Method of controlling quality of printed images of color printing press and apparatus for controlling quality of printed images

A printing image and quality management technology, applied to general parts of printing machinery, printing machines, color measuring devices, etc., can solve problems such as color tone deviation, dot thickness state change, and poor reproduction of highlights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

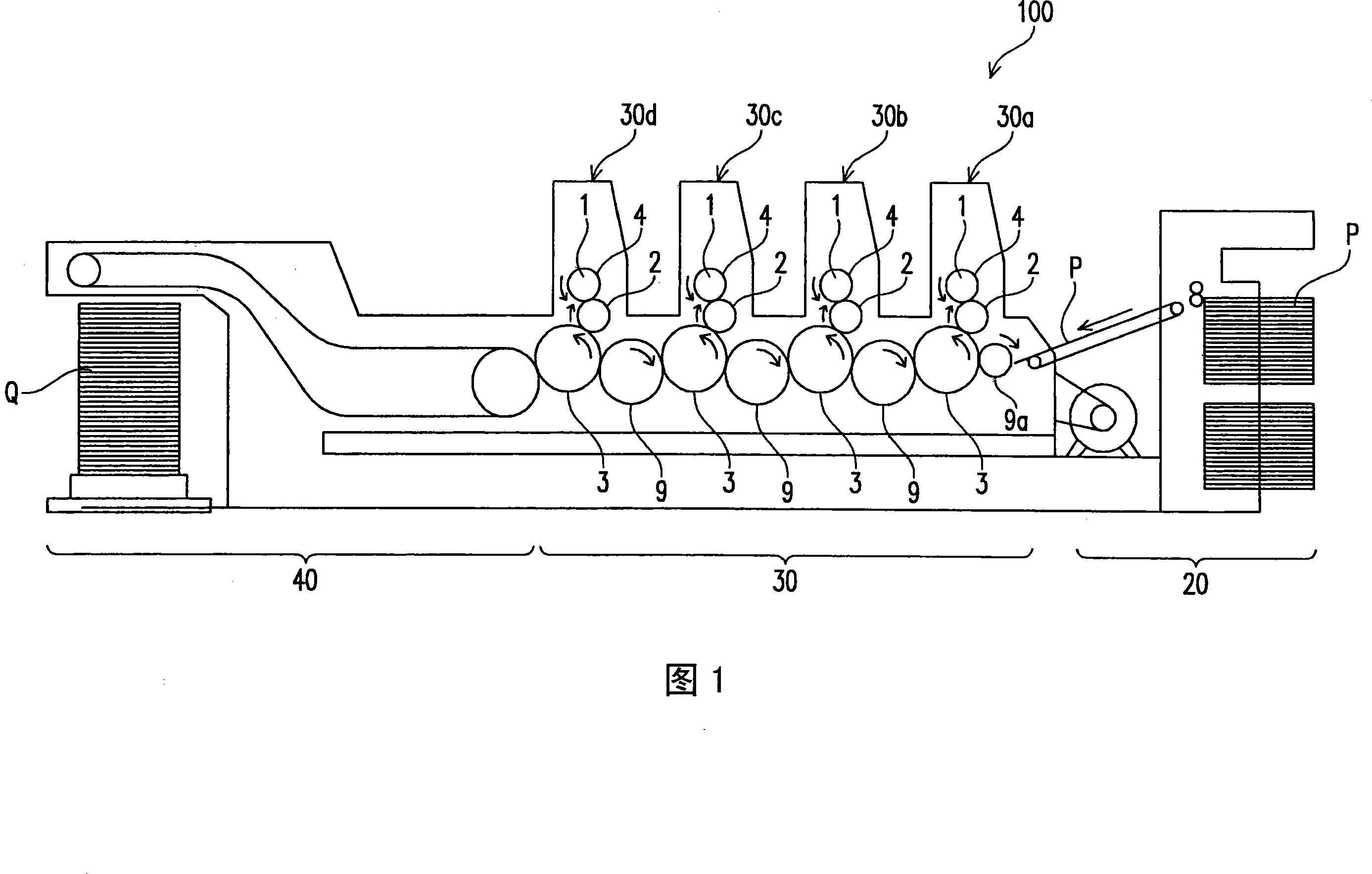

[0066] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings. FIG. 1 is a diagram showing a schematic configuration of an example of a color printing press 100 which is an example of a color printing system for implementing the printing image quality management method of the color printing press of the present invention. In addition, the color printing system includes a control unit S shown in FIG. 3 to be described later, in addition to the above-described color printing machine 100 . In FIG. 1 , the same reference numerals are attached to components having substantially the same configuration and function.

[0067] As shown in FIG. 1 , the color printing machine 100 uses a plurality of different primary color printing inks, and here it is composed of cyan (C), magenta (M), yellow (Y), and black (Bk), respectively. The C, M, Y, Bk primary color images formed by the four primary colors are sequentially printed on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com