Transformer device and measurement system formed therewith

A transducer and equipment technology, applied in the direction of specific gravity measurement, measurement capacity, measurement device, etc., can solve problems such as measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

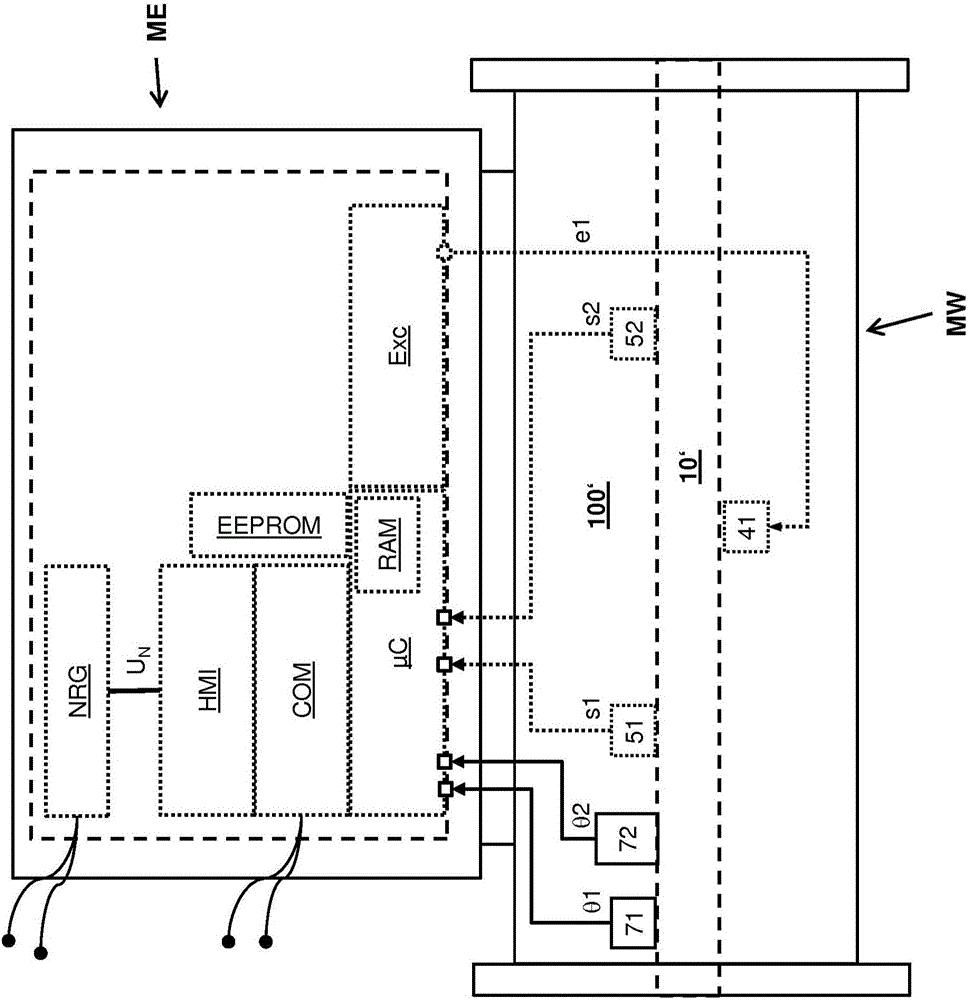

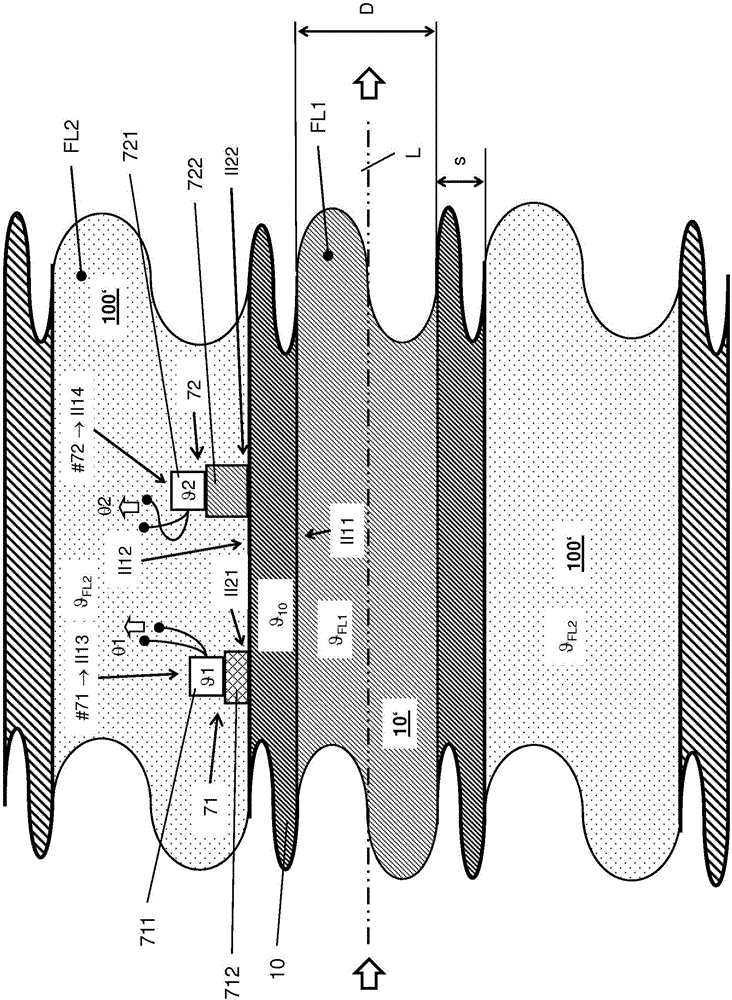

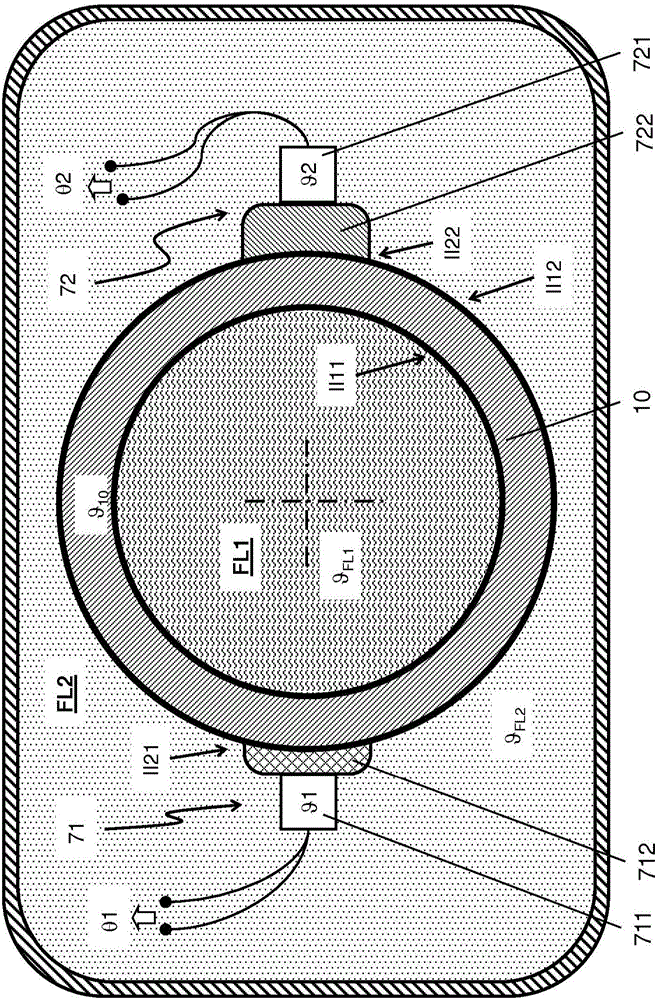

[0054] figure 1 Schematic illustration for measuring fluid temperature with a measurement A measurement system of at least one measured variable x (which may be a time variable in a given case) of a flow fluid FL1 (measurement fluid) such as a gas, liquid or flowable diffuser. The measuring system is used to cyclically determine the measured value X that instantaneously represents the measured variable x . The measured variable x can be, for example, density or viscosity and is thus a measured variable that has a certain correlation with the corresponding measured fluid temperature and / or is converted into the corresponding measured value x x In the case of transducer devices, temperature-dependent measurement errors are caused. However, the measured variable can also be, for example, a temperature of interest (hereinafter also referred to as target temperature) at a device reference point (poi) predetermined for the measurement system and located within the transducer dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific heat capacity | aaaaa | aaaaa |

| heat capacity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com