Intelligent Gieseler fluidity tester

A technology of Gibbs fluidity and measuring instruments, which is applied in the direction of flow characteristics, instruments, measuring devices, etc., can solve the problems of unfriendly data exchange in the automation system, high technical level requirements for personnel, poor scientificity and reliability, etc., and achieve remote control. The effect of intelligent collaborative operation, lower requirements for operation skills, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

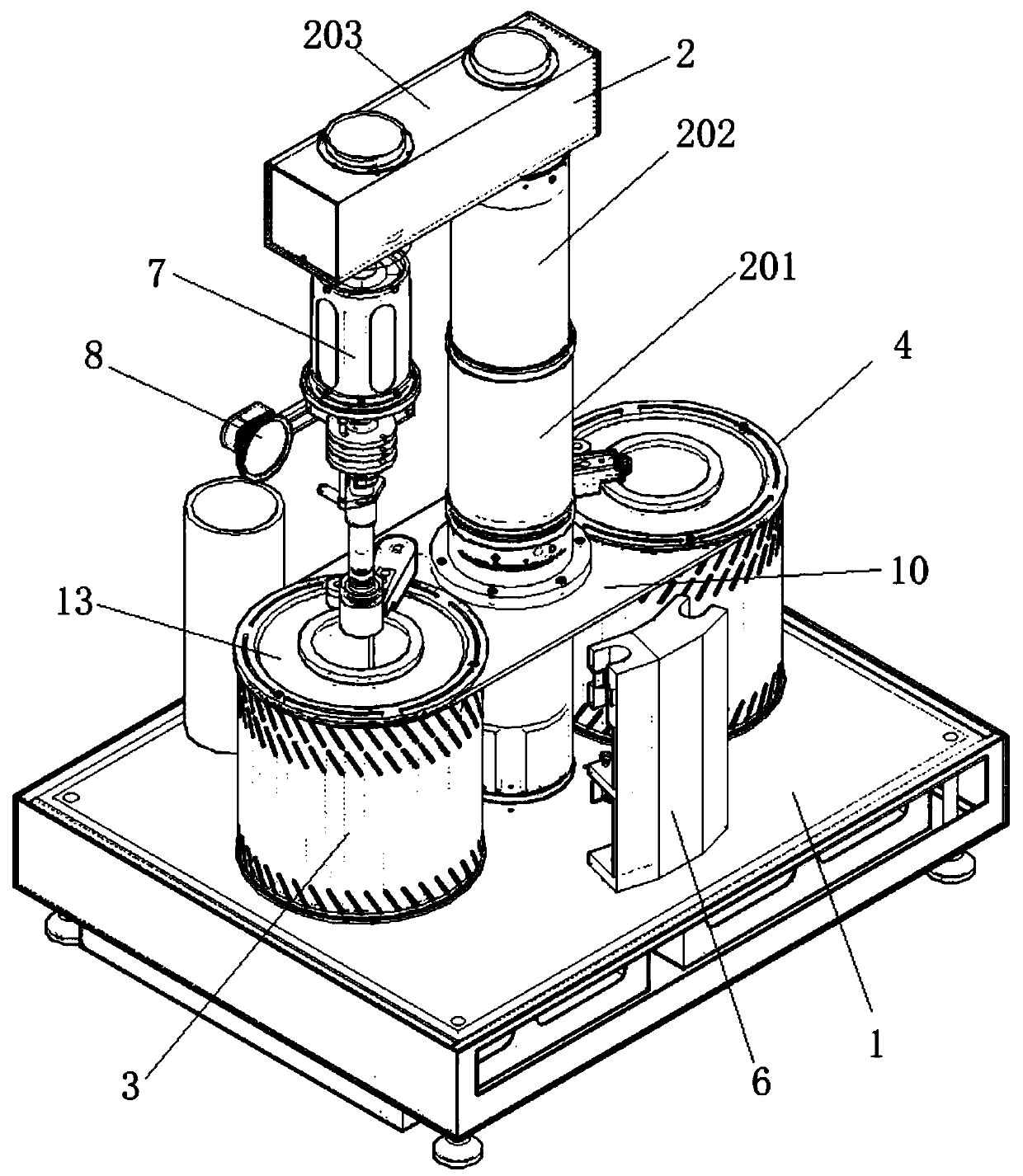

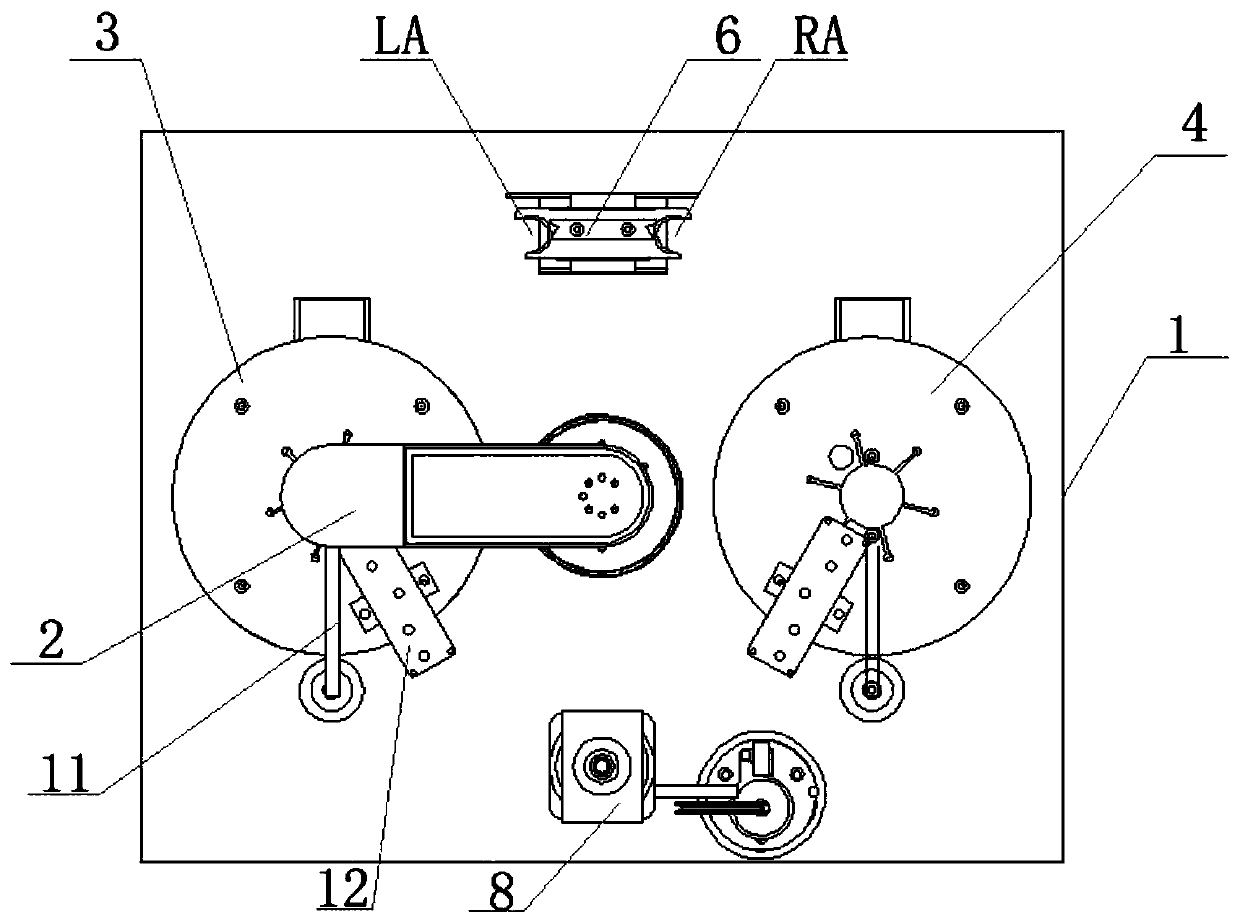

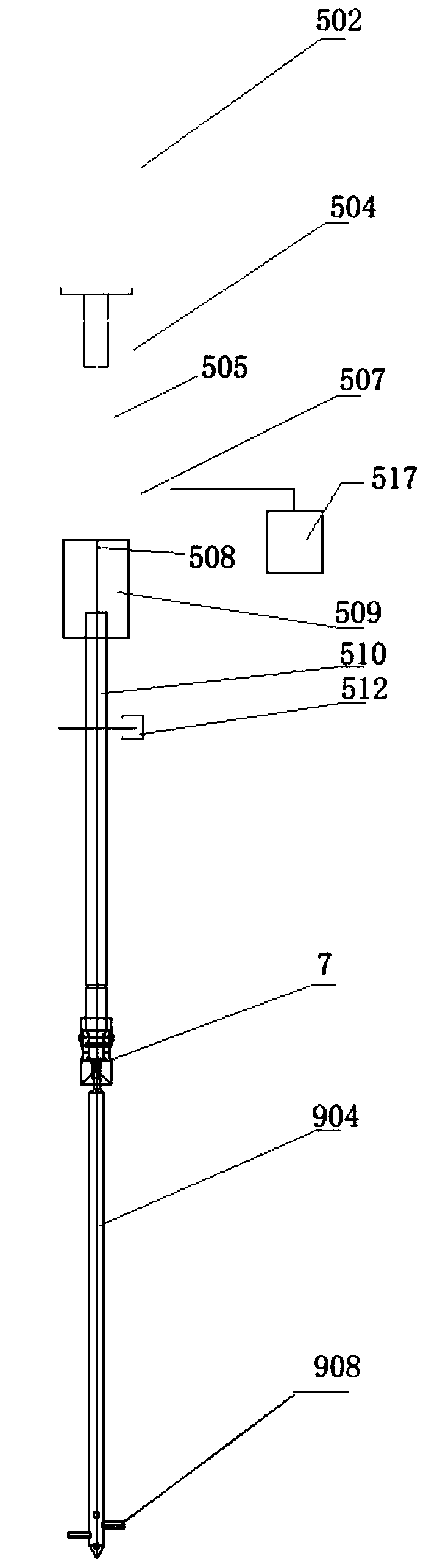

[0044] like figure 1 , figure 2 As shown, a kind of intelligent Gibberer fluidity tester of the present invention comprises a base 1, a mechanical arm 2, a heating furnace 3, a heating furnace 4, a constant torque transmission device 5, a retort device 6 and a control system; The first heating furnace 3 and the second heating furnace 4 are arranged on the base 1, and the mechanical arm 2 is arranged between the first heating furnace 3 and the second heating furnace 4. Connection composition, the rotating arm 201 drives the lifting arm 202 and the horizontal arm 203 to rotate horizontally, the lifting arm 202 drives the horizontal arm 203 to lift vertically; the constant torque transmission device 5 is arranged on the horizontal arm 203, and the constant torque transmission device 5 is provided with a transmission shaft 510 , the stirring paddle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com