Patents

Literature

69 results about "Solid density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Density of solid. Density refers to the mass contained within a unit volume under specified conditions. Data given here refer to the solid. Density is temperature dependent and different allotopes of one element possess different densities.

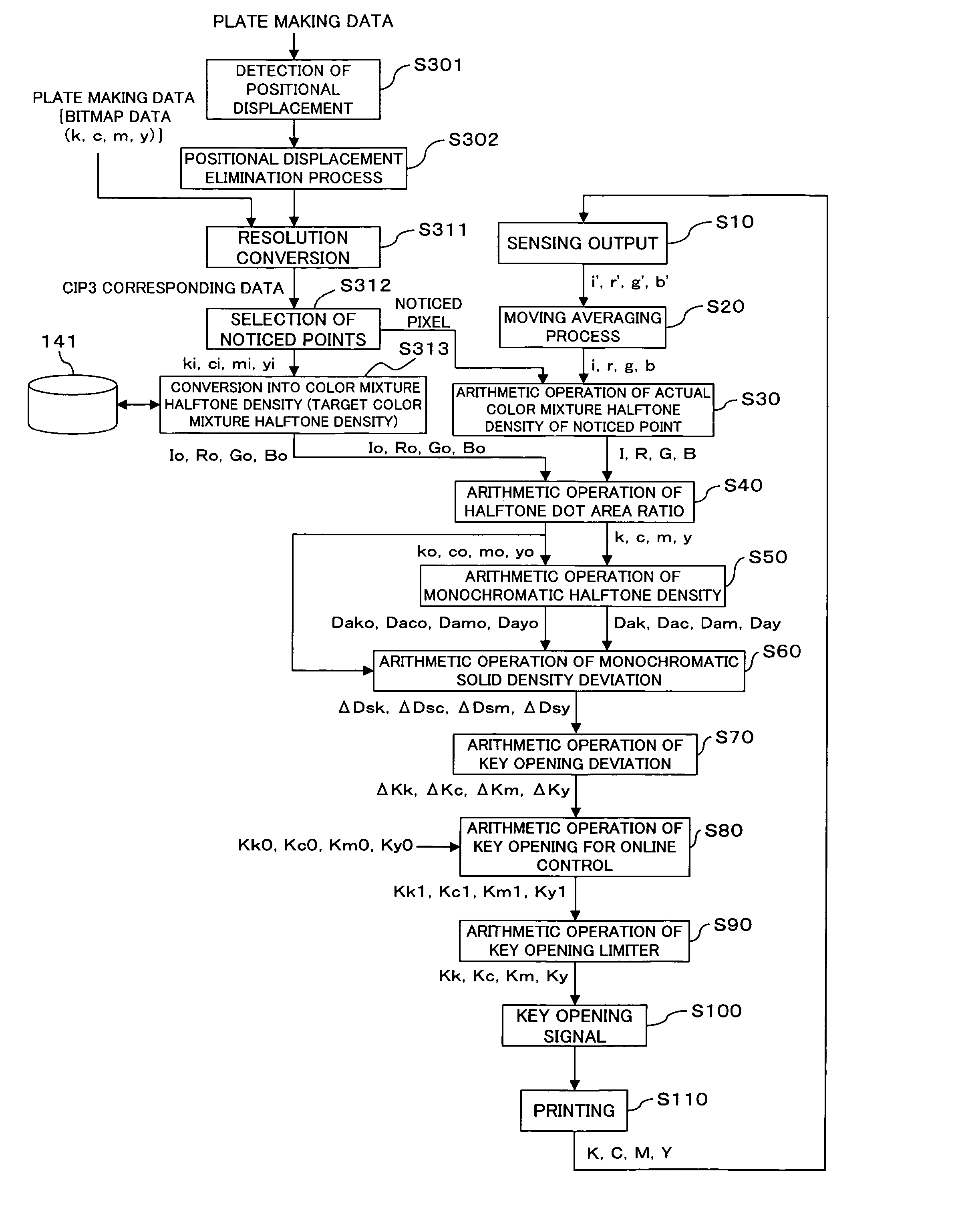

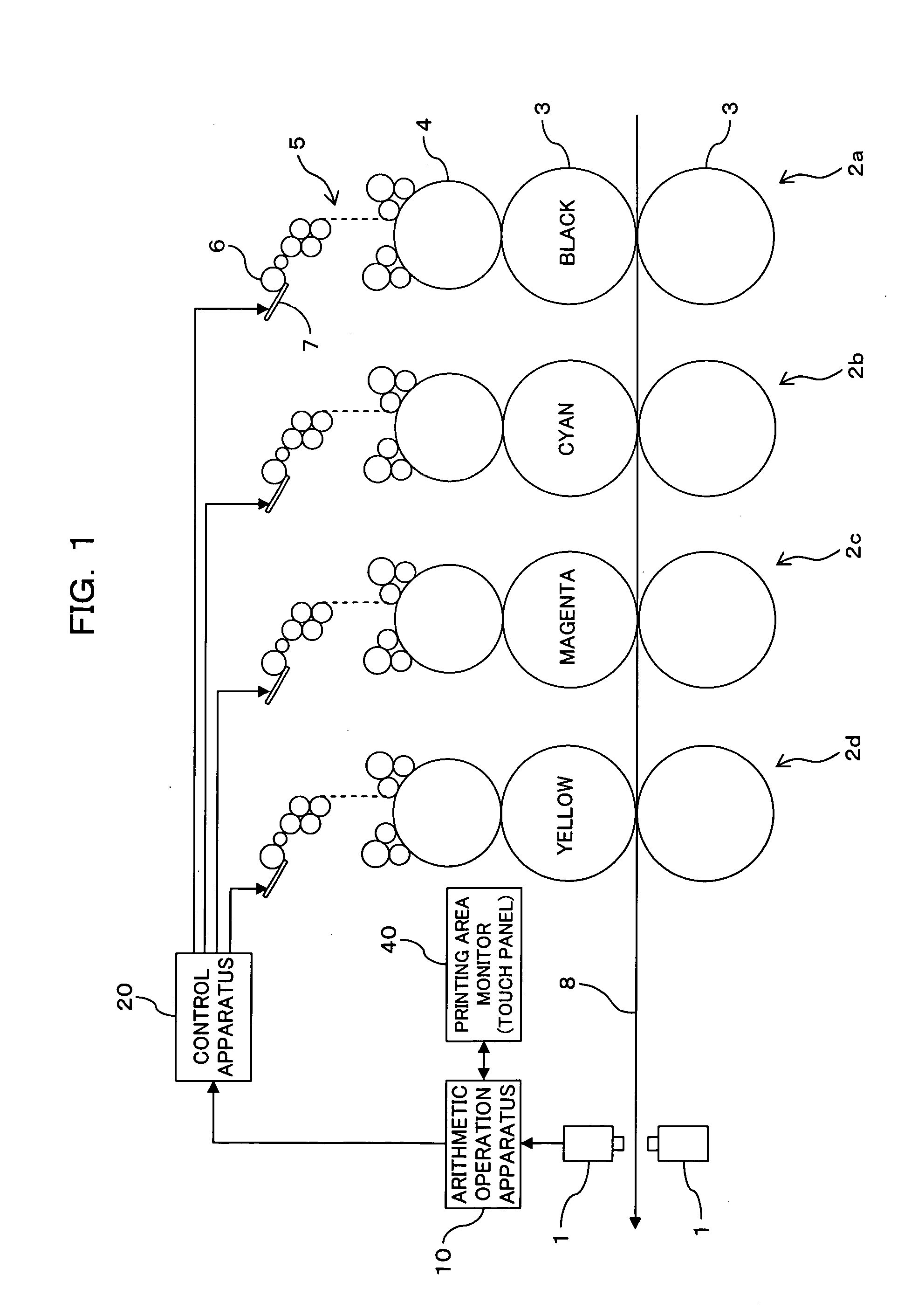

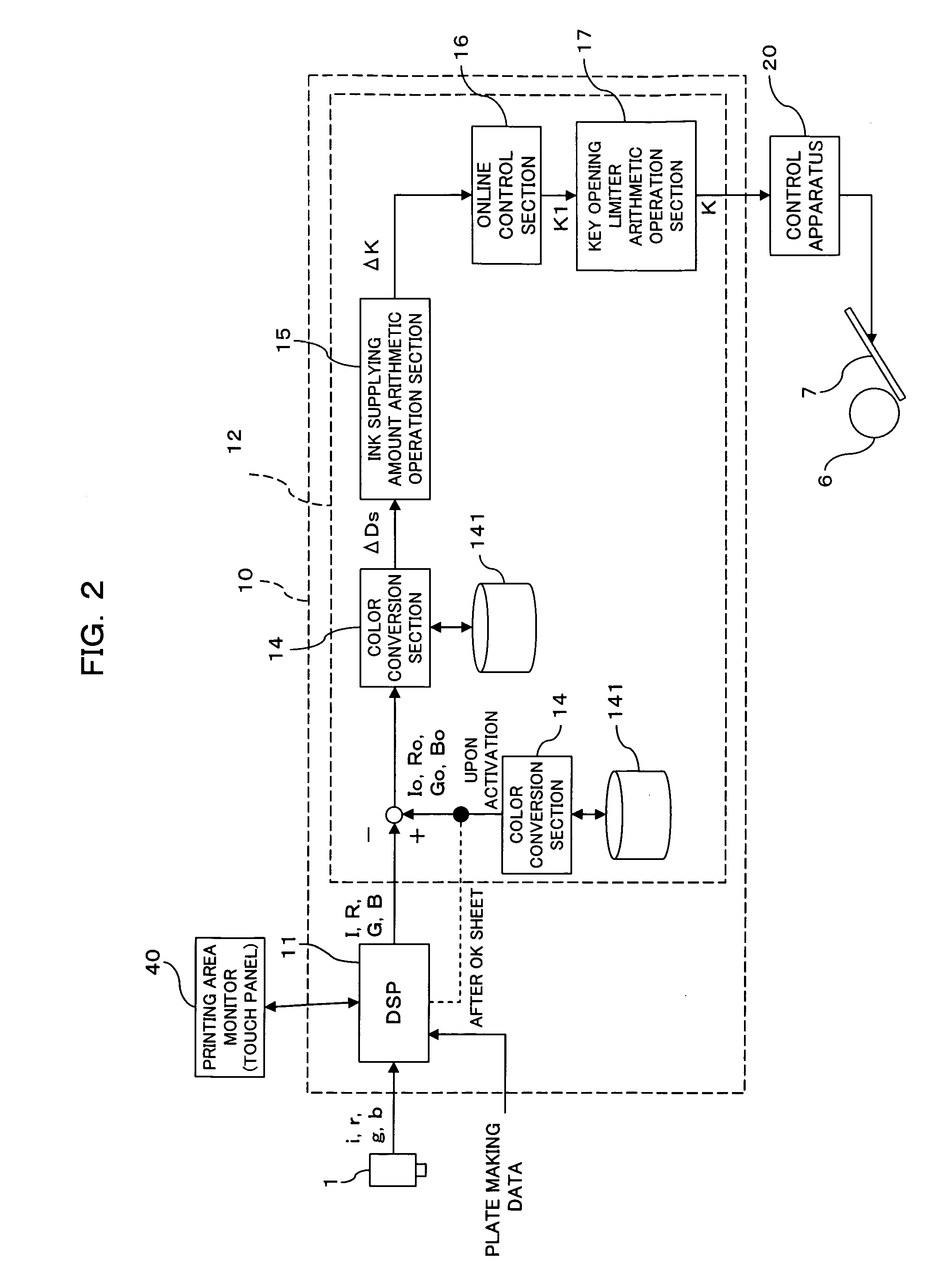

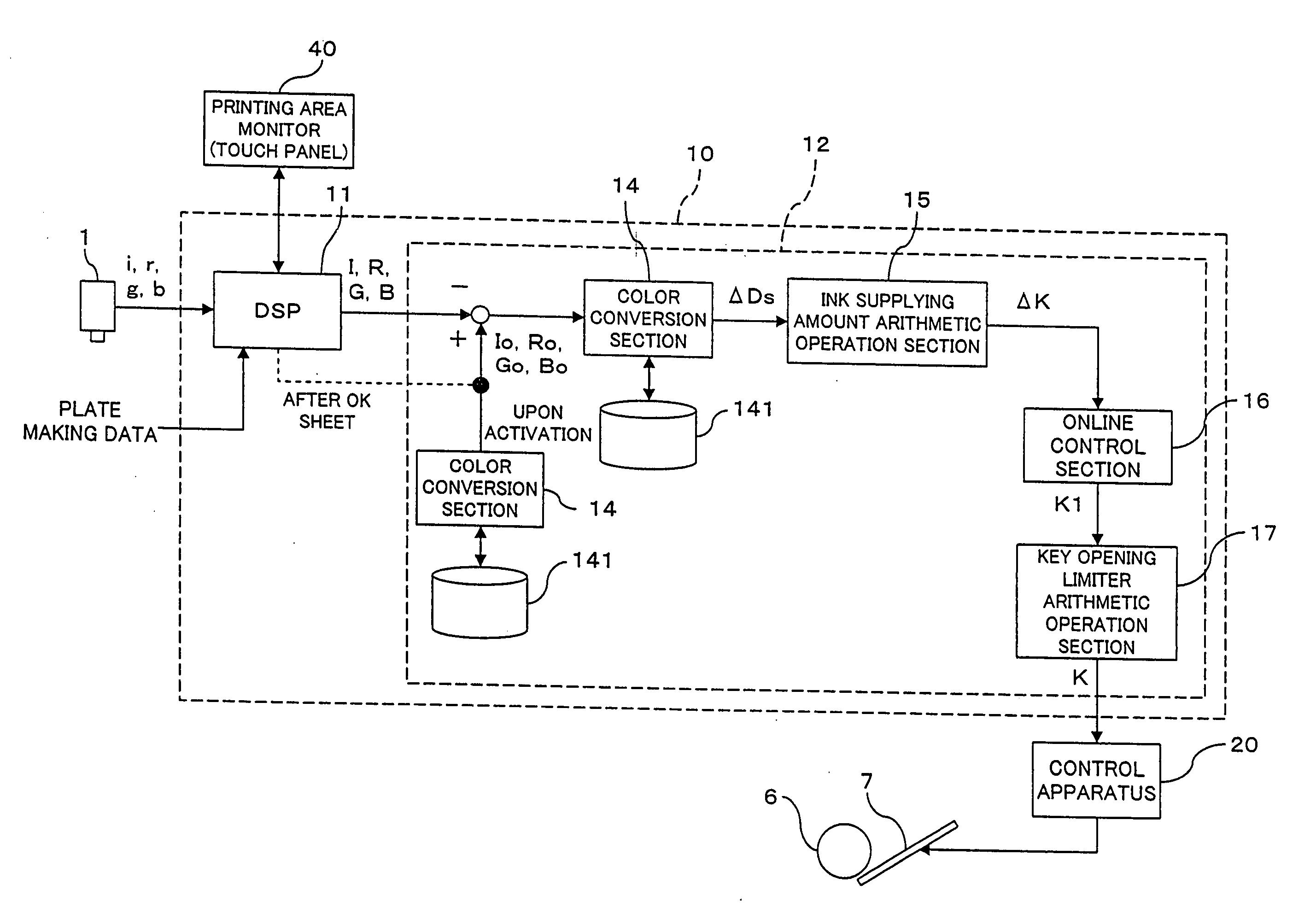

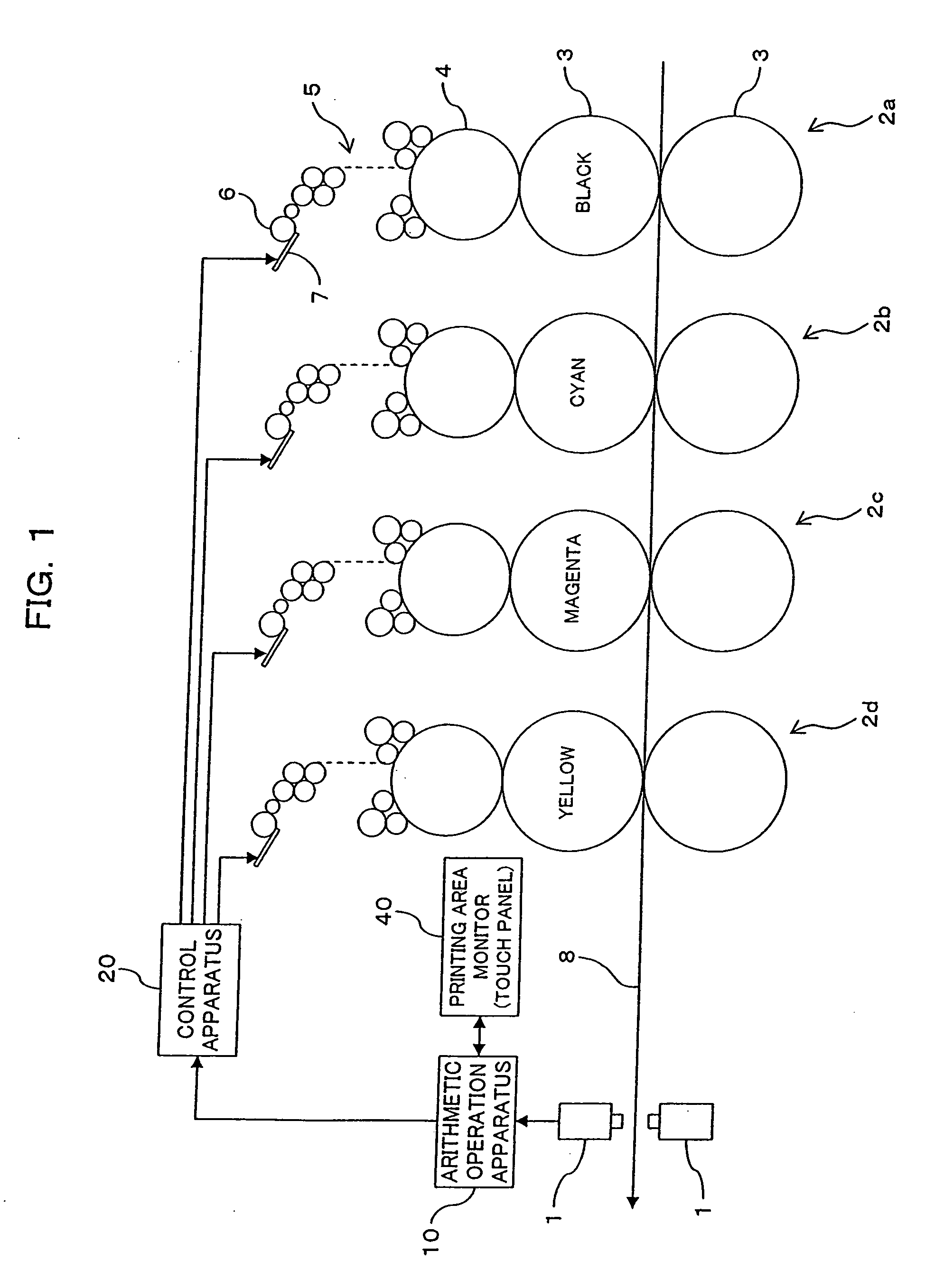

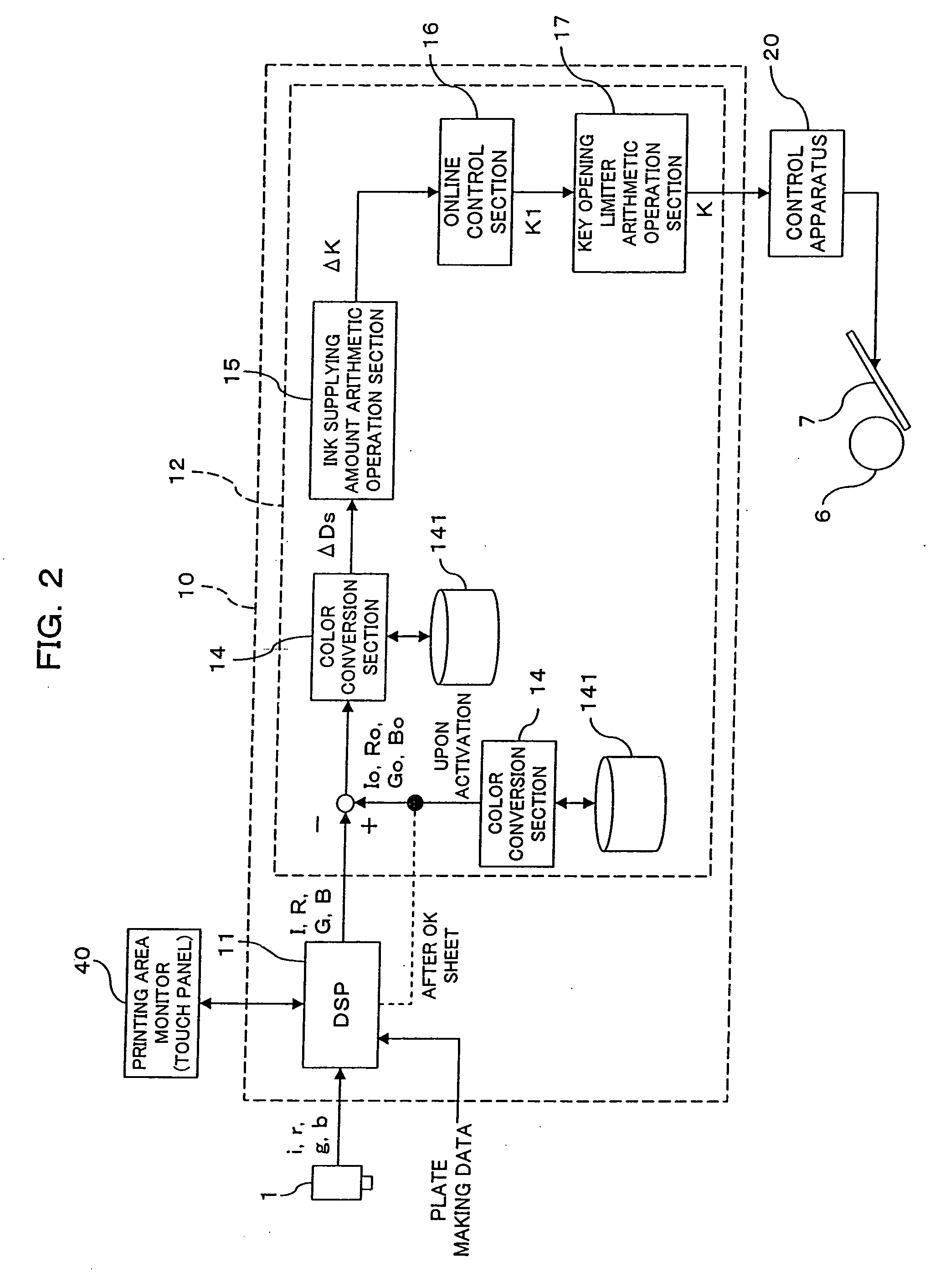

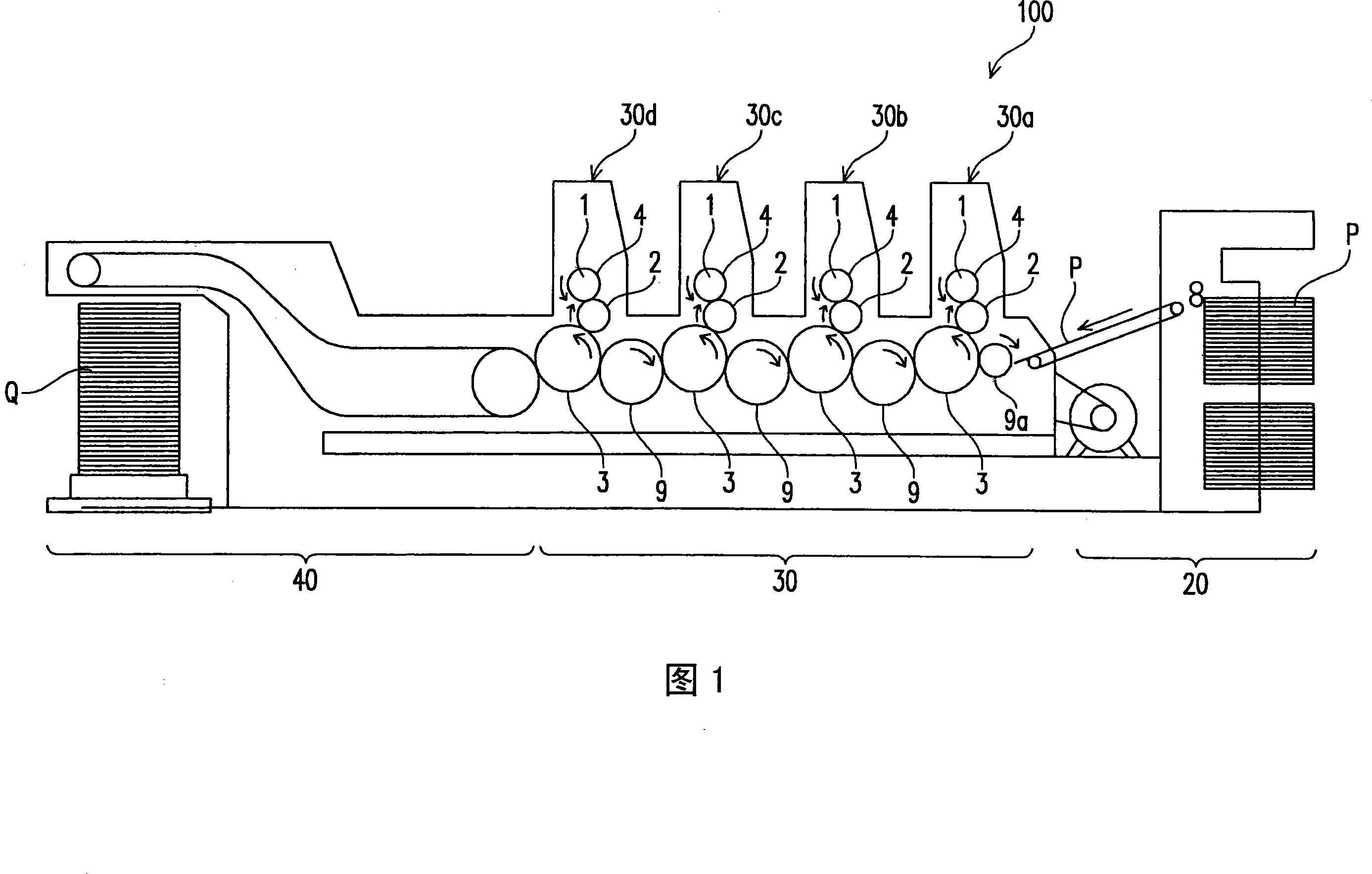

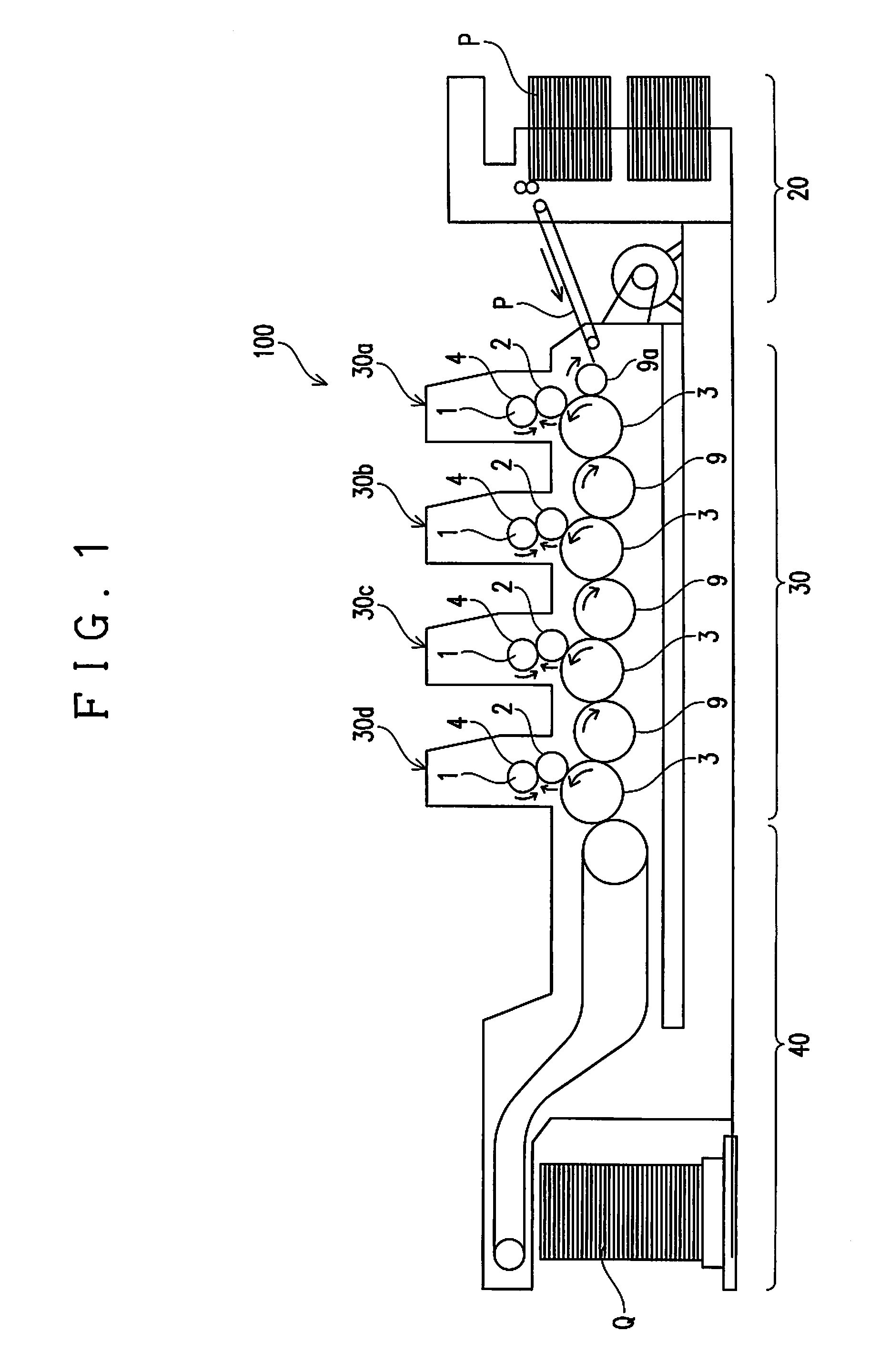

Picture color tone controlling method and apparatus

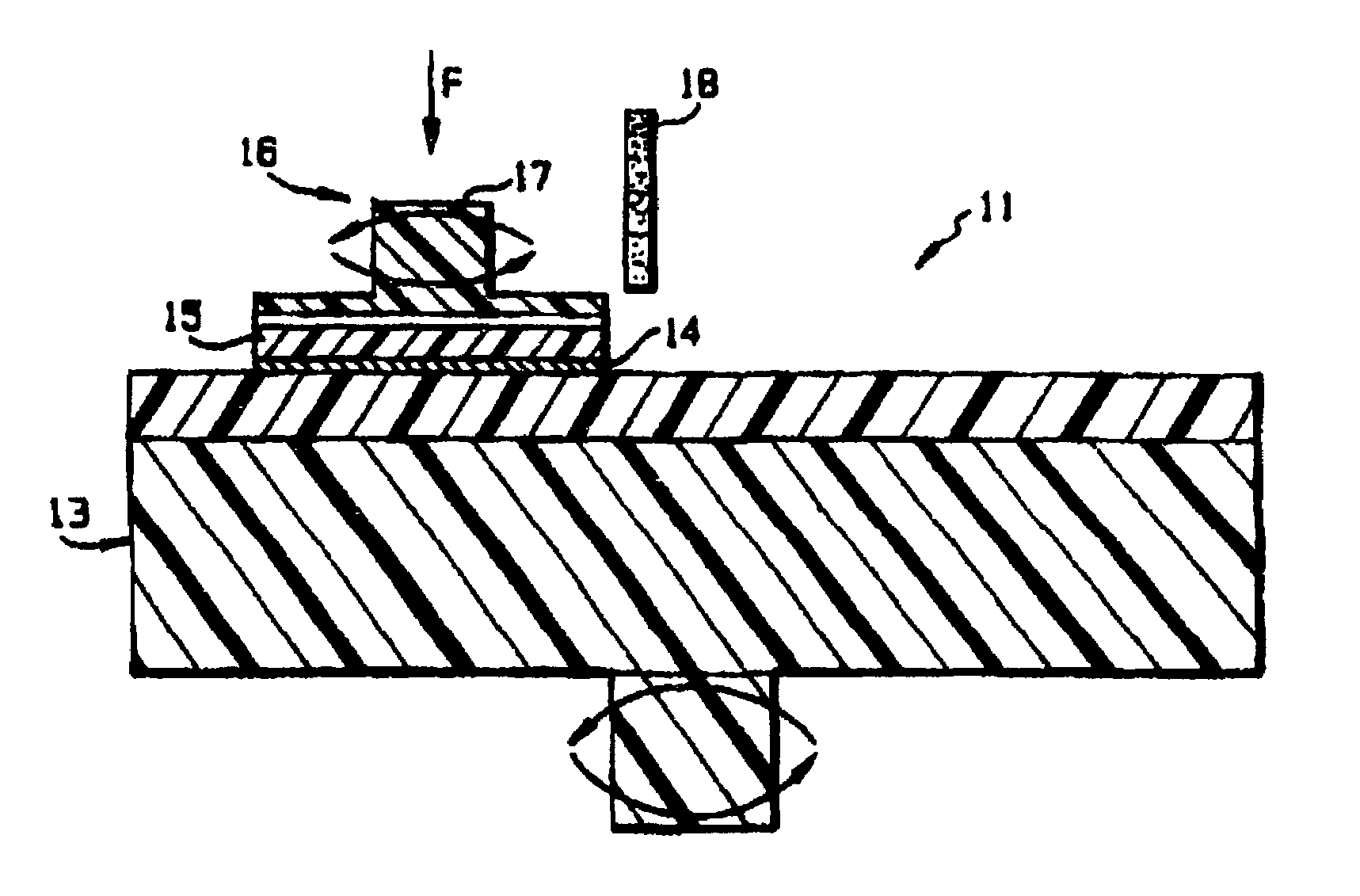

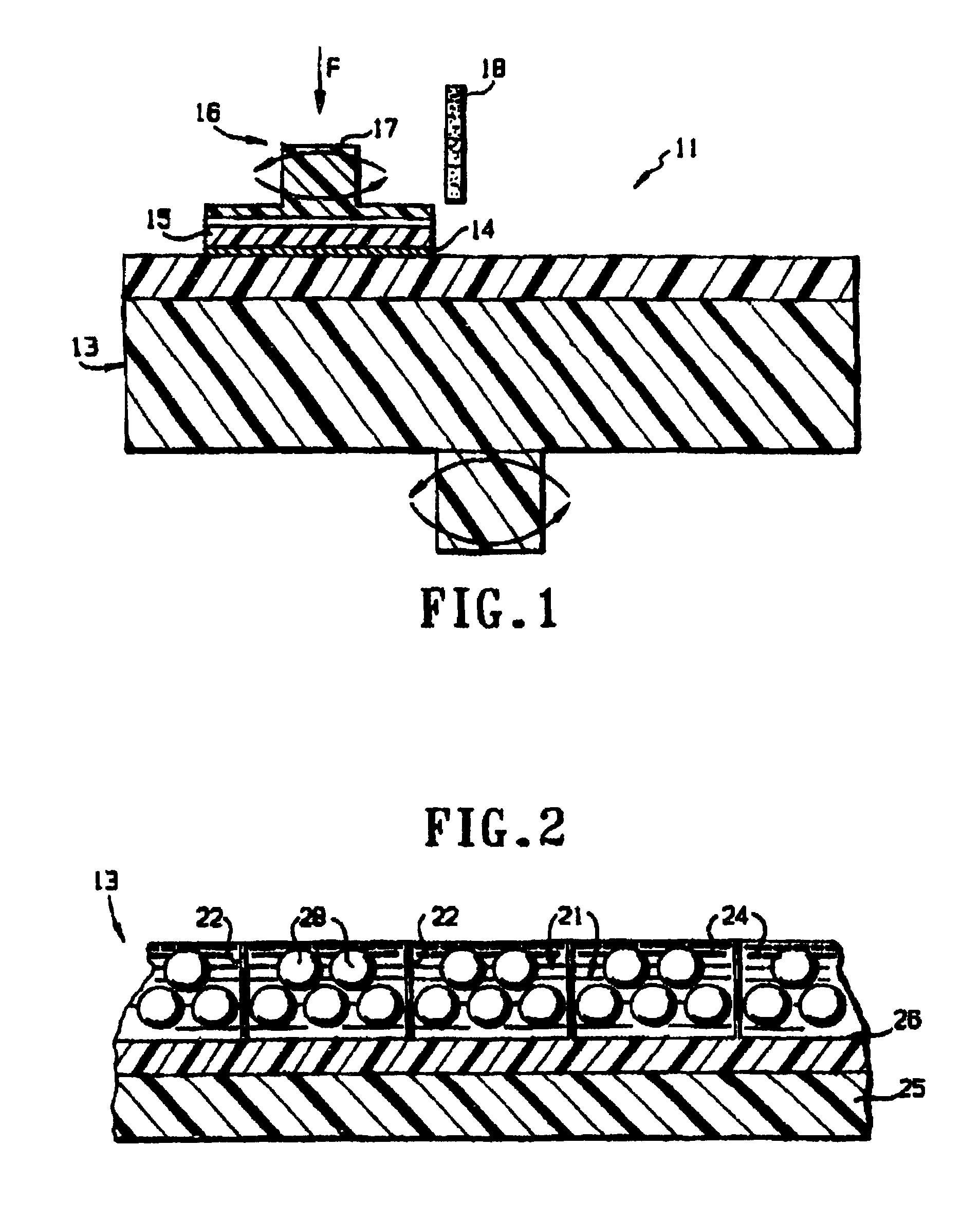

InactiveUS20060050320A1Low costReadily and rapidly eliminate a positional displacementVisual presentationColor matchingSolid densityComputer graphics (images)

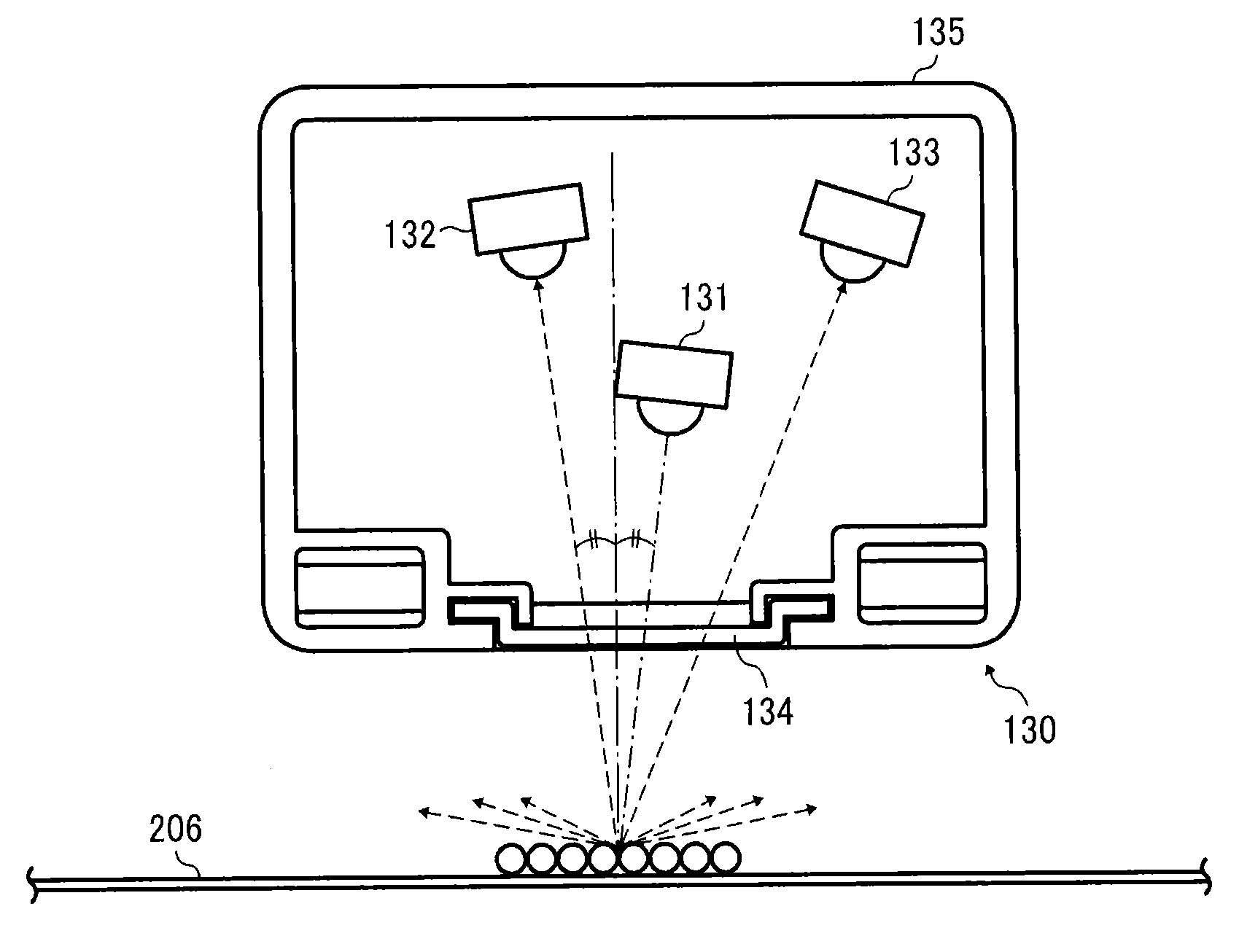

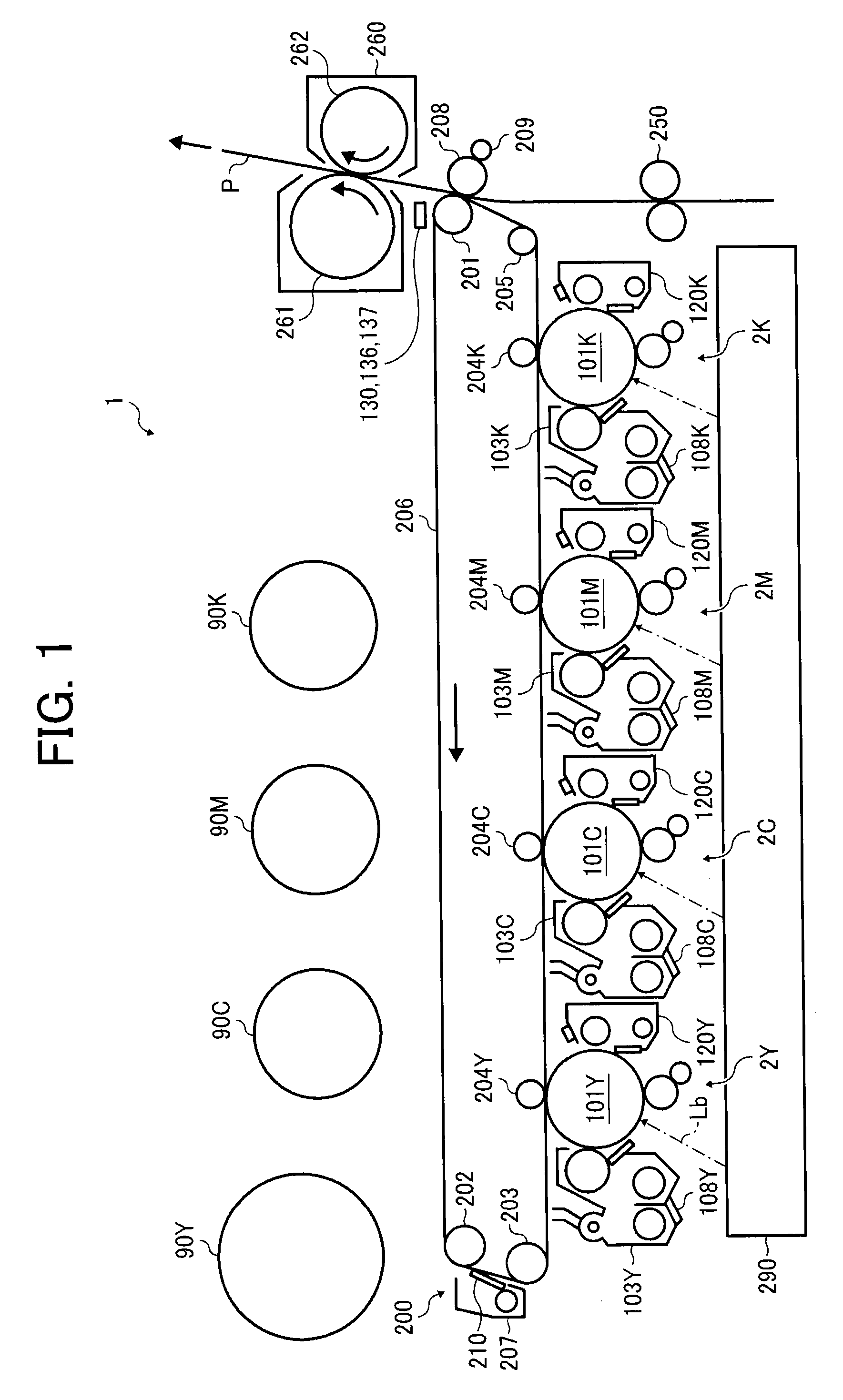

A picture color tone controlling method and apparatus for a printing press is disclosed which can readily and rapidly eliminate a positional displacement between a plate making image and an actual machine image and can appropriately perform color tone control in which an IRGB densitometer is used. A plate making picture position obtained from plate making data is moved so that a positional displacement between the plate making picture position and an actual picture position obtained from a result of actual printing. A target color mixture halftone density for each ink supplying unit width when a printing picture is divided with an ink supplying unit width of an ink supplying apparatus is set. An IRGB densitometer is used to measure the actual color mixture halftone density for each ink supplying unit width of an actually printed sheet obtained by printing. The color mixture halftone densities are individually converted into halftone dot area ratios and further into monochromatic halftone densities. Then, the Yule-Nielsen expression or the like is used to determine a solid density deviation corresponding to a deviation between the target monochromatic halftone density and the actual monochromatic halftone density, and the ink supplying amount is adjusted for each ink supplying unit width in response to the solid density deviation.

Owner:MITSUBISHI HEAVY IND LTD

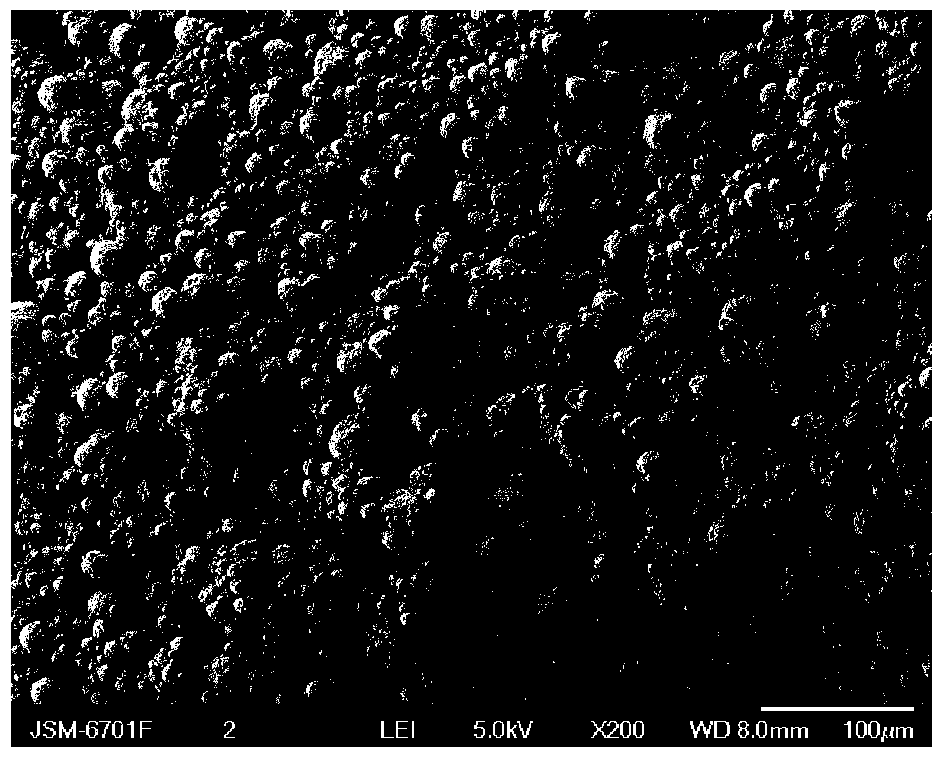

Dust-free and pore-free, high-purity granulated polysilicon

ActiveUS20050135986A1Reduce the ratioAvoid problemsBy pulling from meltCeramic shaping apparatusSolid densitySurface roughness

A polycrystalline granulated silicon is made of particles which have a density of greater than 99.9% of the theoretical solid density and therefore have a pore content of less than 0.1% and have a surface roughness Ra of less than 150 nm.

Owner:WACKER CHEM GMBH

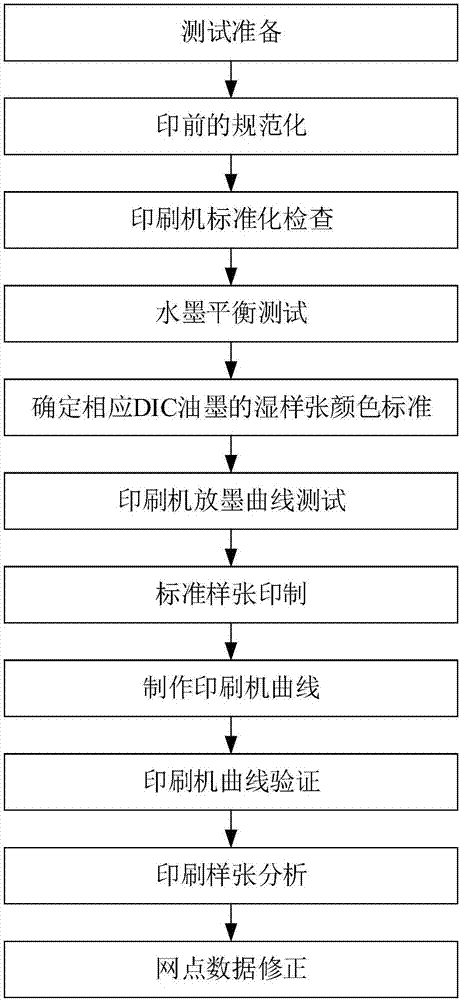

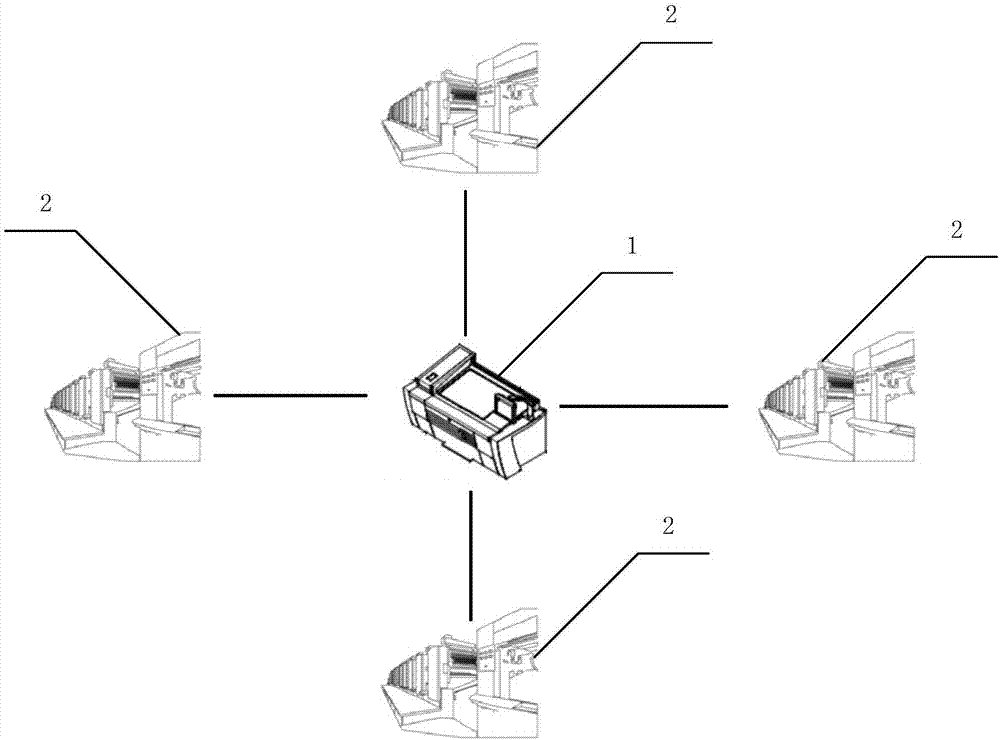

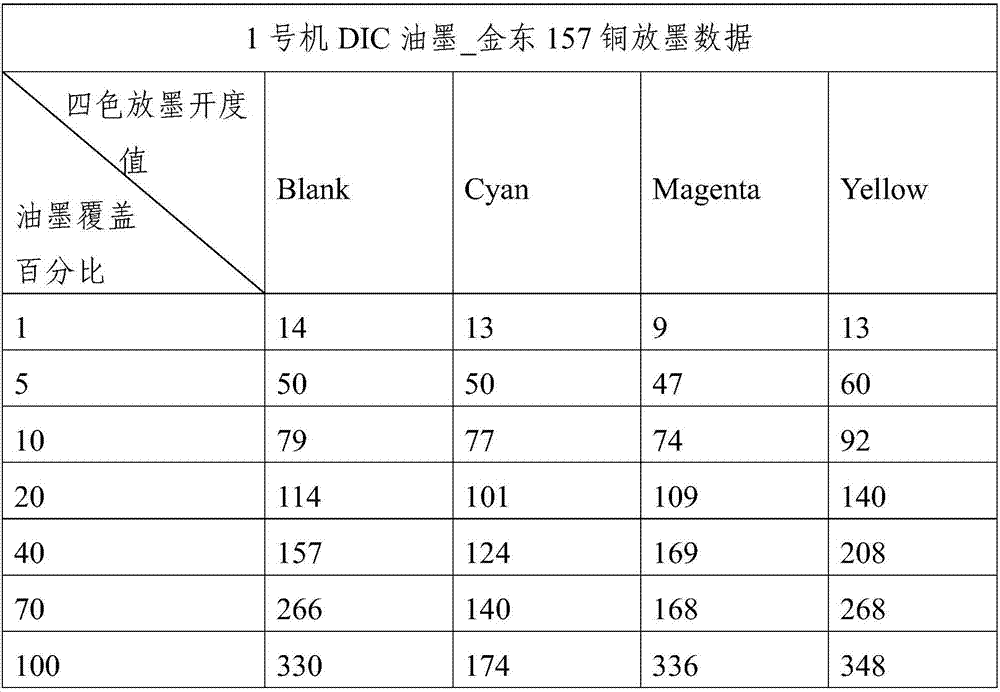

Printing color quality measurement method

ActiveCN107042689AEfficient analysisEffective correctionPrinting press partsSolid densityWater balance

The invention discloses a printing color quality measurement method. The method comprises the steps of measurement pre-preparation, pre-printing normalization, standardization inspection of a printing machine, ink-water balance measurement, determination of optimal solid density, ink outputting curve measurement of the printing machine, printing of standard samples, manufacturing a printing machine curve, verification of the printing machine curve, analysis of the printing samples, and correction of network data. According to the printing color quality measurement method, printing data is effectively analyzed and corrected through the strict and normal measurement, and the method has quite high practical value and wide application prospects.

Owner:北京奇良海德印刷股份有限公司

Method for obtaining optimal solid density for coated paper printing

ActiveCN103714245ARapid Density DeterminationHigh densitySpecial data processing applicationsPrinting press partsSolid densityVolumetric Mass Density

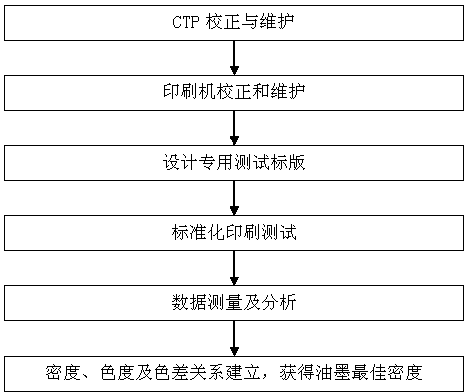

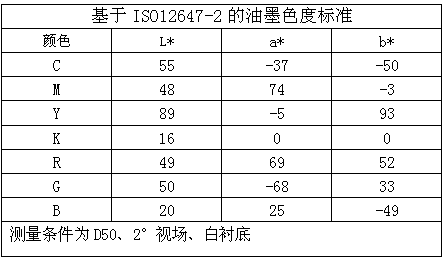

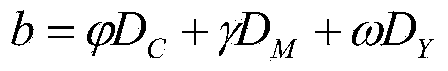

The invention discloses a method for obtaining the optimal solid density for coated paper printing. The method comprises the steps that 1, a CTP process control system is built, and the CTP device calibration work is finished; 2, a printer process control system is built, and the printer device calibration work is finished; 3, a printing test standard version is designed, a printing test is conducted through a standardized test method, and standard test specimen page is obtained; 4, data measurement is conducted on the density and chromaticity parameters of the specimen page; 5, according to the measured result, the optimal solid density for coated paper printing is calculated and obtained. According to the method for obtaining the optimal solid density for coated paper printing, on the basis of calibrating a CTP and a printer, the printing test is standardized, the eligible test specimen page is selected, the density and chromaticity values of a specimen paper designated color piece are measured, and a corresponding relation table for the chromaticity and density is built, so that the optimal density of the printed matter is rapidly determined, the defect that the optimal solid density is obtained through relative contrast is overcome, and accurate reappearance of color reproduction is achieved.

Owner:北京汇林印务有限公司

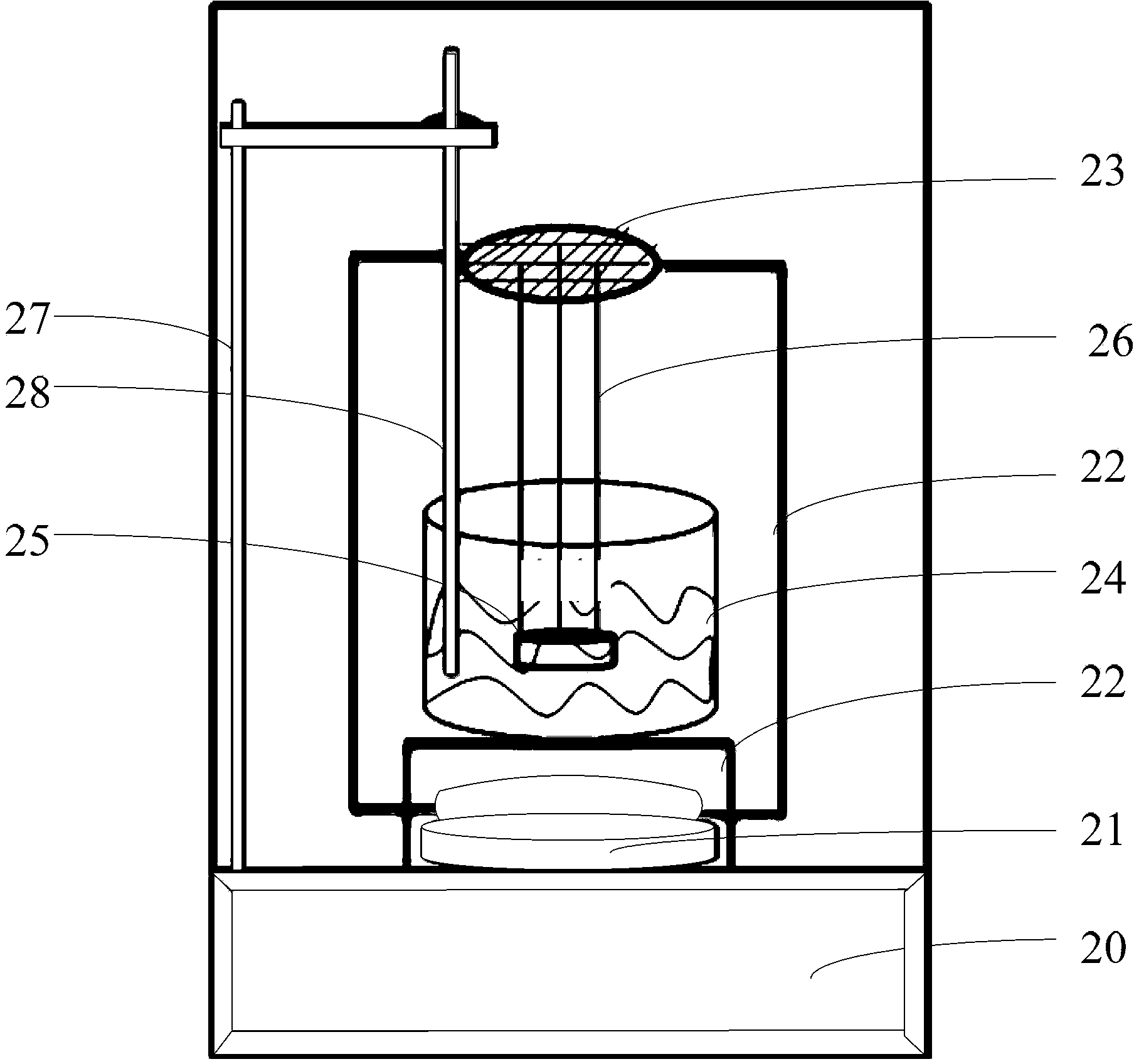

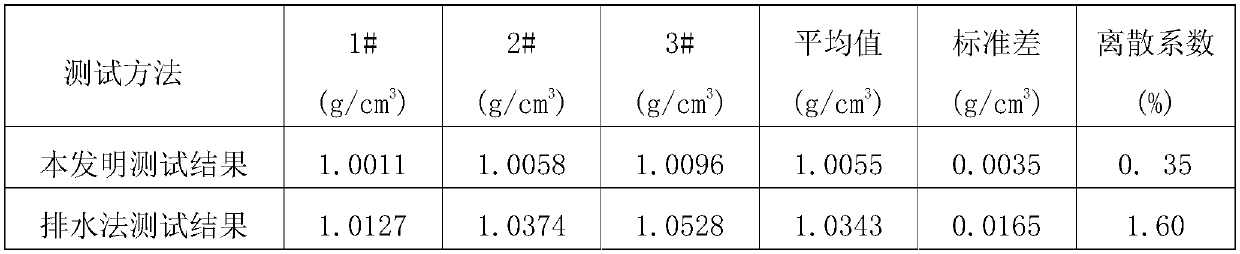

Solid density measure method and method for detecting density qualification of target material

ActiveCN103913399AThe method of whether the density is qualified is accurateExact density methodSpecific gravity measurementSolid densityDensity of air

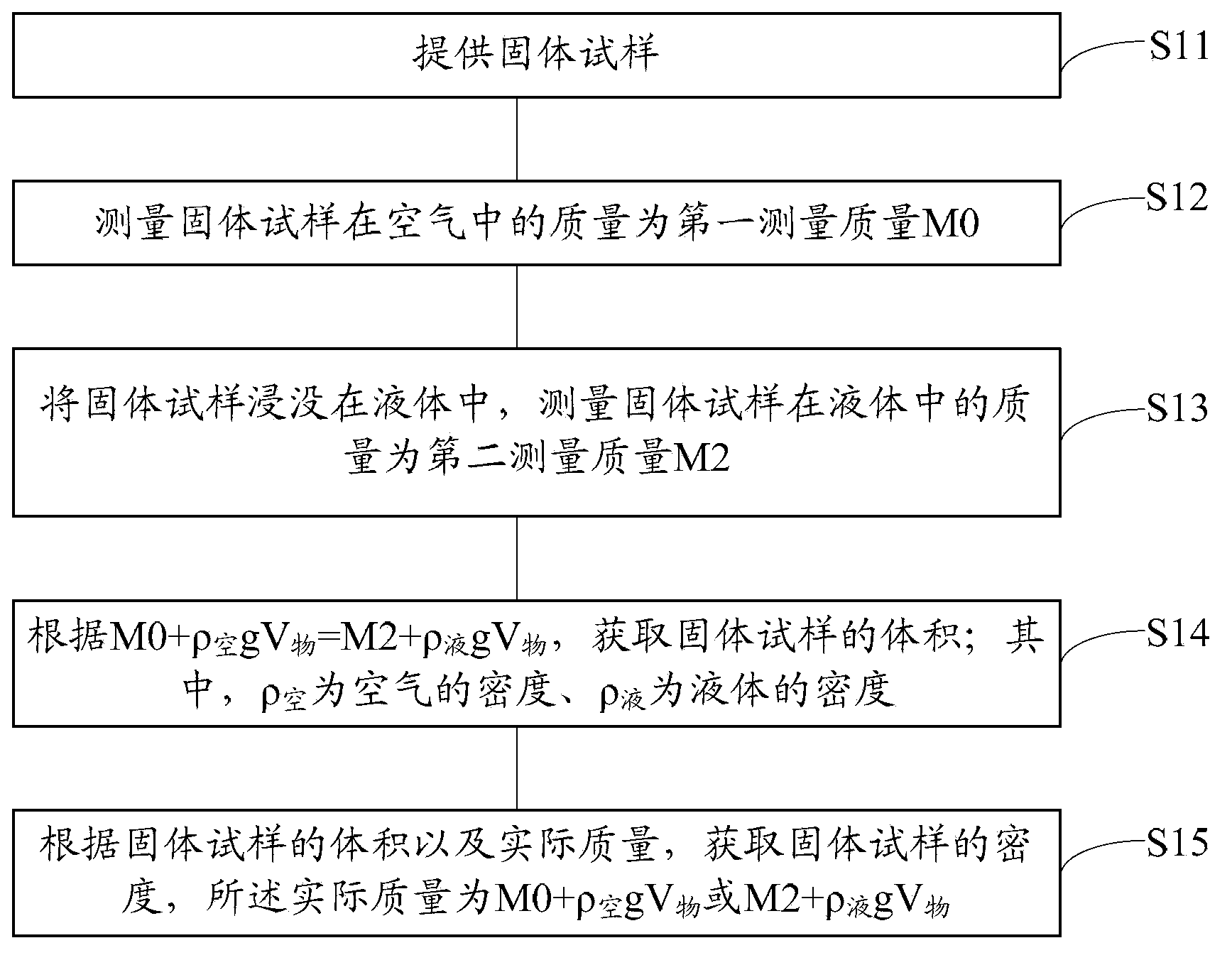

The invention provides a solid density measure method and a method for detecting density qualification of a target material. The solid density detection method comprises: providing a solid sample; measuring the mass of the solid sample in air as a first measure mass M0; submerging the solid sample in a liquid and measuring the mass of the solid sample in the liquid as a second measure mass M2; according to a formula of M0+rho<air>gV<sample>=M2+rho<liquid>gV<sample> to acquire the volume of the solid sample, wherein rho<air> is the density of air, rho<liquid> is the density of the liquid; and according to the volume of the solid sample and the real mass to acquire the density of the solid sample, wherein the real mass is M0+rho<air>gV<sample> or M2+rho<liquid>gV<sample>. The invention also provides the method for detecting the density of a target material is qualified. The solid density measure method disclosed by the invention is capable of improving the detection precision of the target material and improving the film plating quality in sputtering technology.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

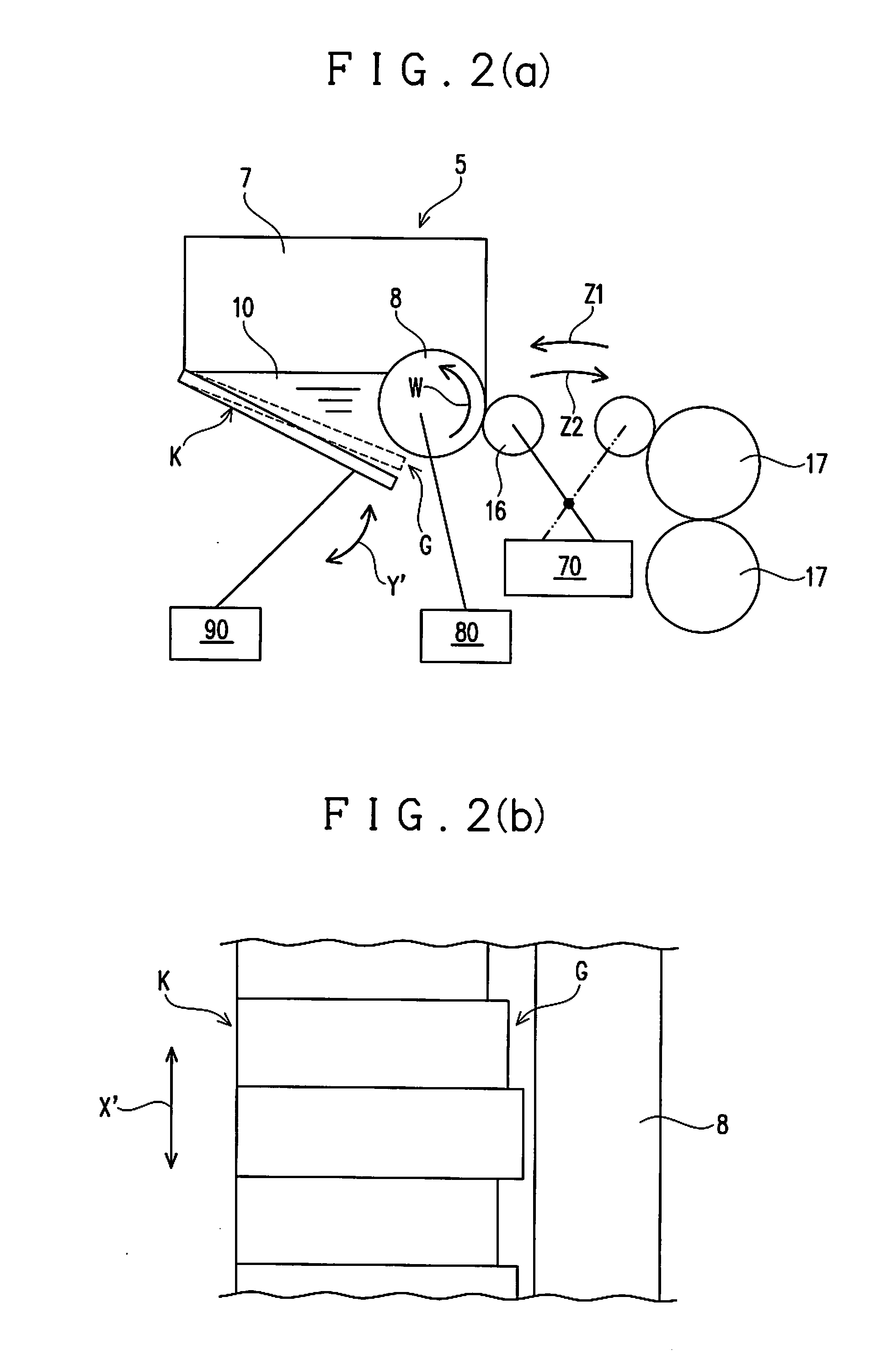

Picture color tone controlling method and apparatus

InactiveUS20060055948A1Improve accuracyDigitally marking record carriersDigital computer detailsSolid densityComputer graphics (images)

A picture color tone controlling method and apparatus for a printing press is disclosed by which a noticed pixel for control can be set appropriately and the accuracy in color tone control can be enhanced. For each of ink supplying unit widths, a region which has a high autocorrelation for each of the ink colors is selected in a sensor pixel unit of a densitometer, and a region obtained by removing an edge portion of the pertaining ink color having a width of a predetermined number of pixels from the selected region is set as a noticed pixel for each of the ink colors. Then, a target color mixture halftone density is set for each of the ink supplying unit widths, and an actual color mixture halftone density for each of the ink supplying unit widths of an actually printed sheet is measured using the densitometer. Further, the color mixture halftone density is converted into a halftone dot area ratio and further into a monochromatic halftone density. Then, a solid density deviation is determined, and the ink supplying amount is adjusted for each of the ink supplying unit widths in response to the solid density deviation.

Owner:MITSUBISHI HEAVY IND LTD

Chemical mechanical polishing slurry

InactiveUS6976904B2Minimize damageDamaging contacts of the solid abrasive particles with one another are minimizedPolishing machinesRevolution surface grinding machinesLiquid densitySolid density

A liquid suspension for planarizing an outer surface of a material comprises a liquid suspension medium of a specific liquid density; and a plurality of solid, contact-sensitive abrasive particles of a constant solid density and suspended in the liquid suspension medium. The liquid and solid densities are approximately the same so that the abrasive particles freely and stably suspend in the liquid suspension medium, without gravitational separation by settling down or floating up. In this way, damaging contacts of the solid abrasive particles with one another are minimized.

Owner:LI FAMILY HLDG

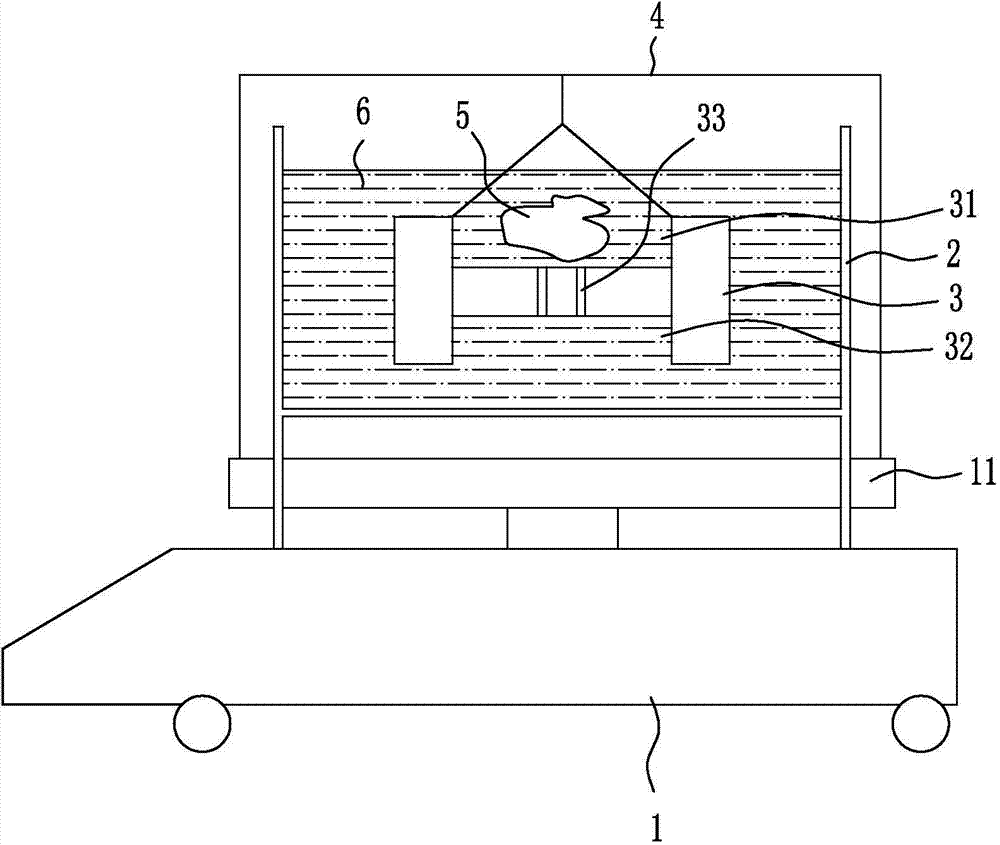

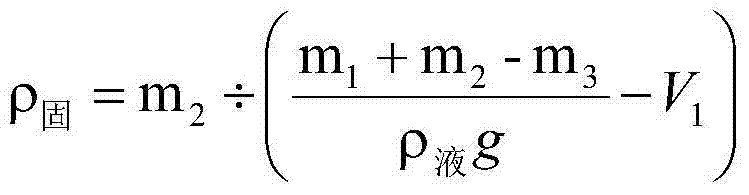

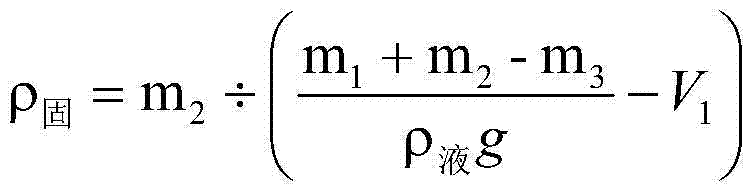

Solid density detection method and device

InactiveCN104280312ADensity is accurateDensity made easy and preciseSpecific gravity measurementSolid densityPhysical chemistry

The invention discloses a solid density detection method, comprising the following steps: preparing a special weight capable of bearing or pressing a to-be-detected solid to immerse into liquid, wherein the weight has known V1 and mass m1 and is not infiltrated by the liquid; weighing the mass m2 of the to-be-detected solid; weighing the mass m3 of the special weight together with the to-be-detected solid immersed into the liquid with the known density being rho(liquid); and determining the density rho(solid) of the to-be-detected solid by virtue of a formula. A detection device adopting the method comprises a container and a special weight, wherein the container is used for weighing and containing the liquid; the special weight is partitioned into an upper cavity and a lower cavity; and a communicating hole is formed between the upper cavity and the lower cavity of the weight. Due to adoption of the solid density detection method and device disclosed by the invention, measurement of the solid density is simple and accurate, and on-site rapid and accurate measurement of the density of a solid sample can be achieved.

Owner:MODENA TECH LTD

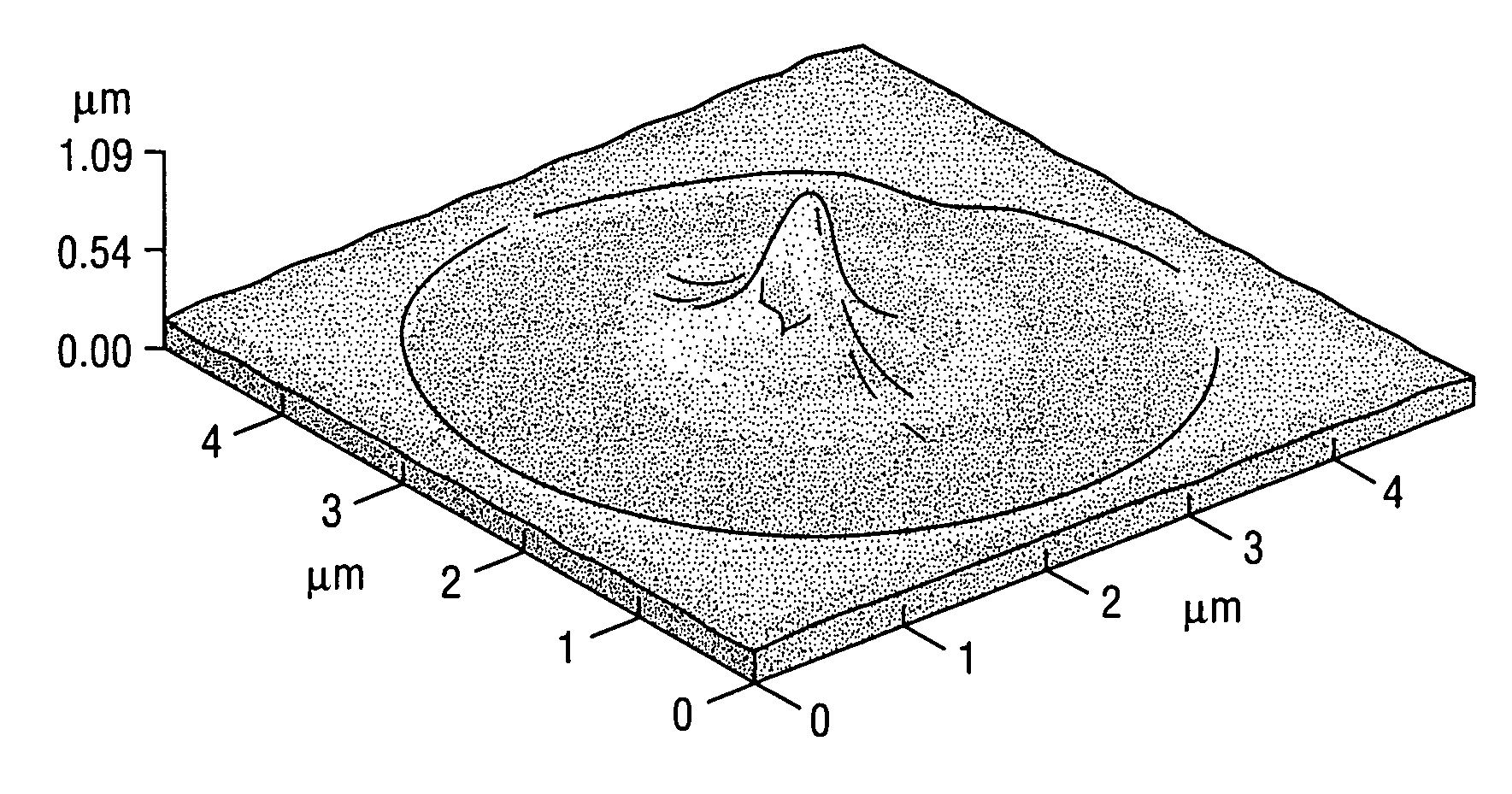

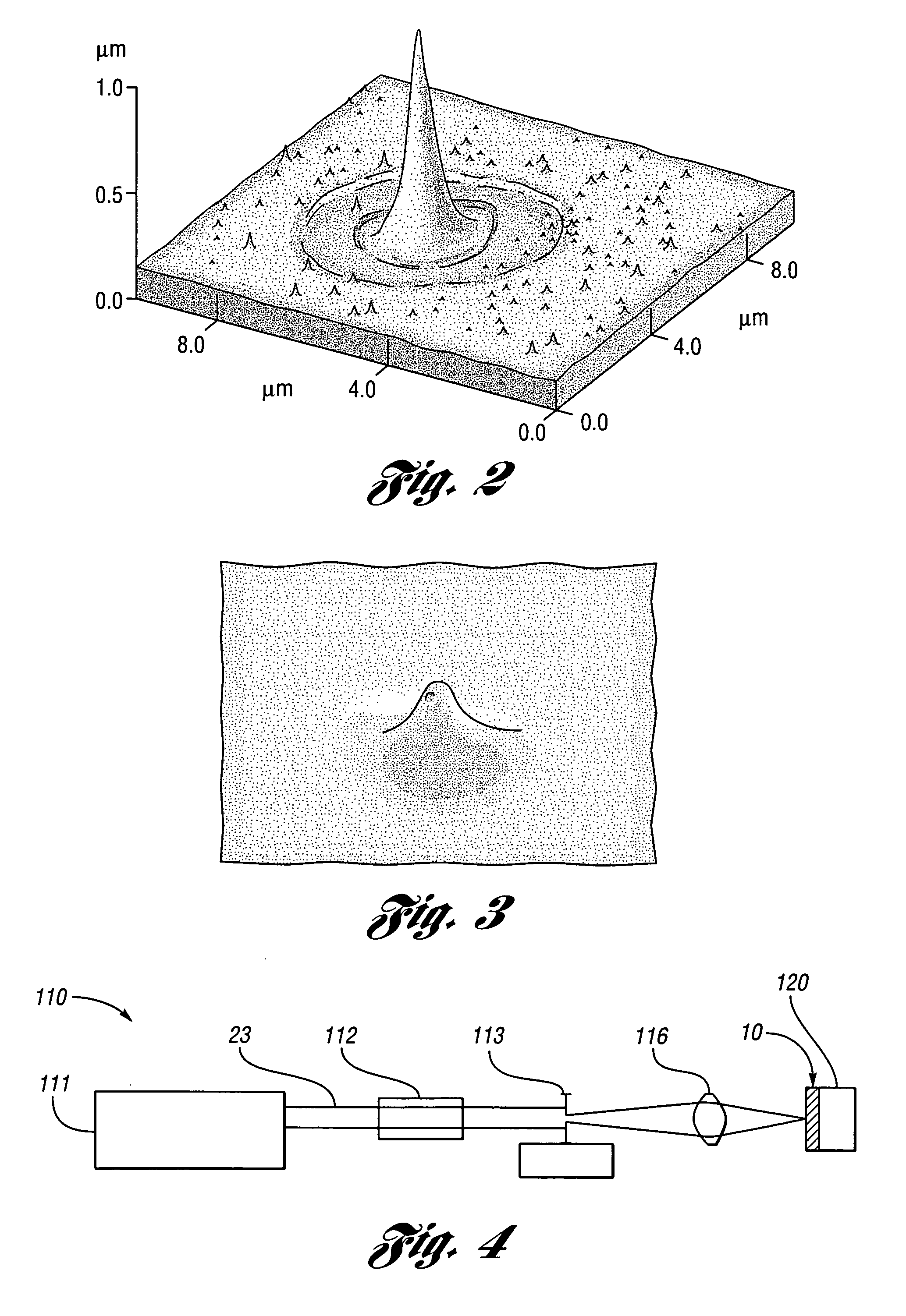

Method of forming micro-structures and nano-structures

InactiveUS20060258133A1Efficient manufacturingNanotechSemiconductor/solid-state device manufacturingMicro structureLiquid density

Methods of forming a nano-structure for electron extraction are disclosed. One method of forming a nano-structure comprises irradiating an area on a first surface of a thermal conductive film to melt the area across the film. The film is insulated on a second surface to provide two-dimensional heat transfer across the film. The liquid density of the film is greater than the solid density thereof. The method further comprises cooling the area inwardly from the periphery thereof to form a nano-structure having an apical nano-tip for electron extraction.

Owner:WAYNE STATE UNIV

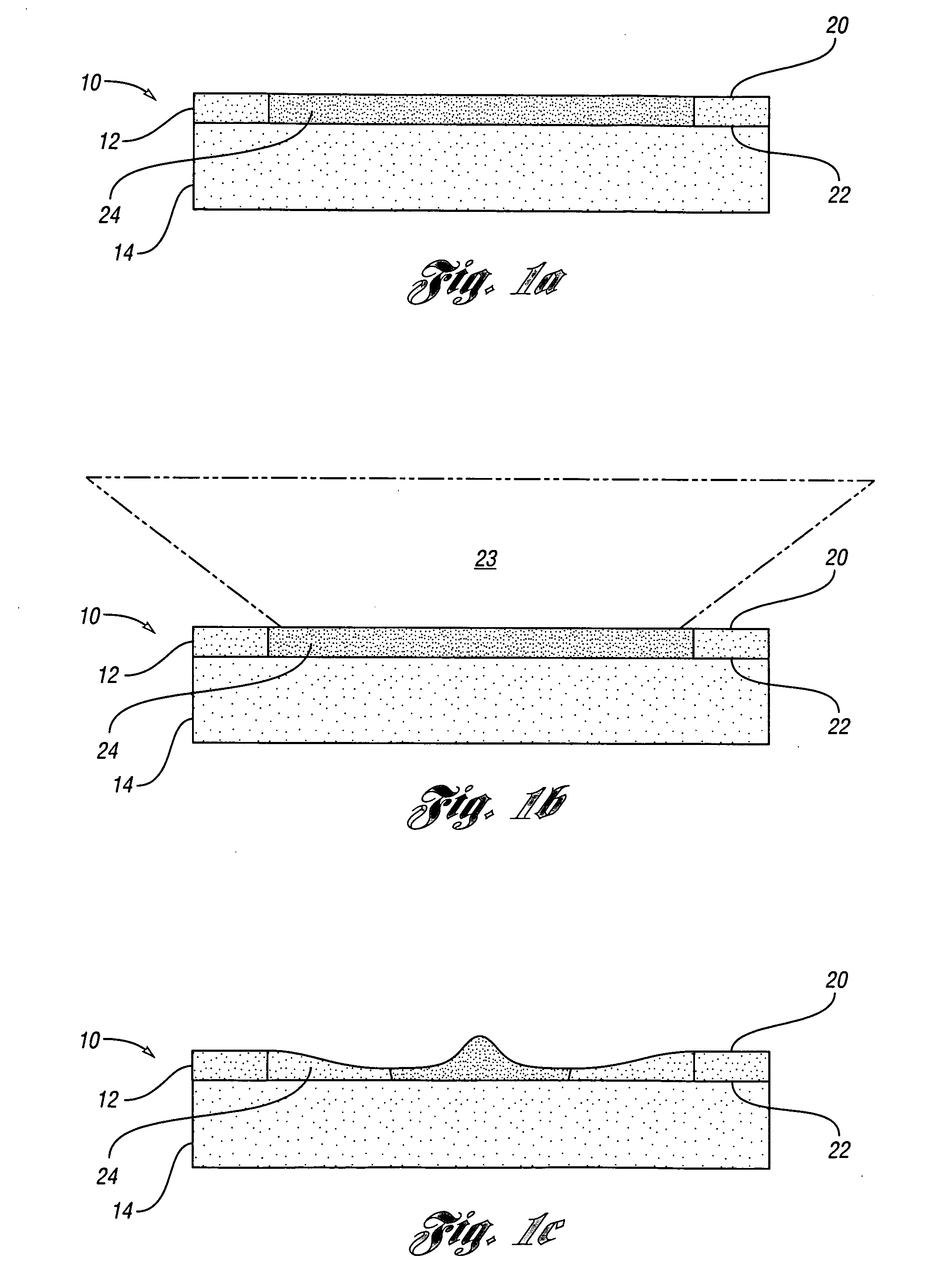

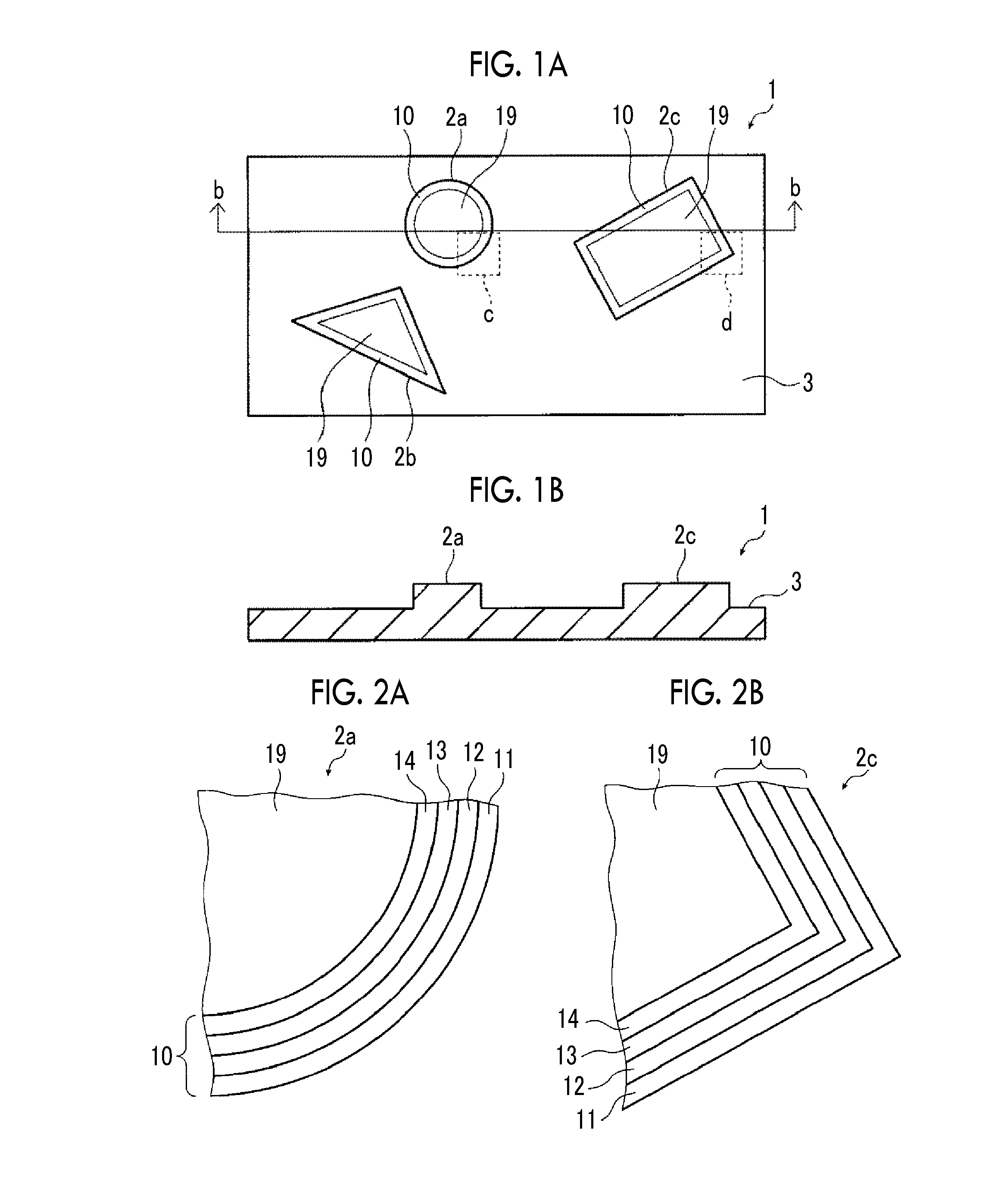

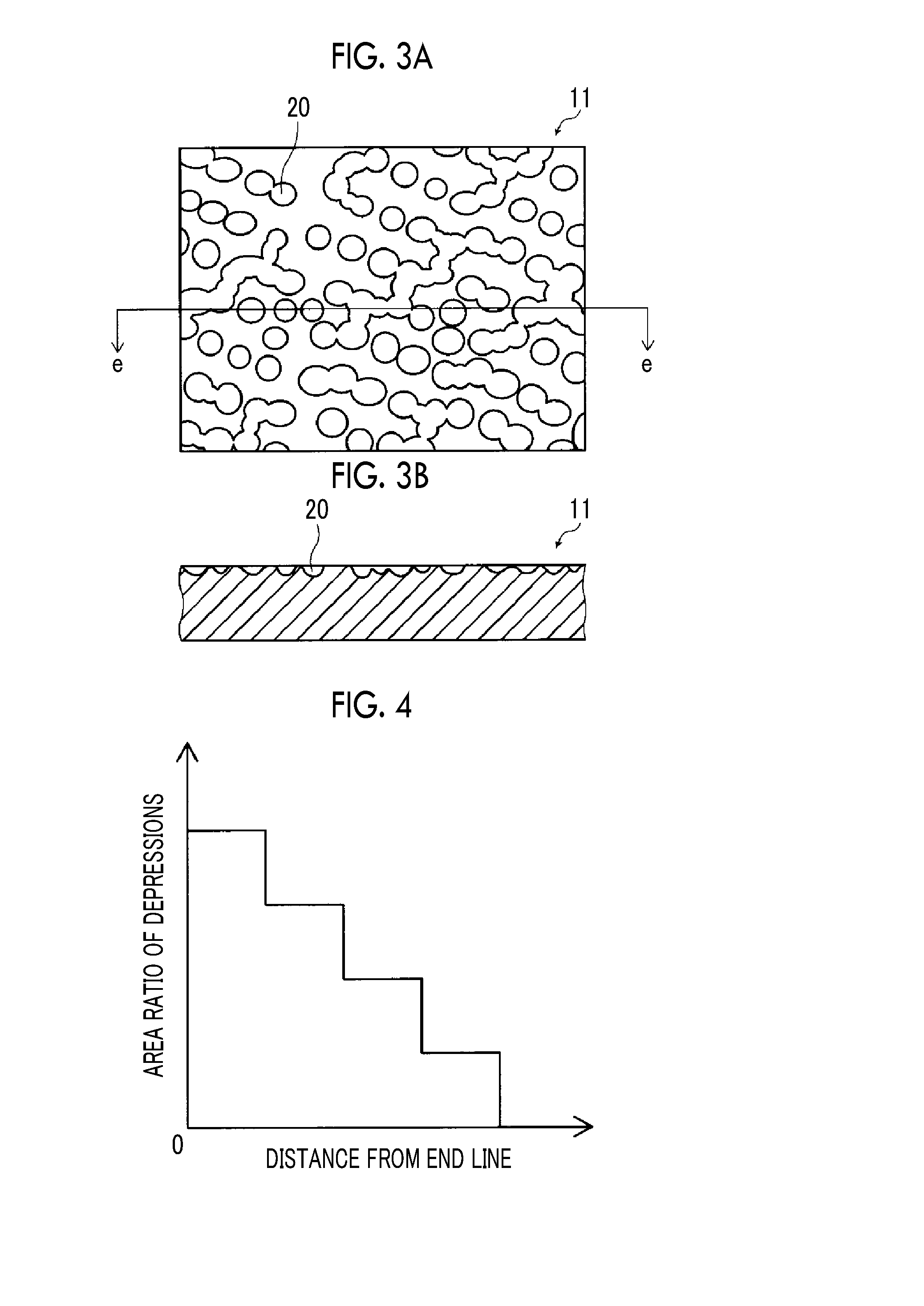

Flexo printing plate

InactiveUS20160221379A1Decrease in solid densityAvoid discontinuitiesPlate printingFoil printingSolid densityEngineering

Provided is a flexo printing plate which enables printing that inhibits the occurrence of voids in the rear end portion of an image portion while preventing decrease in solid density and prevents discontinuity of density from becoming visible. The flexo printing plate has one or more image portions, and in at least one of the image portions, a plurality of depressions having a predetermined width measured from the edge is formed. The depressions have a depth of 2 μm to 9 μm, and an area ratio of the depressions in the end region is a maximum at the edge side and a minimum at the central side of the image portion.

Owner:FUJIFILM CORP

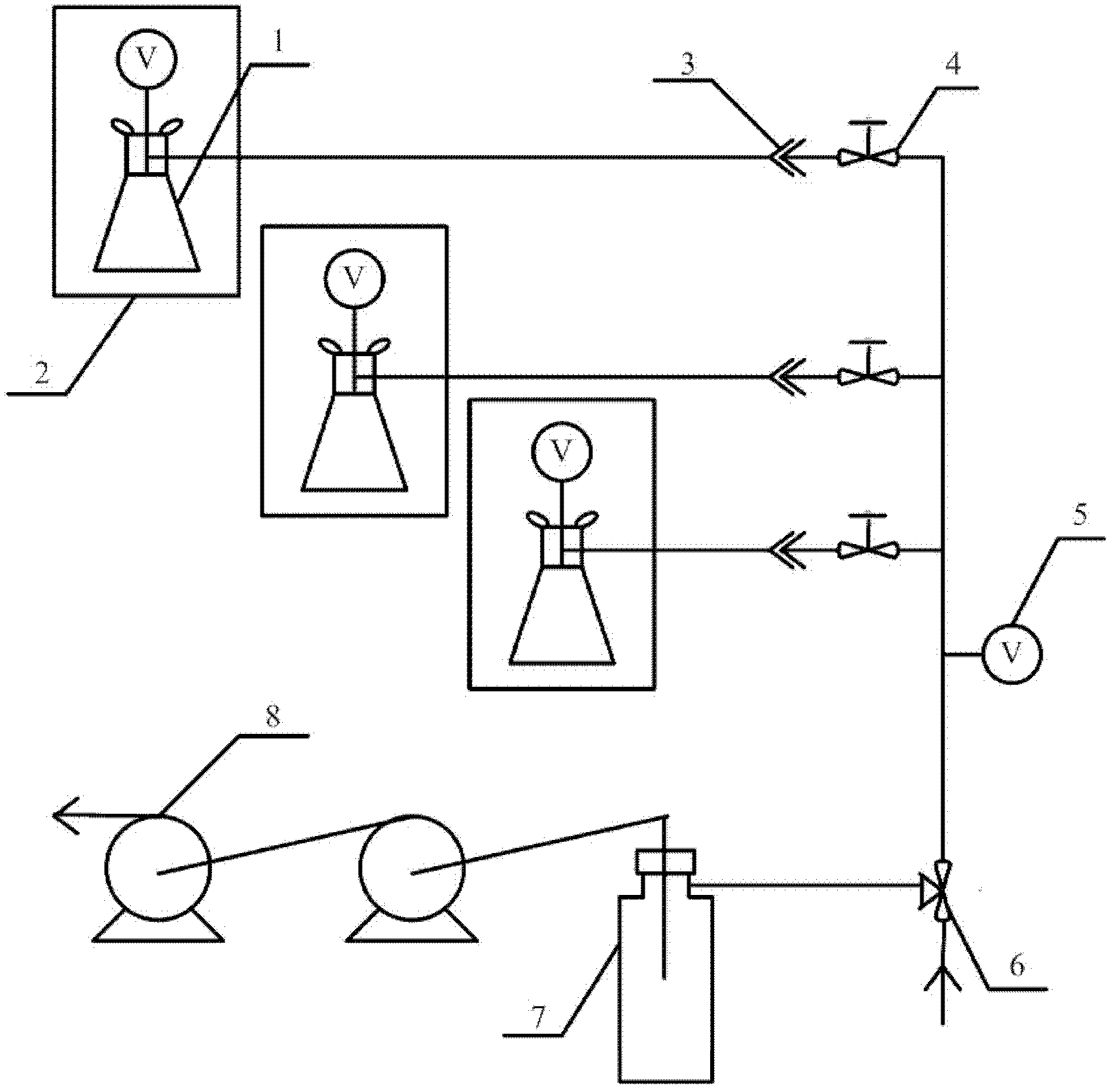

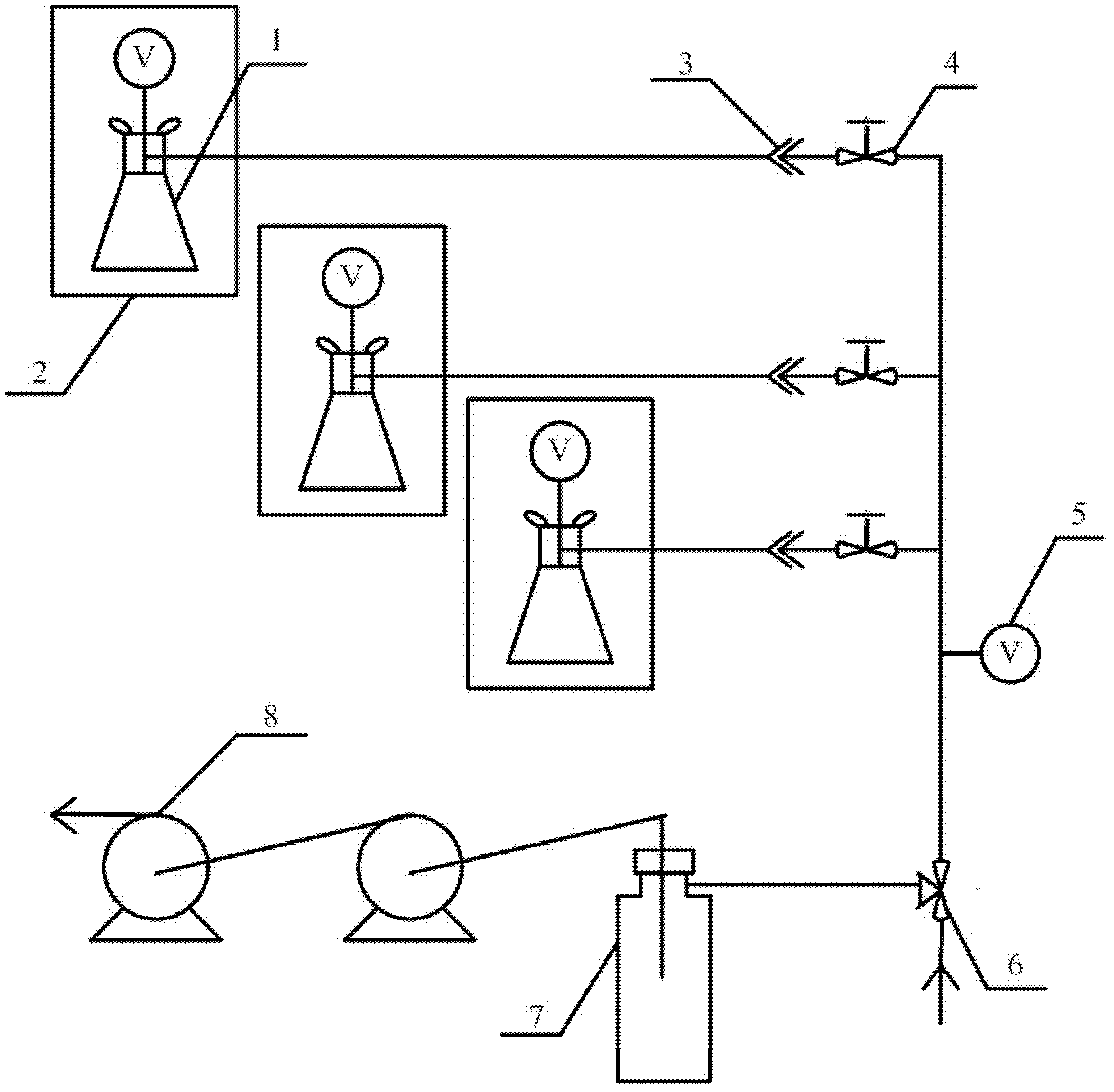

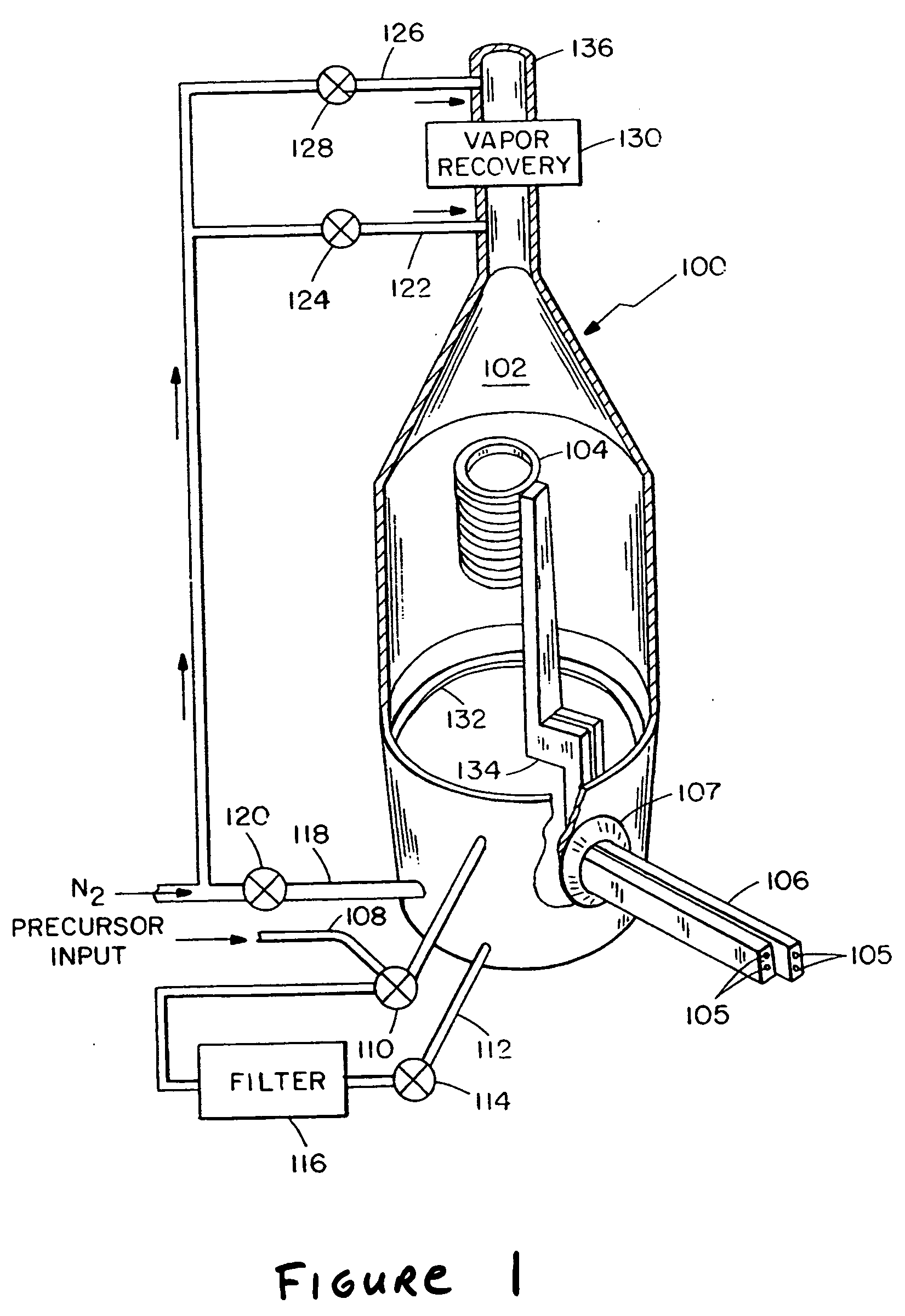

Modularized vacuum system of saturated vapor pressure and solid density of tested substance and applications

InactiveCN102607993AFlexible replacementAchieve interchangeSpecific gravity measurementDead volumeSolid density

The invention relates to a modularized vacuum system of saturated vapor pressure and solid density of a tested substance and applications thereof. The system comprises constant temperature heating devices, integrated devices, quick couplers, vacuum valves and a three-way valve, wherein each integrated device consisting of a bottle, a valve and vacuum meters is arranged in a constant temperature heating device; the quick couplers, the vacuum valves and the three-way valve are sequentially connected with the integrated devices through pipelines; one joint of the three-way valve is connected with a buffer bottle connected with cascade vacuum pumps; and the system can be used for calculating the density of the substance. Compared with the prior art, the system has the advantages that the dead volume and the connecting point number of the system are furthest reduced by optimized design, and the problems of multiple pipeline connecting points, leakage and single test module and measuring range in the conventional saturated vapor pressure testing vacuum device are solved.

Owner:SHANGHAI RES INST OF CHEM IND

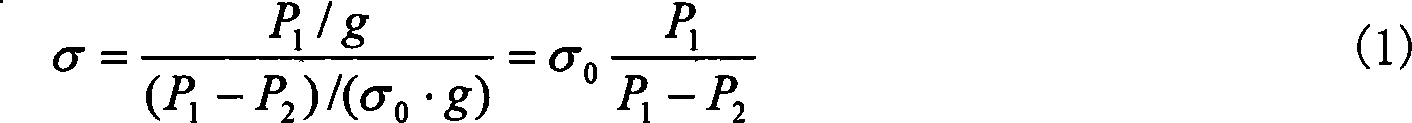

Solid density measuring method

InactiveCN101078677ASolving Density Measurement MethodsDensity measurement achievedSpecific gravity measurementSolid massSolid density

The invention discloses a measuring method for density physical parameter of solid material or other solid specimen, especially the measuring method for physical parameter of solid material specimen with any shape and density less than 1g / cm3. Based on the function of density measuring device for solid substance, weight P1 of measured specimen is measured in air by the density measuring device for solid substance. A standard substance with known weight and cubage is added on the measured specimen and they are immerged into liquid or water completely. P2 is measured by the density measuring device for solid substance. By formula (3) the density of specimen with irregular shape and density smaller than 1g / cm3 can be obtained. The density measuring method for specimen with irregular shape and density smaller than 1g / cm3 can be solved and density measurement for specimen with density smaller than 1g / cm3 can be realized. Analysis for geophysical exploration and building material or measuring class of specimen can be added.

Owner:JILIN UNIV

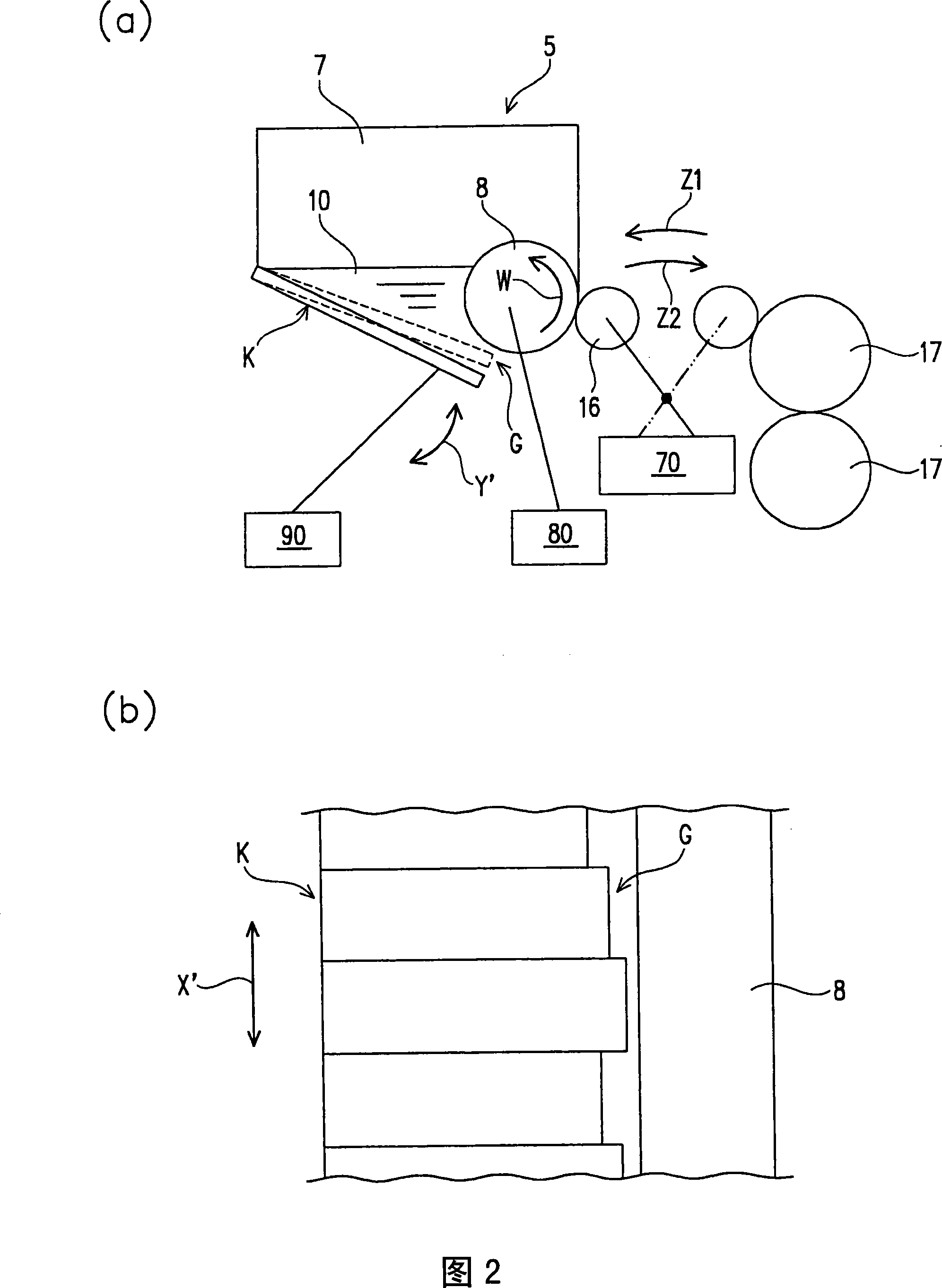

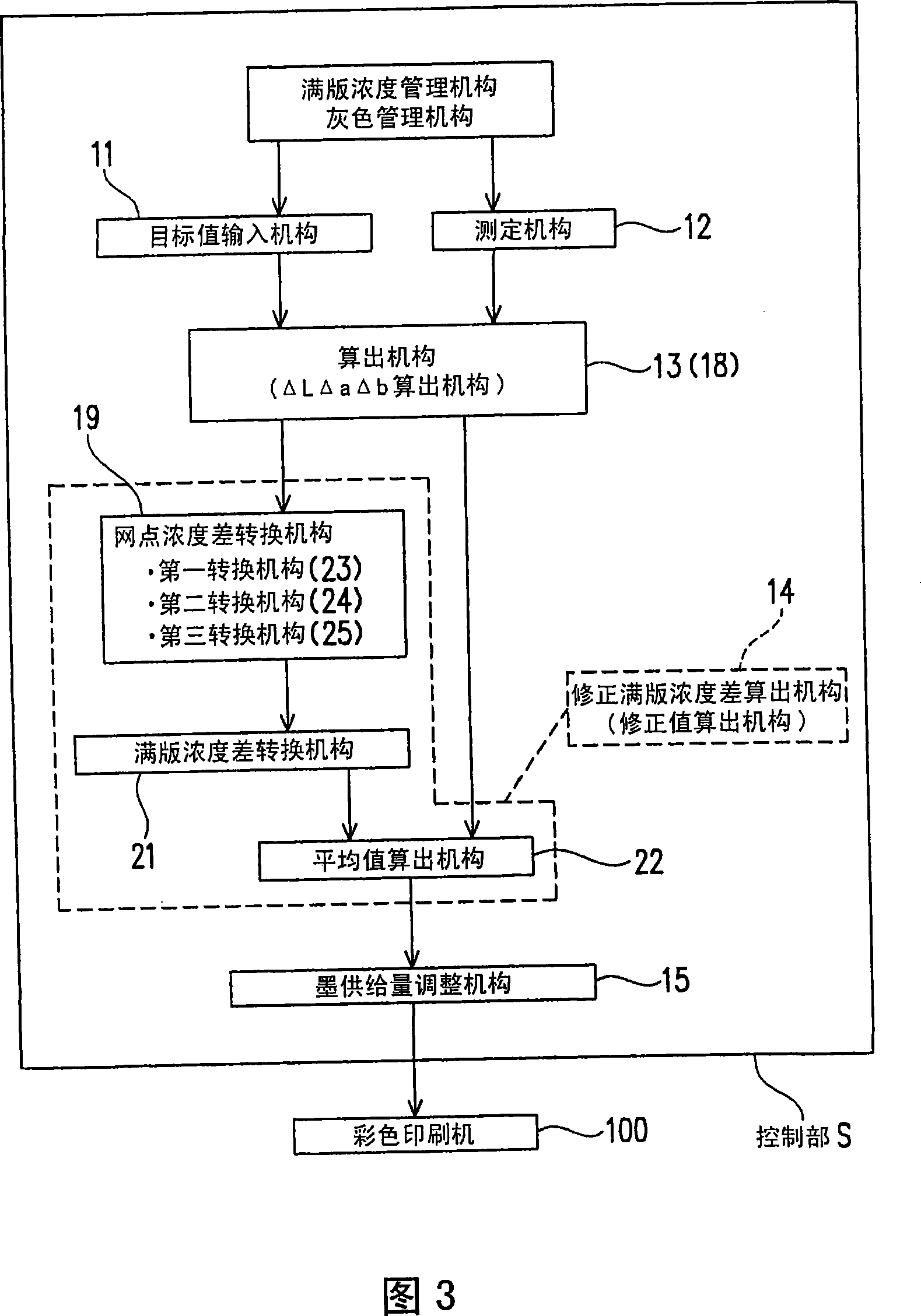

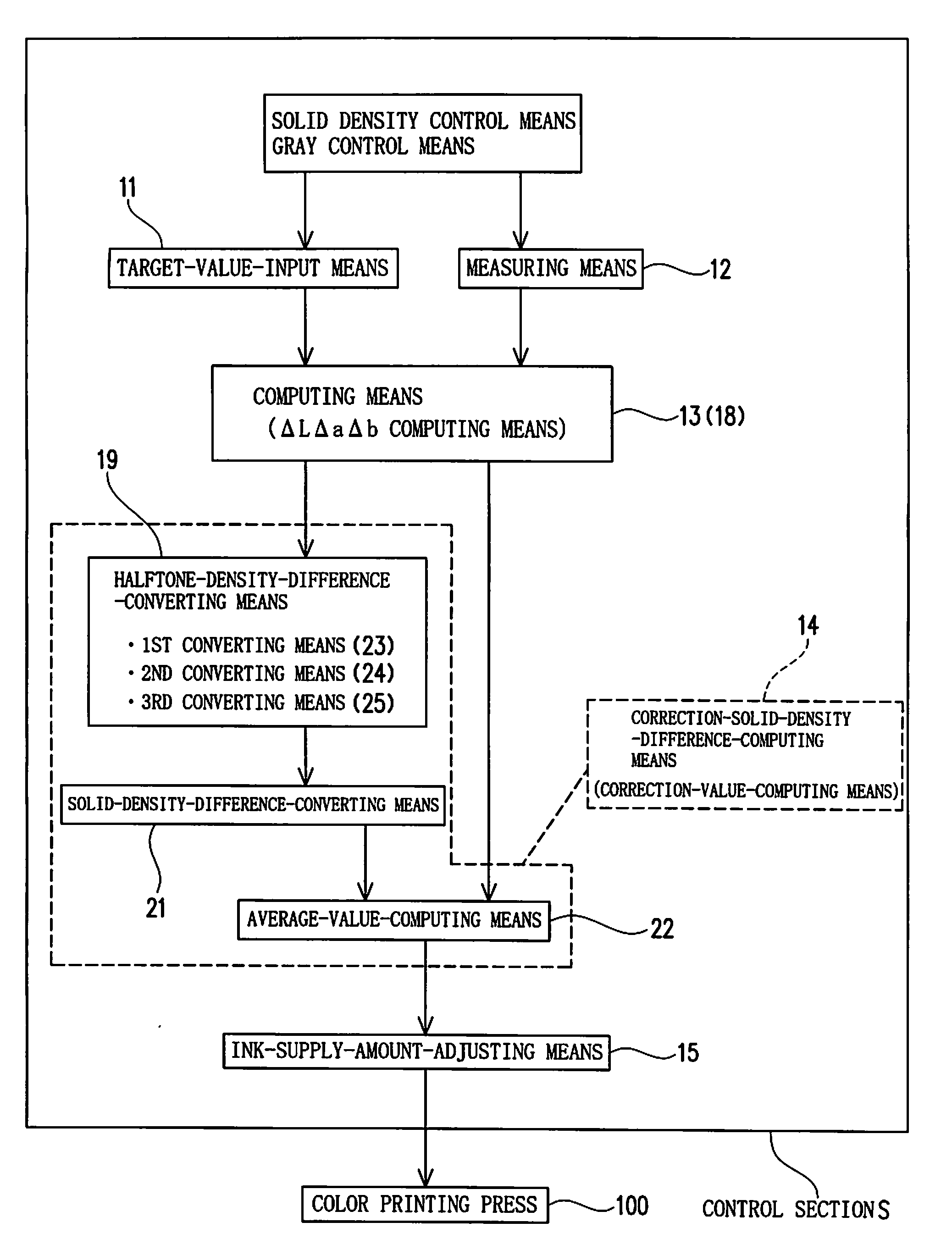

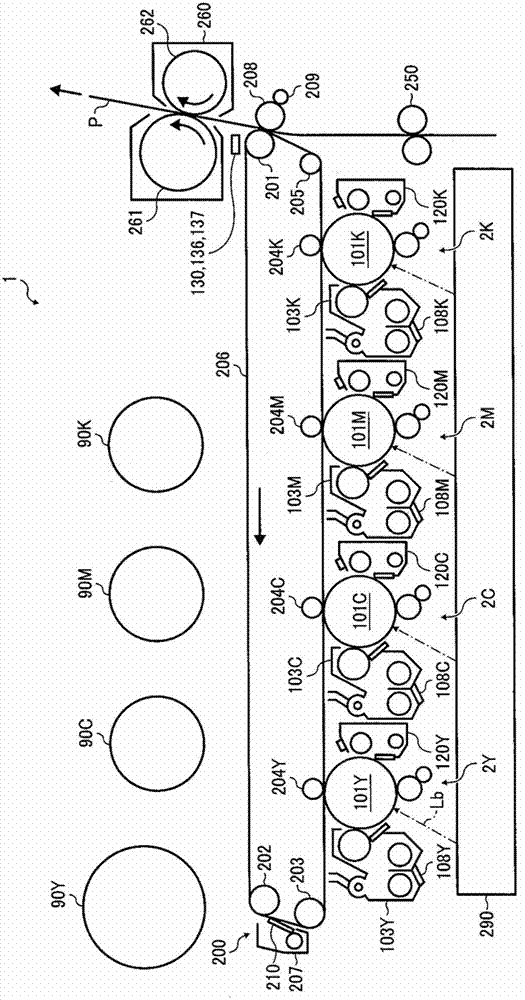

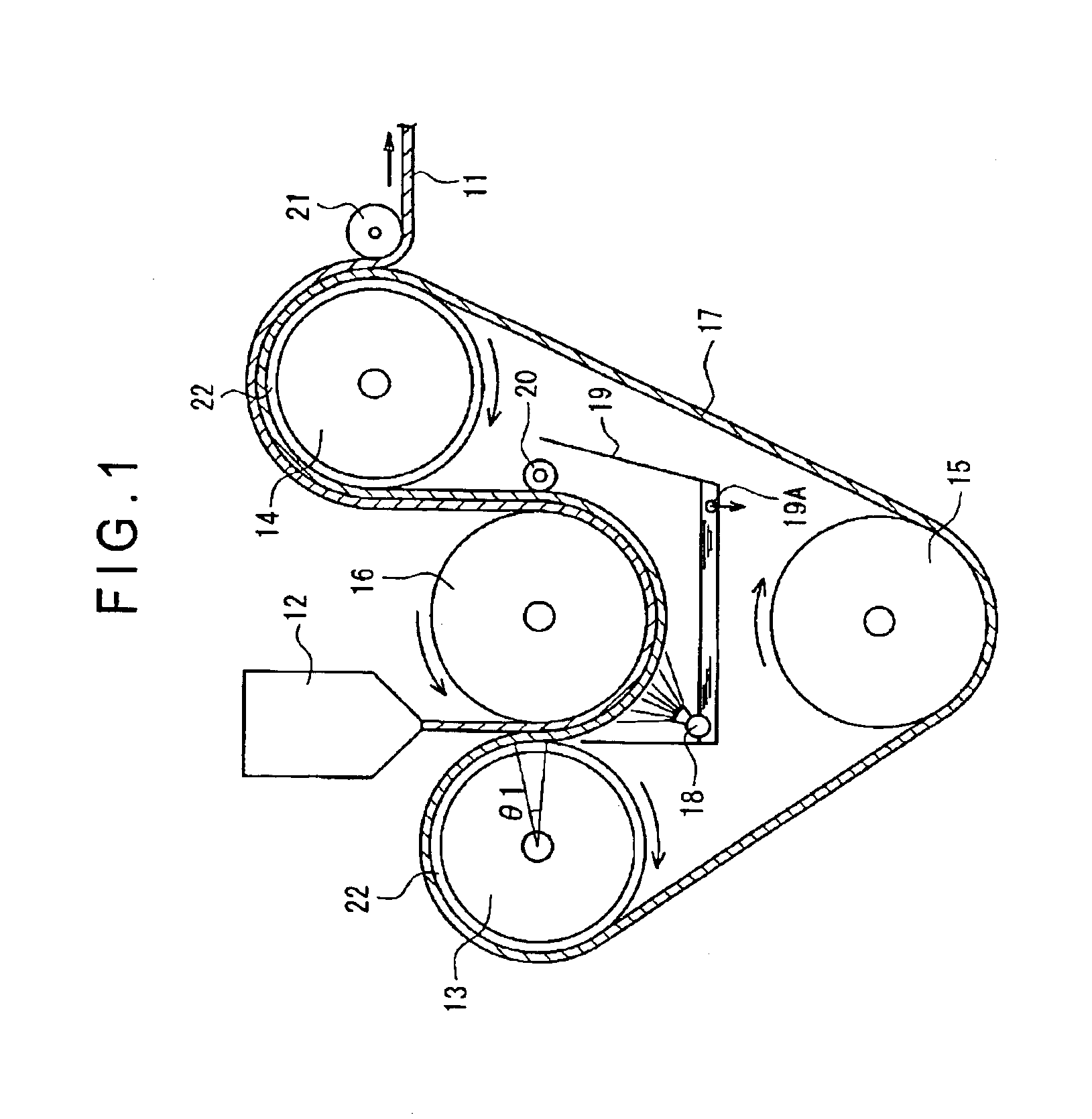

Method of controlling quality of printed images of color printing press and apparatus for controlling quality of printed images

InactiveCN101190598AAvoid poor reproductionRealize sharingColor measuring devicesPrinting press partsColor printingSolid density

The present invention provides a printing image quality management method of a color printing machine and a printing image quality management device of a color printing machine, which can reliably avoid reproduction defects in highlight parts and middle parts and shadow parts caused by state changes of the printing machine. cause poor reproduction. It includes: a measuring mechanism (12) for measuring the solid density and gray balance of the printed color printing image, and a calculation method for calculating the difference between the solid density value and the gray balance value measured by the measuring mechanism (12) and the target value. The mechanism (13), the correction value calculation mechanism (14) that calculates the correction value according to each difference calculated by the calculation mechanism (13), adjusts each of the plurality of ink cartridge keys according to the correction value calculated by the correction value calculation mechanism (14). An ink supply volume adjustment mechanism (15) for individual ink supply volumes.

Owner:RYOBI MHI GRAPHIC TECH

Clutch or brake device formed of composite foam

InactiveUS20050115791A1Low costImprove permeabilityFriction clutchesFriction liningDevice formSolid density

An improved clutch or brake device in which at least two members are mounted for relative rotation and engagement, the members having friction material rotatable therewith, and the friction material of the members having surfaces confronting each other, characterized in that the friction material has a solid density of greater than 30% and includes an open lattice of carbon ligaments forming a network of three dimensionally interconnected cells; and a pyrolytic carbon coating on the open lattice of carbon ligaments.

Owner:SAFRAN LANDING SYSTEMS

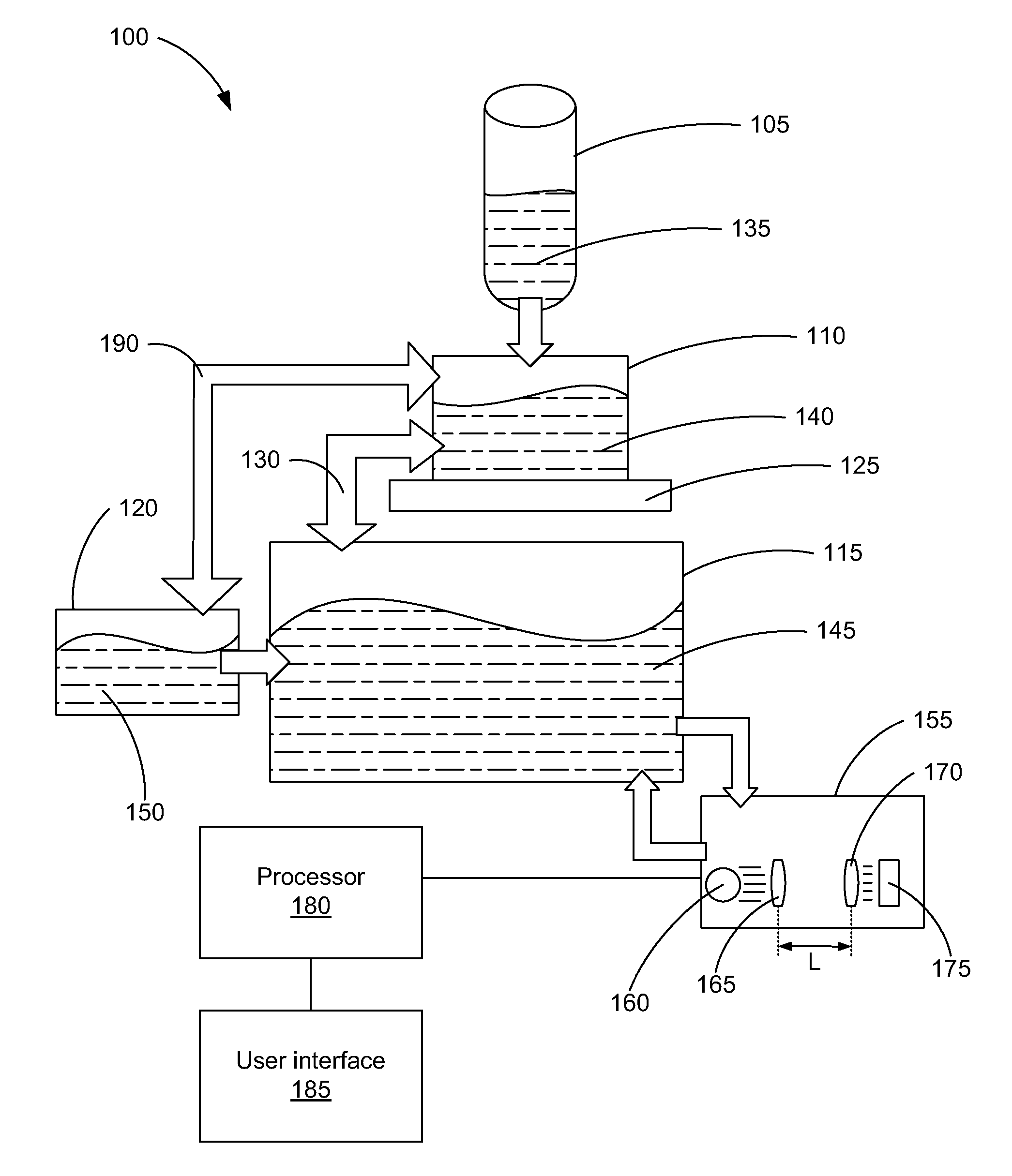

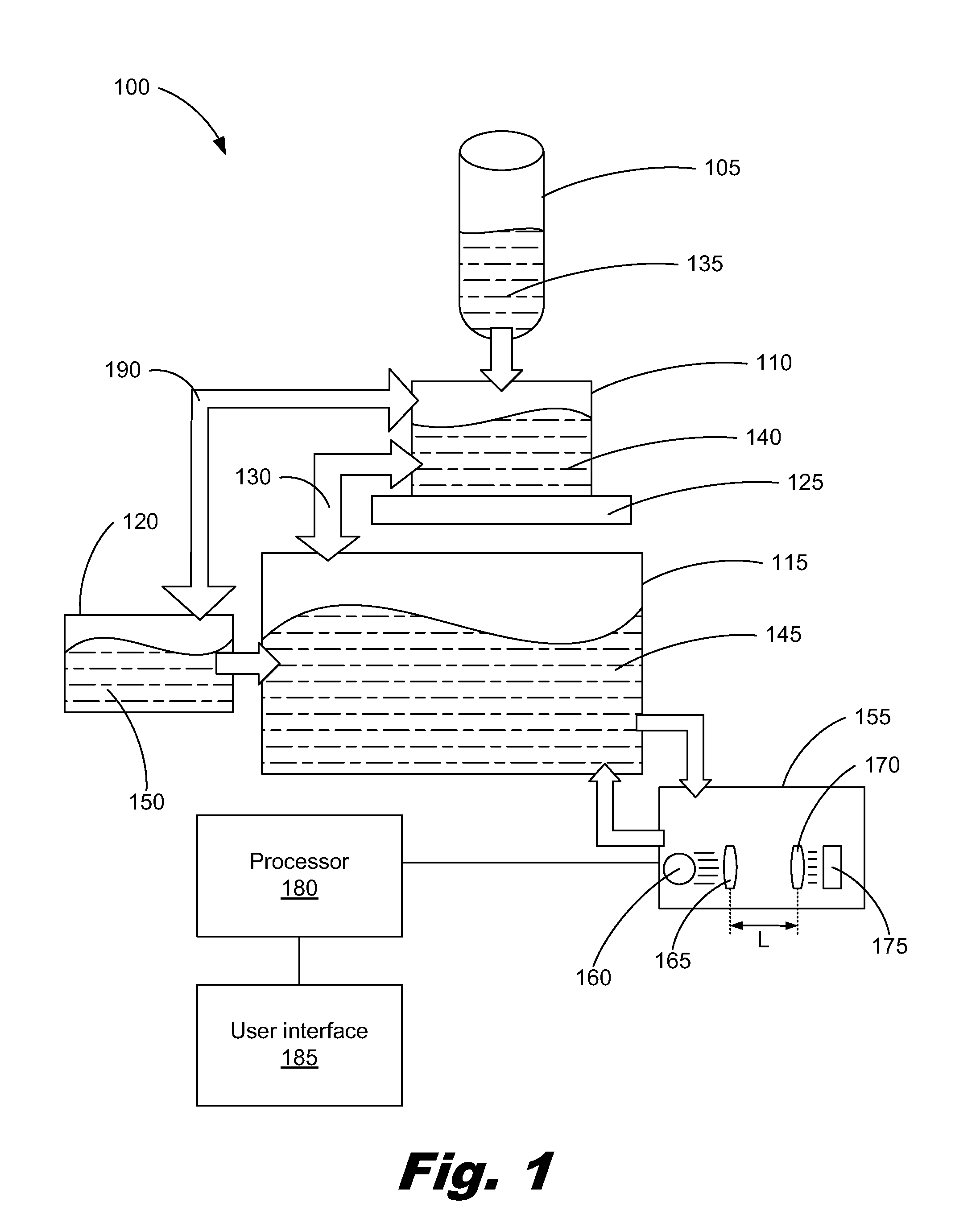

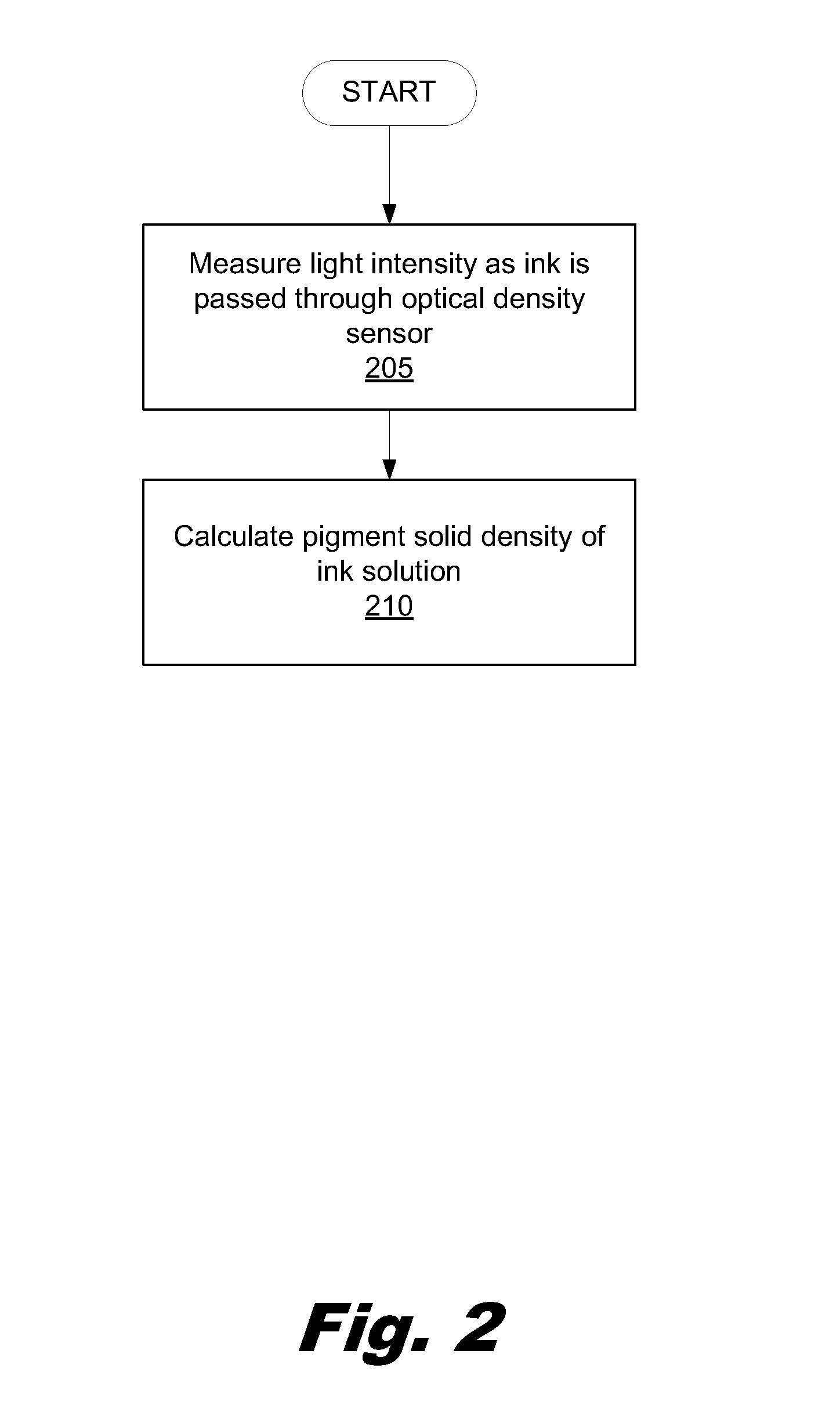

Optical Density Sensor Calibration and Self Fixing

A method of calibrating an optical density sensor comprising calculating a first pigment solid density value of an ink solution using a current first electrical output signal value from a photodetector, a current second electrical output signal value from a photodetector, and a current lens gap value, calculating a second pigment solid density value of the ink solution using a previously measured first electrical output signal value, a previously measured second electrical output signal value, and a previously measured lens gap value, comparing the current first electrical output signal value, the current second electrical output signal value, and the current lens gap value with the previously measured first electrical output signal value, the previously measure second electrical output signal value, and the previously measured lens gap value, and comparing the first pigment solid density value with the second pigment solid density value.

Owner:HEWLETT PACKARD DEV CO LP

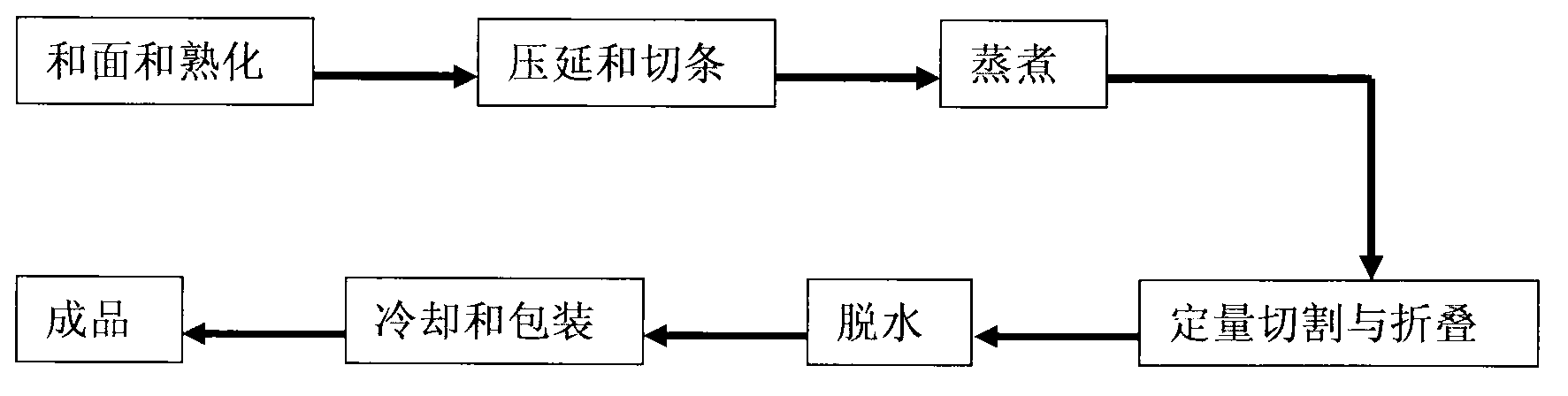

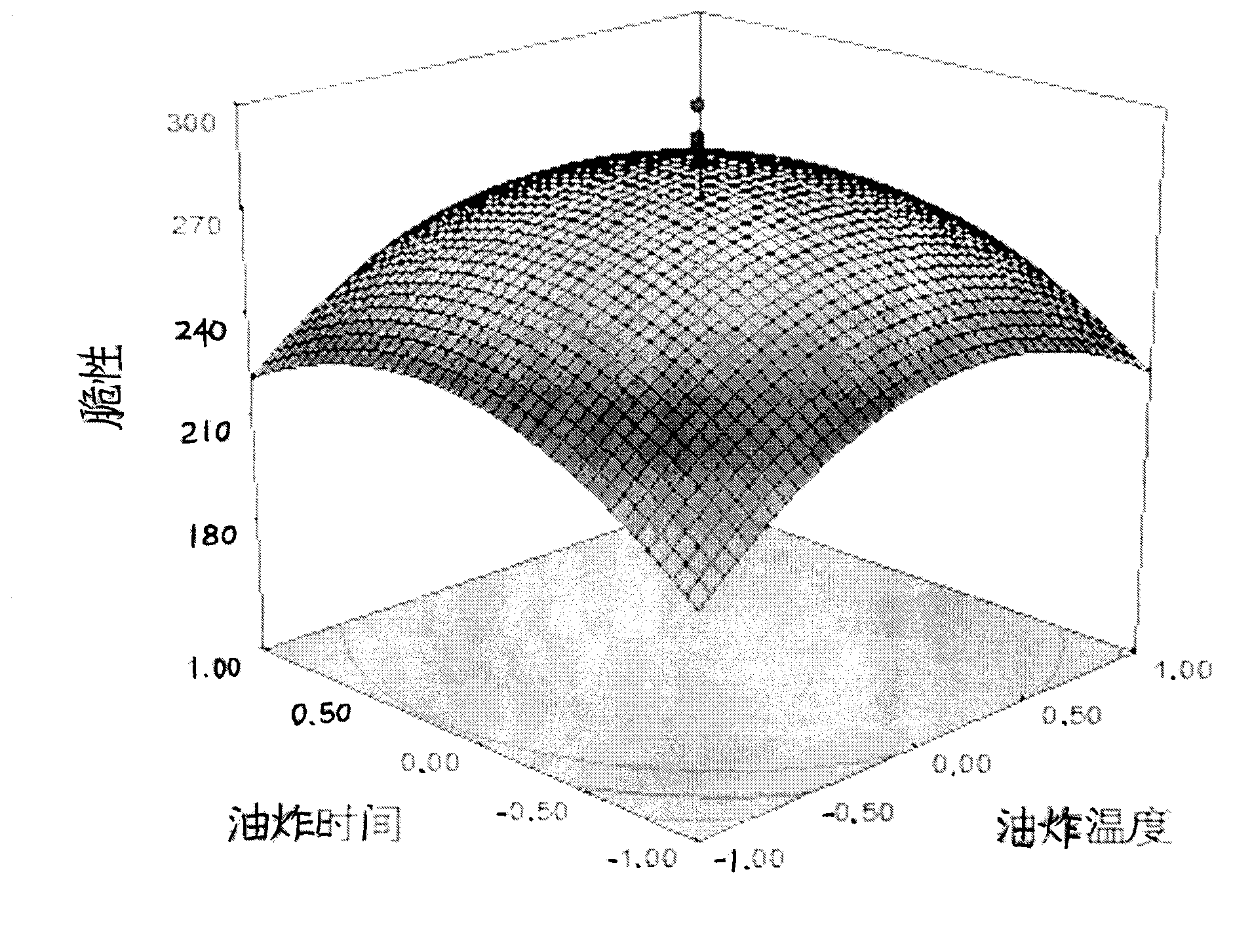

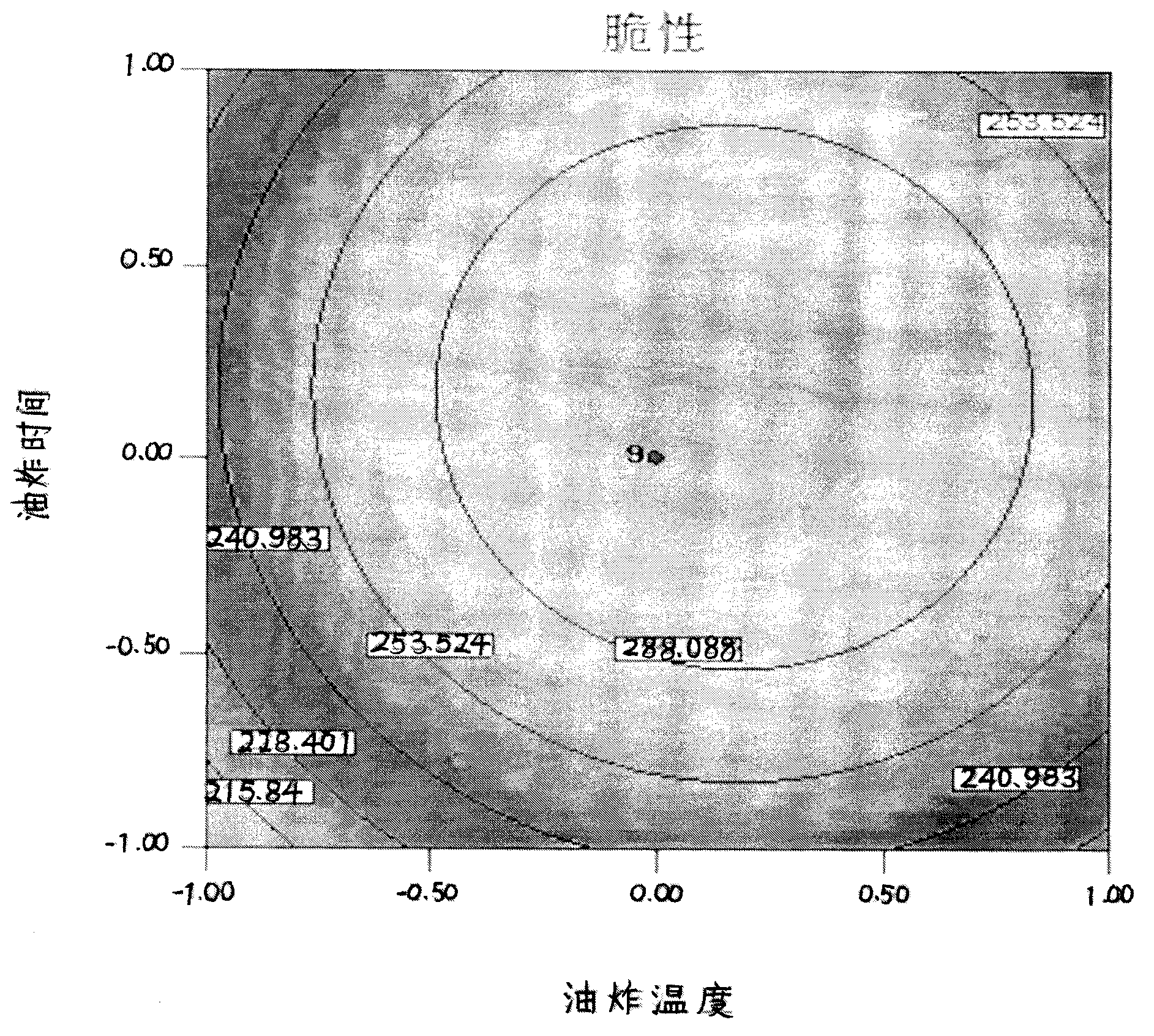

Preparation method of fried instant noodle with good brittleness and good brittleness keeping performance

InactiveCN103284071AGreat tasteImprove textural propertiesFood preparationUniform designSolid density

The invention discloses a preparation method of fried instant noodle with good brittleness and good brittleness keeping performance. The preparation method disclosed by the invention comprises the following steps of: selecting factors which obviously influence the texture of the fried instant noodle by the uniform design, researching the influence of each factor to the texture indexes of the fried instant noodle, such as the WAI (work ability index), the WSI, the volume density and the solid density, by a single factor experiment, confirming the values of the factors, and confirming the optimum preparation technology of the fried instant noodle through the response surface analysis. The brittleness and the brittleness keeping performance are taken as the indexes, and the optimum technology parameters are as follows: the frying temperature is 148 DEG C, the frying time is 62s, the water content is 50%, and the salt content is 1.8%. The preparation method disclosed by the invention can quickly and simply test the brittleness and the brittleness keeping performance of the processed instant noodle, and the fried instant noodle with good brittleness and good brittleness keeping performance processed by the preparation method has a wide and practical value.

Owner:XINJIANG UNIVERSITY

Method Of Controlling Quality Of Printed Images Of Color Printing Press And Apparatus For Controlling Quality Of Printed Images

InactiveUS20080127849A1Exact reproductionPreventing incorrect reproduction of highlightAddressographsPlaten pressesSolid densityColor printing

An object is to securely prevent incorrect reproduction of a highlight portion and an intermediate portion due to the change in condition of the printing press and incorrect reproduction of a shadow portion. The printing press includes a measuring means 12 for measuring the solid densities and the gray balance, of a printed color print image; a computing means 13 for computing respectively the differences between the solid density values and the gray balance measured by the measuring means 12 and their target values; a correction-value-computing means 14 for computing the correct values based on their differences respectively computed by the computing means 13; and an ink-supply-amount-adjusting means 15 for adjusting the amount of the ink of each of the basic colors to be supplied through each of plural ink fountain keys, based on the correction values computed by the correction-value-computing means 14.

Owner:RYOBI

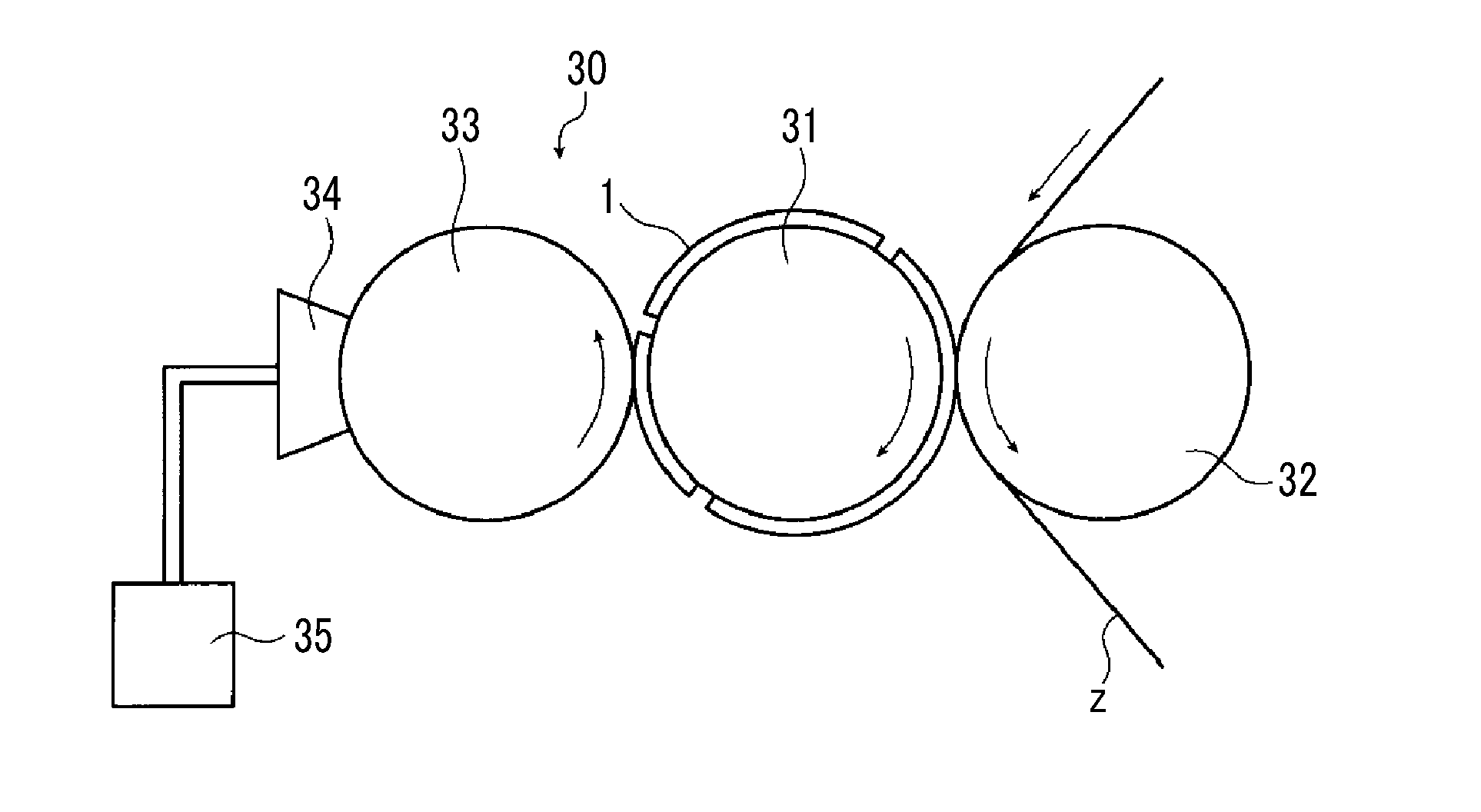

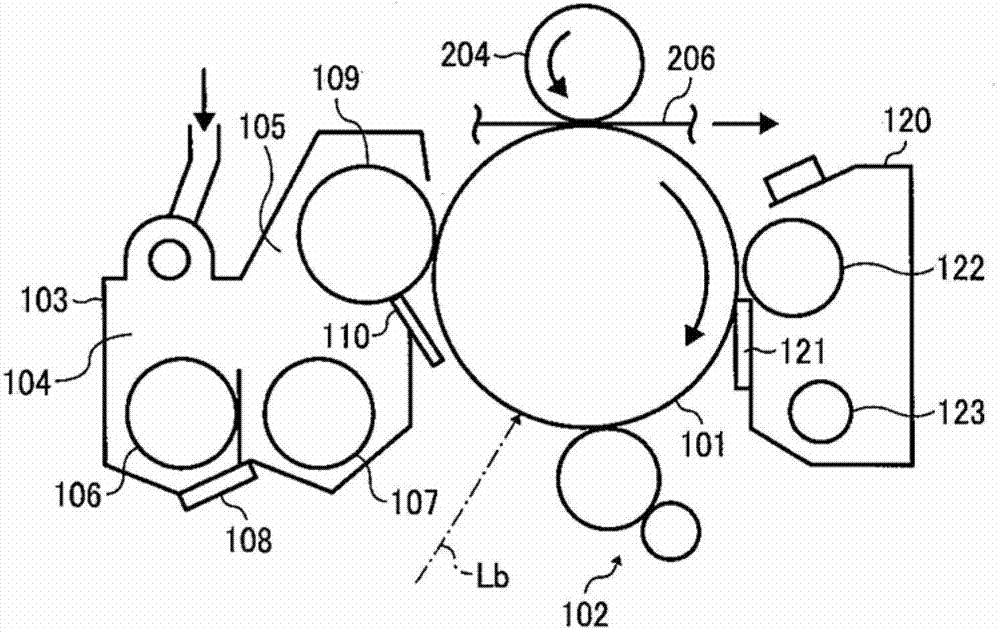

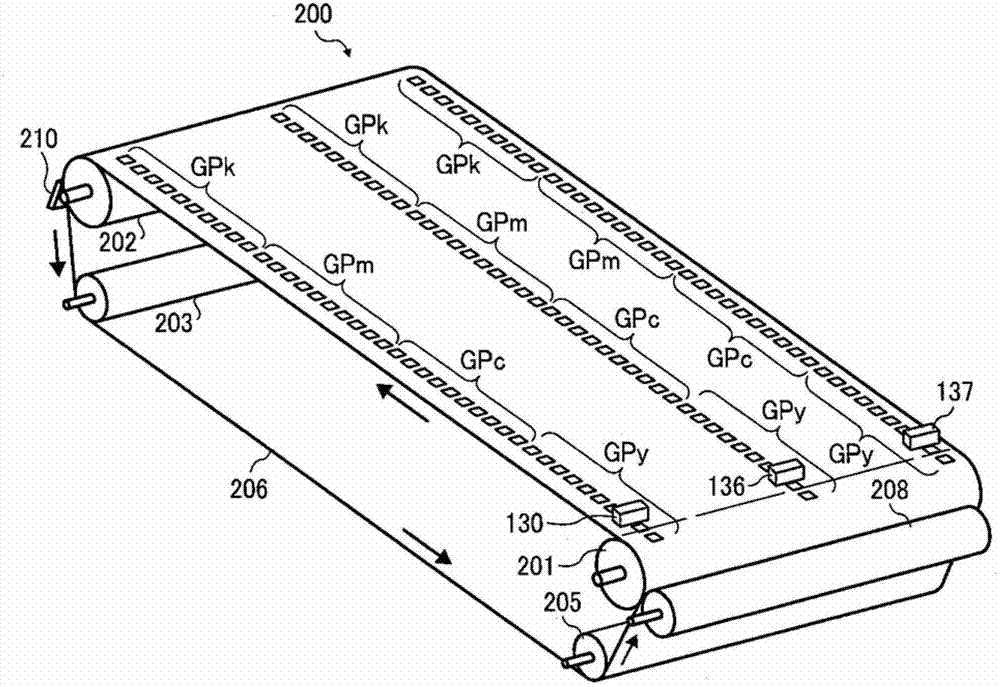

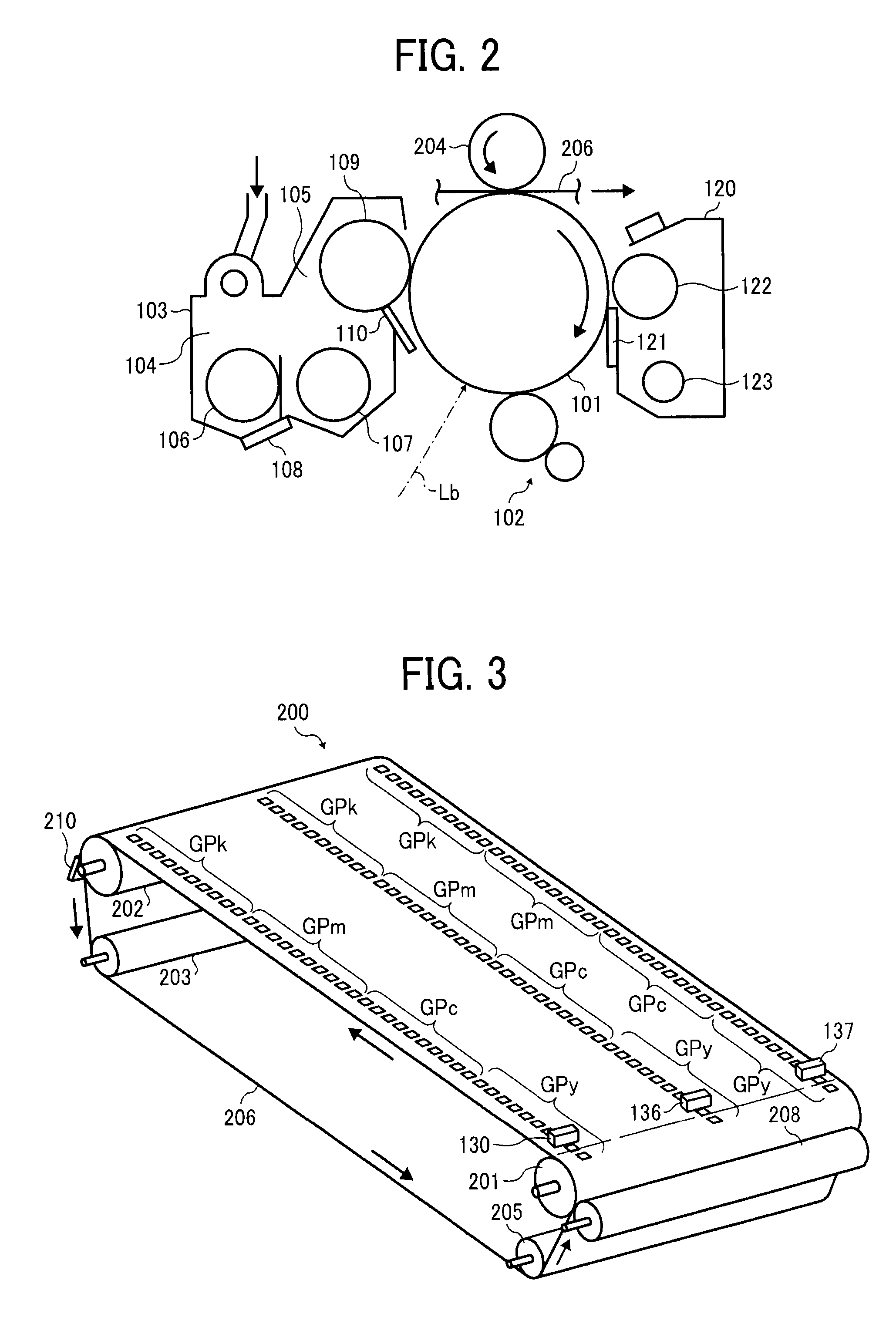

Image forming apparatus and image forming method

In an image forming apparatus, a processor performs: a solid density stabilization of adjusting, according to detected toner adhesion amounts of solid toner images of solid tone patterns, a condition to form solid images with respective target image densities; a misregistration reduction of adjusting, according to detection timing of position detection toner images of misregistration detection patterns, a condition to reduce misregistration of toner images; and a halftone density stabilization of adjusting, according to detected toner adhesion amounts of area coverage modulation toner images, a condition to form halftone images with respective target image densities. The processor continuously performs the solid density stabilization and the misregistration reduction, and starts the halftone density stabilization when the solid density stabilization is completed and the misregistration reduction is not completed, to concurrently perform a step of the misregistration reduction and at least a step of the halftone density stabilization.

Owner:RICOH KK

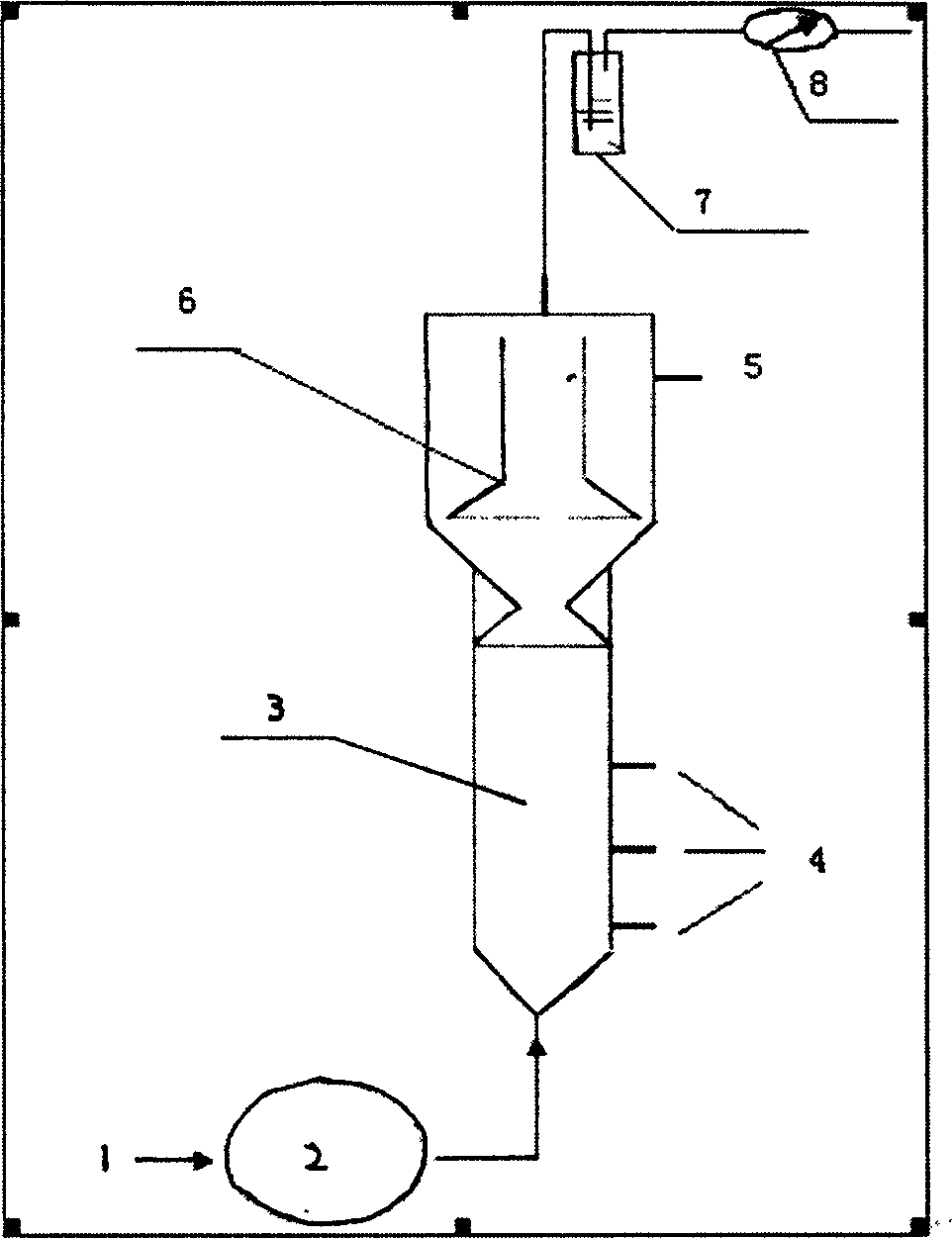

Biological hydrogen production method for improving hydrogen generation efficiency and stability

The invention discloses a biological hydrogen production method by culturing hydrogen production granular sludgesto to improve the hydrogen production efficiency and stability characterized in charging methane floccule sludges into the reactor to make the volatile suspended solid density be 3-7g / L in the reactor, controlling the flow rate of the organic wastewater flowing through the reactor to make the organic wastewater stay in the reactor for 5-20 hours; regulating the solution pH to 4.0-4.5 in the reactor, and the hydraulic loading to 15-30g / (L.d) from 2-5g(L.d) by increasing 0.1-0.5g(L.d) day by day; steadily operating till a hydrogen production granular sludge containing bultyric acid bacillus mainly and coccus forms in the reactor, then steadily operating till the volume of the hydrogen production granular sludges is 50-70% of the reacting area volume in the reactor. The invention solves the problems of low hydrogen production efficiency by floccule sludges, no steady and continuous hydrogen production existing in known biological hydrogen production method using organic wastewater, and the hydrogen production efficiency can be 1.22-1.37molH.

Owner:UNIV OF SCI & TECH OF CHINA

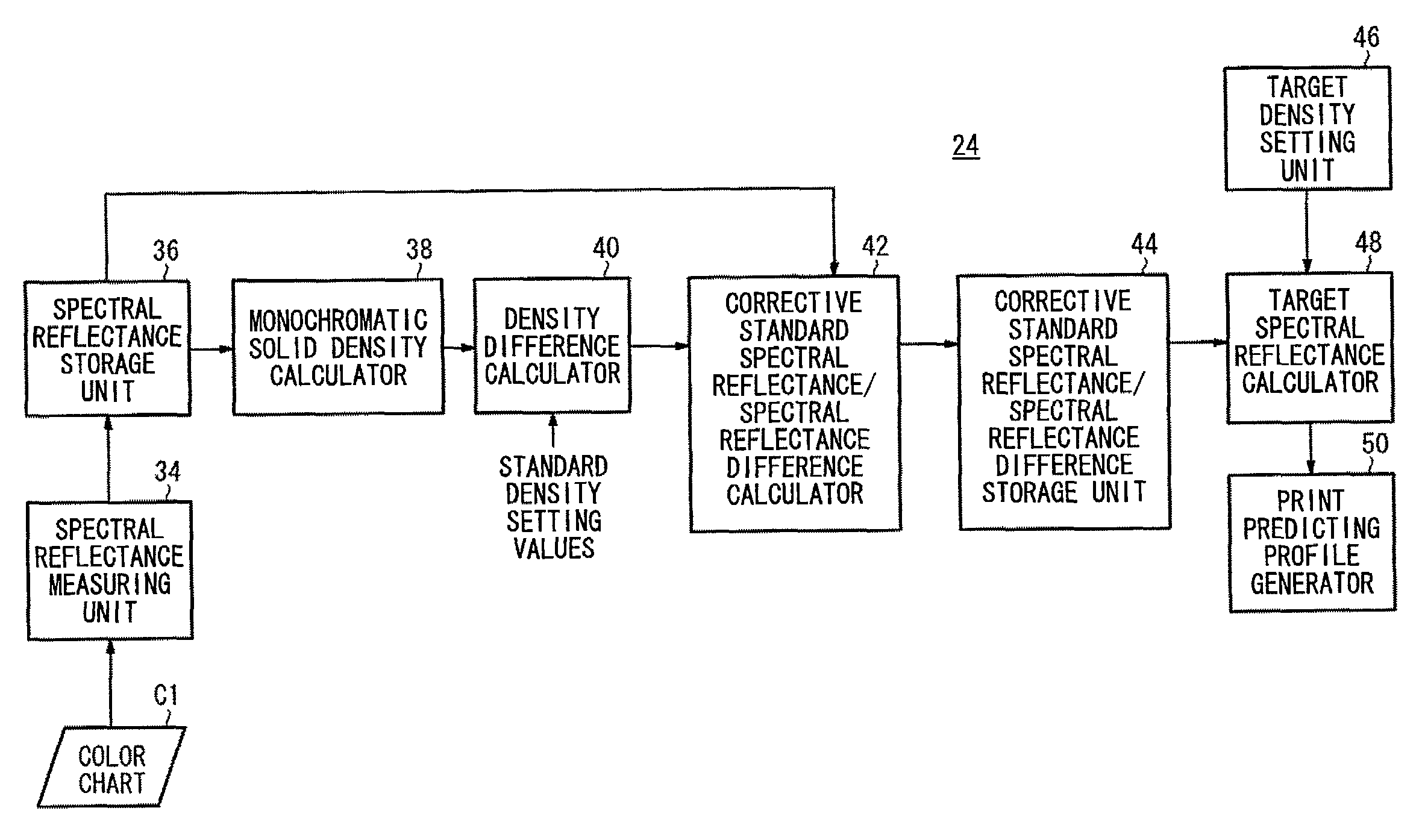

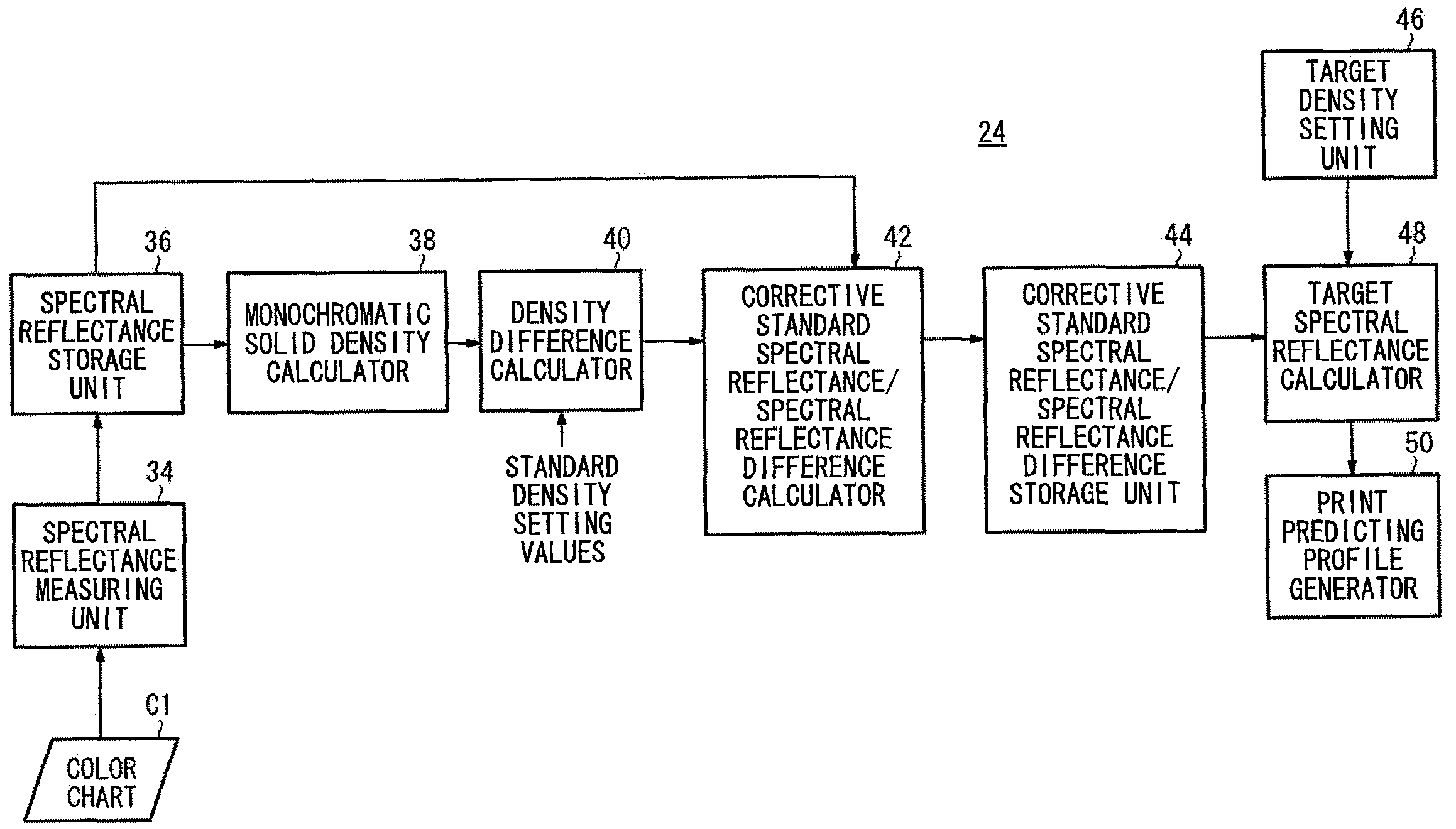

Method of and system for predicting print colors

InactiveUS8311321B2Exact matchEasily and quickly colorDigitally marking record carriersDigital computer detailsChange densitySolid density

Owner:FUJIFILM CORP

Image forming apparatus and image forming method

ActiveUS20120294637A1Reduce misregistrationElectrographic process apparatusPictoral communicationSolid densityImage formation

In an image forming apparatus, a processor performs: a solid density stabilization of adjusting, in accordance with detected toner adhesion amounts of solid toner images of solid tone patterns, a condition to form solid images with respective target image densities; a misregistration reduction of adjusting, in accordance with detection timing of position detection toner images of misregistration detection patterns, a condition to reduce misregistration of toner images; and a halftone density stabilization of adjusting, in accordance with detected toner adhesion amounts of area coverage modulation toner images, a condition to form halftone images with respective target image densities. The processor continuously performs the solid density stabilization and the misregistration reduction, and starts the halftone density stabilization when the solid density stabilization is completed and the misregistration reduction is not completed, to concurrently perform a step of the misregistration reduction and at least a step of the halftone density stabilization.

Owner:RICOH KK

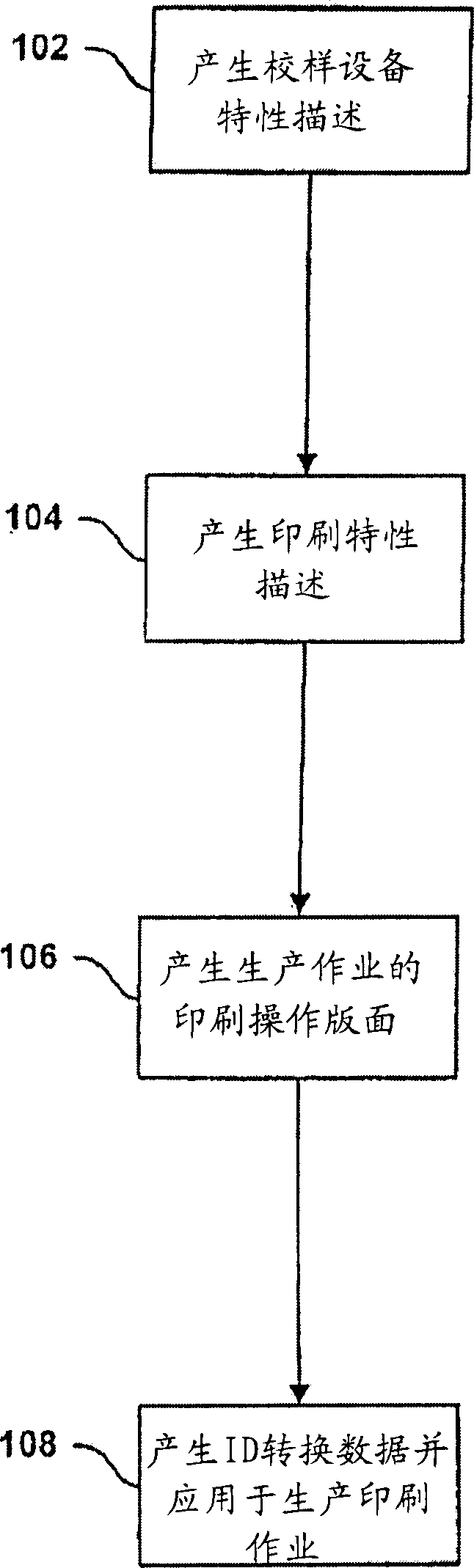

Printing adjustment system and method

A printing adjustment method includes providing a plurality of solid and screened density values produced by a proofing device that represent intended density values. The method also includes providing a plurality of solid and screened density values produced by a press output device. The method also provides calculating, in response to selected ones of the plurality of density values produced by the press output device and selected ones of the plurality of density values produced by the proofing device, required percent dot values to be used to print on the press output device a plurality of adjusted density values that approximately correspond to the intended density values. In a particular embodiment, the plurality of solid density values produced by the press output device are varied approximately linearly in density along a first axis, the first axis approximately perpendicular to direction in which output of the press output device is produced.

Owner:THE ACKLEY MARTINEZ MGI STUDIO

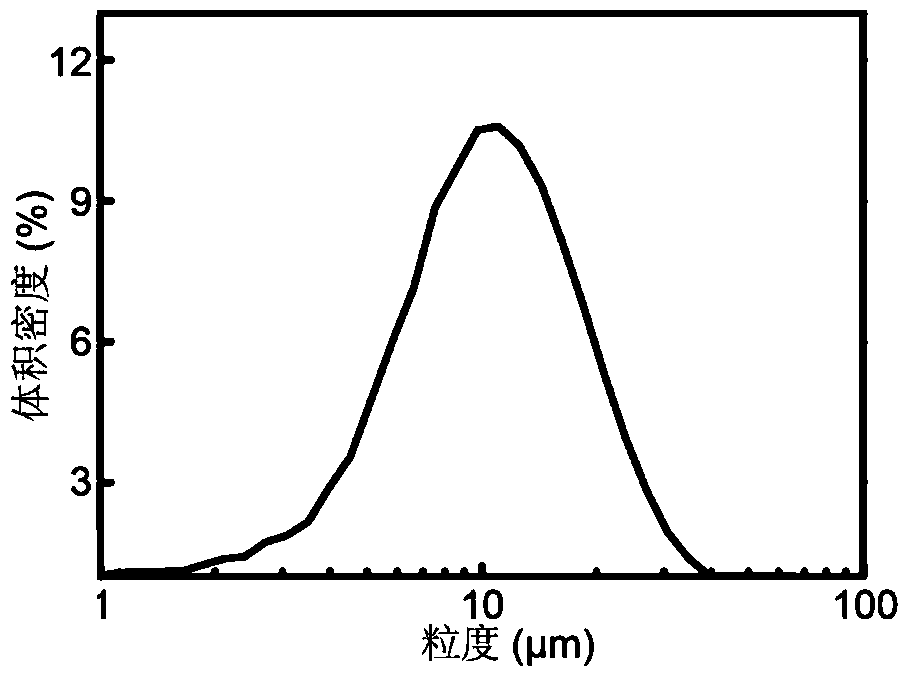

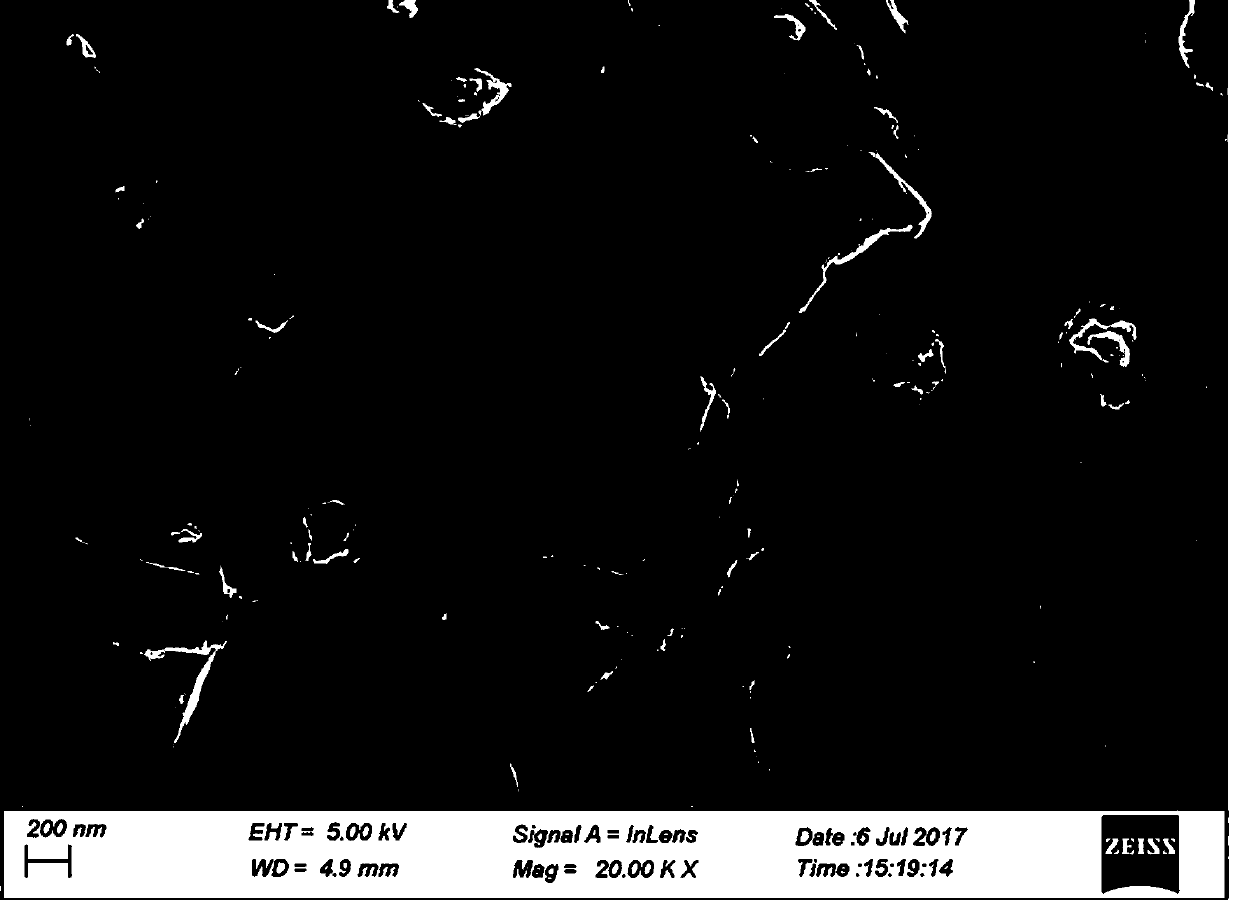

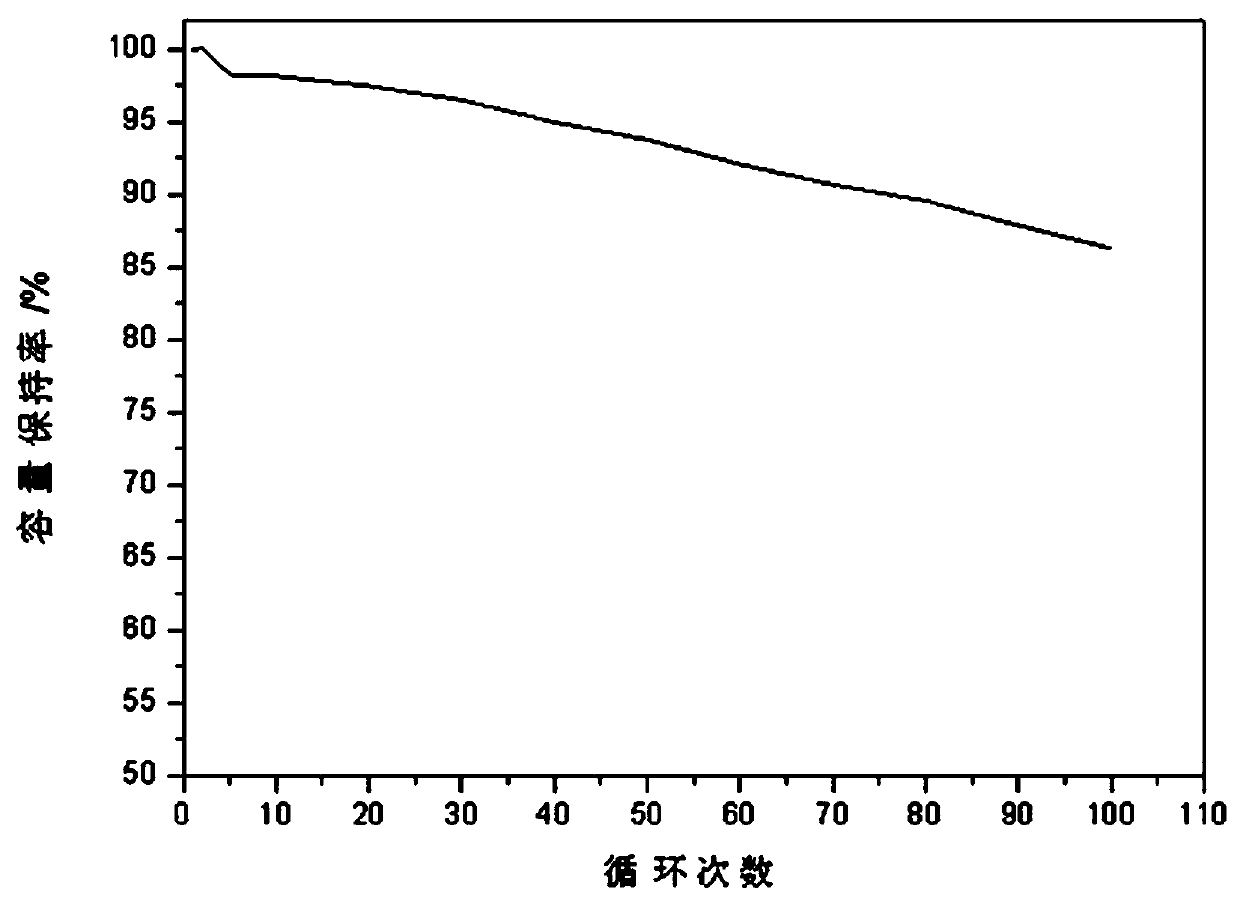

A high compaction density silicon carbon anode material and its preparation method and application

ActiveCN105932245BIncrease compaction densityEasy to prepareCell electrodesSecondary cellsCarbon compositesSolid density

The invention provides a high-compaction density silicon-carbon negative electrode material and a preparation method and an application thereof. The silicon-carbon negative electrode material is formed by mixing silicon powder, graphite and an additive at a certain ratio; and the final product is obtained by burning, coating and re-burning the silicon-carbon negative electrode material, wherein the silicon-carbon composite material is of a porous spherical structure; silicon is evenly dispersed into porous silicon carbon balls in a form of nanometer silicon; the particle sizes of the silicon are smaller than 200nm; and a uniform coating layer is formed on the surface of the silicon. The high-compaction density silicon-carbon negative electrode material is high in efficiency, high in capacity and good in cycling stability when applied to a lithium-ion battery, low in cost and suitable for large-scale production and the preparation method is simple.

Owner:JIANGXI IAMETAL NEW ENERGY TECH CO LTD

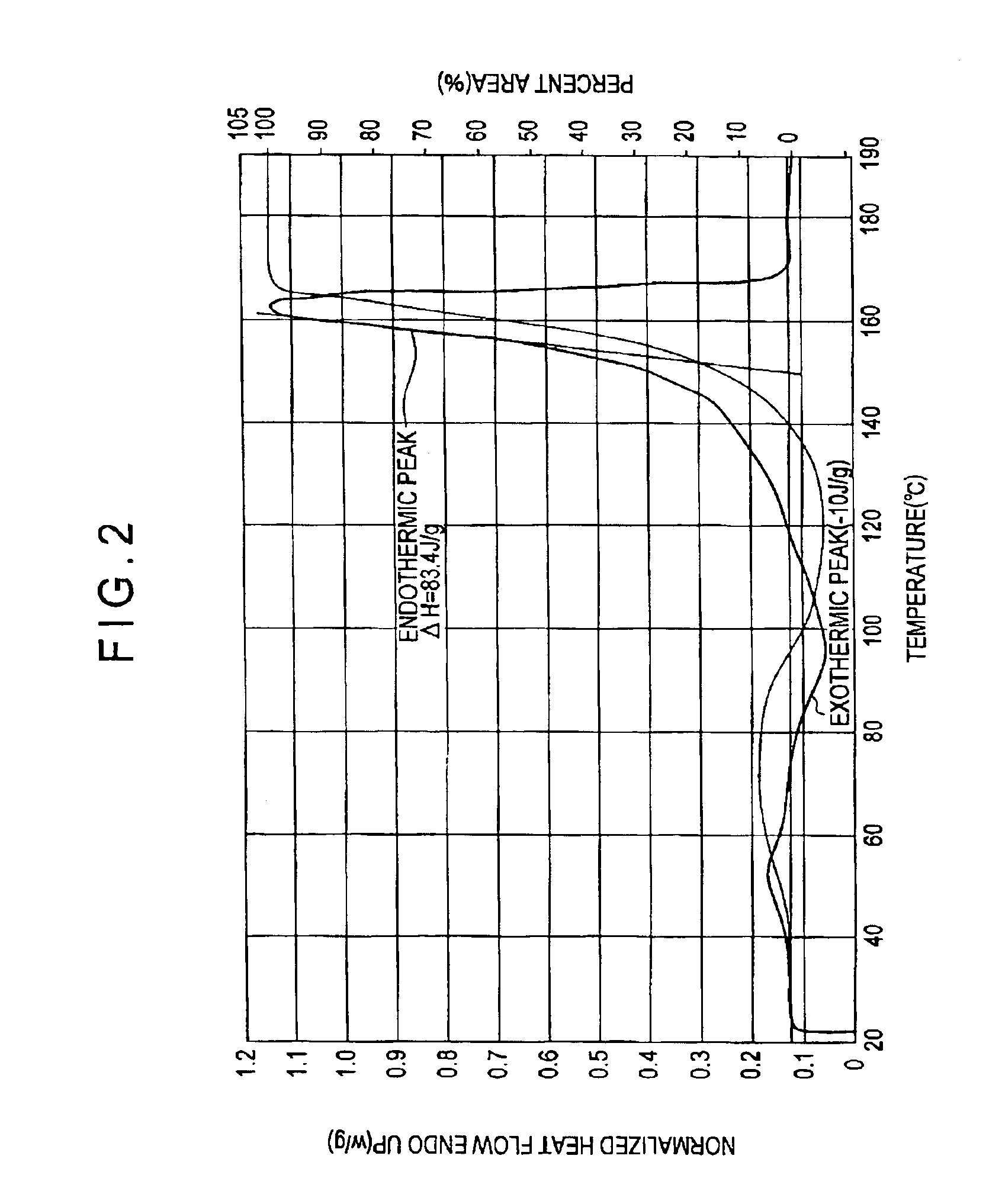

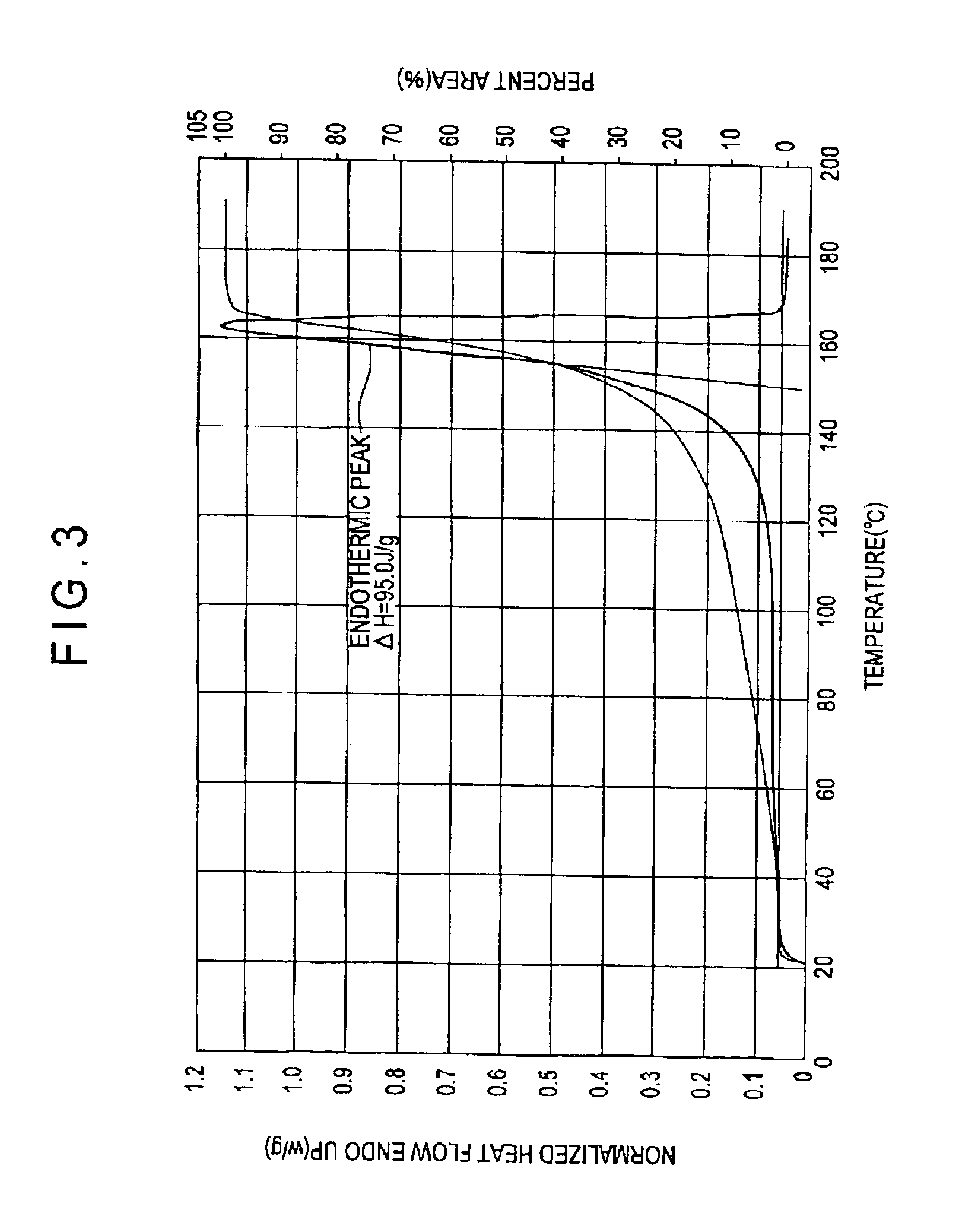

Low crystallizability polypropylene sheet

InactiveUS6943229B2Facilitate thermoforming operationReduce pointsSynthetic resin layered productsHollow wall articlesSolid densityVolumetric Mass Density

A low crystallizability polypropylene sheet which has an average spherulite radius between 0.1 μm and 4 μm, an average number of spherulites of 600 / mm2 or less in a sheet cross section, a solid density of 0.895 g / cm3 or less, a fusion enthalpy H of less than 90 J / g at the highest endothermic peak of the differential scanning calorimetry (DSC) curve, a degree of gloss of 90% or higher on at least one side and shows an exothermic peak of 1 J / g or higher at the low temperature side of said highest endothermic peak and a thickness of 50 μm or more.

Owner:IDEMITSU KOSAN CO LTD

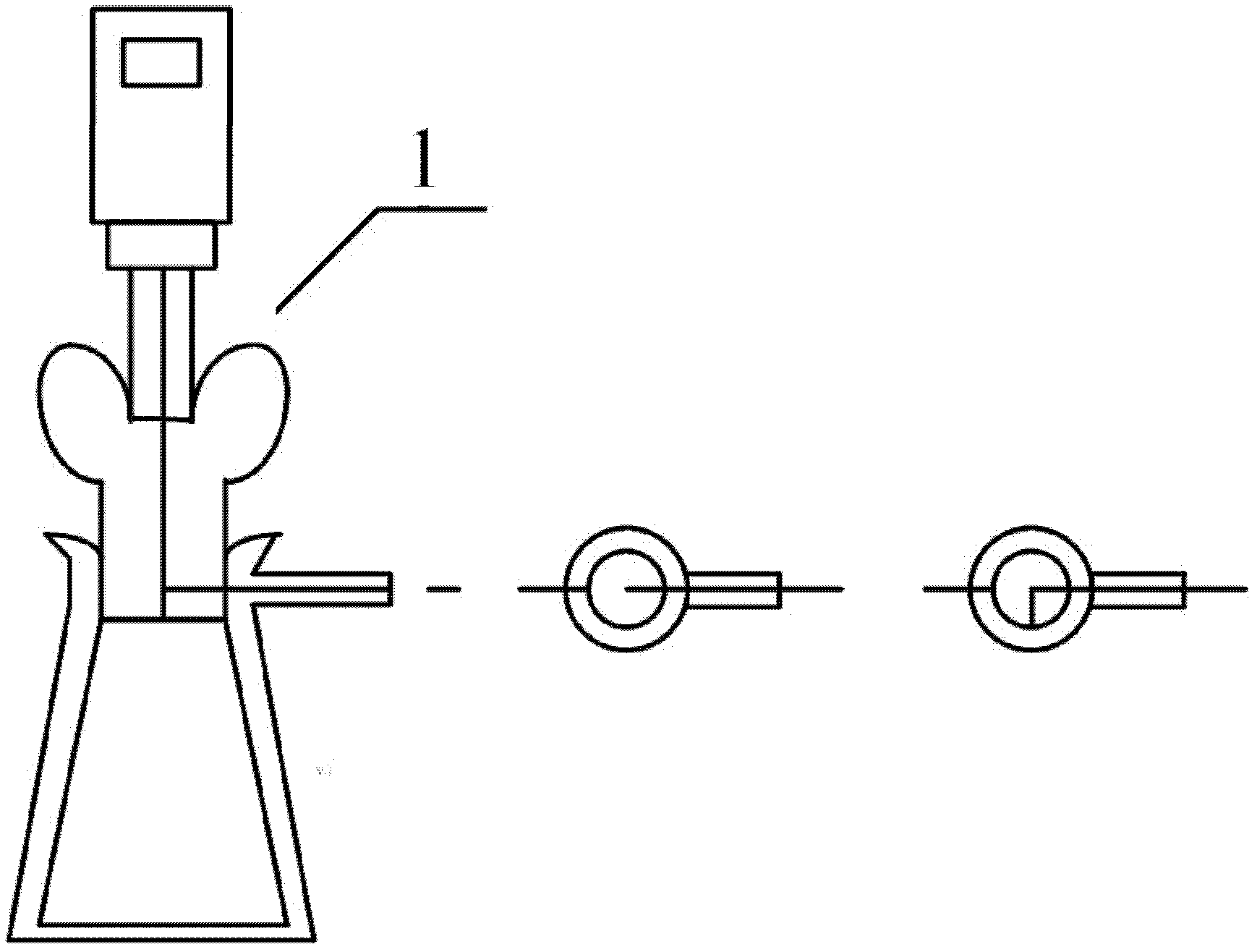

Rider-type solid-density measuring instrument

InactiveCN103364307AMeasured density valueReduce volumeMaterial analysis by measuring buoyant forcesData displayMeasuring instrument

The invention relates a rider-type solid-density measuring instrument which converts solid density measurement to length measurement, and achieves length measurement, data processing and data display by utilization of an electronic digital display vernier. According to the measuring instrument, a rider that is the electronic digital display vernier is disposed on a lever. The lever is balanced by adjusting the position of the rider on the lever. Then a solid to be measured is hung on one side of the level, and at the same time the rider is moved a distance (L[2]) to balance the level a second time. Then the solid is immersed in water, and at the same time the rider is moved a distance (L[3]) to balance the level a third time. The two distances of the rider are measured and a ratio (L[2] / L[3]) is calculated by utilization of the electronic digital display vernier; and the ratio is displayed in an electron screen as the density, in a unit of g / cm<3>, of the solid to be measured. The measuring instrument is mainly used for directly measuring the solid density, and the density of the solid to be measured can be directly read out on the electron screen.

Owner:郑玉龙

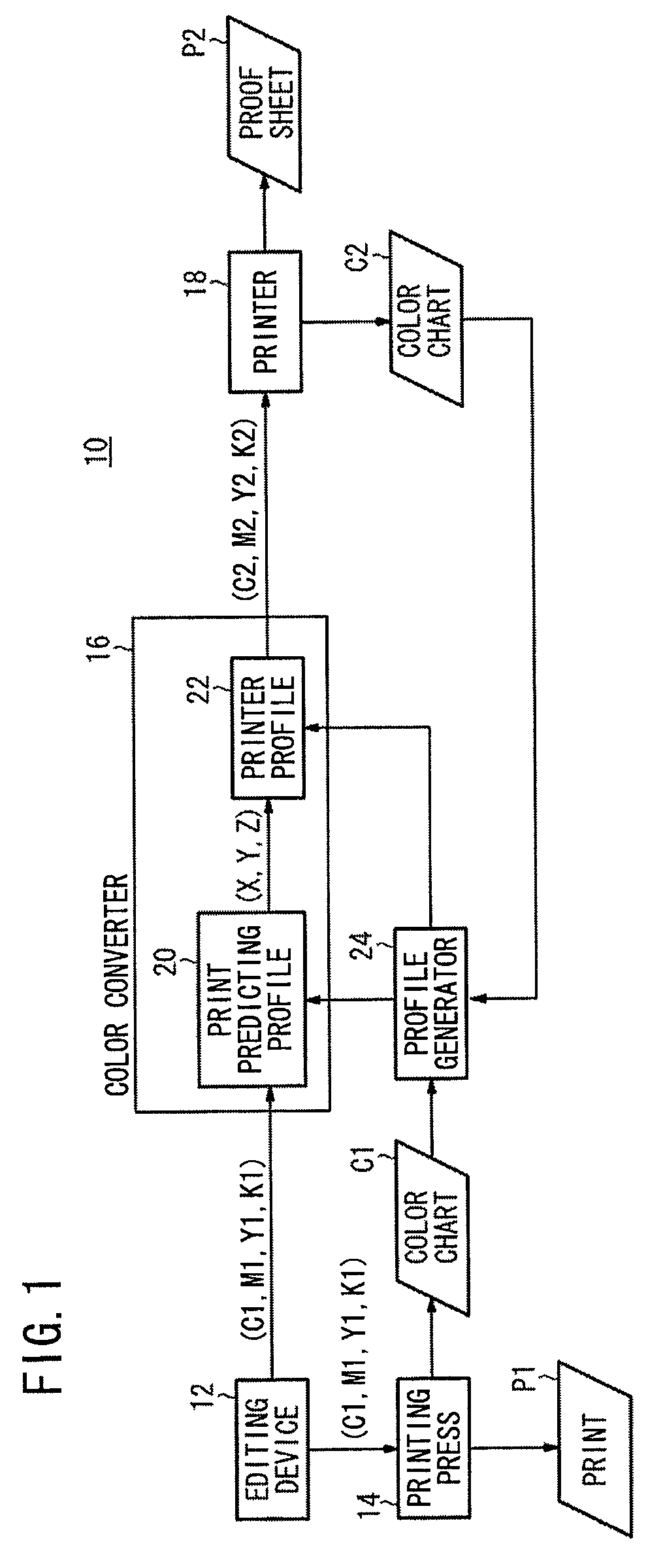

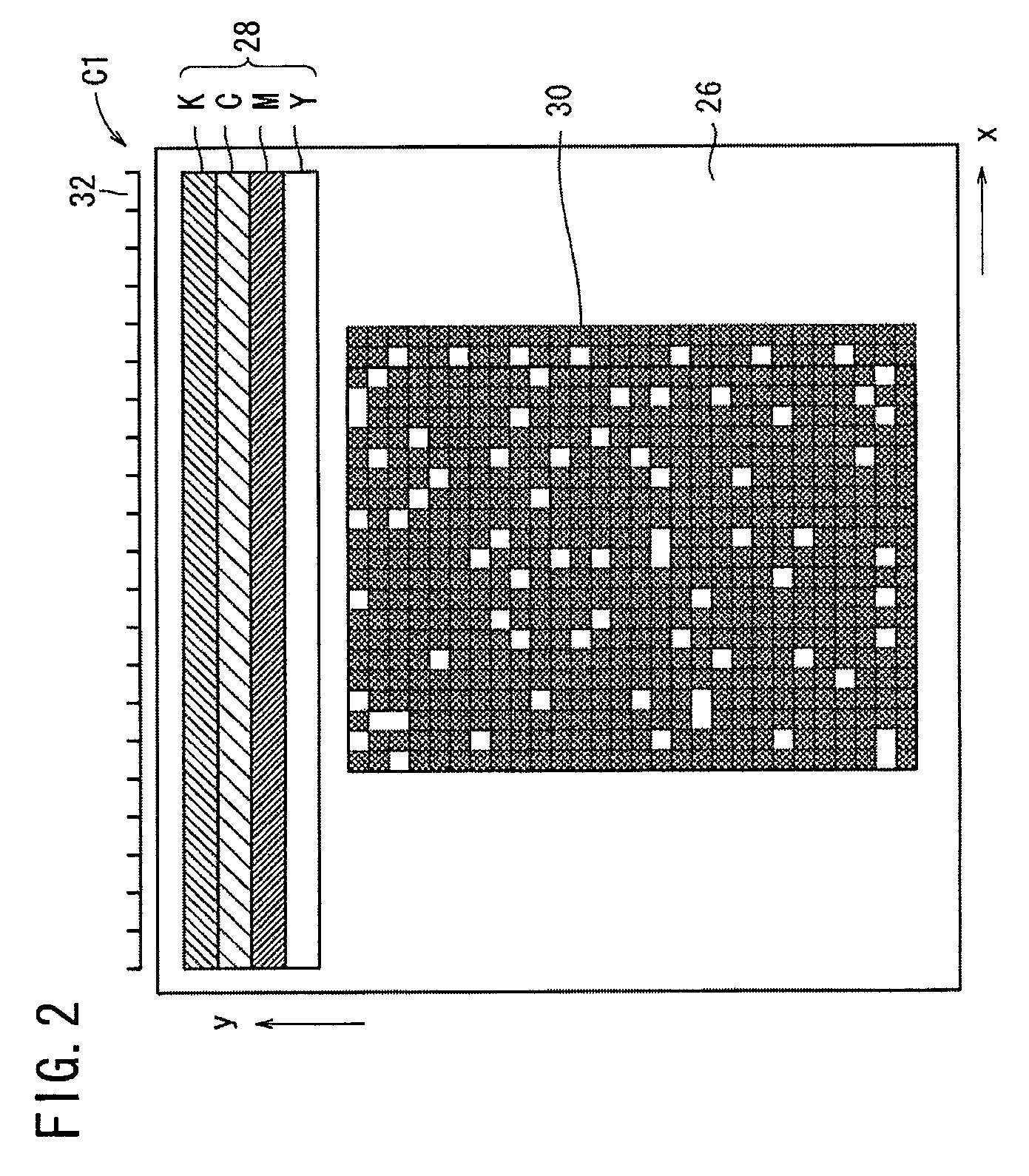

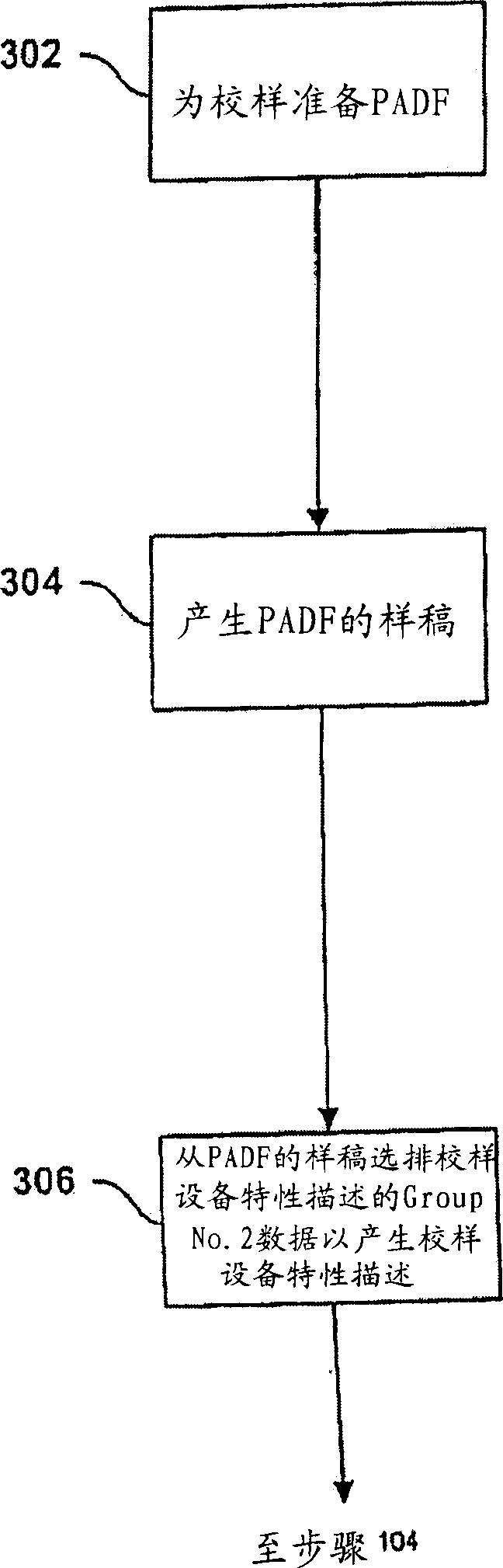

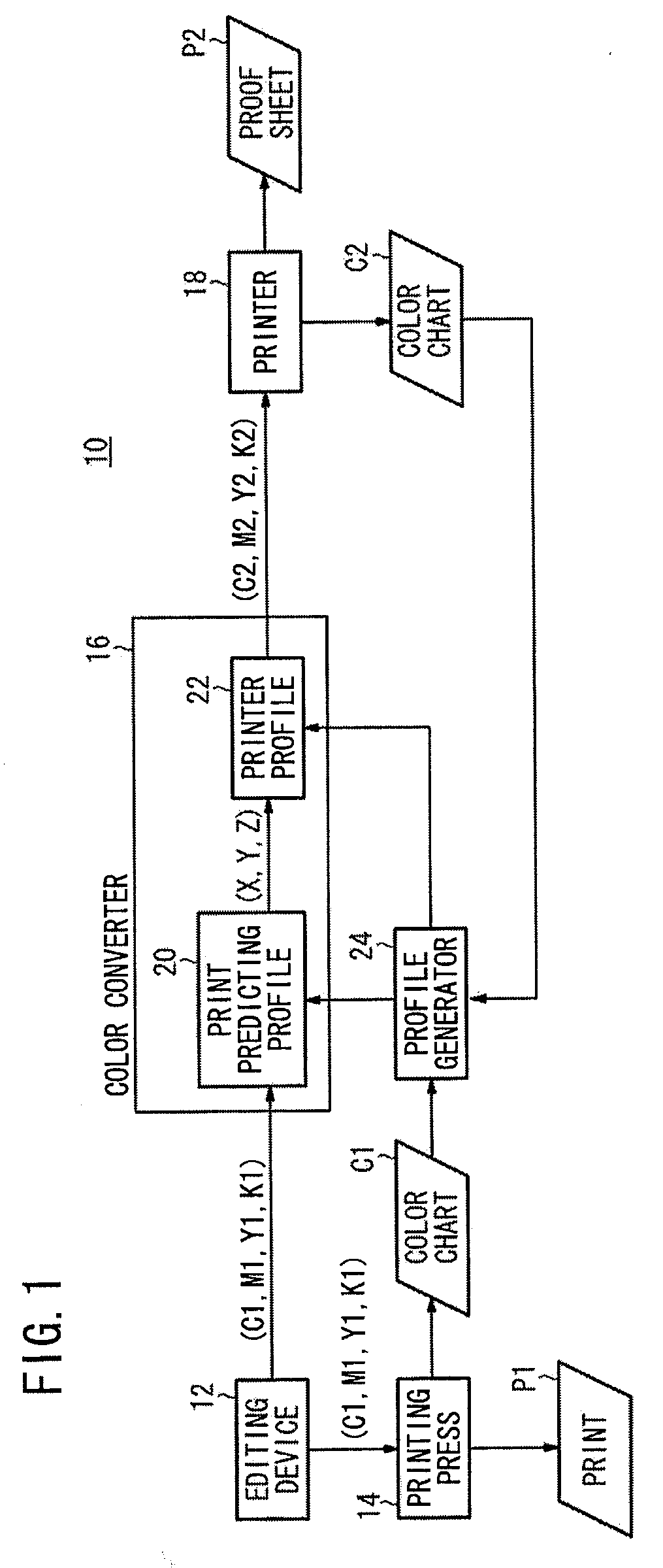

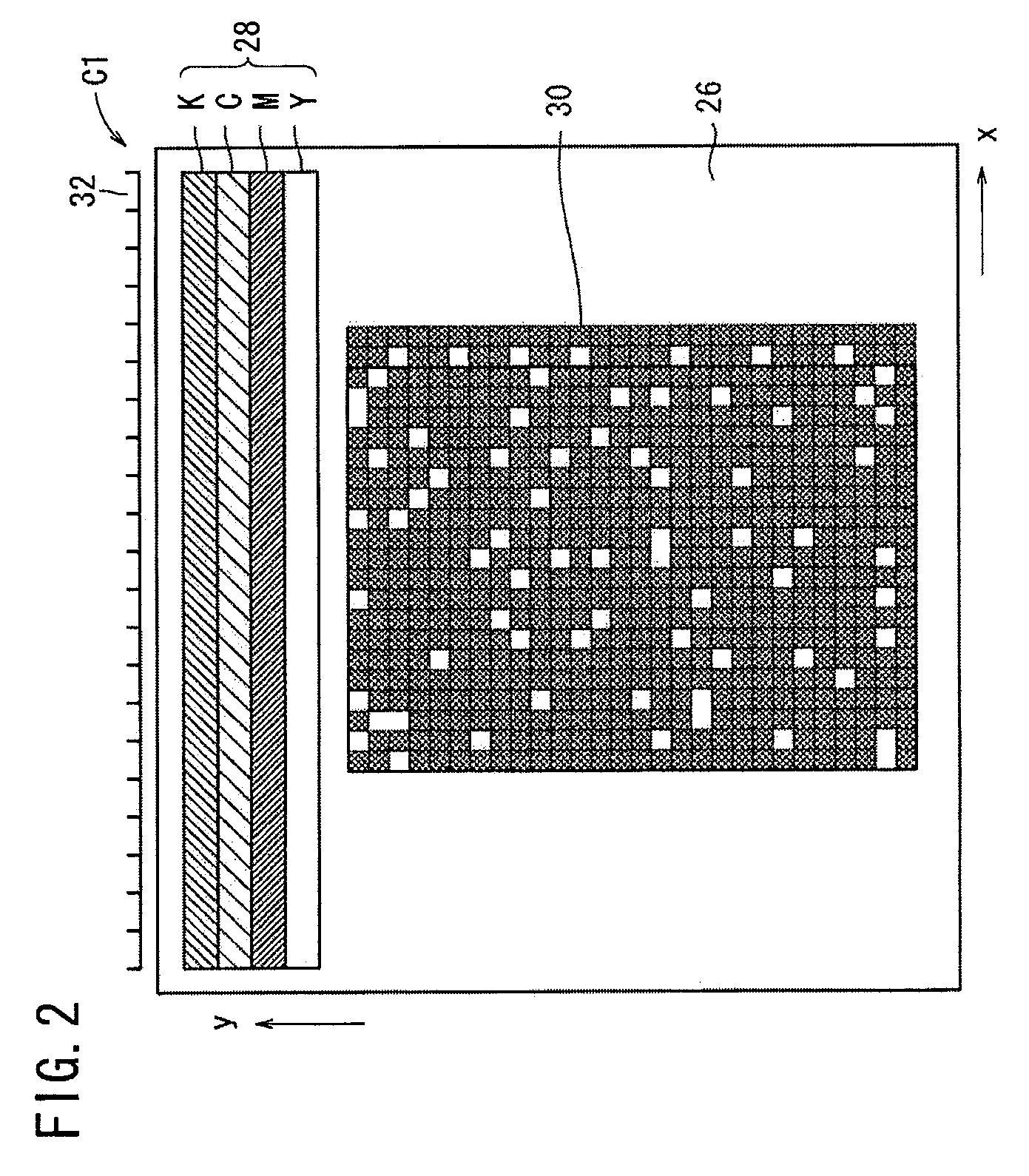

Method of and system for predicting print colors

InactiveUS20100067783A1Exact matchEasily and quickly colorDigitally marking record carriersDigital computer detailsChange densitySolid density

In a method of and a system for predicting print colors, a profile generator corrects the standard spectral reflectances of a color chart printed under standard density conditions and the differences between the spectral reflectances of color charts for the respective colors in which the density of one of the colors C, M, Y, K is changed to a changed density setting value and the densities of the other colors are fixed to standard density setting values, using density differences with the standard density setting values which are calculated by a monochromatic solid density calculator. The profile generator then generates a print predicting profile for desired target densities based on the corrected corrective standard spectral reflectances and the spectral reflectance differences, and highly accurately predicts the colors of a print using the print predicting profile when the densities of desired ones of the colors are changed.

Owner:FUJIFILM CORP

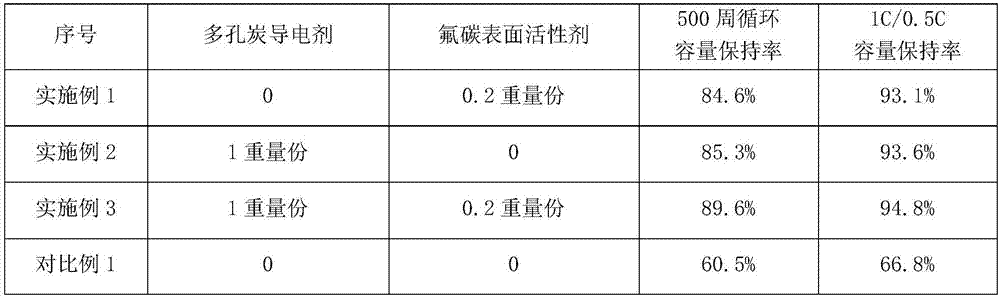

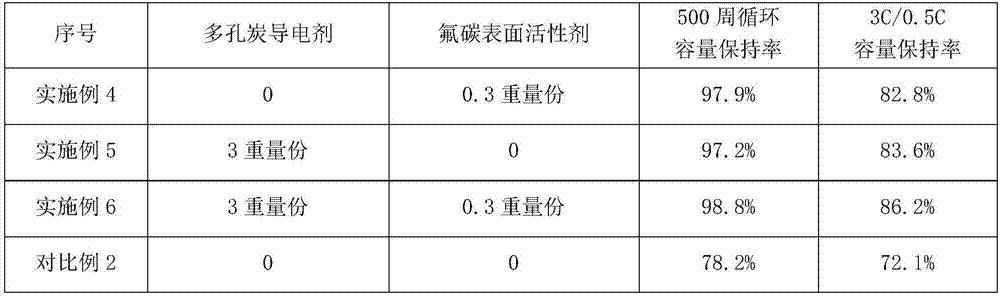

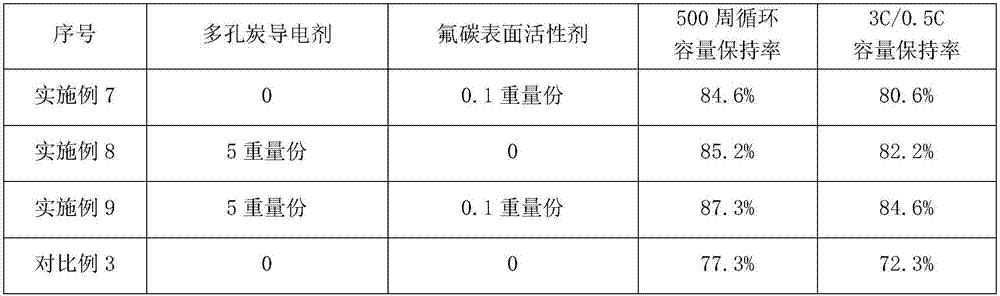

Preparation method of positive electrode slice of high voltage solid density high energy density lithium ion battery

InactiveCN107068982AImprove electronic conductivityImprove ionic conductivitySecondary cellsElectrode collector coatingInternal resistanceHigh energy

The invention relates to an anode paste of lithium ion battery and a positive plate, a lithium ion battery of the positive slurry, therein the positive slurry includes positive electrode active material, positive electrode binder, positive conductive agent and positive additive. The positive conductive agent is porous carbon conductive agent. The positive additive is fluorocarbon surfactant. Related to existing technology, the porous carbon conductive agent of this preparation method has excellent electronic conductivity and ionic conductivity, which internal resistance of the battery can be greatly reduced and the power and magnification performance of high voltage solid density cell will be improved. Further, fluorocarbon surfactant effectively reduces the surface tension of the positive paste, improves the effect that the positive slurry is wetted, flat and coated on the surface of the positive collector and enhances the absorption and preservation of electrolyte to positive plate. The use of porous carbon conductive agent and fluorocarbon surfactant can obviously improve the conductivity of the positive electrode of high voltage solid density, and obtain a high-performance energy density battery.

Owner:上海汇平新能源有限公司

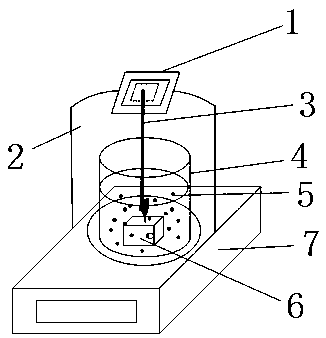

Multifunctional density testing device and application

PendingCN108627422ASimple structureEasy to useMaterial analysis by measuring buoyant forcesLiquid densitySolid density

The invention relates to a multifunctional density testing device. The multifunctional density testing device comprises a balance, wherein the balance is connected with a weight scale through a sensor; a through hole is formed in the middle of the weight scale and is clamped with a connecting rod; the lower end of the connecting rod is connected with a weighing basket through a hook; the weighingbasket is immersed in a container holding a solution; the balance corresponding to the container is provided with a groove. The multifunctional density testing device disclosed by the invention can beused for measuring solid density, stacking density and liquid density and has wide application range and greater practical value.

Owner:江苏海基新能源股份有限公司

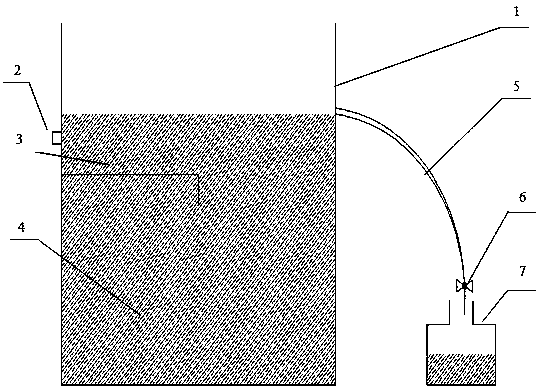

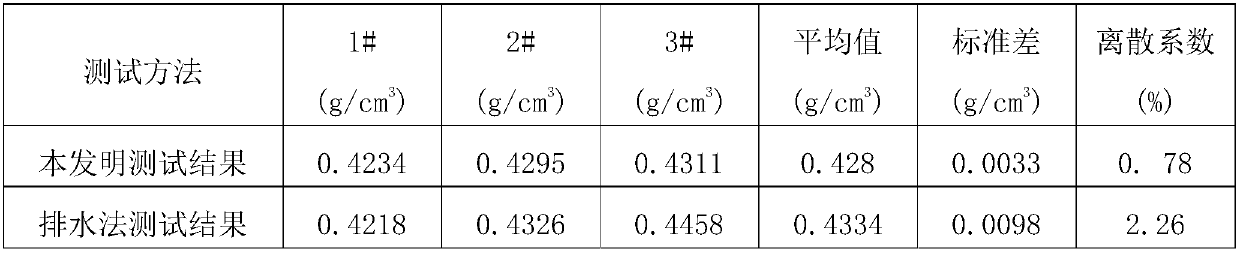

Irregular shape nonporous solid density detection method and apparatus thereof

The invention relates to an irregular shape nonporous solid density detection method. The method is characterized in that deionized water is added in a polytetrafluoroethylene container, addition of the deionized water stops after the deionized water submerges an overflow pipe, after flowing out of the deionized water stops, a ball valve is closed and the container is weighted, a to-be-measured sample is weighted, the surface of a solid is uniformly coated with a layer of Vaseline, then weighting is carried out, the sample is placed below a solid test baffle plate in the container, after a liquid surface is stable, the ball valve is opened, after water is completely discharged, the container is weighted, the solid density is calculated, 3 blocks of each sample are prepared for testing, andan average value of test results is taken. The method has the advantages of rapidity and accuracy, and aims at any irregular shapes.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Multiple times mixed coating high compacted density silicon carbon negative electrode material and preparation method thereof

ActiveCN109360946BIncrease compaction densityPromote circulationCell electrodesSecondary cellsActivated carbonSolid density

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com