Secondary-emission rare earth-molybdenum material and its preparing process

An emissive material, secondary technology, applied in the direction of electrical components, exhaust connections/feeds, gas discharge tubes/containers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

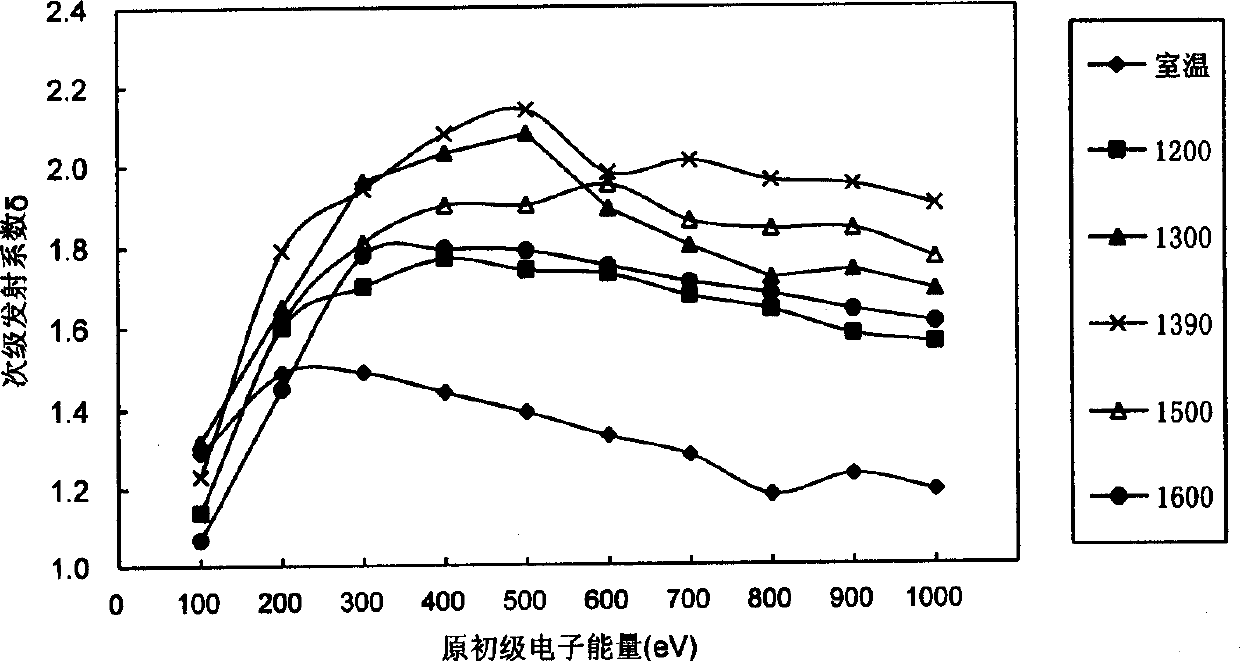

[0013] Example 1, 3.32 grams of lanthanum nitrate and 11.07 grams of yttrium nitrate were dissolved in water respectively, and added to 120.02 grams of powdered MoO 2 in (where La 2 o 3 Accounting for 2.5% by weight of molybdenum, Y 2 o 3 The weight ratio of molybdenum is 7.5%), the doped MoO 2 The powder is kept at 500°C under hydrogen for 2 hours to decompose rare earth nitrates into rare earth oxides, and then doped MoO in a multi-stage hydrogen furnace at 800-1000°C 2 Powder reduced to doped La 2 o 3 and Y 2 o 3 The composite rare earth aluminum powder is made into a rare earth molybdenum rod with a certain size after pressing and sintering. After machining, a rare earth molybdenum sheet of φ10×1mm is made. Then laser welding is used to weld the rare earth molybdenum sheet with the molybdenum cylinder and the metal tungsten wire used for heating, and after exhausting and activation treatment, the rare earth molybdenum experimental magnetron is made. The secondary...

example 2

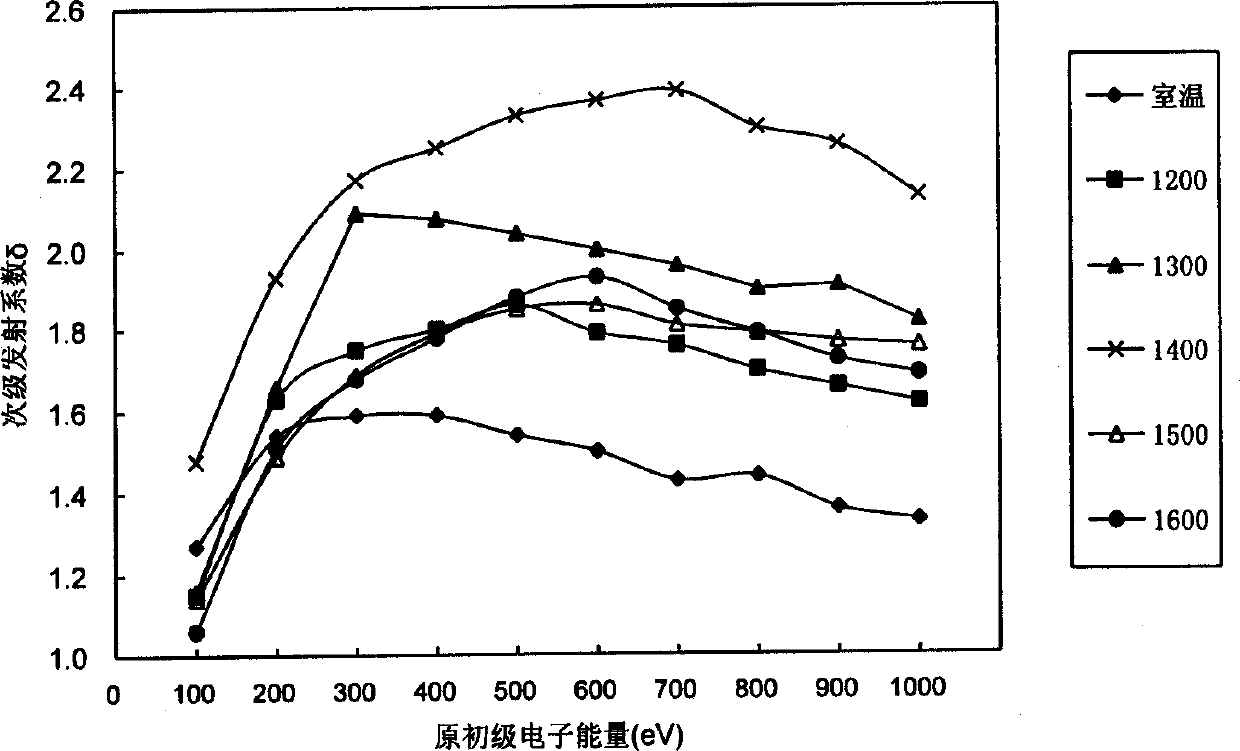

[0014] Example 2, 4.98 grams of lanthanum nitrate and 16.60 grams of yttrium nitrate were dissolved in water respectively, and added to 113.35 grams of powdered MoO 2 in (where La 2 o 3 The weight ratio of molybdenum is 3.75%, Y 2 o 3 The weight ratio of molybdenum is 11.25%), the doped MoO 2 The powder is kept at 500°C under hydrogen for 2 hours to decompose rare earth nitrates into rare earth oxides, and then doped MoO in a multi-stage hydrogen furnace at 800-1000°C 2 Powder reduced to doped La 2 o 3 and Y 2 o 3 The composite rare earth molybdenum powder is made into a rare earth molybdenum rod with a certain size after pressing and sintering. After machining, a rare earth molybdenum sheet of φ10×1mm is made. Then laser welding is used to weld the rare earth molybdenum sheet with the molybdenum cylinder and the metal tungsten wire used for heating, and after exhausting and activation treatment, the rare earth molybdenum experimental magnetron is made. The secondary...

example 3

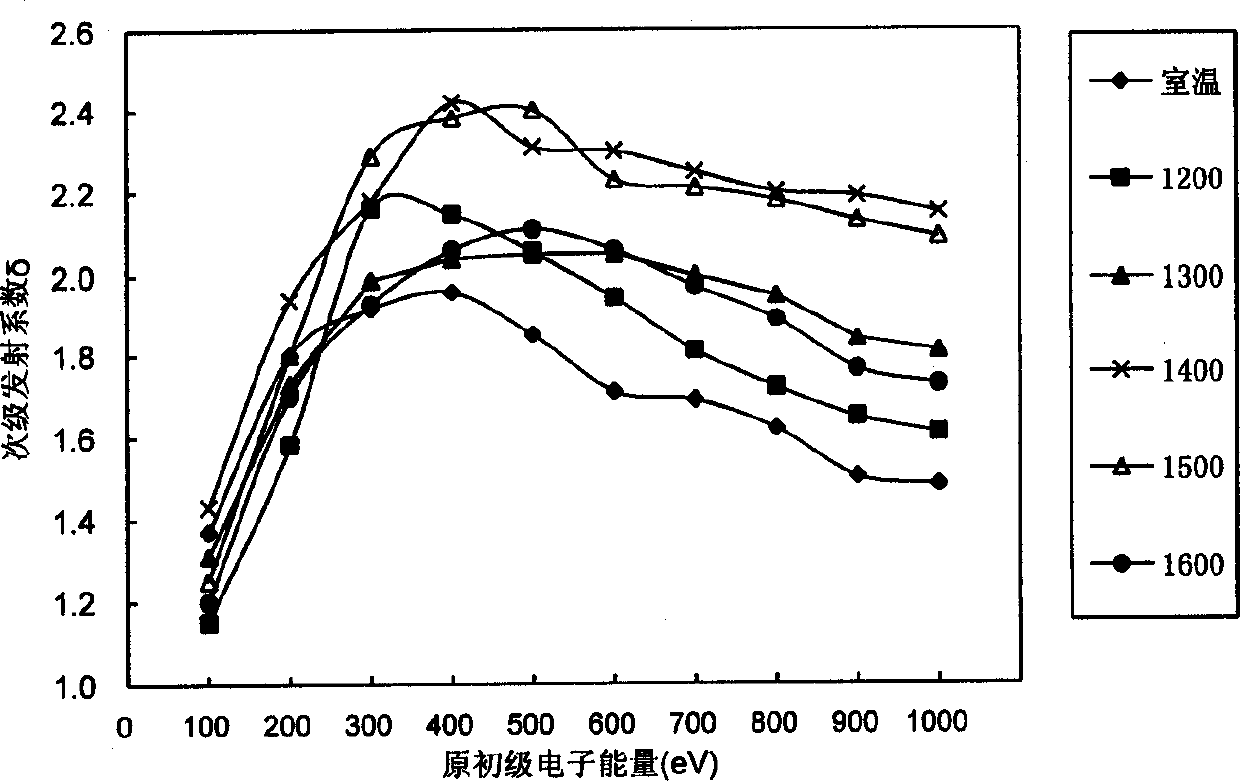

[0015] Example 3, 6.64 grams of lanthanum nitrate and 22.14 grams of yttrium nitrate were dissolved in water respectively, and added to 106.68 grams of powdered MoO 2 in (where La 2 o 3 Accounting for 5% by weight of molybdenum, Y 2 o 3 The weight ratio of molybdenum is 15%), the doped MoO 2 The powder is kept at 500°C under hydrogen for 2 hours to decompose rare earth nitrates into rare earth oxides, and then doped MoO in a multi-stage hydrogen furnace at 800-1000°C 2 Powder reduced to doped La 2 o 3 and Y 2 o 3 The composite rare earth molybdenum powder is made into a rare earth molybdenum rod with a certain size after pressing and sintering. After machining, a rare earth molybdenum sheet of φ10×1mm is made. Then laser welding is used to weld the rare earth aluminum sheet with the molybdenum cylinder and the metal tungsten wire used for heating, and after exhausting and activation treatment, the rare earth molybdenum experimental magnetron is made. The secondary em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com