Patents

Literature

113results about "Viscometer maintainance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System and method for determining oil grade

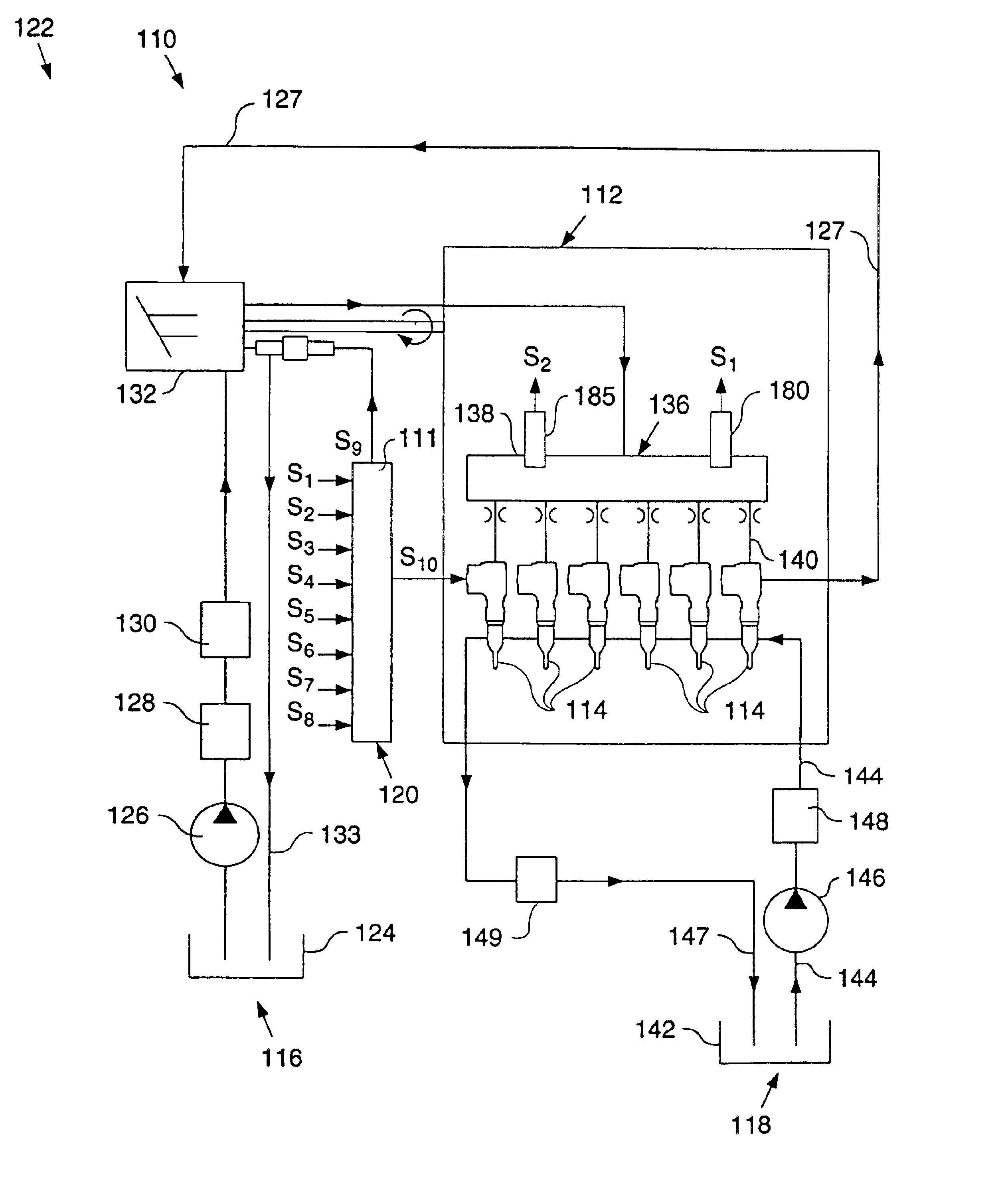

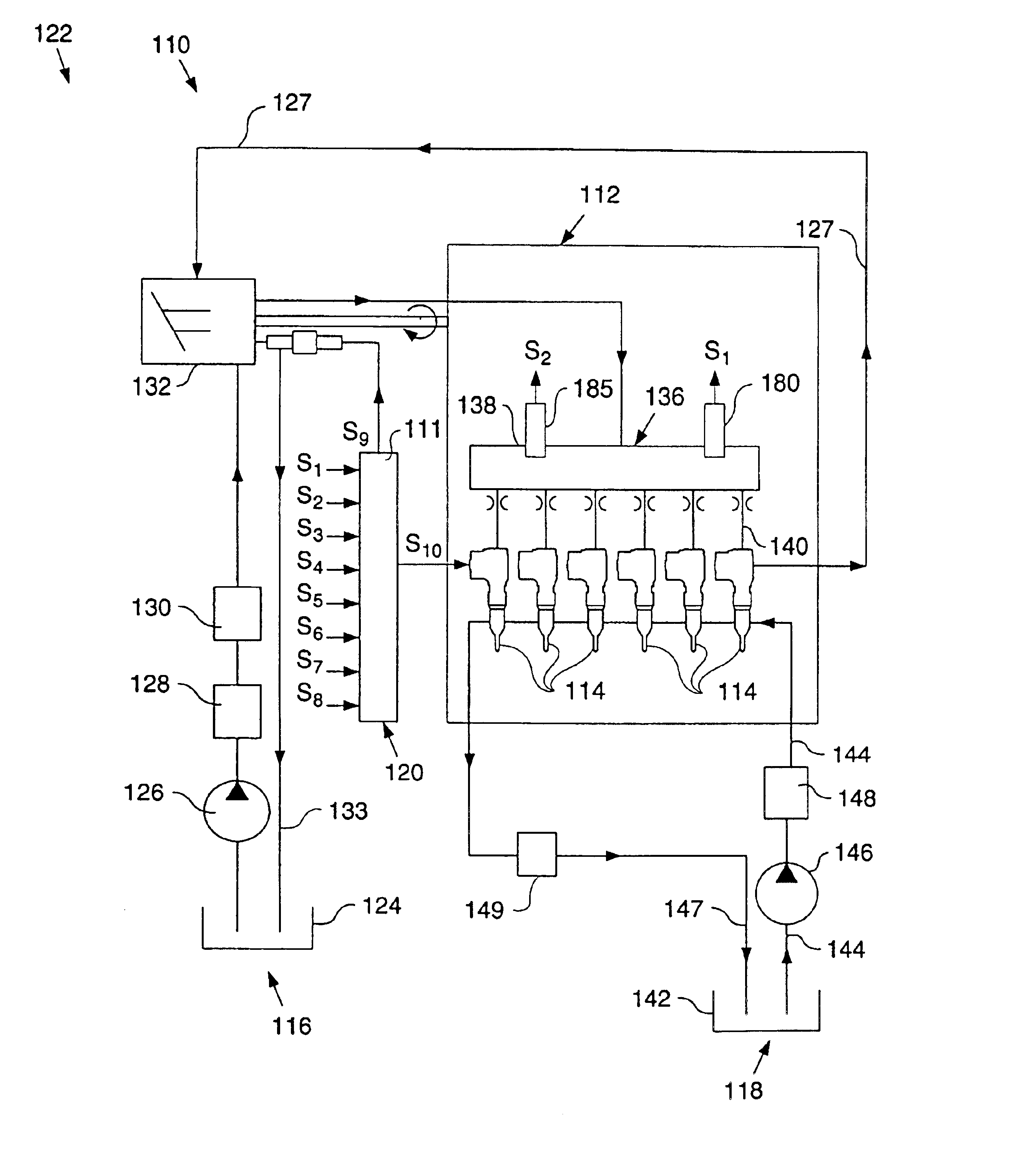

The grade of oil used in a machine or apparatus can be determined by determining a temperature and pressure within an oil supply and determining the oil grade in response to determining the temperature and pressure.

Owner:CATERPILLAR INC

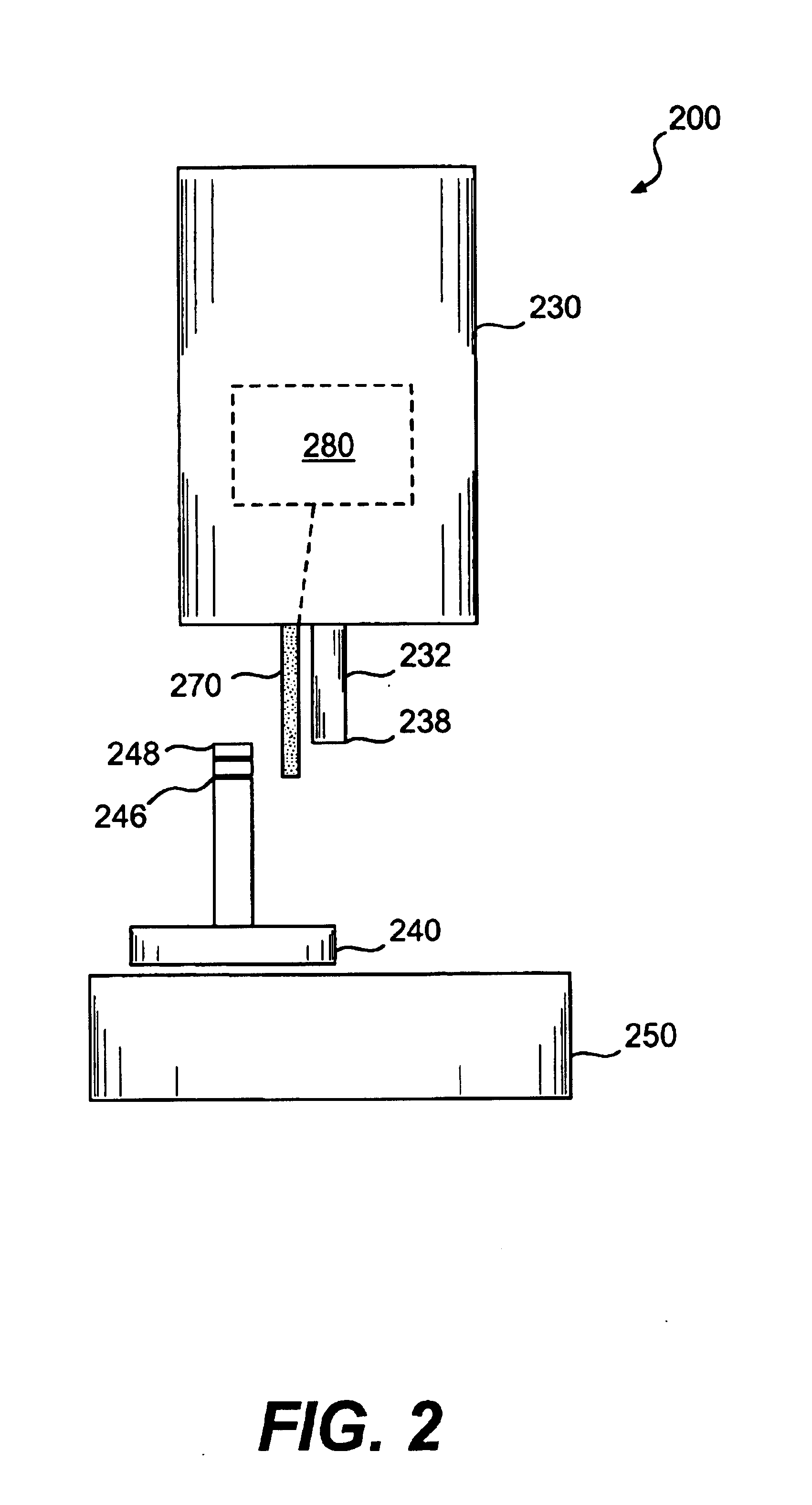

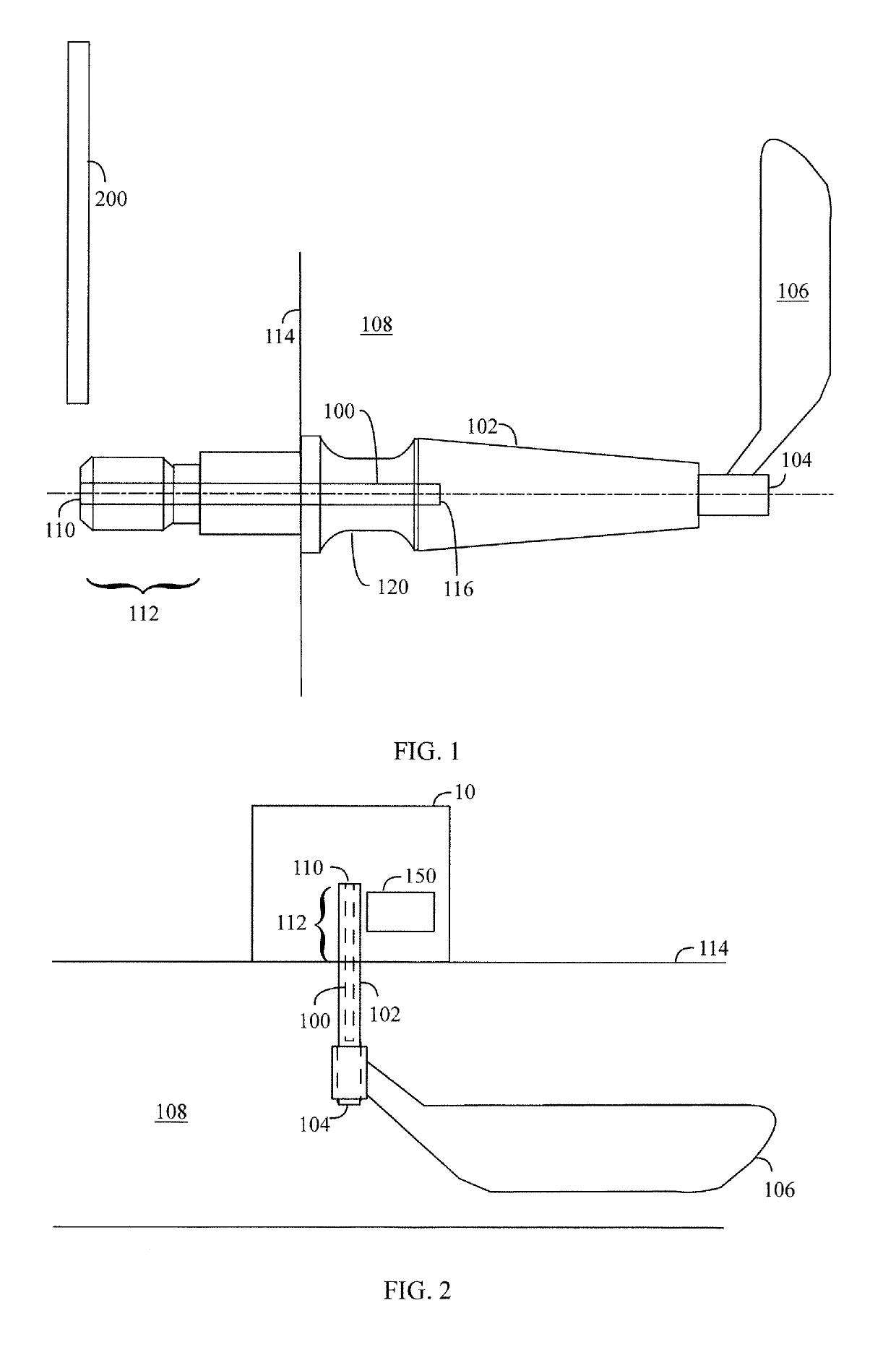

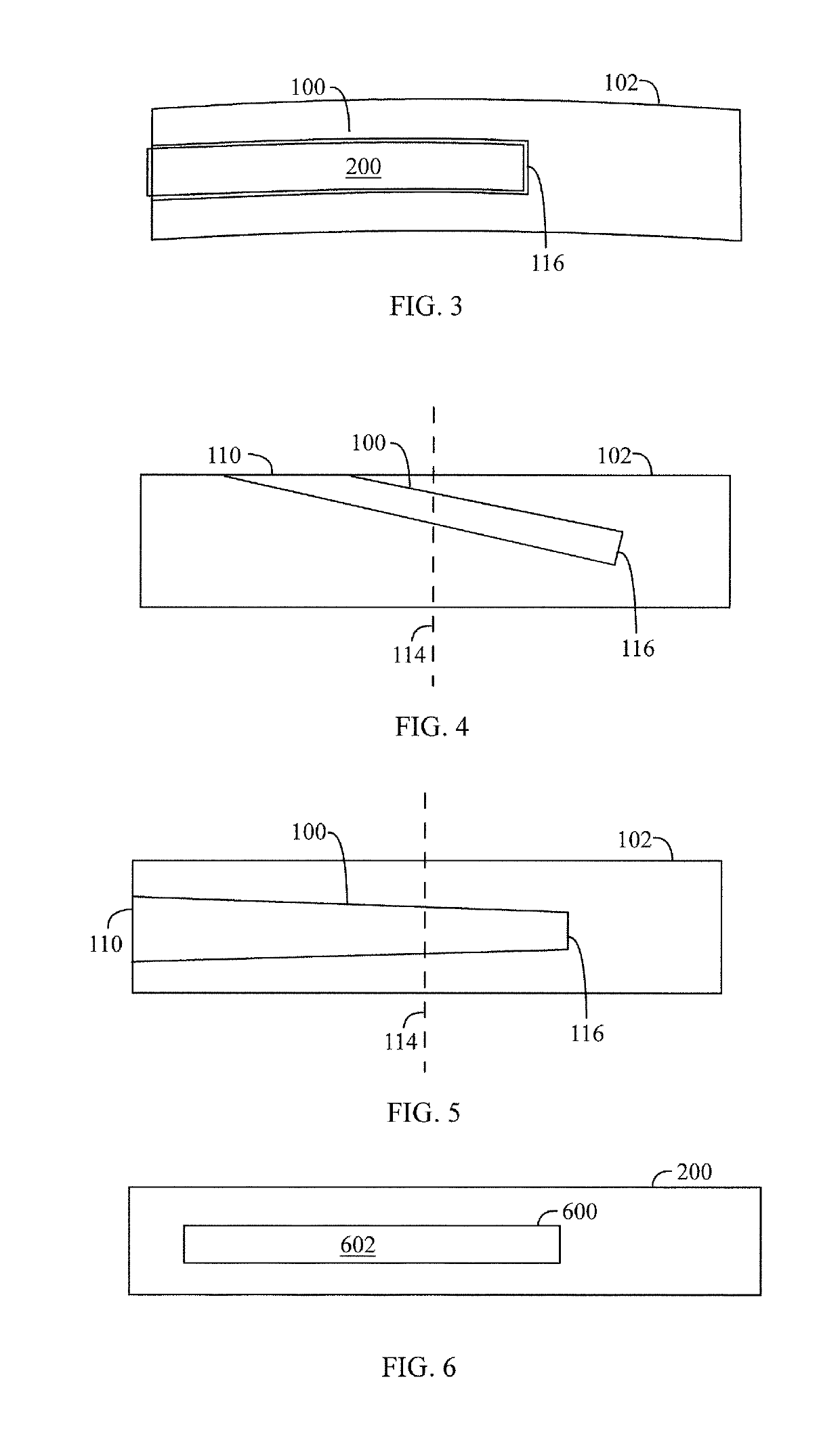

System and method for automatic identification of a detachable component of an instrument

InactiveUS6952950B2Viscometer maintainanceAltering/correcting law of variationBarcodeComputer science

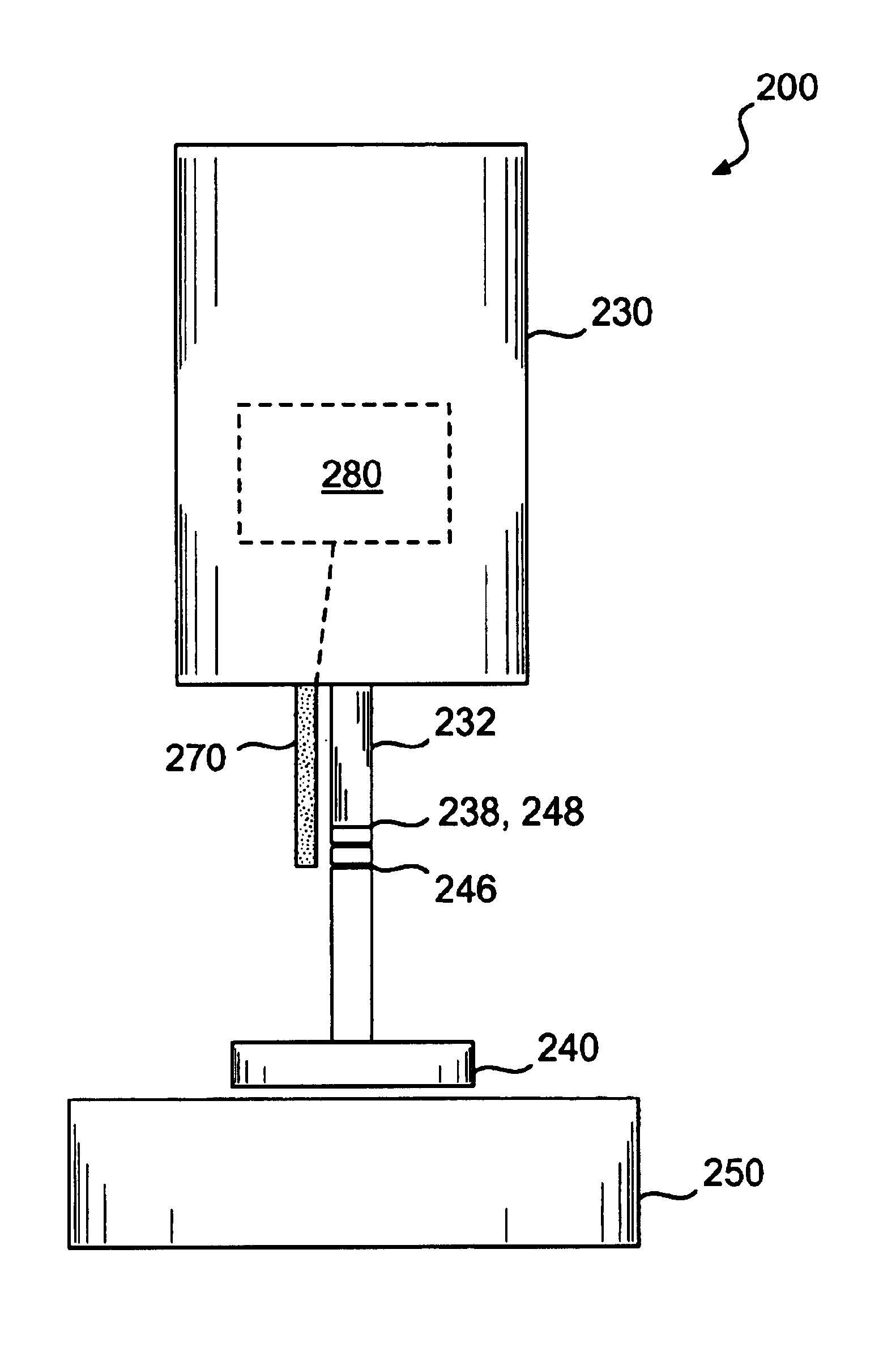

A system and method for automatic identification of a detachable component of an instrument is disclosed. The detachable component includes a machine-readable device that contains information associated with the detachable component. The machine-readable device can be a bar code, a variable depth pattern, a magnetic stripe, or the like. The information contained within the machine-readable device can include one or more of serial number, type, material, dimensions, and calibration data of the detachable component. The instrument includes a reader that is configured to obtain the information from the machine-readable device.

Owner:WATERS TECH CORP

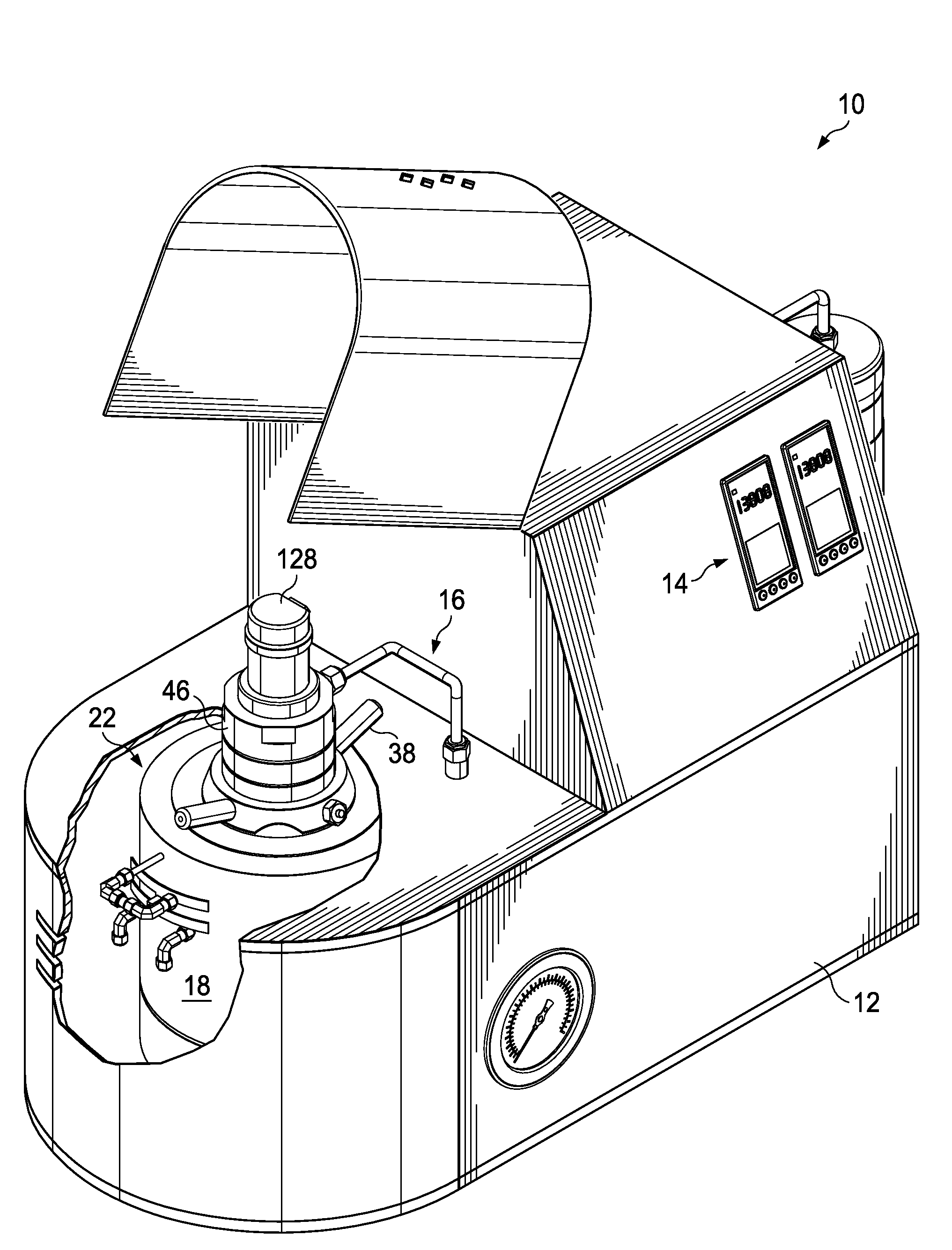

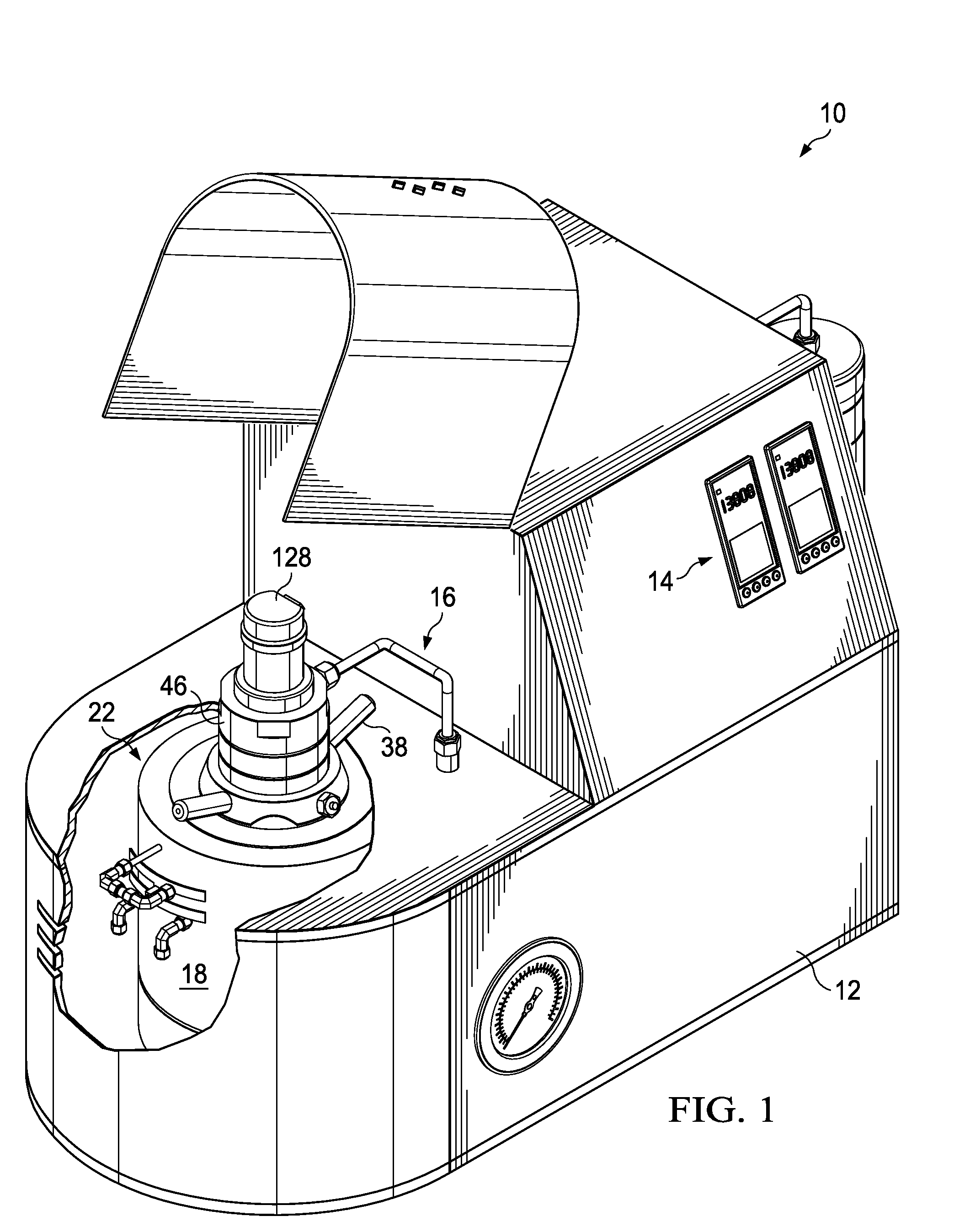

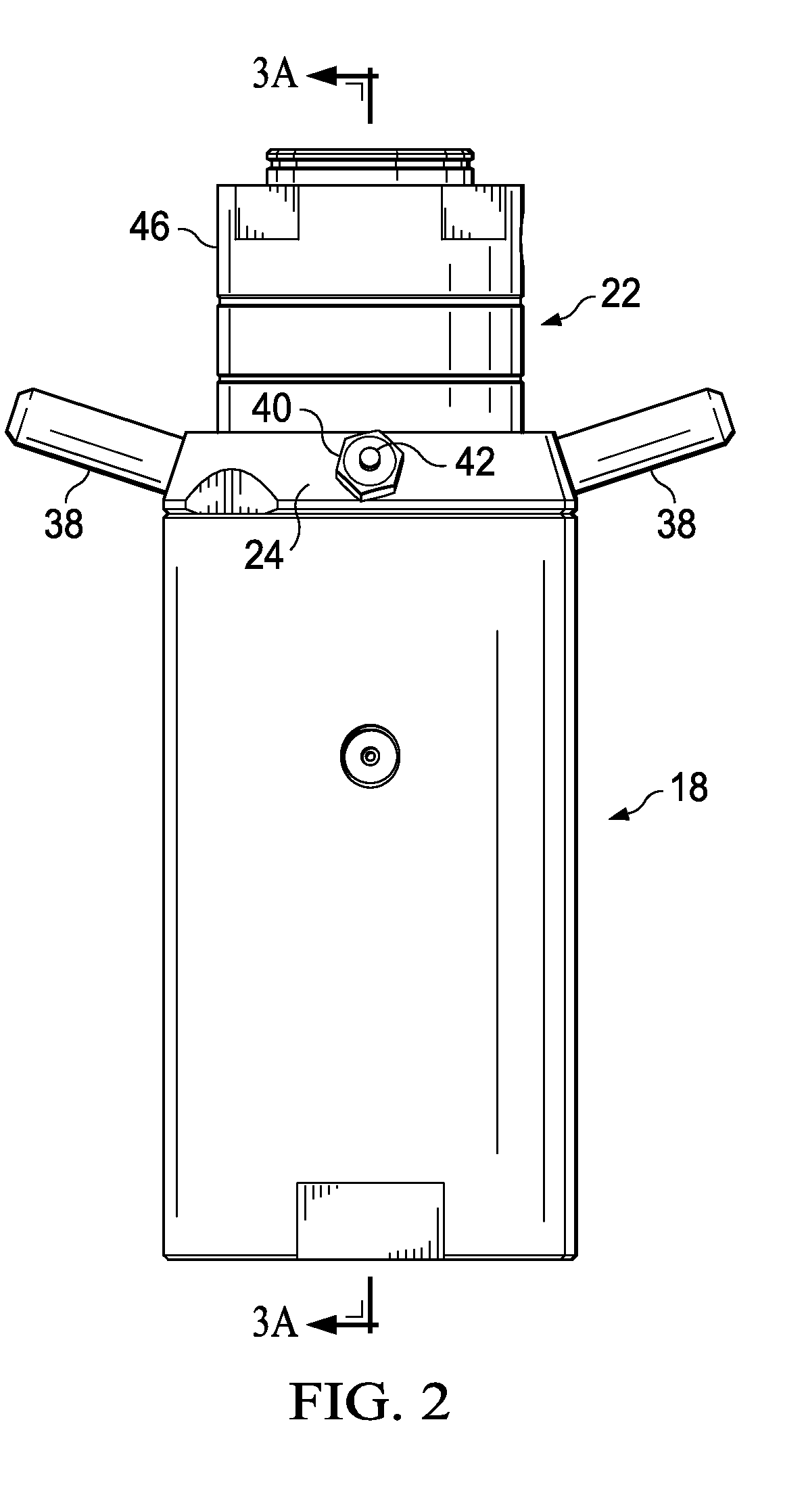

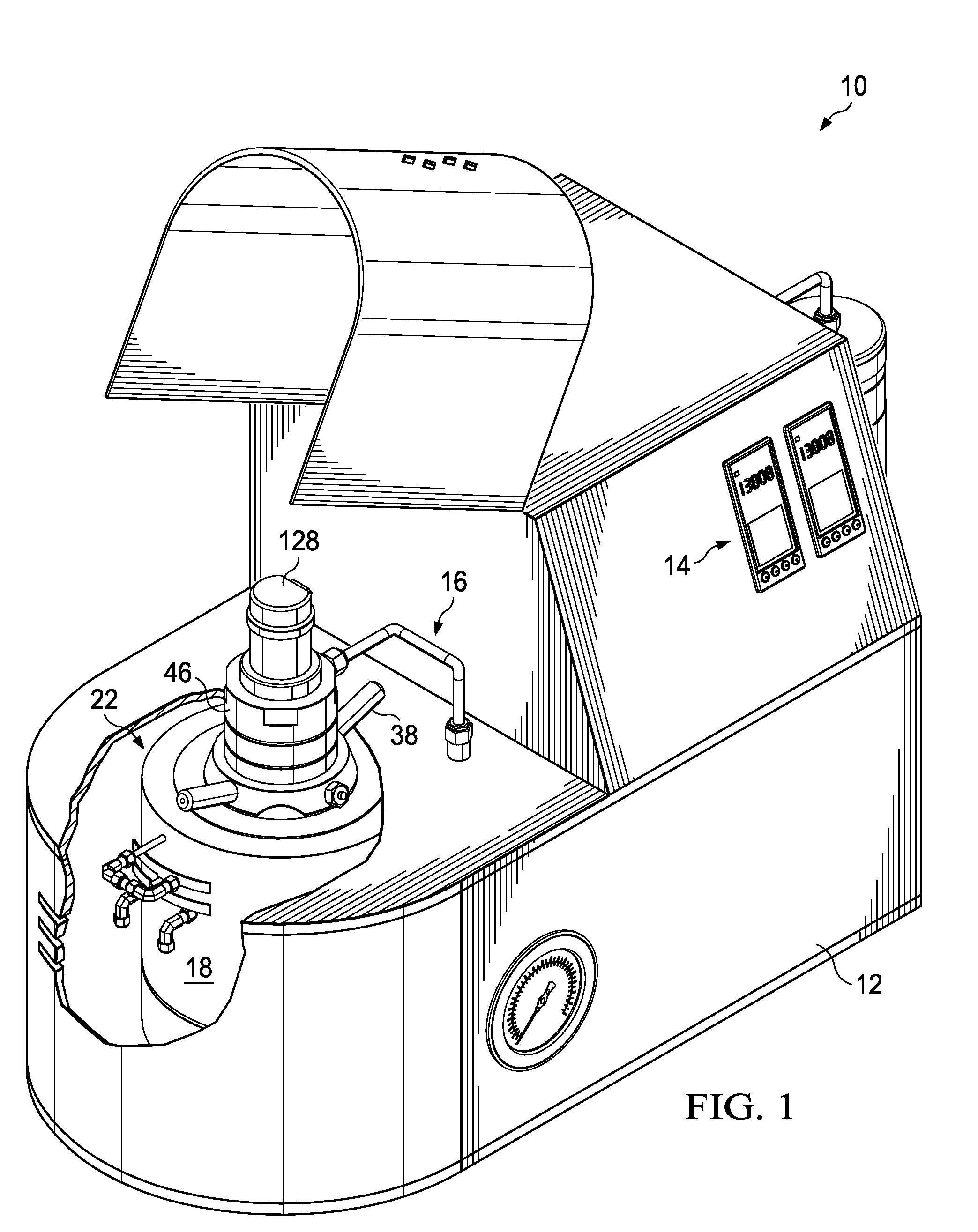

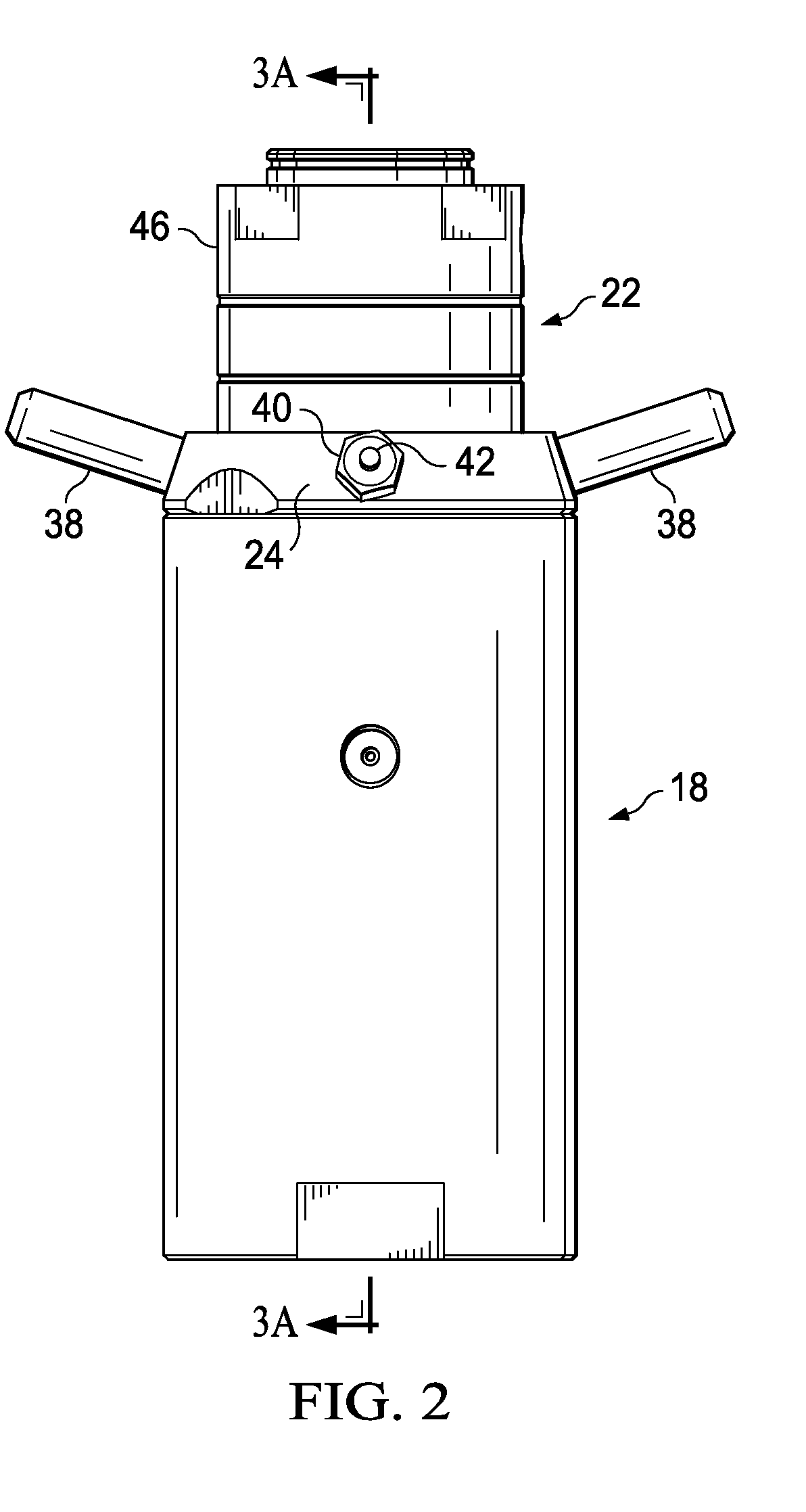

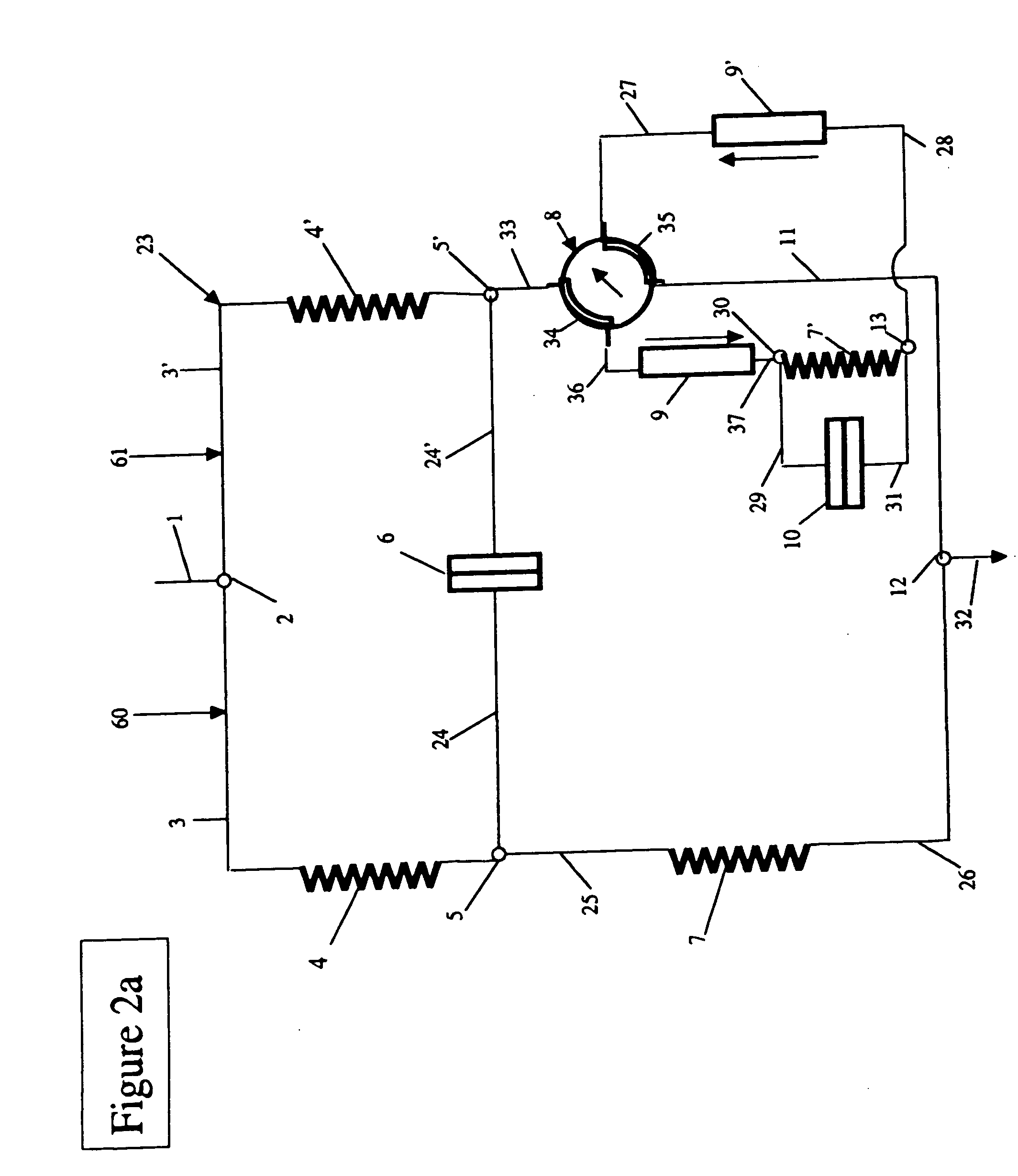

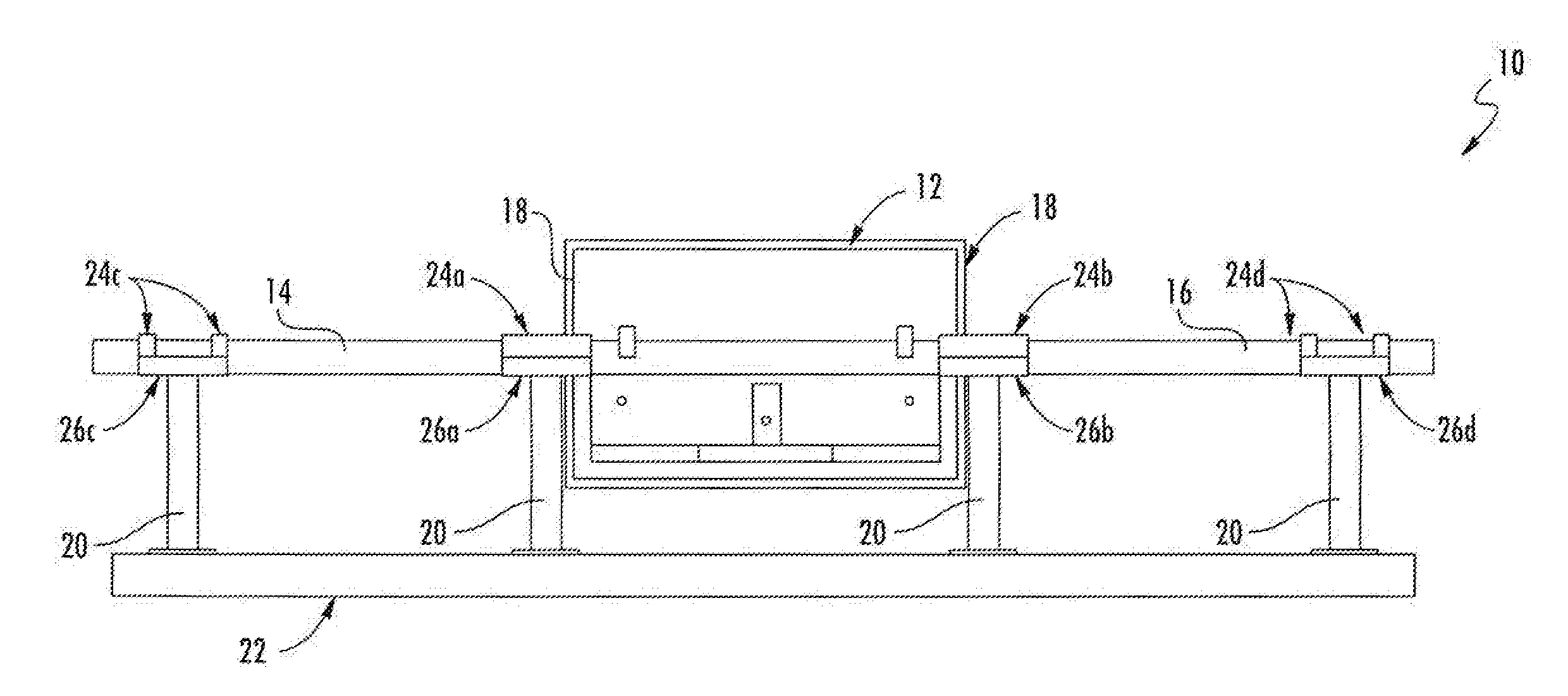

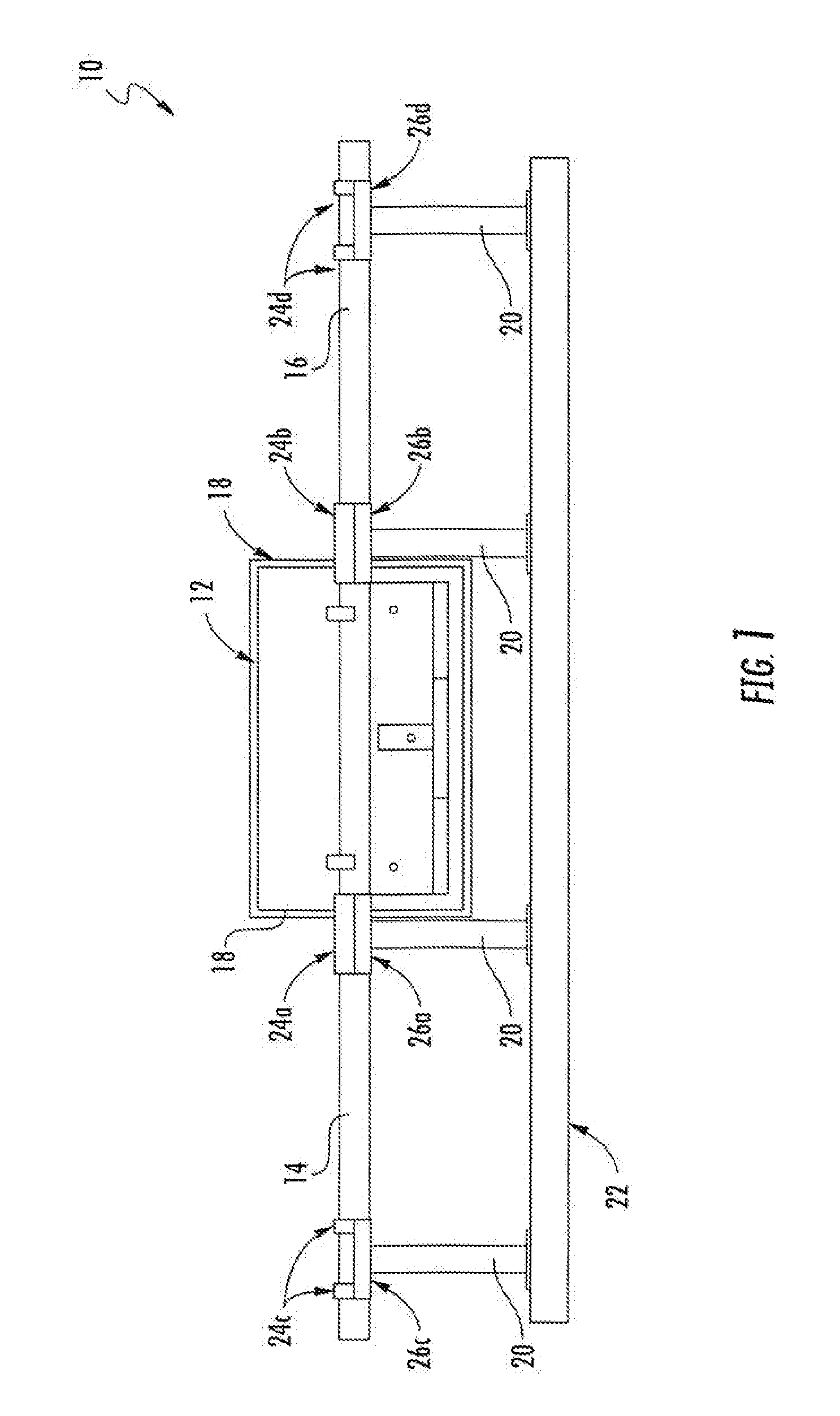

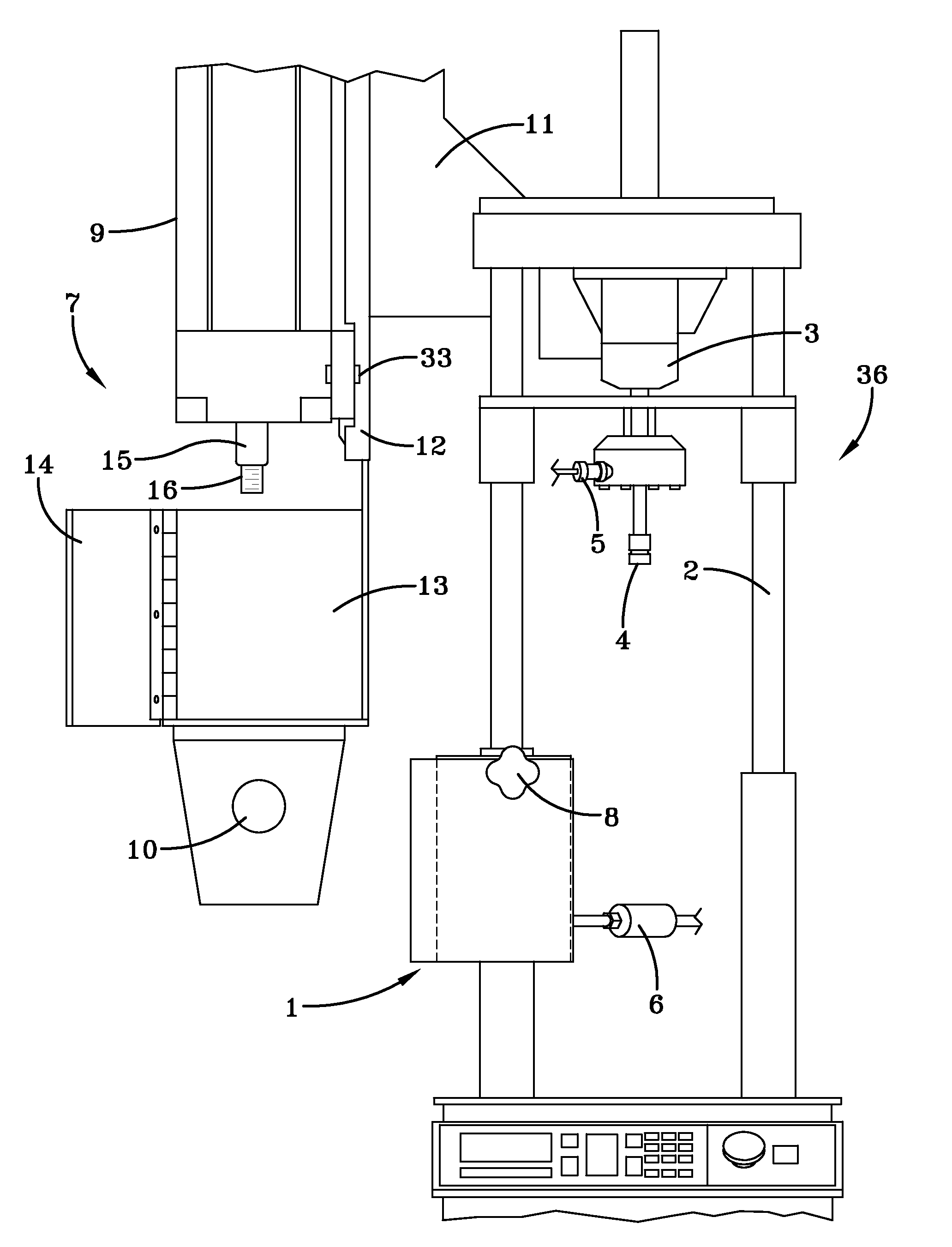

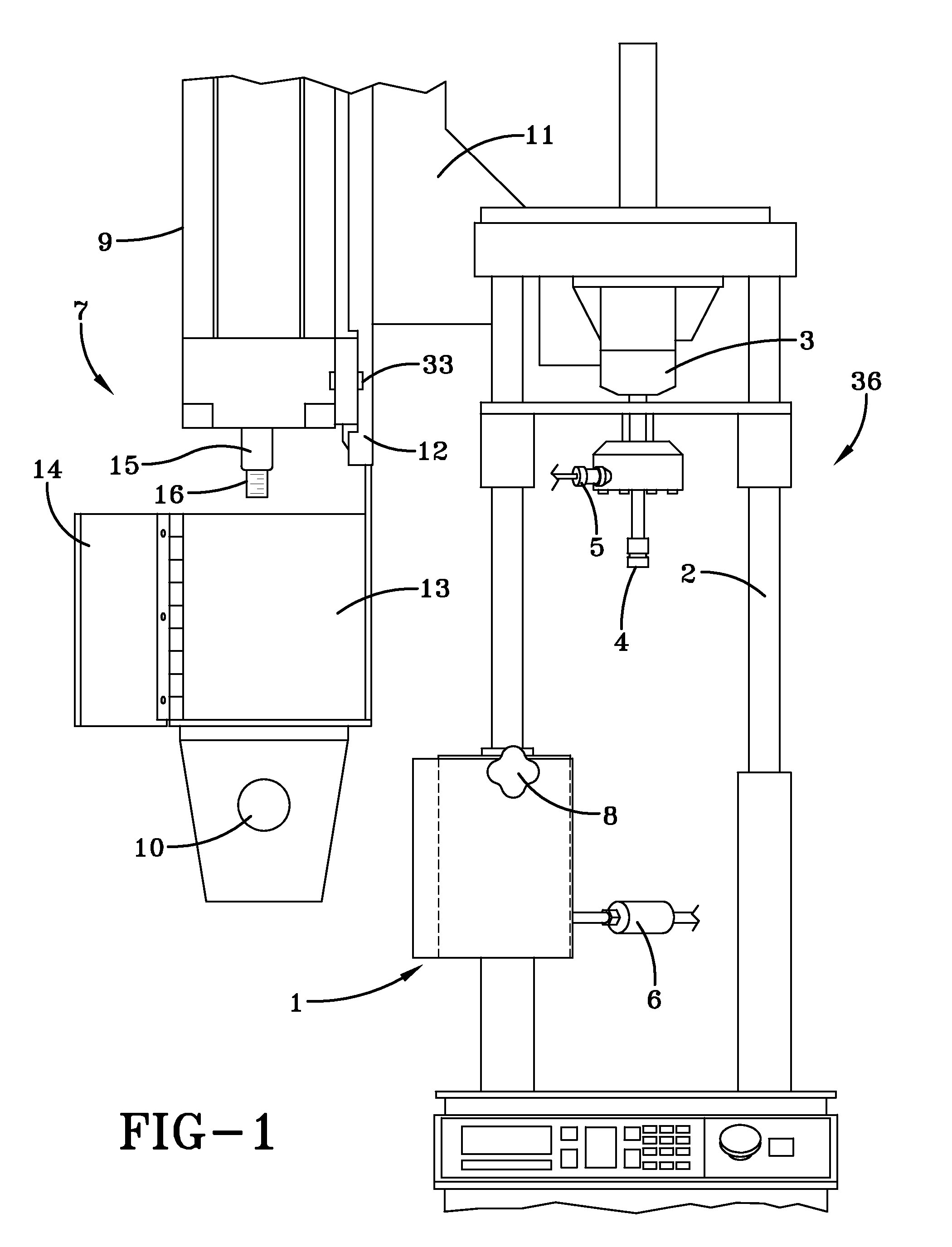

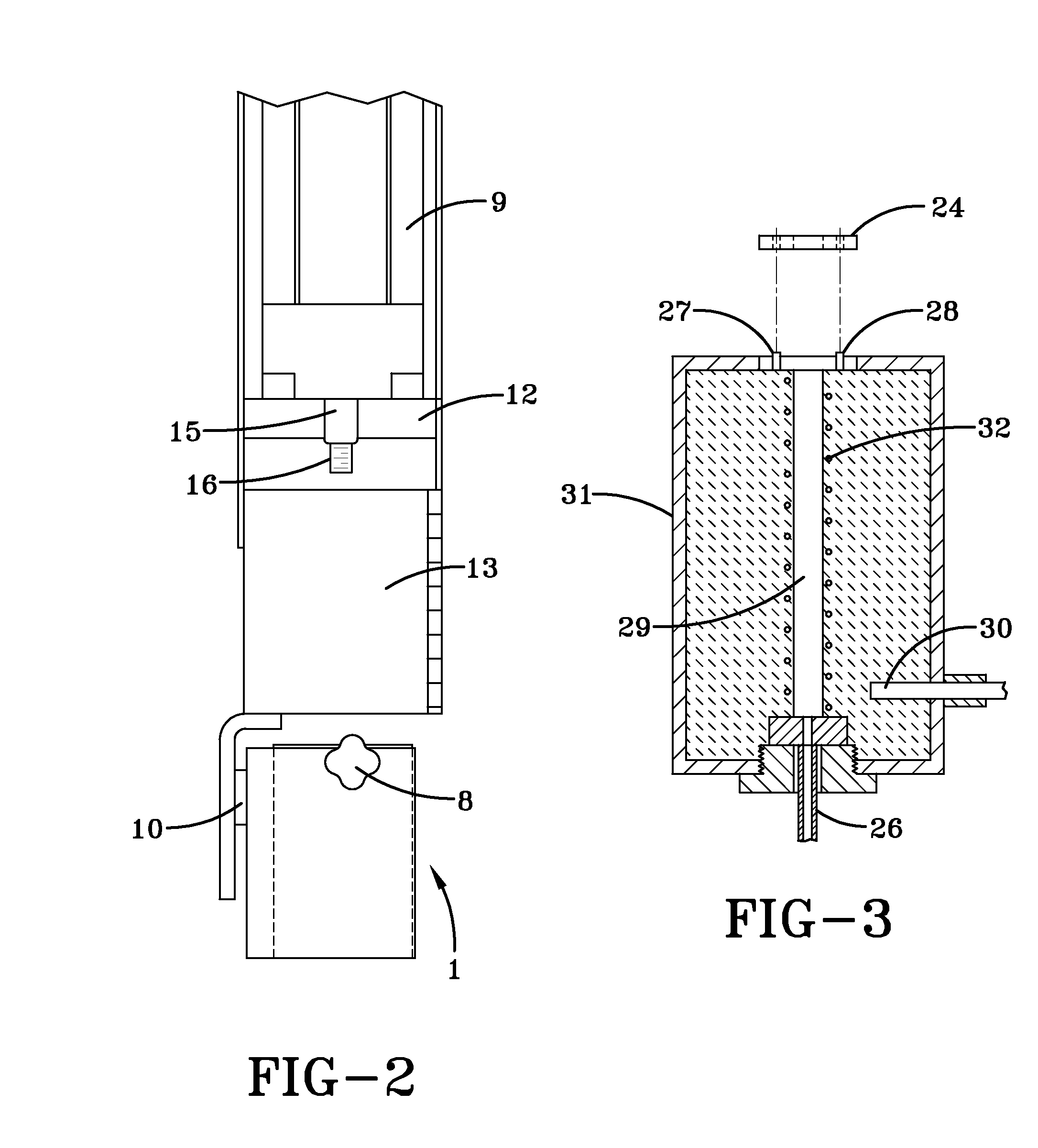

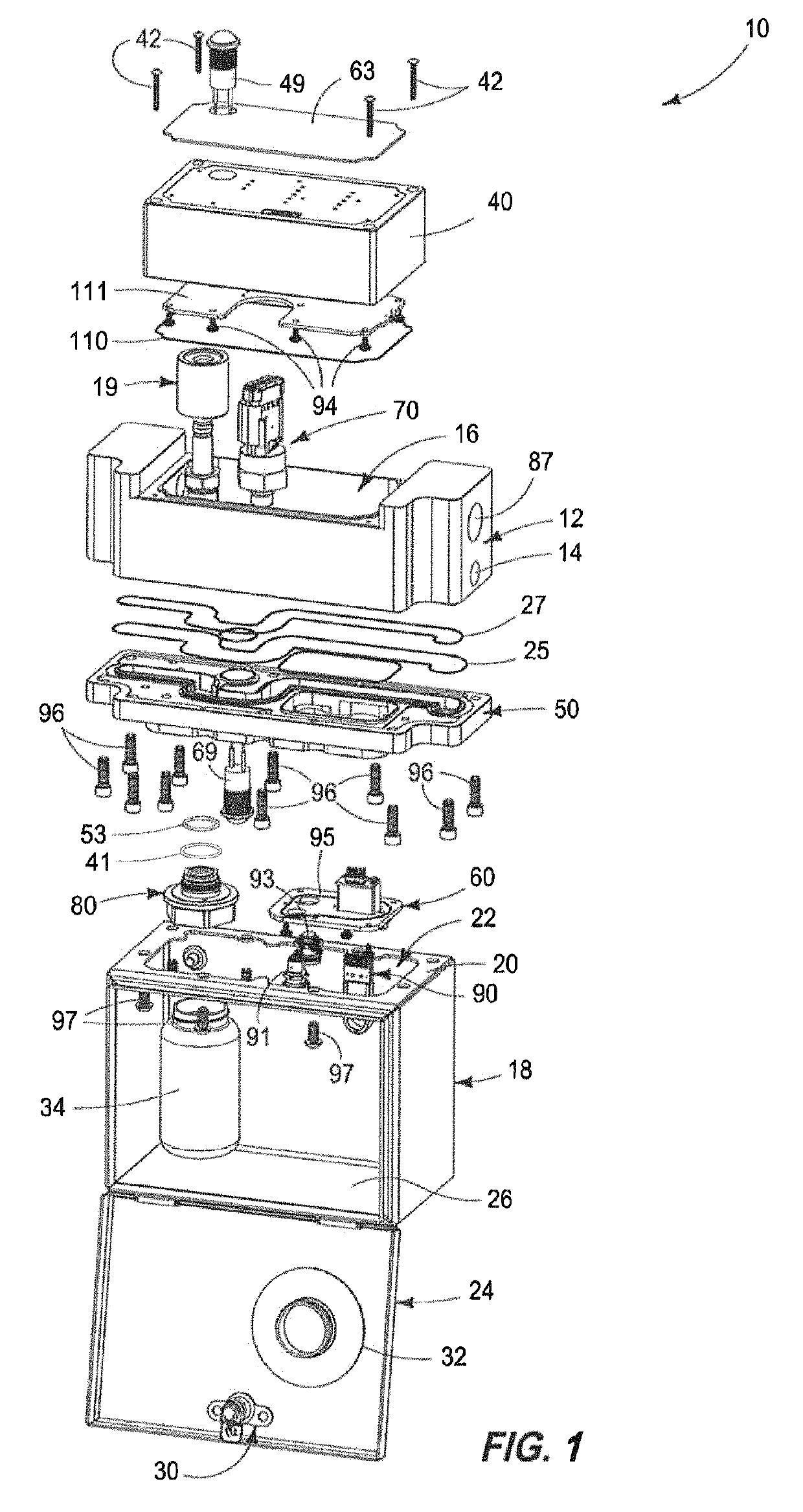

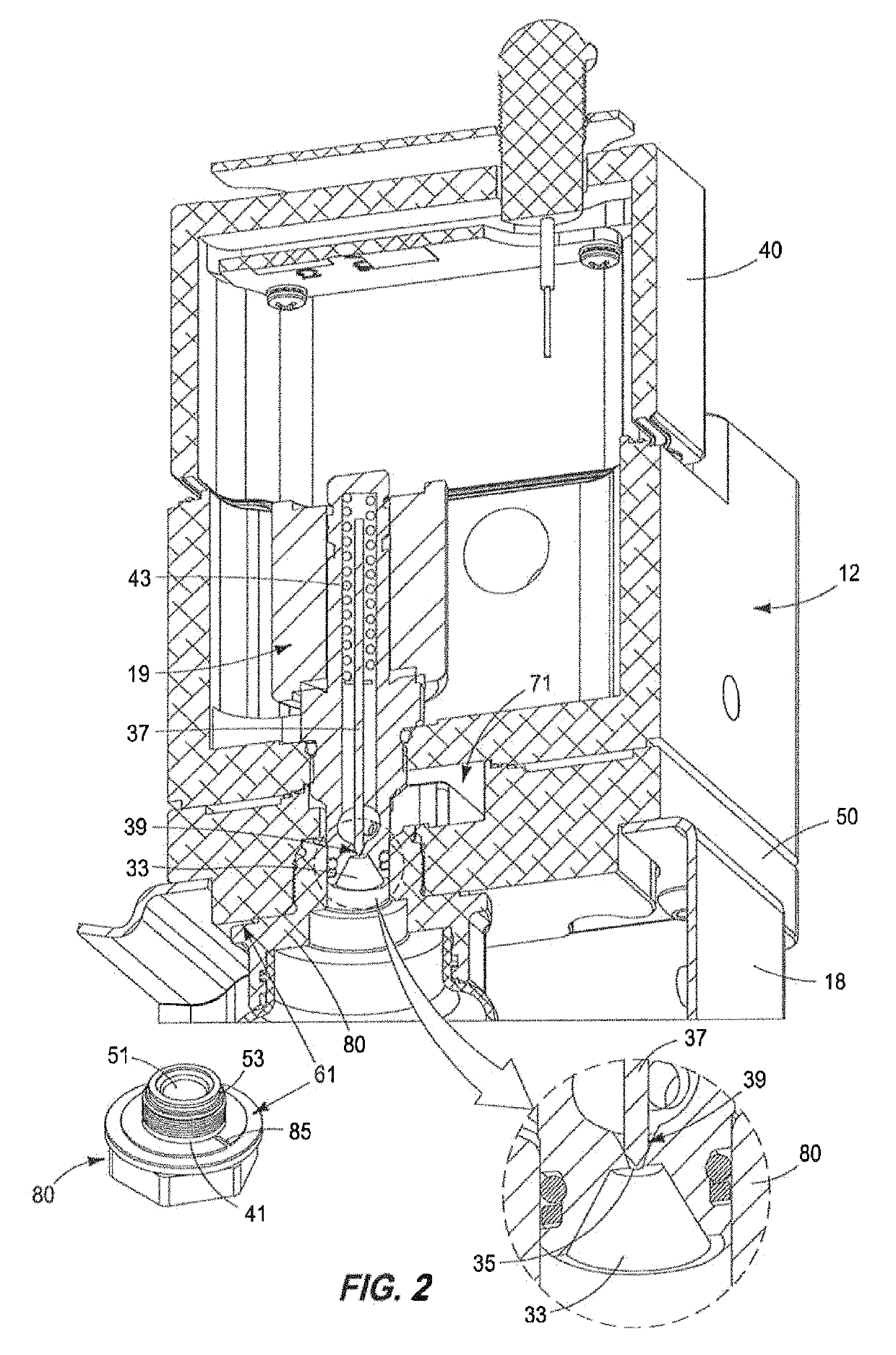

High pressure high temperature viscometer

ActiveUS20100071442A1Easy to disassembleAccurate measurementMaterial thermal analysisViscometer maintainanceEngineeringHigh pressure

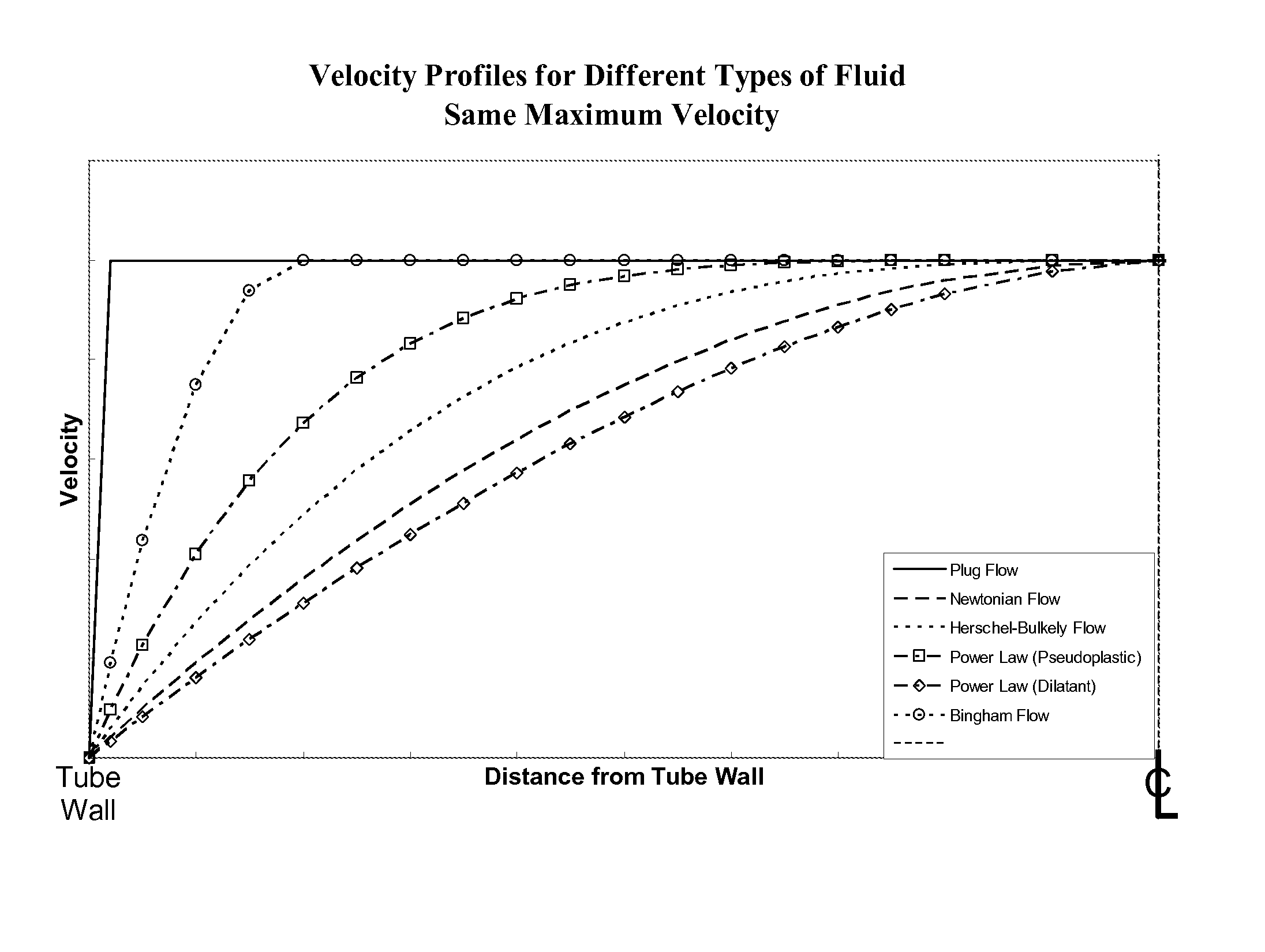

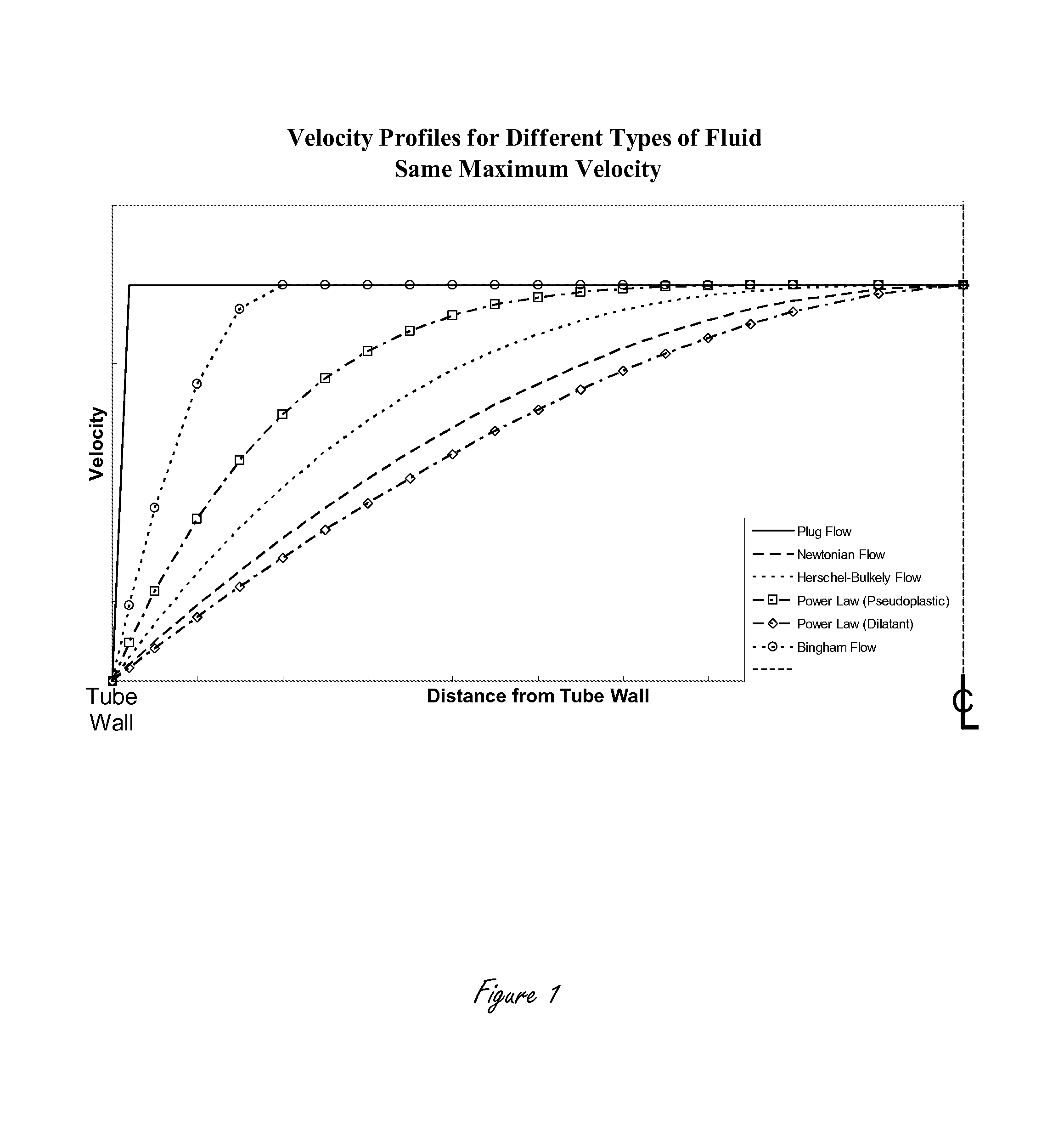

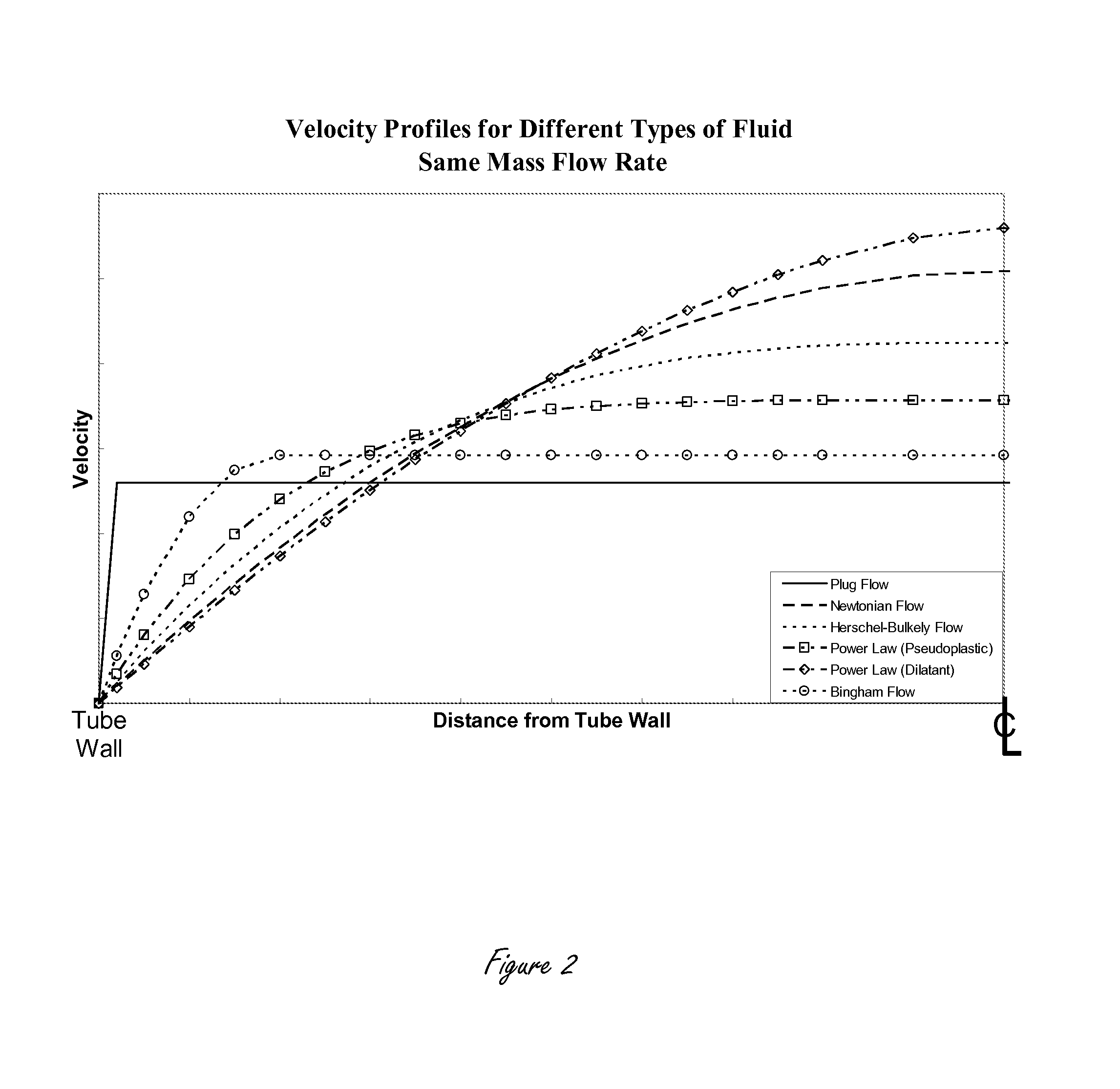

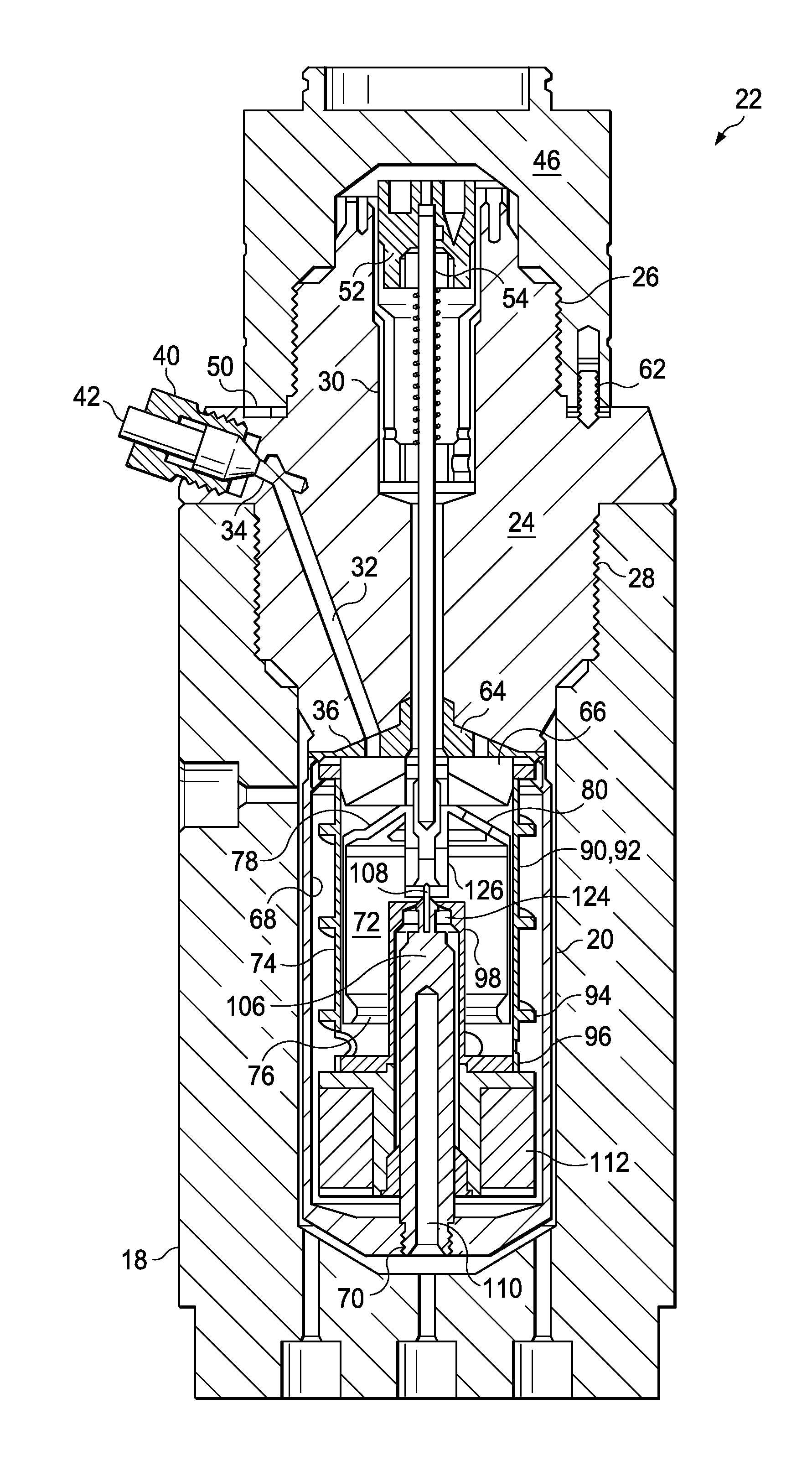

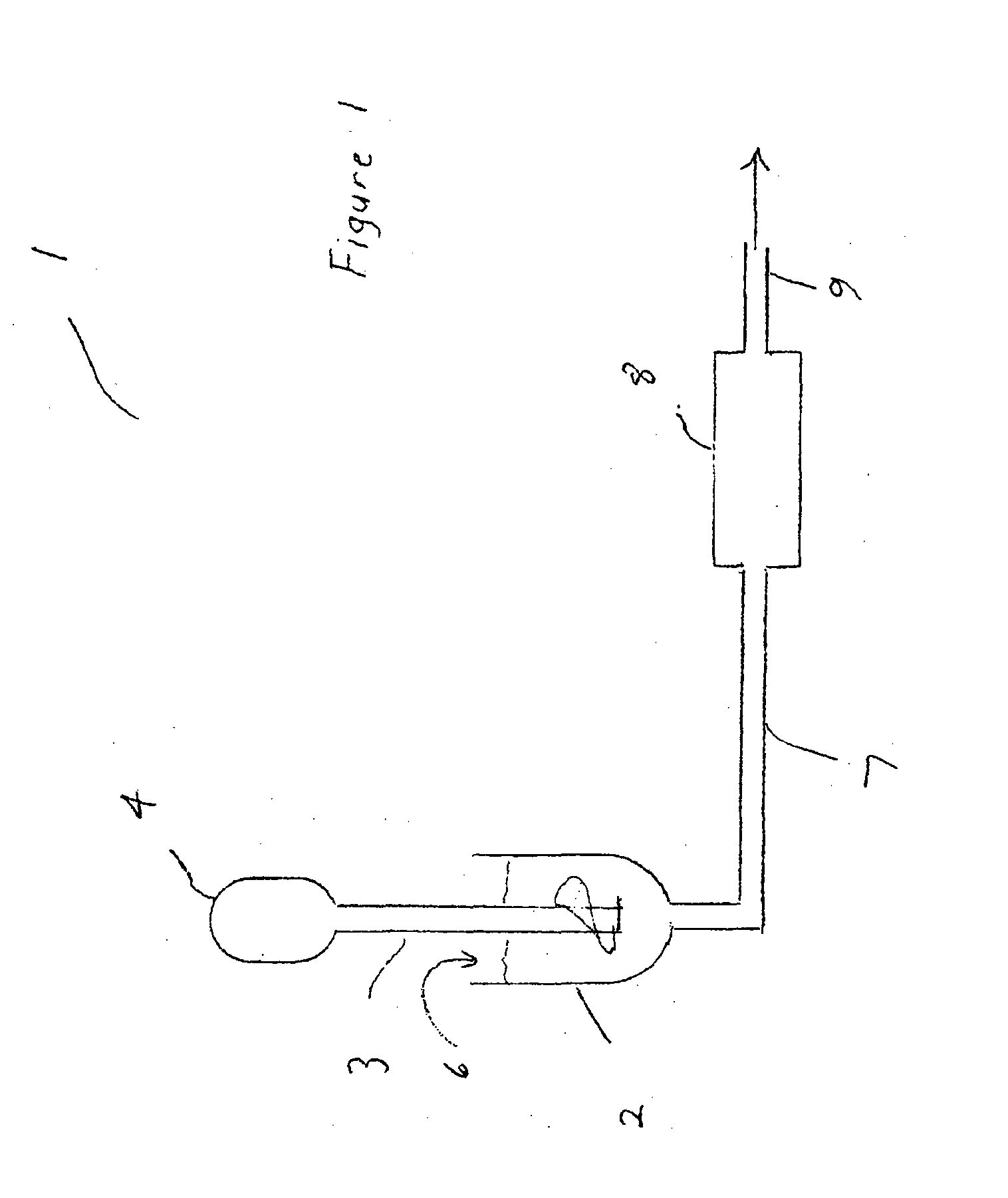

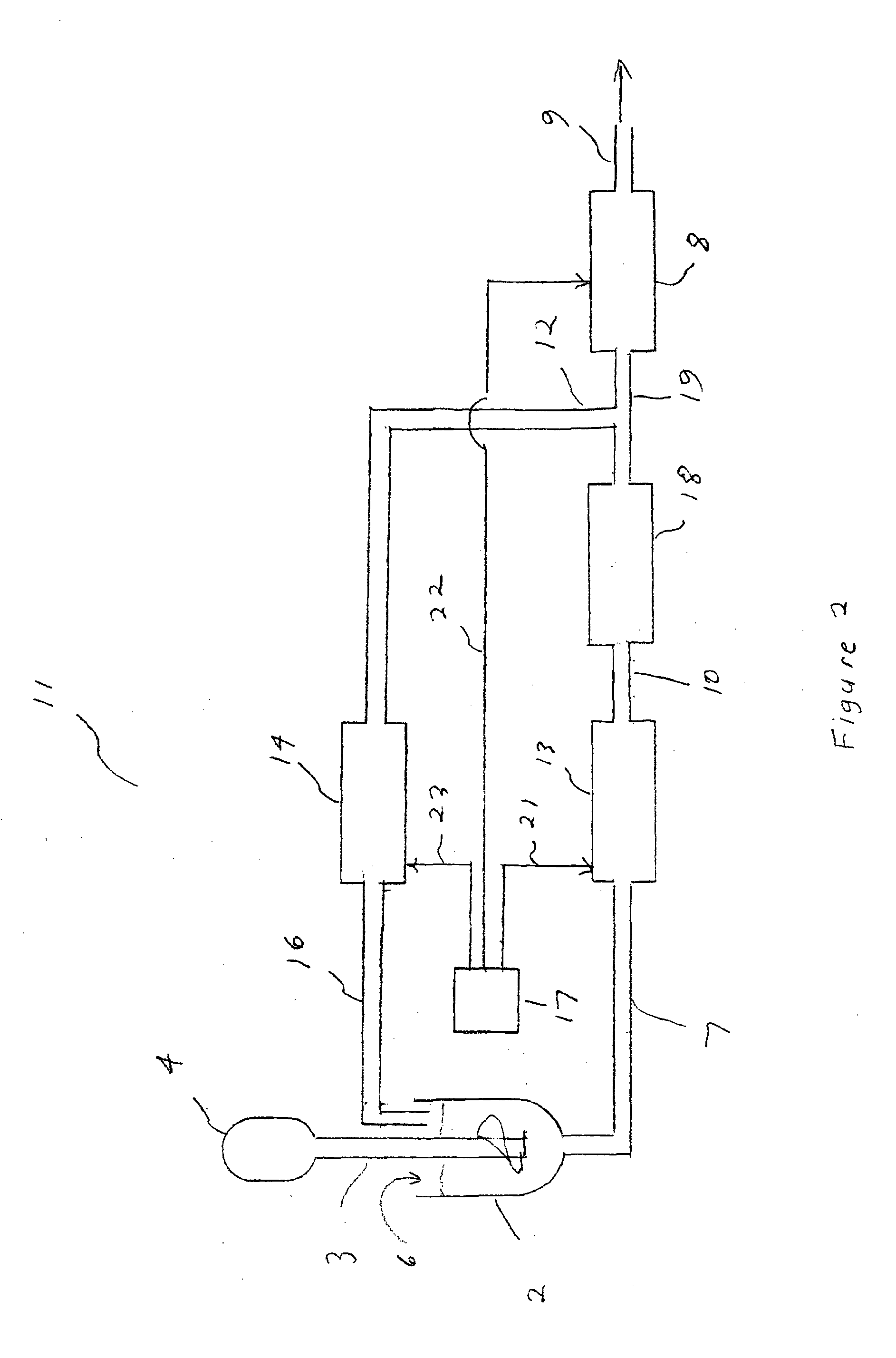

A couette viscometer used to determine the rheological properties of Newtonian or non-Newtonian solid-laden or non-solid-laden fluids used as completion or treatment fluids in oil and / or gas wells. The instrument is capable of measuring the properties of a heated, e.g., 600° F. / 316° C., and pressurized sample, e.g., 30,000 psig / 207 MPa, at a variety of temperatures, pressures, and shear rates. The pressure vessel is mounted in the chassis of the instrument and the vessel plug containing the viscometer components and sample may be removed as an assembly. This arrangement reduces the mass of the plug assembly, eliminating the need to transport the pressure vessel and assists in separating the sample from the pressurizing fluid. Ultimately, this arrangement improves the usability, convenience and maintenance associated with operating the instrument.

Owner:CHANDLER INSTR

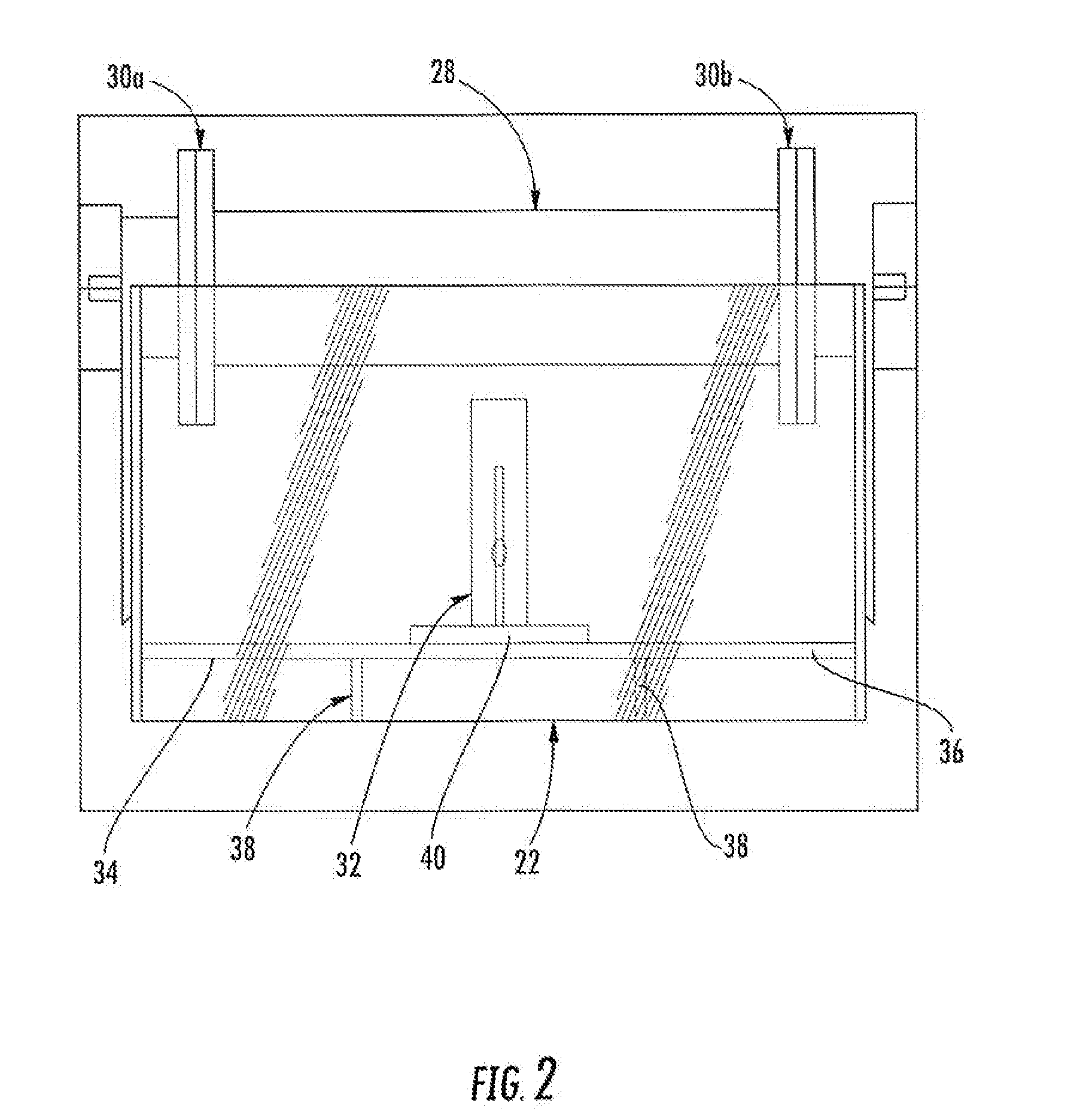

Measurement of properties of fluids using MRI

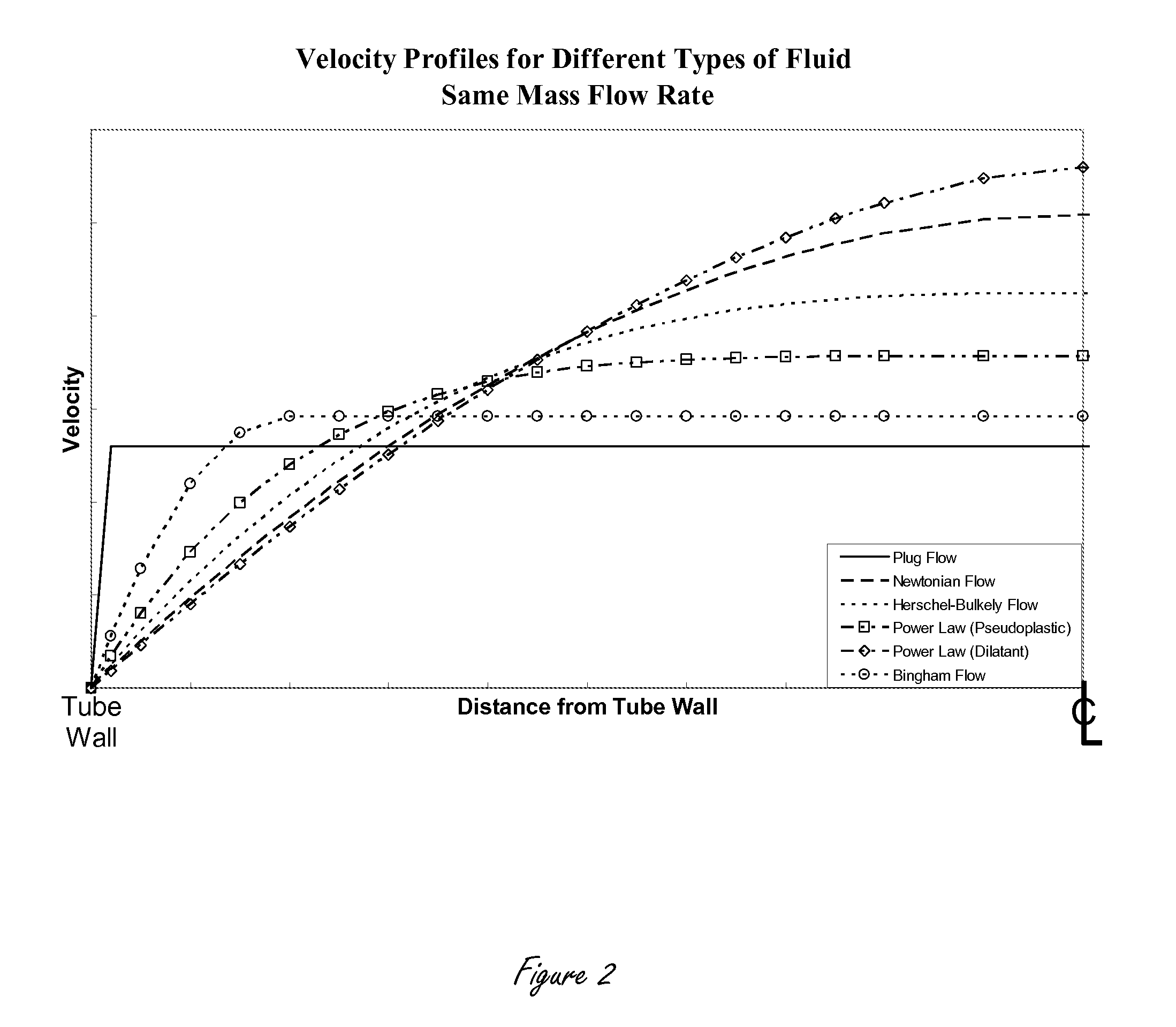

ActiveUS20140049257A1Magnetic measurementsVolume/mass flow measurementNMR - Nuclear magnetic resonanceVoxel

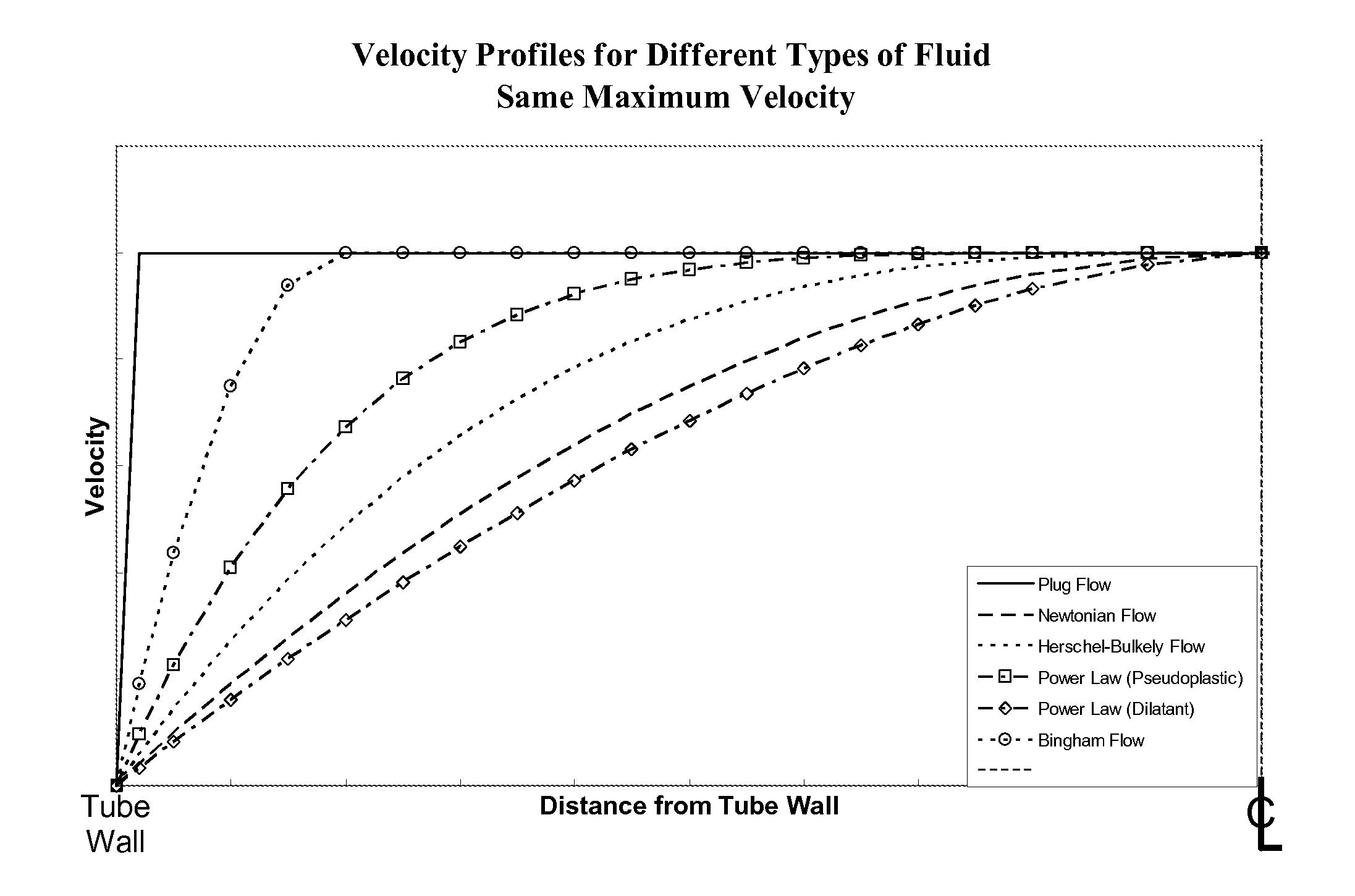

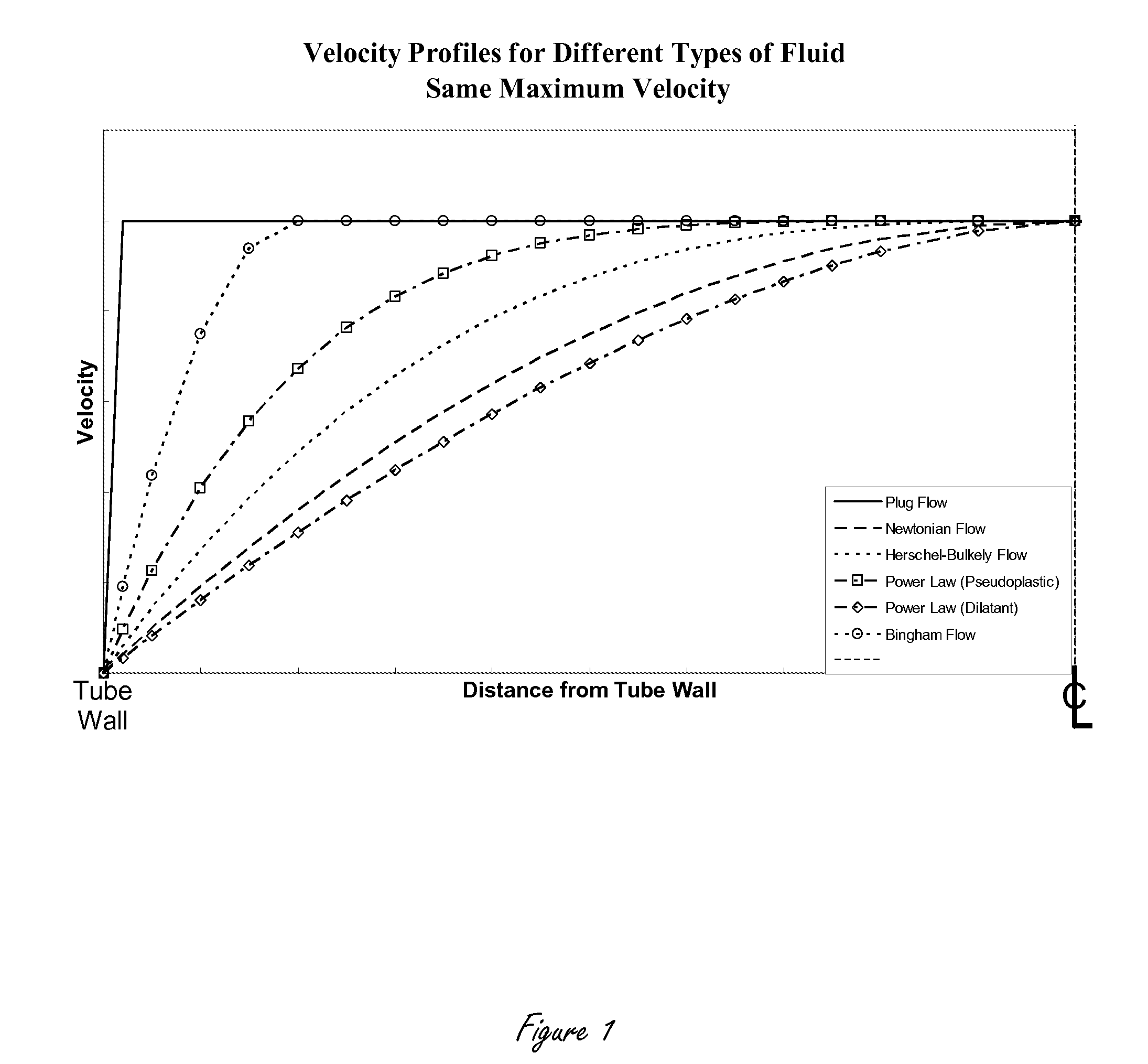

A method of determining rheological properties of a fluid. The method includes: providing an open-bore tube and defining within the bore a three dimensional grid (3DG) of voxels; defining at least an inlet cross section (ICS) and an outlet cross section (OCS); defining a volume of interest within the bore between the ICS and the OCS; obtaining rheological properties of the fluid; applying a pressure gradient to the bore between the ICS and the OCS; and nuclear magnetic resonance imaging the fluid within the volume of interest to determine various aspects of the fluid.

Owner:ASPECT AI

High pressure high temperature viscometer

ActiveUS8230723B2Easy to disassembleAccurate measurementMaterial thermal analysisViscometer maintainanceEngineeringHigh pressure

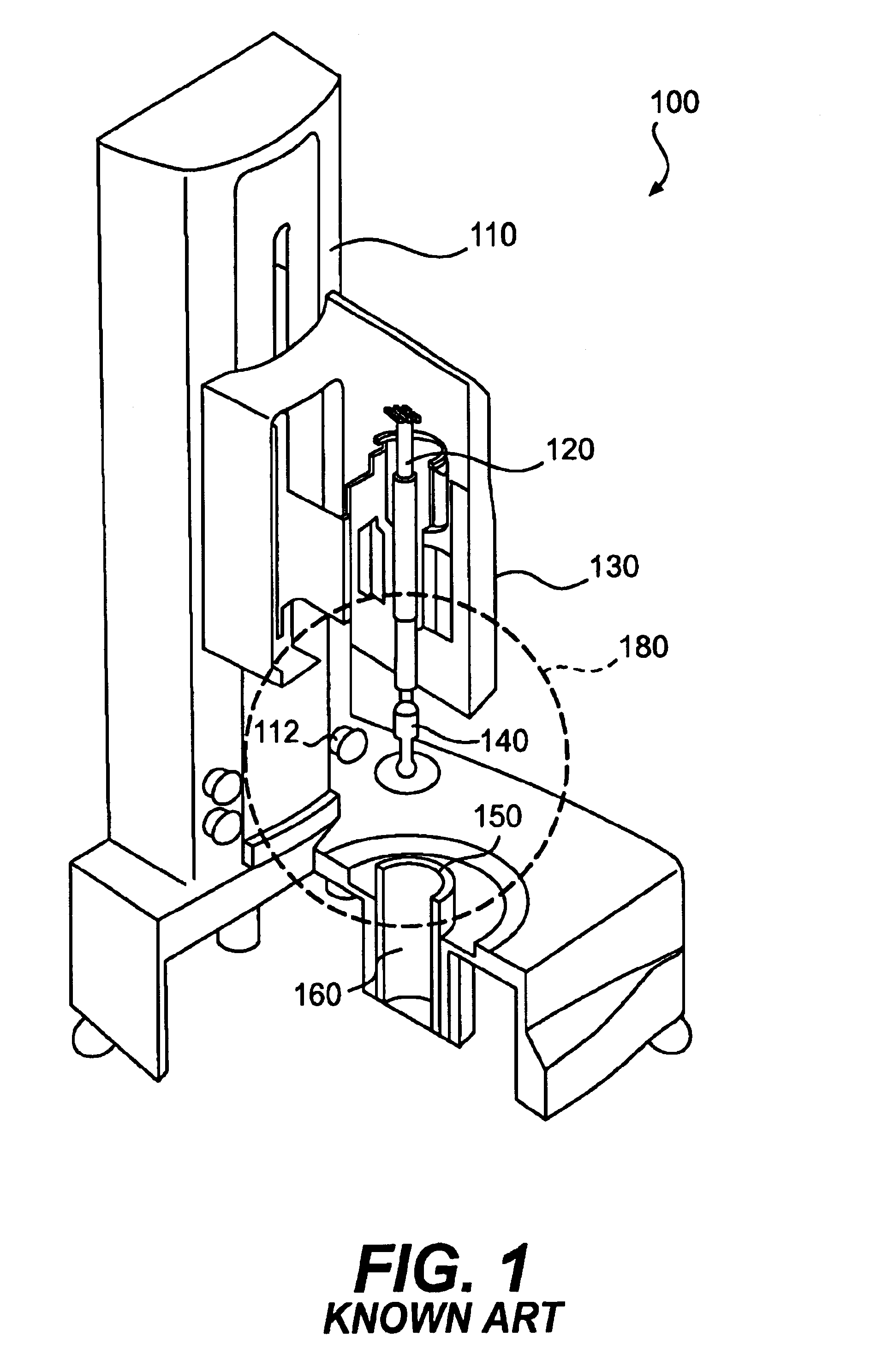

A couette viscometer used to determine the rheological properties of Newtonian or non-Newtonian solid-laden or non-solid-laden fluids used as completion or treatment fluids in oil and / or gas wells. The instrument is capable of measuring the properties of a heated, e.g., 600° F. / 316° C., and pressurized sample, e.g., 30,000 psig / 207 MPa, at a variety of temperatures, pressures, and shear rates. The pressure vessel is mounted in the chassis of the instrument and the vessel plug containing the viscometer components and sample may be removed as an assembly. This arrangement reduces the mass of the plug assembly, eliminating the need to transport the pressure vessel and assists in separating the sample from the pressurizing fluid. Ultimately, this arrangement improves the usability, convenience and maintenance associated with operating the instrument.

Owner:CHANDLER INSTR

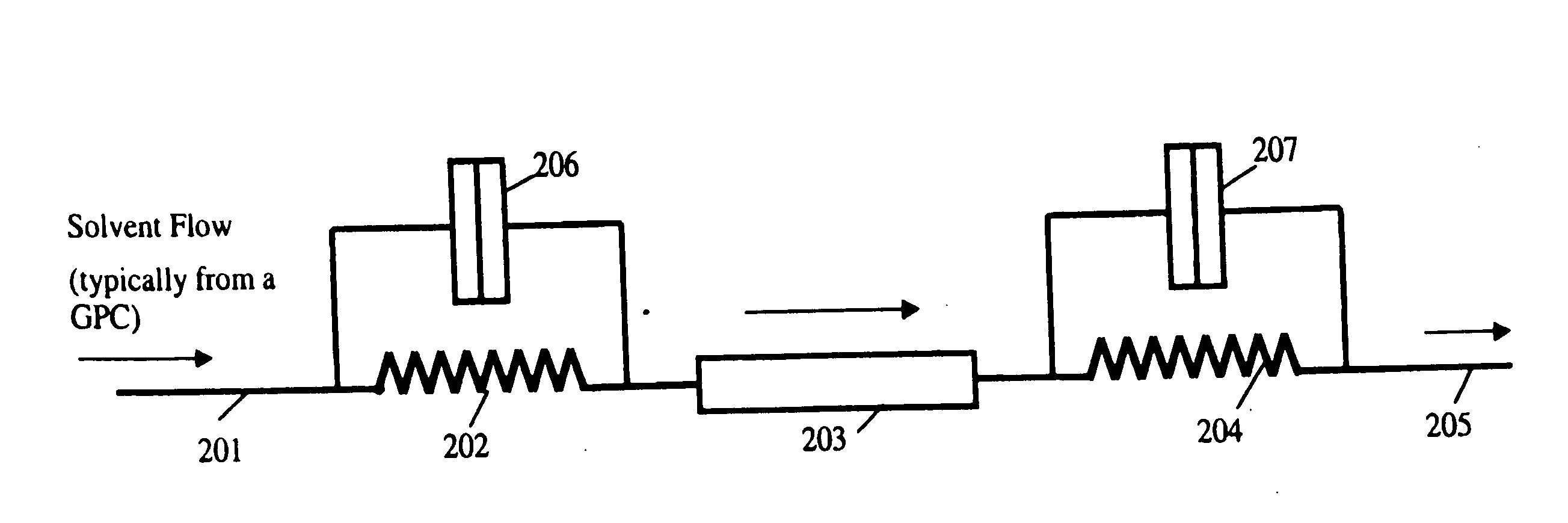

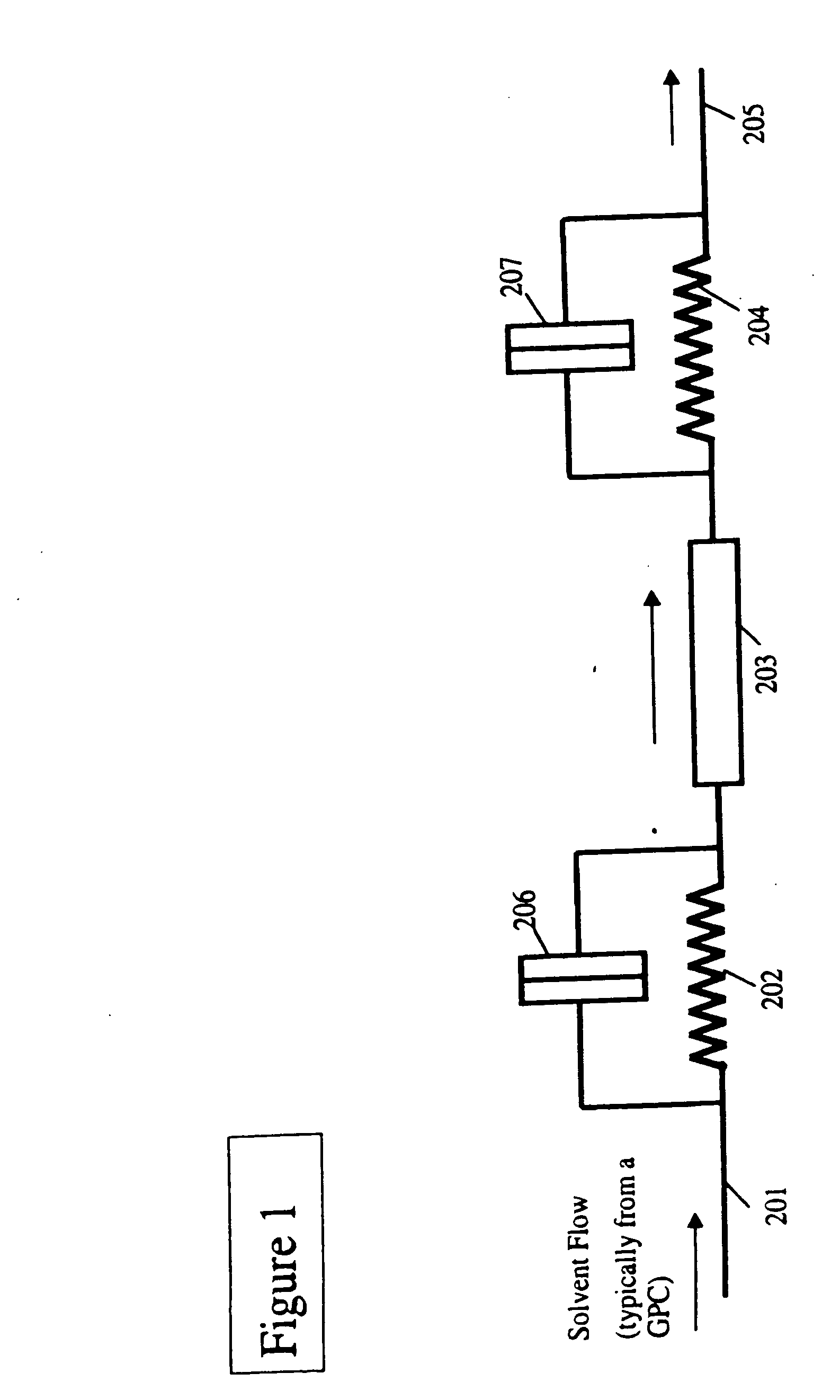

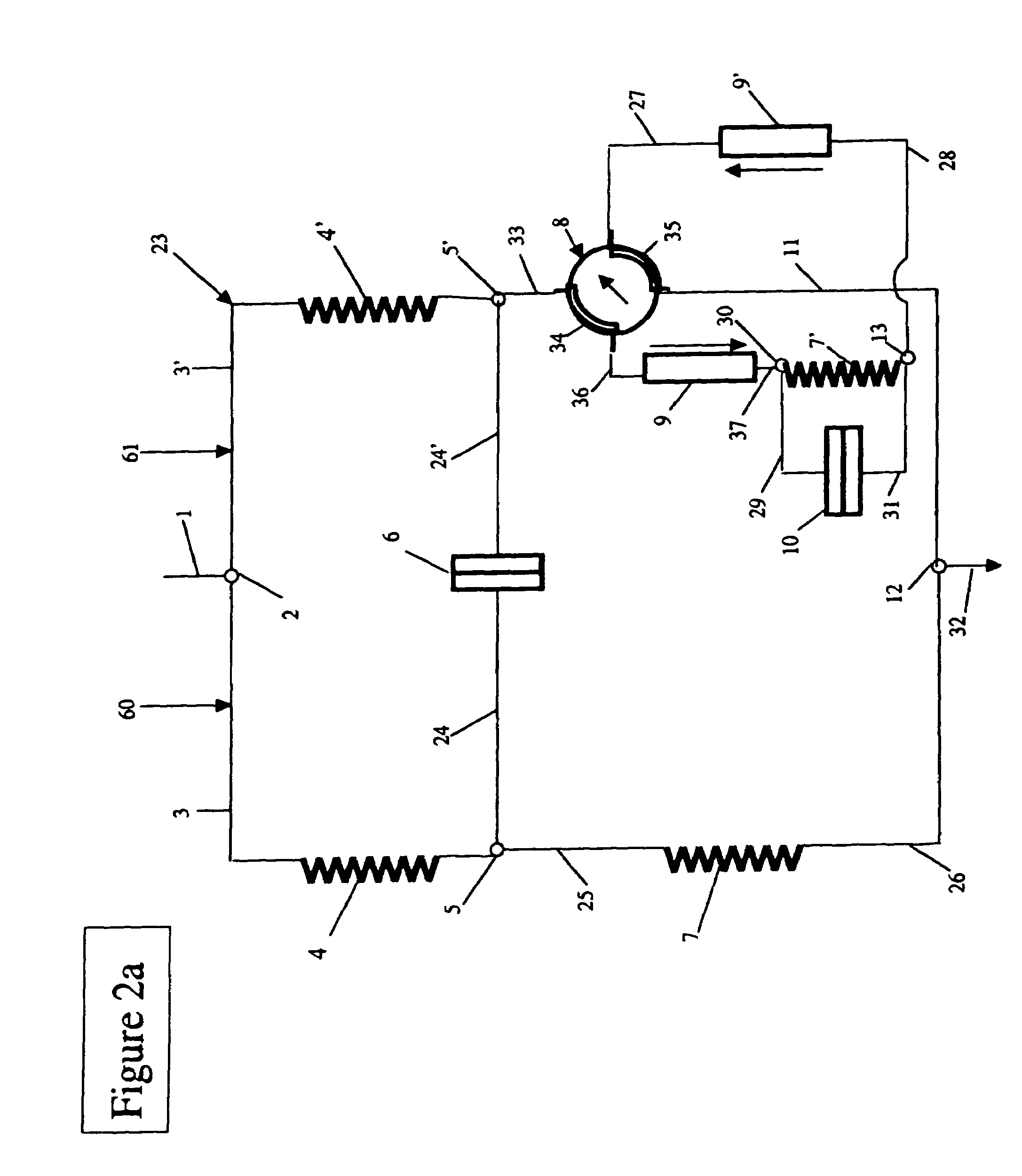

Apparatus and method for eliminating the breakthrough peak in differential detectors

The method comprising the steps of engaging the flow circuit of the detector with a reference fluid, accepting a sample in the flow circuit of the detector, sensing an attribute of the sample for determining a characteristic of the sample, changing the direction of the flow of the sample in the flow circuit, and purging the sample from the flow circuit such that the flow circuit is ready to accept another sample. Another method provides the steps of engaging the flow circuit of the detector with a reference fluid, inserting a sample in the flow circuit juxtaposed to the reference fluid, sensing an attribute of the sample for determining a characteristic of the sample, and deviating the direction of the flow of the sample from the flow circuit for purging the sample from the flow circuit such that the reference fluid is maintained in the flow circuit.The apparatus comprises a detector for analyzing a sample comprising a reference cell and a sample cell such that the detector is charged with a reference fluid, a switching valve in communication with the sample cell of the detector, and one or more delay volumes and the reference cell in communication with the switching valve. The sample is juxtaposed the reference fluid for engaging the sample cell for analysis, the analyzed sample engages the switching valve for alternately diverting the analyzed sample from the flow circuit and for maintaining the detector charged with the reference fluid.

Owner:MALVERN INSTRUMENTS

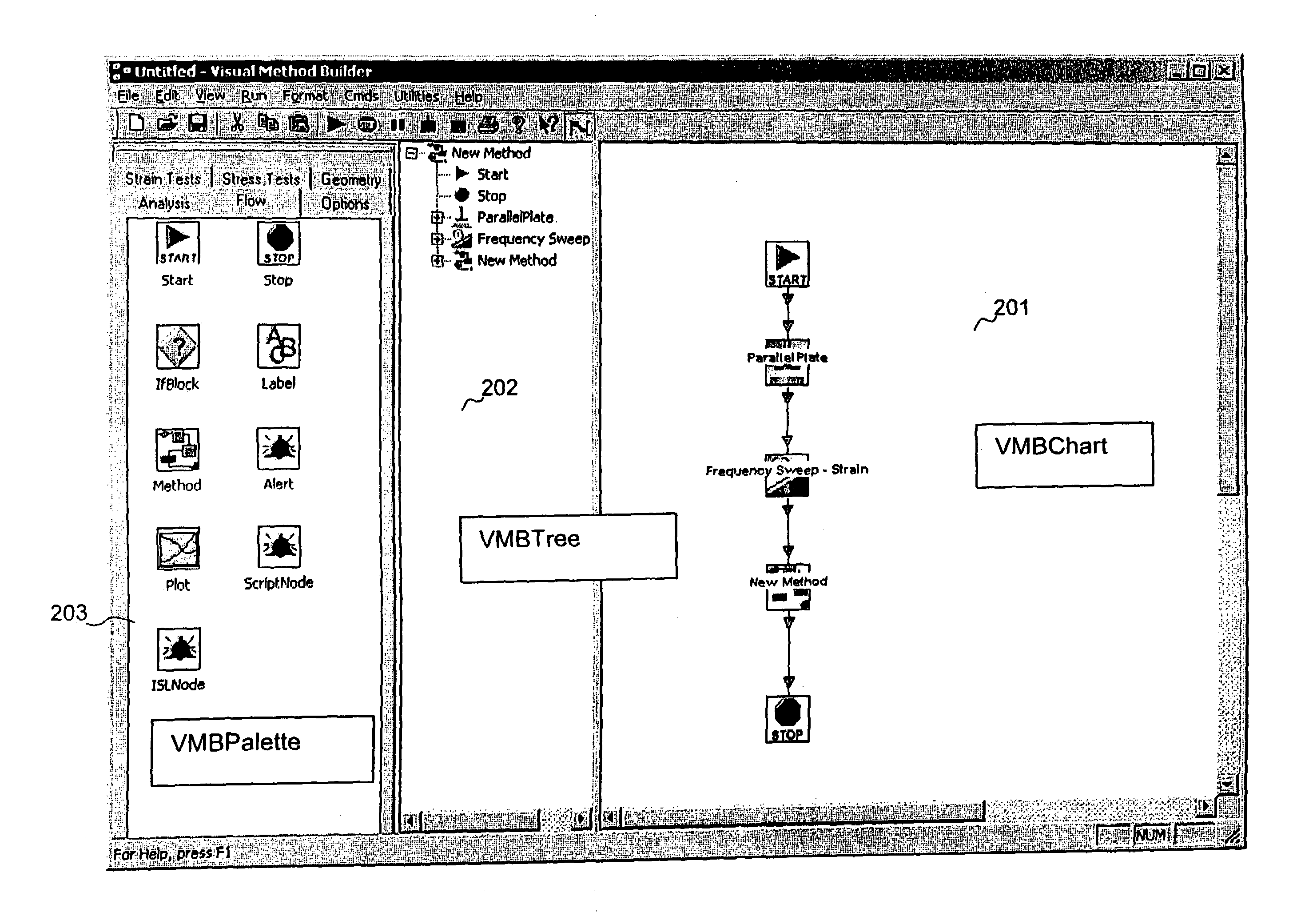

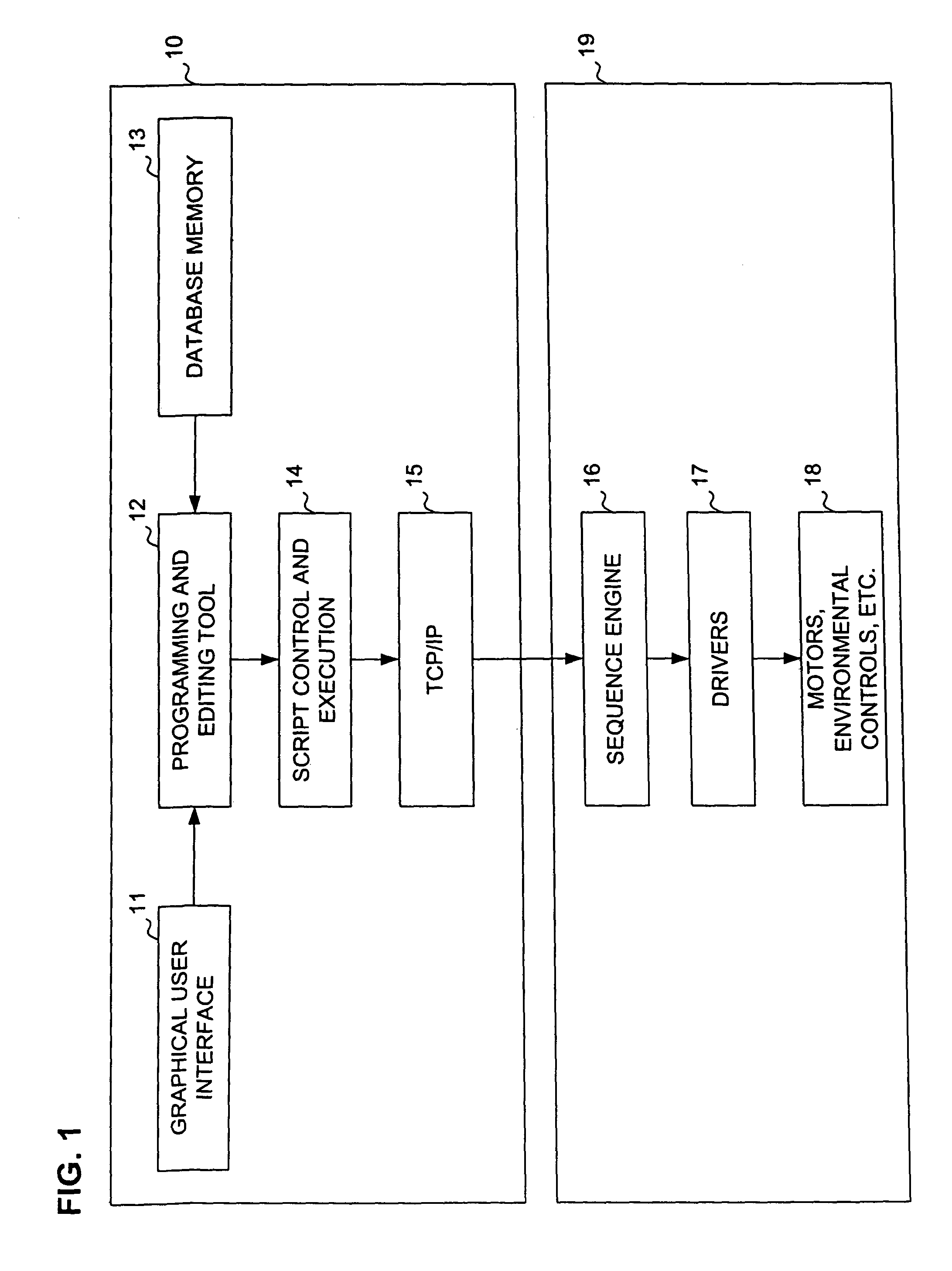

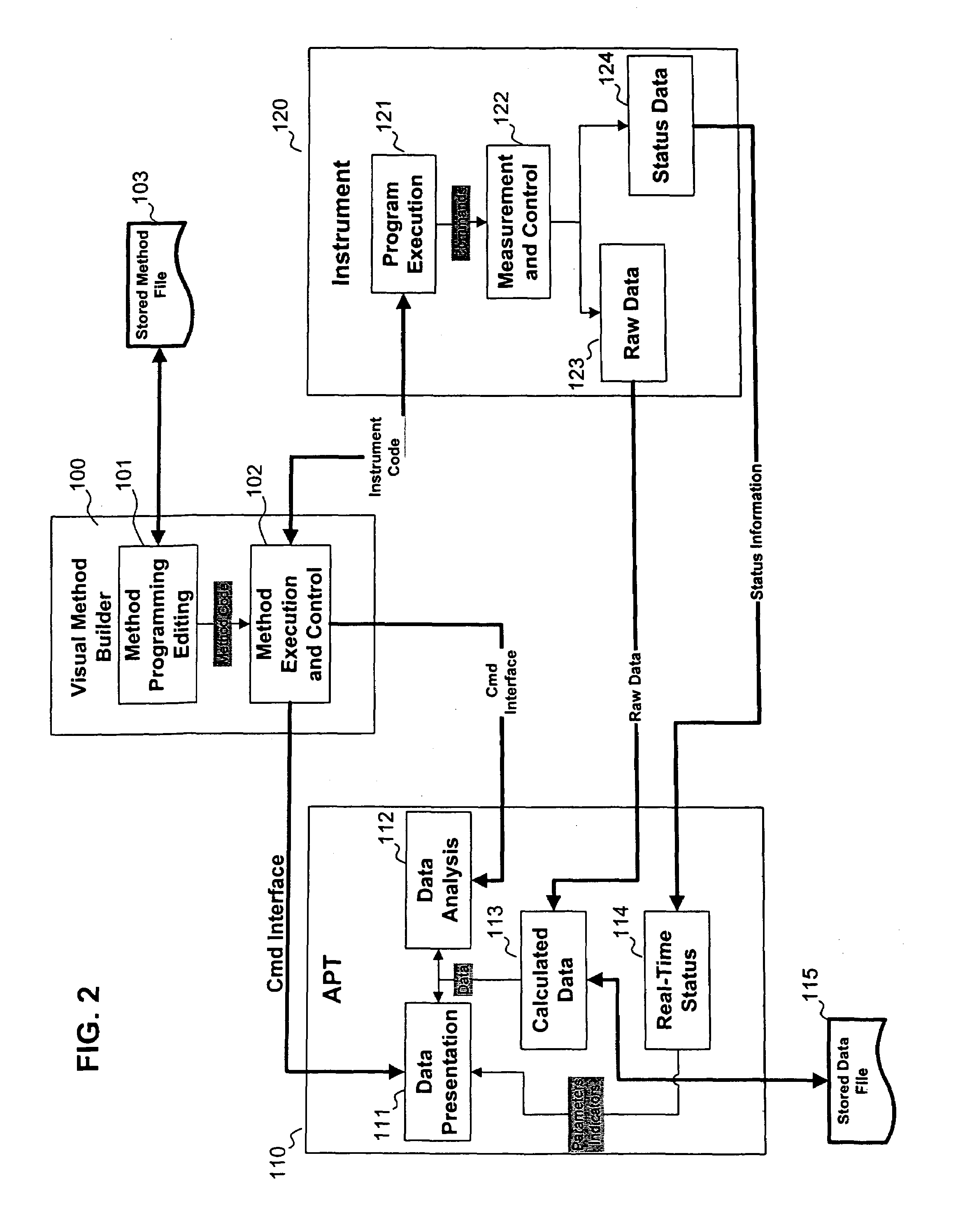

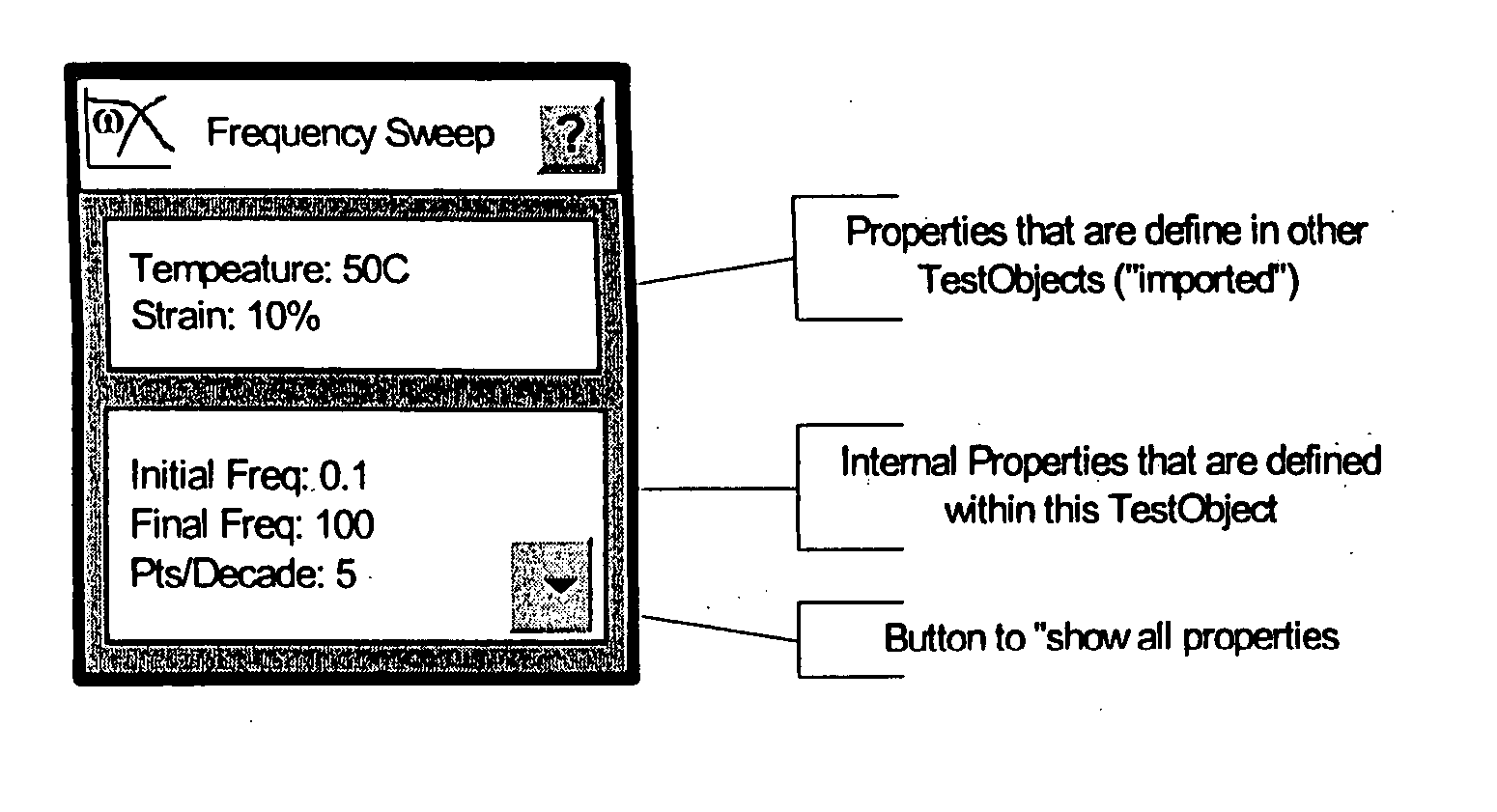

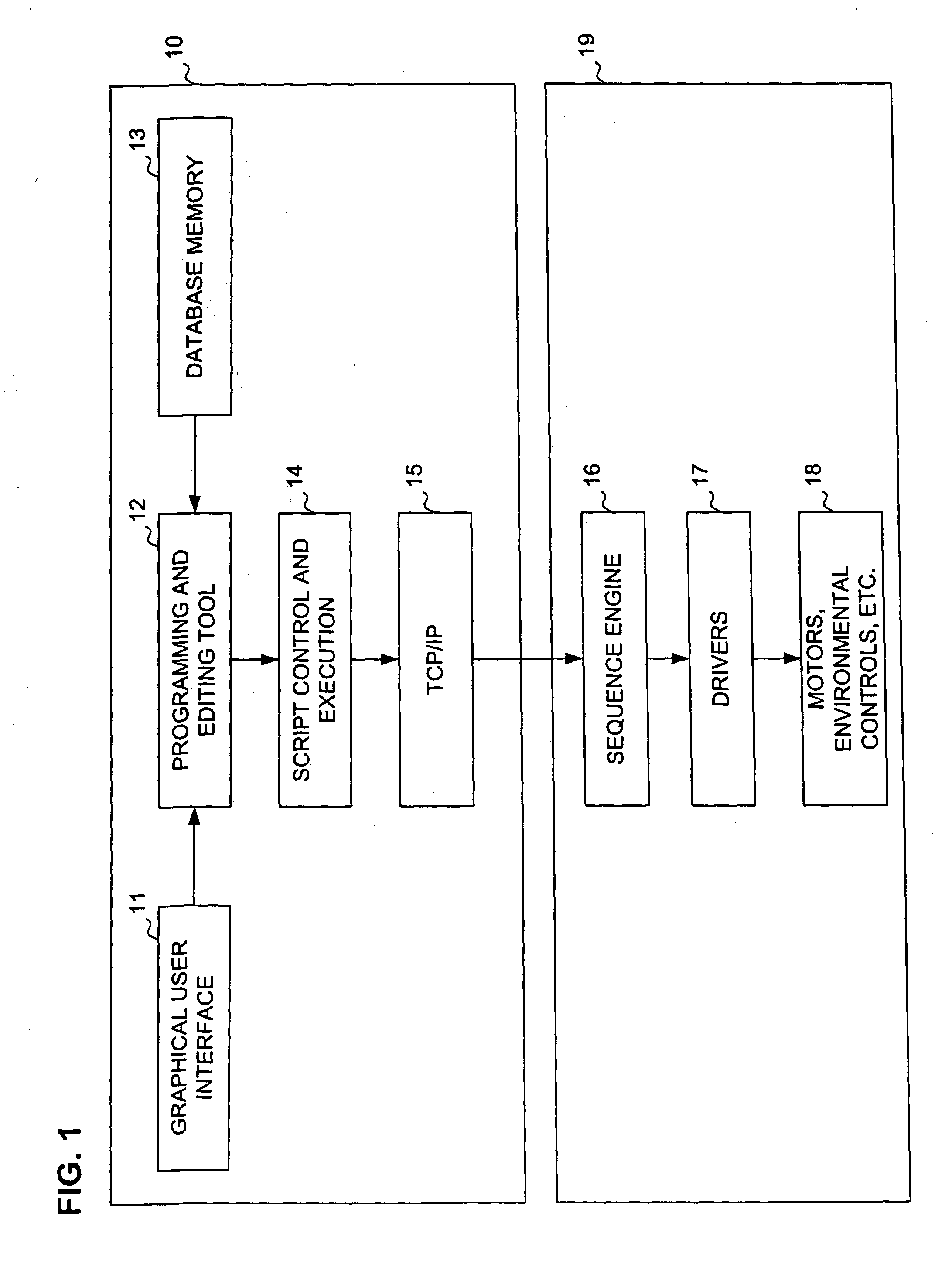

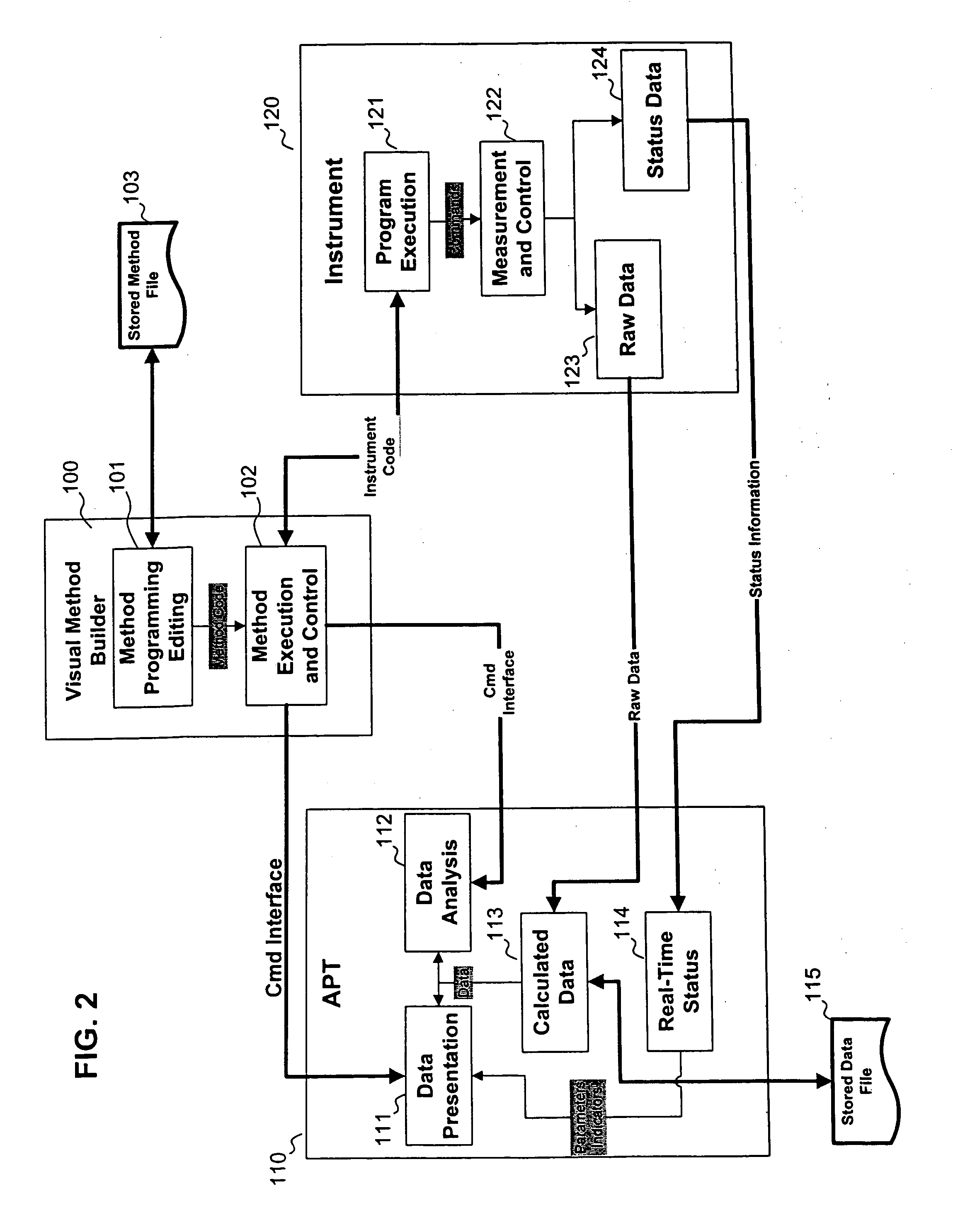

System and method for dynamically controlling operation of rheometric instruments

ActiveUS7607098B2OptimizationVisual/graphical programmingProgram loading/initiatingComputer scienceInstrumentation

System and methods are described for dynamically controlling operation of a rheometer. A program is created on a programming interface for executing a test upon a sample in a rheometer by receiving user selections of a plurality of nodes and connections of each node to another node according to directional connection indicators. Nodes indicate steps for performing a test upon a sample or configuring a rheometer for performing a test upon a sample. Scripts are created for generating a sequence of instructions to the rheometer. The scripts include instructions for performing steps indicated by each of the selected nodes and in accordance with the directional connection indicators. Low-level instructions are downloaded from the scripts for execution in the rheometer, and drivers in the rheometer are instructed for performing the downloaded instructions.

Owner:WATERS TECH CORP

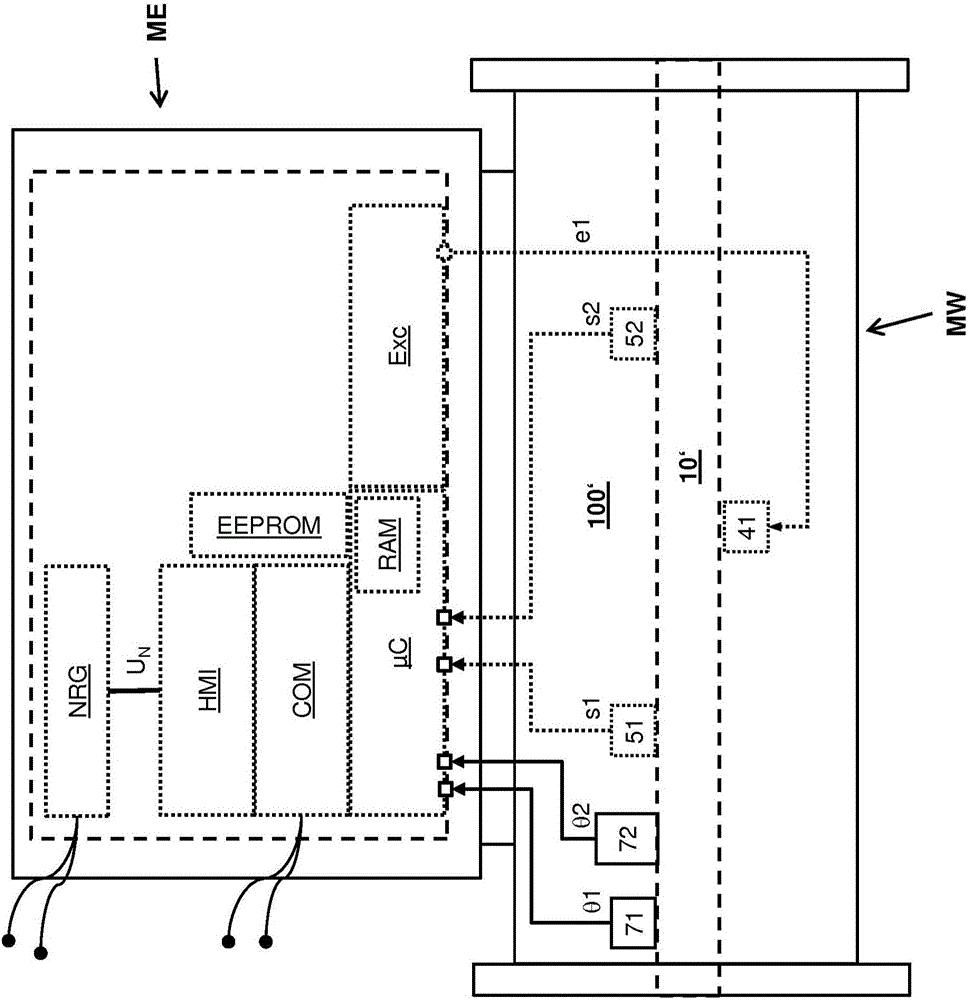

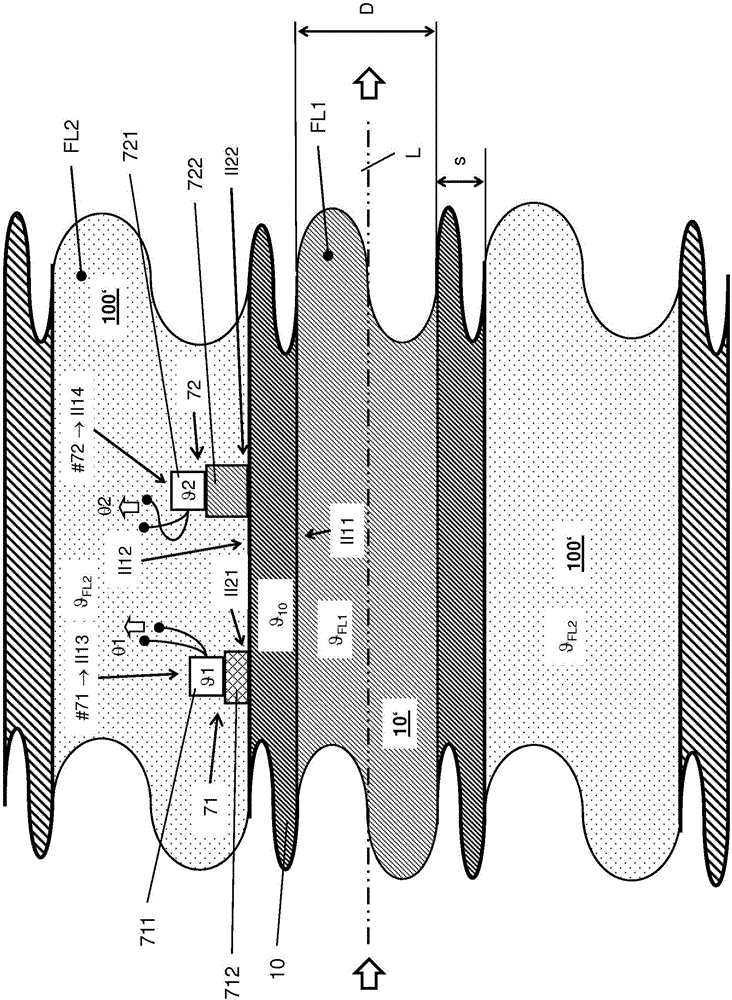

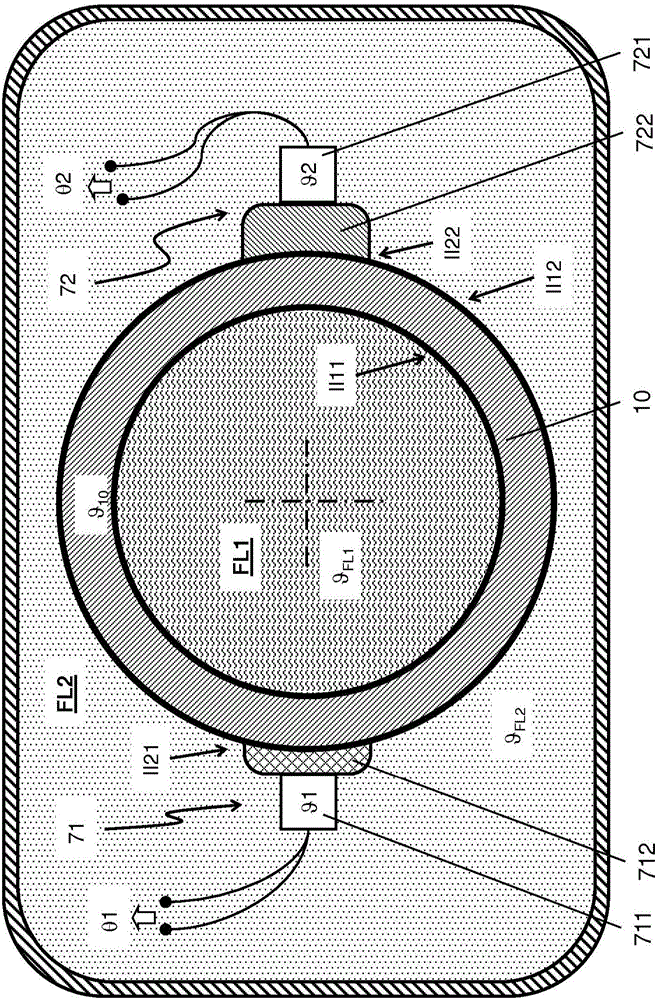

Transformer device and measurement system formed therewith

ActiveCN106104223AVolume variation compensation/correction apparatusViscometer maintainanceElectricityTransformer

The invention relates to a transformer device comprising a transformer housing (100), a pipe (10), a temperature sensor (71), and a temperature sensor (72). The pipe is arranged within a cavity of the transformer housing such that, between an inner surface (100+) of a wall of the transformer housing facing the cavity and a shell surface (10#) of a wall of the pipe facing the cavity, an intermediate chamber (100') is formed. Furthermore, the pipe is designed to conduct a fluid (FL1) in the lumen thereof such that an inner surface (10+) of the wall of the pipe facing said lumen contacts the fluid conducted in the lumen. Each of the temperature sensors (71; 72) is formed by a temperature sensor (711; 721) arranged within the intermediate chamber (100') and by a coupling element (712; 722) coupling the temperature sensor (711; 721) to the wall of the pipe in a thermally conductive manner and is additionally designed to detect a measurement point temperature ([theta]1; [theta]2), namely a temperature at a first or second temperature measurement point formed by the temperature sensor (711; 721) and to transform said temperature into a corresponding temperature measurement signal ([theta]1; [theta]2), namely an electrical measurement signal representing the measurement point temperature ([theta]1; [theta]2).

Owner:ENDRESS HAUSER FLOWTEC AG

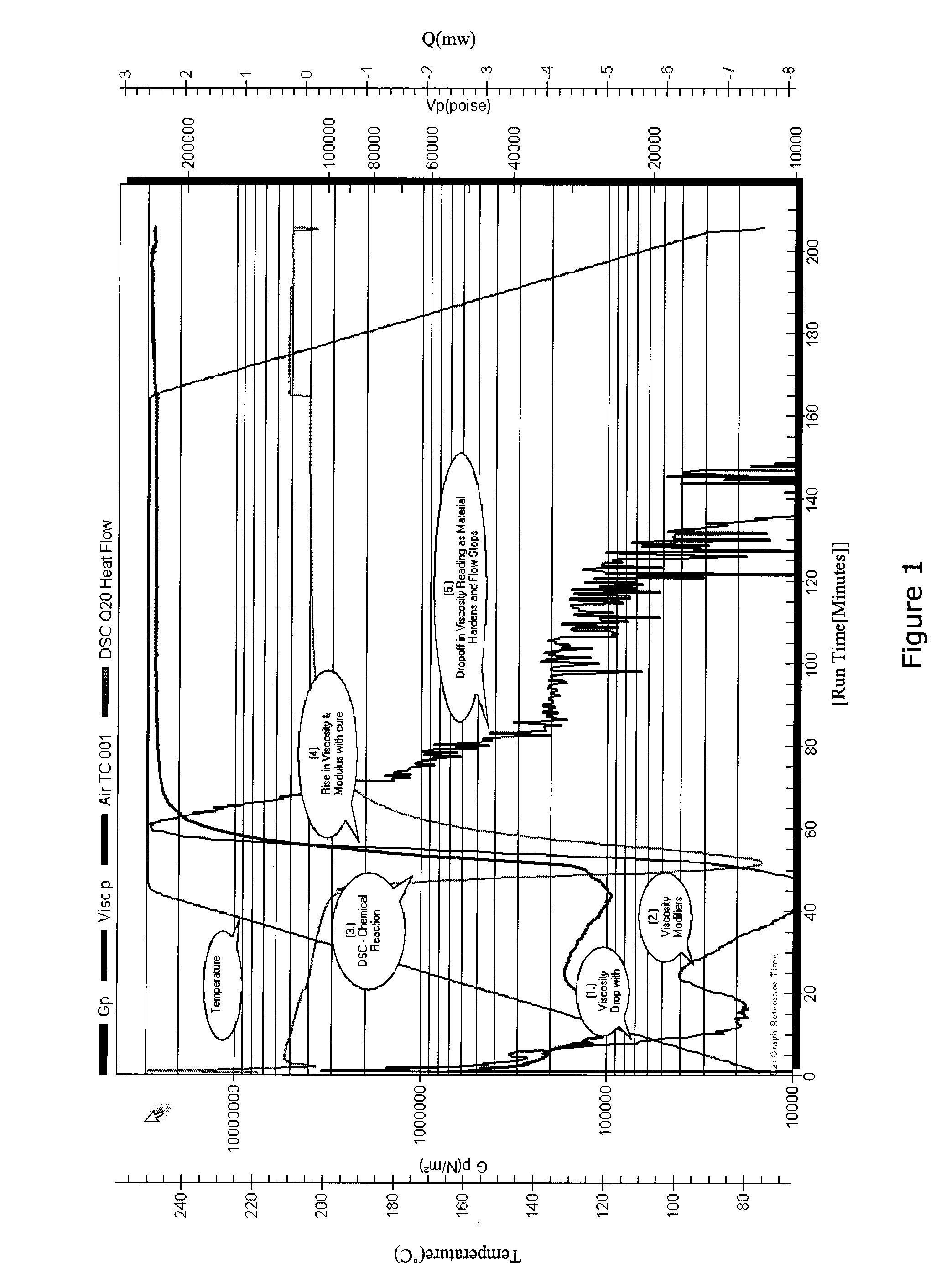

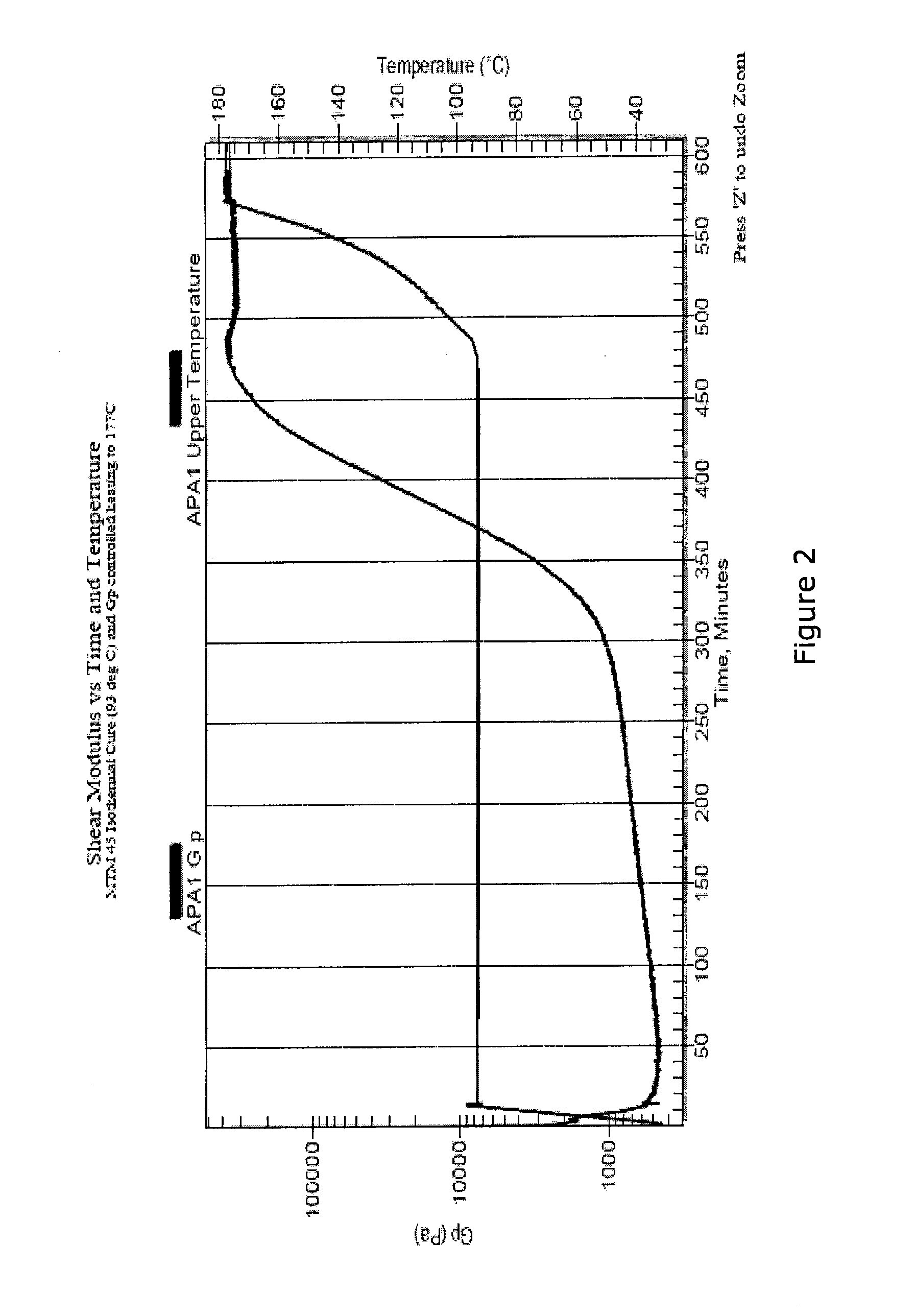

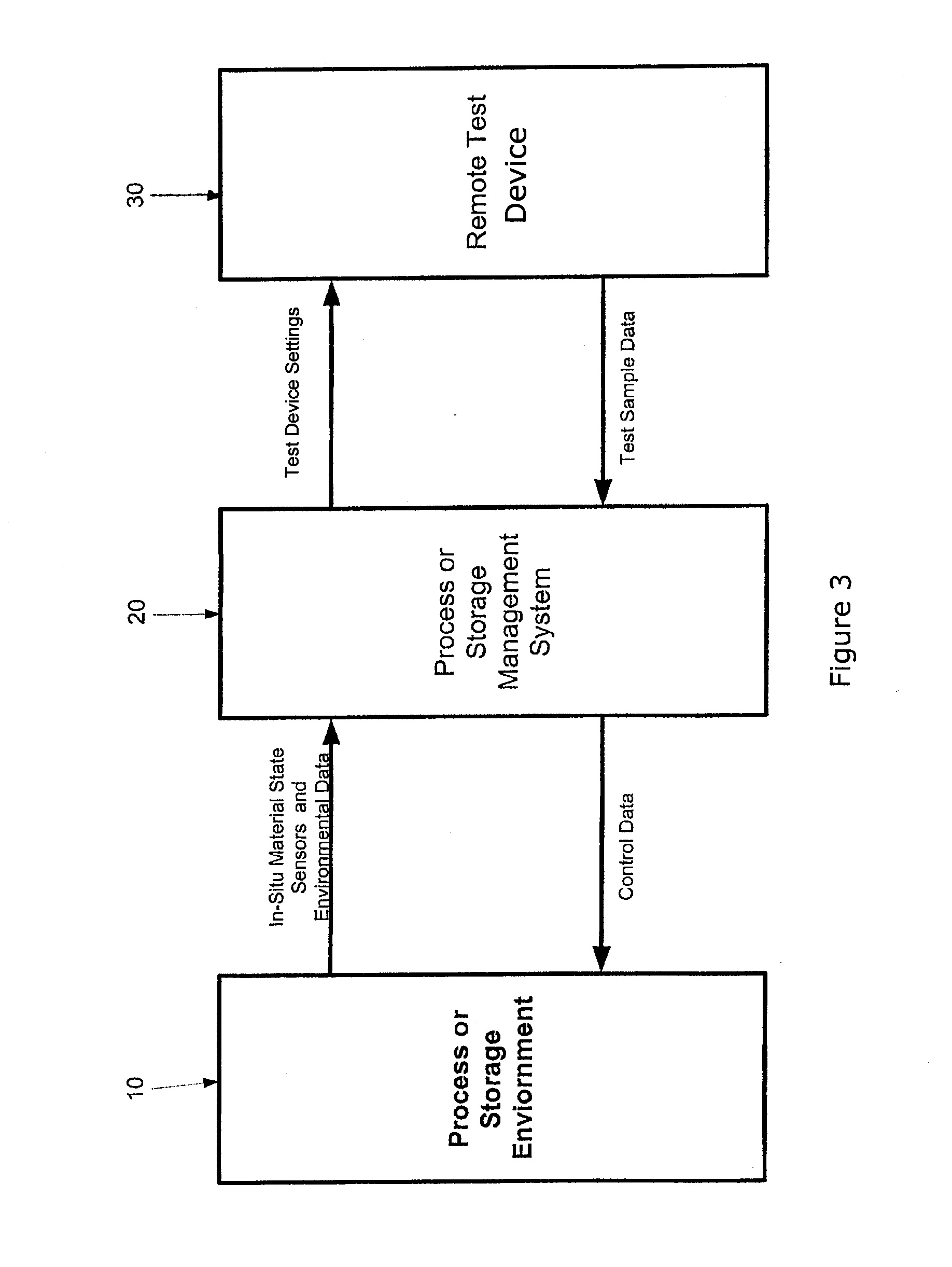

System and method for monitoring and controlling production of composite materials

A method and system for analyzing and controlling the curing of a composite material part using information derived from composite material test samples obtained using an ex-situ analytical device.

Owner:ROCK CREEK RES

System and method for dynamically controlling operation of rheometric instruments

ActiveUS20040177678A1Visual/graphical programmingProgram loading/initiatingComputer scienceInstrumentation

System and methods are described for dynamically controlling operation of a rheometer. A program is created on a programming interface for executing a test upon a sample in a rheometer by receiving user selections of a plurality of nodes and connections of each node to another node according to directional connection indicators. Nodes indicate steps for performing a test upon a sample or configuring a rheometer for performing a test upon a sample. Scripts are created for generating a sequence of instructions to the rheometer. The scripts include instructions for performing steps indicated by each of the selected nodes and in accordance with the directional connection indicators. Low-level instructions are downloaded from the scripts for execution in the rheometer, and drivers in the rheometer are instructed for performing the downloaded instructions.

Owner:WATERS TECH CORP

Apparatus and methods for determining gravity and density of solids in a liquid medium

ActiveUS20170045432A1Viscometer maintainanceSpecific gravity measurementContinuous measurementLiquid medium

Apparatus and methods for the continuous measurement of specific gravity or density of solids in a fluid medium are disclosed. A system for continuous measurement of density of a flowing medium comprises a cartridge connected in series to an inflow pipe and an outflow pipe, a displacement sensing device adapted to monitor displacement changes of the cartridge when a medium flows through the cartridge, a base configured to provide a support for the displacement sensing device, a pressure sensor, a temperature sensor, and a processor configured to calculate density of the flowing media based on measured displacement change, temperature and pressure.

Owner:RED METERS LLC

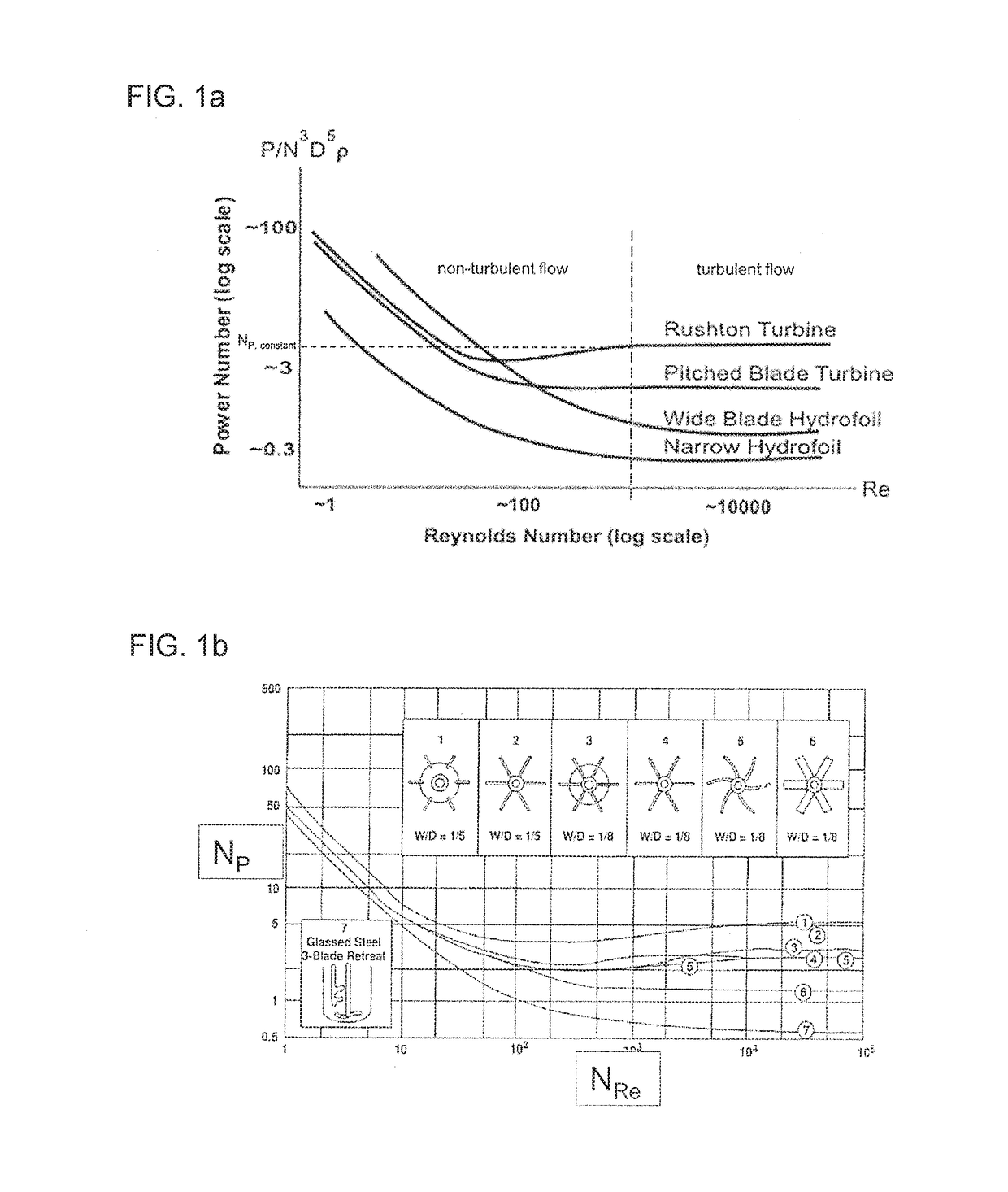

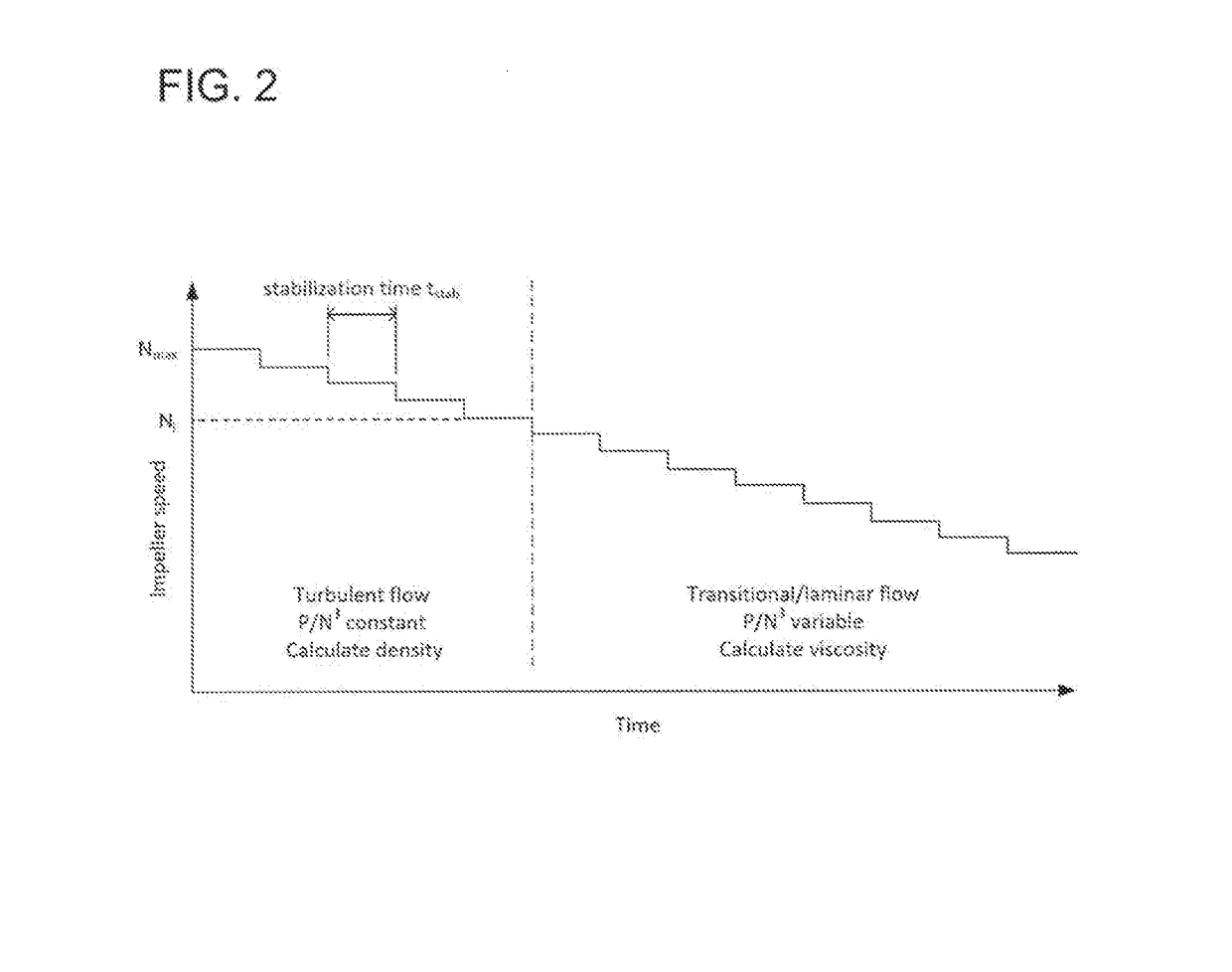

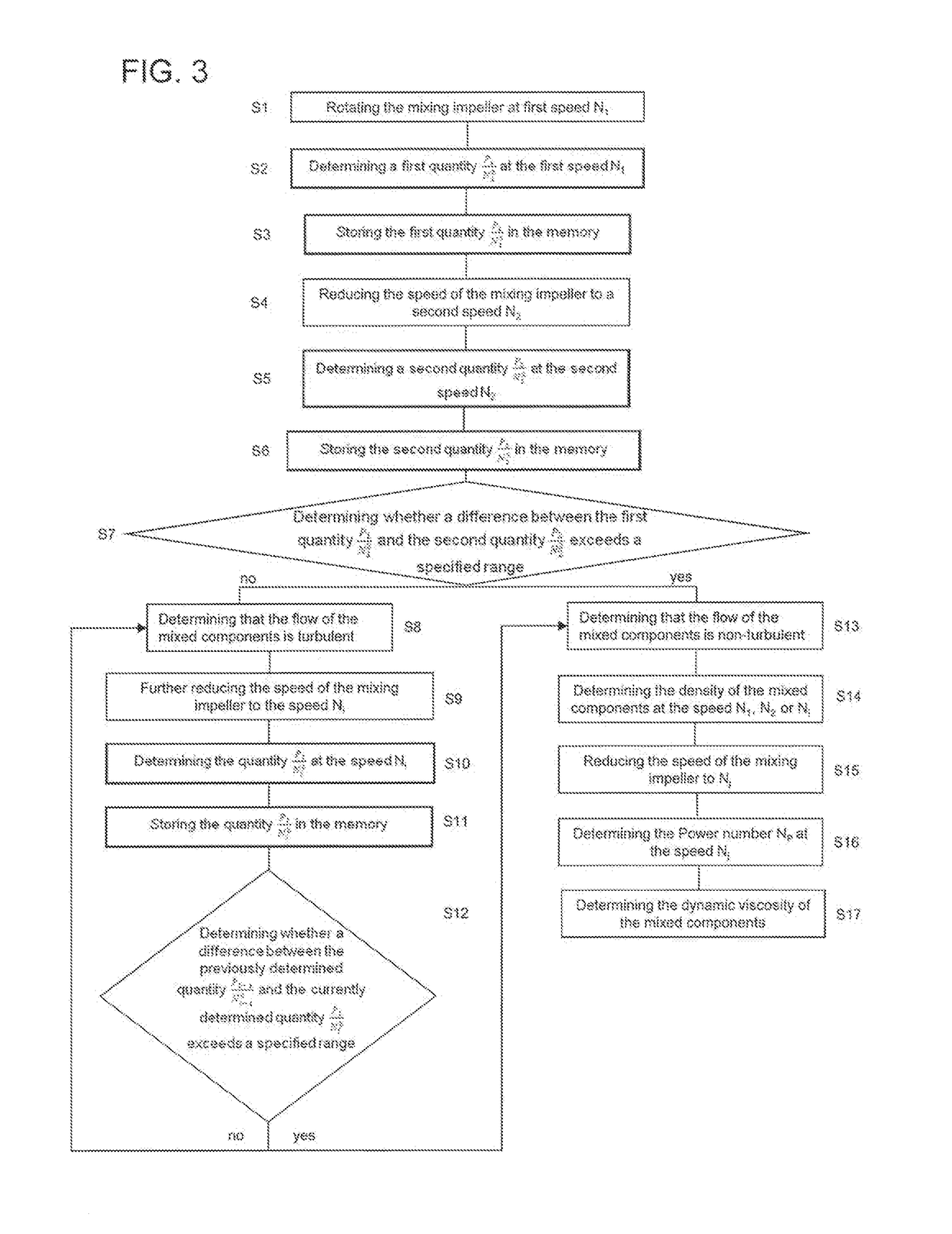

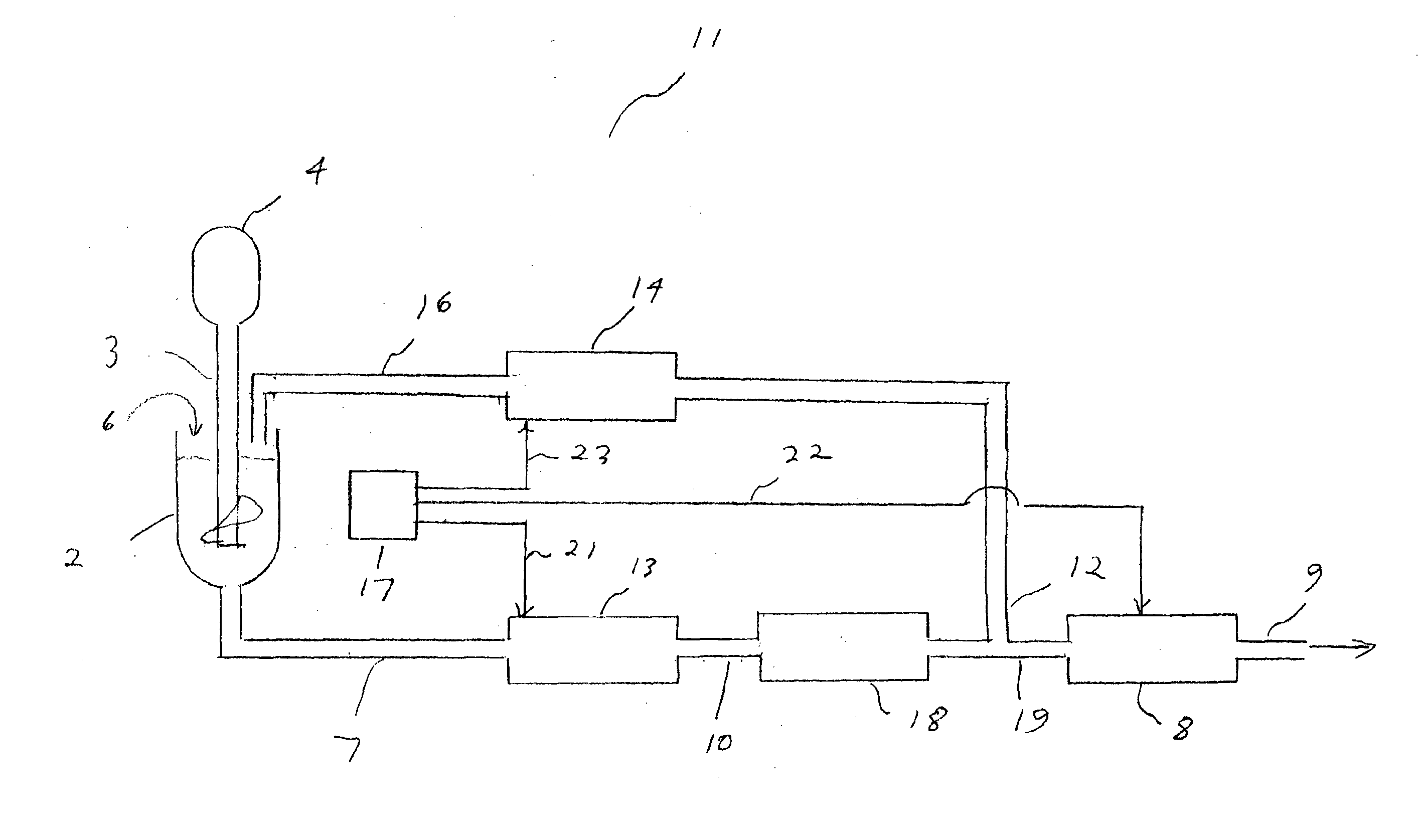

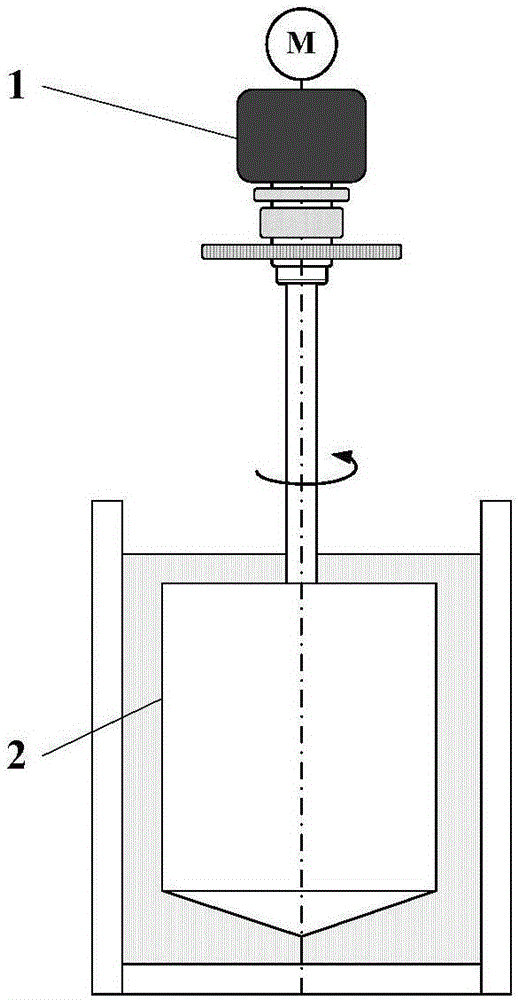

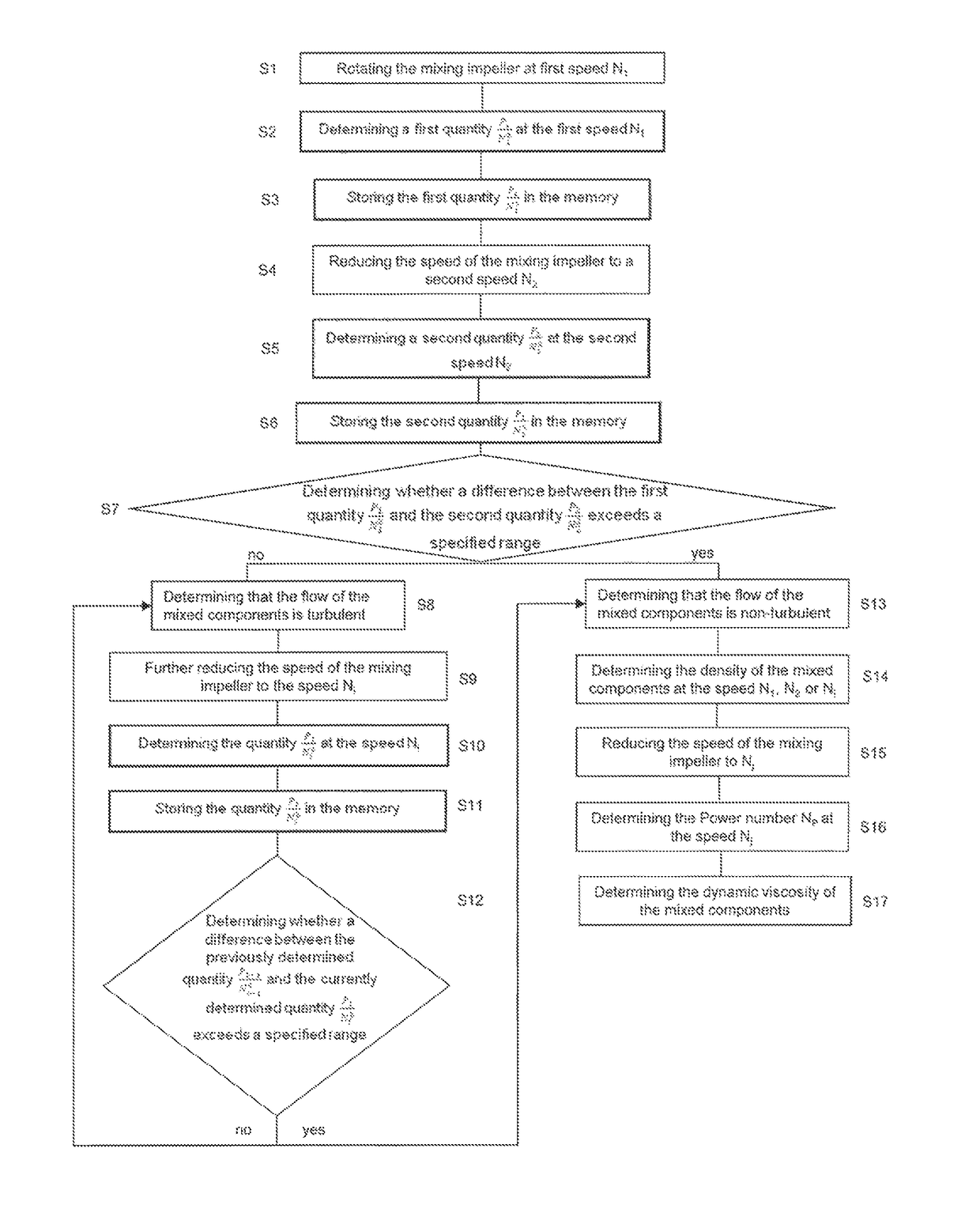

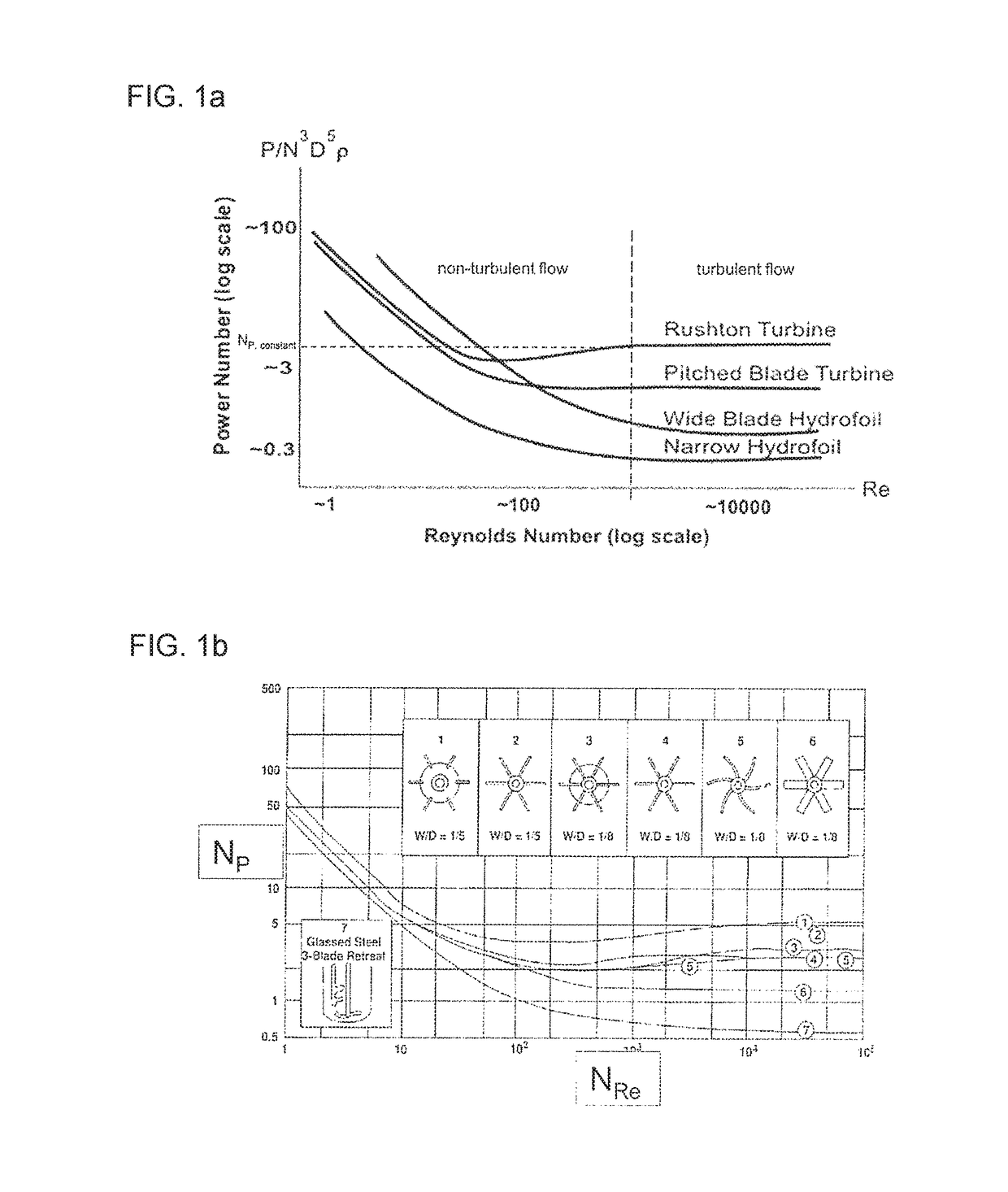

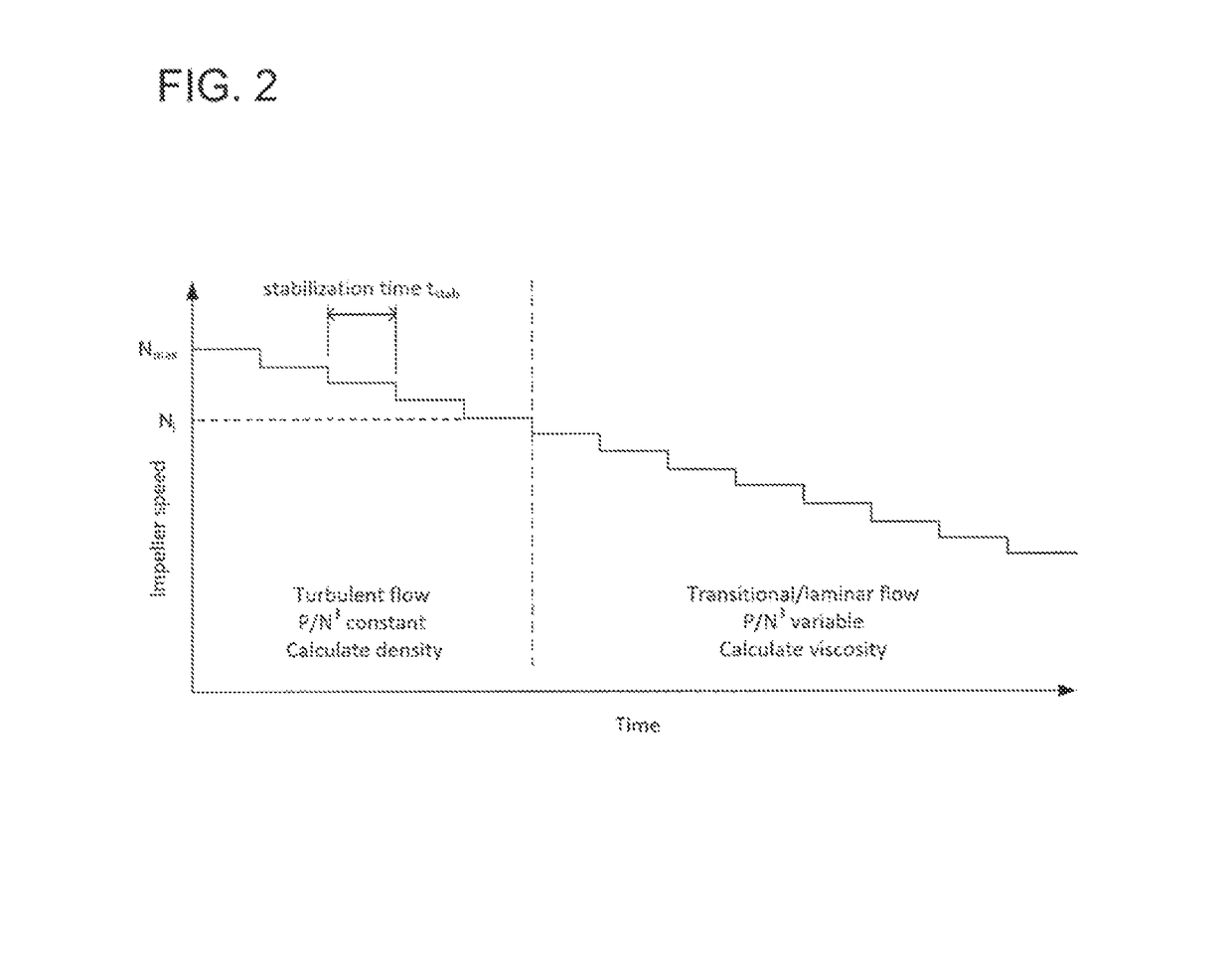

Methods of mixing impeller sensing

ActiveUS20170216798A1Accurate valueShorten speedSamplingRotary stirring mixersImpellerRotation velocity

A method is provided for monitoring a flow behavior of mixed components without requiring additional instrumentation or sampling. The method is carried out by determining ratios of the power required to rotate a mixing impeller at different rotational speeds and then comparing the ratios. Characteristics about the mixed components are determined based on differences between the ratios.

Owner:SARTORIUS STEDIM BIOTECH GMBH

Re-calibration of instruments

InactiveUS20130291620A1FlushingTesting/calibration of speed/acceleration/shock measurement devicesEngineeringPressure difference

Owner:MEZURX

Measurement of properties of fluids using MRI

ActiveUS9448093B2Magnetic measurementsVolume/mass flow measurementNMR - Nuclear magnetic resonanceVoxel

A method of determining rheological properties of a fluid. The method includes: providing an open-bore tube and defining within the bore a three dimensional grid (3DG) of voxels; defining at least an inlet cross section (ICS) and an outlet cross section (OCS); defining a volume of interest within the bore between the ICS and the OCS; obtaining rheological properties of the fluid; applying a pressure gradient to the bore between the ICS and the OCS; and nuclear magnetic resonance imaging the fluid within the volume of interest to determine various aspects of the fluid.

Owner:ASPECT AI

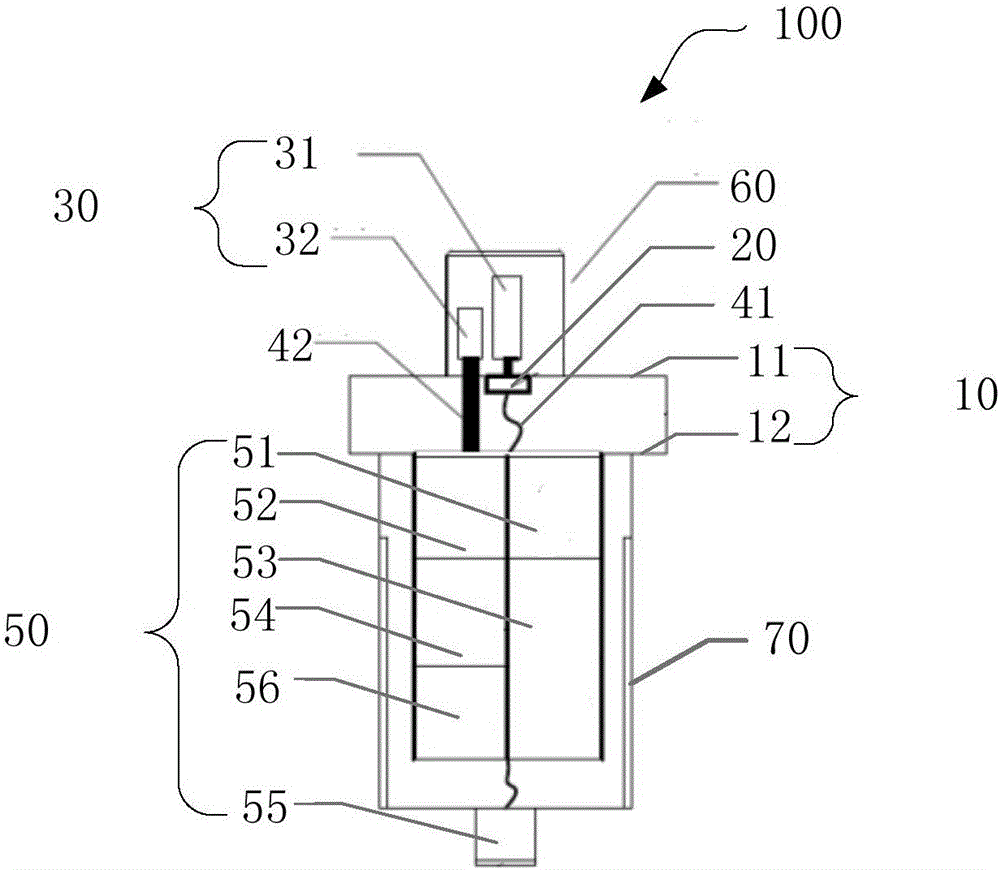

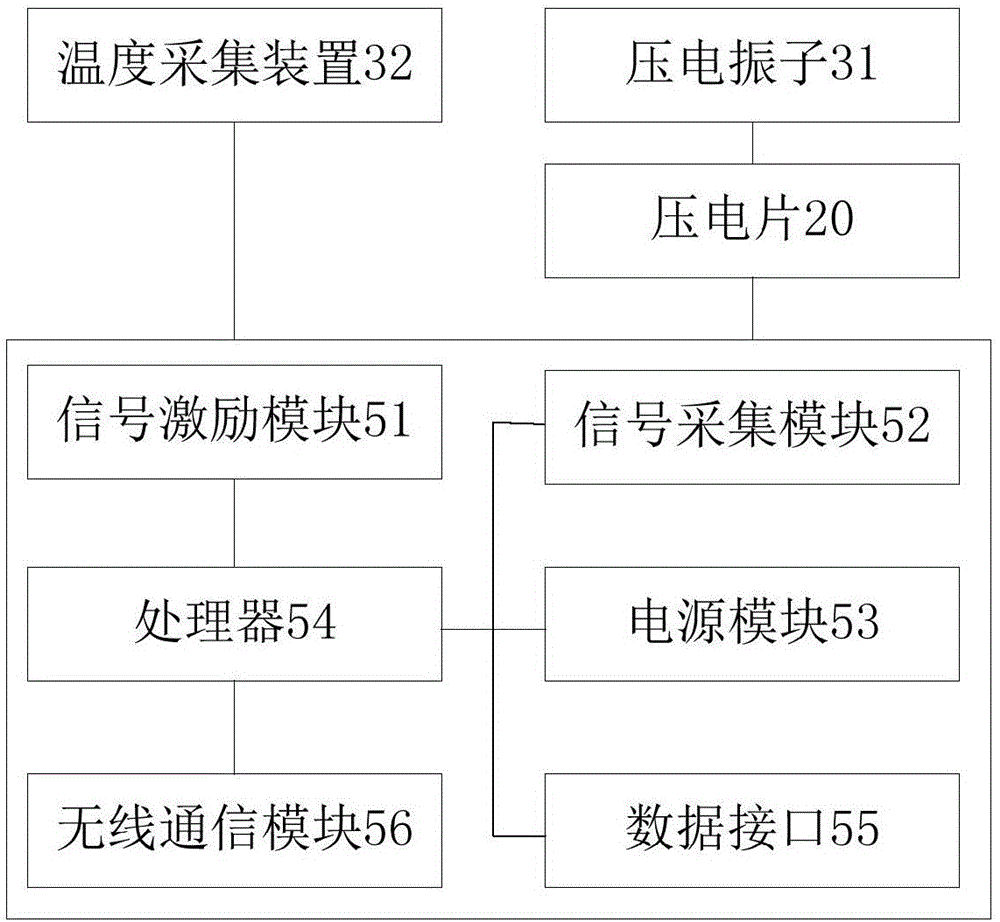

Device for online detection of oil product density and viscosity

PendingCN106338451AComply with online monitoringCompliant with miniaturizationViscometer maintainanceSpecific gravity measurementEngineeringViscosity index

The invention provides a device for online detection of oil product density and viscosity, The device comprises an electrode sealing casing, a piezoelectric plate arranged in the electrode sealing casing, a detection unit and a processing unit, wherein the detection unit and the processing unit are arranged on two opposite end faces outside the electrode sealing casing. The detection unit comprises a piezoelectric vibrator, and the processing unit comprises a processor, a signal stimulation module and a signal collection module. The piezoelectric plate is electrically connected with the processing unit through a first electrode lead, and the electrode sealing casing is provided with a through hole for the first electrode lead to penetrate. The signal stimulation module stimulates the piezoelectric plate to vibrate. The processor calculates the oil product density and viscosity according to vibration frequency and vibration impedance of the piezoelectric vibrator collected by the signal collection module in an oil product. The device detects density and viscosity indexes of the oil product simultaneously, the problems of poor timeliness in off-line measurement and laboratory measurement are solved, and outburst faults can be timely captured to avoid or reduce a loss.

Owner:SHENZHEN YINGLI MONITORING TECH LIMITED

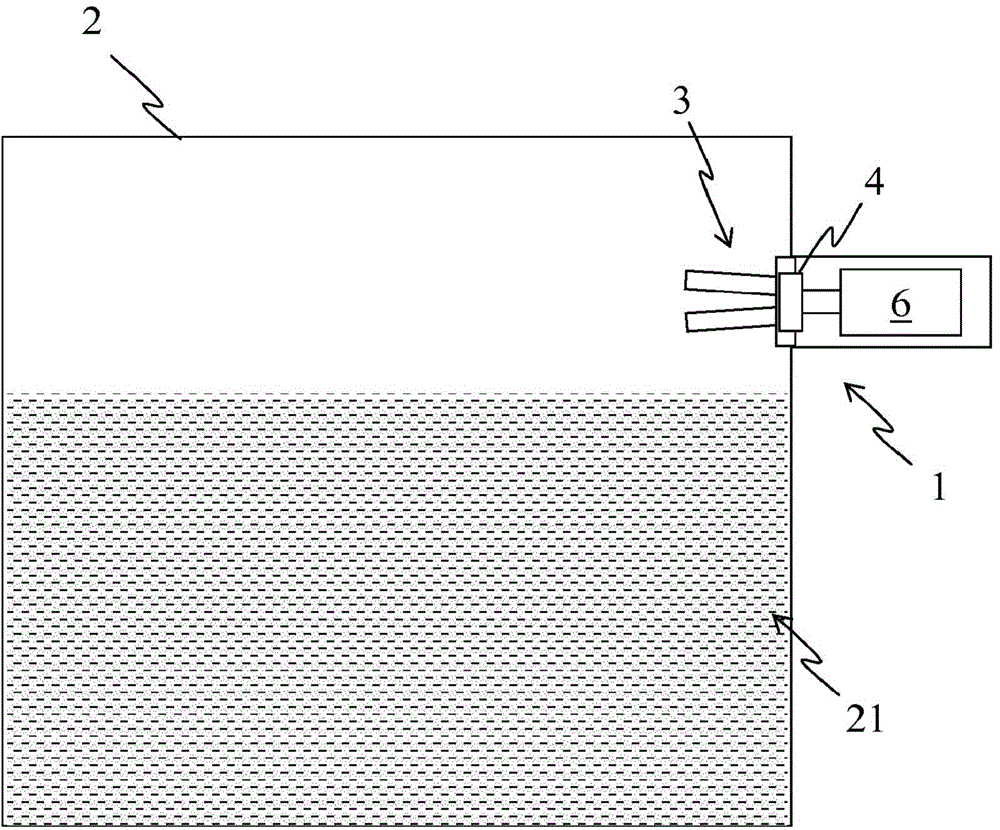

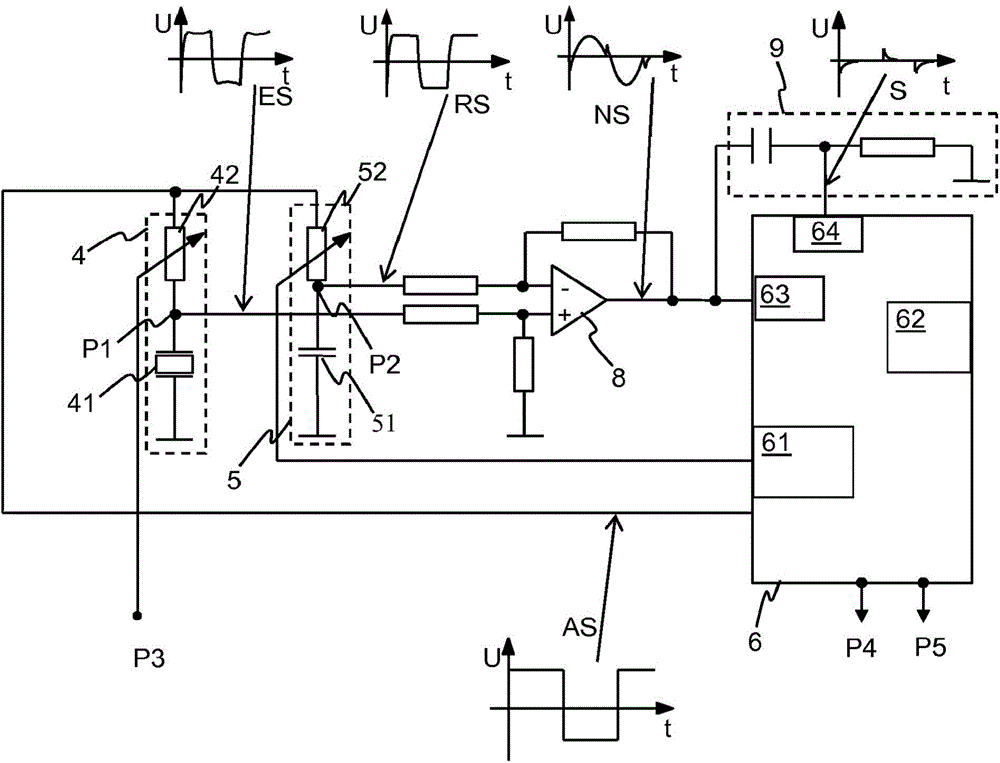

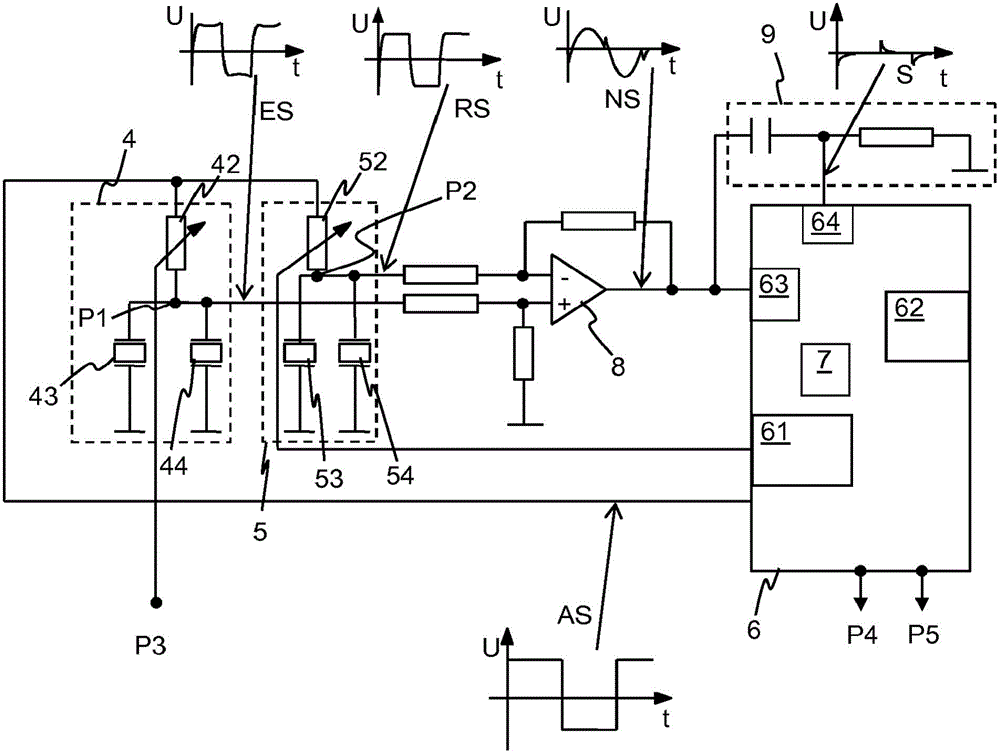

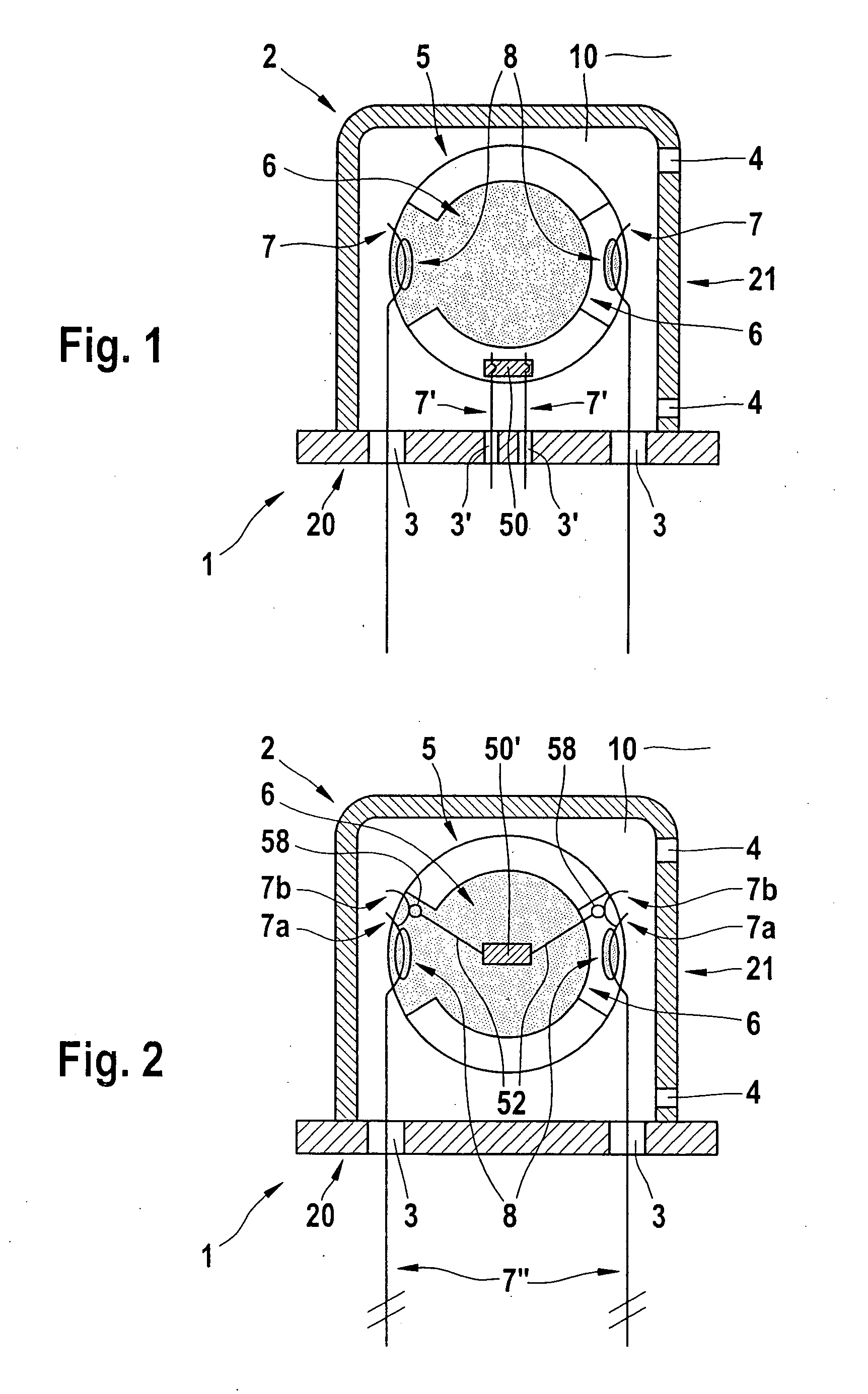

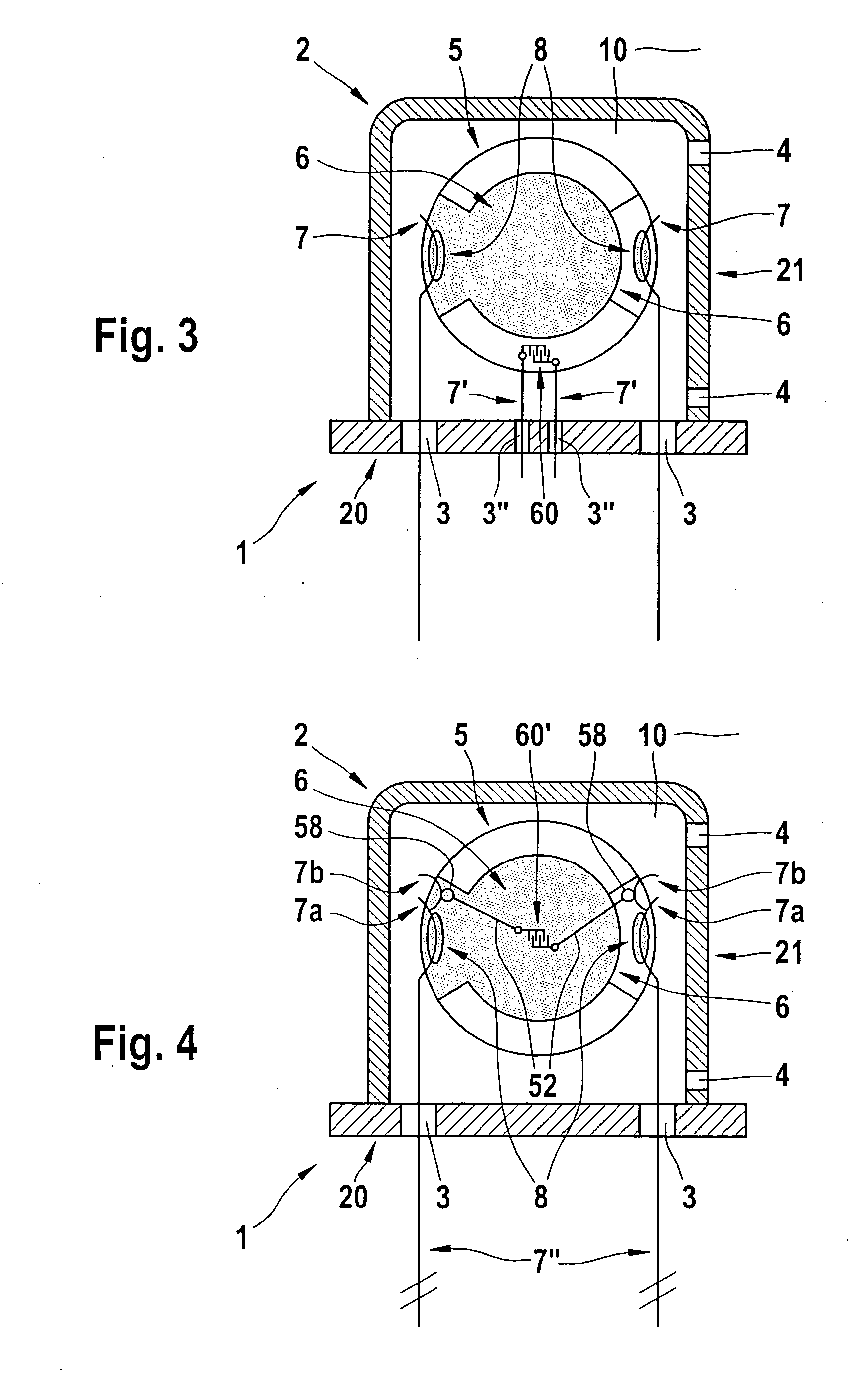

Device for determining and/or monitoring at least one process variable

Device for determining and / or monitoring at least one process variable of a medium (21) in a container (22), comprising a mechanically oscillatable unit (3), an electromechanical converter unit (4) which has at least one piezoelectric or inductive converter element (41), causes the oscillatable unit (3) to oscillate mechanically under the effect of an excitation signal (AS), and receives oscillations from the oscillatable unit (3) and converts said oscillations into an electrical receive signal (ES), a reference element (5) having a first component (42) operated using an electrically adjustable variable, wherein said reference element (5) is connected in parallel to the electromechanical converter unit (4), is impinged upon by the same excitation signal (AS), and generates a reference signal (RS) that is not influenced by the oscillations of the oscillatable unit (3), and an electronic unit that extracts a useful signal (NS) from the receive signal (ES) and the reference signal (RS) and uses said useful signal (NS) to determine and / or monitor the process variable. According to the invention, the electromechanical converter unit (4) has a second component (42) operated using an electrically adjustable variable.

Owner:EHNDRESS KHAUZER GMBKH KO KG

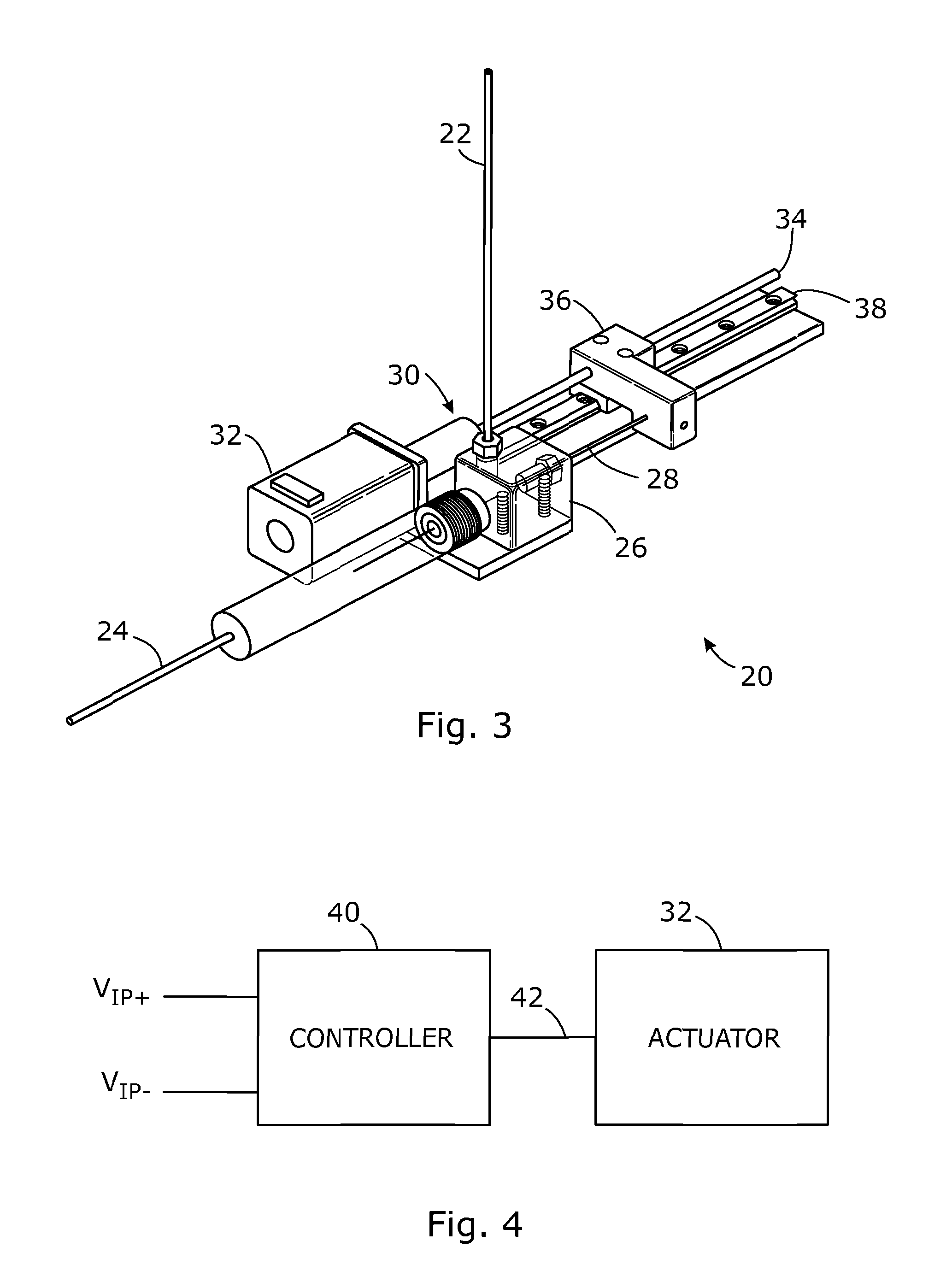

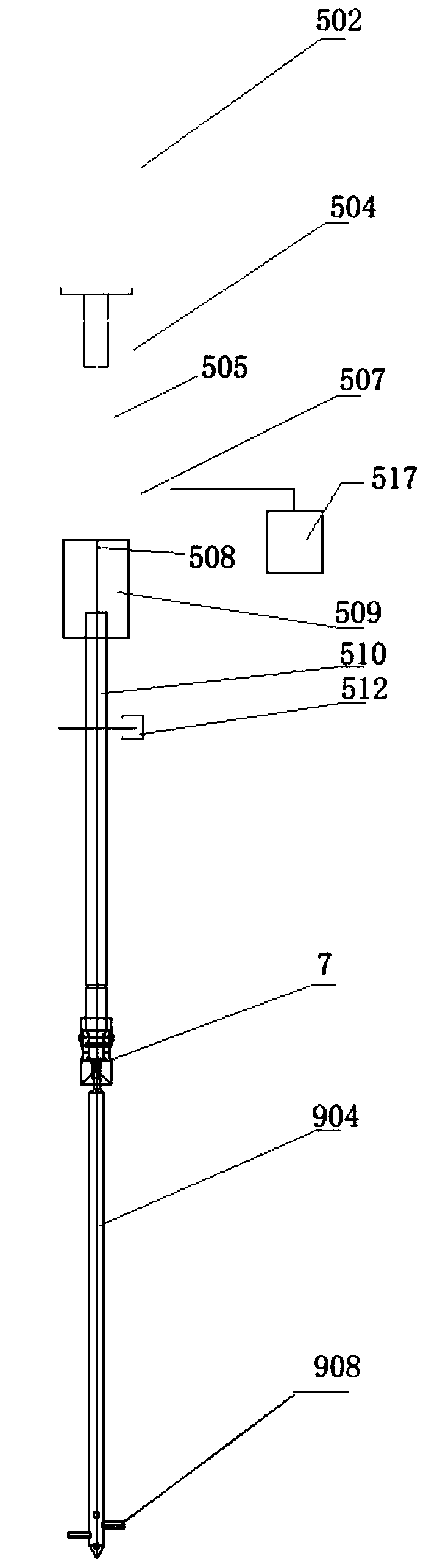

Capillary rheometer with instrumented cleaning and packing device

InactiveUS20080110246A1Quick cleanViscometer maintainanceDirect flow property measurementLinear motionEngineering

The present invention is a capillary rheometer cleaning and packing device comprising: (a) a linear motion device for creating controlled linear motion in a linear motion rod, wherein the linear motion rod is adapted to receive a cleaning / packing rod; (b) a housing securing means wherein the securing means is adapted to secure an existing capillary rheometer housing to the cleaning and packing device such that a barrel mounted concentrically within the capillary rheometer housing is positioned coaxially below the linear motion rod; and (c) a means of attaching the capillary rheometer cleaning and packing apparatus to an existing capillary rheometer.

Owner:TICONA LLC

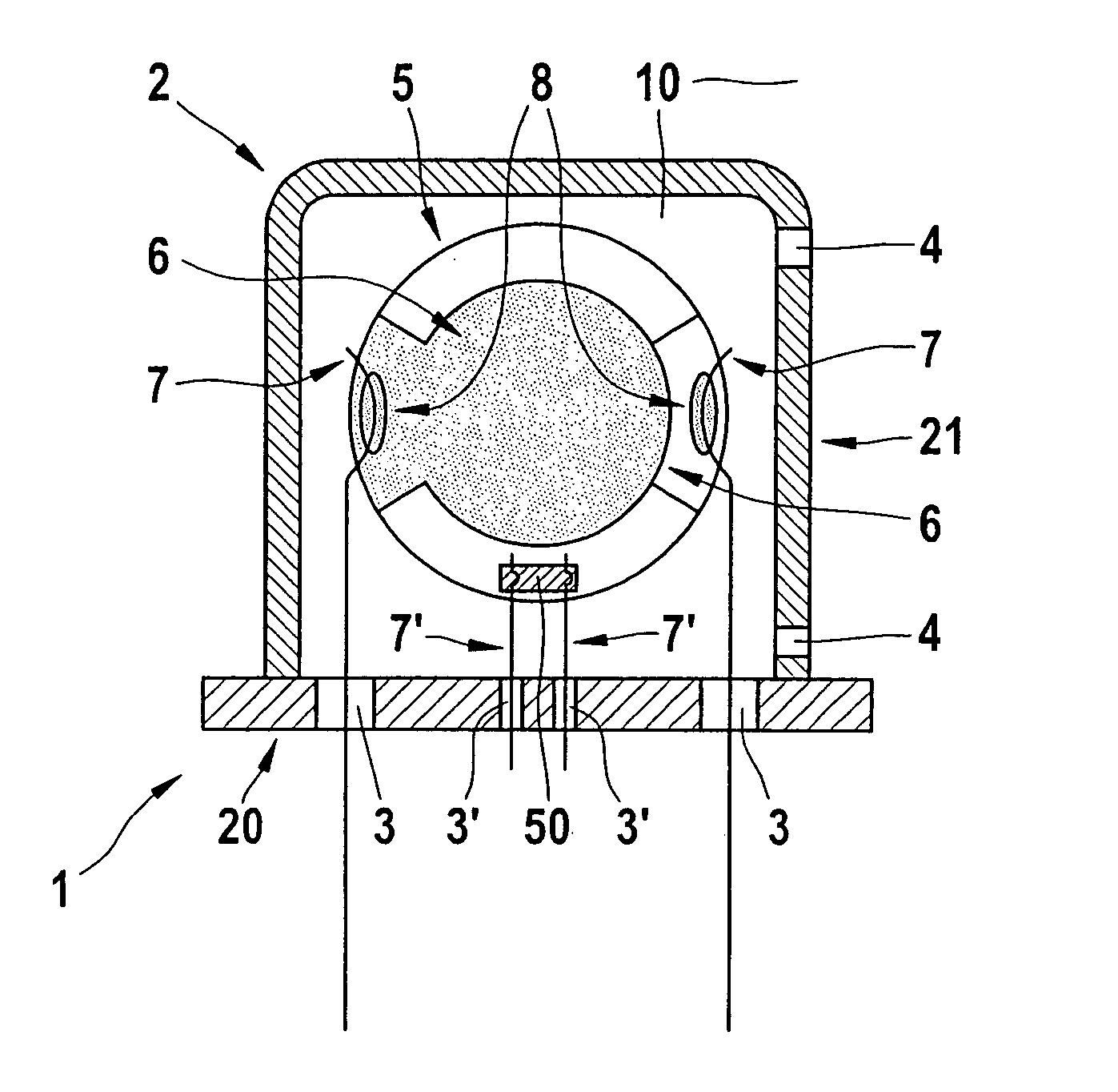

Viscosity sensor system

A viscosity sensor system for measuring the viscosity of a liquid and at least one additional property of the liquid using a piezoelectric viscosity sensor device that is situated completely in the liquid that is to be measured, and that has: electrical contact points for an electrical controlling of volume oscillations on its surface, these contact points being resistant in relation to the liquid; first electrical supply lines that are resistant in relation to the liquid and that are connected on the one hand with a control / evaluation electronics unit situated outside the liquid and on the other hand with the contact points on the surface of the viscosity sensor device; and a second sensor device for acquiring the at least one additional property of the liquid, this second device being provided on the surface of the viscosity sensor device and having electrical contact points on the surface of the viscosity sensor device for an electrical controlling, these electrical contact points being resistant in relation to the liquid; and second electrical supply lines that are resistant in relation to the liquid and that are connected on the one hand to the control / evaluation electronics unit situated outside the liquid and on the other hand to the contact points of the second sensor device.

Owner:ROBERT BOSCH GMBH

Viscosity detector

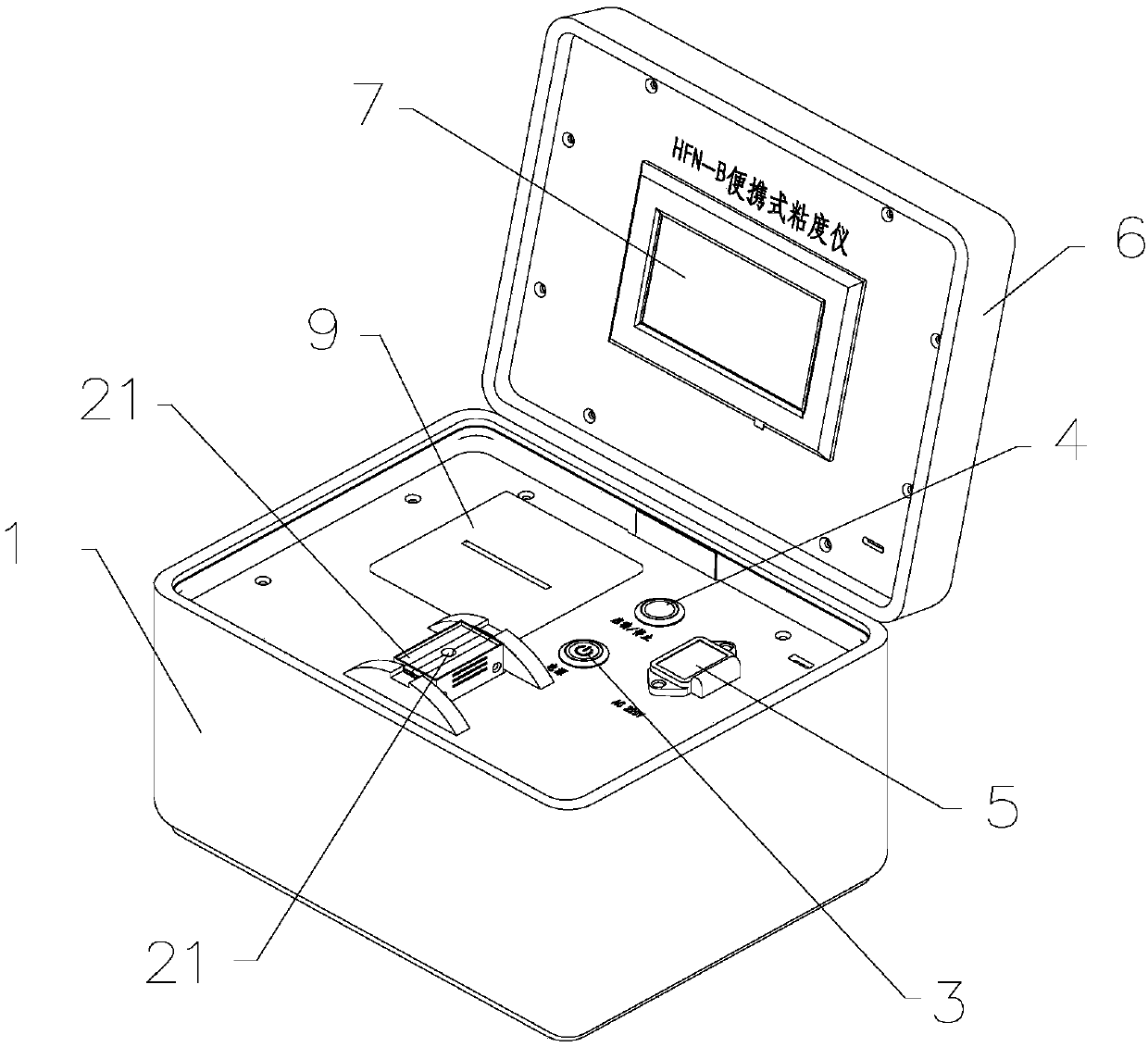

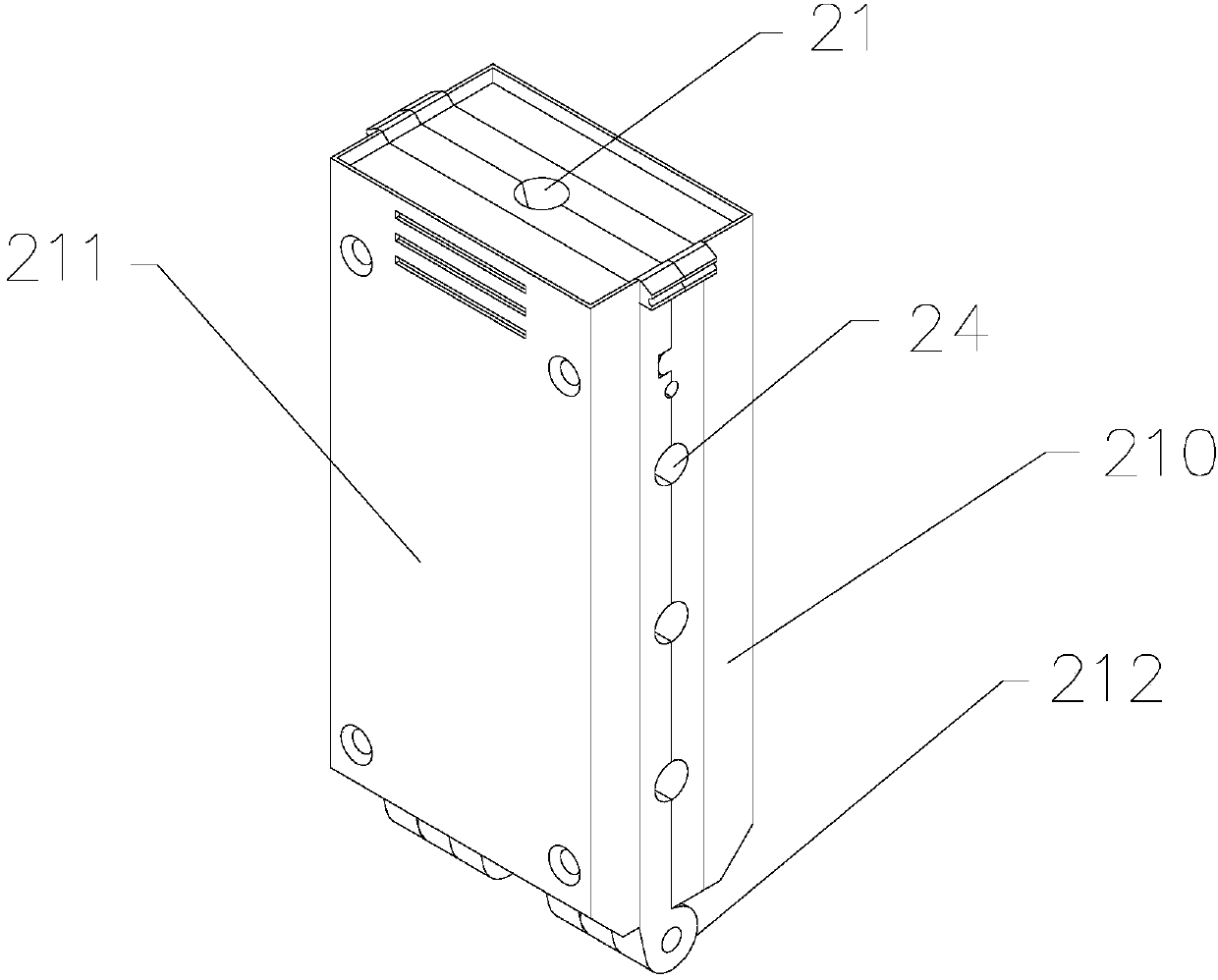

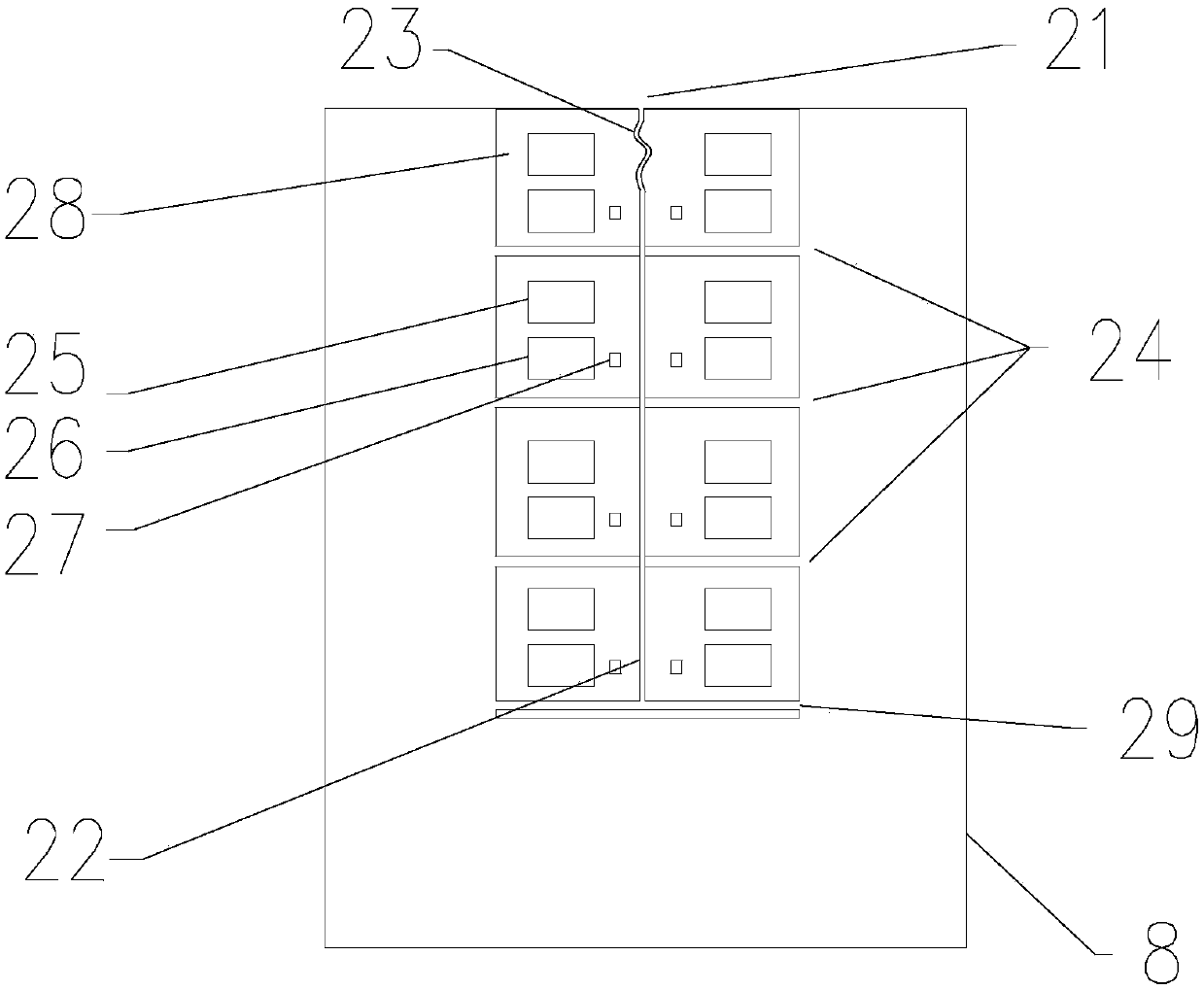

InactiveCN107796735AHeating fastFast cooling effectTemperature control using electric meansViscometer maintainanceThermal insulationDisplay device

The invention provides a viscosity detector, comprising a main unit box (1), and a control device, a display device and a detection device arranged in the main unit box (1). The detection device comprises a detection platform (2) arranged in the main unit box (1), the top of the detection platform (2) is provided with an injection hole (21), a capillary (22) is arranged in the detection platform (2) and is connected with the injection hole (21) through a labyrinth passage (23), two sides of the detection platform (2) are provided with opposing detection holes (24) to detect viscosity of a liquid in the capillary, and a heating device (25), a refrigerating device (26) and a temperature sensor (27) are arranged on two sides of the capillary (22) inside the detection platform. The viscosity detector can provide quick heating, refrigerating and thermal insulation, allows oil to be injected more conveniently and reasonably, allows pressure in the capillary to be more stable and provides effectively improved detection precision.

Owner:北京航峰精诚装备技术有限公司

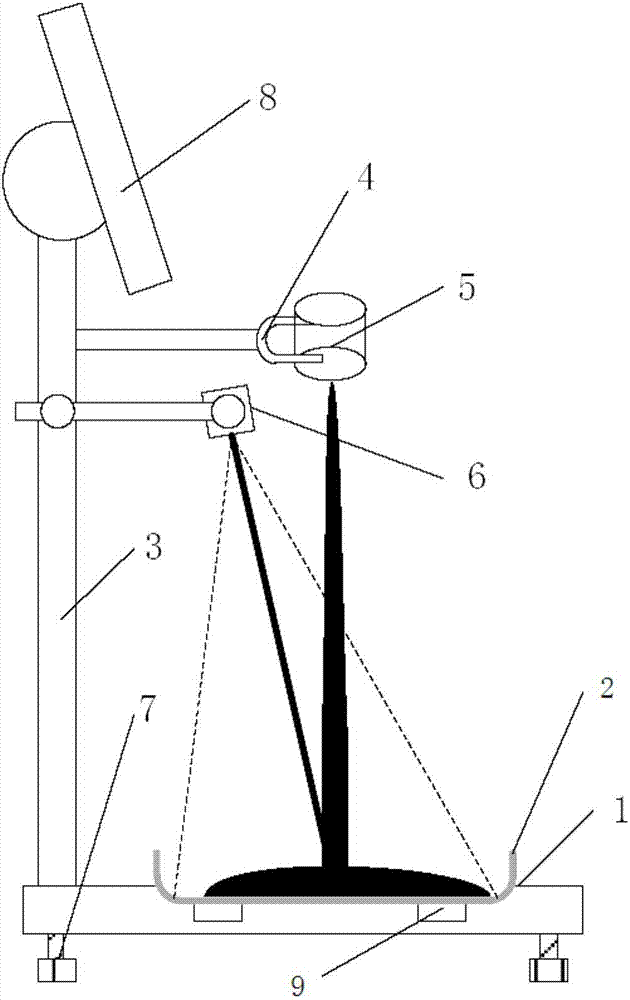

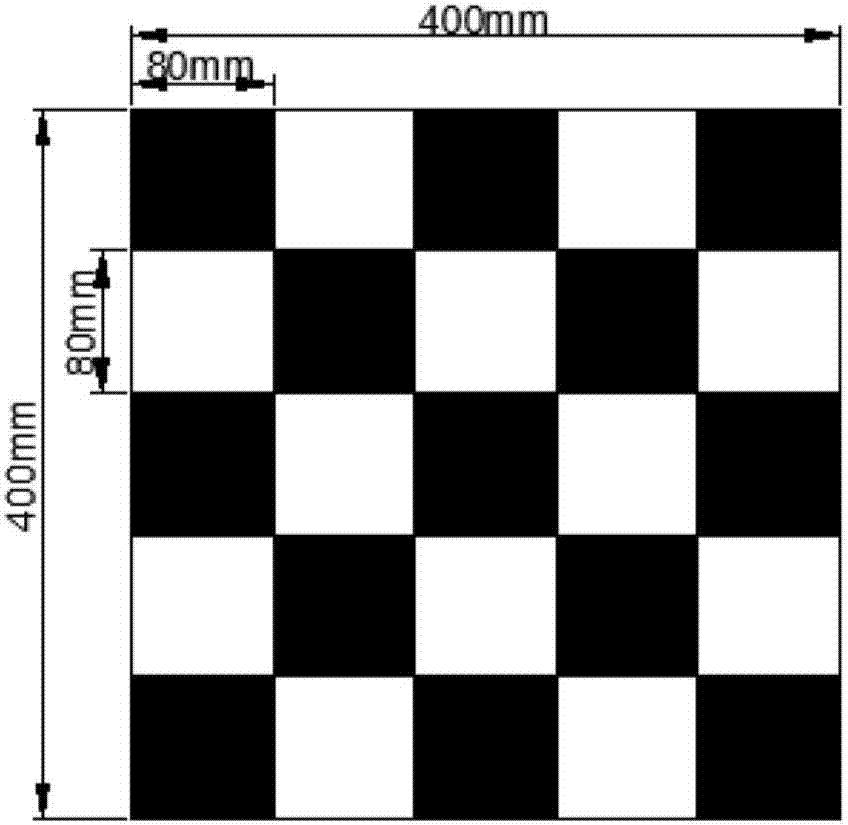

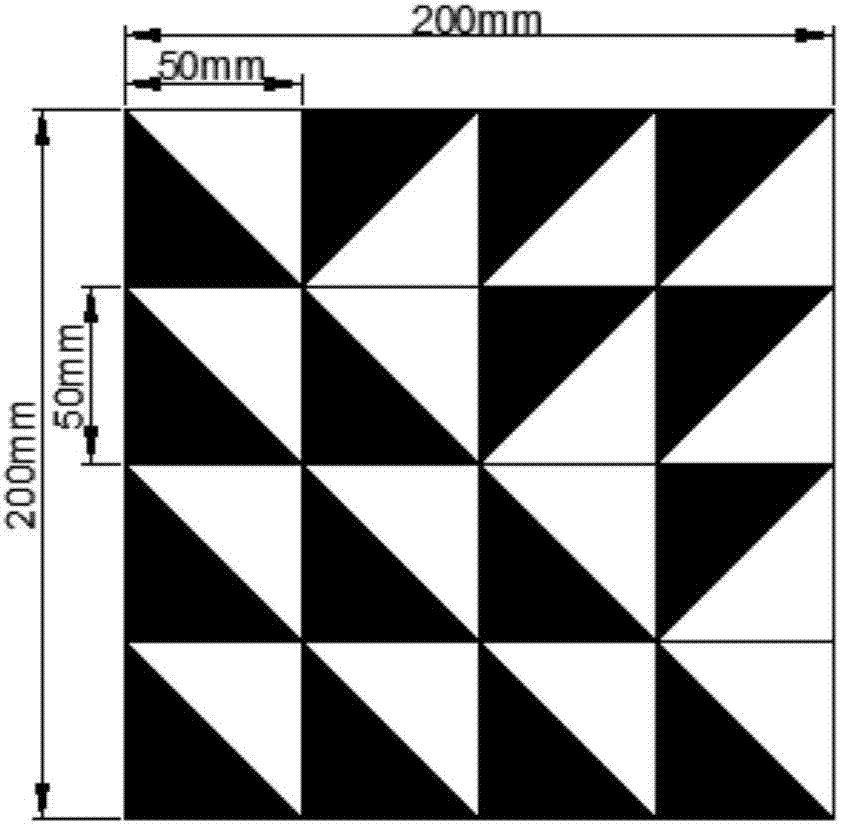

Determination apparatus and determination method of flowability of coal water slurry based on digital image technology

PendingCN106908353AAvoid Measuring InaccuraciesImprove accuracyViscometer maintainanceFlow properties on non-Newtonian fluidsCoal waterRobotic arm

The invention relates to a determination apparatus and determination method of flowability of coal water slurry based on digital image technology. The determination apparatus is characterized by comprising a pedestal, a charging tray, a vertical support, a robotic arm guide rail, a power apparatus, a robotic arm clamping device, a container, a shooting device and a control apparatus. The top of the pedestal is provided with a groove, the charging tray for loading released coal water slurry is fixed in the groove, the vertical support is fixed at one side of the top of the pedestal, and the robotic arm guide rail is in slide arrangement with the vertical support and is in fixed connection to an output end of the power apparatus. One end of the robotic arm clamping device is in fixed connection to the robotic arm guide rail, and the other end of the robotic arm clamping device clamps and fixes the container for holding coal water slurry. The shooting apparatus is in fixed connection to the vertical support and is in electrical connection to the control apparatus fixed on the vertical support. The determination apparatus and determination method can be widely applied to quantitative and qualitative determination process of flowability of coal water slurry.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

Apparatus for checking need for maintenance and viscometer

InactiveUS10429285B2Without of process operationViscometer maintainanceReliability engineeringViscometer

An apparatus for checking a need for maintenance of a viscometer measuring consistency of suspension comprises a rigid rod and an elongated cavity in a measuring arm of the viscometer. The rigid rod is matched with the cavity for the rod to be movable in the cavity. The cavity is configured to become mismatched with respect to the rod in response to a bending of the measuring arm, the mismatch indicating a need for maintenance of the viscometer.

Owner:VALMET AUTOMATION OY

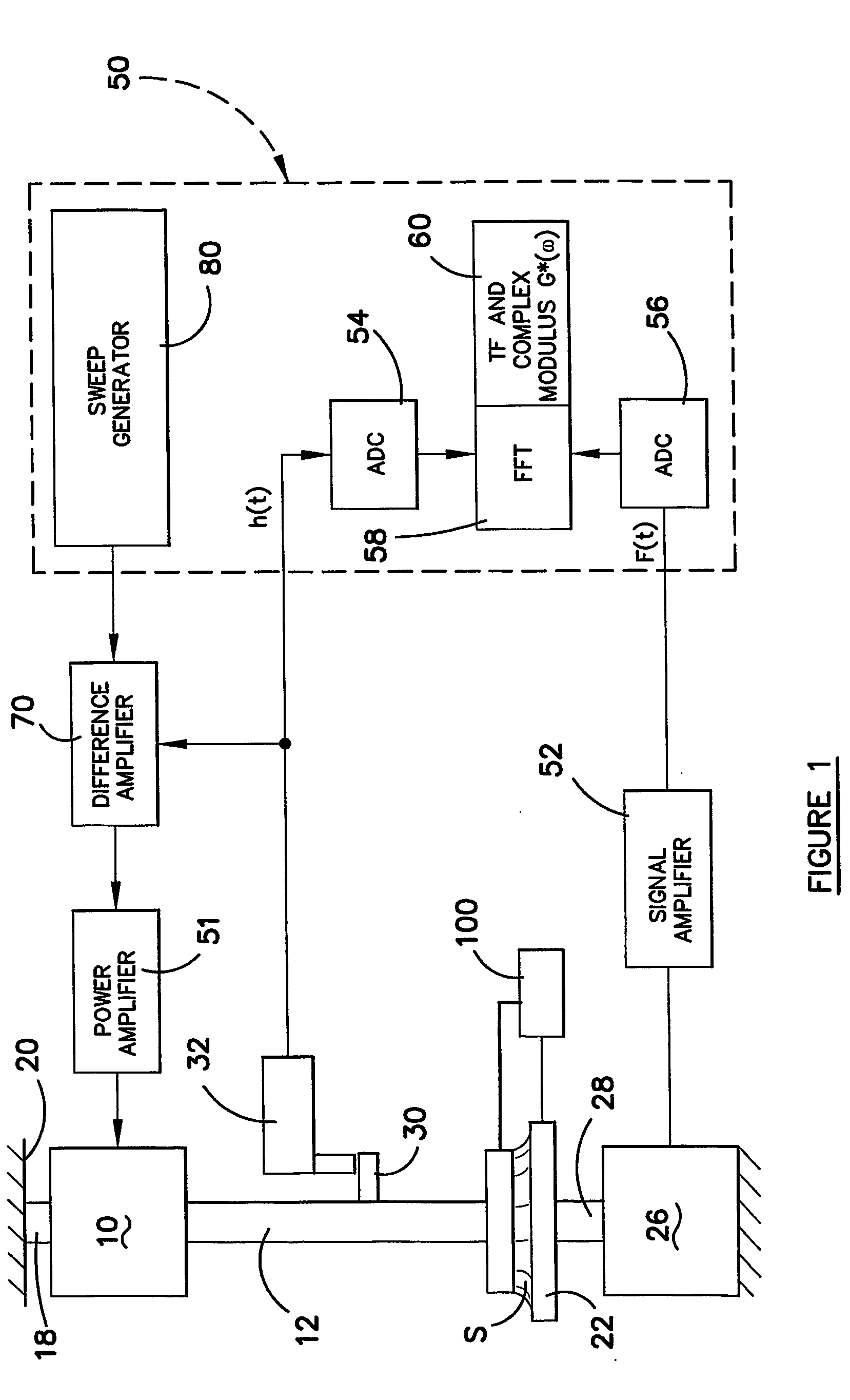

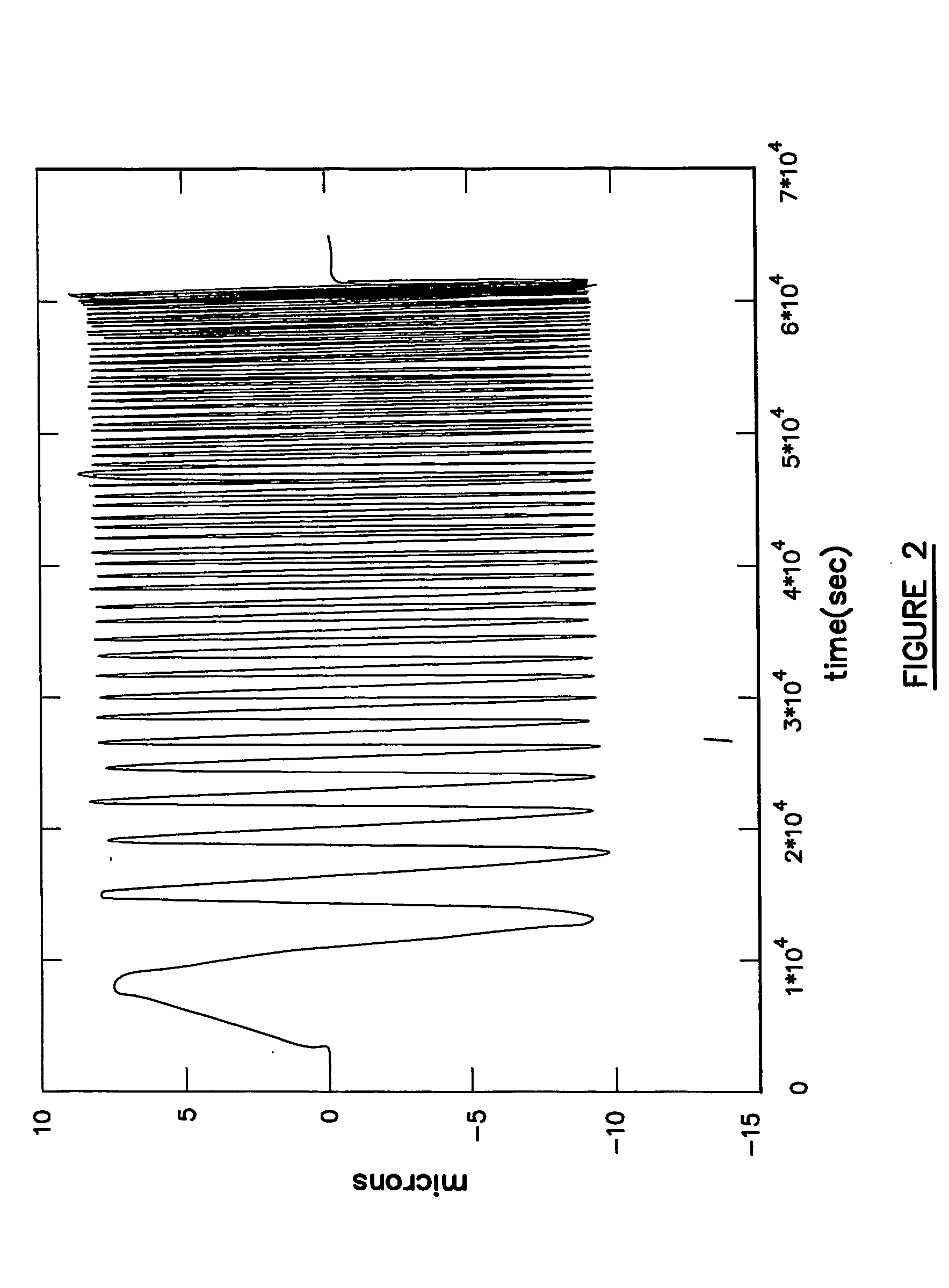

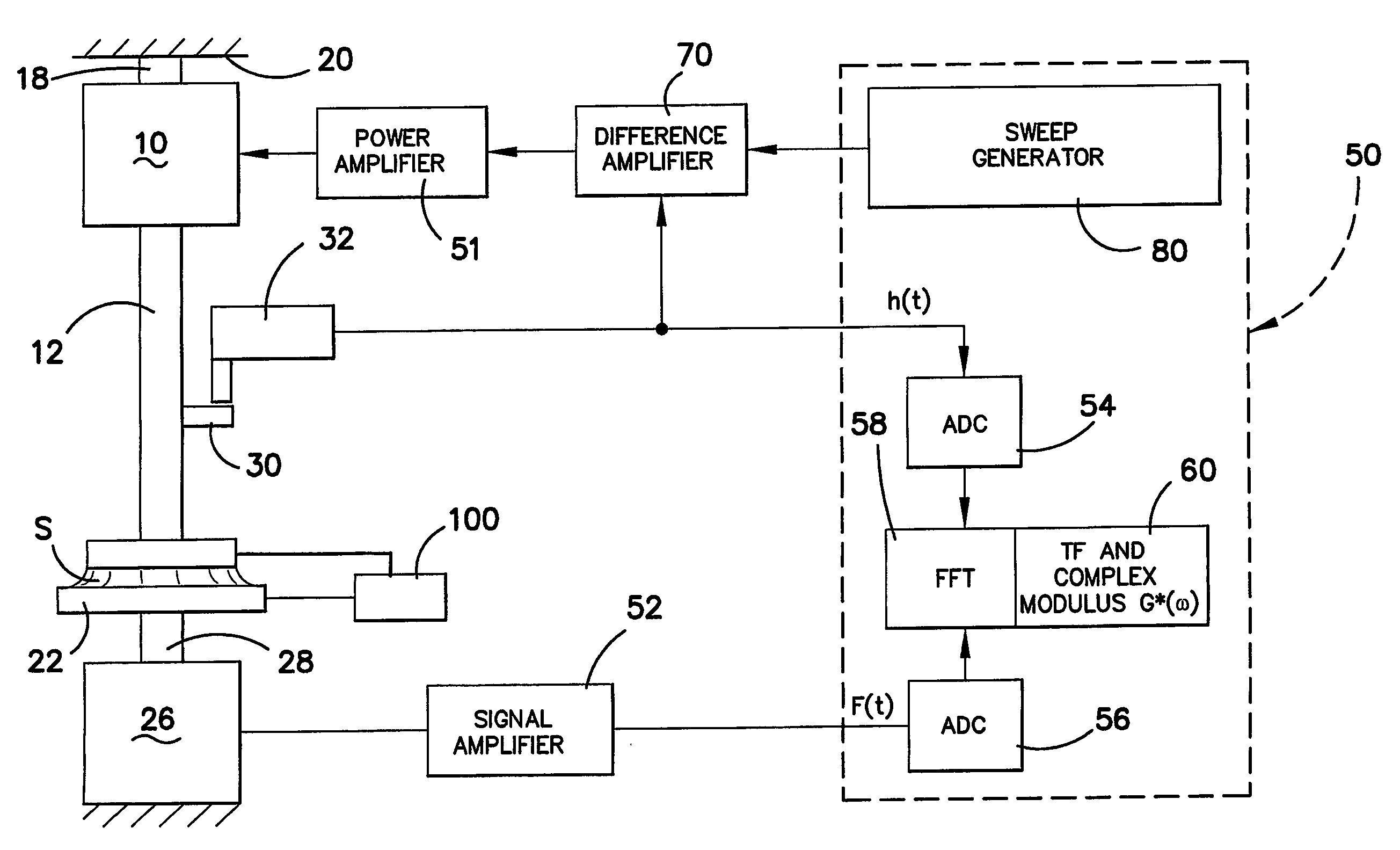

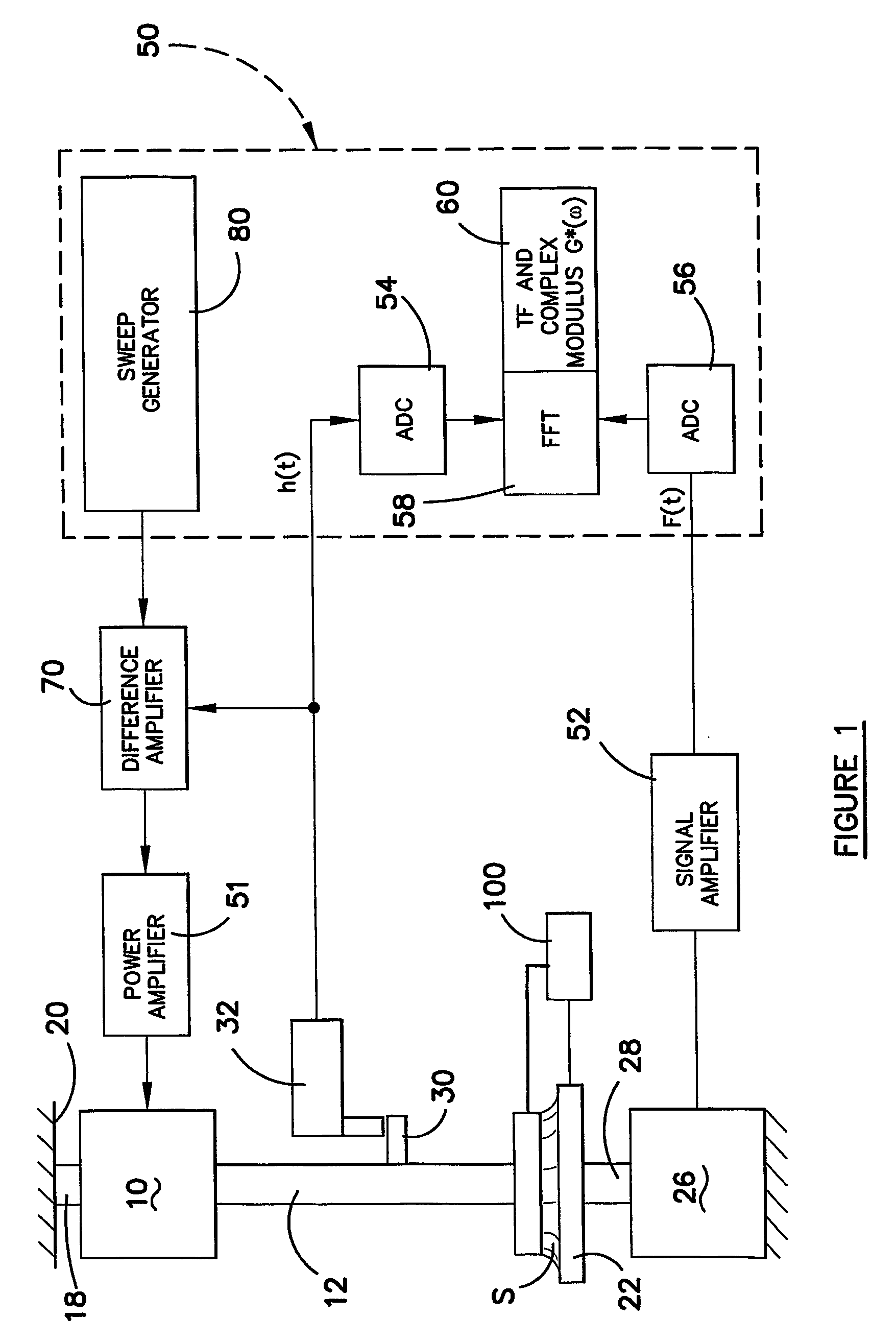

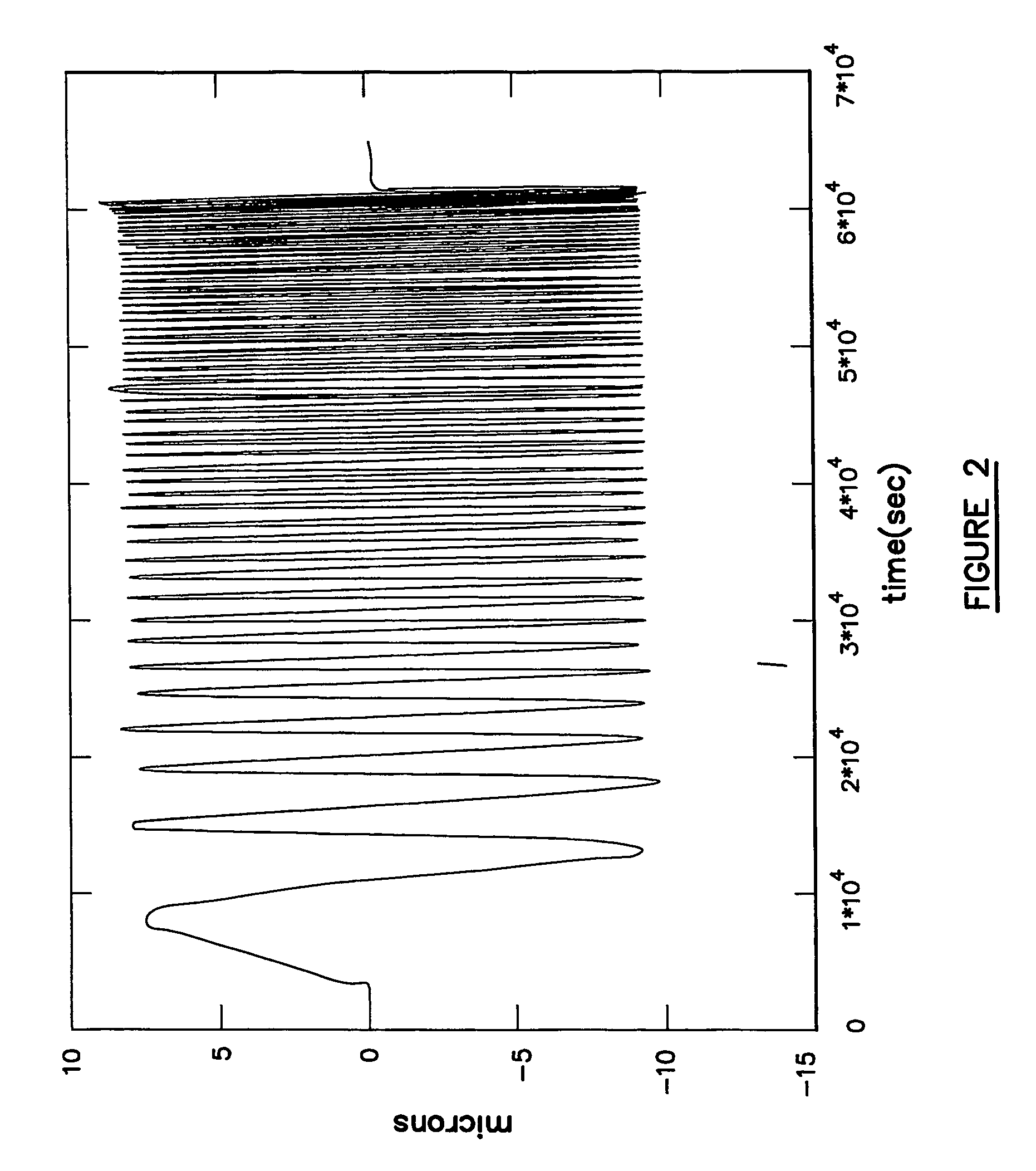

Rheometer

InactiveUS20050247115A1Accurate measurementFluid pressure measurement by mechanical elementsMachines/enginesThermal expansionEngineering

A rheometer and method of making rheological measurements is disclosed, in which a sample is supported between plates and an alternating movement is applied by a driver, support rod and plate. Force and displacement measurements are taken and the property determined from those measurements. The vibrating signal which is applied is in the form of a frequency sweep signal having a monotonic group delay function. The top plate is provided with a surface which causes a meniscus to form up a side edge of the plate to reduce the spring nature of the sample when the movement is supplied to the sample, and a supporting rod which supports the top plate is preferably formed from a material having a low coefficient of thermal expansion so that the gap between the plates is maintained substantially constant if the sample is heated to take measurements at different temperatures.

Owner:GBC SCI EQUIP

Fluid monitoring and management devices, fluid monitoring and management systems, and fluid monitoring and management methods

A fluid monitoring and management device that includes a housing with a fluid passageway. The fluid monitoring and management device further includes a fluid property sensor with a sensing element in the fluid passageway. A valve is in the fluid passageway of the fluid monitoring and management device. A removable bottle mount is aligned with the valve to be selectively in fluid communication with the fluid passageway.

Owner:LOGILUBE LLC

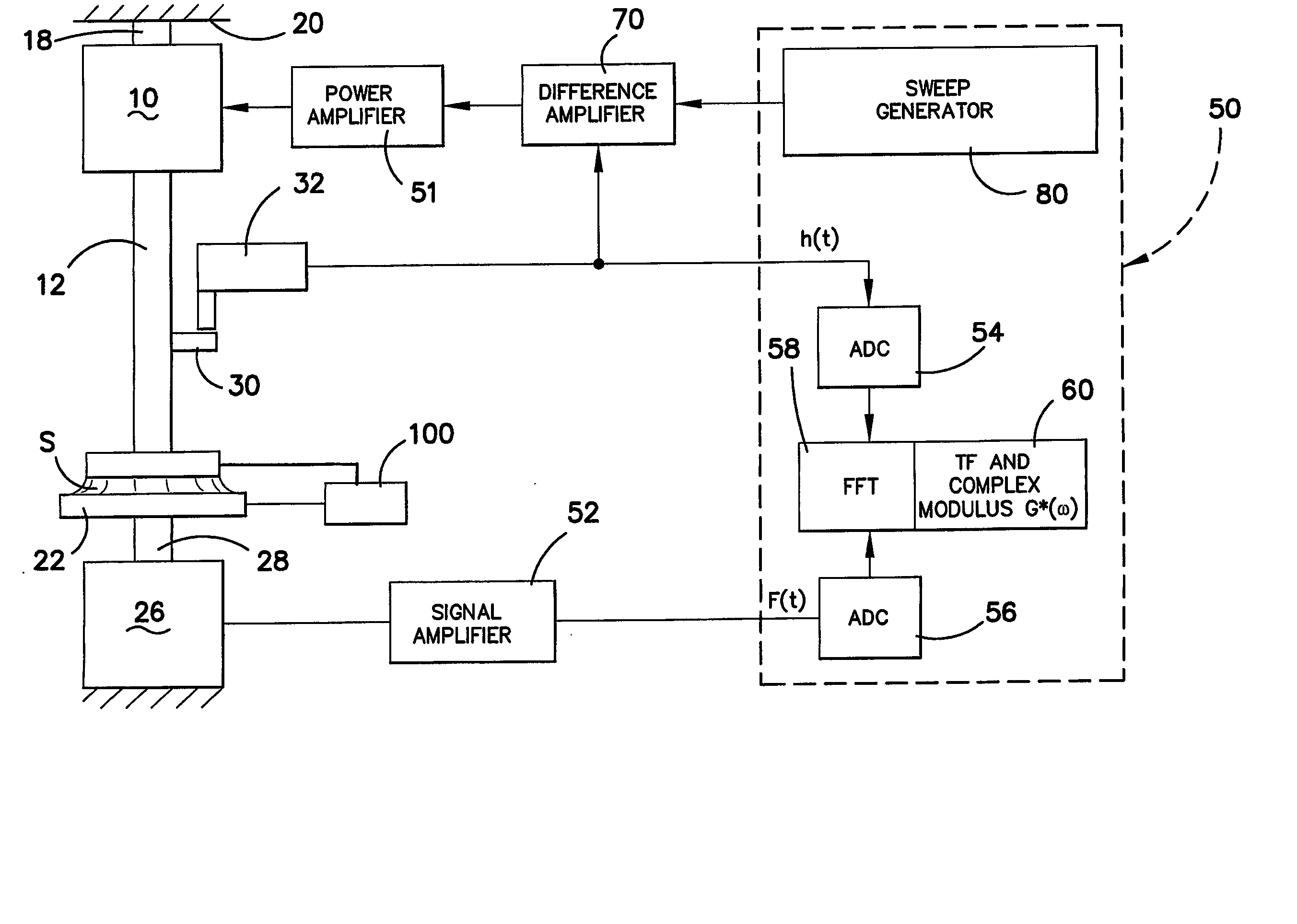

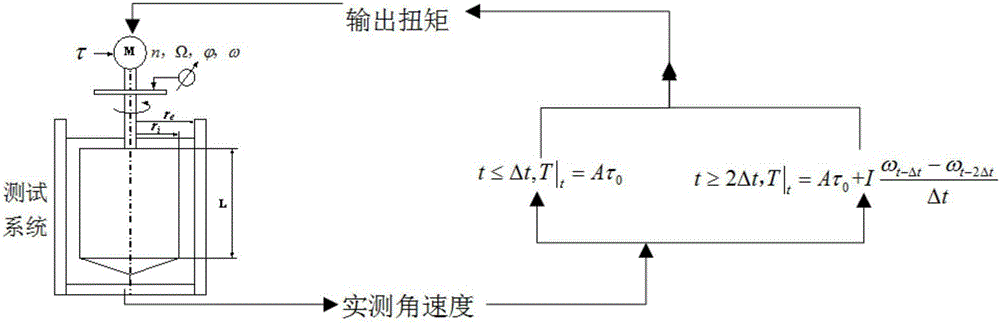

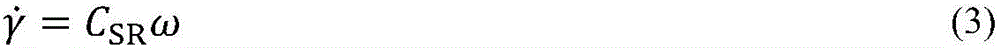

Feedback and control system and method for rheometer shearing stress in unsteady test phase

ActiveCN106774485AGuaranteed True Shear StressAvoid measurement errorsMechanical power/torque controlViscometer maintainanceTest phaseMoment of inertia

The invention discloses a feedback and control system and method for rheometer shearing stress in an unsteady test phase. The method comprises the steps that on the premise that a rheological curve of a test sample is smooth and continuous, discretization is conducted in a rheometer initial torque loading time domain; a mathematic relation between the actually-measured rotor angle speed and the torque should be applied at a next moment is determined; the rotor angle accelerated speed of the next moment is approximately acquired according to the measured rotor speed, and a torque value should be applied at the next moment is calculated according to preset shearing stress, the rotor angle accelerated speed and the rotating inertia of a rheometer rotating part, and control is conducted with the torque value. Accordingly, it is guaranteed that the real shearing stress on the rotor surface accords with a preset value, and the system and method are suitable for a rheological test operated under the condition that shearing stress loading is controlled by fluid of which the rheological property is related with time and have the certain universality and applicability.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

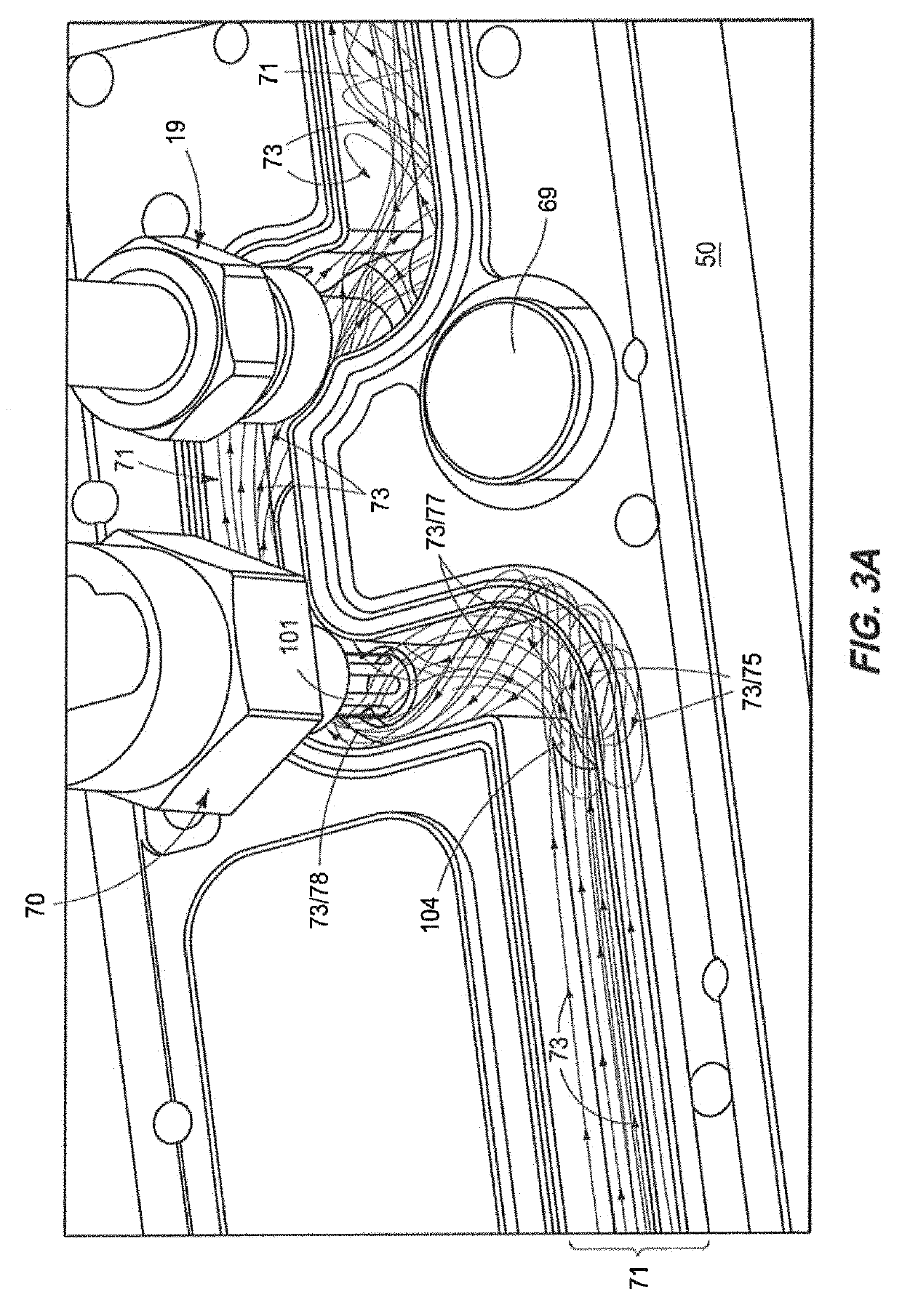

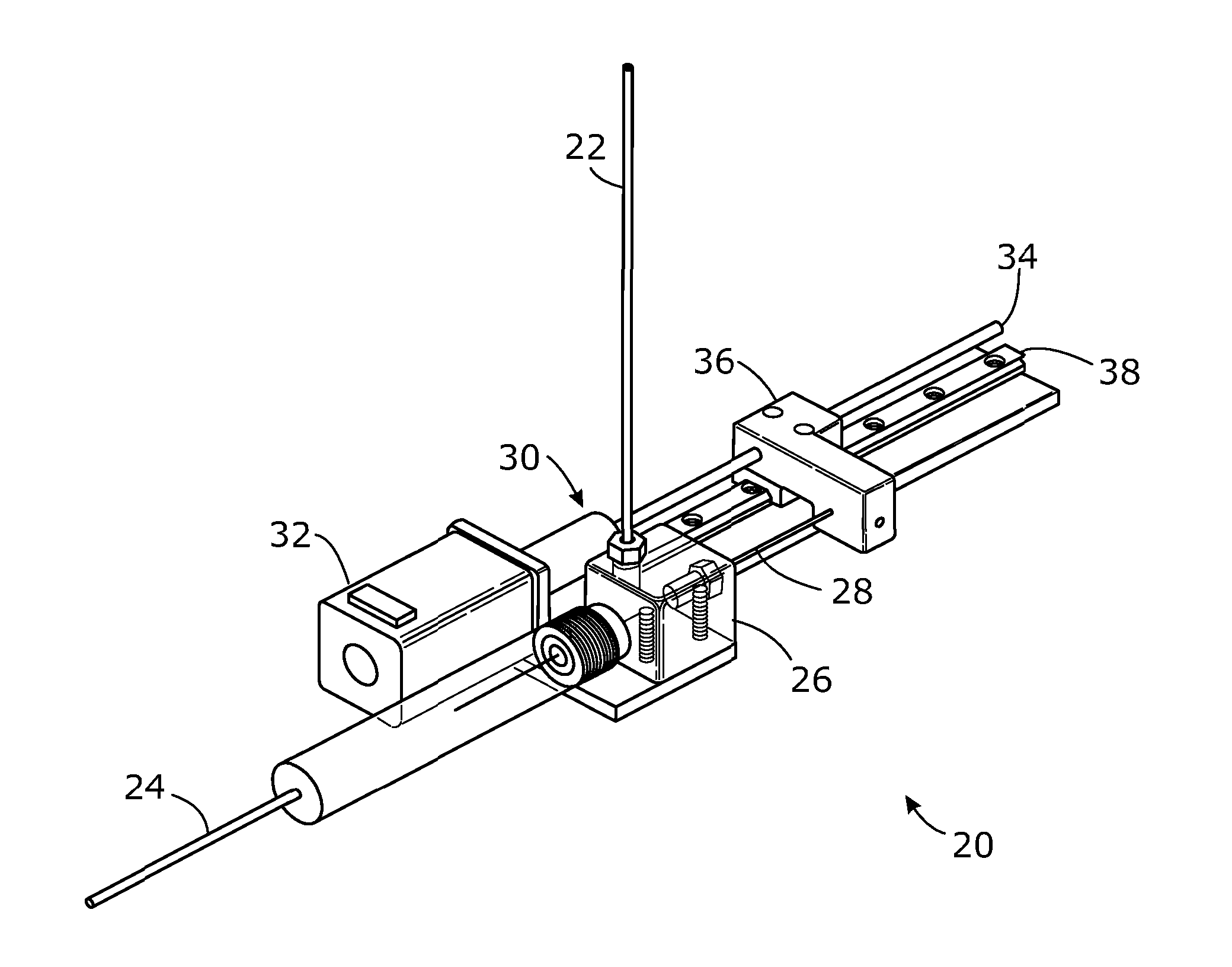

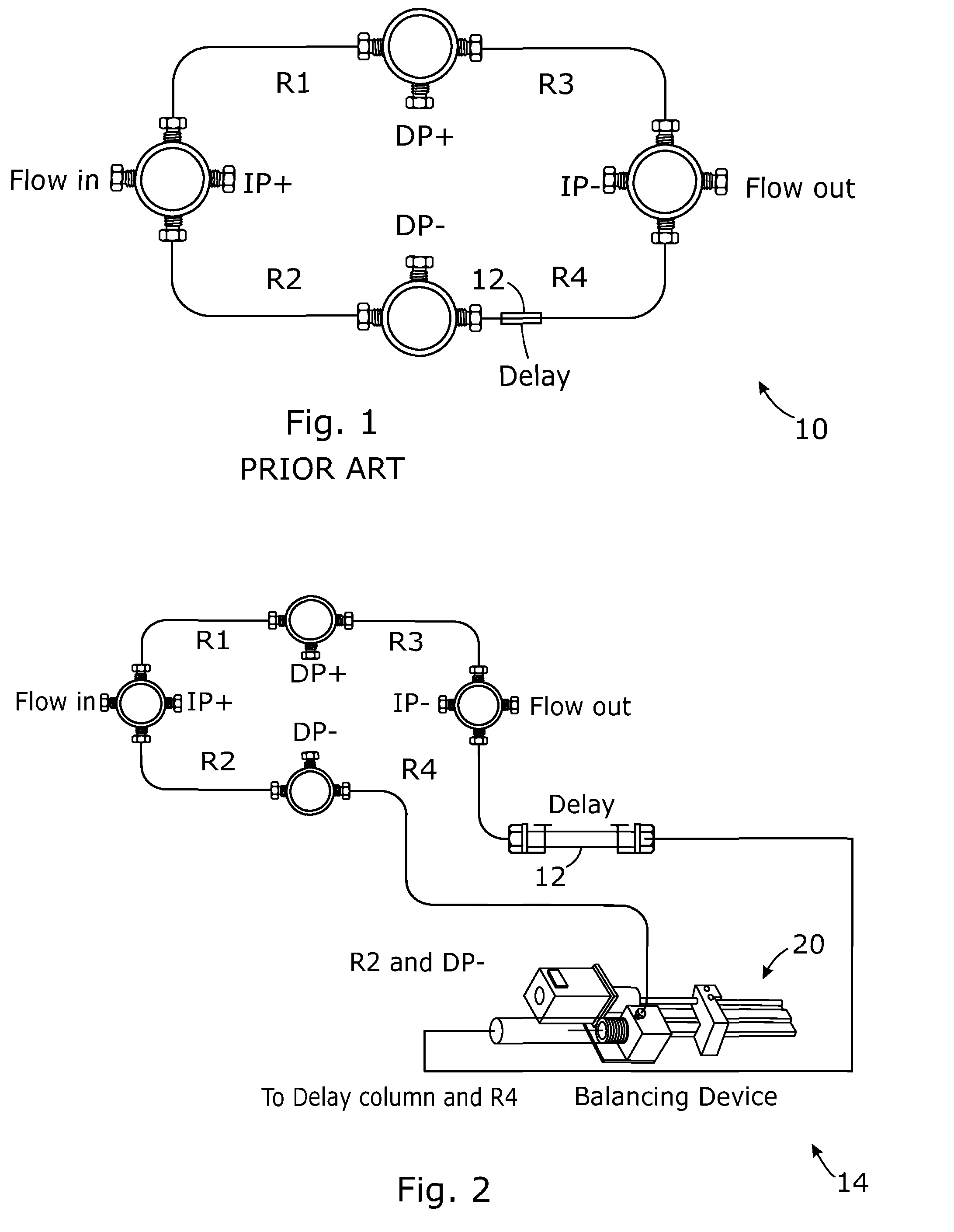

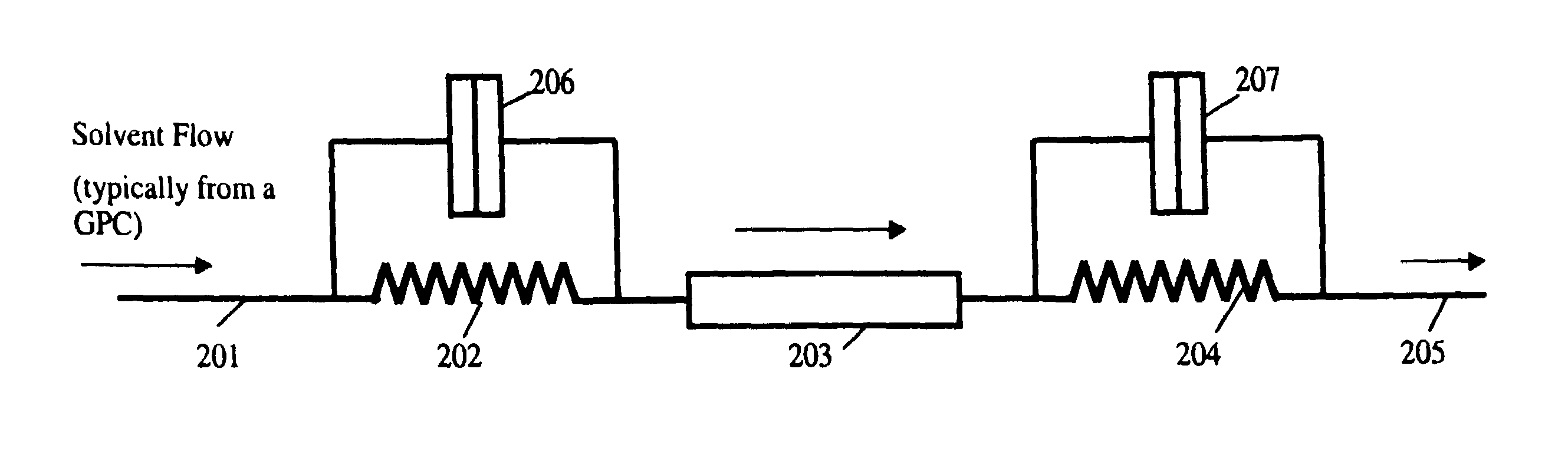

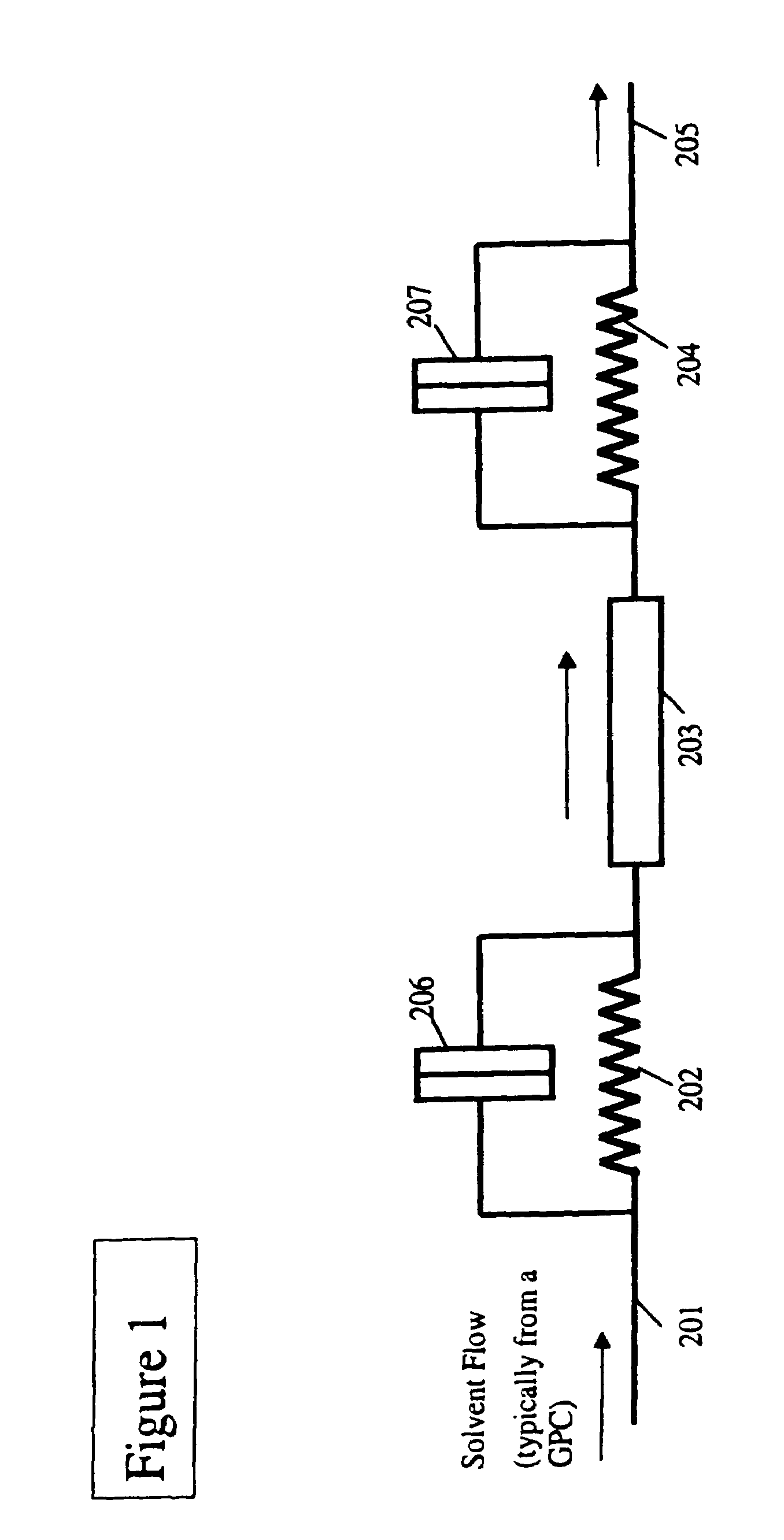

Balanced capillary bridge viscometer

ActiveUS20140144214A1Flow control without auxillary powerViscometer maintainanceCapillary bridgesCapillary Tubing

A capillary bridge viscometer, comprises an input port (flow in) an output port (flow out) a first capillary tubing arm (R1) in a first hydraulic path between the input port and a first differential detection point (DP+), a second capillary tubing arm (R3) in a second hydraulic path between the first differential detection point (DP+) and the output port (flow out), a third capillary tubing arm (R2) in a third hydraulic path between the input port (flow in) and a second differential detection point (DP−), a fourth capillary tubing arm (R4) in a fourth hydraulic path between the second differential detection point (DP−) and the output port (flow out), an adjustable mechanical flow restrictor (20) in one of the first, second, third, and fourth hydraulic paths, wherein the adjustable mechanical flow restrictor (20) is operative to mechanically adjust a resistance to flow of a fluid while the fluid flows through the adjustable mechanical flow restrictor.

Owner:MALVERN PANALYTICAL INC

Apparatus and method for eliminating the breakthrough peak in differential detectors

Owner:MALVERN INSTRUMENTS

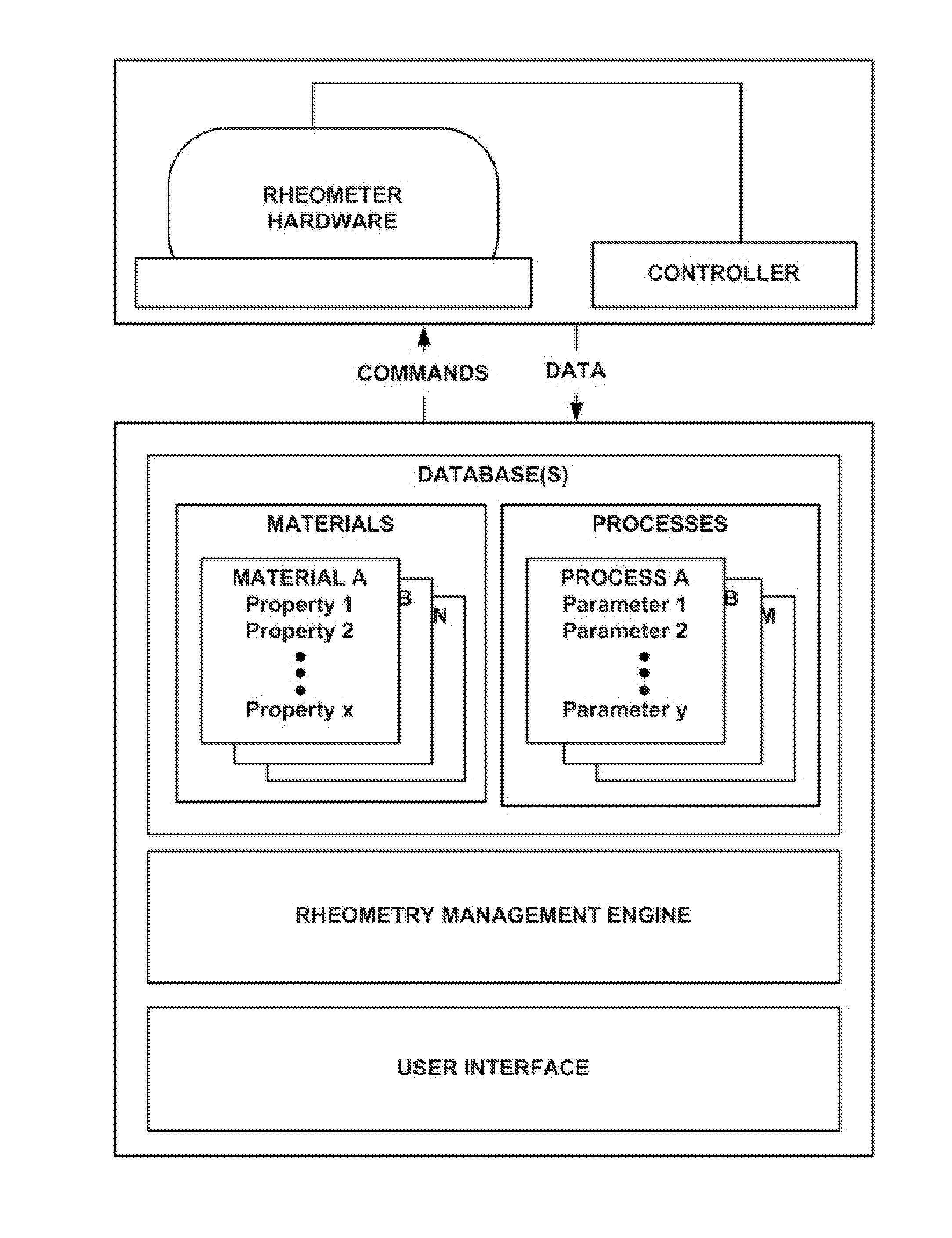

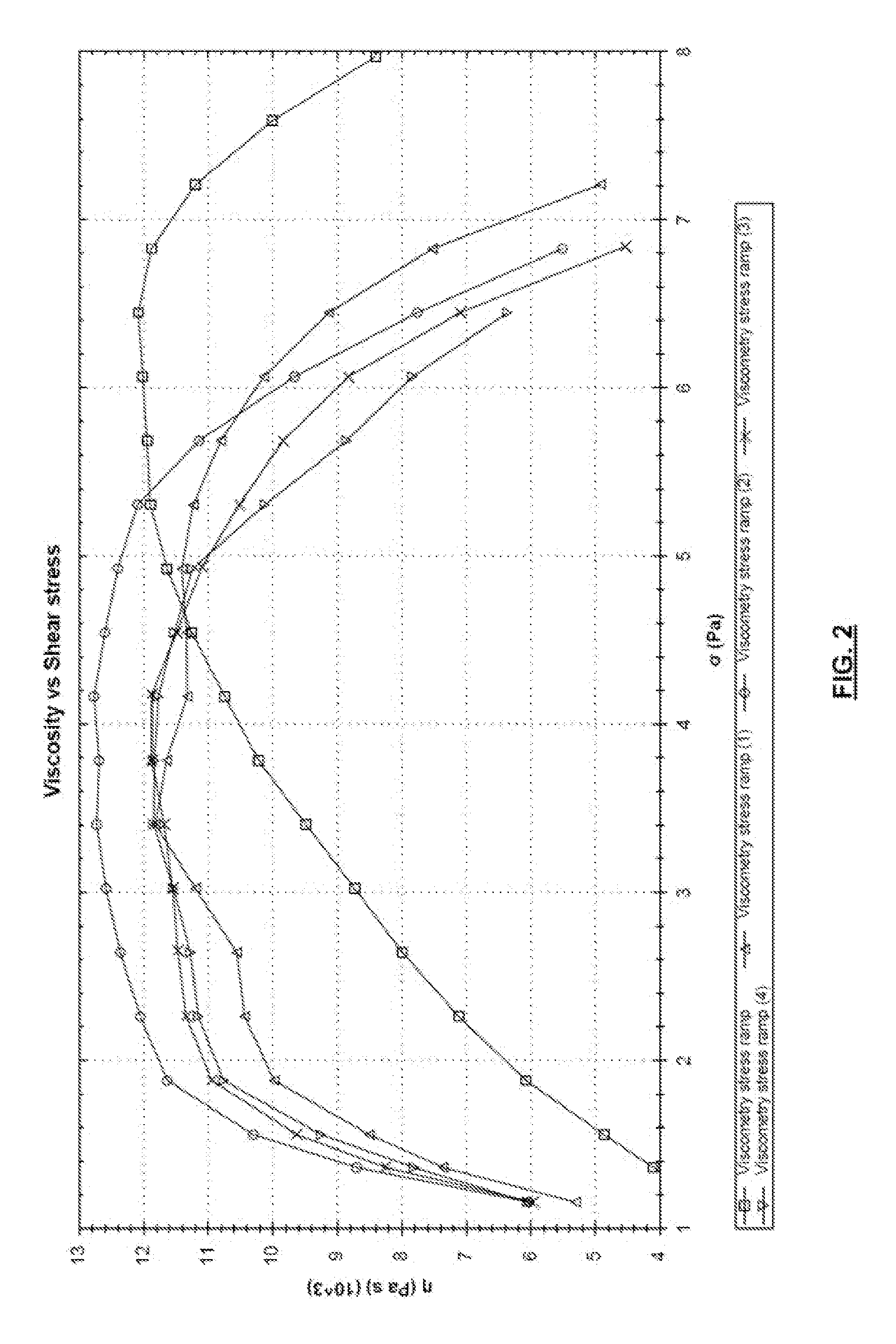

Expert-system-based rheology

A rheometer is disclosed that includes rheometry logic that is responsive to a material selection control, to an objective selection control, to material property storage, and to process parameter storage, and is operative to assist the user with a measurement using the rheometer. In another general aspect, a rheometer includes sample history storage operative to store a history that spans a plurality of different operations performed by the rheometer on a same sample.

Owner:NETZSCH GERATEBAU GMBH

Methods of mixing impeller sensing

ActiveUS10112162B2Accurate valueShorten speedBioreactor/fermenter combinationsBiological substance pretreatmentsImpellerEngineering

A method is provided for monitoring a flow behavior of mixed components without requiring additional instrumentation or sampling. The method is carried out by determining ratios of the power required to rotate a mixing impeller at different rotational speeds and then comparing the ratios. Characteristics about the mixed components are determined based on differences between the ratios.

Owner:SARTORIUS STEDIM BIOTECH GMBH

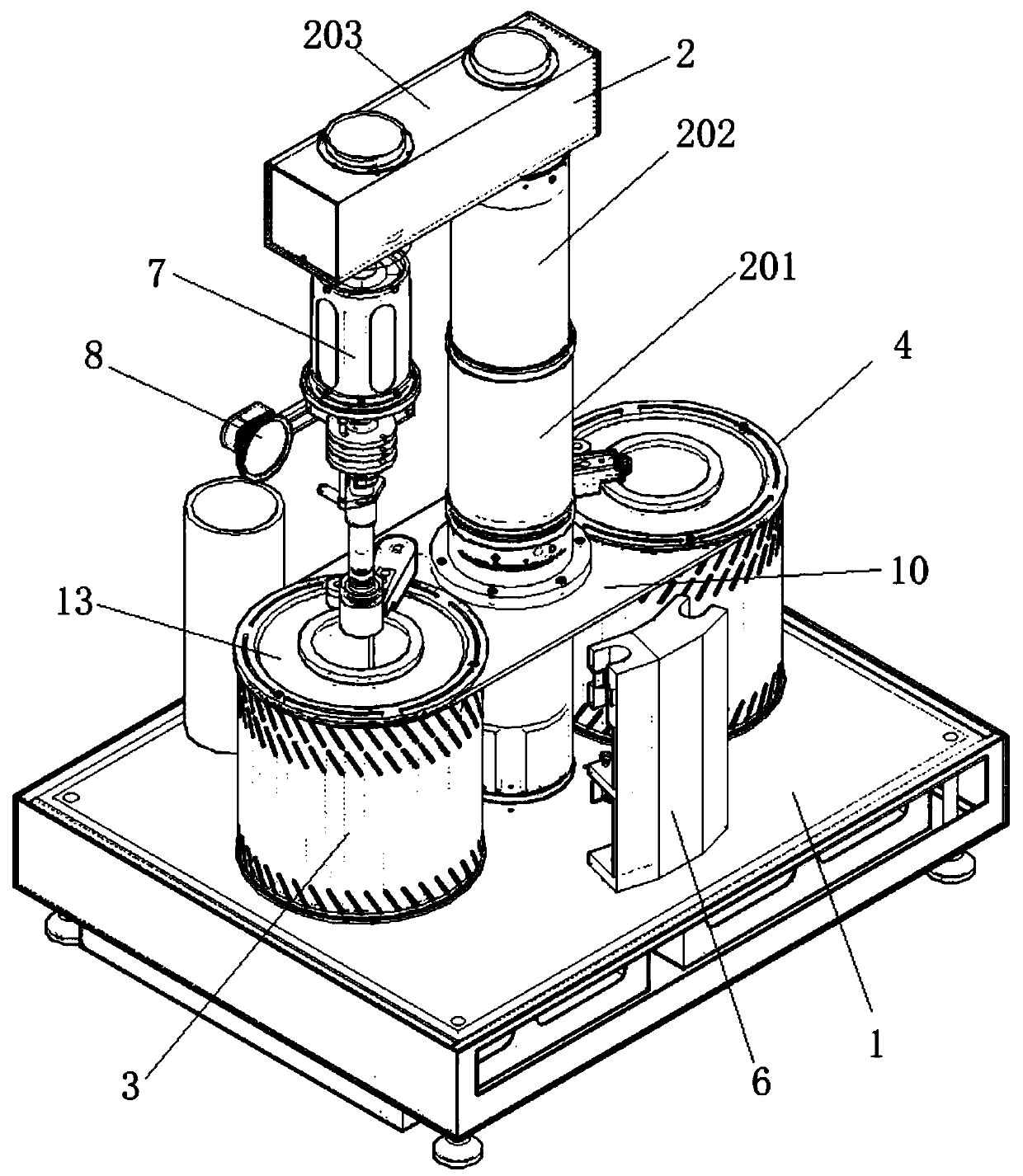

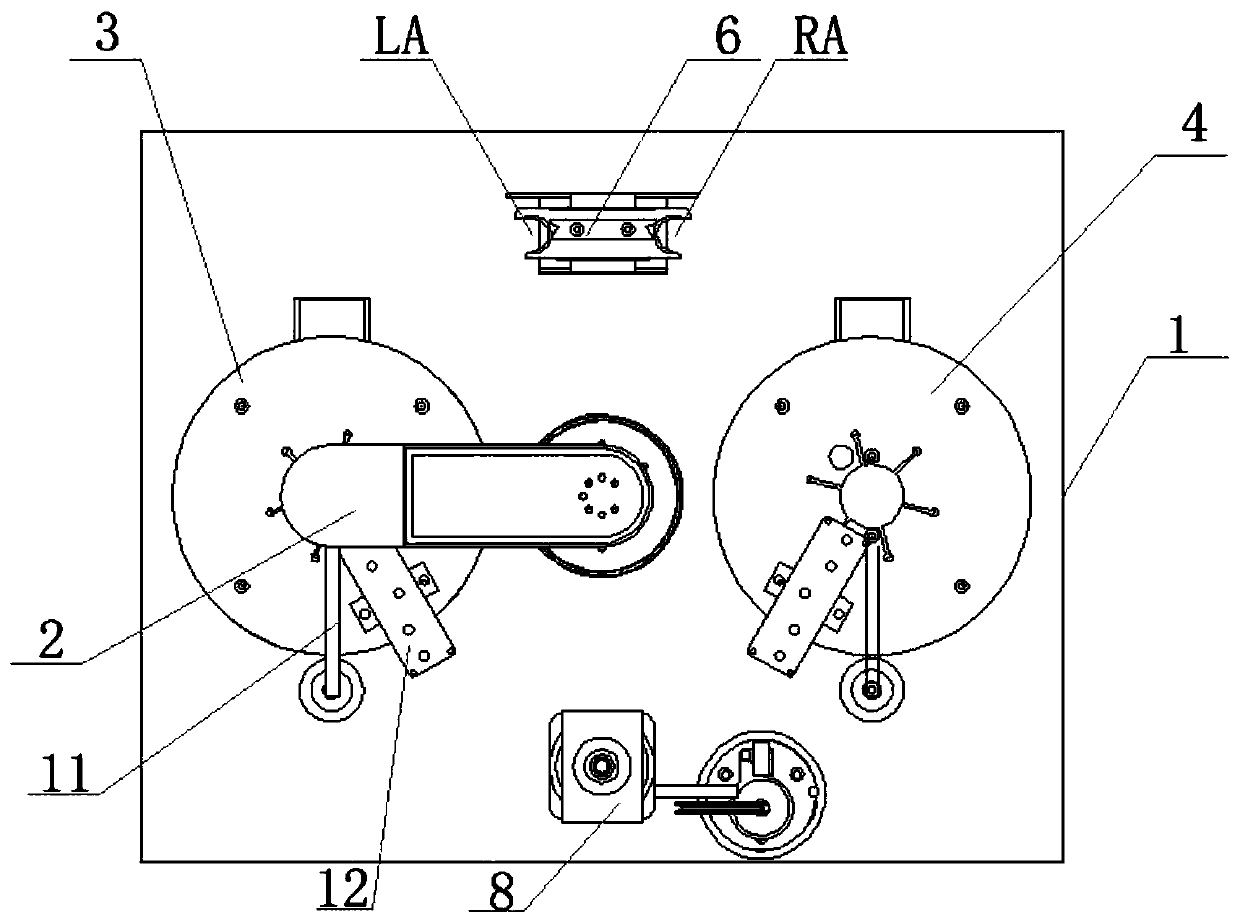

Intelligent Gieseler fluidity tester

PendingCN111307665AImprove reliabilityHigh degree of automationUsing optical meansViscometer maintainanceControl systemDrive shaft

The invention relates to an intelligent Gieseler fluidity tester which comprises a base, a mechanical arm, a heating furnace I, a heating furnace II, a constant torque transmission device, a steamingrack device and a control system, wherein the heating furnace I and the heating furnace II are arranged on the base, the mechanical arm is arranged between the heating furnace I and the heating furnace II and is formed by sequentially connecting a rotating arm, a lifting arm and a horizontal arm, the constant-torque transmission device is arranged on the horizontal arm, and a transmission shaft inthe constant-torque transmission device is in butt joint with a stirring shaft in a coal steamer; the heating furnace I and the heating furnace II are arranged on a rotating path of the horizontal arm, a retort frame device is further arranged on the rotating path of the horizontal arm, and coal retort clamping and sleeving positions are arranged on the two sides of the retort frame device respectively and used for containing coal retorts; the control system is used for coordination control of the mechanical arm, the first heating furnace, the second heating furnace, the constant-torque transmission device and the steaming rack device. The invention has the characteristics of high reliability, high automation degree, high working efficiency and high experimental precision, and can bettermeet the requirements of modern coking or iron and steel enterprises.

Owner:ANSHAN S Y D SCI & TECH

Rheometer

InactiveUS7194895B2Accurate measurementFluid pressure measurement by mechanical elementsMachines/enginesRheometryThermal expansion

A rheometer and method of making rheological measurements is disclosed, in which a sample is supported between plates and an alternating movement is applied by a driver, support rod and plate. Force and displacement measurements are taken and the property determined from those measurements. The vibrating signal which is applied is in the form of a frequency sweep signal having a monotonic group delay function. The top plate is provided with a surface which causes a meniscus to form up a side edge of the plate to reduce the spring nature of the sample when the movement is supplied to the sample, and a supporting rod which supports the top plate is preferably formed from a material having a low coefficient of thermal expansion so that the gap between the plates is maintained substantially constant if the sample is heated to take measurements at different temperatures.

Owner:GBC SCI EQUIP

Popular searches

Fuel injecting pumps Fuel injection control Special data processing applications Material analysis by using resonance Electric/magnetic detection Acoustic wave reradiation Material analysis by optical means Input/output processes for data processing Direct mass flowmeters Transportation and packaging

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com