Device for online detection of oil product density and viscosity

A temperature detection device and technology of detection device, which are used in measurement devices, viscometer maintenance, specific gravity measurement, etc., can solve the problem of rising production costs, inability to monitor the operation of oil in use in real time, and difficulty in simultaneous measurement of density and viscosity, etc. problems, to achieve the effect of saving losses, advanced preventive maintenance, and achieving preventive maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

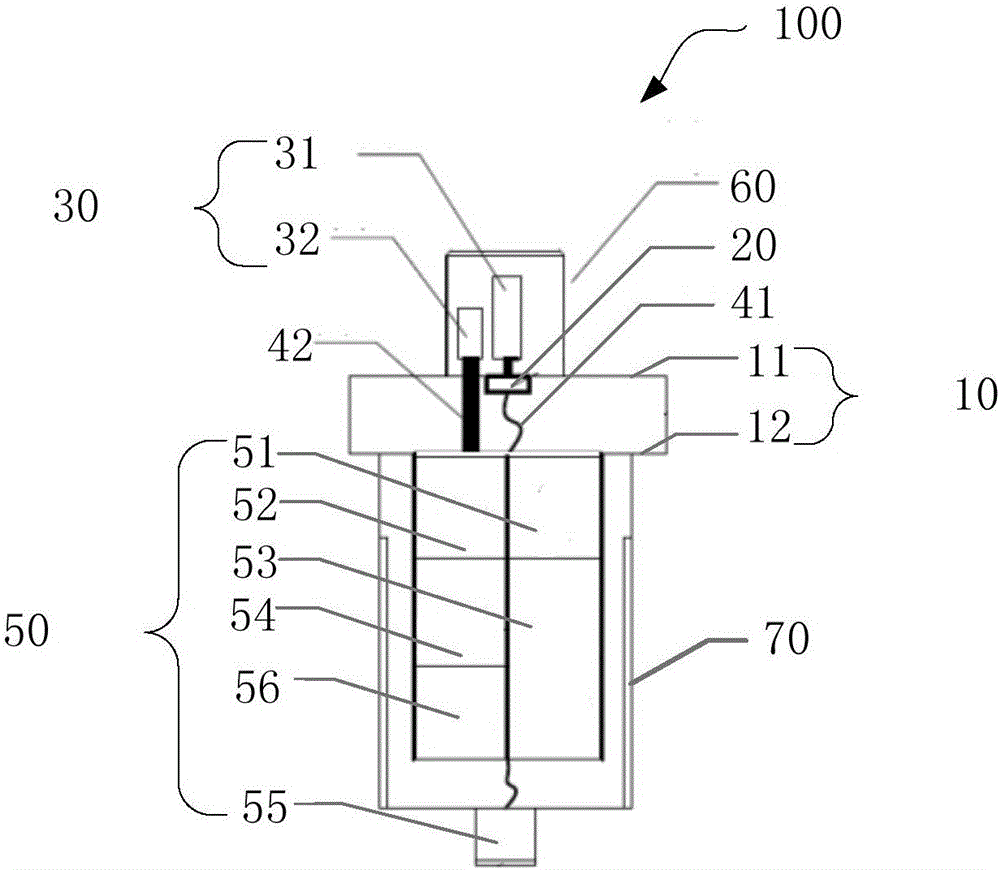

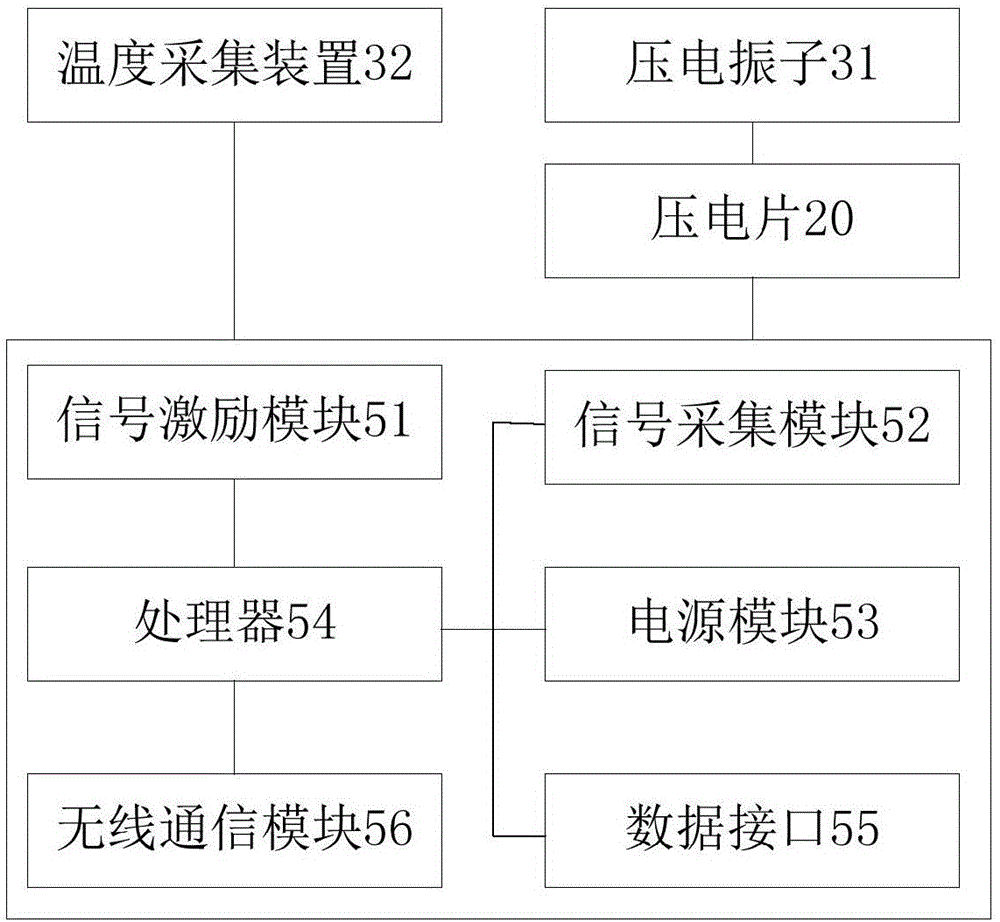

[0041] figure 1 with figure 2 A schematic structural diagram and a schematic module diagram of the online detection device for oil product density and viscosity provided by the embodiment of the present invention are respectively shown.

[0042] Please also refer to figure 1 with figure 2 As shown, an online oil density and viscosity detection device 100 provided by an embodiment of the present invention includes an electrode sealing shell 10 , a piezoelectric film 20 , a detection unit 30 and a processing unit 50 . The piezoelectric sheet 20 is disposed inside the electrode sealing case 10 , and the detection unit 30 and the processing unit 50 are respectively disposed on opposite ends of the electrode sealing case 10 .

[0043] The electrode sealing case 10 may be a cube or a cylinder with a hollow cavity. The electrode sealing case 10 includes a first end surface 11 and a second end surface 12 opposite to each other.

[0044]The piezoelectric sheet 20 is a piezoelect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com