Patents

Literature

45 results about "Density of solids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength hot rolled steel sheet being free from peeling and excellent in surface properties and burring properties, and method for manufacturing the same

ActiveUS20100108201A1Improve surface propertiesMaintain good propertiesHot-dipping/immersion processesFurnace typesSheet steelReduction ratio

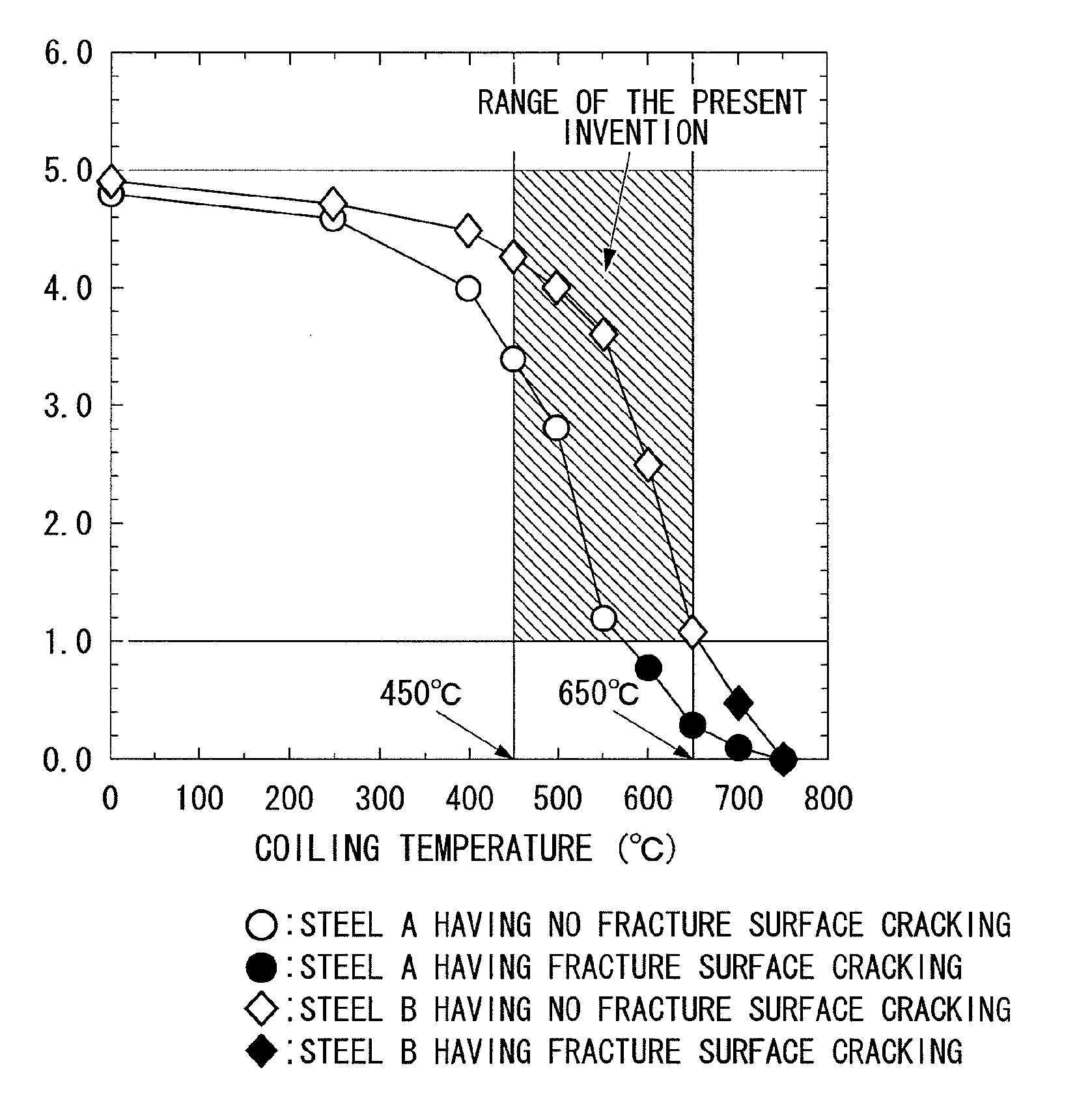

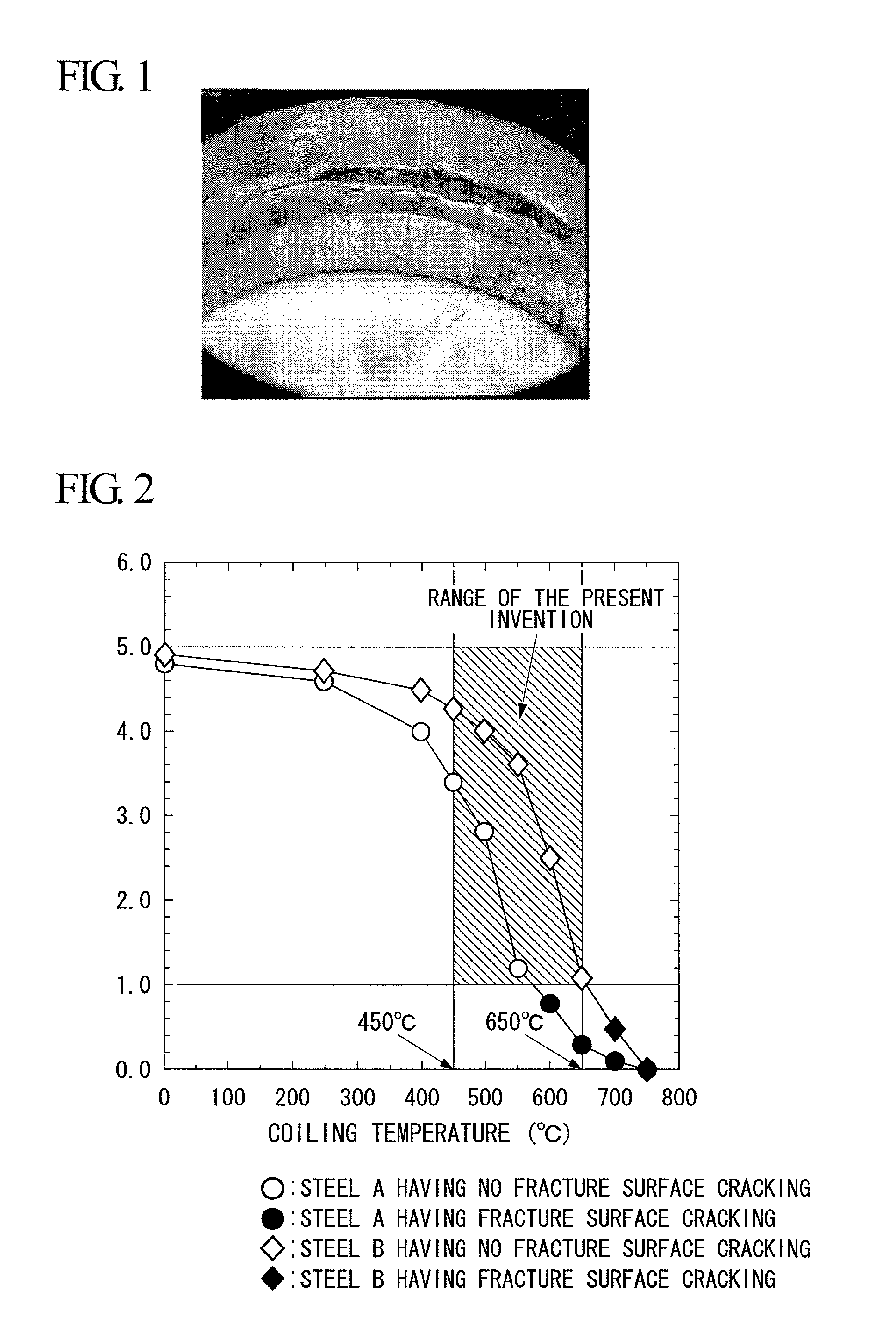

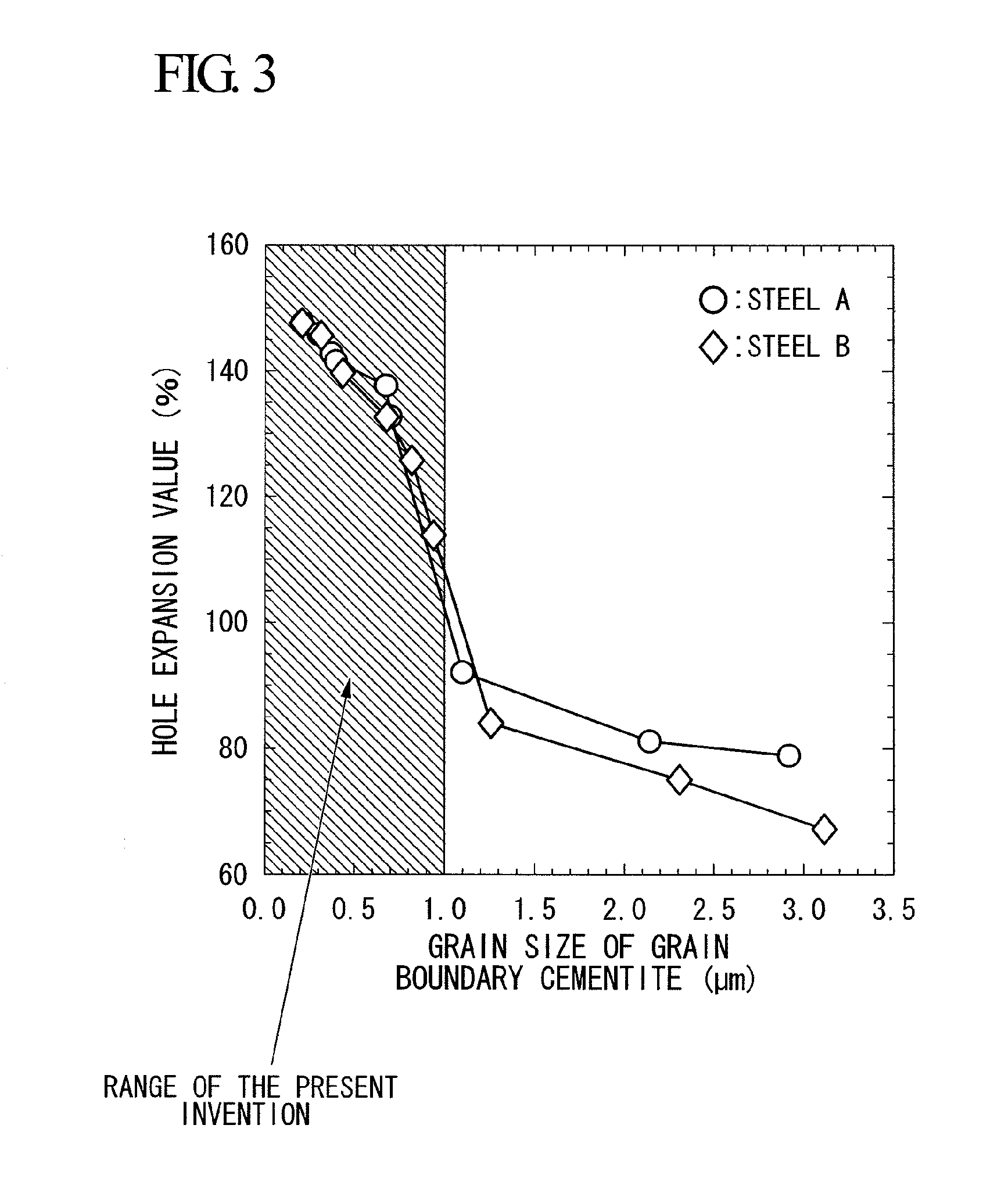

This hot rolled steel contains, in terms of mass %, C: 0.01 to 0.1%, Si: 0.01 to 0.1%, Mn: 0.1 to 3%, P: not more than 0.1%, S: not more than 0.03%, Al: 0.001 to 1%, N: not more than 0.01%, Nb: 0.005 to 0.08%, and Ti: 0.001 to 0.2%, with a remainder being iron and unavoidable impurities, wherein a formula: [Nb]×[C]≦4.34×10−3 is satisfied, a grain boundary density of solid solution C is not less than 1 atom / nm2 and not more than 4.5 atoms / nm2, and a grain size of cementite grains precipitated at grain boundaries within the steel sheet is not more than 1 um. This method for manufacturing a hot rolled steel sheet includes: heating a steel slab having the same composition as the above hot rolled steel sheet at a temperature that is not less than a temperature of SRTmin (° C.) and not more than 1,170° C.; performing rough rolling at a finishing temperature of not less than 1,080° C. and not more than 1,150° C.; subsequently starting finish rolling within not less than 30 seconds and not more than 150 seconds at a temperature of not less than 1,000° C. but less than 1,080° C.; completing the finish rolling within a temperature range from not less than an Ar3 transformation point temperature to not more than 950° C. so as to achieve a final pass reduction ratio of not less than 3% and not more than 15%; and conducting cooling at a cooling rate exceeding 15° C. / sec from a cooling start temperature to a temperature within a range from not less than 450° C. to not more than 550° C., and then coiling the steel sheet.

Owner:NIPPON STEEL CORP

Uniform phase distribution device in liquid contained multiphase fluidized system

A uniform phase-distributing apparatus in the liquid-contained multi-phase fluidizing system where the density of solid phase is higher than that of liquid phase features that the material feeding inlet is arranged on the bottom of case, the sleeve pipe structure consisting of at least two nested pipes is arranged on the top of case, and the predistributor and master distributor are used. Its advantage is stable fluidizing state.

Owner:TIANJIN UNIV

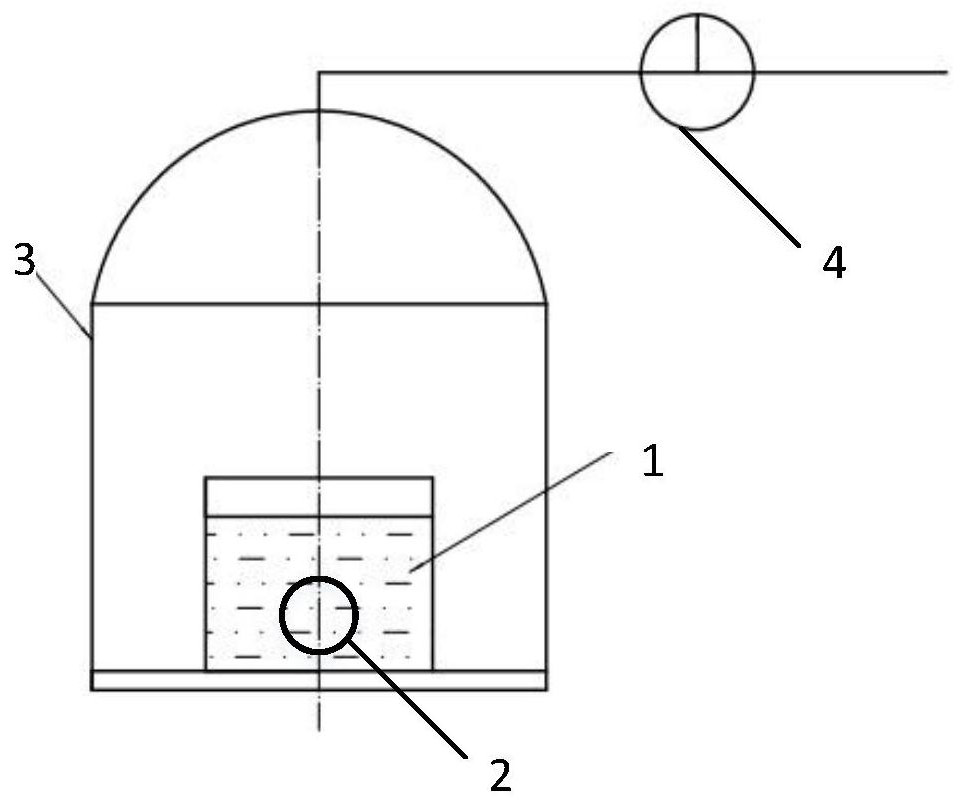

Measurement method for density of solid material

InactiveCN103323368ASimple methodFast wayMaterial analysis by measuring buoyant forcesMeasurement precisionElectron

The invention relates to a measurement method for the density of a solid material, which is mainly applied to experiment teaching of universities and technical secondary schools. The method comprises the following steps of: measuring the mass m3 of a solid material sample to be detected by an electronic scale; placing a container containing water with the density of Rho0 on the electronic scale, and immersing a special sample container into the water, wherein the special sample container does not contact the container for containing the water, and the reading of the electronic scale is m2; placing the solid material sample to be detected into the special sample container and immersing the sample and the sample container into the water, wherein the sample does not contact the sample container, and the reading of the electronic scale at the moment is m4; and solving the density of the sample to be detected. The method disclosed by the invention is simple, convenient, rapid and high in measurement precision and is applicable to solid material samples with different densities and different shapes.

Owner:HUNAN UNIV OF TECH

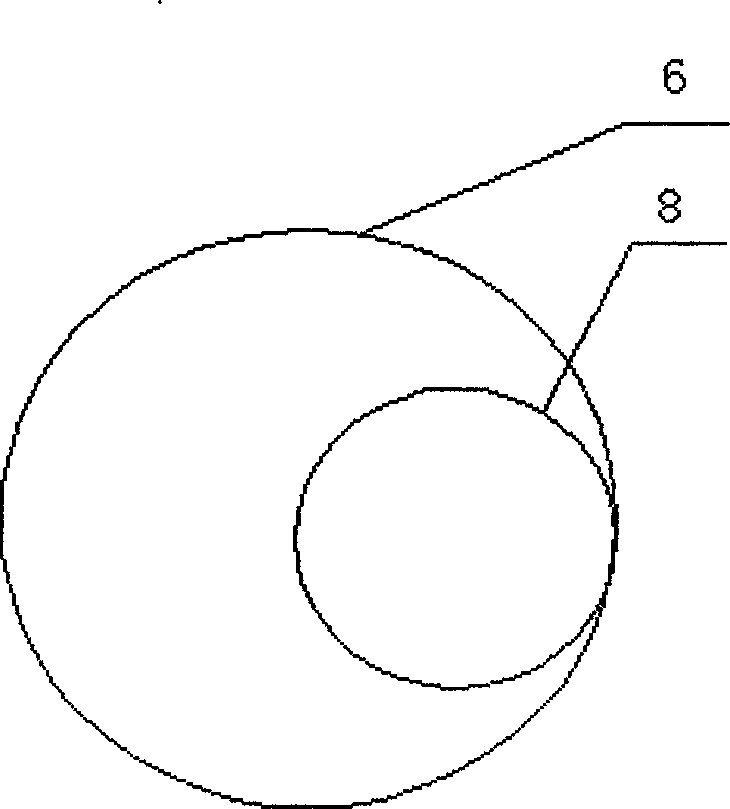

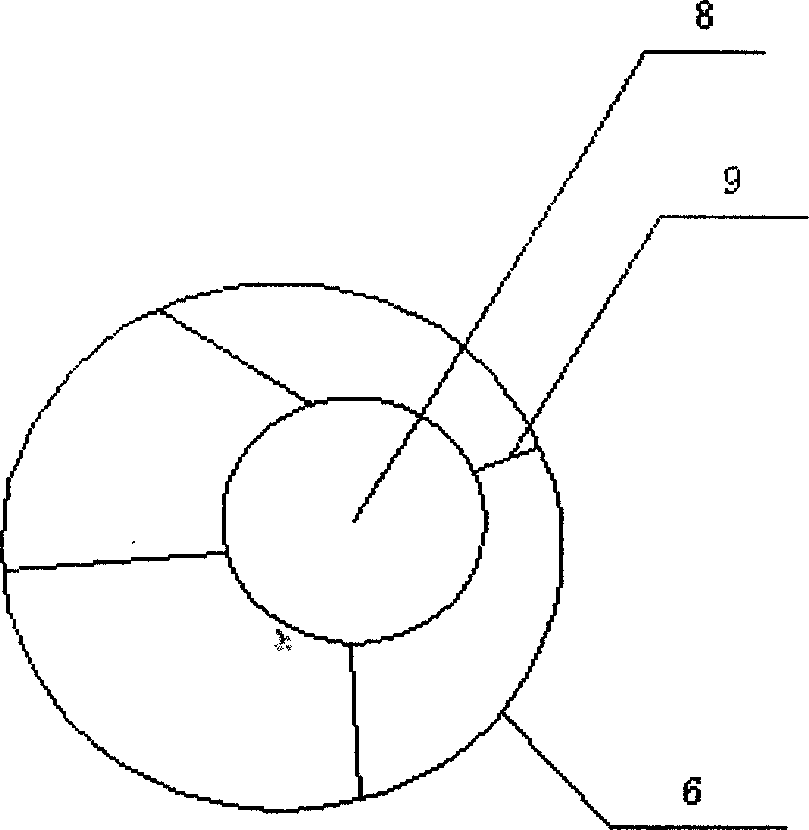

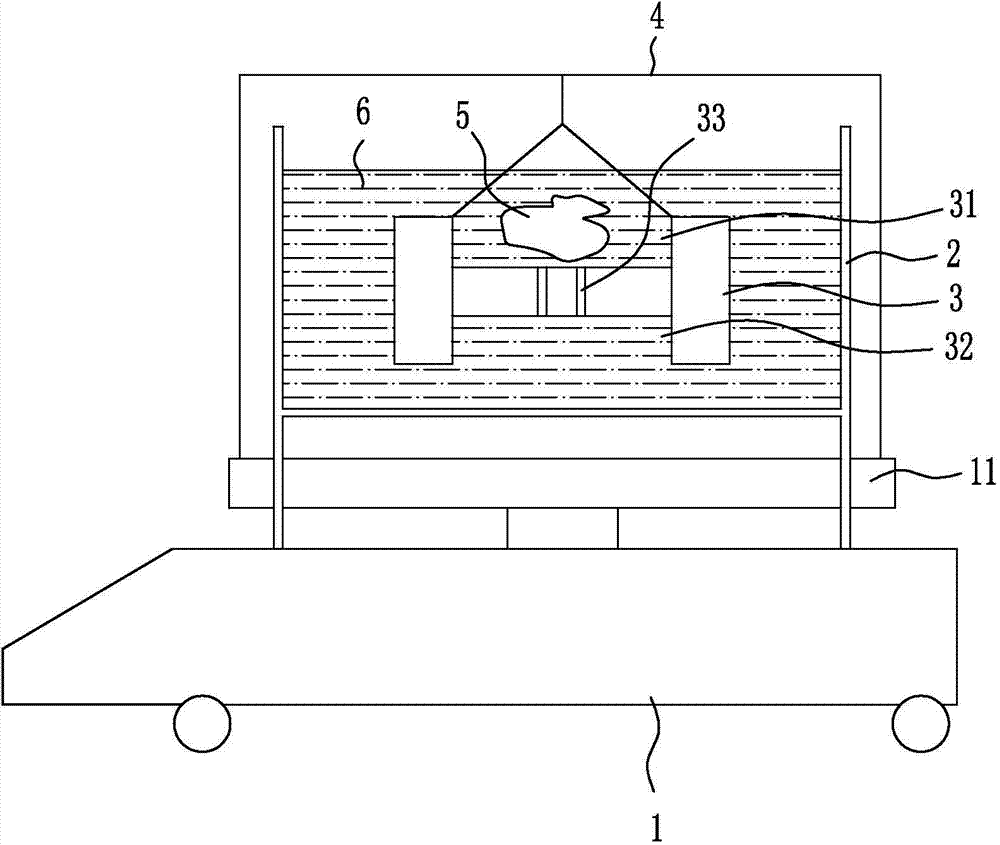

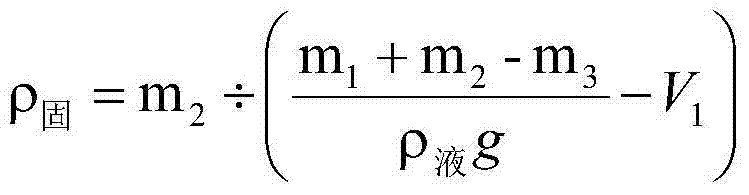

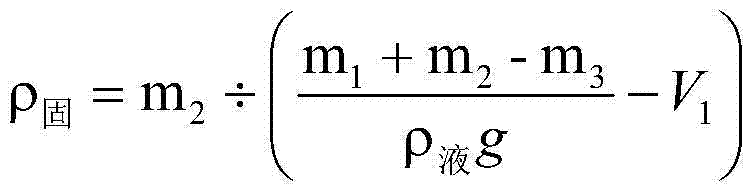

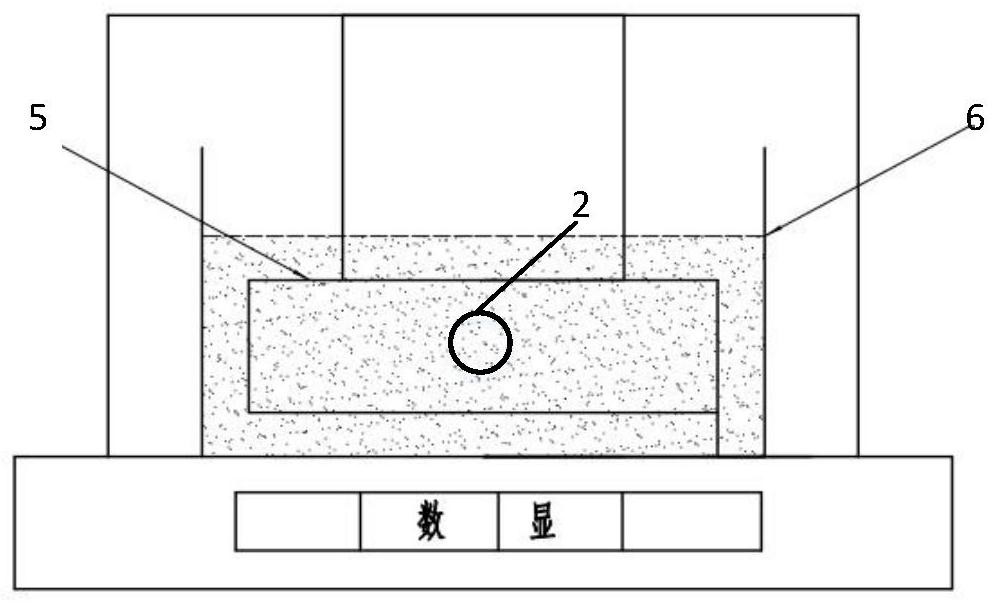

Solid density detection method and device

InactiveCN104280312ADensity is accurateDensity made easy and preciseSpecific gravity measurementSolid densityPhysical chemistry

The invention discloses a solid density detection method, comprising the following steps: preparing a special weight capable of bearing or pressing a to-be-detected solid to immerse into liquid, wherein the weight has known V1 and mass m1 and is not infiltrated by the liquid; weighing the mass m2 of the to-be-detected solid; weighing the mass m3 of the special weight together with the to-be-detected solid immersed into the liquid with the known density being rho(liquid); and determining the density rho(solid) of the to-be-detected solid by virtue of a formula. A detection device adopting the method comprises a container and a special weight, wherein the container is used for weighing and containing the liquid; the special weight is partitioned into an upper cavity and a lower cavity; and a communicating hole is formed between the upper cavity and the lower cavity of the weight. Due to adoption of the solid density detection method and device disclosed by the invention, measurement of the solid density is simple and accurate, and on-site rapid and accurate measurement of the density of a solid sample can be achieved.

Owner:MODENA TECH LTD

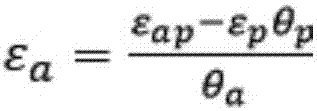

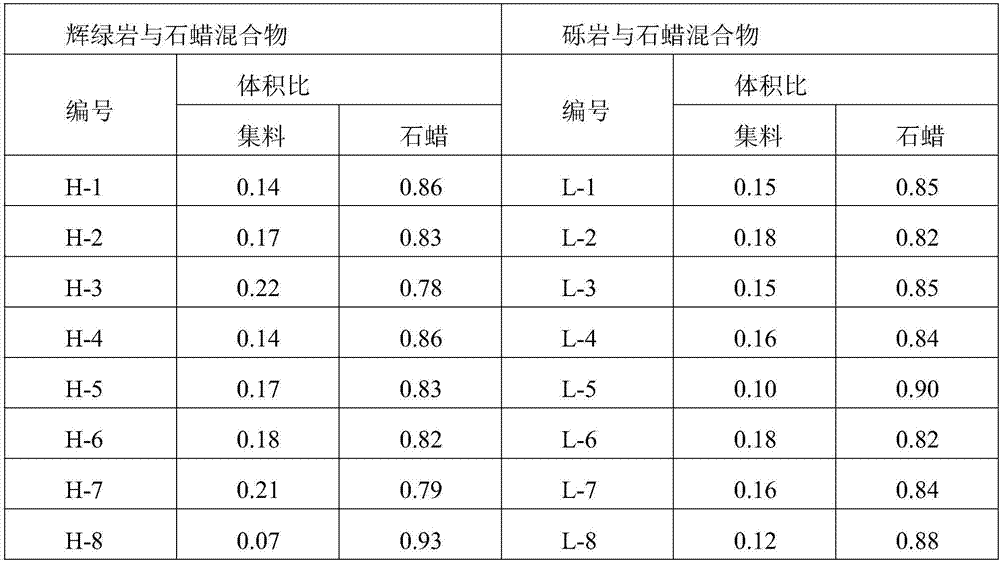

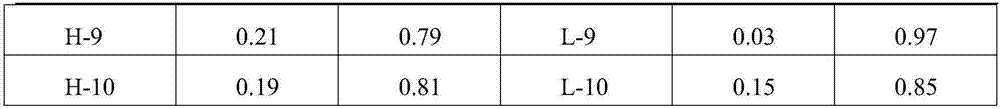

Method for detecting dielectric constant of irregularly-shaped aggregate

InactiveCN106932651AImprove detection accuracyGood application effectDielectric property measurementsDielectricParaffin oils

The present invention discloses a method for detecting the dielectric constant of an irregularly-shaped aggregate. The method comprises the following steps that: after being weighed, the irregularly-shaped aggregate is mixed with liquid paraffin, and the mixture of the irregularly-shaped aggregate and the liquid paraffin is poured into a mold, after the mixture is cooled, so that a regularly-shaped paraffin and aggregate two-phase mixture can be obtained; a pure paraffin sample is prepared with the same mold; the sample is weighed, and the volume of the sample is calculated, so that the density of solid paraffin is obtained, and the volume ratio of the paraffin to the aggregate in the paraffin and aggregate two-phase mixture is obtained; the dielectric constants of the pure paraffin sample and the two-phase mixture are measured through a dielectric constant test system; and a composite material linear model is inferred, so that the dielectric constant calculation formula of the aggregate can be obtained. The test method used in the invention is simple and convenient, can measure the dielectric constant of the irregularly-shaped aggregate and is of great significance for the research of the dielectric properties of asphalt mixtures and the improvement of the detection precision and applicability of ground penetrating radars. The test method can meet actual requirements from the aspects of the rationality of test schemes and the convenience of test operation.

Owner:WUHAN UNIV OF TECH

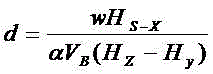

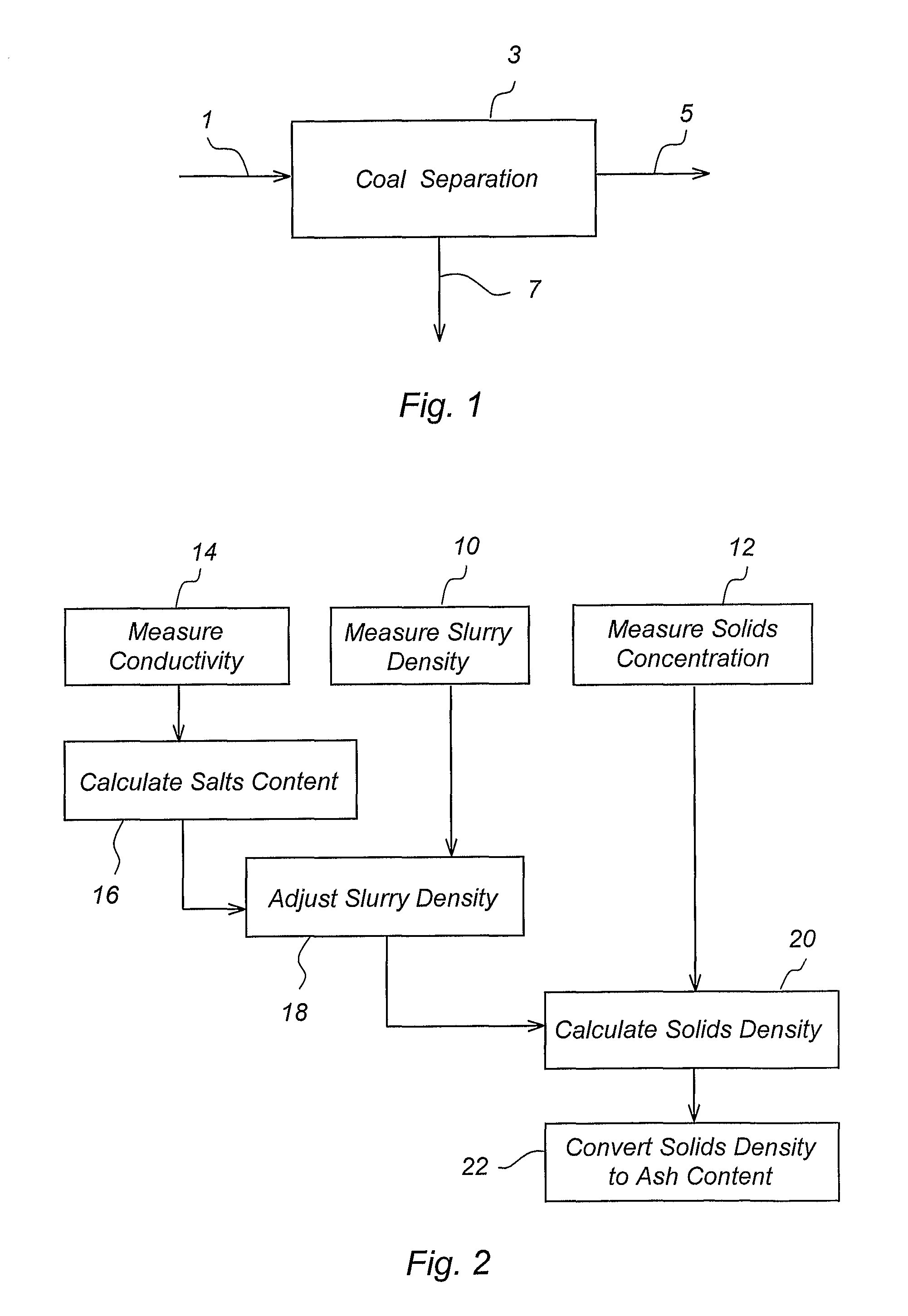

Method of Analysis and an Analyzer

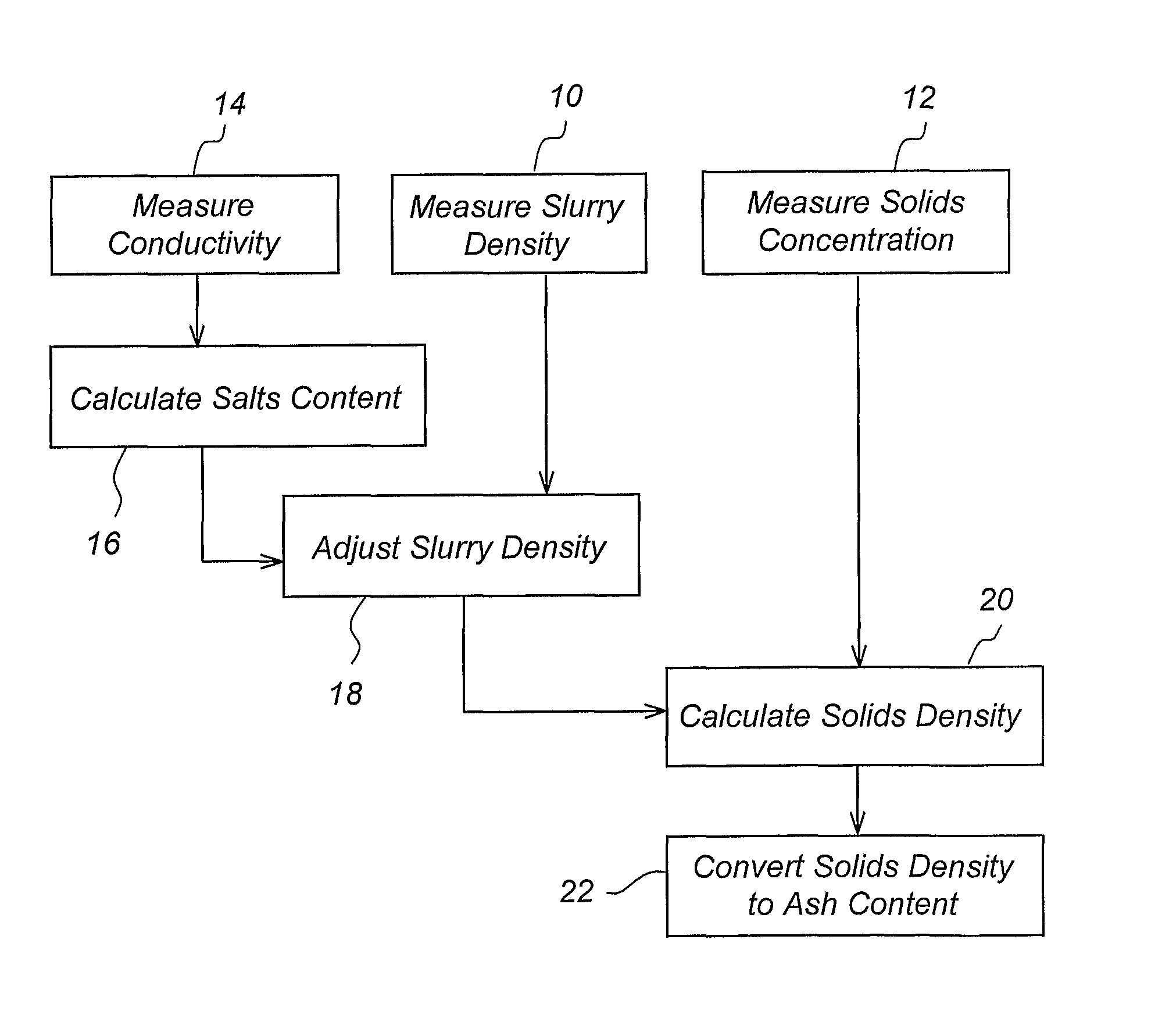

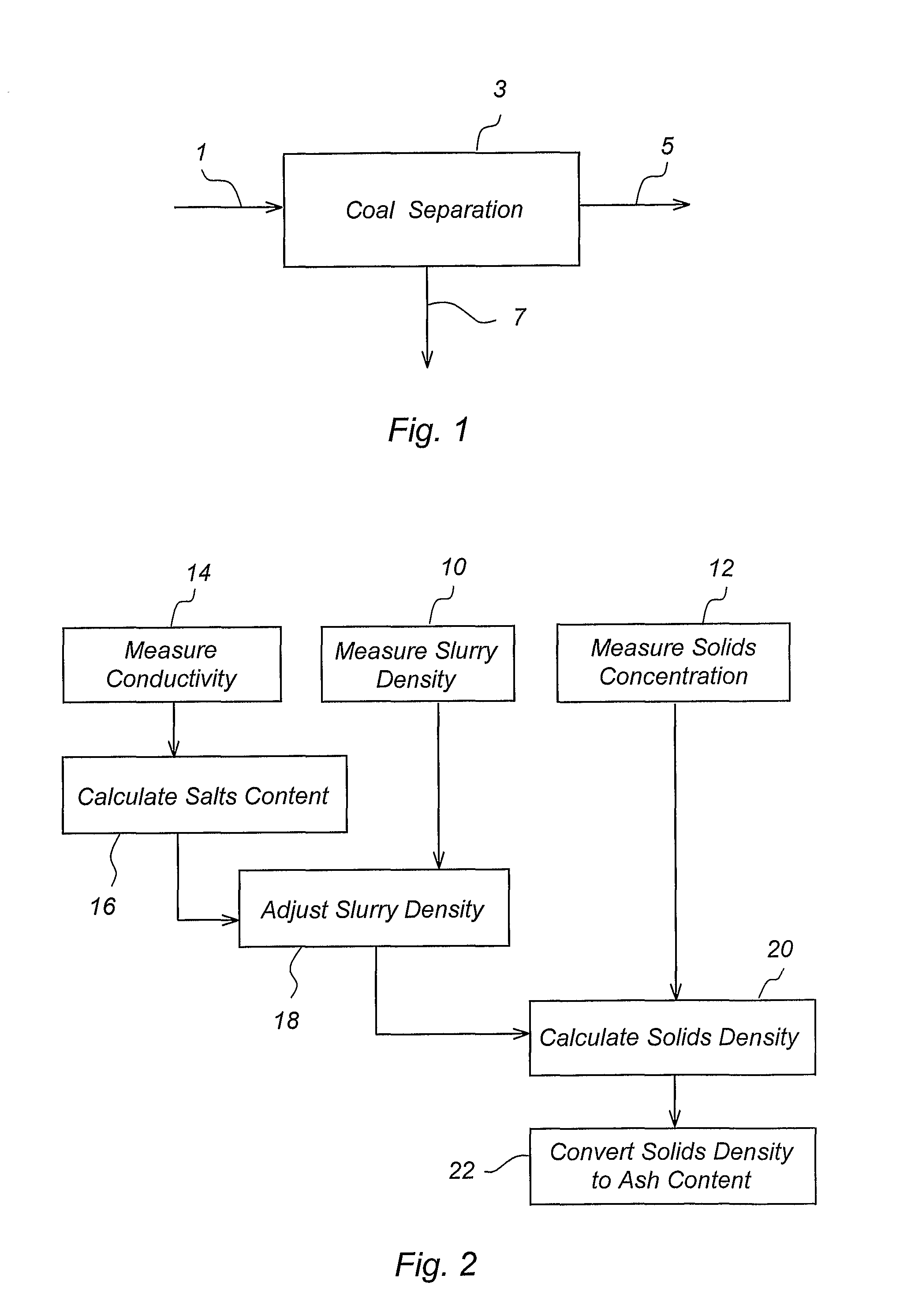

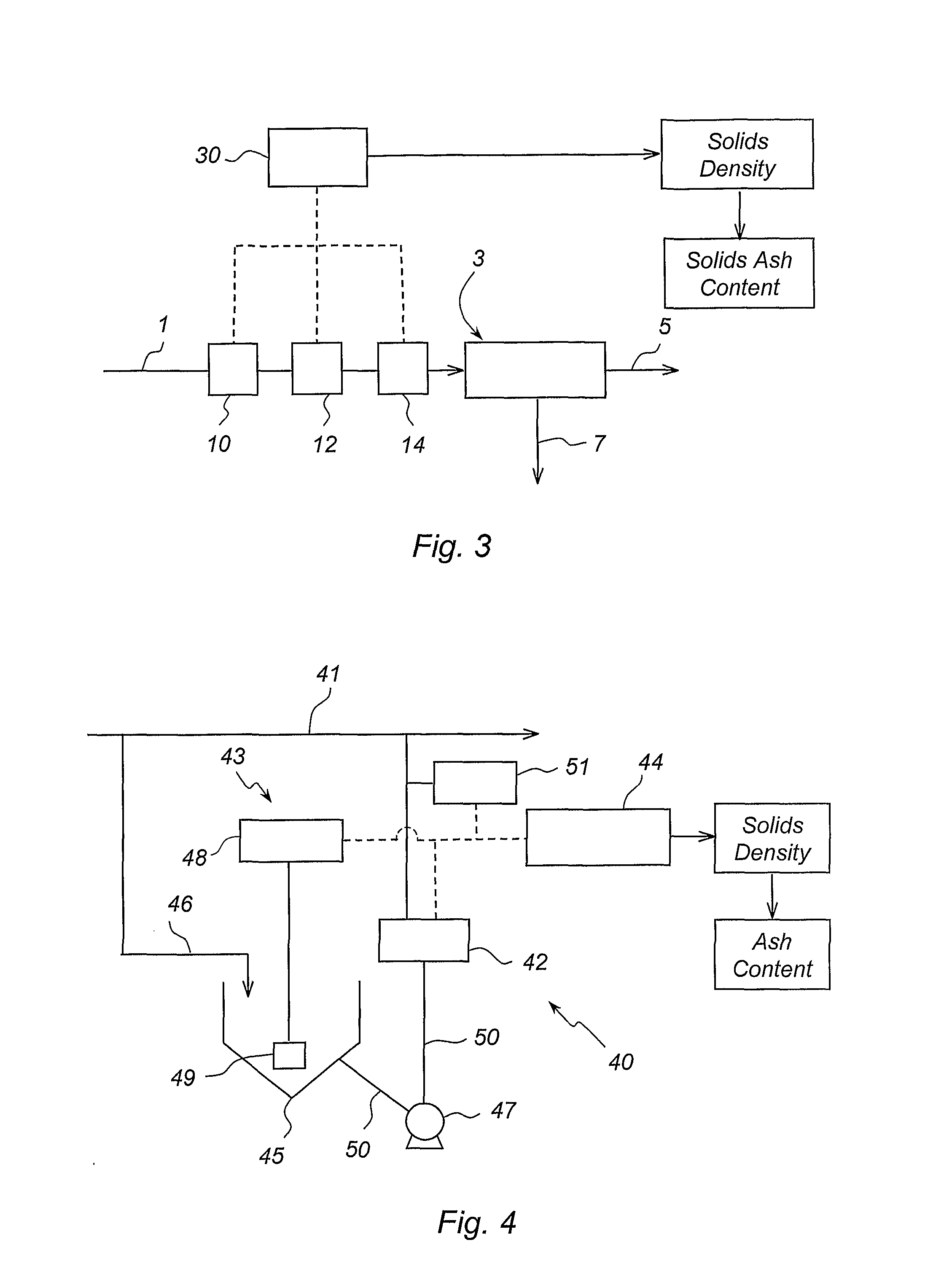

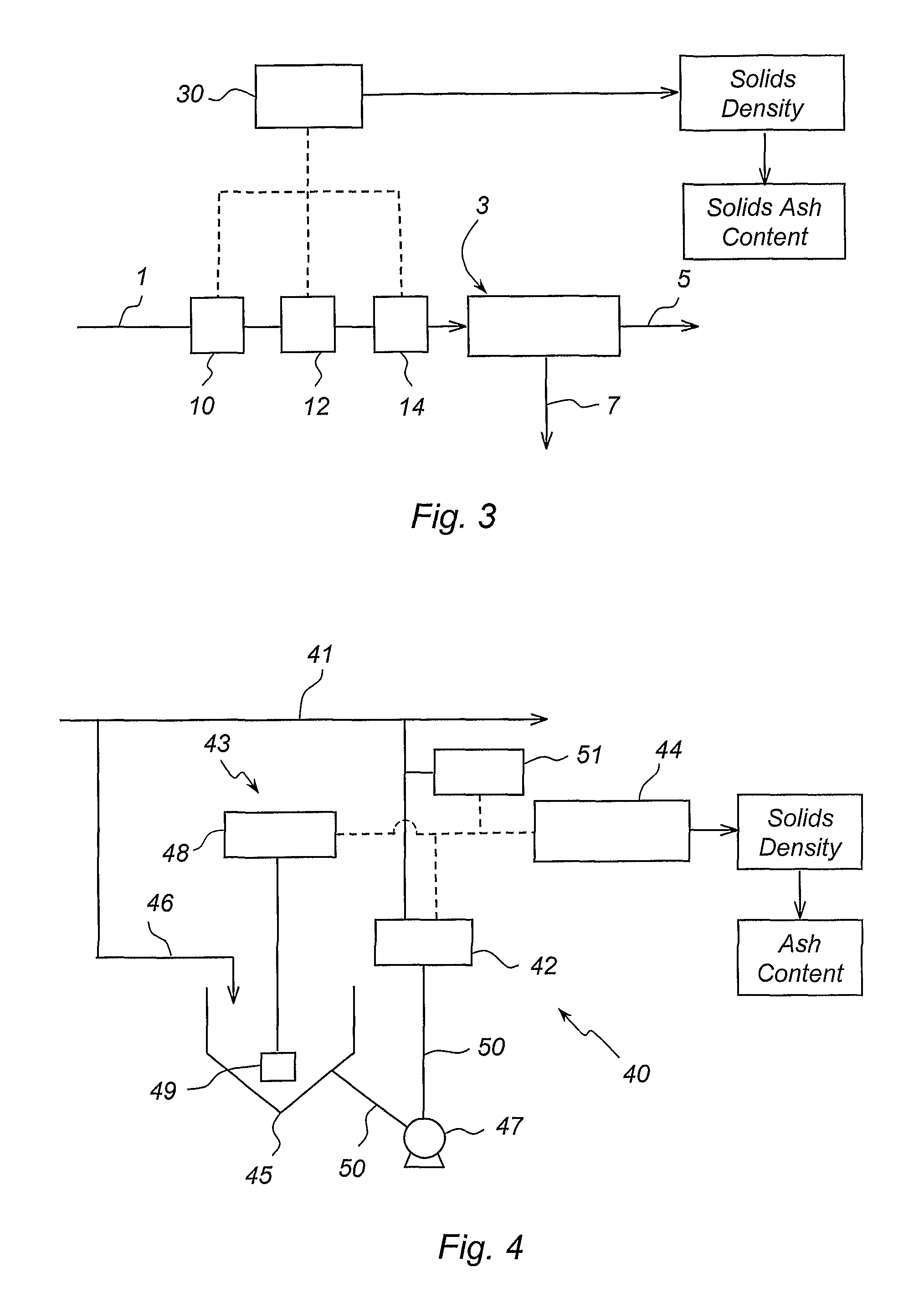

InactiveUS20080262783A1Avoid the needEasy to separateDigital computer detailsFlotationSlurryAnalysis method

The present invention provides a method of online analysis of mineral waste content of a slurry in a mineral separation process, said method including the steps of: measuring the density of said slurry (10); measuring the concentration of solids in said slurry (12); calculating the density of solids in said slurry from said slurry density and said solids concentration (20); and calculating said mineral waste content from said solids density (22). The present invention also provides an online analyser for mineral waste content of a slurry in a mineral separation process.

Owner:NEWCASTE INNOVATION LTD

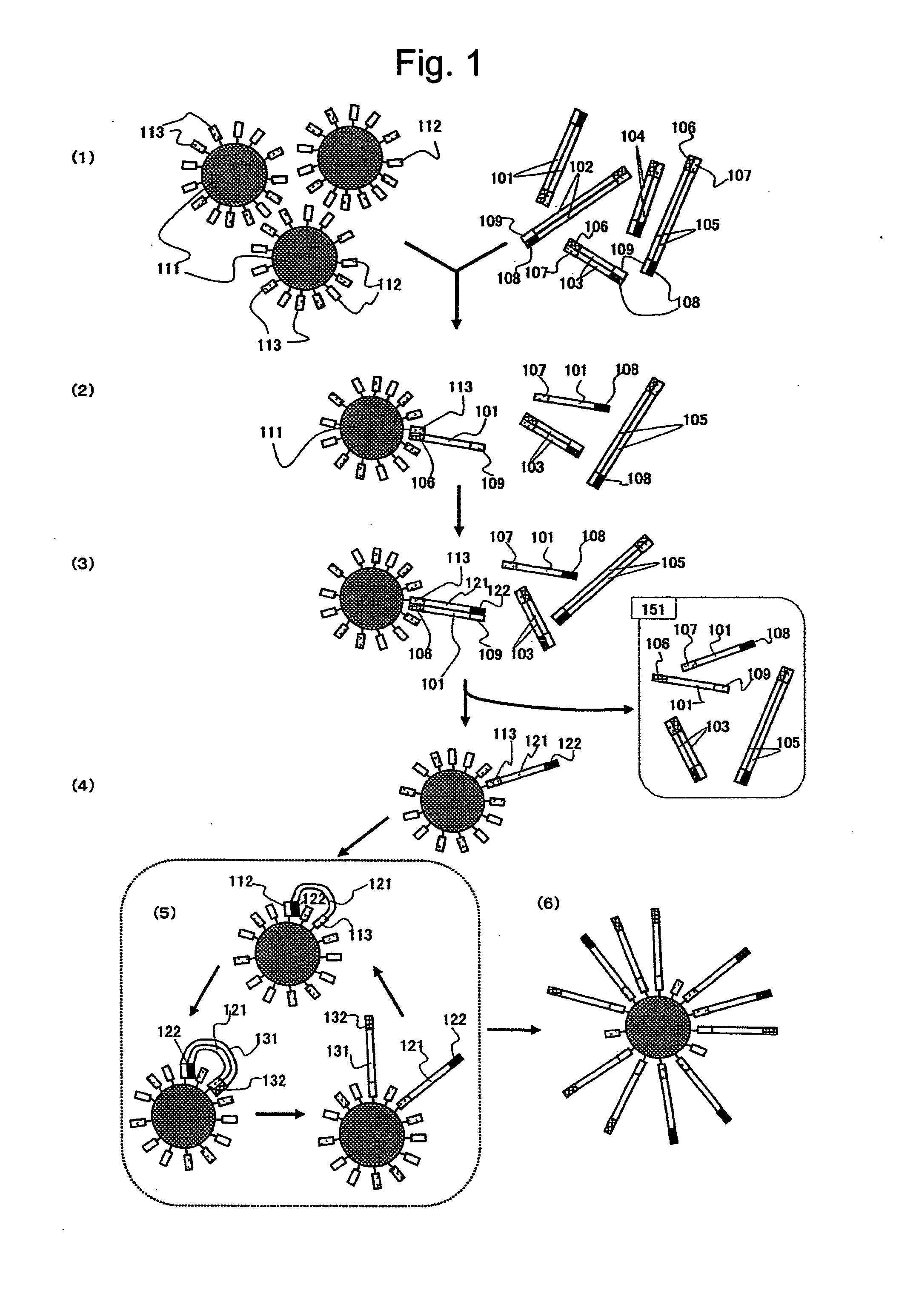

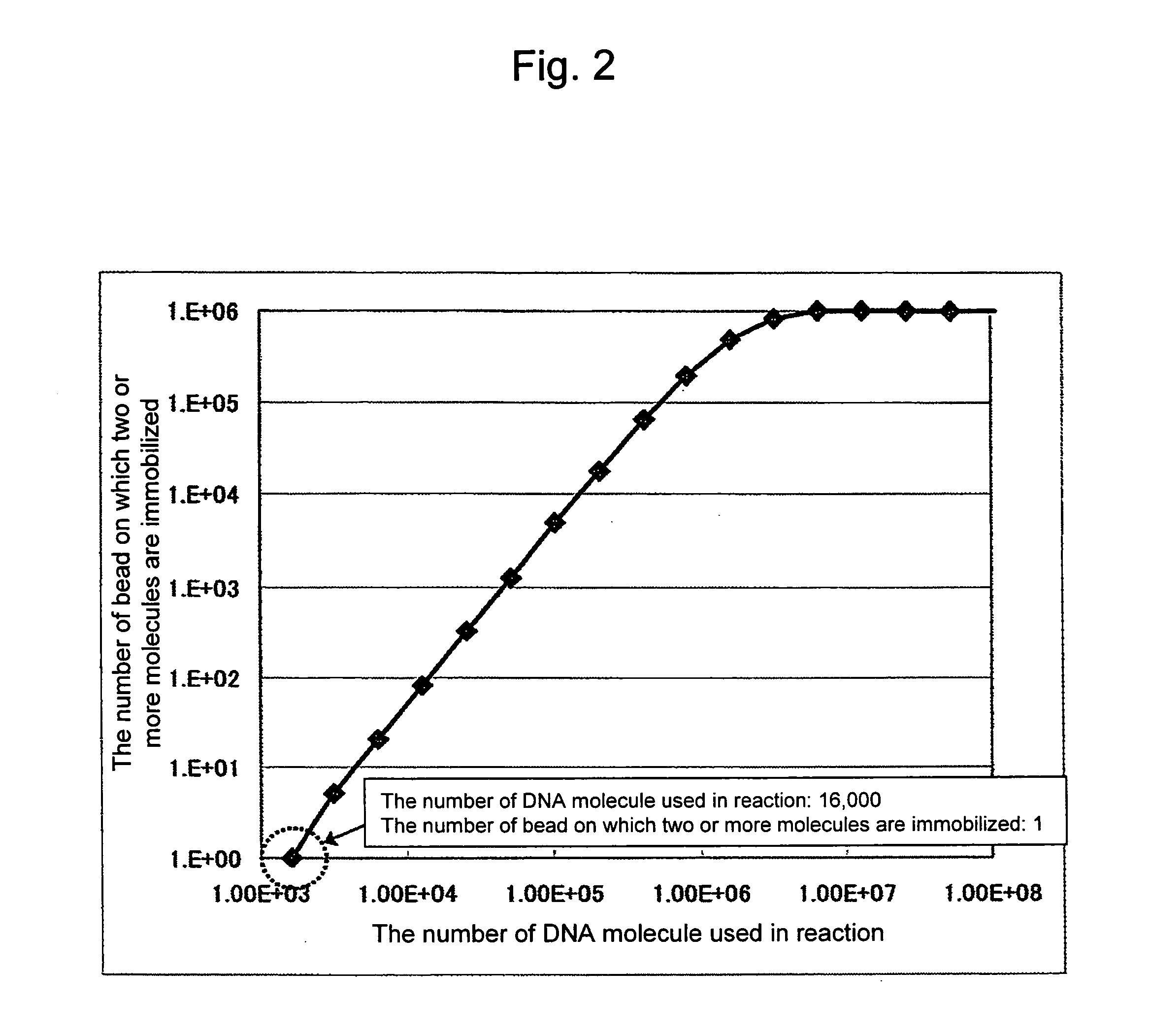

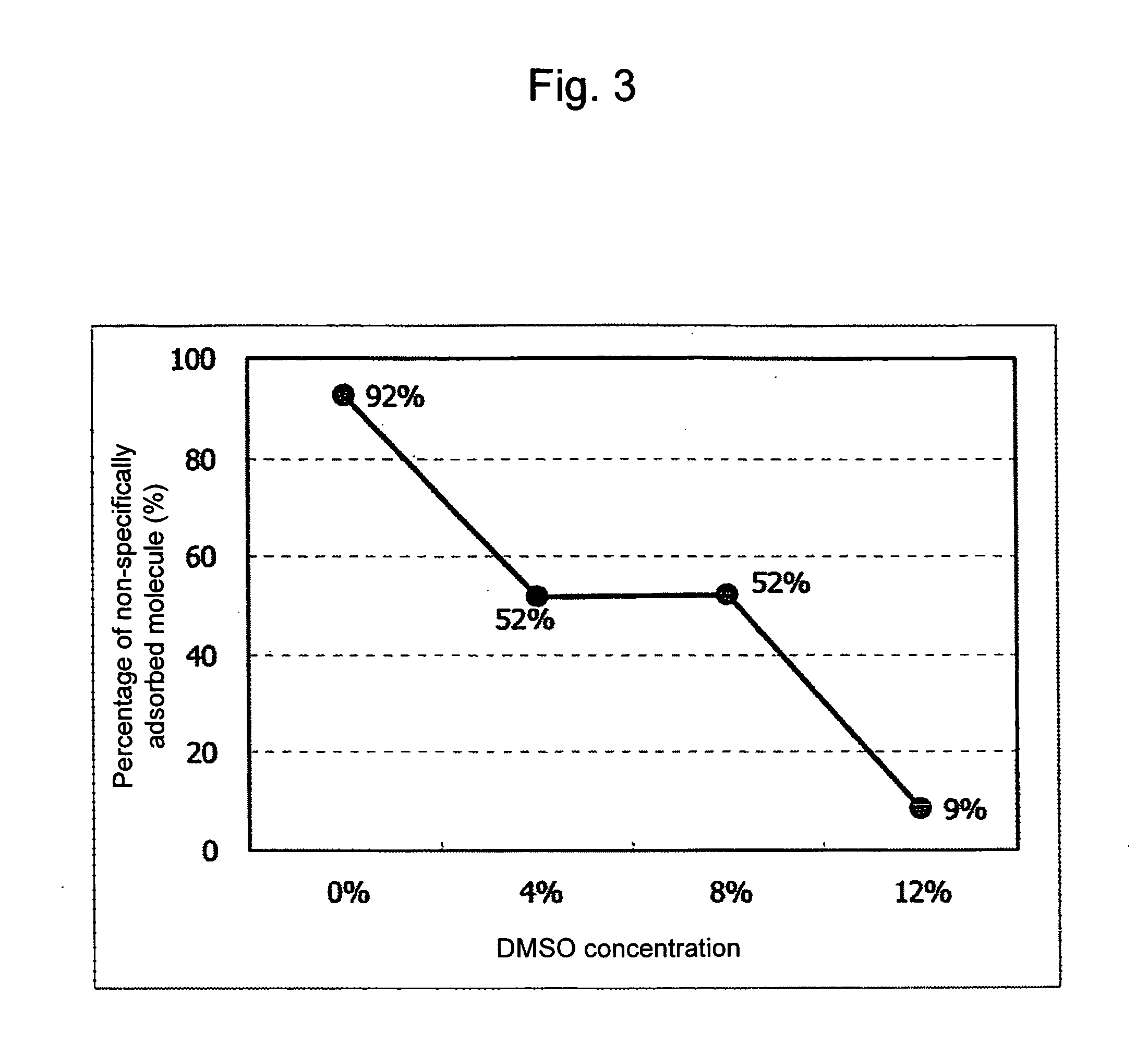

Large-scale parallel nucleic acid analysis method

It is intended to provide a technique for amplifying, individually and in parallel, nucleic acids contained in a mixture of plural kinds of nucleic acid samples. The present invention provides a nucleic acid analysis method comprising amplification means, whereby amplification reaction is performed in a reaction solution comprising a homogeneous solvent and comprising at least plural template nucleic acids and solid phase carriers comprising one or more kinds of amplification probes immobilized on the surface, to prevent amplified products attributed to two or more template nucleic acids from being replicated in one solid phase carrier. According to the present invention, plural kinds of analyte nucleic acid samples in a mixed state can be amplified individually and in parallel. This method achieves one solid phase carrier-one nucleic acid. Therefore, a higher density of solid phase carriers with obtained amplified products is easily achieved, leading to improved throughput of amplified product analysis. Reactions in all the amplification reaction steps are performed under homogeneous solvent conditions. Therefore, the method of the present invention is performed by convenient procedures and as such, is suitable to automation.

Owner:HITACHI LTD

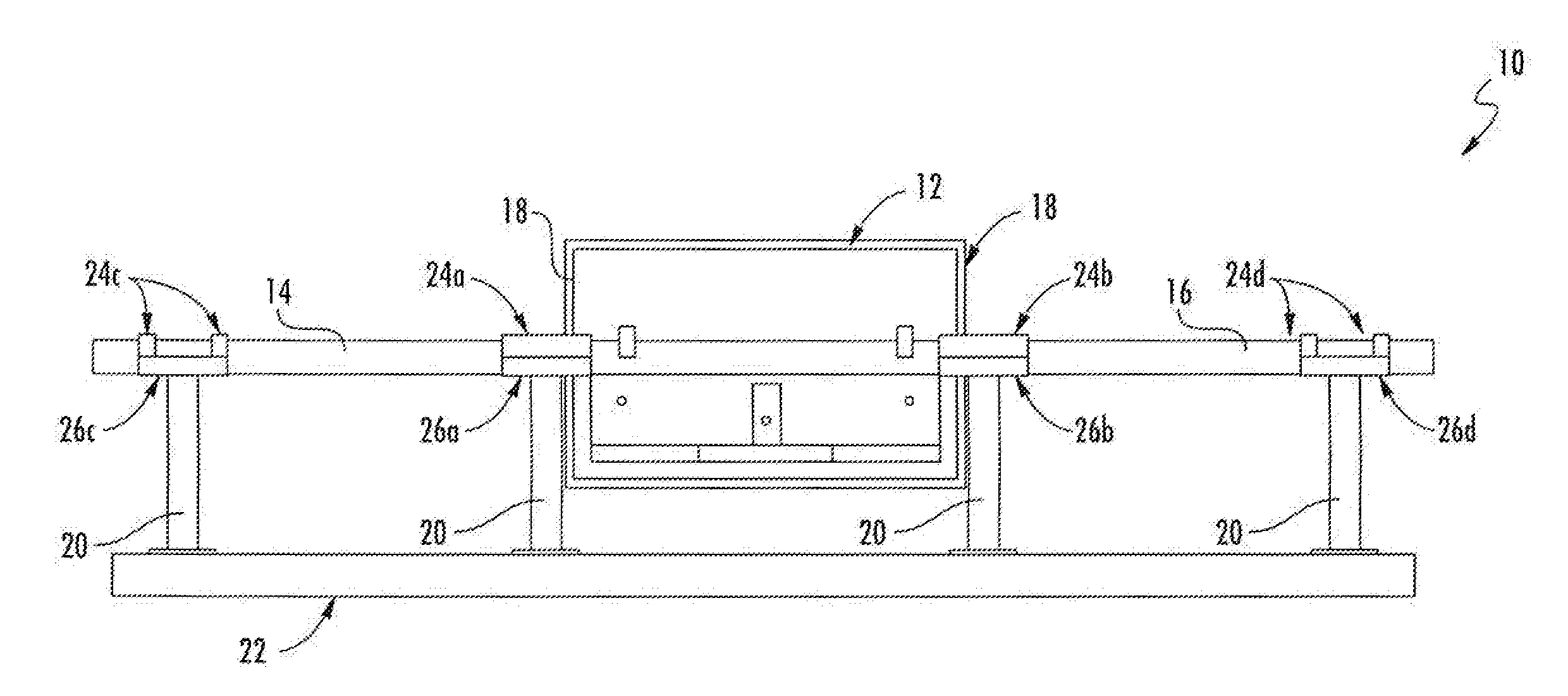

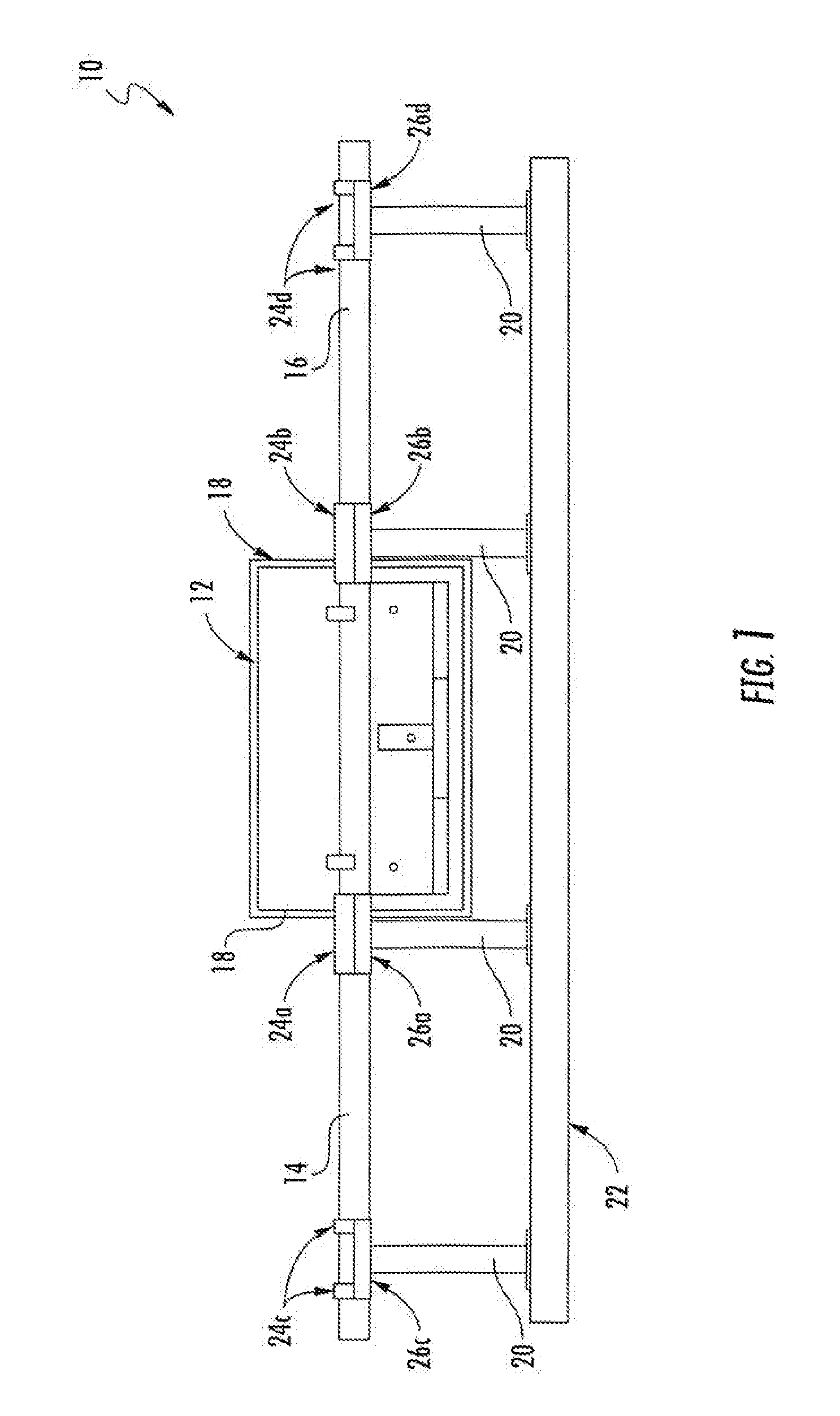

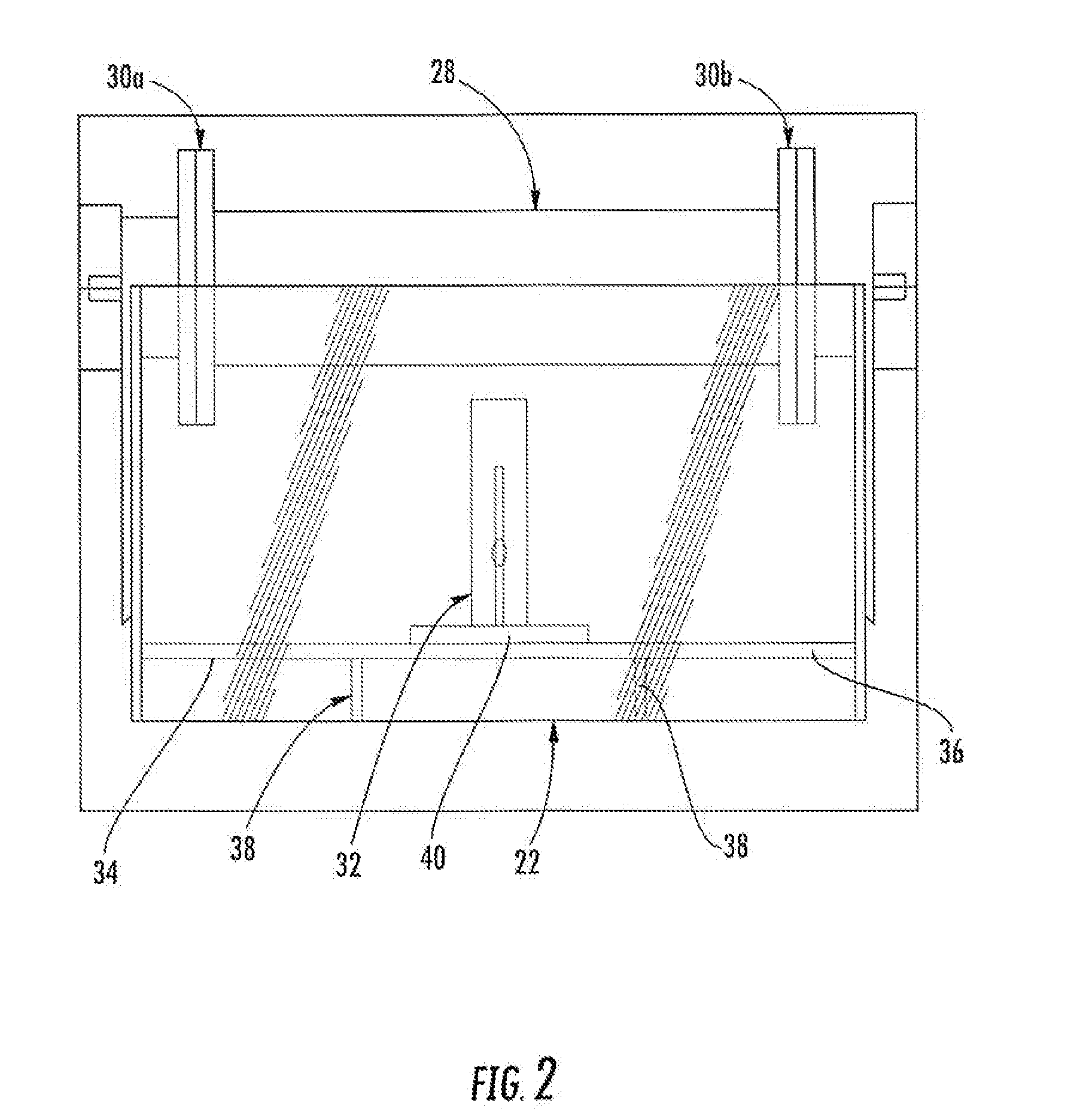

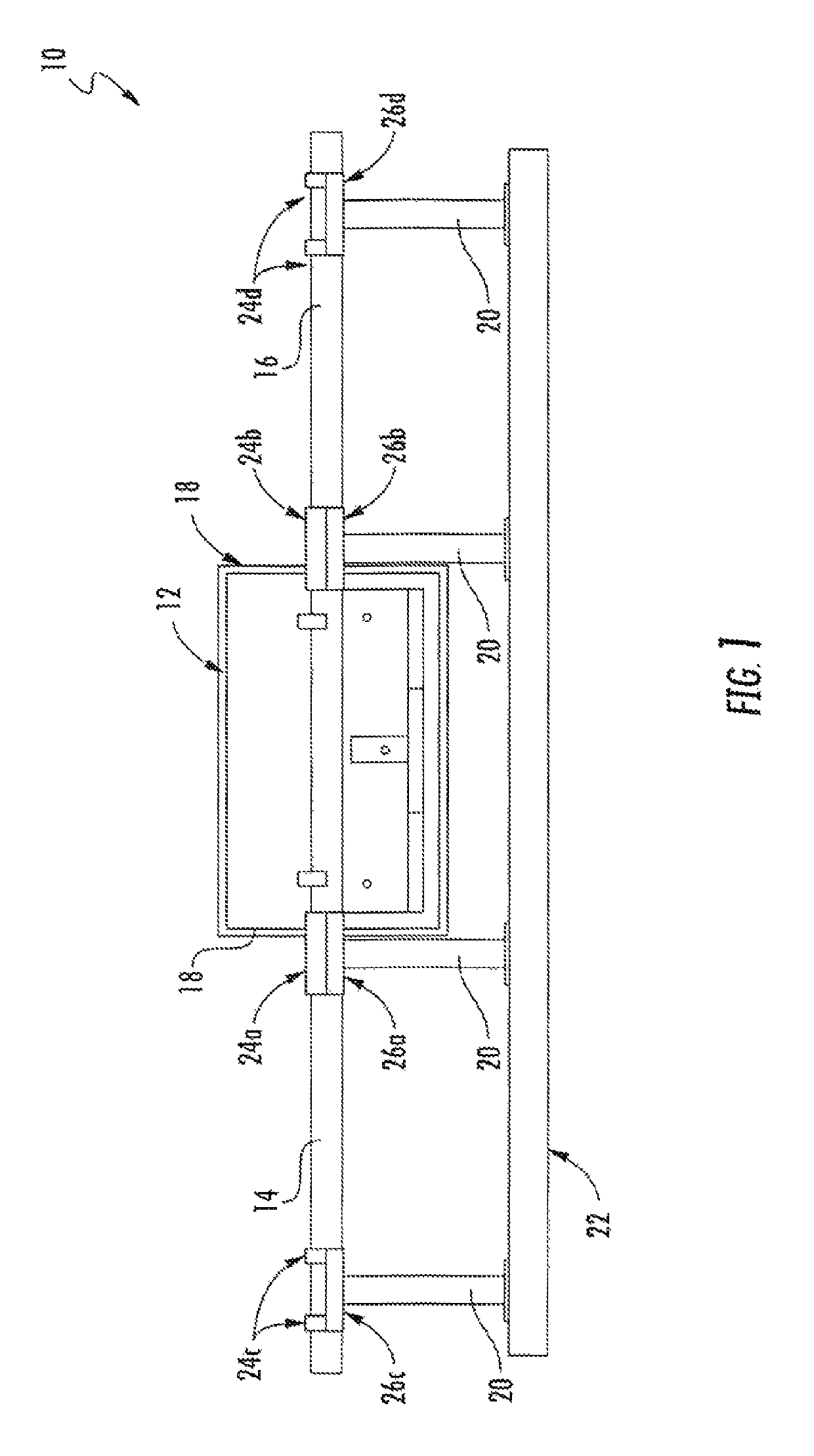

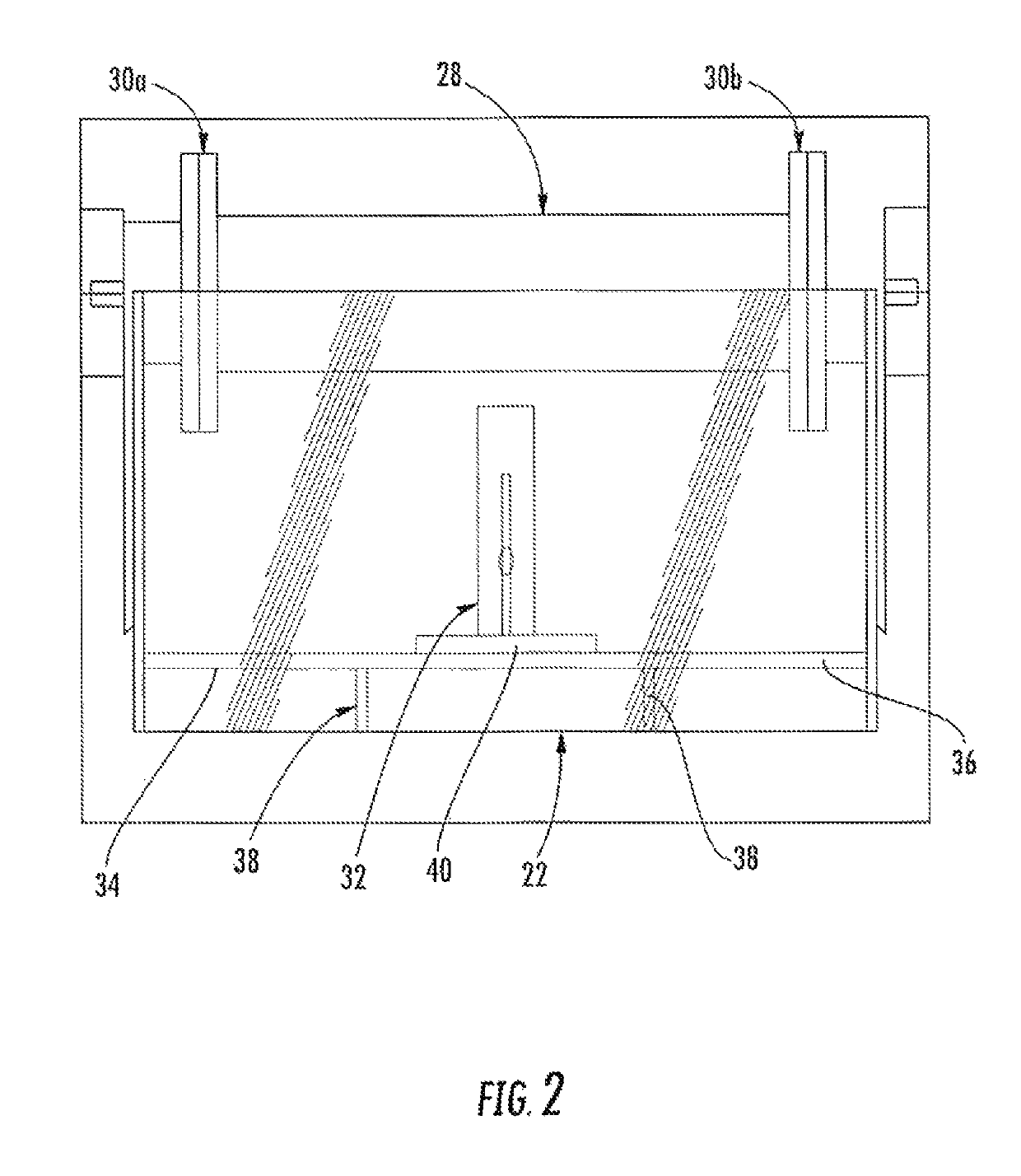

Apparatus and methods for determining gravity and density of solids in a liquid medium

ActiveUS20170045432A1Viscometer maintainanceSpecific gravity measurementContinuous measurementLiquid medium

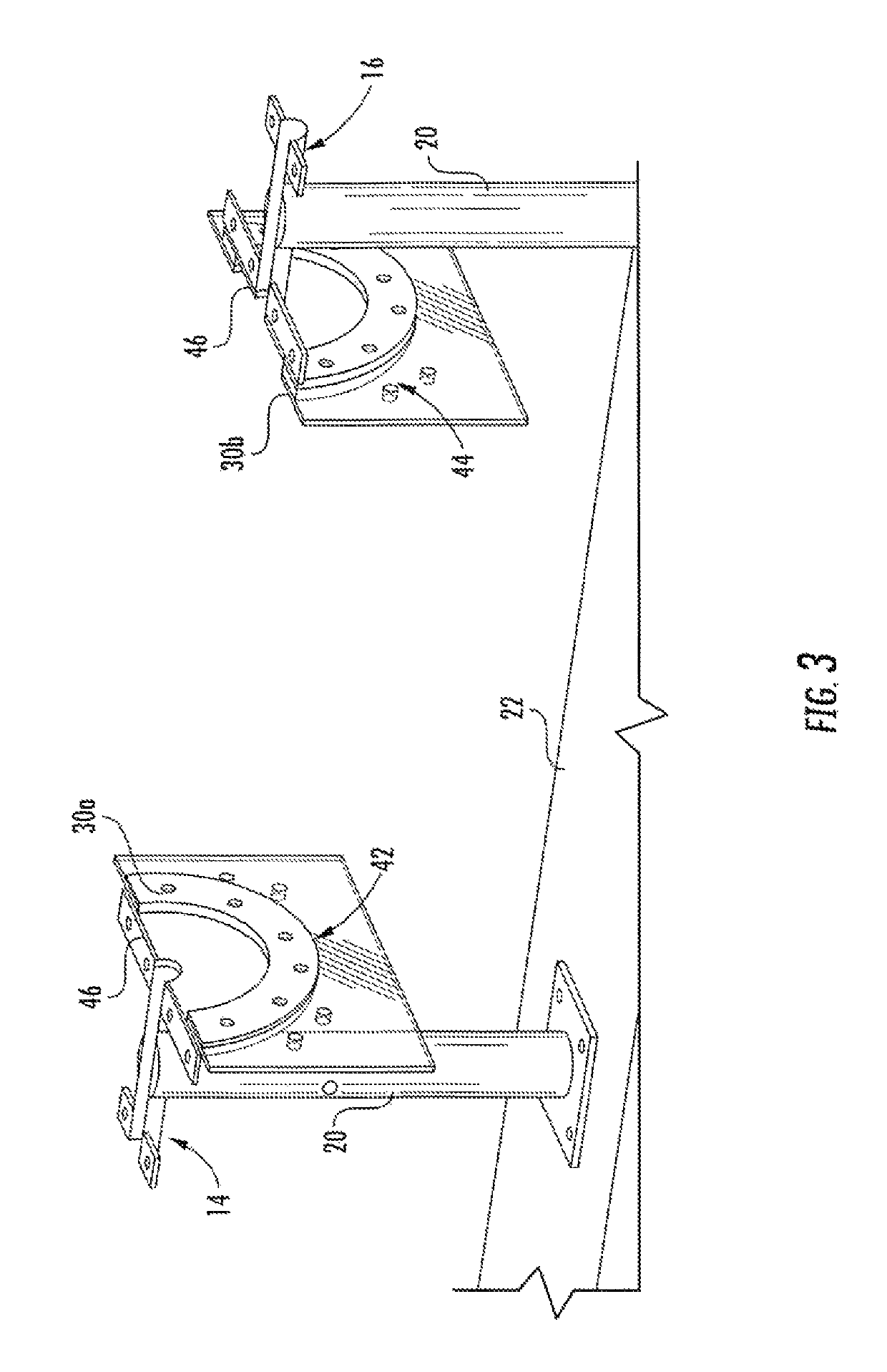

Apparatus and methods for the continuous measurement of specific gravity or density of solids in a fluid medium are disclosed. A system for continuous measurement of density of a flowing medium comprises a cartridge connected in series to an inflow pipe and an outflow pipe, a displacement sensing device adapted to monitor displacement changes of the cartridge when a medium flows through the cartridge, a base configured to provide a support for the displacement sensing device, a pressure sensor, a temperature sensor, and a processor configured to calculate density of the flowing media based on measured displacement change, temperature and pressure.

Owner:RED METERS LLC

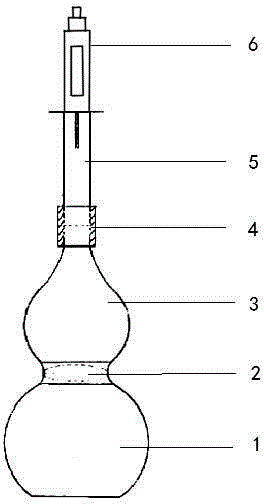

Method and apparatus for determining apparent density of pervasive solid substance

ActiveCN104964895ASolve SolubleSolve easy infiltrationSpecific gravity measurementApparent densityThermodynamics

The invention relates to a method and apparatus for determining apparent density of a pervasive solid substance. A specific gravity bottle or Webster balance can be used for determining the density of insoluble solid, the density of soluble solid can be determined by utilizing a gas specific gravity method, but the requirement for the instrument manufacturing precision is high, and the economic performance and convenience are poor. The method is characterized in that solid fluid is adopted as a volume replacement medium; the volume of a to-be-detected substance is determined by utilizing a special volume determination apparatus; the mass of the to-be-detected substance is determined by utilizing an analytic balance; the determination of the apparent density is realized by virtue of calculation of a special formula. The apparatus consists of a lower bottle body, a middle bottle body, an upper bottle body, a measuring range tube and charged solid fluid. The apparatus is simple in structure, practical and economical; the solid fluid can be reutilized and is environment-friendly; the solid fluid is charged in one step, the to-be-detected substance is separated from the solid fluid by utilizing a fixed screen in the process for inverting the apparatus, and the operation is very convenient; the apparatus is suitable for determining the apparent density of all solid substances, and the difficulty for determining the apparent density of soluble or wettable solid substances with irregular shape can be solved.

Owner:SHAANXI UNIV OF SCI & TECH

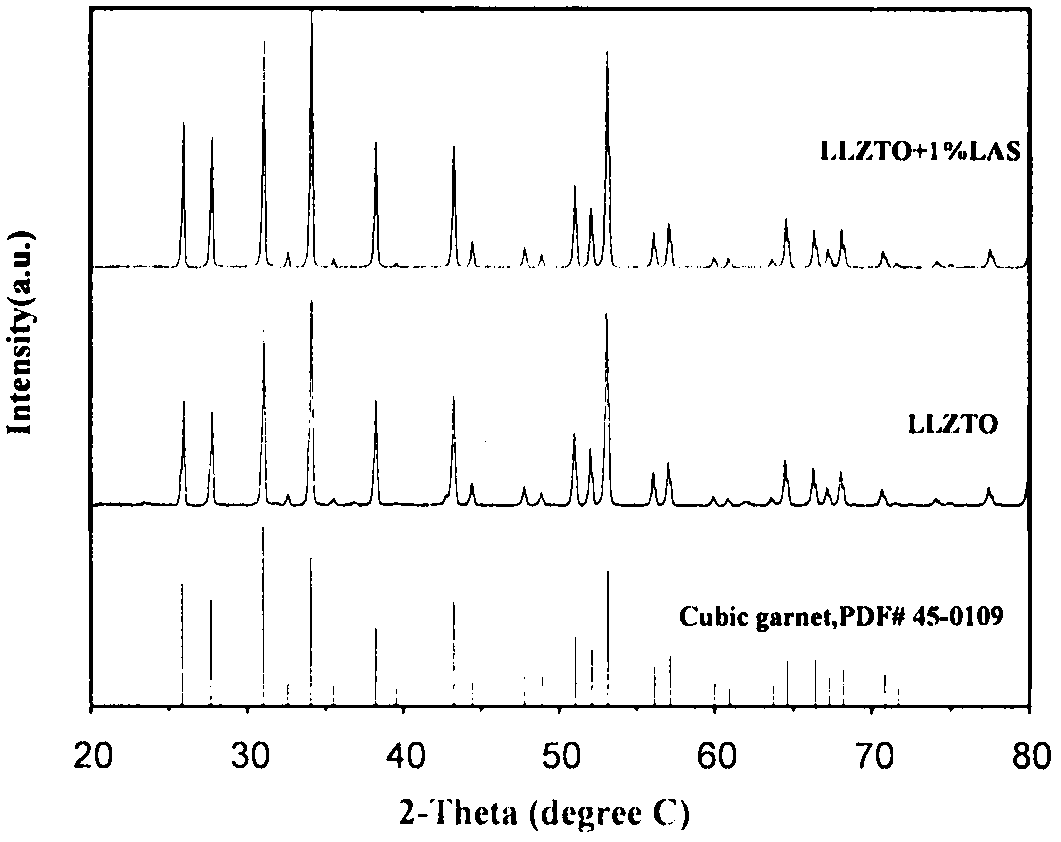

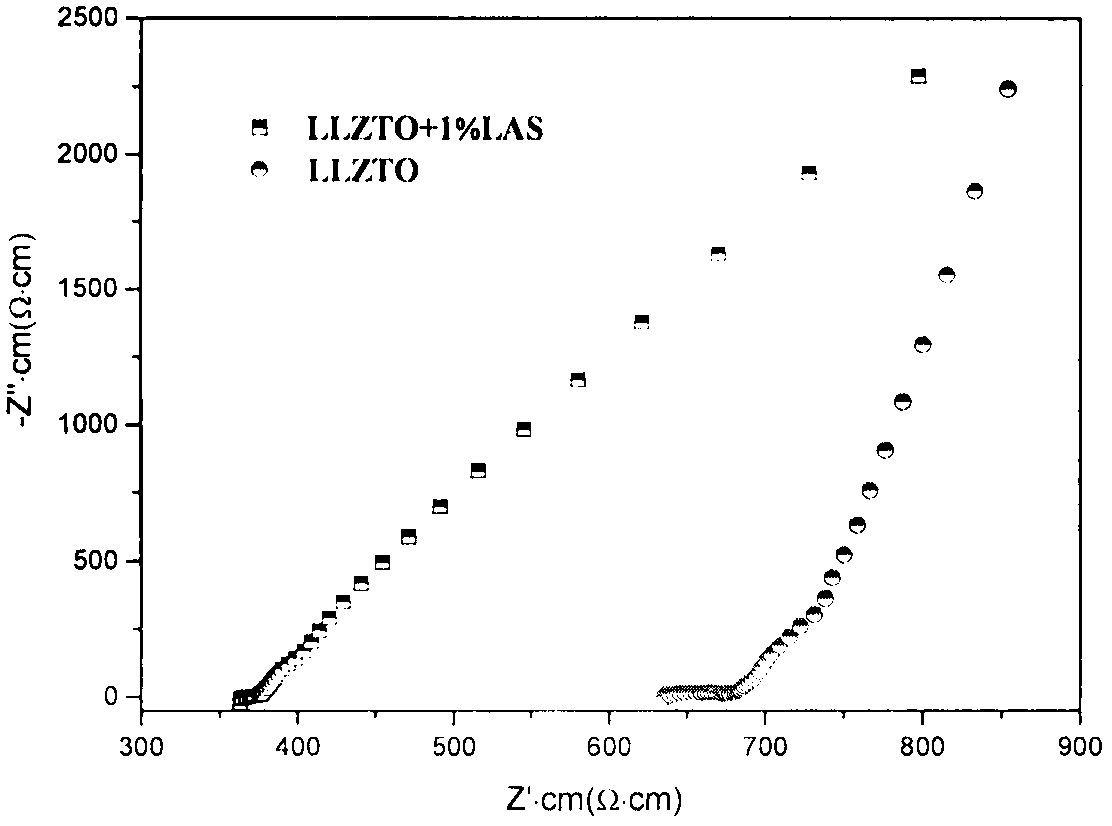

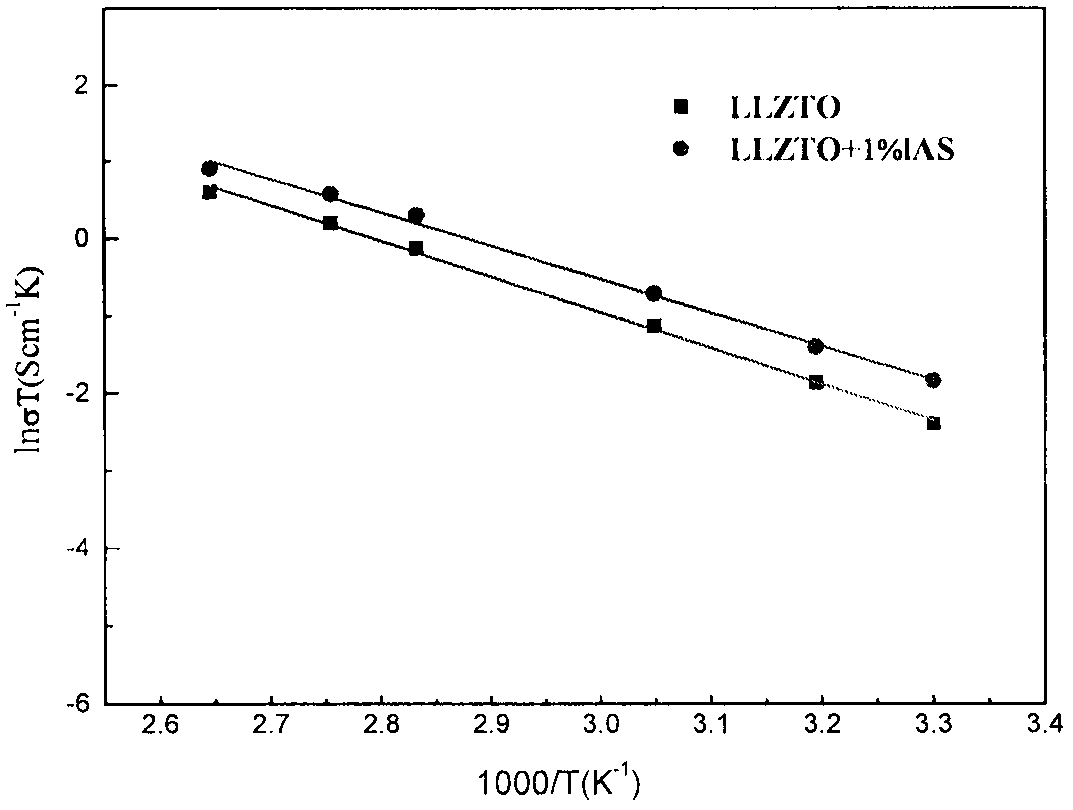

Preparation process for improving density of solid electrolyte

InactiveCN110247105AHigh densityImprove ionic conductivitySecondary cellsElectrolytesSolid state electrolyteElectrolysis

The invention relates to a preparation process for improving the density of a solid electrolyte to enhance the conductivity of lithium ion. The main component of an additive is lithium aluminum silicate, and the content of the lithium aluminum silicate is 0.5-4 wt%. The preparation process comprises the following steps of: adding lithium aluminum silicate into presintered tantalum doped lithium lanthanum zirconium oxide, performing ball-milling, adding a binder for ball-milling again, performing tabletting, performing sintering at a low temperature to remove the binder, and performing burning in the mother powder to obtain a final electrolyte. The density of the obtained electrolyte sheet reaches 91.5%, and the lithium ion conductivity can reach 5.14*10<-4>S / cm (298K) at a normal temperature.

Owner:CHONGQING ACADEMY OF SCI & TECH

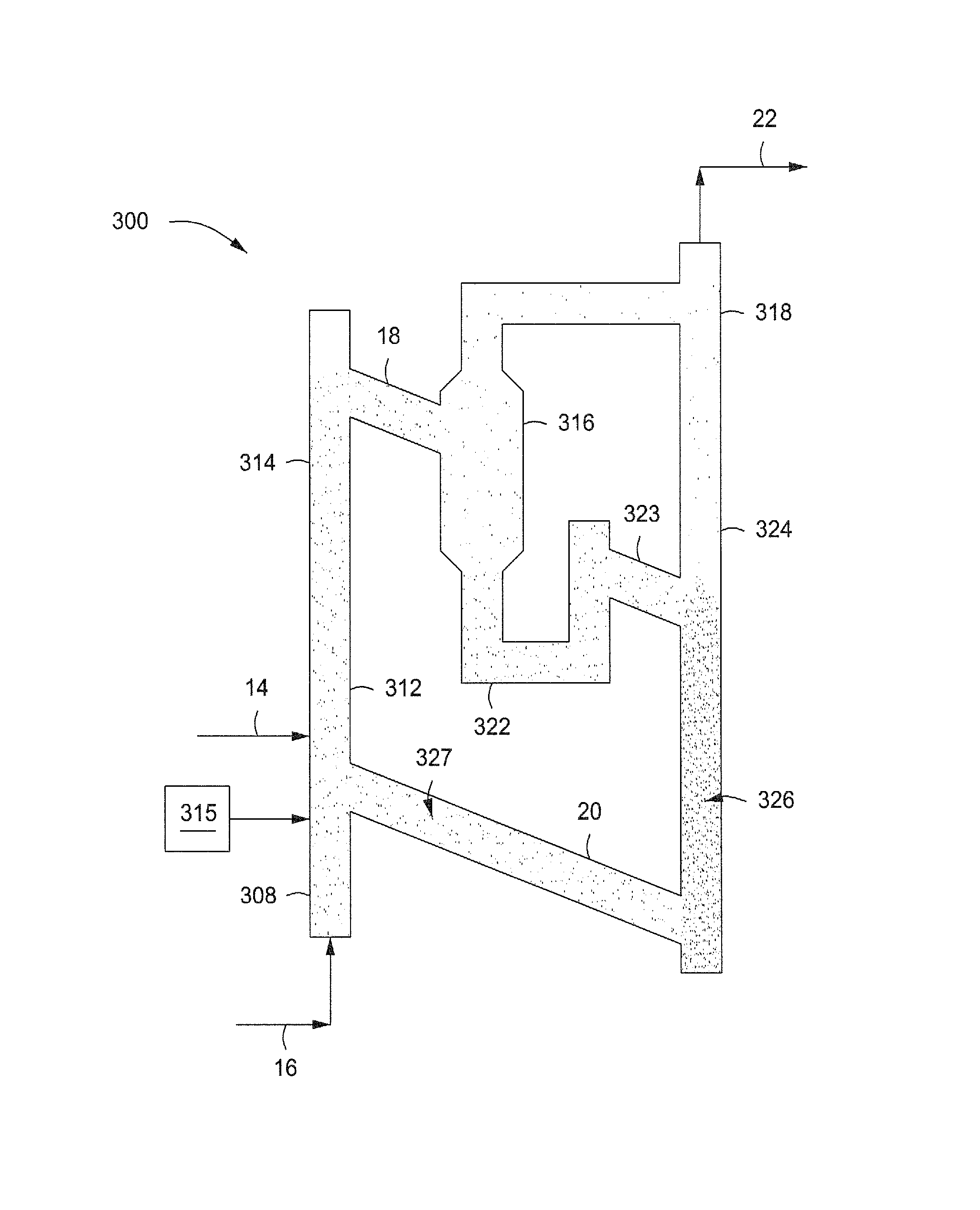

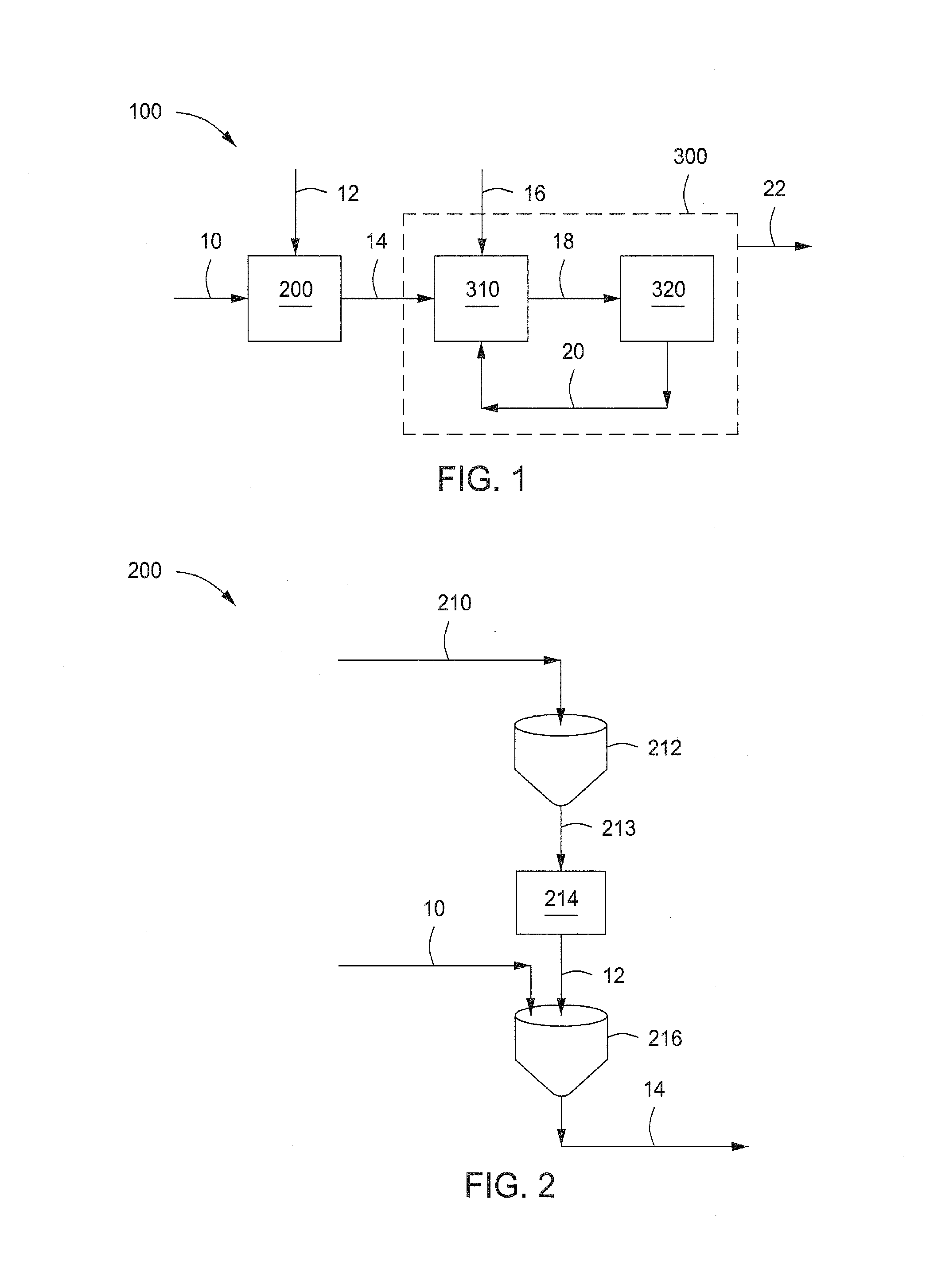

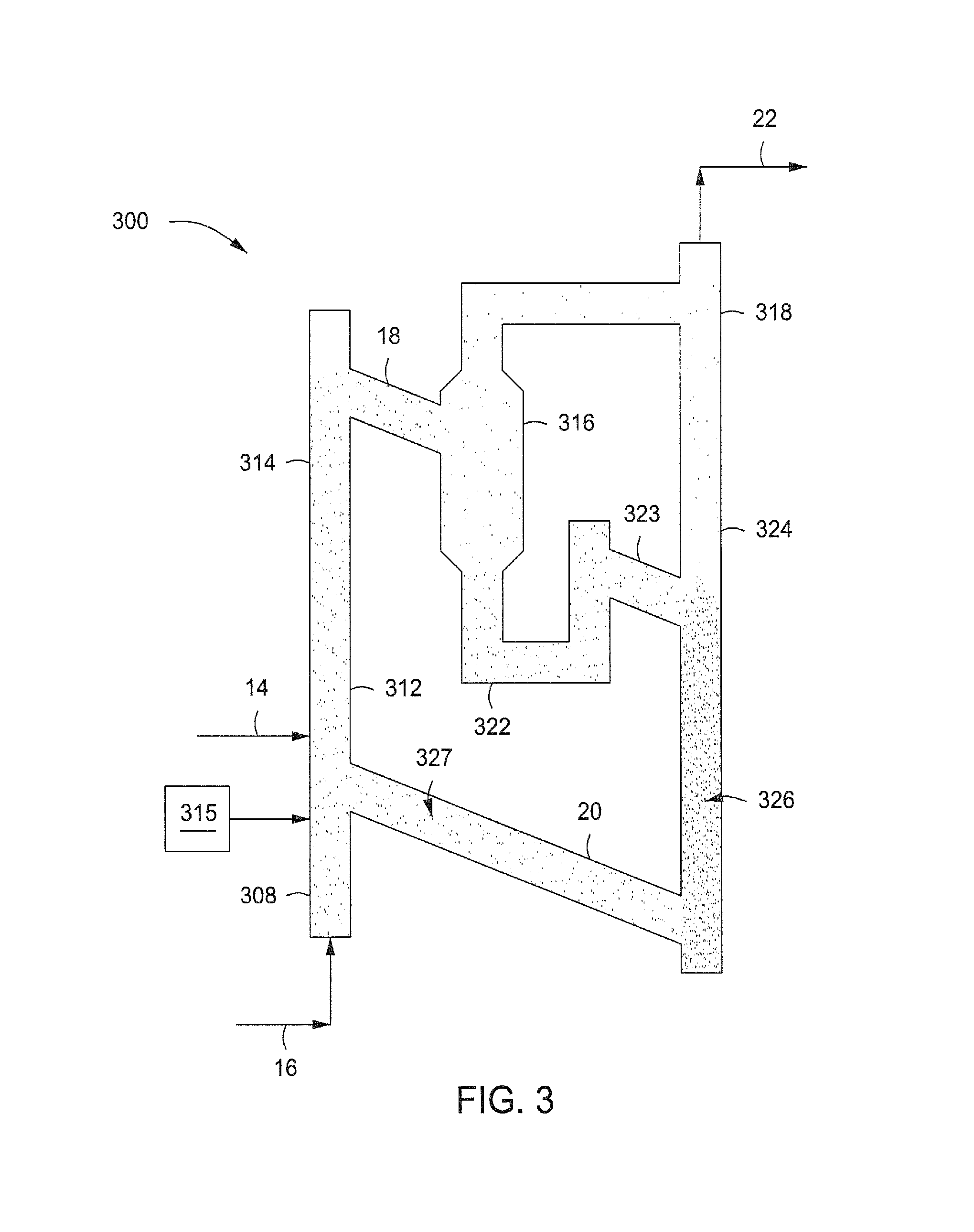

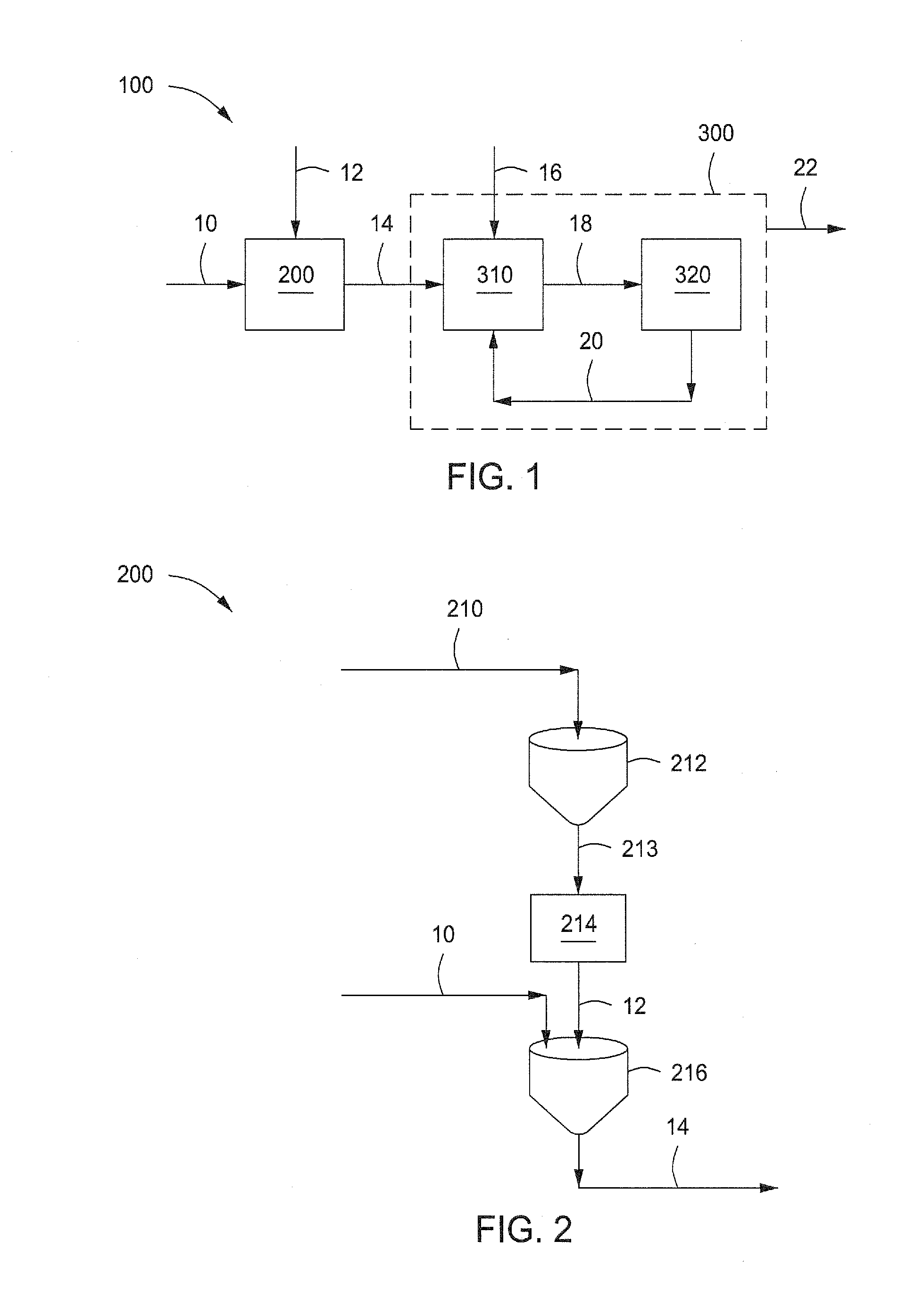

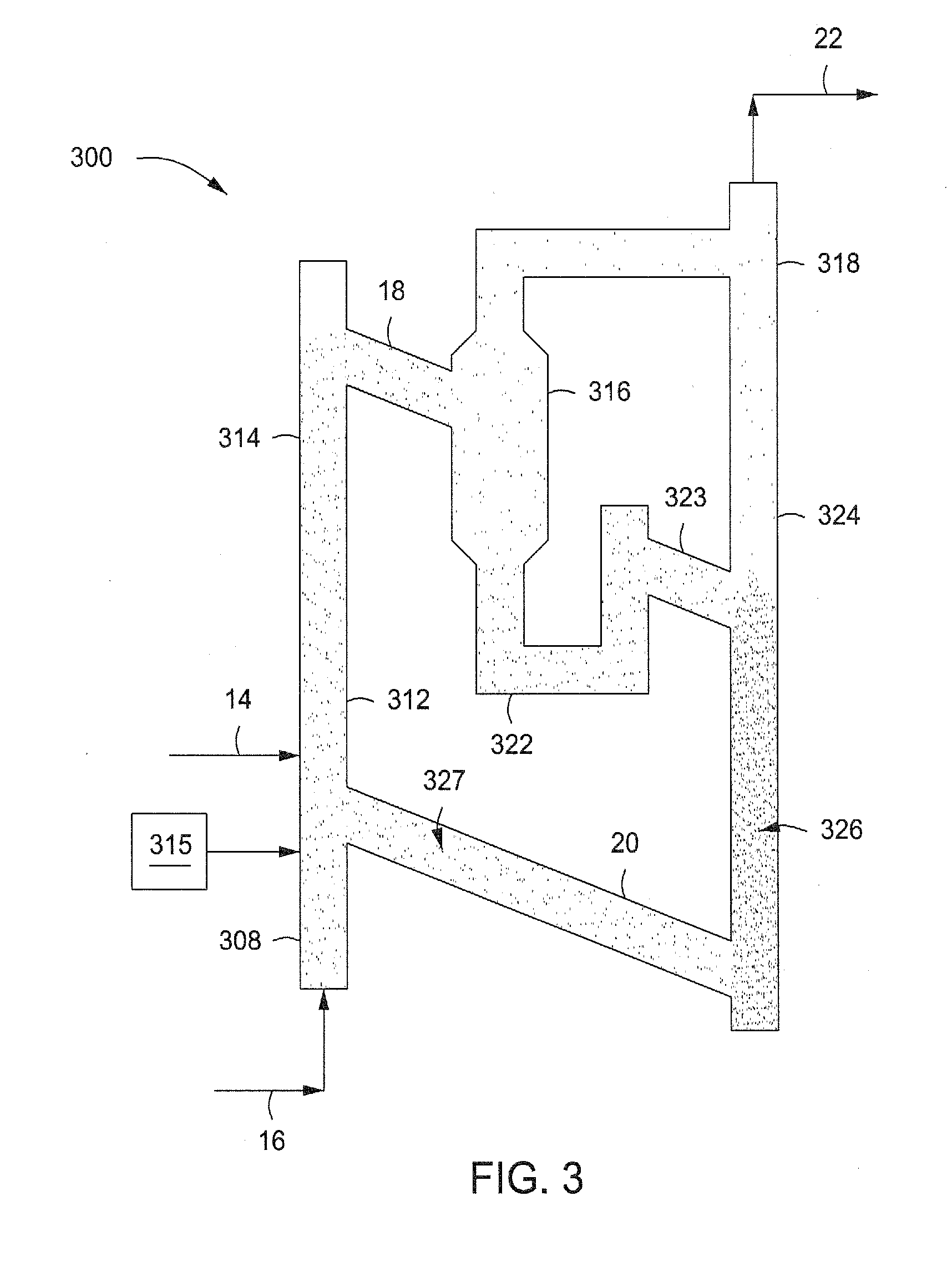

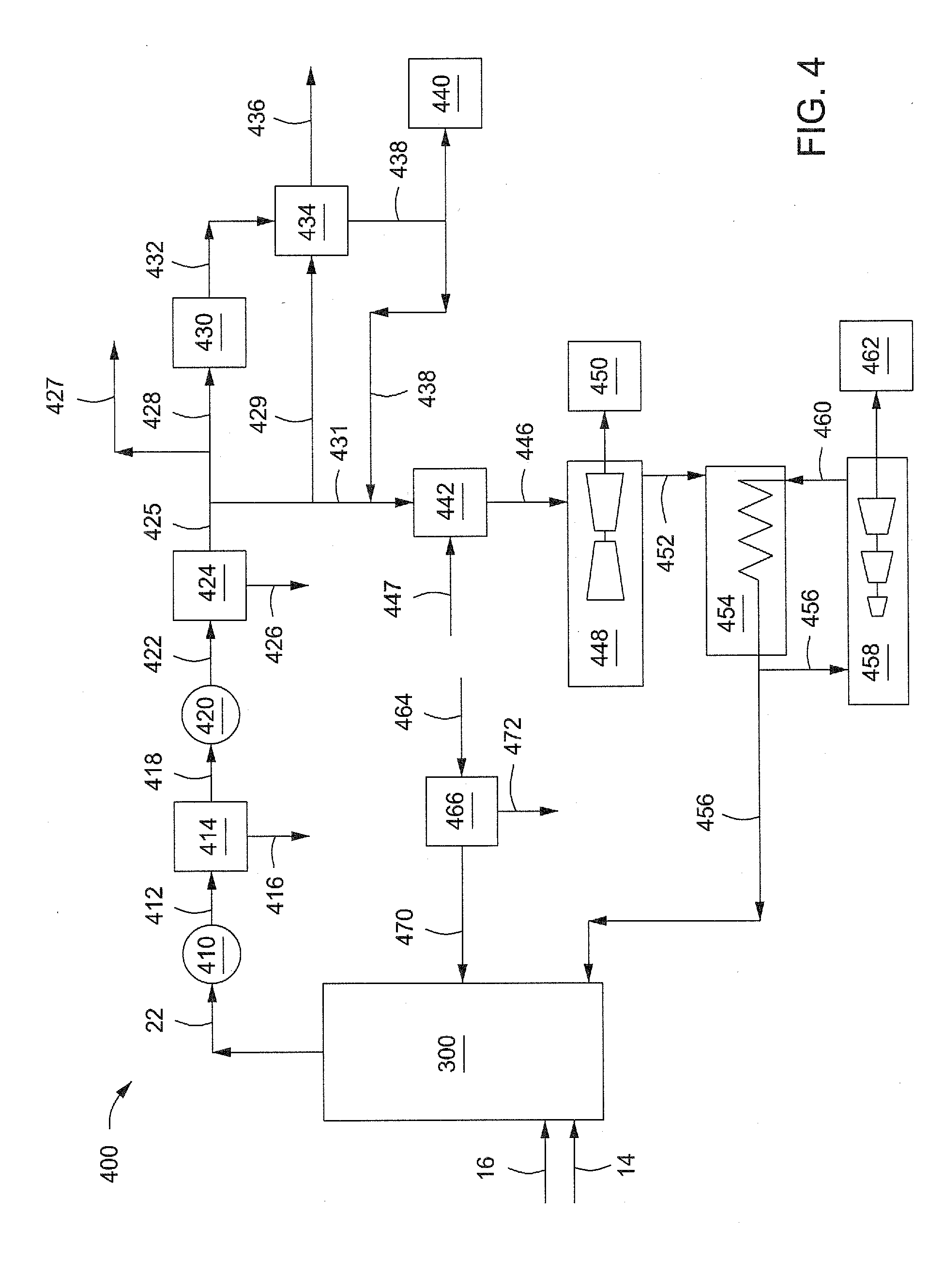

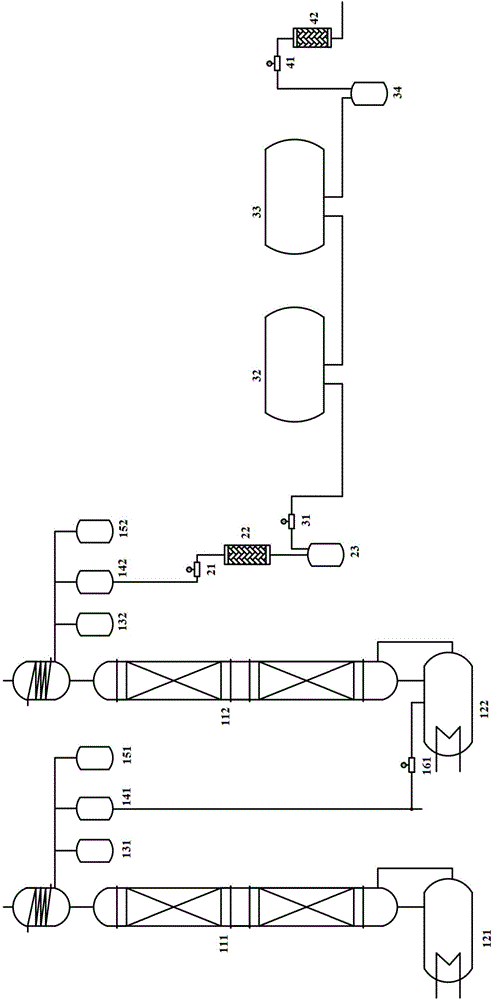

Systems and methods for gasifying a feedstock

Owner:KELLOGG BROWN & ROOT LLC

Systems and methods for gasifying a feedstock

Systems and methods for gasifying a feedstock are provided. The method can include combining one or more feedstocks and one or more solid components in a treatment zone to provide a treated feedstock. At least a portion of the treated feedstock can be introduced to a reaction zone of a gasifier. The one or more solid components can have an average density and an average cross-sectional size that adjusts at least one of an average density of solids within a solids bed of the gasifier and an average cross-sectional size of the solids within the solids bed of the gasifier.

Owner:KELLOGG BROWN & ROOT LLC

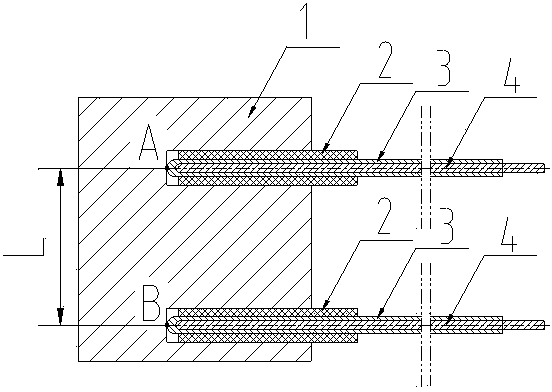

Measuring method for heat flux density of solid metal

InactiveCN103353466ASimple temperature measurement structureWide measurement rangeMaterial heat developmentHeat fluxHeat flow

The invention discloses a measuring method for the heat flux density of a solid metal. The method comprises the following steps: (A) determining a heat conductivity coefficient 1 (W / m. DEG C) of a to-be-measured object; (B) processing measuring holes; (C) respectively installing temperature measuring devices in the measuring holes; (D) respectively measuring temperatures at a point A and a point B by using the temperature measuring devices respectively located at the point A and the point B so as to obtain the temperature TA of the point A and the temperature TB of the point B; and (E) calculating heat flux density of the to-be-measured object in the direction from point A and point B according to a formula. According to the invention, existence of the measuring holes poses little influence on a to-be-measured solid, heat flux density between measured points in a metal solid can be accurately measured in real time, and a measuring apparatus used in the invention has the advantages of a simple structure, easily realizable manufacturing process, a wide measurement range of heat flux density, capacity of realizing high precision measurement of heat flux density in a range of 1 kW / m<2> to 10 MW / m<2> , high stability, good anti-interference capability, etc.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Method for rapidly measuring density of solid insusceptible to absorbing water

InactiveCN101726450AQuick Comparative AnalysisReduce human errorMaterial analysis by measuring buoyant forcesFast measurementRoom temperature

Owner:JIANGSU UNIV

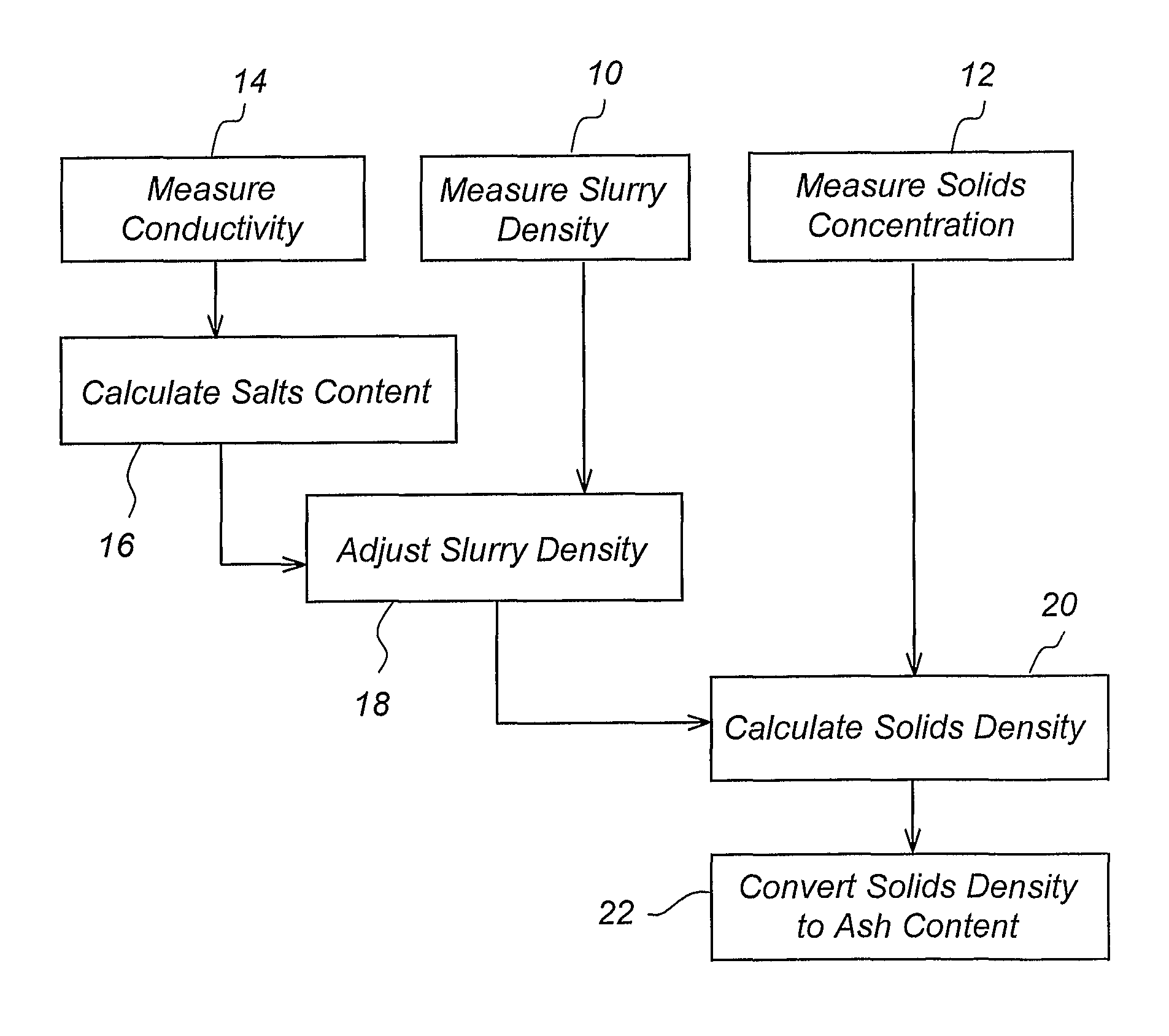

Method of analysis and an analyzer

InactiveUS7835882B2Easy to separateFacilitated releaseDigital computer detailsFlotationSlurryAnalysis method

The present invention provides a method of online analysis of mineral waste content of a slurry in a mineral separation process, said method including the steps of: measuring the density of said slurry (10); measuring the concentration of solids in said slurry (12); calculating the density of solids in said slurry from said slurry density and said solids concentration (20); and calculating said mineral waste content from said solids density (22). The present invention also provides an online analyzer for mineral waste content of a slurry in a mineral separation process.

Owner:NEWCASTE INNOVATION LTD

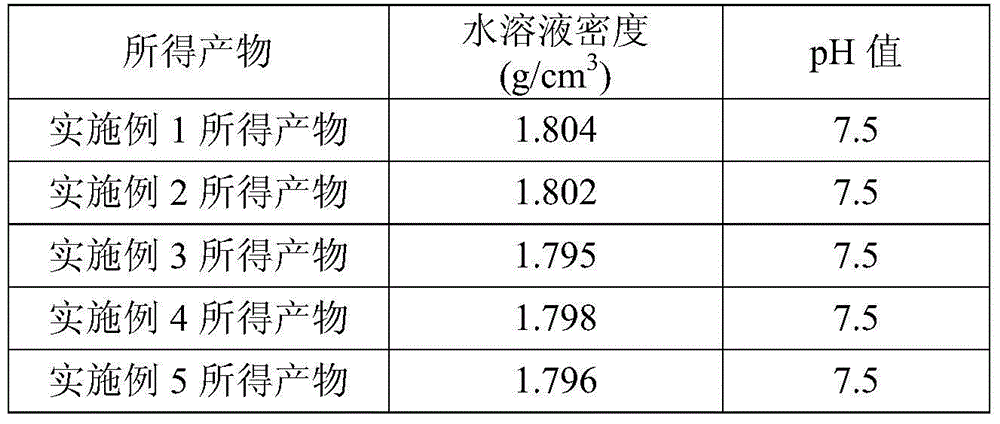

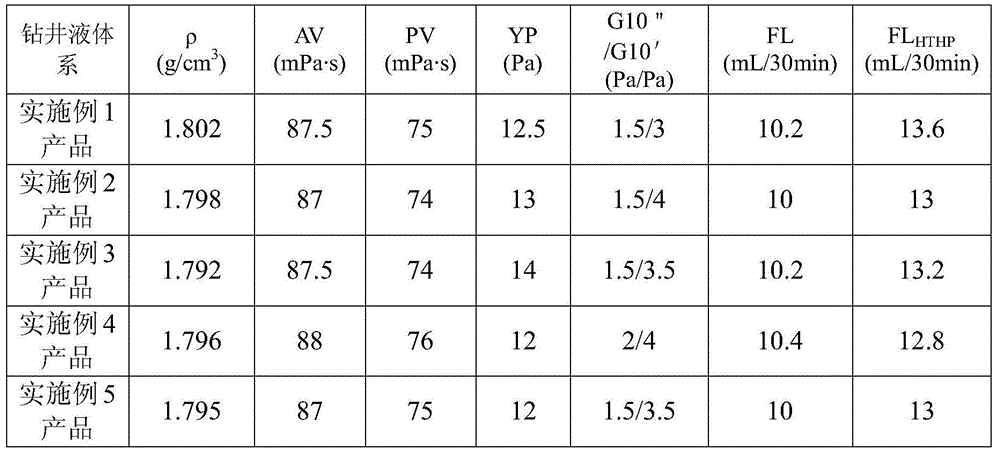

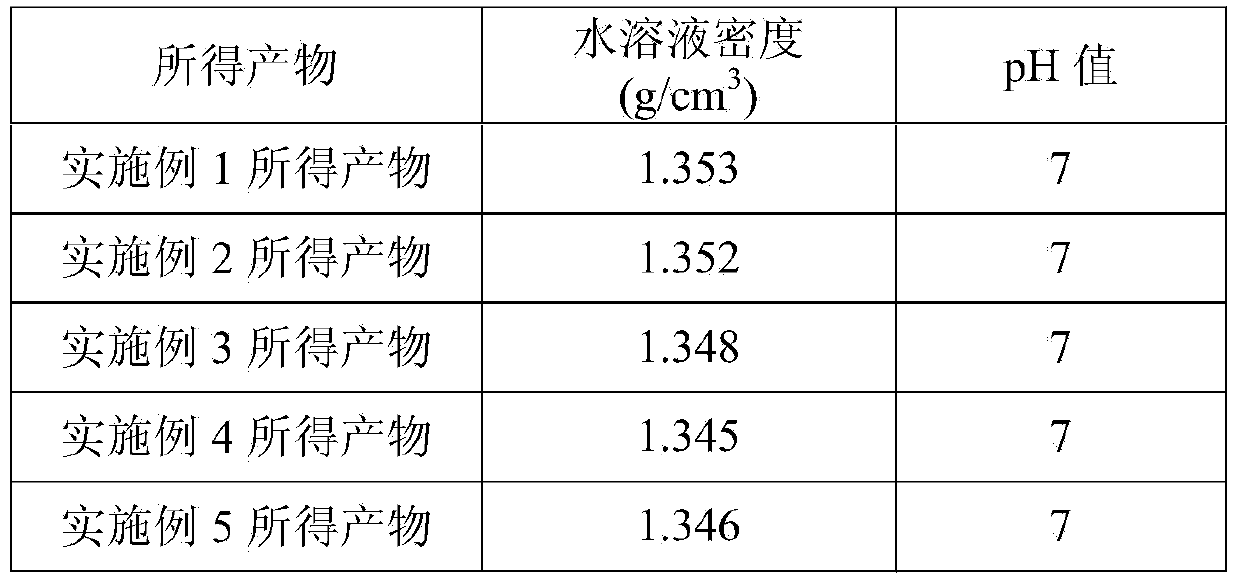

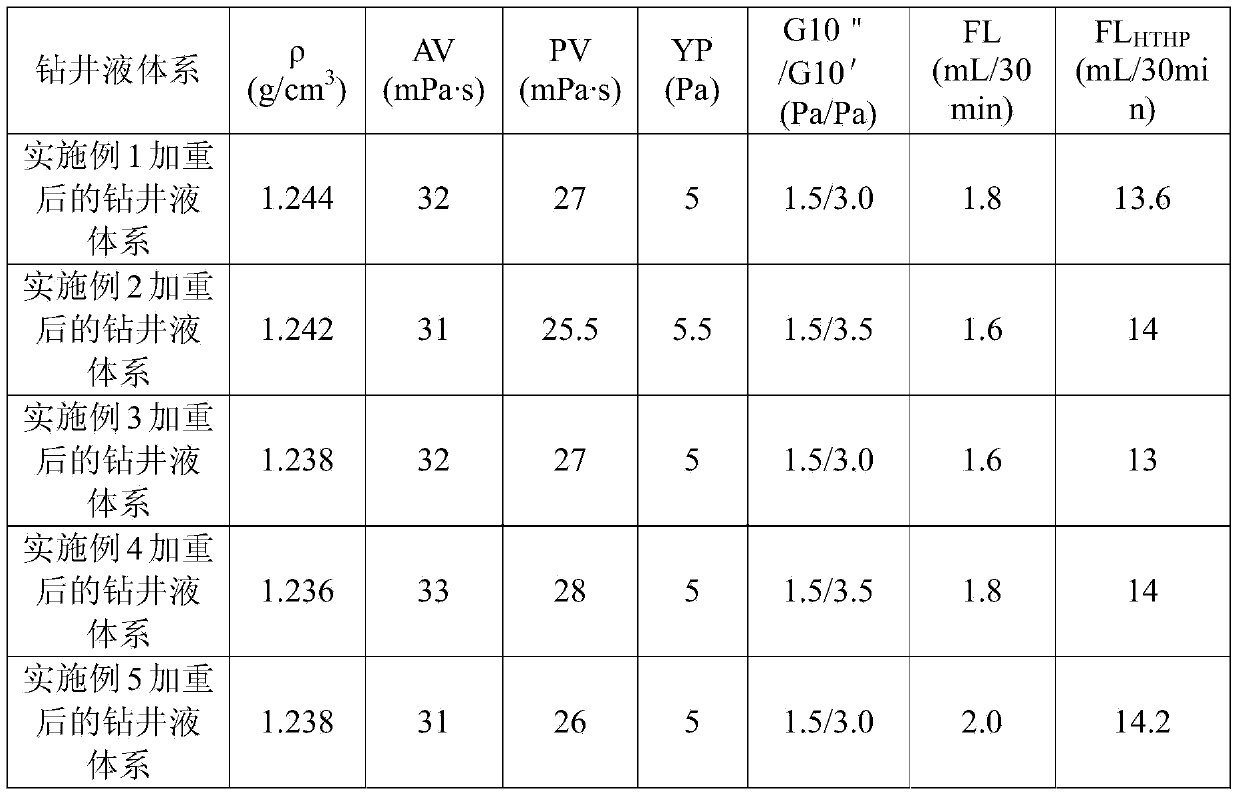

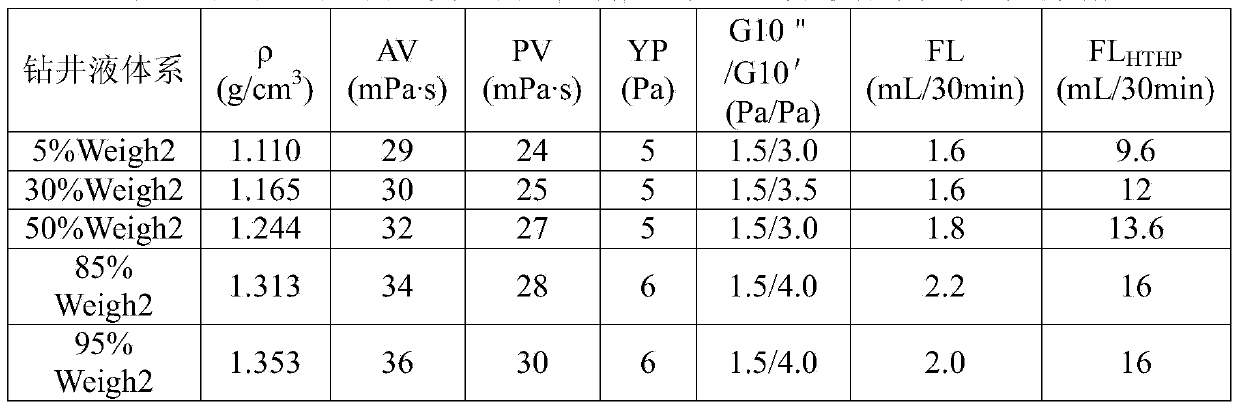

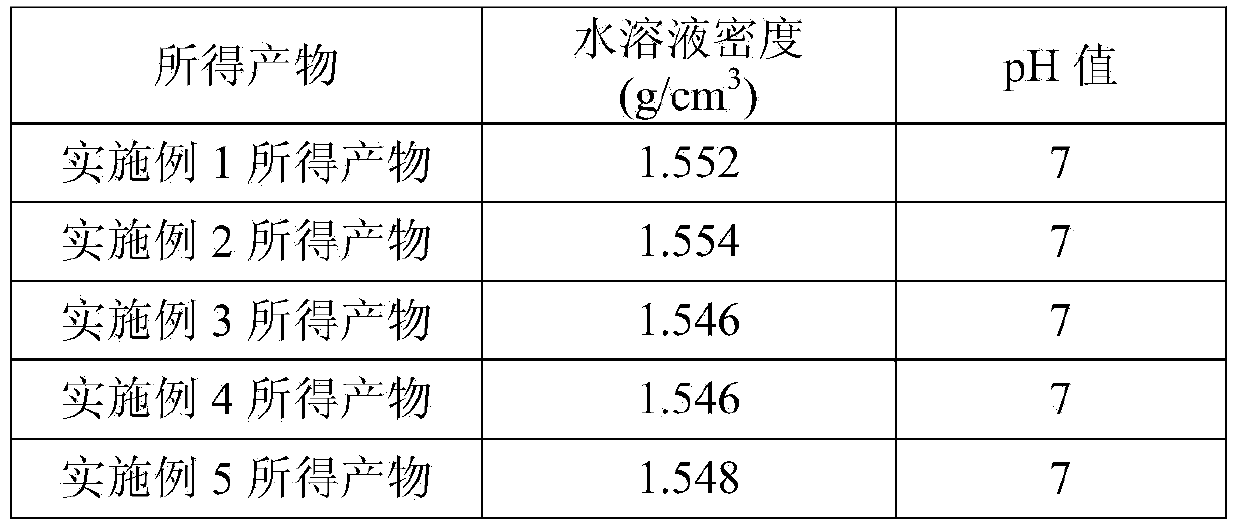

Water-soluble organic salt weighting agent for drilling fluid for oilfields as well as preparation method and application thereof

The invention provides a water-soluble organic salt weighting agent for drilling fluid for oilfields as well as a preparation method and application thereof. The method comprises the steps of preparing an organic acid mixture containing bromine atoms, wherein the organic acid mixture comprises C1-C6 organic acids; adding composite alkali containing NaOH, KOH, ammonia water, N(CH3)3 and epoxy chloropropane to the organic acid mixture, stirring the materials to react, and evaporating water until the product is pasty or half-dry, wherein the mass ratio of composite alkali to organic acids is (0.15-1.5):1; drying the product at 80-120 DEG C for 6-24 hours, and grinding the dried product, thus obtaining the granular product. The weighting agent can not only improve the density of solid-free water-based drilling fluid base fluid but also improve the inhibitive capacity of the drilling fluid.

Owner:北京培康佳业技术发展有限公司

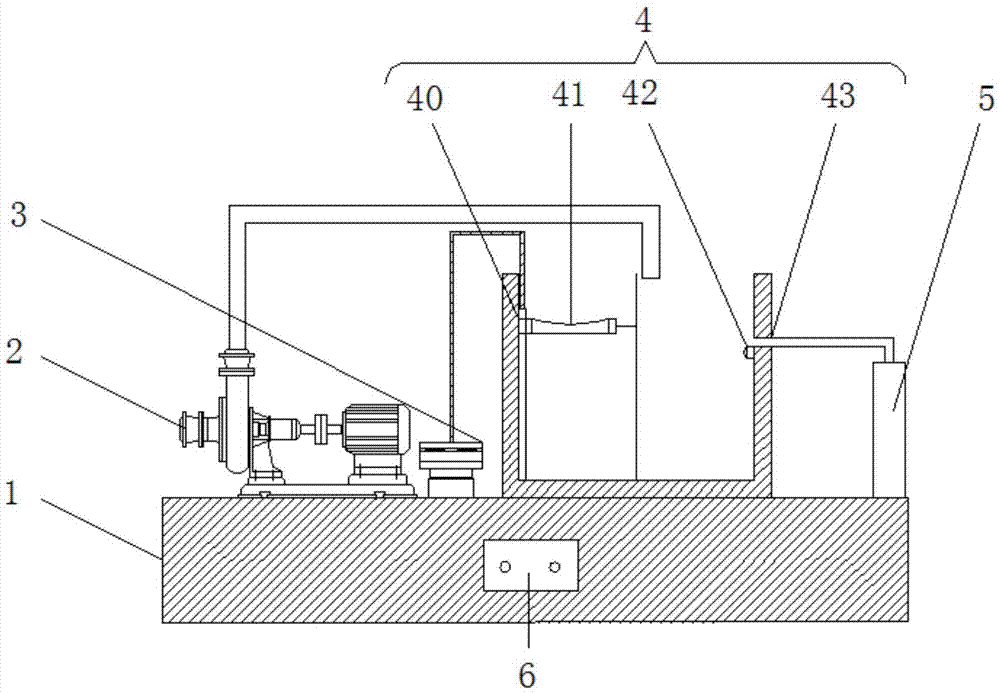

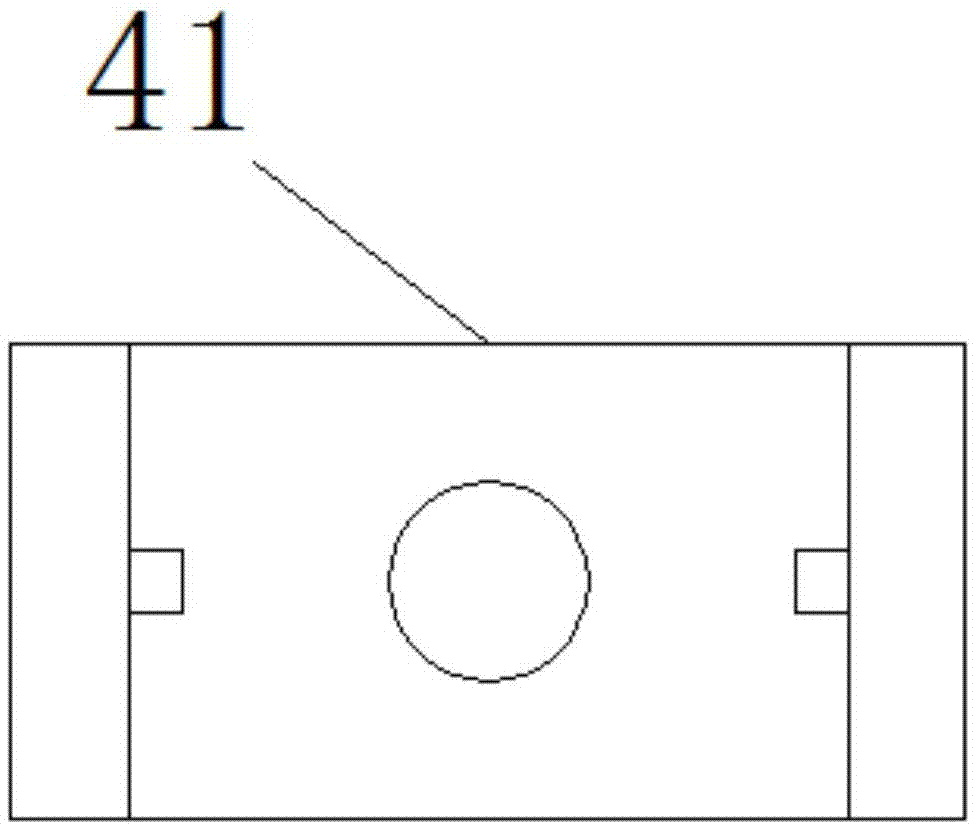

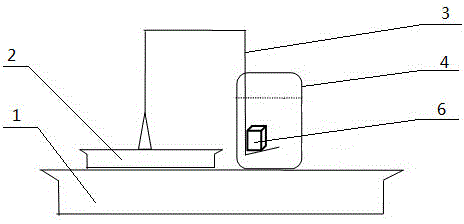

Device for fast measuring density of solid and liquid

InactiveCN106872307AQuick measurementMeasure the density of substances in a wide rangeMaterial analysis by observing immersed bodiesDensity of solidsWater pipe

The invention discloses a device for rapidly measuring the density of solid and liquid. The water pump is installed on the left side of the base, and the water pump is provided with a water pipe and an intermediate relay. The pneumatic device is installed in the middle of the base. The water pool and The measuring cylinder is installed on the right side of the abutment, and guide rails, item tables, liquid level sensors and drainage pipes are installed in the pool, a vacuum generator is arranged between the guide rails and the pneumatic device, and the end of the drainage pipe is connected to the measuring cylinder , the operating table is fixed on the side of the abutment, and operation buttons are arranged on the operating table. The object table of the device for quickly measuring solid-liquid density can be fixed to place solids and liquids, and calculate the density of the object through the volume difference between the volume of the object floating and completely immersed in the water discharged from the pool to the volume of the measuring cylinder, when the water in the pool is lower than the liquid level When the sensor is activated, the water pump draws water to the pool to ensure the next measurement.

Owner:CHONGQING LIYOU SOFTWARE TECH CO LTD

Liquid detergent compositions with low-density particles

Process for reducing the density of solid detergent ingredients by forming said ingredients into hollow-core particles. The density of ingredients such as sodium citrate, sodium carbonate and / or sodium silicate, when formed into such hollow-core particles, allows them to be stably incorporated into non-aqueous liquid laundry detergents.

Owner:THE PROCTER & GAMBLE COMPANY

Method for measuring density of solid and measuring device of method

InactiveCN105319146AFast measurement speedImprove measurement efficiencyMaterial analysis by measuring buoyant forcesGravitationDensity of solids

The invention relates to the field of measuring the density of a solid, specifically to a method for measuring the density of a solid and a measuring device of the method. The measuring device comprises a big gravity measuring device and a small gravity measuring device, a support, and a liquid container. The method comprises the following steps: (1) firstly, pouring a liquid with the known density into the liquid container, marking the density as rho liquid, and recording readings of the two gravity measuring devices at present as G large and G small; (2) then, putting the to-be-measured solid at one end, deep in the container, of the support, and recording readings of the two gravity measuring devices at present as G large1 and G small1; and (3) finally, substituting the recorded data into a formula of rho solid=(G large1-G large)*rho liquid / [(G large1-G large)-(G small1-G small)] to calculate the density, rho solid, of the solid. The measuring device is simple in structure, and the method is accurate in measurement, and high in measurement speed and measurement efficiency.

Owner:WUXI HODGEN TECH CO LTD

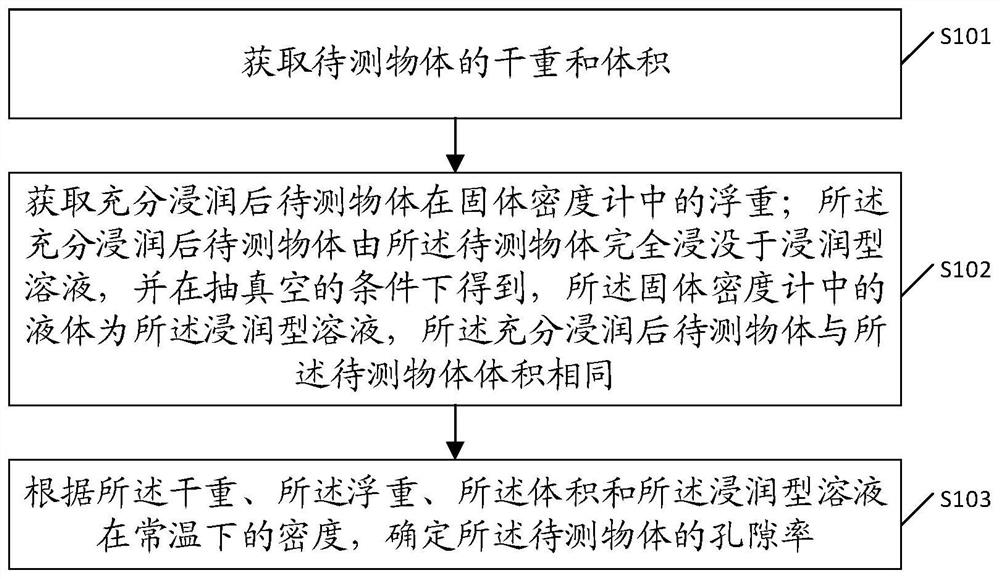

Porosity measuring method, device, equipment and system

PendingCN113607624AFully infiltratedHigh speedWeighing by removing componentPermeability/surface area analysisPorosityMechanical engineering

The invention discloses a porosity measuring method, device, equipment and system. The porosity measuring method comprises the following steps: acquiring dry weight and volume of a to-be-measured object; obtaining the buoyancy weight of the to-be-measured object in the solid density meter after the to-be-measured object is fully infiltrated; obtaining the to-be-measured object by completely immersing the to-be-measured object in the infiltration type solution under a vacuumizing condition after the to-be-measured object is fully infiltrated, wherein the liquid in the solid density meter is the infiltration type solution, and the to-be-measured object is the same as the to-be-measured object in volume after the to-be-measured object is fully infiltrated; and determining the porosity of the to-be-measured object according to the dry weight, the buoyancy weight, the volume and the density of the infiltrating type solution at normal temperature. The to-be-measured object is completely immersed in the infiltration type solution and vacuumized, it can be guaranteed that the to-be-measured object is fully infiltrated, the speed of infiltrating the to-be-measured object can be increased, the fully infiltrated to-be-measured object is placed in the solid density meter to obtain the buoyancy weight, and the volume of the fully infiltrated to-be-measured object is the same as that of the to-be-measured object. The infiltrating type solution does not influence the volume of the object to be measured, so that the porosity measurement precision is ensured.

Owner:SHANDONG SACRED SUN POWER SOURCES

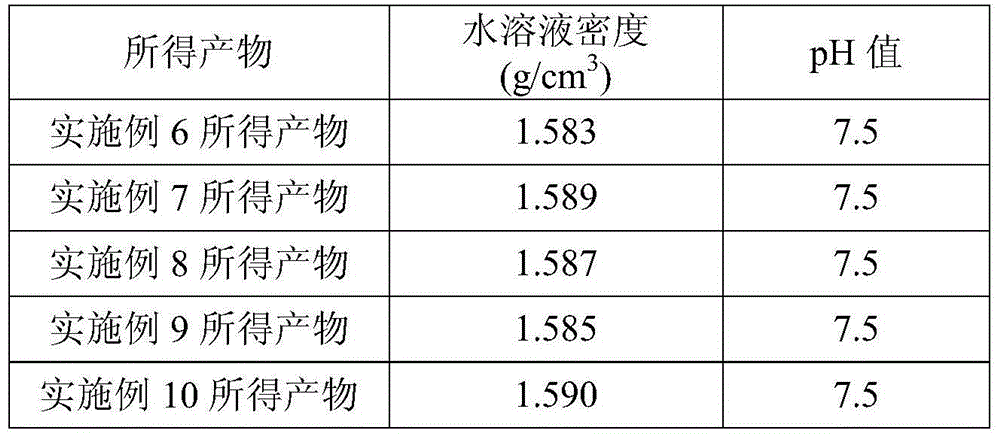

Water-soluble organic salt weighting agent for drilling fluid for oilfields as well as preparation method and application thereof

The invention provides a water-soluble organic salt weighting agent for drilling fluid for oilfields as well as a preparation method and application thereof. The method comprises the steps of preparing an organic acid mixture containing chlorine atoms, wherein the organic acid mixture comprises C1-C6 organic acids; adding composite alkali containing NaOH, KOH, ammonia water, N(CH3)3 and epoxy chloropropane to the organic acid mixture, stirring the materials to react, and evaporating water until the product is pasty or half-dry, wherein the mass ratio of composite alkali to organic acids is (0.2-2):1; drying the product at 80-120 DEG C for 6-24 hours, and grinding the dried product, thus obtaining the granular product. The weighting agent Weigh2 can not only improve the density of solid-free water-based drilling fluid base fluid but also improve the inhibitive capacity of the drilling fluid.

Owner:北京培康佳业技术发展有限公司

Preparation method of high-purity organosilicone monomer

InactiveCN104558015AEasy to operateImprove product qualitySilicon organic compoundsFiltrationDistillation

The invention provides a preparation method of a high-purity organosilicone monomer and particularly relates to a method for preparing an electronic grade high-purity organosilicone monomer by carrying out the following steps on an industrial organosilicone monomer: multiple rectifying; membrane filtration; multiple sub-boiling distillation and the like. The method provided by the invention is simple in process operation and high in safety, the purity of the prepared organosilicone monomer is greater than 99.99%, the content of a single metal ion impurity is less than 0.1ppb and the density of solid particles which are greater than or equal to 0.5 micron is less than 5 / ml. Moreover, the product is stable in quality and can satisfy the preparation requirement of an ultra large scale integration circuit.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

Apparatus and methods for determining gravity and density of solids in a liquid medium

ActiveUS10295450B2Viscometer maintainanceSpecific gravity measurementContinuous measurementLiquid medium

Apparatus and methods for the continuous measurement of specific gravity or density of solids in a fluid medium are disclosed. A system for continuous measurement of density of a flowing medium comprises a cartridge connected in series to an inflow pipe and an outflow pipe, a displacement sensing device adapted to monitor displacement changes of the cartridge when a medium flows through the cartridge, a base configured to provide a support for the displacement sensing device, a pressure sensor, a temperature sensor, and a processor configured to calculate density of the flowing media based on measured displacement change, temperature and pressure.

Owner:RED METERS LLC

Device and method for continuous detection of changes of density in fluids and solids as well as use of the device

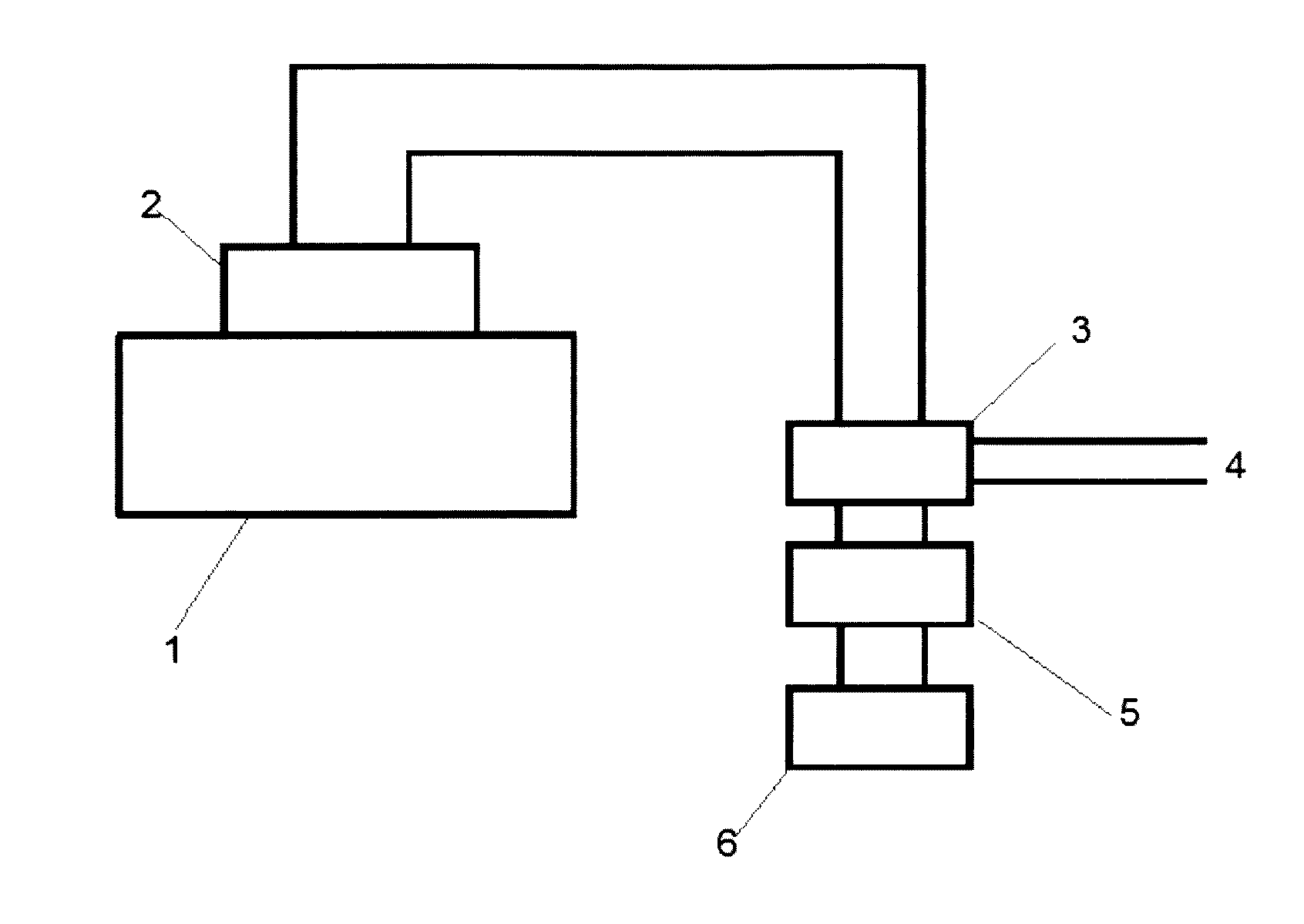

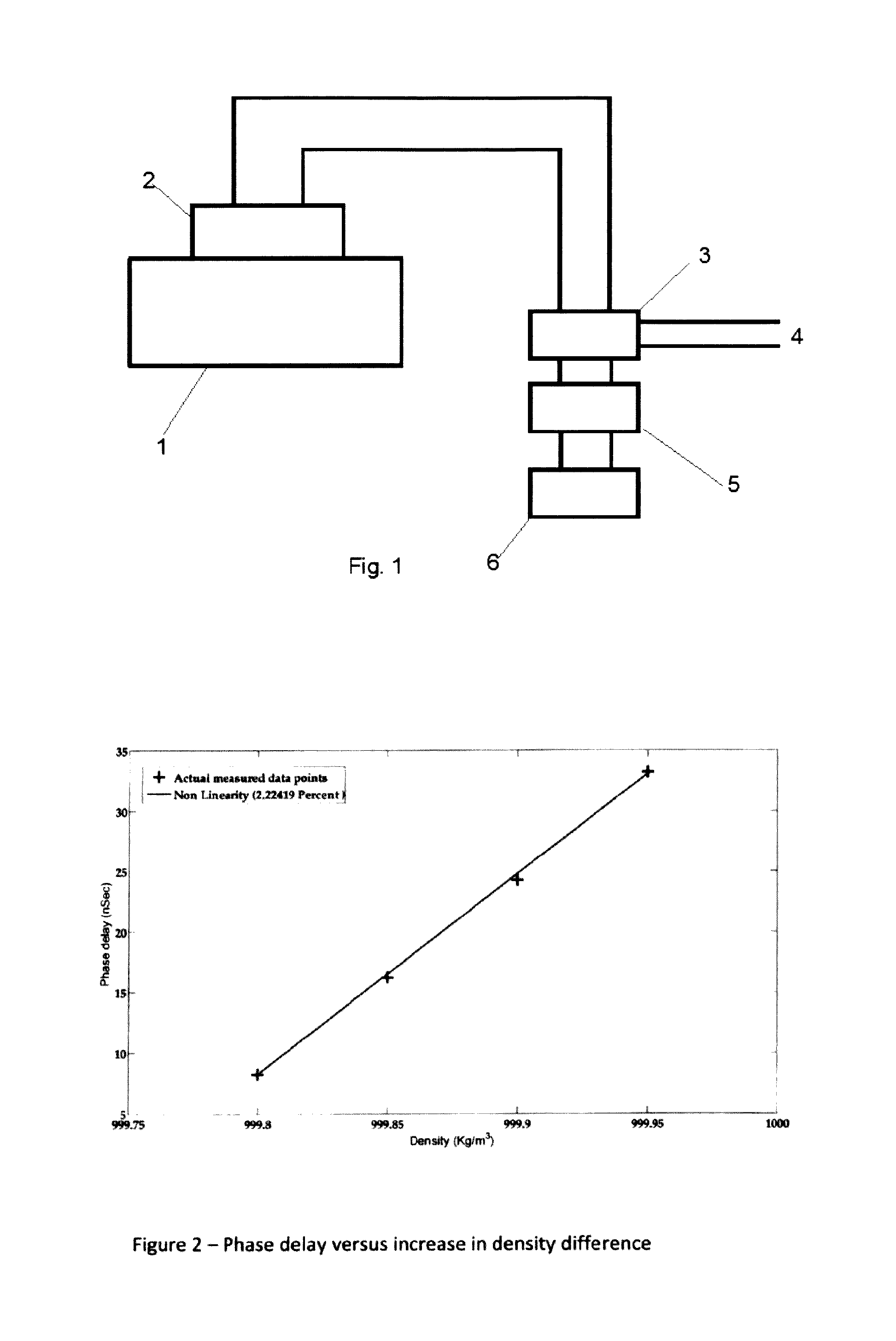

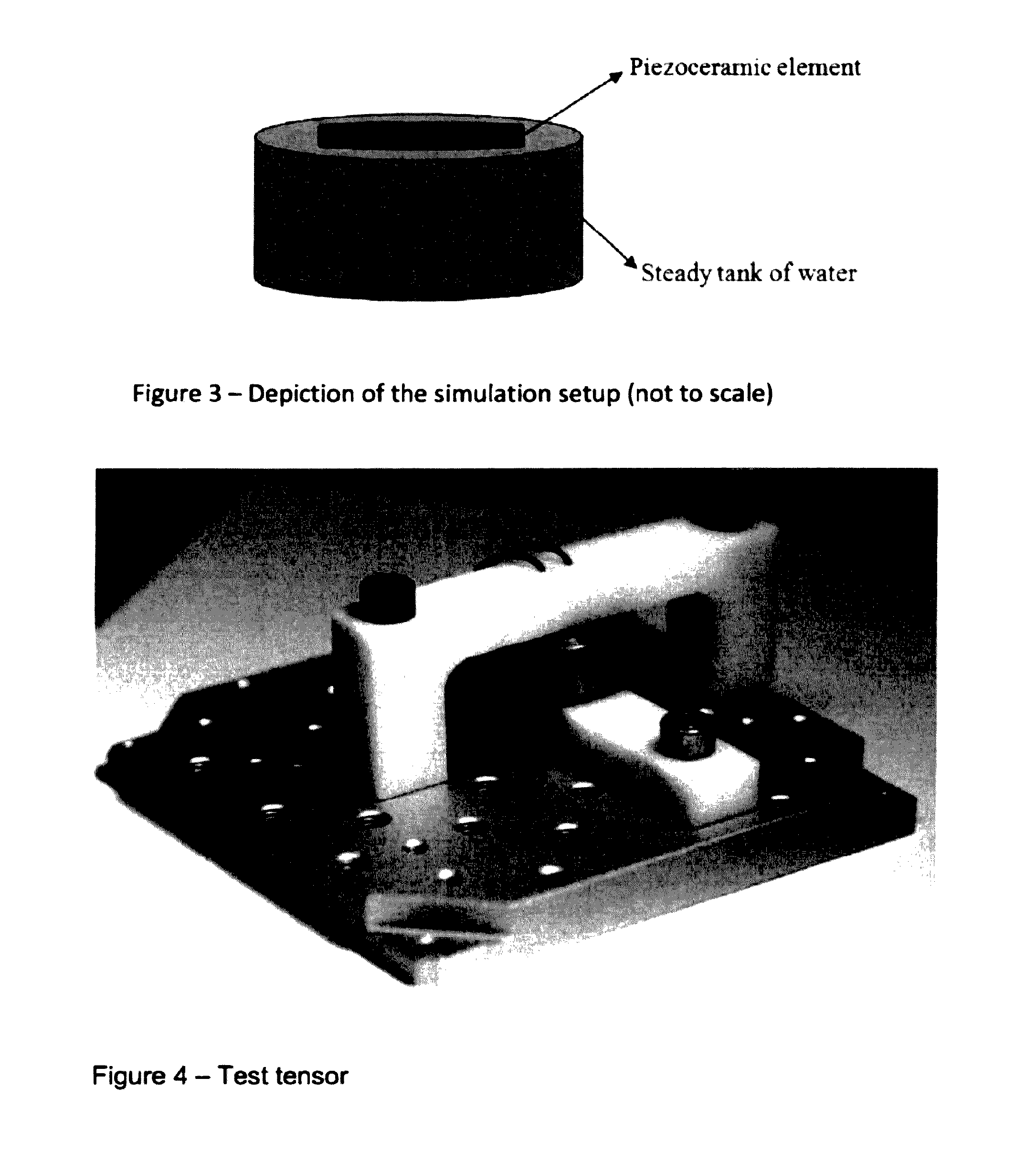

ActiveUS20160109346A1Material analysis using sonic/ultrasonic/infrasonic wavesDiagnostics using vibrationsBiological fluidEnvironmental geology

A sensor is for continuous detection of minute changes of density in fluids and biological fluids, solids and semisolid bodies by use of a transducer. A method continuously detects changes of density of fluids or solids. The method can be carried out using the sensor.

Owner:MECSENSE

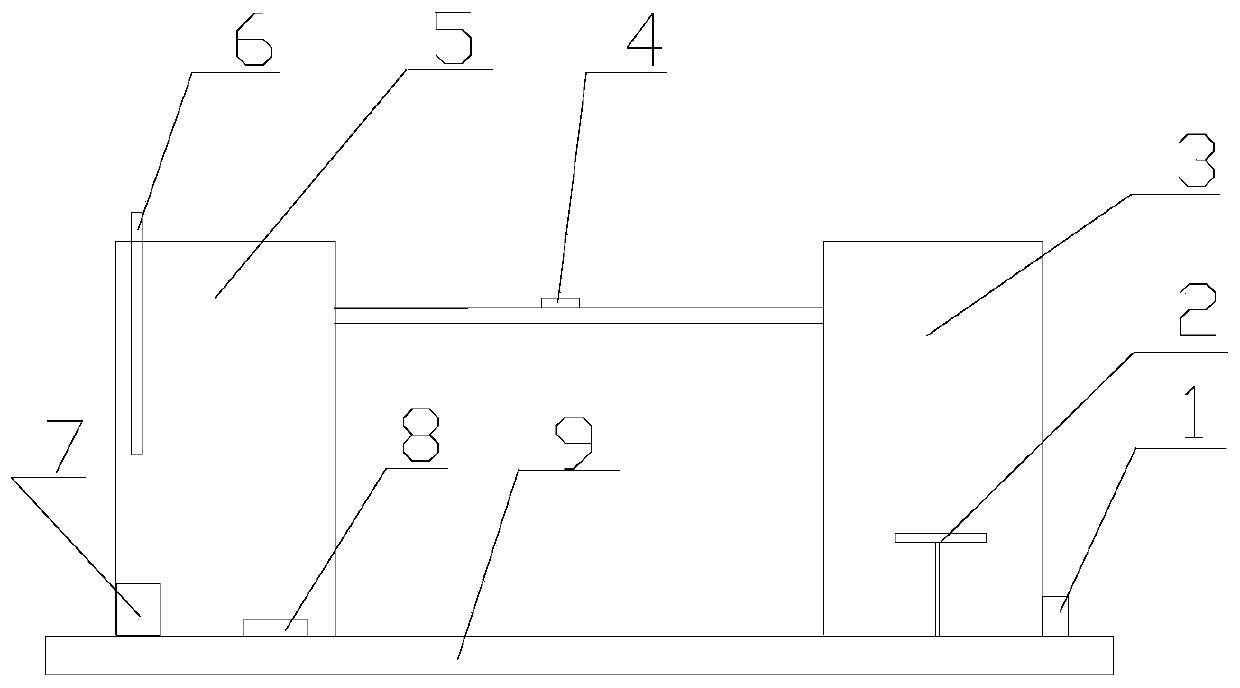

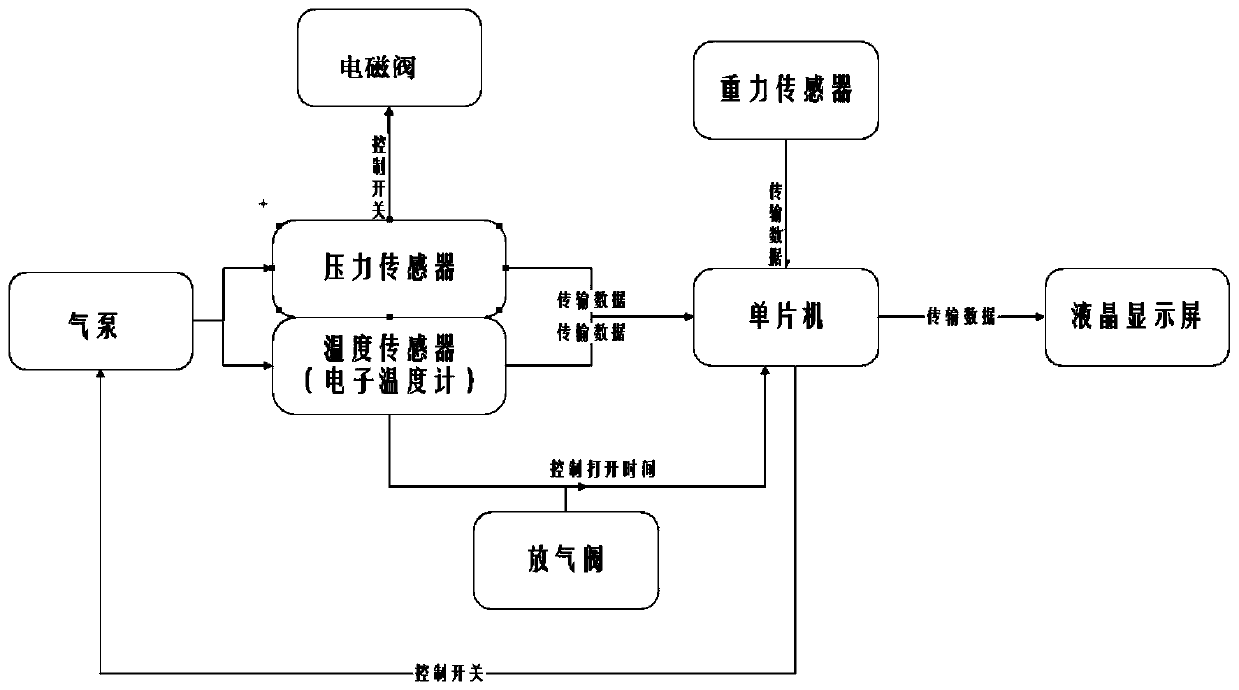

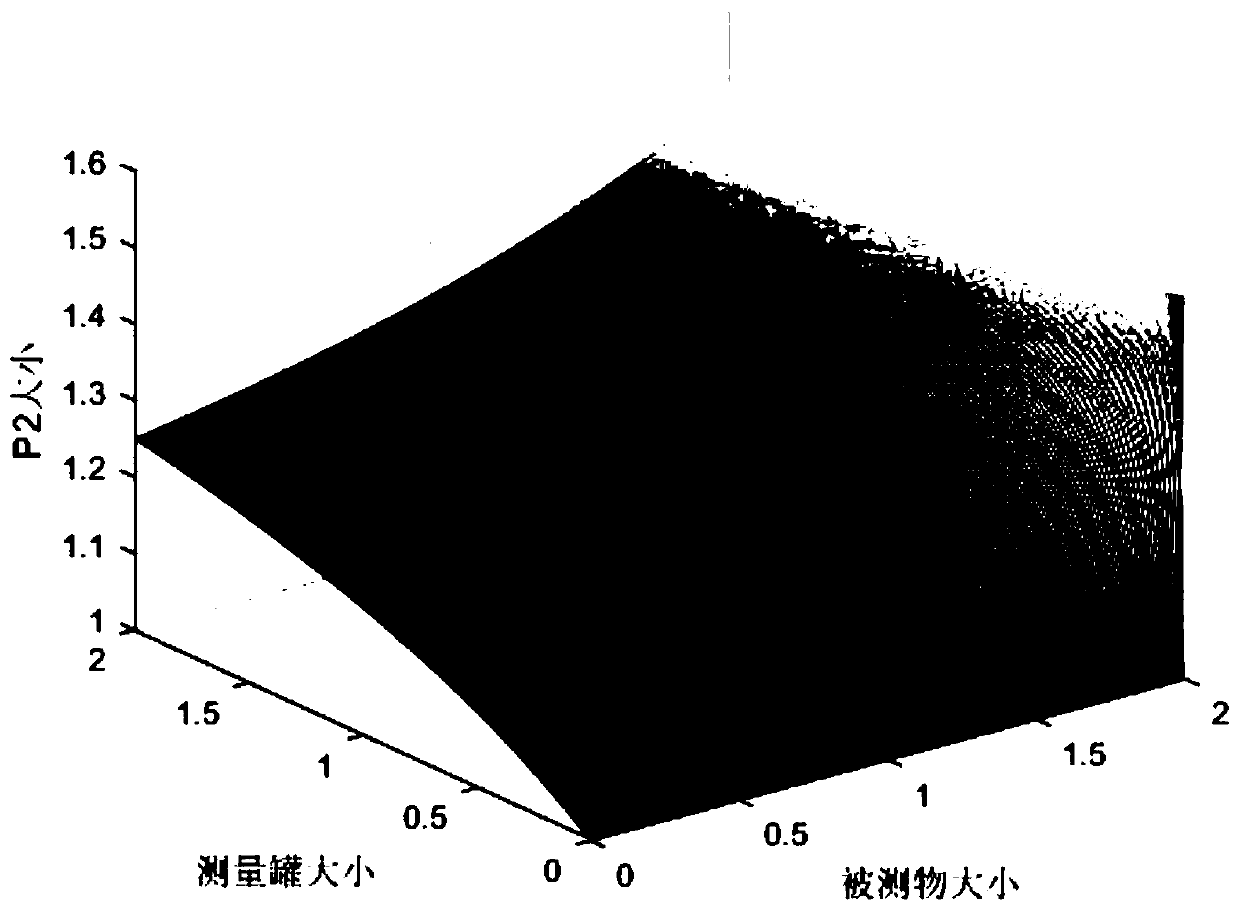

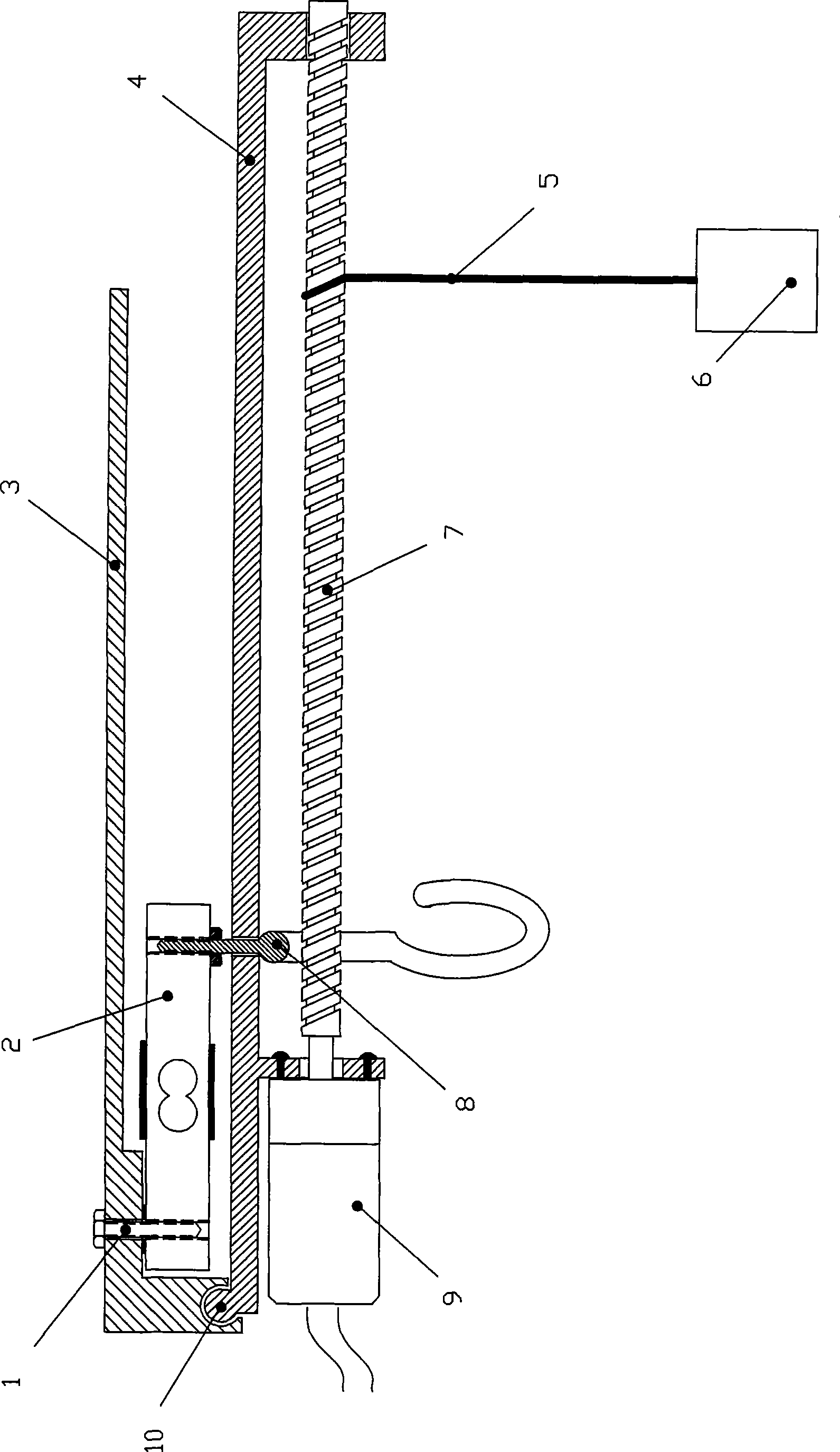

Portable specific gravity instrument based on air pressure measurement and specific gravity measurement method

InactiveCN109856007AMeasuring Energy SavingsMeasuring Environmental ProtectionSpecific gravity measurementAir pumpEngineering

The invention relates to a portable specific gravity instrument based on air pressure measurement and a specific gravity measurement method. The portable specific gravity instrument comprises a firstsealed space, a second sealed space, a temperature sensor, a pressure sensor and a controller, wherein the first sealed space is used for placing a measured object, and the first sealed space is internally provided with a gravity sensor and an air release valve; the connection between the second sealed space and the first sealed space is controlled by an electromagnetic valve, and the second sealed space is internally provided with an air pump so as to inflate the second sealed space; the temperature sensor is arranged in the second sealed space and used for measuring the temperature before and after the pressure intensity changes; the pressure sensor is arranged in the second sealed space and used for measuring the pressure intensity; and the controller is used for controlling the measurement time sequence, receiving the temperature, pressure intensity and gravity data and processing the data. The portable specific gravity instrument completes the accurate measurement of the density of solid and liquid substances to the greatest extent through measuring the pressure intensity change in the same sealed container and calculating the relevant formula, and completes the energy-saving,environment-friendly and non-loss efficient measurement.

Owner:JILIN UNIV

Sustained-release agent for in-situ remediation of chlorohydrocarbon-contaminated groundwater in deep mine

InactiveCN110407266AHigh densityImprove degradation efficiencyWater treatment parameter controlWater treatment compoundsPersulfateSolid particle

The invention provides a sustained-release agent for in-situ remediation of chlorohydrocarbon-contaminated groundwater in a deep mine. The sustained-release agent is prepared from, by weight, 10-40% of peroxide, 5-30% of iron tourmaline, 20-50% of persulfate, 1-5% of a surfactant and 5-20% of a binder. According to the provided sustained-release agent for the in-situ remediation of the chlorohydrocarbon-contaminated groundwater in the deep mine, the density of solid particles is large, the sustained-release agent can enter the bottom layer of underground contaminated water by using the sedimentation action of the gravity when injected into the groundwater in the deep mine, a double oxidation system is formed after the sustained-release agent is dissolved in the water, chlorohydrocarbon contaminants sunk at the water bottom are degraded, the degradation efficiency is obviously improved, and the pH value of an aqueous solution can also be adjusted, so that the aqueous solution tends to be neutral.

Owner:山东省地质矿产勘查开发局八〇一水文地质工程地质大队

Method for detecting solid density and densitometer using the method

InactiveCN101398364AEasy to measureImprove linearityMaterial analysis by measuring buoyant forcesEngineeringLinearity

The invention discloses a method used for measuring the density of solid, comprising the steps as follows: the article is hung on a lever; the other force arm of the lever is acted on an electronic balance; the suspension point of the article is adjusted so as to lead the reading of the electronic balance to be 1; subsequently, the article is submerged in water; therefore, the obtained result is the ratio of the weight of the article in water and the weight of the article in air; the detection result is compared with the ratio of the weight of various materials in water and weight thereof in air calculated in advance, thus obtaining the density value of the article; as the weight of the article to be measured in air is not measured, the measurement is simpler; and a strain sensor is used for measuring the value by lever adjustment, thus having good linearity.

Owner:王洋

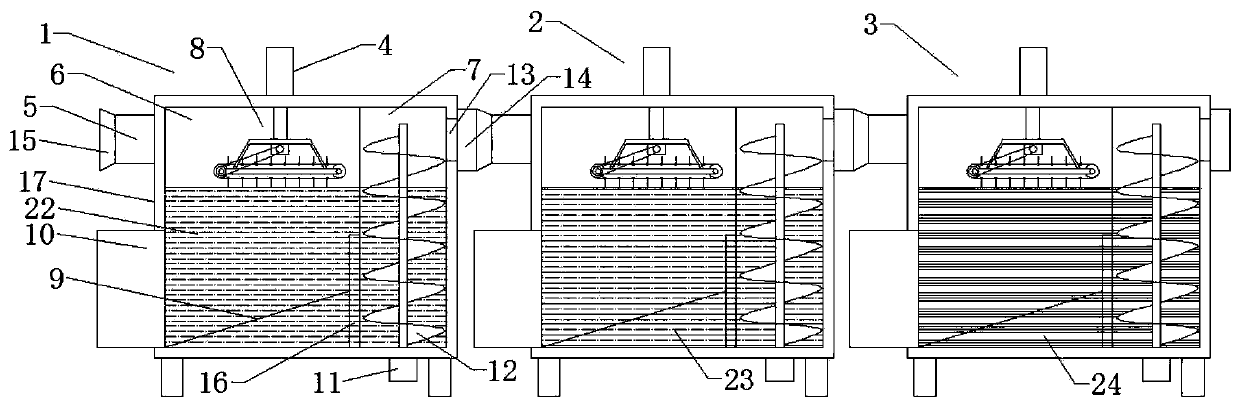

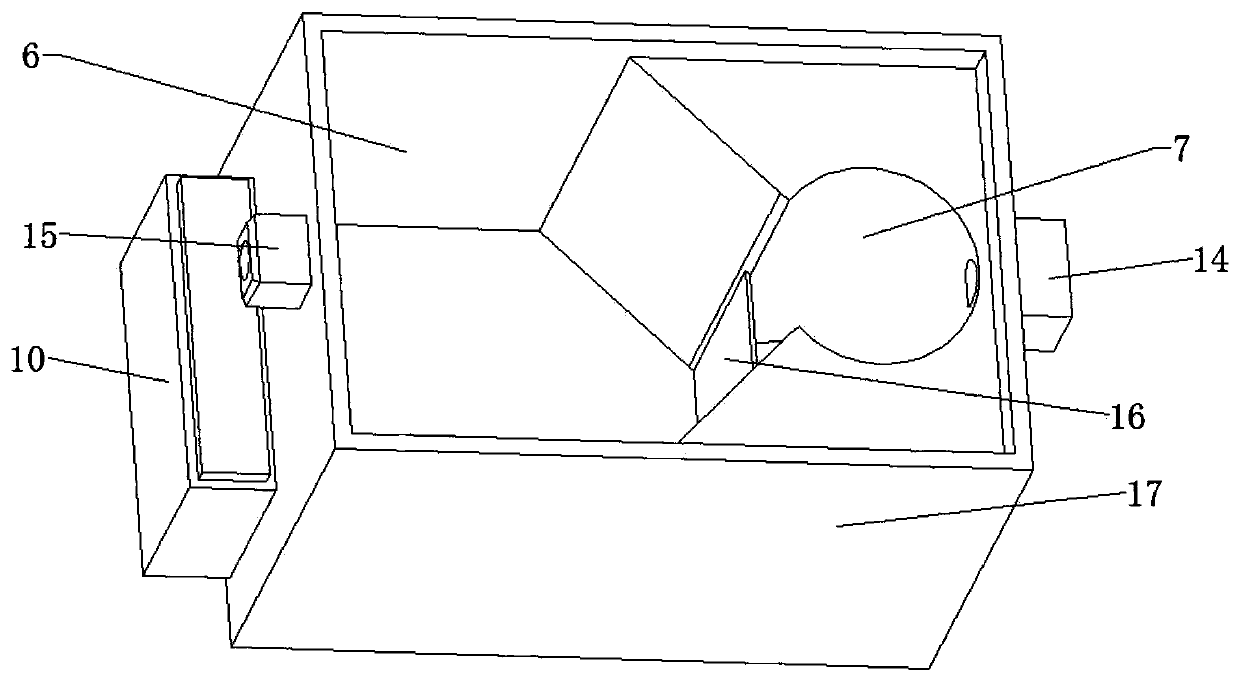

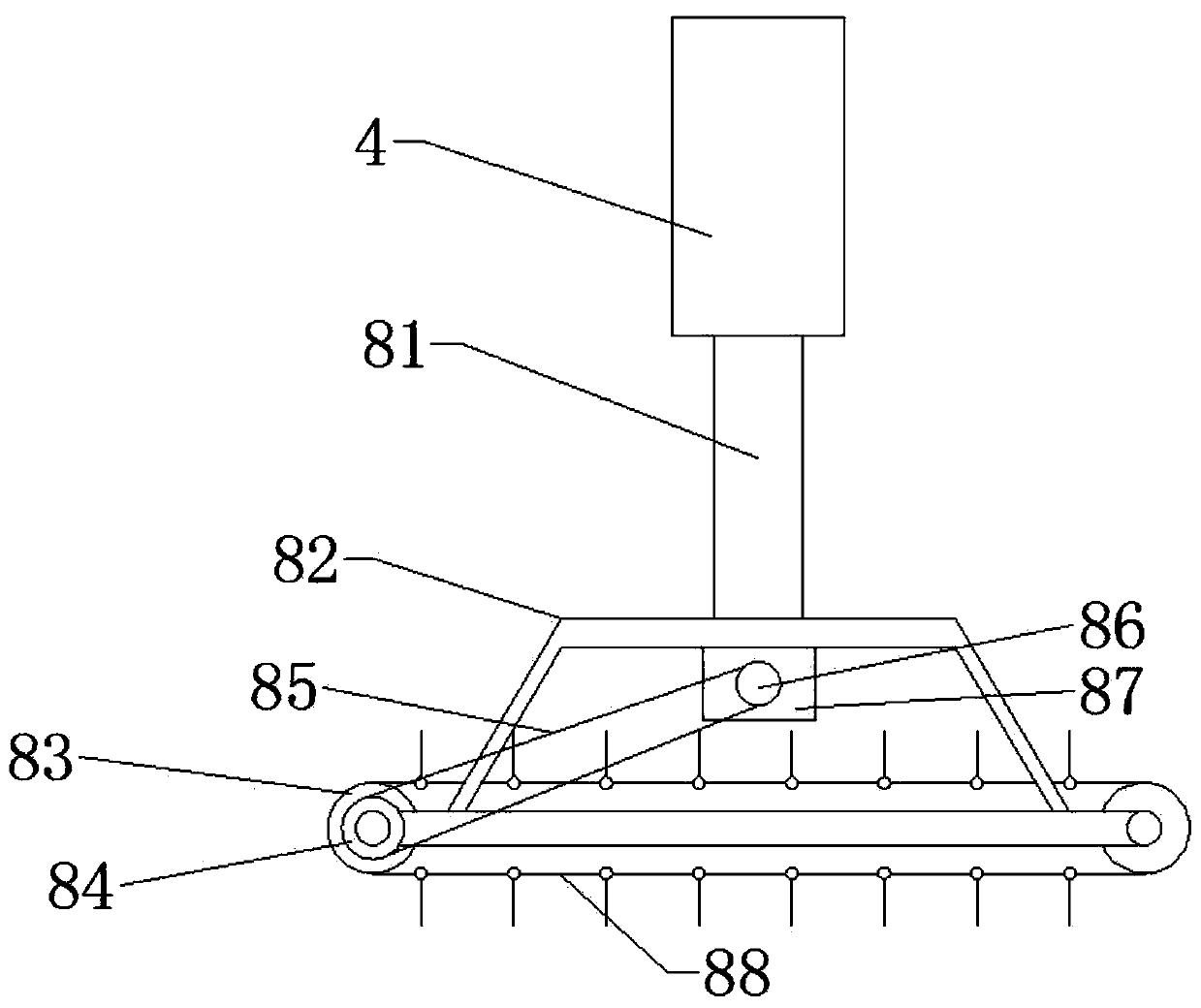

Solid waste screening and separating treatment system

ActiveCN110124847AMove quicklyEasy to collectMechanical material recoveryWet separationEnvironmental engineeringAtmospheric pressure

The invention relates to the field of environmental protection, and particularly discloses a solid waste screening and separating treatment system. The solid waste screening and separating treatment system comprises a plurality of separation tanks communicated in sequence, separating liquid is filled in each separating box, and the density of the separating liquid is reduced in sequence; the separating box comprises a box body, and the interior of the box body is divided into a sedimentation cavity and a material lifting cavity; a material stirring mechanism capable of ascending and descendingin the vertical direction is arranged in the sedimentation cavity, and the upper end of the material stirring mechanism is fixedly connected to an air pressure lifting device; and the outer end of afeeding hole is covered with a collecting cover, and the outer end of a discharging hole is in communication with a sealing cover matched with the collecting cover. According to the solid waste screening and separating treatment system, a plurality of separation tanks are arranged, separation liquid with different densities is filled in each separation tank, separation is carried out according tothe density of solid wastes, solid wastes with different densities are separated, and collection is facilitated, and manual sorting is not needed; the multiple separation boxes are in communication with each other, so that the separation treatment is continuously carried out, and the treatment efficiency is improved; the solid waste screening and separating treatment system can select different numbers according to the types of solid wastes, and is flexible to use and wide in application range.

Owner:侯马市威创动力机械有限公司

Method of measuring volume and density of solid object

PendingCN111272250ASolution volumeSolve densityContainer/cavity capacity measurementSpecific gravity measurementParticle transferEngineering

The invention relates to a method for measuring the density of an object. The method comprises the following steps of preparing fine particles with uniform texture and a container with known mass (m)and volume (V1) in advance; firstly, filling the container with fine particles; weighing to obtain the total mass m1; obtaining the density rho particulate matters of the fine particulate matters according to the formula rho particulate matters = (m1-m) / v1, weighing and recording the mass m of the measured object; transferring part of fine particles out of the container for storage; reserving a small amount of fine particles at the bottom of the container; putting a solid substance to be measured into the container; and filling the container with the fine particles transferred from the container, weighing and recording the mass m2 of the remaining fine particles taken out from the container, calculating the volume of the remaining fine particles according to the equation v measured object=m2 / rho particulate matters to obtain v measured object, and calculating the density of the measured object according to the v measured object. According to the invention, the volume and density measurement problem of the solid object with a complex shape is solved, and the measurement precision is relatively higher.

Owner:GANSU AGRI UNIV

Water-soluble organic salt weighting agent for drilling fluid for oilfields as well as preparation method and application thereof

The invention provides a water-soluble organic salt weighting agent for drilling fluid for oilfields as well as a preparation method and application thereof. The method comprises the steps of preparing an organic acid mixture containing chlorine atoms and bromine atoms, wherein the organic acid mixture comprises C1-C6 organic acids; adding composite alkali containing NaOH, KOH, ammonia water, N(CH3)3 and epoxy chloropropane to the organic acid mixture, stirring the materials to react, and evaporating water until the product is pasty or half-dry, wherein the mass ratio of composite alkali to organic acids is (0.2-1.8):1; drying the product at 80-120 DEG C for 6-24 hours, and grinding the dried product, thus obtaining the granular product. The weighting agent Weigh3 can not only improve the density of solid-free water-based drilling fluid base fluid but also improve the inhibitive capacity of the drilling fluid.

Owner:北京培康佳业技术发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com