Rider-type solid-density measuring instrument

A density tester and floating code technology, which is applied in the direction of material analysis by measuring buoyancy, can solve the problems of high environmental requirements, inaccuracy, and large weighing errors of electronic scales.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

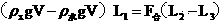

[0075] figure 2The collar (7) in the middle is sleeved on the lever (5) and is close to the surface of the lever and can slide freely on the lever. There is a fastening screw (6) on the collar (7). When the fastening screw is unscrewed, the collar can slide freely on the lever. When the fastening screw is tightened, the collar is temporarily locked. fixed on the lever. The two ear ends of the lifting lug (8) are hung on the front and rear sides of the collar (7) respectively, and the lifting lug and the collar are connected by live rivets, regardless of whether the collar (7) has been fastened by the screw (6) Fixed, the lifting lug (8) can freely rotate around the live rivet in a clockwise or counterclockwise direction. One end of the thin wire (9) passes through a small hole in the center of the bottom of the lifting ear (8) and is fixed. Two weighing pans are suspended on the thin wire (9), wherein one of the weighing pans (10) is in the air, and the other is in the air....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com