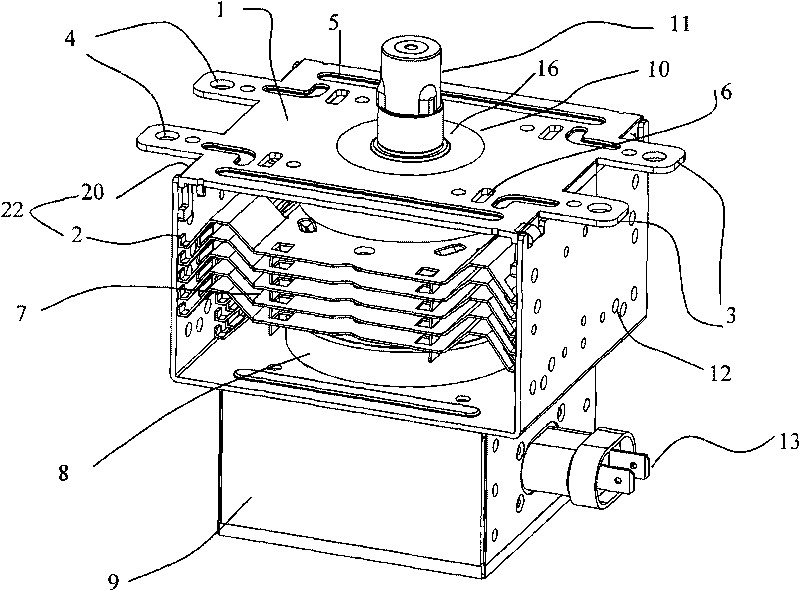

Upper yoke plate structure of magnetron of microwave oven

A technology of magnetron and microwave oven, applied in magnetron, discharge tube, transit time type electron tube, etc., can solve the problems of inconvenient disassembly and assembly, increase of production cost and technical requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

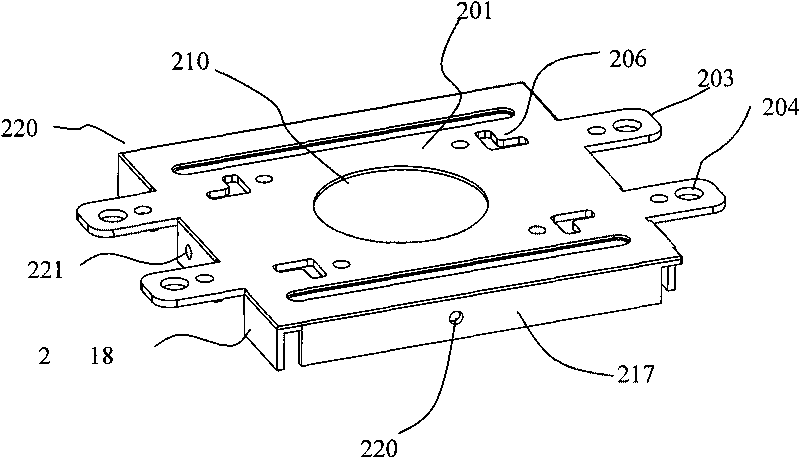

[0040] image 3 It is a schematic diagram of the upper yoke plate of the first embodiment of the present invention, and the upper yoke plate 220 shown can be installed on the lower yoke plate alternatively in the horizontal direction and in the vertical direction. from image 3 It can be seen that the two ends of the upper yoke plate 220 are symmetrically provided with four protruding pieces 203; each protruding piece 203 is provided with two mounting holes 204; The part outside 204 bends inward and extends along the direction perpendicular to the upper yoke plate 220 to form the first side baffle 218, wherein the first side baffle 218 is provided with a mounting hole 221; the upper yoke plate 220 The remaining two ends are bent inward and extend in a direction perpendicular to the upper yoke 220 to form a second side baffle 217 , and the second side baffle is provided with a mounting hole 220 . The installation hole 221 is located on the middle first baffle 218 , and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com