Biological hydrogen production method for improving hydrogen generation efficiency and stability

A technology of biological hydrogen production and stability, applied in the field of hydrogen production, can solve the problems of unstable and continuous hydrogen production, low hydrogen production efficiency of floc sludge, etc., and achieve the effect of strong resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Preparation of synthetic organic wastewater: Add 5g / L sucrose to tap water and add 374mg / L NH at the same time 4 HCO 3 , 97mg / LK 2 HPO 4 .3H 2 O, be mixed with organic waste water; The chemical oxygen demand concentration of organic waste water is 5.3g / L, and organic waste water pH is controlled at 7.0 by 2mol / L HCl and 2mol / L NaOH solution, puts into refrigerator and makes the temperature of organic waste water keep as 4°C.

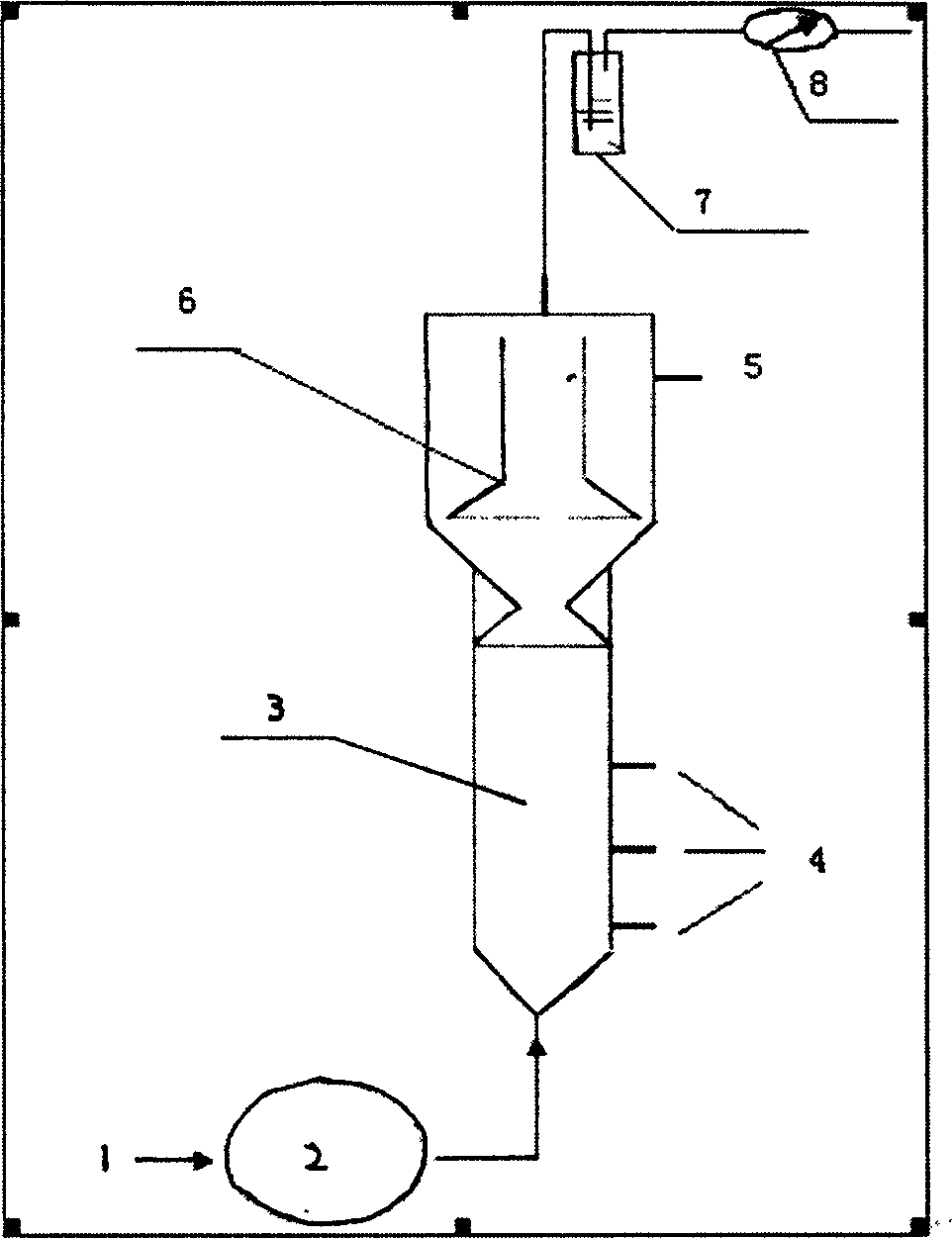

[0011] First add methanogenic floc sludge in reactor 3, make the concentration of volatile suspended solids in the reactor be 6.3g / L, then organic waste water 1 enters reactor 3 by feed pump 2, the diameter of reactor 100mm, total The volume is 4.7L, of which the volume of the reaction zone is 2.1L. The anaerobic sludge inoculated in the reactor was anaerobic methanogenic floc sludge from the treatment of citric acid wastewater by Biobroad Chemical Co., Ltd., with an initial pH of 7.1. The flow rate of the feed pump is controlled so that the...

Embodiment 2

[0016] Preparation of synthetic organic wastewater: Add 7.5g / L sucrose to tap water and add 846mg / LNH at the same time 4 HCO 3 , 221mg / L K 2 HPO 4 .3H 2 O, formulated as organic wastewater; the chemical oxygen demand concentration of organic wastewater is 8g / L, and the pH of organic wastewater is controlled at 7.0 by 2mol / L HCl and 2mol / L NaOH solution, and the temperature of organic wastewater is kept at 4 in the refrigerator ℃.

[0017] First add anaerobic methanogenic floc sludge to the reactor 3, so that the concentration of volatile suspended solids in the reactor is 6.3g / L, and then the organic waste water 1 enters the reactor 3 through the feed pump 2, and the diameter of the reactor is 100mm , the total volume is 5.0L, of which the volume of the reaction zone is 2.6L. The anaerobic sludge inoculated in the reactor is anaerobic methanogenic floc sludge from the treatment of citric acid wastewater by Fengyuan Chemical Co., Ltd. The initial pH is 7.1, and the flow ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com