Viscometer for newtonian and non-newtonian fluids

A non-Newtonian fluid and viscometer technology, which is applied in the flow characteristics of non-Newtonian fluids, direct mass flowmeters, direct current flow characteristics measurement, etc., can solve problems that are not suitable for viscometer measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

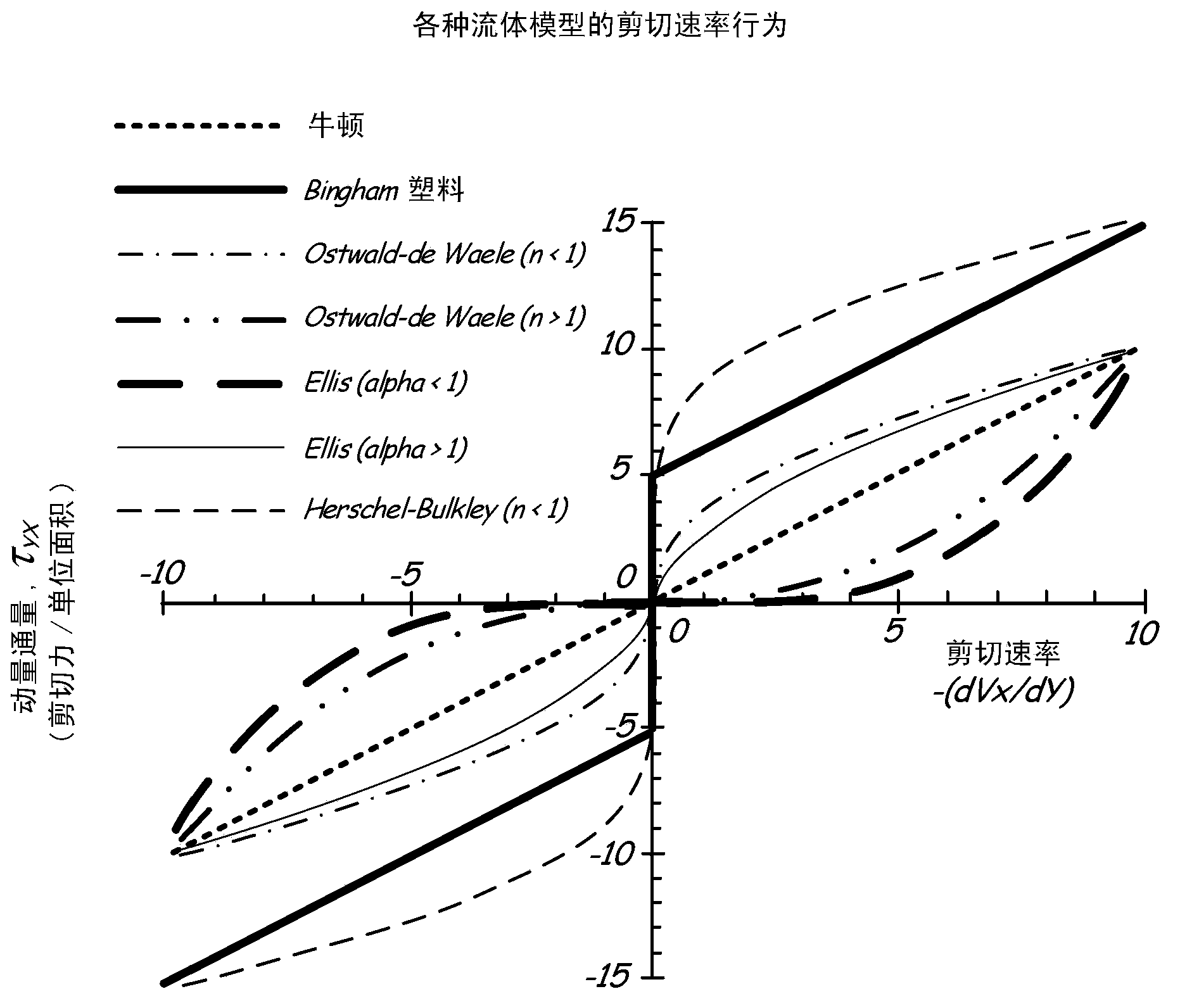

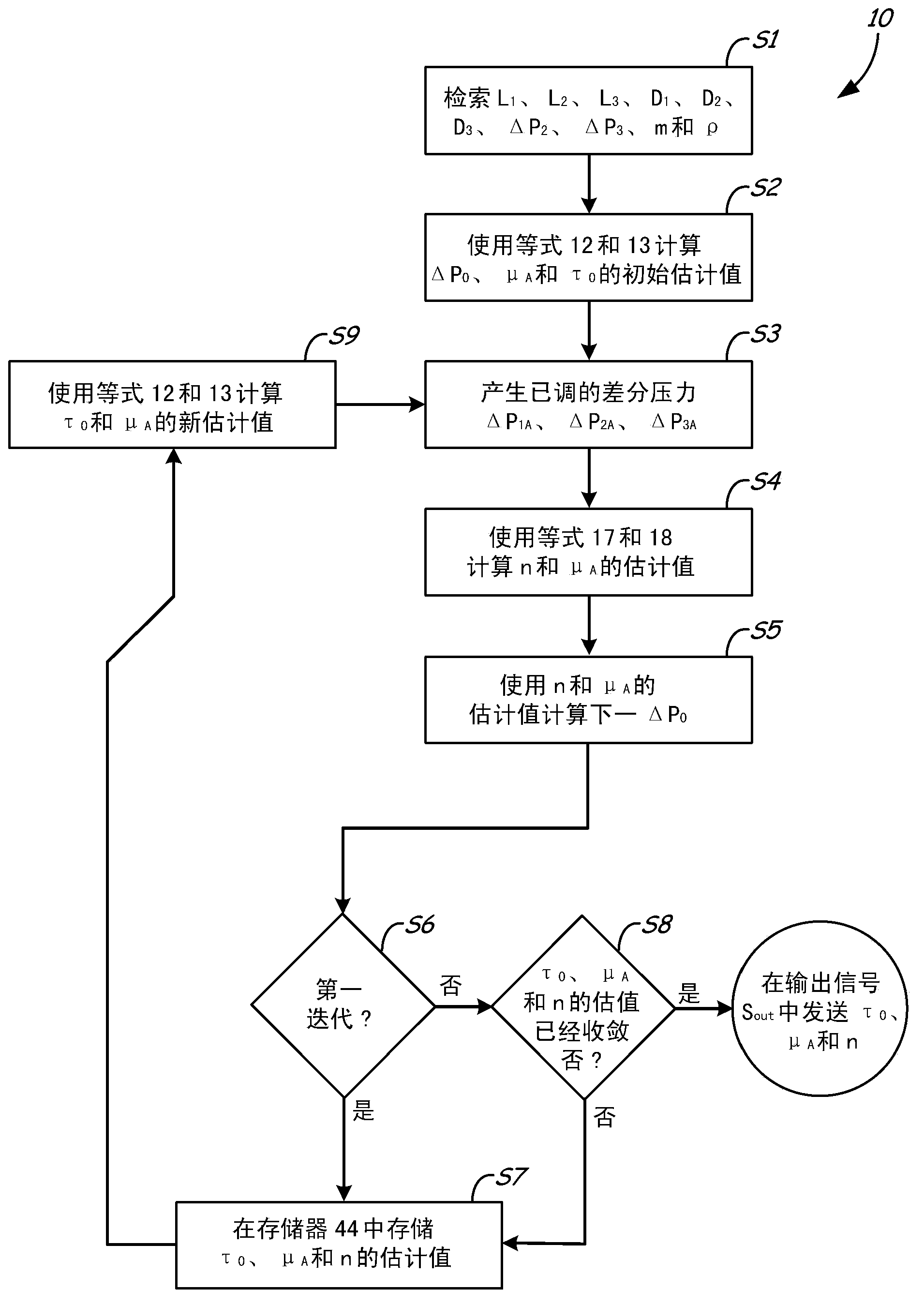

[0026] In general, the present invention relates to embedded viscometers capable of handling any of a variety of Newtonian and non-Newtonian fluids including Bingham plastics and Ostwald-deWaele, Ellis and Herschel-Bulkley fluids.

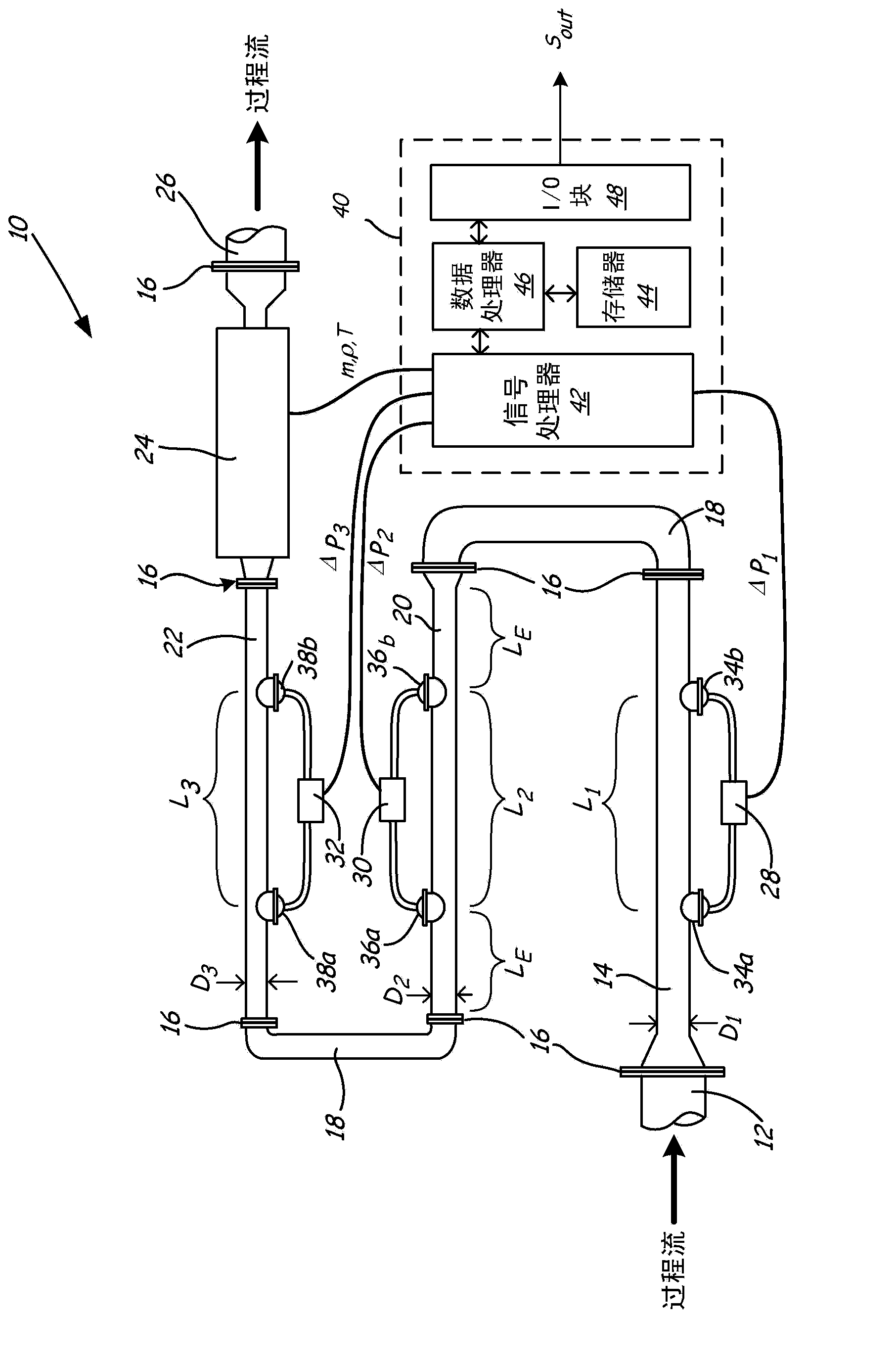

[0027] Viscometer Hardware

[0028] figure 2 An illustrative embodiment of a viscometer 10 is depicted, including a process inlet 12, a first capillary 14, a seam seal 16, a connecting tube 18, a second capillary 20, a third capillary 22, a Coriolis mass meter 24 , process outlet 26, first differential pressure transducer 28, second differential pressure transducer 30, third differential pressure transducer 32, first isolation diaphragms 34a and 34b, second isolation diaphragms 36a and 36b, third isolation diaphragm 38a and 38b, and the process transmitter. Process transmitter 40 also includes signal processor 42 , memory 44 , data processor 46 , and input / output block 48 .

[0029] according to figure 2 In an embodiment, the first, second an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com