Intelligent vacuum contactor

A vacuum contactor, intelligent technology, applied in high-voltage air circuit breakers, electrical components, electrical switches, etc., can solve the problems of complex process, temperature rise, increased safety risks, etc., to achieve compact volume space, easy installation, lightening product The effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

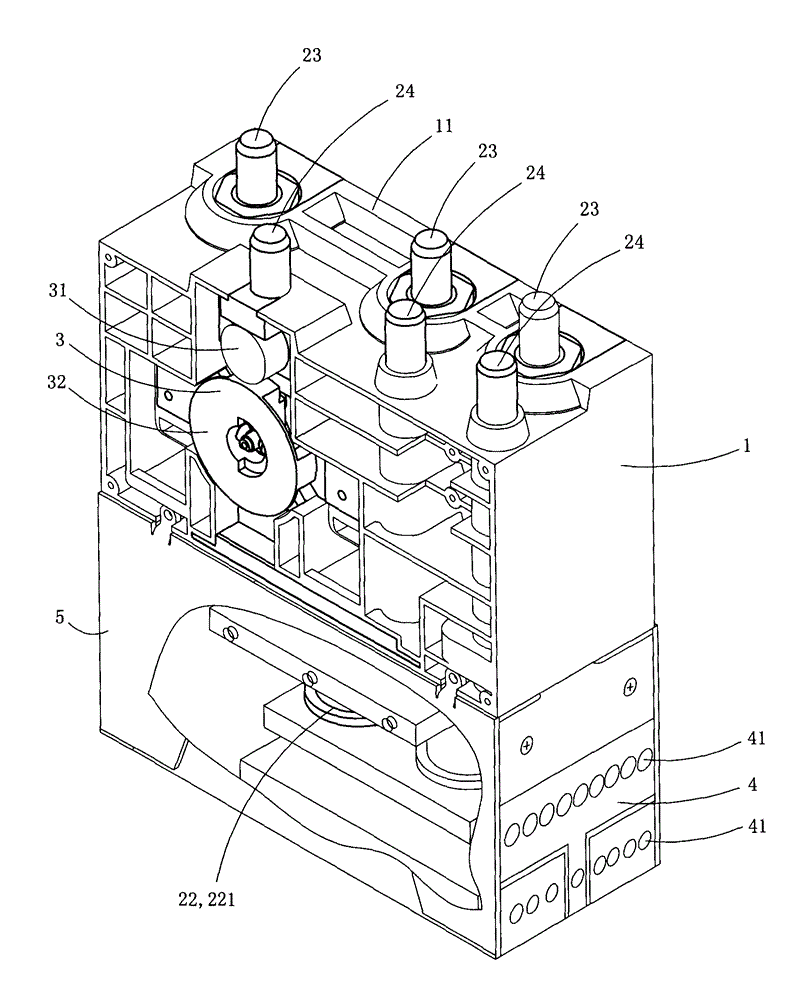

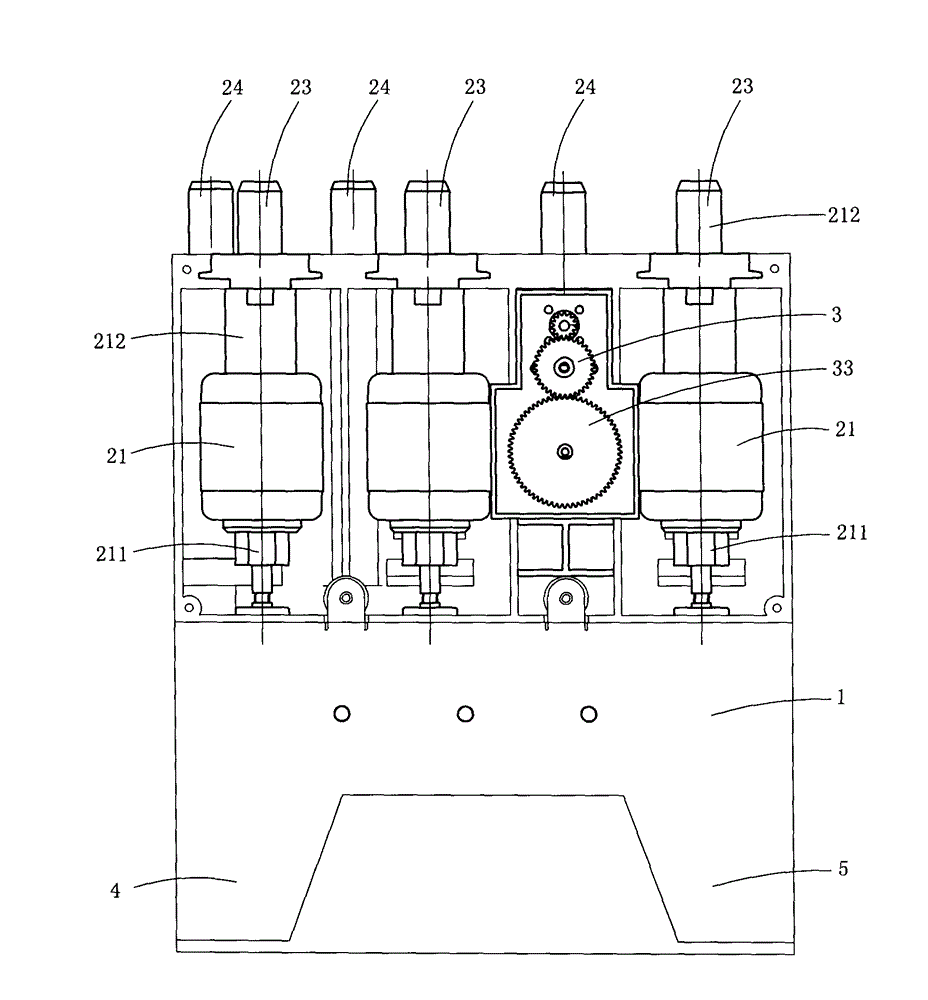

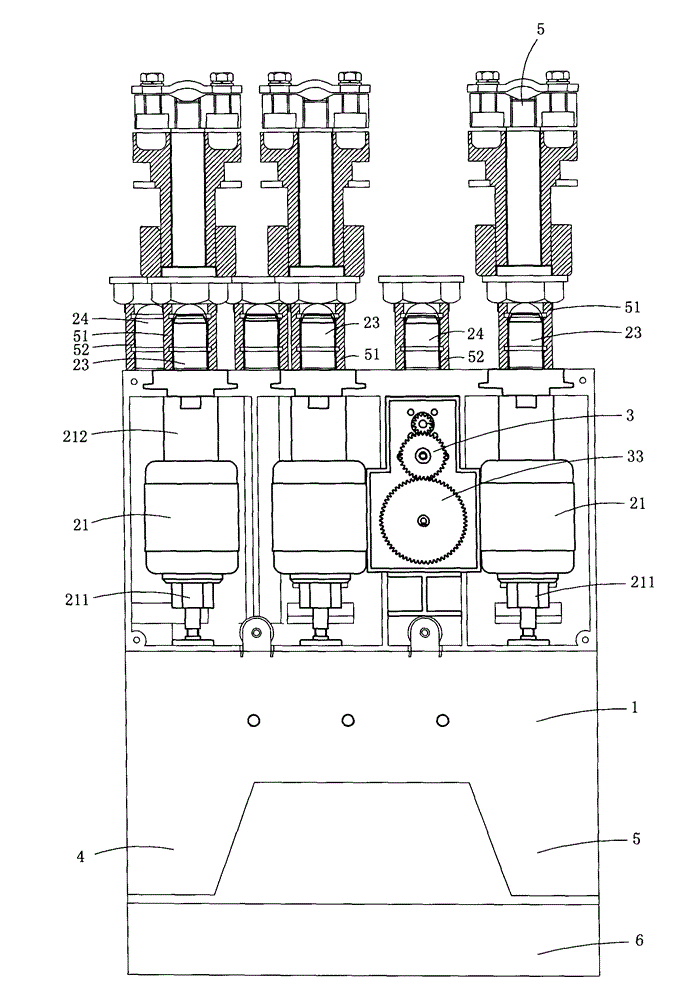

[0013] figure 1 and figure 2 A specific embodiment of the invention is shown in which figure 1 It is a schematic diagram of a three-dimensional structure of the present invention; figure 2 yes figure 1 A schematic diagram of the structure of the vacuum contactor shown when viewed from the other side.

[0014] This embodiment discloses an intelligent vacuum contactor, see figure 1 and figure 2 As shown, it includes a frame 1, a vacuum contactor 2, an electric reversing mechanism 3 and a comprehensive protector 4 arranged on the frame; the vacuum contactor, the electric reversing mechanism and the comprehensive protector are integrated through the frame.

[0015] The frame is preferably made of bakelite or reinforced nylon.

[0016] The vacuum contactor includes three vacuum switch tubes 21 arranged along the plumb line and a permanent magnet operating mechanism 22 arranged below the vacuum switch tubes. The permanent magnet operating mechanism drives the moving parts i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com