Patents

Literature

114results about "Flow properties on non-Newtonian fluids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

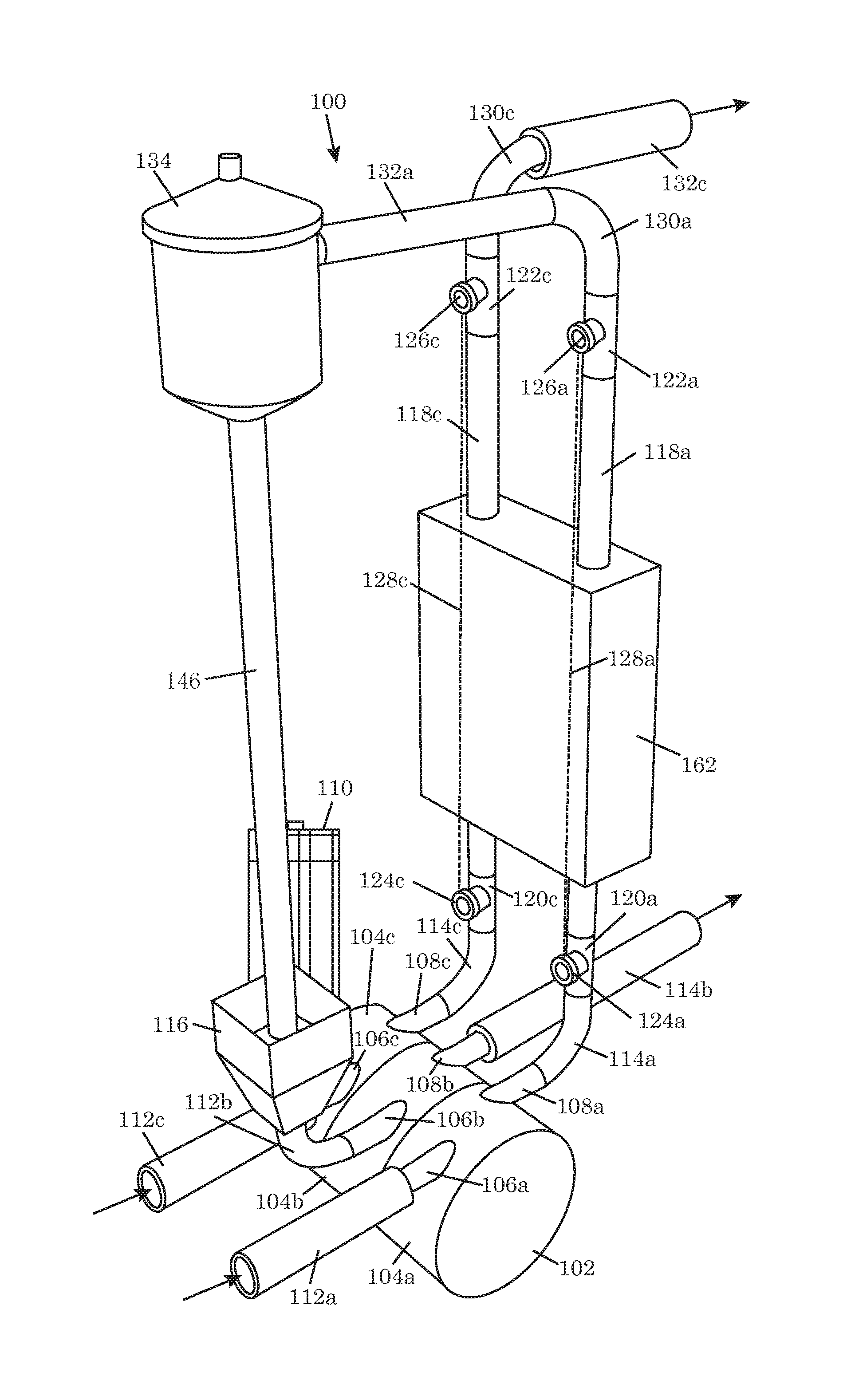

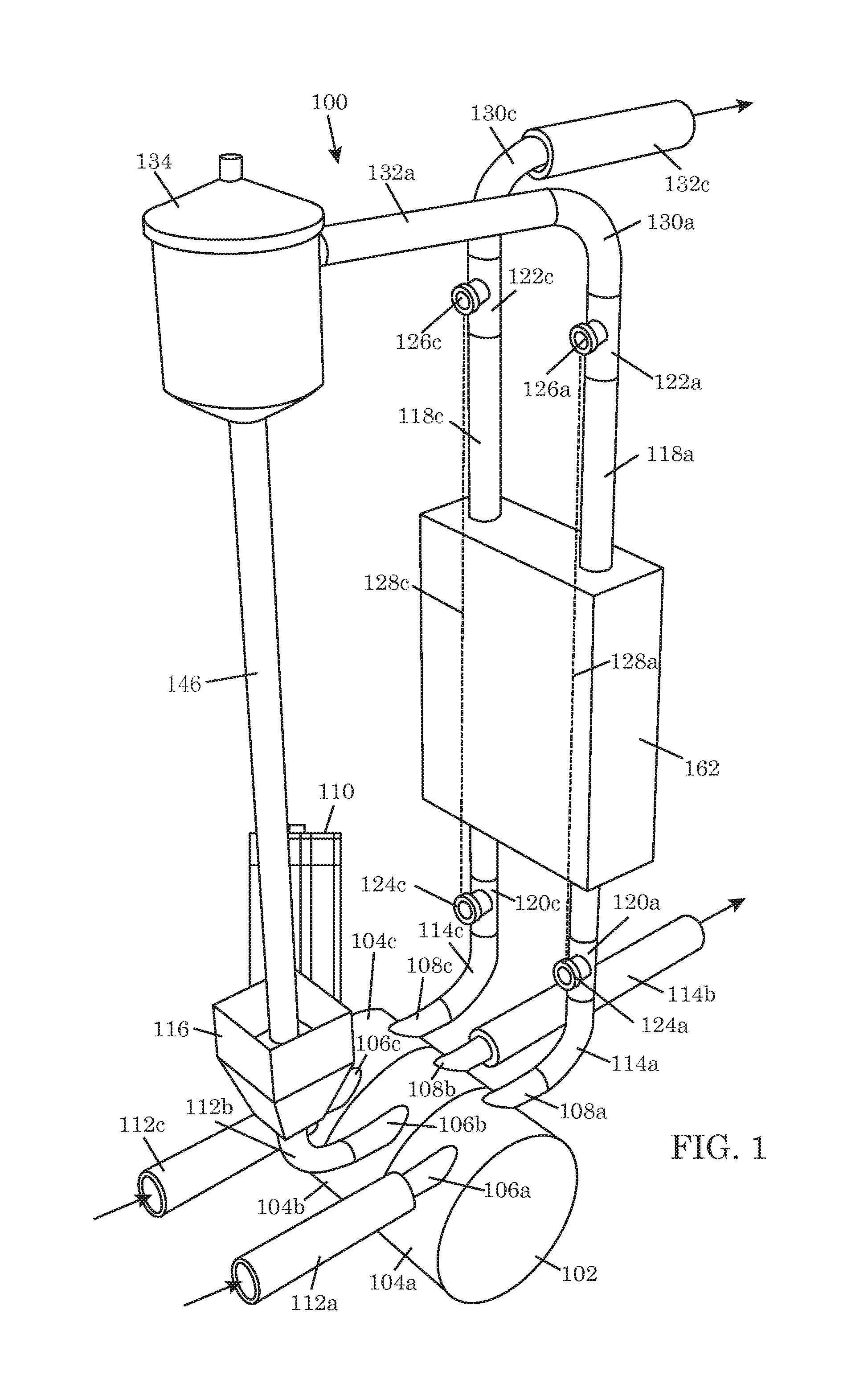

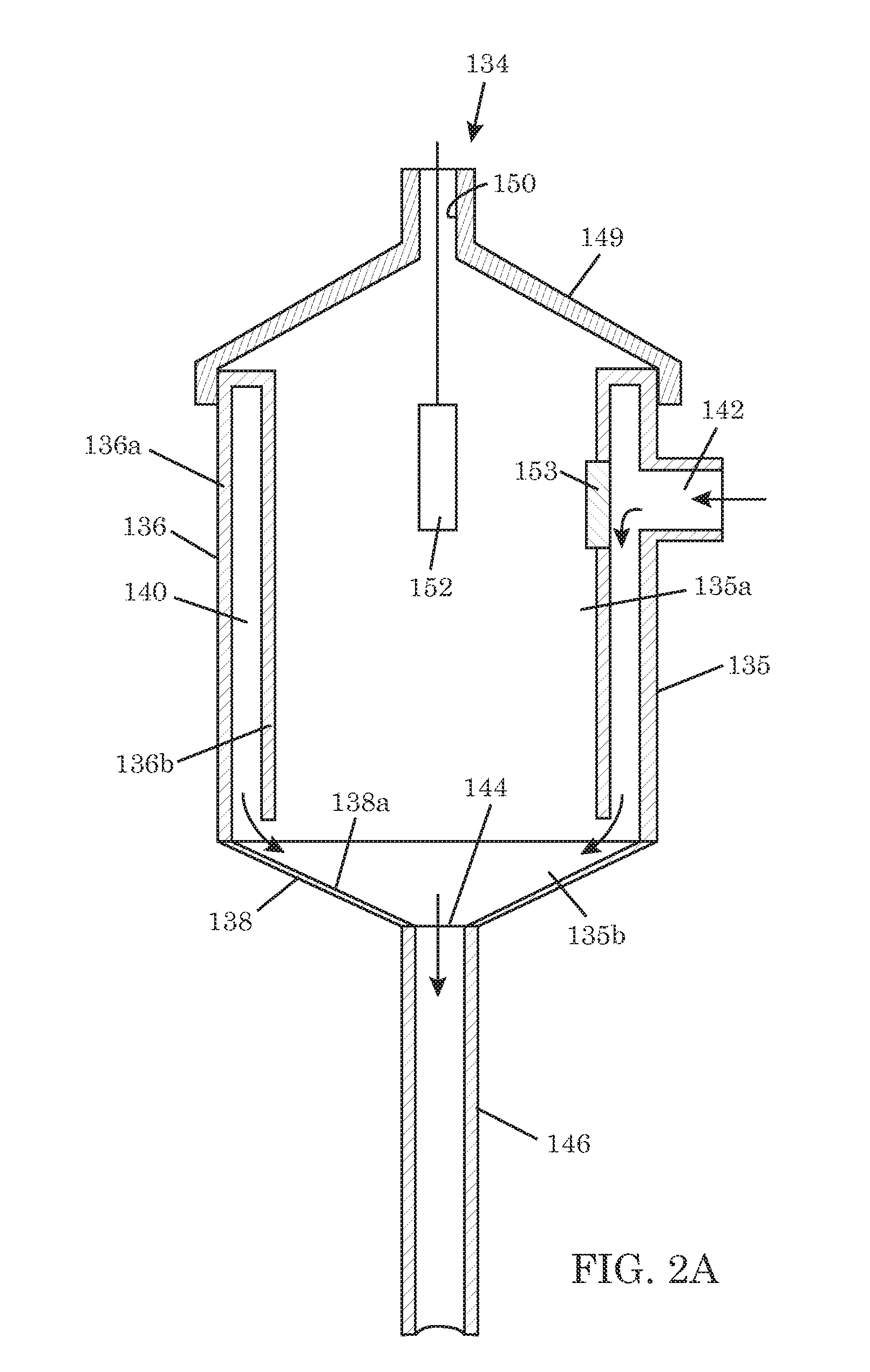

Method and apparatus for measuring drilling fluid properties

As system for measuring drilling fluid properties includes a capillary rheometer that is adapted to measure viscosity parameters of drilling fluid. The capillary rheometer includes a feed chamber, the feed chamber having a cavity, at least a first drain port for draining fluid out of the cavity, a double wall defining an annulus that opens to the cavity, and a feed port in an outer portion of the double wall that is in fluid communication with the annulus. The capillary rheometer also includes at least a first capillary tube coupled to at least the first drain port. Additionally, the disclosed system further includes a pump that is adapted to pump fluid to the feed port.

Owner:NAT OILWELL VARCO LP

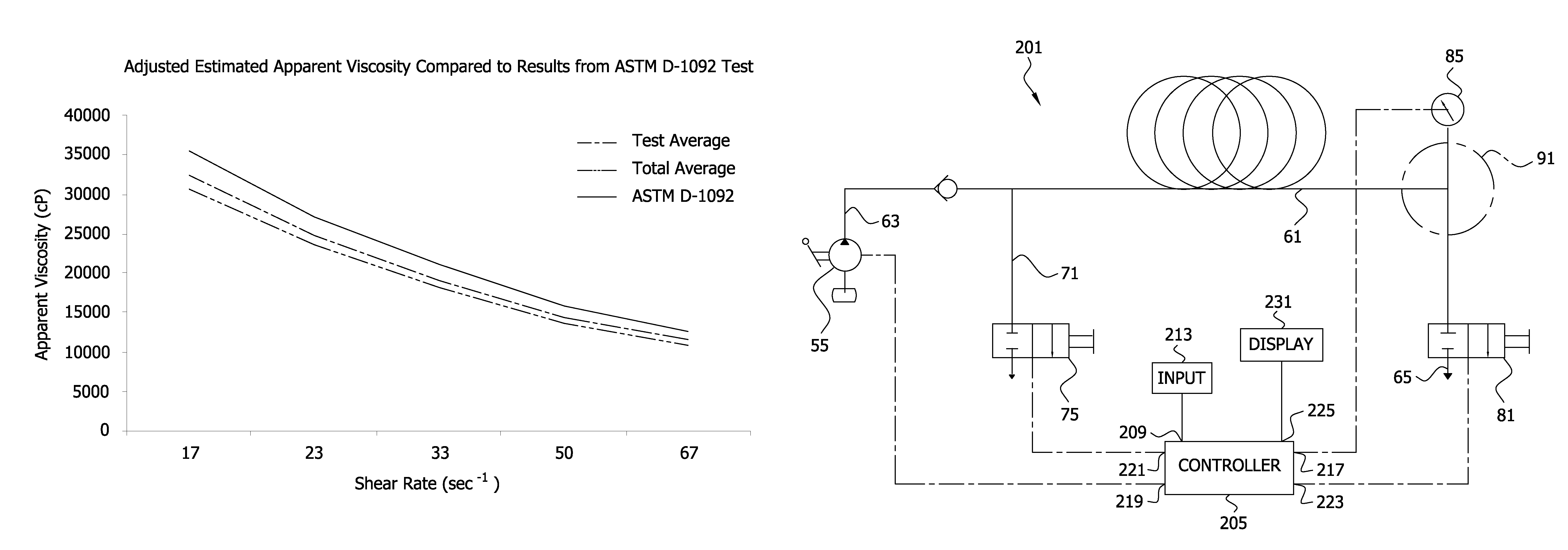

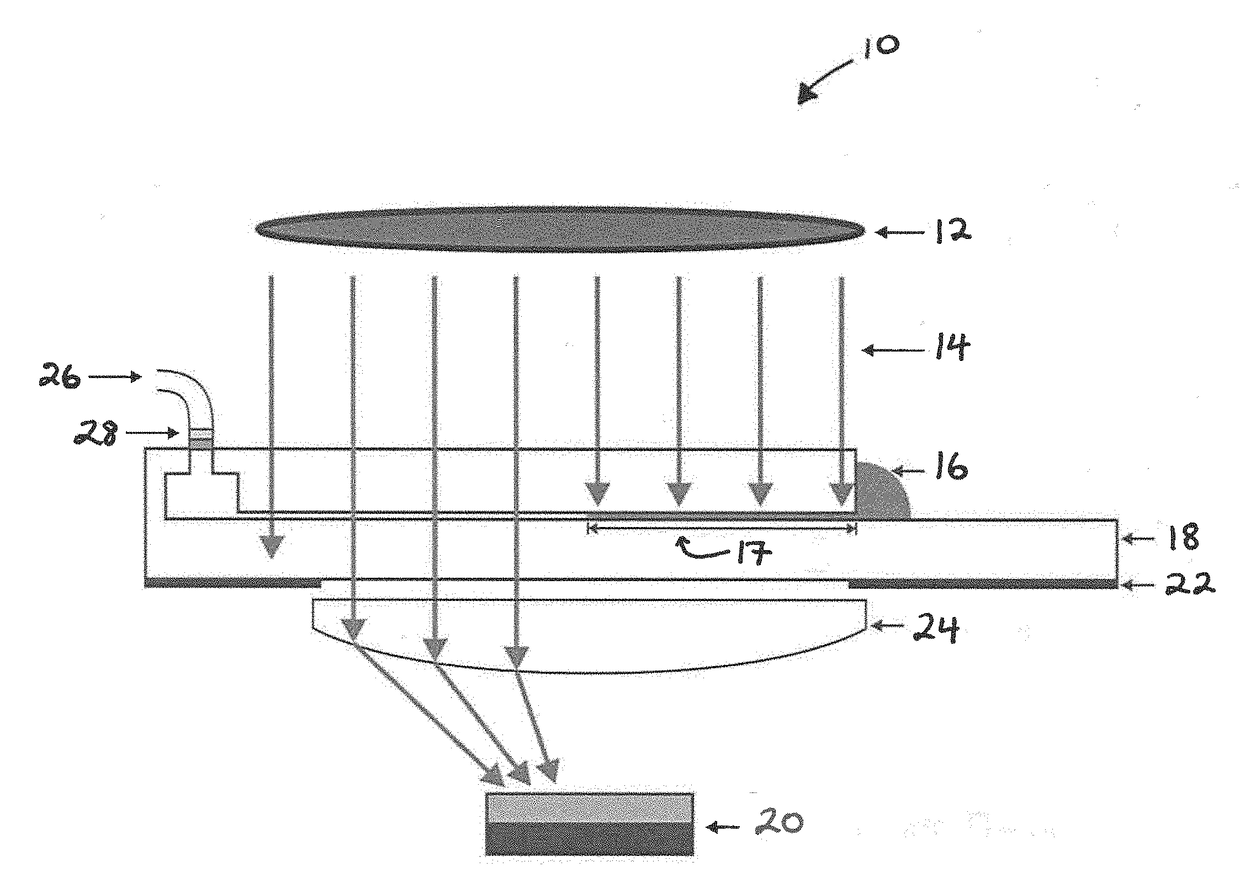

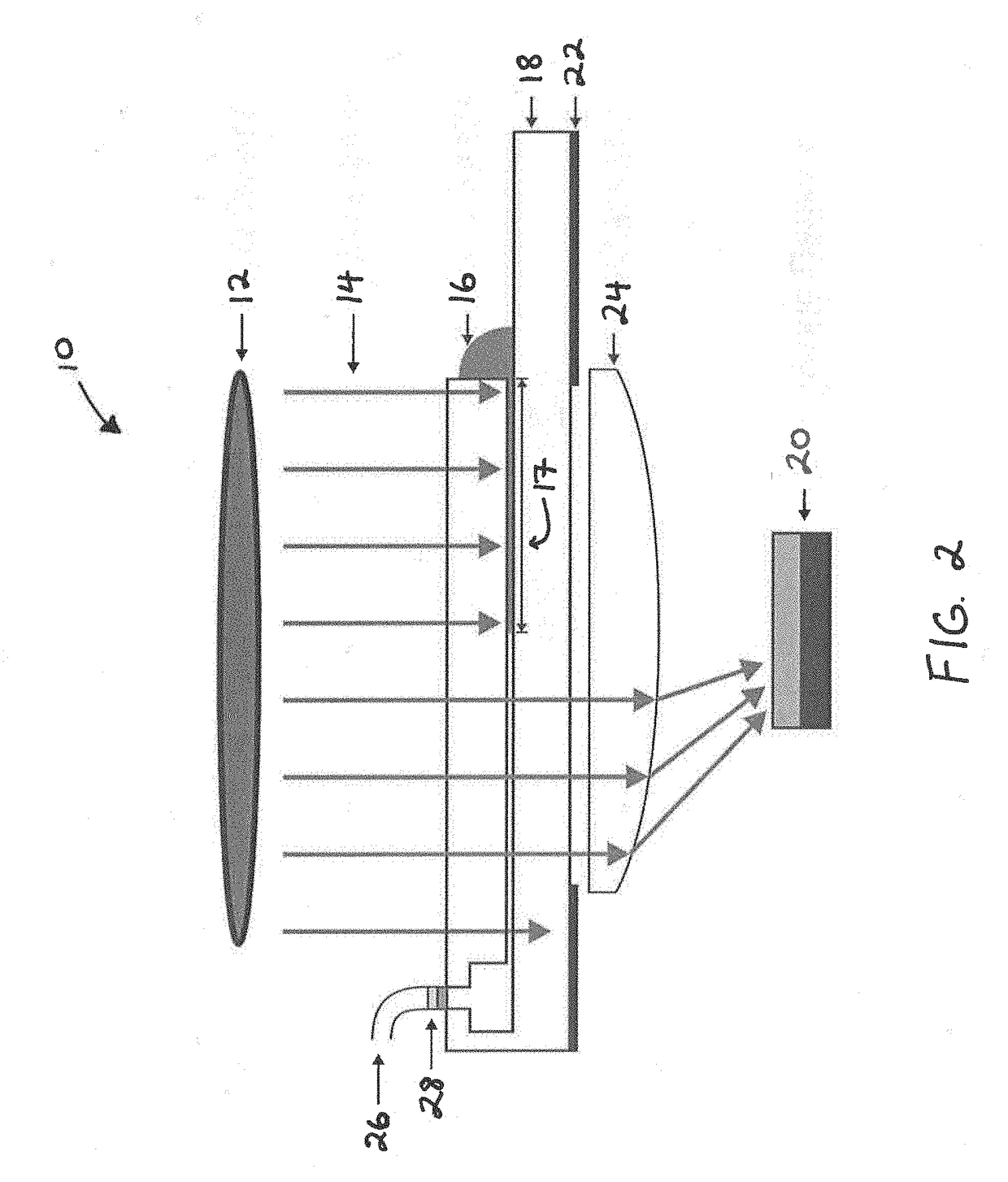

System and method for estimating apparent viscosity of a non-newtonian fluid

ActiveUS7980118B2Material analysis by optical meansFlow properties on non-Newtonian fluidsApparent viscosityNon-Newtonian fluid

Method and apparatus for estimating an apparent viscosity of a non-Newtonian fluid. The results may be used for selecting equipment for pumping systems.

Owner:LINCOLN INDUSTRIES CORP

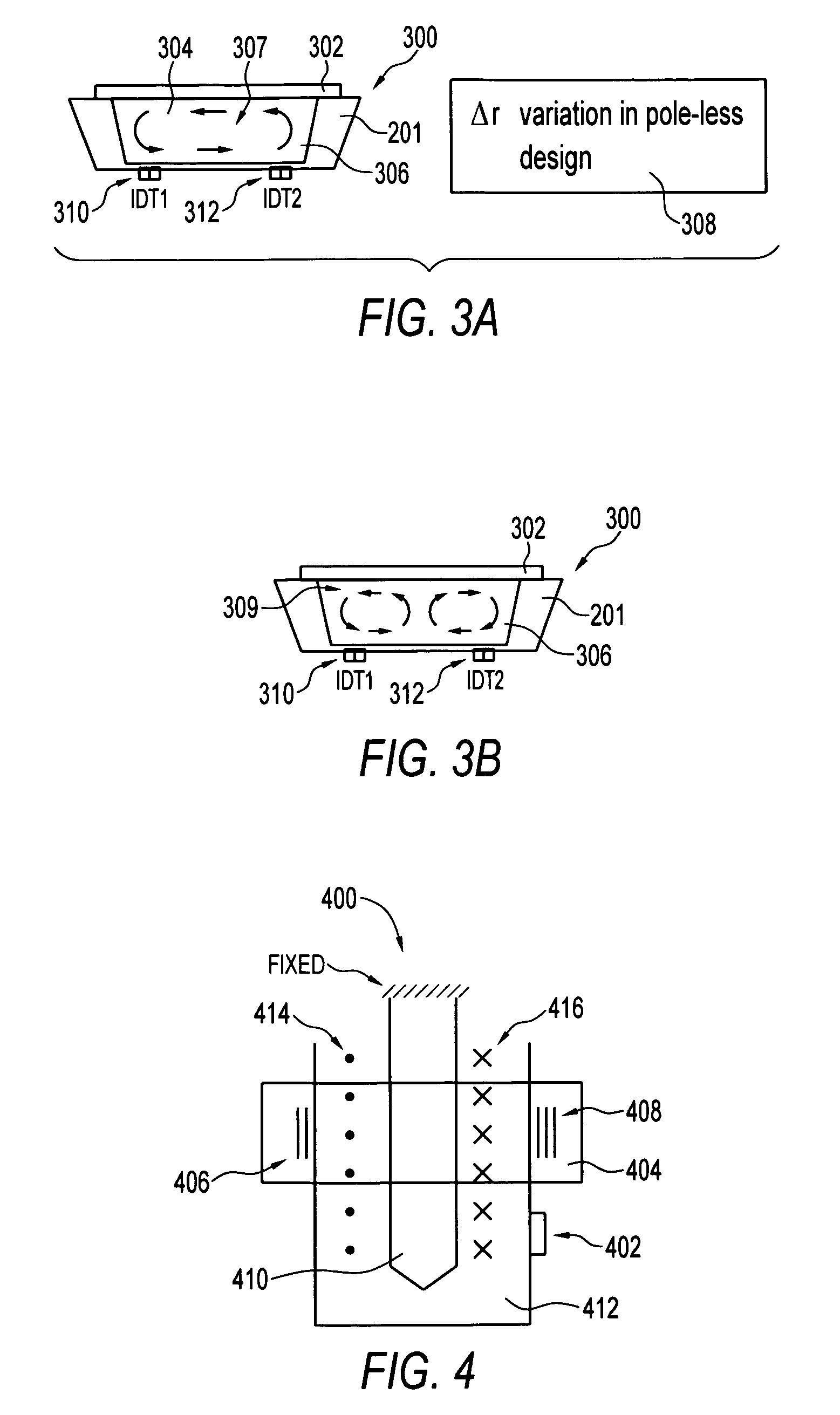

Micro-rheometer

InactiveUS20070056358A1Shear rate can be alteredMaterial analysis using sonic/ultrasonic/infrasonic wavesFlow properties on non-Newtonian fluidsShear rateCam

A rheometer apparatus includes an acoustic wave viscosity sensor associated with a flexural plate wave device configured to include a central cavity through which a fluid flows. A plurality of interdigital transducers cam be associated with the flexural plate wave device, wherein each interdigital transducer (IDT) thereof can measure viscosity associated with the fluid over a variable range of shear rates. The variable range of shear rates can be achieved by varying the flow rate of the fluid due to an adjustment of a vibrating amplitude associated with the flexural plate wave (FPW) device (e.g., an FPW pump).

Owner:HONEYWELL INT INC

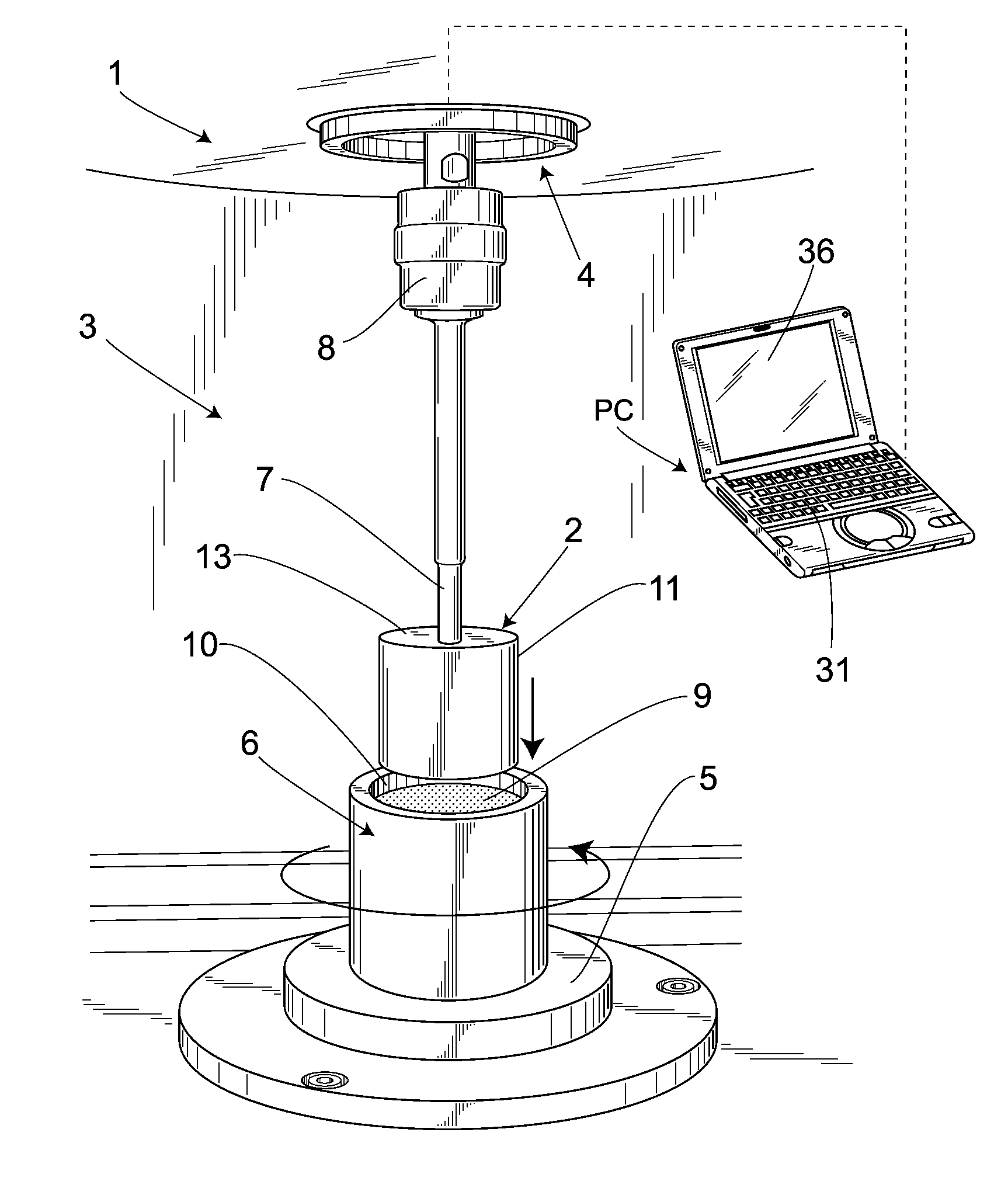

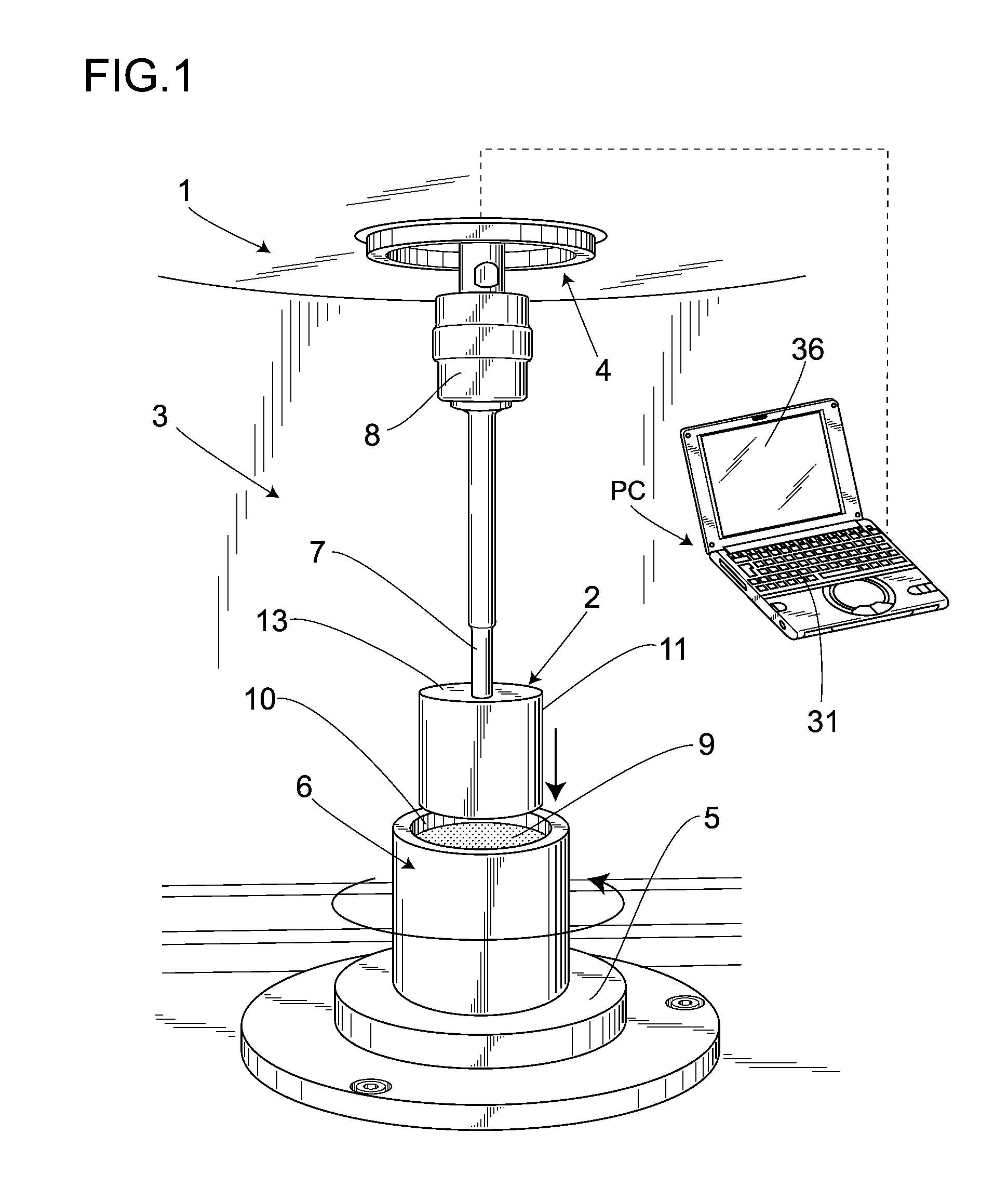

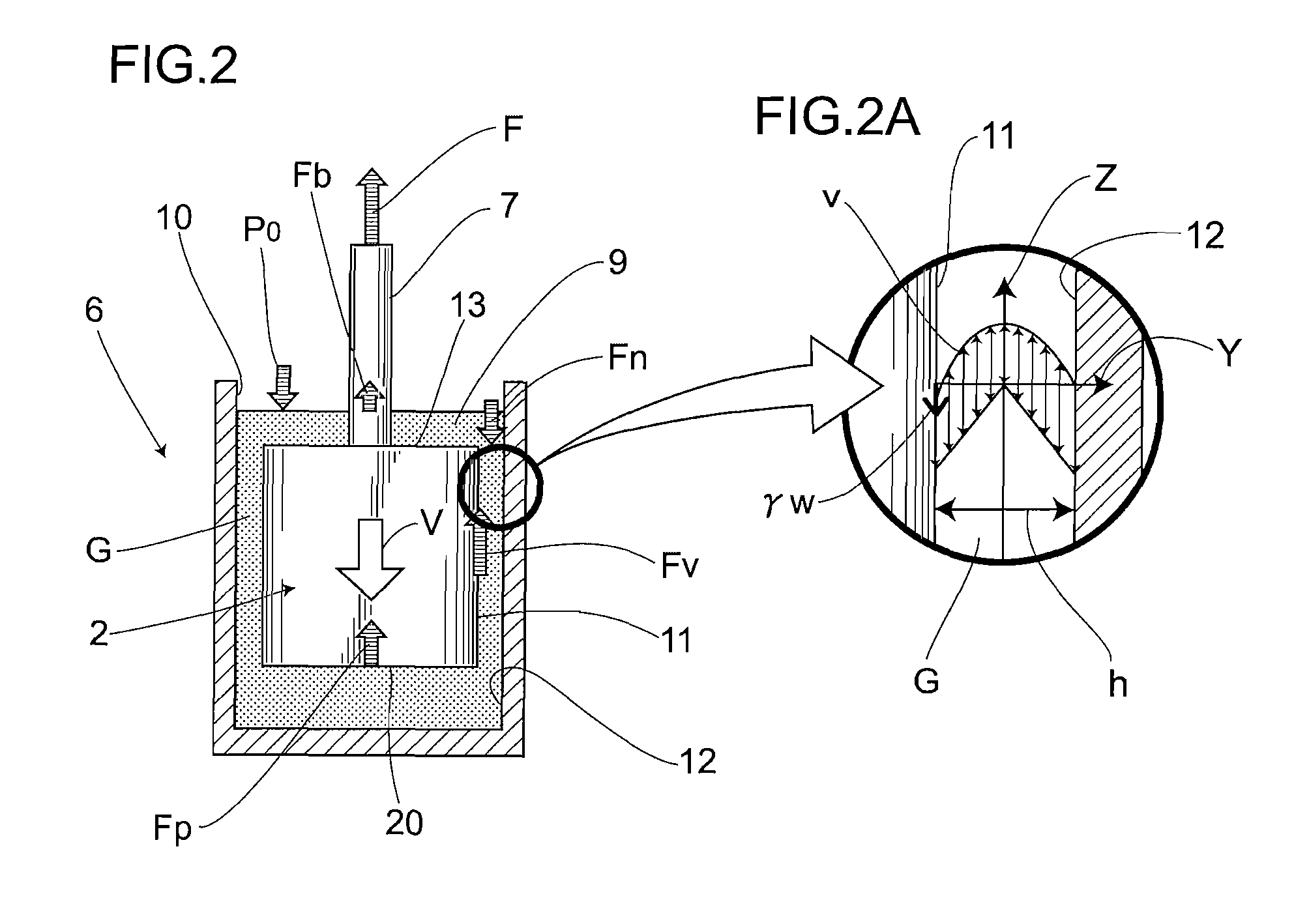

Fluid analysis method and fluid analysis device

InactiveUS20100274504A1Easy to analyzeFluid pressure measurement by mechanical elementsMachines/enginesEngineeringAnalysis method

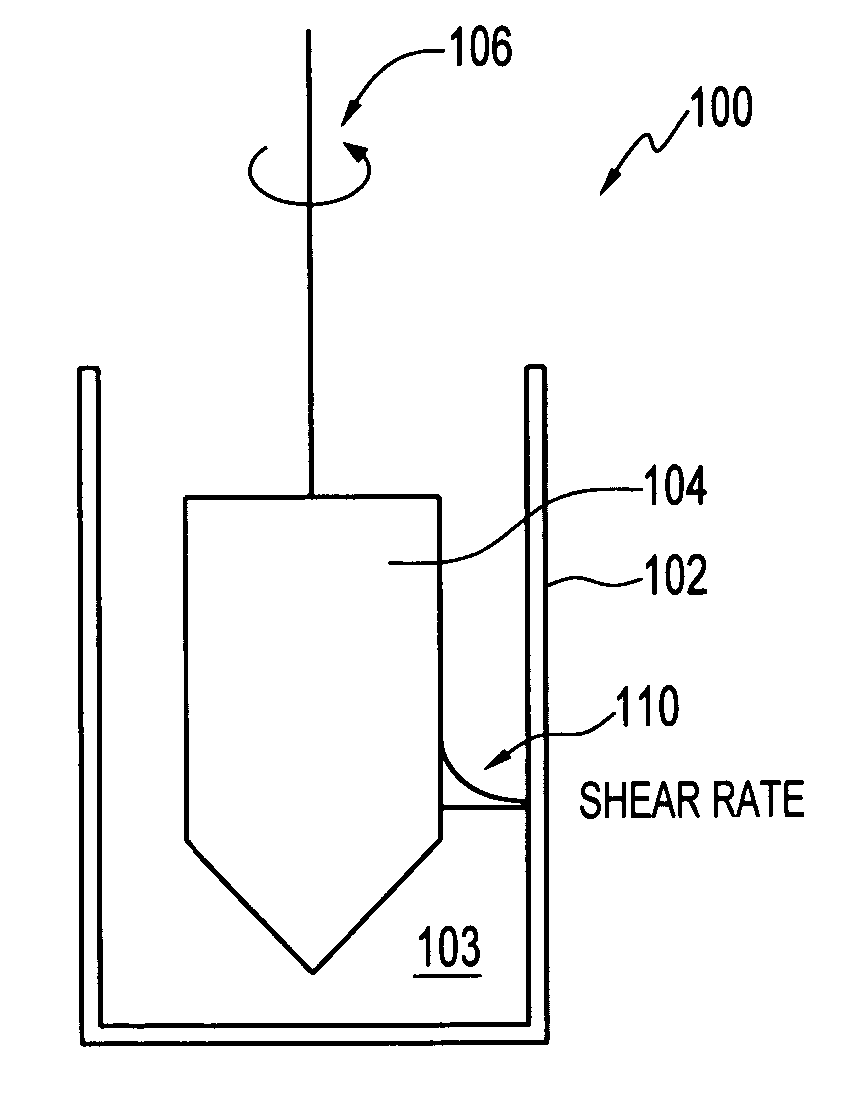

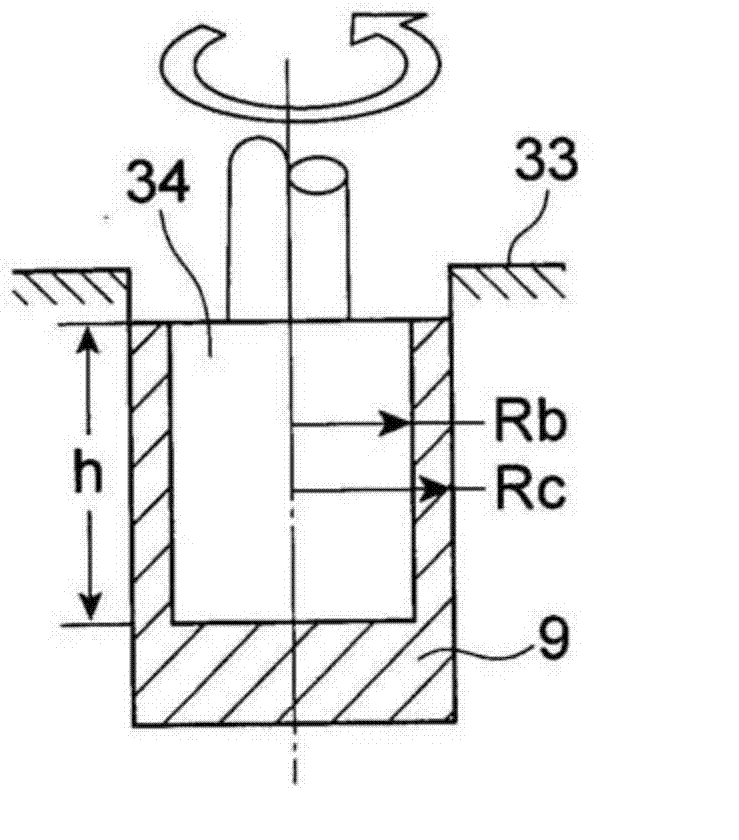

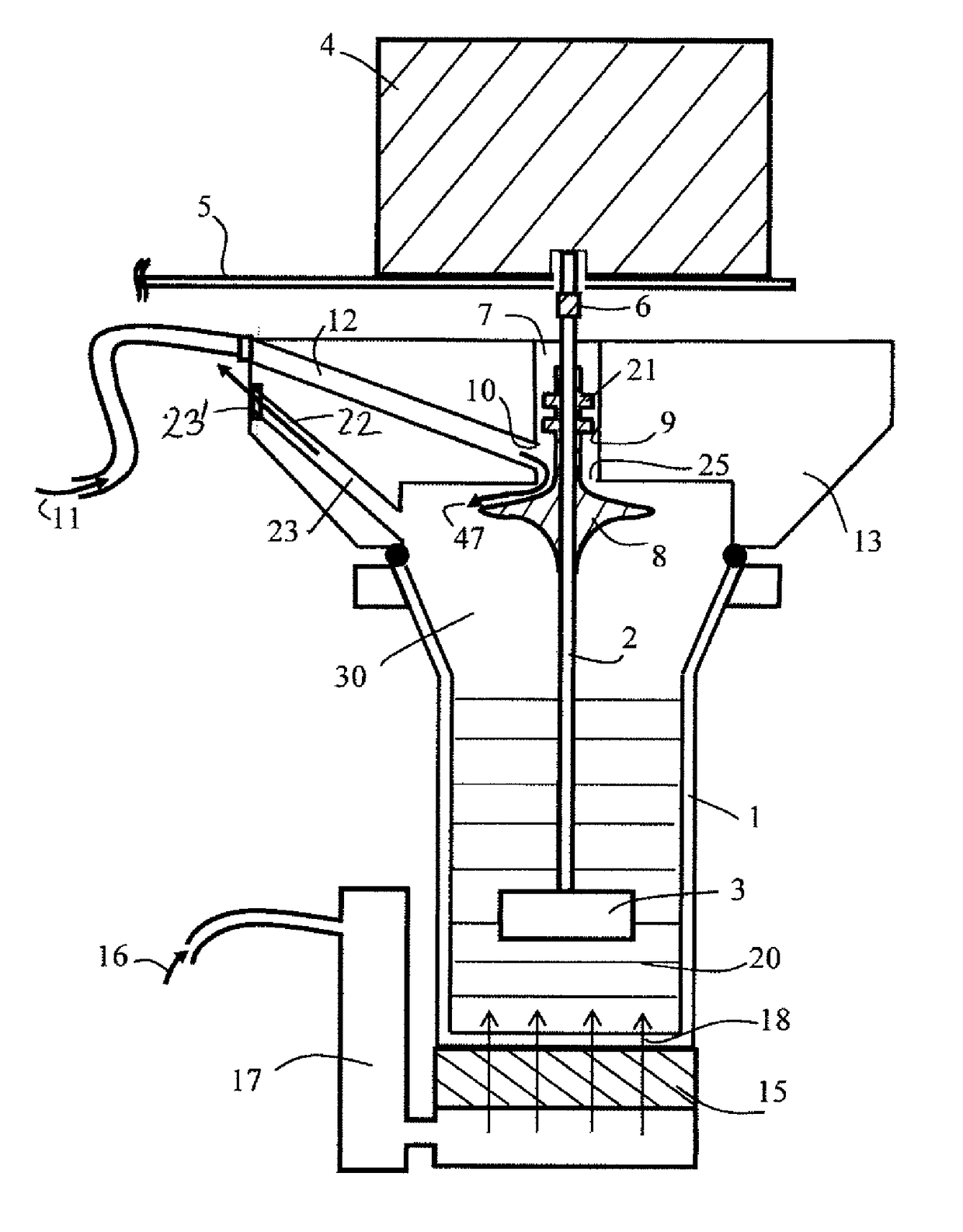

There is provided a fluid analysis method and its device which are capable of easily analyzing a normal stress difference of a low-viscosity fluid in addition to that of a high-viscosity fluid. A shearing fluidity is applied to a non-Newtonian fluid within a lateral-side gap by pushing a cylindrical bob into a container. At that time, reactive force applied to the cylindrical bob is measured. Then, by practicing an arithmetic process in a given form using the reactive force and each of conditions input by a user, the normal stress difference of the low-viscosity non-Newtonian fluid which is hard to form in a solid state can be certainly determined. Thus, with respect to the low-viscosity non-Newtonian fluid in addition to the high-viscosity non-Newtonian fluid, the normal stress difference can be easily analyzed.

Owner:NAT UNIV CORP NAGAOKA UNIV TECH

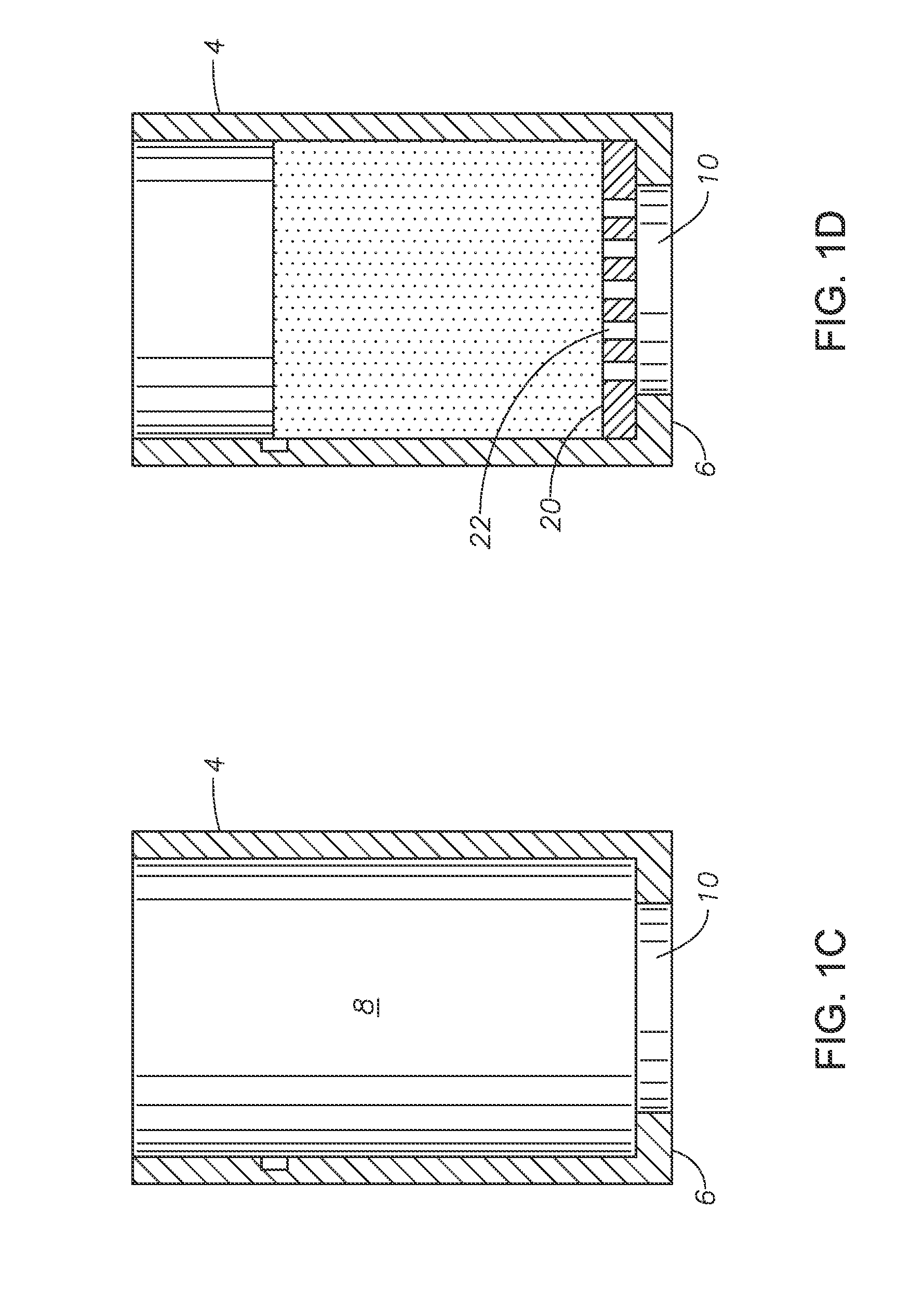

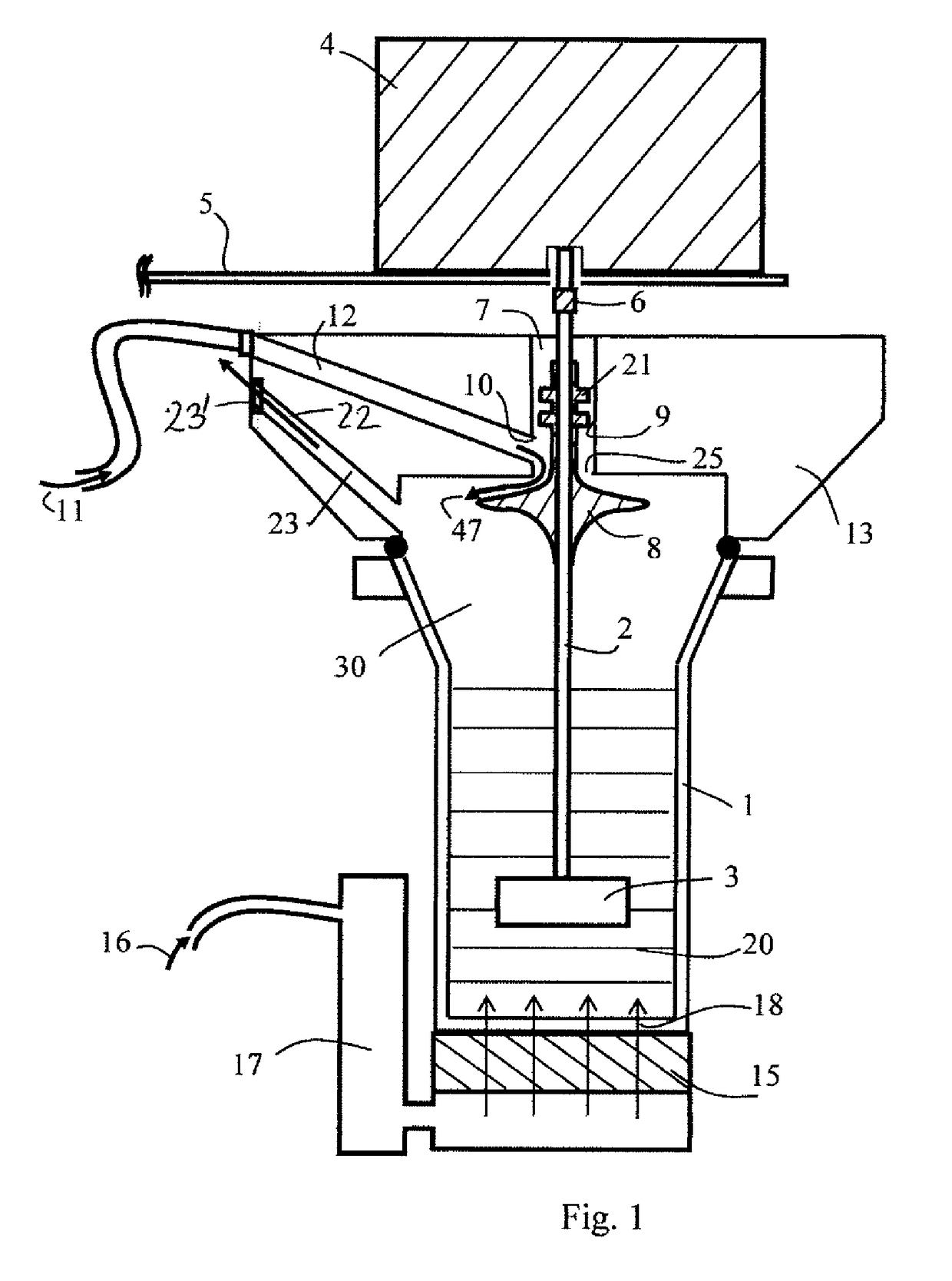

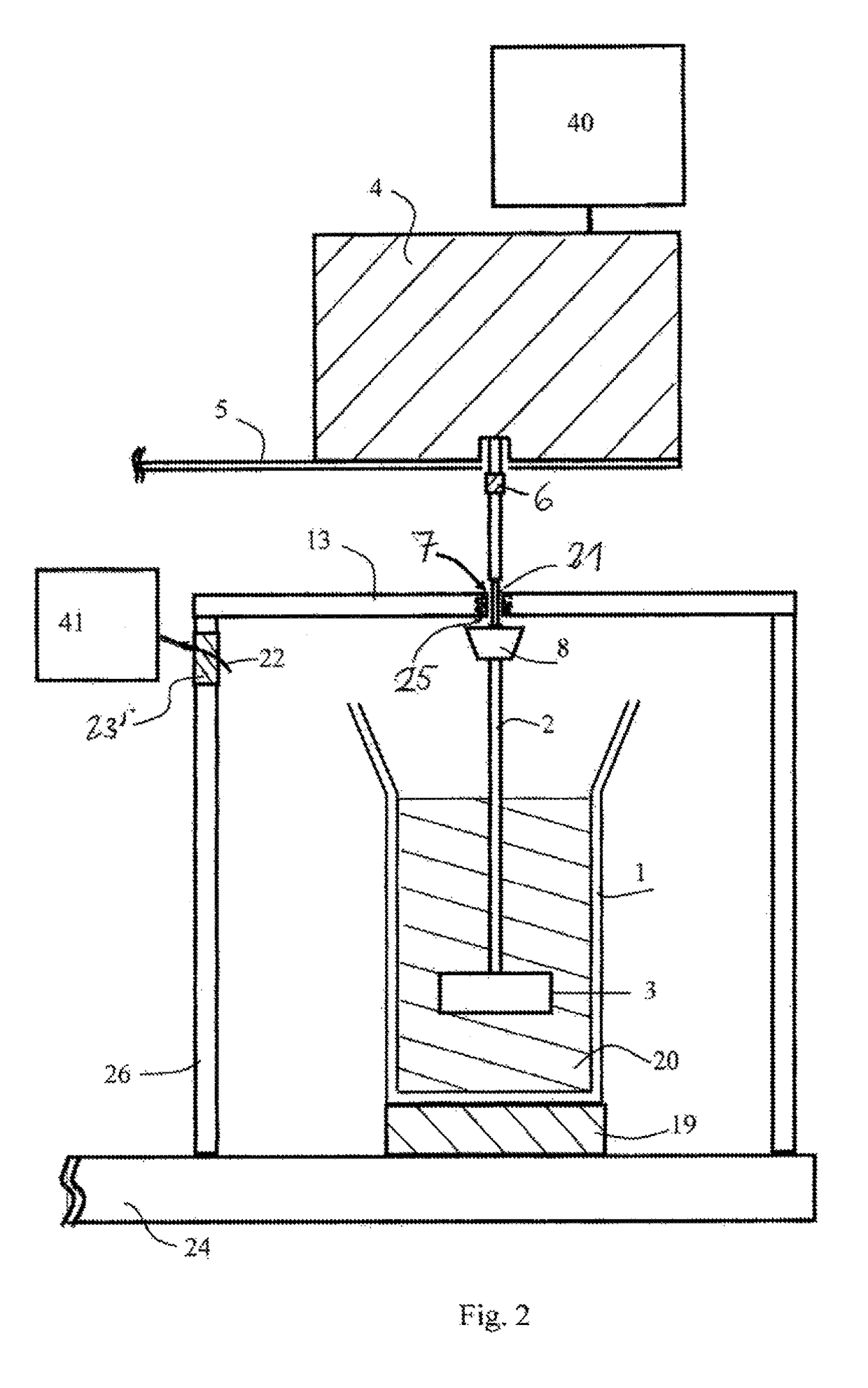

Rheometer

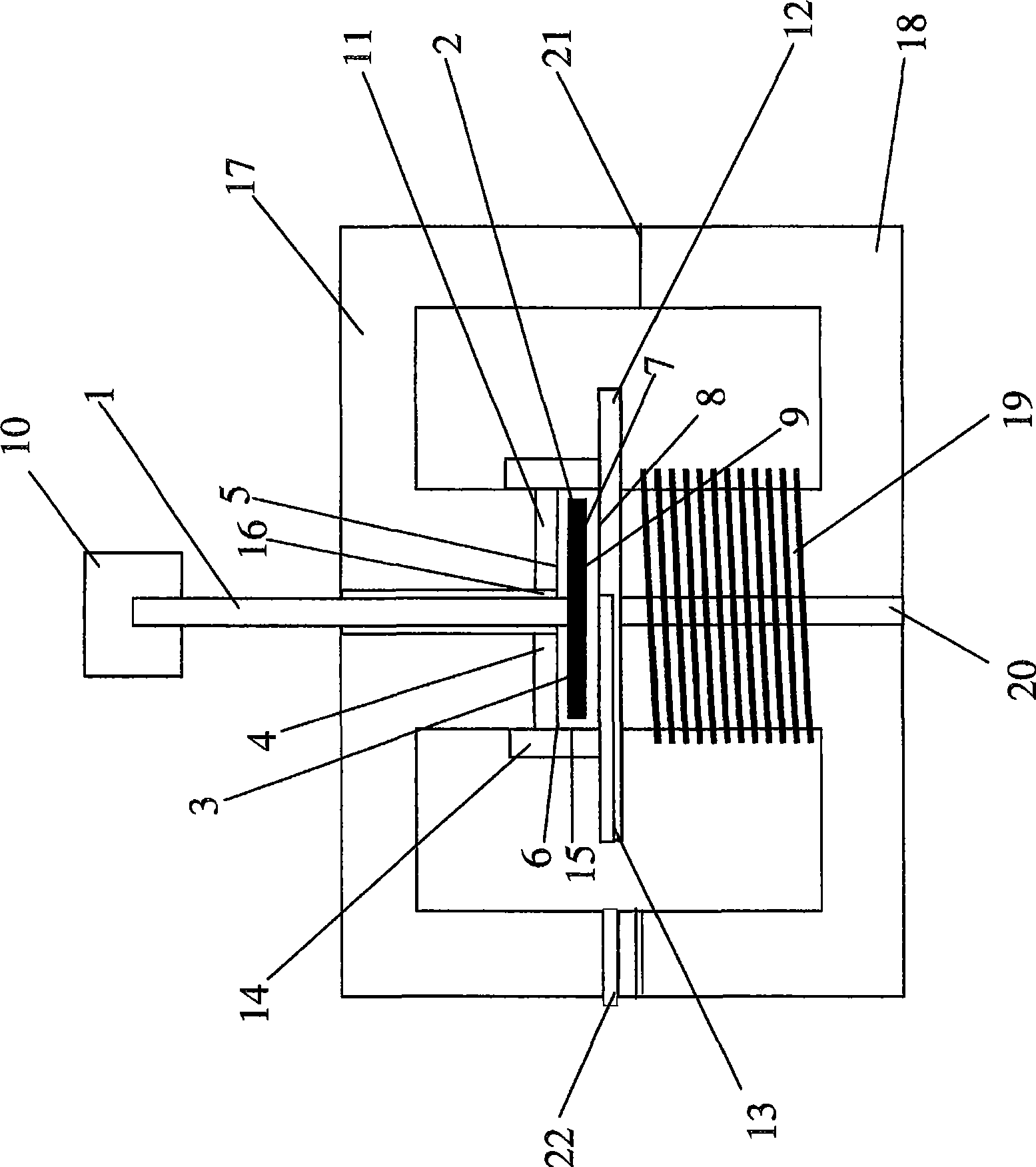

ActiveCN101506640AIncrease shear rateHigh magnetic flux densityMaterial analysis by electric/magnetic meansFlow properties on non-Newtonian fluidsEngineeringMagnet

The invention relates to a rheometer, comprising a rotatable shaft (1), to which a rotor plate (2) is fixed, and a measuring device (10), for measuring torques exerted on the rotor plate (2) by a substance under investigation during a rotation of the shaft (1), wherein a first measuring gap (5), for accommodating the substance (6) under investigation, is formed between a first side (3) of the rotor plate (2) and a first shear surface (4) and a second measuring gap (9), for accommodating the substance (6) under investigation, is formed between a second side (7) of the rotor plate (2) away fromthe first and a second shear surface (8). The rheometer contains a magnet for generating a magnetic field in the first and second measuring gaps (5, 9).

Owner:安东帕有限责任公司

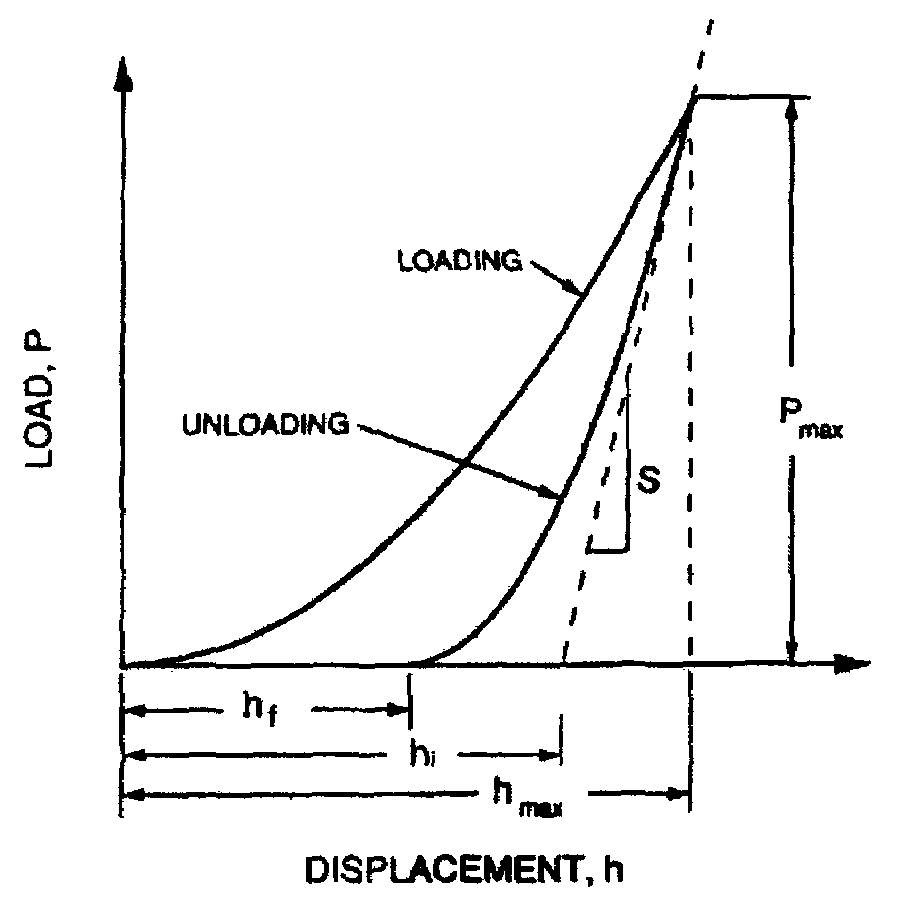

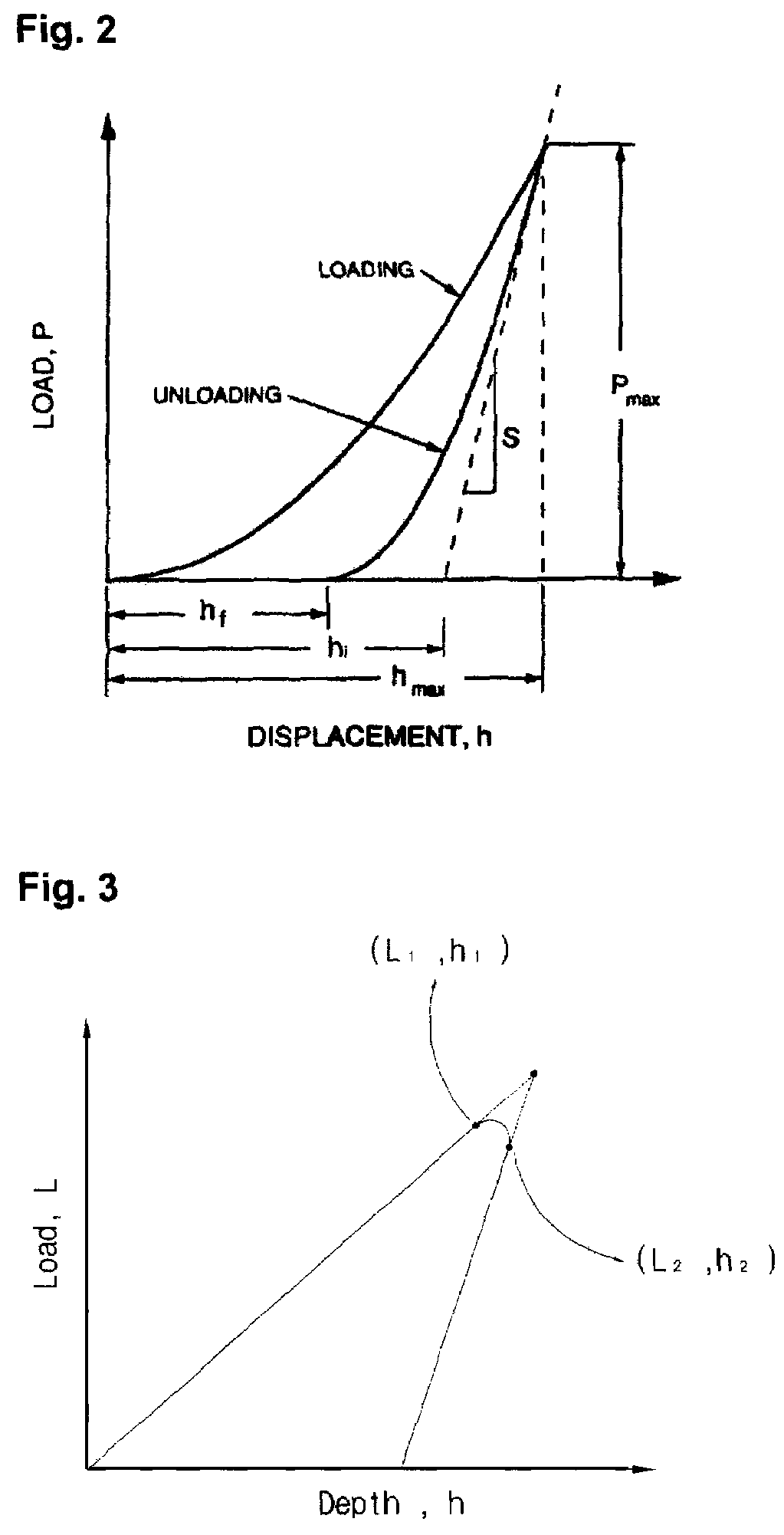

Evaluating method of the residual stress determining method using the continuous indentation method

ActiveUS7472603B2Error minimizationAccurate estimateAnalysing solids using sonic/ultrasonic/infrasonic wavesMeasurement arrangements for variablePresent methodStress relieving

Owner:FRONTICS +1

Method of testing rubber composition for kneaded state and process for producing rubber composition

InactiveUS20030018113A1Good dispersionStable kneading statusConductive materialOrganic conductorsPolymer sciencePolymer chemistry

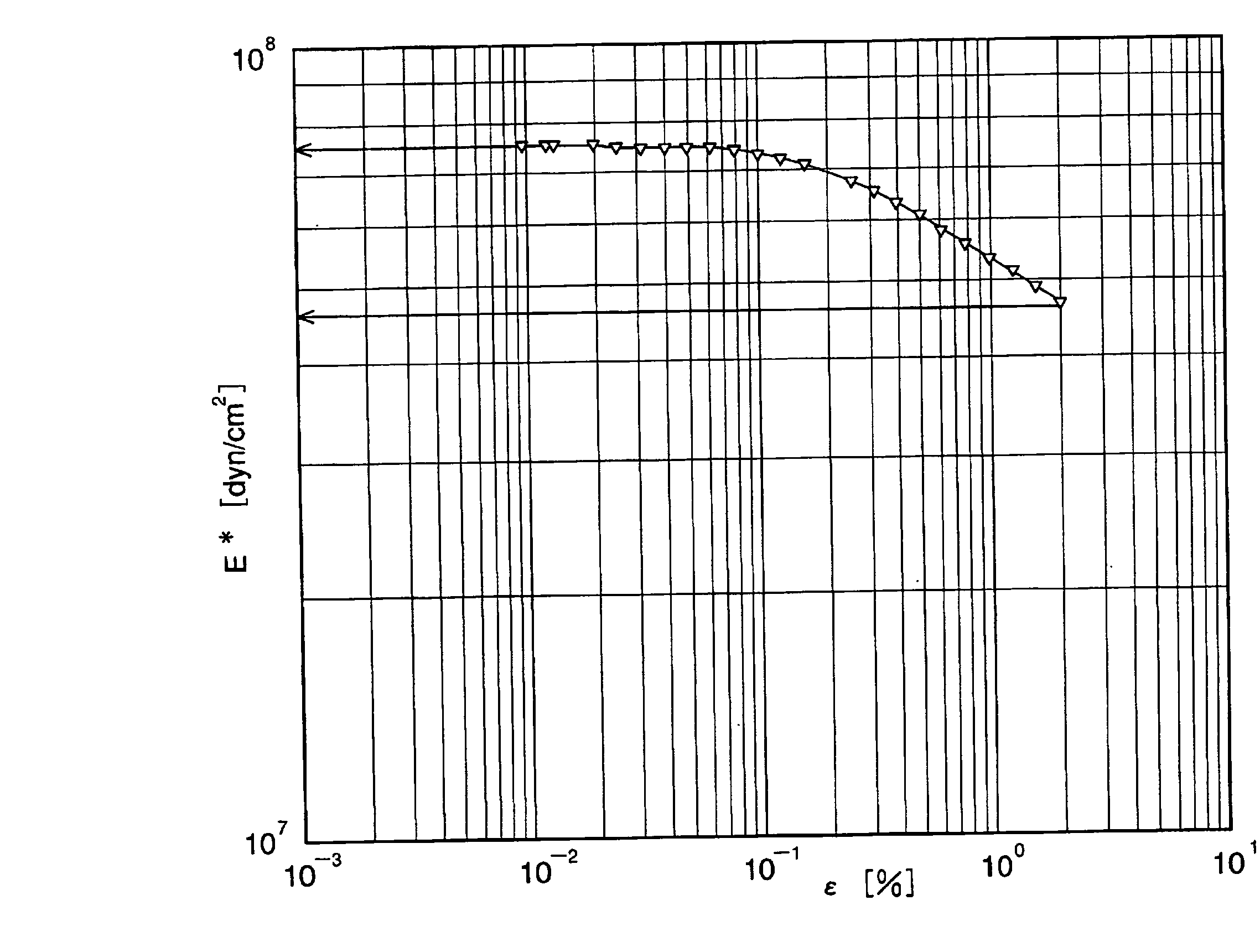

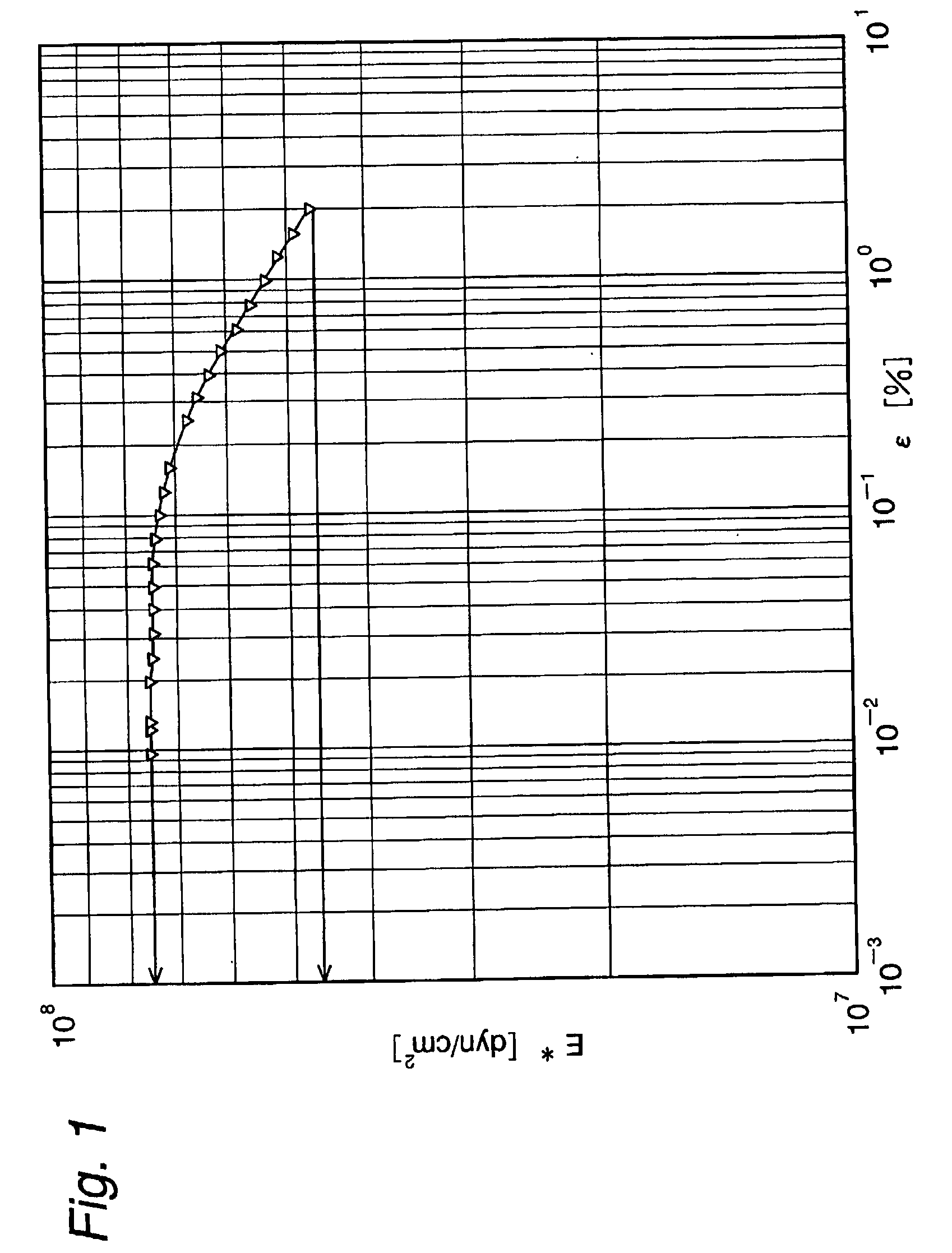

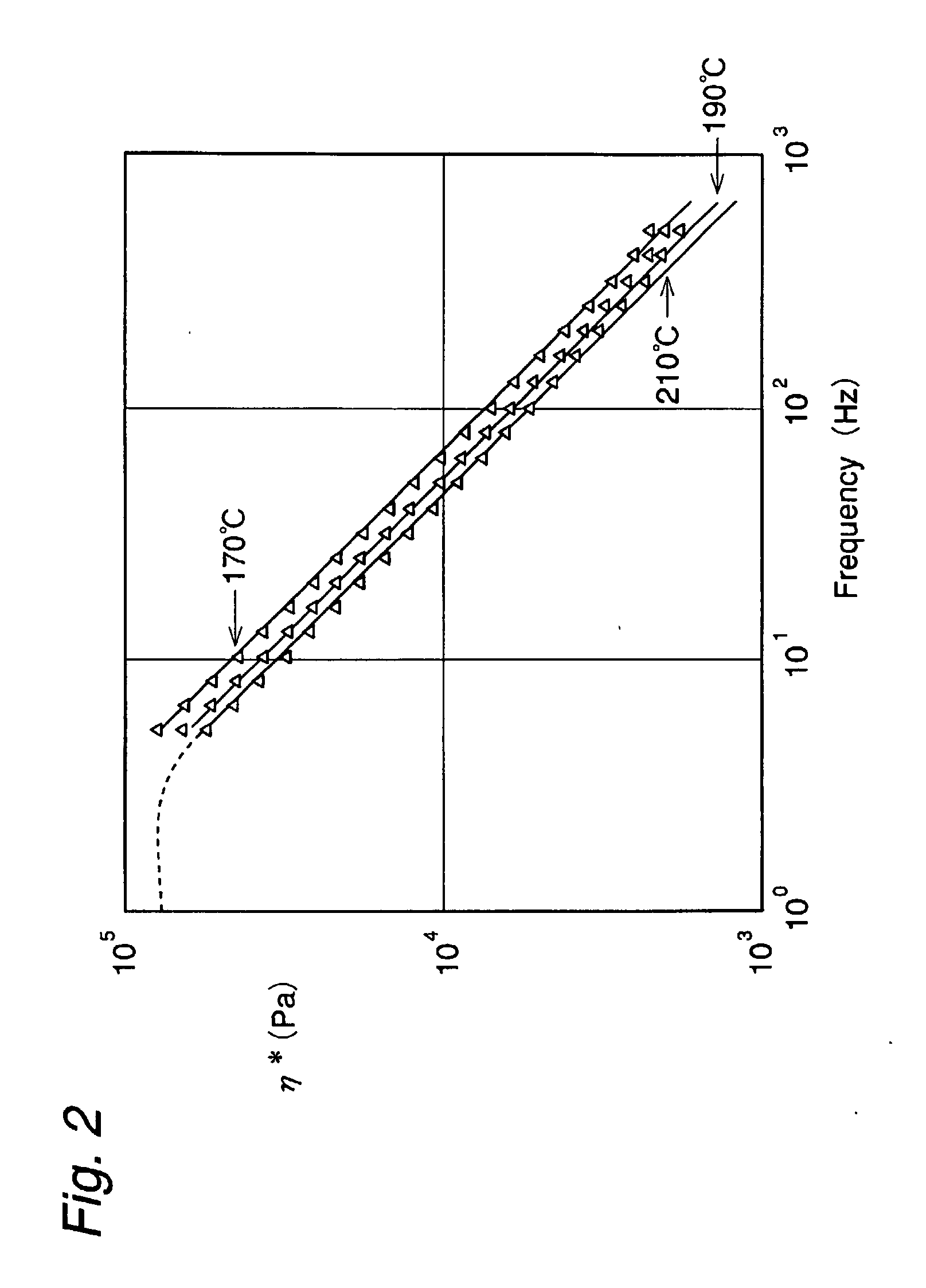

A kneading status evaluation method for a rubber composition containing at least a rubber and a filler comprises the steps of a complex modulus measurement step (1) in which a complex modulus E*(a) at a given strain epsi a and a complex modulus E*(b) at a given strain epsi b differing from the strain epsi a of the rubber composition (I) are measured, a filler dispersion index calculation step (2) in which a filler dispersion index (N) of the rubber composition (I) is calculated with complex elastic moduli E*(a) and E*(b) obtained in the previous step (1) according to the equation shown below, and a comparison step (3) to compare a predetermined target filler dispersion index (R) with the filler dispersion index (N) calculated in the previous step (2), and / or a complex viscosity coefficient measurement step (5) to measure a complex viscosity coefficient eta* of the rubber composition (I) under at least two different temperatures, and a kneading status monitor index calculation step (6) to calculate a kneading status monitor index (M) of the rubber composition (I) according to the equation shown below on the basis of a temperature dependency of the complex viscosity coefficient eta* obtained at the previous step (5), and a comparison step (7) to compare a predetermined target kneading status monitor index (P) with the kneading status monitor index (M) calculated in the previous step (6); <paragraph lvl="0"><in-line-formula>Filler dispersion index (N)=|E*(a)| / |E*(b)|< / in-line-formula><paragraph lvl="0"><in-line-formula>|eta*(T)|=A exp (-M / RT) < / in-line-formula>where eta*: complex viscosity coefficient, A: proportional constant, R: gas constant, and T: measuring temperature (° K). A manufacturing method for a rubber composition is characterized by carrying out the evaluation methods described above. Implementation of the evaluation methods described above makes it possible to evaluate objectively a kneading status of a rubber composition containig at least a rubber and a filler. Further, implementation of the manufacturing methods described above can provide a rubber composition having good filler dispersion and a stable kneading status.

Owner:MITSUI CHEM INC

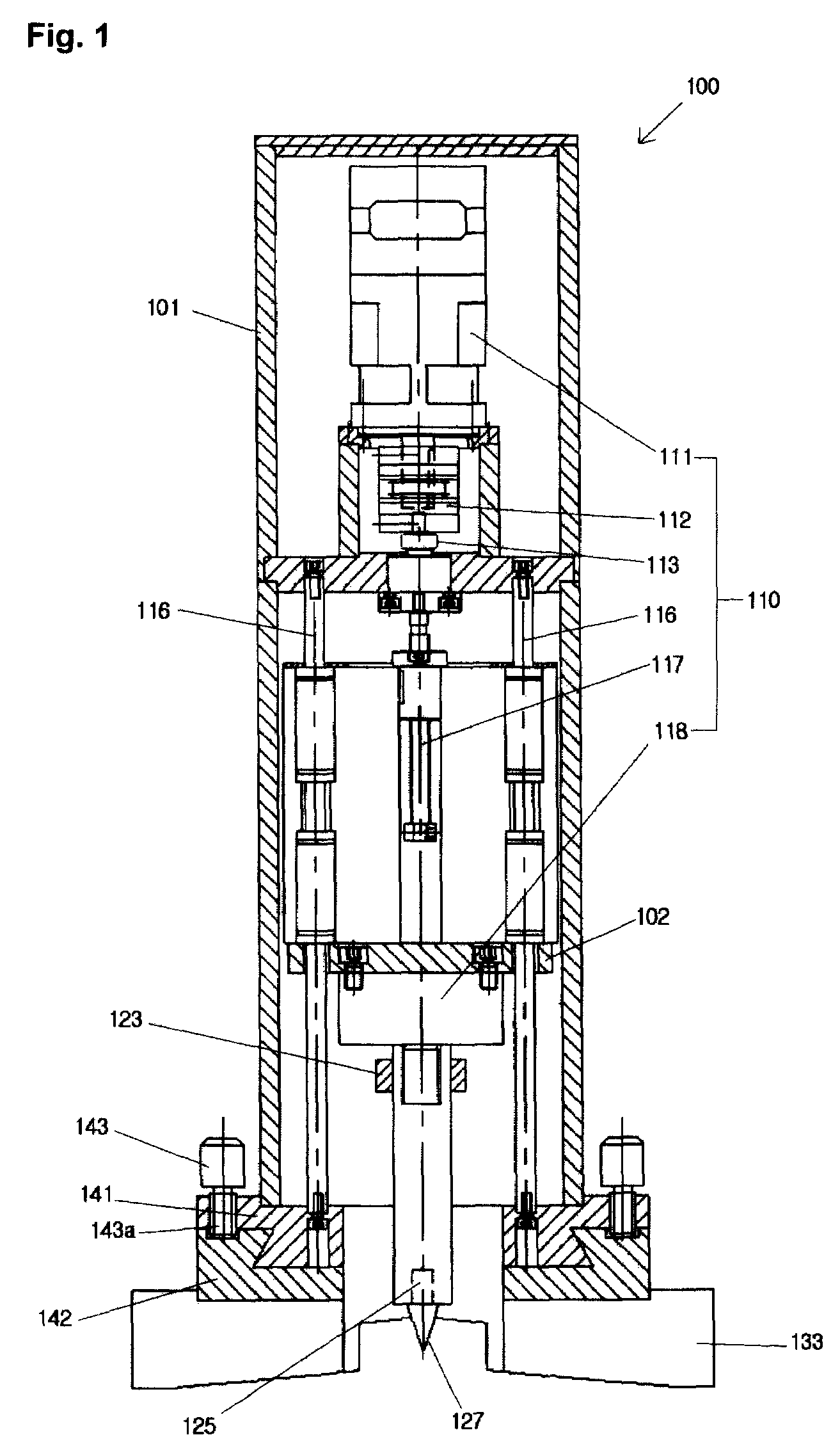

Method and apparatus for testing gel-based lost circulation materials

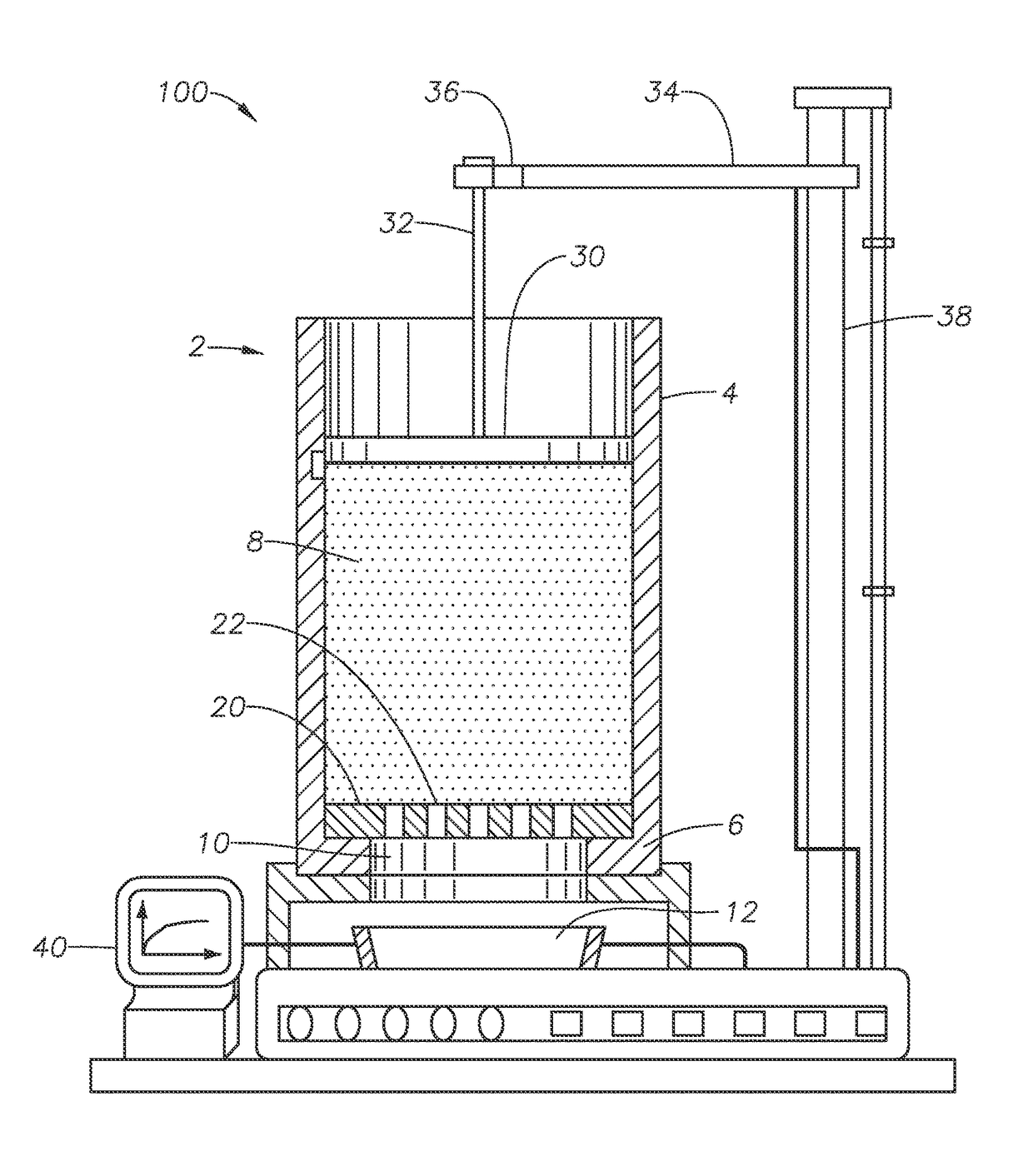

ActiveUS9739694B2Material strength using tensile/compressive forcesElectrical/magnetic solid deformation measurementCircular discGel based

Owner:SAUDI ARABIAN OIL CO

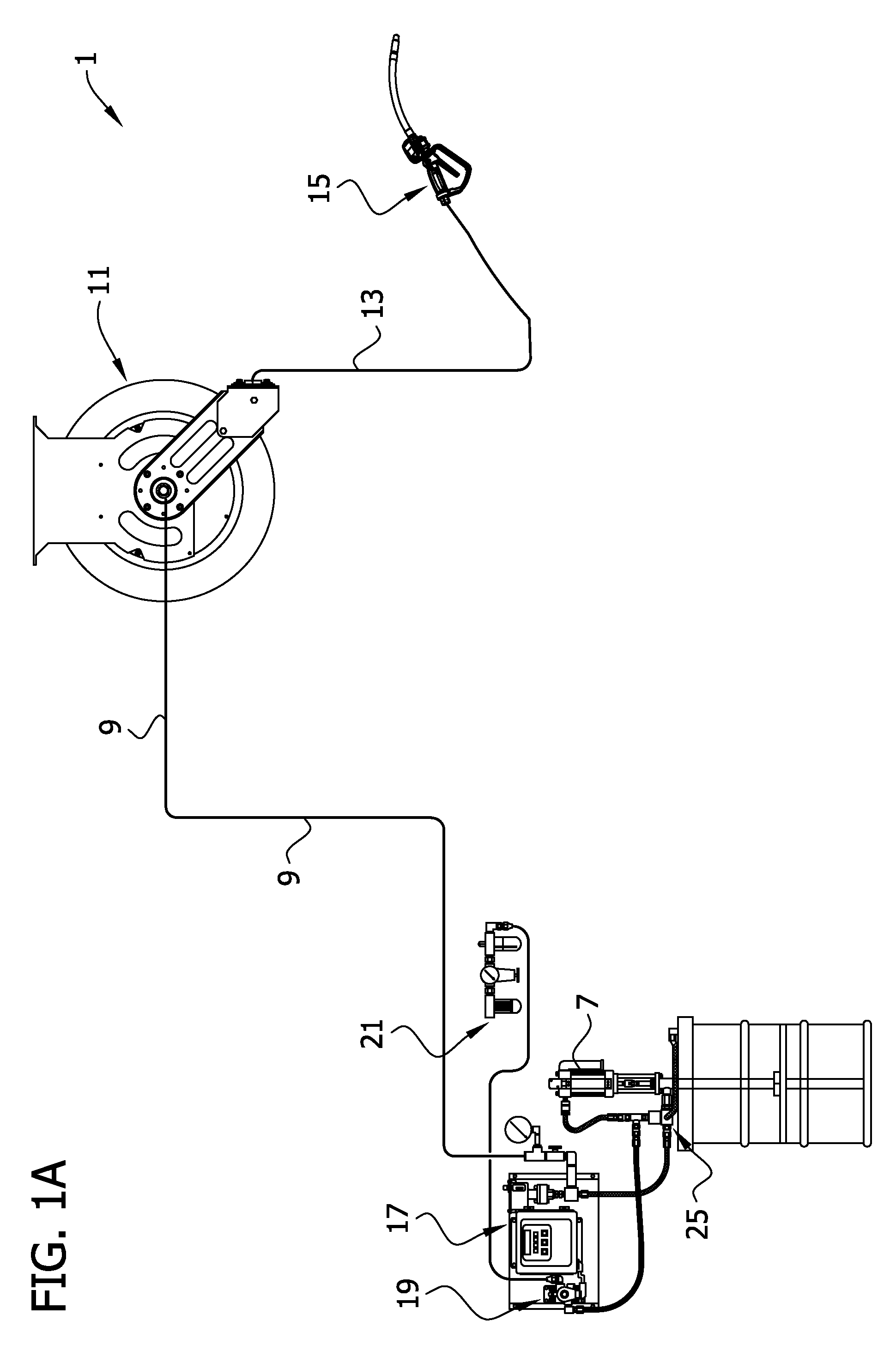

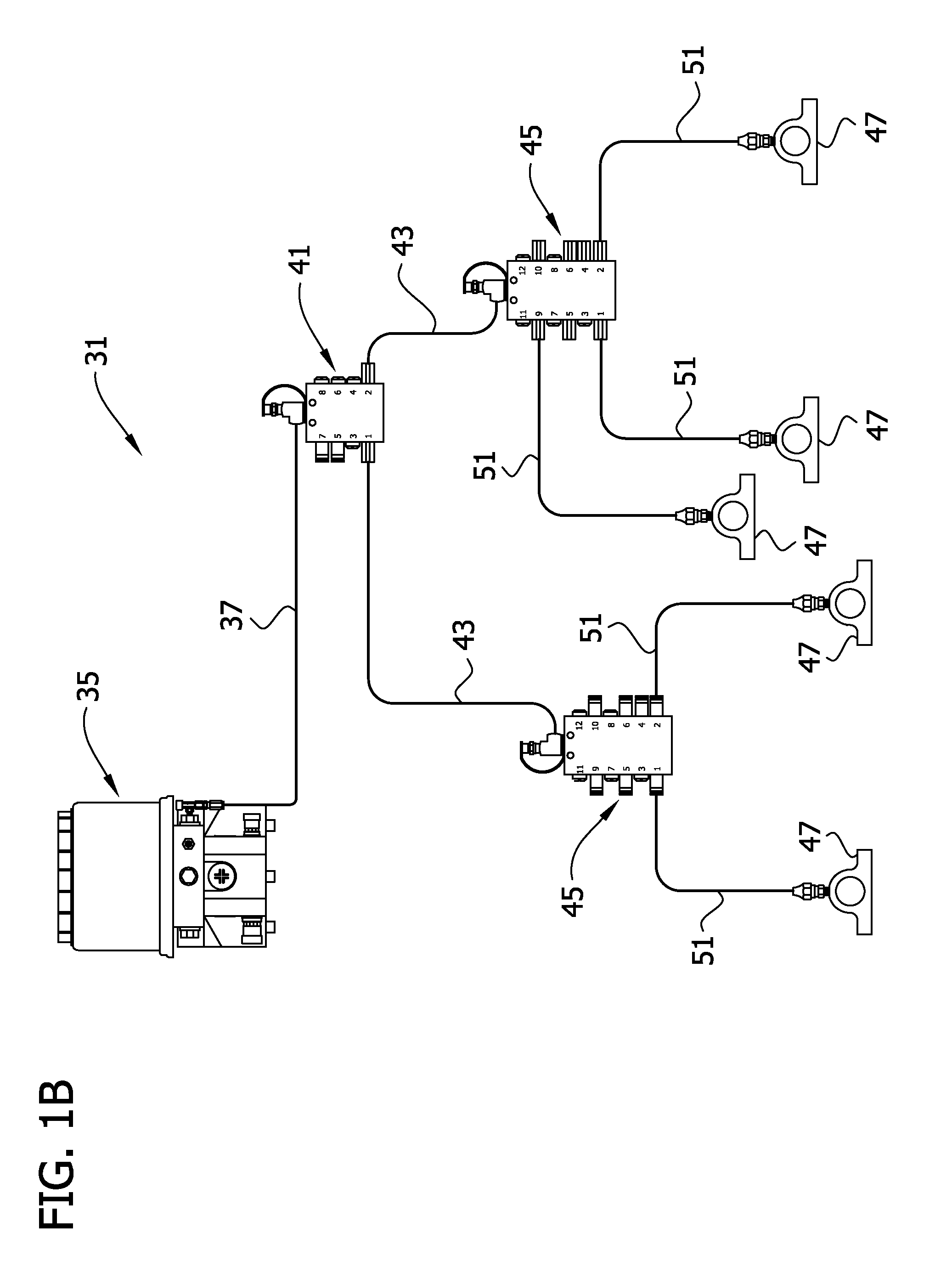

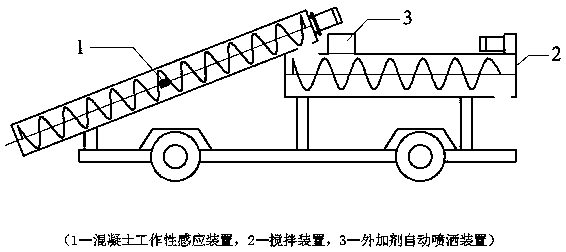

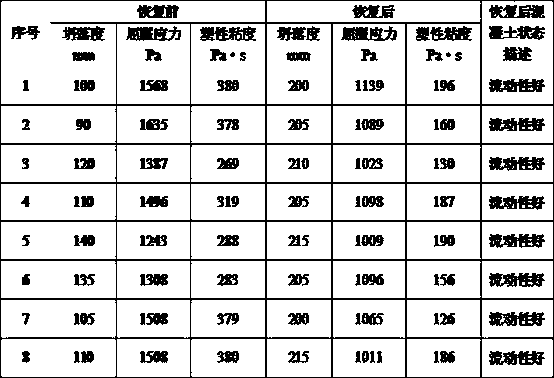

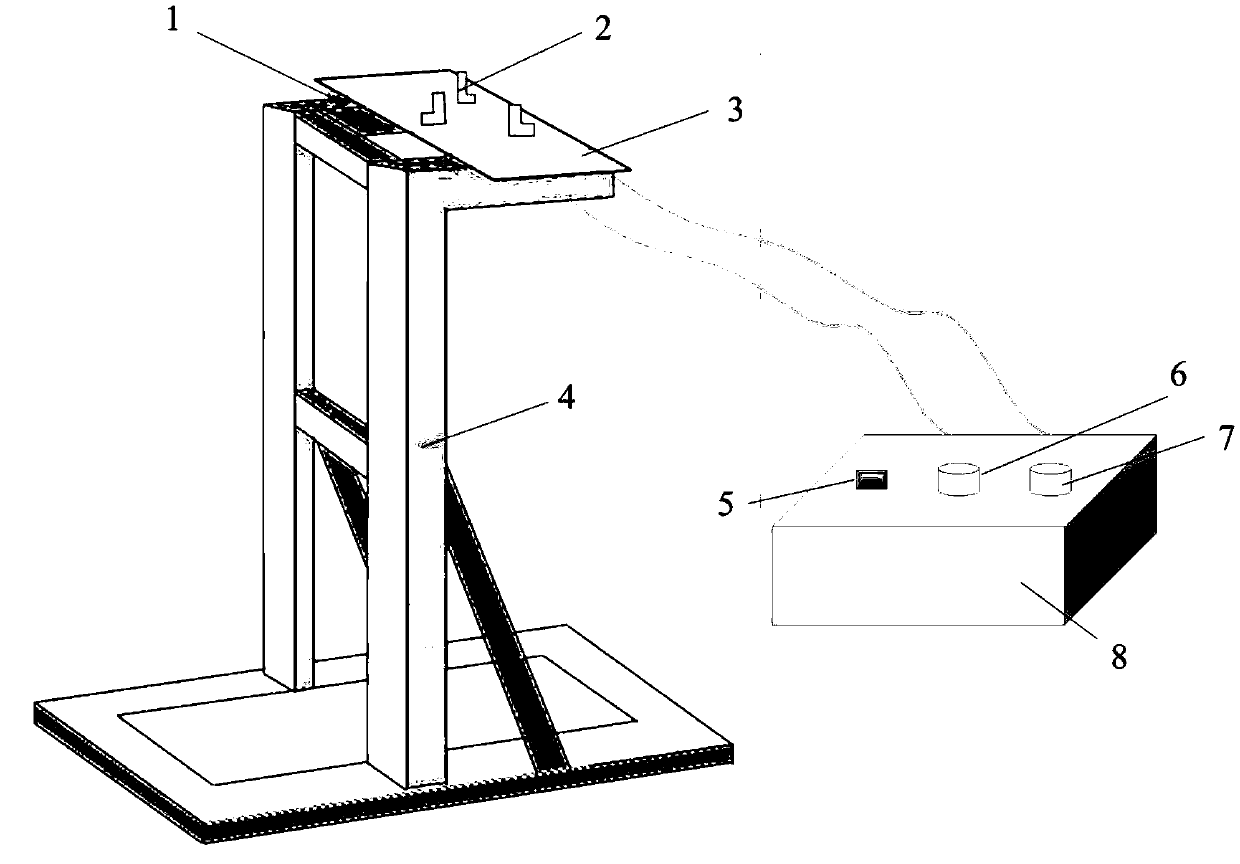

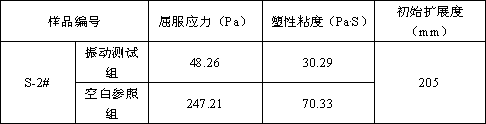

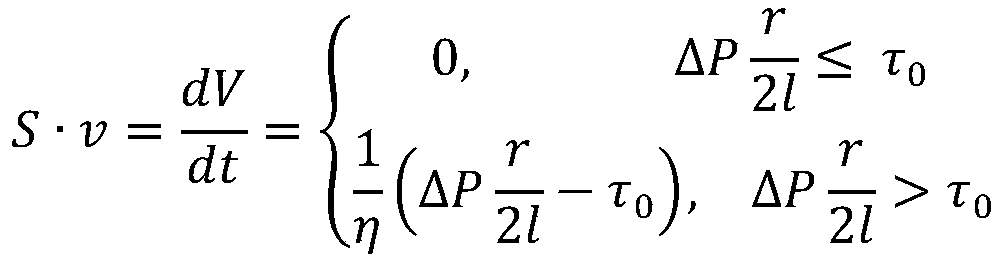

Concrete workability rapid recovery system

PendingCN110480834AImprove work performanceQuality improvementMaterial testing goodsCement mixing apparatusConcrete pumpFast recovery

The invention relates to a concrete workability rapid recovery system. The concrete workability rapid recovery system comprises a workability induction device, a stirring device and an additive automatic spraying device. The system is arranged between a concrete tank truck discharging opening and a concrete pump feeding opening, through the workability induction device, the yield stress and the plastic viscosity of the concrete are measured in real time to judge the concrete workability, data are transmitted to a controller, according to the mixture state, the rotating speed of a stirring blade and the mixing amount of the additive are adjusted in real time, and the concrete workability is rapidly recovered within 15 seconds. The workability rapid recovery system has the advantages of being intelligent, rapid and wide in optimization, the problem that in the construction site, water is added at will can be thoroughly solved, and concrete engineering high-quality construction under adverse factors such as raw material quality fluctuation, environment temperature change and long-distance transportation can be effectively ensured.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

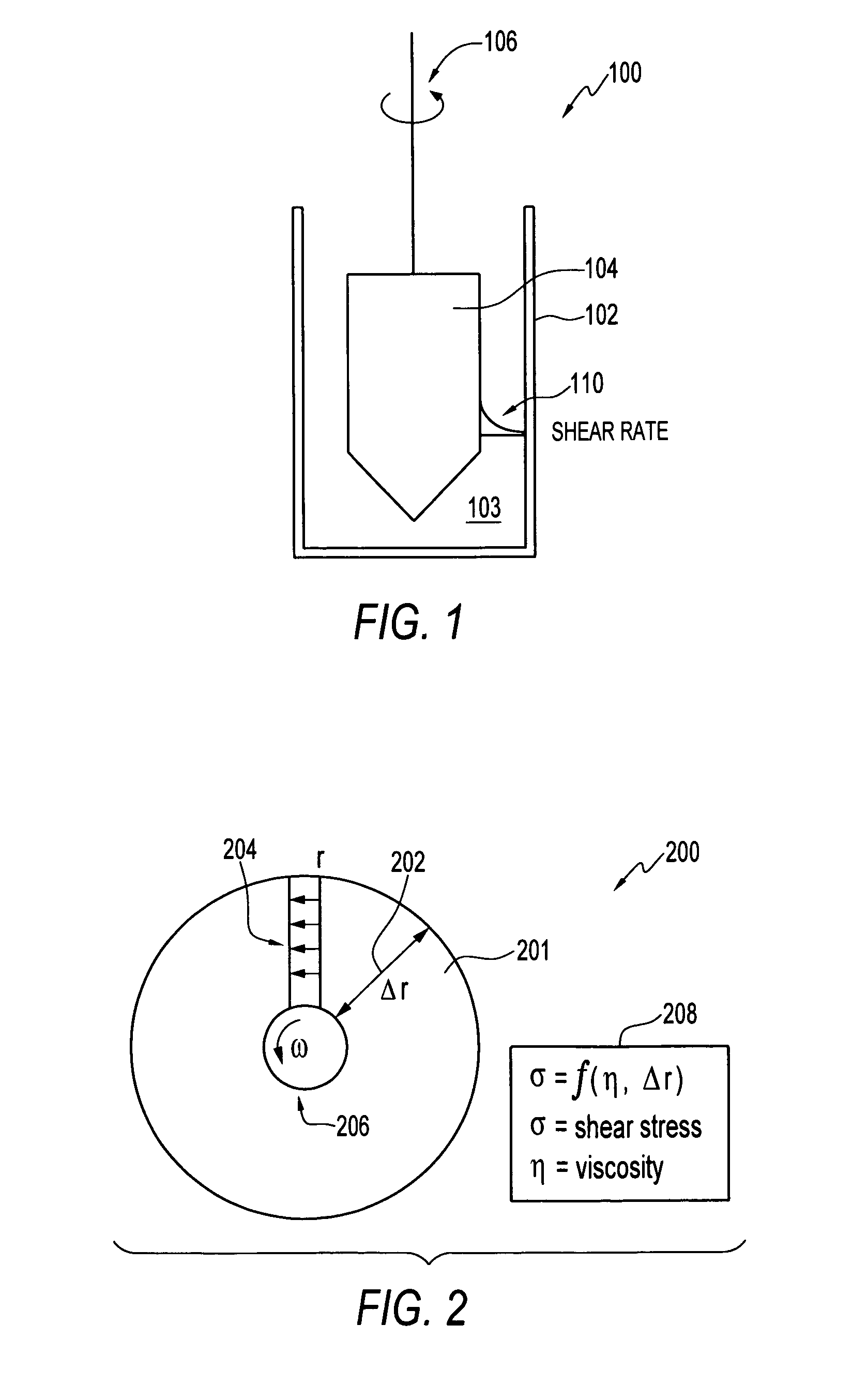

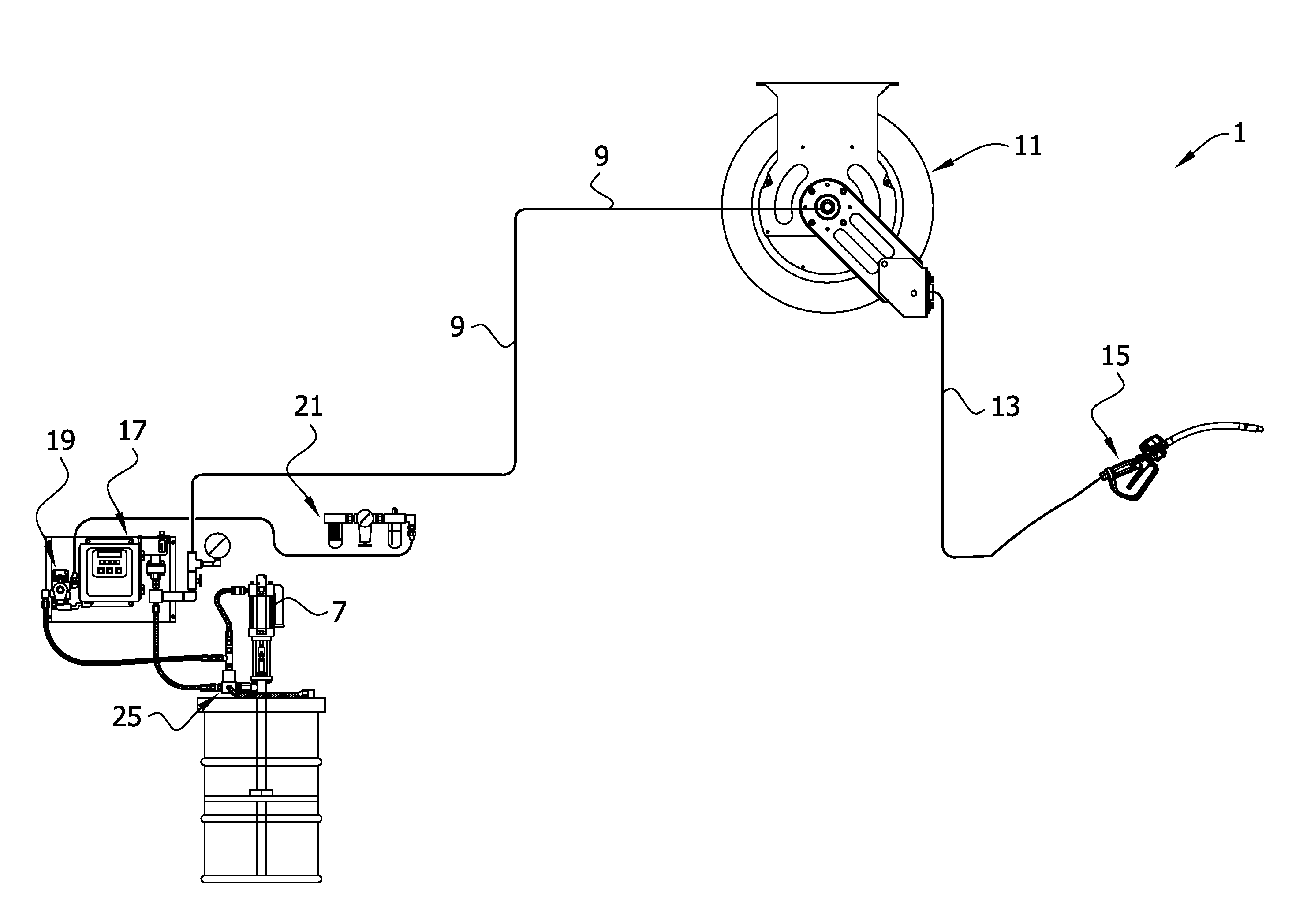

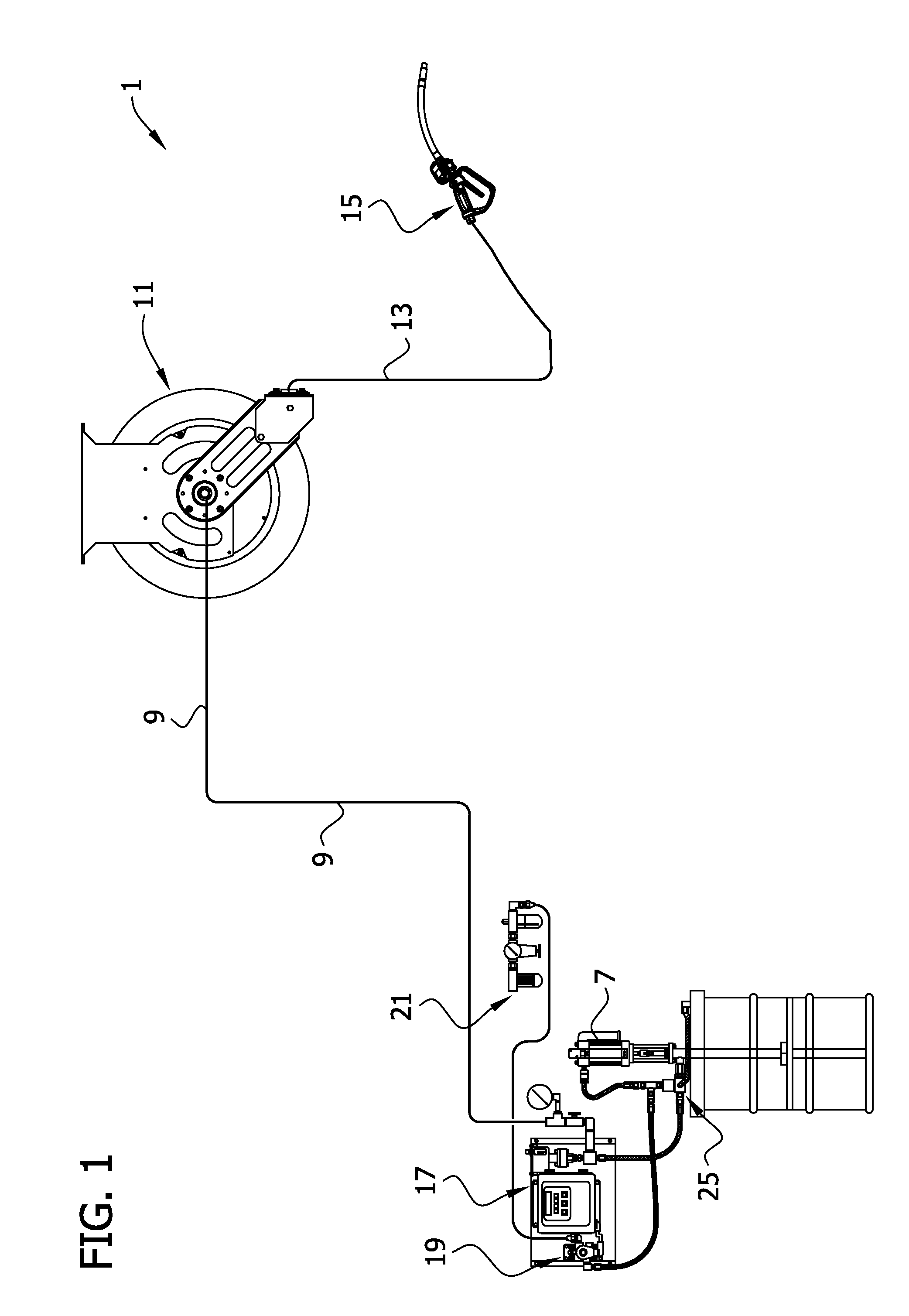

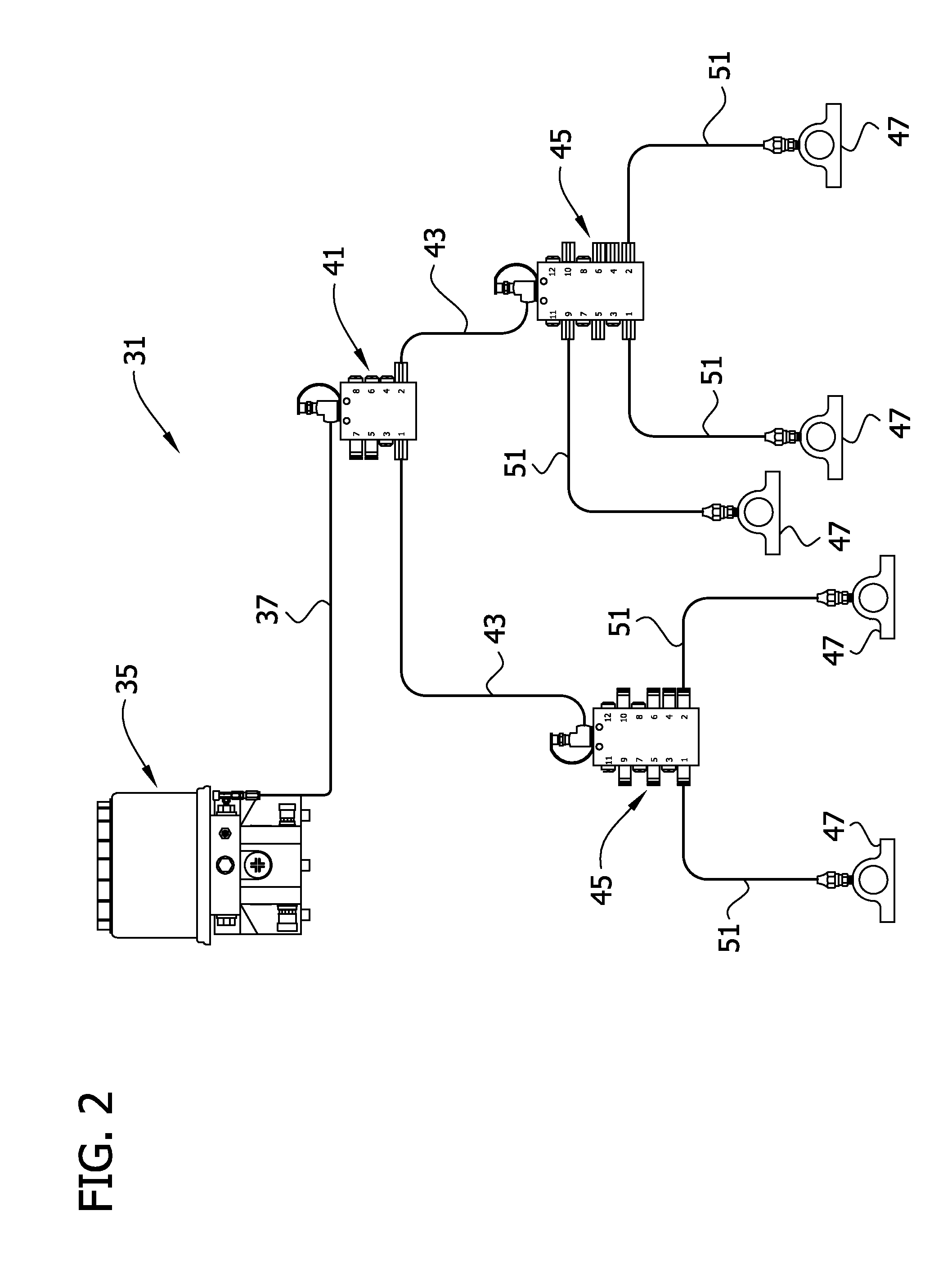

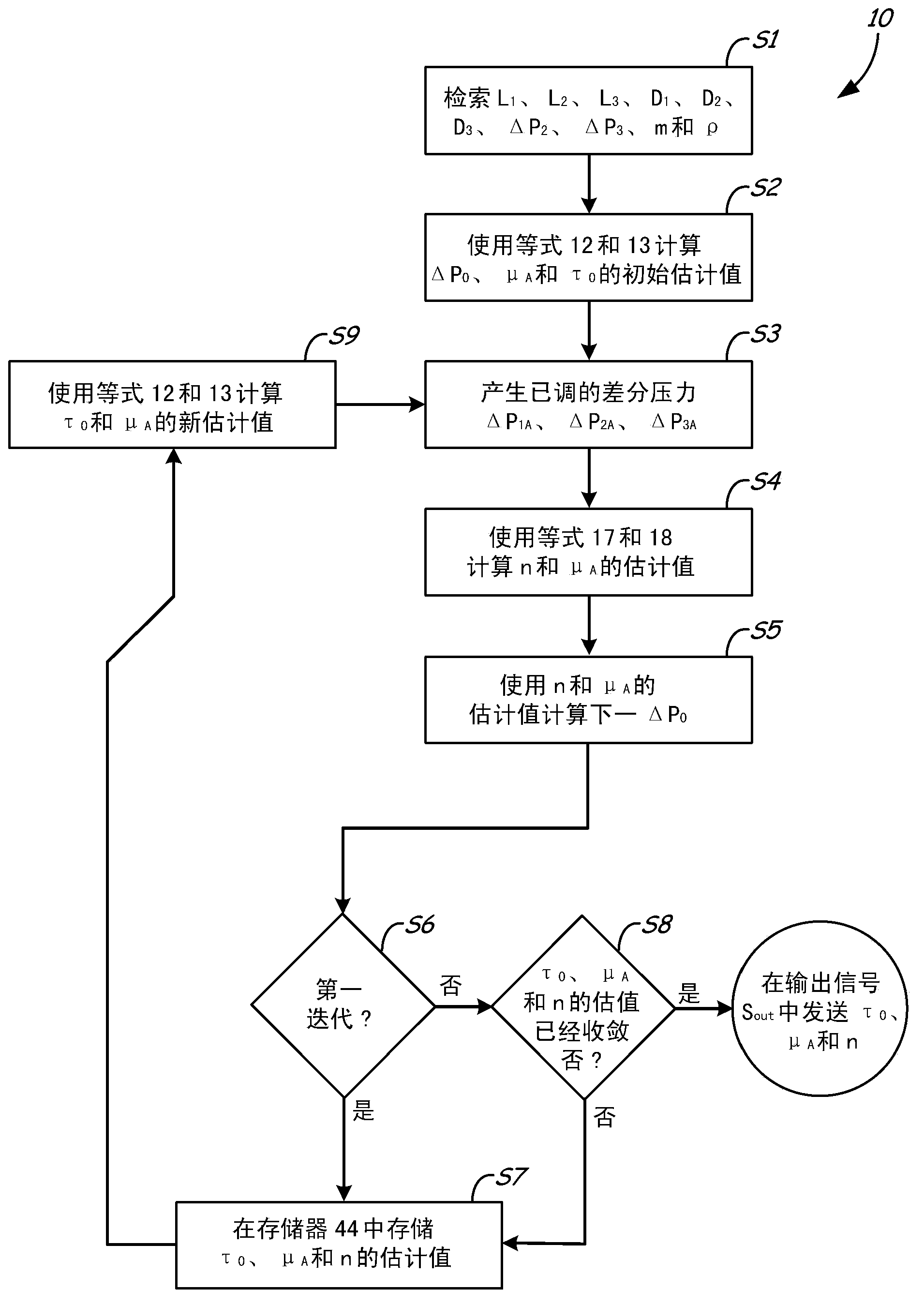

Method and Apparatus for Measuring Apparent Viscosity of a Non-Newtonian Fluid

InactiveUS20130253855A1Precisely apparent viscosityFluid pressure measurement by mechanical elementsMachines/enginesShear stressApparent viscosity

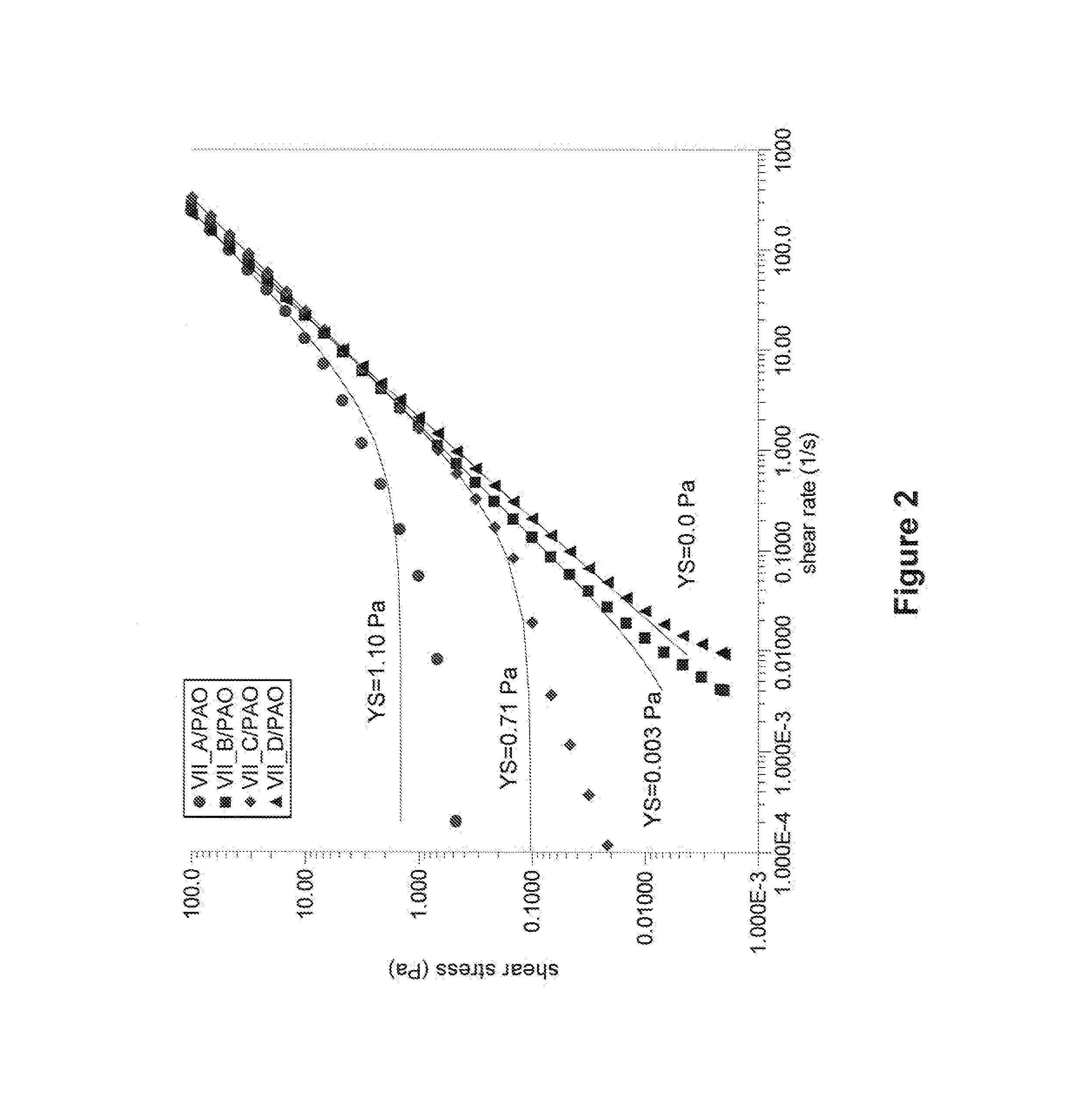

Method and apparatus are disclosed for measuring an apparent viscosity of a non-Newtonian fluid. The method and apparatus involves calculating a power-law number n relating a shear stress of the fluid to a shear rate of the fluid, and then calculating an estimated apparent viscosity ηest of the fluid at a selected shear rate based on a yield stress Y of the fluid and on the calculated power-law number n. The estimated apparent viscosity of the fluid at a selected shear rate is calculated based on the experimental observation that reference shear stress is 1.5 times the yield stress for most shear thinning fluids (e.g., grease).

Owner:LINCOLN INDUSTRIES CORP

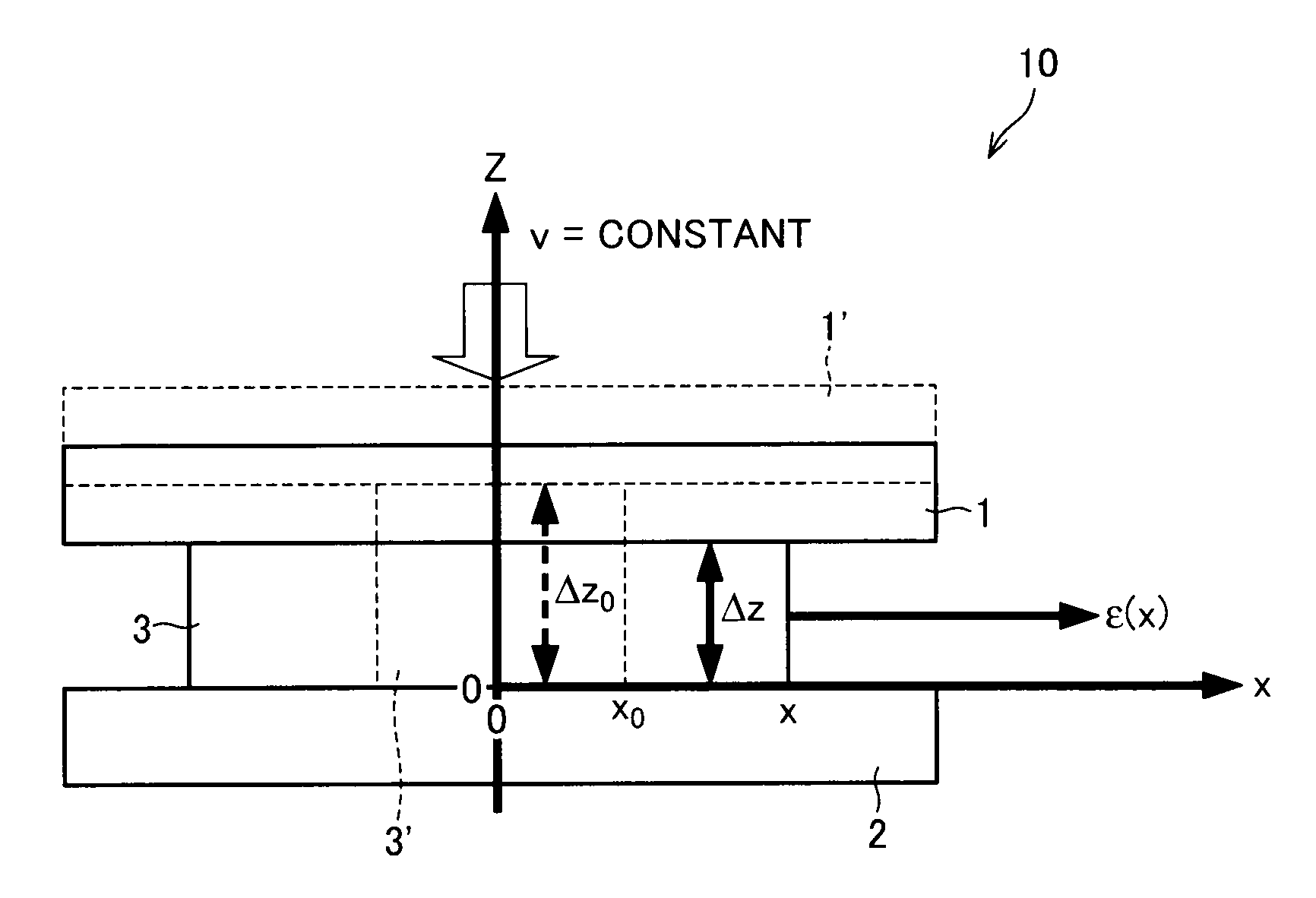

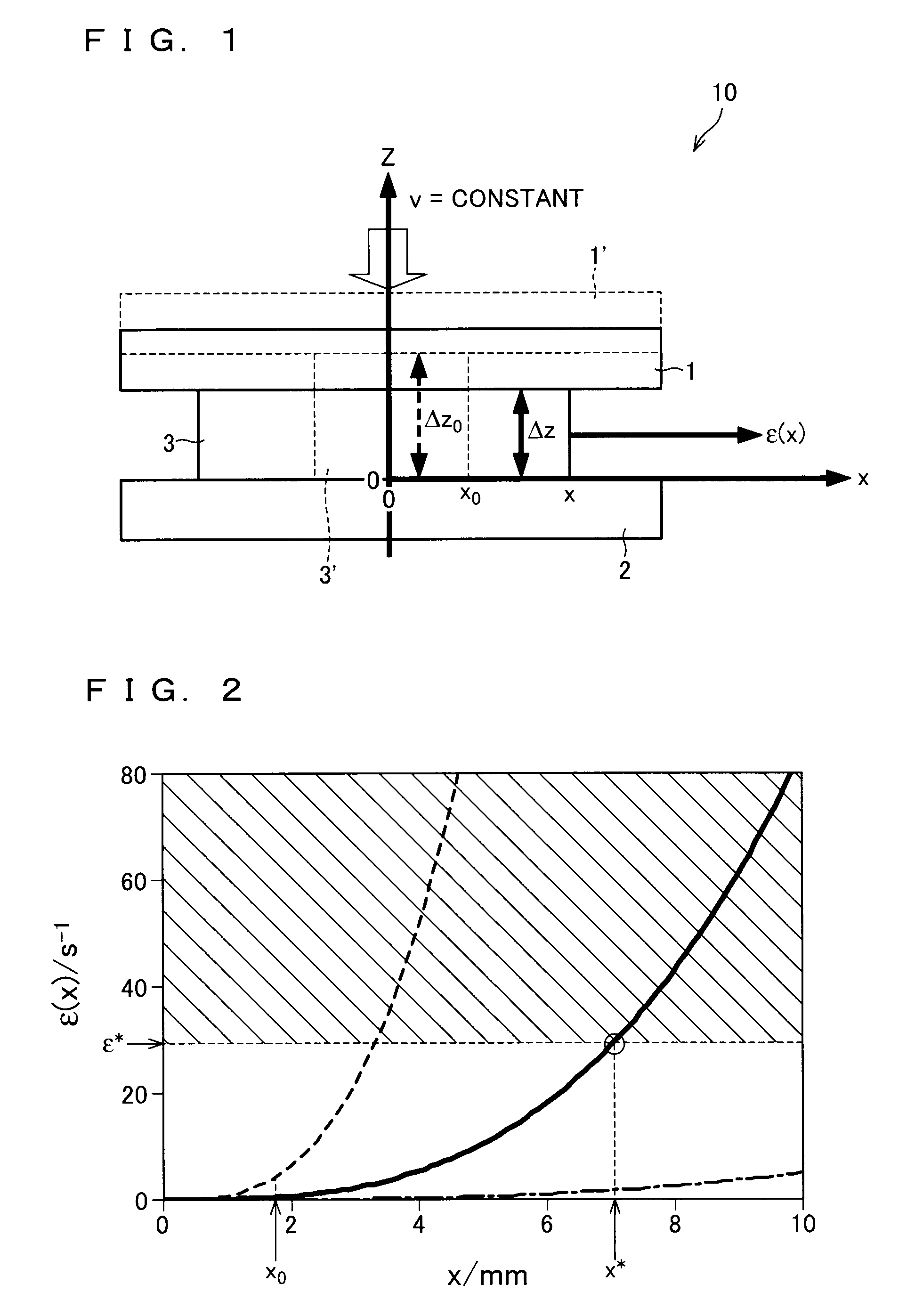

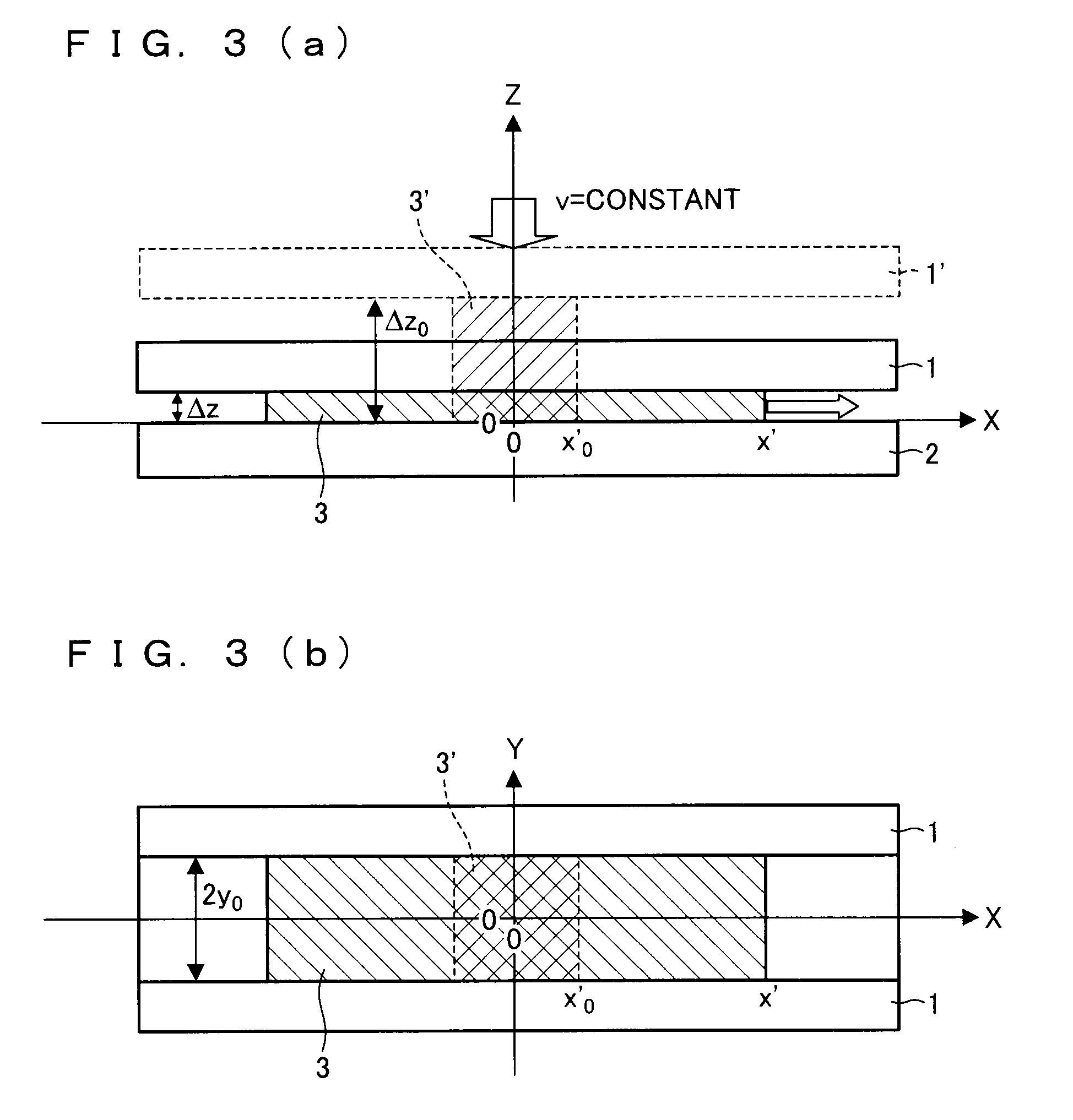

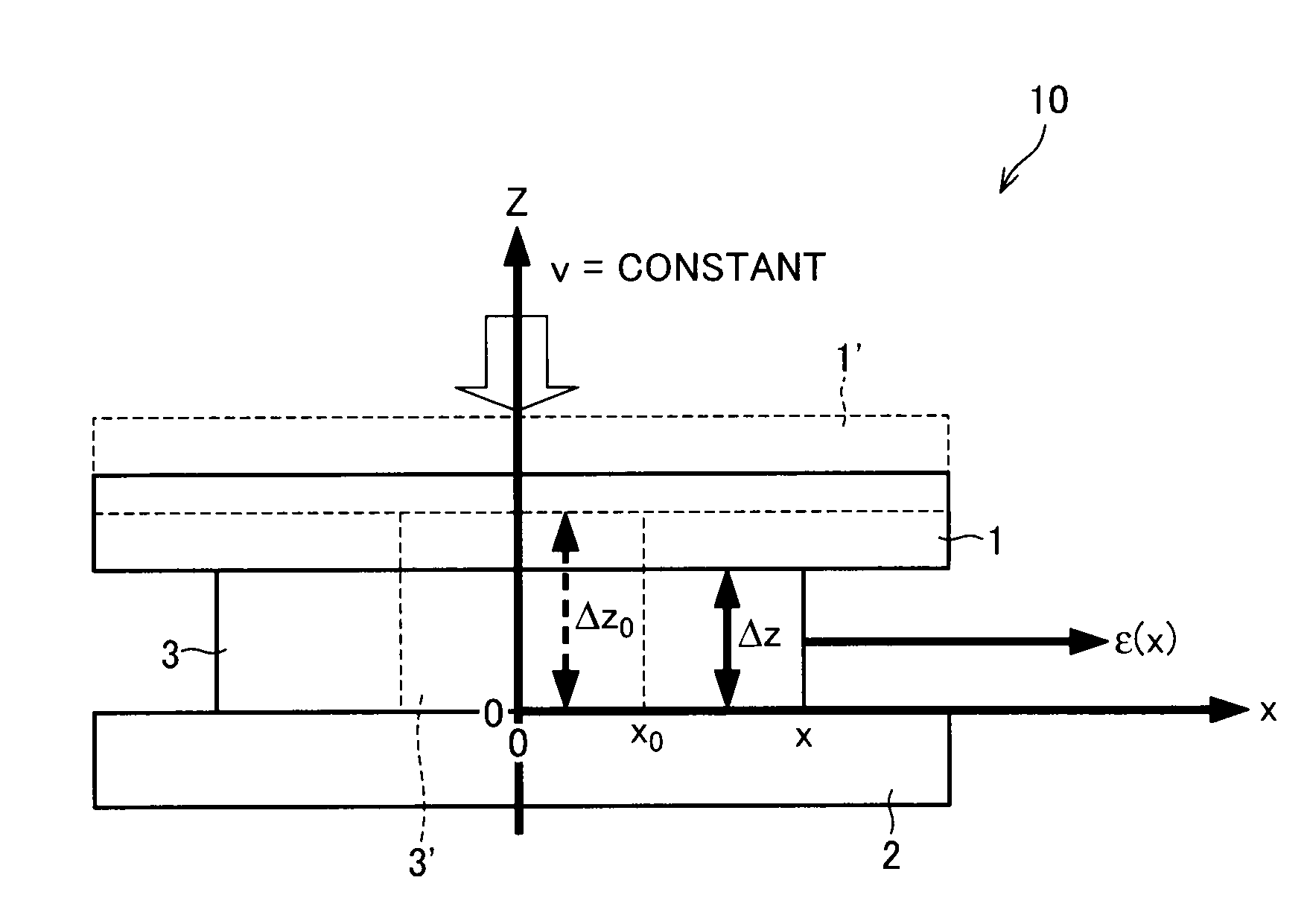

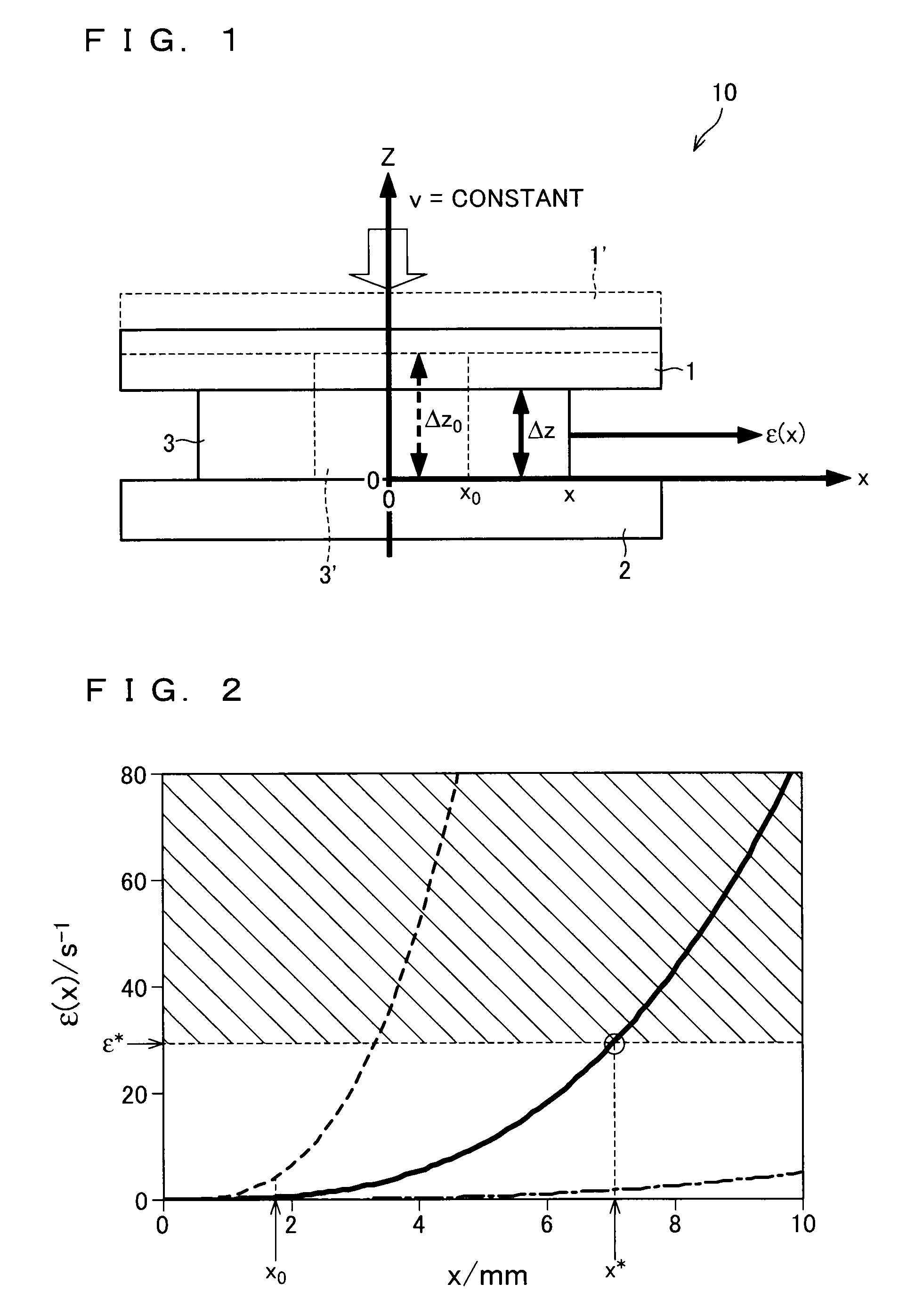

Process for producing polymer oriented crystal, polymer oriented crystal produced by said production process, and method for determining critical elongation strain rate of polymer melt

InactiveUS20090249883A1Delay in testingLow costRecord carriersForce measurementPolymer sciencePolymer melt

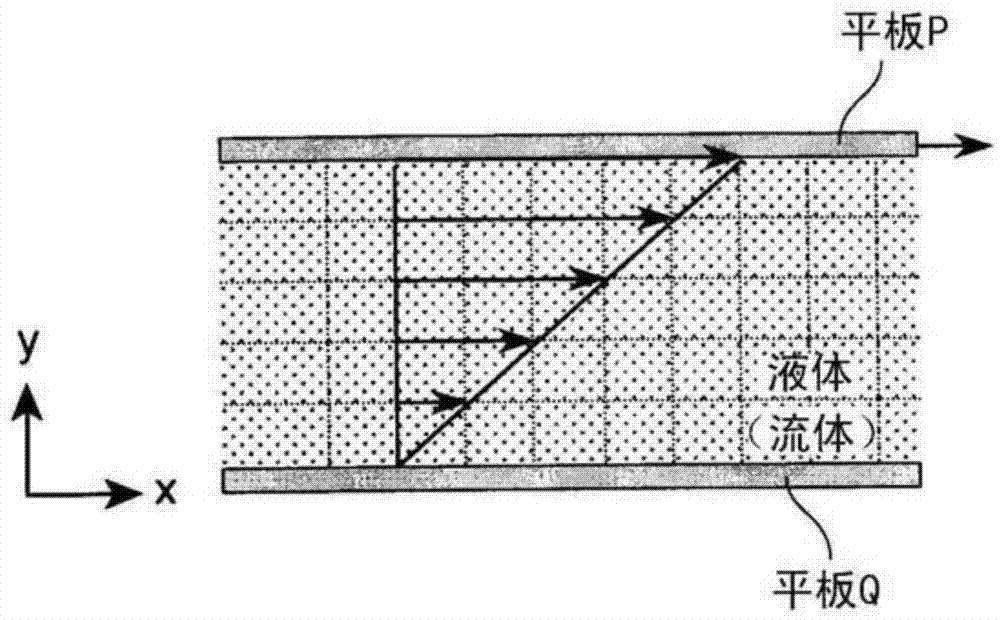

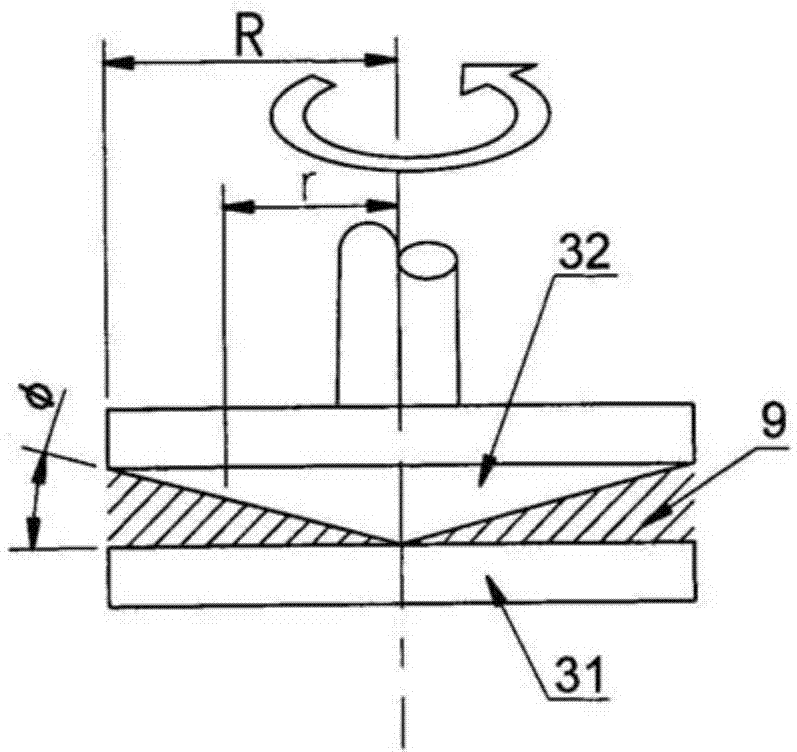

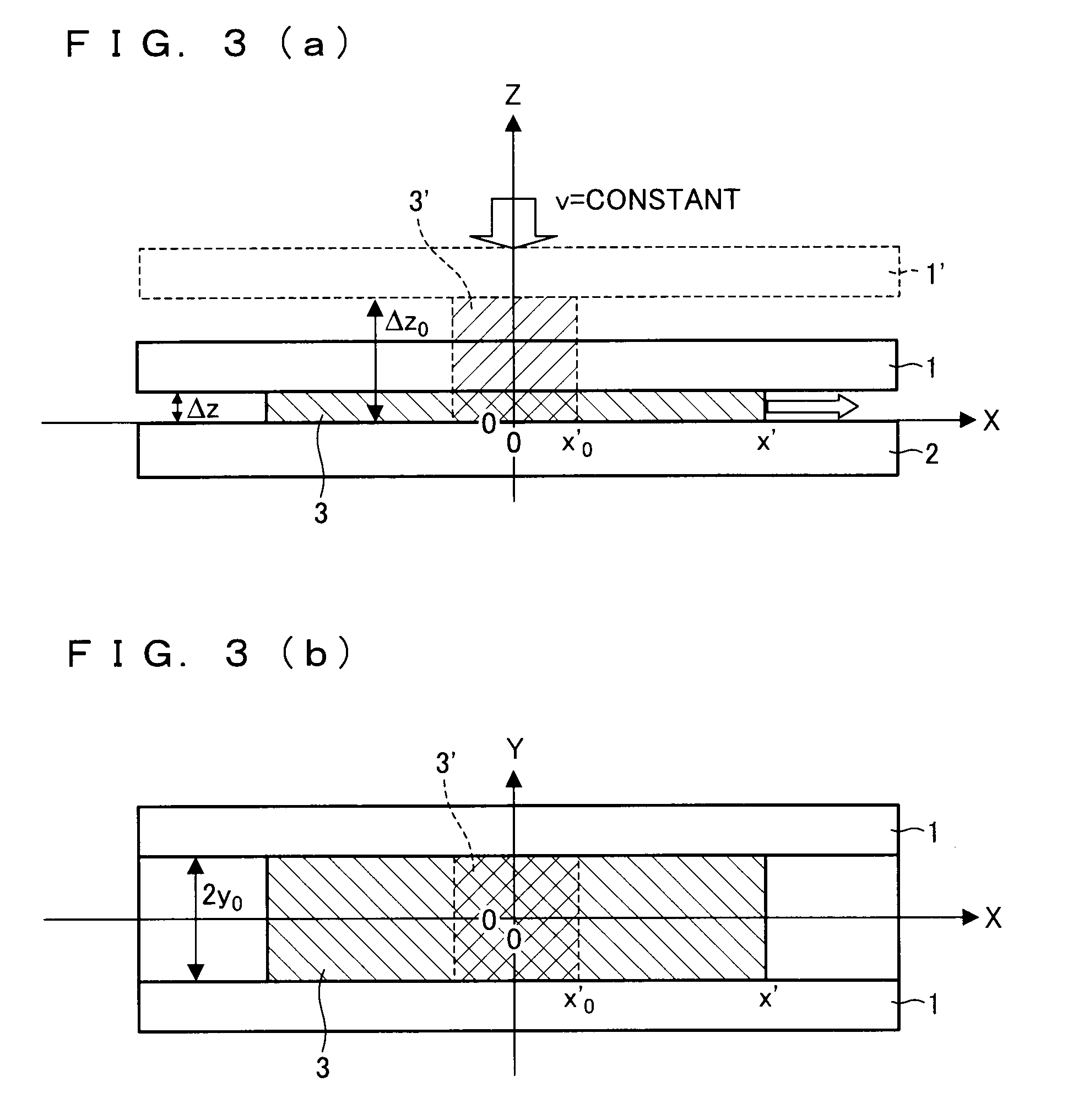

A method and means for determining a critical elongation strain rate of a polymer melt, which make it possible to subject a polymer melt to elongation to prepare a bulk oriented melt, are established, and a process for producing bulk polymer oriented crystals and polymer oriented crystals are provided. In the critical elongation strain rate determination process or critical elongation strain rate determining method, a polymer melt (3) in a disc shape having a radius x0 and a thickness of Δz0 is held between transparent plates (an upper transparent plate (1) and a lower transparent plate (2)). The polymer melt (3) is cooled to a supercooled state and is press in a thickness direction at a constant rate v by using the transparent plates. The critical point radius x*, at which the polymer melt (3) is turned to an oriented crystal, is measured, and the critical elongation strain rate ε is calculated by equation ε=ax*3 wherein α=v / (2Δz0x03)

Owner:HIROSHIMA UNIVERSITY

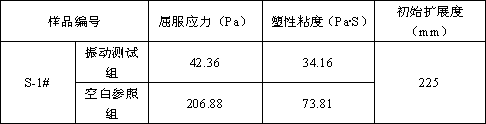

Method for testing vibration rheological properties of cement mortar

PendingCN110595947AAdjustable vibration frequencyAdjustable vibration amplitudeFlow properties on non-Newtonian fluidsVibration testingVibration amplitudeFrequency conversion

The invention relates to a method for testing the vibration rheological property of cement mortar. Frequency conversion vibration equipment is combined with a rheometer to test the rheological property of the cement mortar. In the test method, the composition, vibration frequency range and vibration amplitude of the frequency conversion vibration equipment are defined. The rheometer has the characteristics of rotor rotation speed, torque, resolution, and sample volume suitable for evaluation of mortar rheological property. According to the method for testing the vibration and rheological properties of the cement mortar provided by the invention, the matching simulation of the frequency conversion vibration equipment for the vibration compaction process and the advantage of the rheometer inaccurate evaluation of the rheological properties of the cement mortar are combined; based on the practice of compaction of the cement mortar, the rheological behavior of the cement mortar under thevibration state is accurately evaluated; and an important basis is provided for optimization and control of the working performance.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

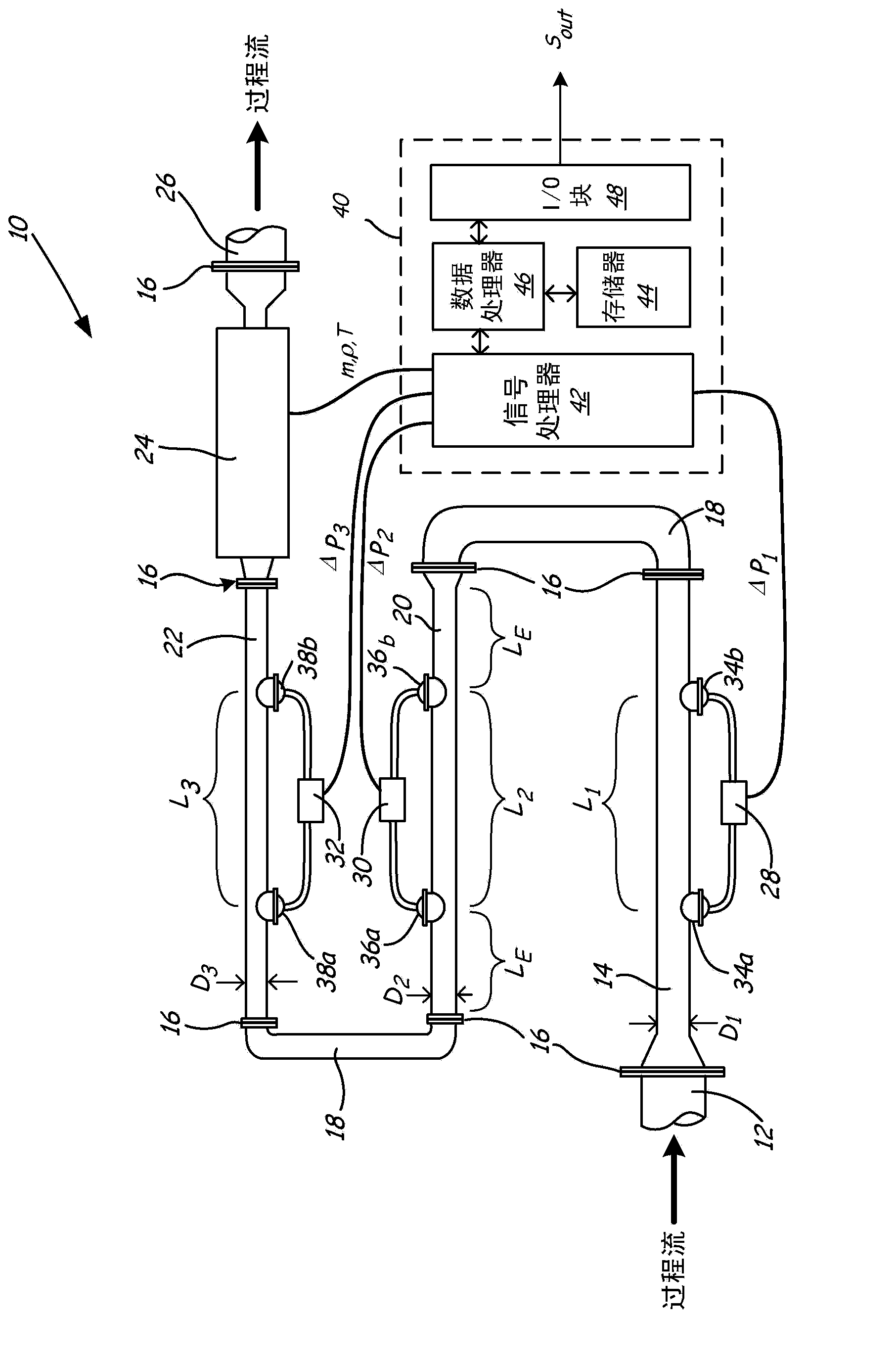

Viscometer for newtonian and non-newtonian fluids

InactiveCN103512833AFlow properties on non-Newtonian fluidsDirect mass flowmetersDifferential pressureTransducer

A viscometer comprises a plurality of capillary tubes connected in series with a mass flow meter. The capillary tubes are smooth, straight, and unimpeded, and each has a different known, constant diameter. Differential pressure transducers sense differential pressure across measurement lengths of each capillary tube, and the mass flow meter senses fluid mass flow rate and fluid density. A data processor connected to the mass flow meter and the differential pressure transducers computes viscosity parameters of fluid flowing through the viscometer using non-Newtonian fluid models, based on the known, constant diameters and measurement lengths of each capillary tube, the sensed differential pressures across each measurement length, the fluid mass flow rate, and the fluid density.

Owner:ROSEMOUNT INC

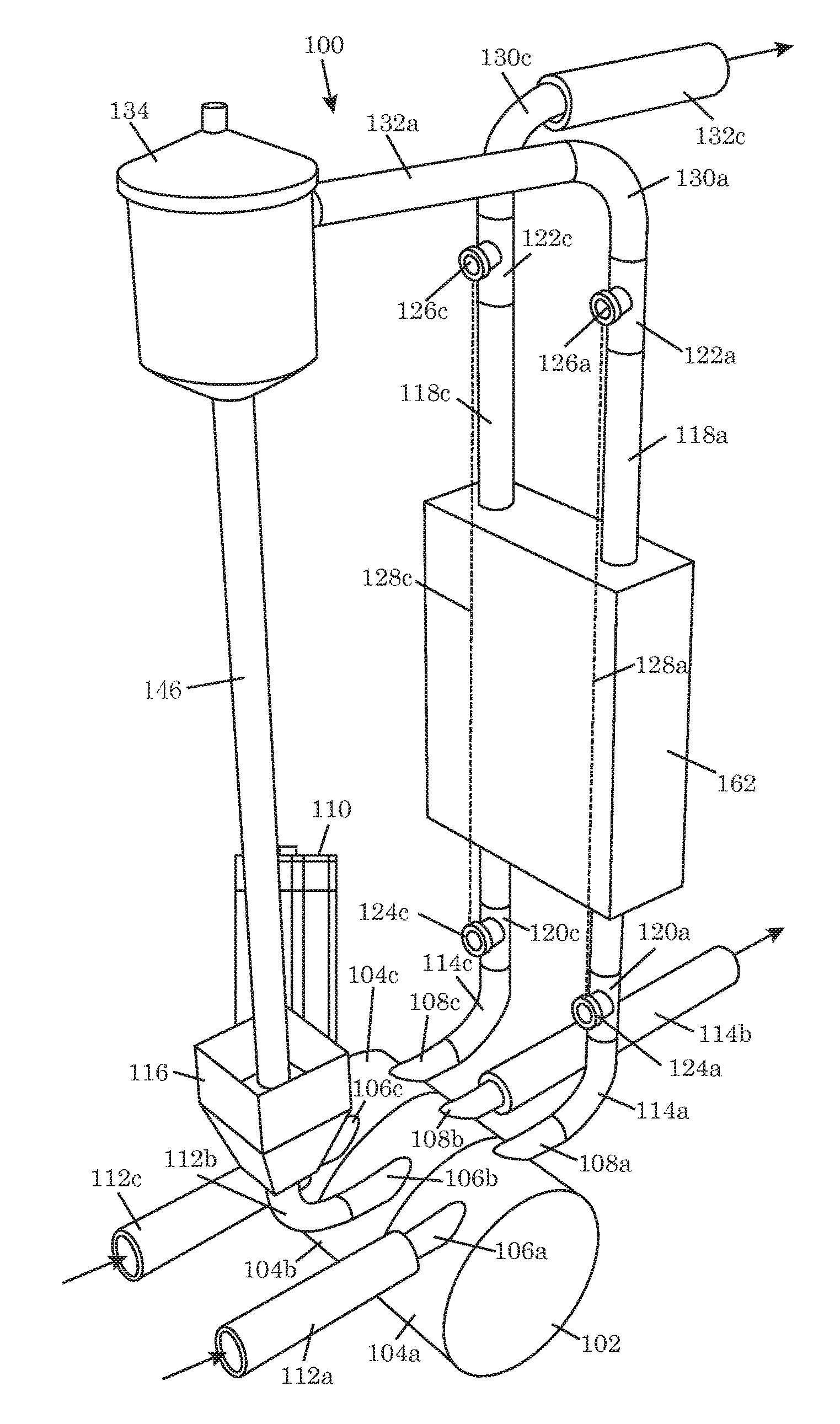

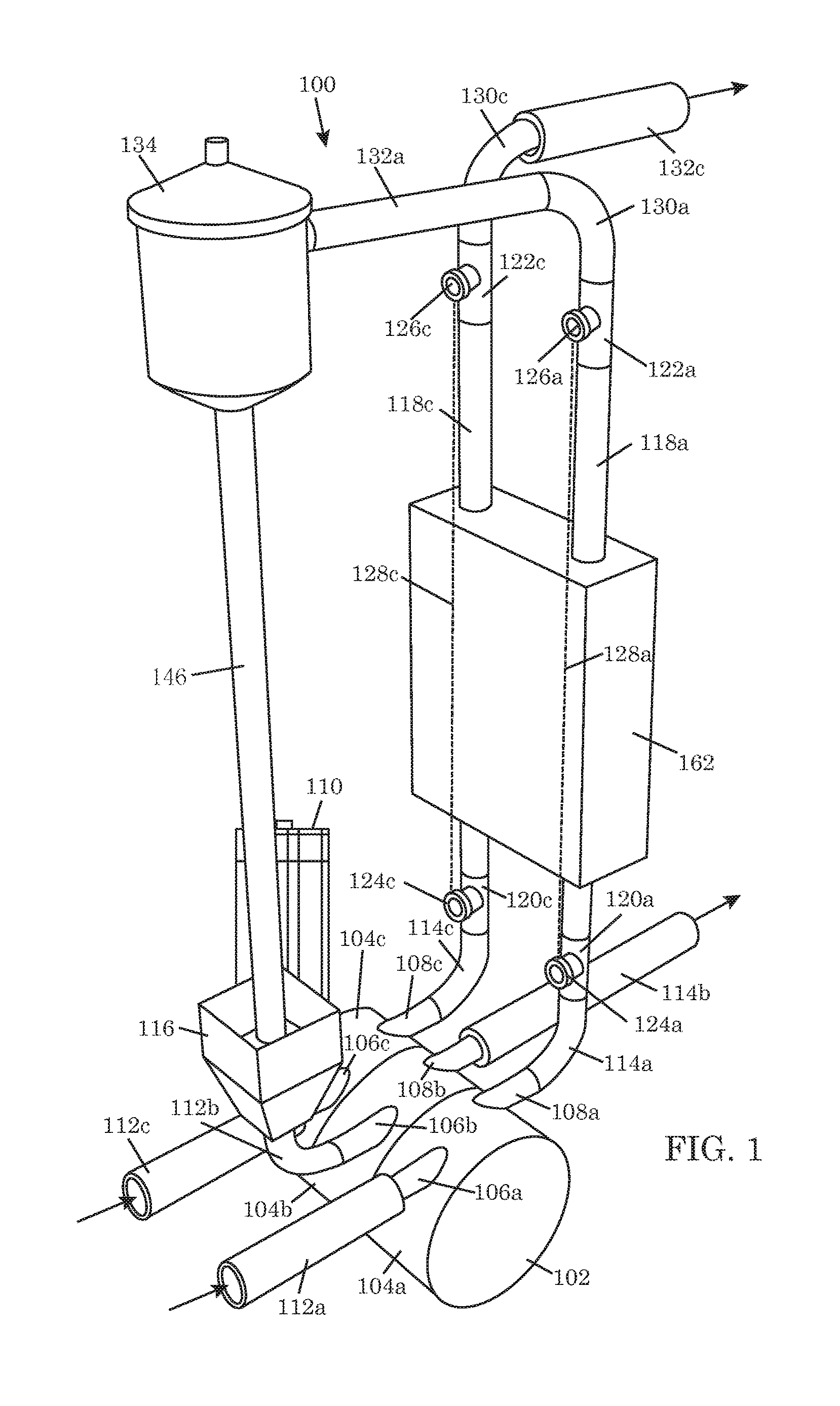

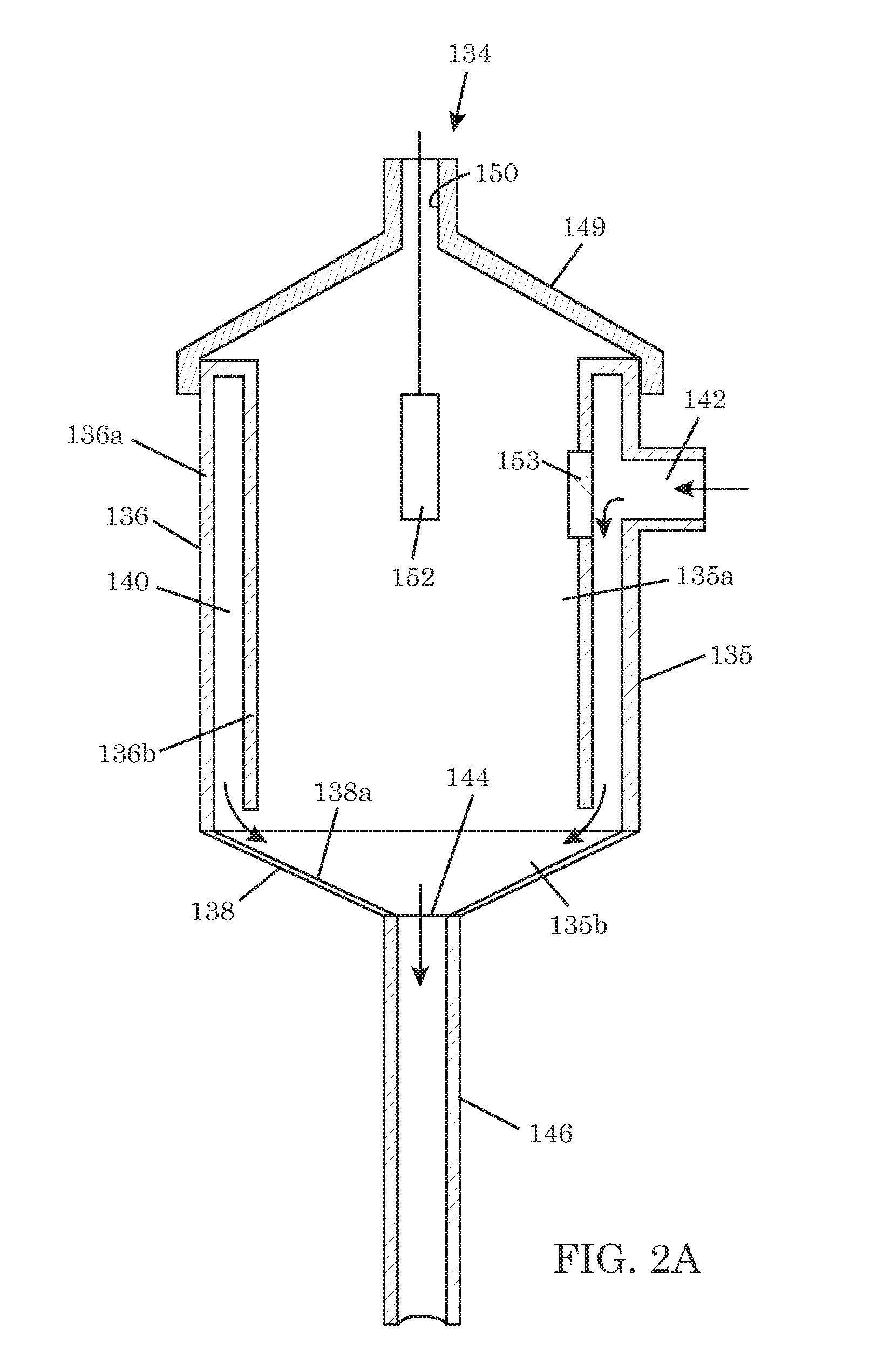

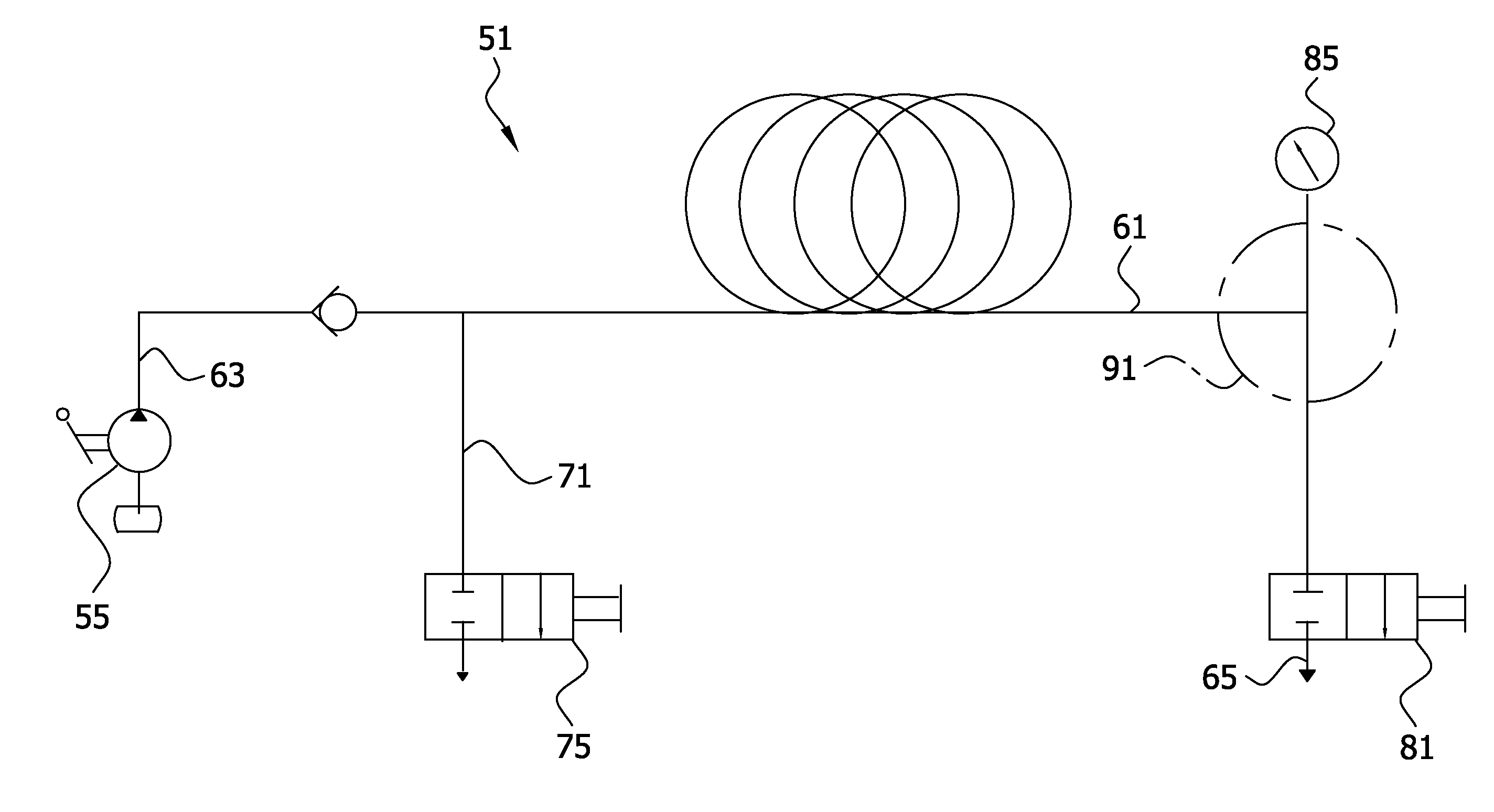

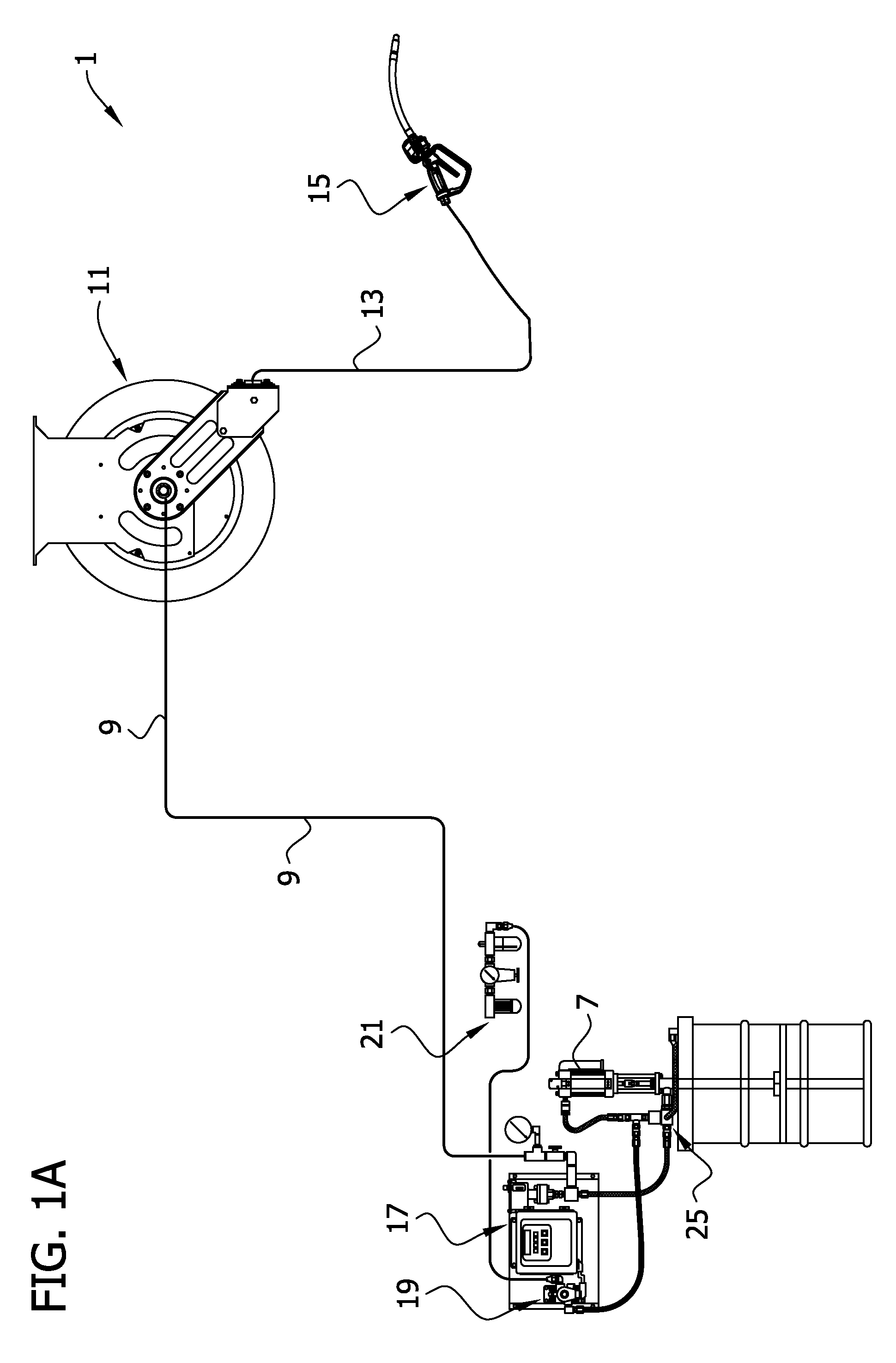

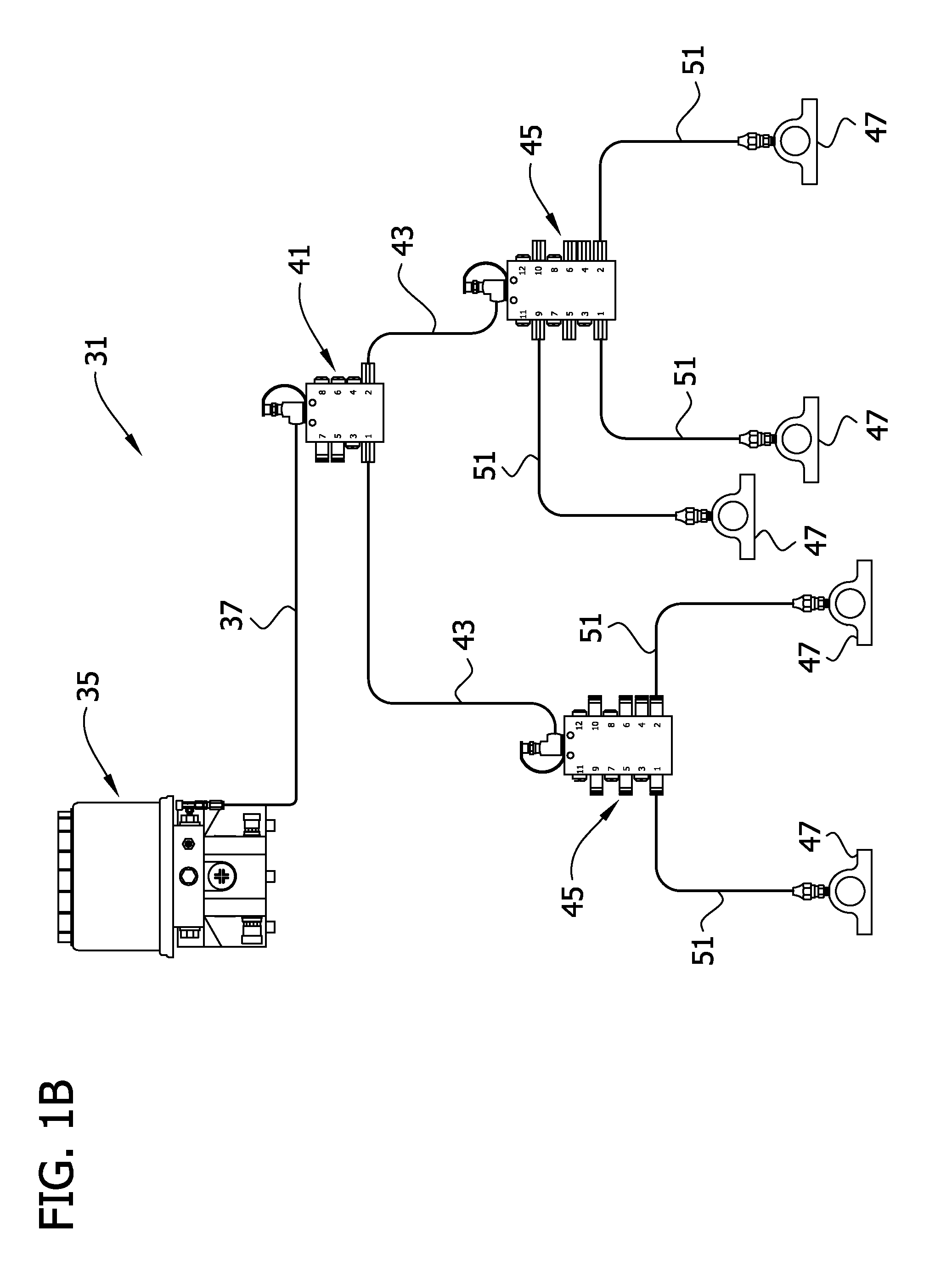

Method and apparatus for measuring drilling fluid properties

As system for measuring drilling fluid properties includes a capillary rheometer that is adapted to measure viscosity parameters of drilling fluid. The capillary rheometer includes a feed chamber, the feed chamber having a cavity, at least a first drain port for draining fluid out of the cavity, a double wall defining an annulus that opens to the cavity, and a feed port in an outer portion of the double wall that is in fluid communication with the annulus. The capillary rheometer also includes at least a first capillary tube coupled to at least the first drain port. Additionally, the disclosed system further includes a pump that is adapted to pump fluid to the feed port.

Owner:NAT OILWELL VARCO LP

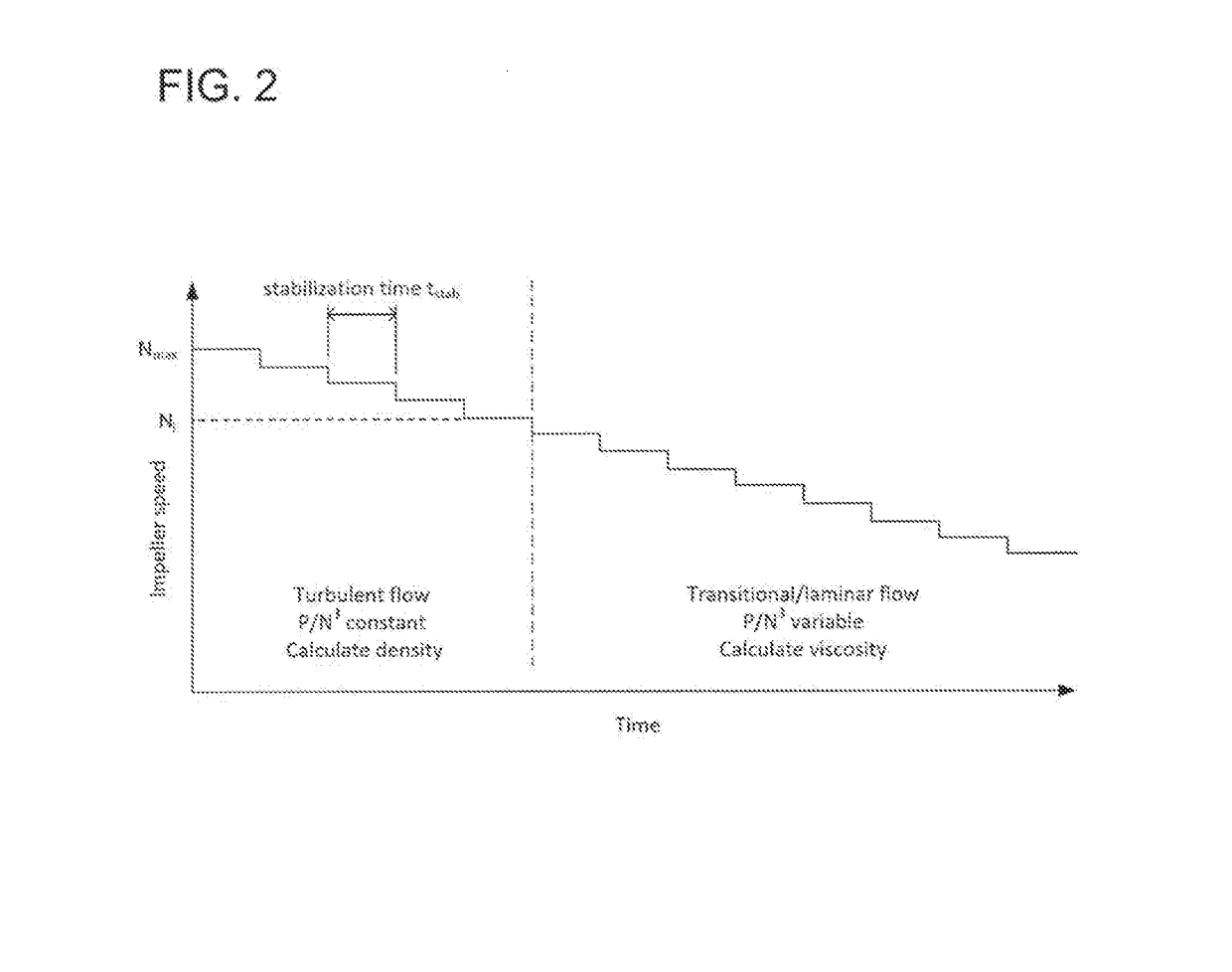

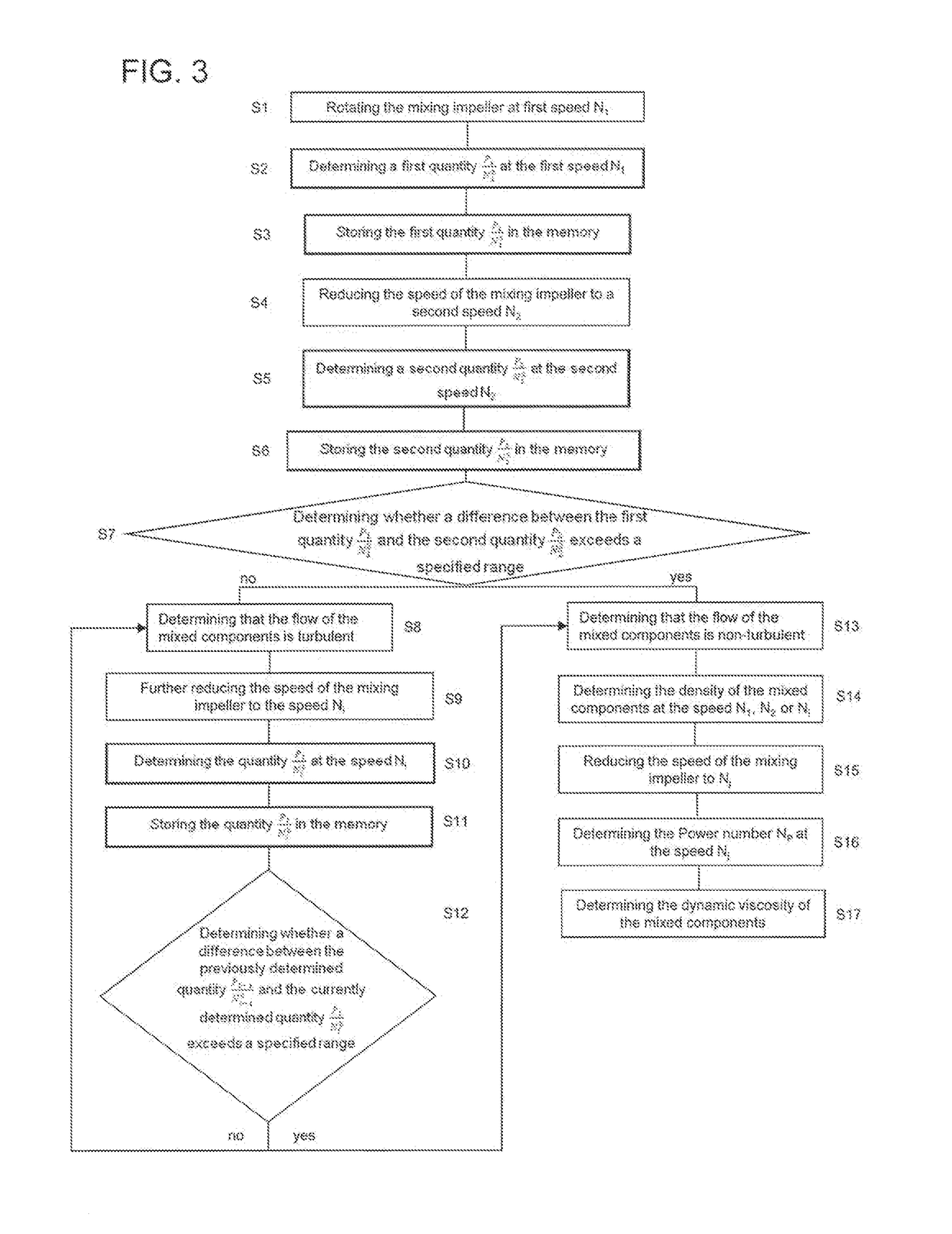

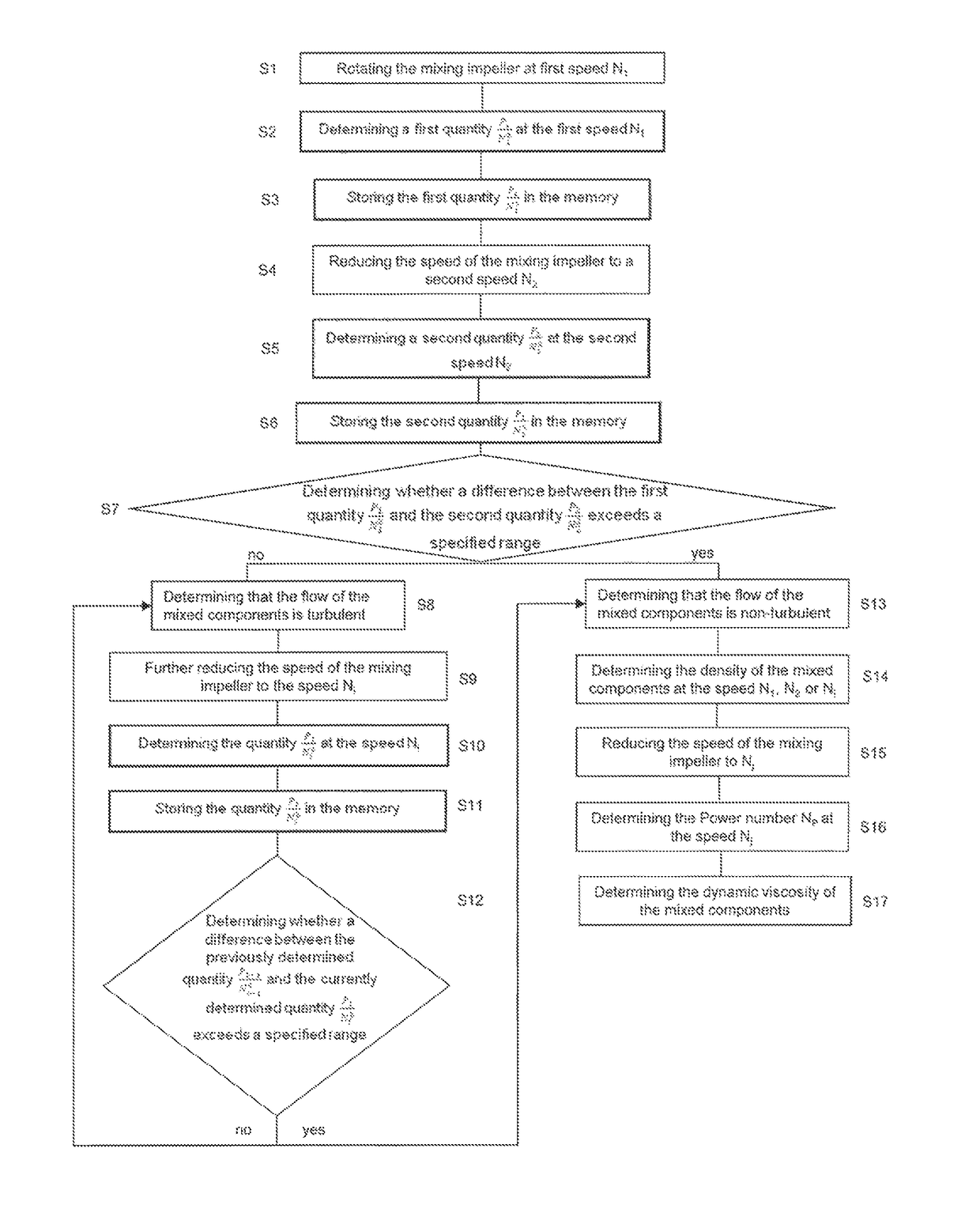

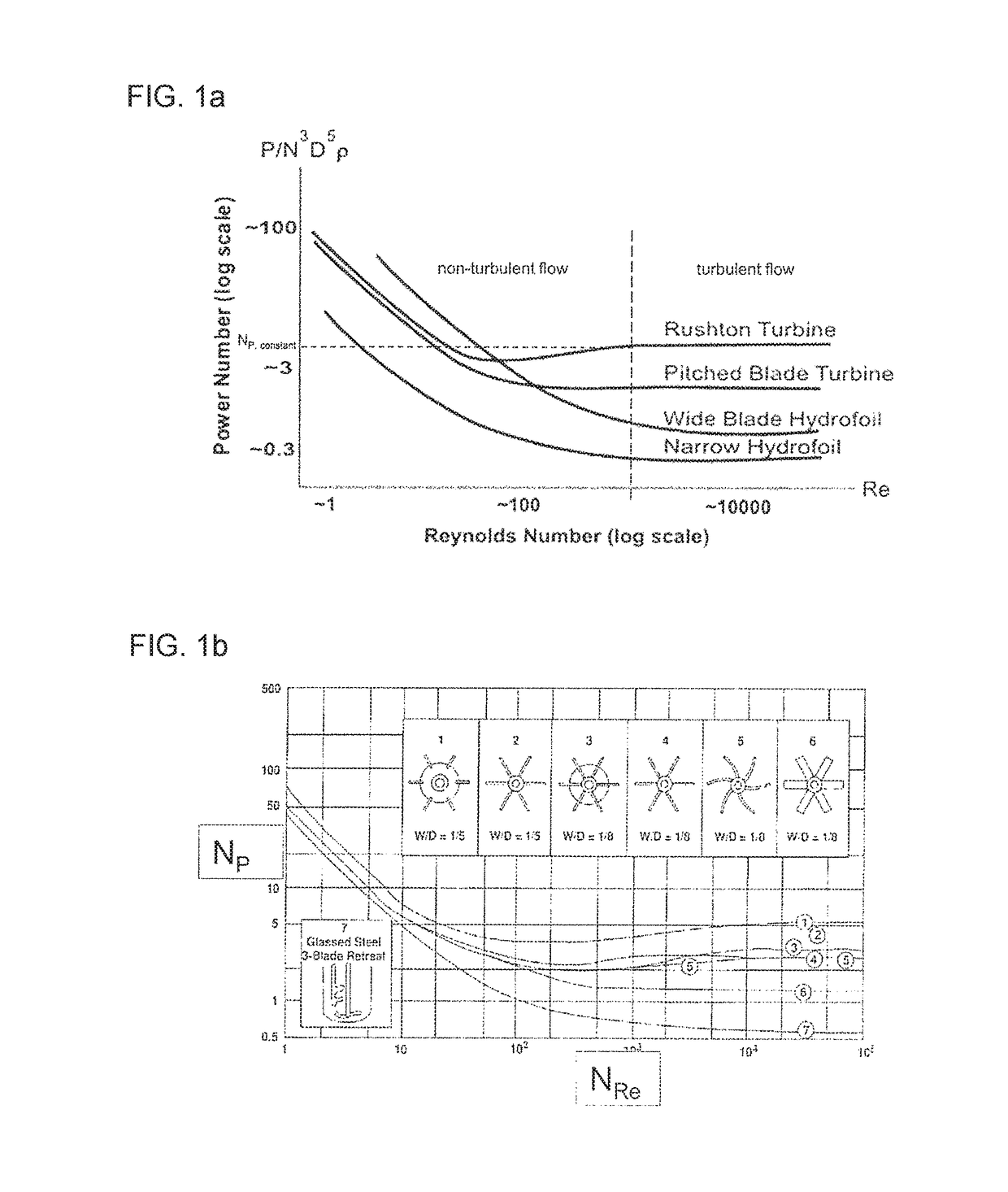

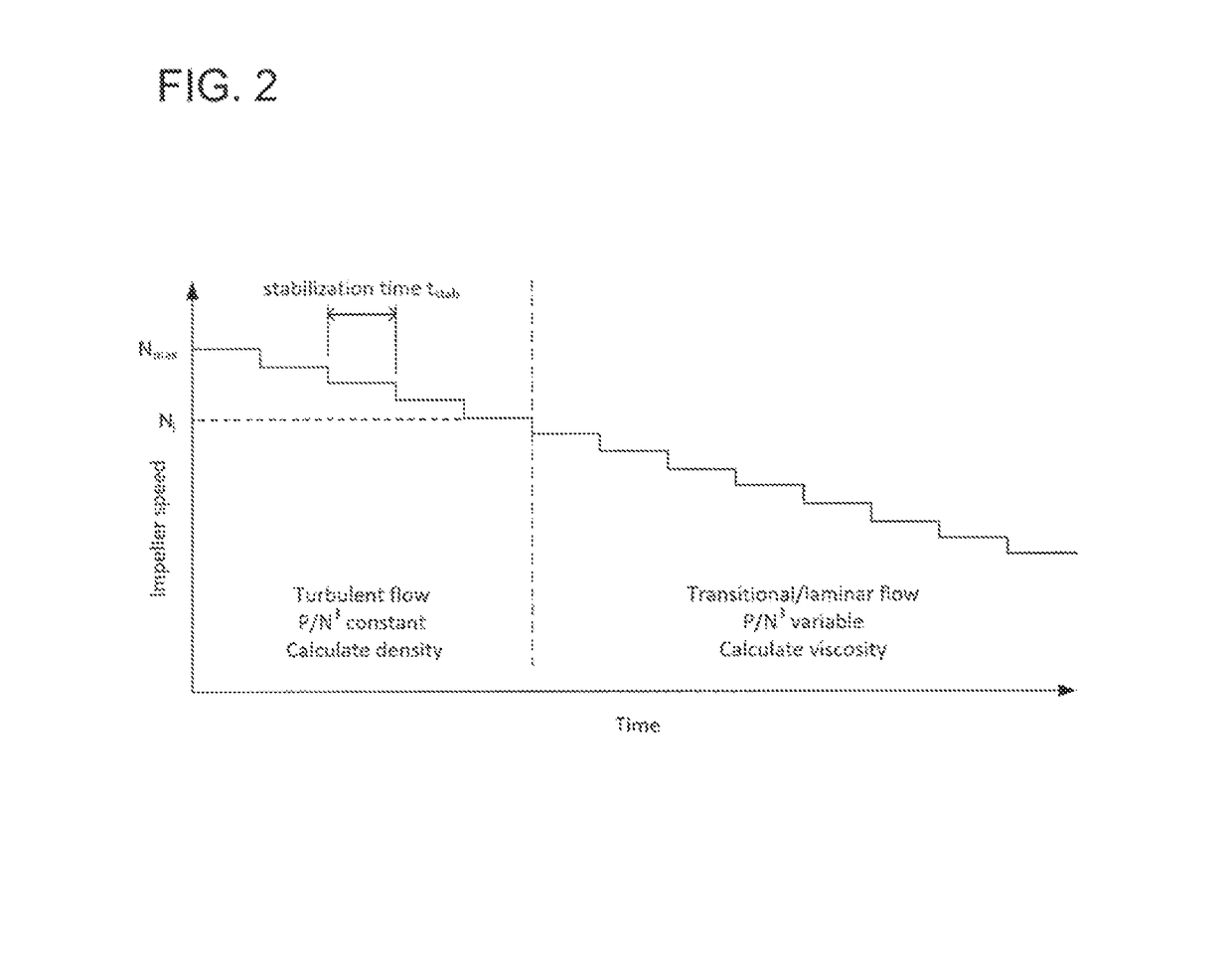

Methods of mixing impeller sensing

ActiveUS20170216798A1Accurate valueShorten speedSamplingRotary stirring mixersImpellerRotation velocity

A method is provided for monitoring a flow behavior of mixed components without requiring additional instrumentation or sampling. The method is carried out by determining ratios of the power required to rotate a mixing impeller at different rotational speeds and then comparing the ratios. Characteristics about the mixed components are determined based on differences between the ratios.

Owner:SARTORIUS STEDIM BIOTECH GMBH

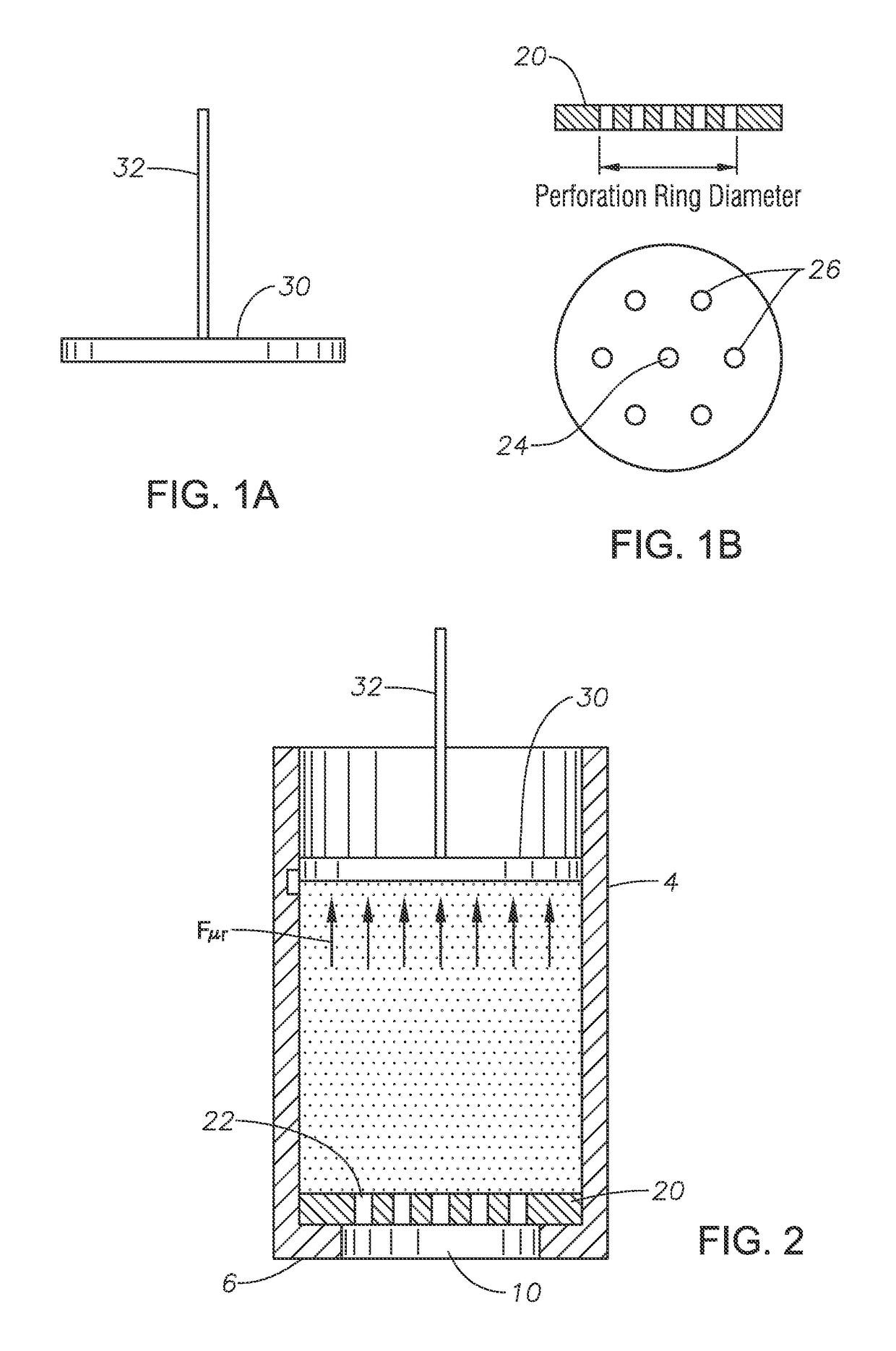

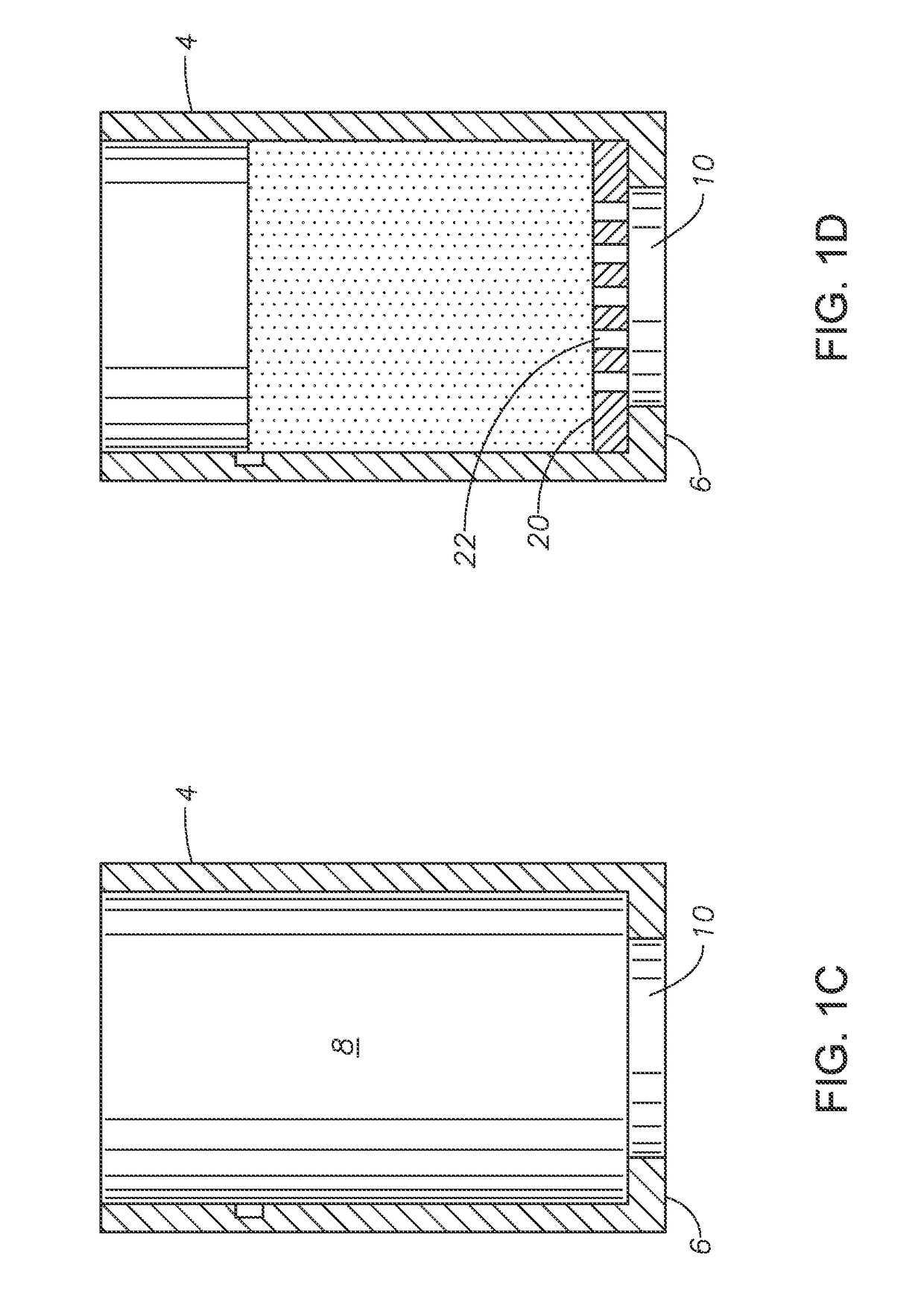

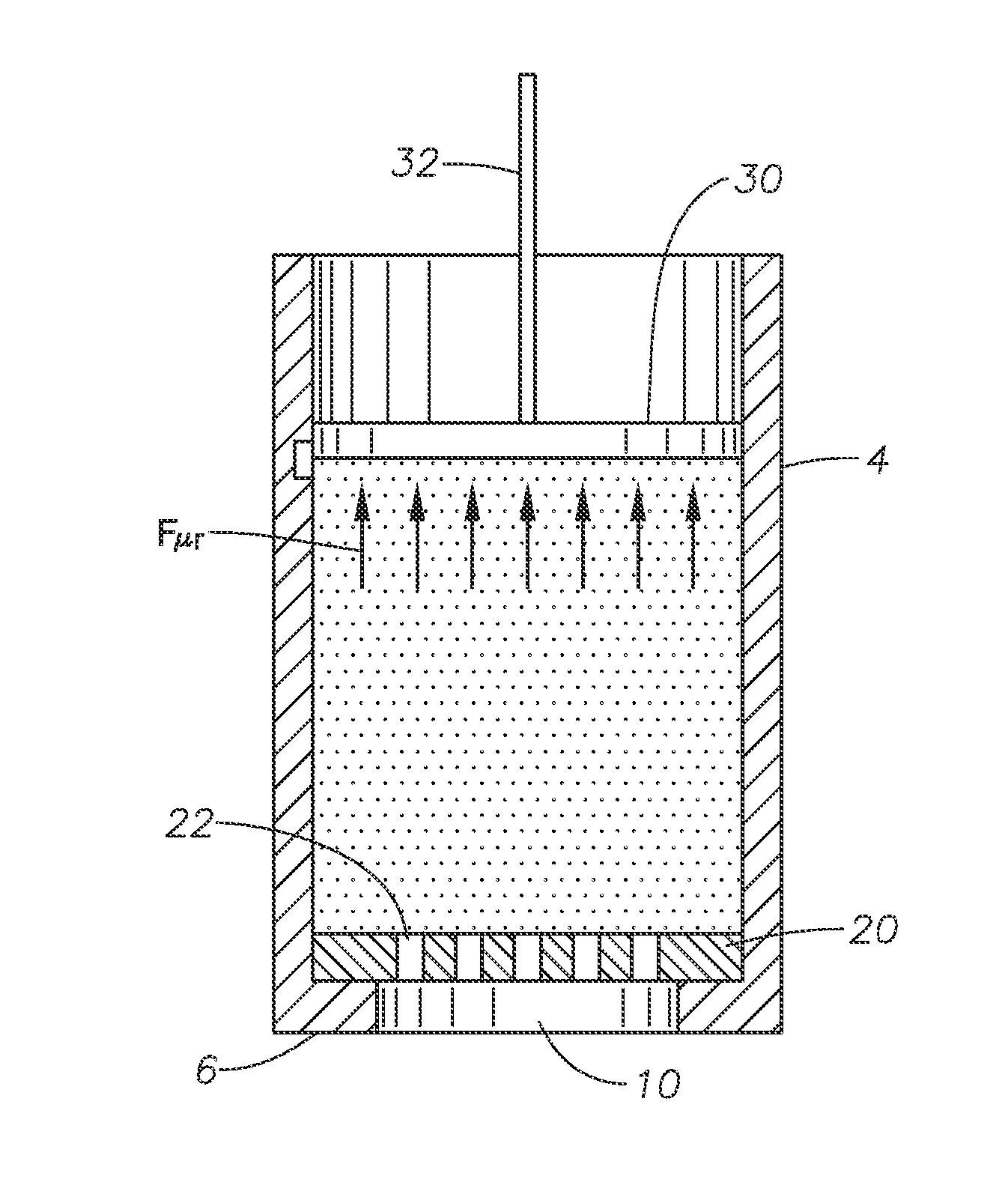

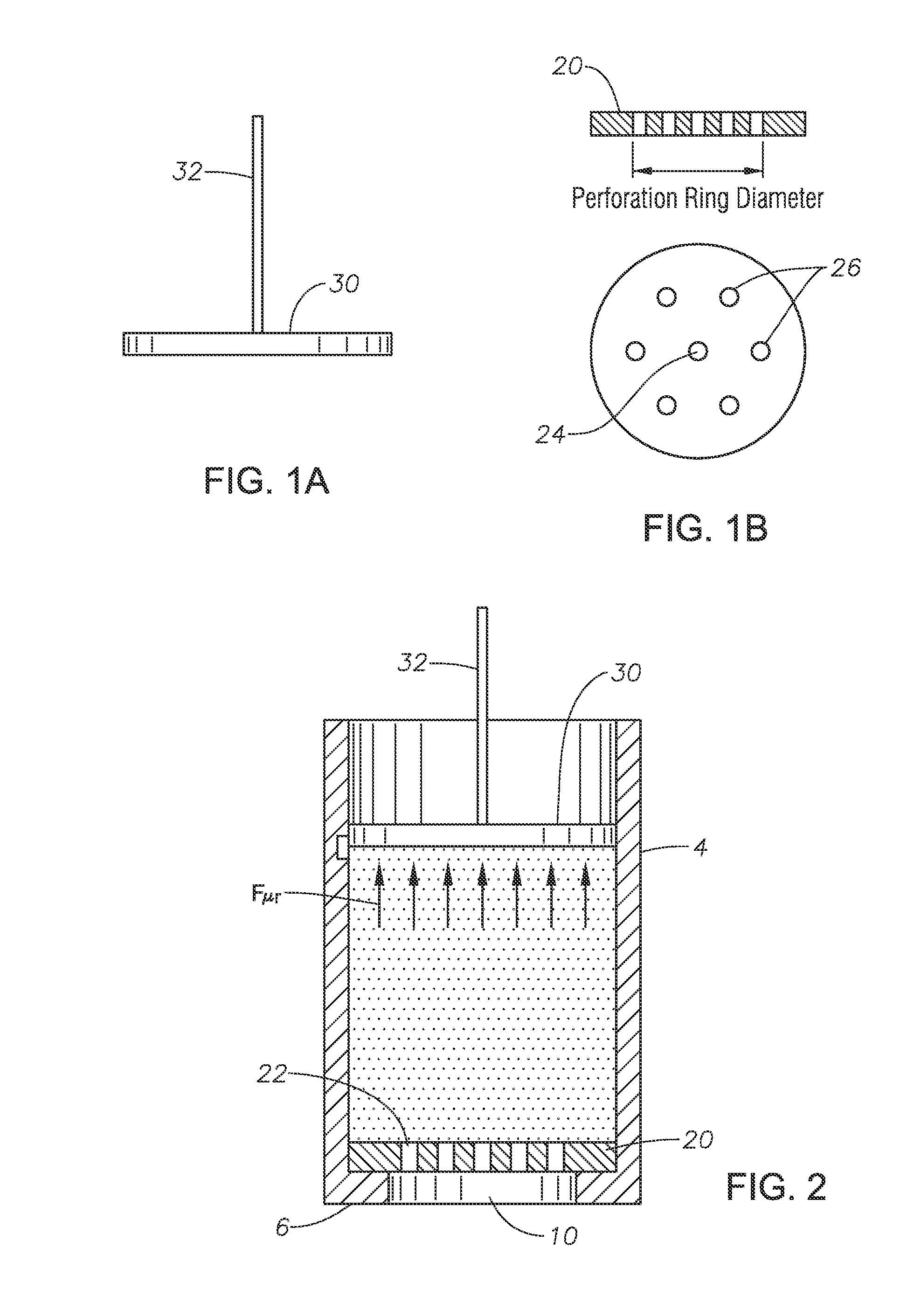

Method and apparatus for testing gel-based lost circulation materials

A compression test rig apparatus for determining a mechanical characterization of a gel-based LCM test sample comprising an LCM test cell configured to contain the gel-based LCM test sample, the LCM test cell comprising a cylinder wall defining a cell space volume configured to hold the gel-based LCM test sample, and a floor defining an extrusion hole configured to extrude the gel-based LCM test sample to create an extruded gel; an extruded gel collector configured to receive the extruded gel from the extrusion hole as an extruded gel volume; a perforated disc comprising perforations, wherein the perforated disc is configured to allow the gel-based LCM test sample to pass through the perforations; and a flat foot disc piston in flush contact with the cylinder wall, the flat foot disc piston configured to compress the gel-based LCM test sample at a displacement speed to produce compression data.

Owner:SAUDI ARABIAN OIL CO

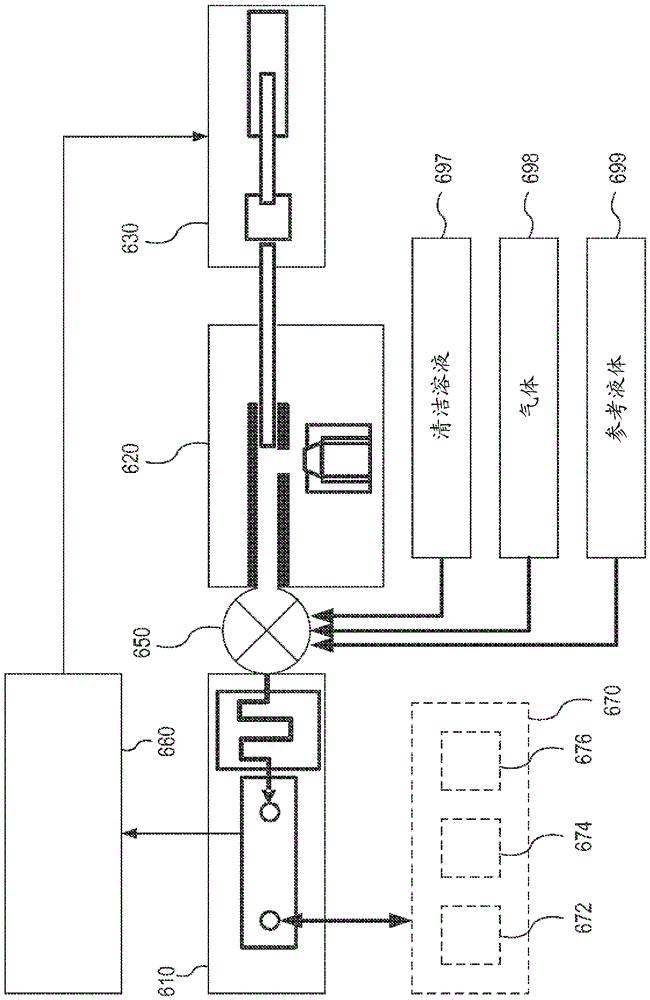

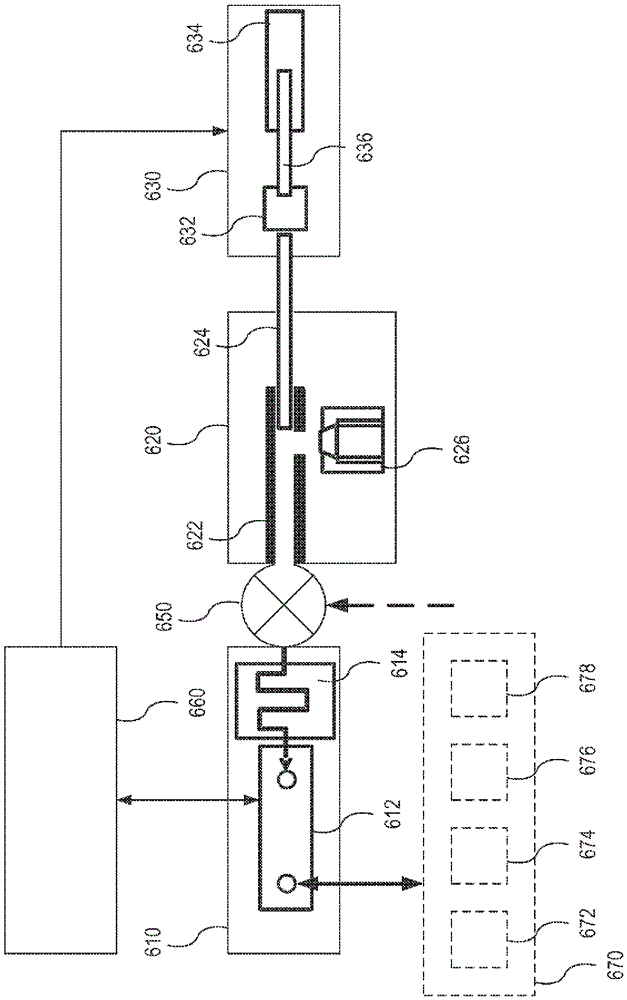

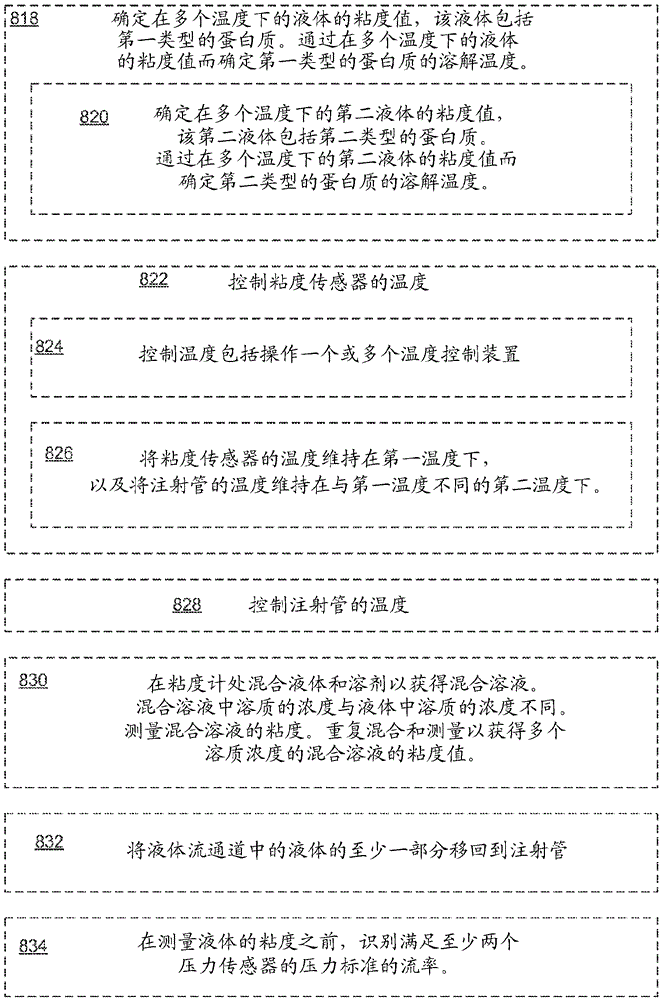

Viscometer and methods for using the same

ActiveCN106415236AFlow properties on non-Newtonian fluidsDirect flow property measurementElectronic controllerEngineering

A viscometer includes a viscosity sensor with a liquid flow channel and at least two pressure sensors positioned along the liquid flow channel and configured to measure a pressure drop of a liquid flowing through the liquid flow channel, and a dispensing mechanism configured to cause dispensing of a liquid from the syringe to the viscosity sensor at a known flow rate. The dispensing mechanism and the viscosity sensor are configured to couple with a syringe configured to contain a liquid. The viscometer further includes an electronic controller configured to control operations of the dispensing mechanism and receive and process data from the viscosity sensor. The viscometer includes a sample loading interface, included in the syringe, through which the viscometer is configured to receive the liquid. The sample loading interface includes a selection valve coupled with, and located between, the viscosity sensor and the syringe.

Owner:RHEOSENSE

System and Method for Estimating Apparent Viscosity of a Non-Newtonian Fluid

ActiveUS20090293594A1Material analysis by optical meansFlow properties on non-Newtonian fluidsApparent viscosityNon-Newtonian fluid

Method and apparatus are disclosed for estimating an apparent viscosity of a non-Newtonian fluid. The results may be used for selecting equipment for pumping systems.

Owner:LINCOLN INDUSTRIES CORP

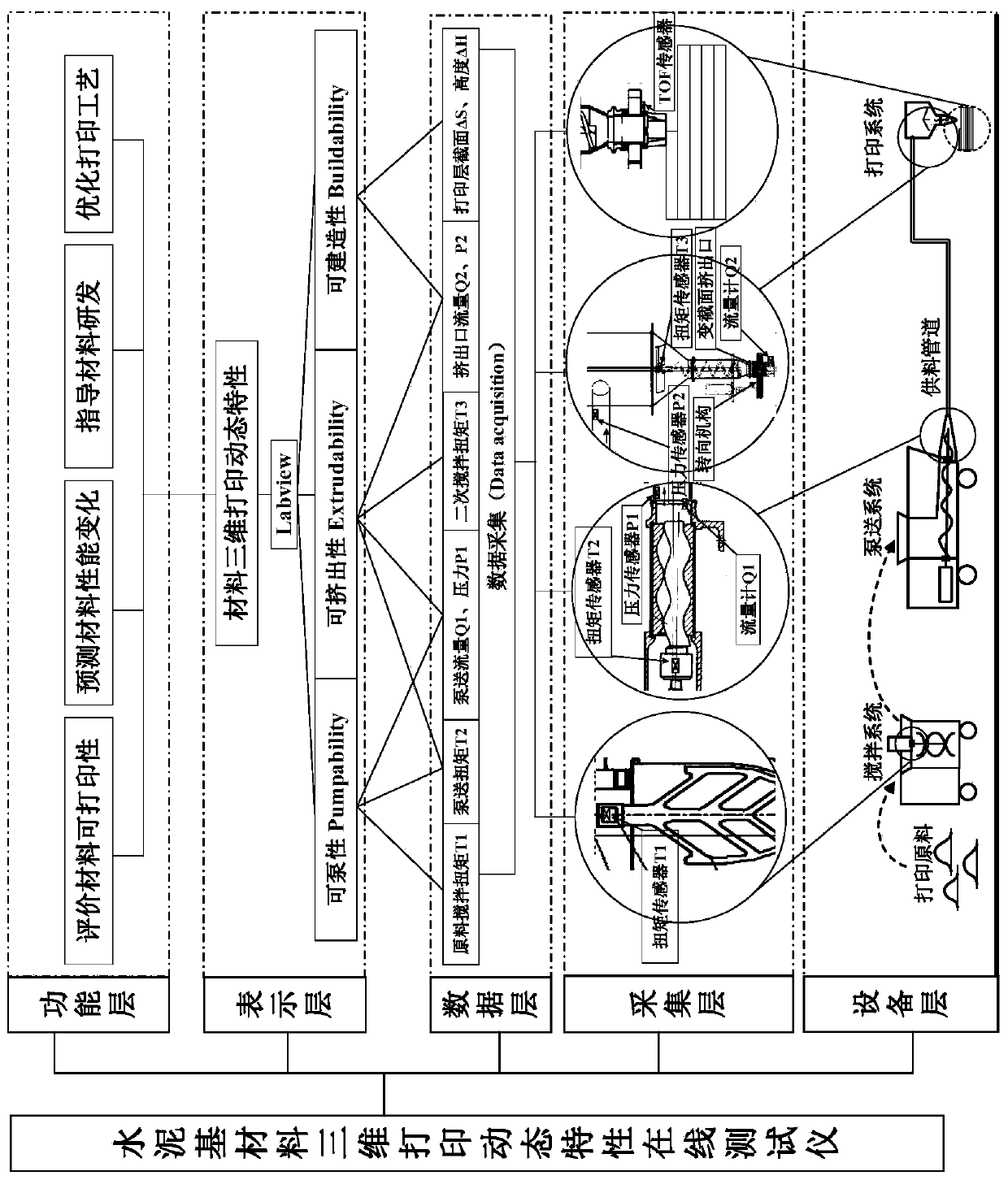

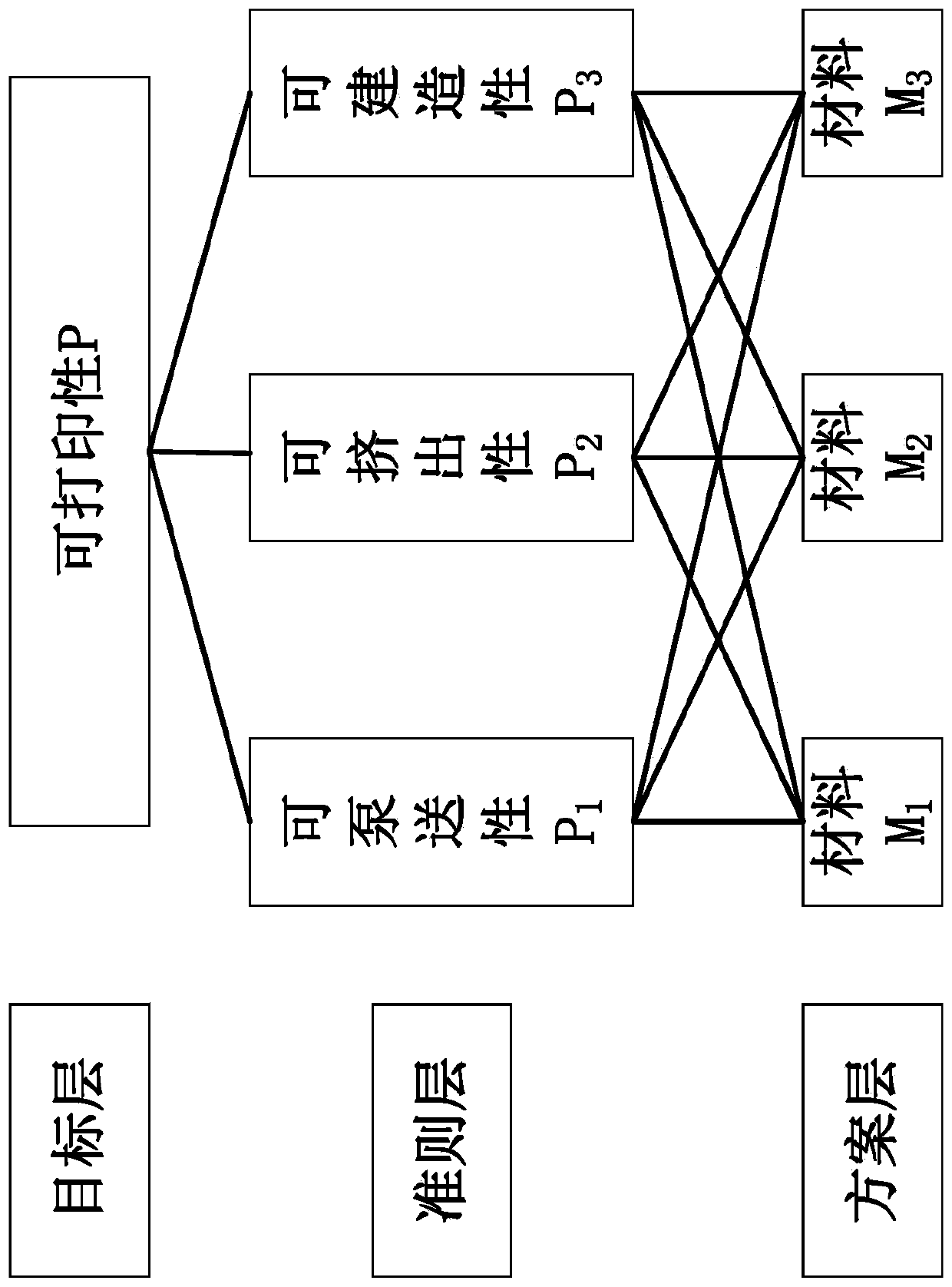

Online testing method for 3D printing dynamic characteristics of cement-based material

ActiveCN110954442ARealization of dynamic featuresReduce human interventionFlow properties on non-Newtonian fluids3d printProcess engineering

The invention relates to an online testing method for 3D printing dynamic characteristics of a cement-based material. The online testing method comprises the following steps of 1) constructing an online testing platform for 3D printing dynamic characteristics of the cement-based material; (2) collecting the printing process parameters in the 3D printing process on line and in real time, and (3) establishing a 3D printing dynamic characteristic prediction model of the cement-based material, and evaluating the 3D printing quality of the cement-based material, namely the printability of the cement-based material. Compared with the prior art, the method has the advantages of comprehensive consideration factors, automatic continuous testing and high applicability.

Owner:TONGJI UNIV

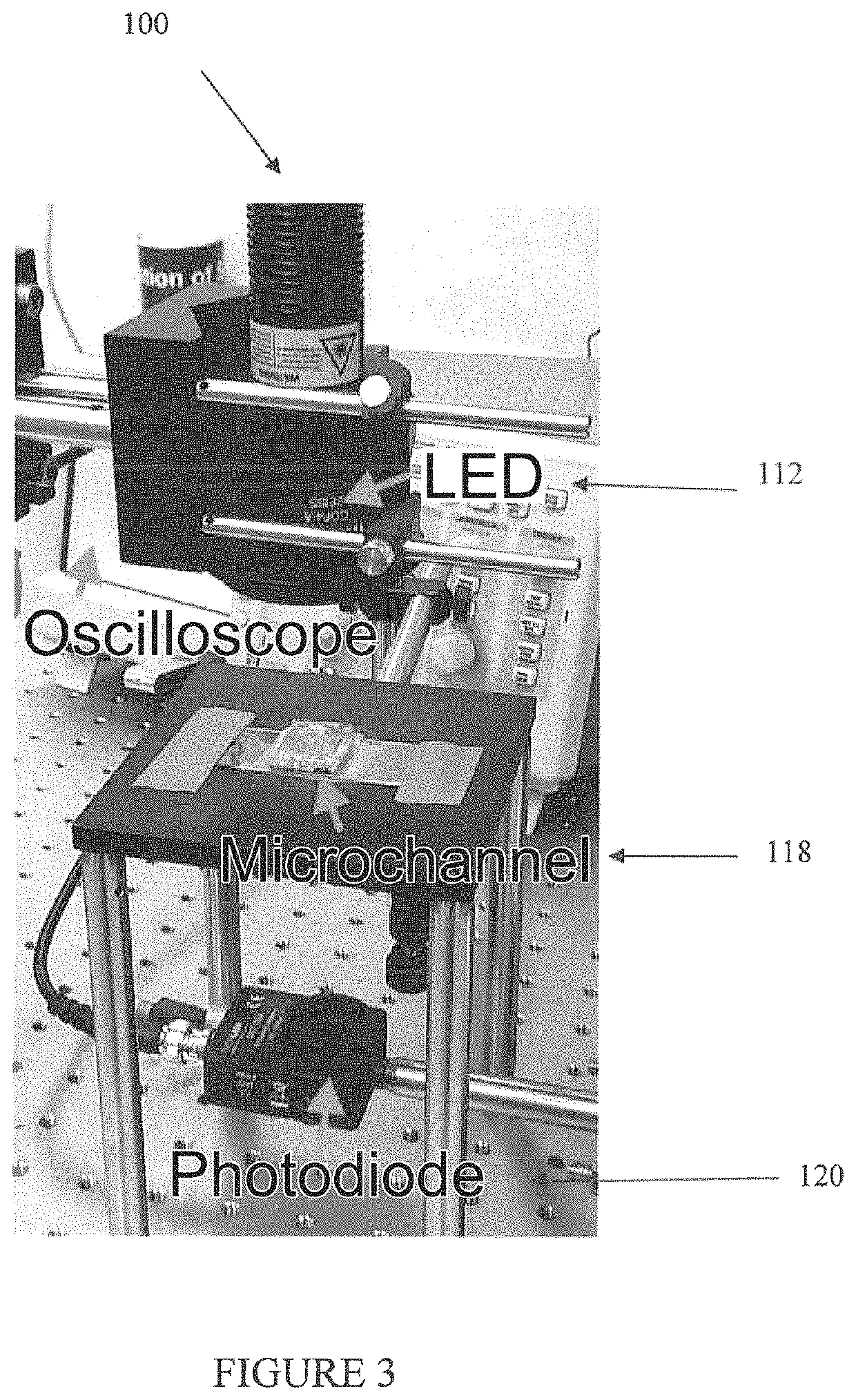

Assembly for measuring the viscosity of fluids using microchannels

ActiveUS10928289B2Easy to assembleBiological testingFlow properties on non-Newtonian fluidsFluid viscosityPhotodiode

Owner:UNIV OF CONNECTICUT

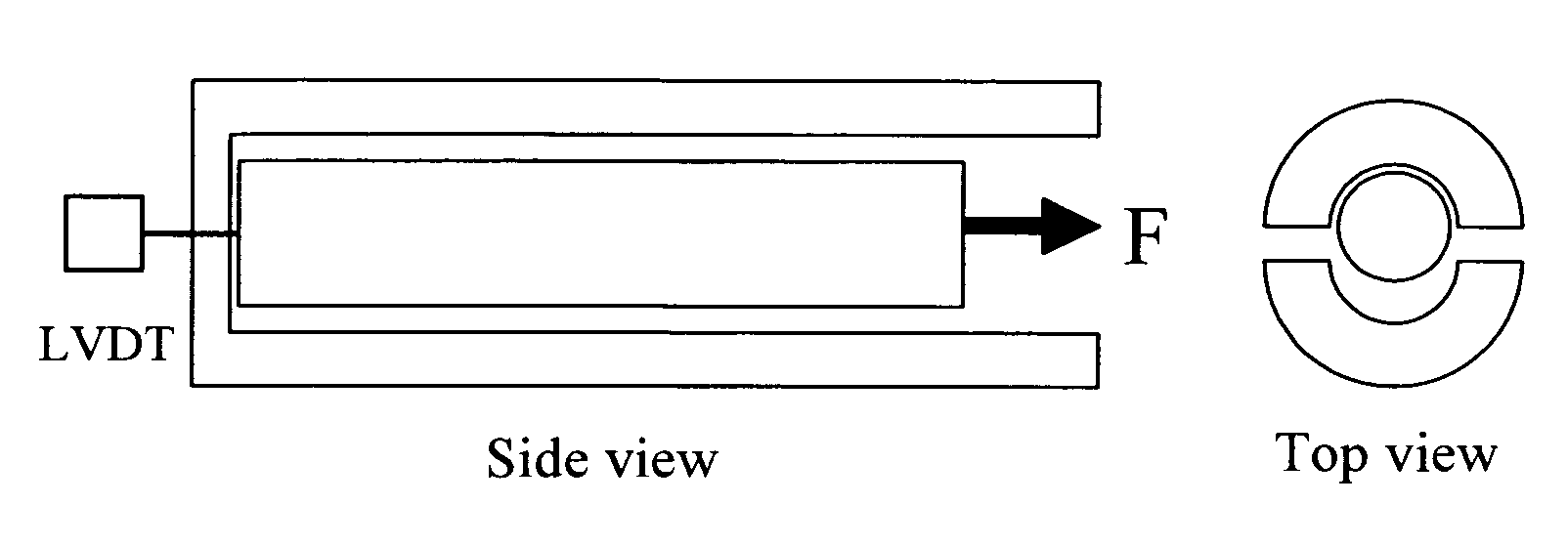

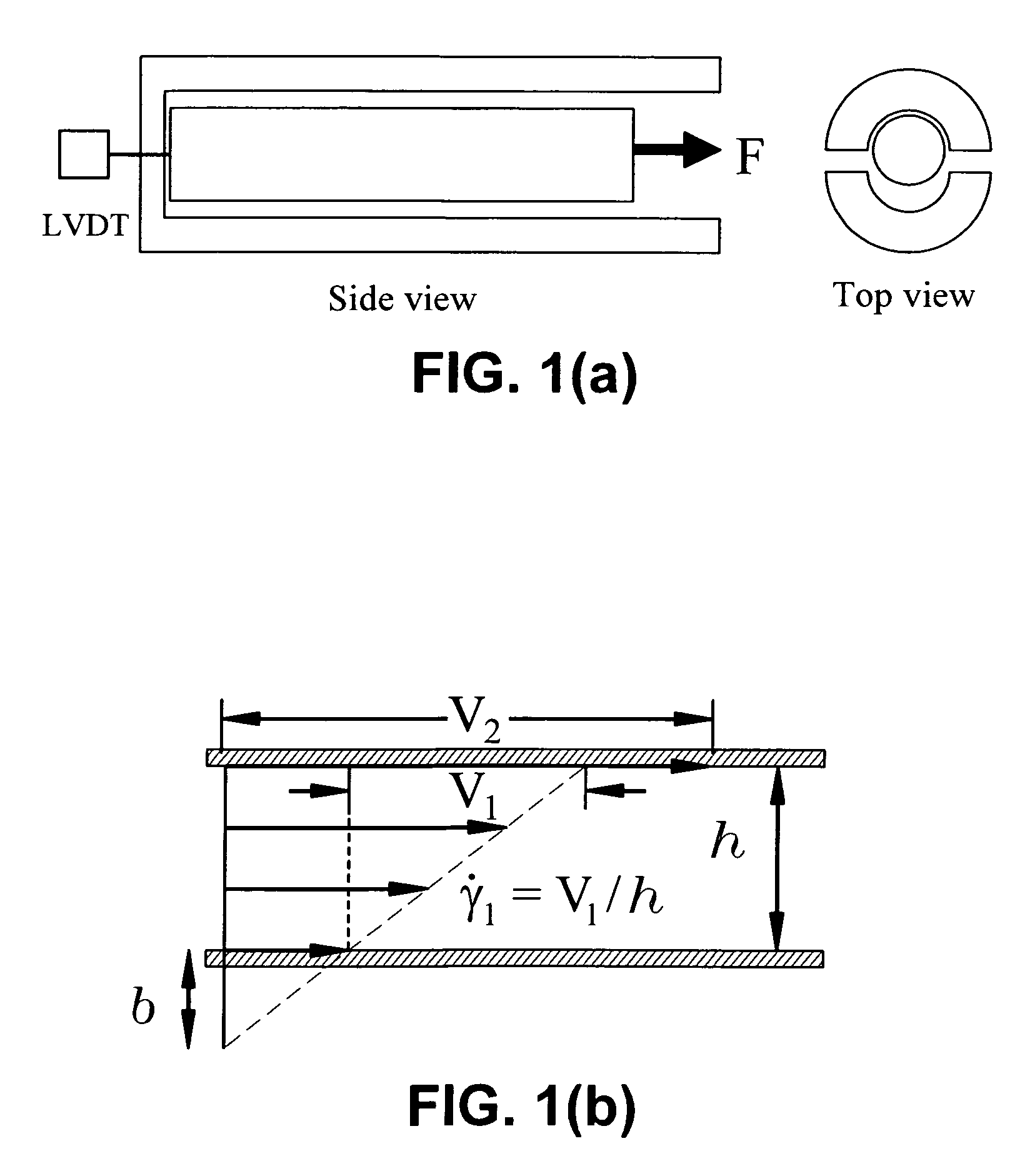

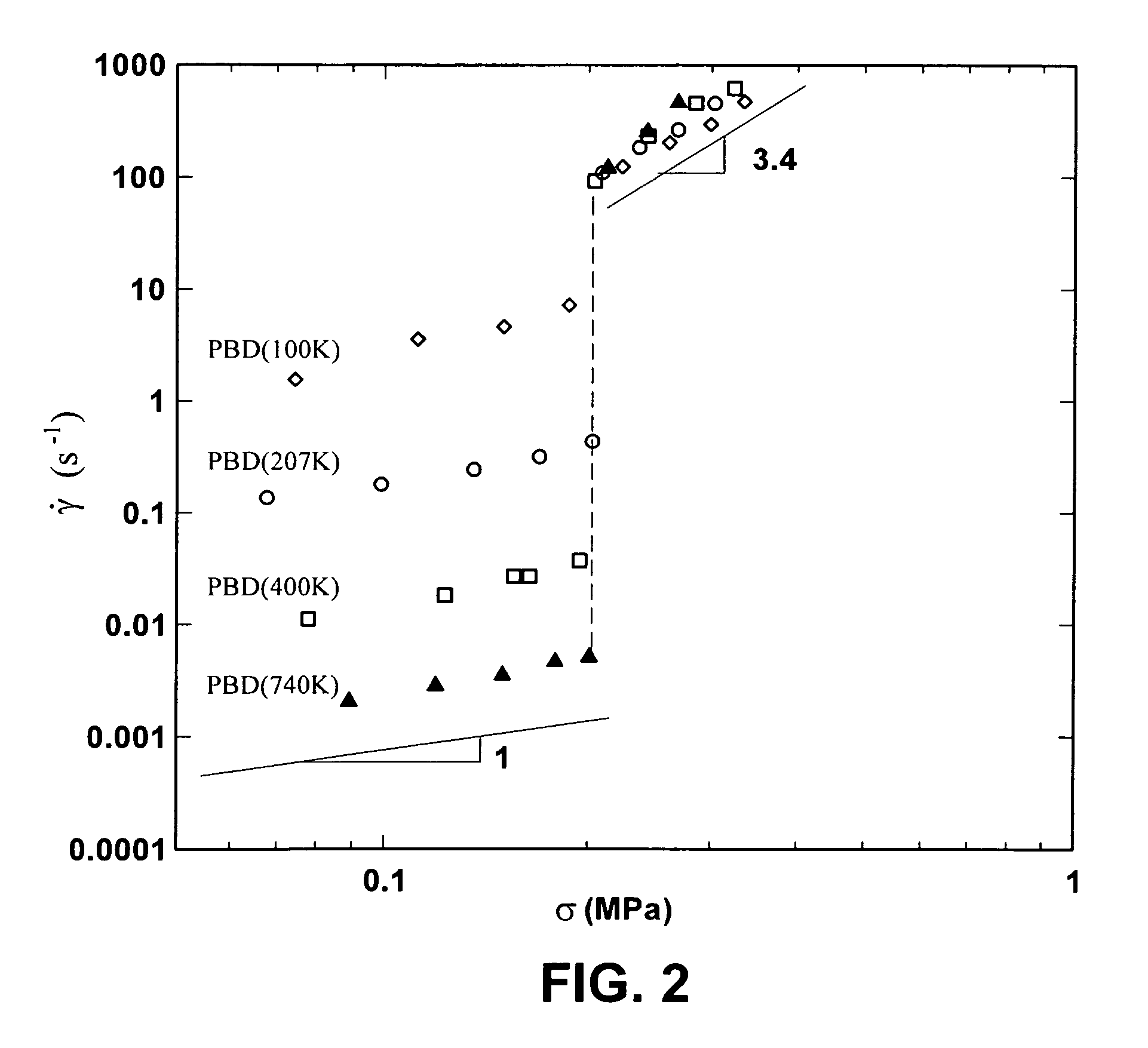

Constant-force rheometer

InactiveUS7526946B2Flow properties on non-Newtonian fluidsDirect flow property measurementConstant forcePolymer melt

The present invention is generally directed to a method for measuring interfacial stick-slip transitions (SST) and an improved constant-force shear capable of measuring interfacial SST. Some embodiments are capable of measuring SST under simple shear conditions and / or in highly entangled polymer melts. Some embodiments include the application of a constant shearing force to a polymer sample.

Owner:THE UNIVERSITY OF AKRON

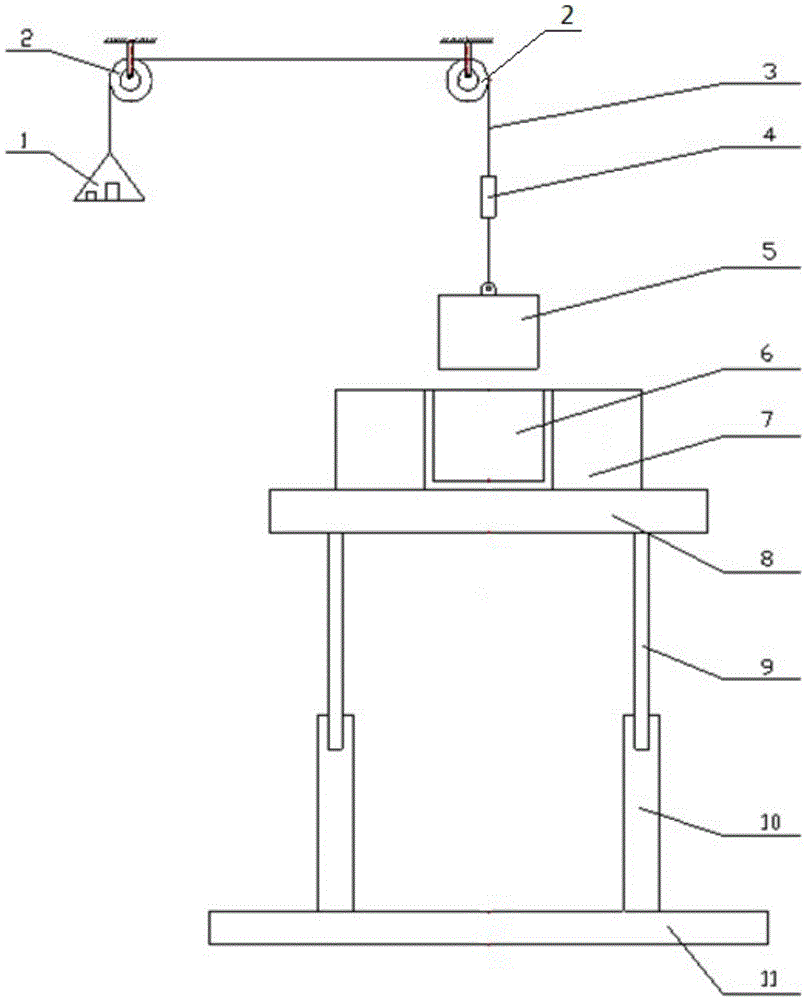

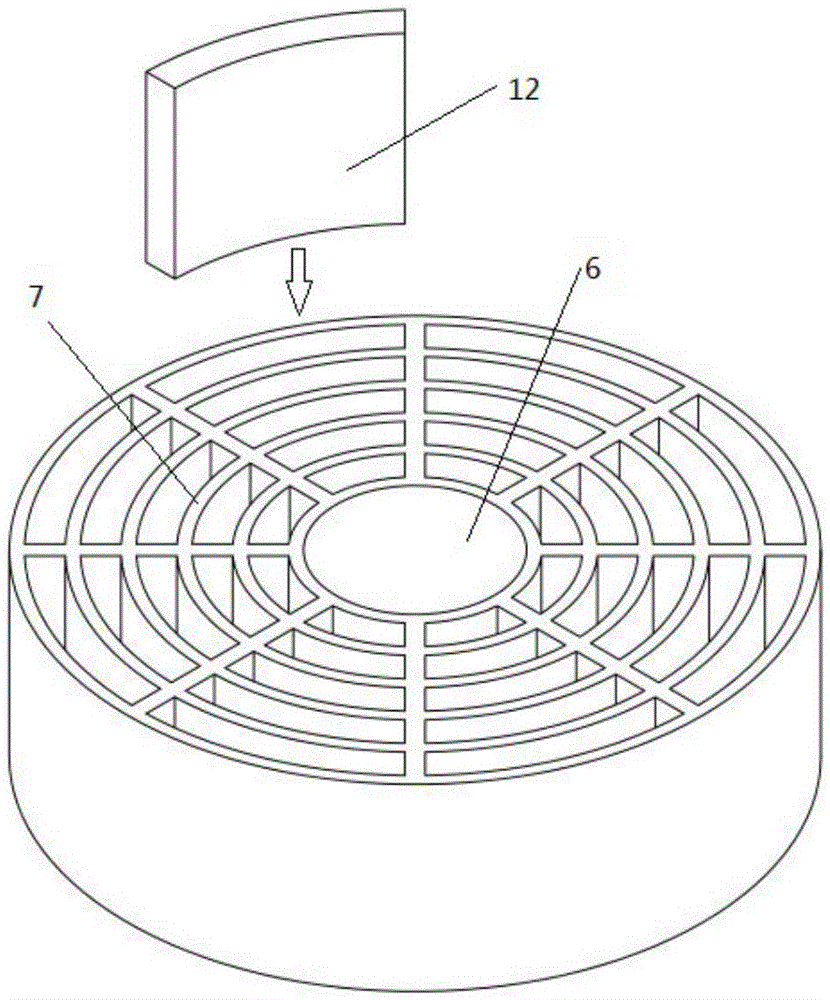

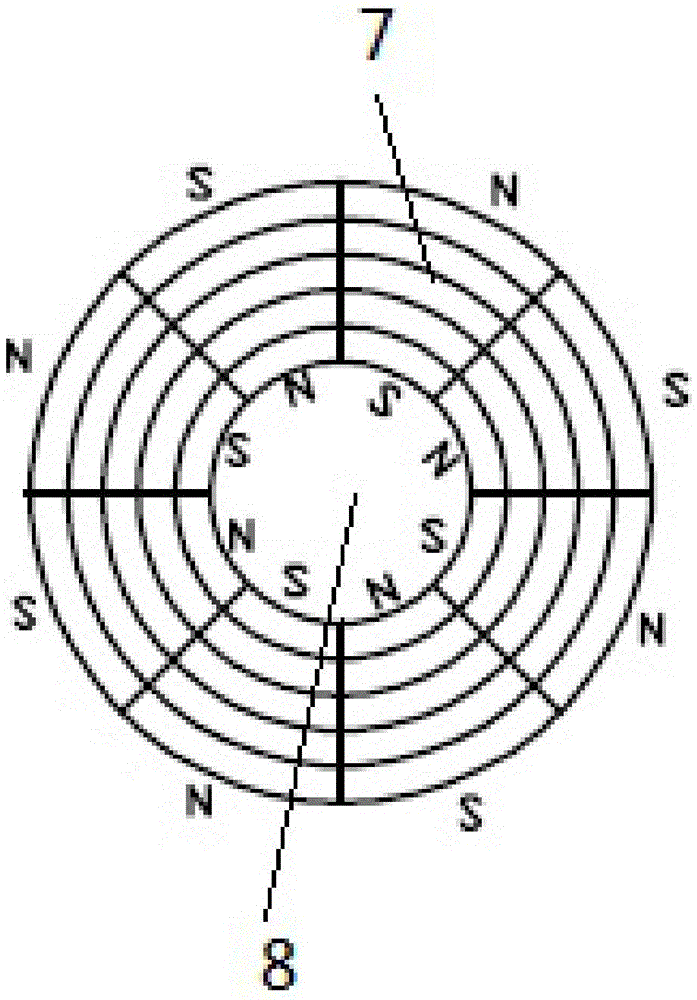

A double-tension-source type yield stress measuring system for a magnetorheological fluid

ActiveCN105547923AEasy to observeEasy to operateFlow properties on non-Newtonian fluidsPull forceStress measures

The invention relates to a double-tension-source type yield stress measuring system for a magnetorheological fluid. The system comprises a lifting device, a magnetic field generating device and a lifting block. The magnetic field generating device comprises a radial multi-stage magnetic ring and a magnetorheological fluid tank. The magnetorheological fluid tank is cylindrical and is disposed in the radial multi-stage magnetic ring. The magnetorheological fluid tank and the radial multi-stage magnetic ring are coaxially arranged. The magnetic field generating device is arranged horizontally. The bottom of the magnetic field generating device is provided with the lifting device. The lifting block is in a cylinder shape. The outer diameter of the lifting block is smaller than the inner diameter of the magnetorheological fluid tank. The lifting block and the magnetorheological fluid tank are coaxially arranged. The lifting block is pulled by a pulling rope to move along the straight line where the axis of the magnetorheological fluid tank is. The pulling rope is provided with a tension sensor. Compared with the prior art, the system is advantaged by accurate measurement results, visual data presentation, and the like.

Owner:SHANGHAI UNIV OF ENG SCI

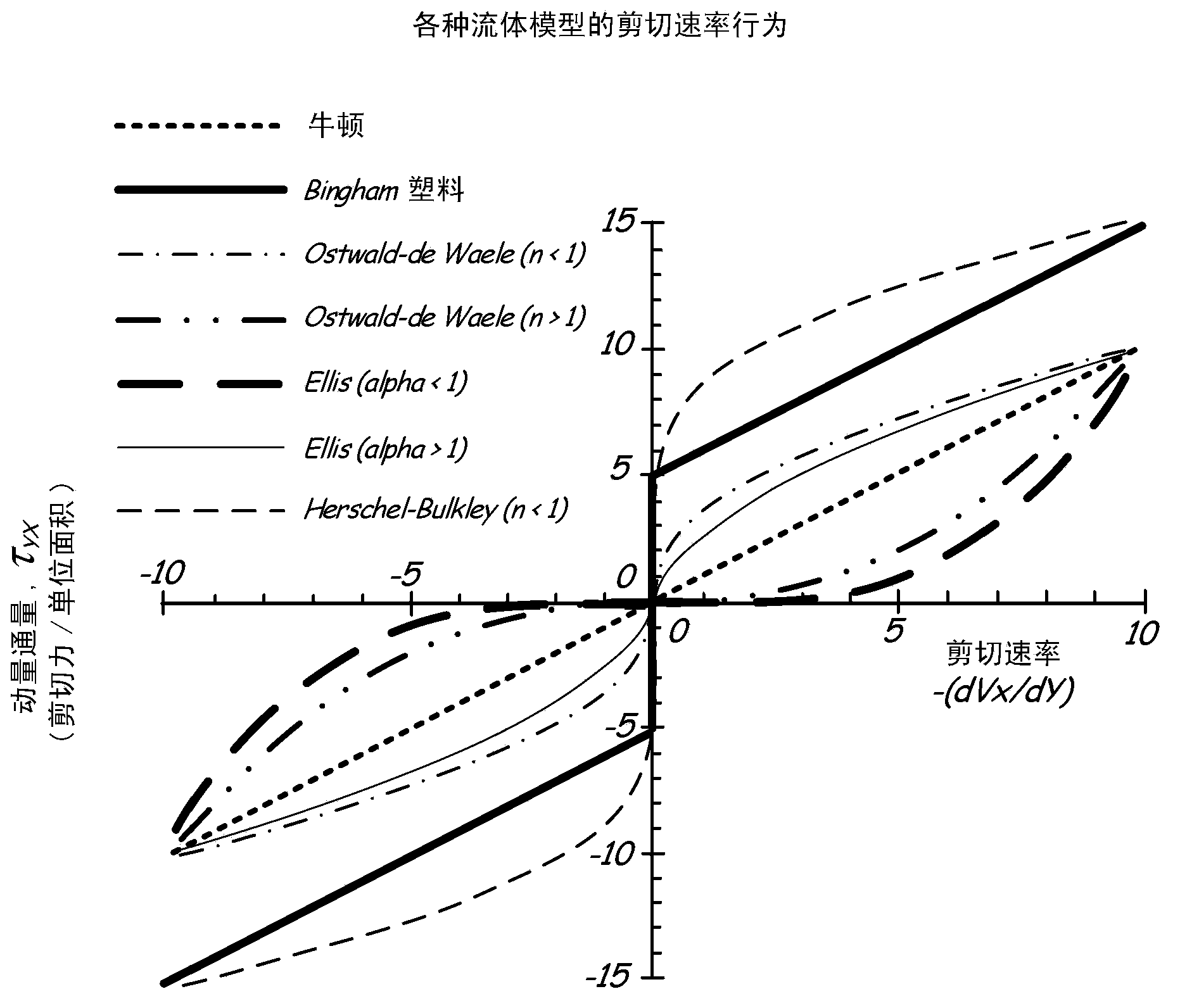

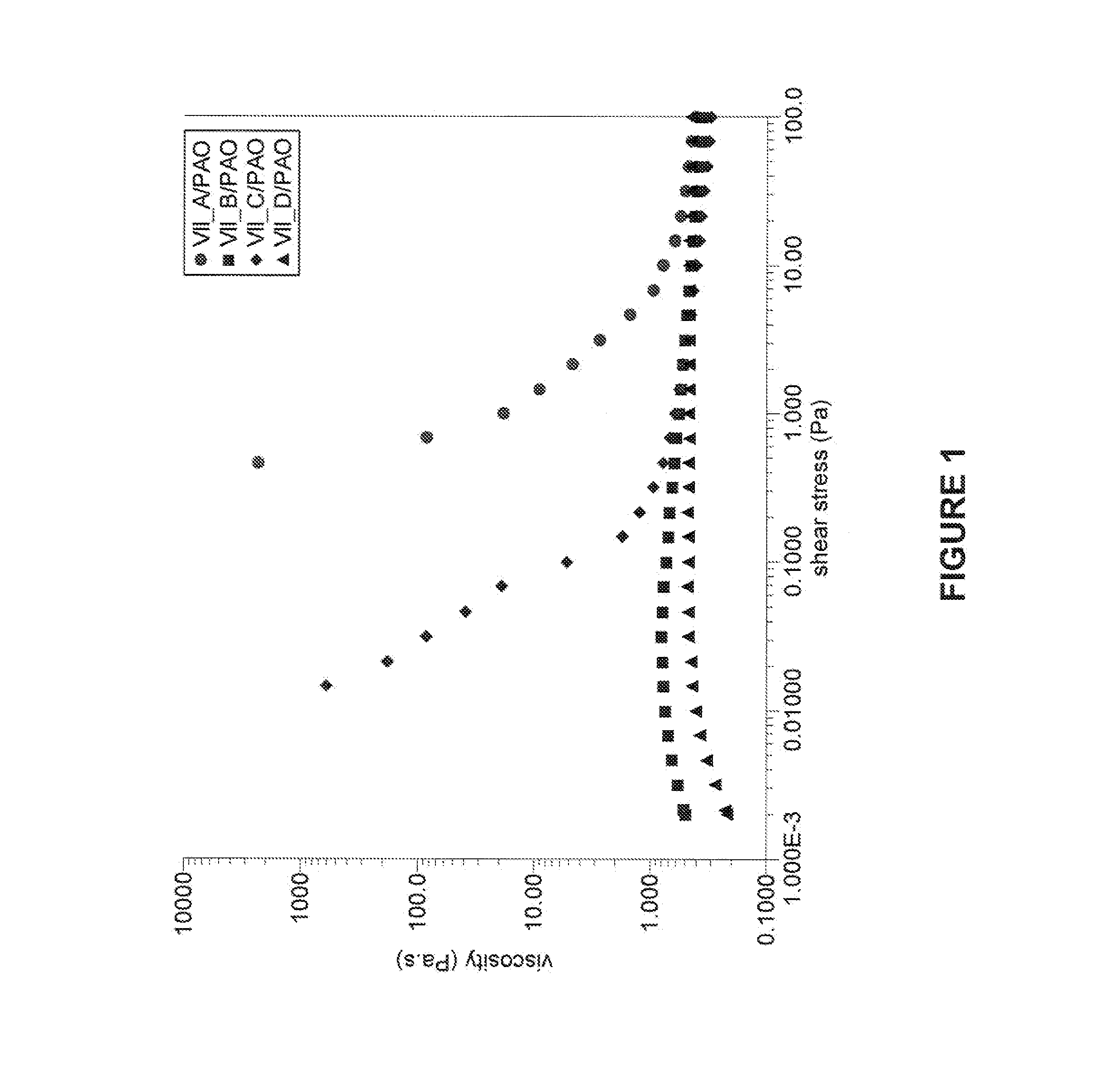

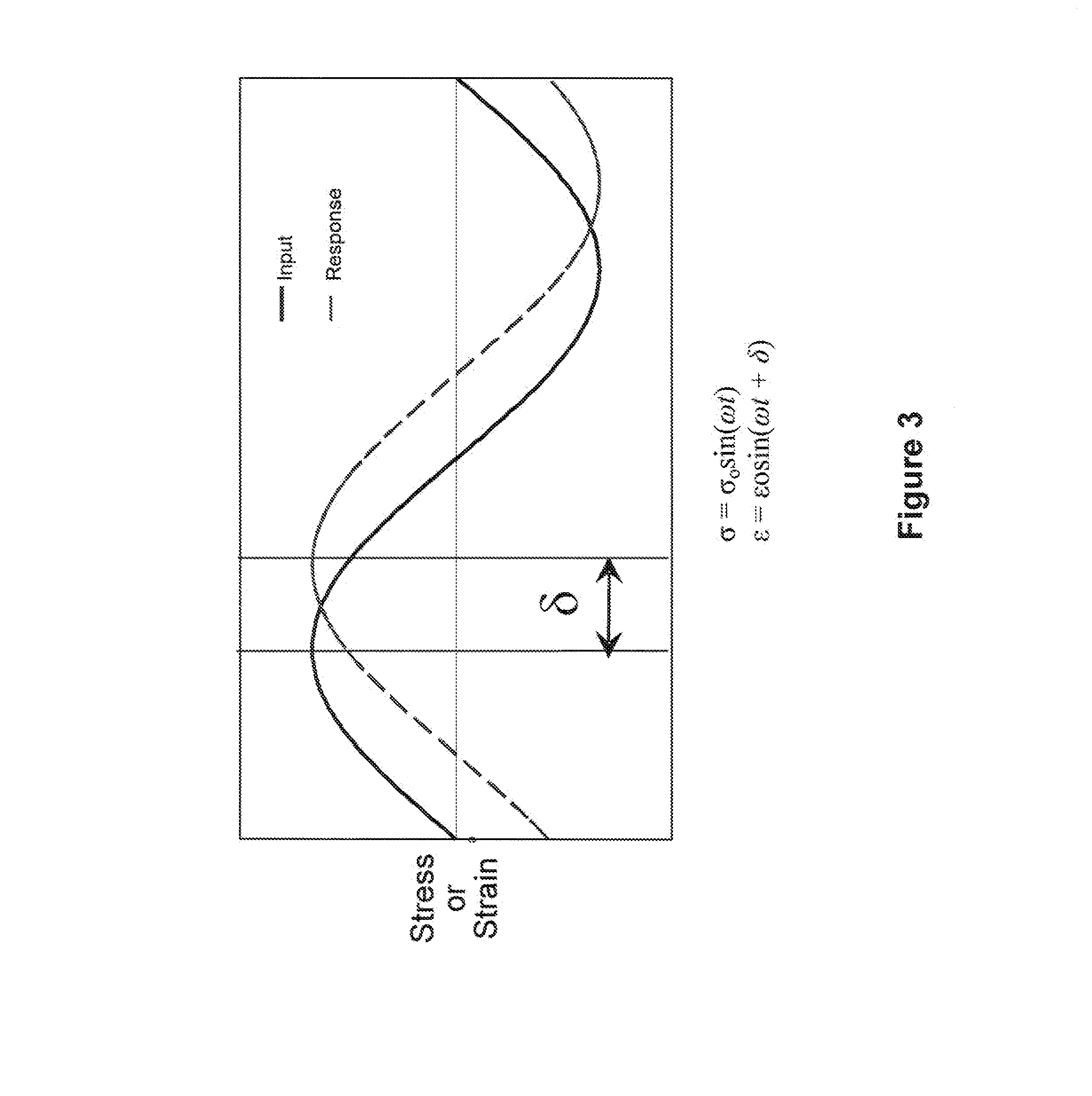

Rheological methods to determine the predisposition of a polymer to form network or gel

A method is provided to determine the predisposition of a polymer to form network or gel in a lubricating oil which comprises obtaining a composition of a polymer in a diluent, measuring the shear stress as a function of shear rate, determining the yield stress using the Herschel-Bulkley equation and assessing the yield stress. A method is also provided to determine the predisposition of a polymer to form network or gel in a lubricating oil which comprises obtaining a composition of a polymer in a diluent, determining at least one of (i) the storage modulus G′ and loss modulus G″ of the composition by subjecting the composition to sinusoidal (oscillating) stress or strain of certain amplitude and frequency, (ii) the phase lag (angle) of the response strain or stress δ, or (iii) the tangent (tan) δ, and (c) assessing at least one of the G′, G″, δ, or tan(δ) determined.

Owner:EXXONMOBIL CHEM PAT INC +1

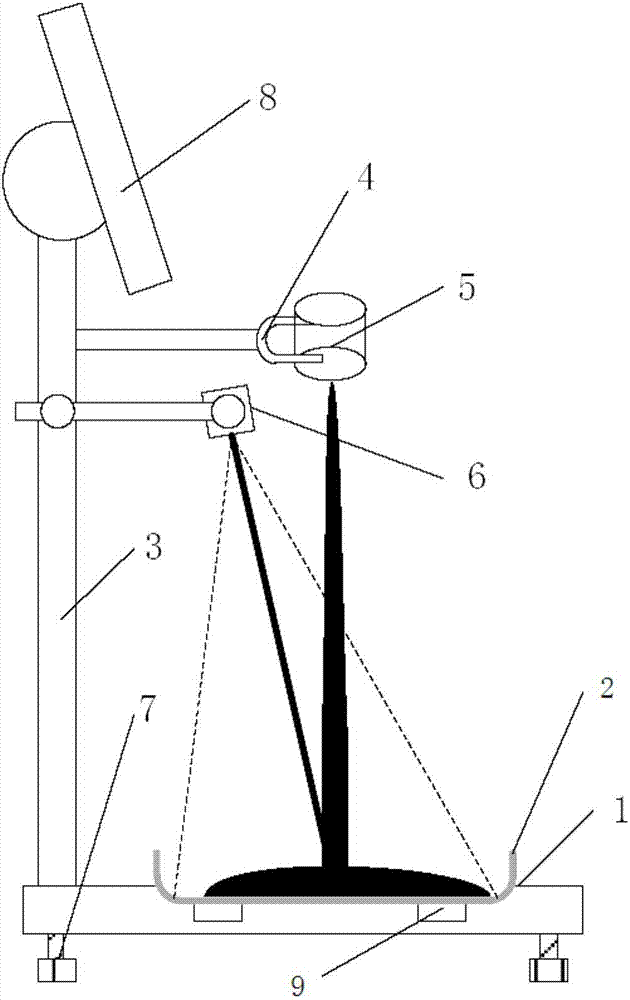

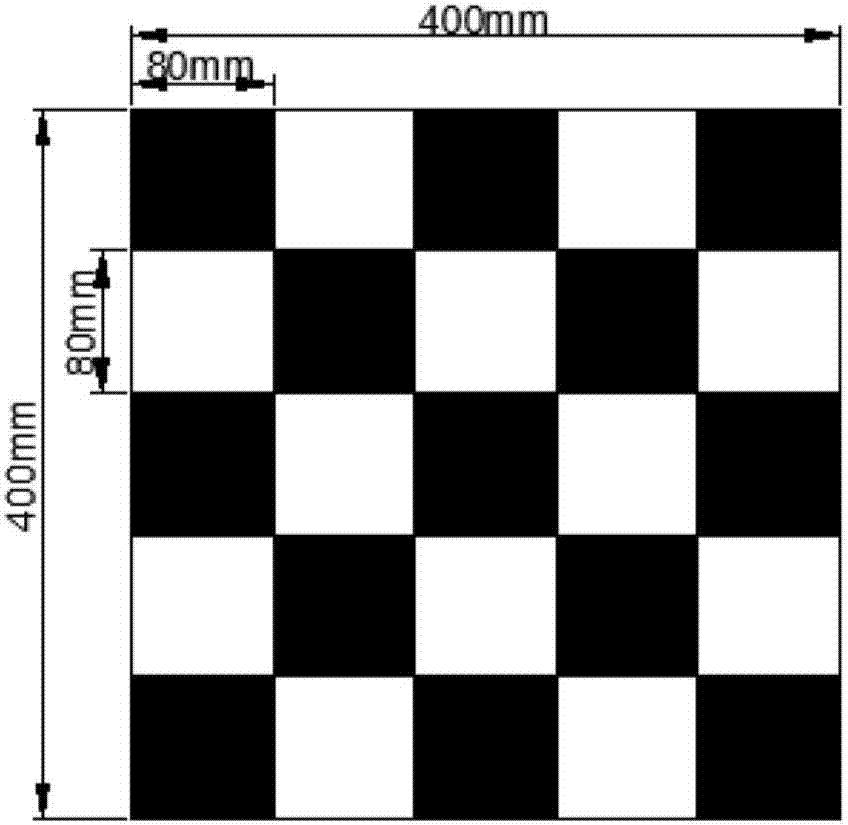

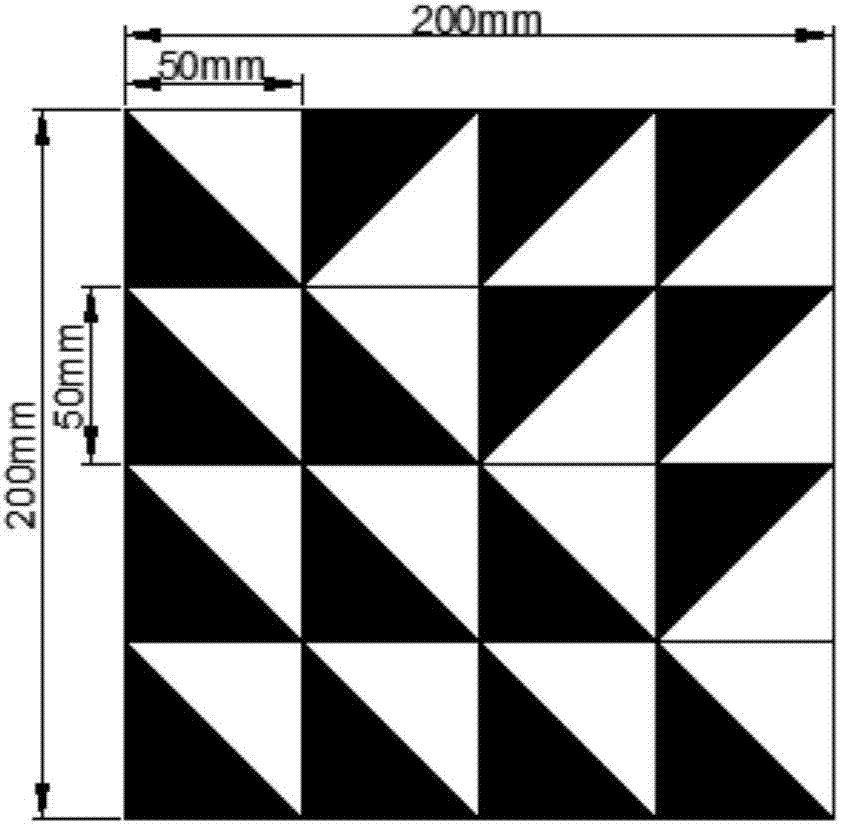

Determination apparatus and determination method of flowability of coal water slurry based on digital image technology

PendingCN106908353AAvoid Measuring InaccuraciesImprove accuracyViscometer maintainanceFlow properties on non-Newtonian fluidsCoal waterRobotic arm

The invention relates to a determination apparatus and determination method of flowability of coal water slurry based on digital image technology. The determination apparatus is characterized by comprising a pedestal, a charging tray, a vertical support, a robotic arm guide rail, a power apparatus, a robotic arm clamping device, a container, a shooting device and a control apparatus. The top of the pedestal is provided with a groove, the charging tray for loading released coal water slurry is fixed in the groove, the vertical support is fixed at one side of the top of the pedestal, and the robotic arm guide rail is in slide arrangement with the vertical support and is in fixed connection to an output end of the power apparatus. One end of the robotic arm clamping device is in fixed connection to the robotic arm guide rail, and the other end of the robotic arm clamping device clamps and fixes the container for holding coal water slurry. The shooting apparatus is in fixed connection to the vertical support and is in electrical connection to the control apparatus fixed on the vertical support. The determination apparatus and determination method can be widely applied to quantitative and qualitative determination process of flowability of coal water slurry.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

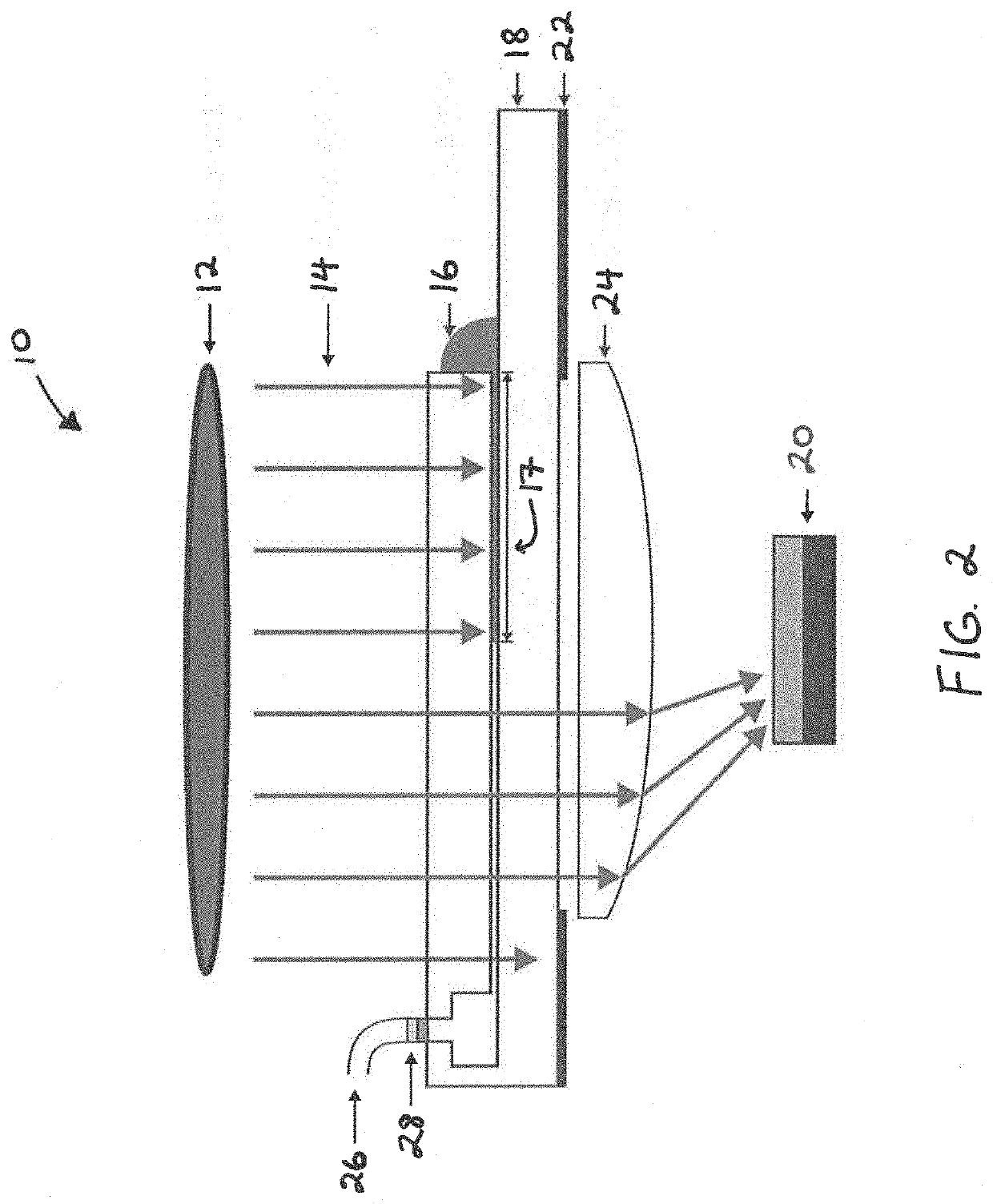

Assembly for Measuring the Viscosity of Fluids Using Microchannels

ActiveUS20180321124A1Improved viscosity measuring assemblyEasy to assembleBiological testingFlow properties on non-Newtonian fluidsHand heldEngineering

The present disclosure provides improved viscosity measuring assemblies, and related methods of use. More particularly, the present disclosure provides advantageous measuring assemblies configured to measure the viscosity of samples / fluids (e.g., opaque or transparent liquids) using microchannels. The present disclosure provides for a viscosity measuring assembly (e.g., hand-held electronic measuring assembly) that is configured to measure the viscosity of samples / fluids (e.g., opaque or transparent Newtonian and non-Newtonian liquids, including blood, etc.), in a short period of time (e.g., within a couple of minutes) utilizing only about a droplet of fluid. The viscosity measuring assembly can include a substrate having a microchannel, a light source (e.g., a collimated low coherence light source), and a sensor (e.g., photodiode). The micro-channeled substrate may be disposable, and some of the other components may be reusable since they are substantially not directly exposed to the sample during operation of the viscosity measuring assembly.

Owner:UNIV OF CONNECTICUT

Method for finding shear rate of fluid, and program and device for same

To propose a new method for finding the shear rate of a fluid and to provide a program and device for the same. A method to find shear rate with a tuning-fork vibration viscometer that calculates the viscosity of the sample fluid (9) by vibrating a pair of oscillators (1, 1) that are submerged in the sample fluid (9) by way of an electromagnetic driver (2) comprising a coil (2b), causing a driving current to flow in the coil (2b) so that the amplitude of the oscillator (1) is the set amplitude value, and measuring the driving current, comprises: a viscosity acquisition step (S1) of acquiring the viscosity ([eta]) of a sample fluid (9); a driving force acquisition step (S2) of finding, from the driving current (I), a driving force (F) in the center of a wetted portion of the oscillator; and a shear stress acquisition step (S3) of finding, from the driving force (F) and the wetted area (A) of the oscillator, the shear stress (S) working on the sample fluid; wherein the shear rate (D) is found from the ratio of the shear stress (S) and the viscosity ([eta]) (S4).

Owner:A&D CO LTD

Rotational rheometer for measuring powdery or granular materials

ActiveUS10031057B2Prevents swirling and releasePrevent leakageEngine sealsBearing componentsEngineeringMechanical engineering

Owner:ANTON PAAR

Process for producing polymer oriented crystal, polymer oriented crystal produced by said production process, and method for determining critical elongation strain rate of polymer melt

InactiveUS7871548B2High strengthImprove toleranceRecord carriersForce measurementPolymer sciencePolymer melt

A method and means for determining a critical elongation strain rate of a polymer melt, which make it possible to subject a polymer melt to elongation to prepare a bulk oriented melt, are established, and a process for producing bulk polymer oriented crystals and polymer oriented crystals are provided. In the critical elongation strain rate determination process or critical elongation strain rate determining method, a polymer melt (3) in a disc shape having a radius x0 and a thickness of Δz0 is held between transparent plates (an upper transparent plate (1) and a lower transparent plate (2)). The polymer melt (3) is cooled to a supercooled state and is press in a thickness direction at a constant rate v by using the transparent plates. The critical point radius x*, at which the polymer melt (3) is turned to an oriented crystal, is measured, and the critical elongation strain rate ε is calculated by equation ε*=ax*3 wherein α=v / (2Δz0x03).

Owner:HIROSHIMA UNIVERSITY

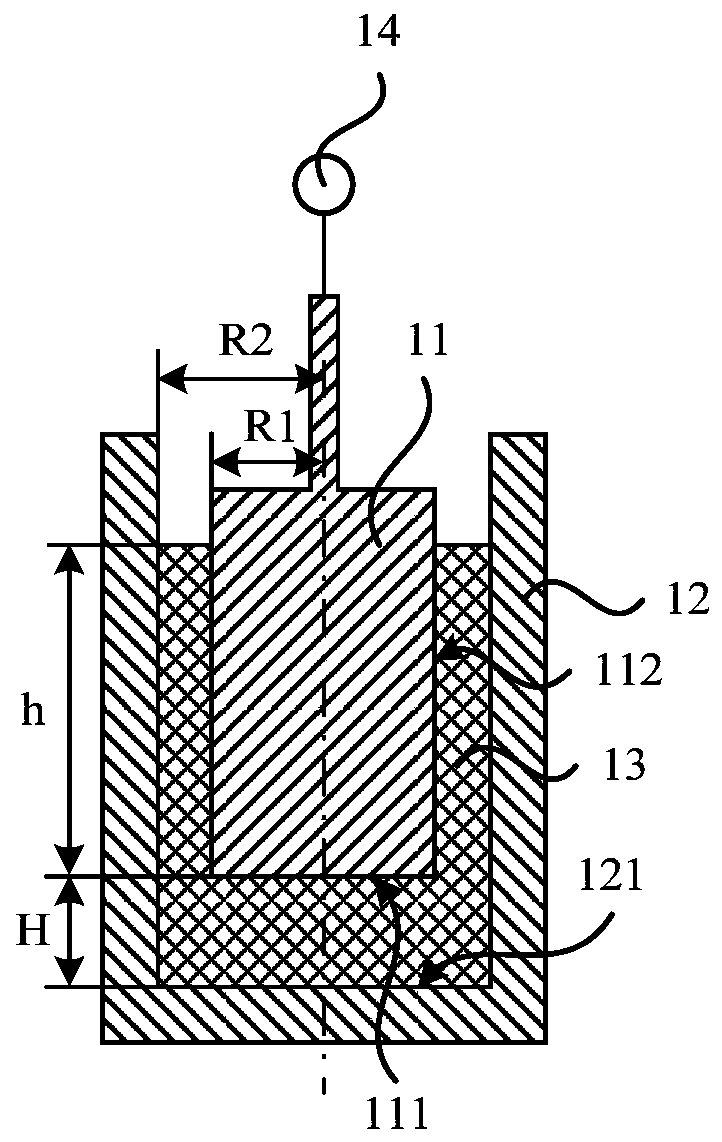

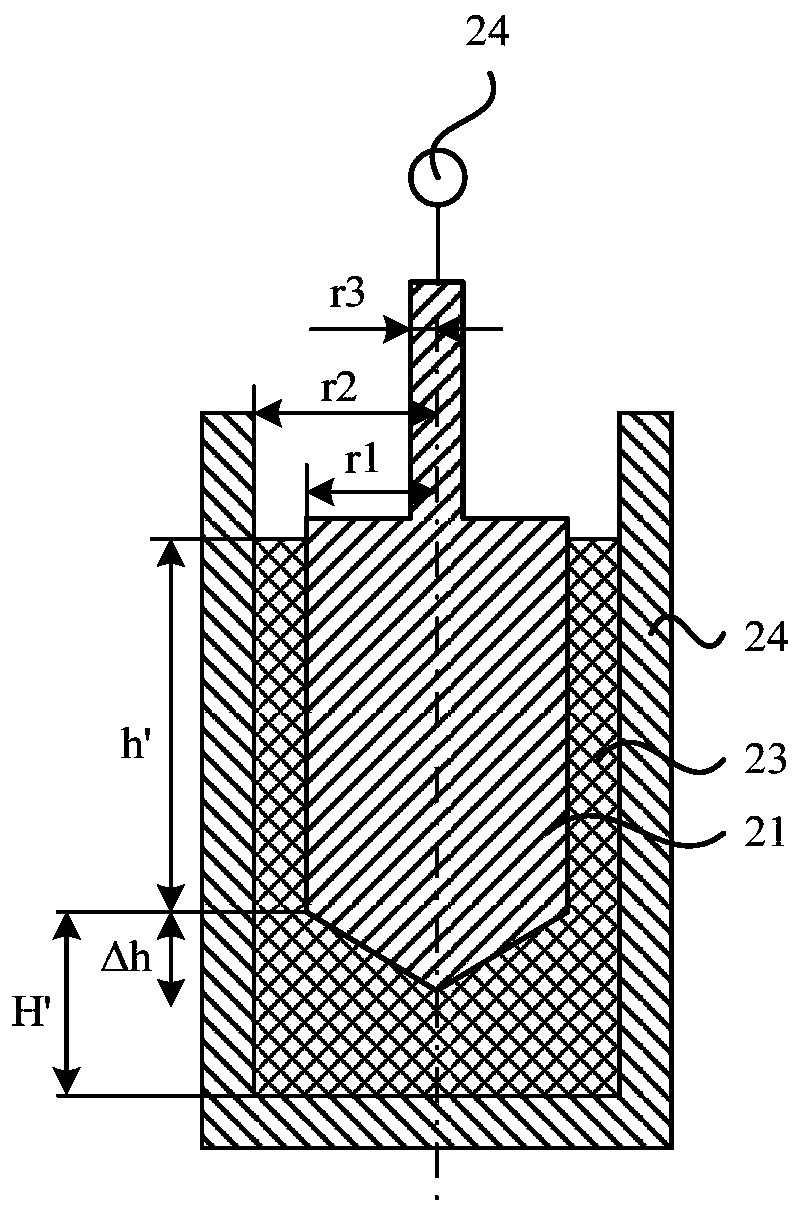

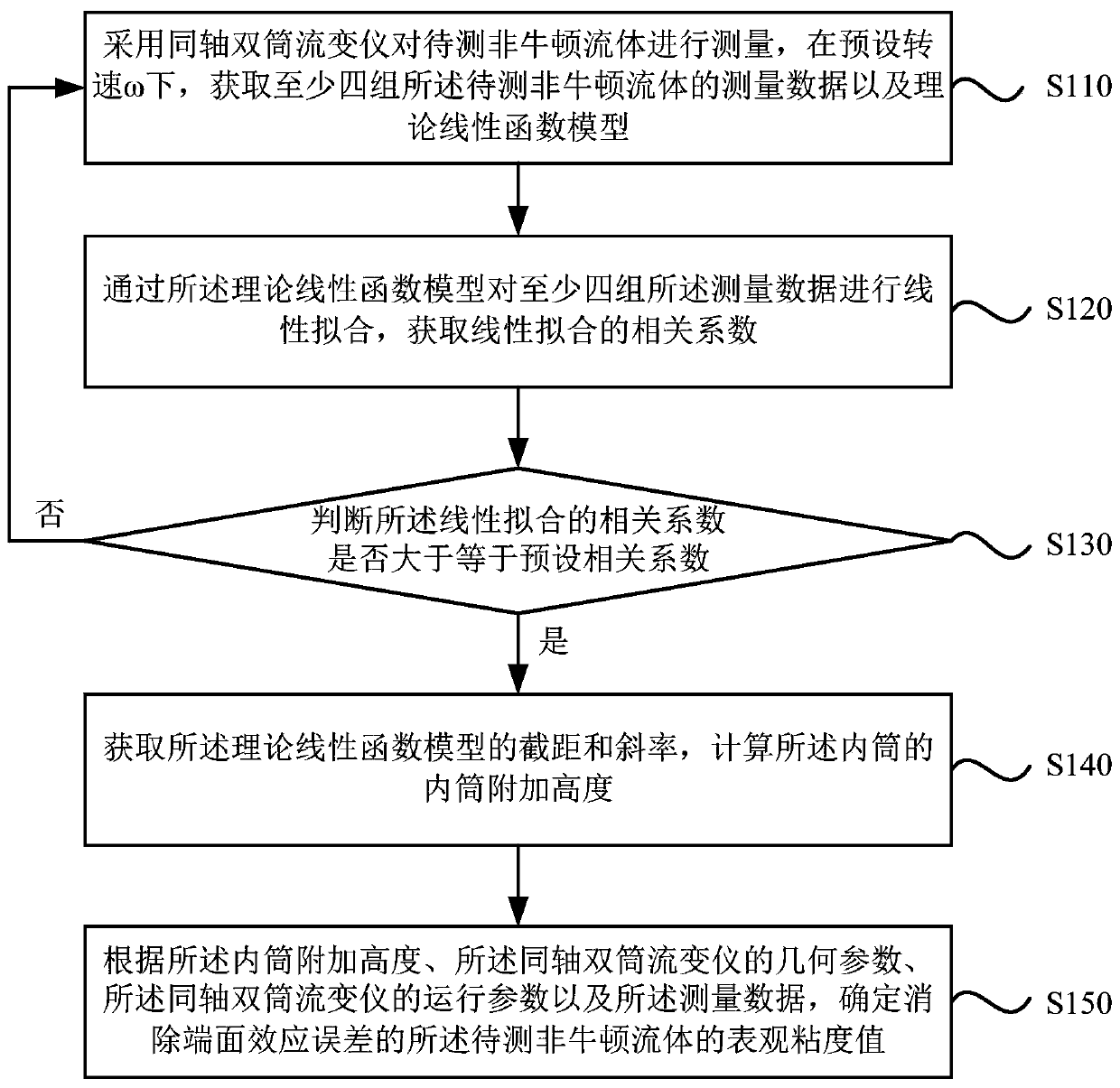

End face effect error elimination method and device for measuring apparent viscosity of non-Newtonian fluid

InactiveCN110631959AImprove measurement accuracyImprove measurement reliabilityFlow properties on non-Newtonian fluidsCorrelation coefficientApparent viscosity

The embodiment of the invention provides an end face effect error elimination method and device for measuring the apparent viscosity of non-Newtonian fluid. At least four groups of measured data of fluid to be measured are measured by using a coaxial double-cylinder rheometer, and linear fitting is performed according to the measured four groups of measured data and a theoretical linear function model to obtain a correlation coefficient after the linear fitting; and when the correlation coefficient of the linear fitting is greater than a preset correlation coefficient, an additional height ofan inner cylinder measured by the coaxial double-cylinder rheometer is calculated by an intercept and a slope of the theoretical linear function model, and a viscosity value in the fluid to be measured after end face effect errors are corrected is determined according to the calculated additional height of the inner cylinder, geometric parameters of the coaxial double-cylinder rheometer, running parameters of the coaxial double-cylinder rheometer and the measured data. The end face effect error elimination method for measuring the apparent viscosity of non-Newtonian fluid provided by the embodiment of the invention has higher operability and better practicality, accuracy, and efficiency.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

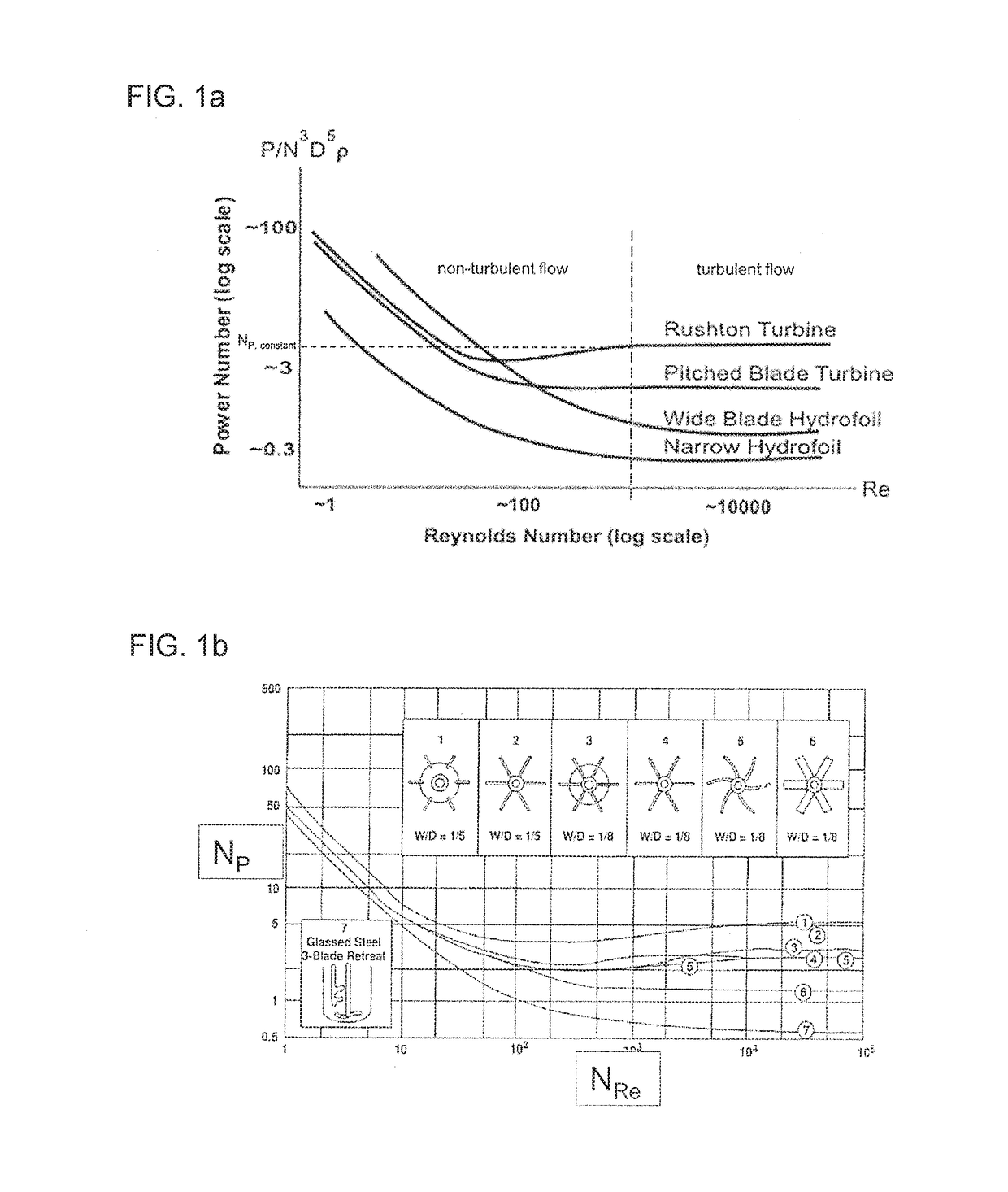

Methods of mixing impeller sensing

ActiveUS10112162B2Accurate valueShorten speedBioreactor/fermenter combinationsBiological substance pretreatmentsImpellerEngineering

A method is provided for monitoring a flow behavior of mixed components without requiring additional instrumentation or sampling. The method is carried out by determining ratios of the power required to rotate a mixing impeller at different rotational speeds and then comparing the ratios. Characteristics about the mixed components are determined based on differences between the ratios.

Owner:SARTORIUS STEDIM BIOTECH GMBH

Popular searches

Drilling composition Container/cavity capacity measurement Level indicators Lubrication indication devices Special data processing applications Strength properties Simultaneous indication of multiple variables Investigating material hardness Mechanical solid deformation measurements Control apparatus

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com