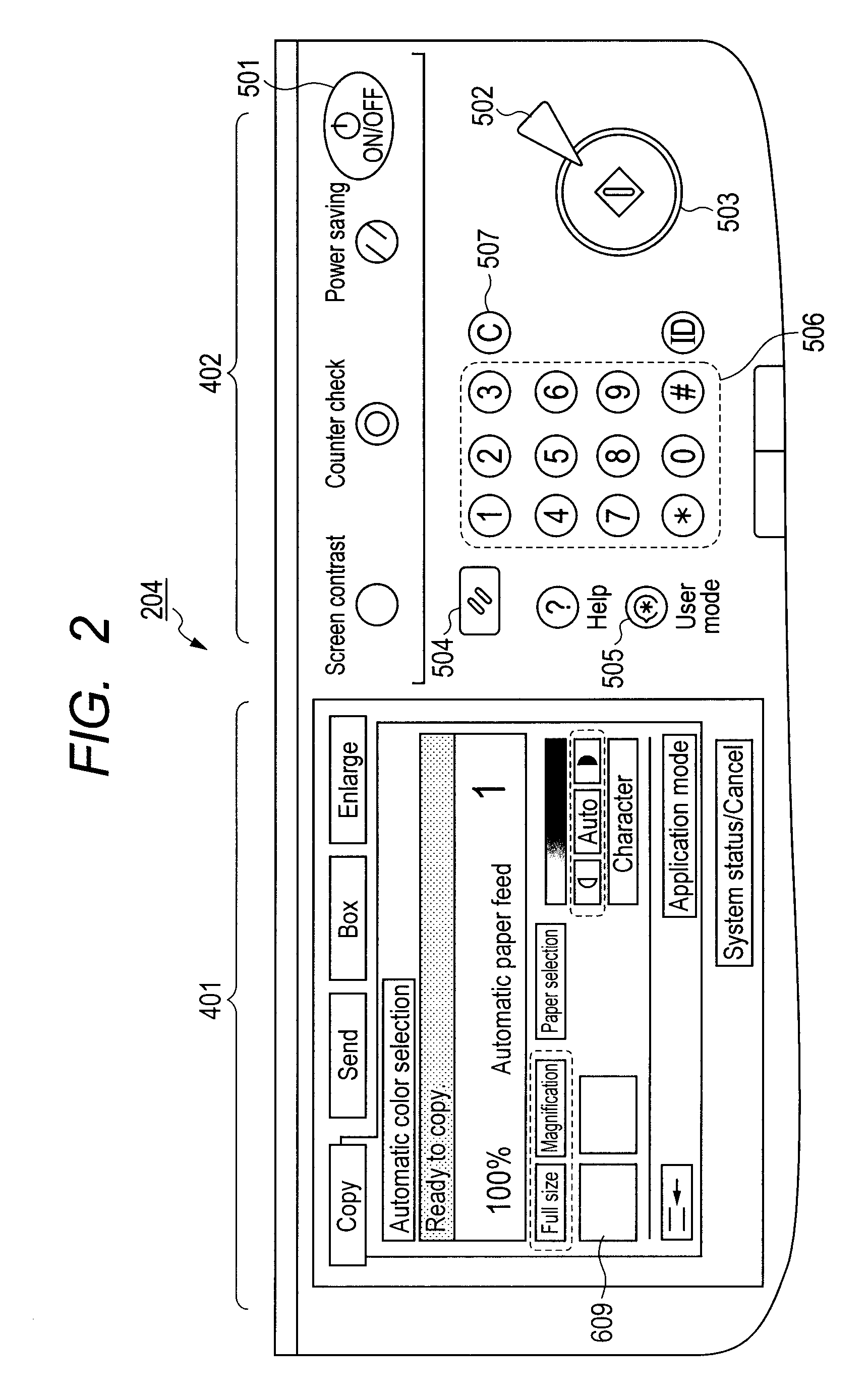

Image pickup apparatus

InactiveUS6667765B1True colorDensity is accurateTelevision system detailsColor television detailsDisplay deviceComputer science

In an image pickup apparatus such as a digital camera with a display serving as a viewfinder, exposure is controlled by changing only an exposure time of an image pickup device without changing size of an aperture for taking an image for the viewfinder. When the exposure time of the image pickup device is insufficient to obtain a proper density of the image, the image signals of the image pickup device is amplified for compensating the insufficient exposure.

Owner:MINOLTA CO LTD

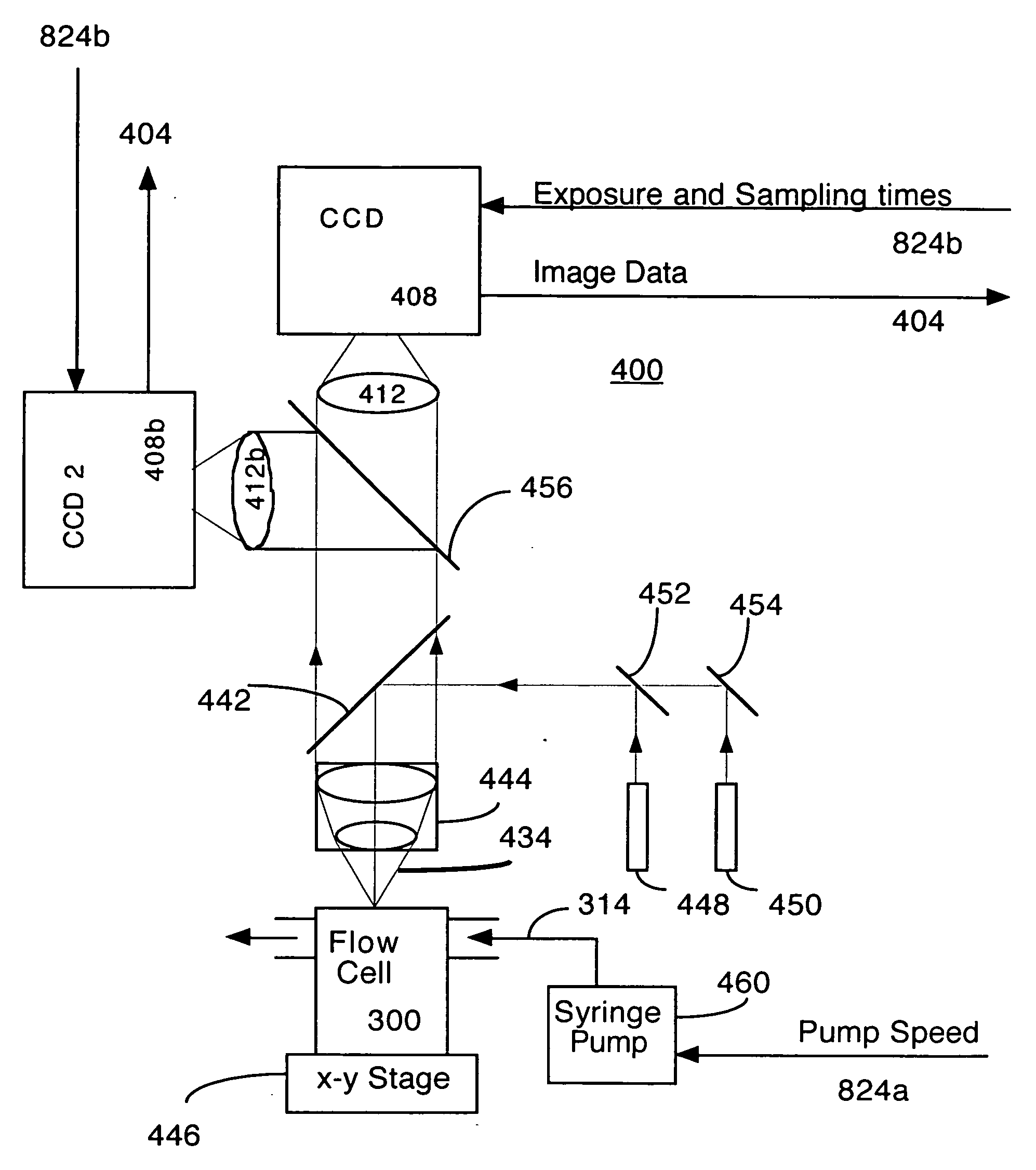

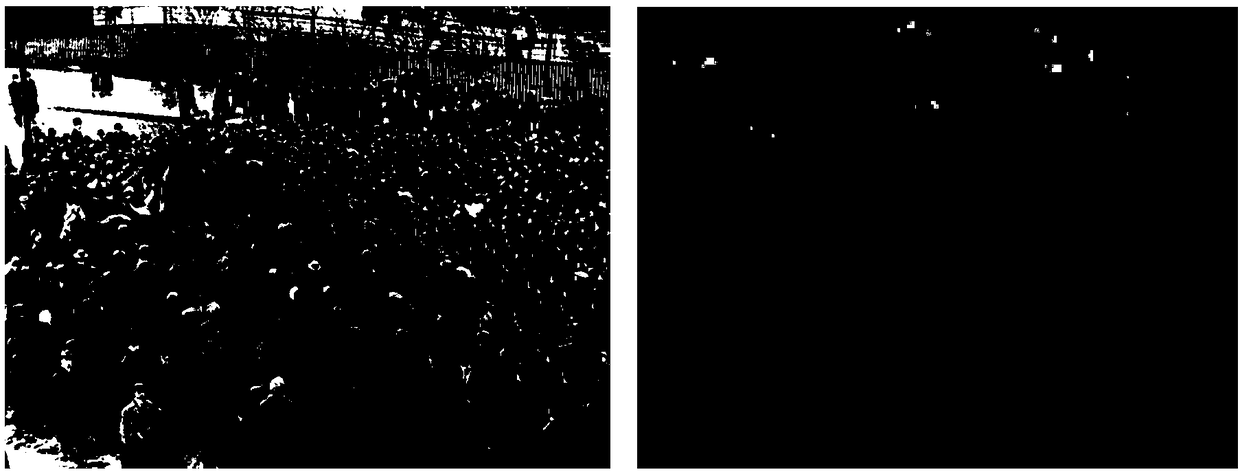

Method and system for counting particles in a laminar flow with an imaging device

ActiveUS20070159627A1Reduce noiseDensity is accurateParticle size analysisCounting objects with random distributionComputational physicsParticle density

An invention is described which allows measurement of the concentration of fluorescent particles in a flowing (laminar) fluid by imaging the flow with a video camera. A beam of illumination is used to illuminate the target particles. Imaging optics are arranged to view the focal plane to form an image of the multiple fluorescent sample particles in the flow stream; a camera records the image formed by the imaging optics, and a counting algorithm enumerates the particles. Operational parameters of the system are adjusted according to an initial estimate of particle density, for example flow rate, exposure time, and sampling interval. In addition, the counting algorithm is selected according to the estimated particle density.

Owner:UNIVERSITY OF WYOMING

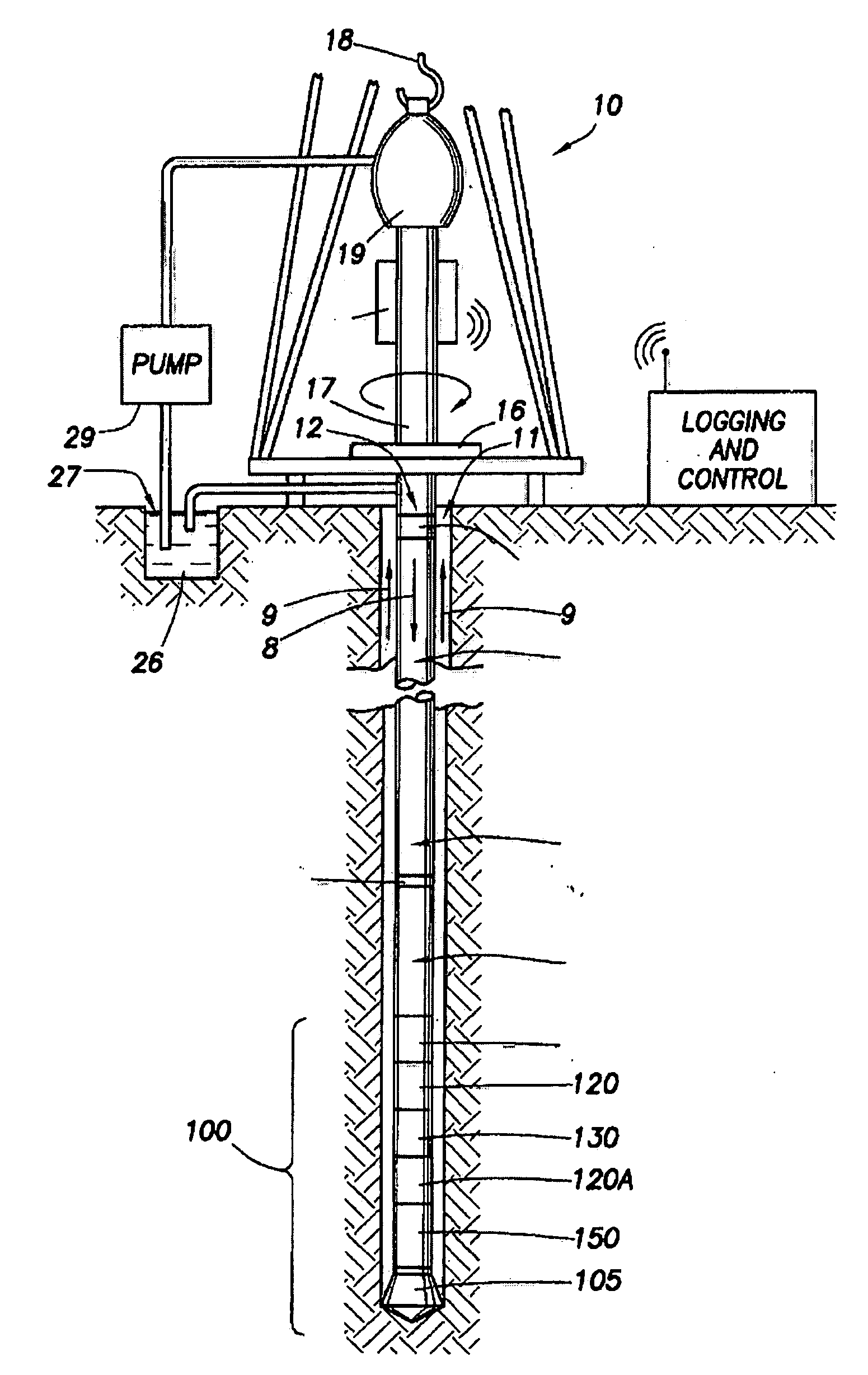

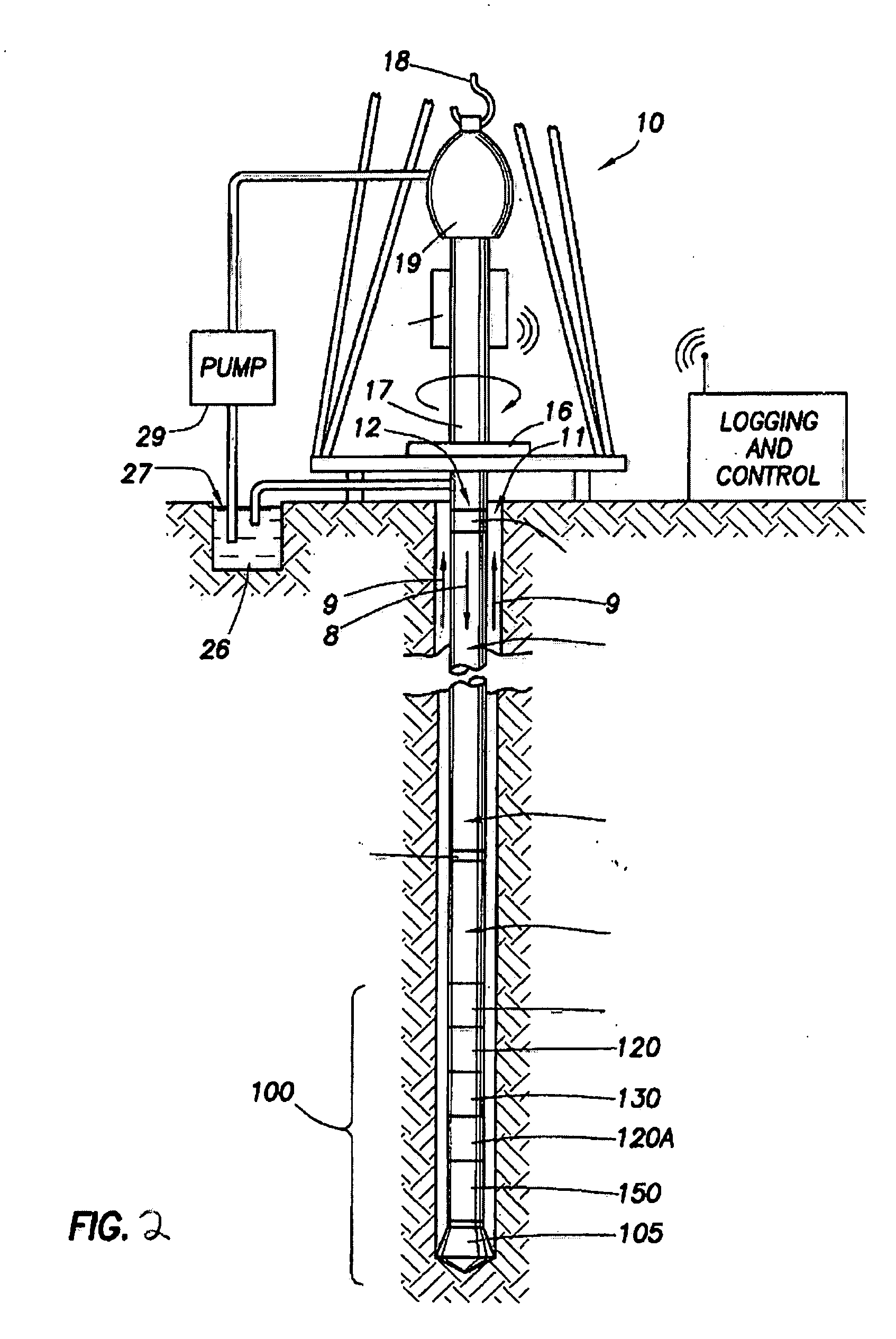

Microfluidic oscillating tube densitometer for downhole applications

ActiveUS20100268469A1Accurately fluid densityQuantity minimizationVibration measurement in solidsResonant frequencyAcousticsAOD use frequency

Devices, methods and systems for determining one or more properties of at least one fluid sample. A tube configured to receive the at least one fluid sample wherein the tube is placed in a pressure housing. Further, an excitation source configured to generate vibration of the tube whereby a circulation of an electrical current along a portion of the tube is subjected to at least one magnetic field produced by at least one magnet. Further still, at least one vibration sensor that converts vibrations of the tube into a measurement signal. Finally, a processor that receives the measurement signal determines a resonant frequency from the measurement signal using a frequency measuring device to determine a property of the one or more properties of the at least one sample fluid.

Owner:SCHLUMBERGER TECH CORP

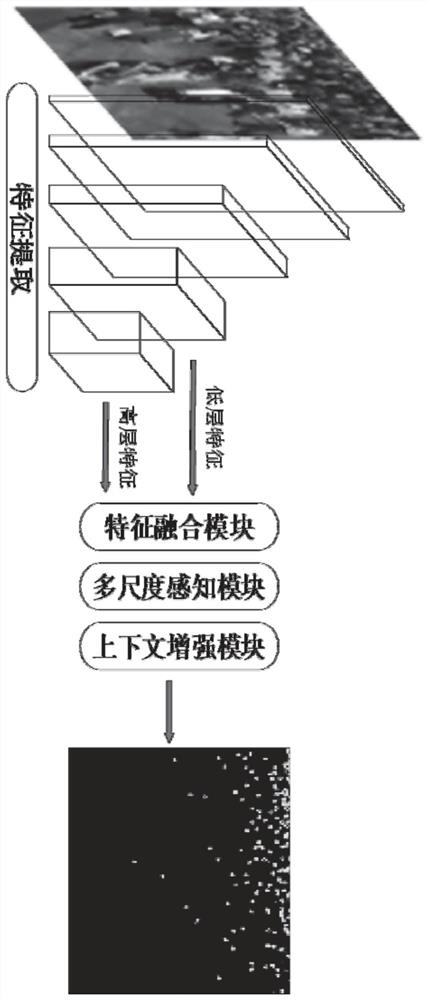

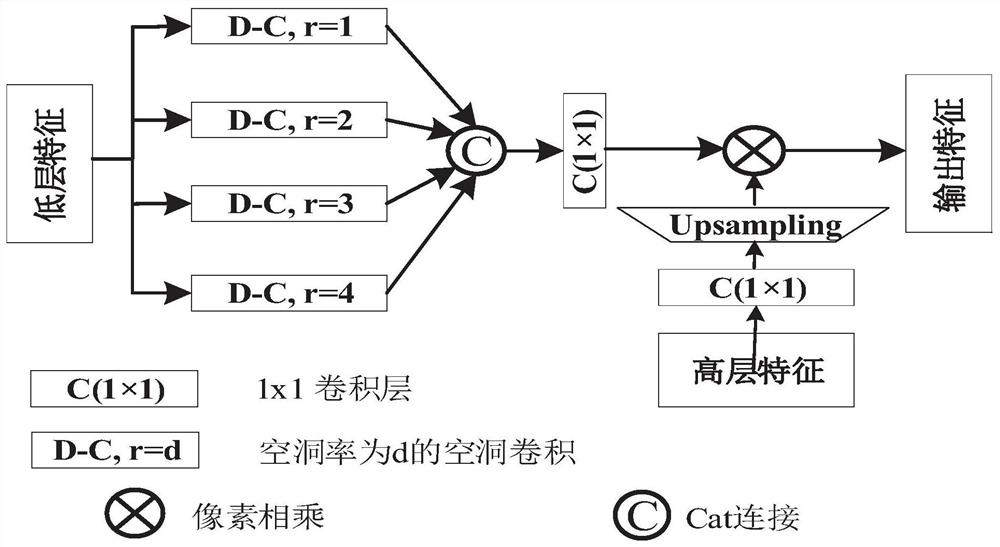

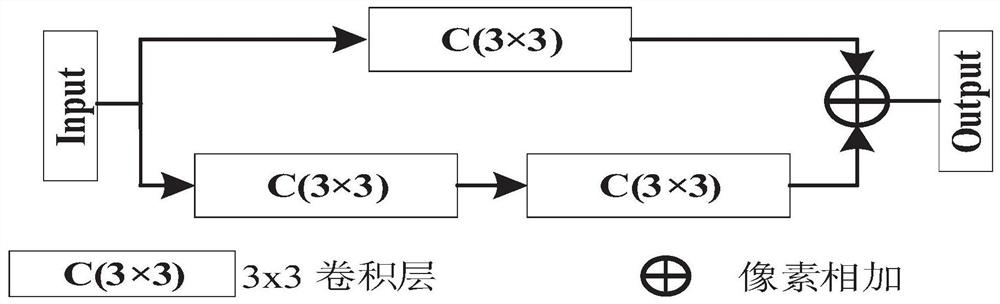

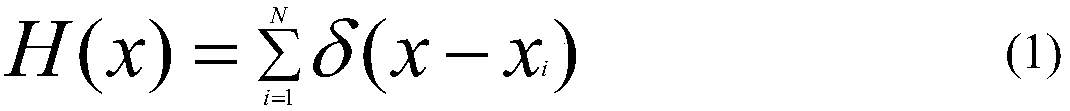

Crowd counting method based on multi-scale context enhancement network

PendingCN112132023ADeal effectively with multi-scale problemsDealing with Multiscale ProblemsCharacter and pattern recognitionNeural architecturesCrowd countingCrowds

The invention provides a crowd counting method based on a multi-scale context enhancement network, which comprises the following steps: inputting a picture, obtaining shallow features and deep features after feature extraction, performing feature fusion through a feature fusion module, sending the fused features into a multi-scale perception module, and finally, encoding the space and channel information of the features through a context enhancement module to obtain a density map with crowd distribution features. The estimated number of people in the current picture can be obtained by summingthe density image pixels. According to the crowd counting method based on the multi-scale context enhancement network, the multi-scale problem existing in crowd counting can be effectively solved, andmore accurate counting and density estimation can be carried out on crowds in a complex scene by modeling space and channel context information of a feature map. The invention is high in robustness,and can provide accurate data for the safety and planning of a large crowd gathering place.

Owner:SHANGHAI INST OF TECH

Multiscale full convolutional network feature fusion-based crowd counting method

PendingCN108596054APracticalImprove robustnessCharacter and pattern recognitionNeural architecturesCrowd countingPattern recognition

The invention discloses a multiscale full convolutional network feature fusion-based crowd counting method. The method comprises the following steps of: inputting a picture and respectively entering three branch networks so as to obtain feature maps with different scales; fusing the obtained feature maps of the branch networks so as to obtain a finally estimated feature map; mapping the output feature map into a density map; and carrying out summation on the density map to realize estimation of the current crowd number. The multiscale full convolutional network feature fusion-based crowd counting method provided by the invention is capable of overcoming severe influences, on crowd counting, of shielding, scene perspective distortion and different crowd distributions, has relatively strongpracticability and good robustness, is capable of accurately carrying out crowd counting or crowd density estimation, and has an important value for monitoring crowd abnormal events.

Owner:SHANGHAI UNIV OF ENG SCI

Sea wind resource evaluation method based on WRF mode

InactiveCN103778572ADensity is accurateThe result is accurateData processing applicationsDensity of airEngineering

The invention discloses a sea wind resource evaluation method based on a WRF mode. The sea wind resource evaluation method based on the WRF mode mainly comprises the steps of obtaining WRF numerical value weather forecast data and anemometer tower data, building a vertical shear model of wind, building a wind speed probability model, evaluating air density and evaluating wind power density and annual energy output. The sea wind resource evaluation method based on the WRF mode evaluates sea wind resources through the WRF numerical value weather forecast data, and effectively overcomes the defect that a traditional wind resource evaluation technology is low in accuracy.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

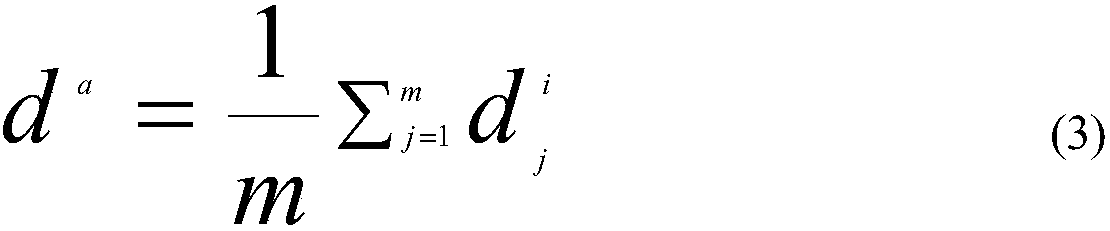

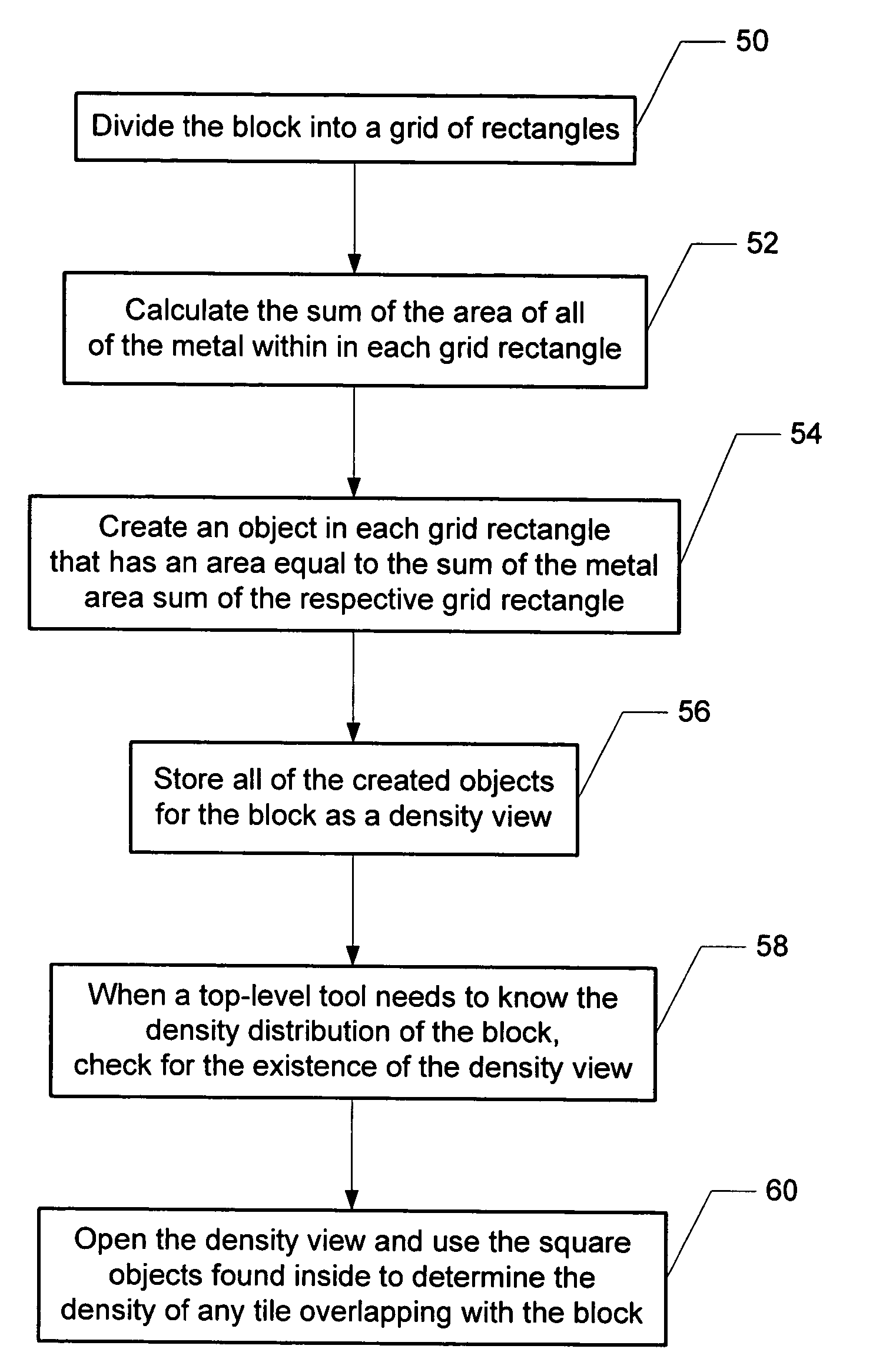

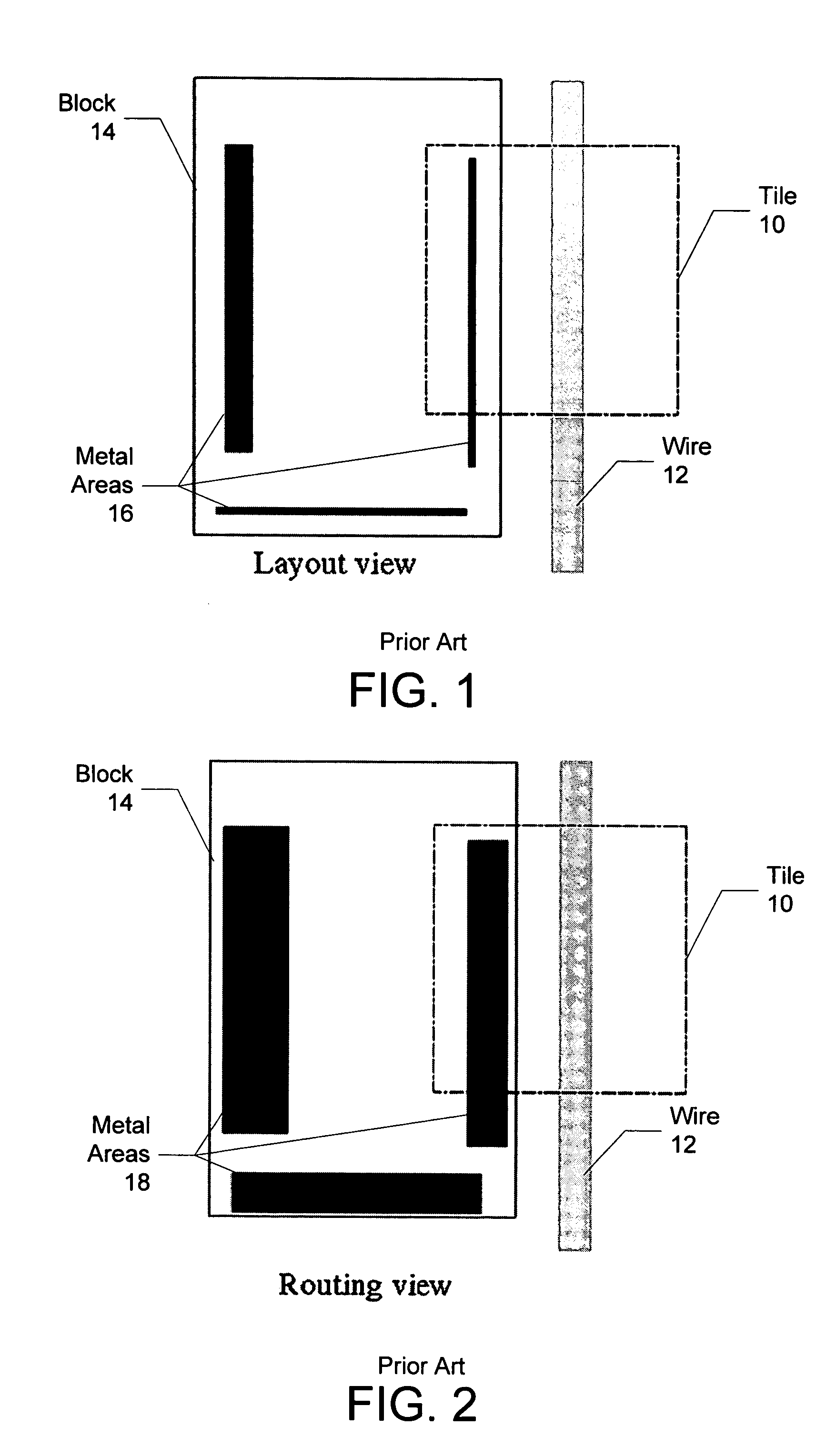

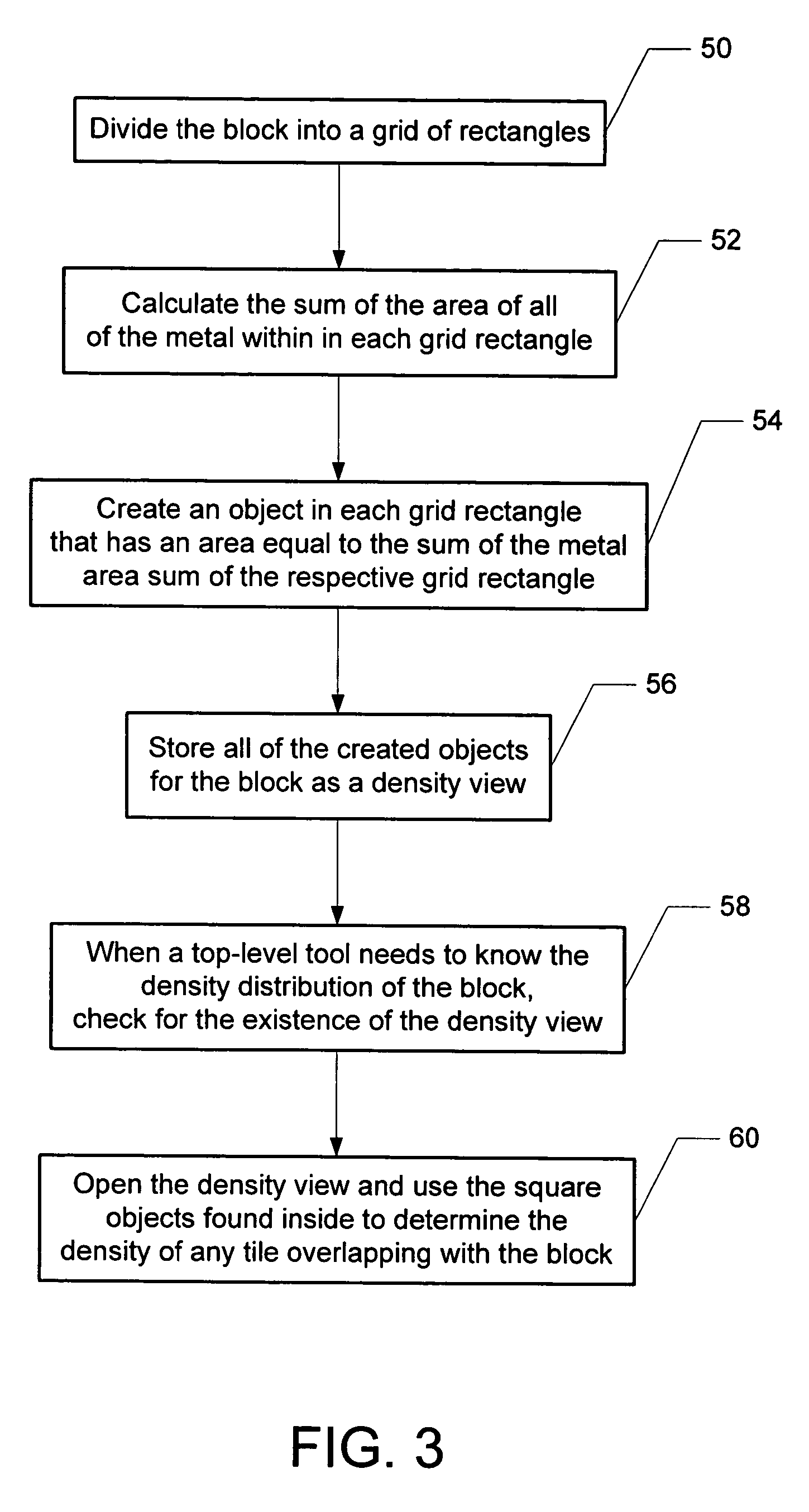

Accurate density calculation with density views in layout databases

ActiveUS20060026551A1Density is accurateDensity is efficientComputer programmed simultaneously with data introductionComputer aided designComputational scienceObject storage

Generating a density abstraction view for an integrated circuit design by dividing each block in the design that is larger than a predetermined size into a grid of rectangles; calculating a sum of metal area in each rectangle in the grid; creating an object in each rectangle having an area equal to the metal area sum of the rectangle; and storing all the created objects for the block as a view. The view may be stored in a layout database along with any other views for the integrated circuit design, and then used to determine density of a tile overlapping with the block by adding the area of the square objects in the density view that overlap with the tile to the tile.

Owner:BELL SEMICON LLC

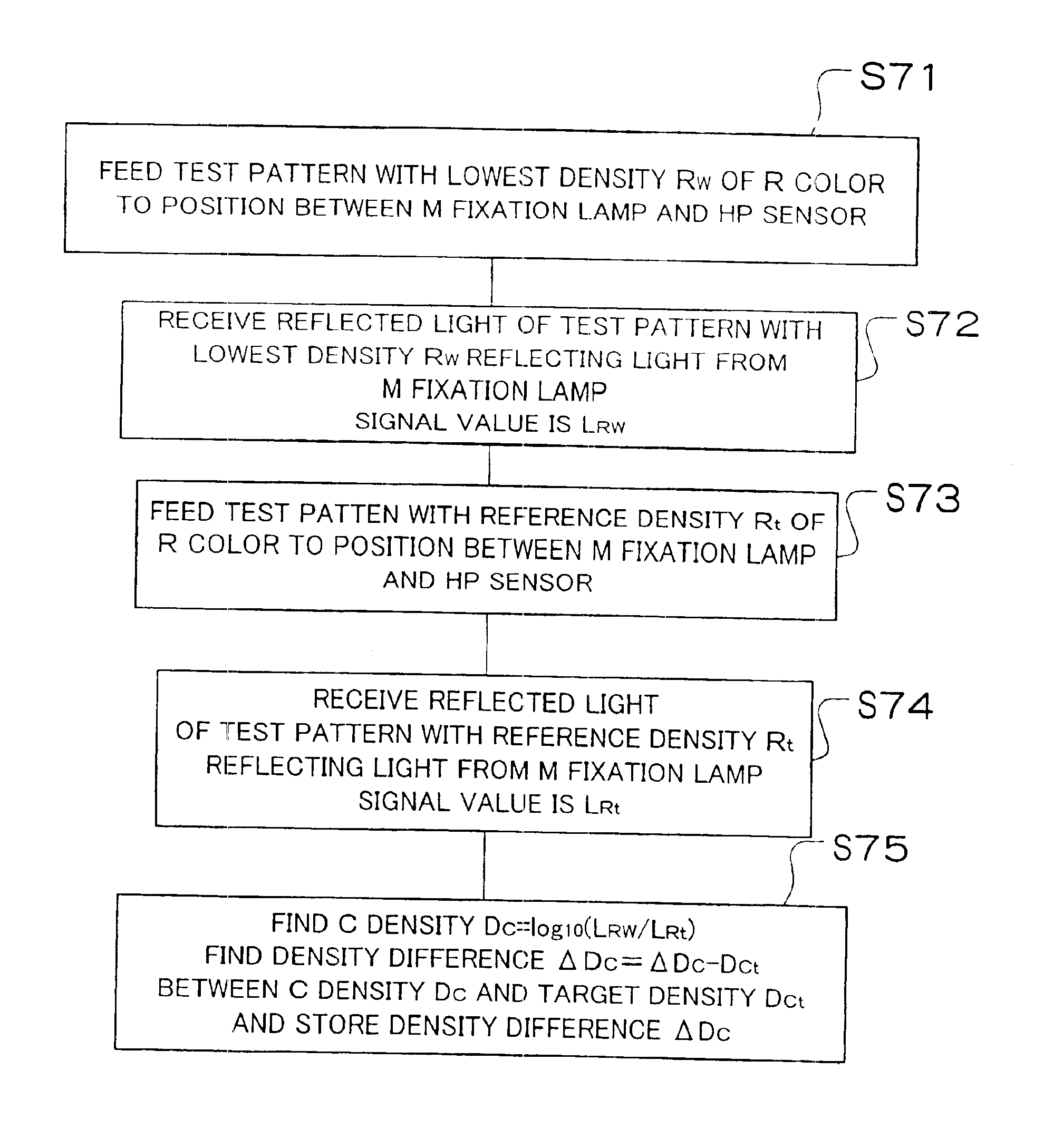

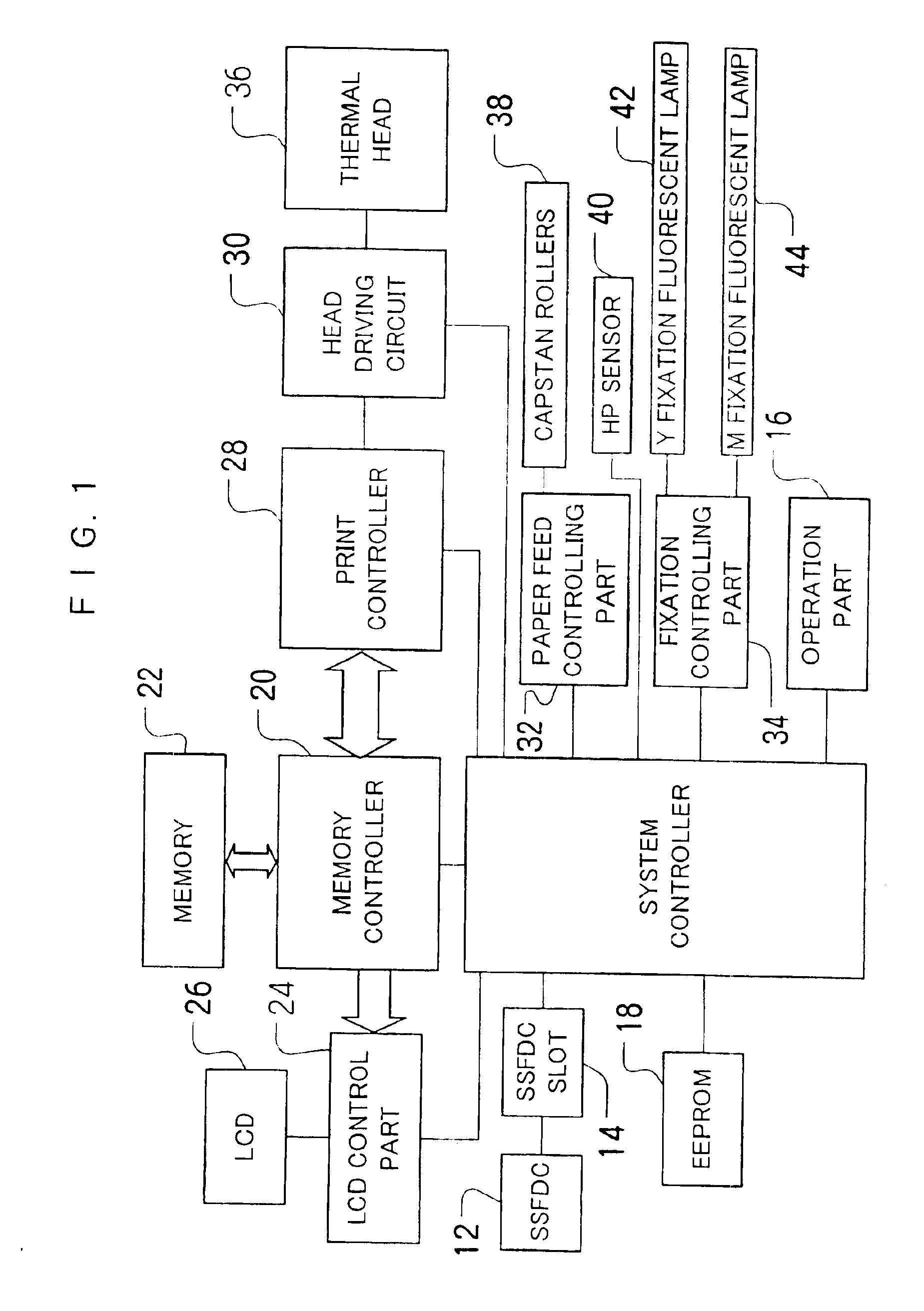

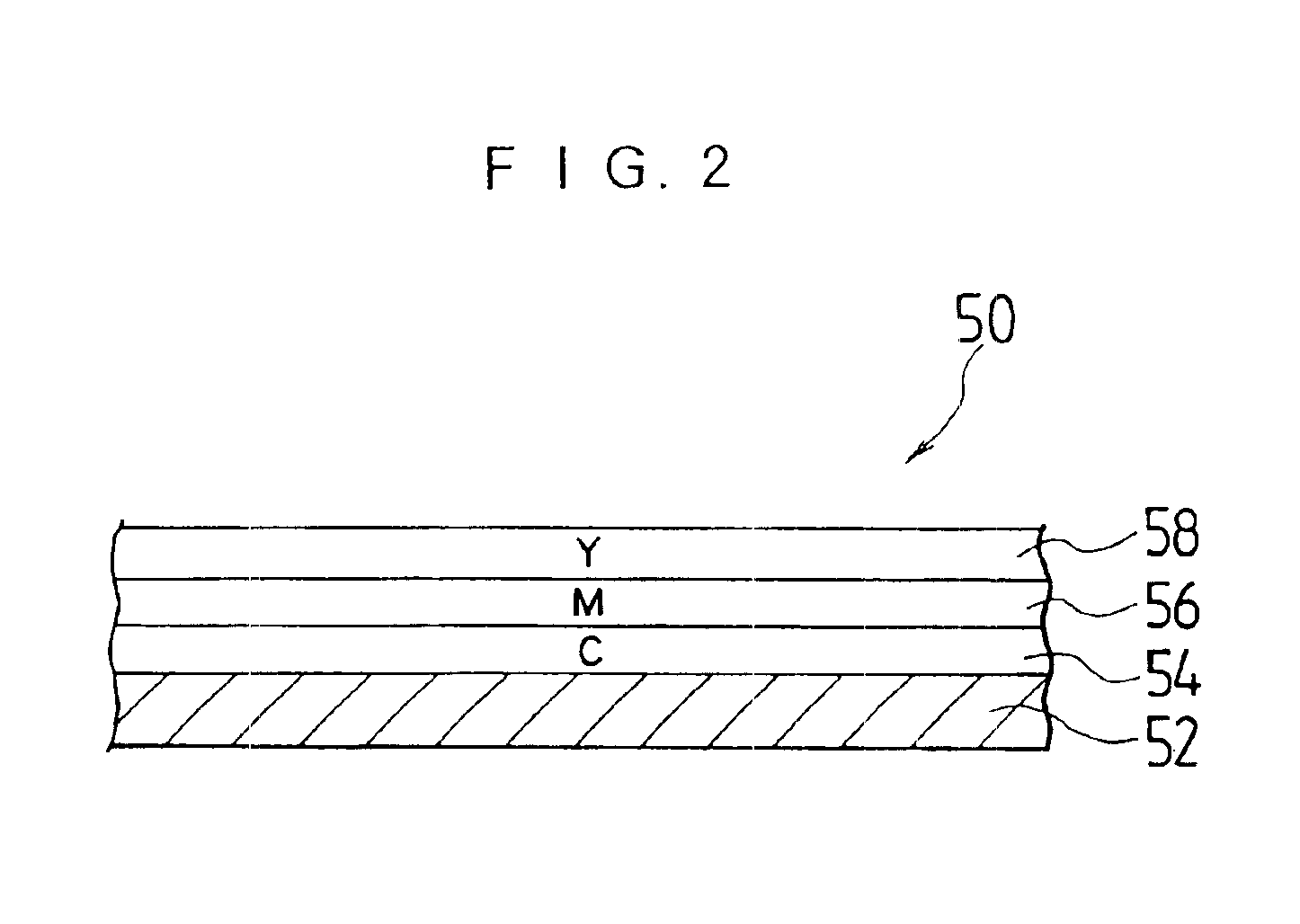

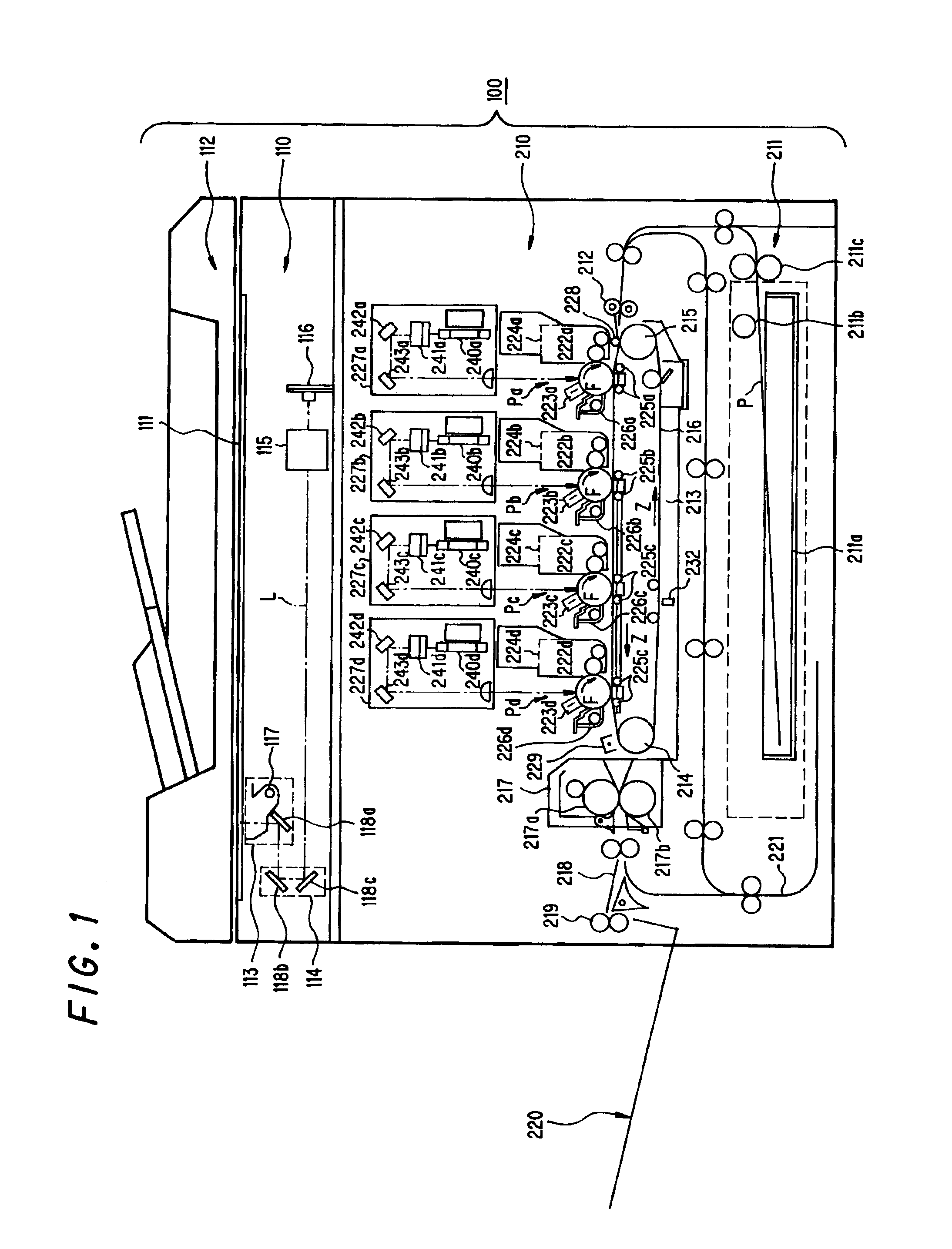

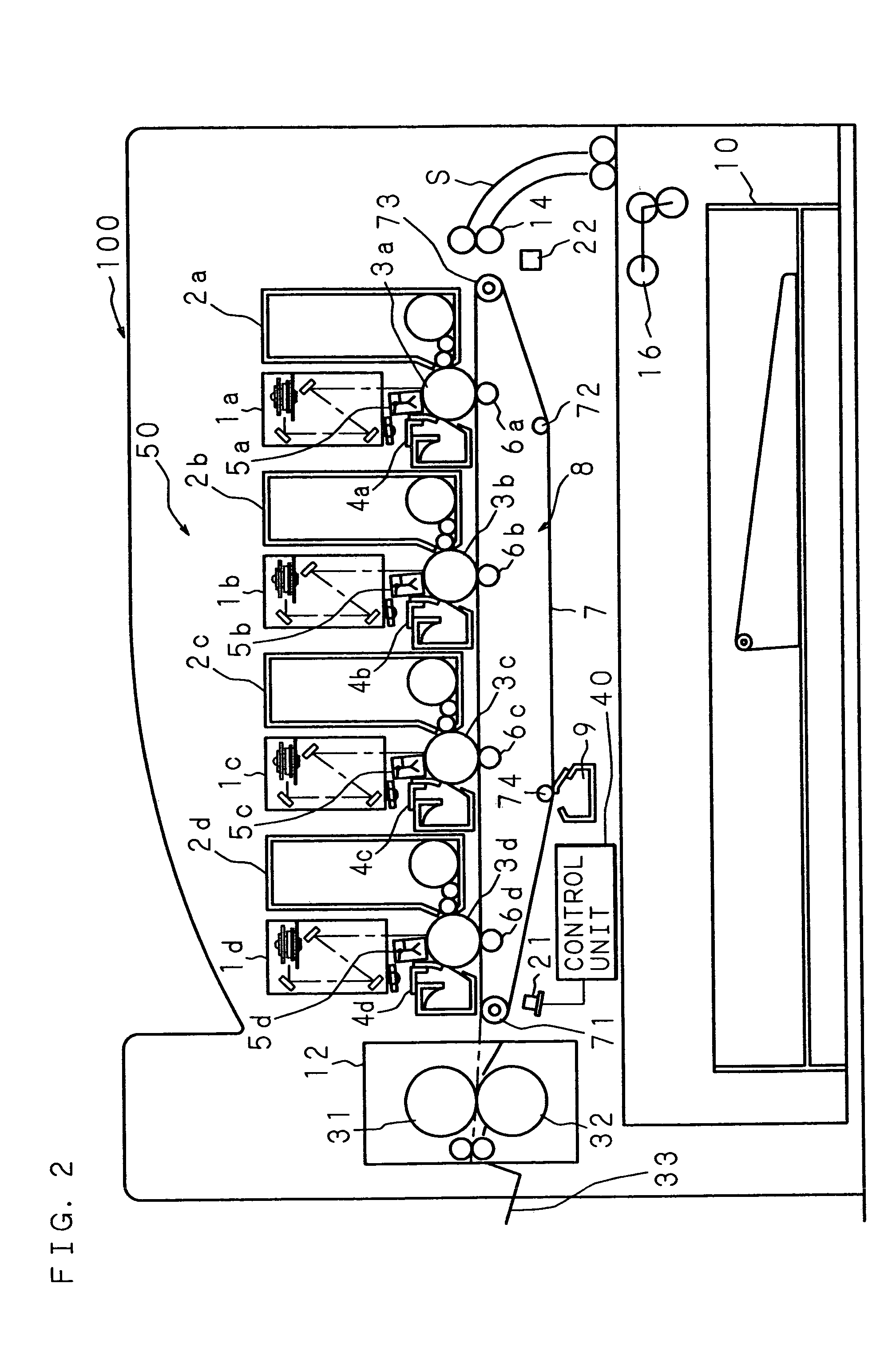

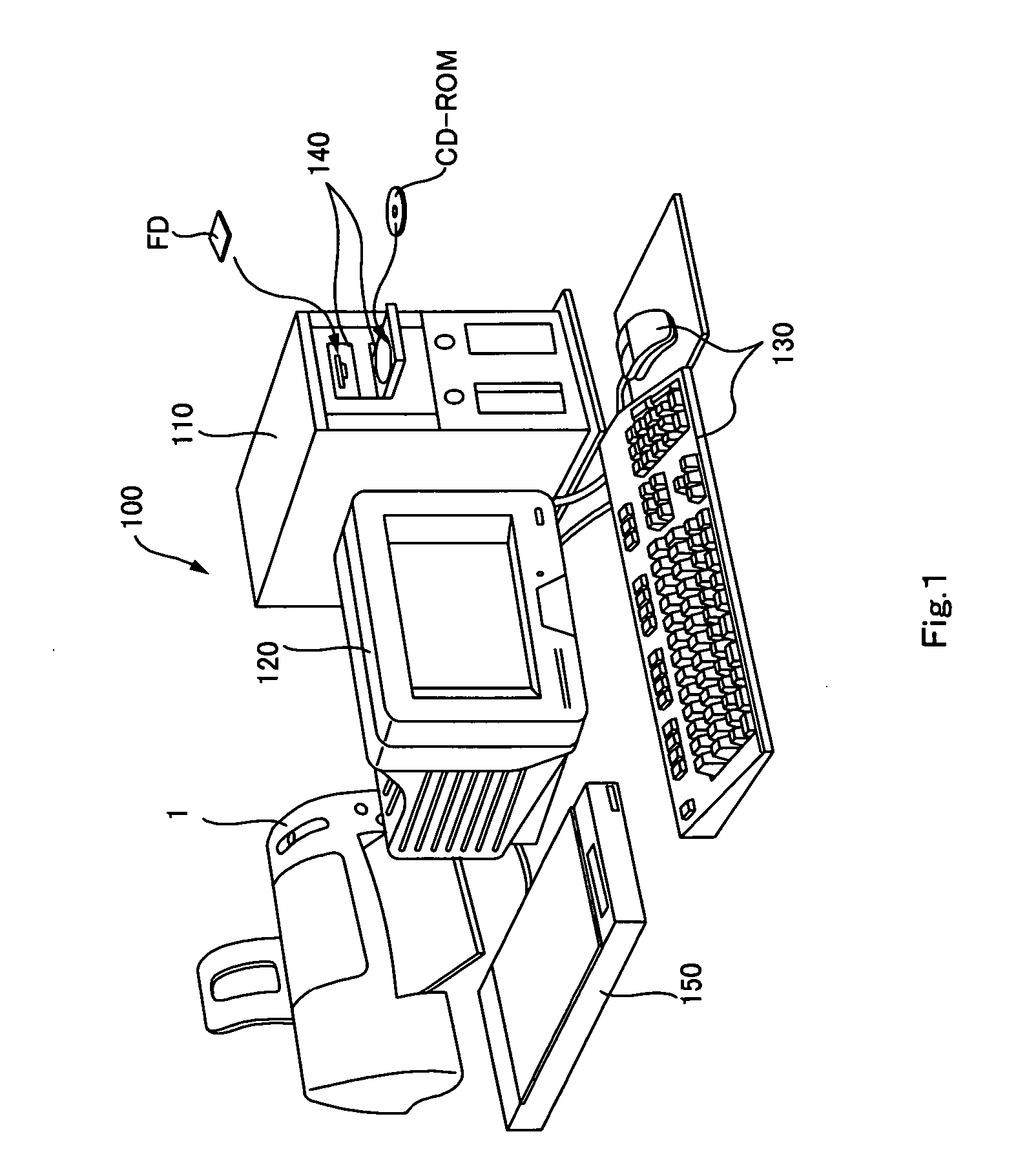

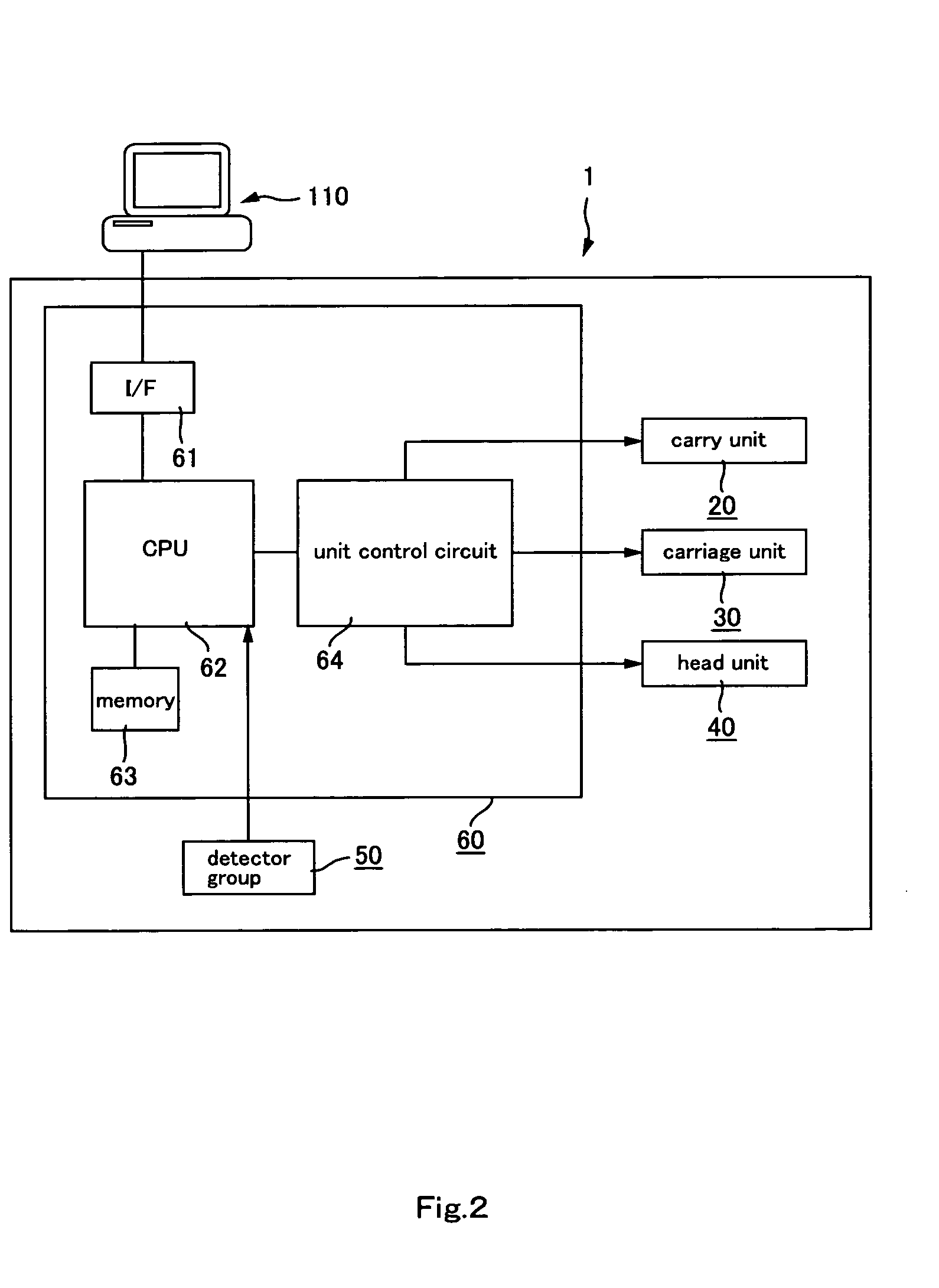

Printer with automatic density adjusting function and density adjusting method of printer

InactiveUS6876467B1Density is accurateRealize automatic adjustmentRecording apparatusDigitally marking record carriersEngineeringLight spectrum

When densities of C, M and Y colors for automatic density adjustment are measured, test patterns of R, G and B colors are printed on TA paper, and a fixing lamp throws lights that have bright line spectrums of R, G and B colors onto the test patterns and amounts of reflected lights of the test patterns of R, G and B colors are measured with a light-receiving sensor that is an HP sensor for determining a reference position of the TA paper. Then, the densities of C, M and Y colors are calculated according to the amounts of the reflected lights. The color production of the C, M and Y layers of the TA paper is adjusted so that the calculated densities of C, M and Y colors are target densities.

Owner:FUJIFILM CORP +1

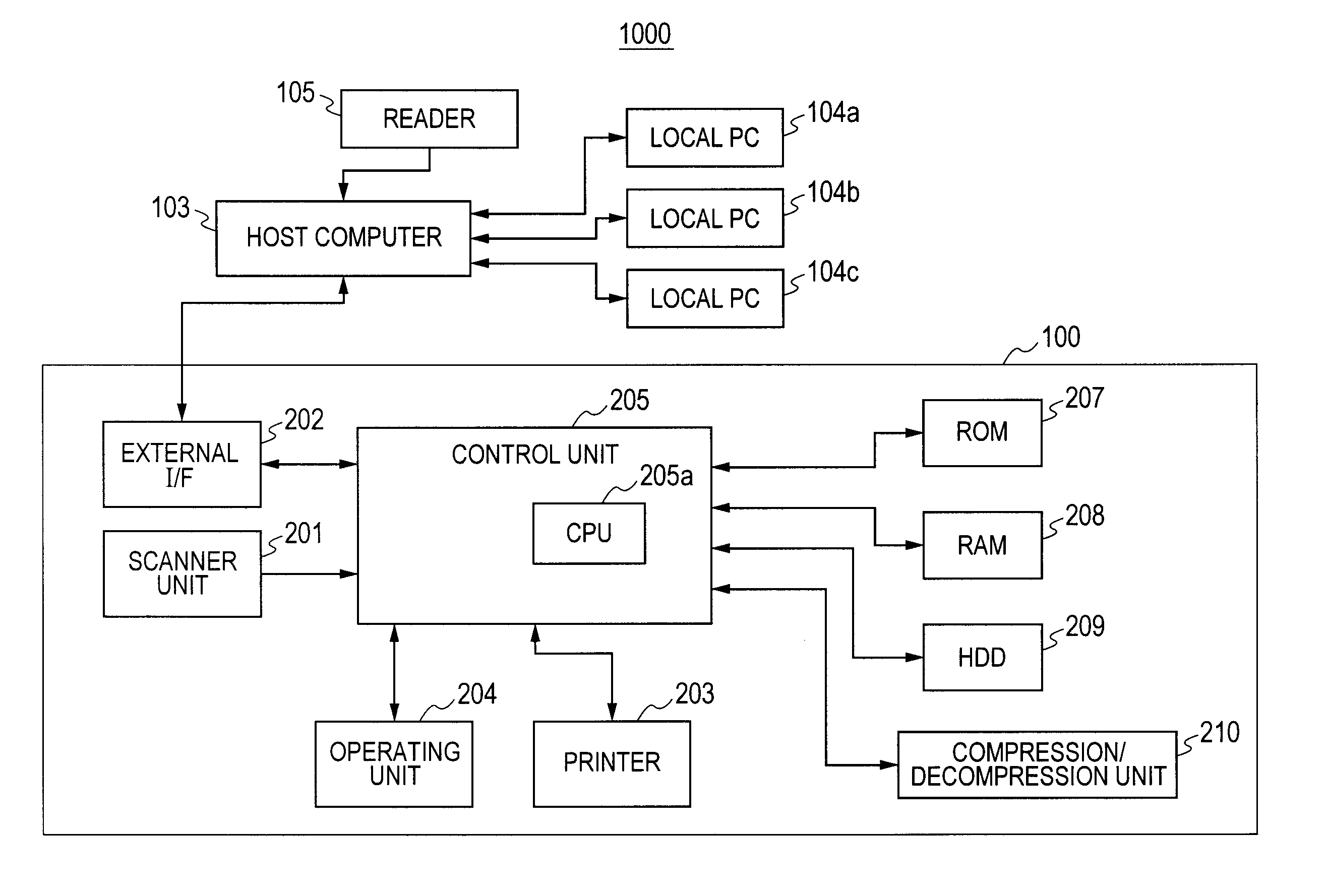

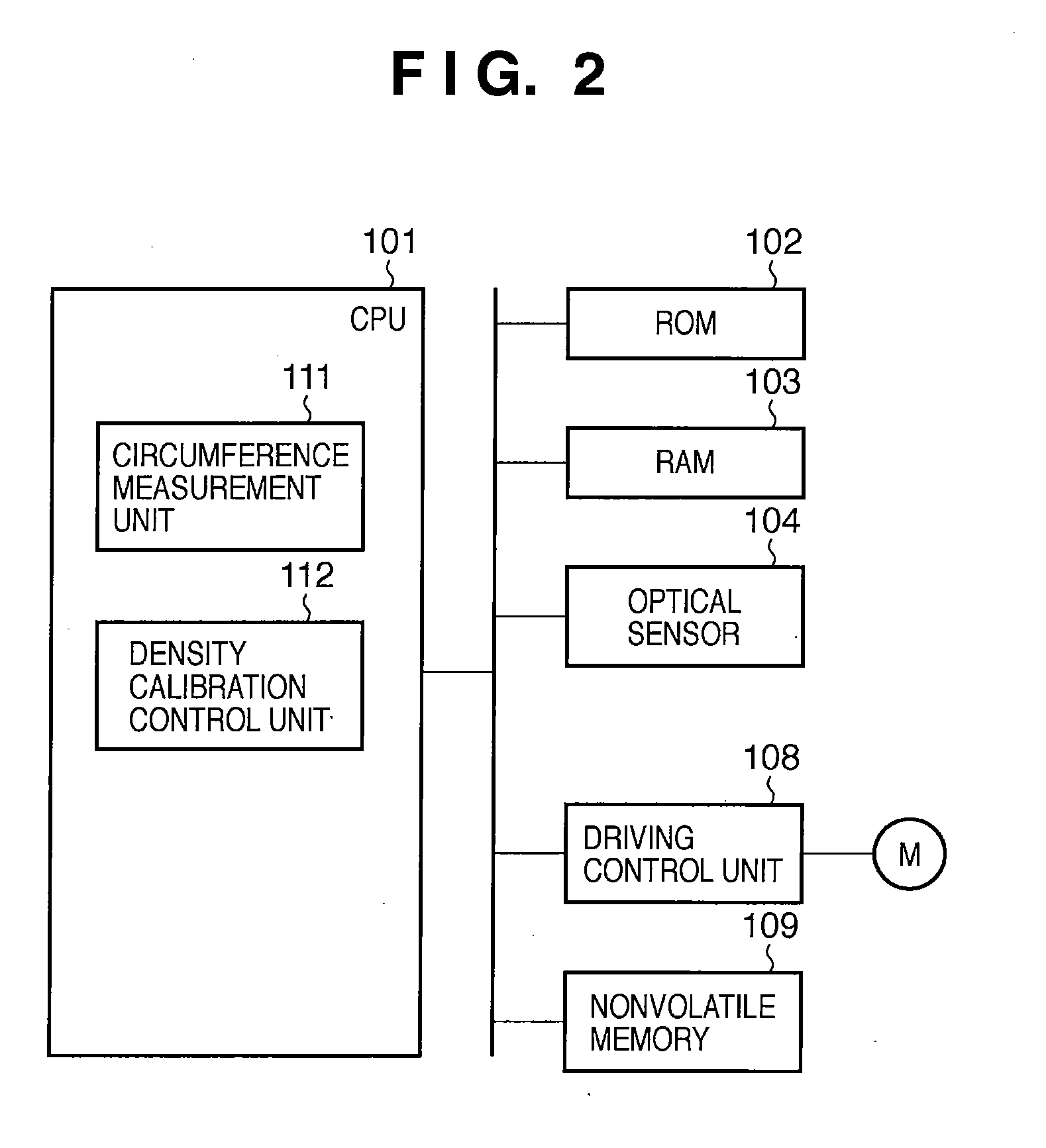

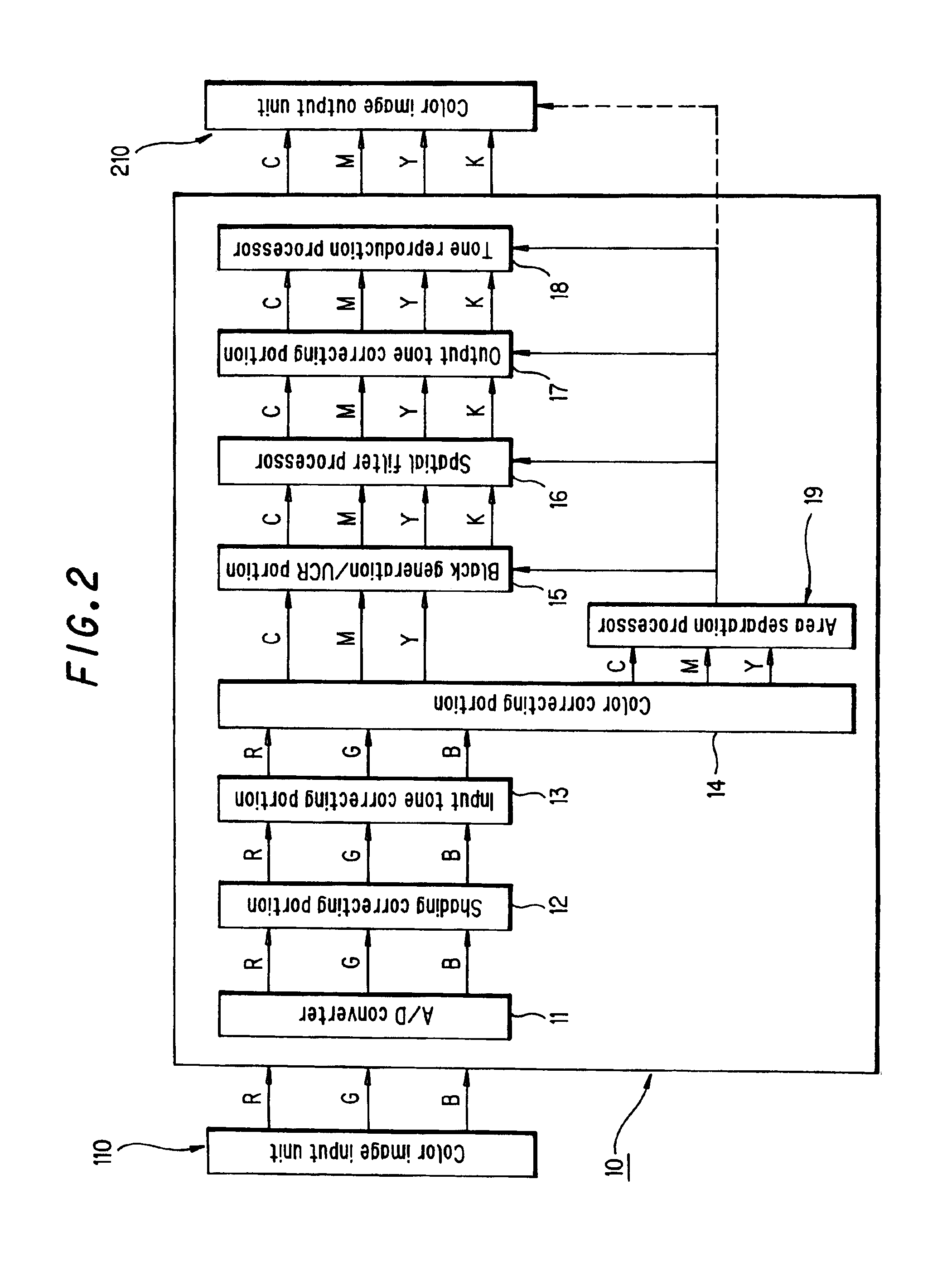

Image processing apparatus and image processing method therefor

InactiveUS20110176155A1High-accuracy density tone correctionReduce the burden onDigitally marking record carriersDigital computer detailsImaging processingVolumetric Mass Density

The present invention relates to an image processing apparatus which performs density tone correction with high accuracy while reducing the burden on the user. The image processing apparatus prints an evaluation image in which a plurality of color patches and a plurality of reference patches are placed on the same main scanning line, measures density of the printed evaluation image, performs density irregularity correction in a main scanning direction using densities of the measured reference patches, and performs density tone correction using densities of the measured color patches. Results of the density irregularity correction are reflected in the density tone correction.

Owner:CANON KK

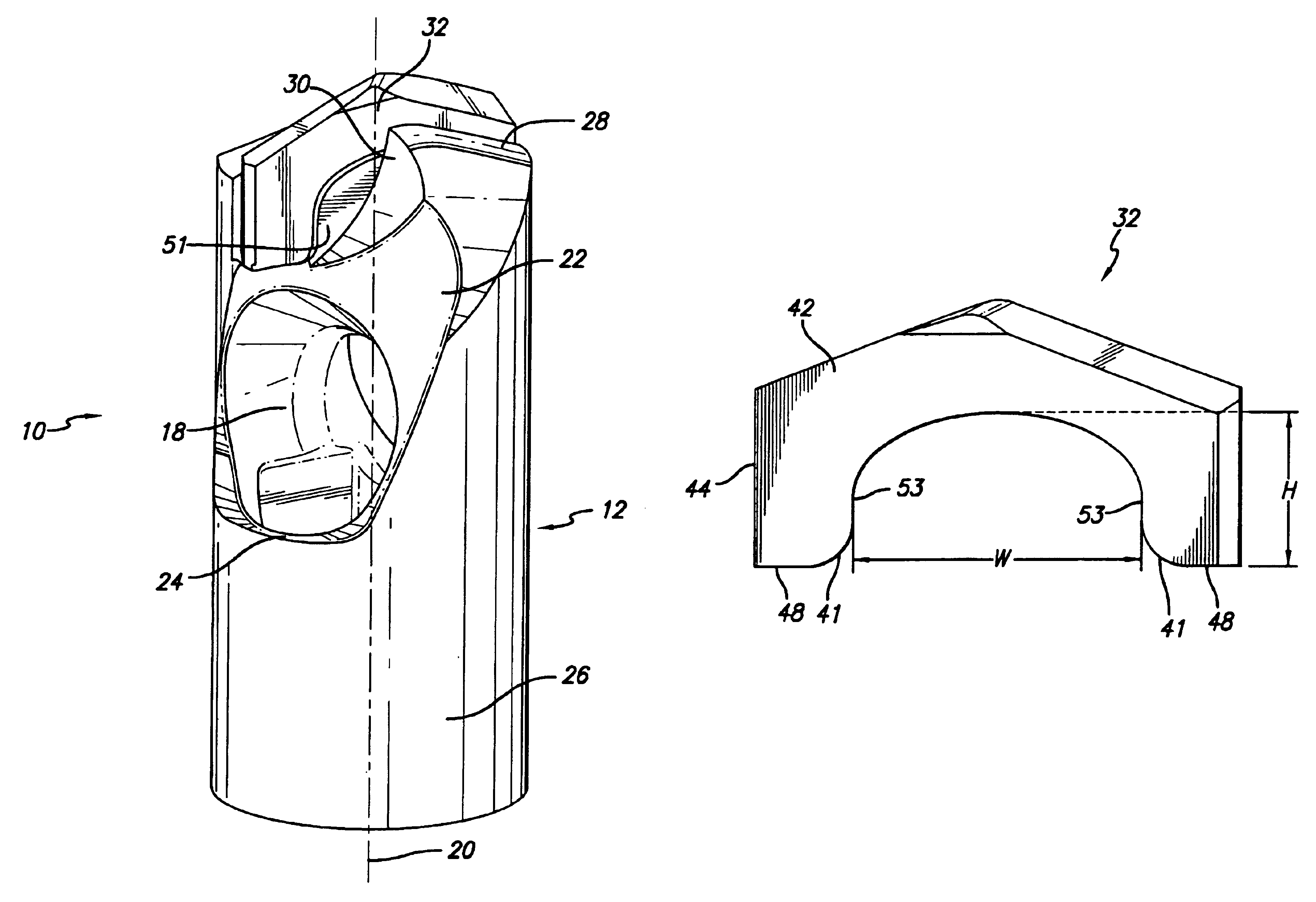

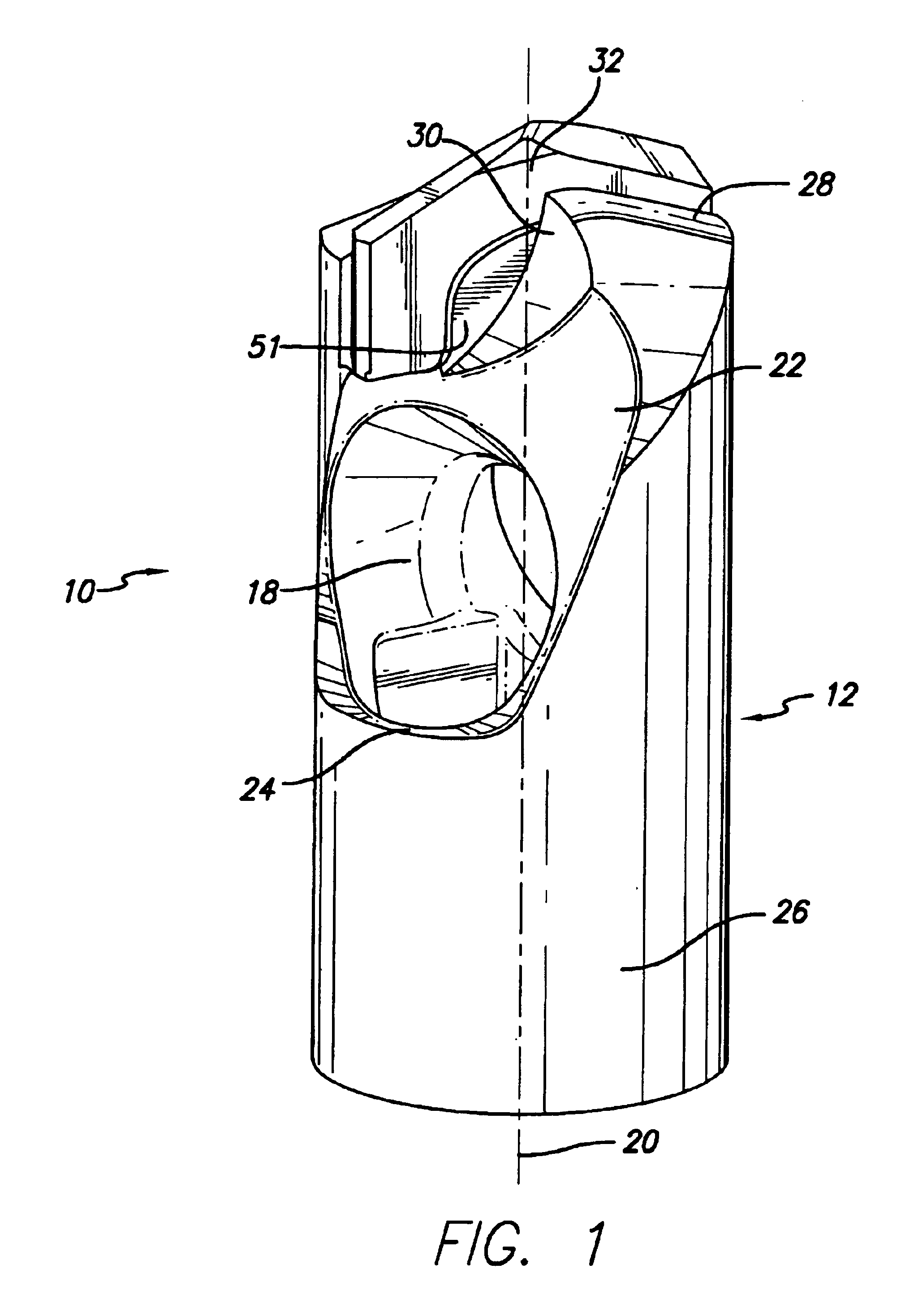

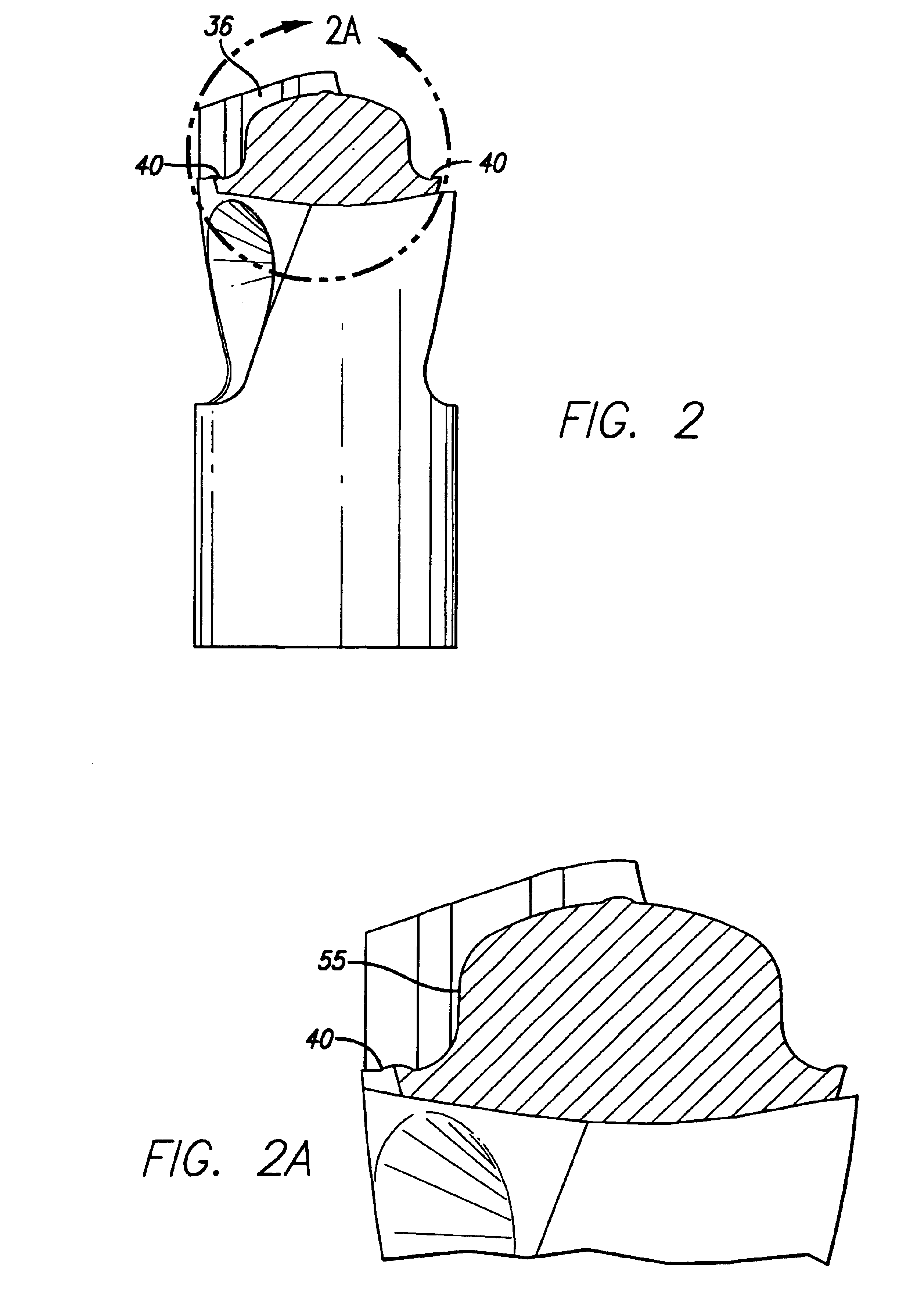

Roof bit and insert assembly

InactiveUS6945340B2Reduce displacementQuality improvementDrill bitsConstructionsMechanical resistanceCarbide

A center vacuum rotary drill bit including a rotary drill bit body and an insert. The bottom surface of the slot has a projecting key that cooperates with a depression keyway of the insert. Generally vertical sidewall surfaces of a depression keyway and vertical surfaces of a projection key provide mechanical resistance against lateral movement of the cutting insert. This mechanical resistance reduces displacement of the insert with respect to the bit body during brazing and thus a high quality, accurately aligned drill bit assembly is provided by applicants' invention. The depression keyway is designed so as to minimize the effect of the axial load on the insert by avoiding sharp corners which tend to amplify nominal stress and provides an insert of a proper carbide density after pressing. Integral bit body protuberance means adequately separate the insert within the slot and permit braze flow between the insert and slot. The protuberance means enhance braze flow when braze is fed between the insert body and bit body.

Owner:KENNAMETAL INC

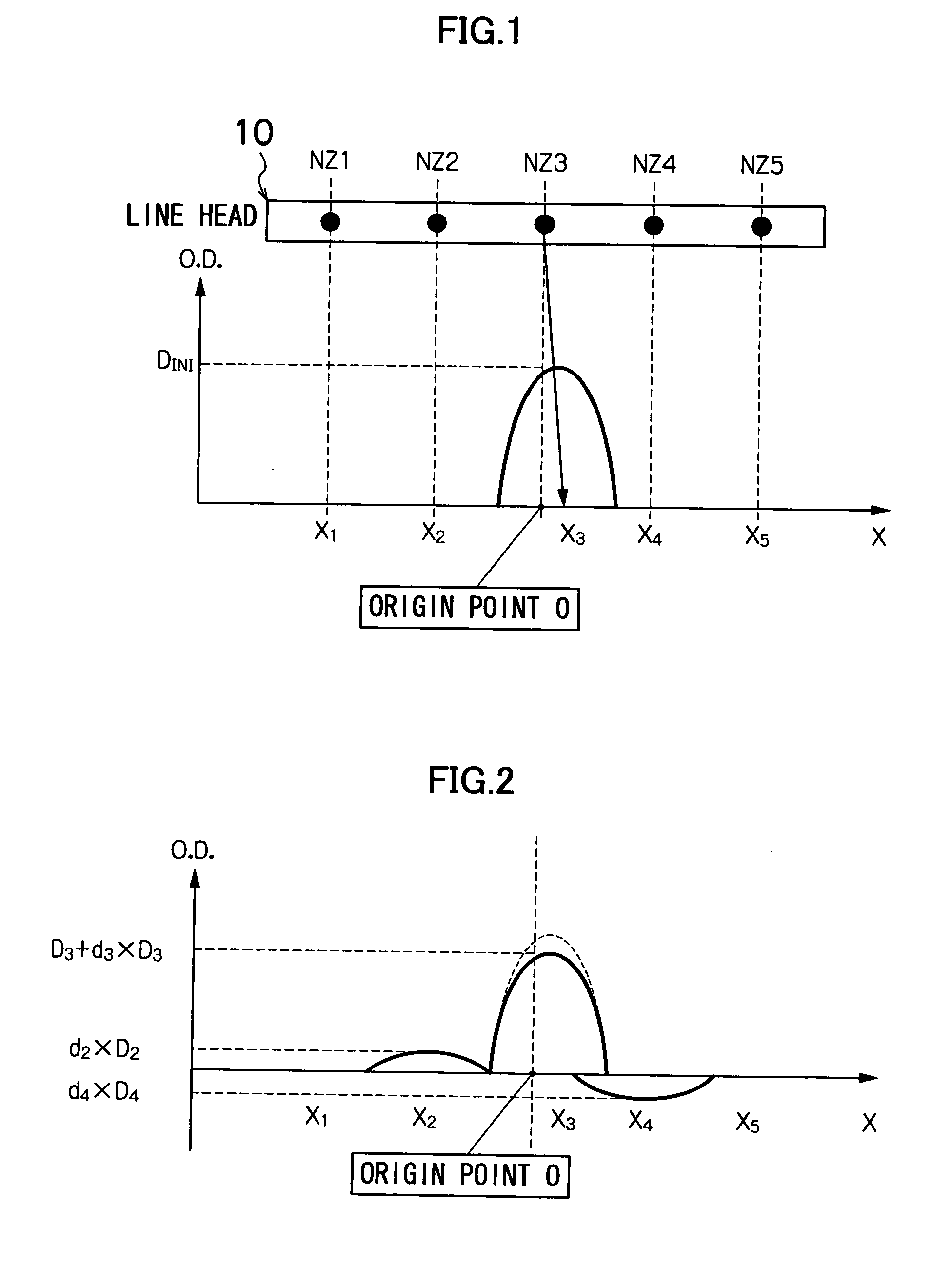

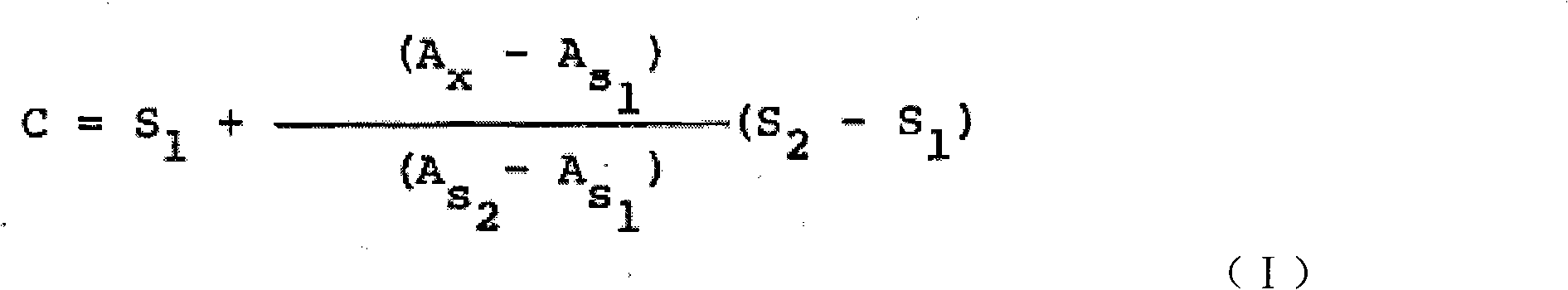

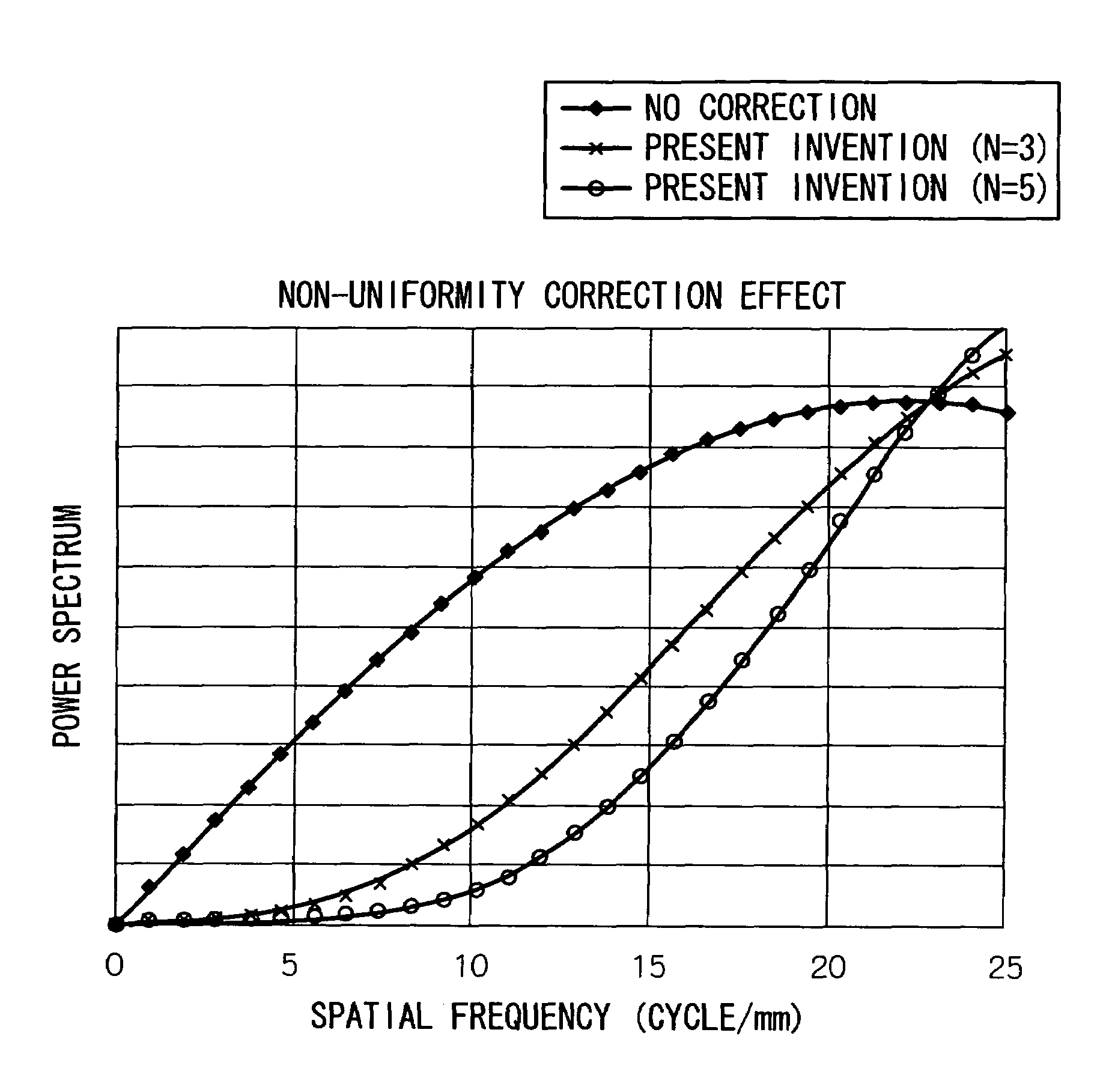

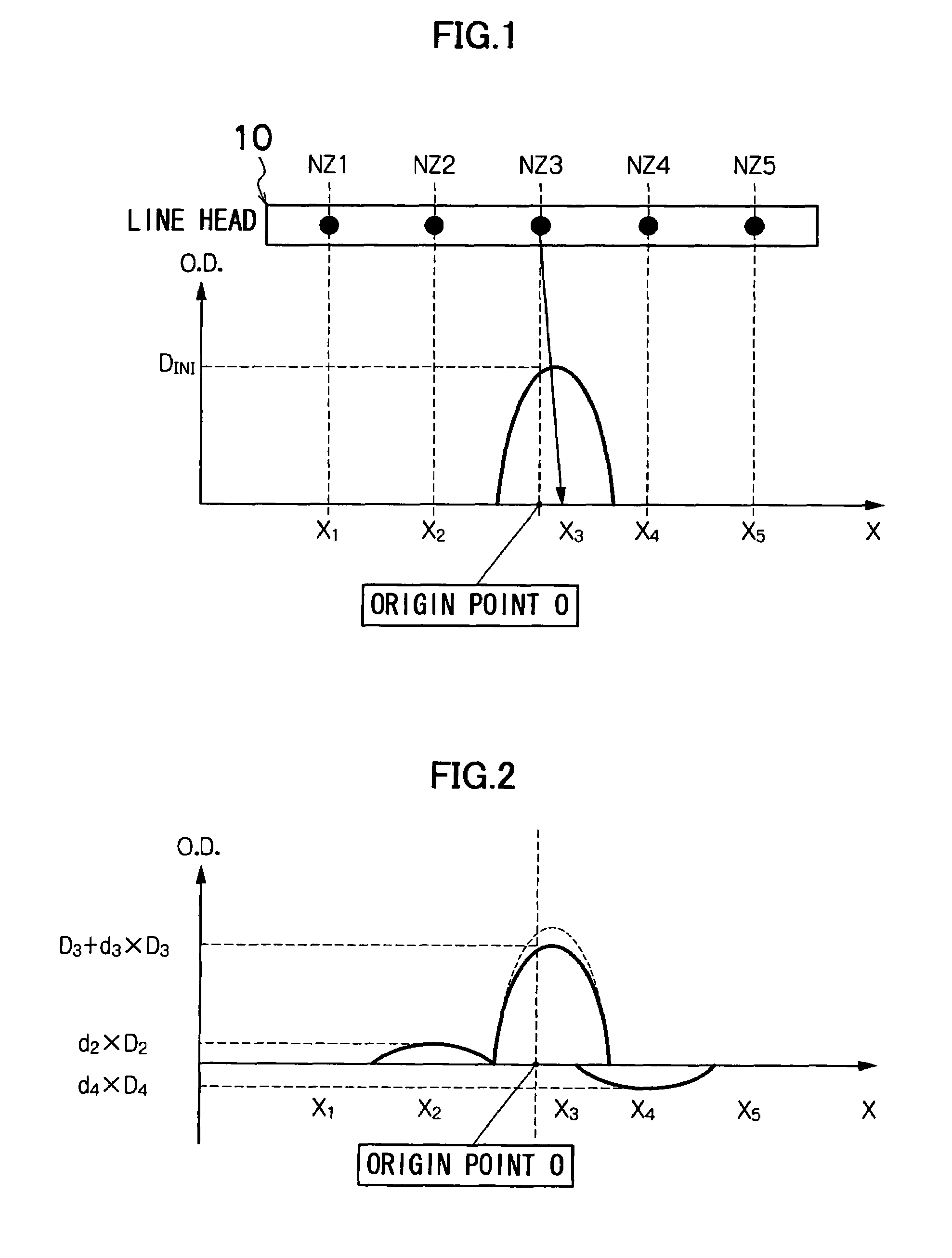

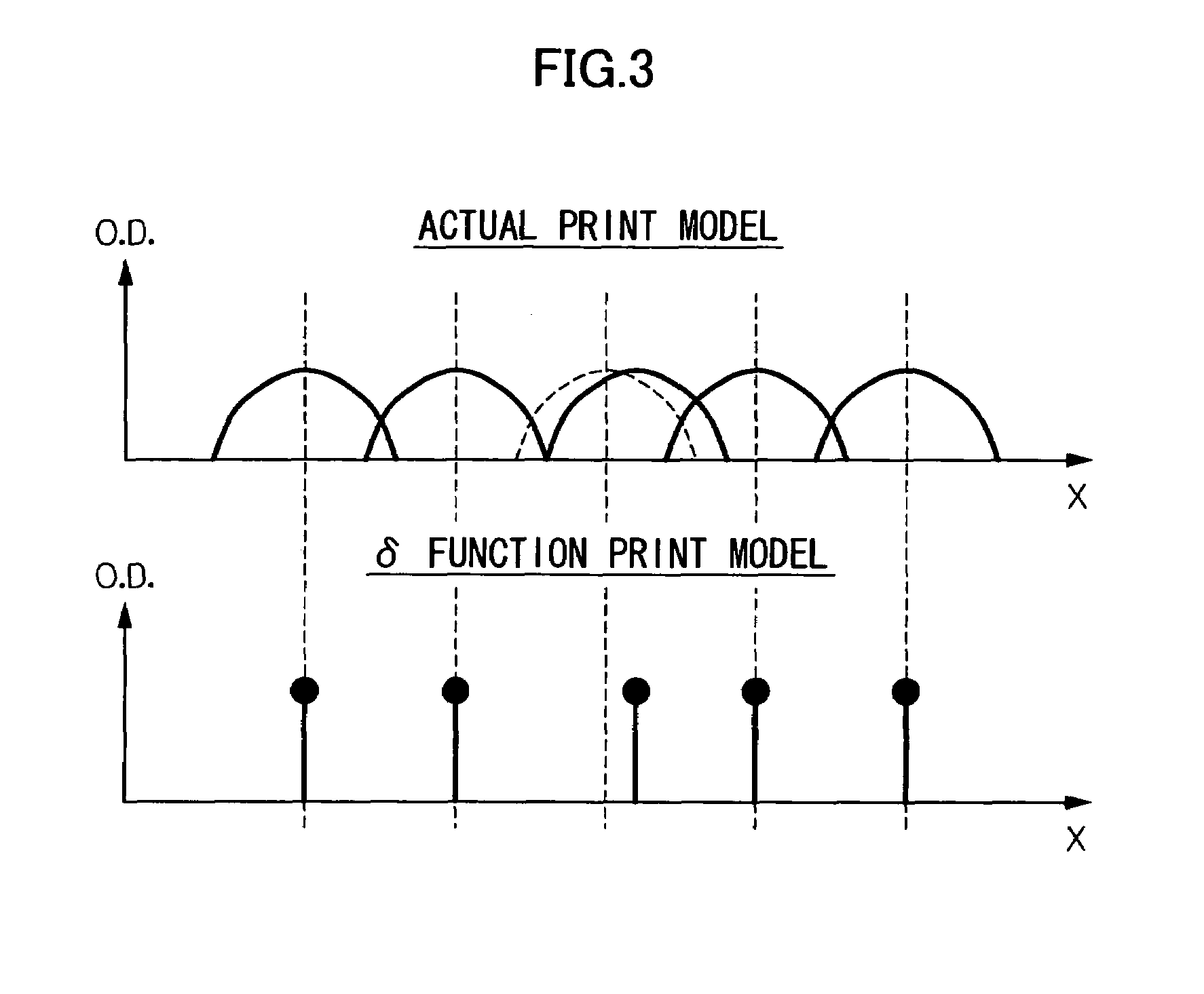

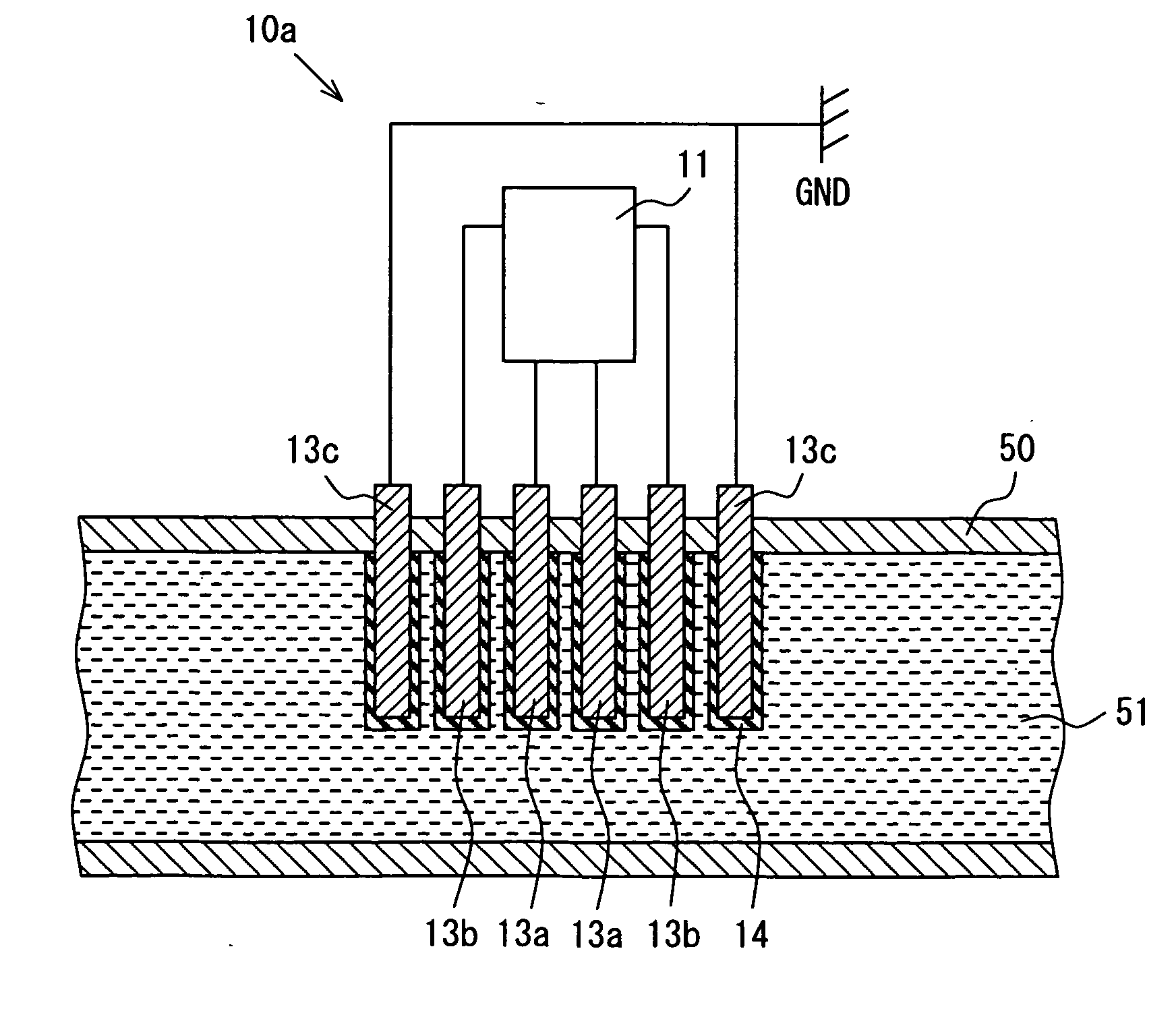

Image recording apparatus and method, and method of specifying density correction coefficients

InactiveUS20060262151A1Correct density non-uniformitiesImprove accuracyDigitally marking record carriersDigital computer detailsImage recordingRecord element

The image recording apparatus comprises: a recording head which has a plurality of recording elements; a conveyance device which causes the recording head and a recording medium to move relatively to each other by conveying at least one of the recording head and the recording medium; a characteristics information acquisition device which acquires information that indicates recording characteristics of the recording elements; a correction object recording element specification device which specifies a correction object recording element from among the plurality of recording elements, a density non-uniformity caused by the recording characteristic of the correction object recording element being corrected; a correction range setting device which sets N correction recording elements (where N is an integer larger than 1) from among the plurality of recording elements, the N correction recording elements being used in correction of output density; a correction coefficient specification device which calculates the density non-uniformity caused by the recording characteristic of the correction object recording element, and specifies density correction coefficients for the N correction recording elements according to correction conditions that reduce a low-frequency component of a power spectrum representing spatial frequency characteristics of the calculated density non-uniformity; a correction processing device which performs calculation for correcting the output density by using the density correction coefficients specified by the correction coefficient specification device; and a drive control device which controls driving of the recording elements according to correction results produced by the correction processing device.

Owner:FUJIFILM CORP

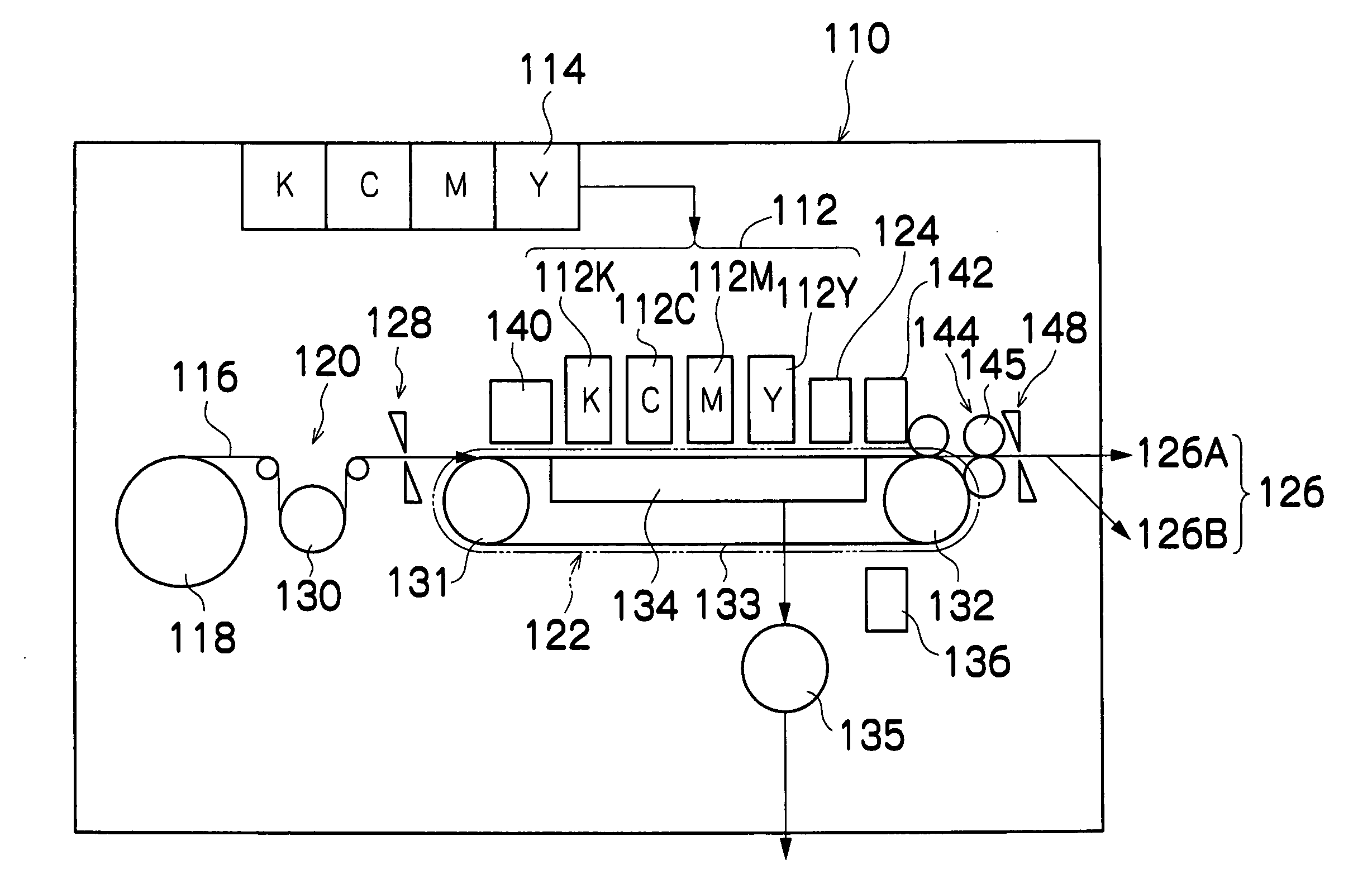

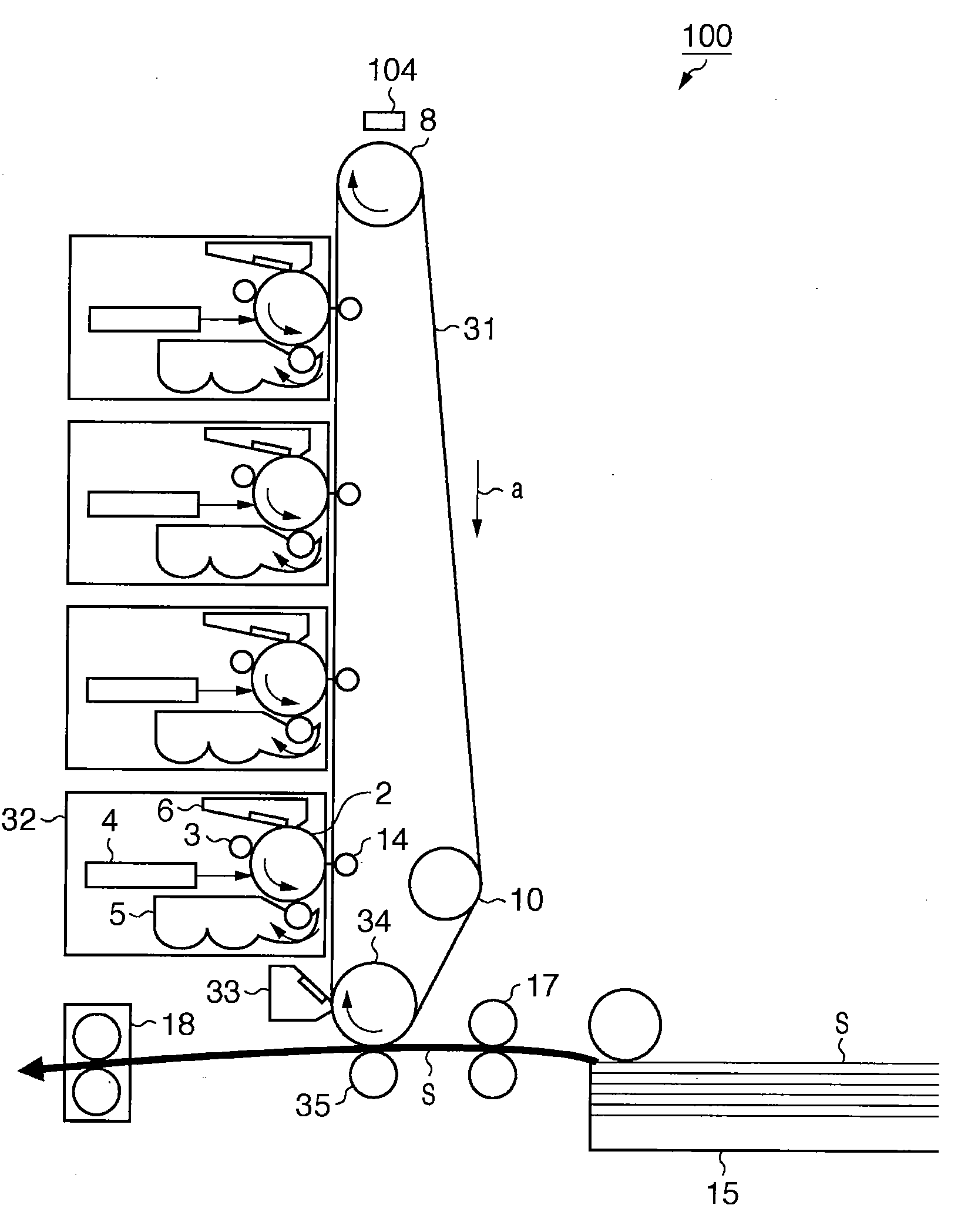

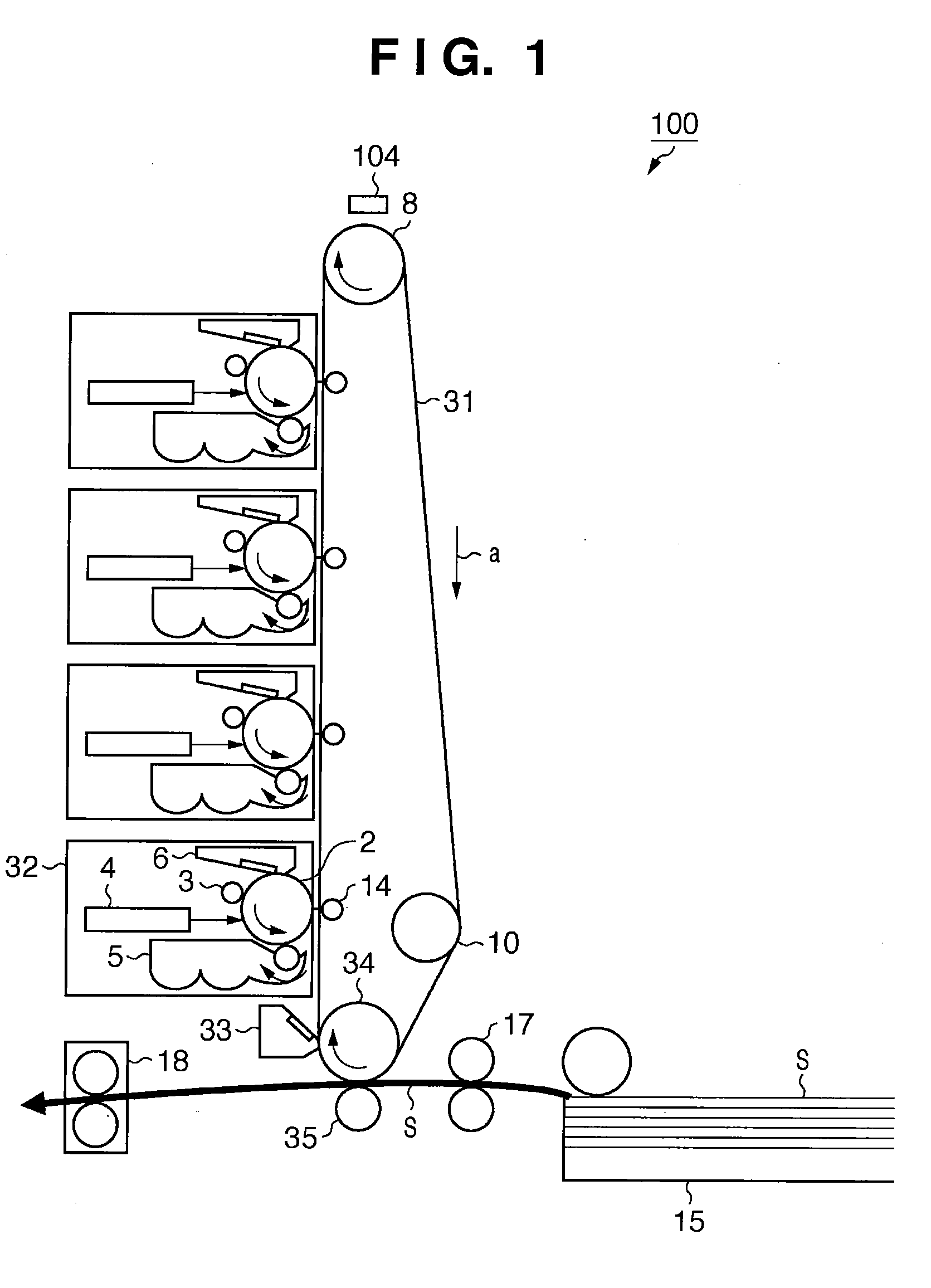

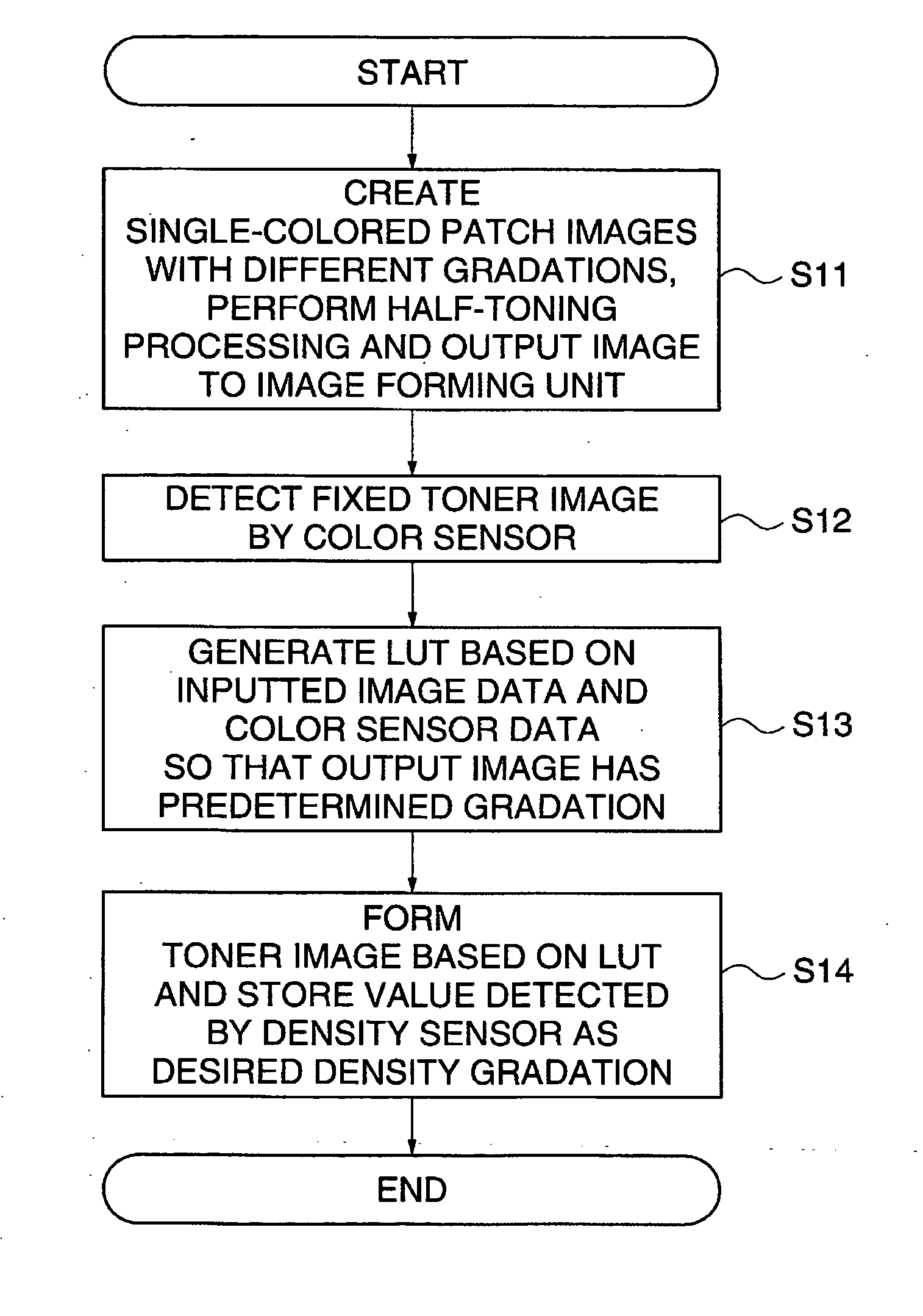

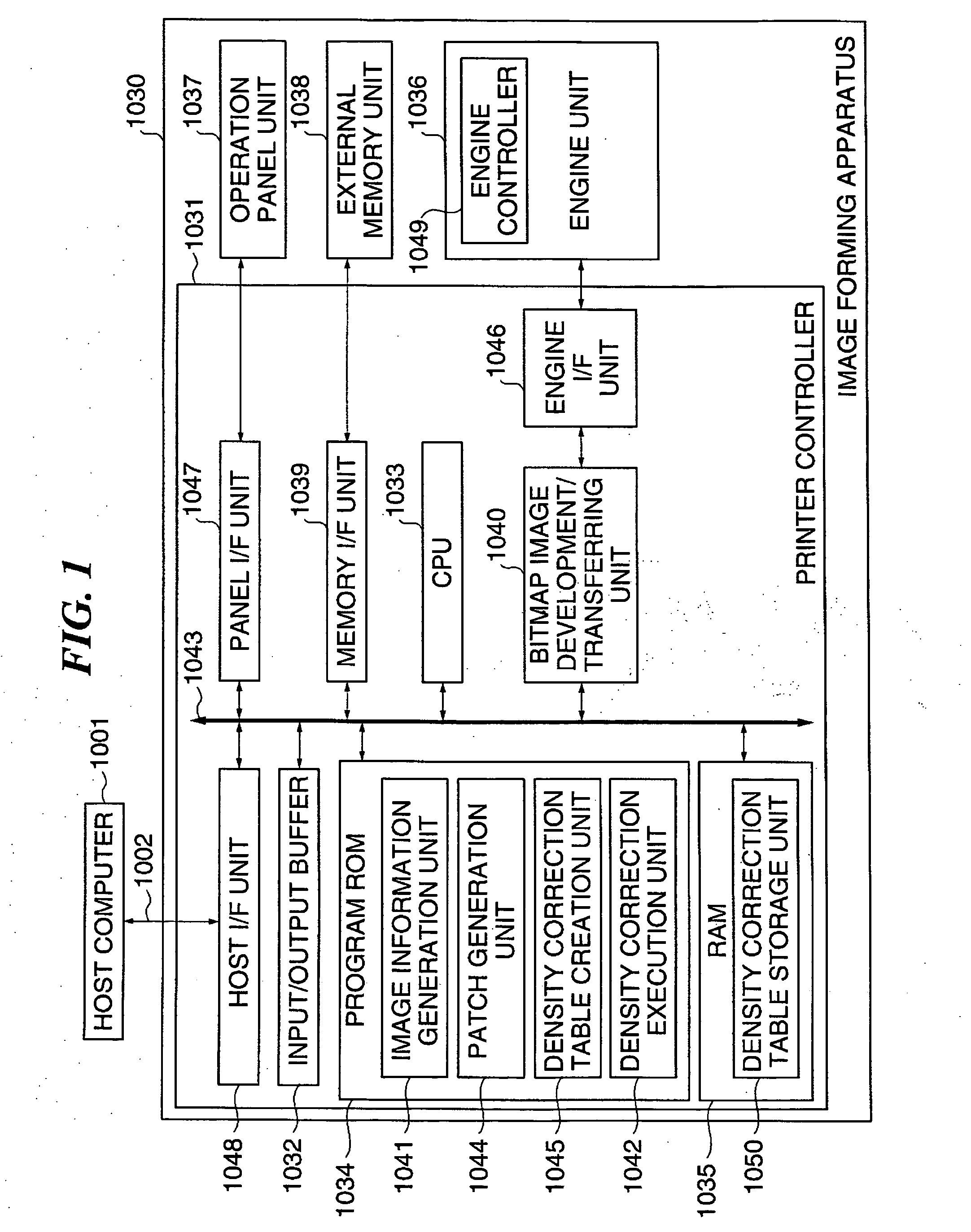

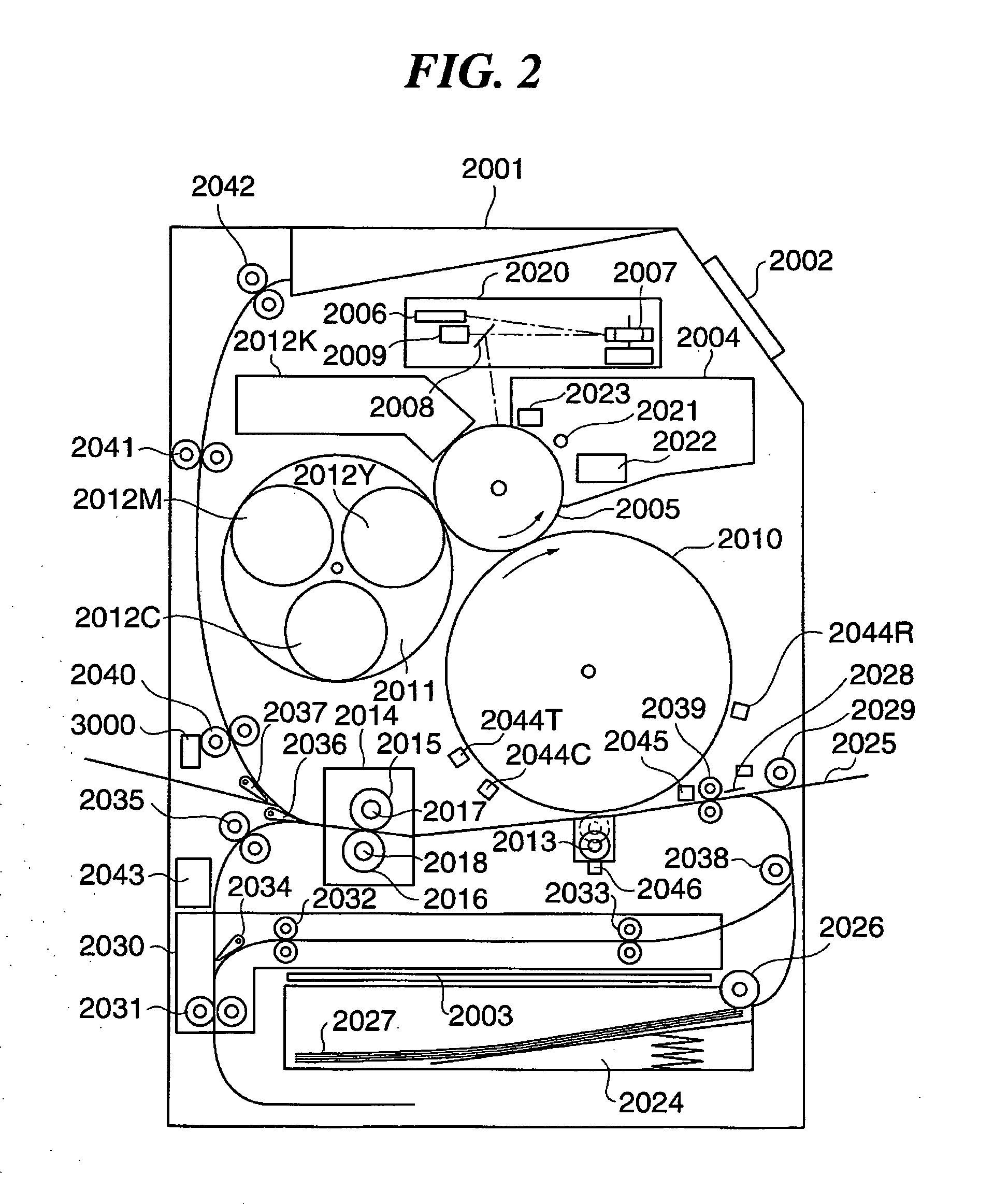

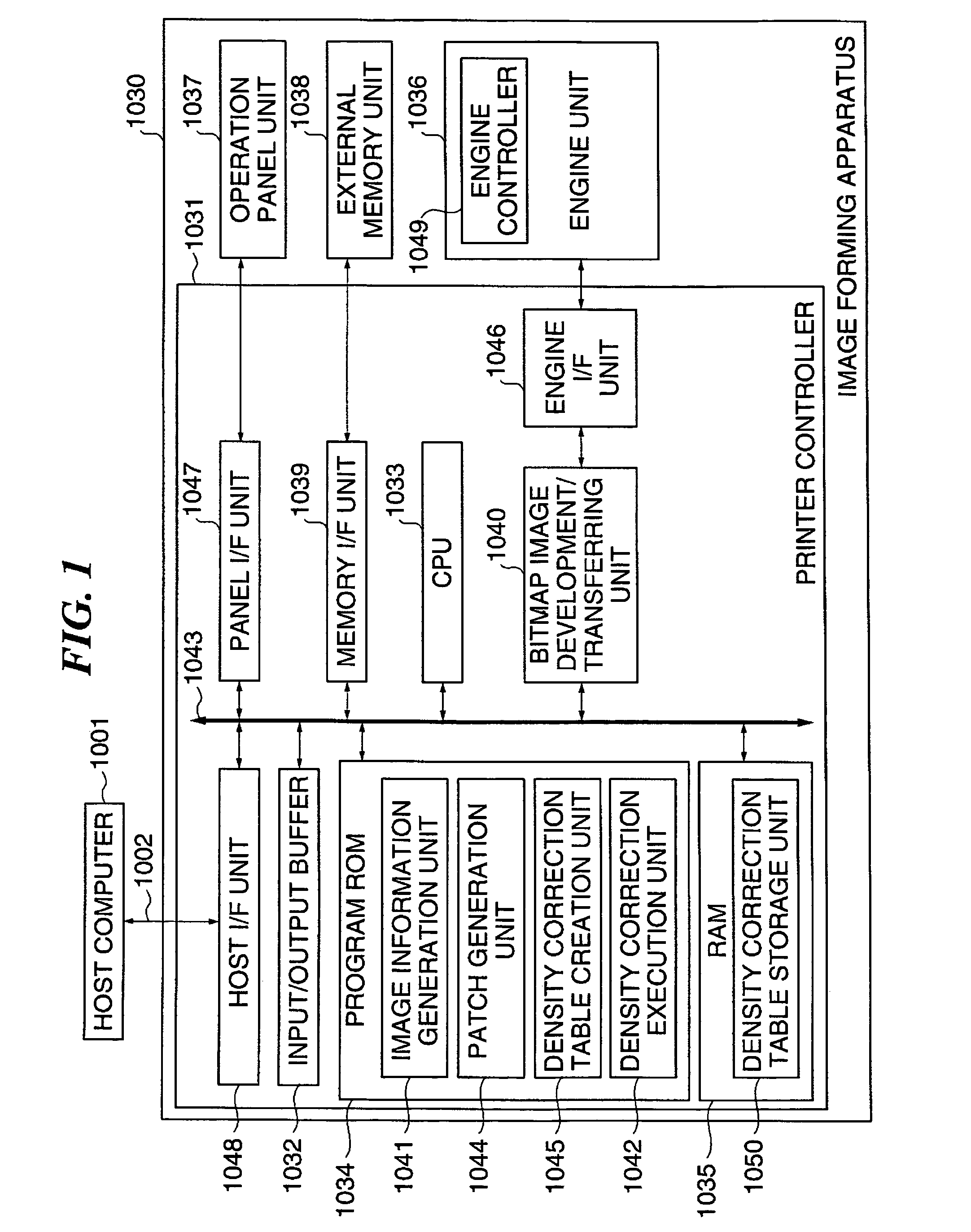

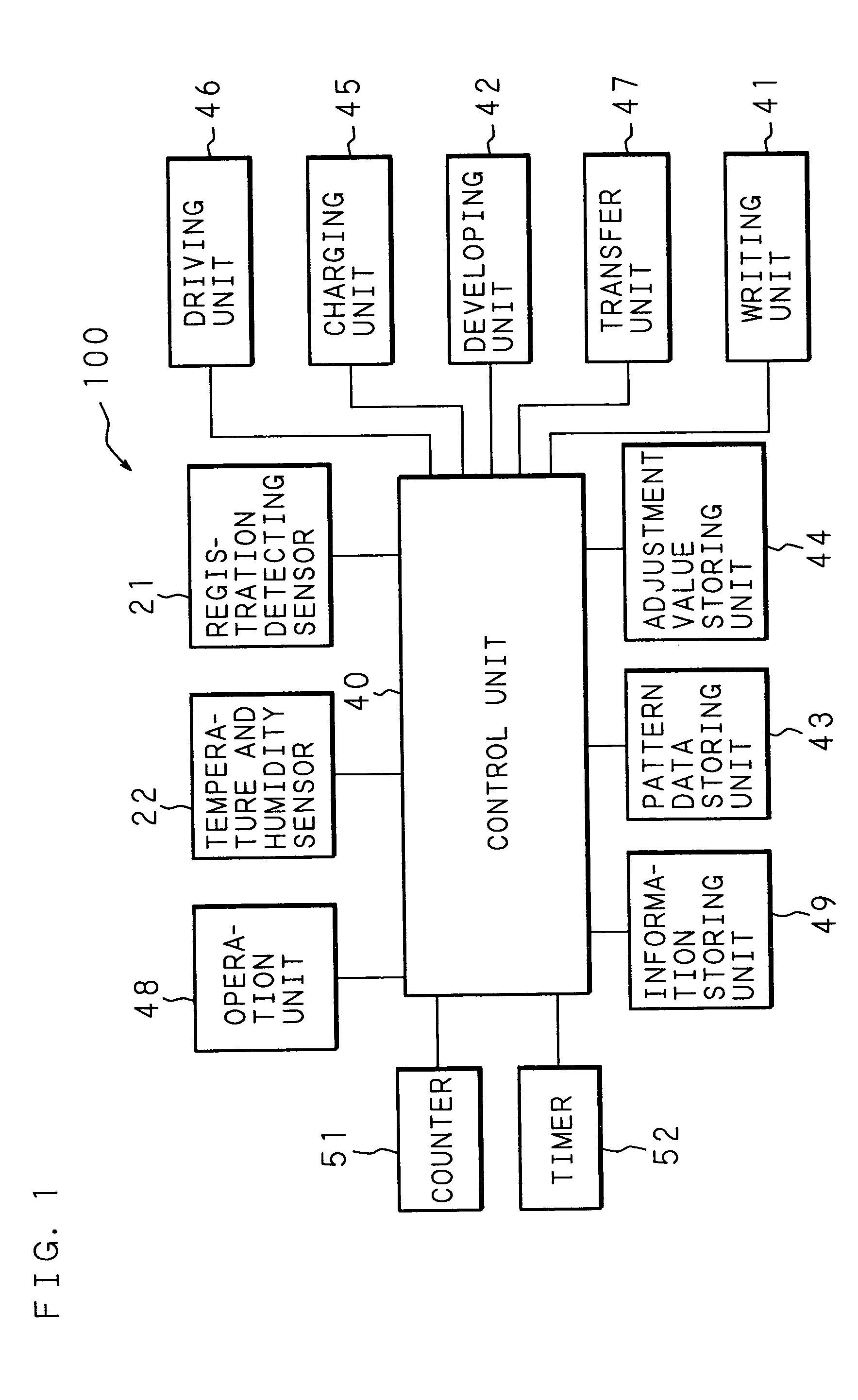

Image forming apparatus and control method thereof

ActiveUS20090296147A1Reduce amount of tonerDensity is accurateDigital computer detailsElectrographic process apparatusMiniaturizationImage formation

Owner:CANON KK

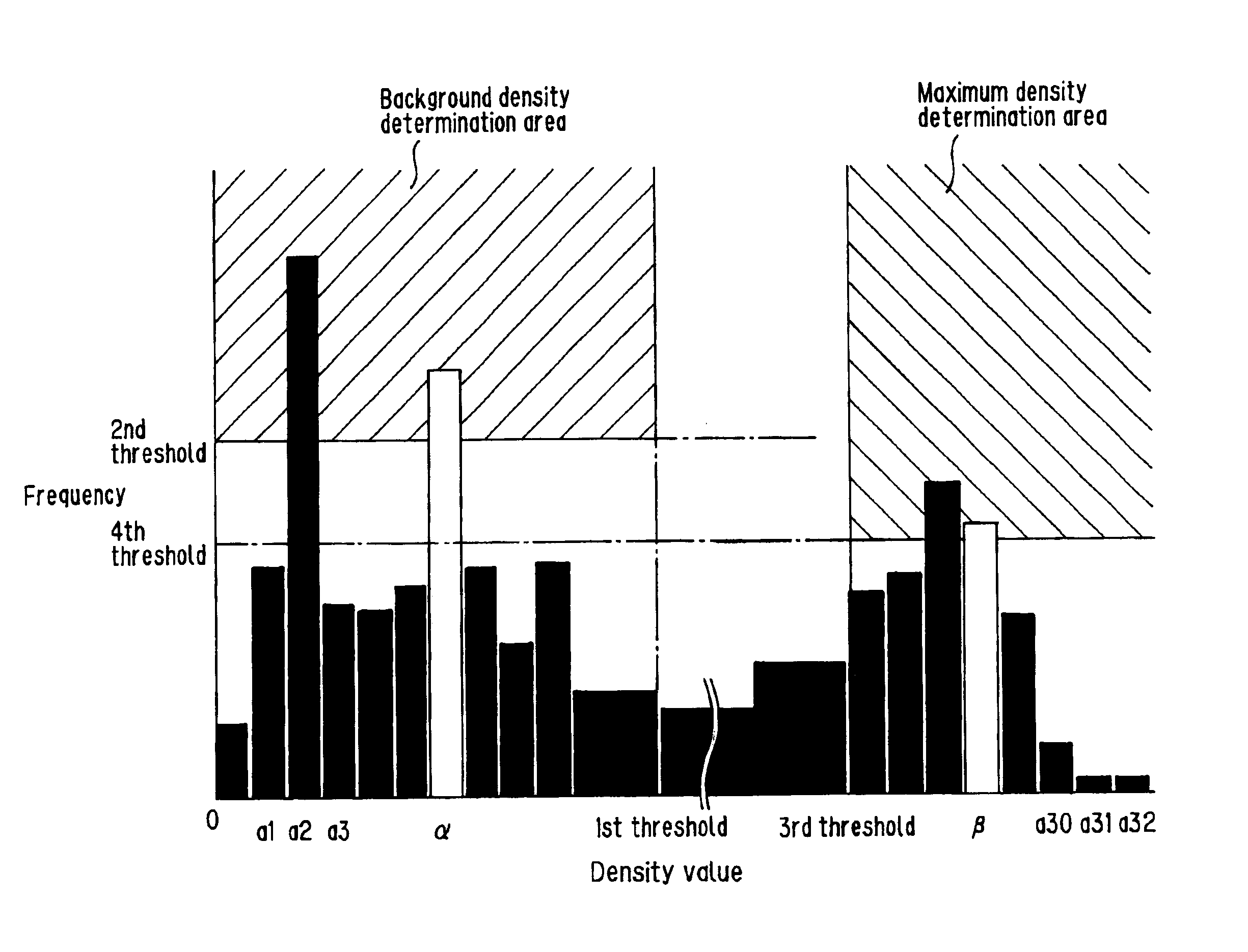

Image processing method and image processing apparatus

InactiveUS6917707B1Optimal density correctionOptimized tone processingImage enhancementImage analysisImaging processingVolumetric Mass Density

A mono-color signal converter extracts a mono-color signal in terms of the CMY system from RGB signals. A histogram generator generates a density histogram based on the density of the pixels in the digital image. At the same time, based on the thresholds determined previously, determination areas for the background density and maximum density are formed. A density class extracting portion extracts the density class of the background density and the density class of the maximum density. Based on the result from the density class extracting portion, a density correction curve generator generates a density correction curve. When the density correction curve needs to be adjusted as desired, the starting point and end point of the density correction curve are renewed through a first correction value and second correction value setting portion. A signal converter converts the mono-color signal into the K-signal.

Owner:SHARP KK

Serum calcium standard substance

ActiveCN101930009AImprove interoperabilityImprove uniformityColor/spectral properties measurementsBiological testingMedicineBiochemistry

The invention discloses a candidate serum calcium standard substance. A method for preparing the candidate serum calcium standard substance comprises the following steps of: diluting in-vitro serum or adding calcium into the in-vitro serum to obtain 5 kinds of serum solution with different calcium concentrations; and fixing a value for each of the 5 kinds of serum solution with different calcium concentrations respectively so as to obtain serum calcium standard substances with 5 calcium concentrations. In the candidate serum calcium standard substance, other substance is not added and only the serum is used as a substrate; the candidate serum calcium standard substance has the advantages of high interoperability, high uniformity, high stability under the -80 DEG C storage condition, reliable traceability of the fixed value and relatively small relative synthesis uncertainty of between 0.83 and 1.55 percent; moreover, compared with other conventional serum calcium standard substances, the candidate serum calcium standard substance has the advantages of low cost and simple preparation method.

Owner:BEIJING CHAOYANG HOSPITAL CAPITAL MEDICAL UNIV

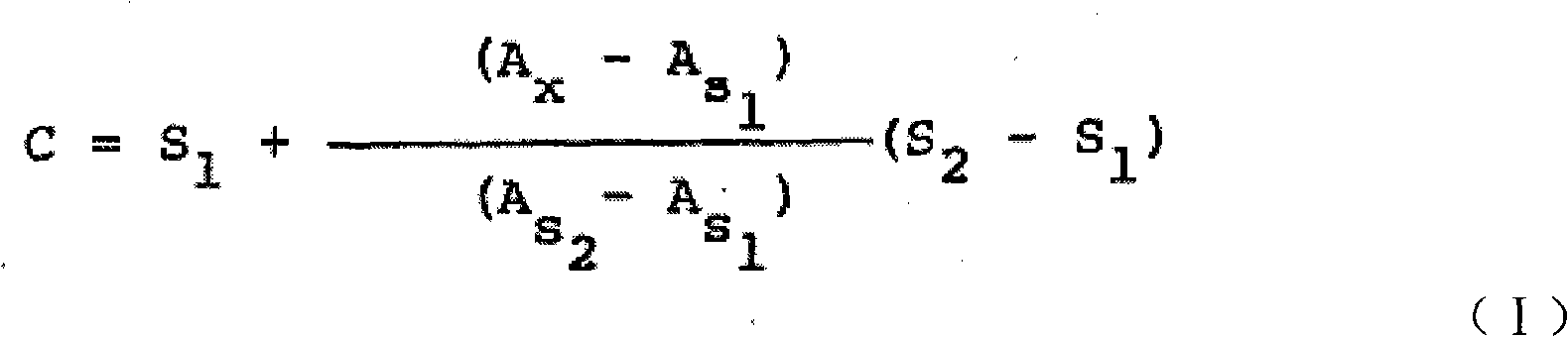

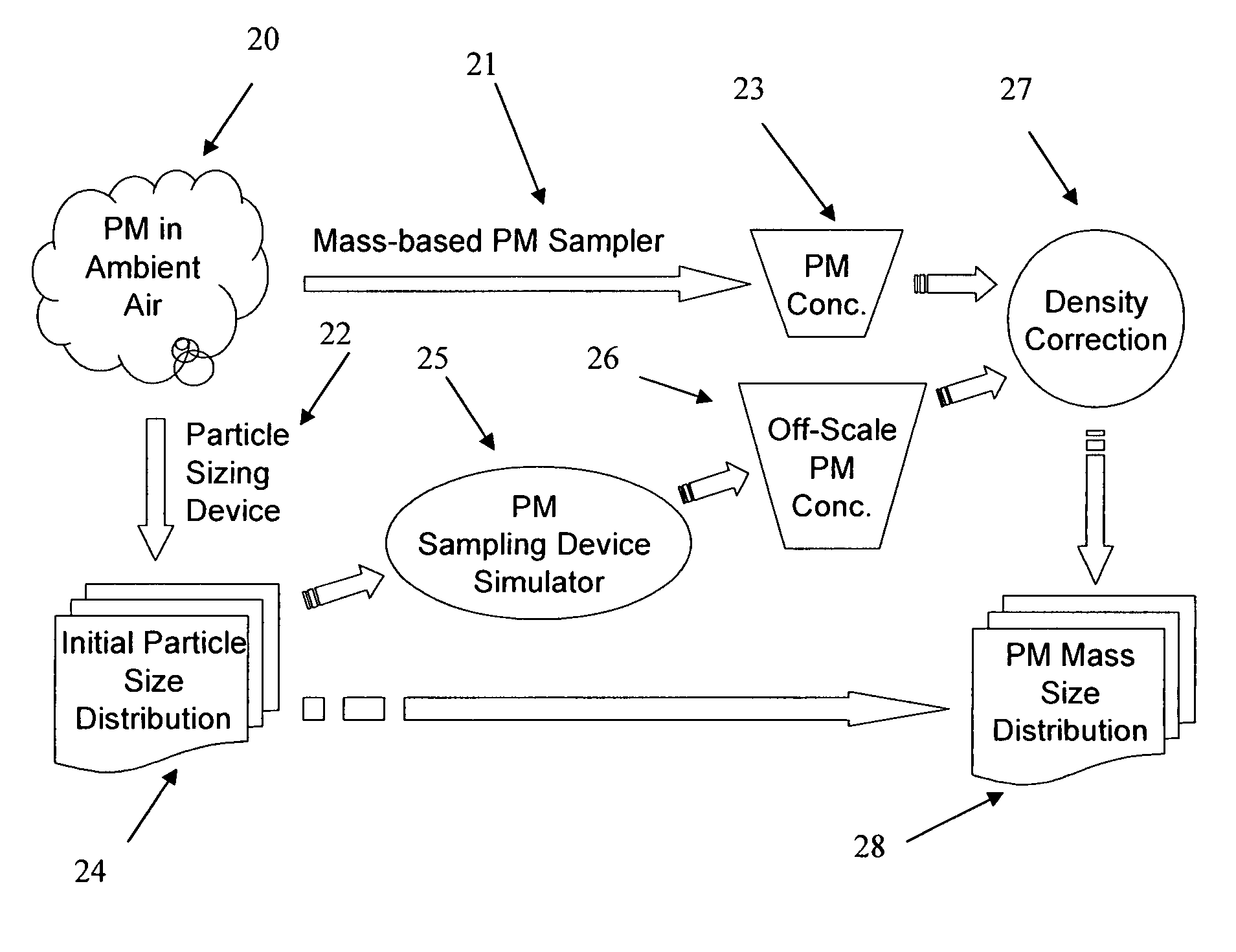

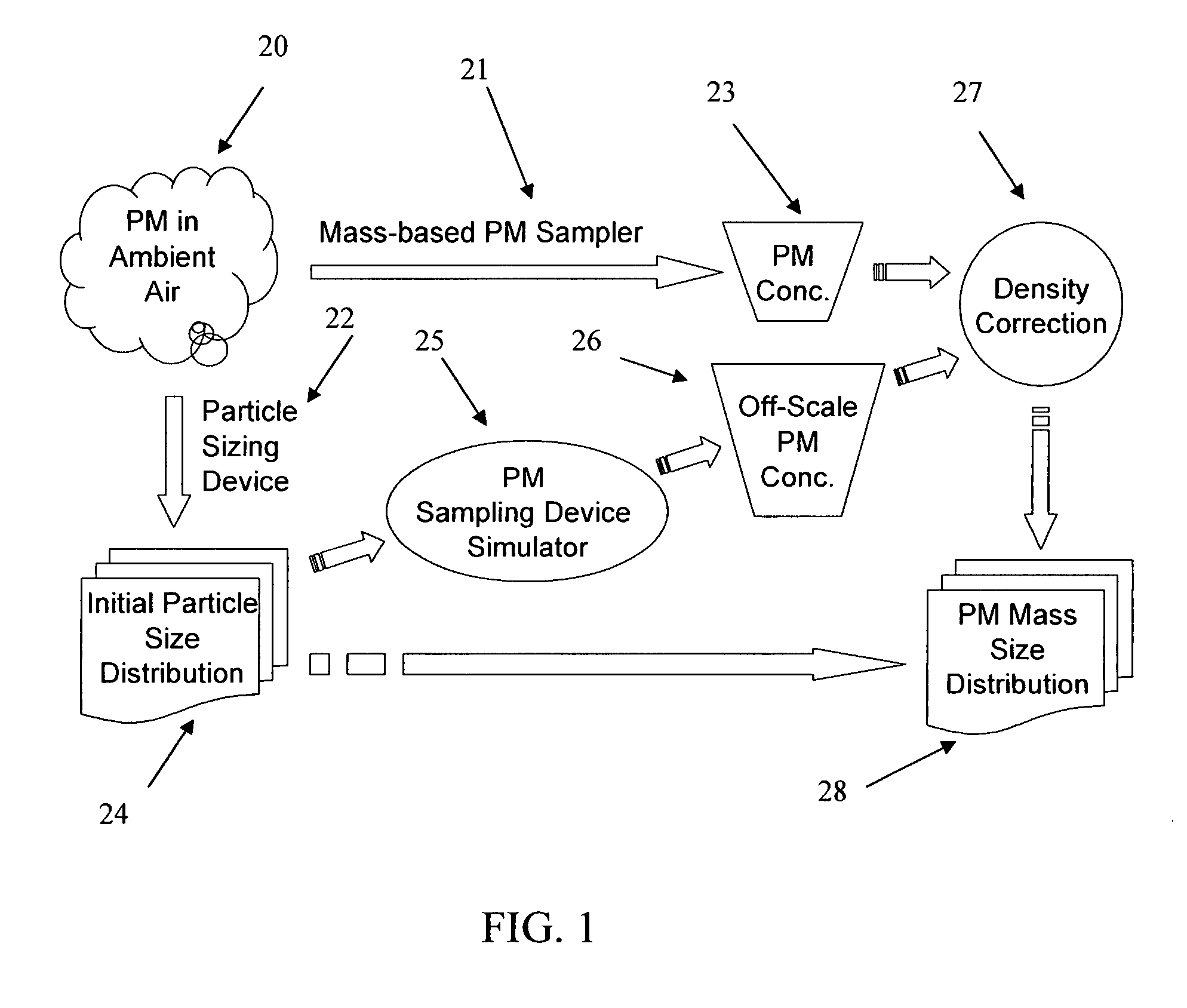

Comprehensive particulate matter measurement system and method for using the same

InactiveUS20070180936A1Density is accurateAccurate measurementMaterial analysisMeasurement deviceAmbient air

A comprehensive particulate matter measurement system (CPMMS) that measures accurate mass size distribution of particulate matter (PM) in ambient air, and a method to measure the accurate mass size distribution of PM are provided. The CPMMS includes a mass-based PM sampler, a particle sizing device, and an analysis system that manipulates data sent from the mass-based PM sampler and the particle sizing device to accurately measure mass size distribution of PM. The mass-based PM sampler measures total mass concentration of PM, and the particle sizing device measures size or volume size distribution of PM. Estimated total mass concentration is obtained from the size distribution predicting an assumed density of PM, and is compared with the actual total mass concentration measured by the mass-based PM sampler. A correct density of PM can be obtained from the actual total mass concentration, and as a result, accurate mass size distribution can be obtained.

Owner:PROVIDENCE ENG & ENVIRONMENTAL GRP LLC A LIMITED LIABILITY COMPANY ORGANIZED UNDER THE LAWS OF THE STATE OF LOUISIANA

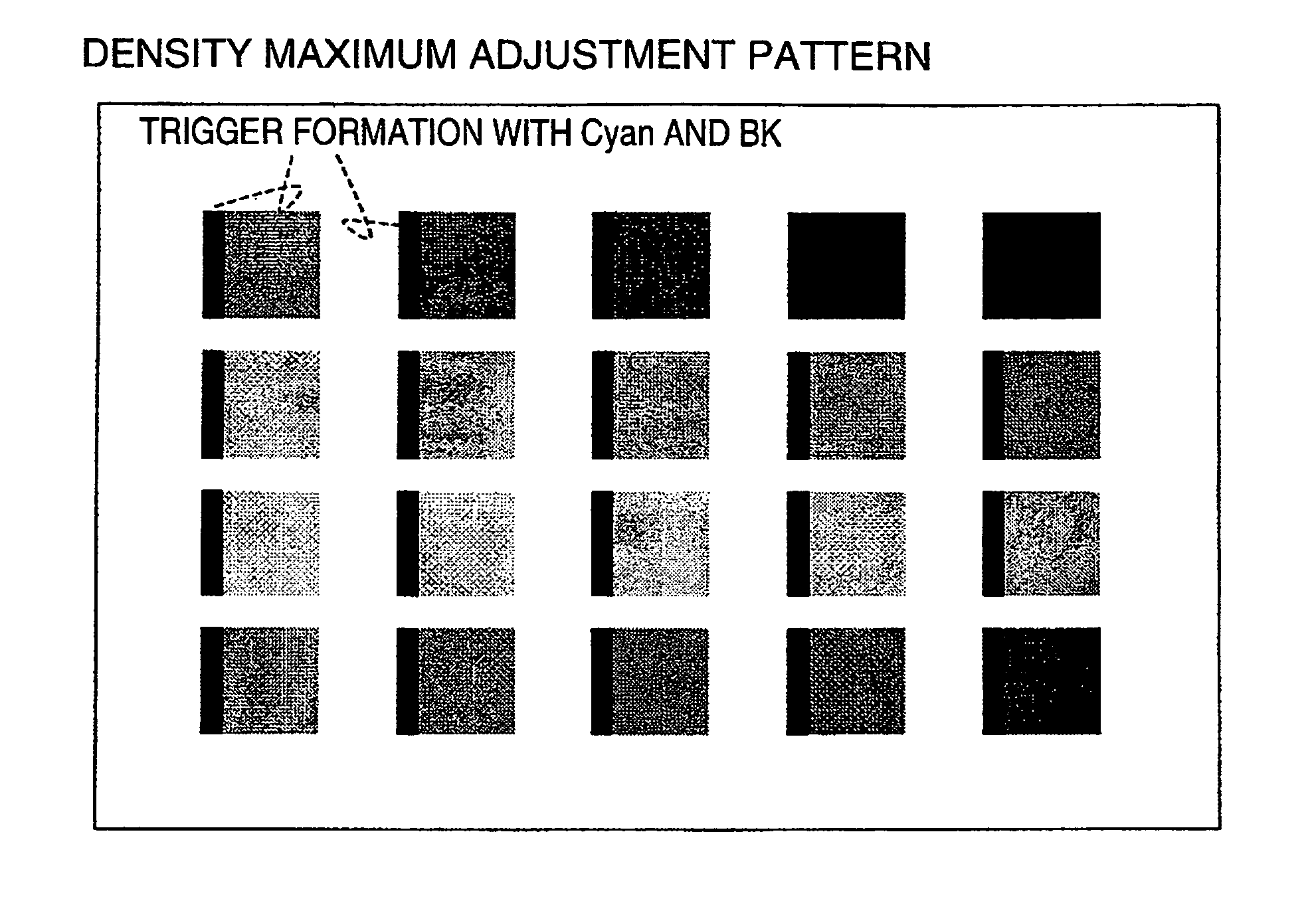

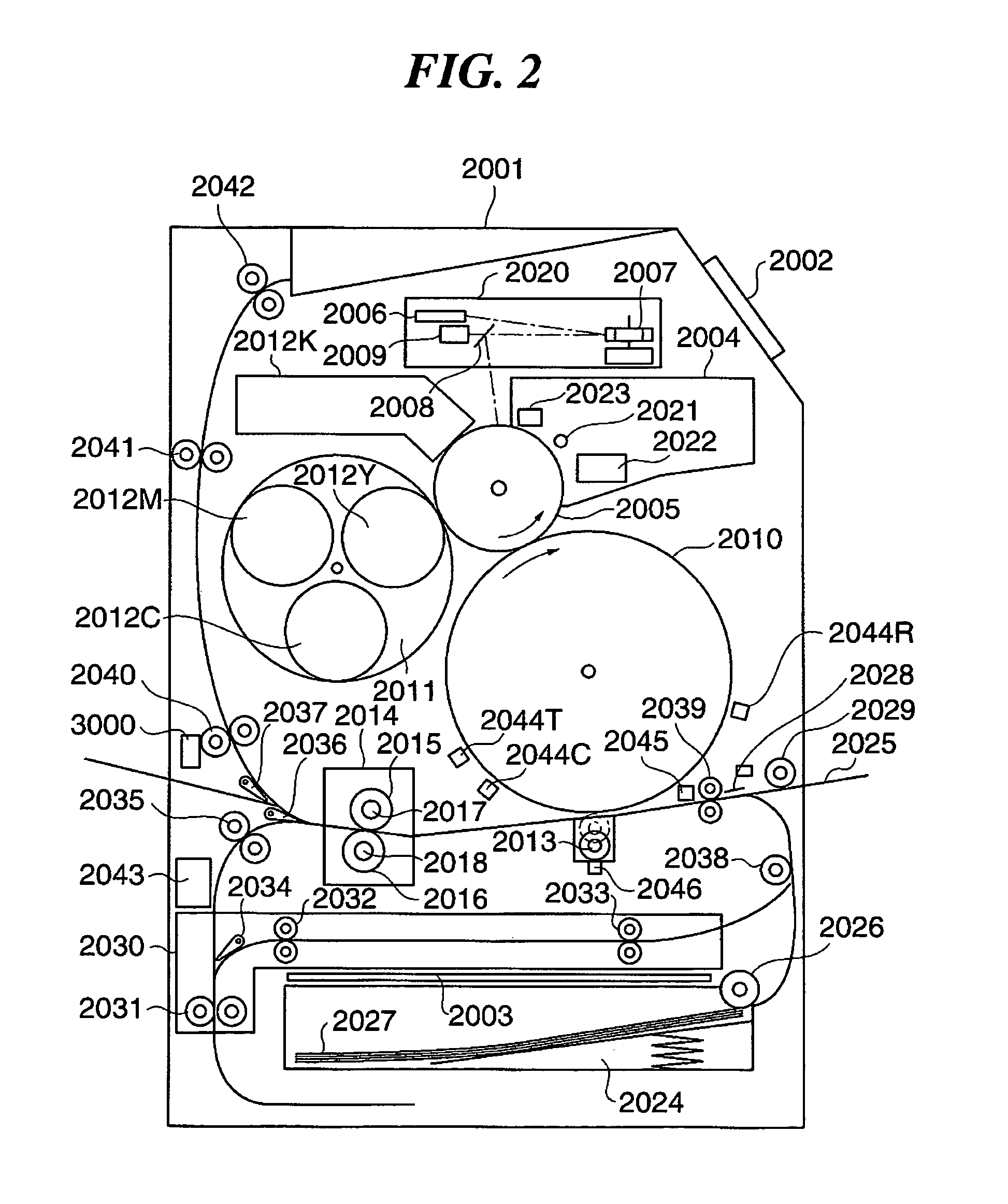

Image forming apparatus and control method for the same

ActiveUS20060198648A1Accurate read timingImproved color stabilityElectrographic process apparatusComputer graphics (images)Image formation

An image forming apparatus that is capable of generating highly accurate read timing of a patch image, thereby achieving highly accurate density adjustment and improving color stability. A patch image for color adjustment is read in read timing generated when a trigger bar is detected. The patch image and the trigger bar that are to be read by a color sensor are formed on a transfer material. Image formation is executed by a printer controller in an image forming condition set differently for the trigger bar and for the patch image.

Owner:CANON KK

Image recording apparatus and method, and method of specifying density correction coefficients

InactiveUS7484824B2Accurate correctionDensity is accurateDigitally marking record carriersDigital computer detailsImage recordingVolumetric Mass Density

Owner:FUJIFILM CORP

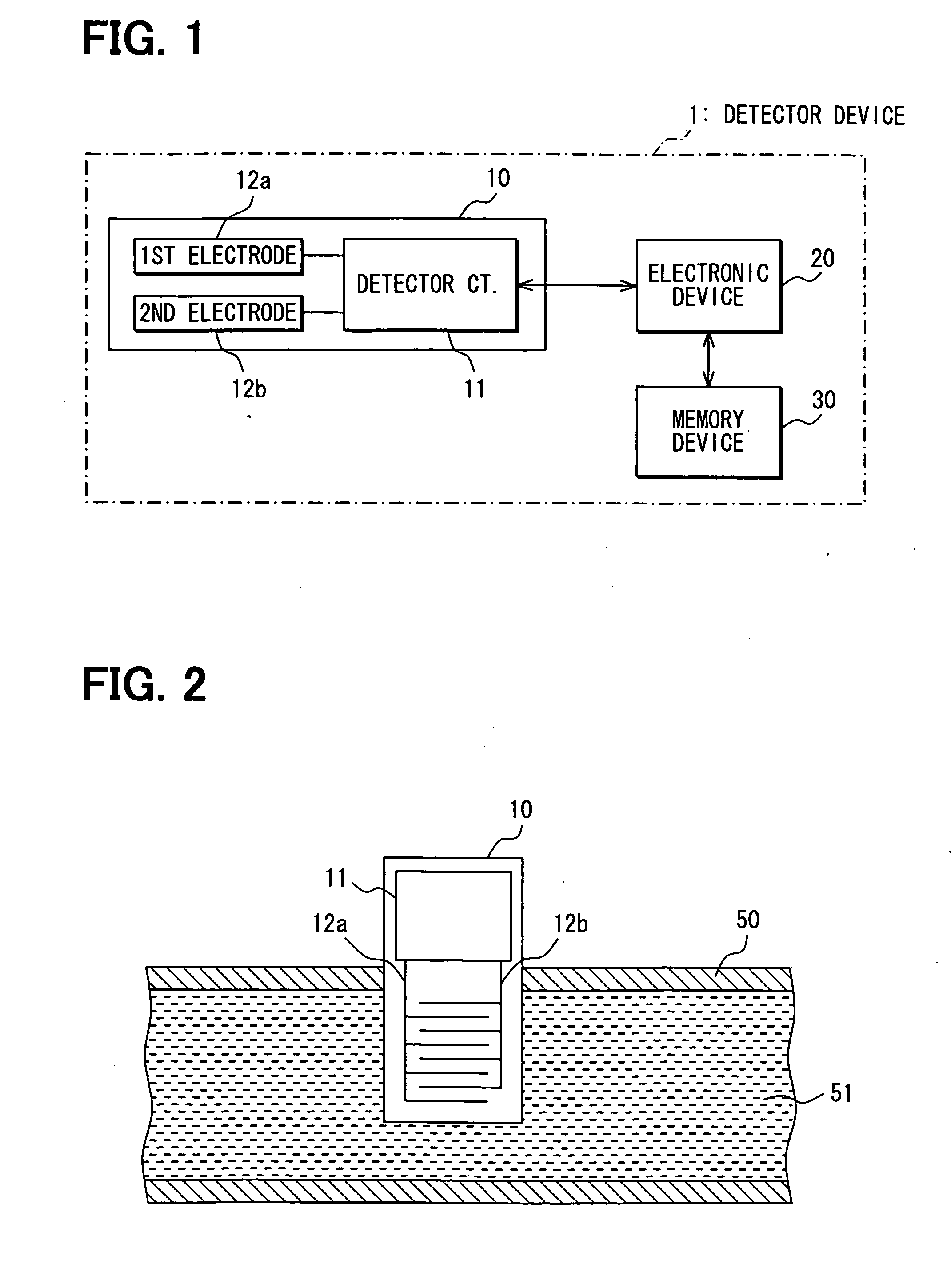

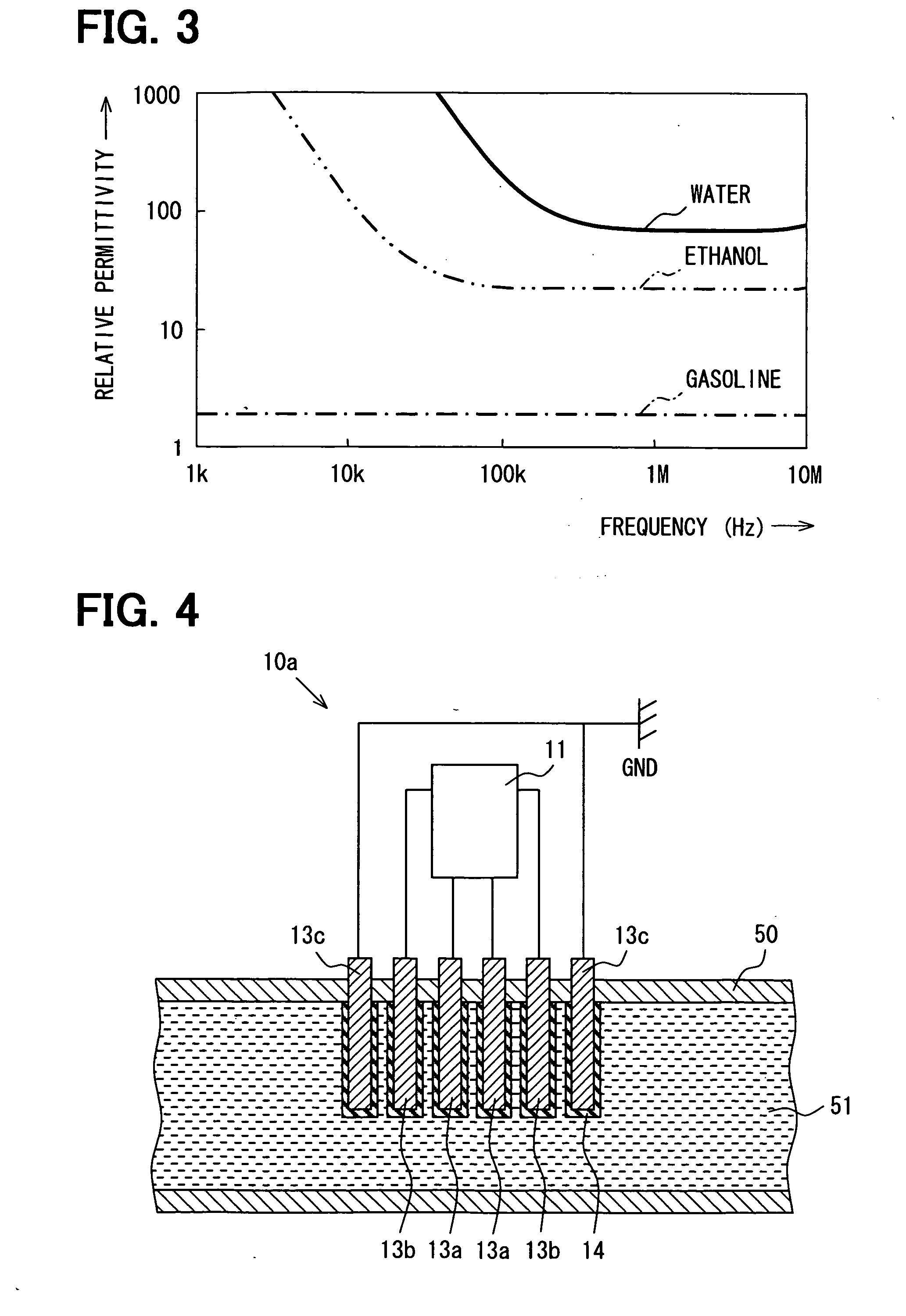

Detector device for detecting component density contained in mixture fuel

InactiveUS20090157345A1Density is accurateAvoid chemical reactionsMaterial analysis by electric/magnetic meansDigital computer detailsGasolineEngineering

A detector device of the present invention detects densities of components, such as gasoline and ethanol, contained in mixture fuel even when some water is included in the mixture fuel. The detector device includes a sensor having a pair or electrodes, an electronic device for calculating the densities and a memory device for storing permittivities of pure components including water measured beforehand. Alternating current having two different frequencies f1, f2 is applied to the pair of electrodes immersed in the mixture fuel to detect the permittivities of the mixture fuel under f1 and f2. The two frequencies, f1 and f2, are so chosen that the premittivities of gasoline and ethanol show no change between f1 and f2, while the permittivitiy of water shows a substantial difference between f1 and f2. The electronic device calculates the densities of the components based on permittivities of the mixture fuel detected by the sensor and those of components stored in the memory device.

Owner:DENSO CORP

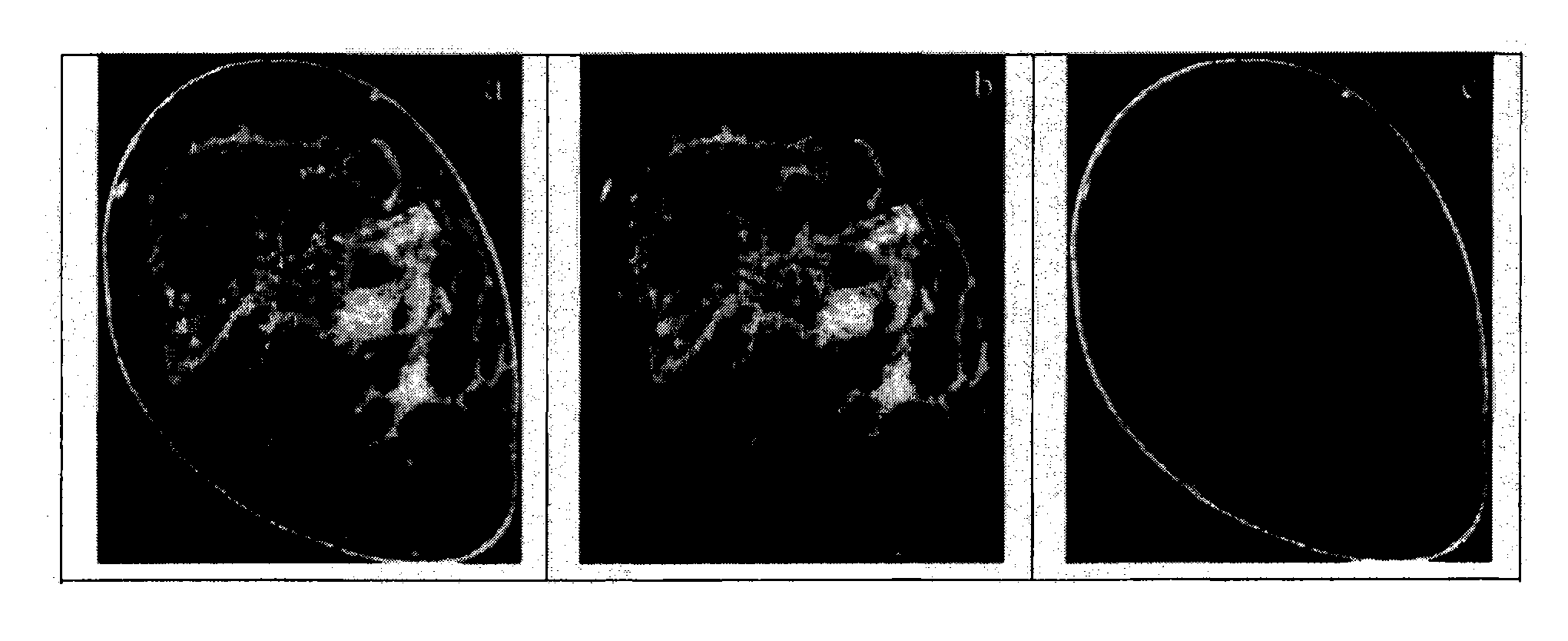

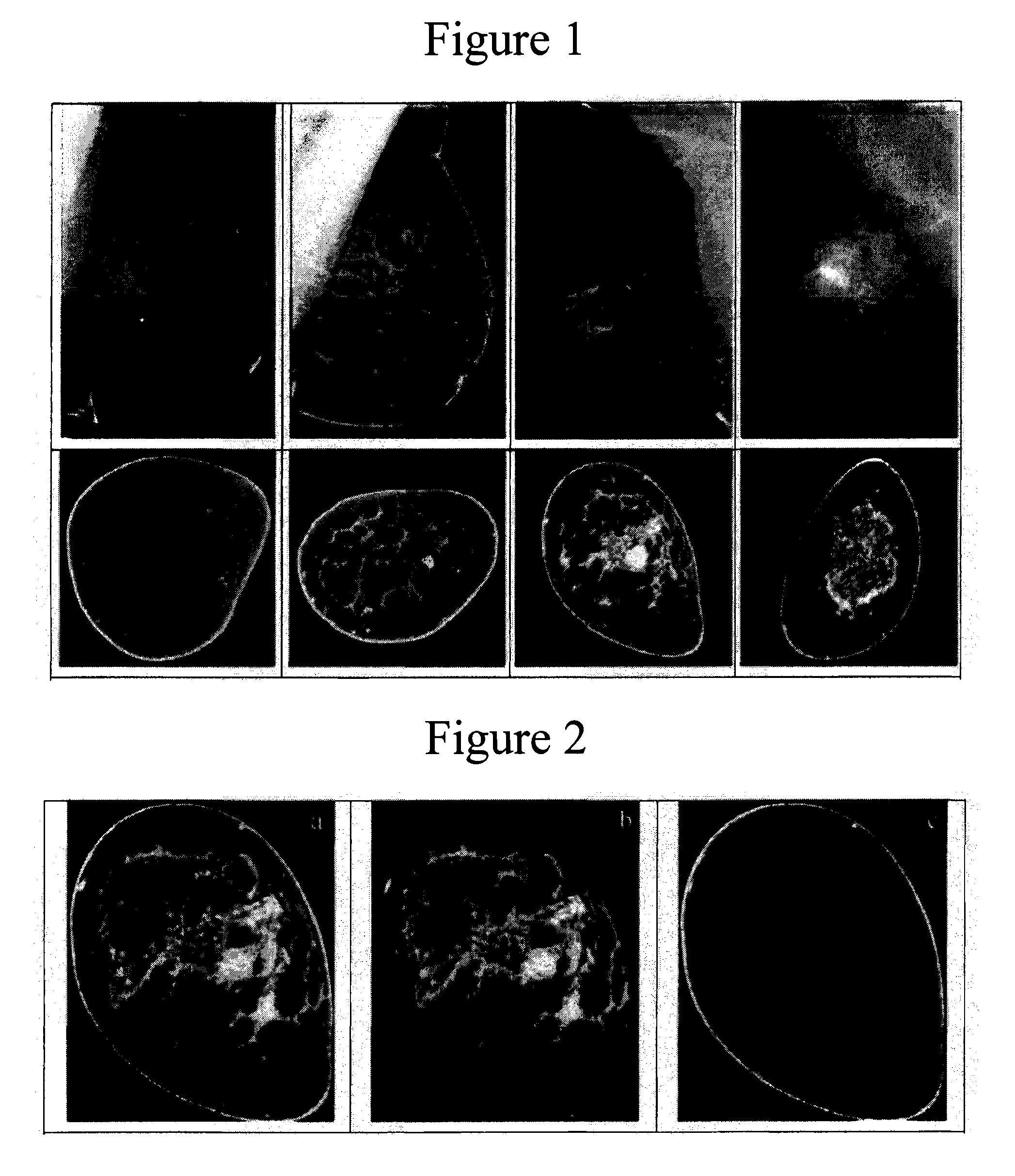

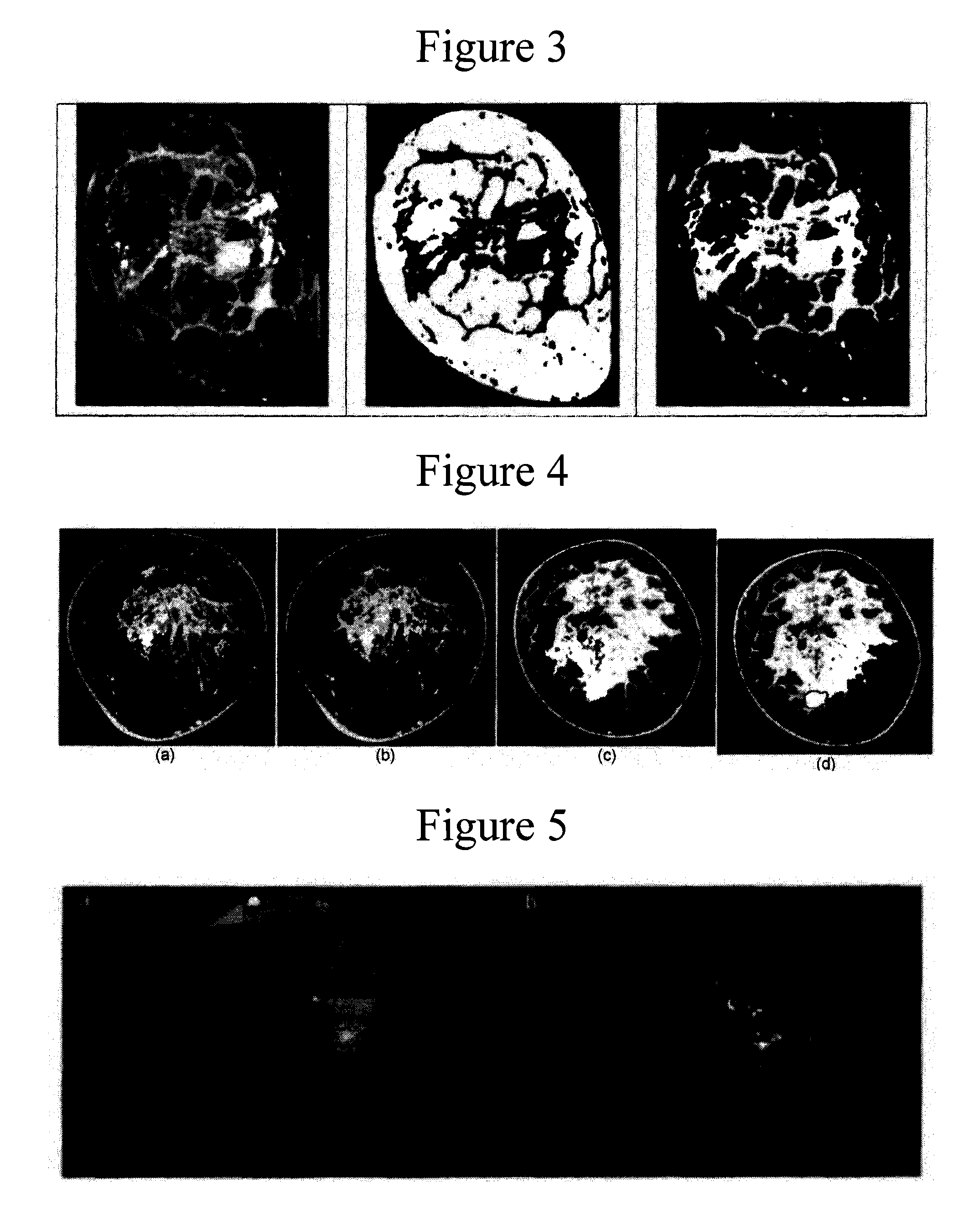

Method and apparatus for cone beam breast CT image-based computer-aided detection and diagnosis

ActiveUS9392986B2Ensure high efficiency and accuracyAccurate assessmentImage enhancementImage analysisBreast densityMalignancy

Cone Beam Breast CT (CBBCT) is a three-dimensional breast imaging modality with high soft tissue contrast, high spatial resolution and no tissue overlap. CBBCT-based computer aided diagnosis (CBBCT-CAD) technology is a clinically useful tool for breast cancer detection and diagnosis that will help radiologists to make more efficient and accurate decisions. The CBBCT-CAD is able to: 1) use 3D algorithms for image artifact correction, mass and calcification detection and characterization, duct imaging and segmentation, vessel imaging and segmentation, and breast density measurement, 2) present composite information of the breast including mass and calcifications, duct structure, vascular structure and breast density to the radiologists to aid them in determining the probability of malignancy of a breast lesion.

Owner:UNIVERSITY OF ROCHESTER +1

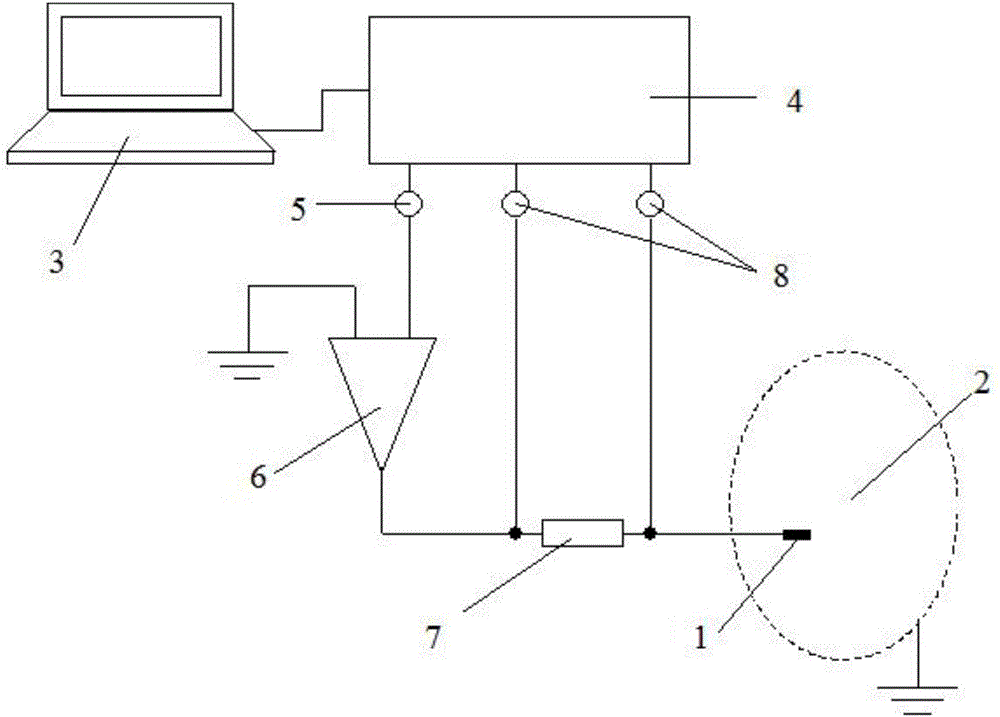

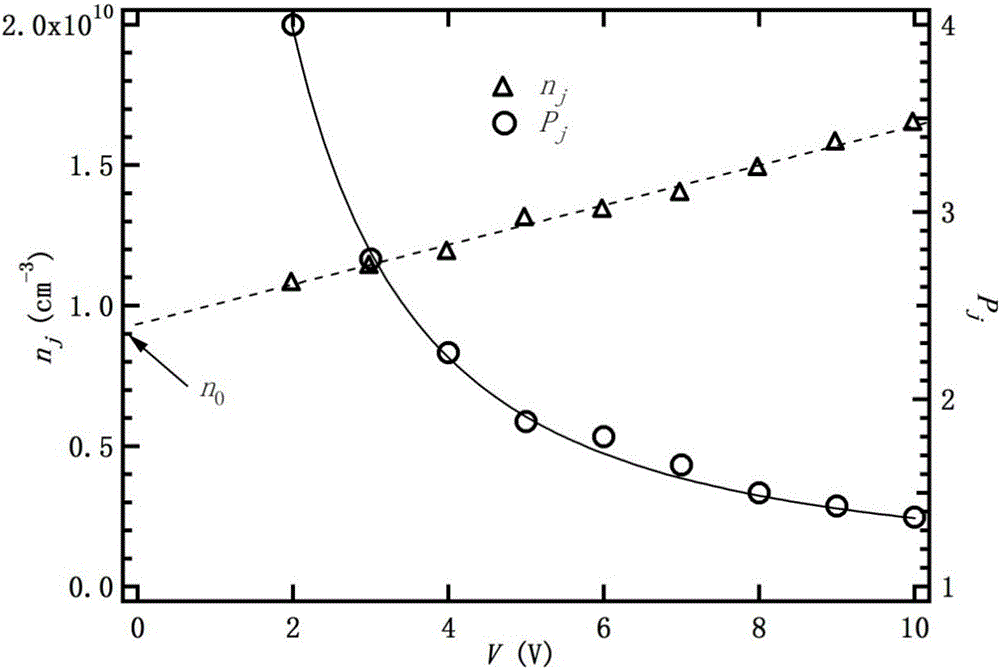

Plasma diagnostic method of multi-amplitude AC bias probe based on data acquisition card

InactiveCN106413237AAccurate temperatureDensity is accuratePlasma techniqueFrequency spectrumSignal on

The invention belongs to the technical field of plasma, and discloses a plasma diagnostic method of a multi-amplitude AC bias probe based on a data acquisition card. The plasma diagnostic method comprises the steps of: generating AC bias signals based on the data acquisition card, driving the signals via a power amplifier, and applying the signals to a probe in plasma through a sampling resistor, meanwhile, acquiring a voltage signal on the sampling resistor by means of a differential simulation input port of the data acquisition card commanded by a computer, sending the voltage signal to the computer, and converting the voltage signal into a current signal by the computer; and carrying out spectral analysis and least square method fitting, and further calculating to obtain an accurate electronic temperature value and an accurate ion density value. The plasma diagnostic method solves the problem that electronic temperature and ion density measured by adopting the existing fixed-amplitude AC bias probe diagnostic technique are inaccurate, can diagnose the plasma especially insulating deposition environment plasma, can automatically complete the plasma diagnosis process, and output the accurate electronic temperature and ion density values.

Owner:DALIAN UNIV OF TECH

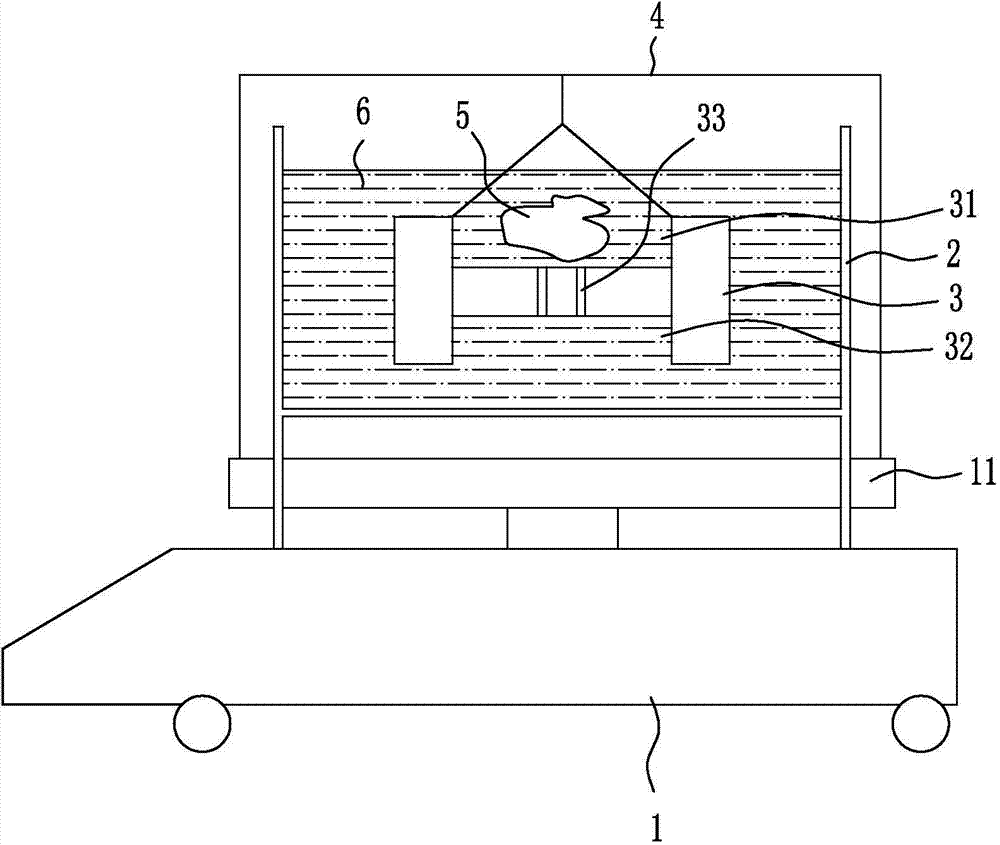

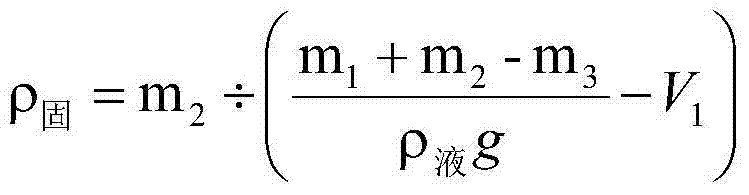

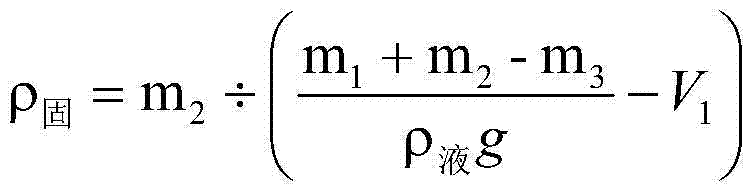

Solid density detection method and device

InactiveCN104280312ADensity is accurateDensity made easy and preciseSpecific gravity measurementSolid densityPhysical chemistry

The invention discloses a solid density detection method, comprising the following steps: preparing a special weight capable of bearing or pressing a to-be-detected solid to immerse into liquid, wherein the weight has known V1 and mass m1 and is not infiltrated by the liquid; weighing the mass m2 of the to-be-detected solid; weighing the mass m3 of the special weight together with the to-be-detected solid immersed into the liquid with the known density being rho(liquid); and determining the density rho(solid) of the to-be-detected solid by virtue of a formula. A detection device adopting the method comprises a container and a special weight, wherein the container is used for weighing and containing the liquid; the special weight is partitioned into an upper cavity and a lower cavity; and a communicating hole is formed between the upper cavity and the lower cavity of the weight. Due to adoption of the solid density detection method and device disclosed by the invention, measurement of the solid density is simple and accurate, and on-site rapid and accurate measurement of the density of a solid sample can be achieved.

Owner:MODENA TECH LTD

Image forming apparatus and control method for the same

ActiveUS7509065B2Accurate timingEasy to adjustElectrographic process apparatusComputer graphics (images)Image formation

An image forming apparatus that is capable of generating highly accurate read timing of a patch image, thereby achieving highly accurate density adjustment and improving color stability. A patch image for color adjustment is read in read timing generated when a trigger bar is detected. The patch image and the trigger bar that are to be read by a color sensor are formed on a transfer material. Image formation is executed by a printer controller in an image forming condition set differently for the trigger bar and for the patch image.

Owner:CANON KK

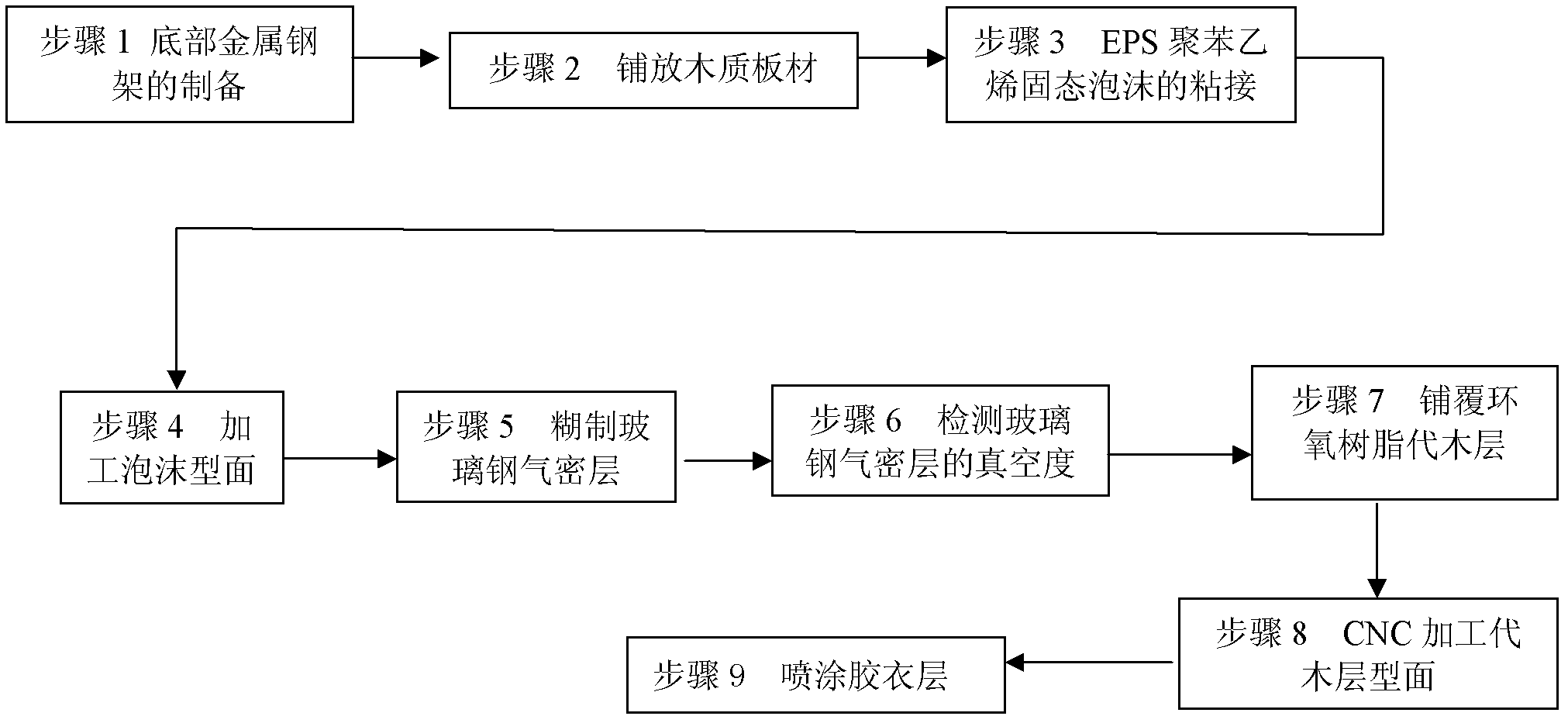

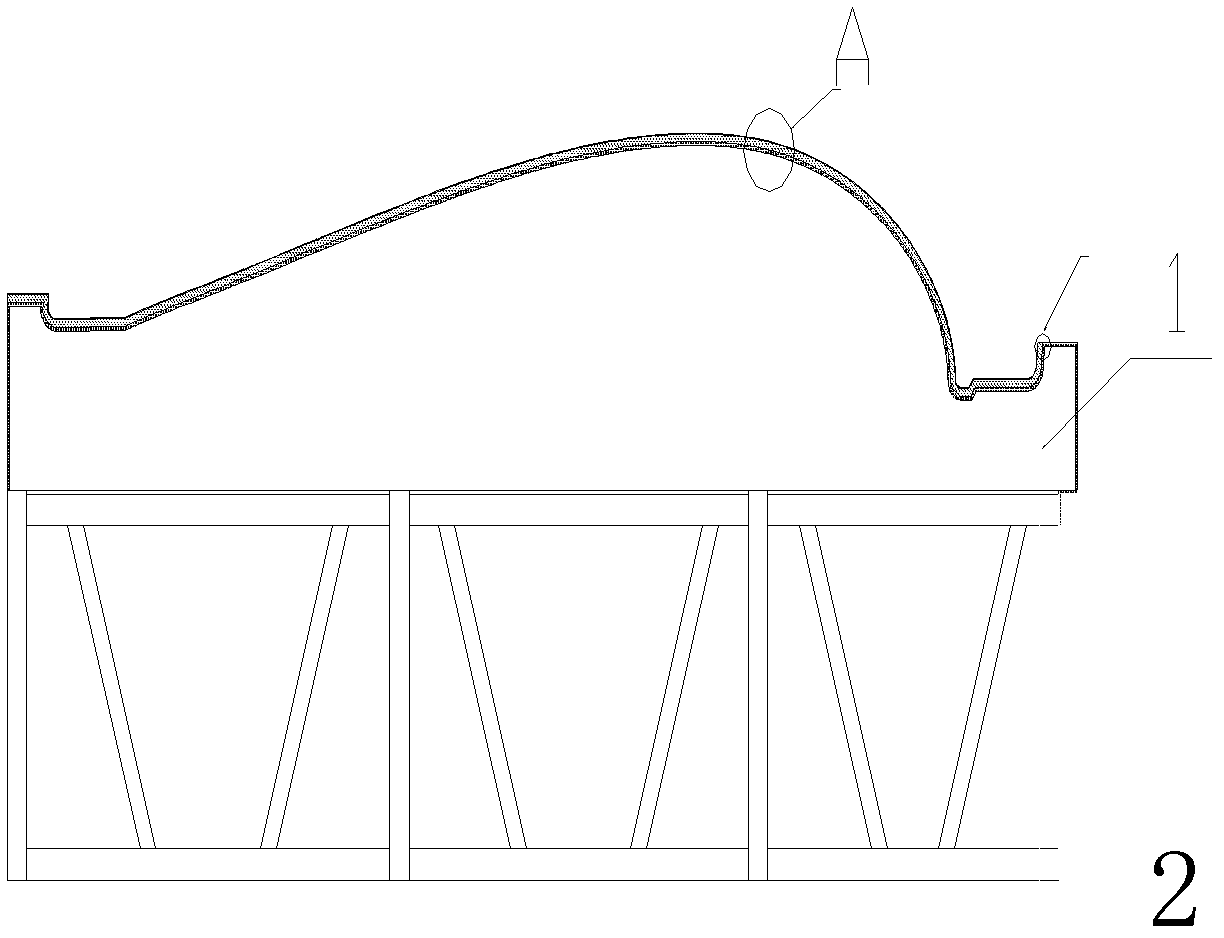

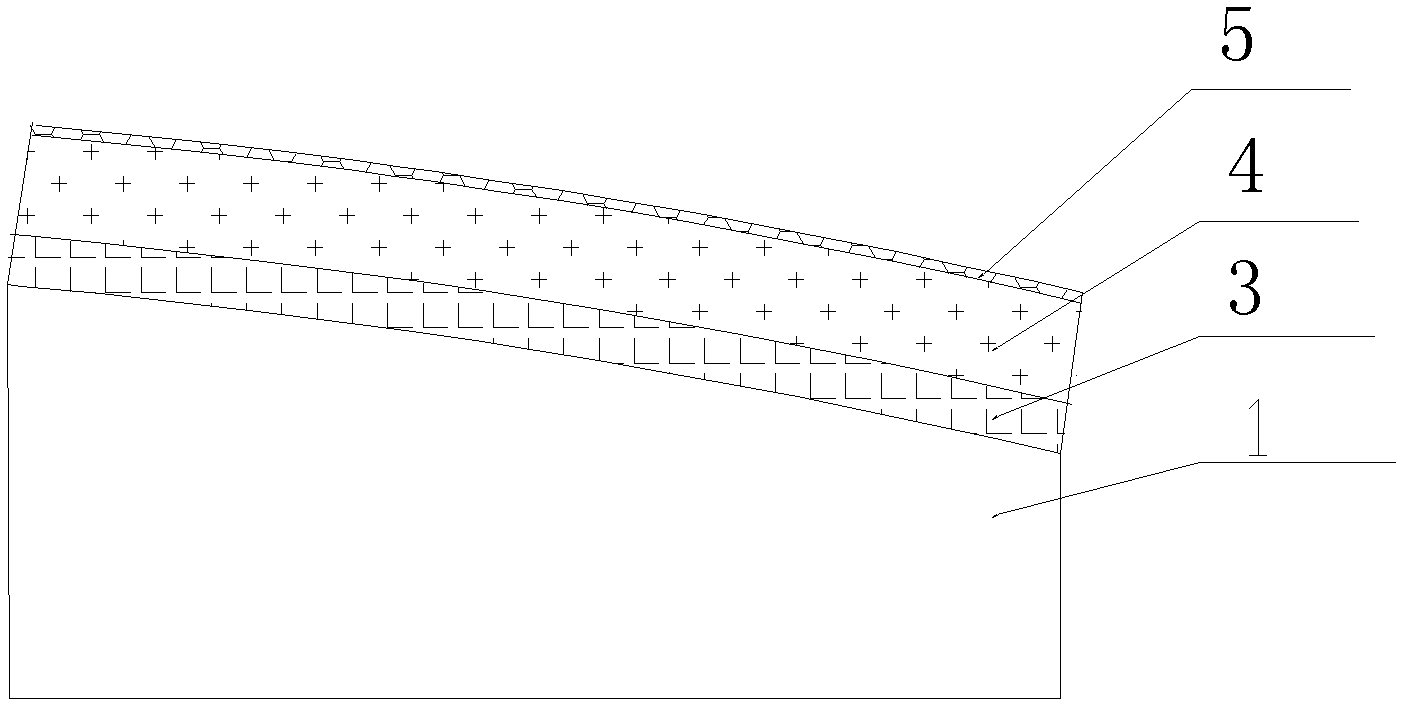

Making process of wind-power blade main model

The invention discloses a making process of a wind-power blade main model, which belongs to the technical field of wind-power blade molding. The process comprises the following steps of: 1) making a metal steel frame platform at the bottom; 2) laying a wood plate; 3) coating epoxy resin white carbon black filler on the surface of the wood plate, placing multiple EPS (Expandable Polystyrene) polystyrene solid foams according to the shape of the designed main model in a laminated way, and bonding and fixing the EPS polystyrene solid foams; 4) machining profiles of the EPS polystyrene solid foams; 5) pasting glass fiber reinforced plastic airtight layers on the machined profiles in the step 4); 6) detecting the vacuum degrees of the glass fiber reinforced plastic airtight layers; 7) uniformly spreading wood substituted epoxy resin layers on the surfaces of the glass fiber reinforced plastic airtight layers which satisfy the vacuum degree requirements, controlling the spreading thicknesses at about 15-35 mm and curing the wood substituted epoxy resin layers at normal temperature; and 8) machining the surfaces of the wood substituted epoxy resin layers; and then coating gel coat layers on the wood substituted epoxy resin layers and curing and molding the wood substituted epoxy resin layers to obtain the main model. The main model made by using the process disclosed by the invention has the advantages of high profile precision, easiness for construction operation, low making cost as well as contribution to promotion and application.

Owner:北玻院(滕州)复合材料有限公司

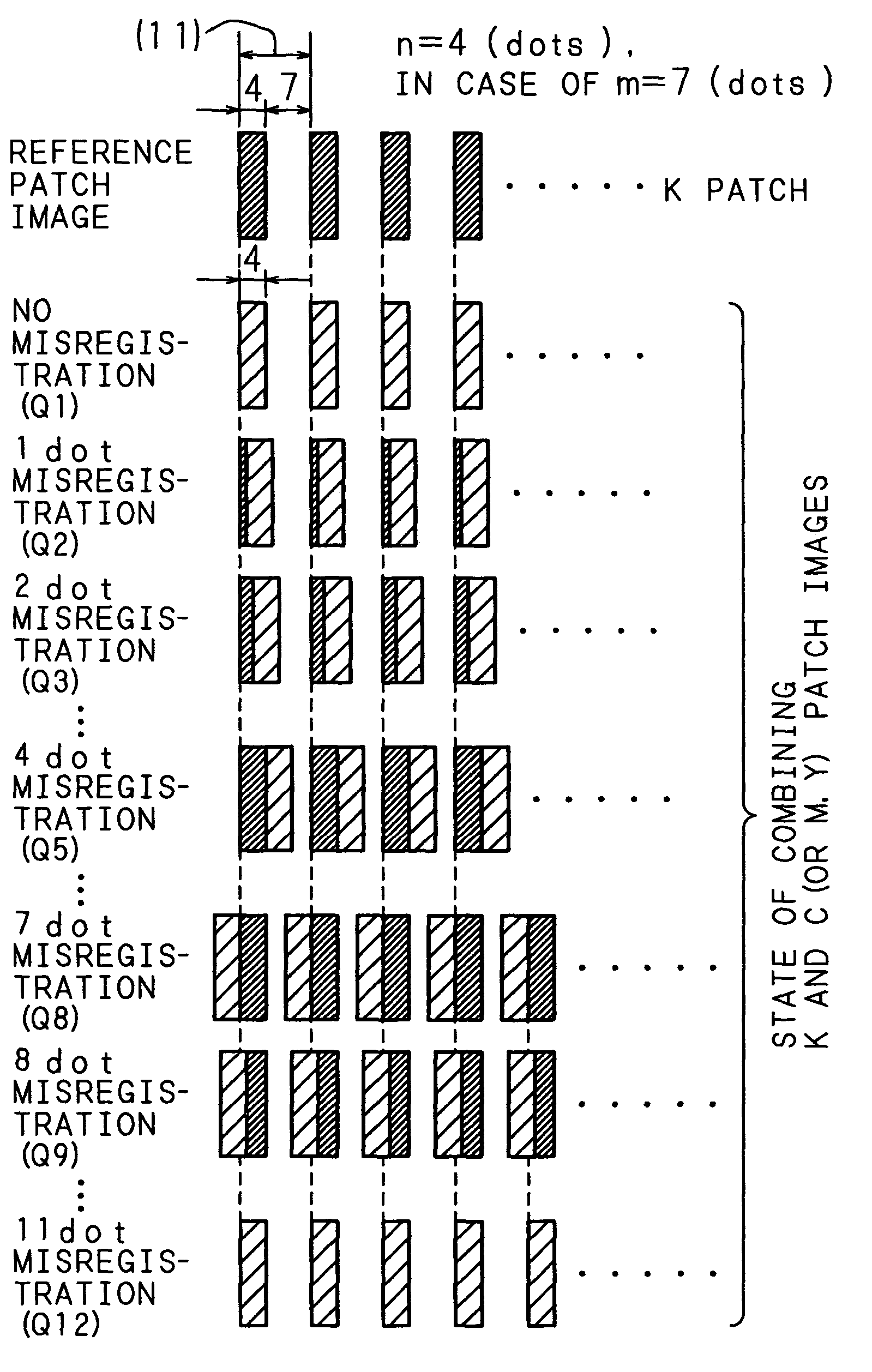

Image adjustment method and image forming apparatus

InactiveUS6970660B2Shorten the timeHighly accurate color registration adjustmentRecording apparatusElectrographic process apparatusReference imageImage formation

Owner:SHARP KK

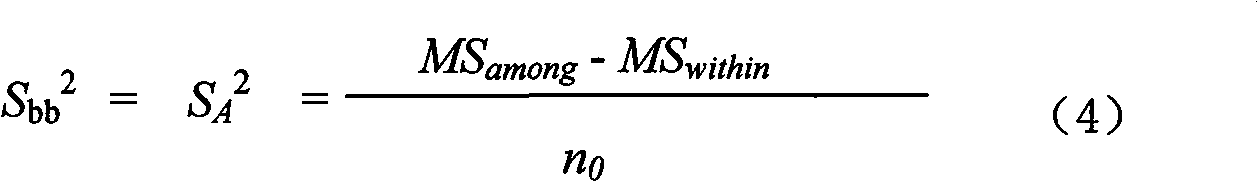

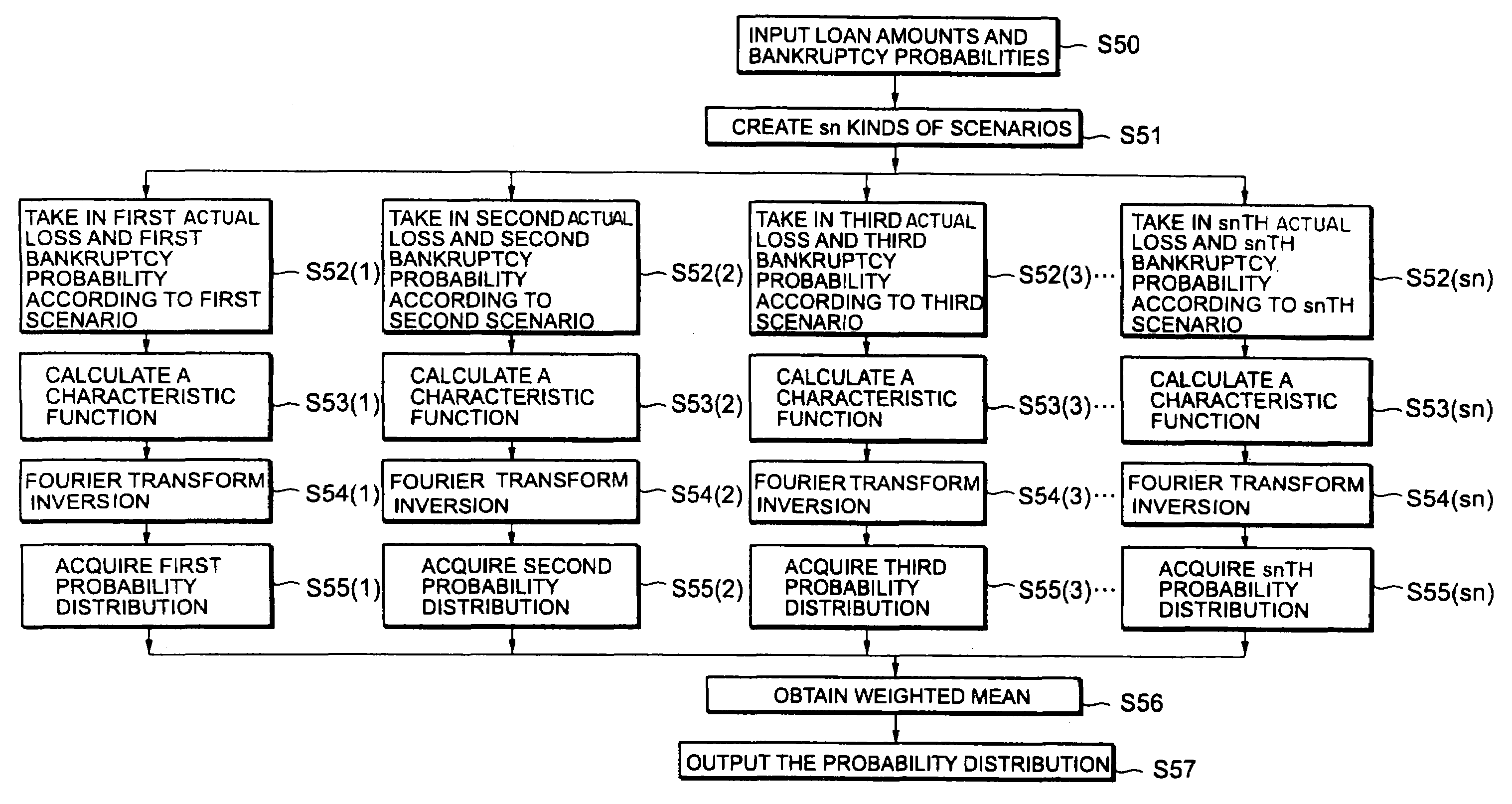

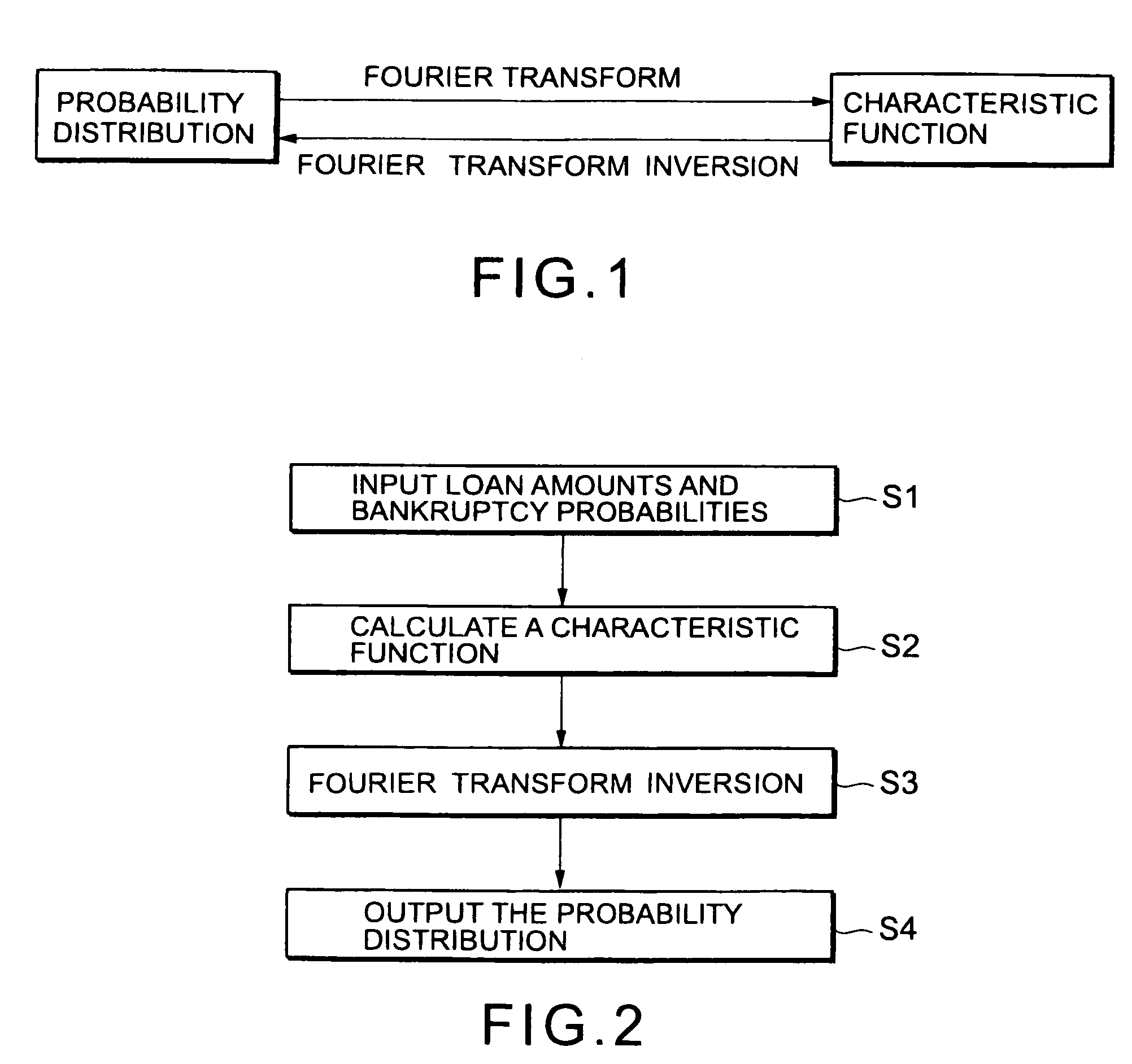

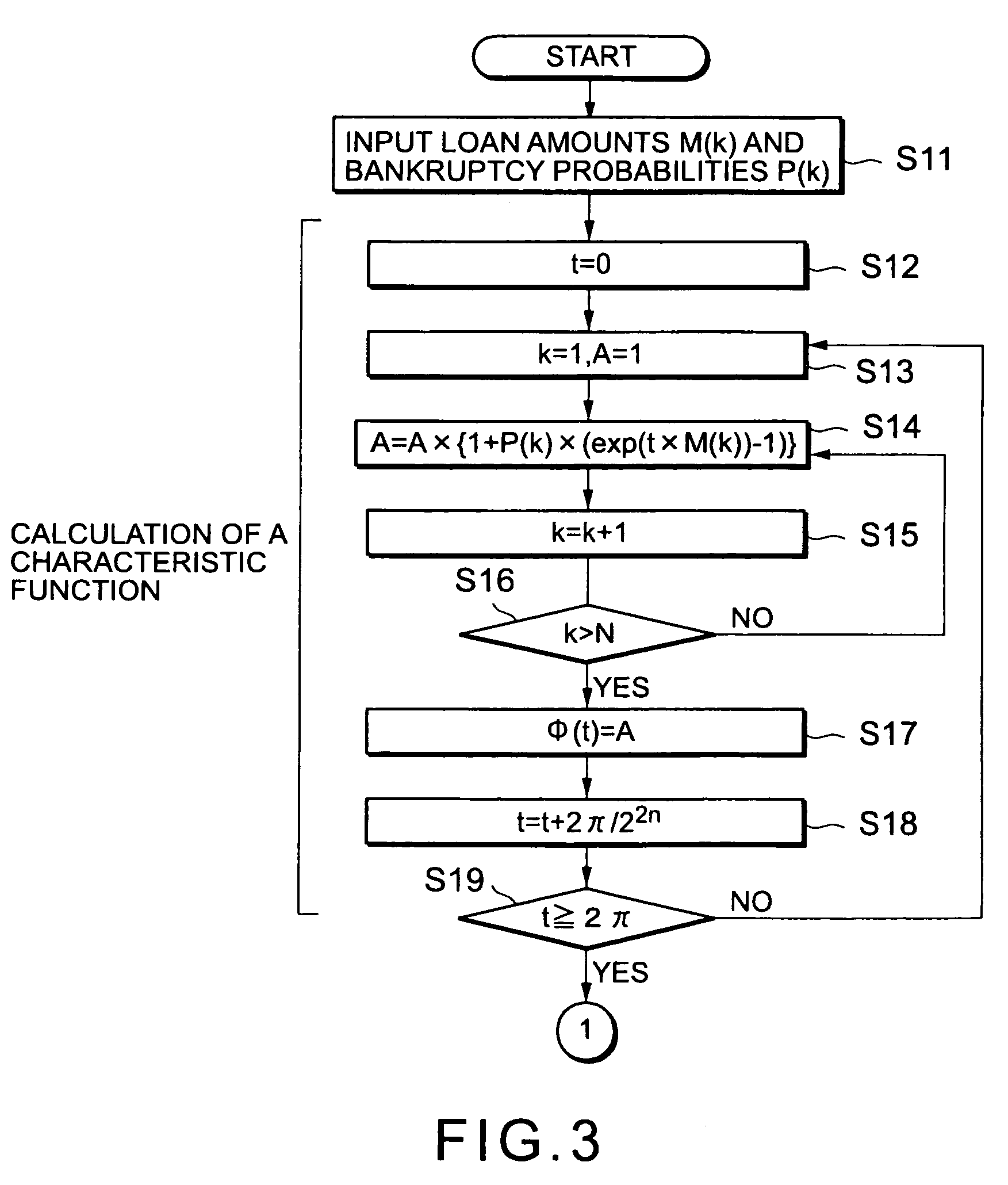

System for computing probability distribution of loan losses

InactiveUS7050999B1The probability distribution is accurateDensity is accurateFinanceCommerceProbabilistic computingFourier transform

A system for computing probability distribution of loan losses includes a loan amount and bankruptcy probability input device for inputting loan amounts and bankruptcy probabilities of individual loan customers, a characteristic function calculating device for calculating a characteristic function from these loan amounts and bankruptcy probabilities. A probability distribution calculating device calculates probability distribution by Fourier transform inversion of the characteristic function, and a probability distribution output device outputs the calculated probability distribution as a graph through a printer.

Owner:RESONA HOLDINGS

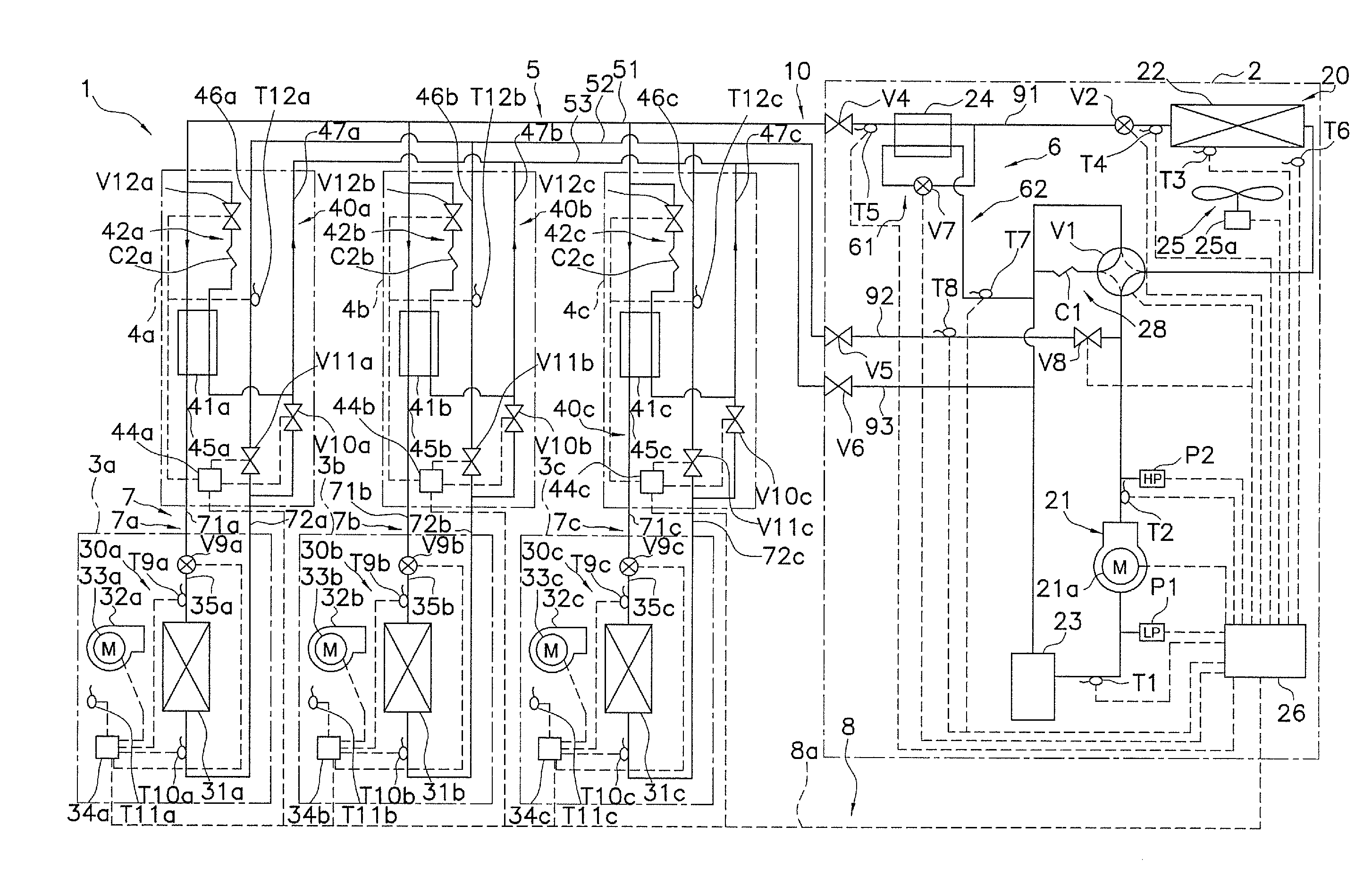

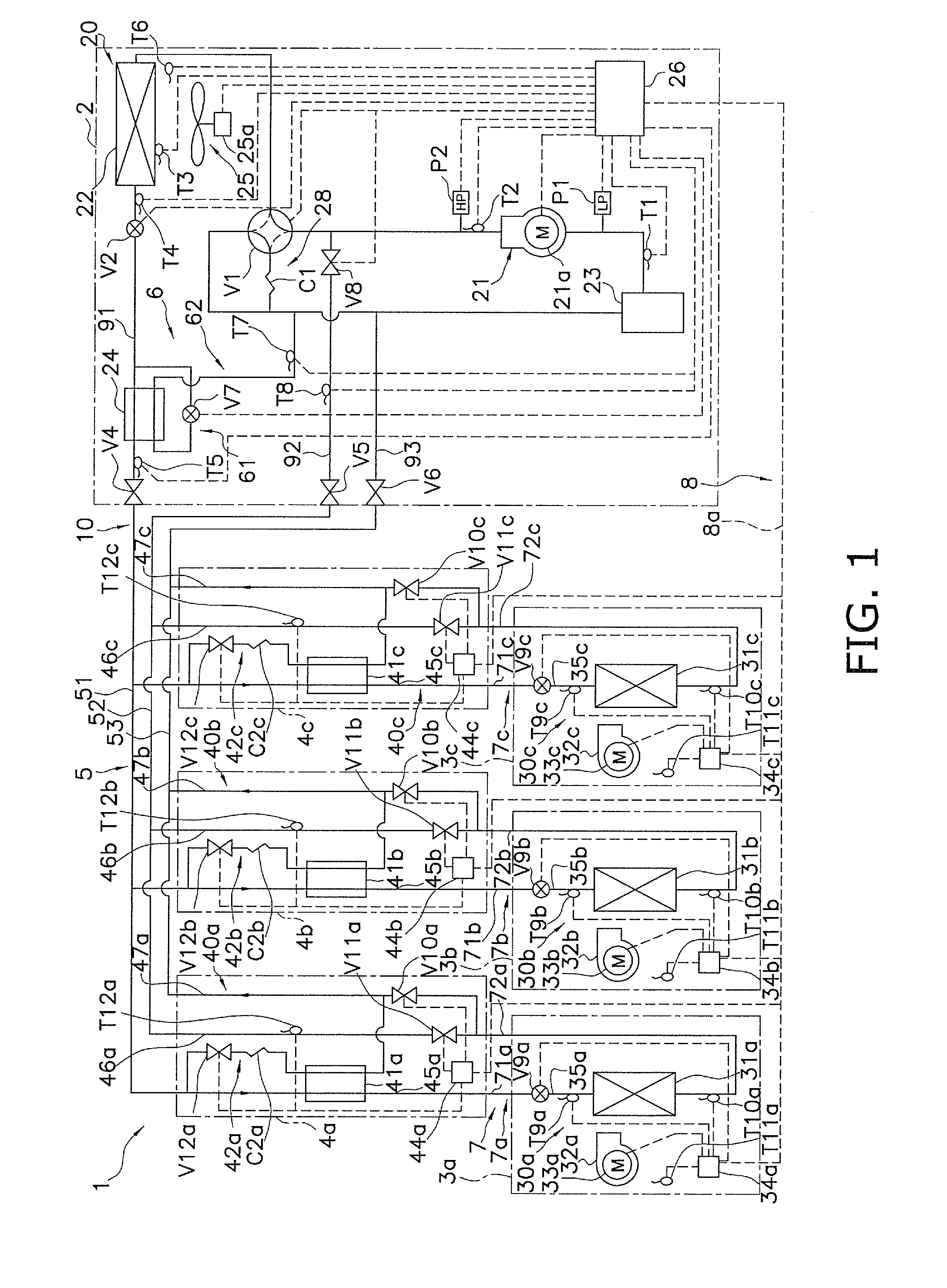

Air conditioner

InactiveUS20100154447A1High accuracyImprove accuracyShow cabinetsFluid circulation arrangementRefrigerantEngineering

An air conditioner performs a refrigerant quantity judging operation to judge the refrigerant quantity in a refrigerant circuit, and includes a heat source unit, utilization units, expansion mechanisms, a first refrigerant gas pipe, a second refrigerant gas pipe, a refrigerant liquid pipe, switching mechanisms, temperature detecting means, and a controller. The heat source unit includes a compression means and a heat source side heat exchanger. The first refrigerant gas pipe is connected to the discharge side of the compression means. The switching mechanism can switch between a first state and a second state. The temperature detecting means are mounted on the first refrigerant gas pipe, and configured to detect a refrigerant temperature on the first refrigerant gas pipe side and output a refrigerant temperature detection value. The controller corrects the refrigerant quantity judged by a refrigerant quantity judging operation based on the refrigerant temperature detection value.

Owner:DAIKIN IND LTD

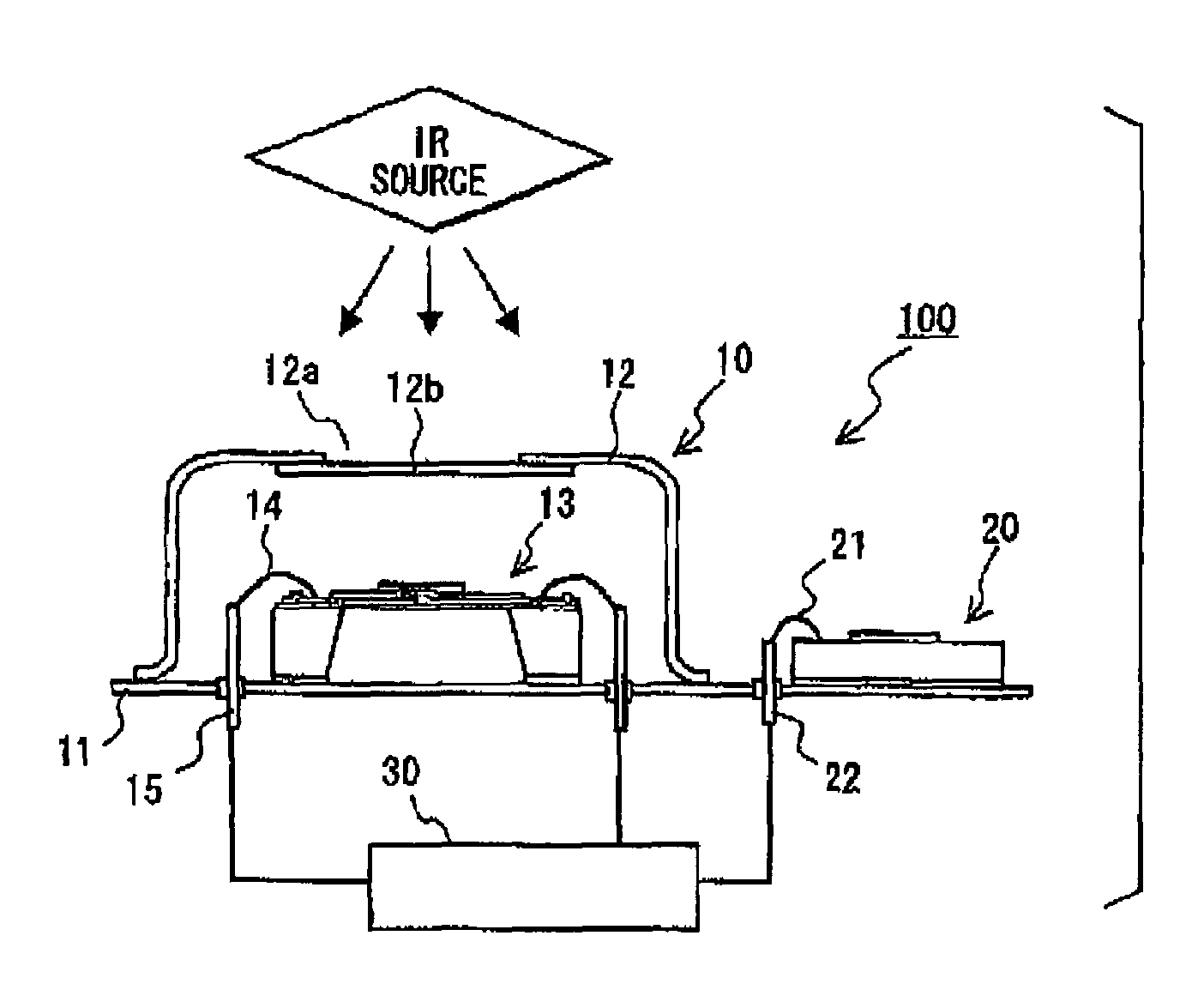

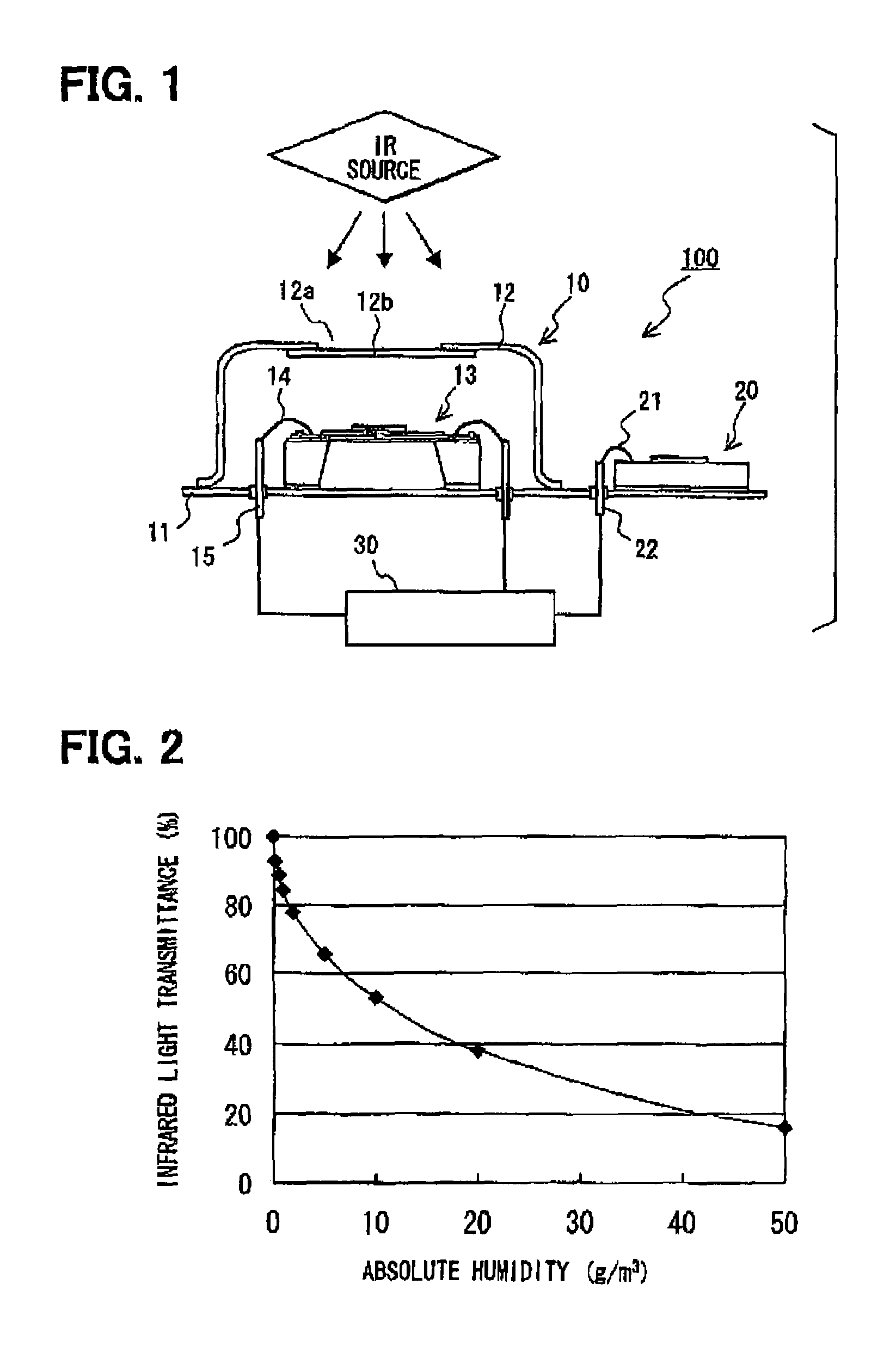

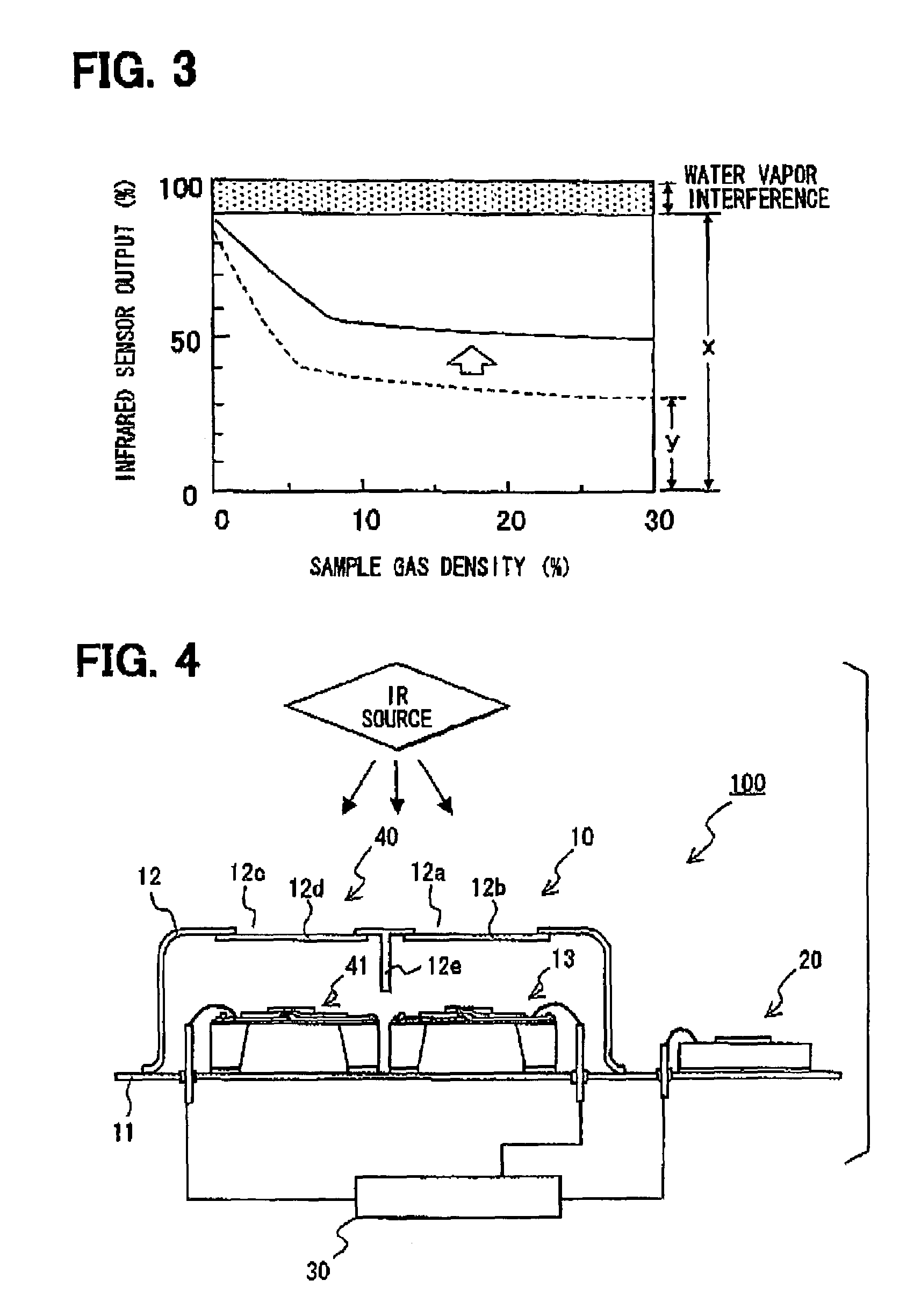

Infrared gas detector and method of the same

InactiveUS7288766B2Reduce package sizeDensity is accurateRadiation pyrometryTransmissivity measurementsGas detectorWater vapor

An infrared gas detector for detecting a density of a sample gas includes an infrared light sensor for detecting the density of the sample gas under an influence of water vapor based on an intensity of received infrared light of a specific wavelength, and a humidity sensor for detecting an absolute humidity of the water vapor in the sample gas based on an intensity of the received infrared light of the specific wavelength. The density of the sample gas is determined by correcting for the influence of the water vapor included therein based on the absolute humidity in the sample gas detected by the humidity sensor.

Owner:DENSO CORP

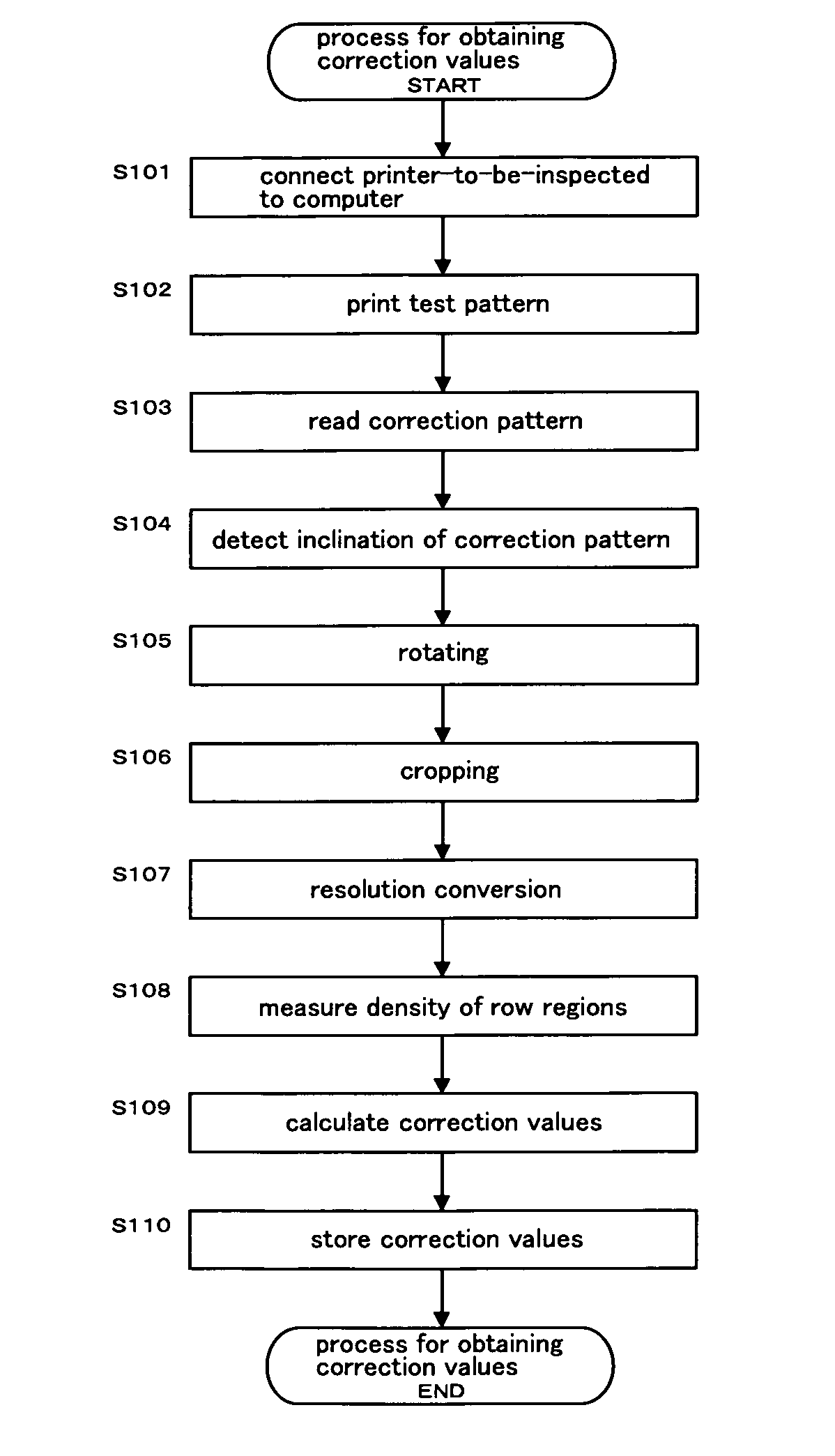

Method for measuring density, printing method, method of calculating correction value, method of manufacturing printing apparatus and method for obtaining correction value

InactiveUS20060262361A1Uneven inhibitory concentrationDensity unevennessOther printing apparatusColour-separation/tonal-correctionEngineeringVolumetric Mass Density

A method for measuring density, includes: forming on a medium a pattern that consists of a plurality of dot rows formed respectively in a plurality of row regions lined up in a direction intersecting a movement direction in which a plurality of nozzles move, by forming each of the dot rows in the row region arranged in the movement direction by ejecting ink from the nozzles; reading the pattern by a scanner; measuring density of each of the row regions of the read pattern; calculating respective modification values corresponding to each of the row regions, based on at least a part of a measurement result of the density of the plurality of the row regions; and modifying respective measured values of the density of each of the row regions based on the respective modification values corresponding to each of the row regions.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com