Patents

Literature

521results about "Magnetrons" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

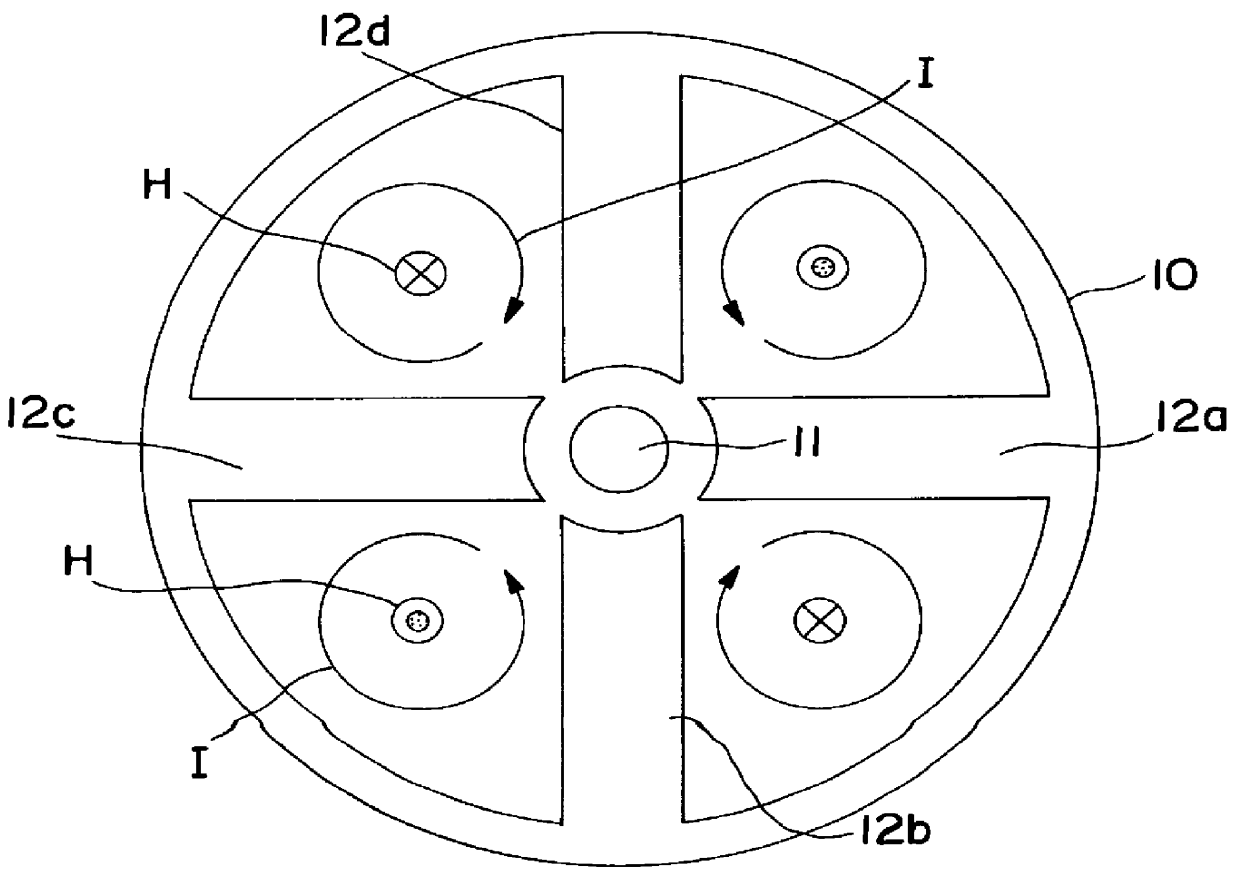

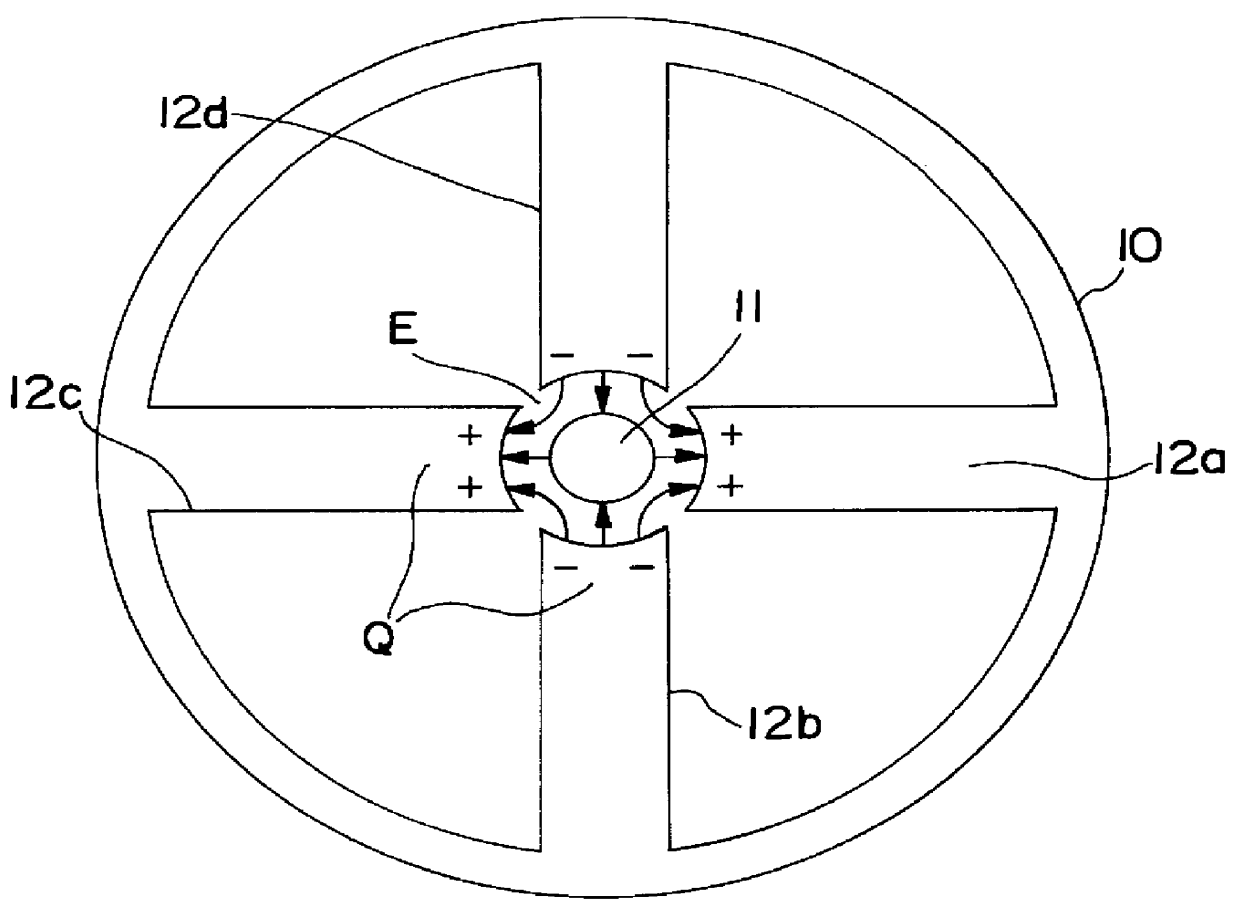

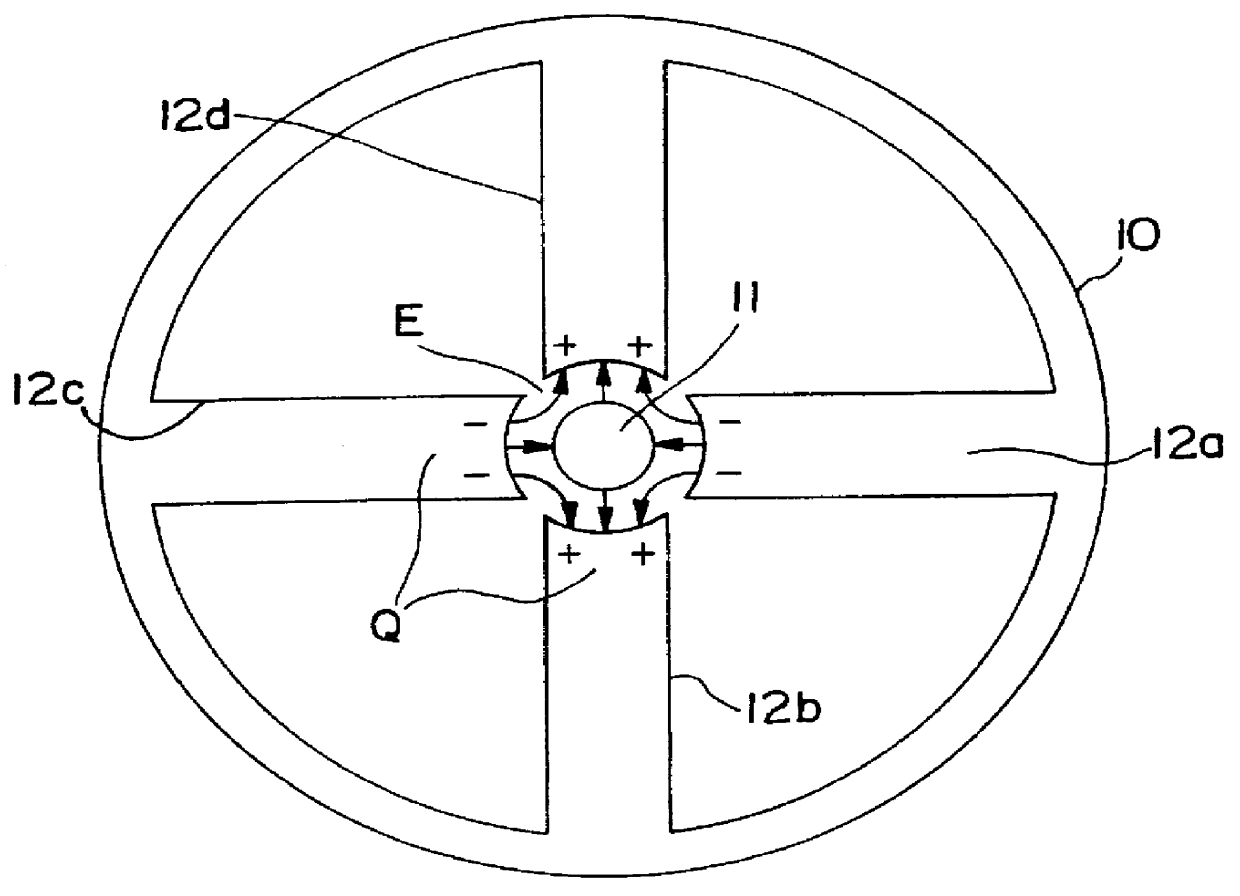

High frequency discharge energy supply means and high frequency electrodeless discharge lamp device

Use of a side resonator group comprising a plurality of side resonators, each including both an electromagnetically inductive function section made of a substantially ringed conductive material and an electrically capacitive function section made of a gap, so arranged in a circle as to make said electrically capacitive function sections opposed to the center as high frequency energy supply means, enables a high frequency discharge to take place in a smaller space than that observed in use of a conventional cavity resonator. Besides, application of said high frequency energy supply means to a high frequency electrodeless lamp device enables high frequency energy to be effectively coupled even with a relatively small size of electrodeless discharge lamp.

Owner:PANASONIC CORP

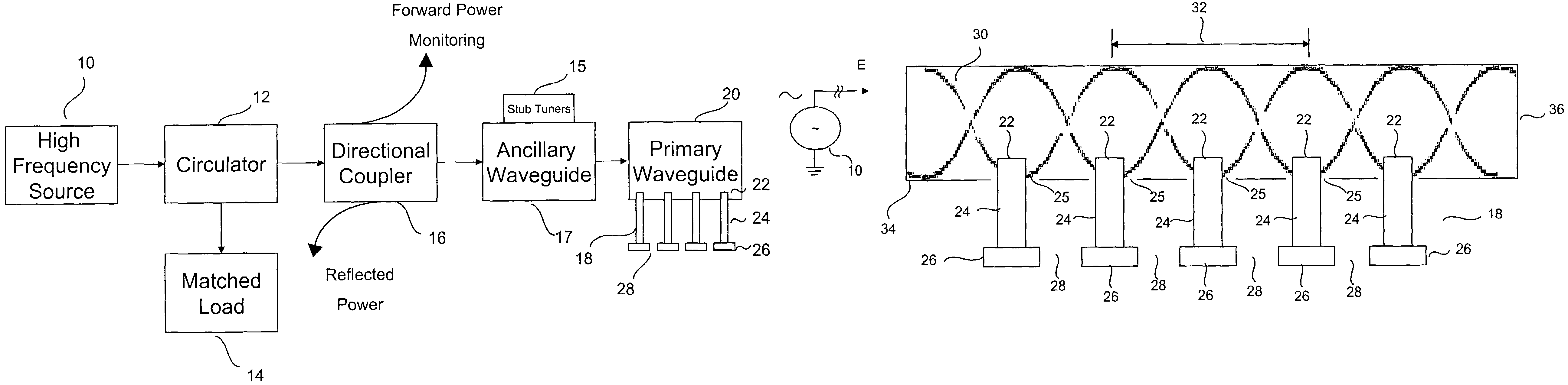

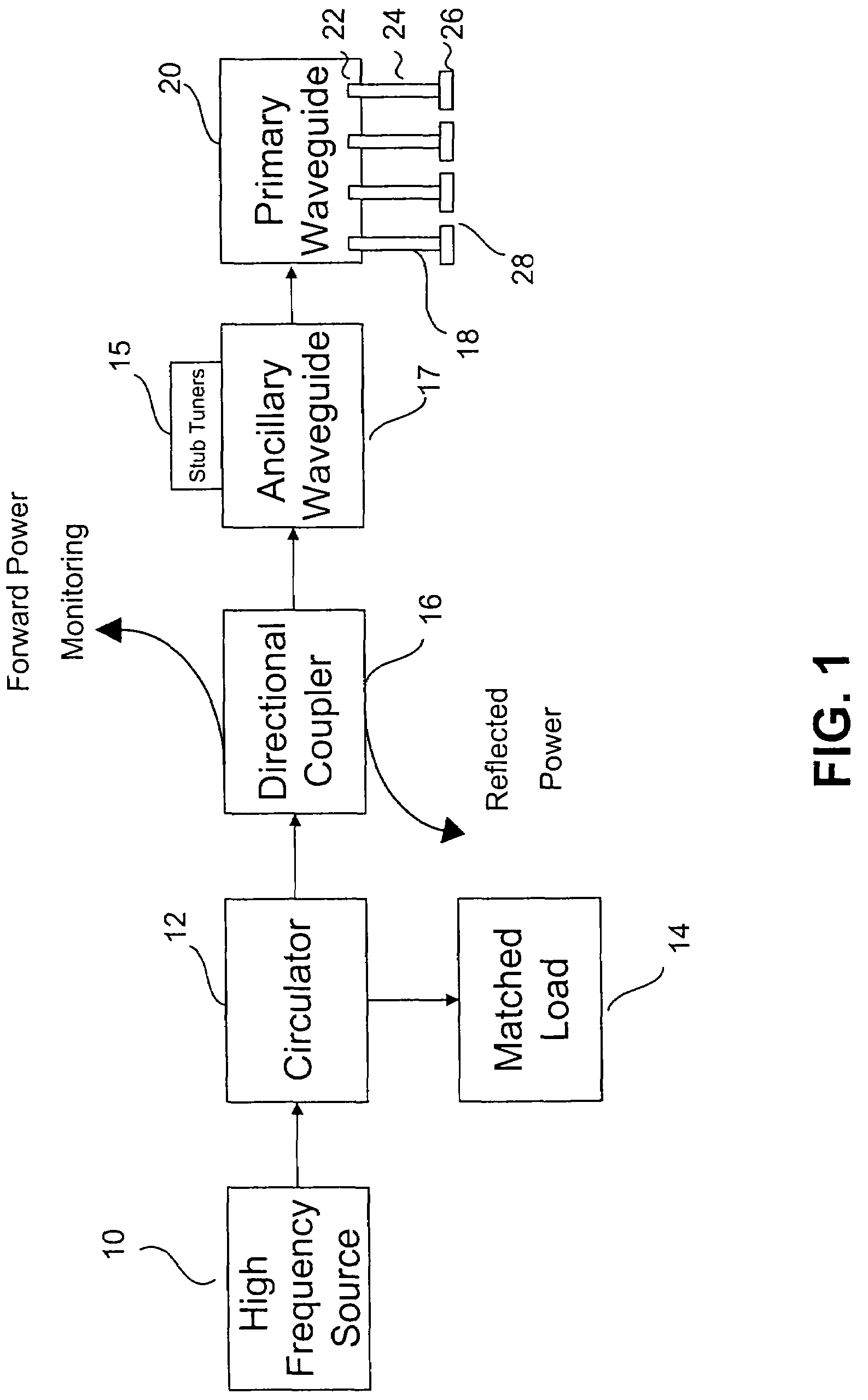

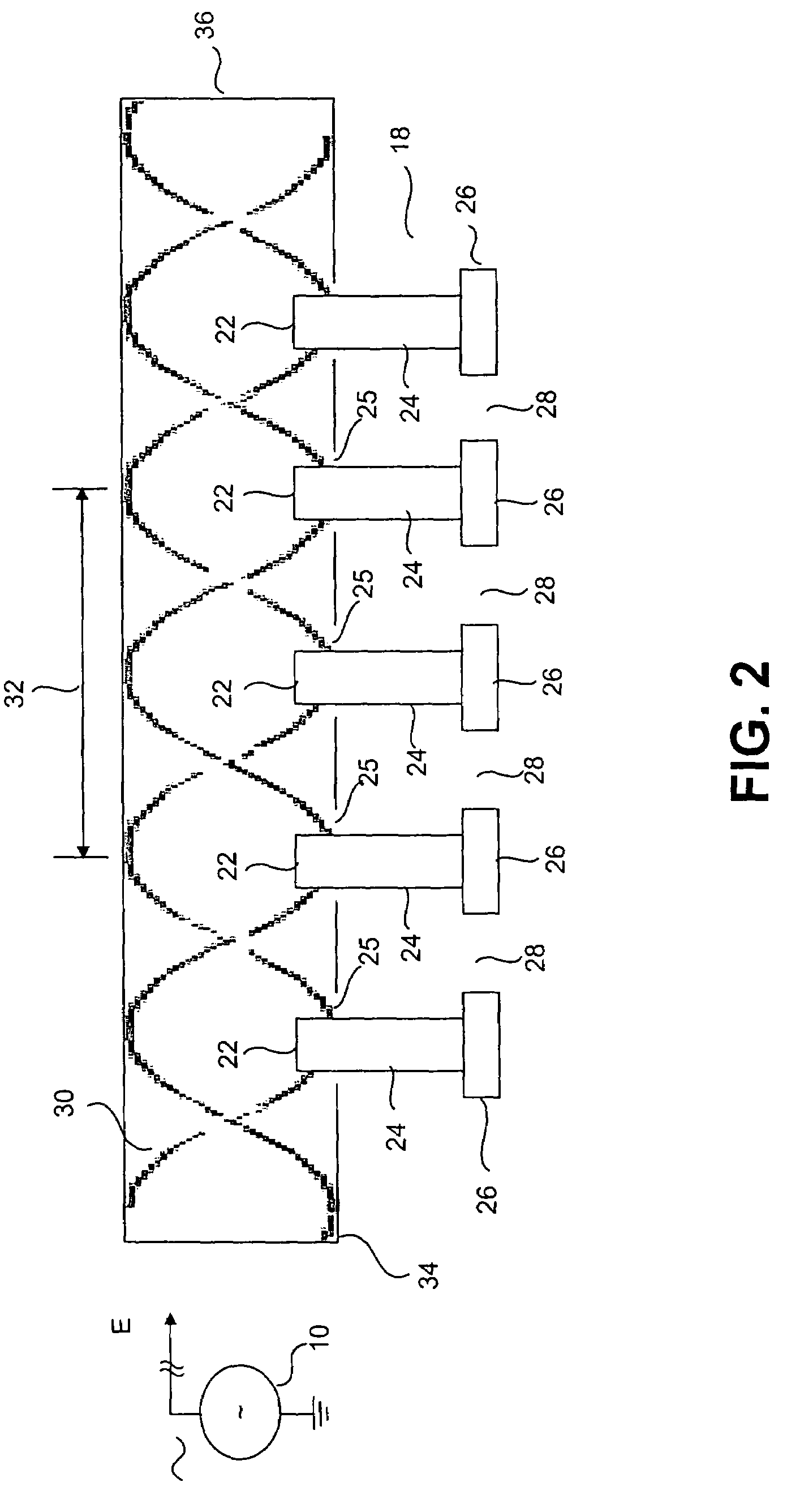

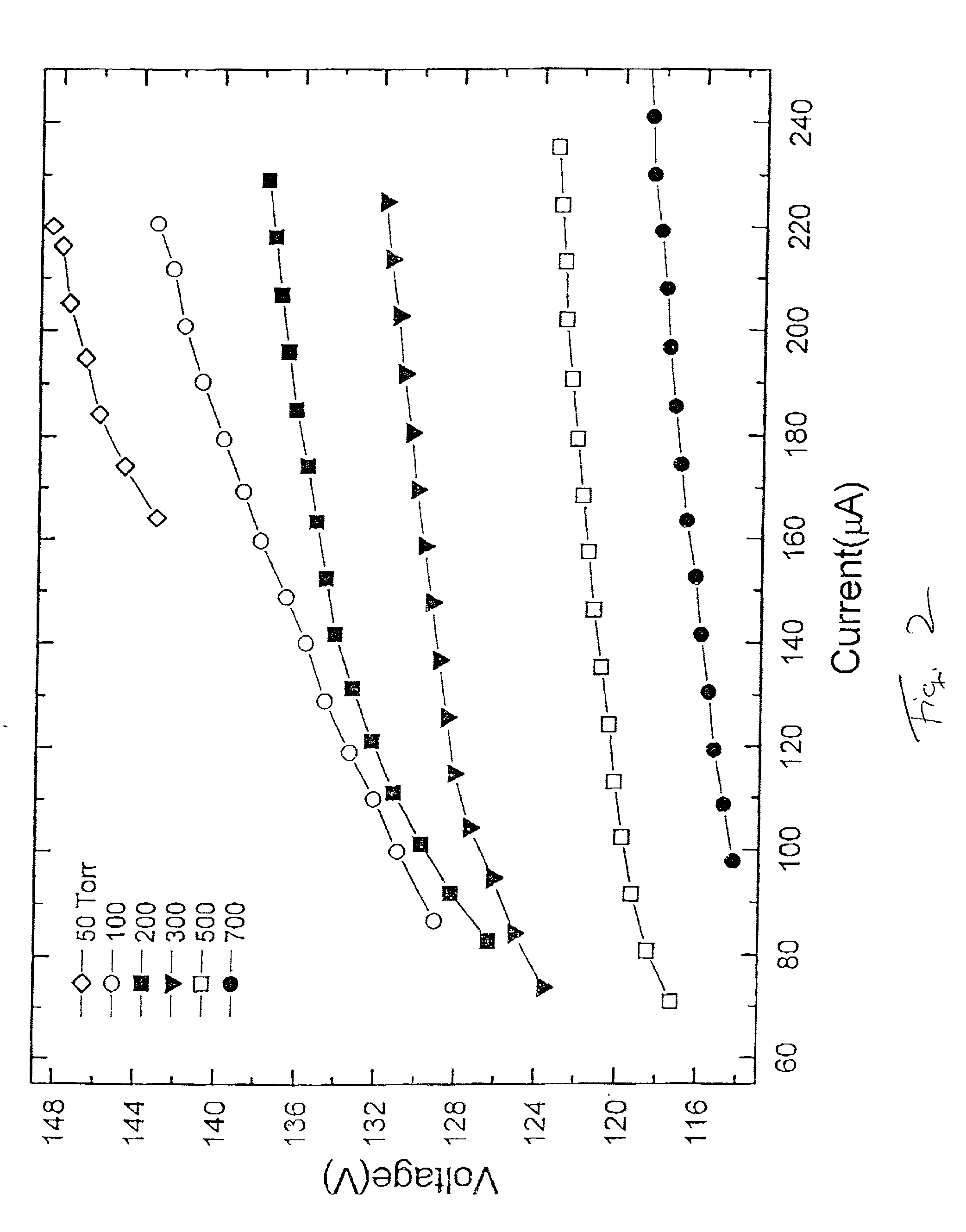

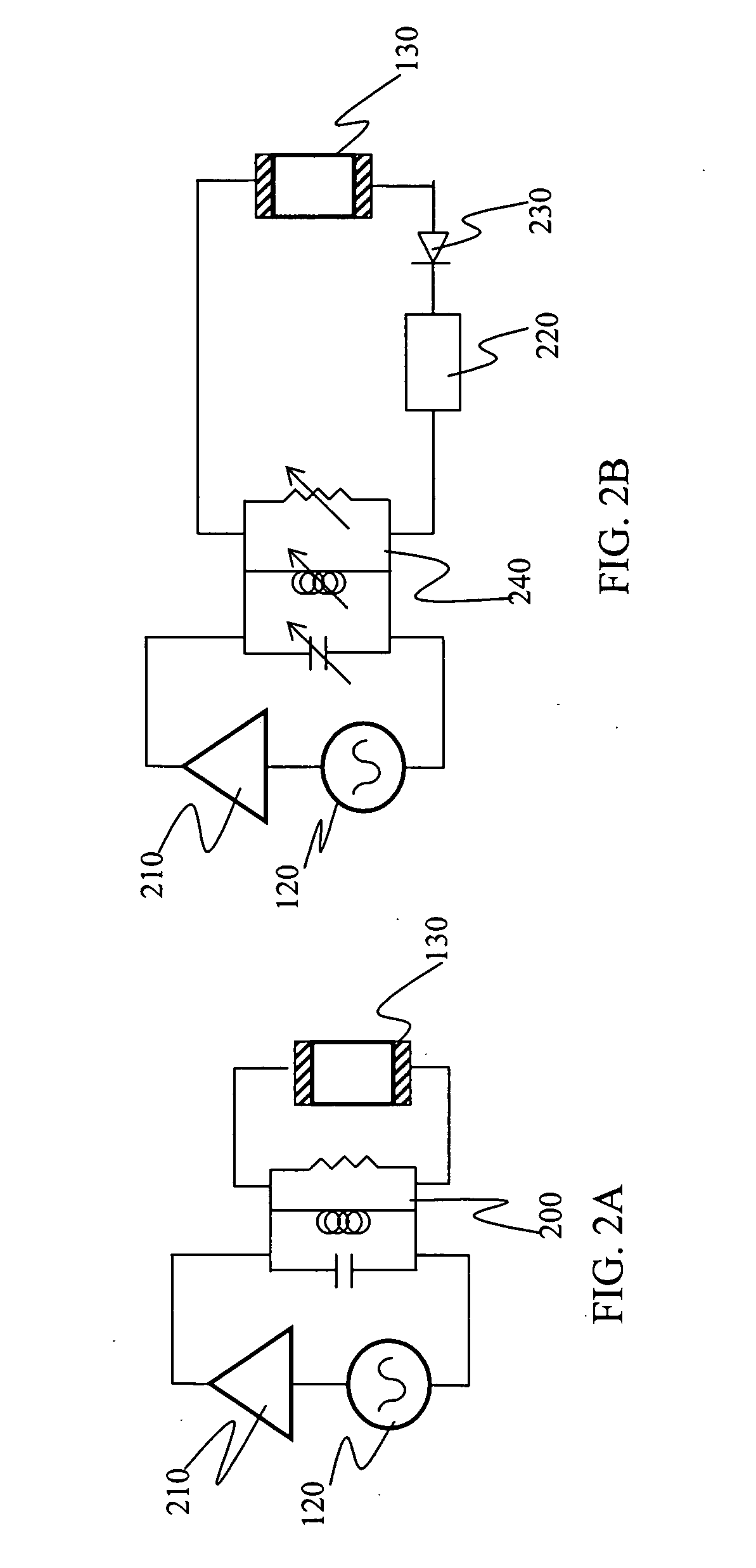

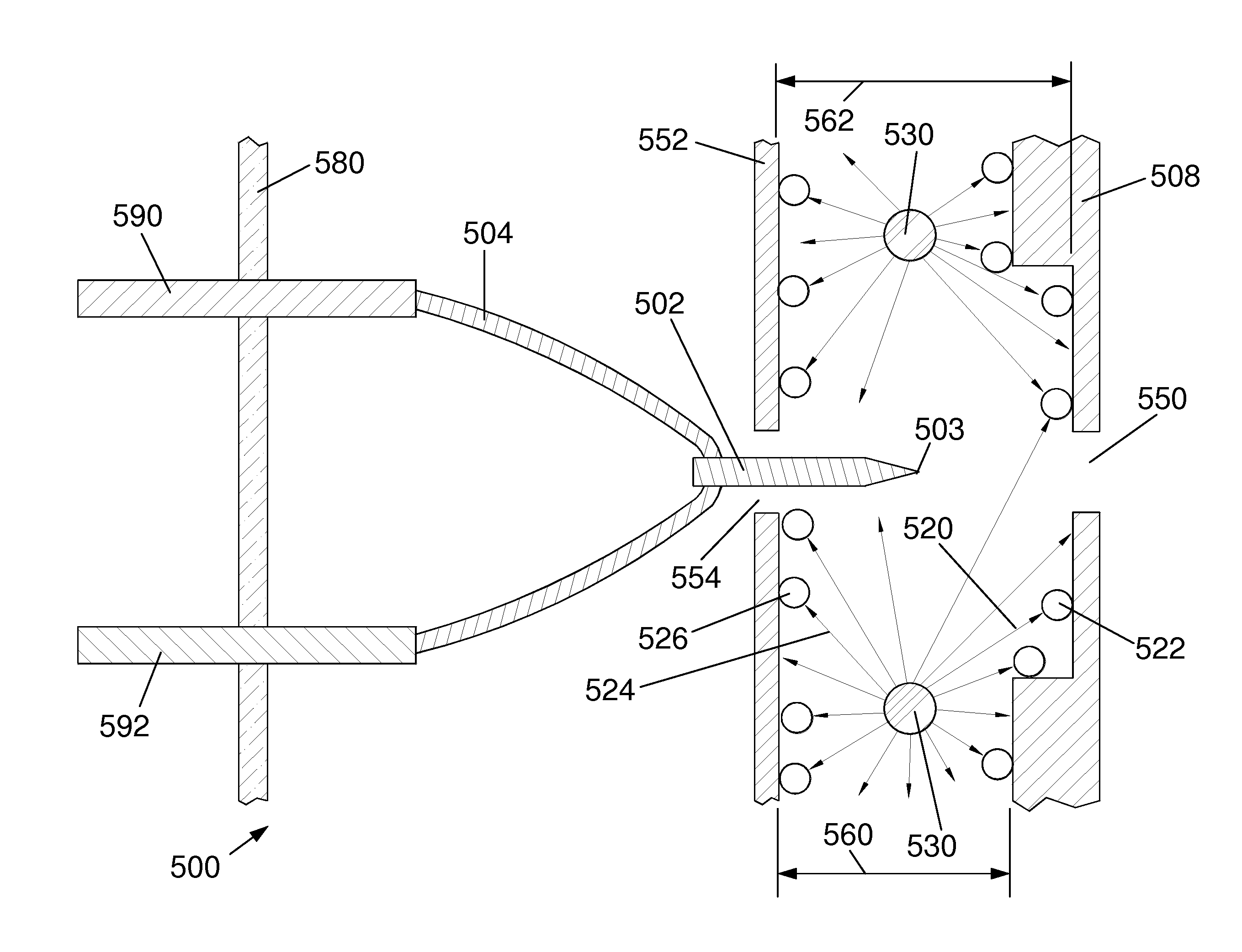

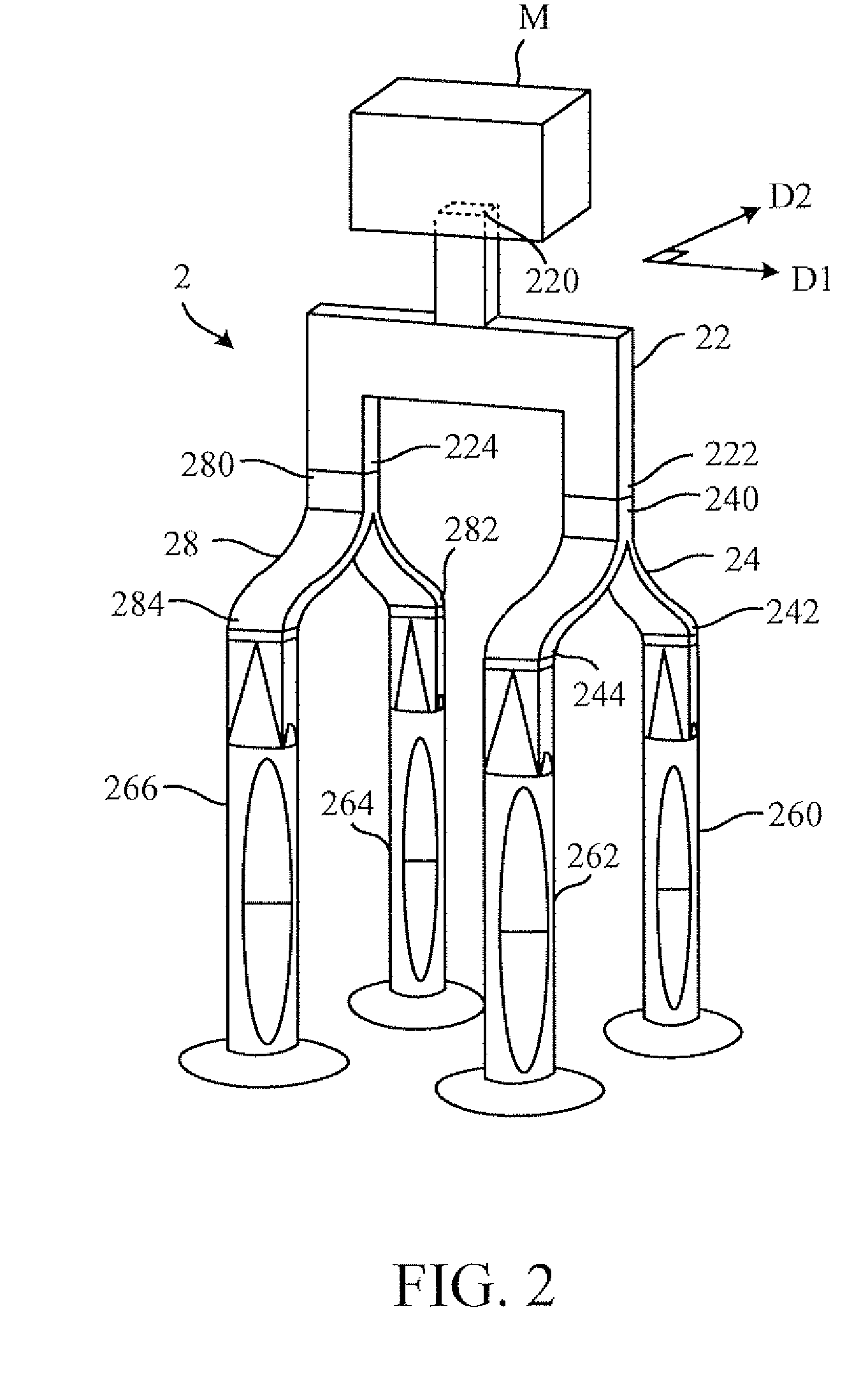

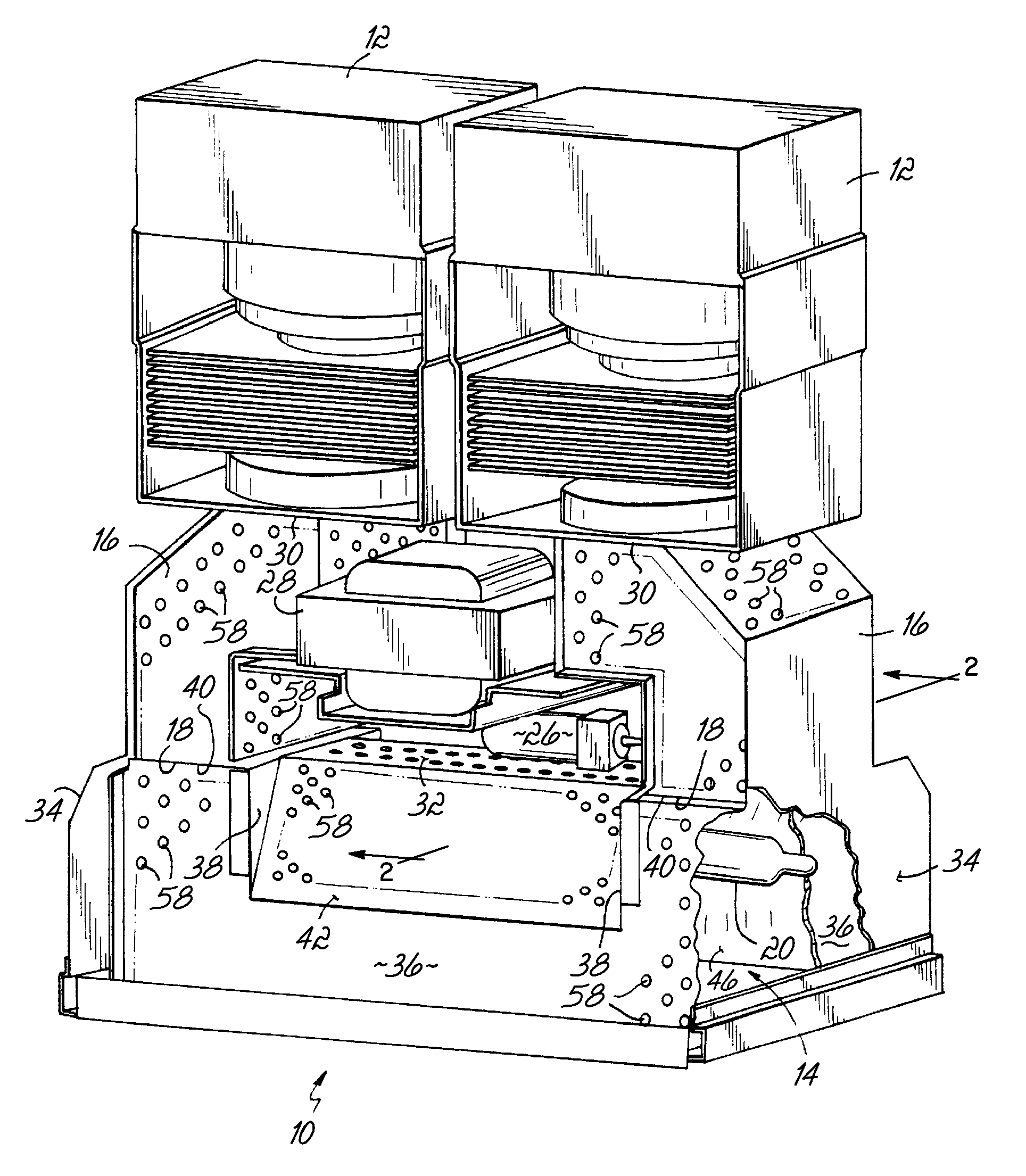

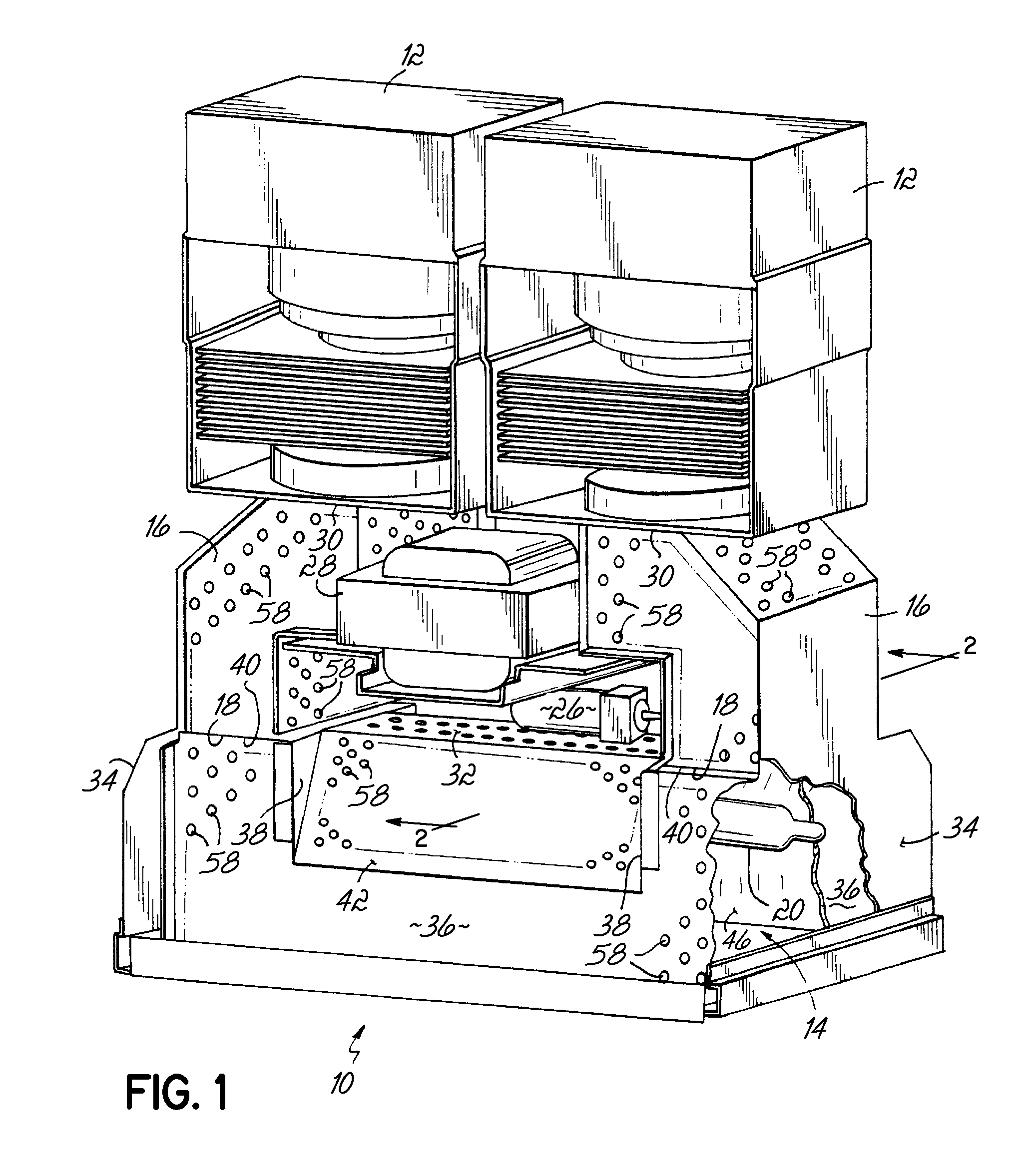

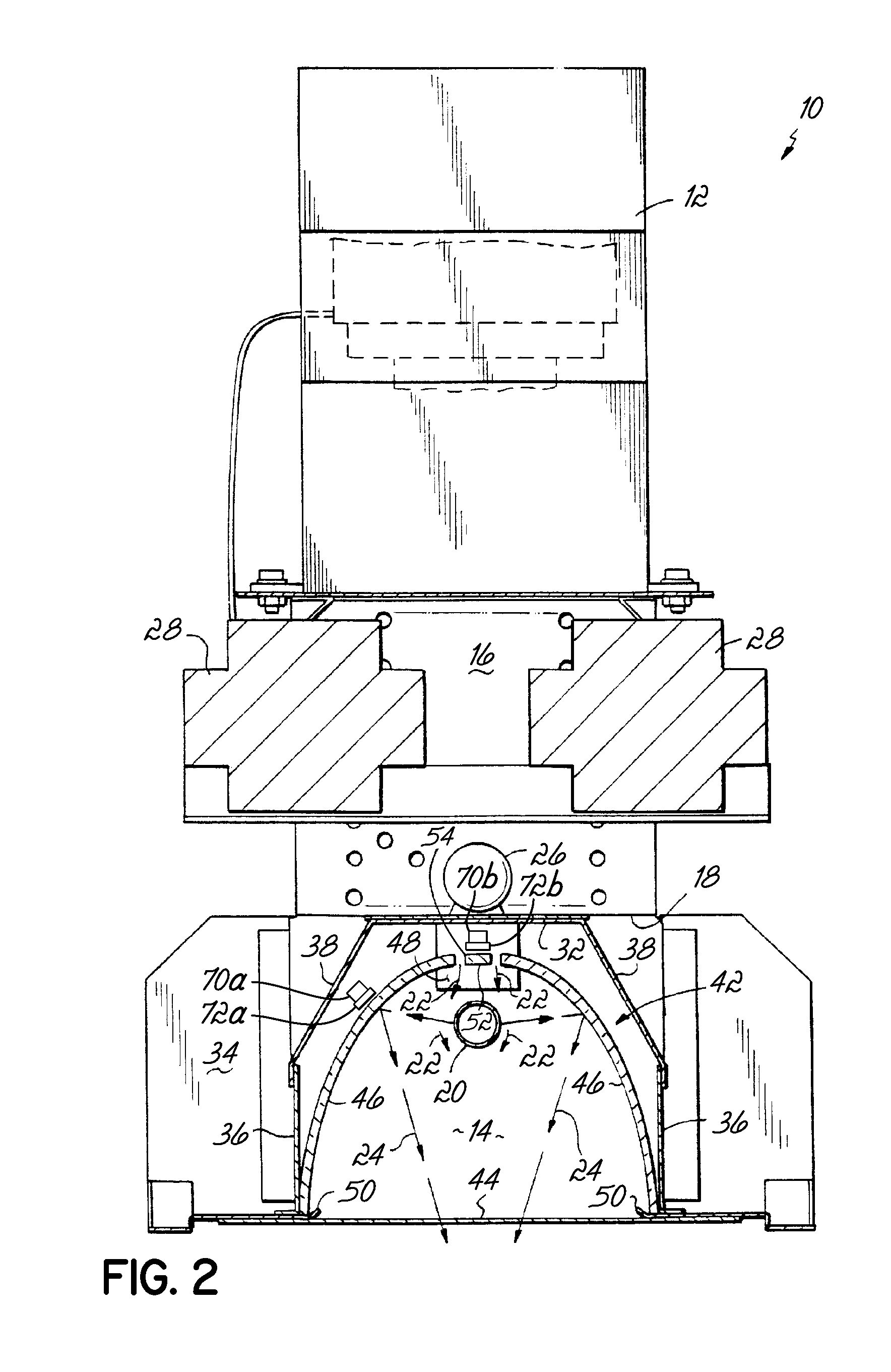

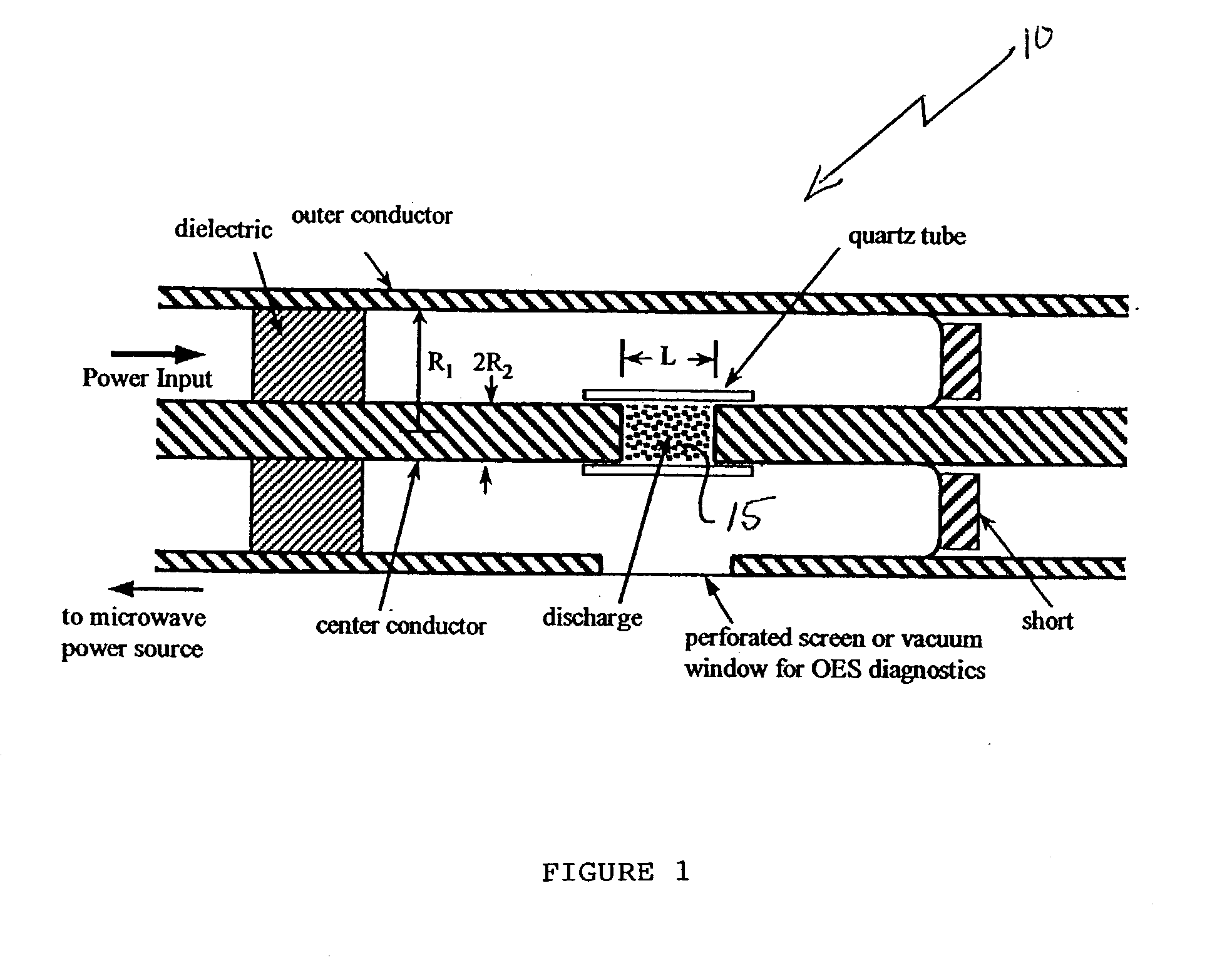

Method and apparatus for producing plasma

InactiveUS7589470B2Low costIncreases electric fieldMagnetronsTravelling-wave tubesHigh frequency powerLength wave

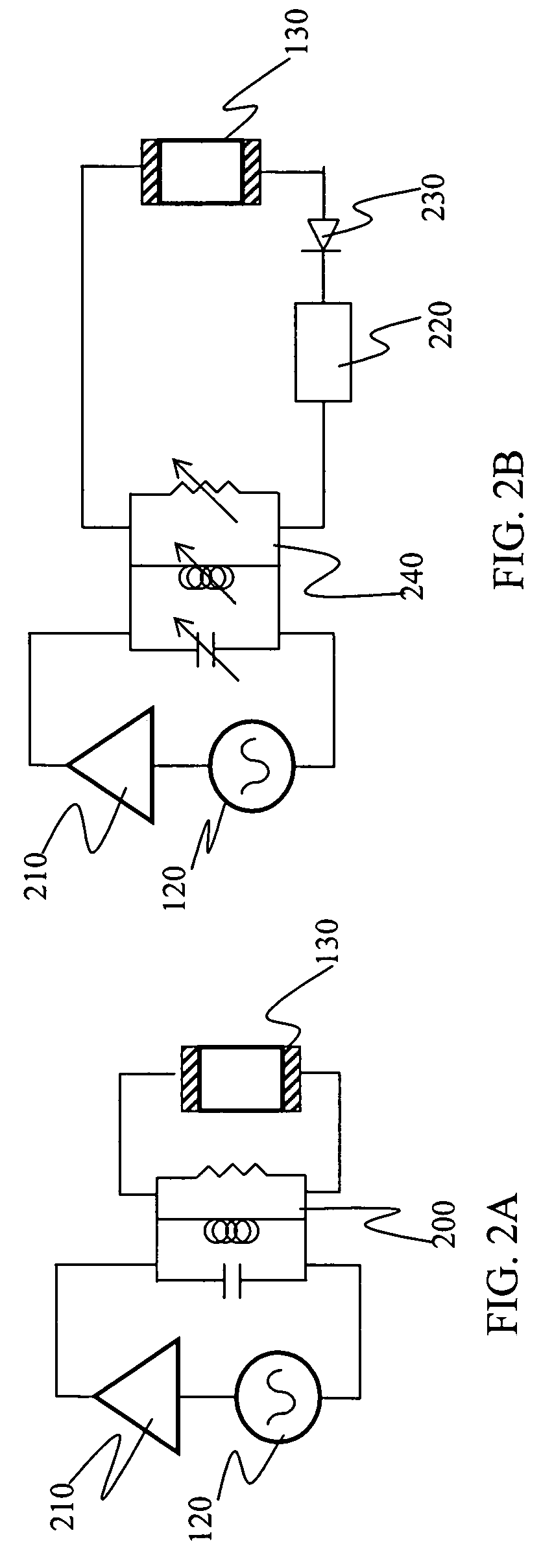

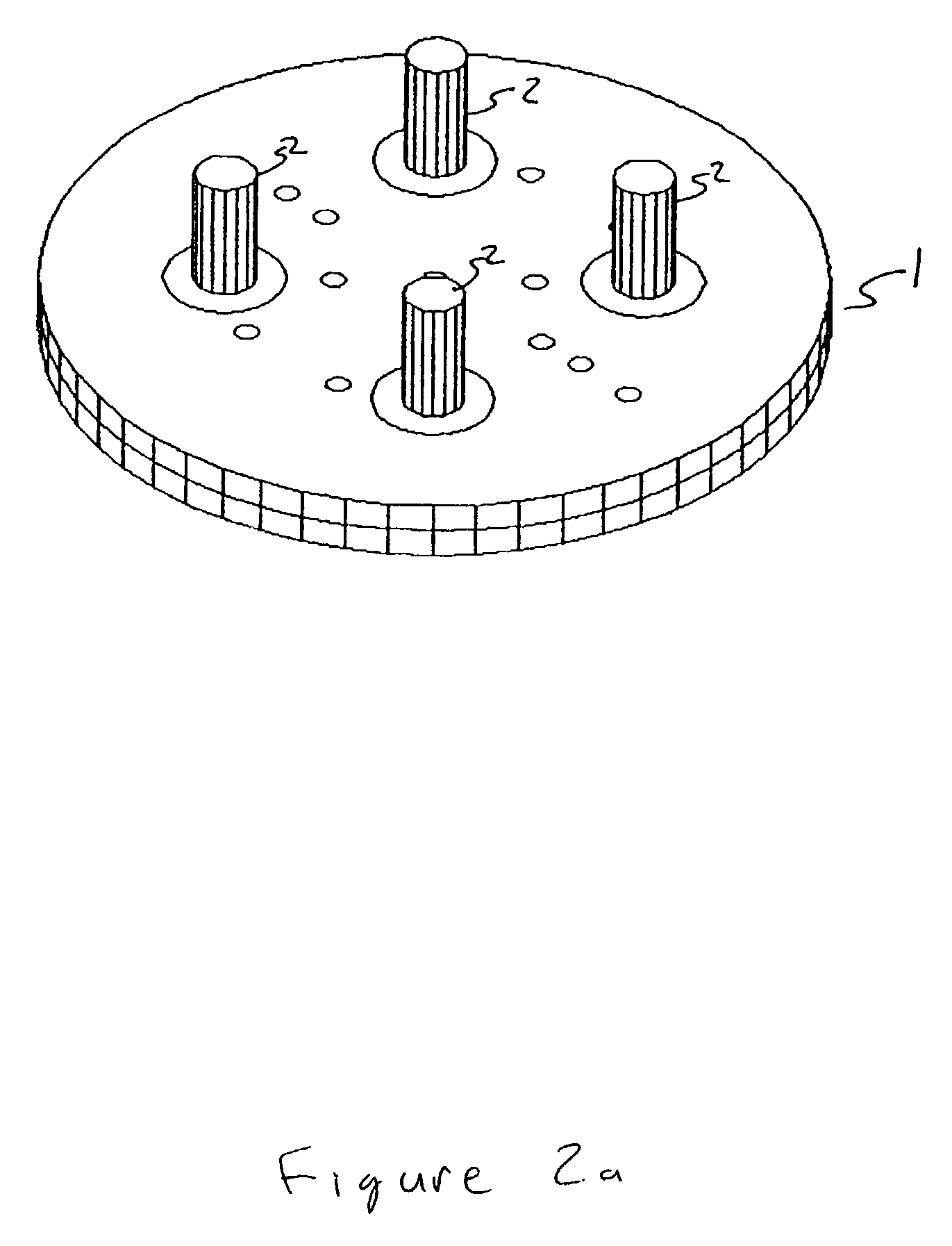

A method and apparatus for producing a distributed plasma at atmospheric pressure. A distributed plasma can be produced at atmospheric pressure by using an inexpensive high frequency power source in communication with a waveguide having a plurality particularly configured couplers disposed therein. The plurality of particularly arranged couplers can be configured in the waveguide to enhance the electromagnetic field strength therein. The plurality of couplers have internal portions disposed inside the waveguide and spaced apart by a distance of ½ wavelength of the high frequency power source and external portions disposed outside the waveguide and spaced apart by a predetermined distance which is calculated to cause the electromagnetic fields in the external portions of adjacent couplers to couple and thereby further enhance the strength of the electromagnetic field in the waveguide. Plasma can be formed in plasma areas defined by gaps between electrodes disposed on the external portions.

Owner:DUBLIN CITY UNIVERSITY

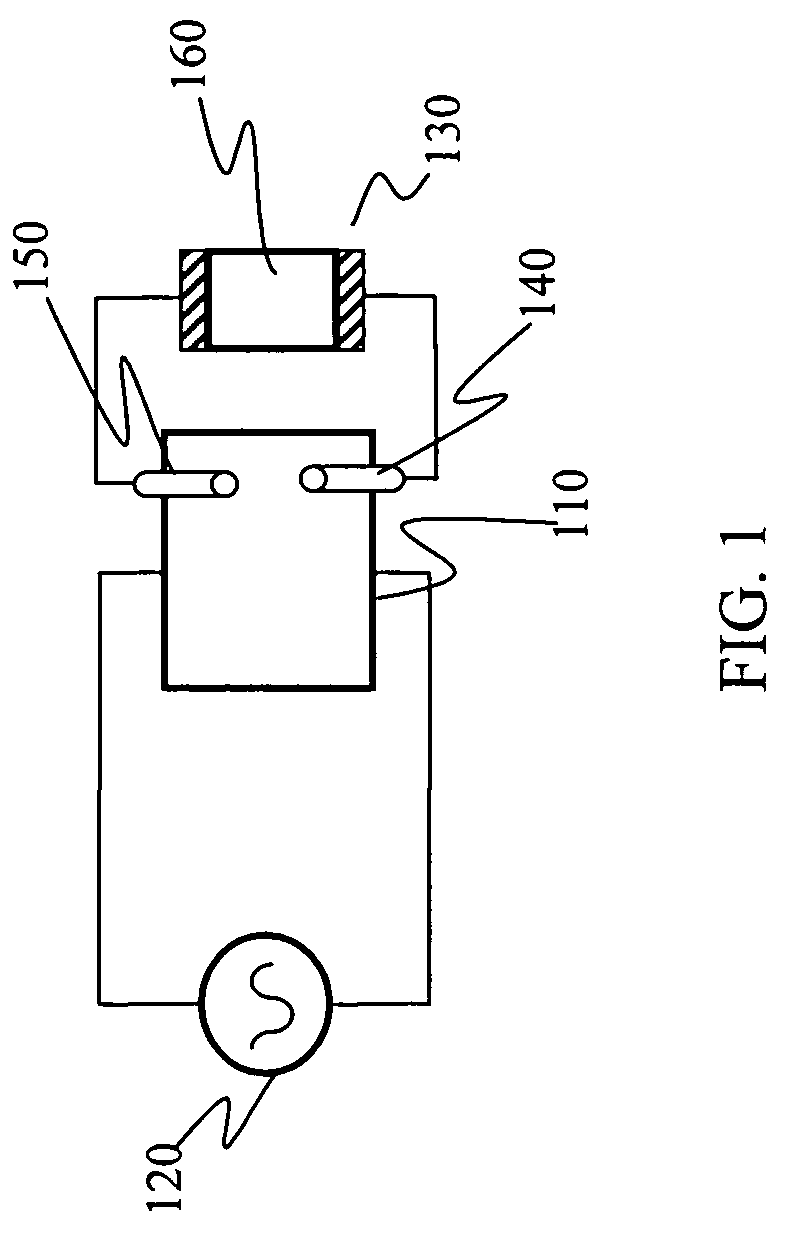

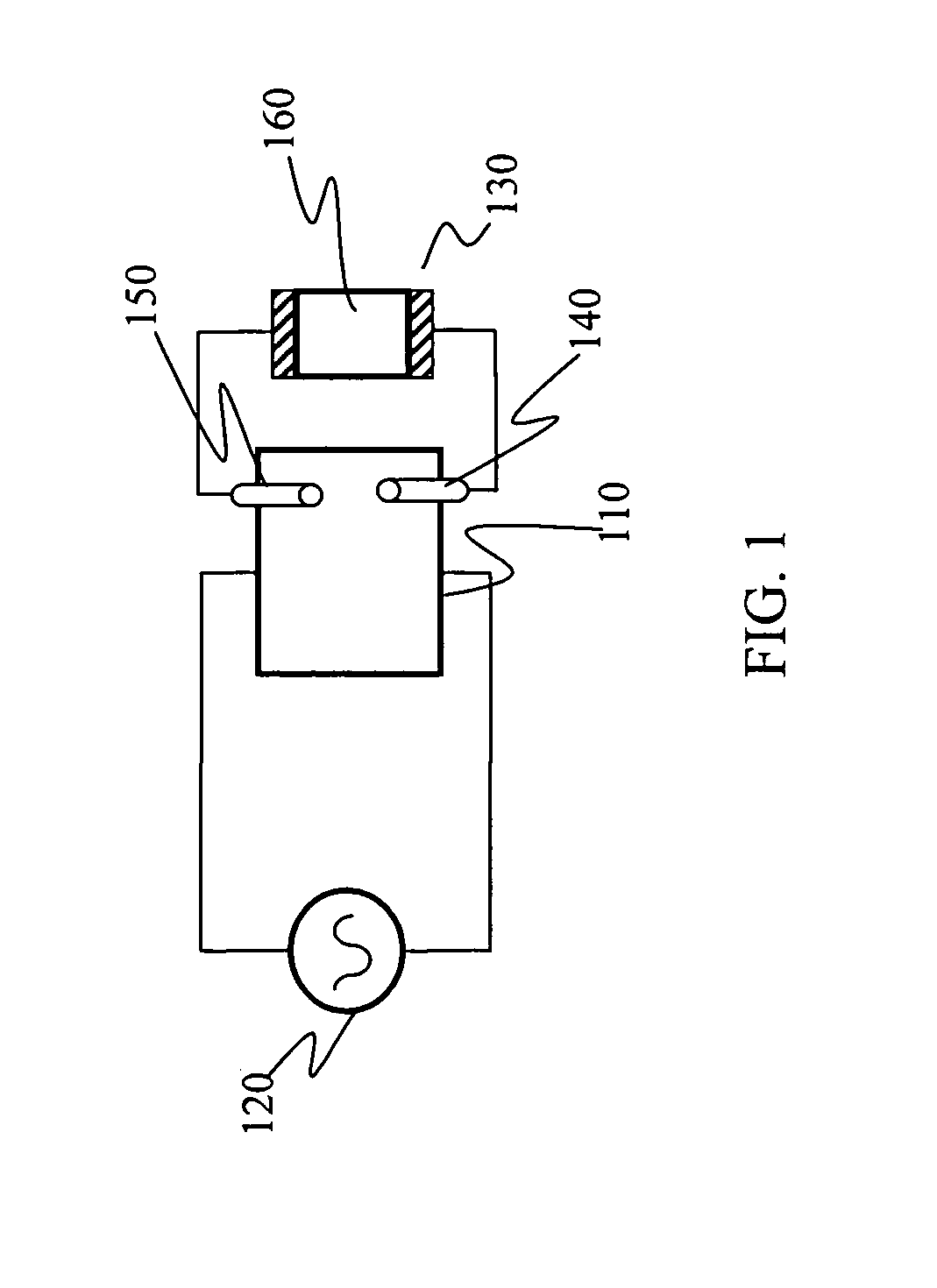

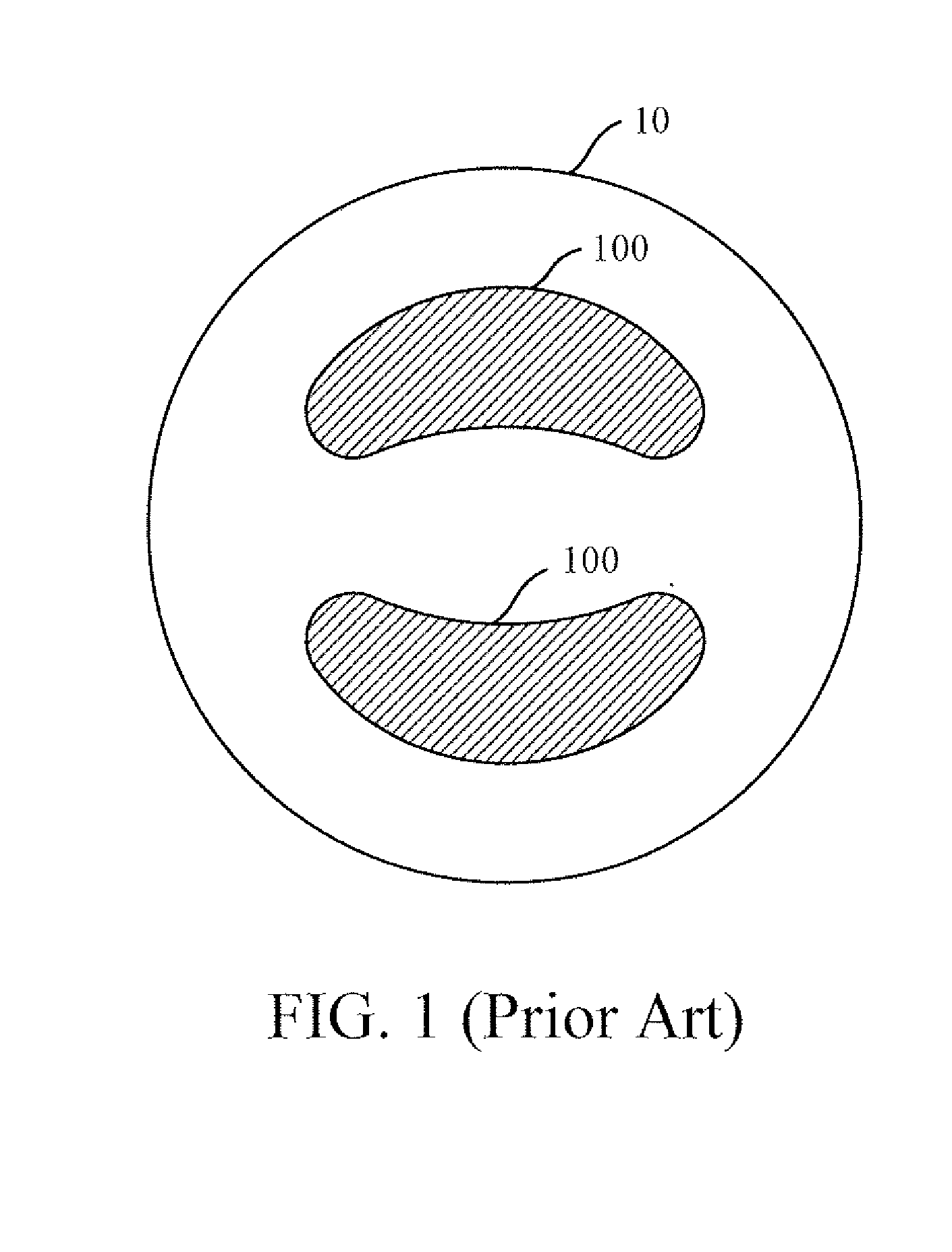

External resonator/cavity electrode-less plasma lamp and method of exciting with radio-frequency energy

ActiveUS7291985B2Increase rangeReduce the cost of the whole lampMagnetronsAlternating current plasma display panelsCapacitanceRadio frequency energy

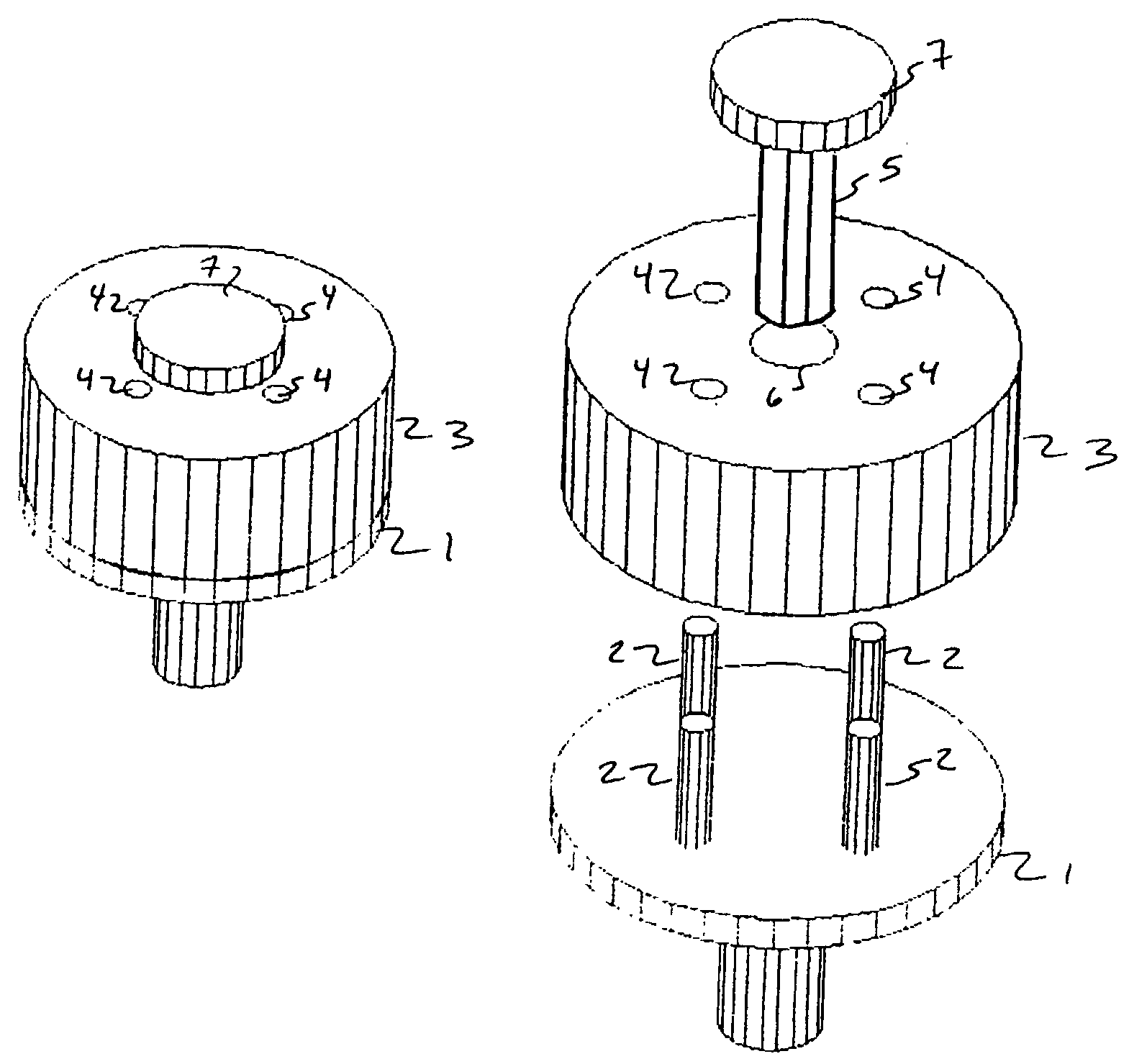

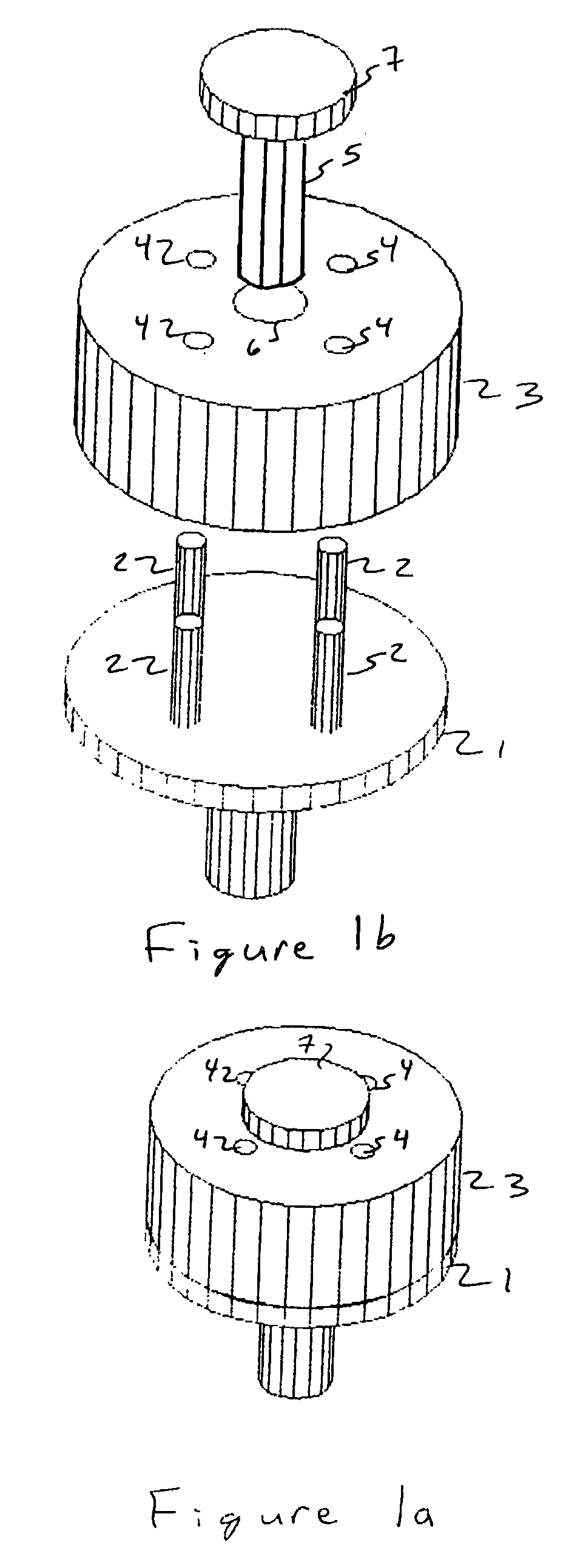

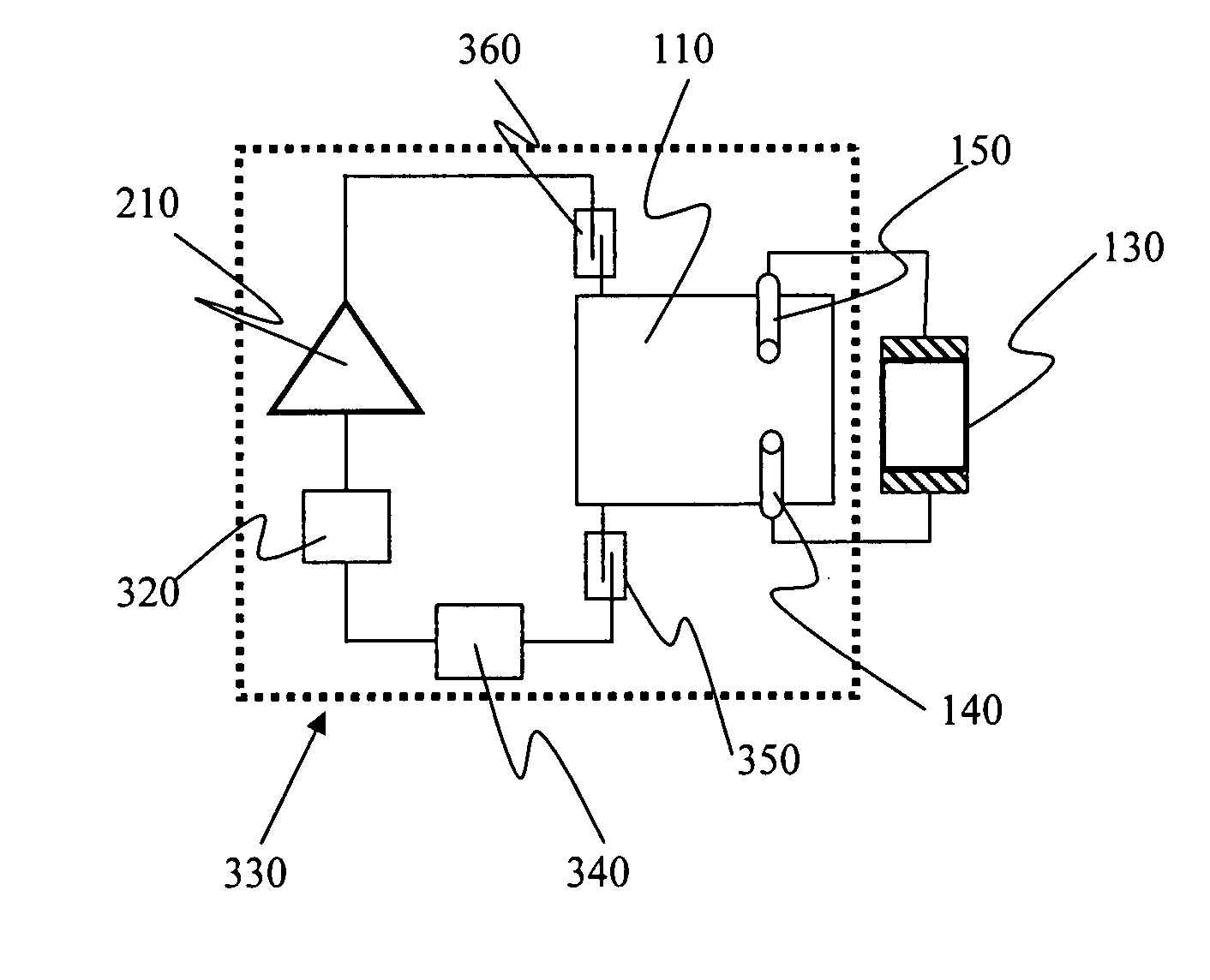

Described is a plasma electrode-less lamp. The device comprises an electromagnetic resonator and an electromagnetic radiation source conductively connected with the electromagnetic resonator. The device further comprises a pair of field probes, the field probes conductively connected with the electromagnetic resonator. A gas-fill vessel is formed from a closed, transparent body, forming a cavity. The gas-fill vessel is not contiguous with (detached from) the electromagnetic resonator and is capacitively coupled with the field probes. The gas-fill vessel further contains a gas within the cavity, whereby the gas is induced to emit light when electromagnetic radiation from the electromagnetic radiation source resonates inside the electromagnetic resonator, the electromagnetic resonator capacitively coupling the electromagnetic radiation to the gas, which becomes a plasma and emits light.

Owner:TOPANGA USA

Generating light from electromagnetic energy

ActiveUS7034464B1Prevent leakageAvoid meltingMagnetronsDischarge tube luminescnet screensElectricityDielectric

A device that converts non-visible electromagnetic energy into light. The device includes a cylindrical electromagnetic resonator with a central through hole, a dielectric (preferably ceramic) material surrounded by symmetrically displaced through holes surrounding the central through hole. The device also includes a base and probes connected to the base. The probes are placed to introduce non-visible electromagnetic energy into the resonator. The device also includes a plasma lamp placed in the central through hole. The plasma lamp is placed to convert the non-visible electromagnetic energy into light. Preferably, the resonator is composed of a ceramic with a metalized surface except for inside the through holes. Also, a device that converts electricity into light and vice versa, a device that emits modulated light based on input modulated non-visible electromagnetic energy, and a device that emits modulated non-visible electromagnetic energy based on input modulated light, all implemented using a cylindrical electromagnetic resonator.

Owner:V SILICON SEMICON (HANGZHOU) CO LTD

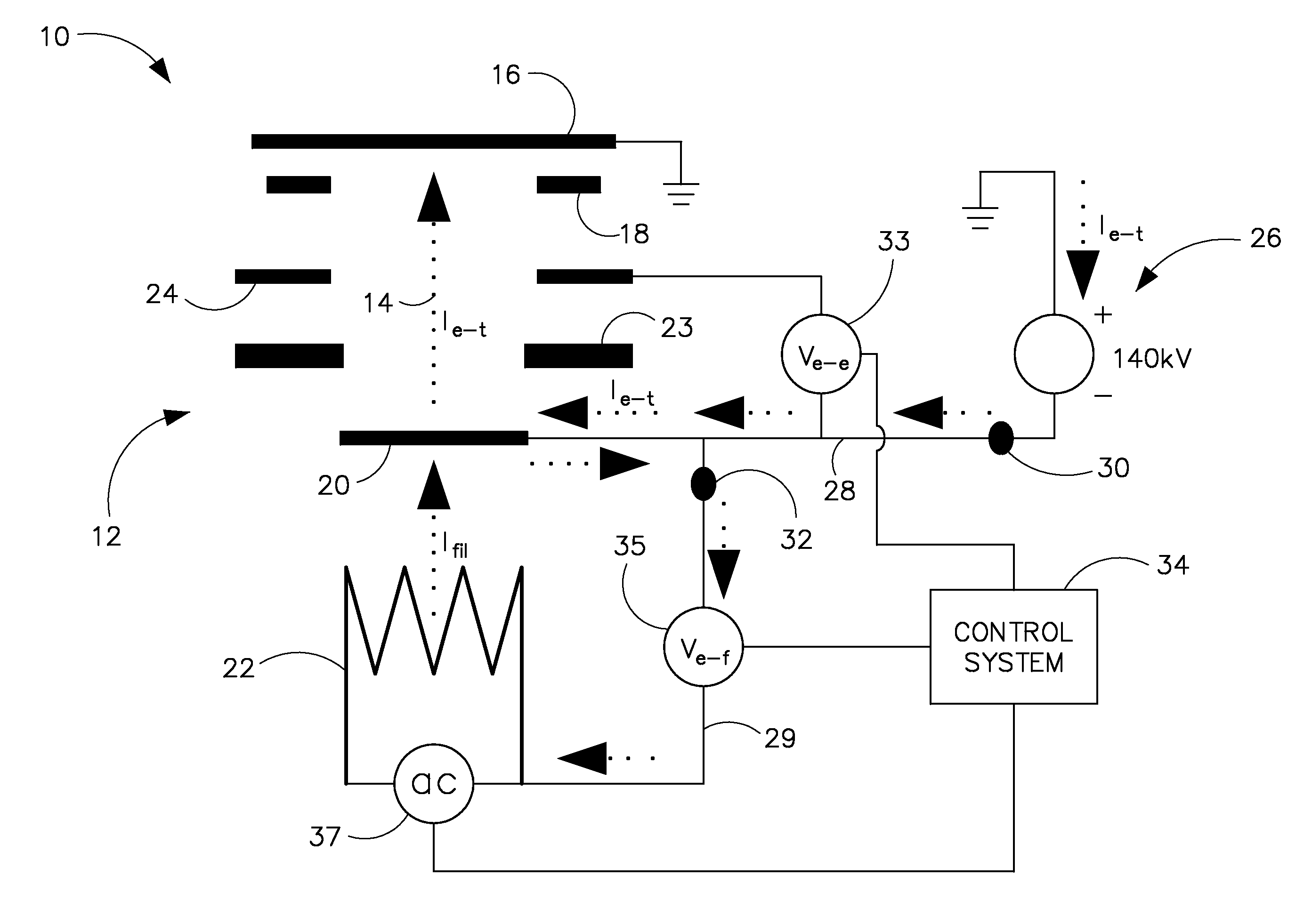

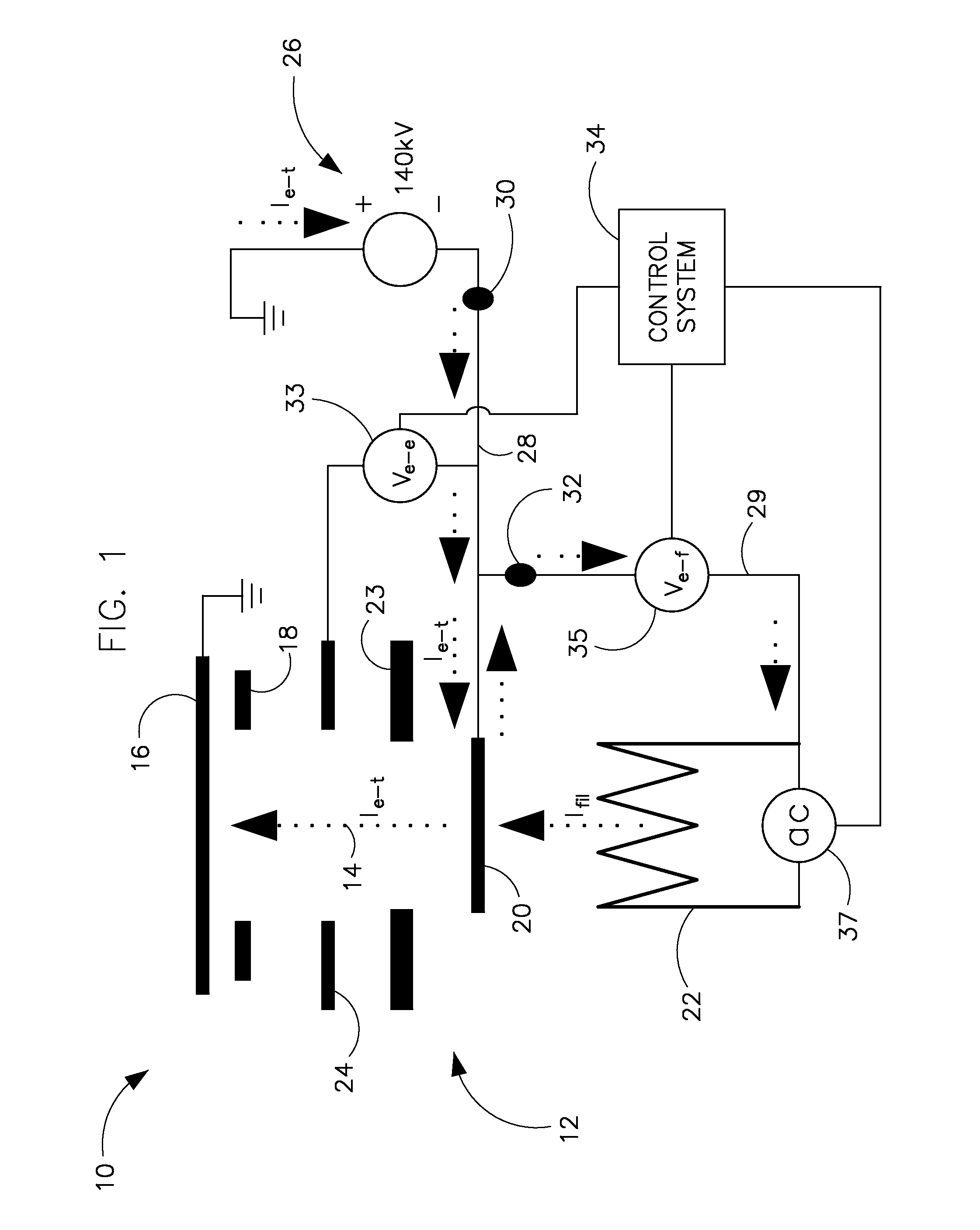

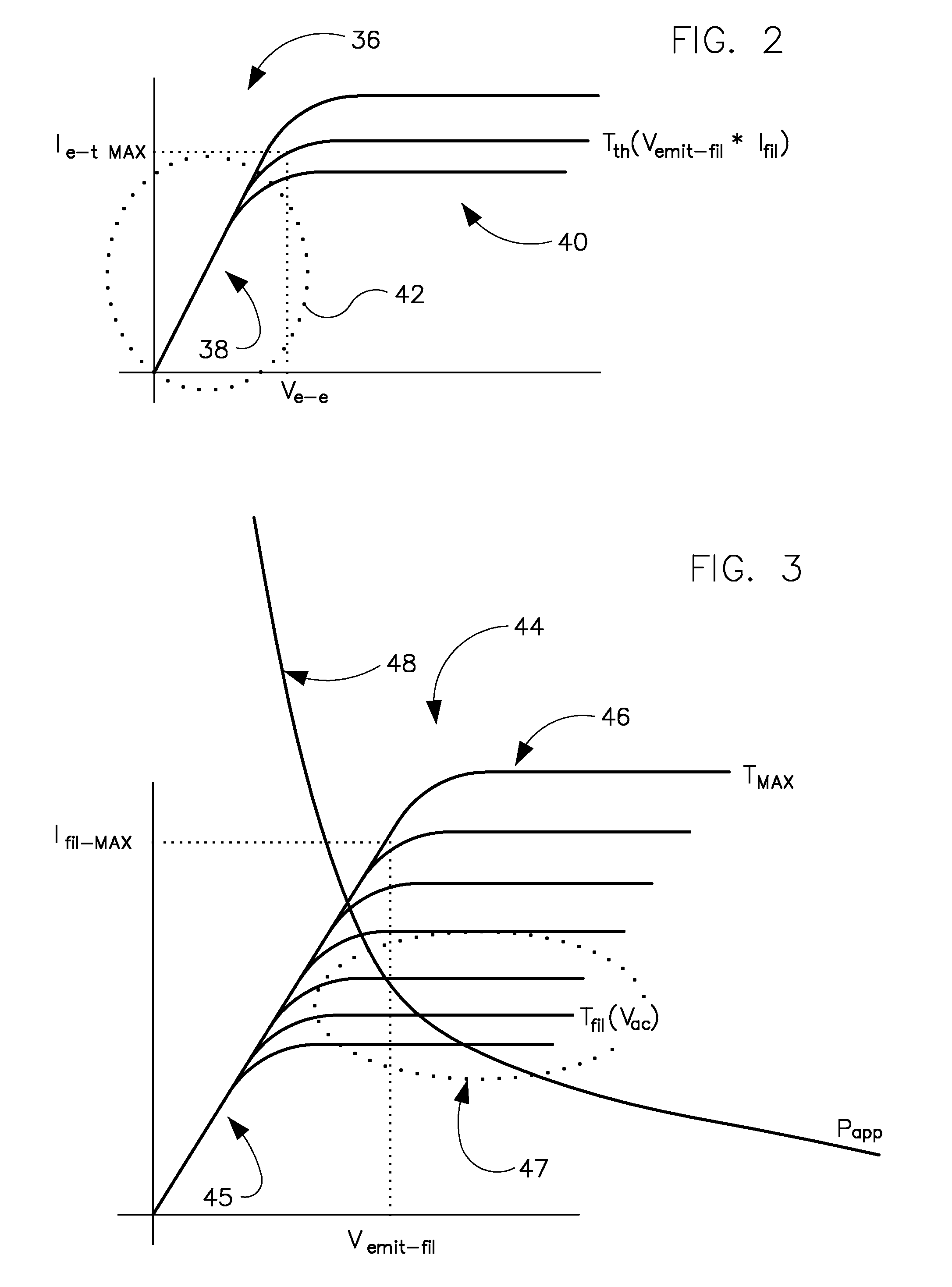

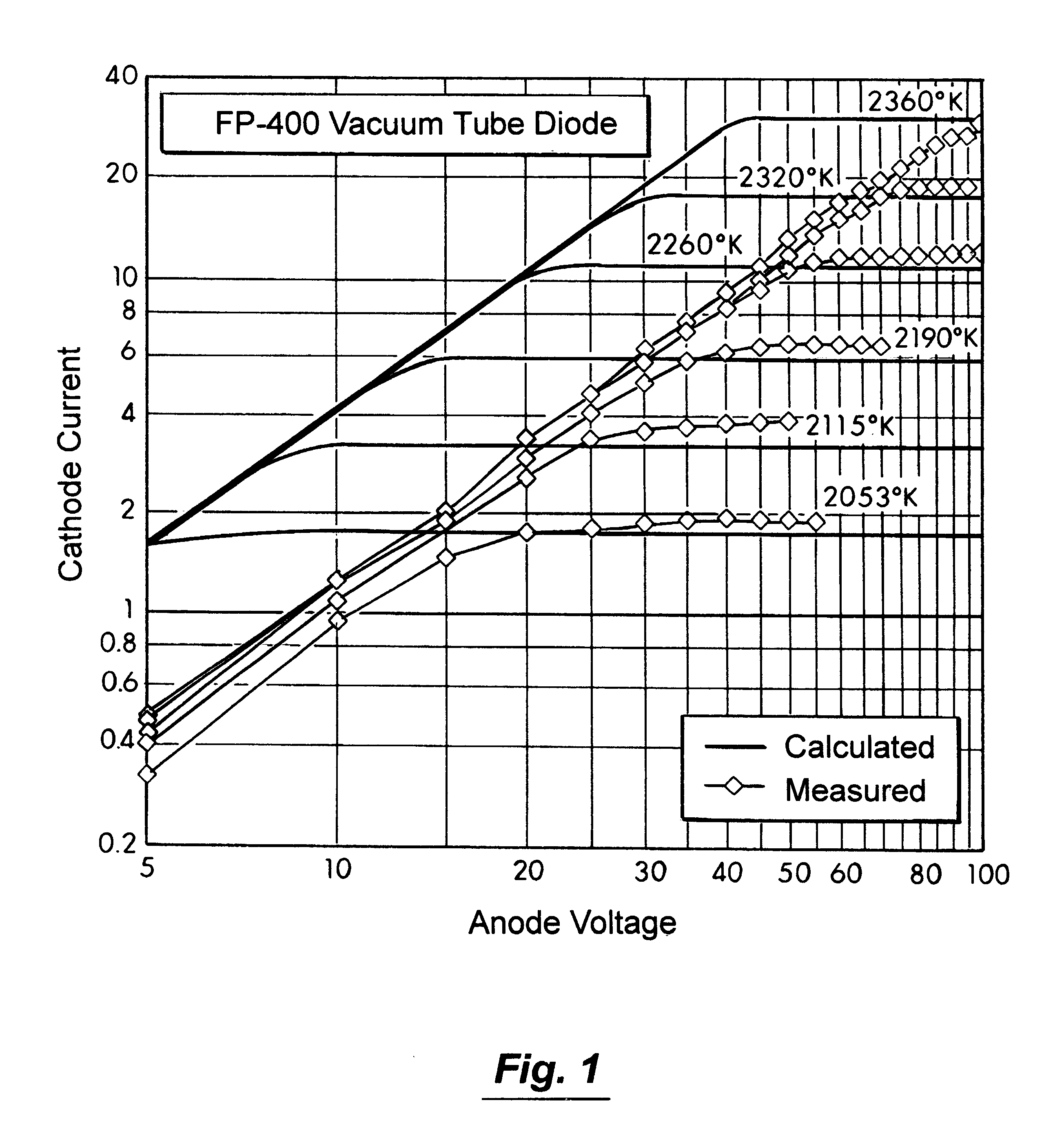

Pierce gun and method of controlling thereof

ActiveUS20110241575A1Minimize operating temperatureMagnetronsX-ray tube electrodesTemperature controlControl system

A system and method for controlling the temperature of both an electron emitter and a filament to their lowest possible operating temperature is disclosed. The apparatus includes a filament, an electron emitter heated by the filament to generate an electron beam, and a power supply configured to supply power to each of the filament and the electron emitter. The apparatus also includes a control system to control a supply of power to each of the filament and the electron emitter, with the control system being configured to receive an input indicative of a desired electron emitter operating temperature, cause a desired voltage to be applied between the electron emitter and the filament, and cause a desired voltage to be applied to the filament based on the desired emitter element operating temperature, so as to minimize an operating temperature of the electron emitter and the filament.

Owner:GENERAL ELECTRIC CO

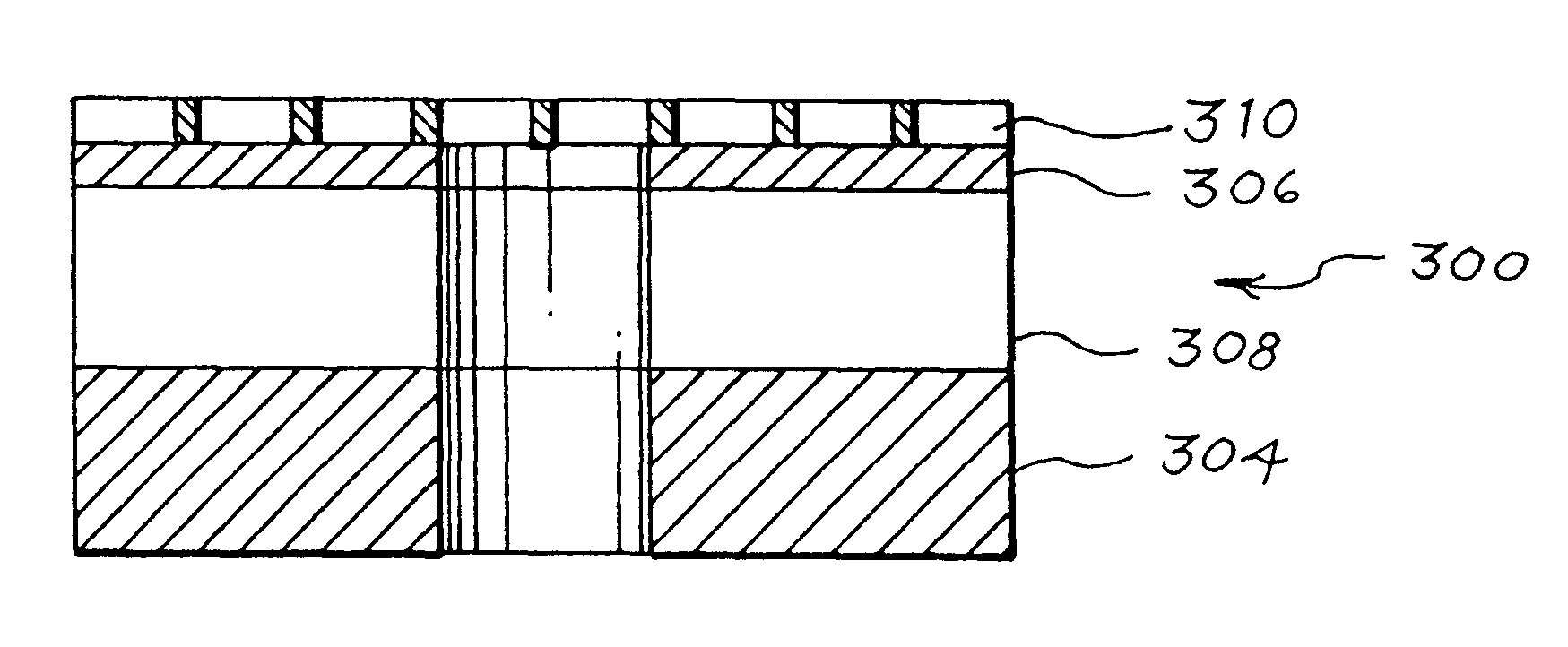

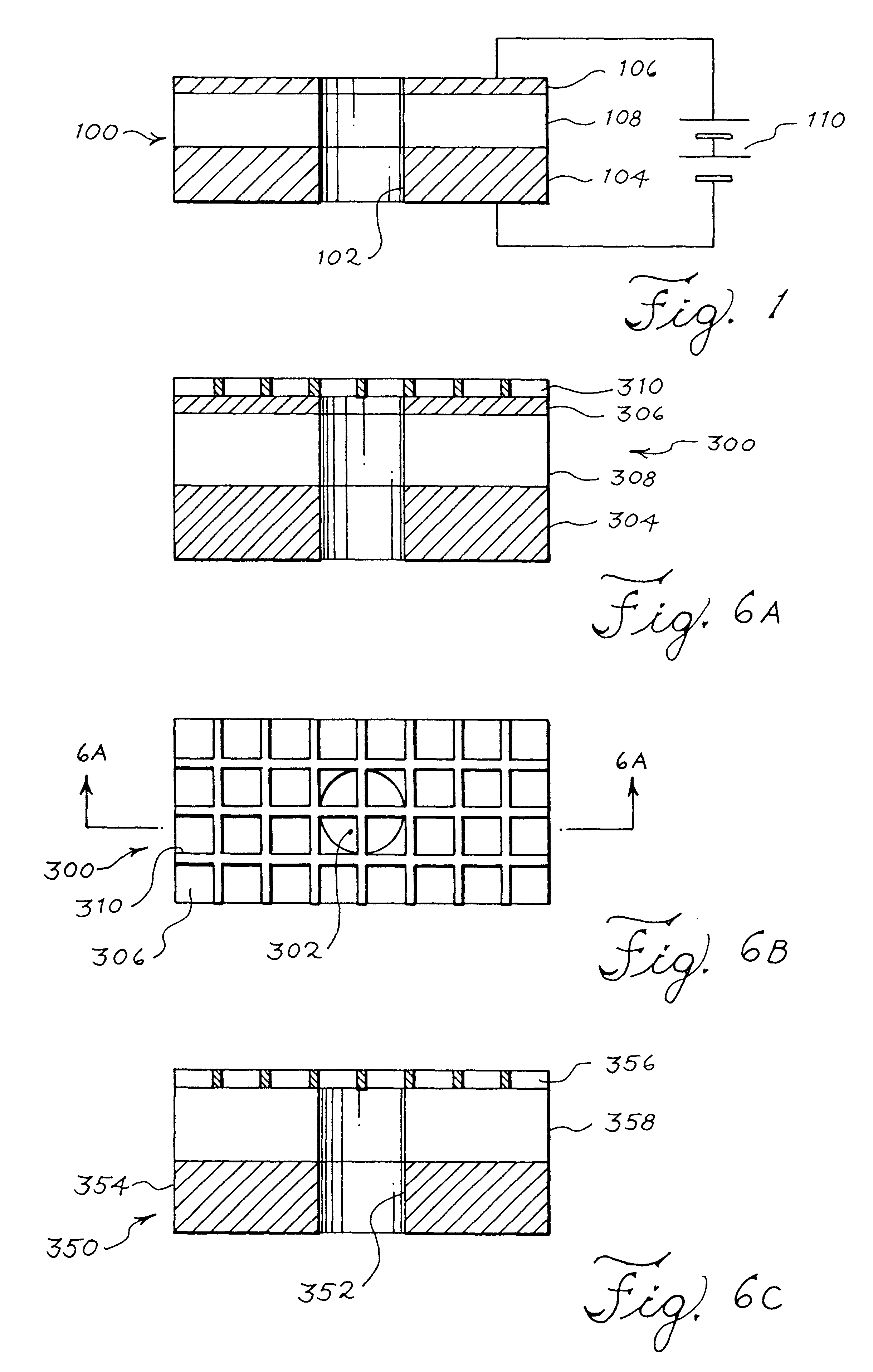

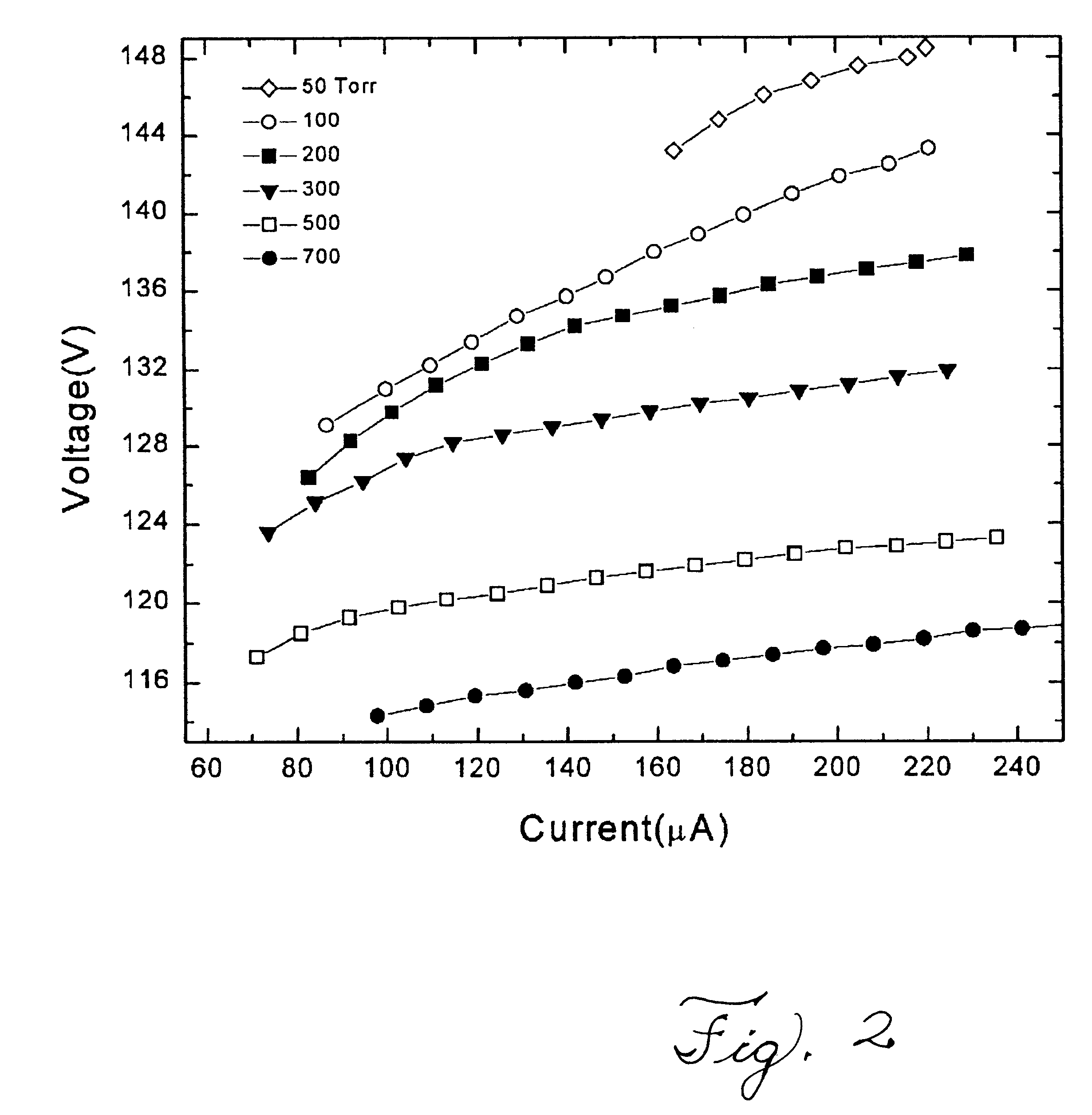

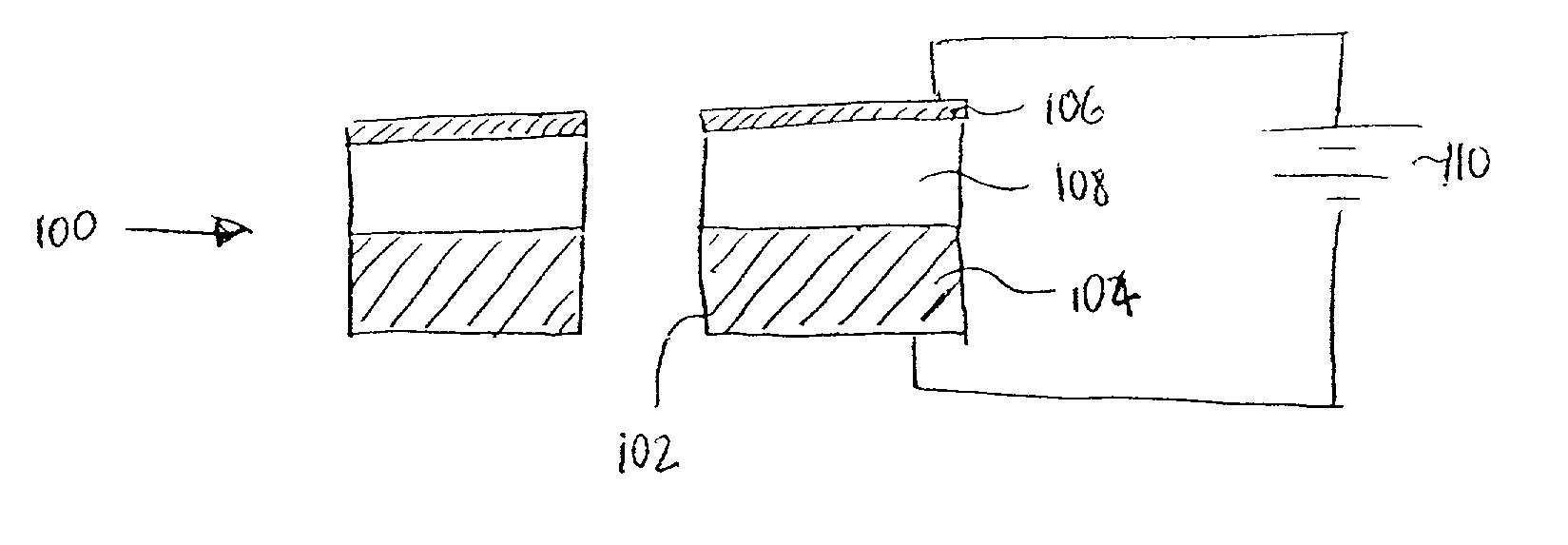

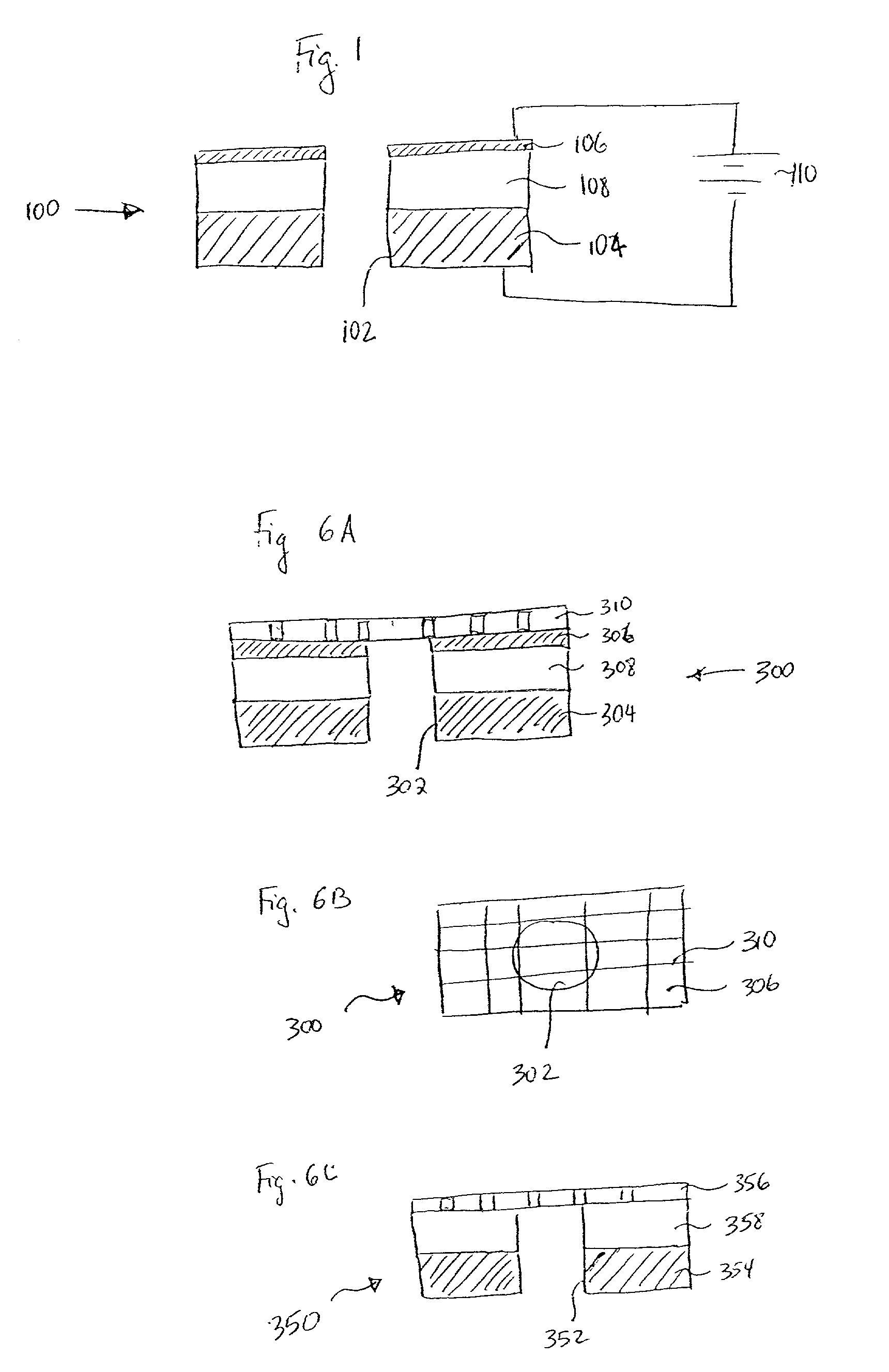

Microdischarge devices and arrays

InactiveUS6695664B2Reduce manufacturing costElectrical and optical characteristicMagnetronsDischarge tube luminescnet screensOptoelectronicsDielectric layer

A discharge device is described that contains an anode, a cathode, and an insulating layer disposed between the anode and the cathode. A cavity is extends entirely through at least one of the anode or cathode and penetrates the dielectric layer. At least one of the anode or cathode may include a screen or the dielectric layer may have a plurality of films with at least two different dielectric constants. The voltage differences between the anode and cathode in each of multiple devices electrically connected together may be limited.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

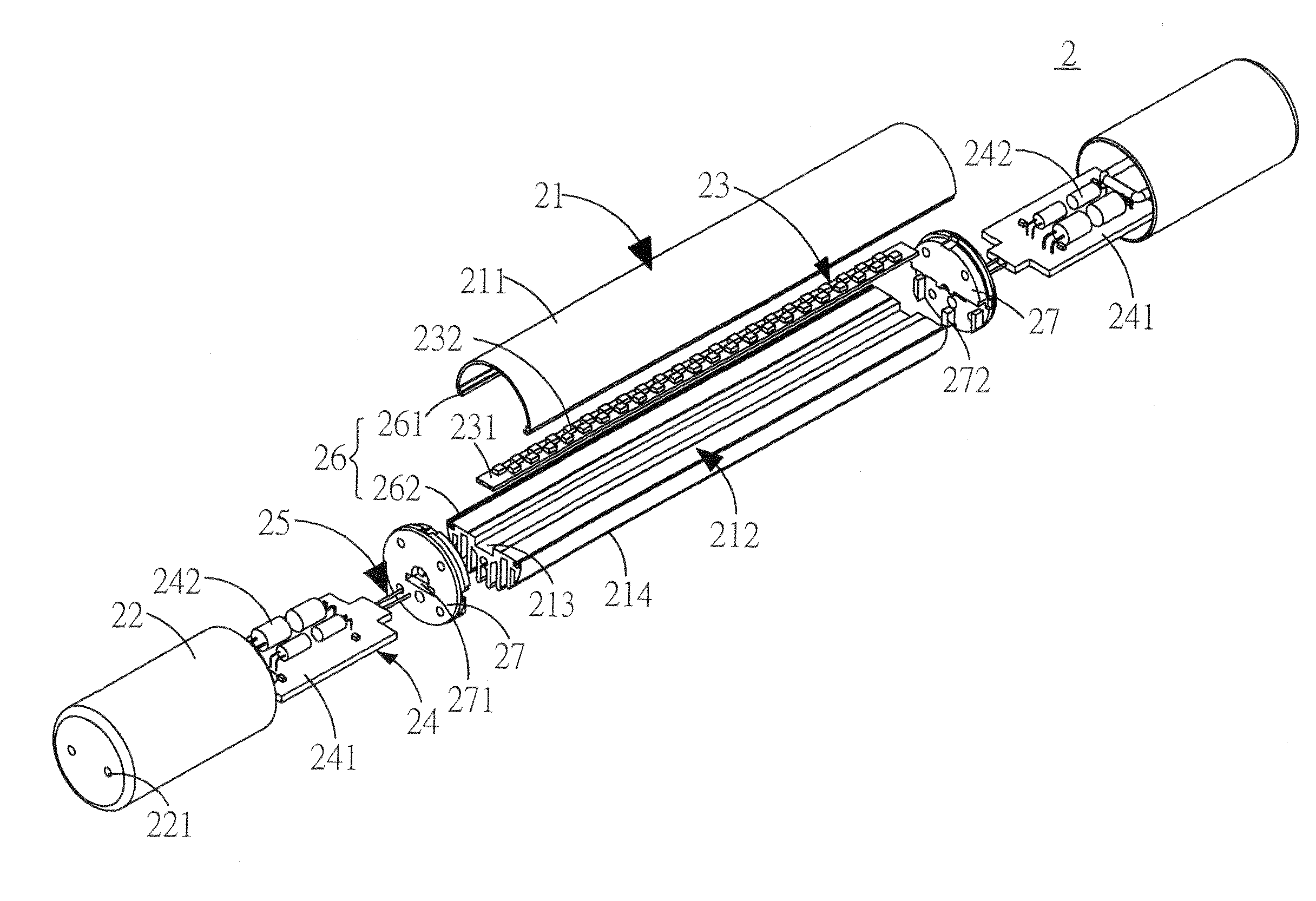

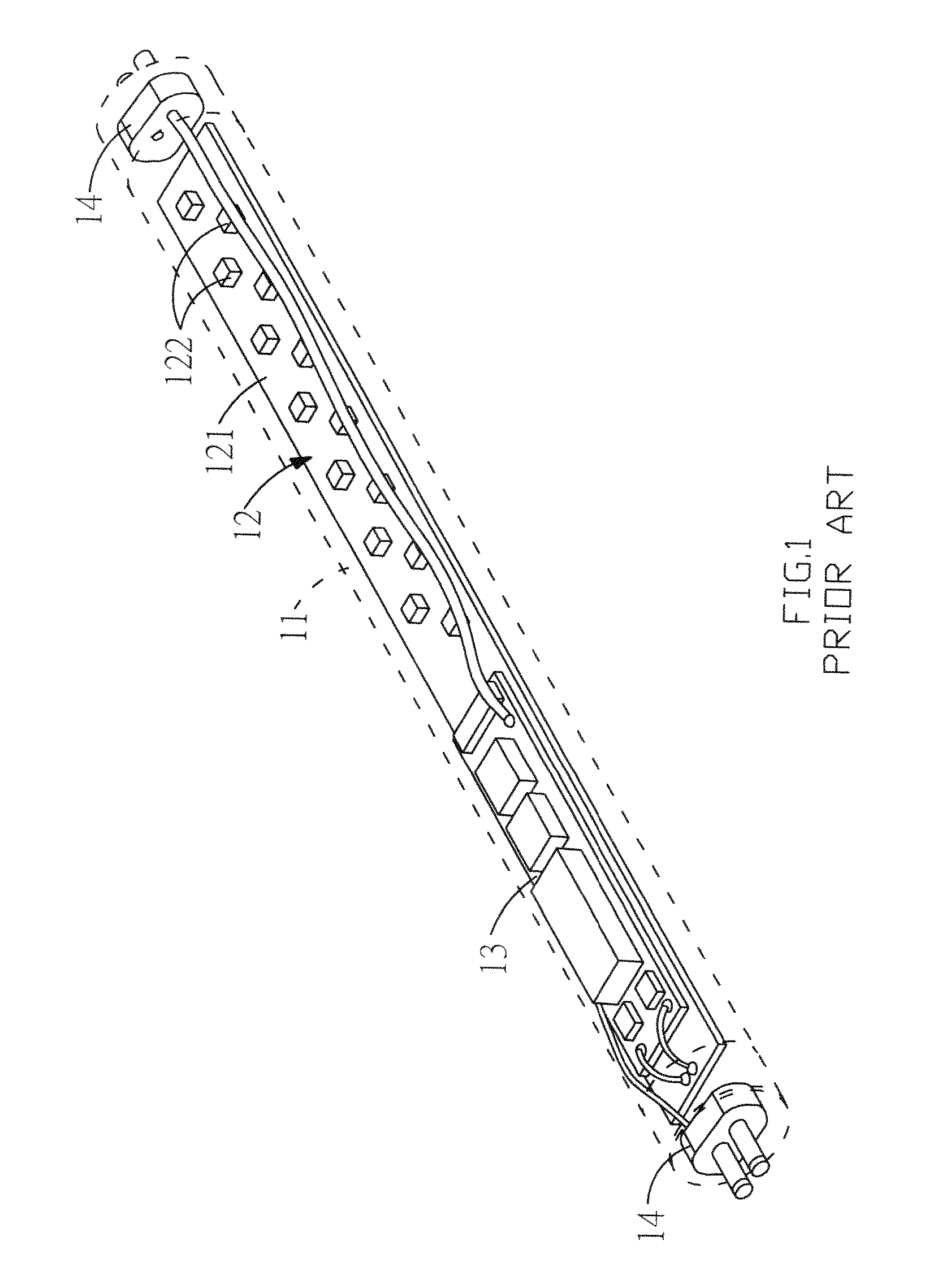

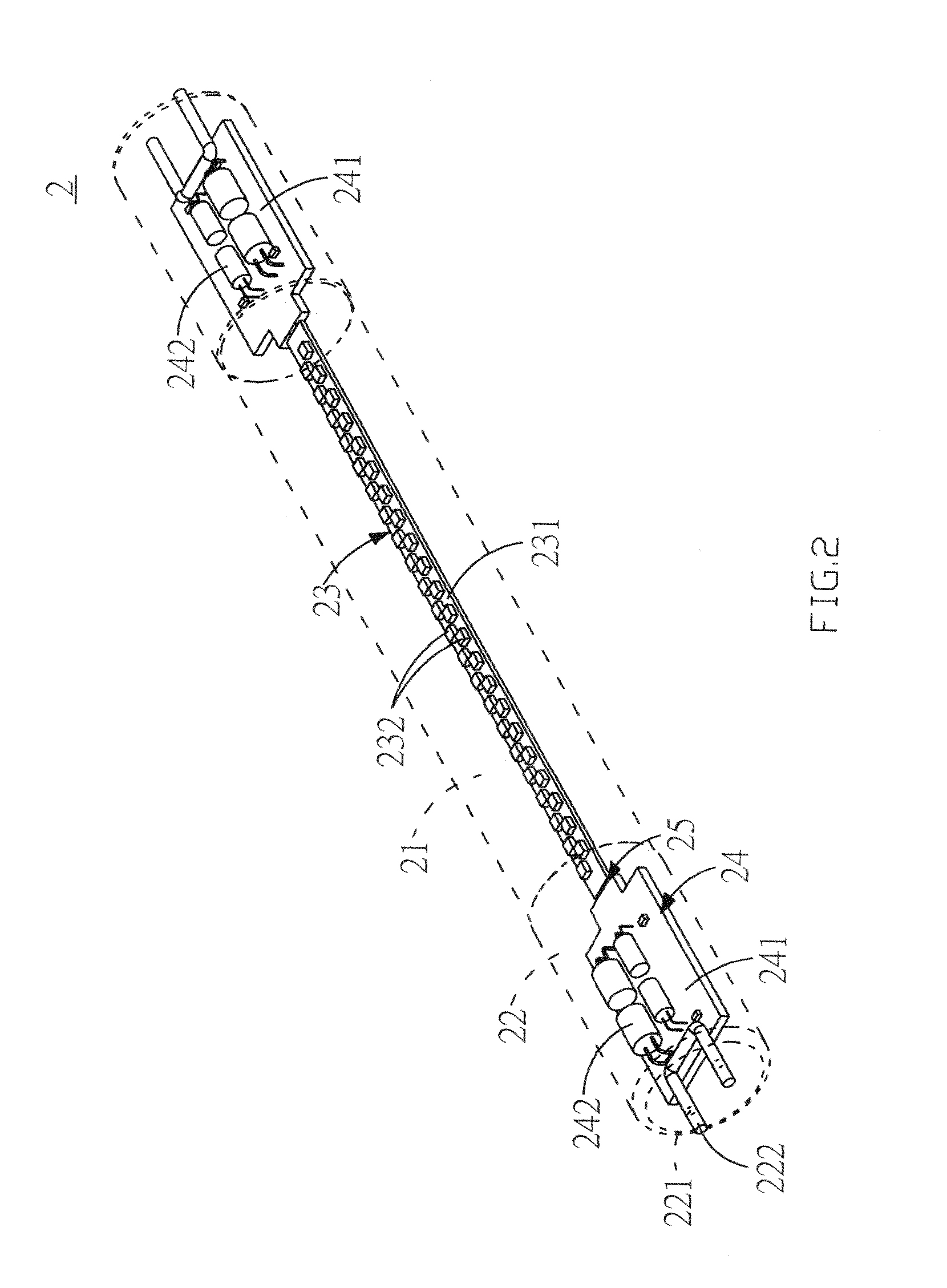

Separate LED lamp tube and light source module formed therefrom

InactiveUS8304993B2Low costPoint-like light sourceElongate light sourcesElectrical connectionEngineering

A lamp tube according to the present invention at least comprises: a tube body, a light-emitting module, a driving module and an electrical connection module. The light-emitting module and the driving module are disposed in the tube body. The light-emitting module is provided with a first circuit board and a plurality of LEDs. The driving module is provided with at least a second circuit board and a drive circuit. The electrical connection module forms an electrical connection between the first and second circuit boards. It is convenient to independently replace or repair the driving module or the light-emitting module without discarding the entire lamp tube so as to effectively save costs and achieve the effects of energy saving and environmental protection.

Owner:LEXTAR ELECTRONICS CORP

Microdischarge devices and arrays

InactiveUS20030080688A1Reduce manufacturing costElectrical and optical characteristicMagnetronsDischarge tube luminescnet screensOptoelectronicsDielectric layer

A discharge device is described that contains an anode, a cathode, and an insulating layer disposed between the anode and the cathode. A cavity is extends entirely through at least one of the anode or cathode and penetrates the dielectric layer. At least one of the anode or cathode may include a screen or the dielectric layer may have a plurality of films with at least two different dielectric constants. The voltage differences between the anode and cathode in each of multiple devices electrically connected together may be limited.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

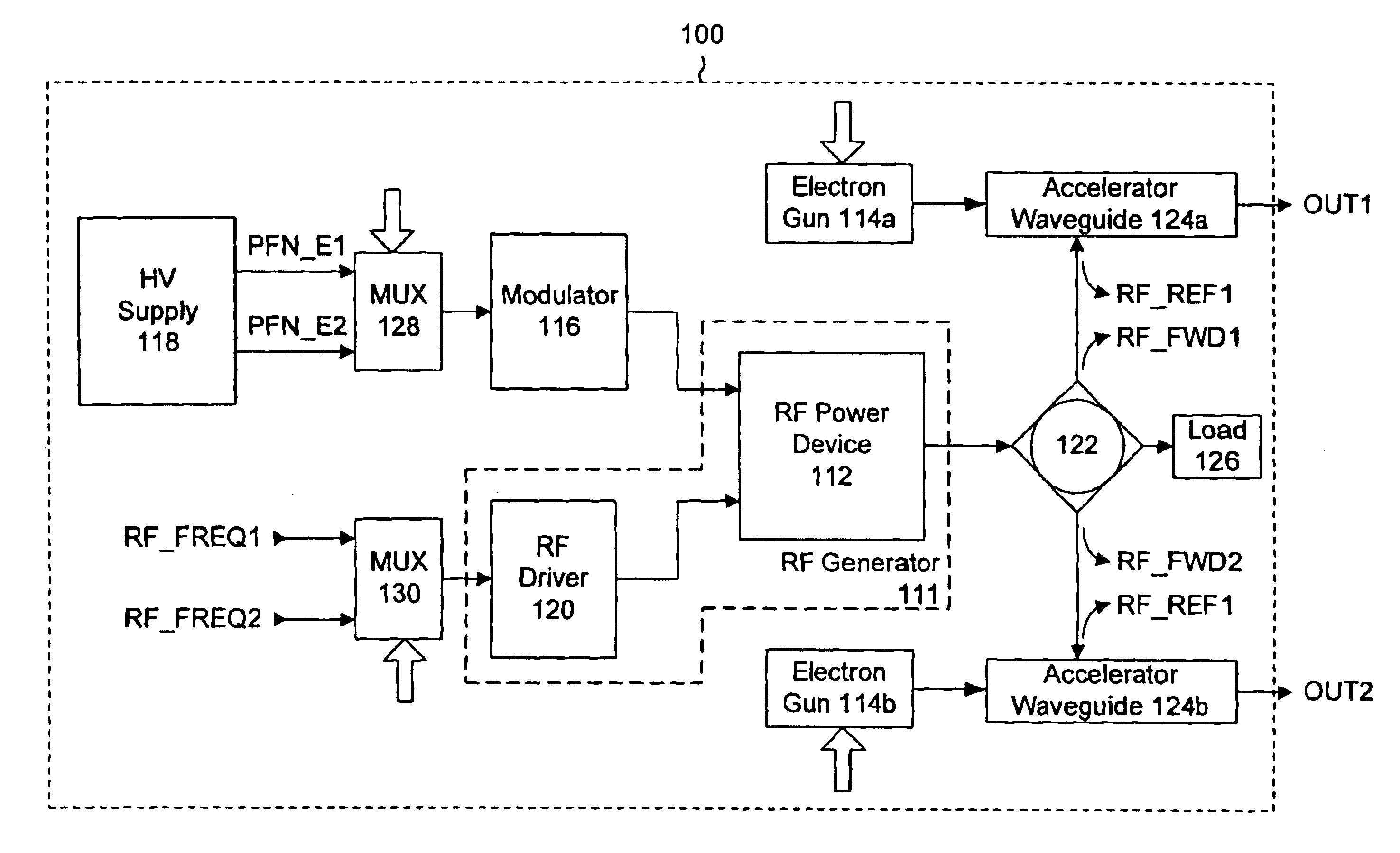

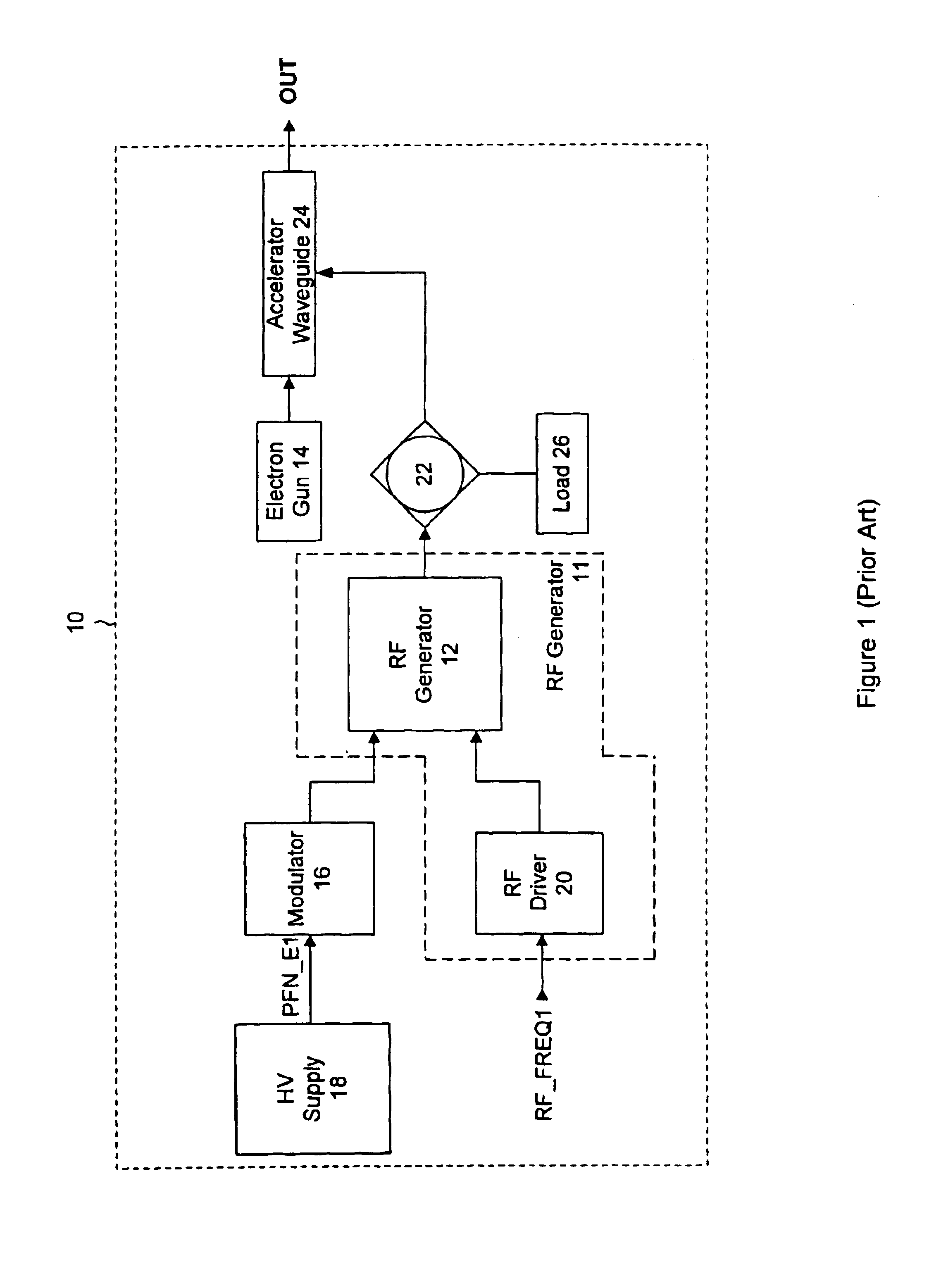

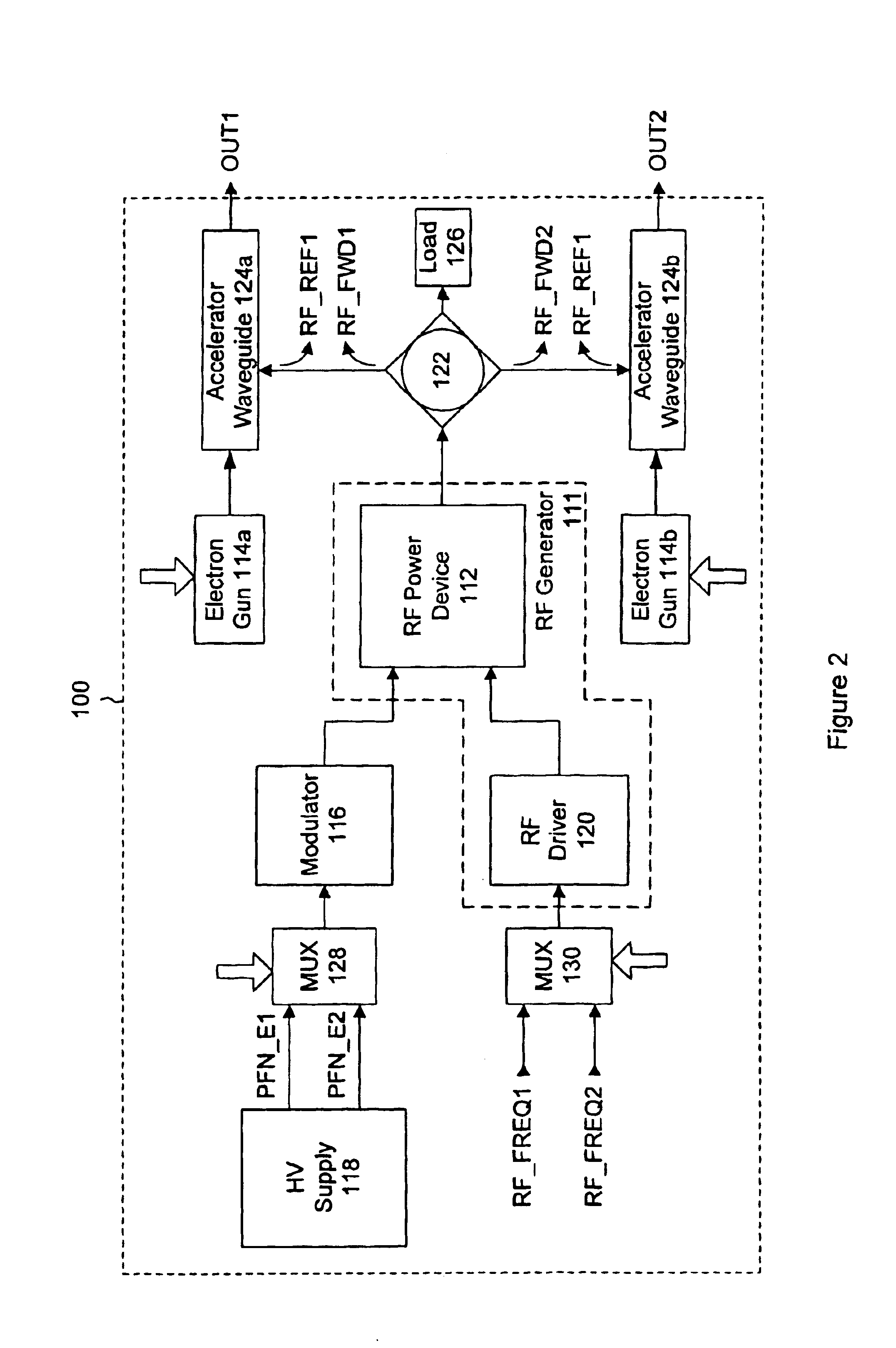

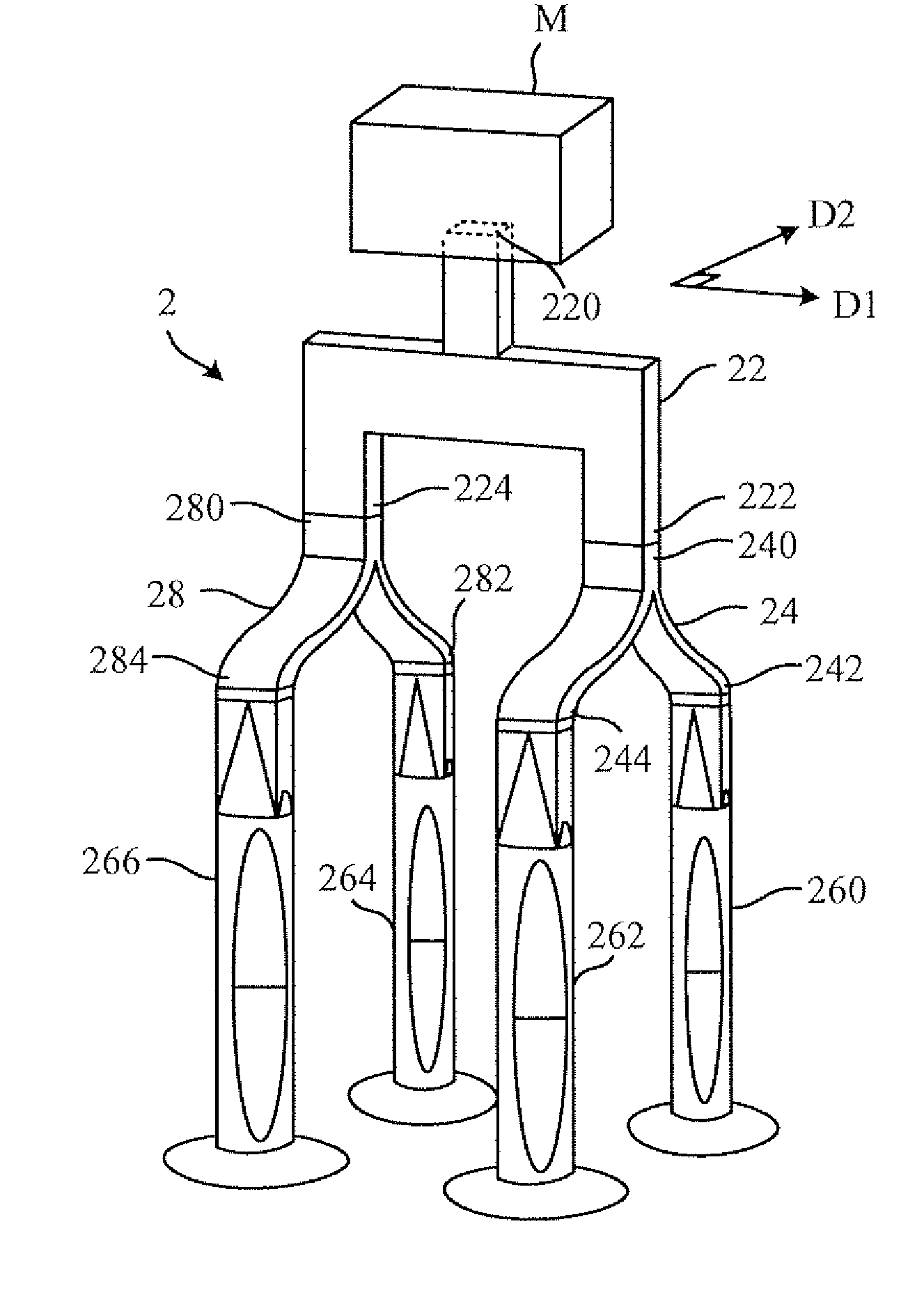

Multiple beam linear accelerator system

A multiple beam linear accelerator system and method where two or more accelerator waveguides are driven by a single high power microwave source. A single RF power system is multiplexed to drive the plurality of accelerator waveguides. Each accelerator waveguide is addressed at a different RF frequency, and the microwave source generates pulses at the appropriate RF frequency for each accelerator waveguide on a pulse-by-pulse basis.

Owner:MEVEX CORP

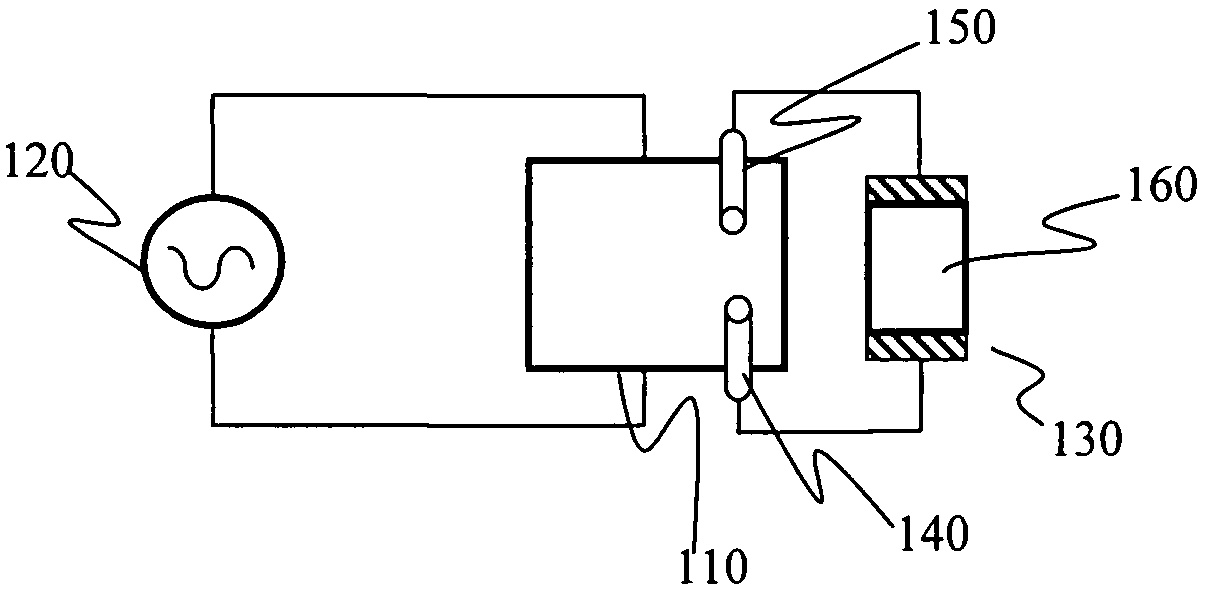

External resonator/cavity electrode-less plasma lamp and method of exciting with radio-frequency energy

ActiveUS20070075652A1Reduce the cost of the whole lampIncrease rangeMagnetronsAlternating current plasma display panelsCapacitanceRadio frequency energy

Described is a plasma electrode-less lamp. The device comprises an electromagnetic resonator and an electromagnetic radiation source conductively connected with the electromagnetic resonator. The device further comprises a pair of field probes, the field probes conductively connected with the electromagnetic resonator. A gas-fill vessel is formed from a closed, transparent body, forming a cavity. The gas-fill vessel is not contiguous with (detached from) the electromagnetic resonator and is capacitively coupled with the field probes. The gas-fill vessel further contains a gas within the cavity, whereby the gas is induced to emit light when electromagnetic radiation from the electromagnetic radiation source resonates inside the electromagnetic resonator, the electromagnetic resonator capacitively coupling the electromagnetic radiation to the gas, which becomes a plasma and emits light.

Owner:TOPANGA USA

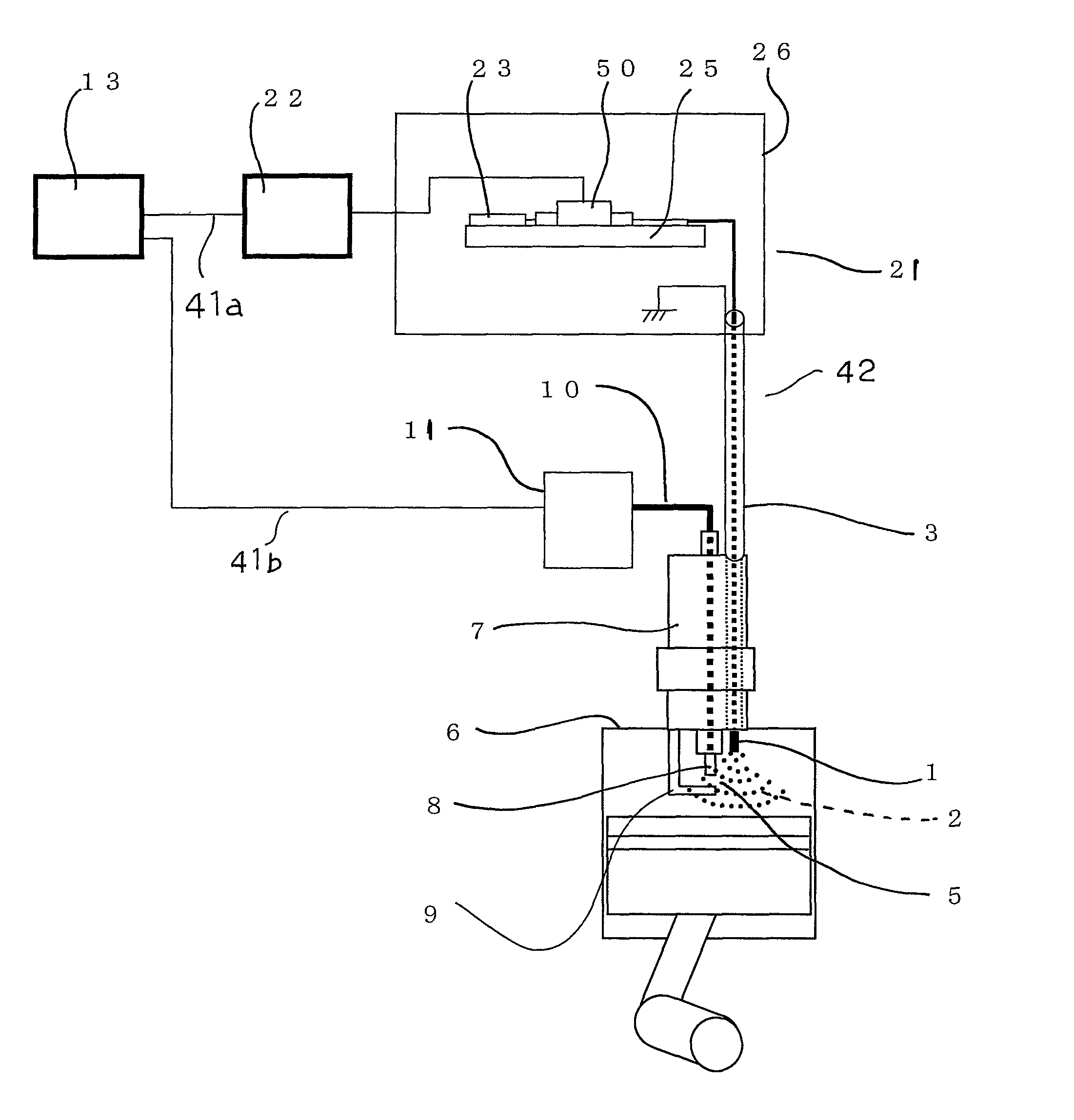

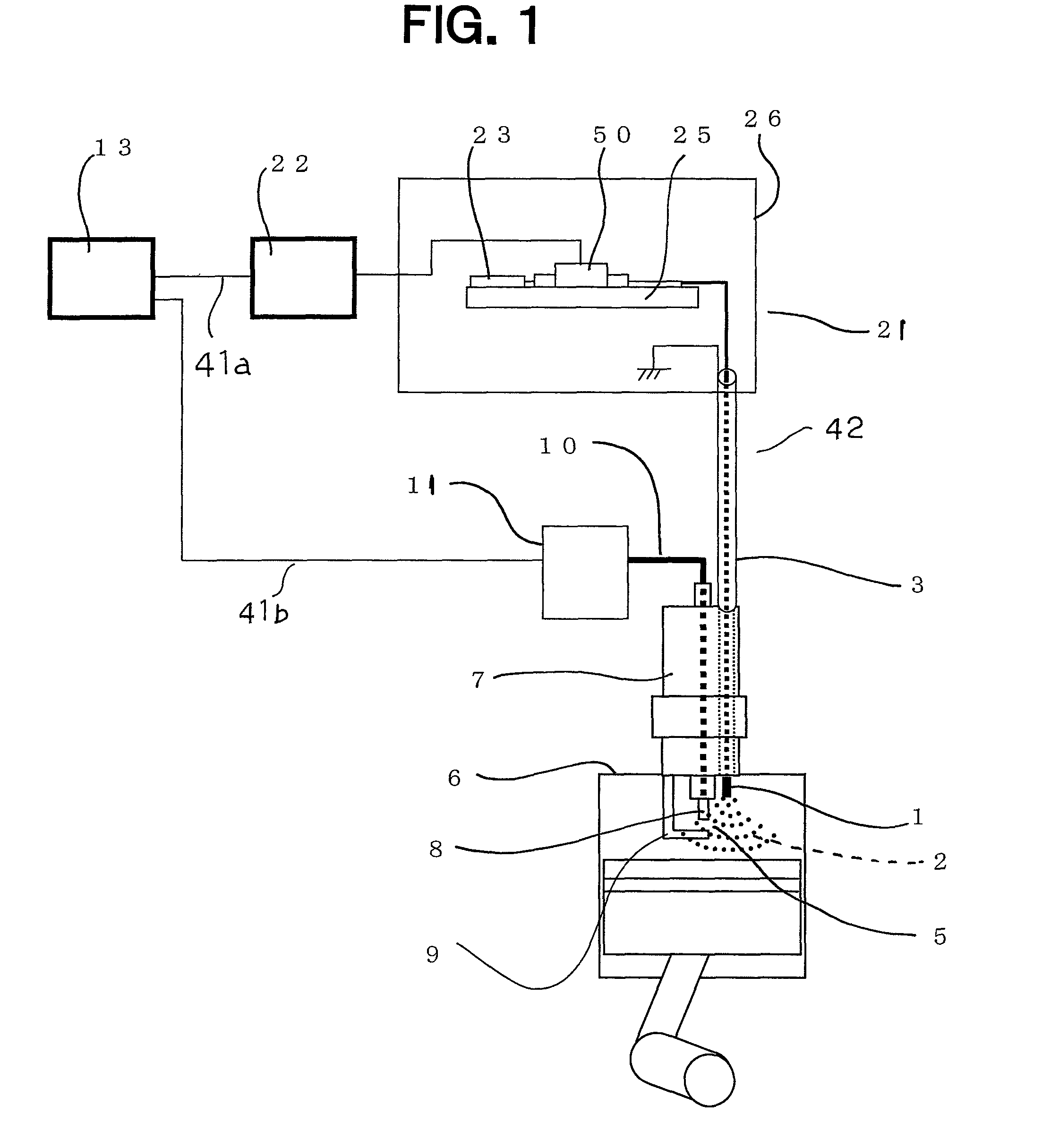

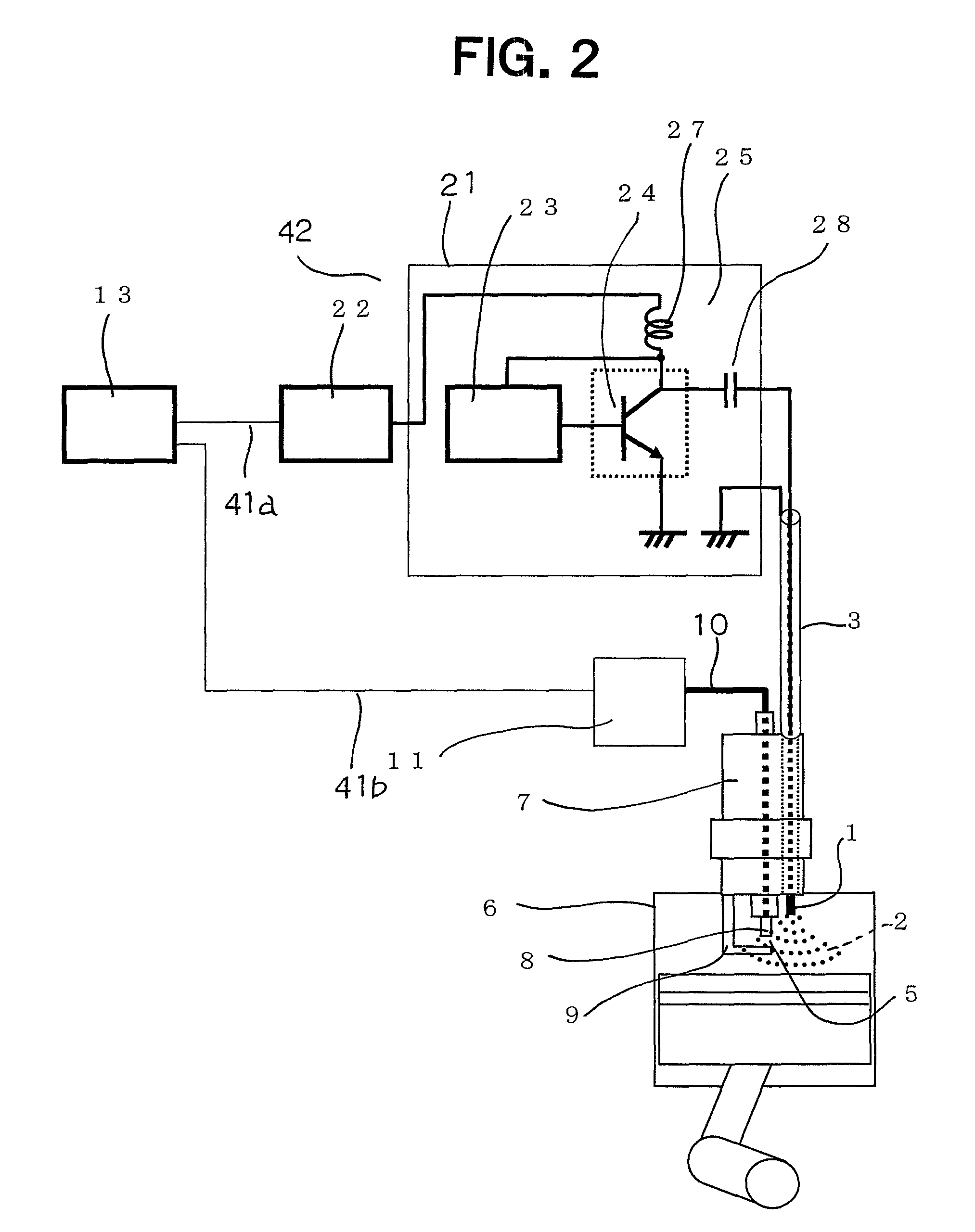

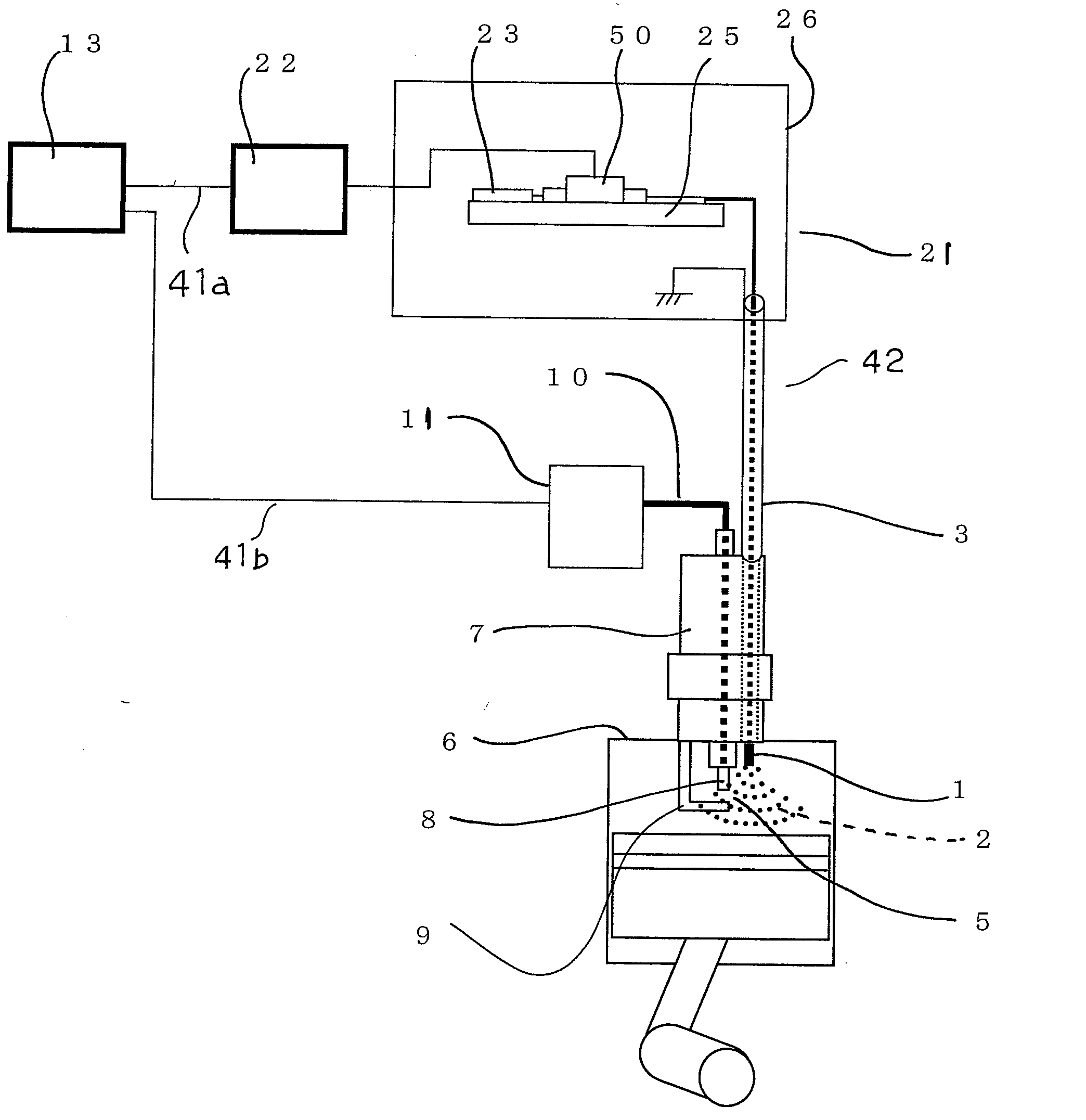

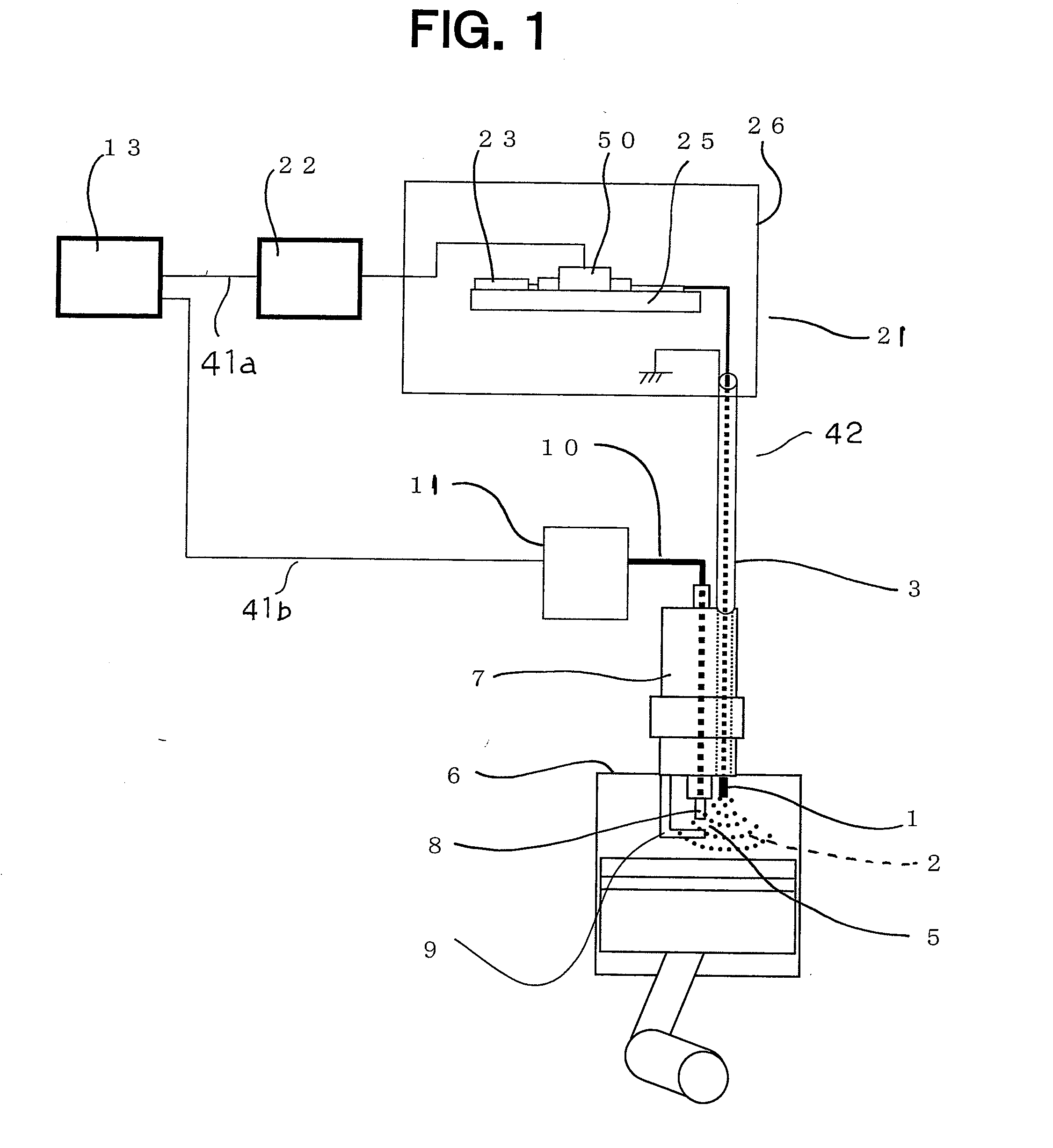

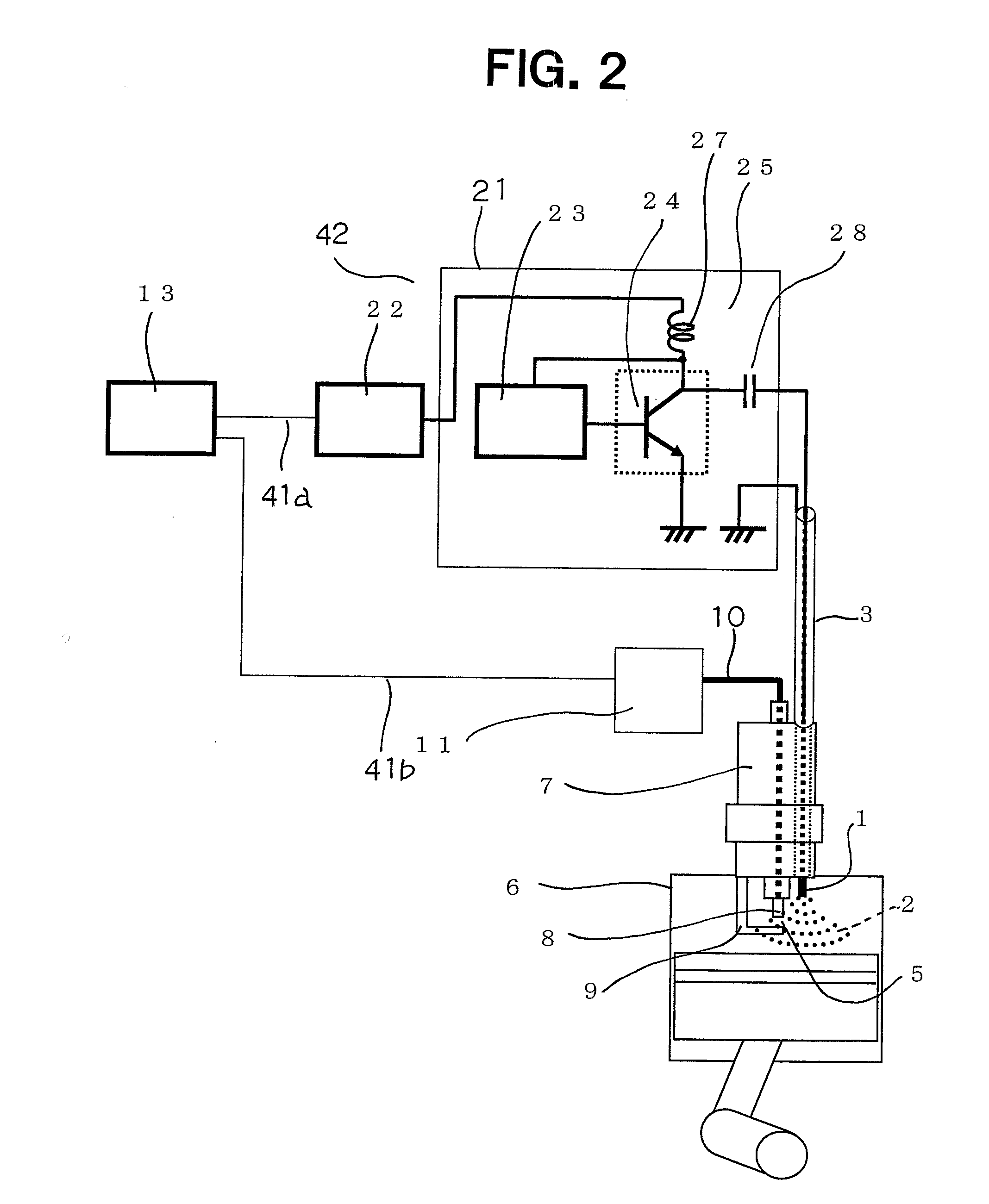

Ignition apparatus for an internal combustion engine

An ignition apparatus for an internal combustion engine is small in size and has high reliability capable of withstanding or enduring a vibration environment of a vehicle to which the ignition apparatus is installed. The ignition apparatus includes a spark plug that has its tip end portion presented in the interior of a cylinder of an internal combustion engine main body, a high voltage generation power supply that serves to apply a high voltage to the spark plug, a microwave oscillation device that has an amplifying element for generating a microwave, and a microwave antenna that is mounted on the spark plug, irradiates the micro wave generated from the microwave oscillation device to the interior of the cylinder, thereby forming a plasma generation region around discharge electrodes of the spark plug. The microwave oscillation device is made into a solid state.

Owner:MITSUBISHI ELECTRIC CORP

Preparation method for oxygen-free copper tube for magnetron

ActiveCN102605192AReduce oxygen contentOxygen isolationMagnetronsTransit-tube cathodesGranularityLanthanum

The invention relates to a preparation method for an oxygen-free copper tube for a magnetron. The preparation method is characterized in that the contents of copper and silver in a material of the oxygen-free copper tube is larger than or equal to 99.97%, and oxygen content is smaller than or equal to 0.001%. The preparation method includes following process steps: 1, smelting: placing number 1 high-purity cathode copper in a power frequency induction furnace with a core, raising the temperature of the furnace to smelt the cathode copper into copper liquid, adding lanthanum with the mass fraction ranging from 0.01% to 0.016% into the copper liquid, keeping the copper liquid at the temperature of 1170 + / -10 DEG , and covering a charcoal layer with the thickness ranging from 100mm to 120mm and the charcoal granularity ranging from 40mm to 60mm on the surface of the copper liquid; 2, upward continuous casting; 3, precise cold rolling; 4, recrystallization; 5, cold drawing forming; and 6,finishing. The oxygen content is low, electric conduction is excellent, yield is high, and metal loss is low.

Owner:江阴和宏特种材料有限公司

Ignition apparatus for an internal combustion engine

An ignition apparatus for an internal combustion engine is small in size and has high reliability capable of withstanding or enduring a vibration environment of a vehicle to which the ignition apparatus is installed. The ignition apparatus includes a spark plug that has its tip end portion presented in the interior of a cylinder of an internal combustion engine main body, a high voltage generation power supply that serves to apply a high voltage to the spark plug, a microwave oscillation device that has an amplifying element for generating a microwave, and a microwave antenna that is mounted on the spark plug, irradiates the micro wave generated from the microwave oscillation device to the interior of the cylinder, thereby forming a plasma generation region around discharge electrodes of the spark plug. The microwave oscillation device is made into a solid state.

Owner:MITSUBISHI ELECTRIC CORP

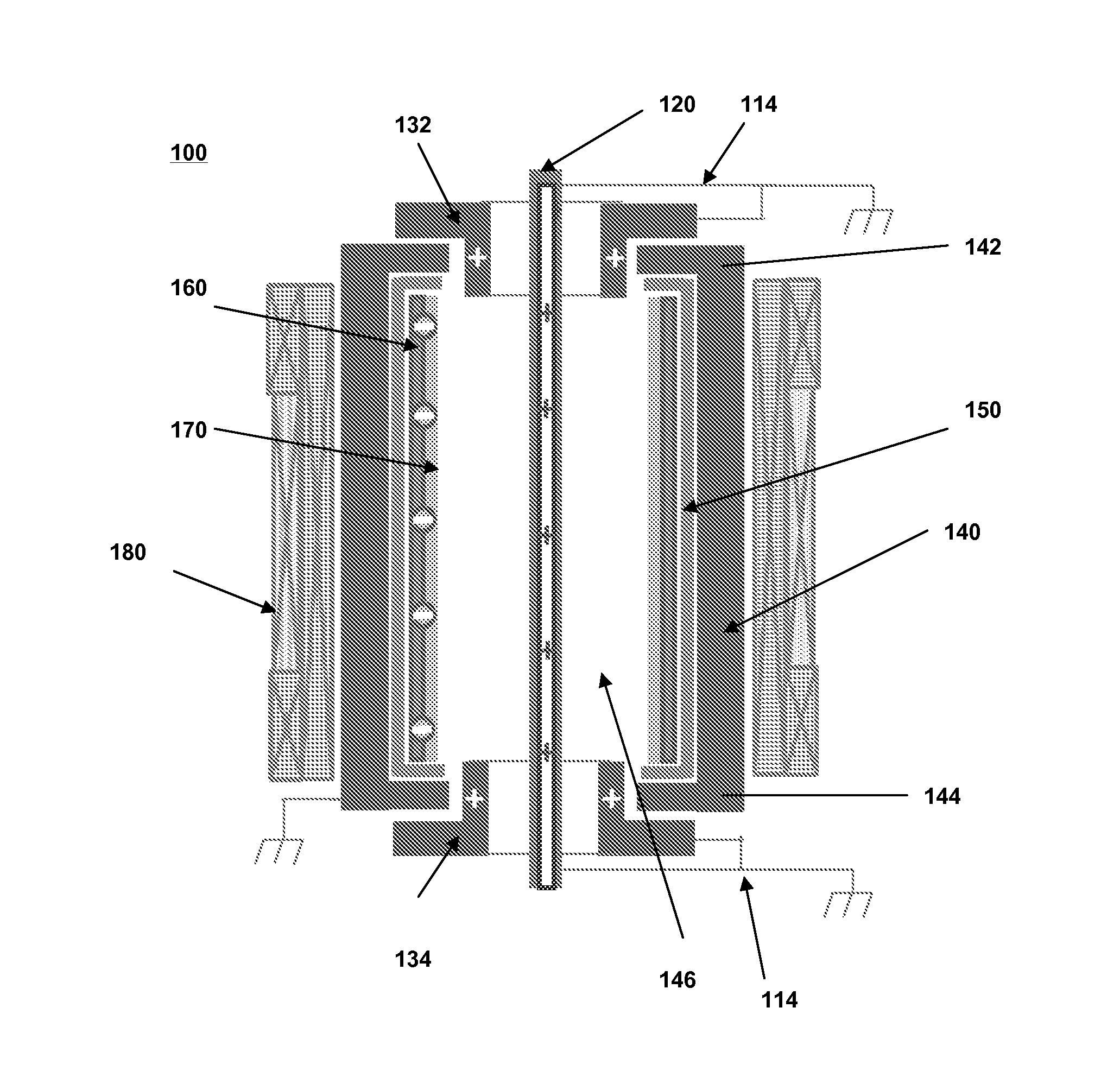

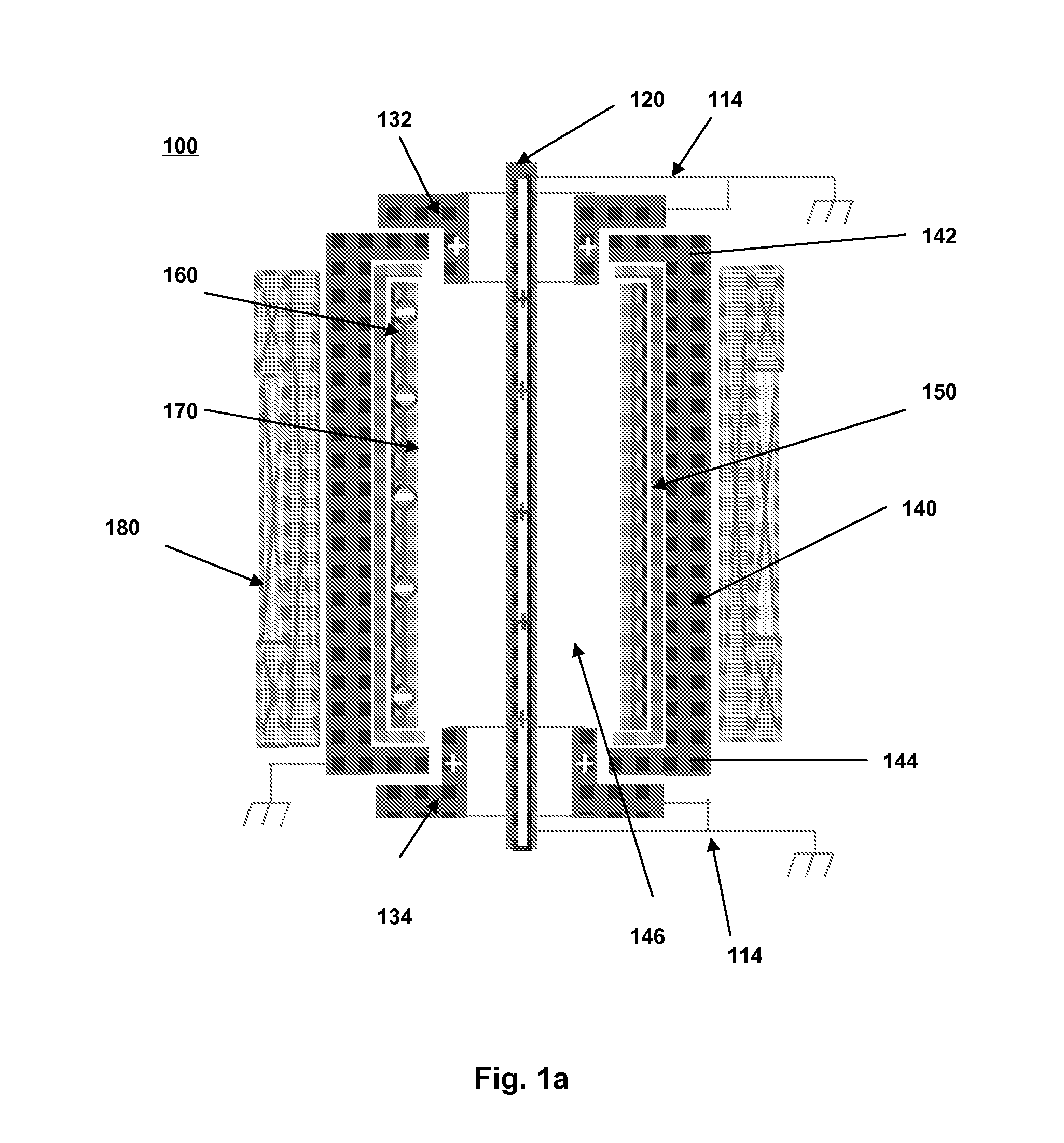

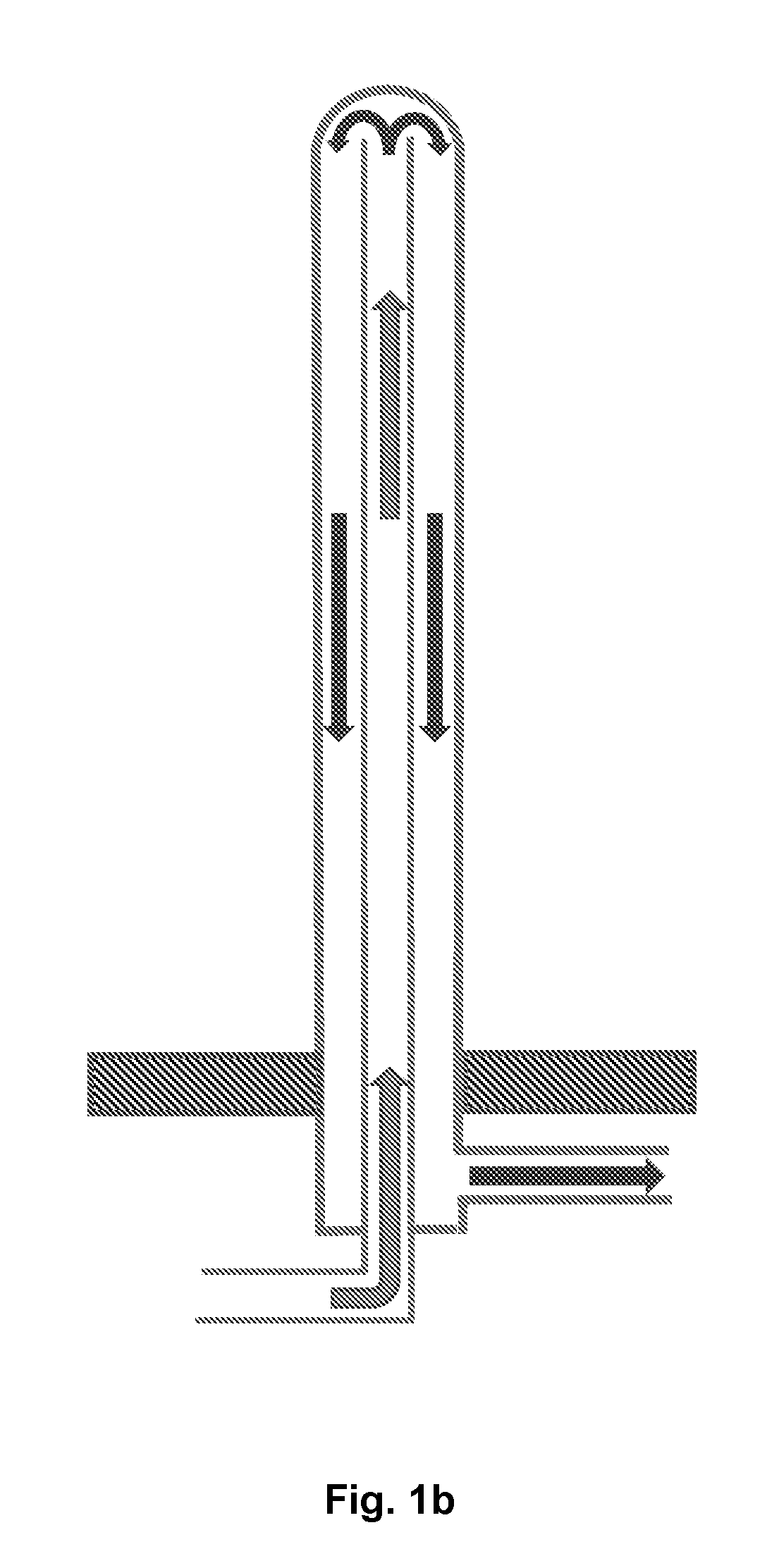

Inverted cylindrical magnetron (ICM) system and methods of use

An Inverted Cylindrical Magnetron (ICM) System and Methods of Use is disclosed herein generally comprising a co-axial central anode concentrically located within a first annular end anode and a second annular end anode; a process chamber including a top end and a bottom end in which the first annular end anode and the second annular end anode are coaxially disposed, whereby the first annular end anode, the second annular end anode, and the central anode form a 3-anode configuration to provide electric field uniformity, and the process chamber including a central annular space coupled to a tube insulator disposed about the central annular space wall; a cathode concentrically coupled to the tube insulator and a target; and a plurality of multi-zone electromagnets or hybrid electro-permanent magnets surrounding the exterior of the process chamber providing a tunable magnetic field.

Owner:VACTRONIX SCI LLC

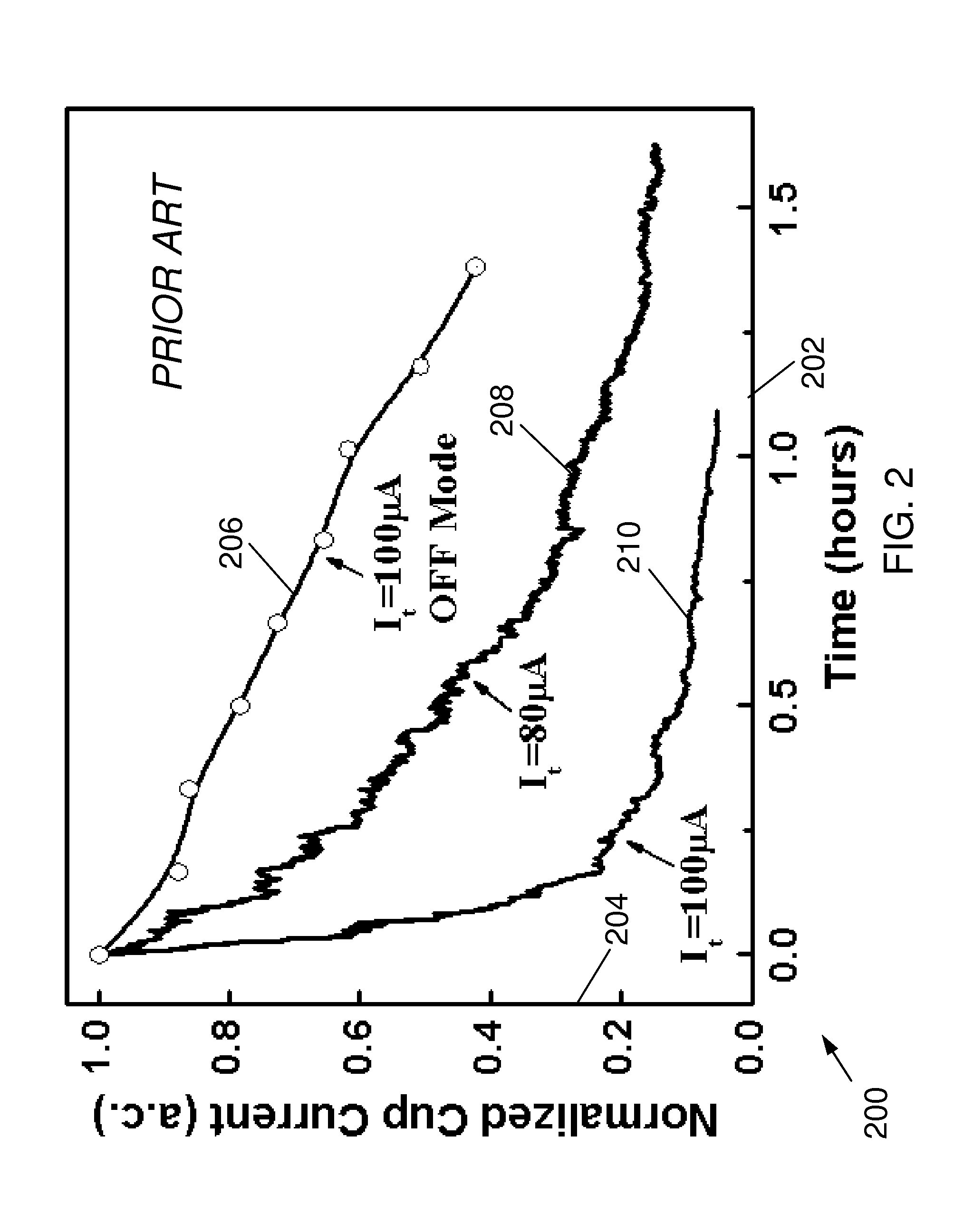

Stable cold field emission electron source

ActiveUS8736170B1Improved emission stabilityReduce noiseMagnetronsTransit-tube electron/ion gunsConventional transmission electron microscopeDesorption

A cold field emission (CFE) electron source for a focused electron beam system such as a transmission electron microscope (TEM), scanning transmission electron microscope (STEM), or scanning electron microscope (SEM) is disclosed. The source employs an emitter enclosure electrode behind the CFE tip which, in conjunction with the extractor electrode, defines a closed volume that can be thoroughly cleaned by electron impact desorption (EID) and radiative heating from a heated filament located between the emitter enclosure electrode and extractor electrode. The extractor electrode may have a counterbore which restricts backscattered electrons generated at the extractor from reaching portions of the source and gun which have not been cleaned by EID. Pre-cleaning of the emitter enclosure electrode and extractor electrode prior to cold field emission substantially improves both source emission stability and frequency noise characteristics, enabling source operation over time intervals adequate for application to TEMs, STEMs, and SEMs.

Owner:FEI CO

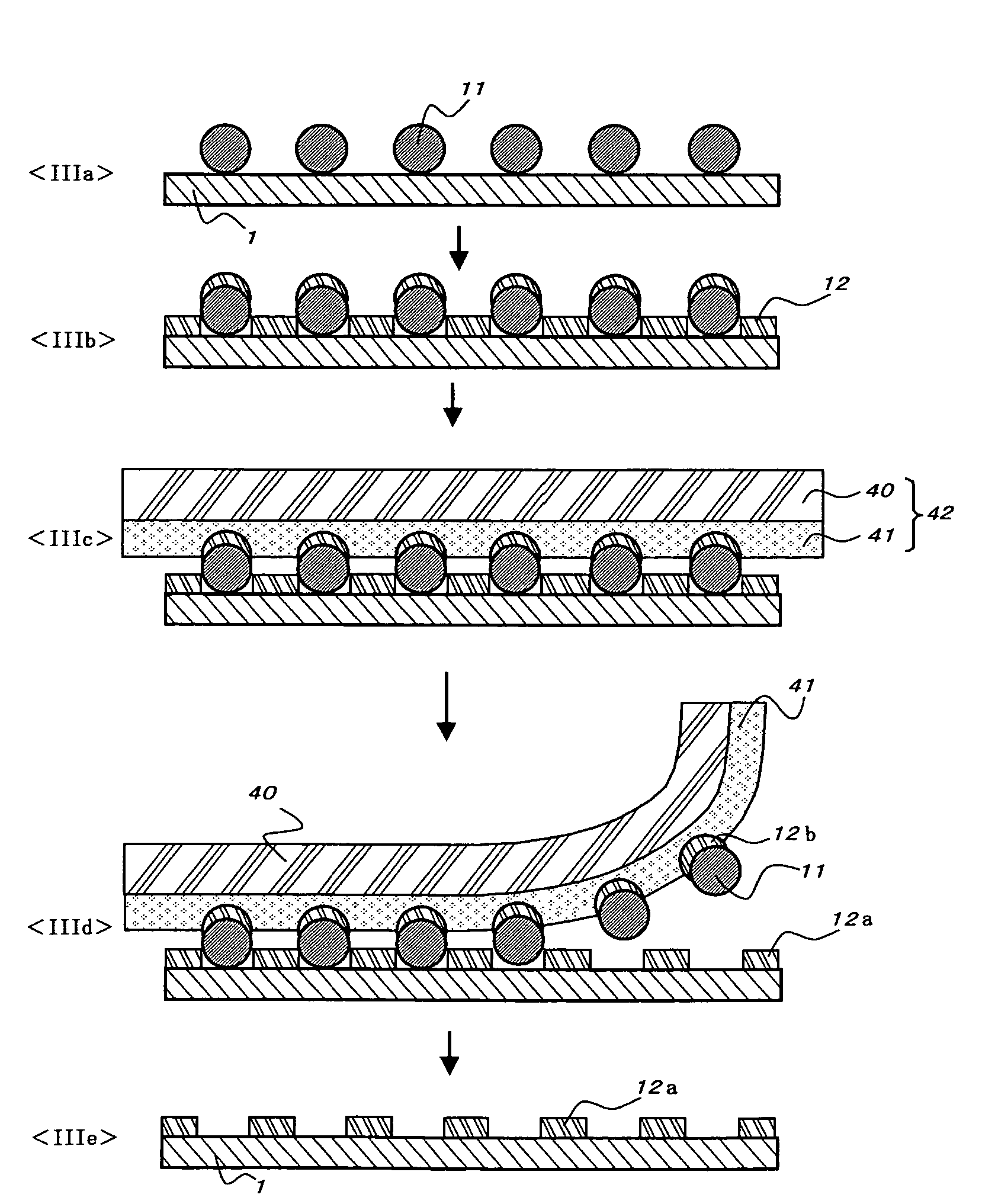

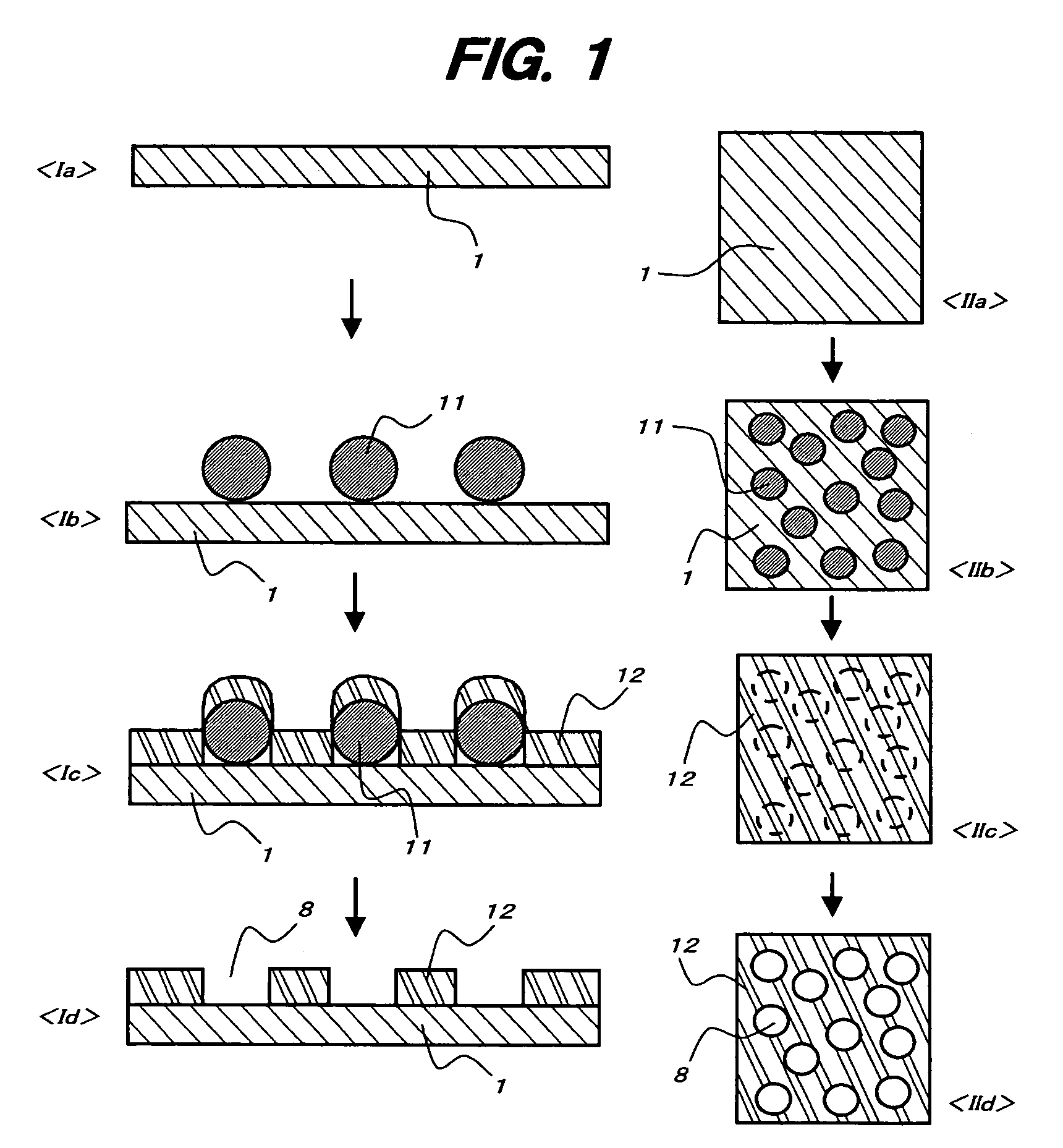

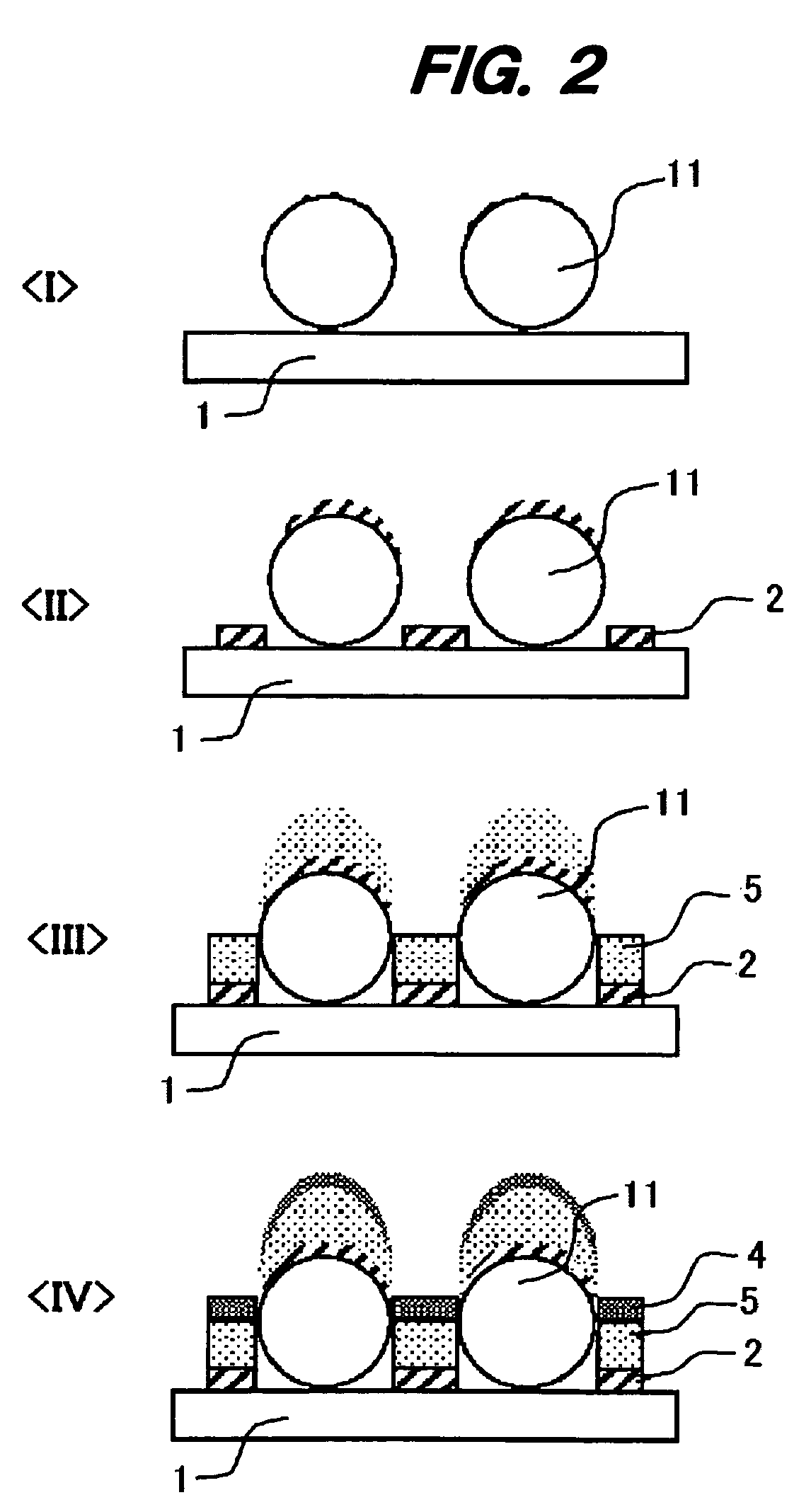

Porous thin-film-deposition substrate, electron emitting element, methods of producing them, and switching element and display element

A method of producing a porous thin-film-deposition substrate, which has the steps of: placing onto a substrate that has an electrostatic charge on its surface, fine particles with a surface electrostatic charge opposite to the electrostatic charge of the substrate surface, depositing a thin film on the fine-particle-placed substrate, and then removing the fine particles to form fine pores in the thin film; further, a method of producing an electron emitting element, which has the steps of: adding a catalyst metal on a substrate, placing fine particles onto the catalyst-added substrate, depositing a thin film on the fine-particle-placed substrate, then removing the fine particles to form fine pores in the film, and growing needle-shaped conductors on the catalyst metal that is exposed on a bottom face of the fine pore.

Owner:FUJIFILM CORP

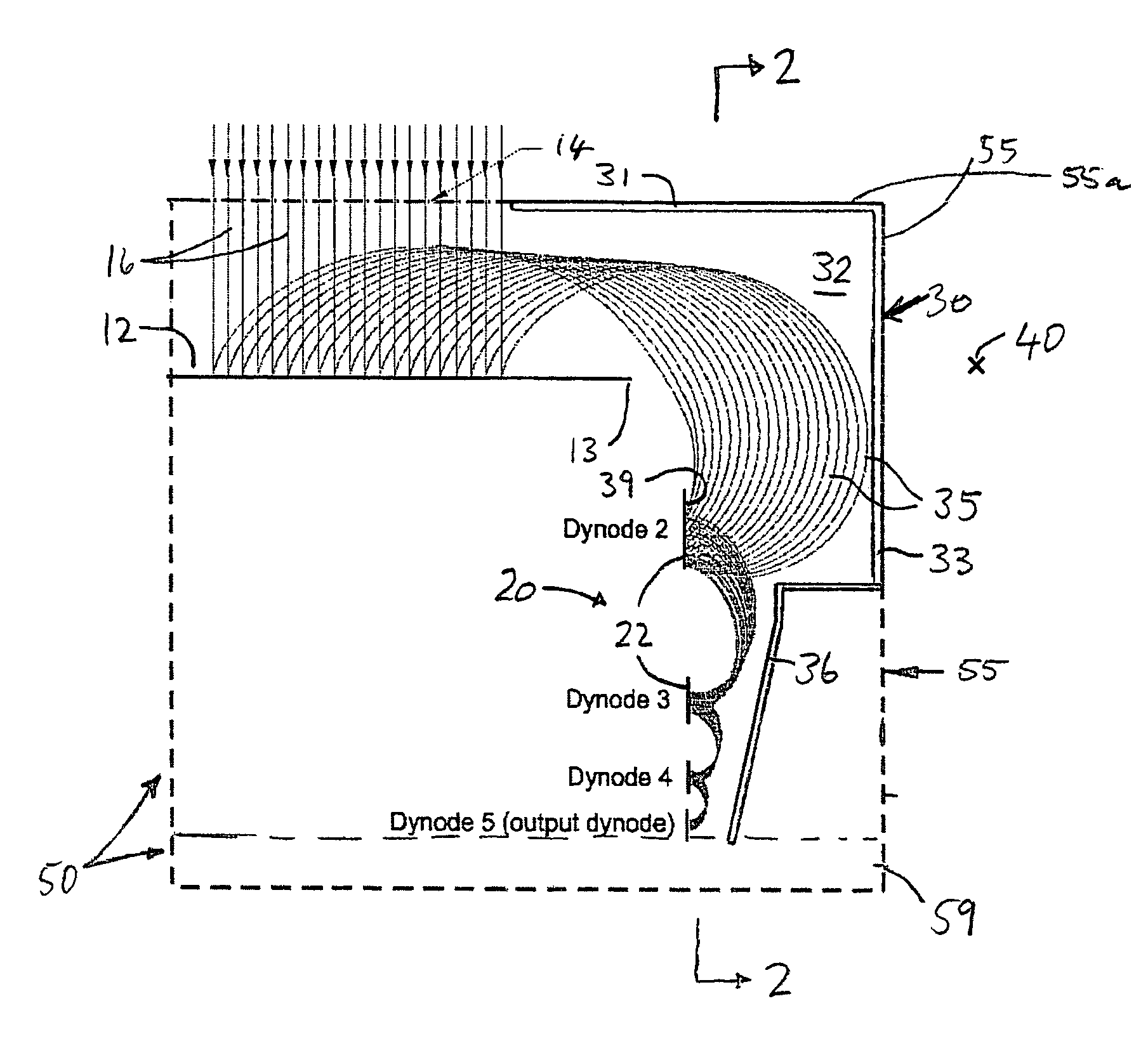

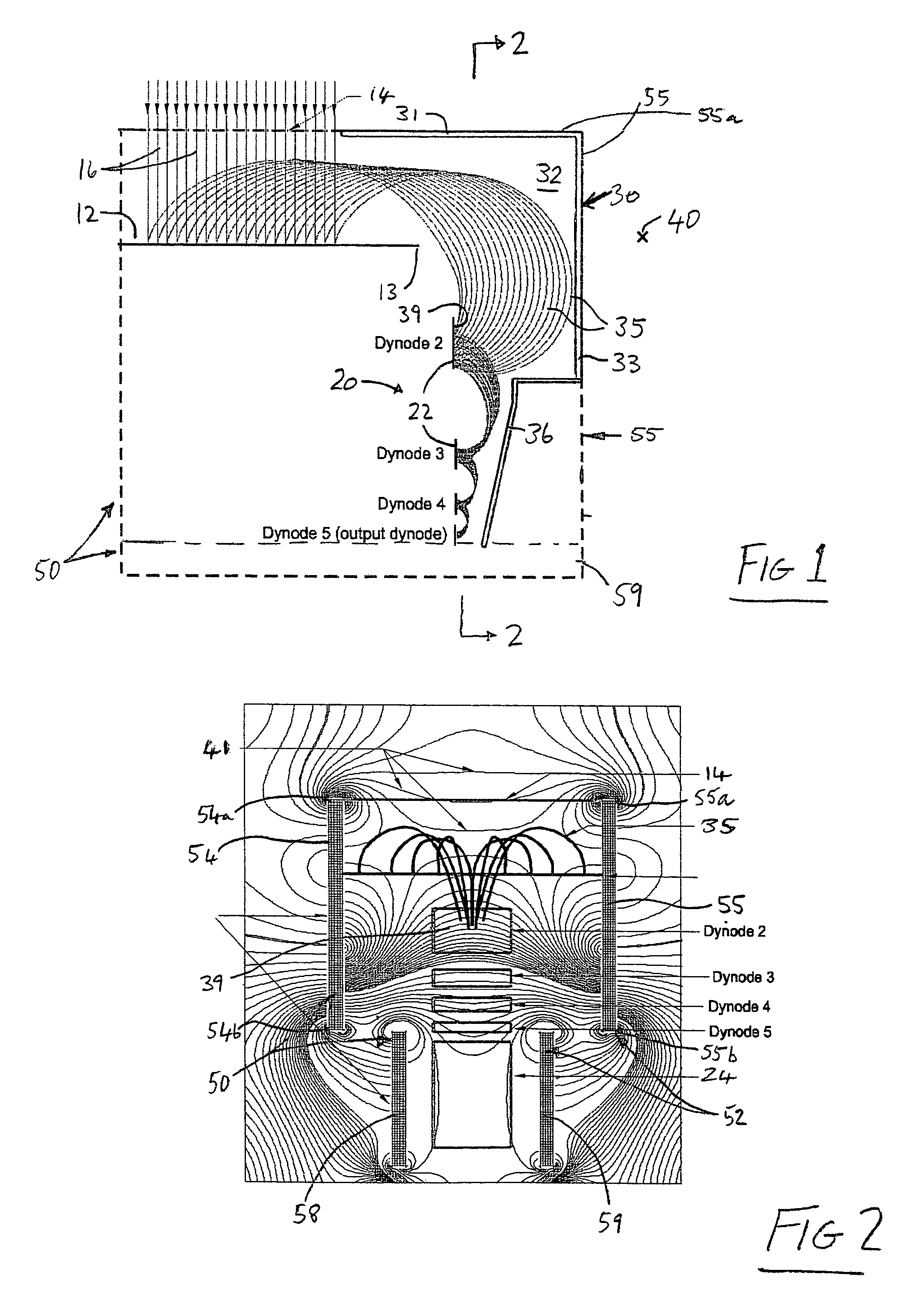

Particle detection by electron multiplication

ActiveUS6982428B2Great magnification and focussing capabilityVacuum tubesMagnetronsElectron multiplicationElectron trajectory

Electron focussing apparatus includes a cathode plate defining an impact surface on which particles impact, which surface has a finite probability of generating at least one electron for each impacting particle having predetermined characteristics. The apparatus also has an electron receiving element, and respective means for generating electrostatic and magnetic fields in a space extending from the impact surface to the electron receiving element. The means for generating the electrostatic and magnetic fields are configured whereby the E / B2 ratio adjacent the electron receiving element is smaller than adjacent the impact surface, whereby to decrease the radius of curvature of the electron trajectories adjacent the electron receiving element relative to adjacent the impact surface and to thereby focus the electron trajectories in at least one dimension. In another aspect the electron receiving element is positioned and the means for generating the electrostatic and magnetic fields are configured to cause the electrons to deflect on average through greater than 180° before impacting the electron receiving element, whereby to focus, in at least one dimension, multiple electrons generated from any given area of the impact surface to a smaller area at the electron receiving element.

Owner:ETP ION DETECT PTY LTD

Microwave supplying apparatus and microwave plasma system

The invention discloses a microwave supplying apparatus including a microwave generator, a first power divider, a second power divider, a first waveguide, and a second wave guide. The first waveguide is connected to the microwave generator and has a first output terminal and a second output terminal to divide a microwave generated by the microwave generator along a first direction. The second power divider is connected to the first output terminal and has a third output terminal and a fourth output terminal to divide the microwave along a second direction. The first waveguide and the second waveguide are connected to the third output terminal and the fourth terminal respectively and receive the microwave through the first power divider and the second power divider to respectively output the microwave fields with approximate intensity distributions.

Owner:NAT CHUNG SHAN INST SCI & TECH

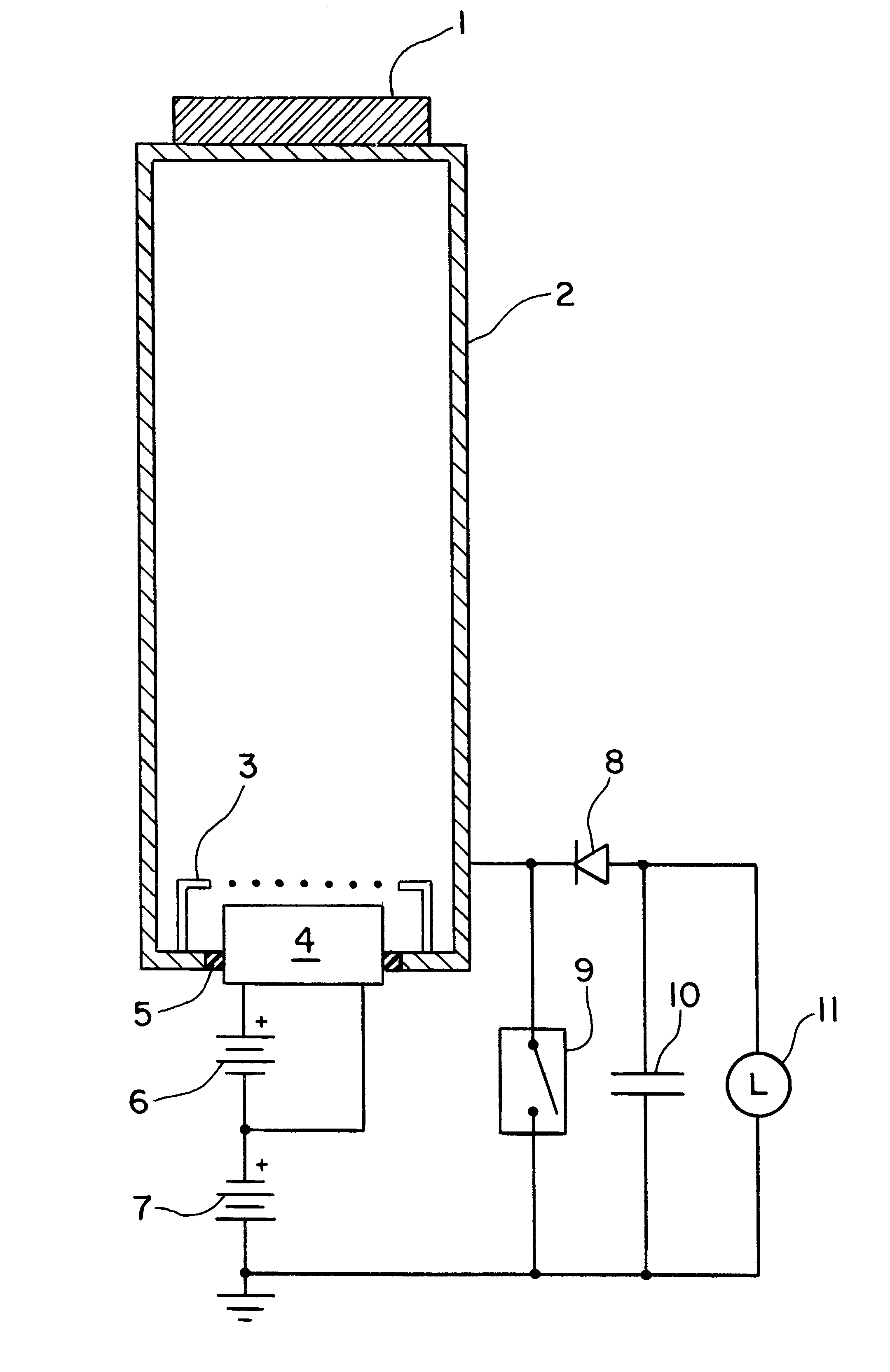

Method and system for energy conversion using a screened-free-electron source

InactiveUS6465965B2Avoid chargingOther heat production devicesExcitation process/apparatusCapacitanceElectron source

A method and device for providing power to a load are disclosed. A beam of free electrons is directed from a free-electron source, such as an electron gun, into an enclosing conductive surface. The free-electron source includes a cathode, which is maintained at a negative voltage with respect to the enclosing conductive surface. A region around the free-electron source is maintained in a vacuum. The system is configured to switch over a time period between two configurations. In the first configuration, the enclosing conductive surface is isolated from a ground. In the second configuration, the enclosing conductive surface is in electrical communication with the ground. Capacitive energy is discharged from the enclosing conductive surface when in the second configuration with an electrical circuit arrangement and provided to the load.

Owner:NELSON LAWRENCE

Ultraviolet lamp system and method for controlling emitted ultraviolet light

Embodiments of the invention provide an apparatus, method, and program product to control a lamp system. The apparatus comprises a plasma lamp bulb (20) and a microwave generator (12) operable to generate a microwave energy field to excite the plasma lamp bulb (20) to emit ultraviolet light (24). The apparatus further comprises a sensor (70) to measure the intensity of the ultraviolet light (24) and a reflector (42) positioned between the plasma lamp bulb (20) and the sensor (70) The reflector (42) is operable to reflect at least a portion of the ultraviolet light (24) generated by the plasma lamp bulb (20). The method comprises receiving a target intensity for the ultraviolet light (24) and measuring an intensity of the ultraviolet light (24) using a sensor (70). The method further comprises comparing the target intensity to the measured intensity and, in response to the comparison, adjusting power to a microwave generator (12) to adjust the intensity of the ultraviolet light (24).

Owner:NORDSON CORP

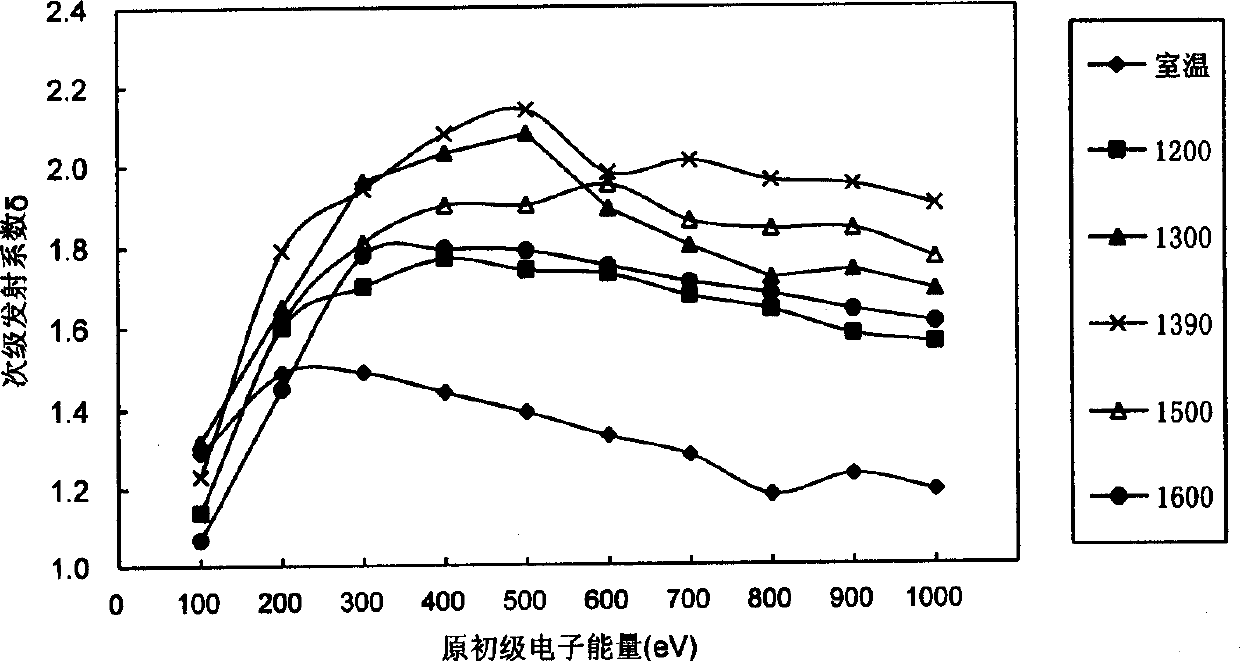

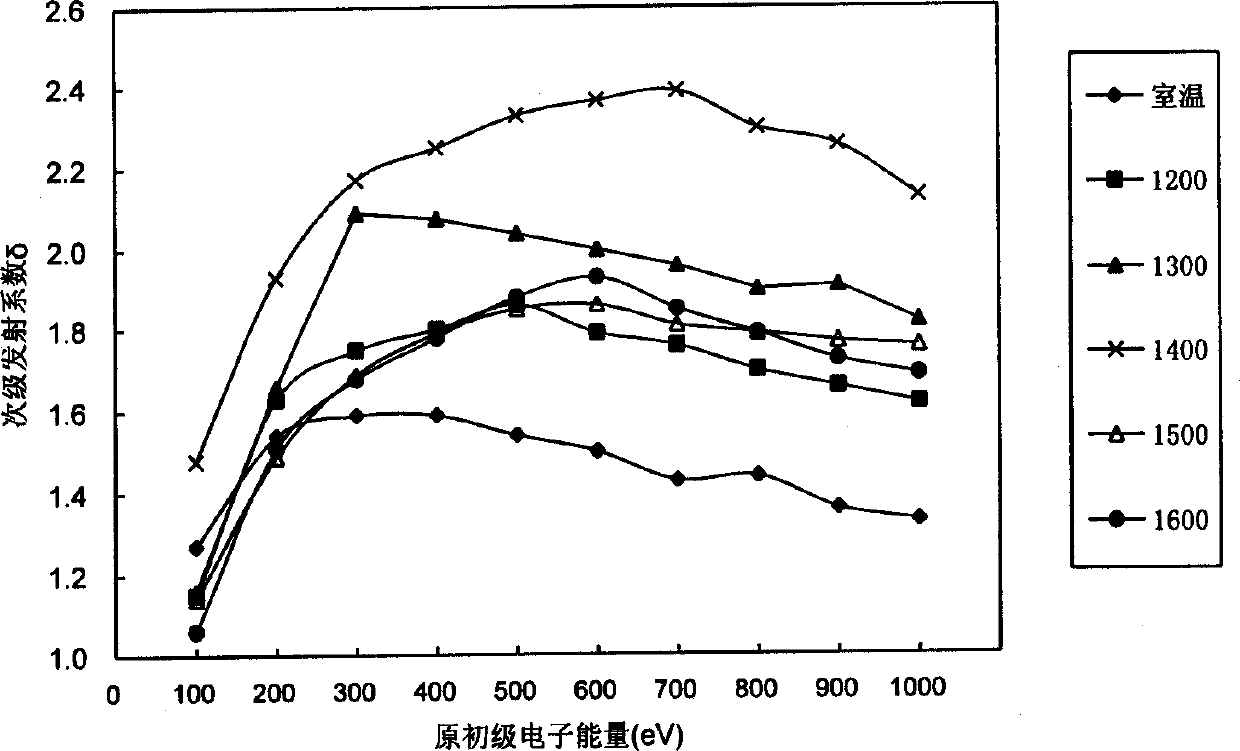

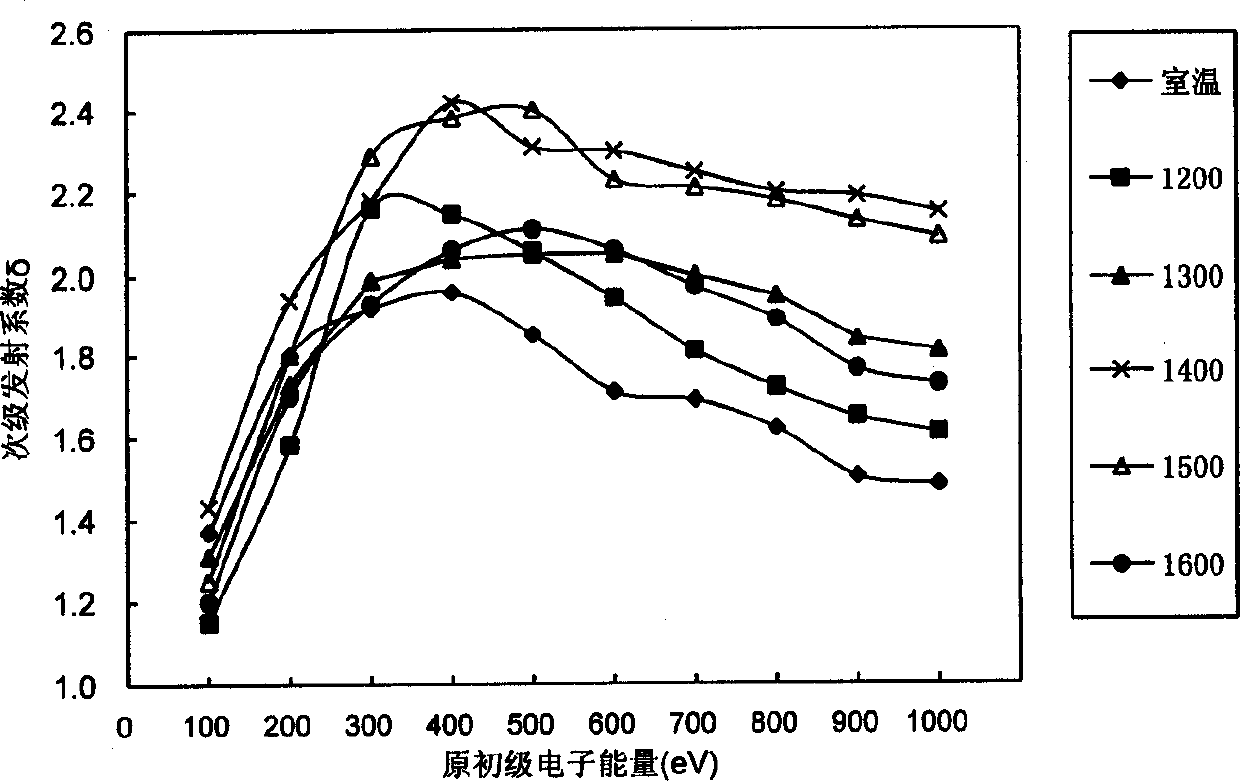

Secondary-emission rare earth-molybdenum material and its preparing process

InactiveCN1360079AImprove machinabilityThe secondary emission coefficient is constantMagnetronsGas discharge connecting/feedingHigh resistanceSecondary emission

A two-element rare-earth / molybdenum material as secondary emission material is characterized by that it contains La2O3 and Y2O3 in a weight ratio of 1:3, and is preapred through adding La2O3 and Y2O3in the form of aqueous solution of their nitrates to molybdenum oxide or Mo powder, treating in hydrogen at 500-550 deg.C for 1-5 hr, reducing at 800-1000 deg.C, and powder metallurgy to obtain said secondary emission material, which has advantages of high emission coefficient, stability and mechinability and high resistance to expose in atomosphere.

Owner:BEIJING UNIV OF TECH

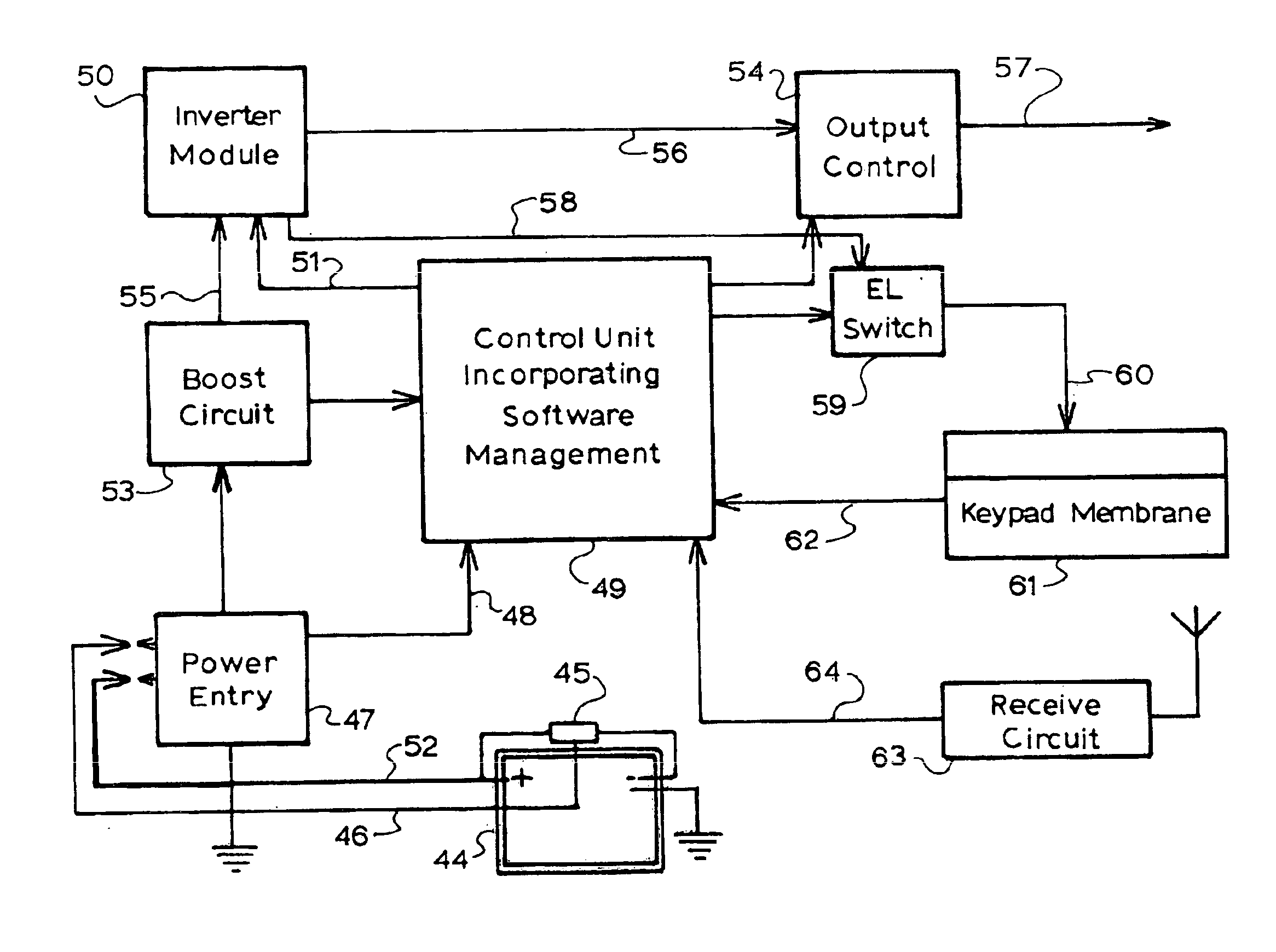

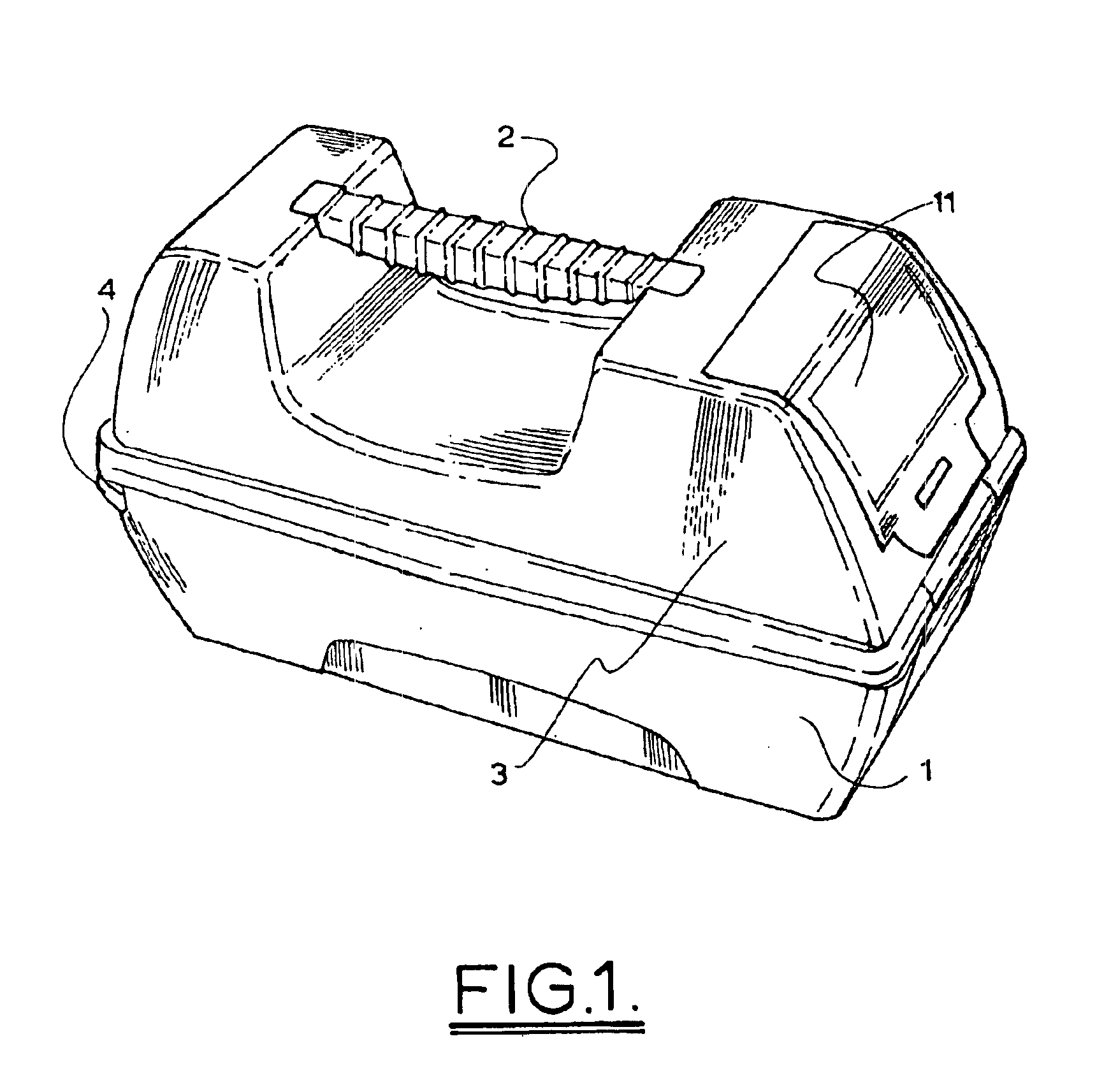

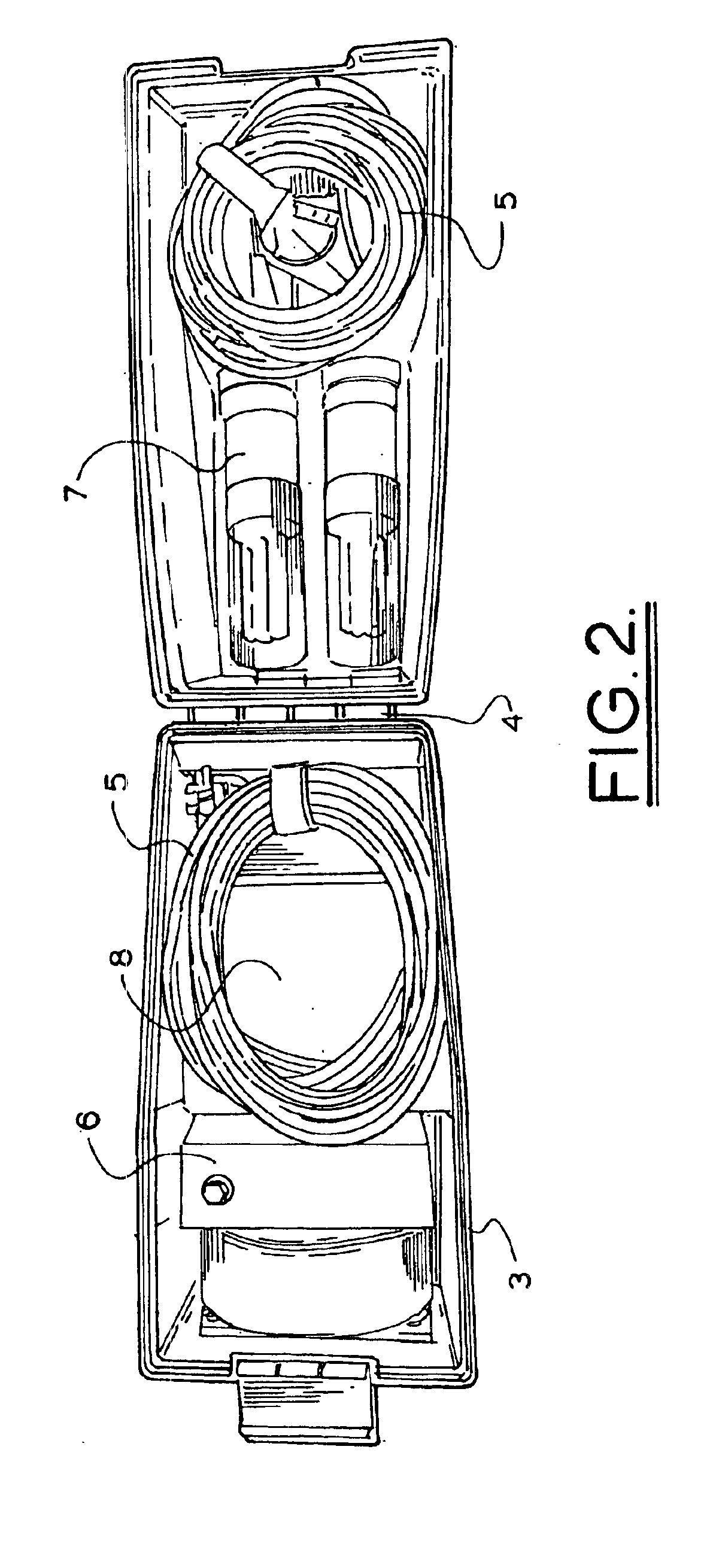

Portable power converter pack

InactiveUS6894439B2Sufficient operationBatteries circuit arrangementsMagnetronsElectricityVoltage converter

A portable power converter comprising input means to receive low voltage DC input, voltage converter means for converting the low voltage DC input into high DC voltage output, the voltage converter means in electrical communication with the input means, output means for operably supplying the high DC voltage to an appliance. The output means is in electrical communication with the converter includes a housing adapted to receive at least one of the input means, the voltage converter means and the output means. Preferably, the portable power converter also includes processing means for controlling some of the functions of the device such as shutting it down when power falls below preselected threshold. The device may also include a remote control which may be manually activated or in an alternative embodiment activated by external environment stimuli.

Owner:THE AUSSIE LIGHT

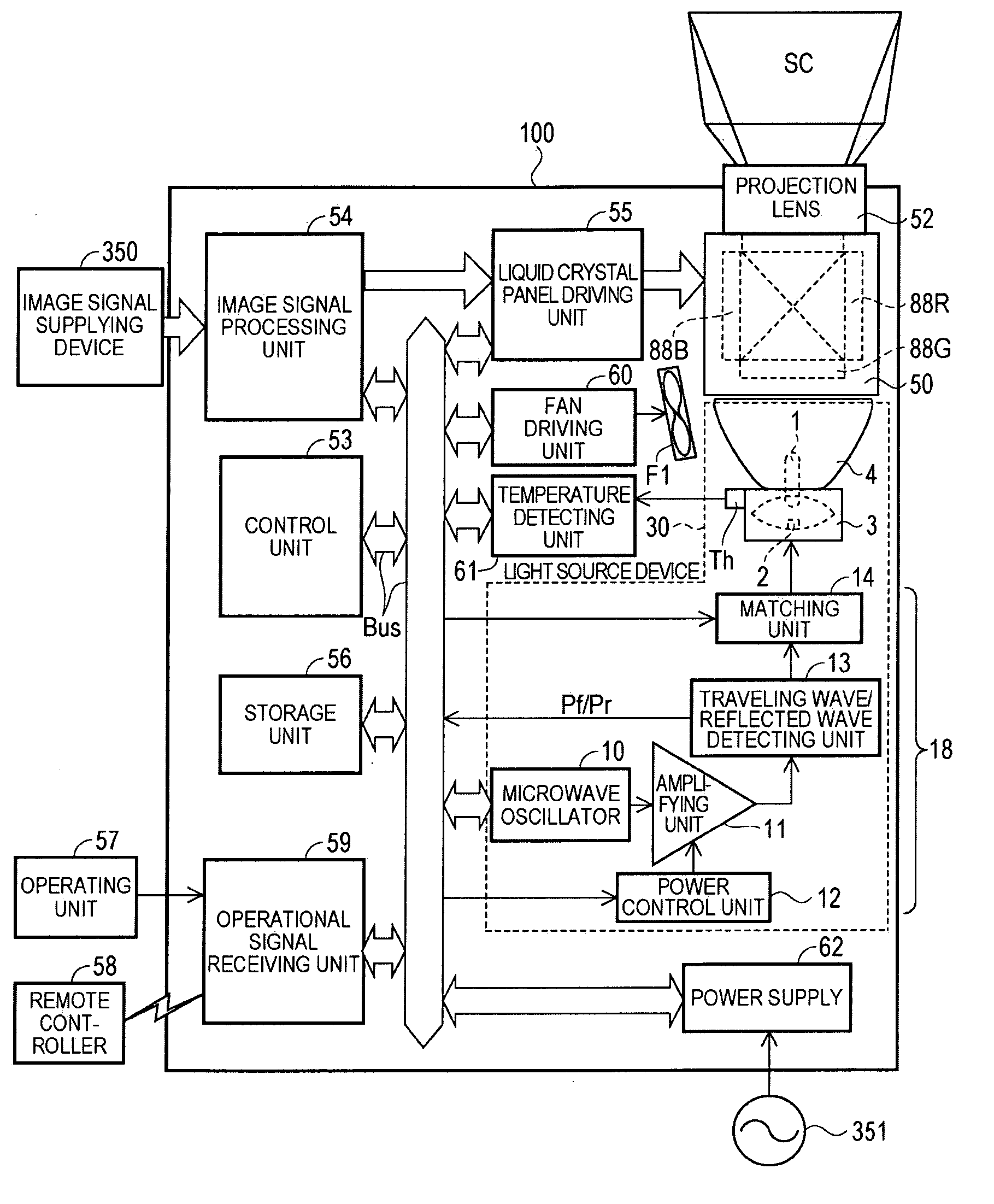

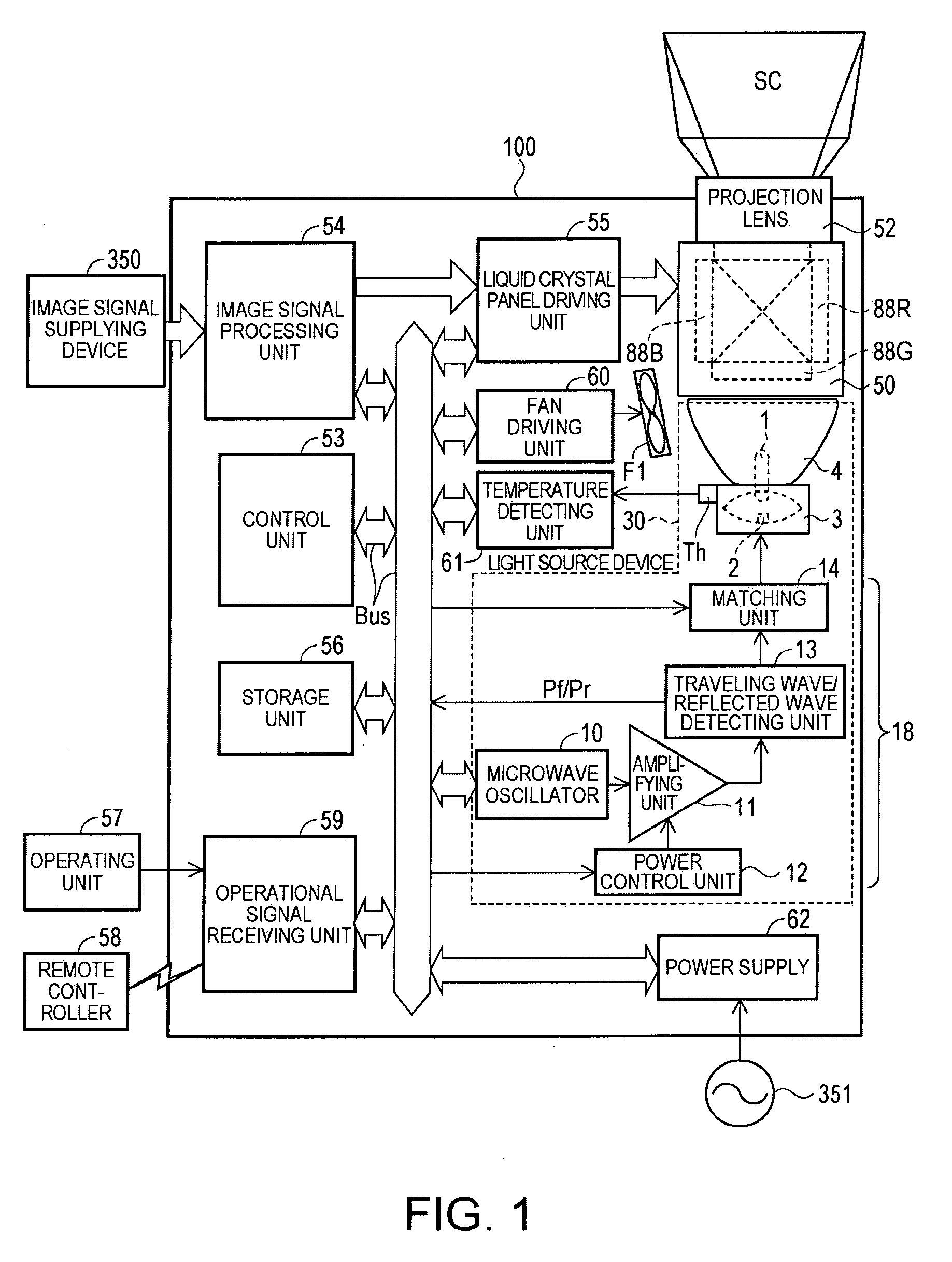

Projector and method of turning on light source device of projector

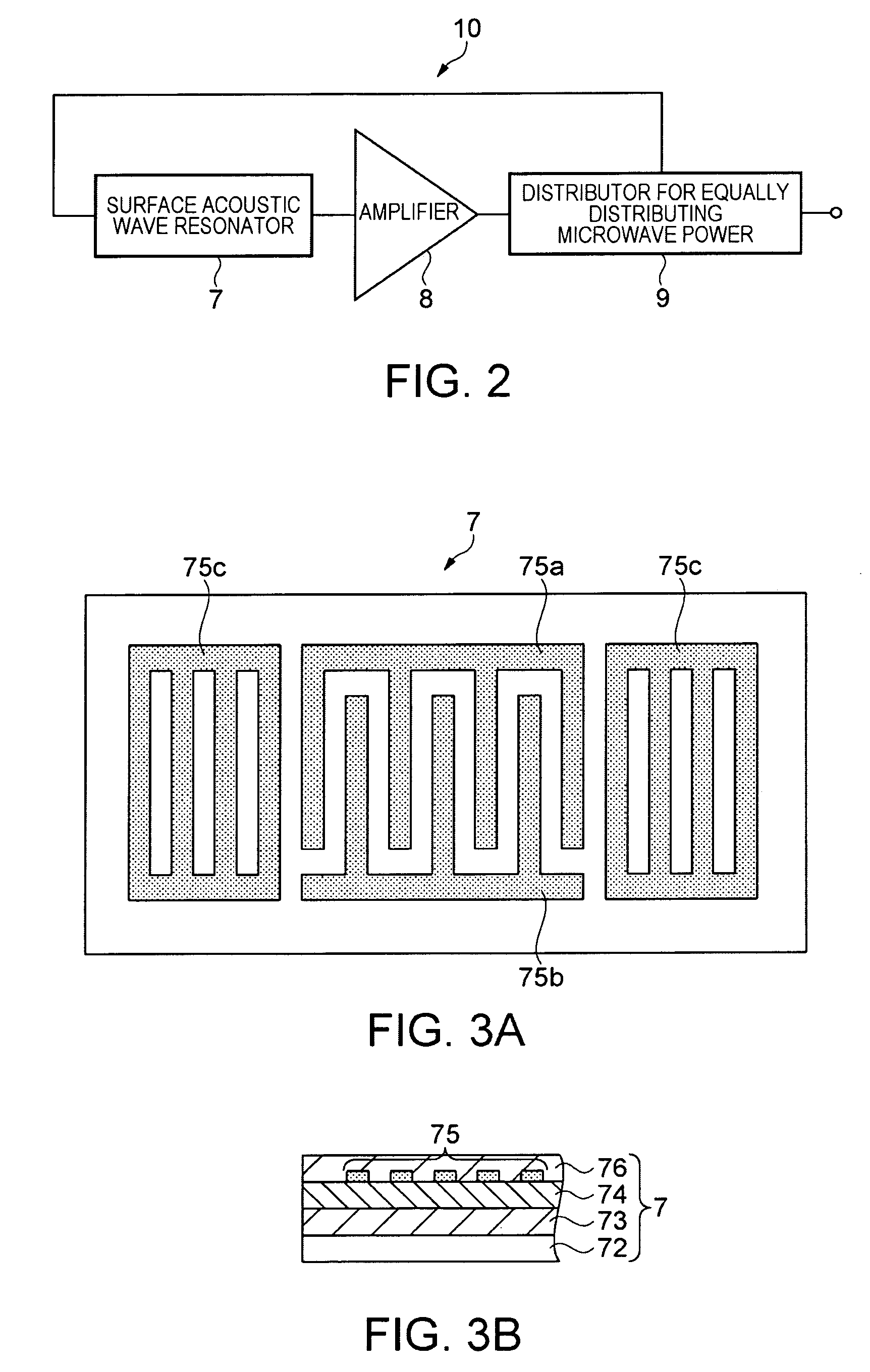

InactiveUS20070103650A1Prevent returnMagnetronsPoint-like light sourceImage resolutionMicrowave power

Task To provide a projector using a light source device that is rapidly and reliably turned on and can stably obtain a desired amount of light and a method of rapidly and reliably turning on a light source device of a projector. Means for Resolution A power control unit adjusts the amplification factor of an amplifying unit for microwaves such that microwave power having a pulse form that is higher than the microwave power radiated to keep an electrodeless lamp emitting light is radiated to turn on the electrodeless lamp. Therefore, a microwave having predetermined power is radiated to the electrodeless lamp at once.

Owner:SEIKO EPSON CORP

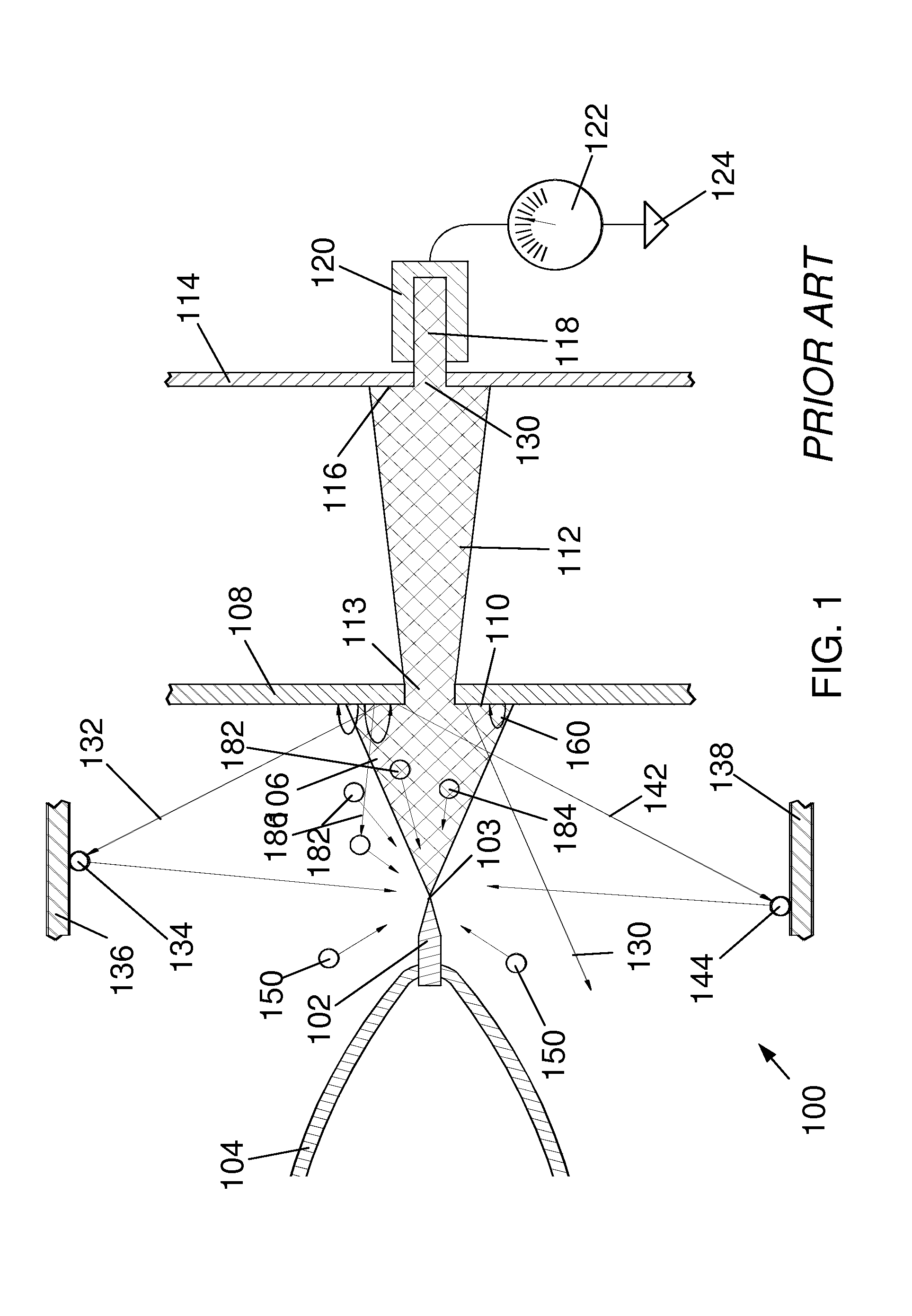

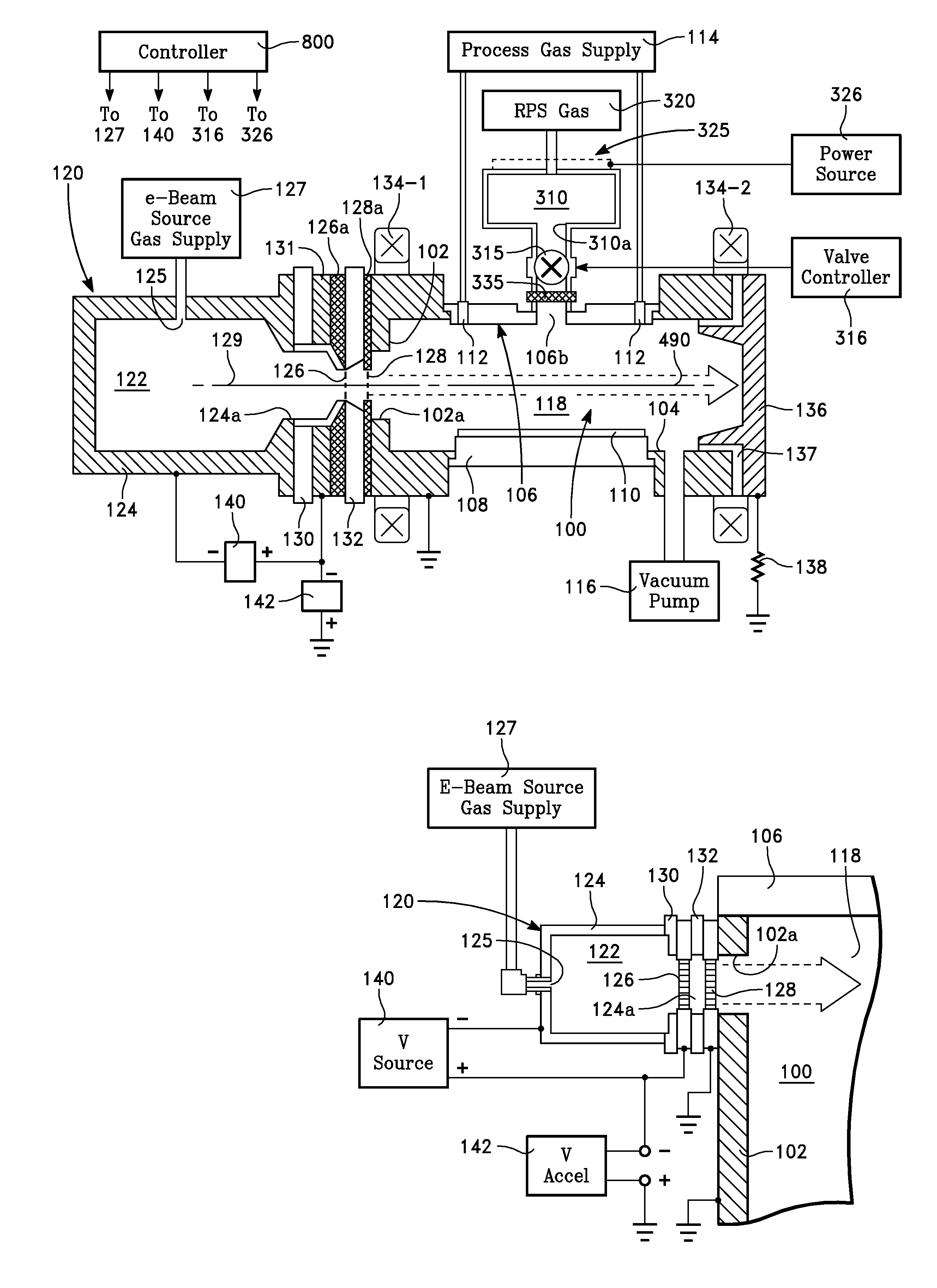

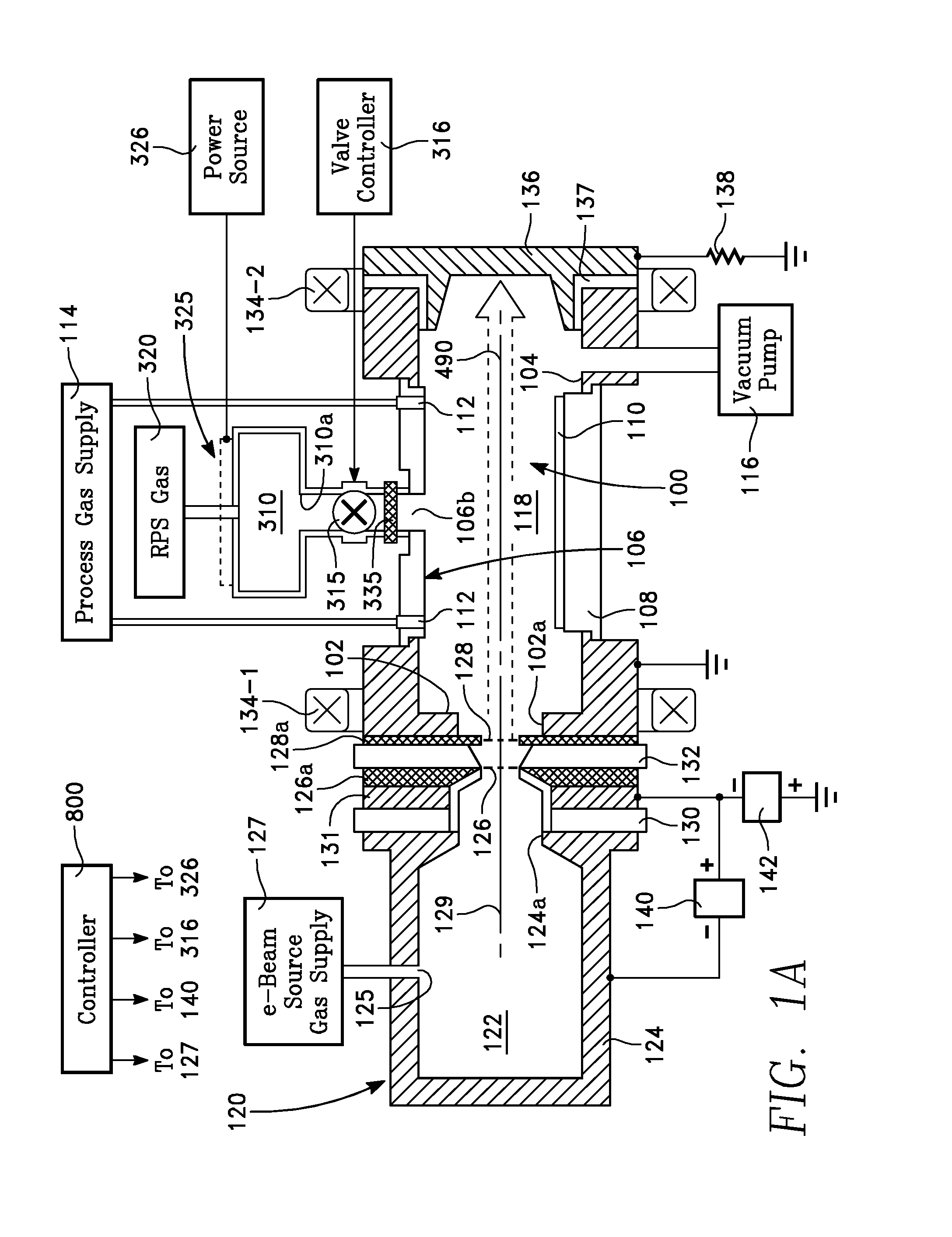

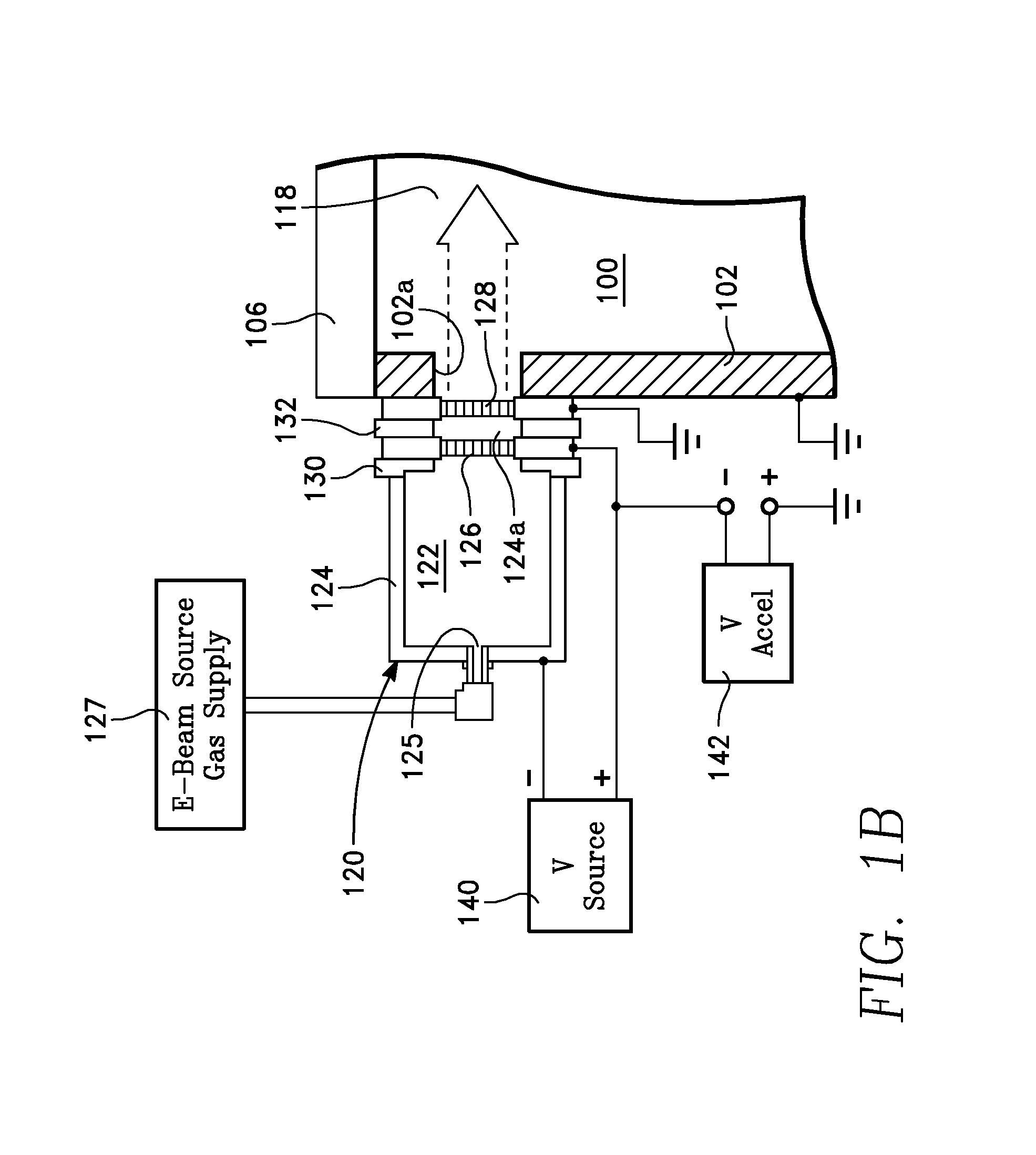

Electron beam plasma source with remote radical source

In a plasma reactor for processing a workpiece, an electron beam is employed as the plasma source, and a remote radical source is incorporated with the process chamber.

Owner:APPLIED MATERIALS INC

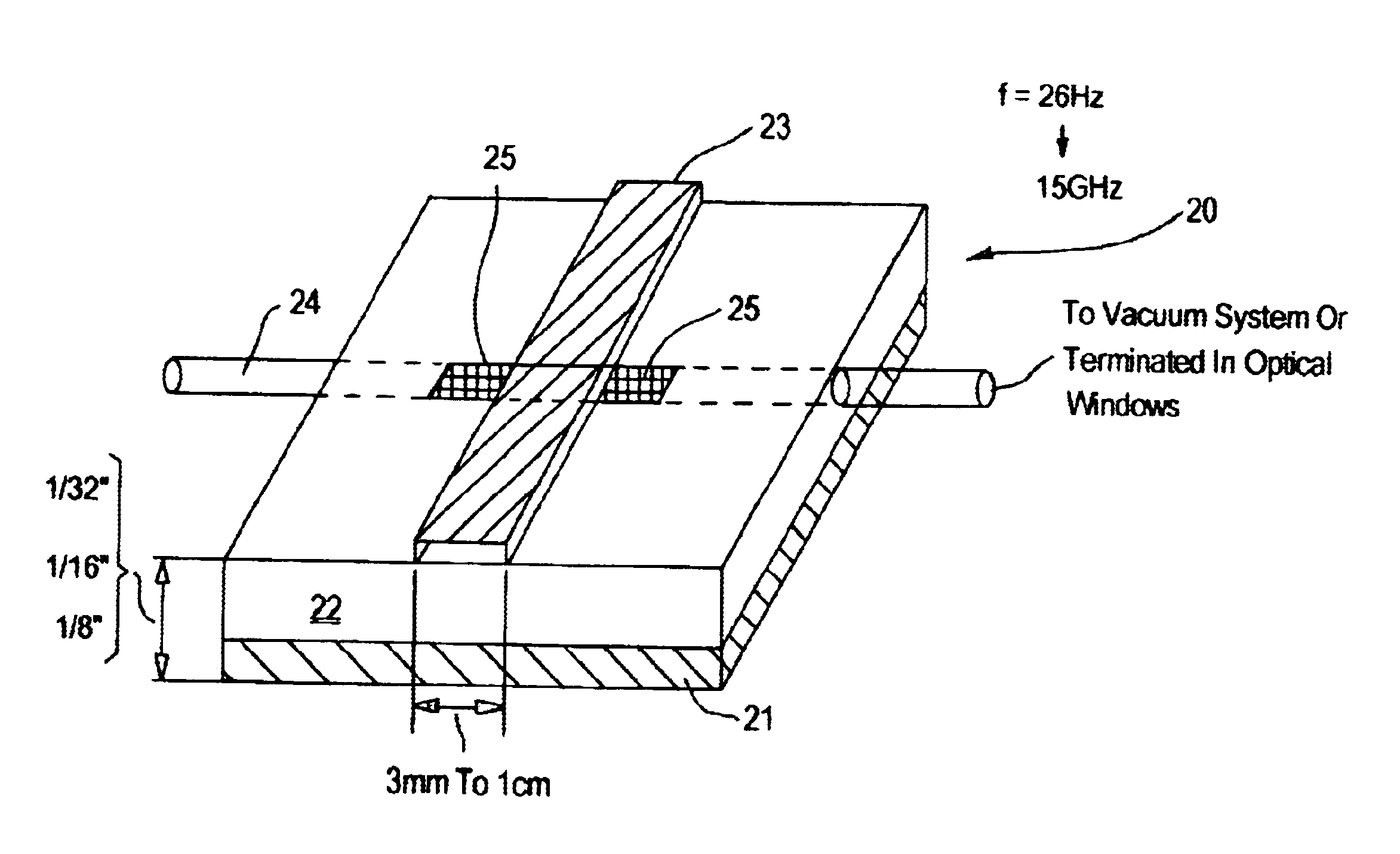

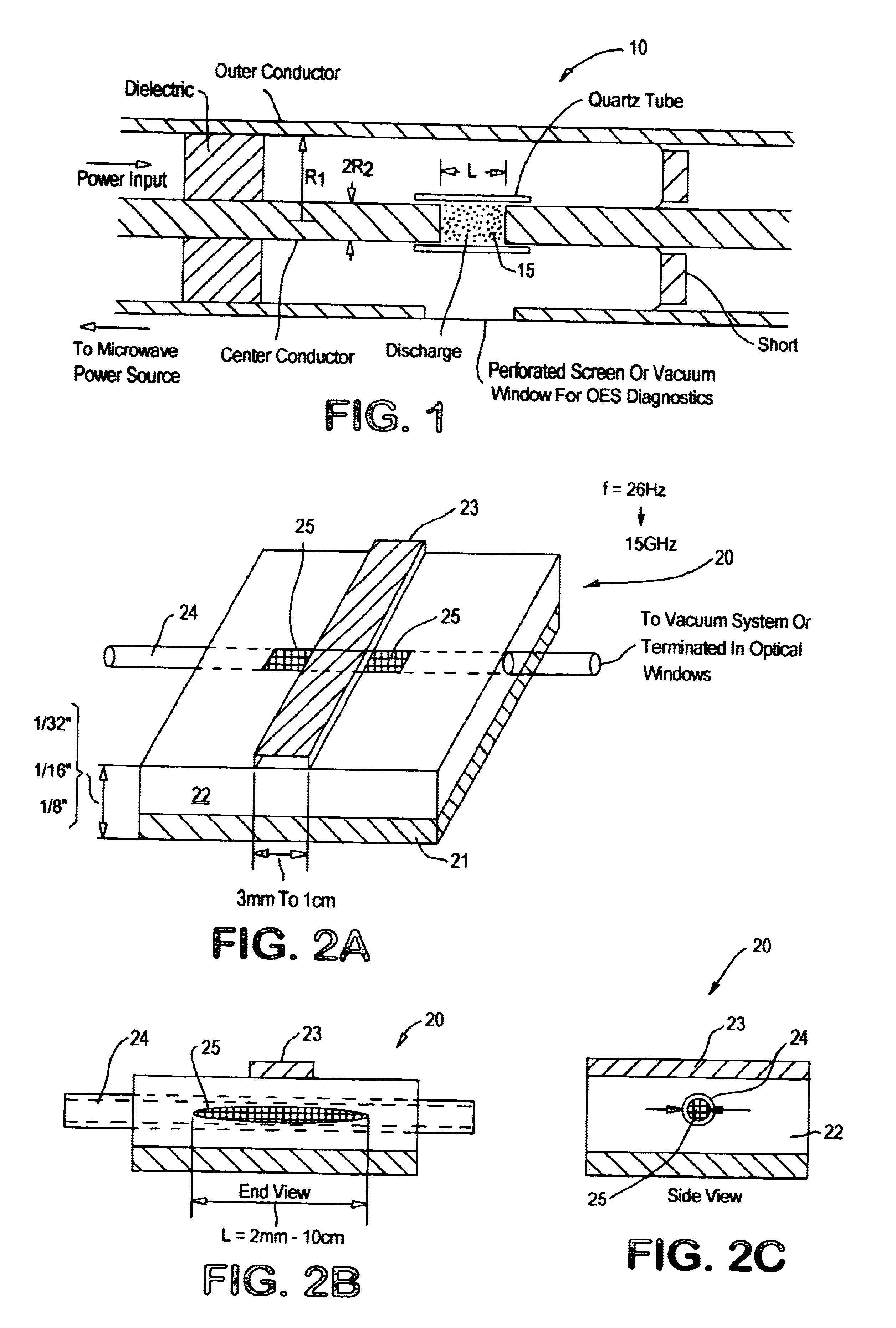

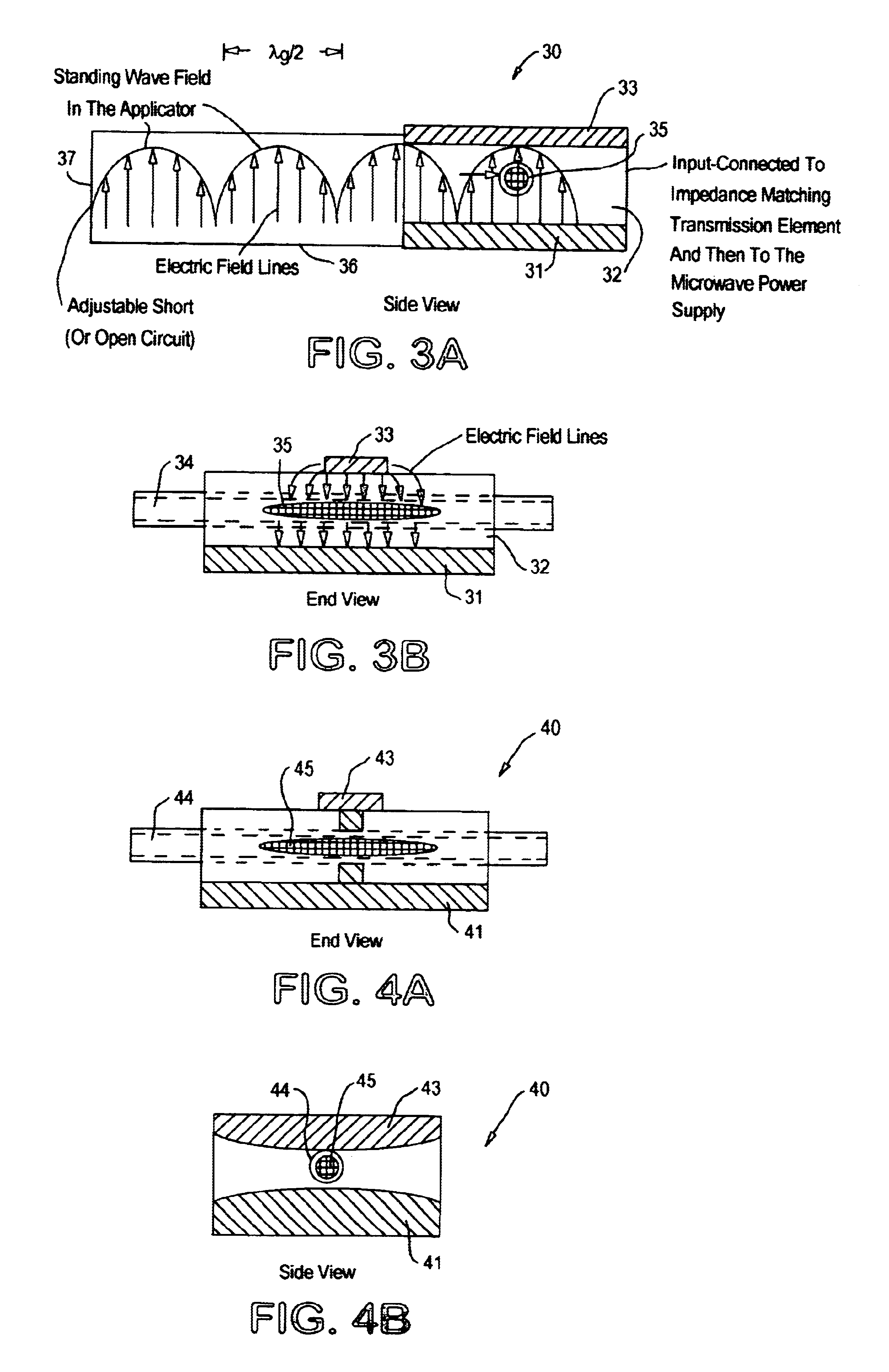

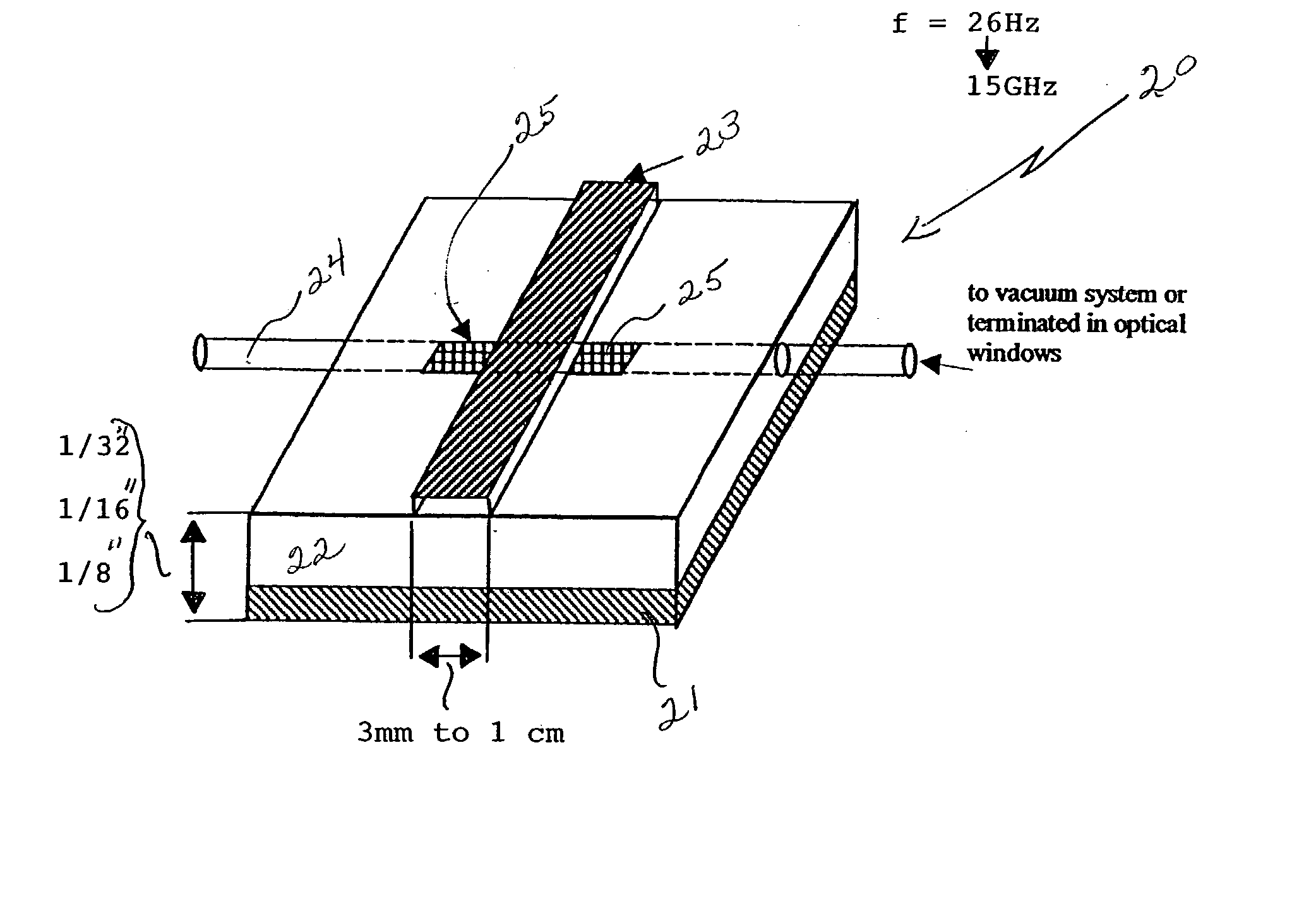

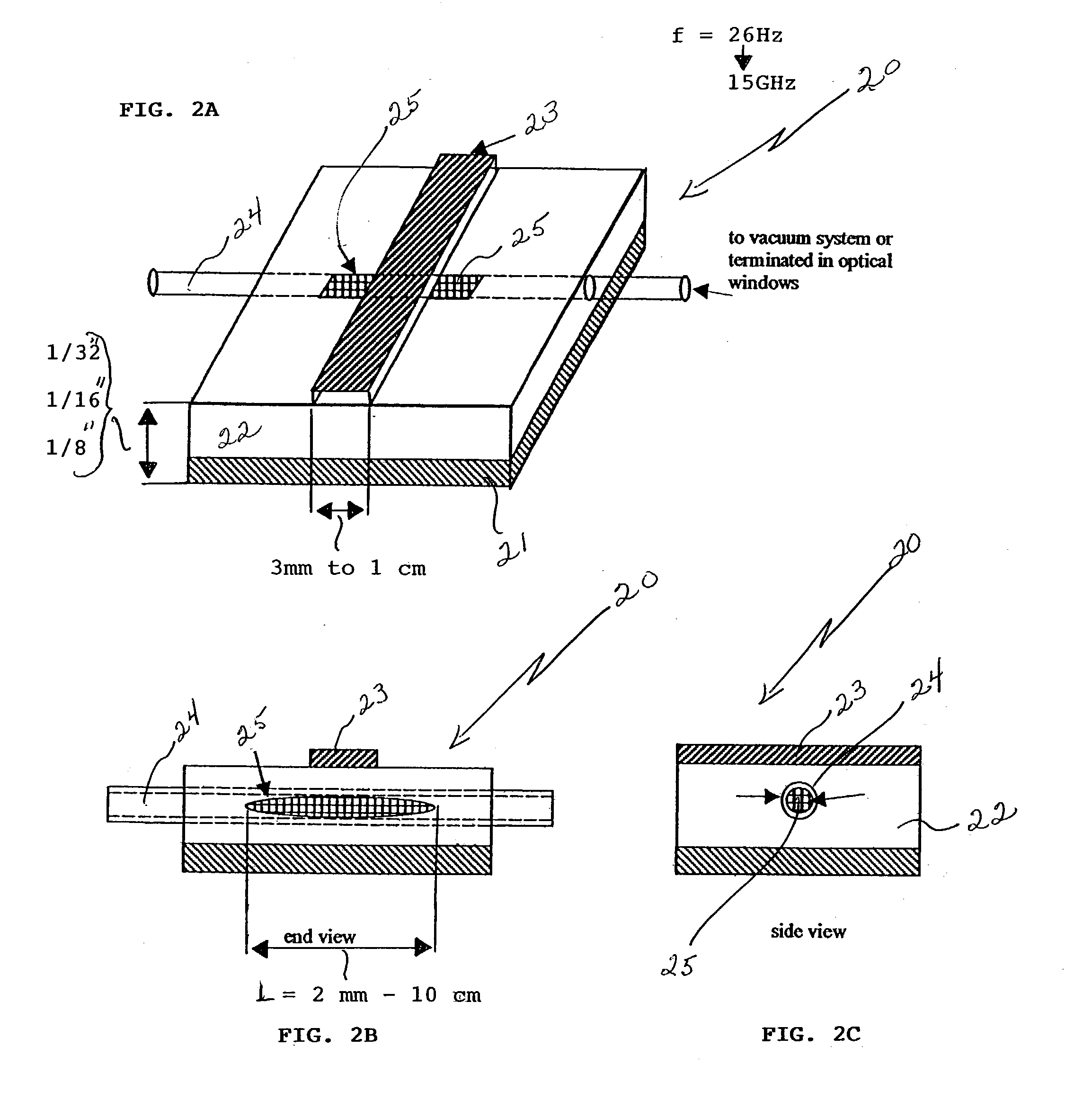

Microwave stripline applicators

An apparatus and method which maintains plasma discharges (for instance 25) in containers (for instance 20) which have an internal section of 1 cm or less in width are described. The very small cross-section plasma discharges are useful in MEMS devices, in spectrometers and in spectroscopy.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

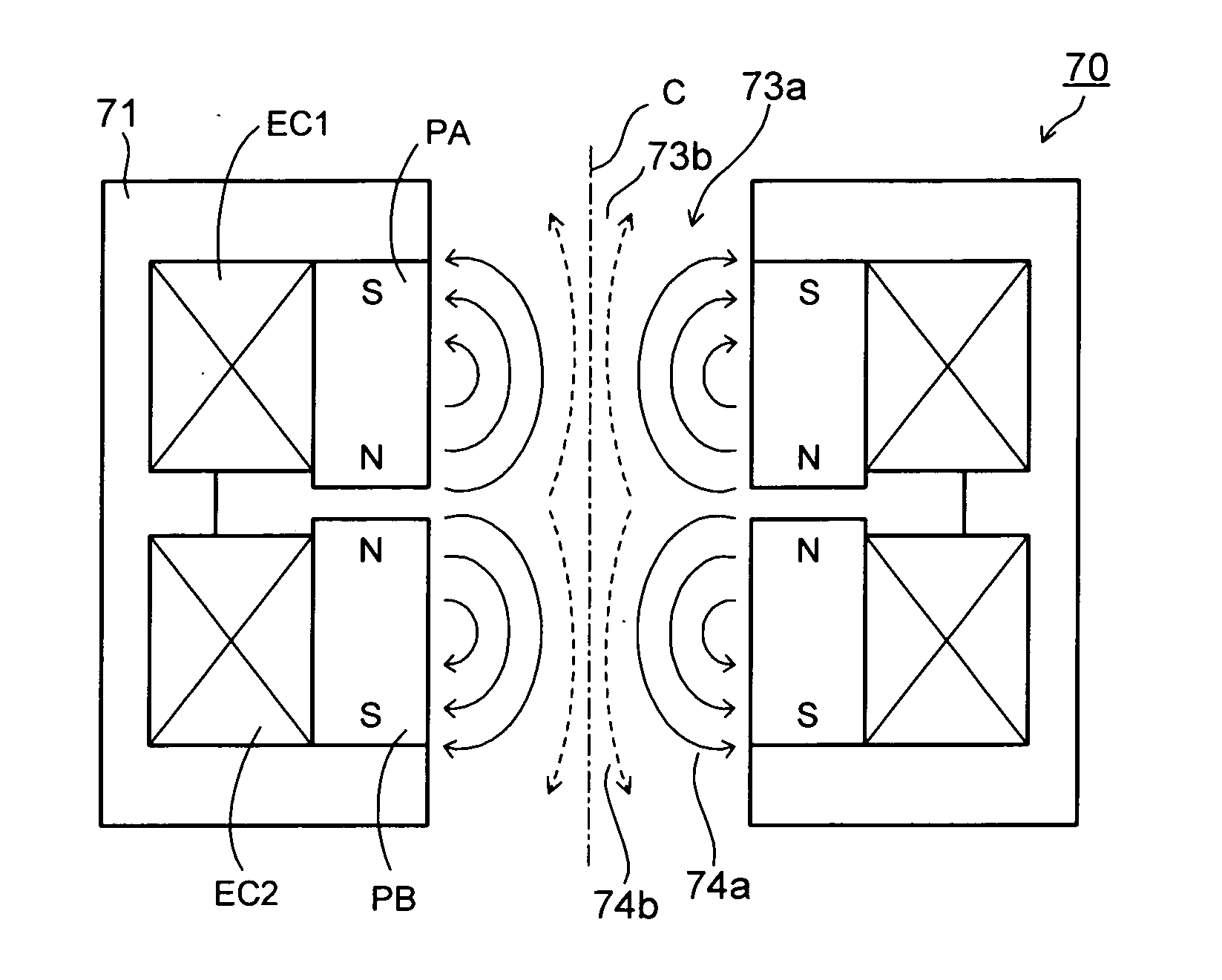

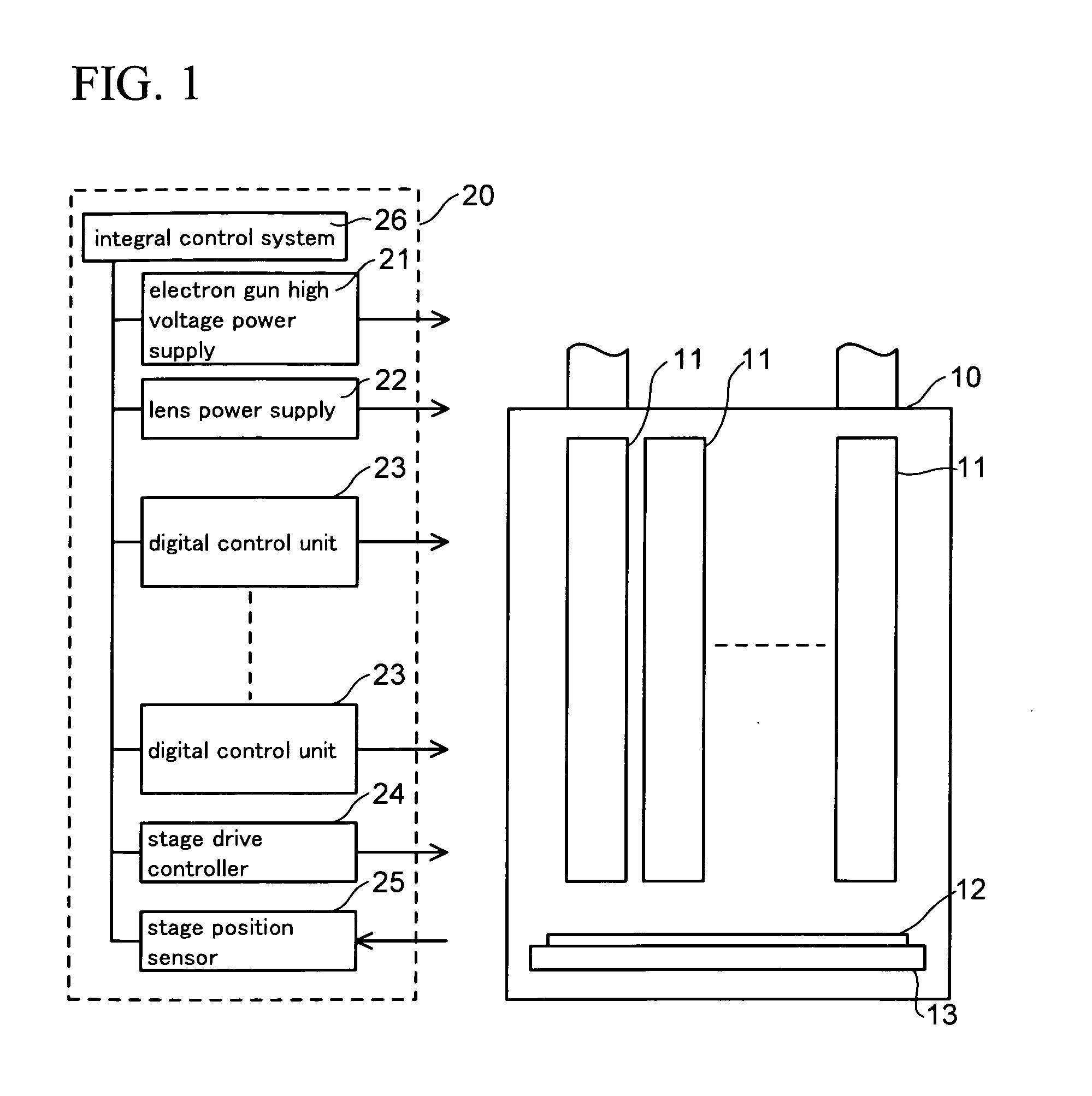

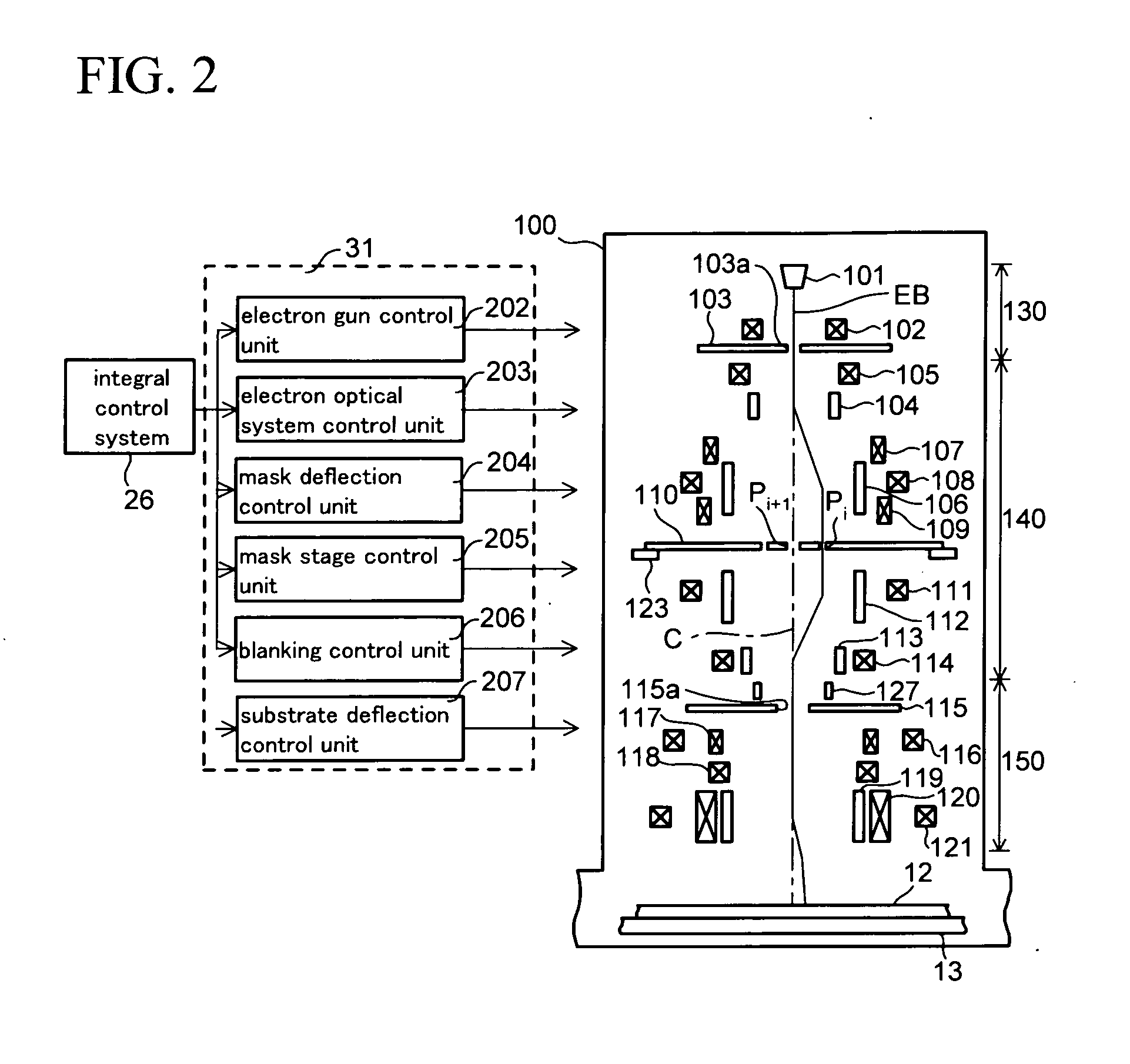

Multi-column electron beam exposure apparatus and magnetic field generation device

ActiveUS20110148297A1Strong magnetic field in a small spaceIntervals between column cells can be made smallMagnetronsTransit-tube focussing arrangementsOptical axisElectron

A multi-column electron beam exposure apparatus includes: multiple column cells; an electron beam converging unit in which two annular permanent magnets and electromagnetic coils are surrounded by a ferromagnetic frame, each of the two annular permanent magnets being magnetized in an optical axis direction and being symmetrical about the optical axis, the electromagnetic coils disposed near the annular permanent magnets and used to adjust magnetic fields of the annular permanent magnets; and a substrate provided with circular apertures through which electron beams used in the column cells pass, respectively, the substrate having the electron beam converging unit disposed in a side portion of each of the circular apertures. The two annular permanent magnets may be disposed one above the other in the optical axis direction with same polarities facing each other, and the electromagnetic coils may be provided inside or outside the annular permanent magnets in their radial direction.

Owner:ADVANTEST CORP

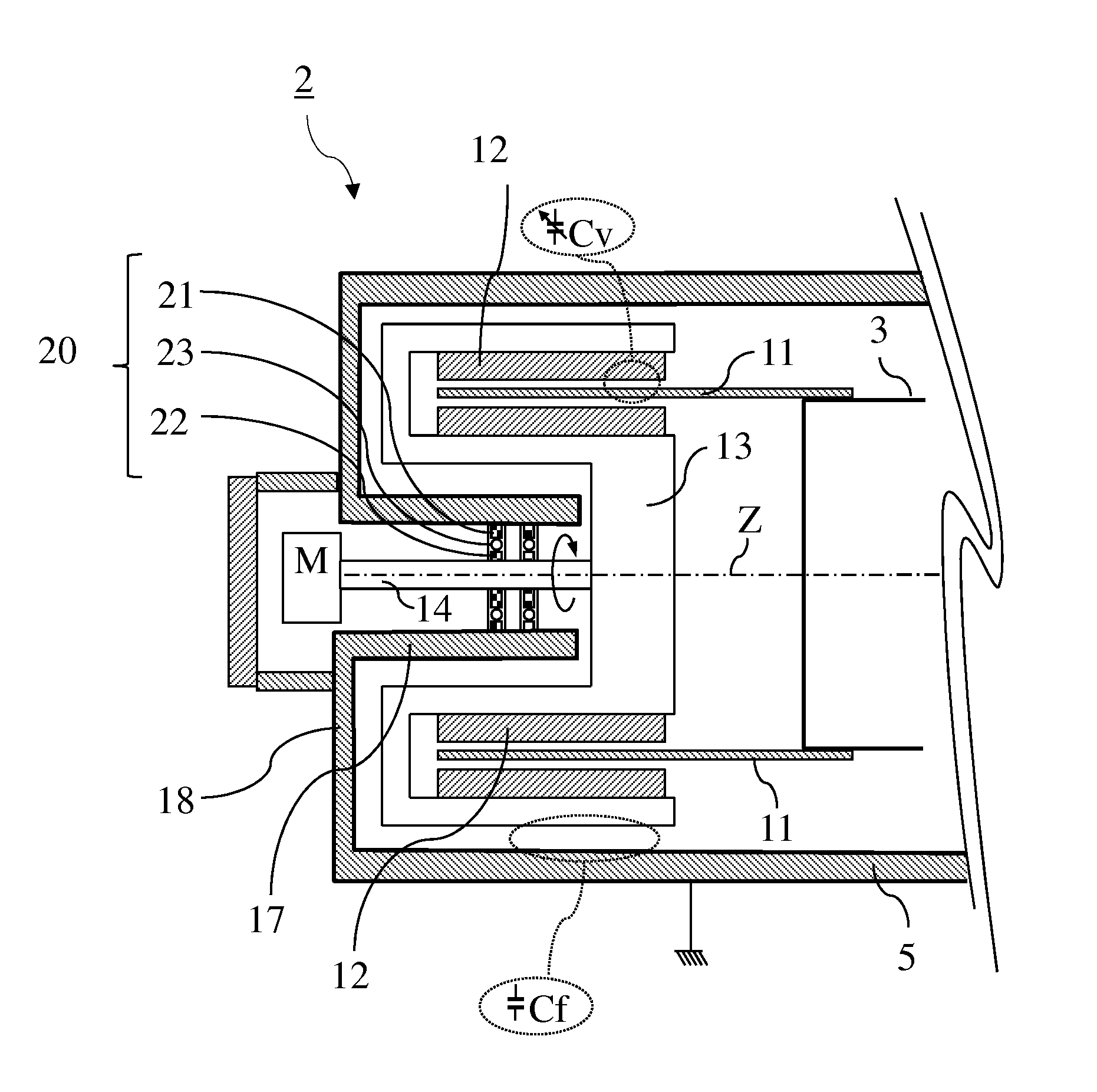

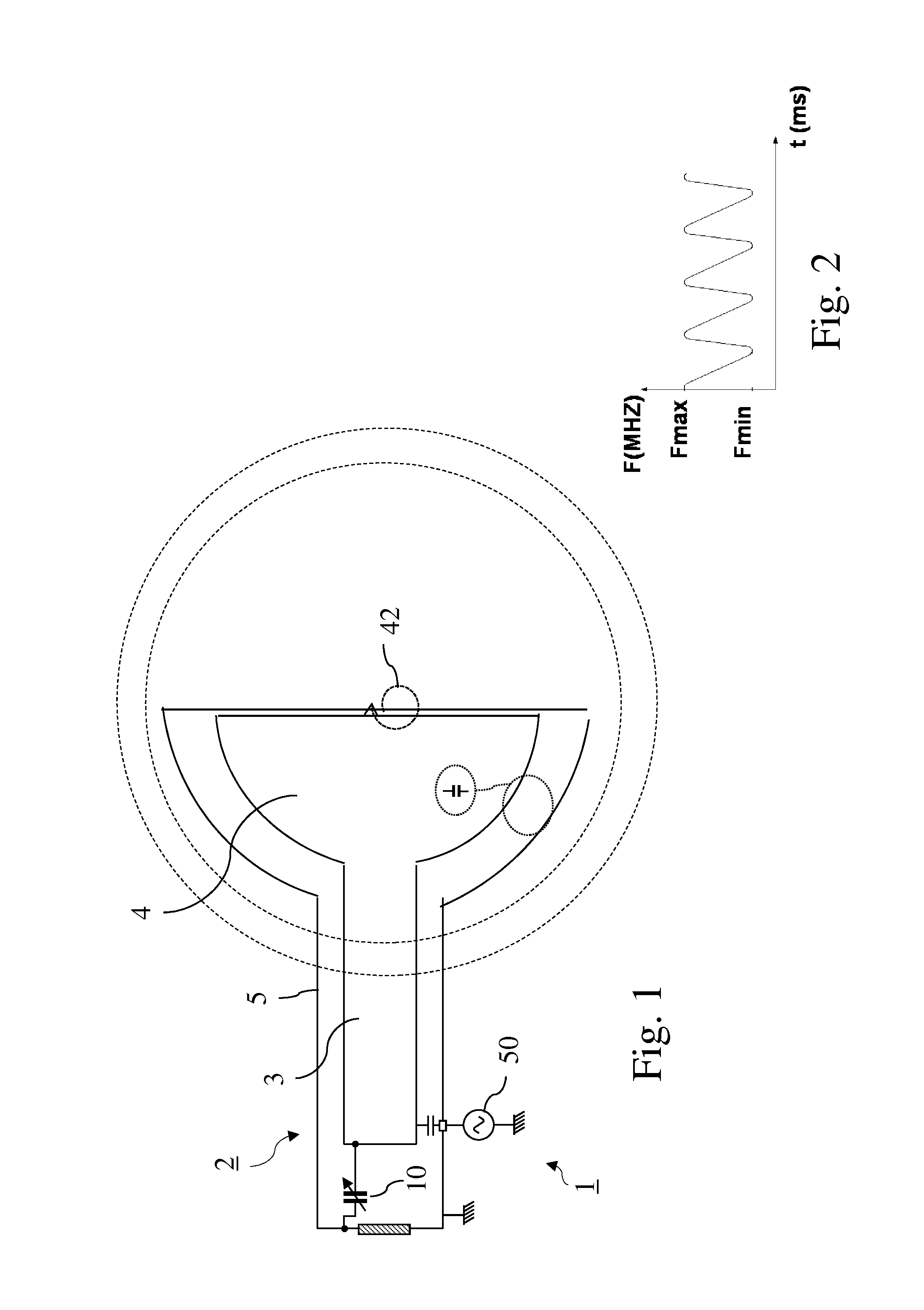

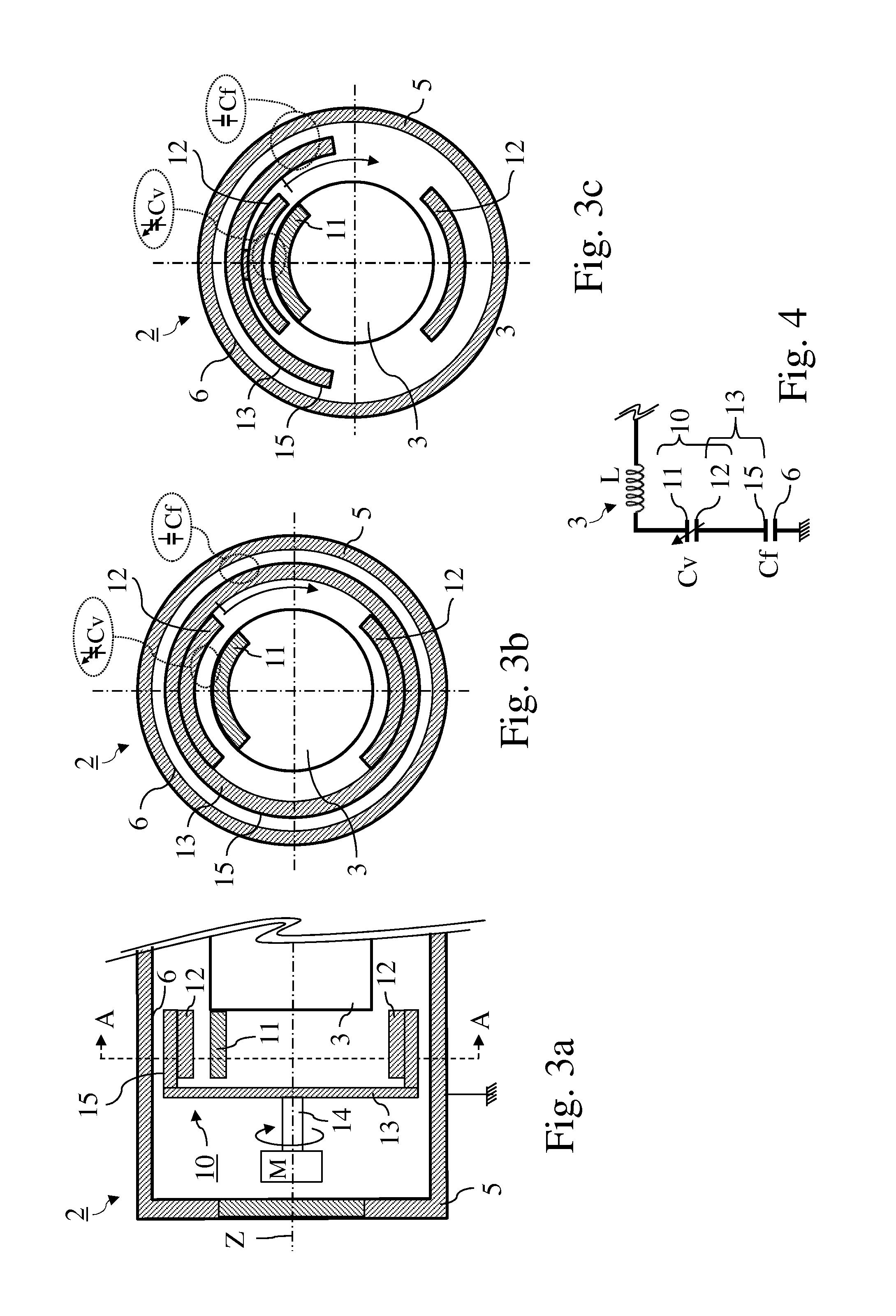

RF device for synchrocyclotron

ActiveUS20140320006A1Low costIncreased durabilityMagnetronsMagnetic resonance acceleratorsCapacitanceResonant cavity

RF device (1) able to generate an RF acceleration voltage in a synchrocyclotron. The device comprises a resonant cavity (2) formed by a grounded conducting enclosure (5) and enveloping a conducting pillar (3) to a first end of which an accelerating electrode (4) is linked. A rotary variable capacitor (10) is mounted in the conducting enclosure at a second end of the pillar, opposite from the first end, comprising at least one fixed electrode (stator) (11) and a rotor (13) exhibiting a rotation shaft (14) supported and guided in rotation by galvanically isolating bearings (20), said rotor (13) comprising one moveable electrode (12) possibly facing the stator (11). When the shaft (14) rotates, the stator and the moveable electrode together form a variable capacitance whose value varies cyclically with time. The rotor (13) is galvanically isolated from the conducting enclosure (5) and from the pillar (3). The stator (11) is connected to the second end of the pillar (3) or to the conducting enclosure (5). The rotor is respectively coupled capacitively to the conducting enclosure or to the pillar. This makes it possible to dispense with sliding electrical contacts between the rotor and respectively the conducting enclosure or the pillar.

Owner:ION BEAM APPL

Microwave stripline applicators

An apparatus and method which maintains plasma discharges (for instance 25) in containers (for instance 20) which have an internal section of 1 cm or less in width are described. The very small cross-section plasma discharges are useful in MEMS devices, in spectrometers and in spectroscopy.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

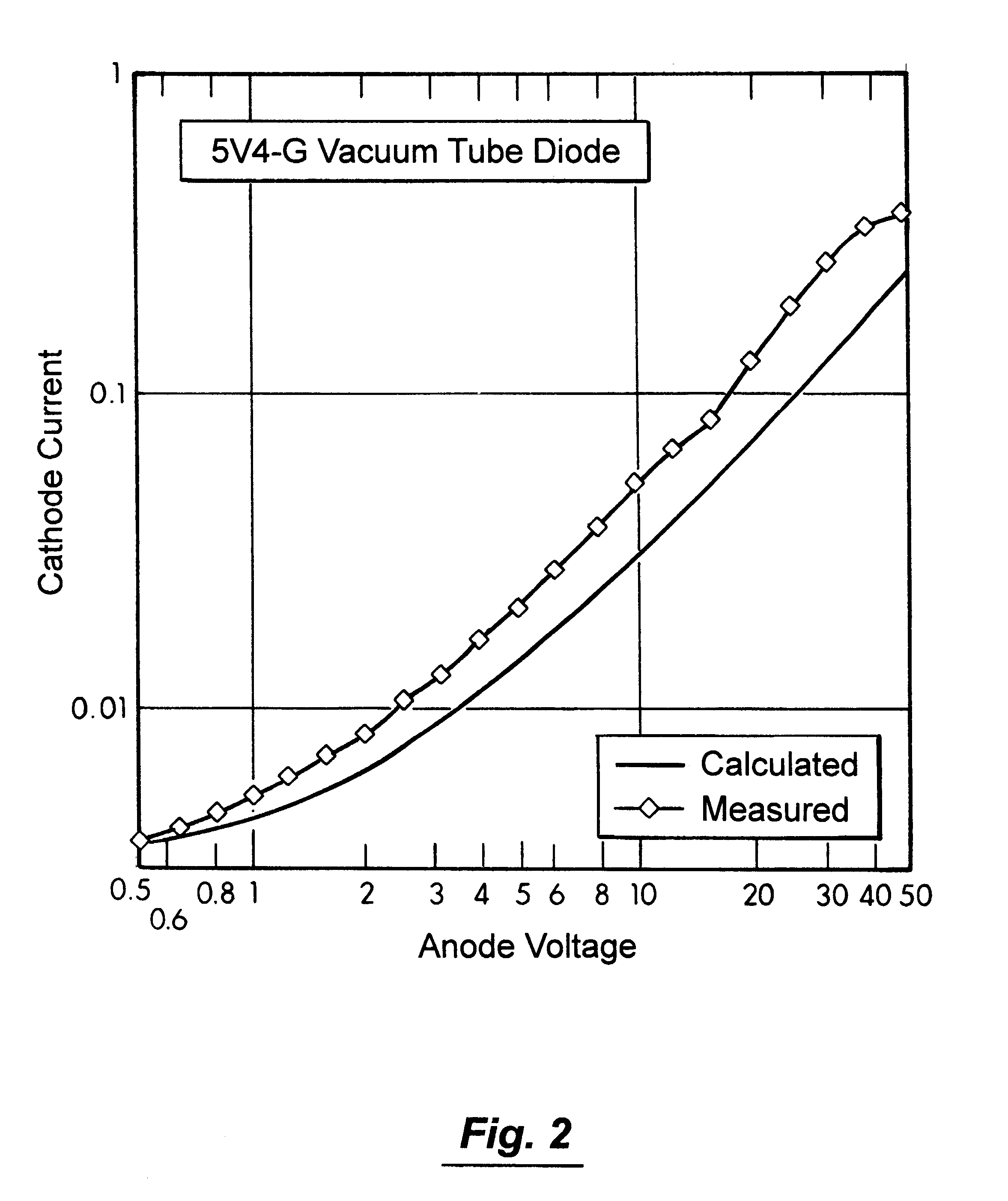

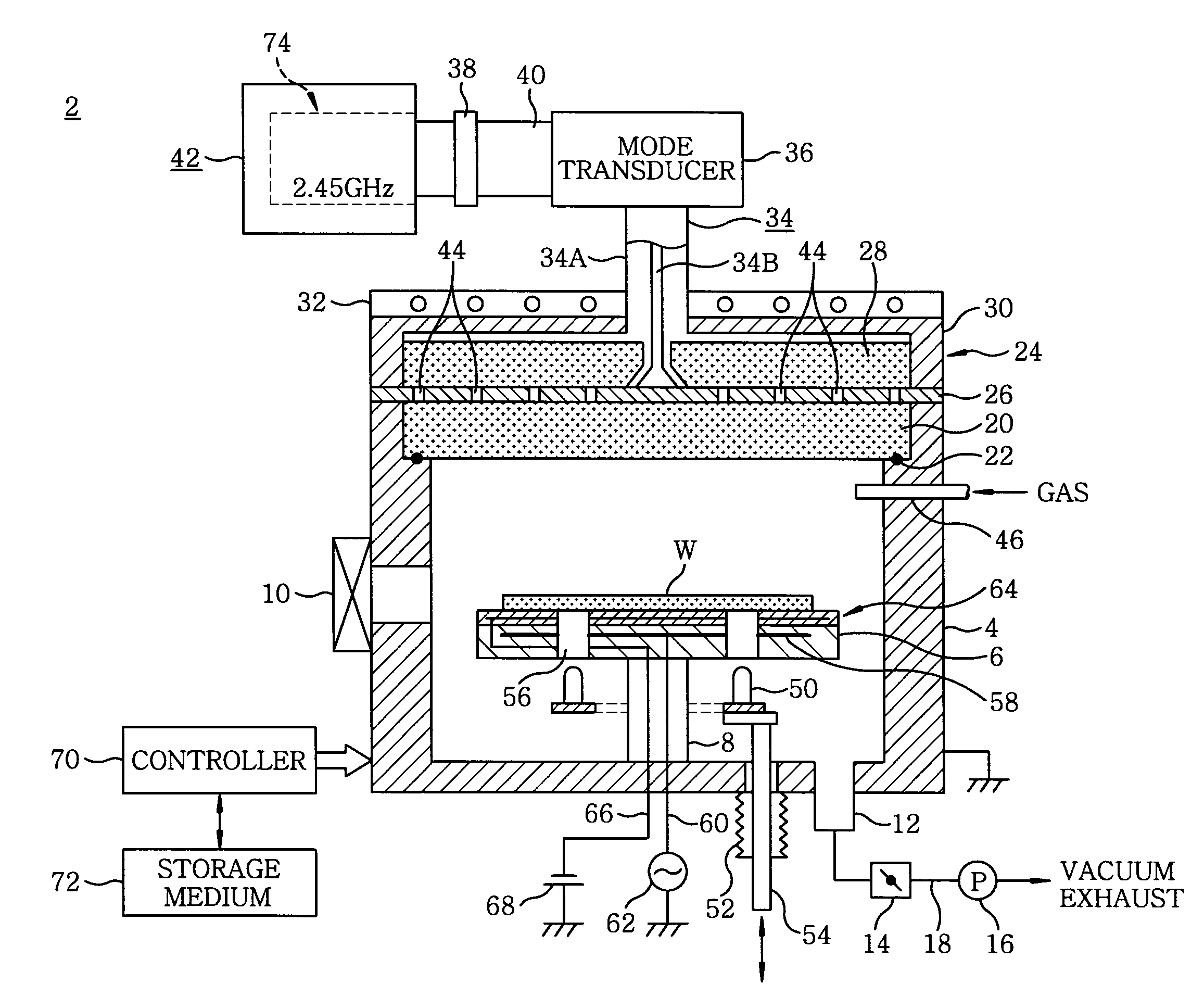

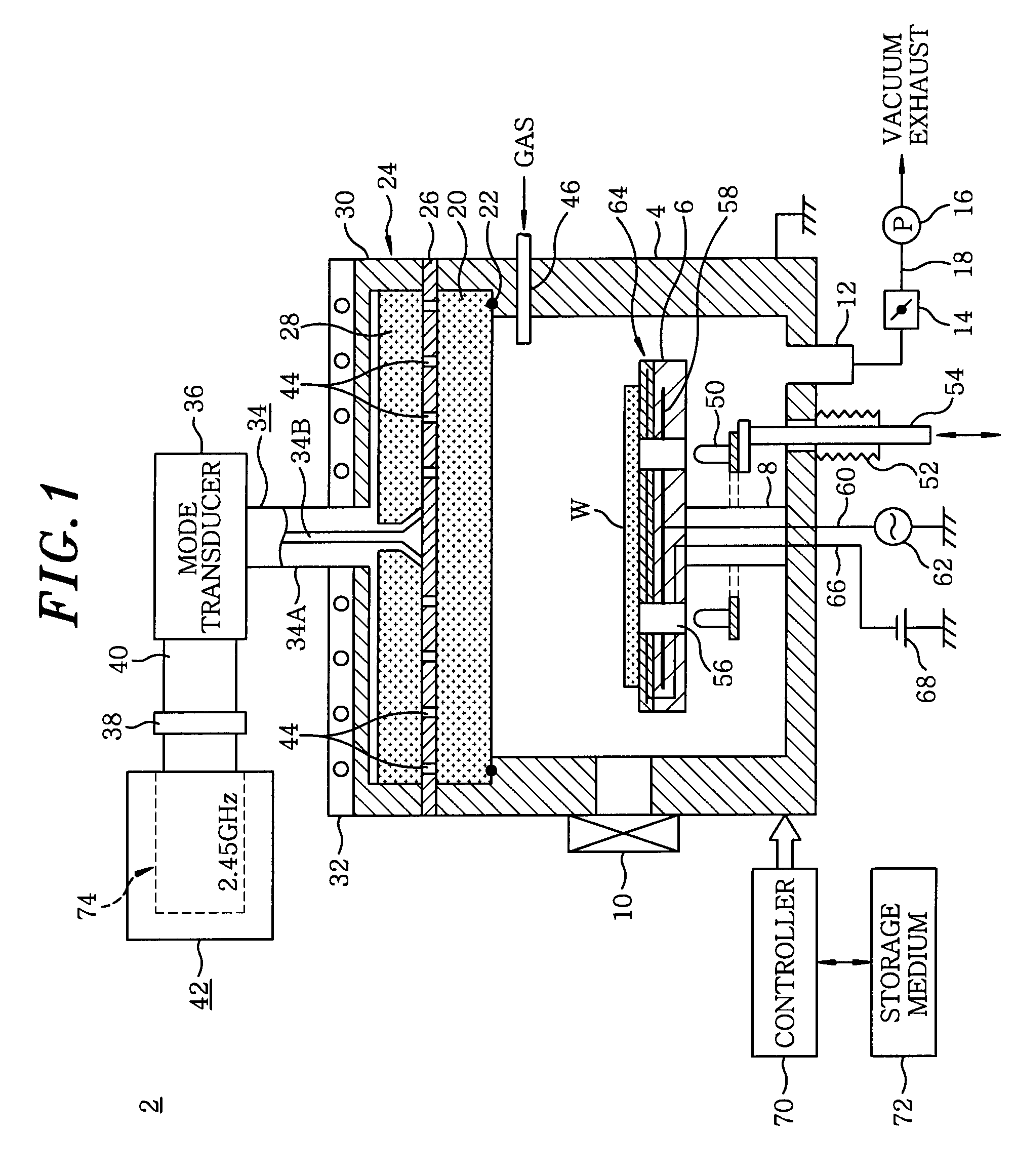

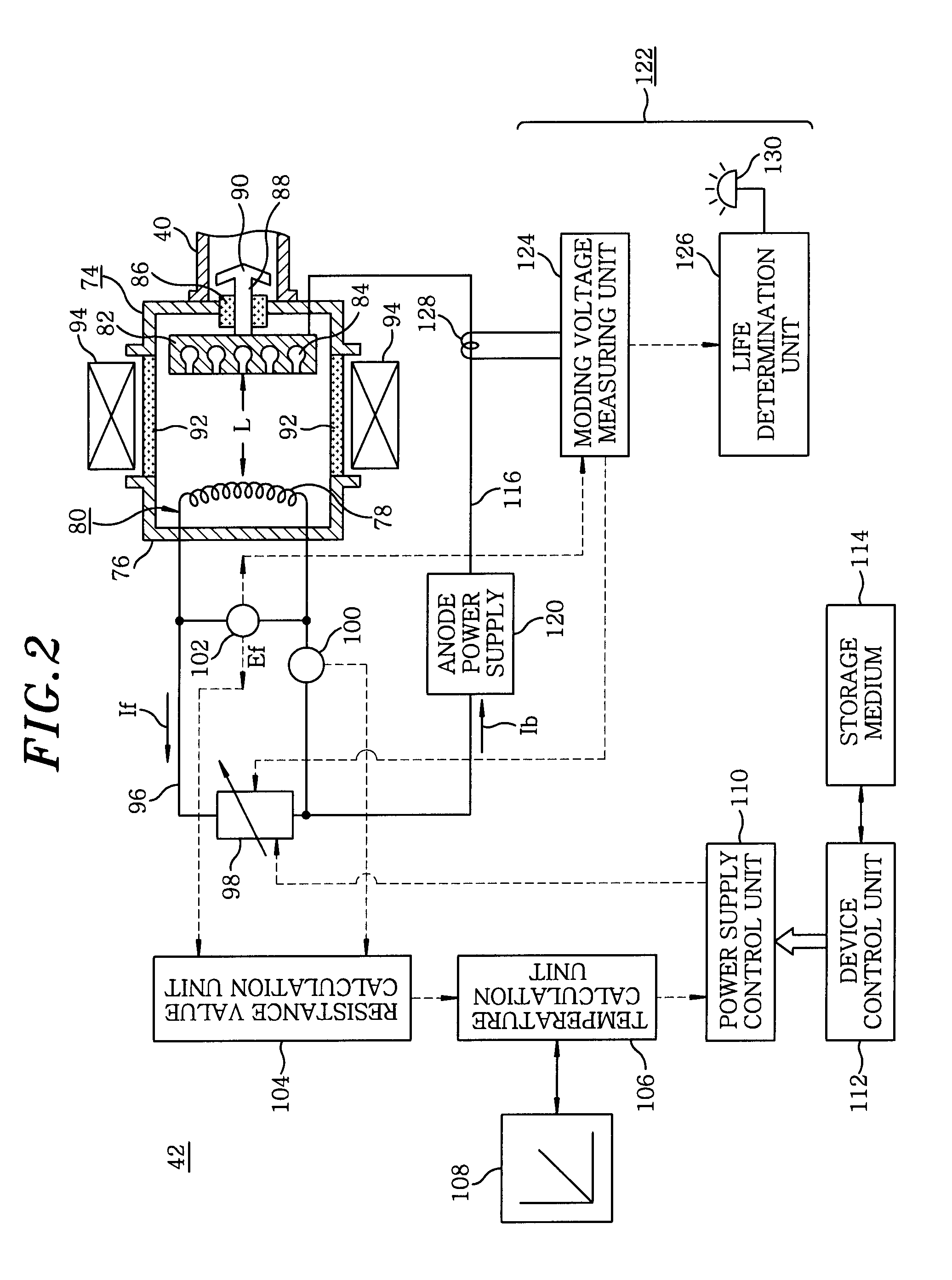

Magnetron control method, magnetron service life judgment method, microwave generation device, magnetron service life judgment device, processing device, computer program, and storage medium

InactiveUS20080309239A1Extended service lifeImprove accuracyMagnetronsSemiconductor/solid-state device manufacturingElectrical resistance and conductanceMicrowave

A microwave generation device includes: a magnetron having a cathode containing a filament and an anode containing a hollow resonator arranged to oppose to each other; a filament current measuring unit; and an application voltage measuring unit for measuring voltage applied to the filament. Based on the current and the voltage obtained by the current measuring unit and the voltage measuring unit, a resistance value calculation unit obtains a resistance value of the filament. A temperature calculation unit calculates the filament temperature from the resistance value and the resistance-temperature dependent characteristic. A filament power source is controlled by a power control unit so that the filament temperature is within a predetermined temperature range.

Owner:TOKYO ELECTRON LTD

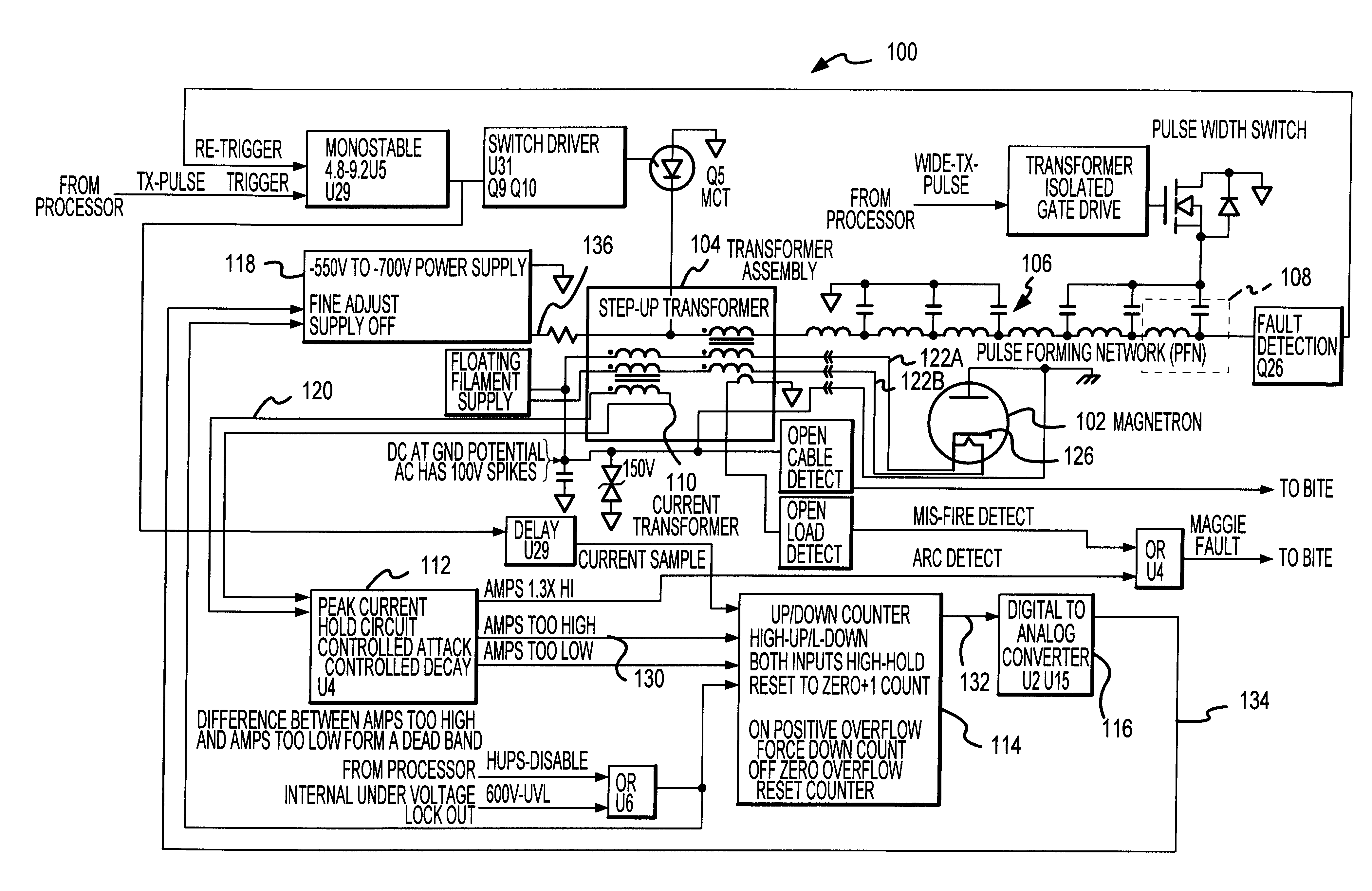

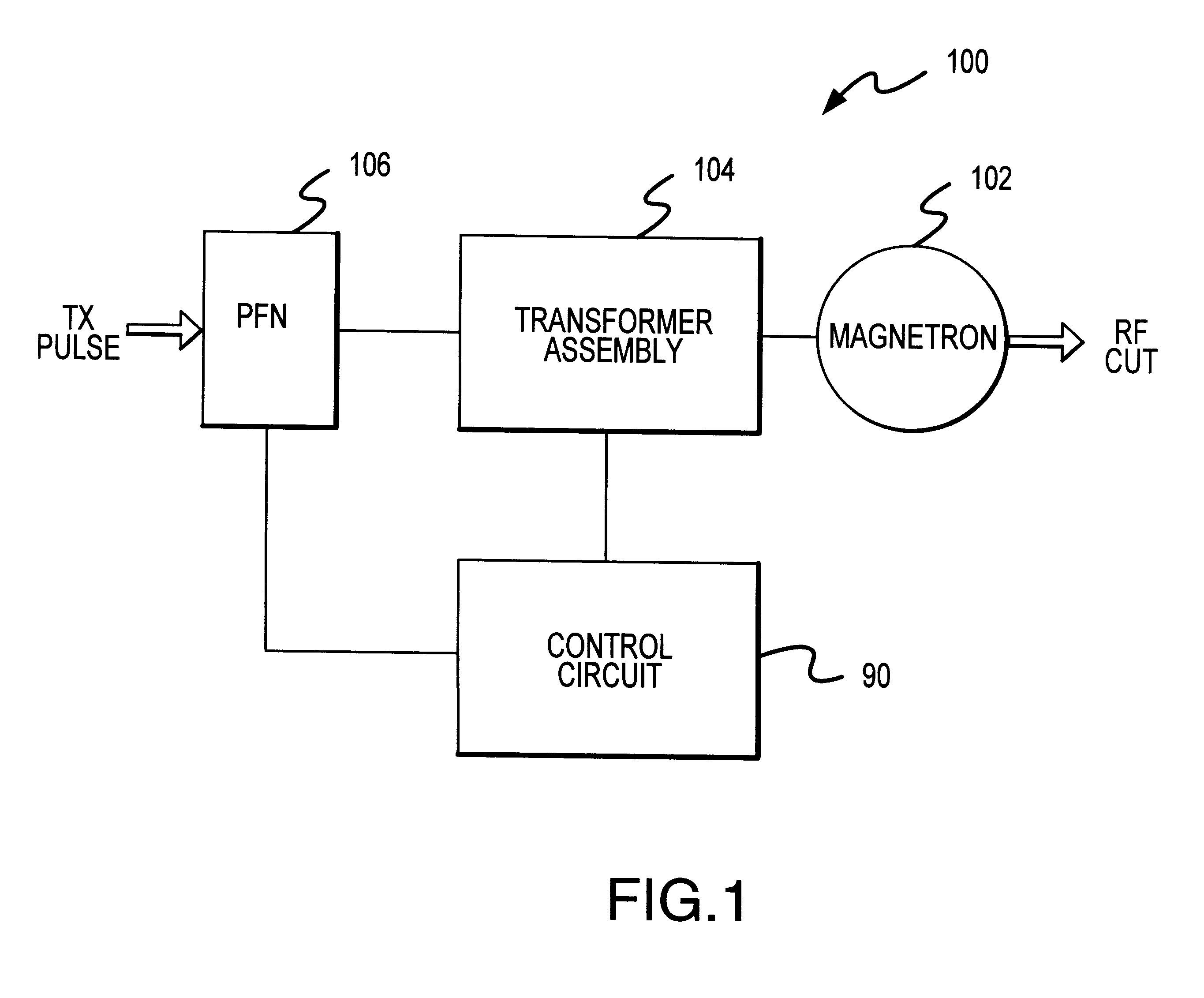

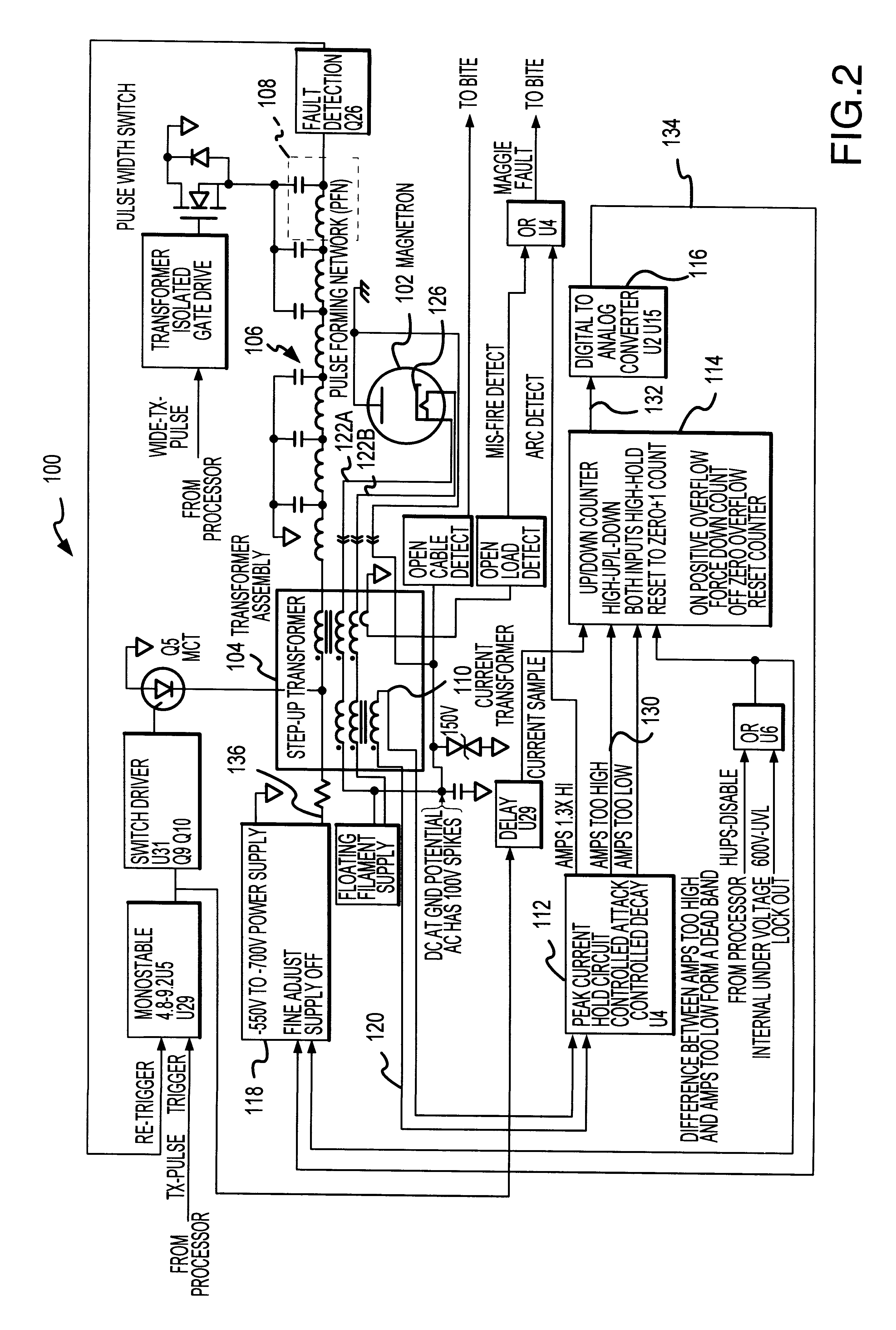

Methods and apparatus for the closed loop control of magnetron current

A fault-tolerant control system facilitates the closed loop control of a magnetron. The control system includes a transformer assembly for applying peak current to a magnetron, a pulse-forming network that conditions a transmit pulse, and a control circuit for adjusting the peak current applied to the magnetron. The control circuit includes a sample and hold circuit for comparing a signal representative of a detected peak current to a desired peak current level. The sample and hold circuit is coupled to a digital up / down counter circuit, and the output of the counter circuit is utilized to adjust the charge voltage of the pulse-forming network.

Owner:HONEYWELL INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com