Patents

Literature

708 results about "Non-Newtonian fluid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A non-Newtonian fluid is a fluid that does not follow Newton's law of viscosity, i.e., constant viscosity independent of stress. In non-Newtonian fluids, viscosity can change when under force to either more liquid or more solid. Ketchup, for example, becomes runnier when shaken and is thus a non-Newtonian fluid. Many salt solutions and molten polymers are non-Newtonian fluids, as are many commonly found substances such as custard, honey, toothpaste, starch suspensions, corn starch, paint, blood, and shampoo.

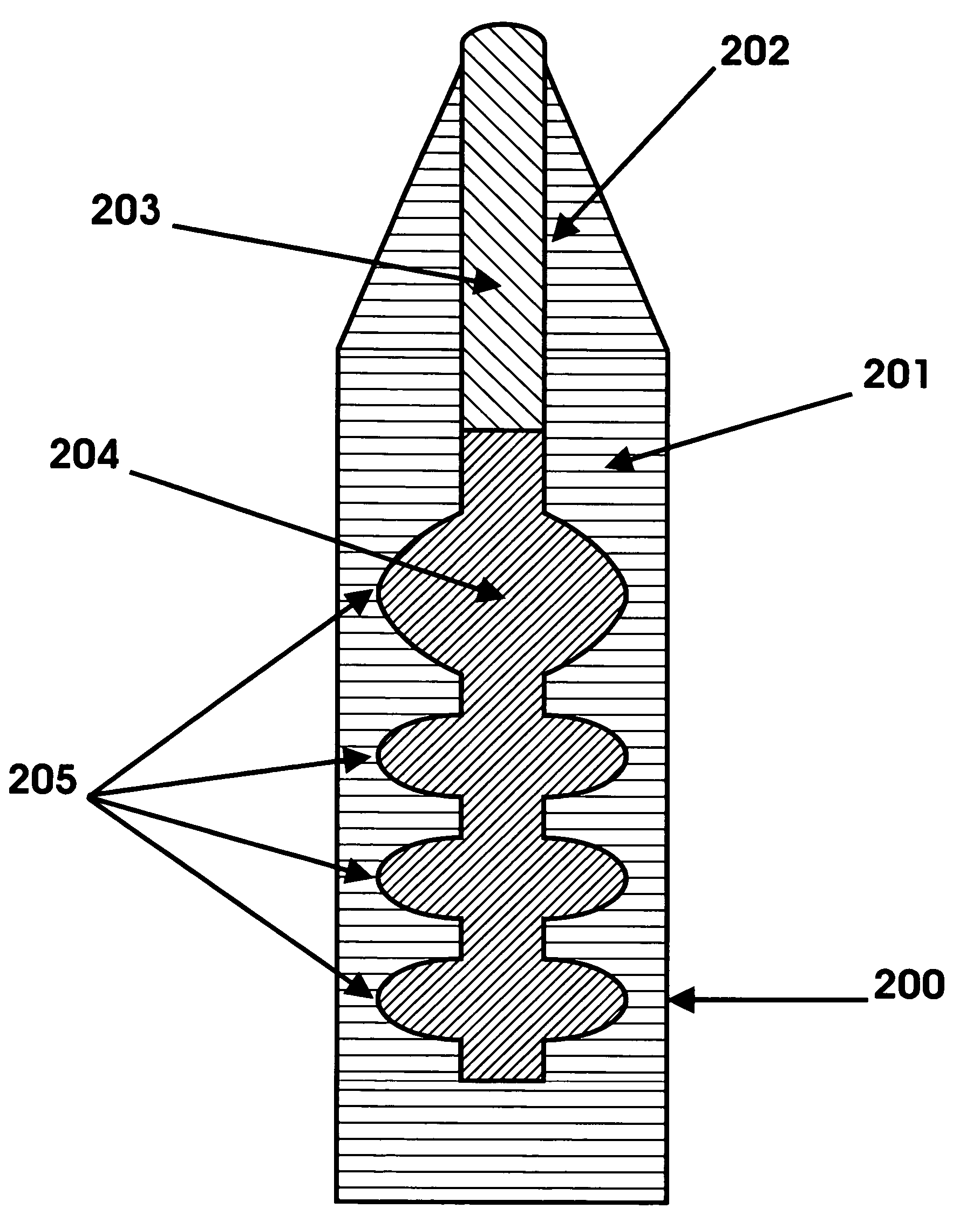

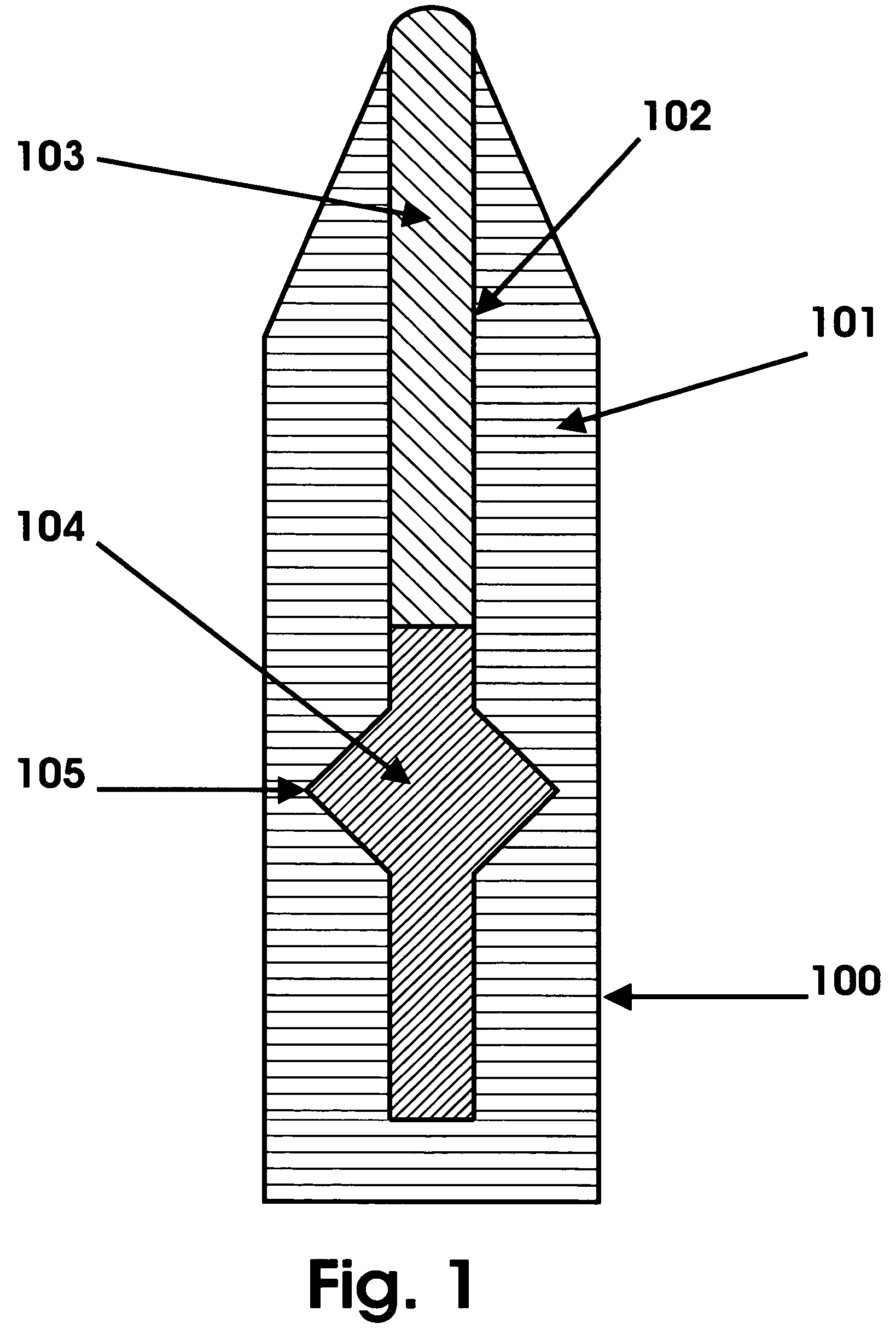

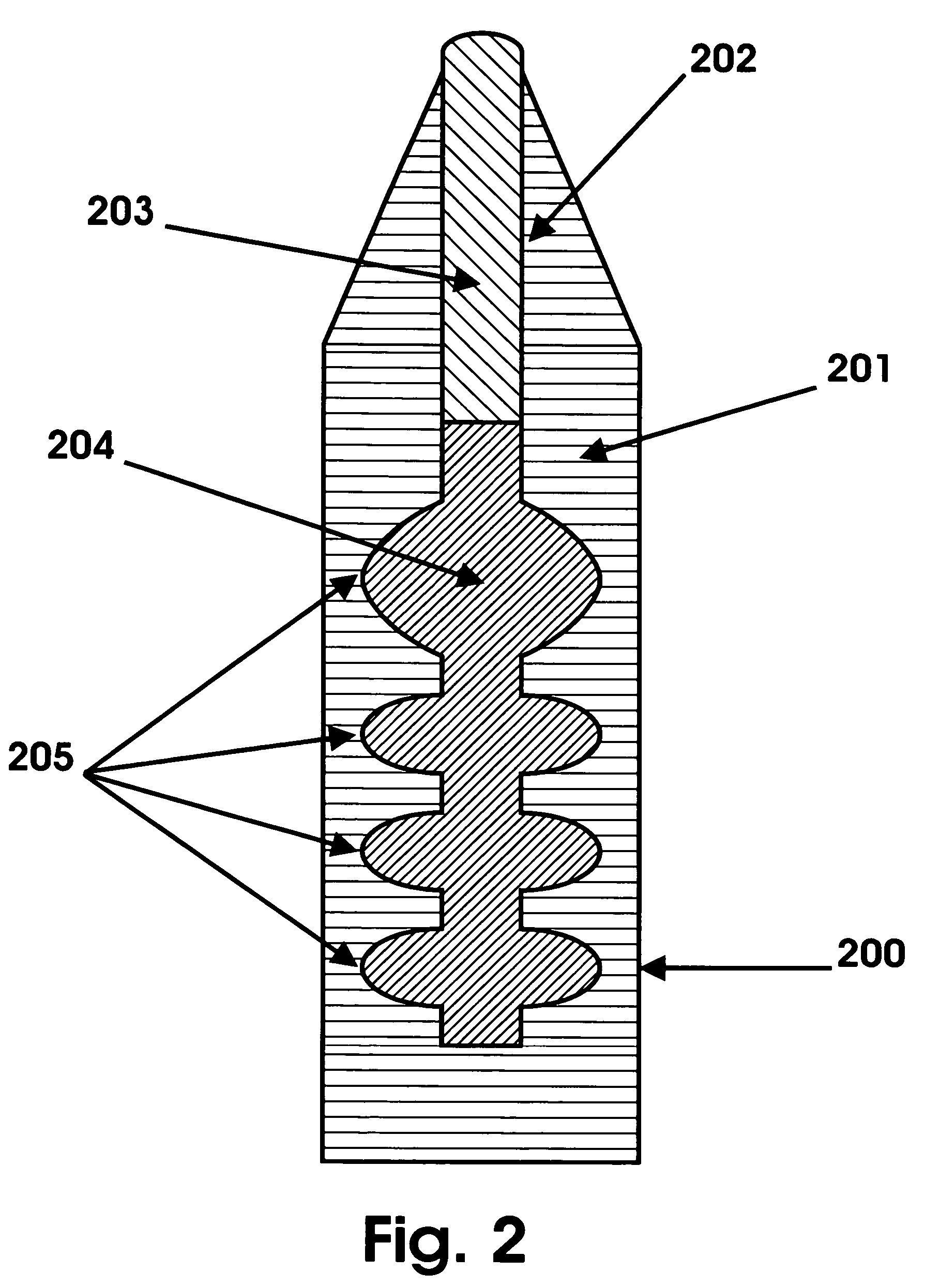

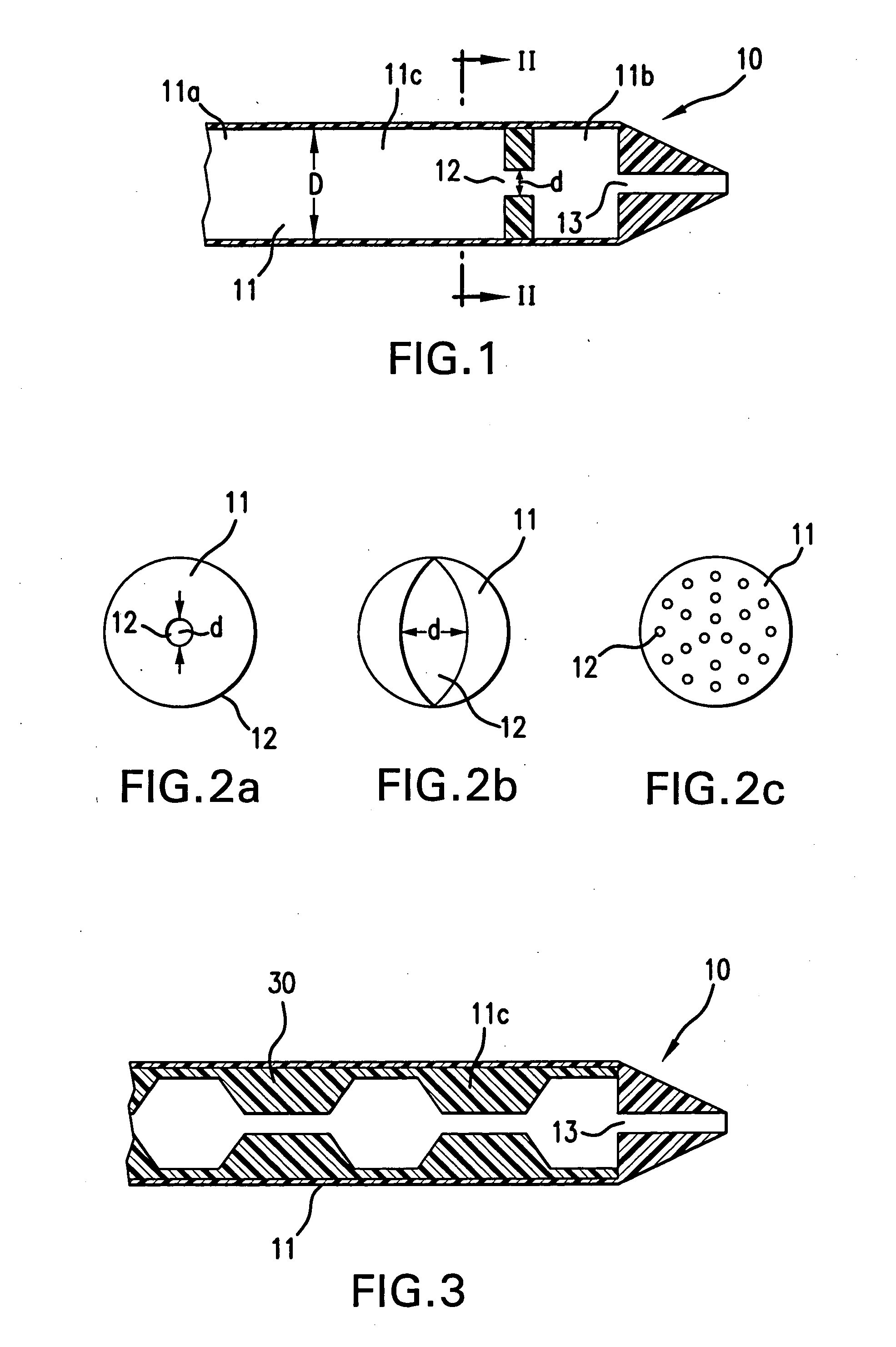

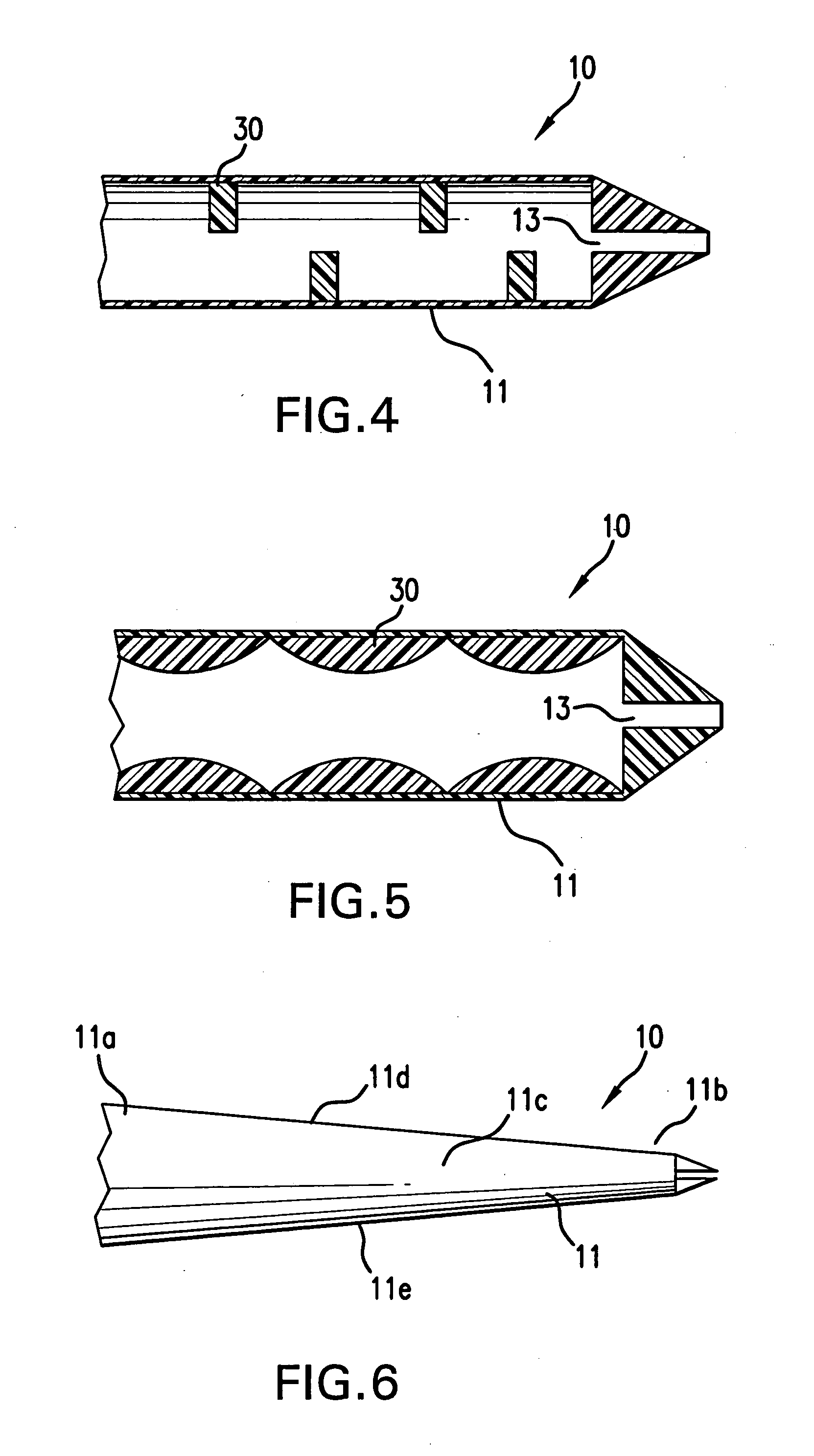

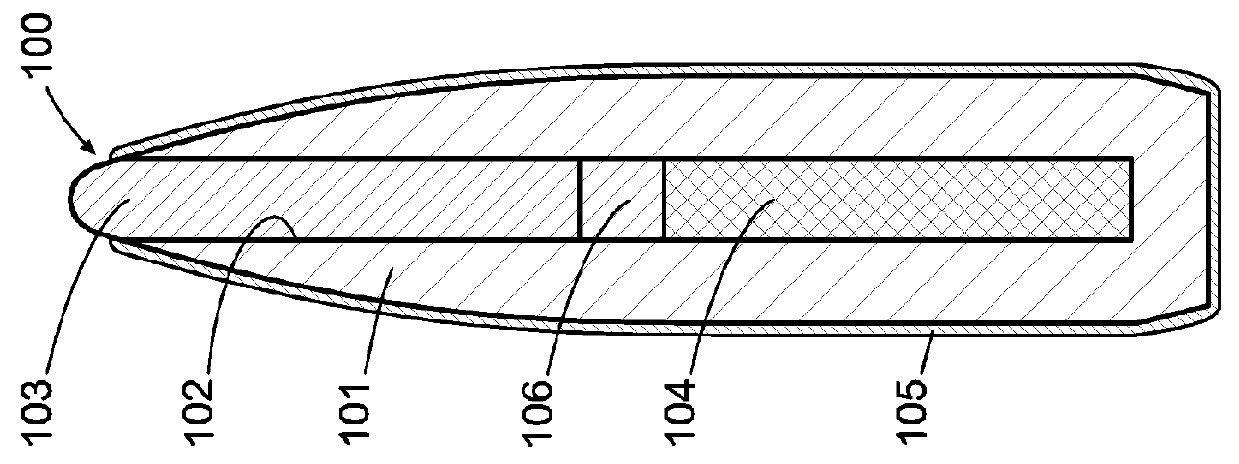

Expanding projectile

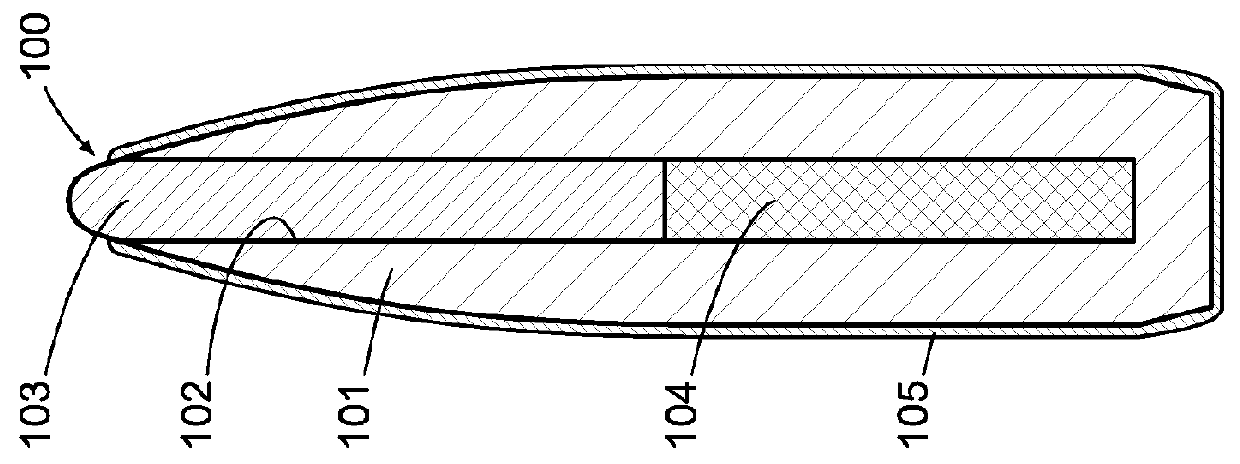

A projectile comprising a body having a channel, one or more recesses in the channel, a plunger in the channel, and a fluid in the channel is provided. When the projectile impacts a target, the plunger is driven down the channel, exerting a force on the fluid. The fluid, in turn, exerts fluidic pressure within the recesses, promoting rapid yet predictable expansion of the projectile. Another embodiment of the present invention provides a projectile utilizing a non-Newtonian fluid to optimize expansion of the projectile upon impacting a target.

Owner:JACKSON JASON STEWART

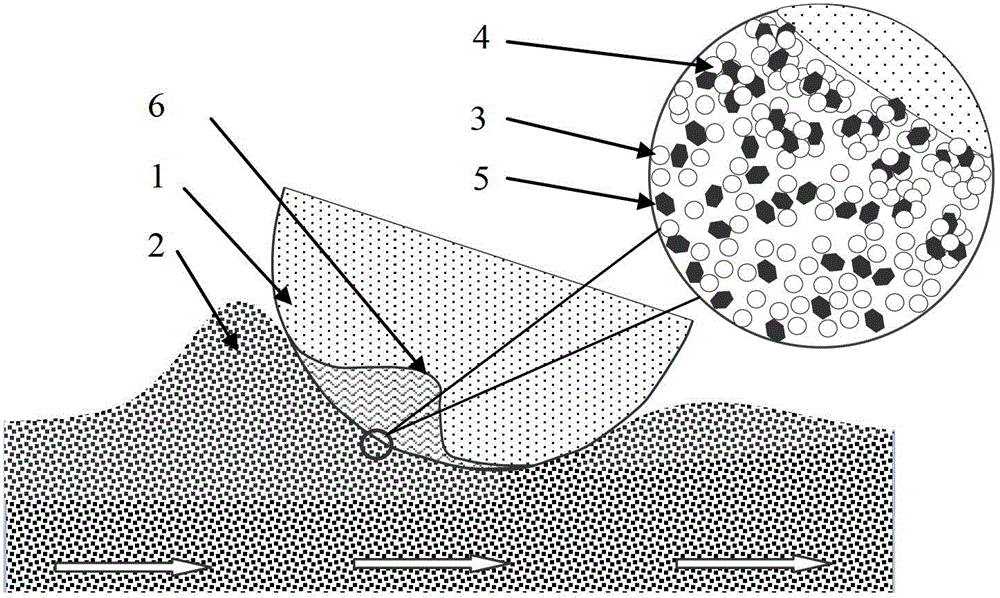

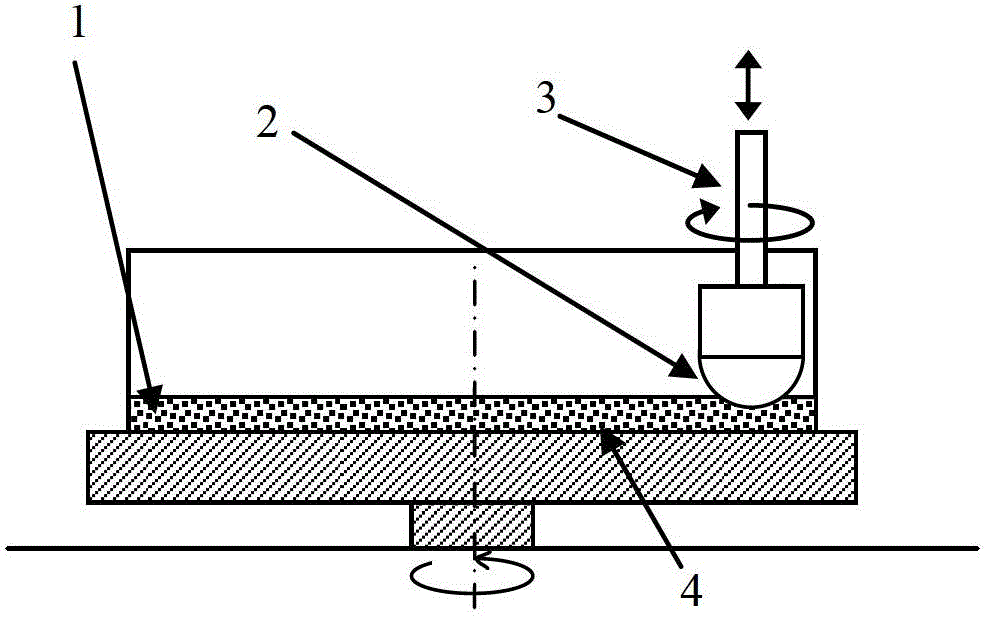

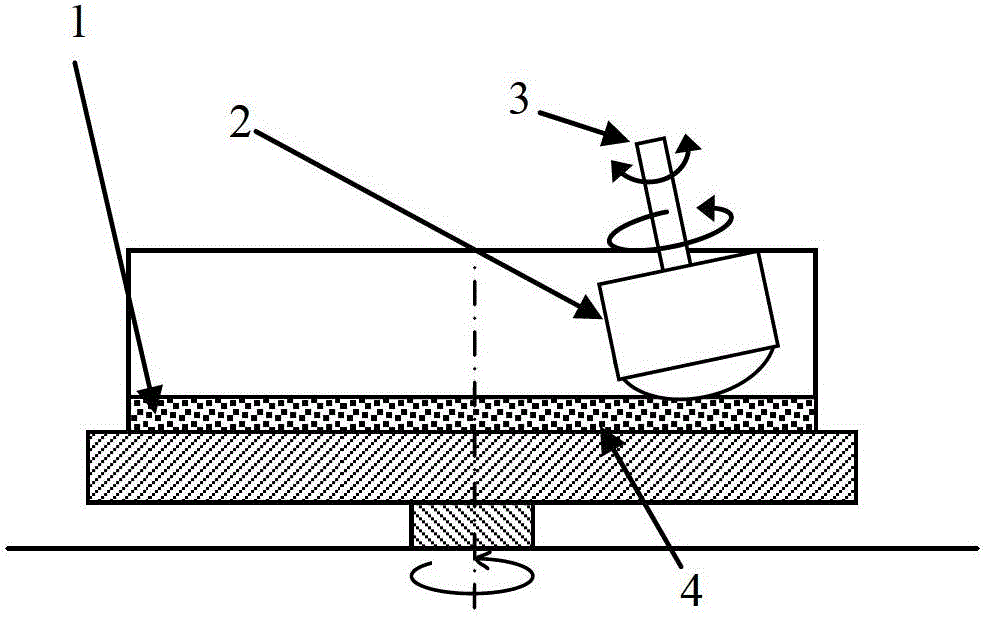

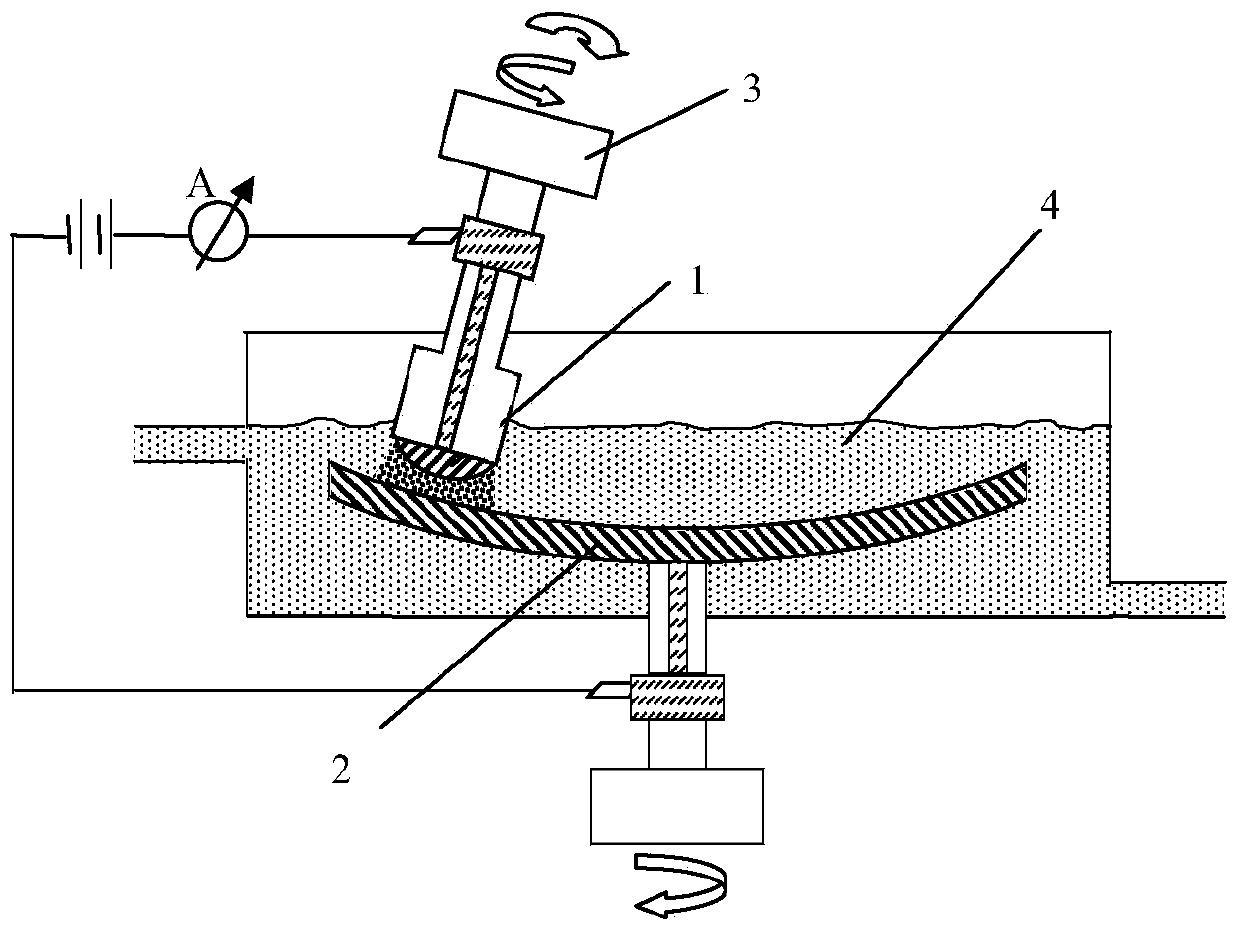

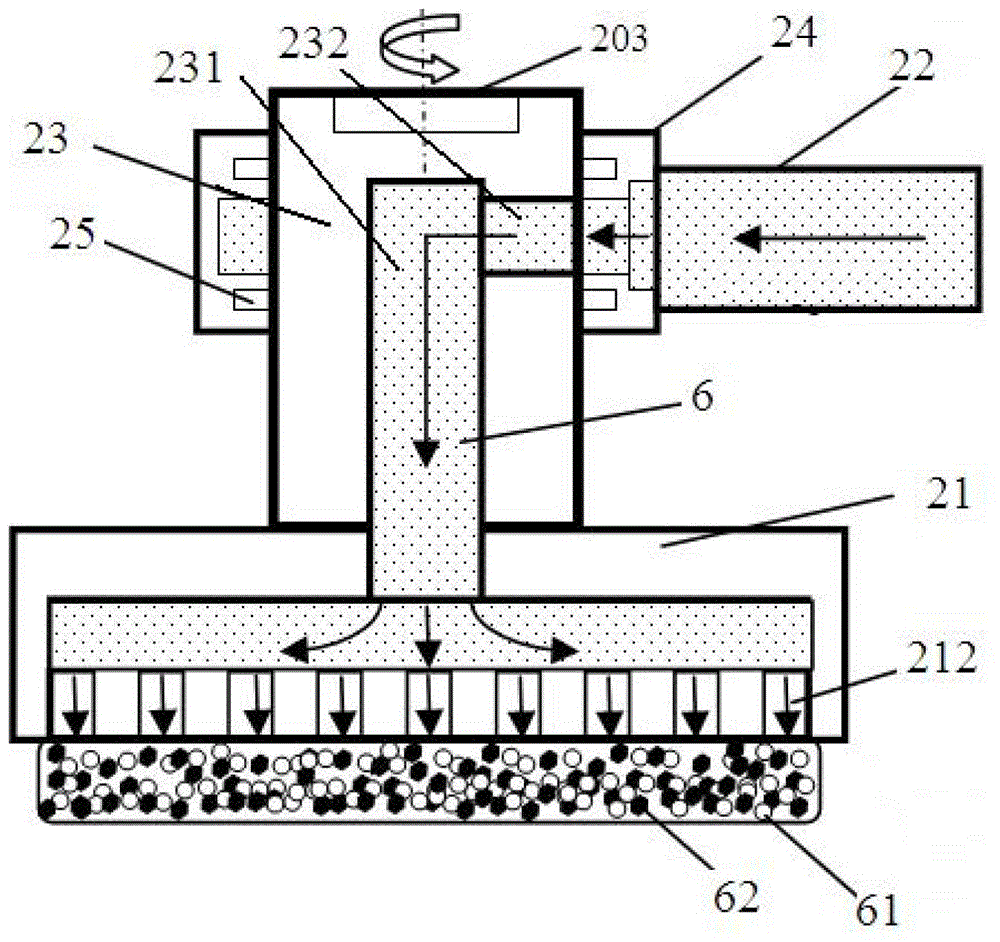

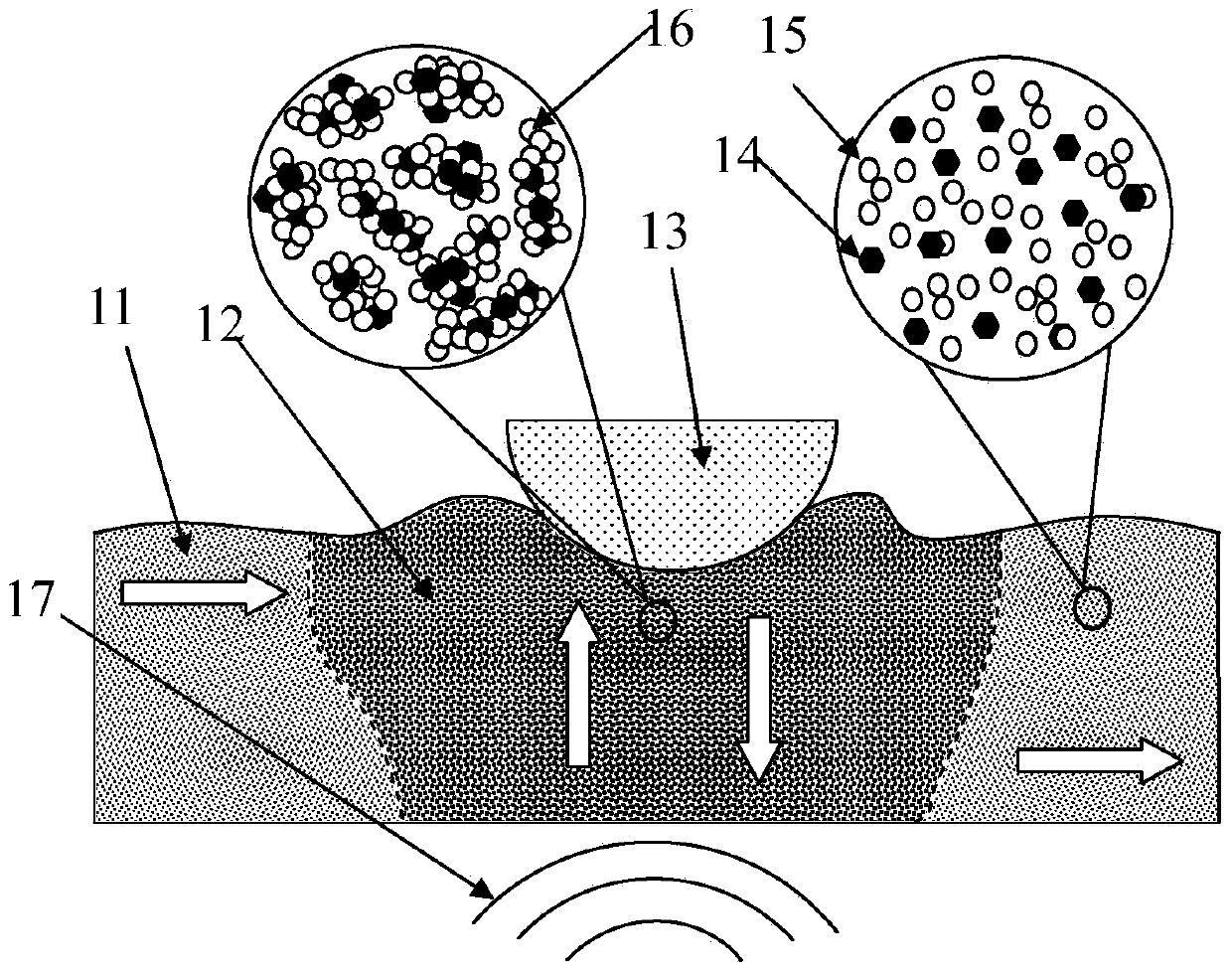

Ultra-precise curved surface finishing method based on non-Newtonian fluid shear thickening effect

ActiveCN102717325AImprove gripAvoid damagePolishing machinesOther chemical processesSocial benefitsSurface finish

The invention discloses an ultra-precise curved surface finishing method based on non-Newtonian fluid shear thickening effect. The method includes: adding abrasive particles or micropowder into non-Newtonian fluid with shear thickening effect to prepare non-Newtonian fluid polishing solution, wherein the non-Newtonian fluid accounts for 50%-90% of the mass of the polishing solution, the abrasive particles or the micropowder account for 10%-50% of the mass of the polishing solution, and the particle size of the abrasive particles or the micropowder ranges from 0.05 micrometer to 50 micrometers. Relative motion is generated between a workpiece and the polishing solution during polishing, shear thickening is generated at a contact portion of the polishing solution and the workpiece under shearing action, viscosity of the polishing solution in the contact area is increased to enhance holding force to the abrasive particles or the micropowder, and removal of workpiece surface materials is achieved under the micro cutting or chemical mechanical action of the adding abrasive particles or micropowder with polishing effect in the polishing solution on the workpiece, so that polishing of the workpiece surface is achieved. The ultra-precise curved surface finishing method based on the non-Newtonian fluid shear thickening effect can achieve efficient and high-quality polishing to various curved surfaces, in particular to complex curved surfaces and has great economic and social benefits.

Owner:ZHEJIANG UNIV OF TECH

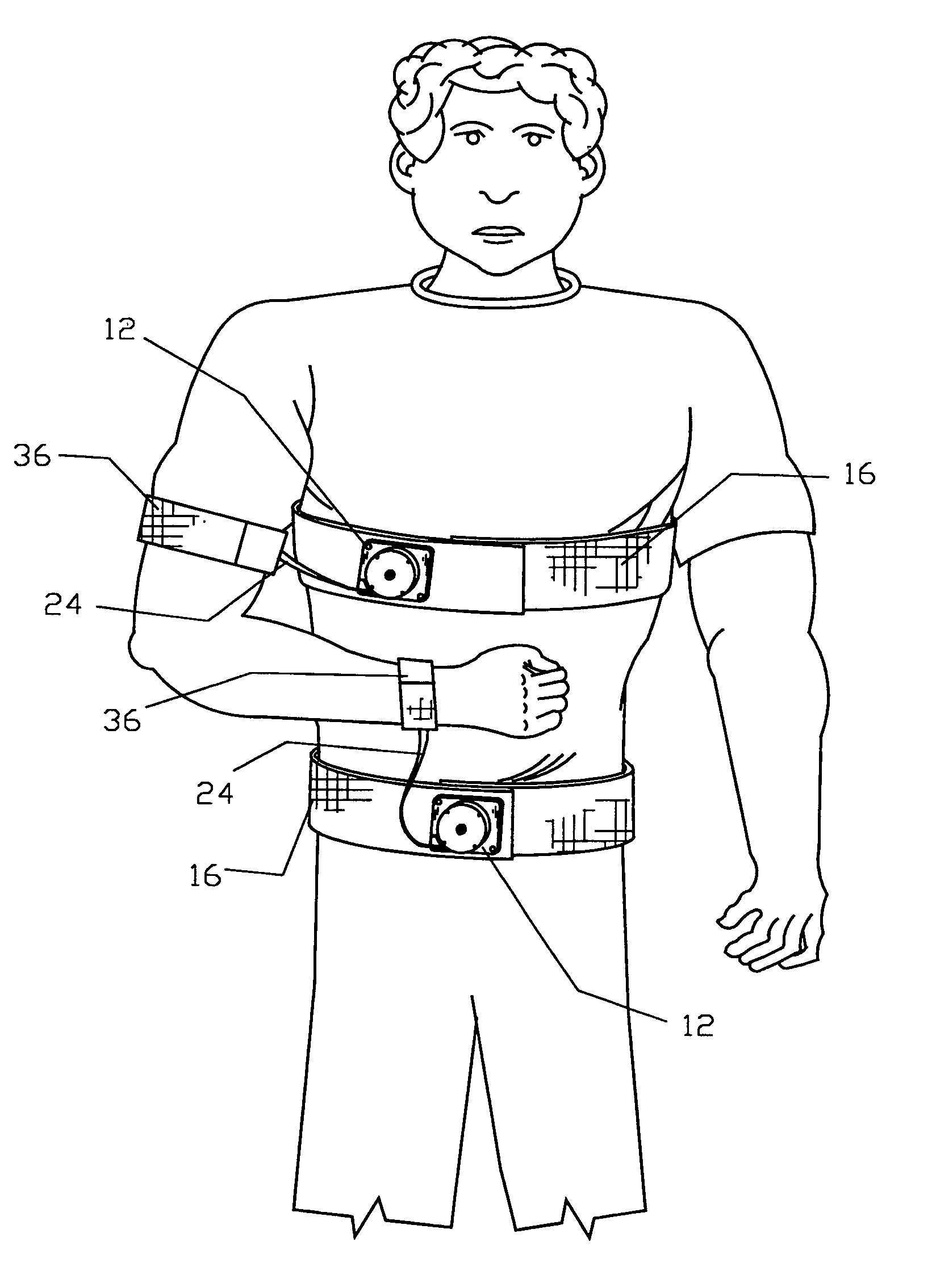

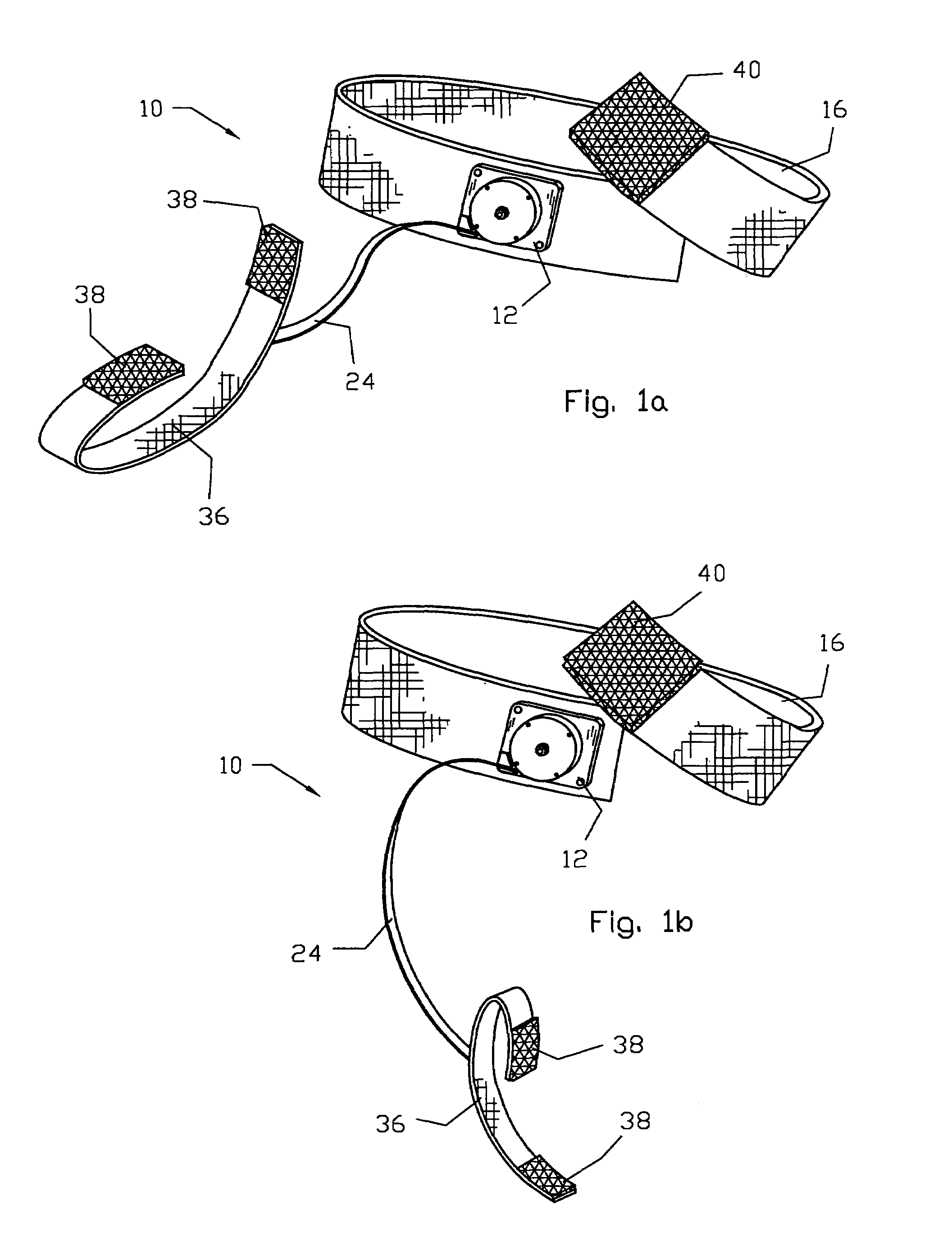

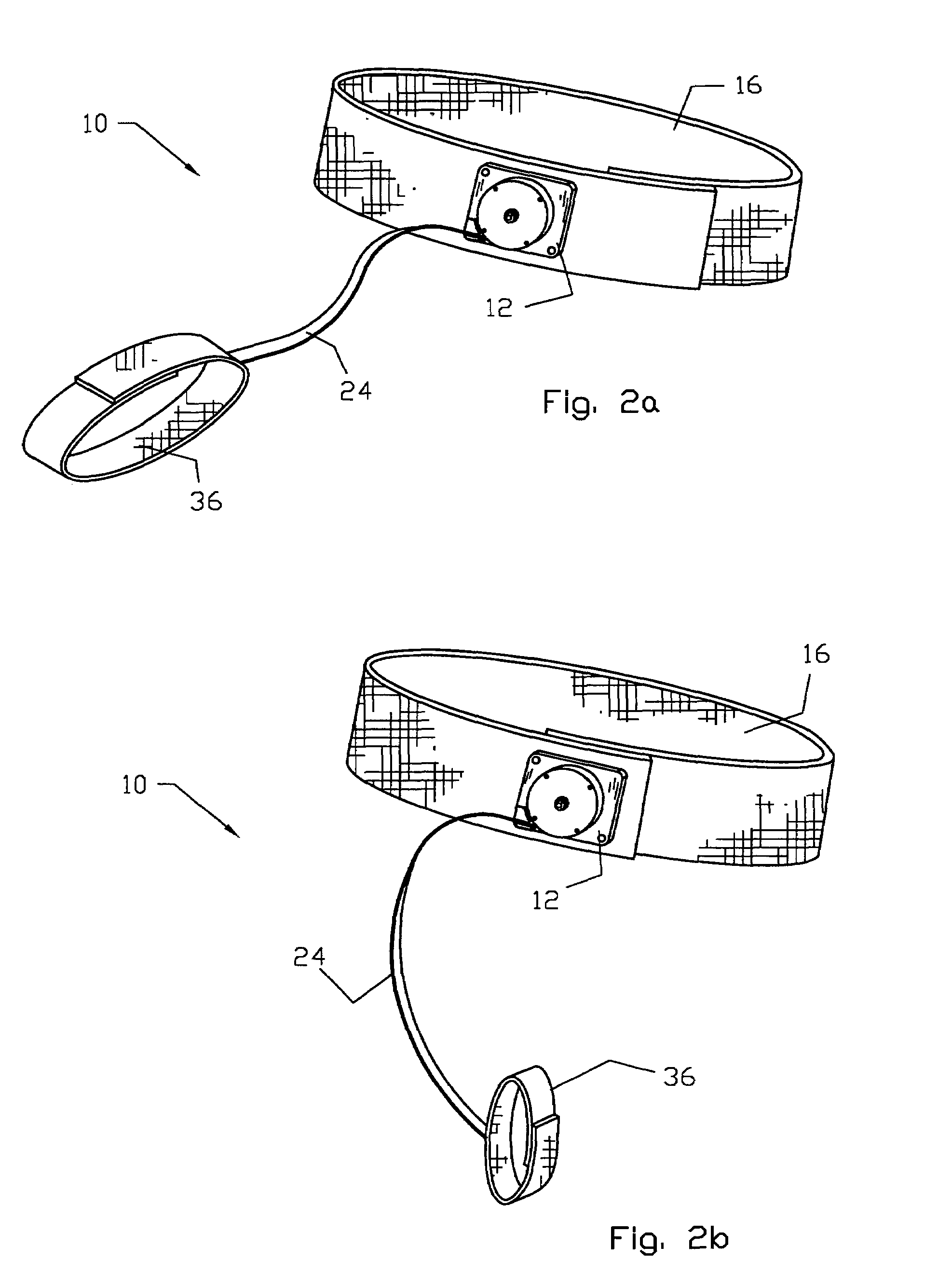

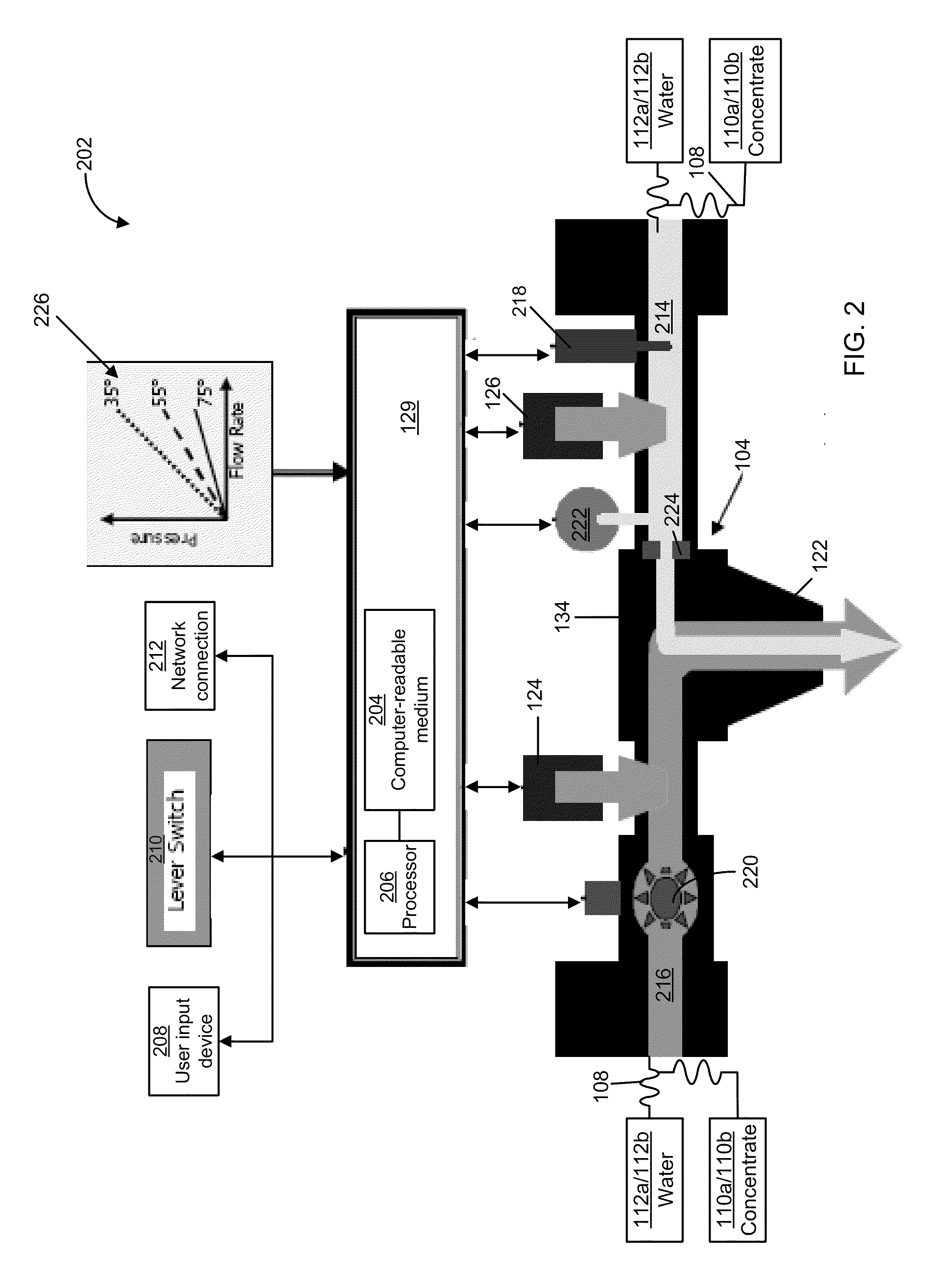

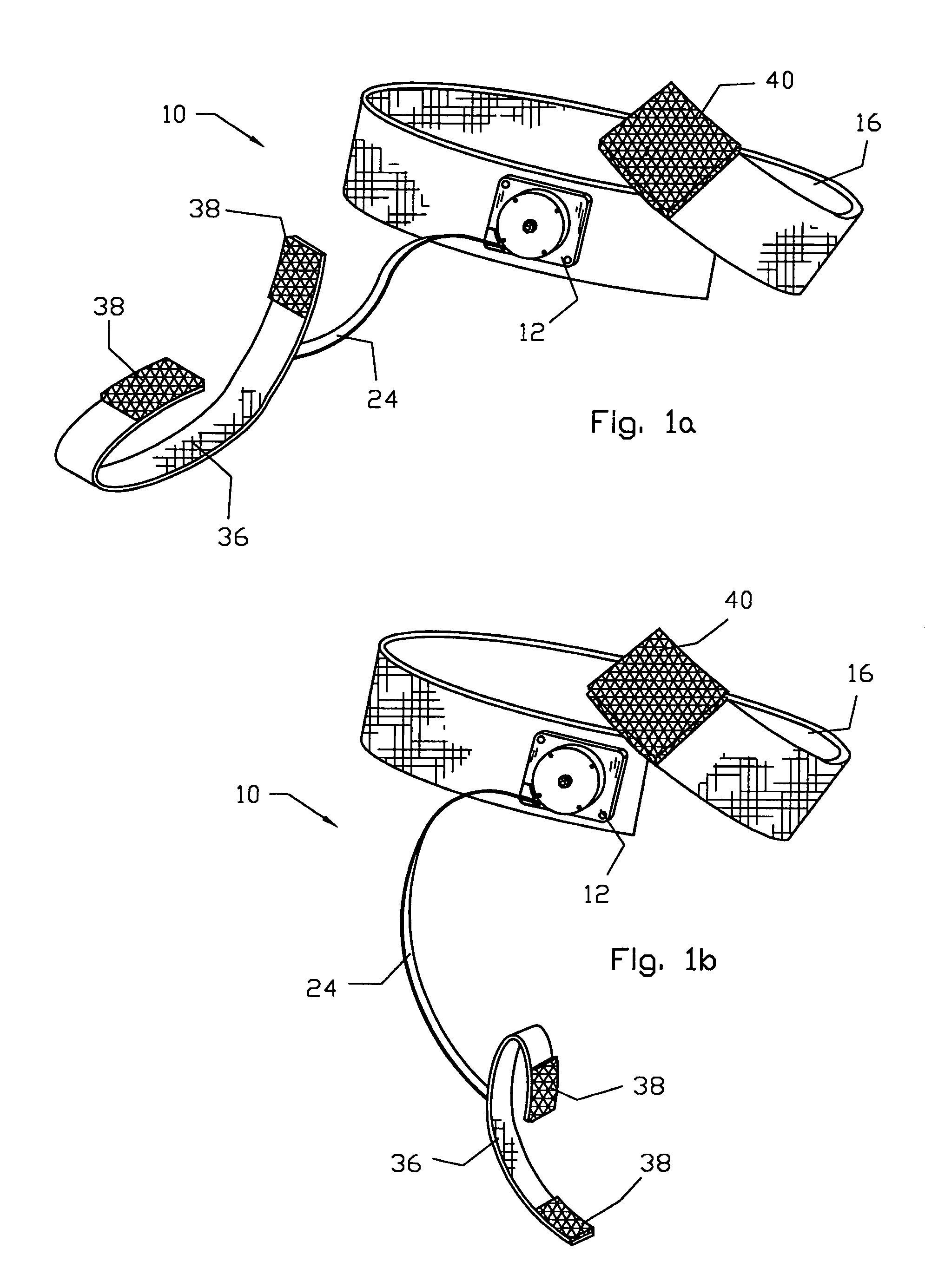

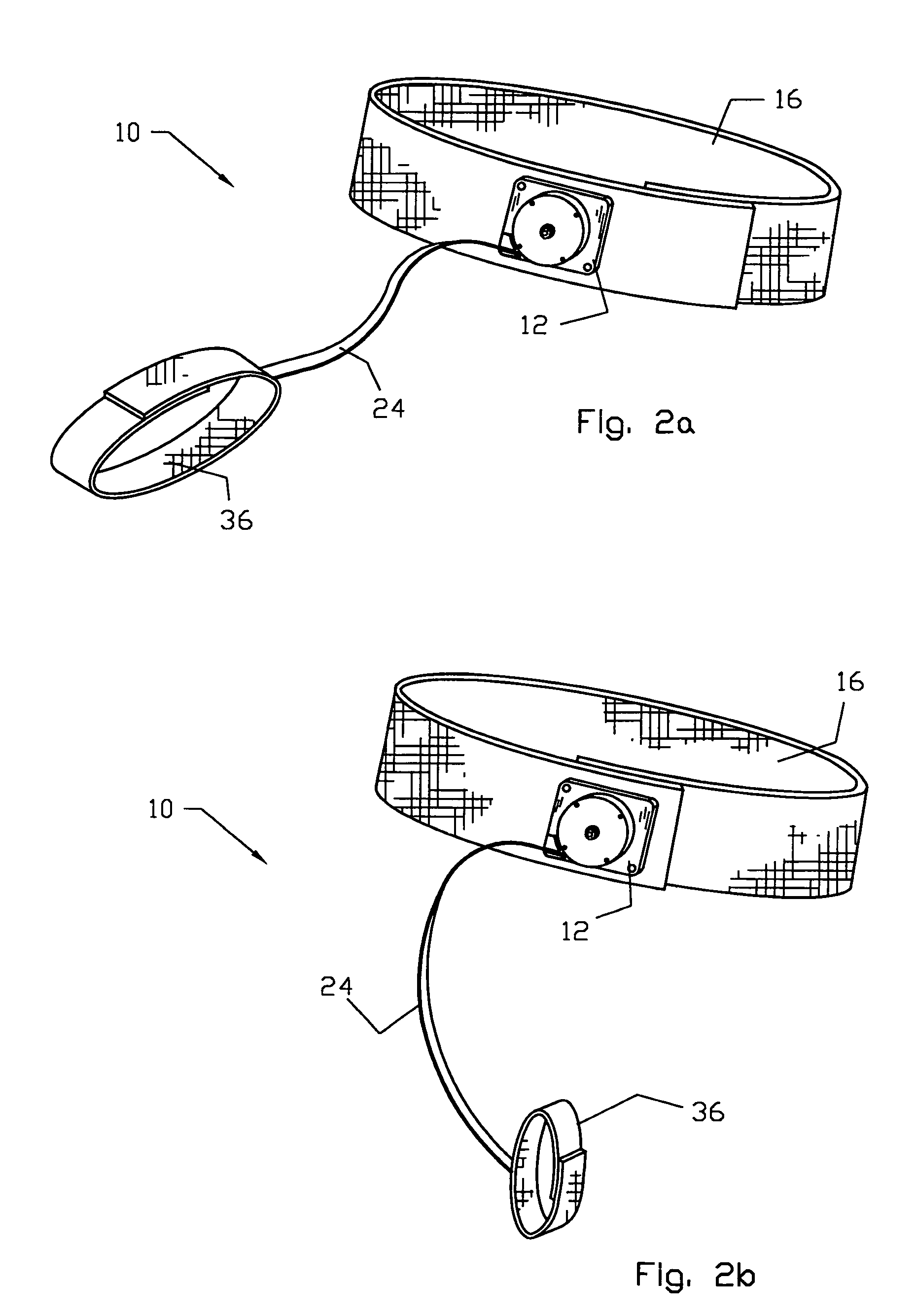

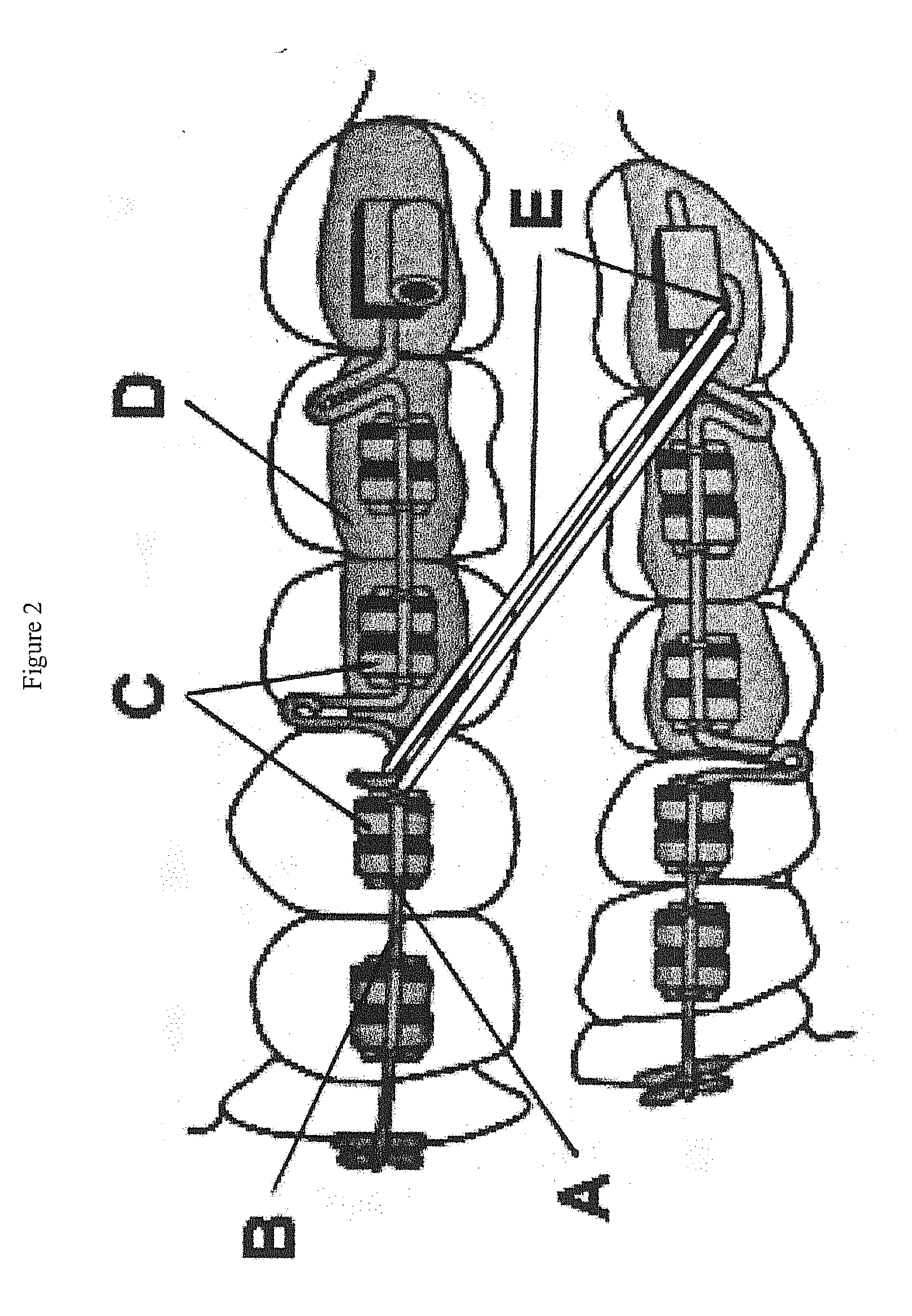

Body limb movement limiter

InactiveUS7402147B1Move fastConvenient design and constructionRestraining devicesNon-surgical orthopedic devicesThighHand arm

A body limb movement limiter restrains the movement of a person's arm so as to protect the person's shoulder or restrains the movement of a person's lower leg with respect to the upper leg so as to protect the person's knee. The device uses a housing having a reel disposed therein with a tether attached thereto and a shear thickening non-Newtonian fluid disposed within the housing so that the fluid acts on the reel during a payout procedure of the tether. The housing is attached to a strap secured about the torso of the person while the free end of the tether is secured about the person's arm. Alternately, a pair of arms are pivotally secured to each other within a housing having the non-Newtonian fluid therein for limiting movement of one arm with respect to the other.

Owner:ALLEN SUSAN DAVIS

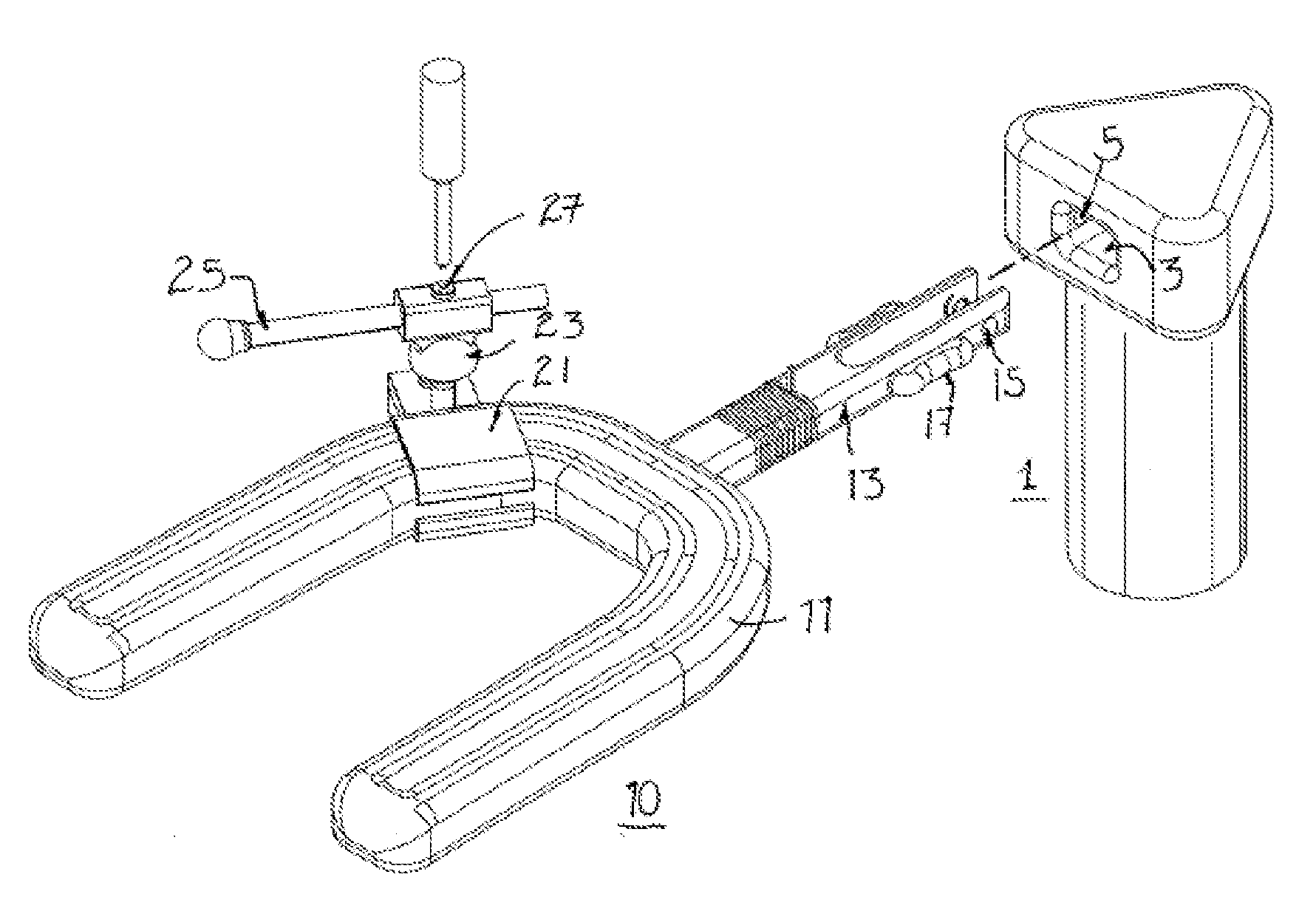

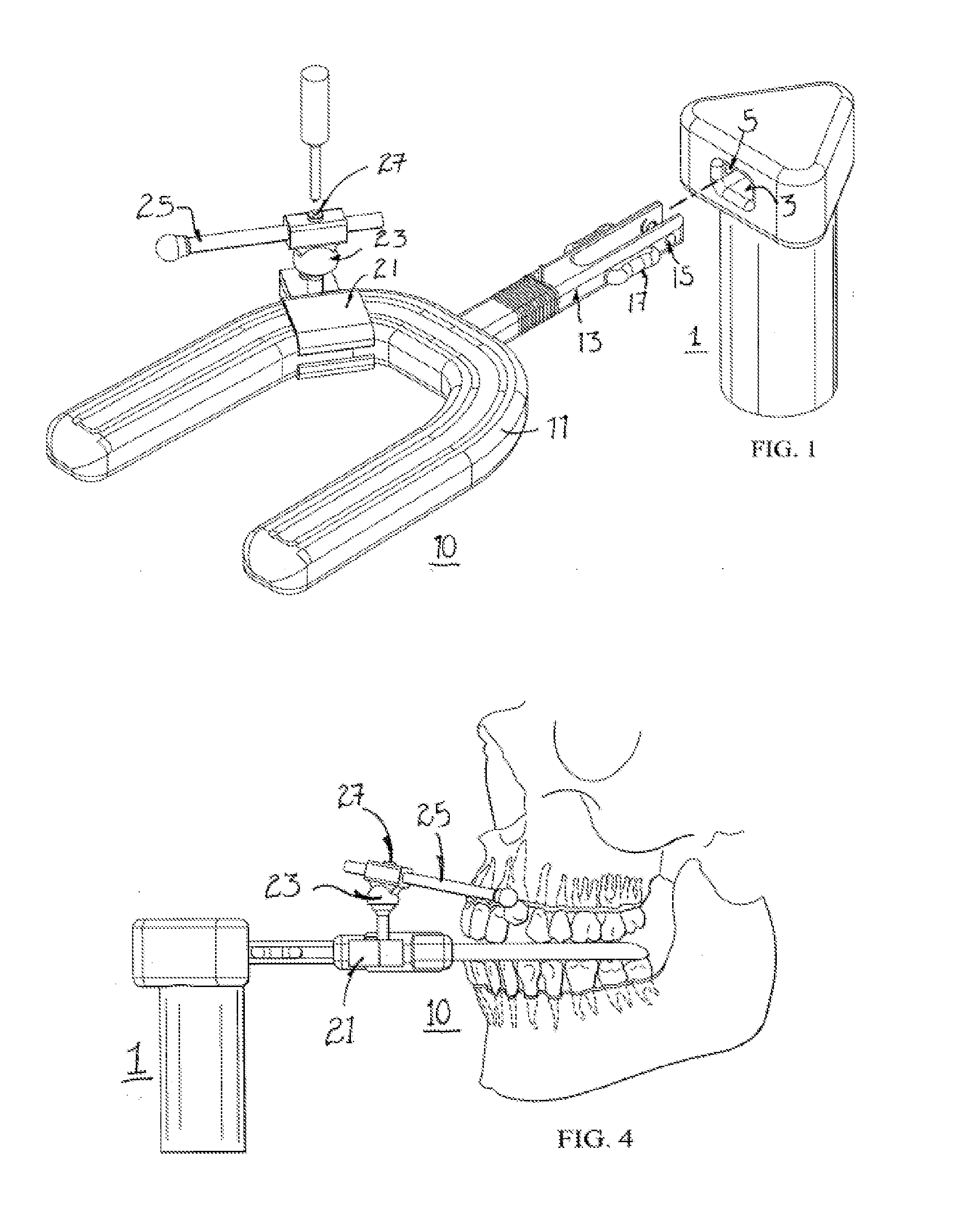

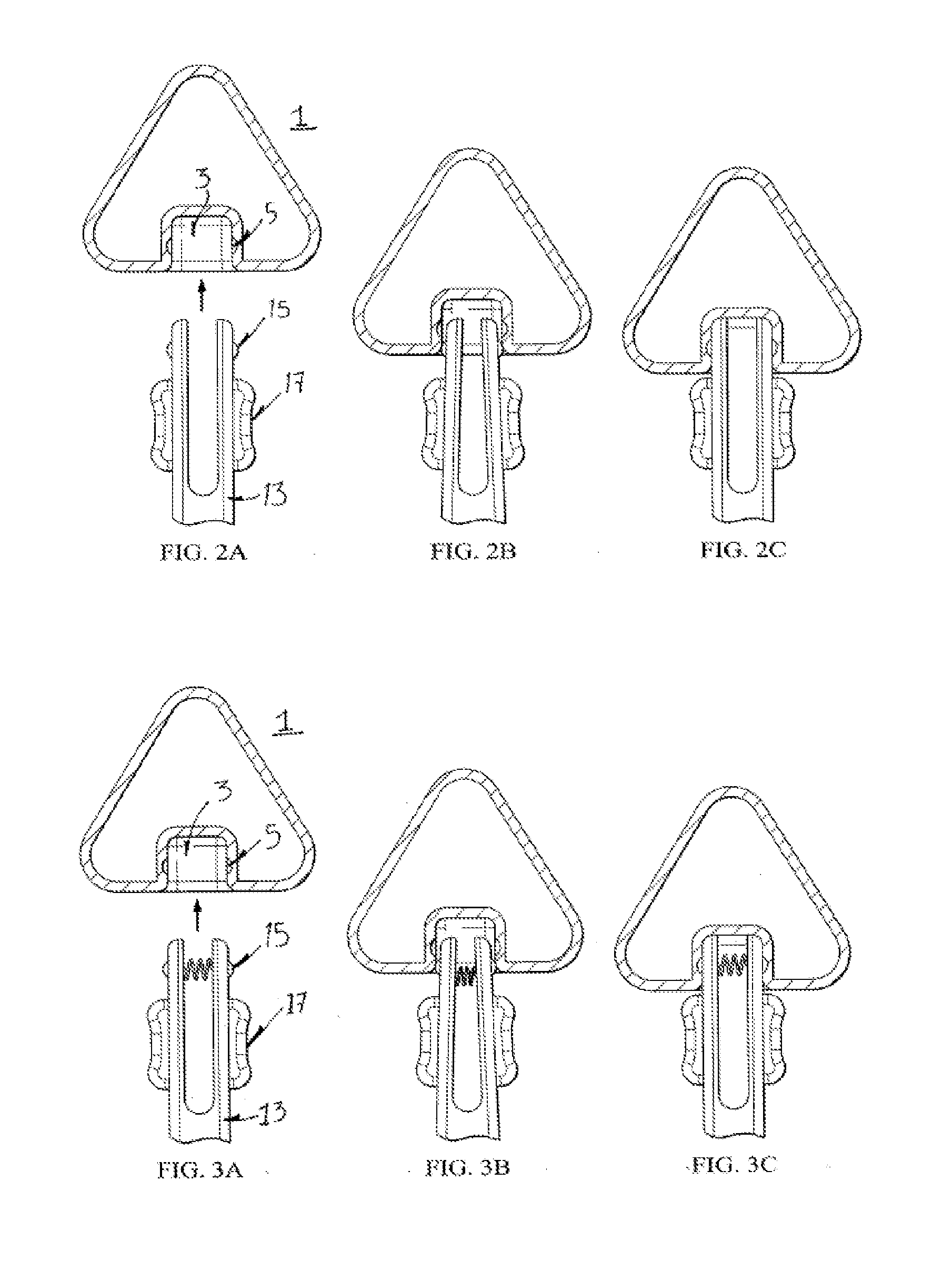

Vibrating dental plate and accessories

ActiveUS20120040300A1Sold at costMaximum lifeOperating chairsOthrodonticsDocking stationDental Equipment

Vibrating dental devices and accessories are provided, including a unique snap fit dental plate and vibrator connection; risers for adjusting the thickness of a dental plate; a pointer or wand that can be clamped onto a dental plate to reach even severely misaligned teeth; a cushioned dental plate having a non-Newtonian fluid therein that allows conformation of the cushion to the dentition, but hardens on use to allow the transmission of vibration to the teeth. Accessories such as carrying cases and docking stations are also provided.

Owner:ADVANCED ORTHODONTICS & EDUCATION ASSOC LLC

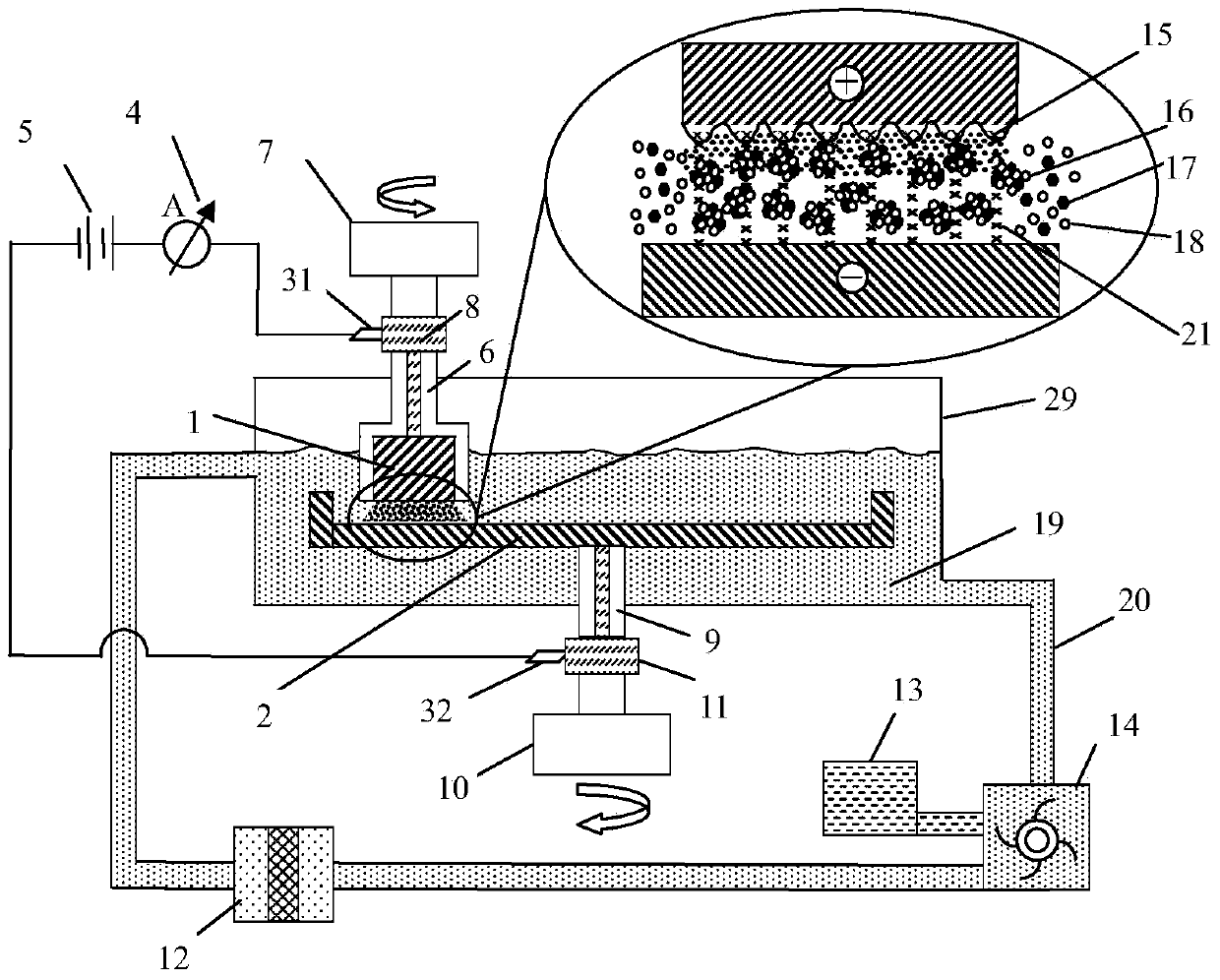

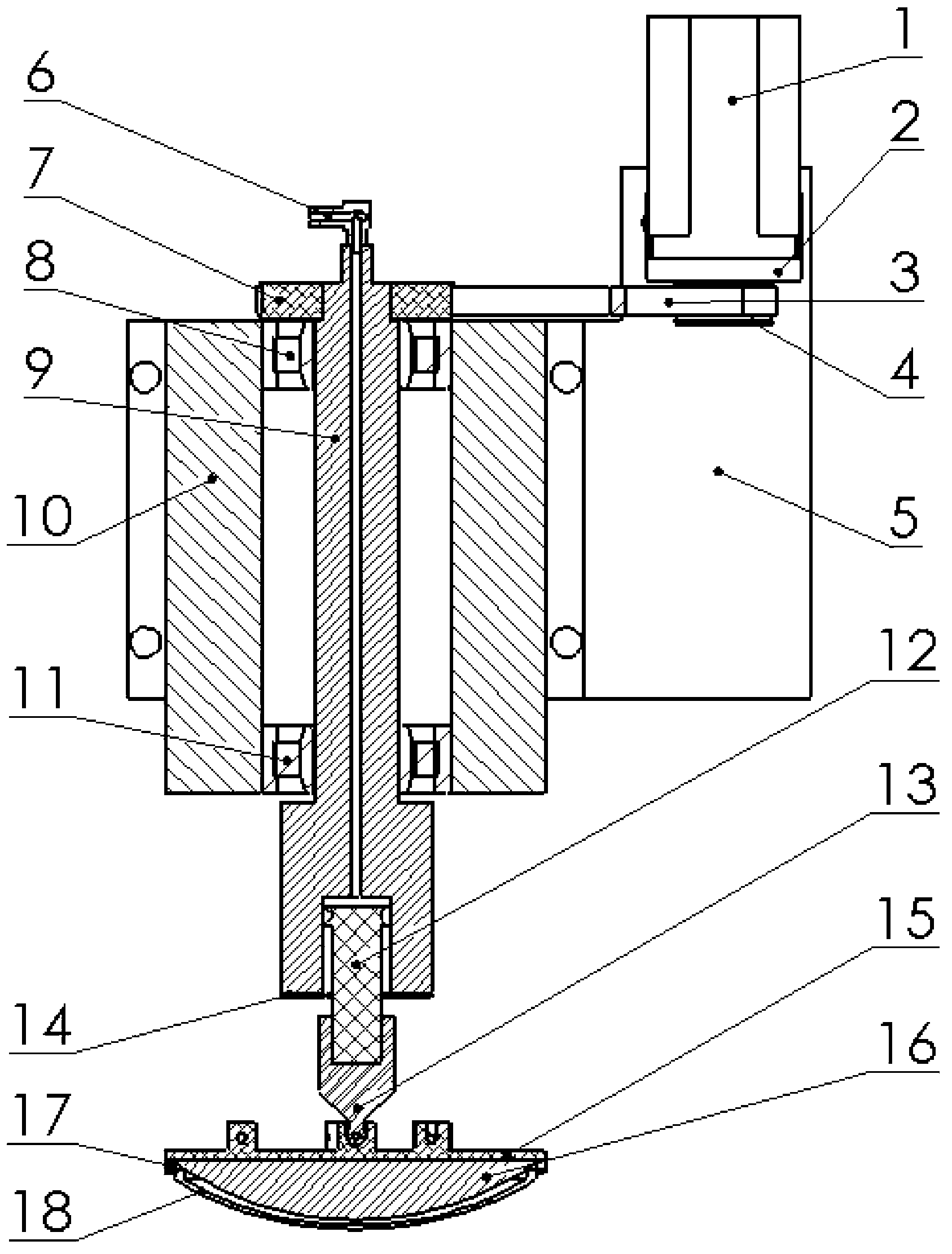

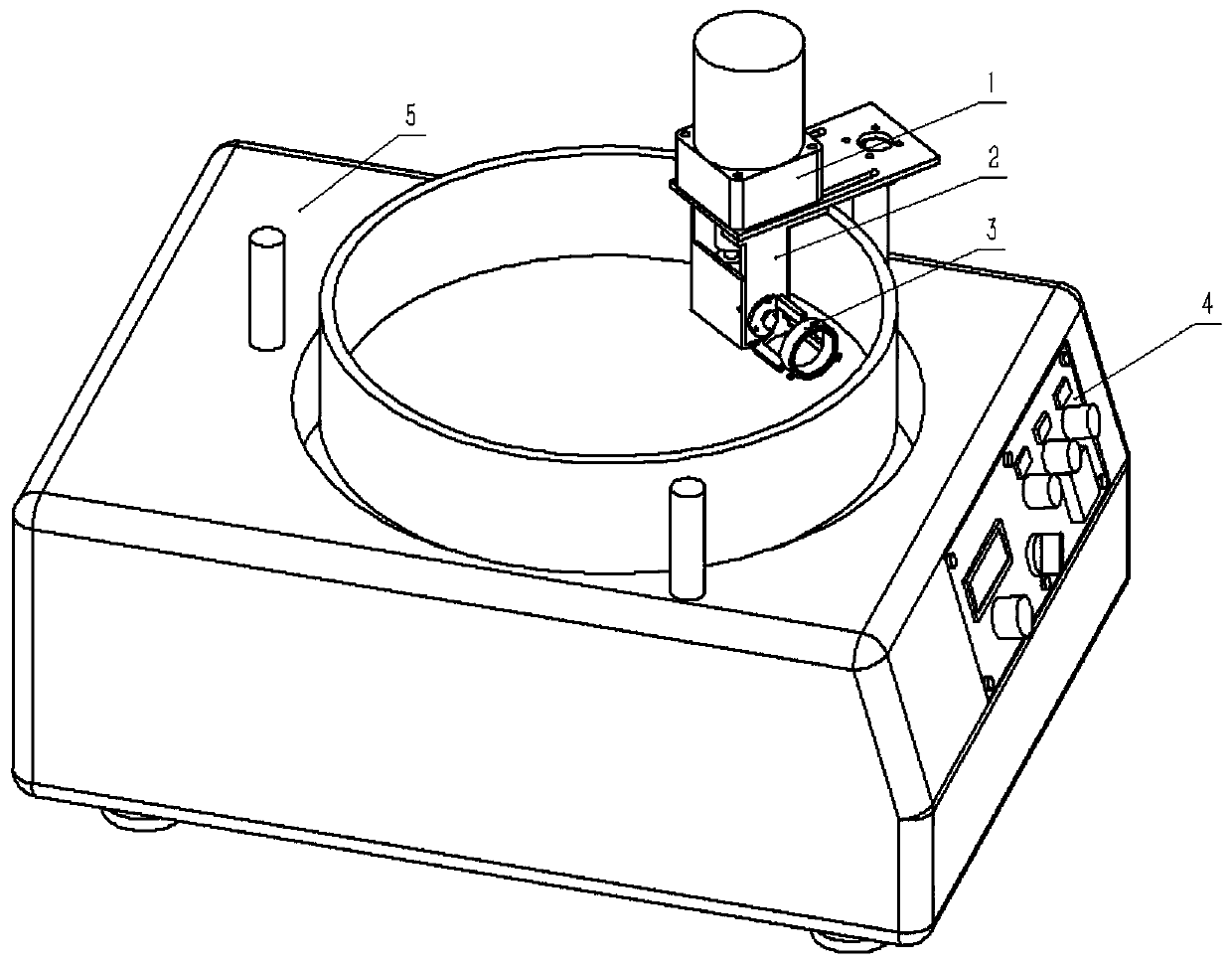

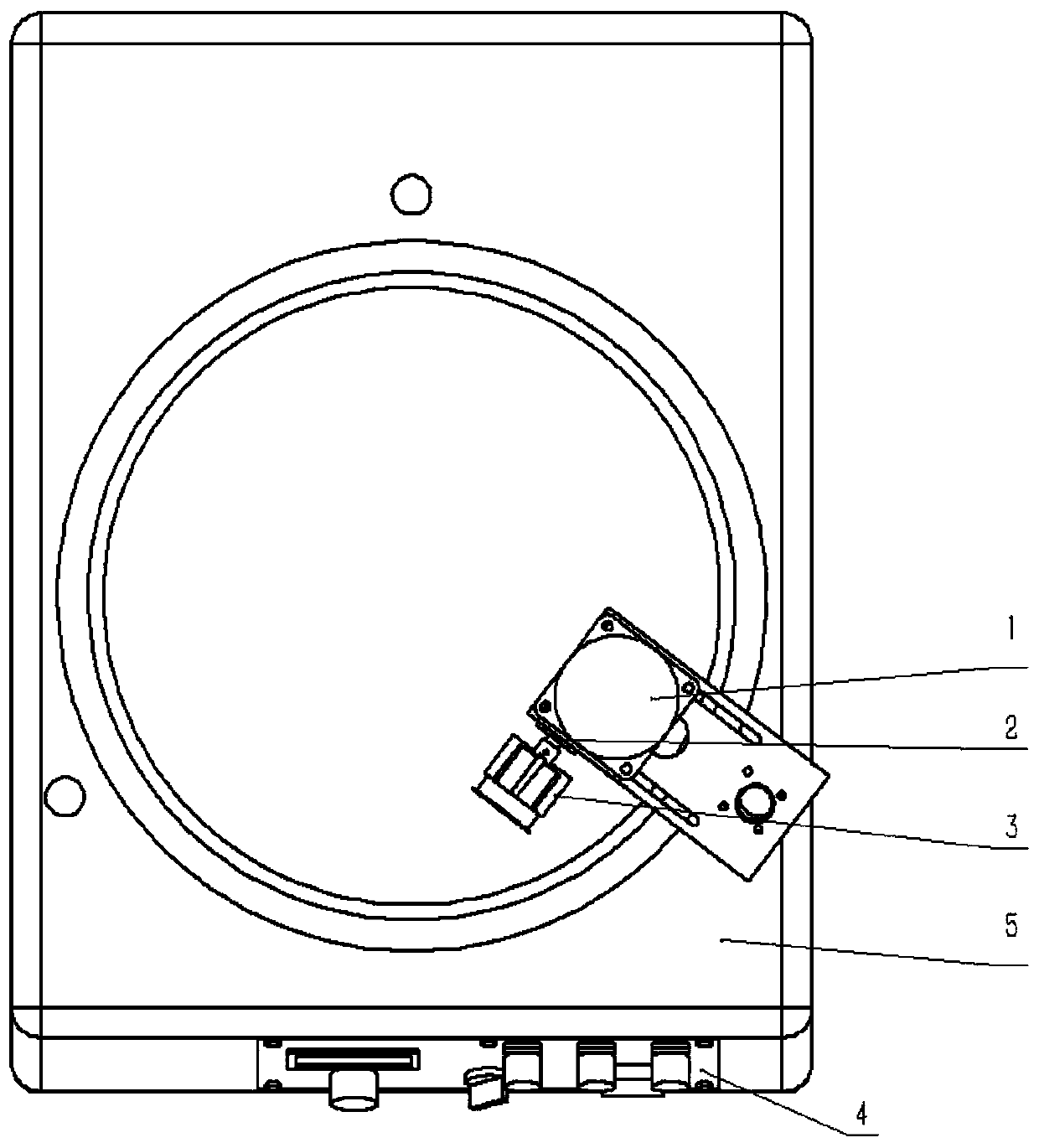

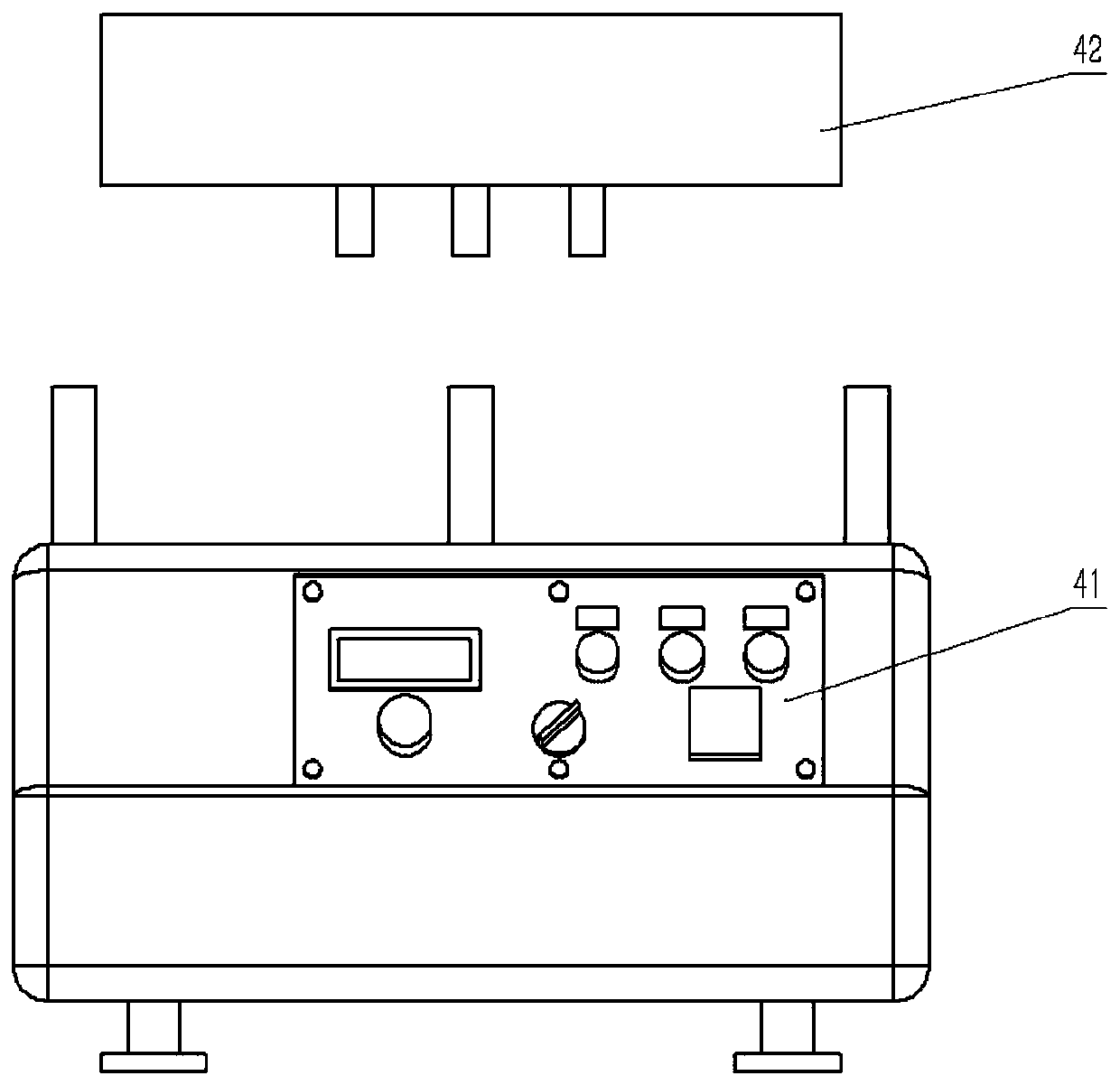

Ultra-precision machining device based on non-Newtonian fluid shear thickening and electrolysis composition effect

ActiveCN104191340AThe result is prone to the problem of spotsImprove processing efficiencyPolishing machinesPolishing compositions with abrasivesElectrolysisComponents of crude oil

An ultra-precision machining device based on non-Newtonian fluid shear thickening and an electrolysis composition effect comprises a polishing tool, a polishing tool clamp, a workpiece clamp and a polishing pool, wherein the polishing tool is located in the polishing pool, polishing liquid is contained in the polishing pool, a workpiece on the workpiece clamp is located in the polishing pool, and a gap is formed between the workpiece and the polishing tool; the workpiece clamp is connected with a workpiece driving mechanism, an electric conducing part of the polishing tool clamp is connected with a polishing tool driving mechanism, an electric conducting part of the workpiece clamp is connected with an anode of a power source, the polishing tool clamp is connected with a cathode of the power source, and abrasive particles or micro powder or electrolyte components are added into non-Newtonian fluid with the shear thickening effect to form the polishing solution. The ultra-precision machining device is wide in application range, high in efficiency and quality, low in cost, simple in device structure and easy to control.

Owner:ZHEJIANG UNIV OF TECH

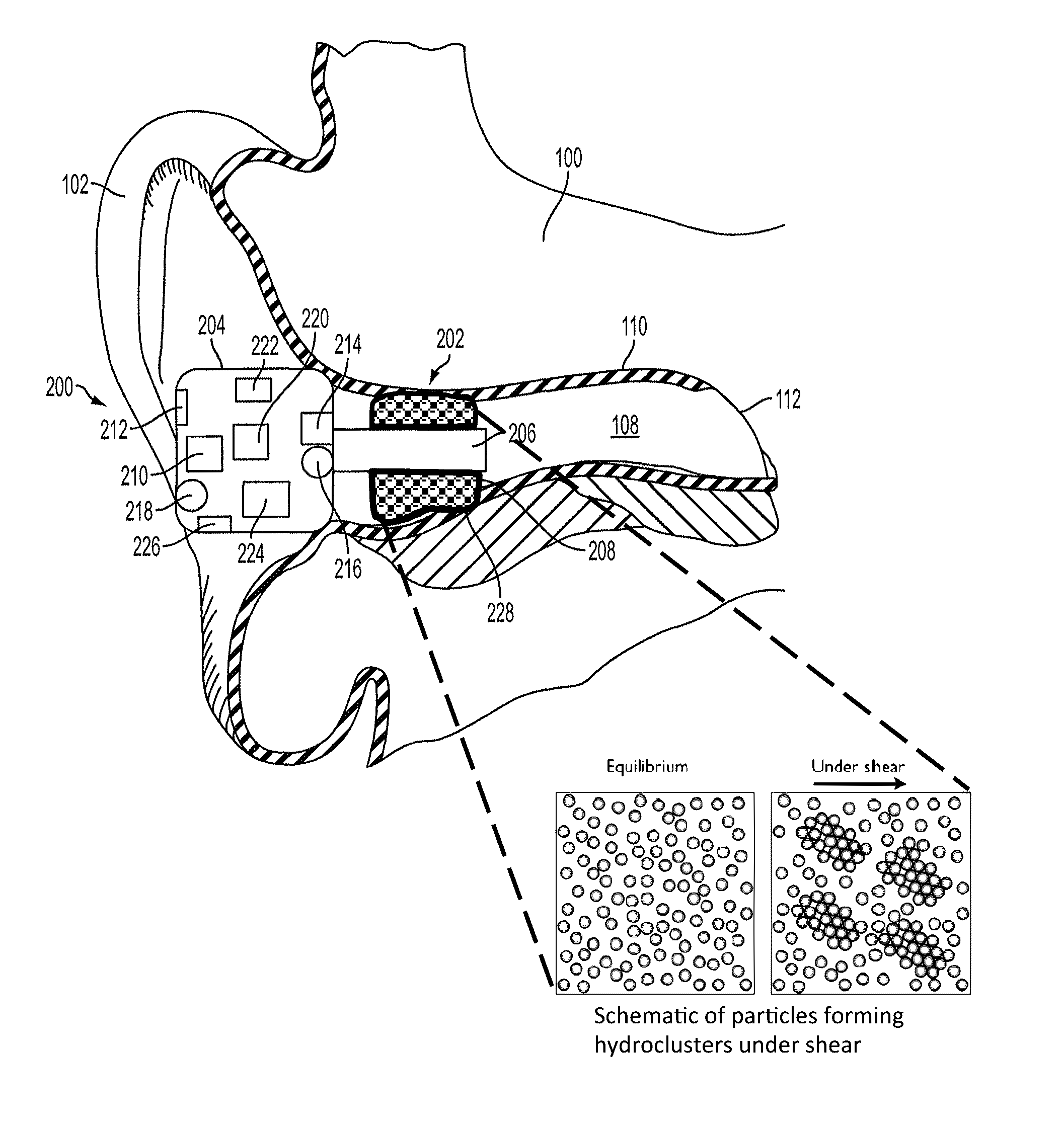

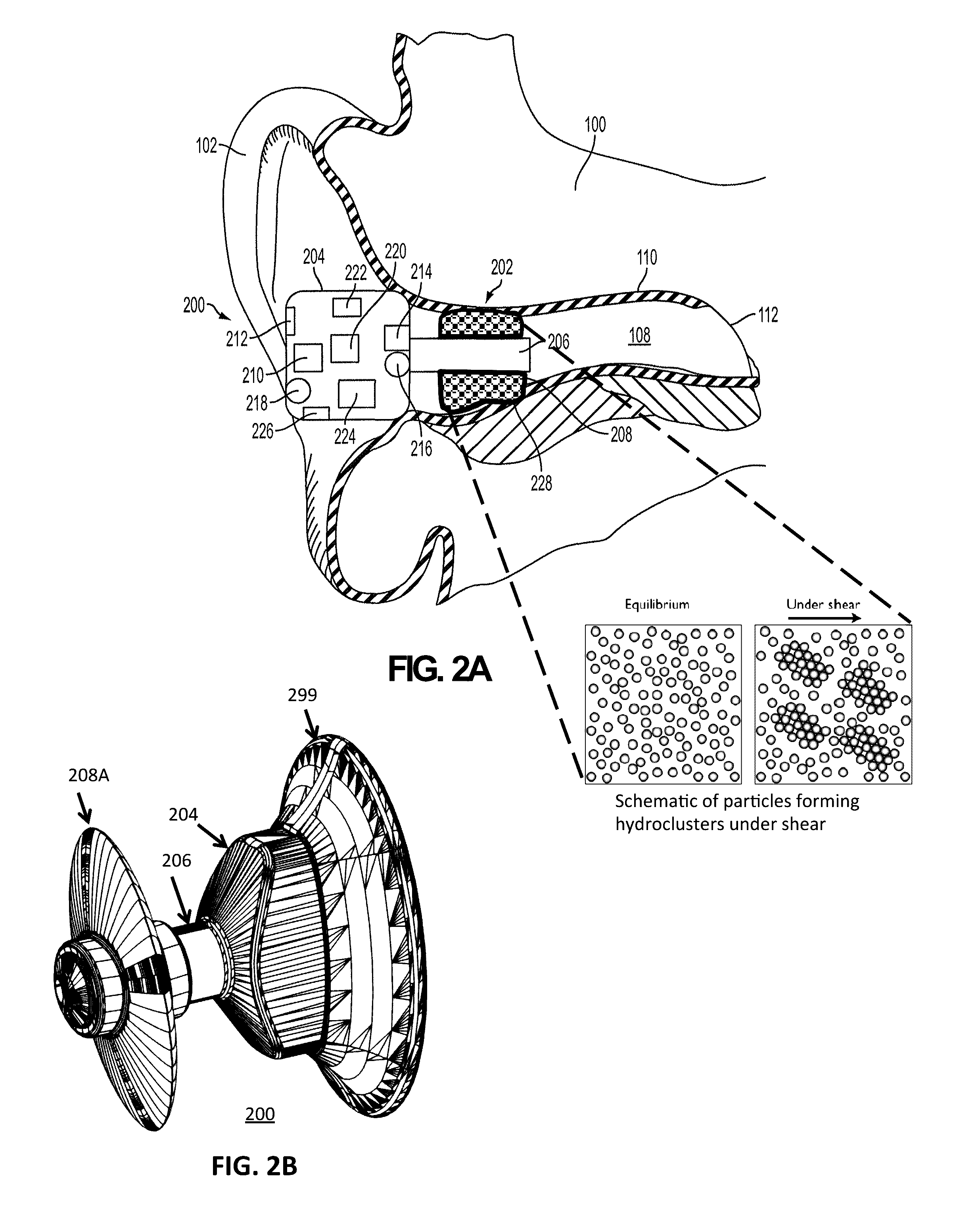

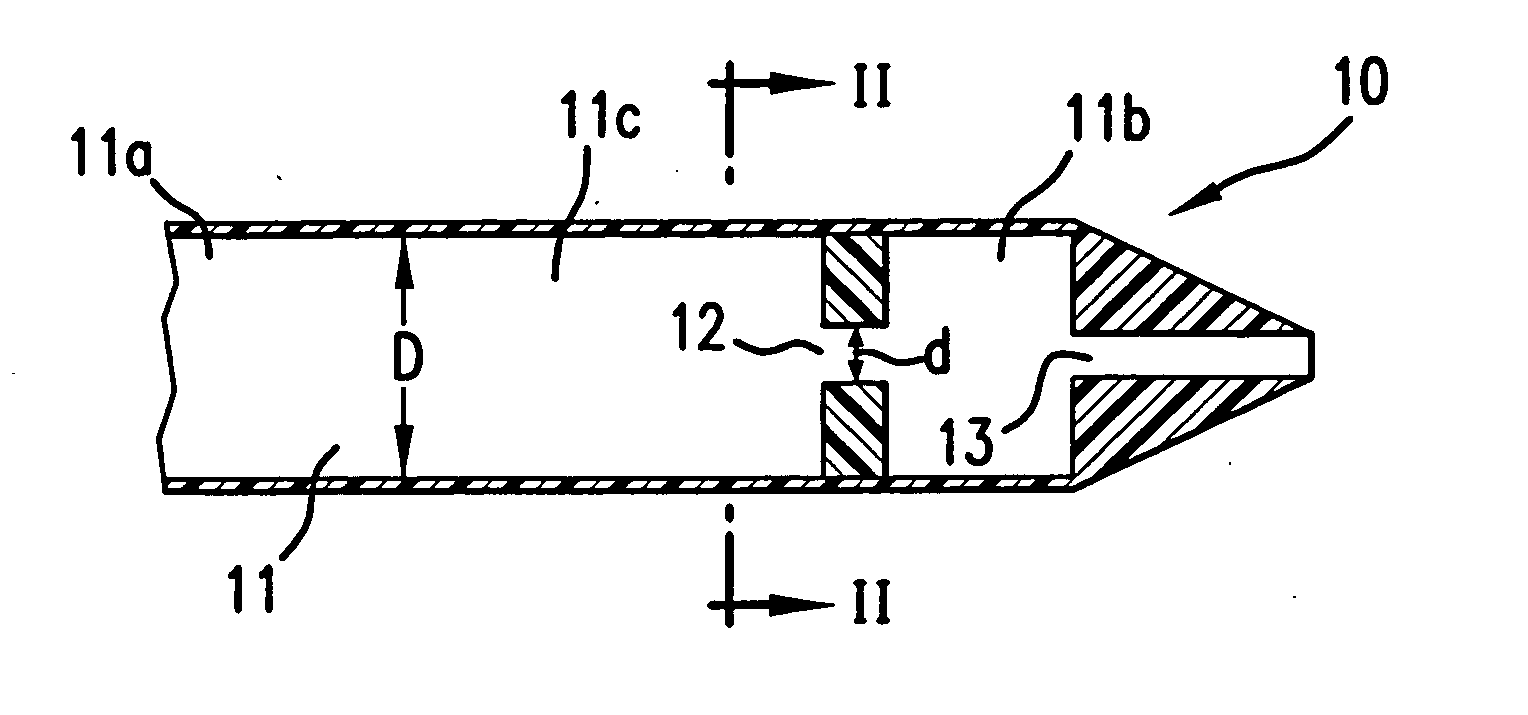

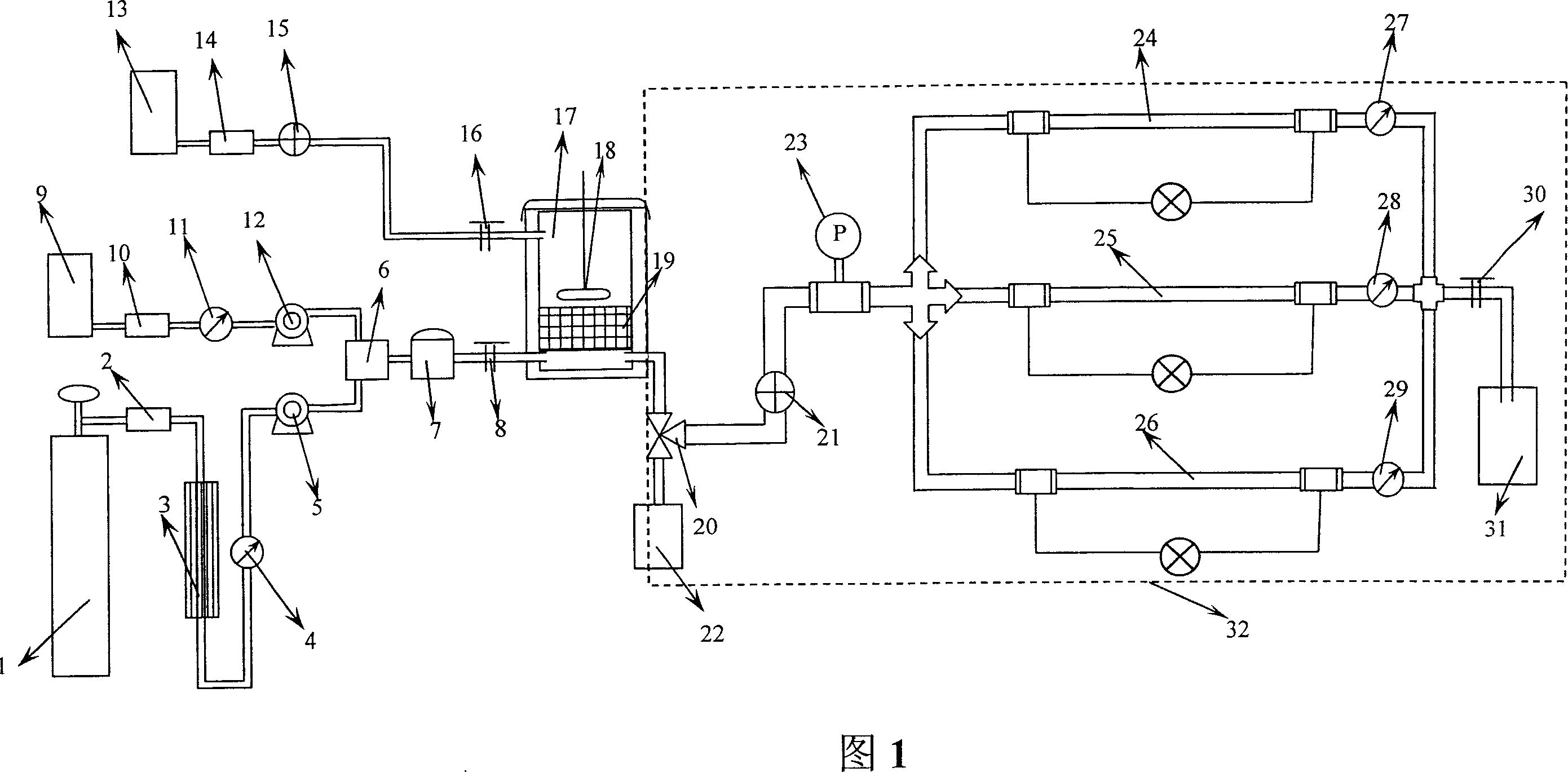

Methods and devices for attenuating sound in a conduit or chamber

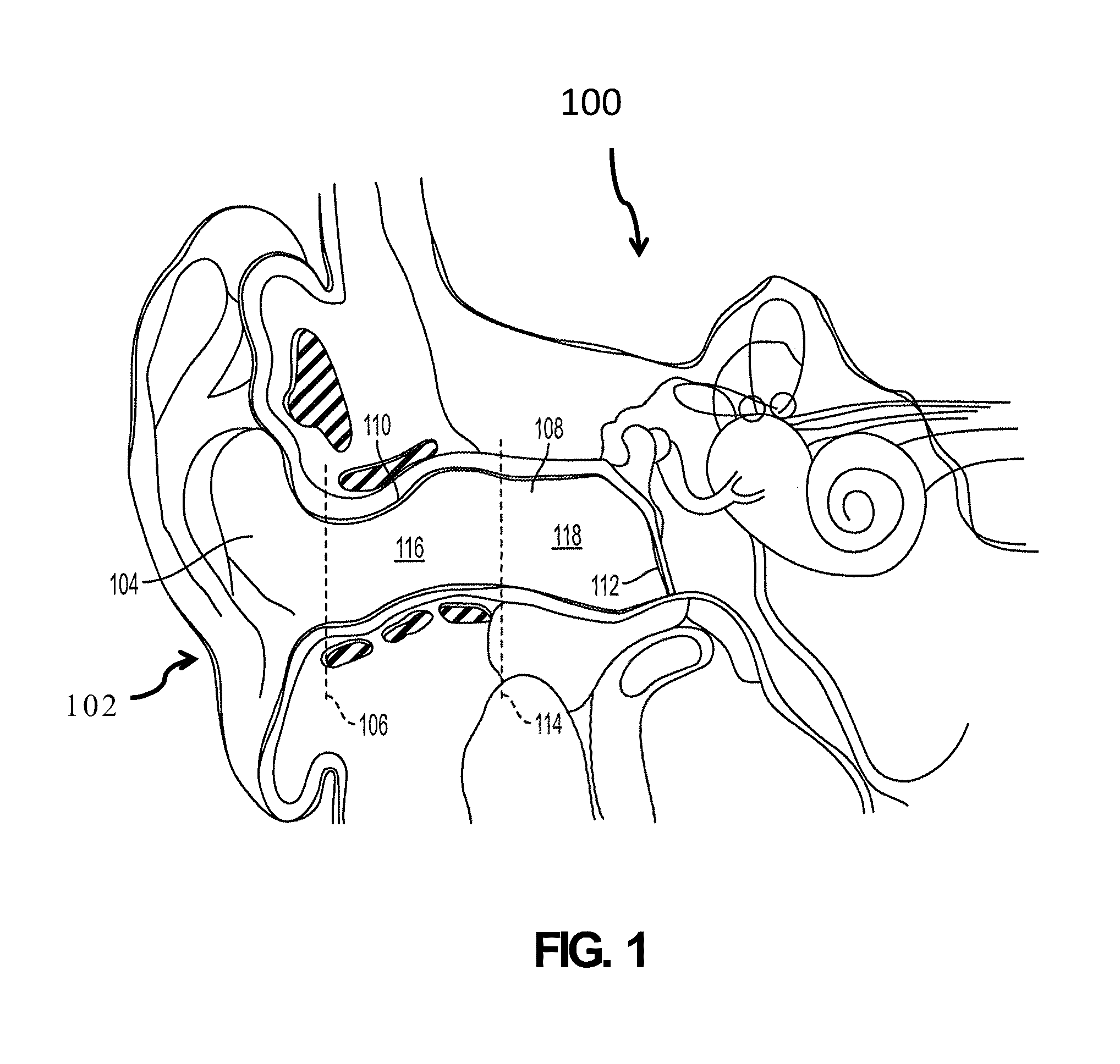

ActiveUS20170040012A1Reduce decreaseIncreases its acoustical impendence (attenuationEarplugsIntra aural earpiecesUltrasound attenuationMedicine

Occlusion devices, earpiece devices and methods of forming occlusion devices are provided. An occlusion device is configured to occlude an ear canal, but other biological and non-biological conduits or chambers can be occluded using the devices and methods herein. The occlusion device includes an insertion element and at least one occluding member or element (which can be expandable) disposed on the insertion element. The occluding member is configured to receive a medium via the insertion element and is configured to expand, responsive to the medium, to contact the ear canal. Alternatively, the occluding member is made of a non-Newtonian fluid and can be enclosed by a balloon or not. Physical parameters of the occlusion device are selected to produce a predetermined sound attenuation characteristic over a frequency band. Use of a non-Newtonian fluid provides additional options or variables in customizing or designing a predetermined sound attenuation characteristic.

Owner:STATON TECHIYA LLC

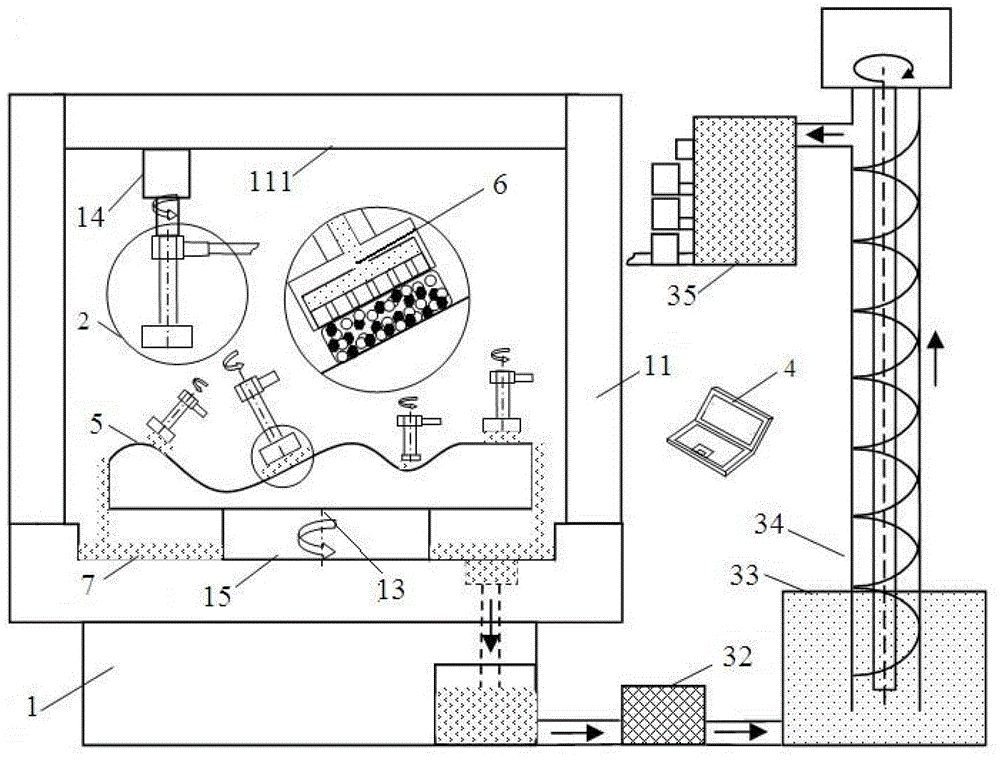

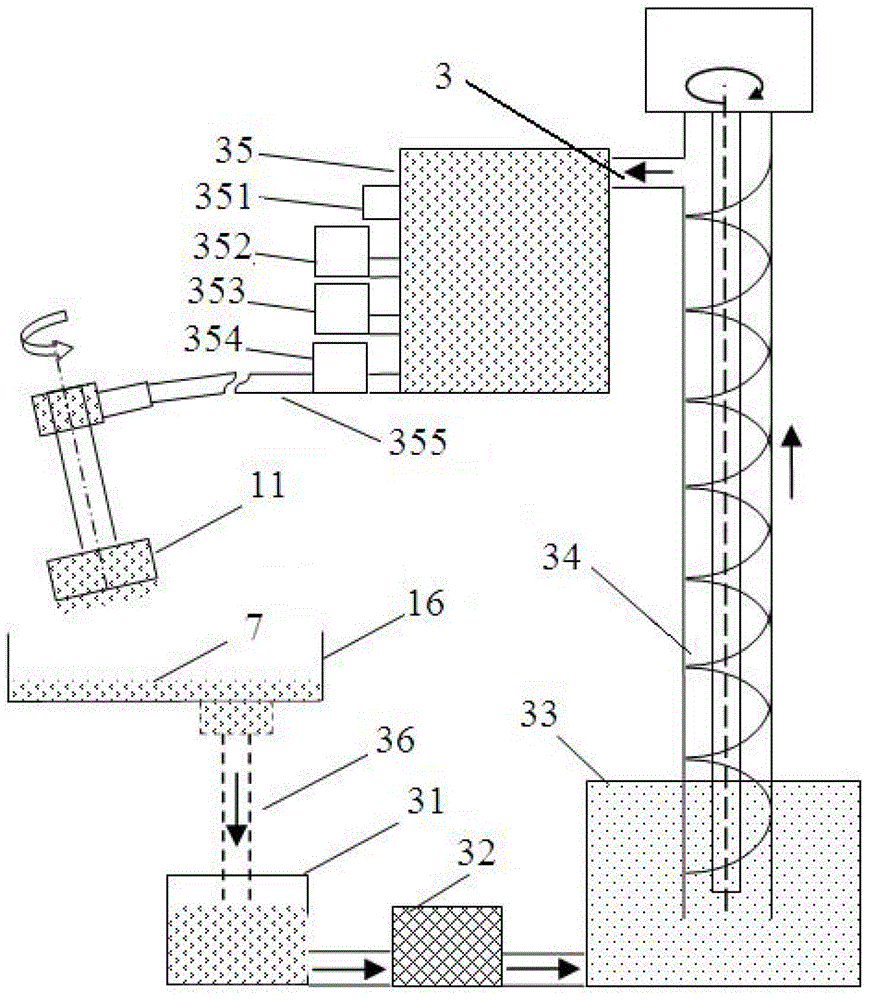

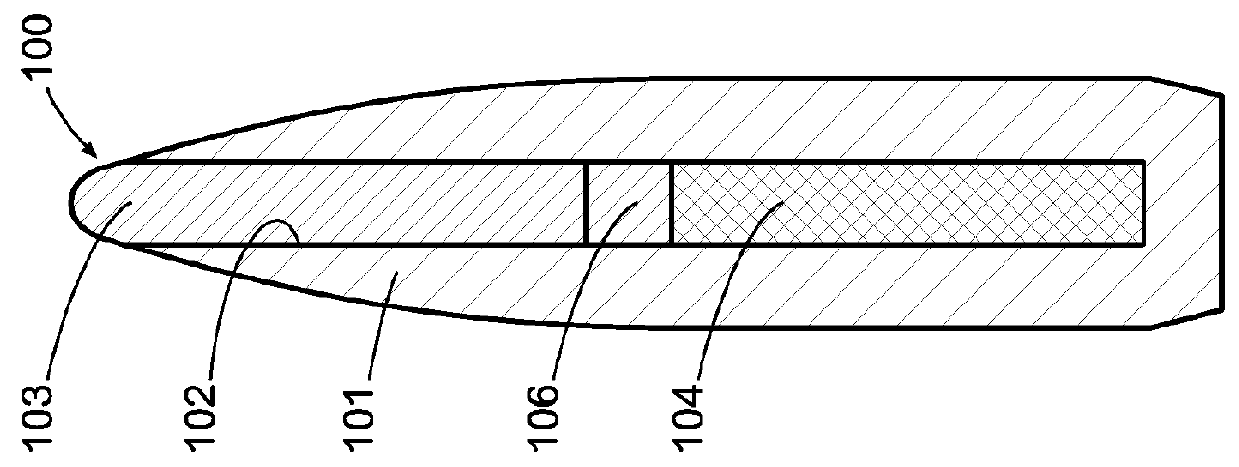

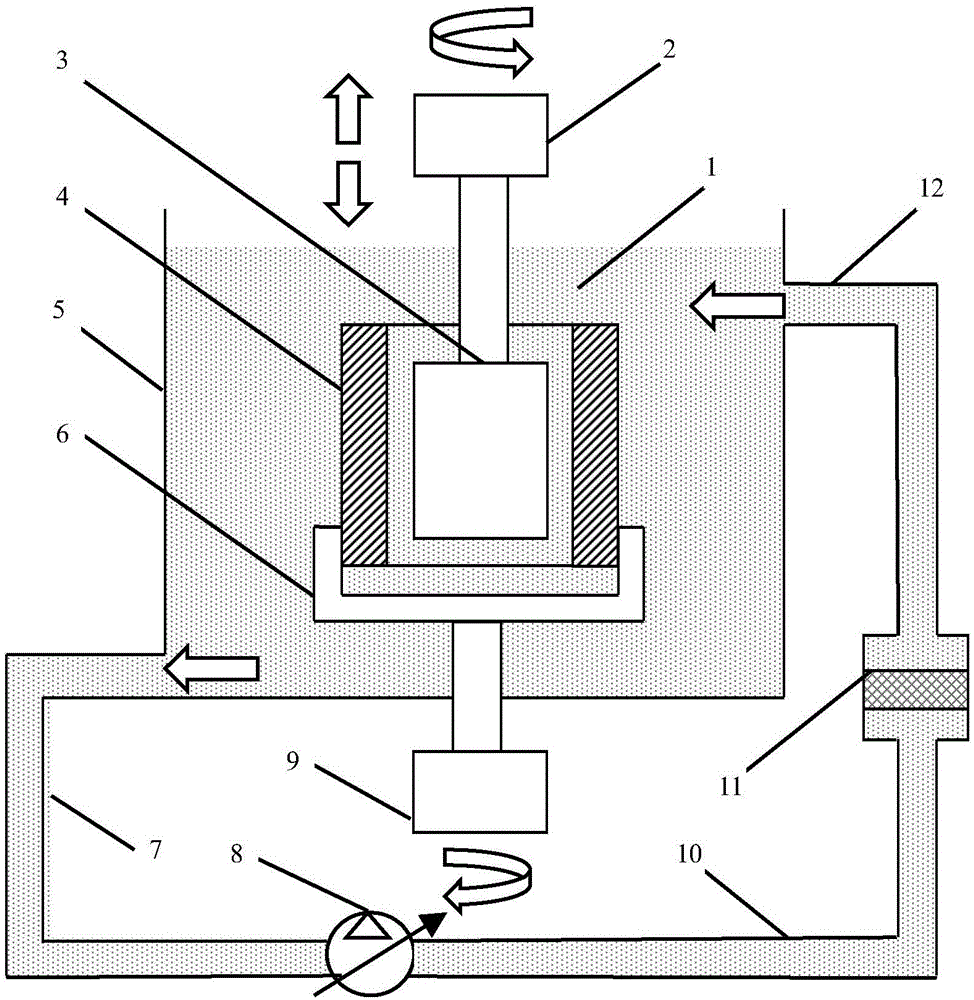

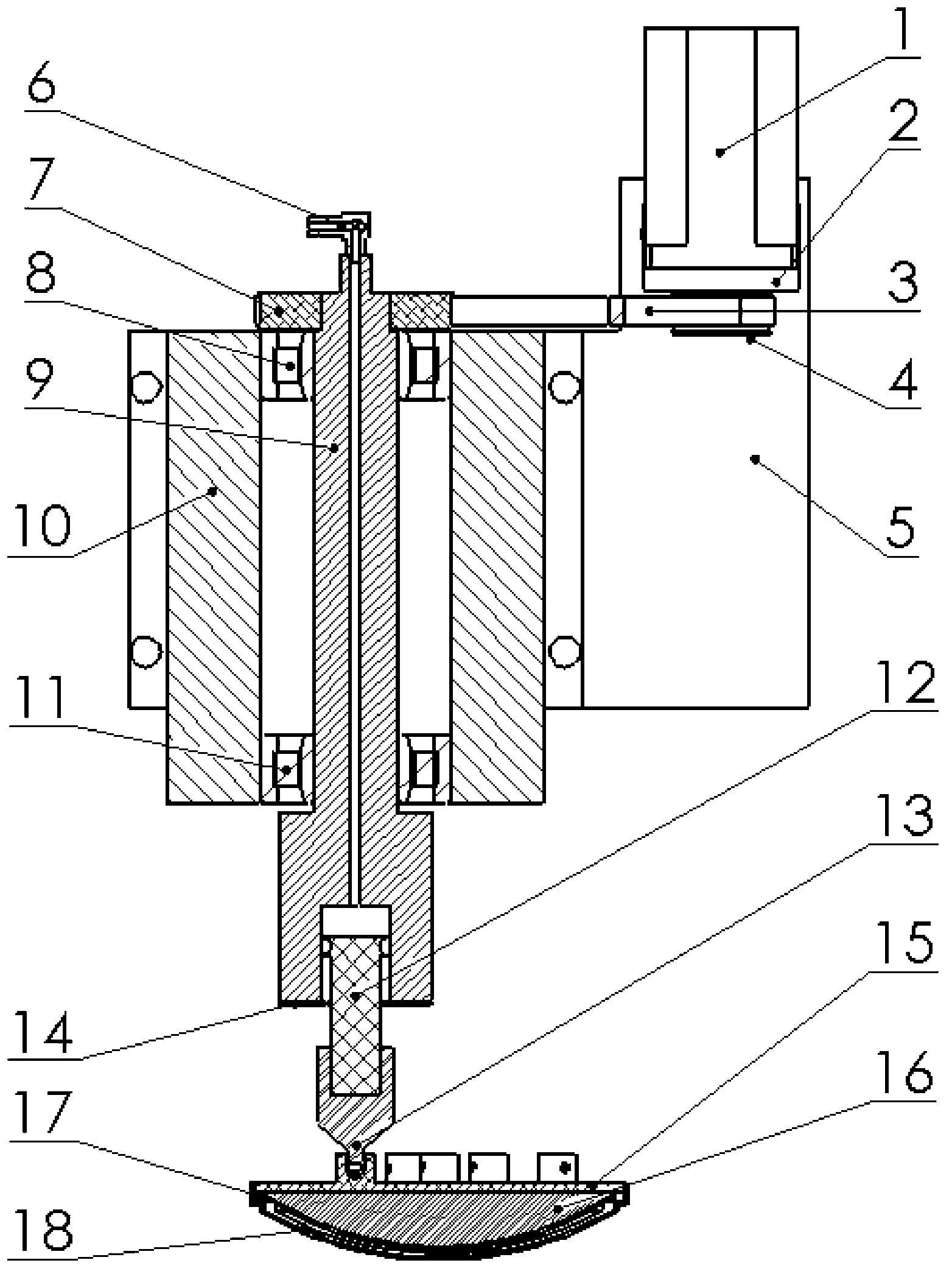

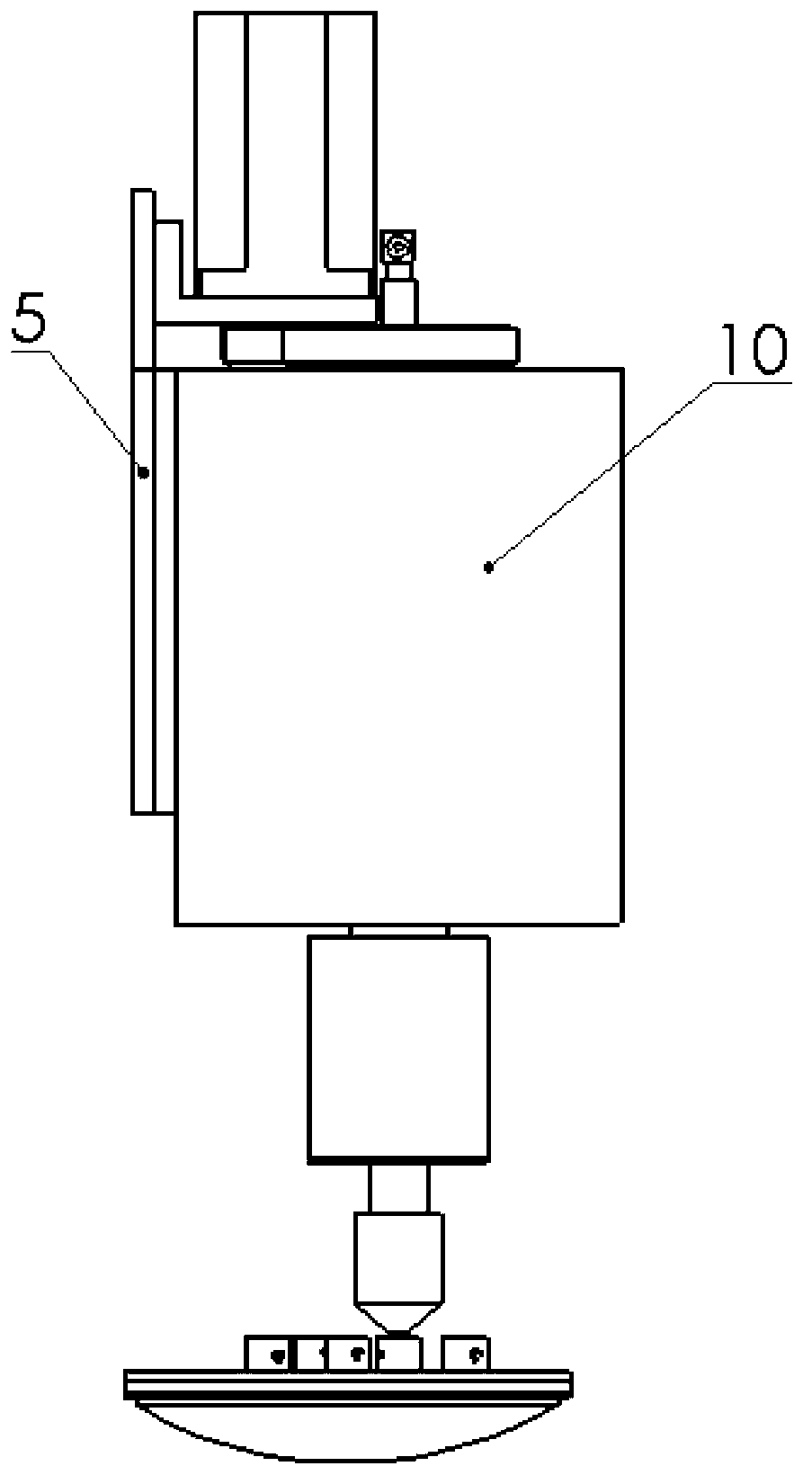

Machining device based on non-Newtonian fluid shear thickening mechanism polishing method

ActiveCN103331685ARealize multi-pose transformationRemovablePolishing machinesEngineeringPortal frame

A machining device based on a non-Newtonian fluid shear thickening mechanism polishing method comprises a workbench, a polishing tool system, an abrasive fluid circulation device and a computer control module, wherein the polishing tool system is installed on a portal frame of the workbench, an inlet of the abrasive fluid circulation device is communicated with an abrasive backflow opening in the workbench, and the workbench, the polishing tool system and the abrasive fluid circulation device are respectively connected with the computer control module. The machining device has the advantages that the application range is wide, the size of machined workpieces is not limited, the structure of the device is simple, the device is controlled easily, a computer controls the operation track of the device, the polishing process of non-Newtonian fluid abrasive fluid and the surfaces of the workpieces can be controlled effectively, a non-Newtonian fluid abrasive fluid circulation system is adopted, and the functions of removing abrasive dust, purifying, recycling, transporting and storing the abrasive fluid, and adjusting performance are achieved.

Owner:ZHEJIANG UNIV OF TECH

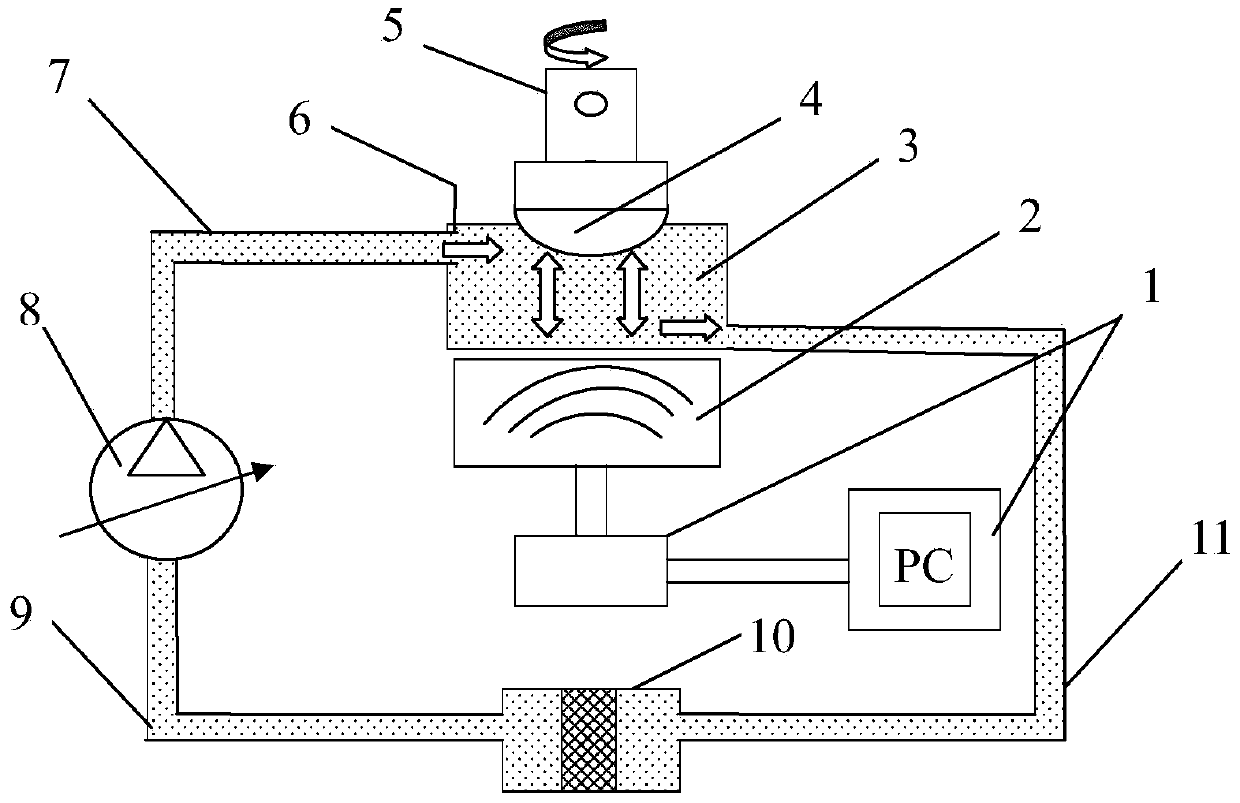

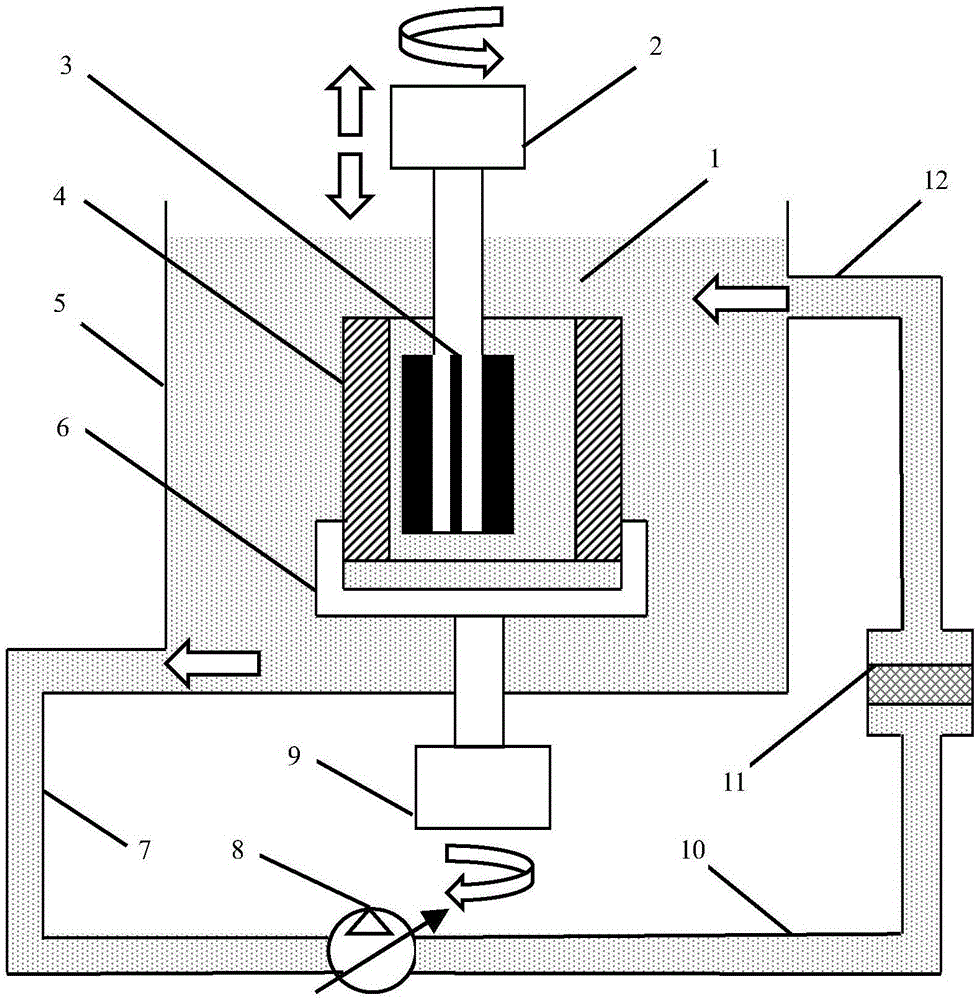

Ultrasonic control shear thickening and polishing method and device

An ultrasonic control shear thickening and polishing method comprises the following steps of 1 adding a non-Newtonian fluid polishing solution mixed with abrasive particles and having the shear thickening effect into a polishing pond and fixing a workpiece on a clamp, wherein the clamp is located above the polishing pond; 2 starting a polishing solution circulating system to enable the non-Newtonian fluid polishing solution to be circularly pumped out of the bottom of the polishing solution and fed into the upper portion of the polishing pond; 3 starting an ultrasonic wave generating device, and meanwhile setting the vibration frequency and vibration amplitude to enable the non-Newtonian fluid polishing solution in the polishing pond to rapidly vibrate and produce a strong shear thickening phenomenon; 4 adjusting the clamp to enable the workpiece to perform relative motion, wherein the abrasive particles having the polishing effect produce the micro-cutting effect or chemical mechanical effect on the workpiece to remove materials on the workpiece surface, and accordingly the workpiece surface polishing is achieved. The invention further provides an ultrasonic control shear thickening and polishing device. The ultrasonic control shear thickening and polishing method and device is high in polishing efficiency and low in cost.

Owner:ZHEJIANG UNIV OF TECH

Device and method for direct delivery of a therapeutic using non-newtonian fluids

A device, system, and method for direct delivery of a therapeutic to a target site that utilizes the non-Newtonian characteristics of shear thinning and shear thickening to allow easy passage of a therapeutic through a delivery lumen yet facilitate retention of the therapeutic in the target site. The device, system, and method includes increasing the shear rate or shear stress of a non-Newtonian fluid having therapeutic properties thereby increasing or decreasing the viscosity of the non-Newtonian fluid.

Owner:BOSTON SCI SCIMED INC

Composite calcium-sulfonate-based tetrapolyurea lubricating grease and preparation method thereof

ActiveCN102453599AGood extreme pressure and anti-wear propertiesLong lubrication lifeThickenersCorrosionSulfonic acid

The invention discloses a composite calcium-sulfonate-based tetrapolyurea lubricating grease and a preparation method thereof. With the weight of the lubricating grease as a reference, the lubricating grease comprises components of: (1) 10-70% of non-Newtonian fluid calcium sulfonate; (2) 1-10% of higher fatty acid calcium; (3) 1-15% of small-molecule inorganic acid calcium or organic acid calcium; (4) 0.5-30% of tetrapolyurea; and (5) 10-80% of lubricating base oil. According to the lubricating grease, calcium petroleum sulfonate or synthesized calcium sulfonate is adopted as a raw material, and the lubricating oil contains a composite calcium thickening agent and a tetrapolyurea compound. The lubricating grease has excellent extreme pressure wear resistance, ultra-long lubricating life, good adhesion, water resistance, colloid stability, high dropping point, thermal stability, corrosion resistance, and salt spray resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

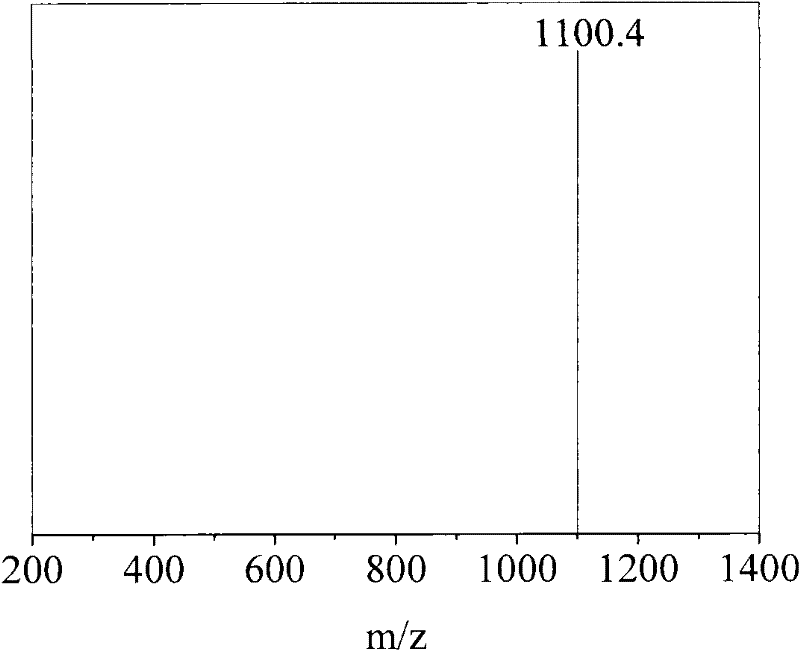

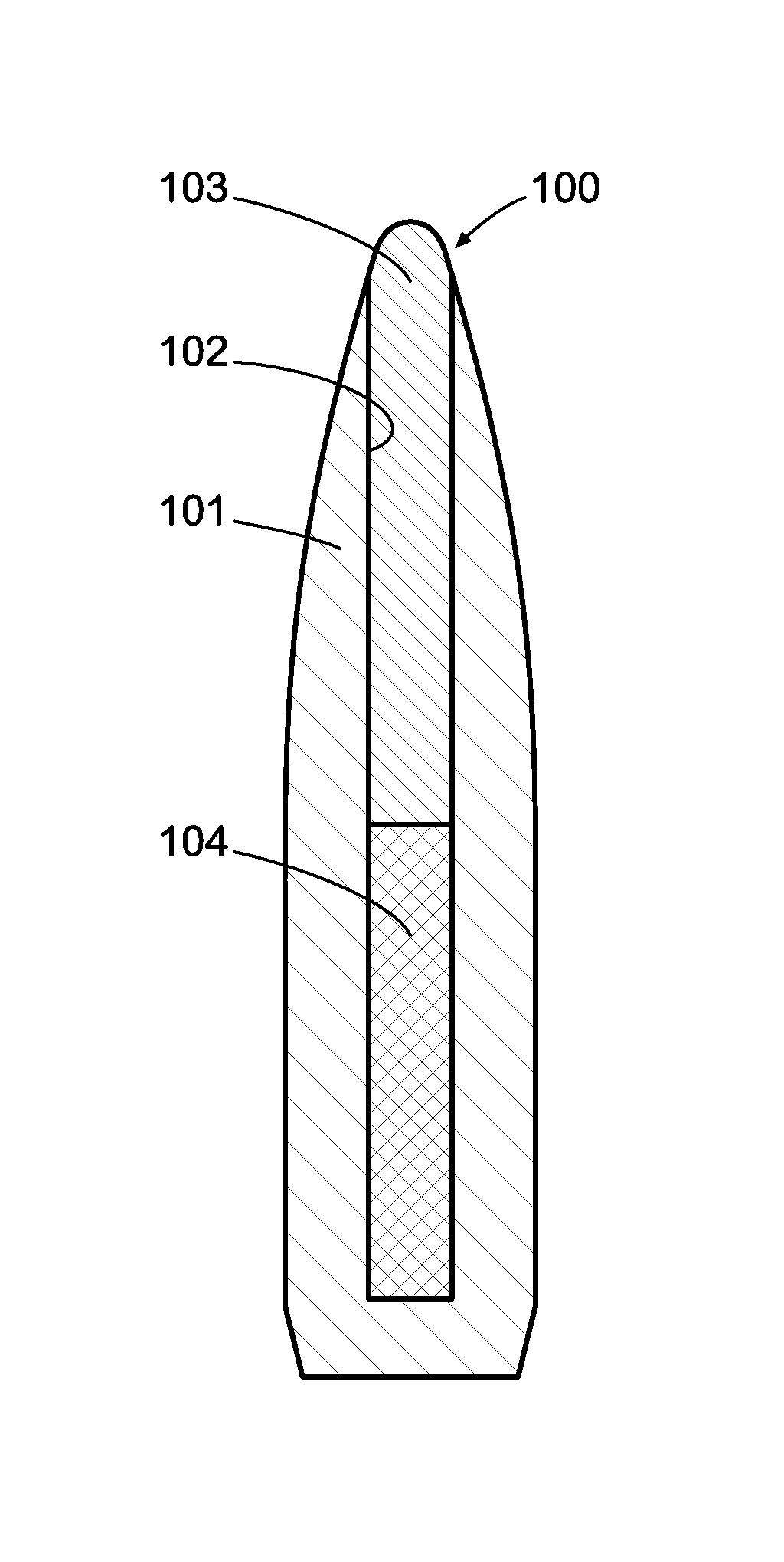

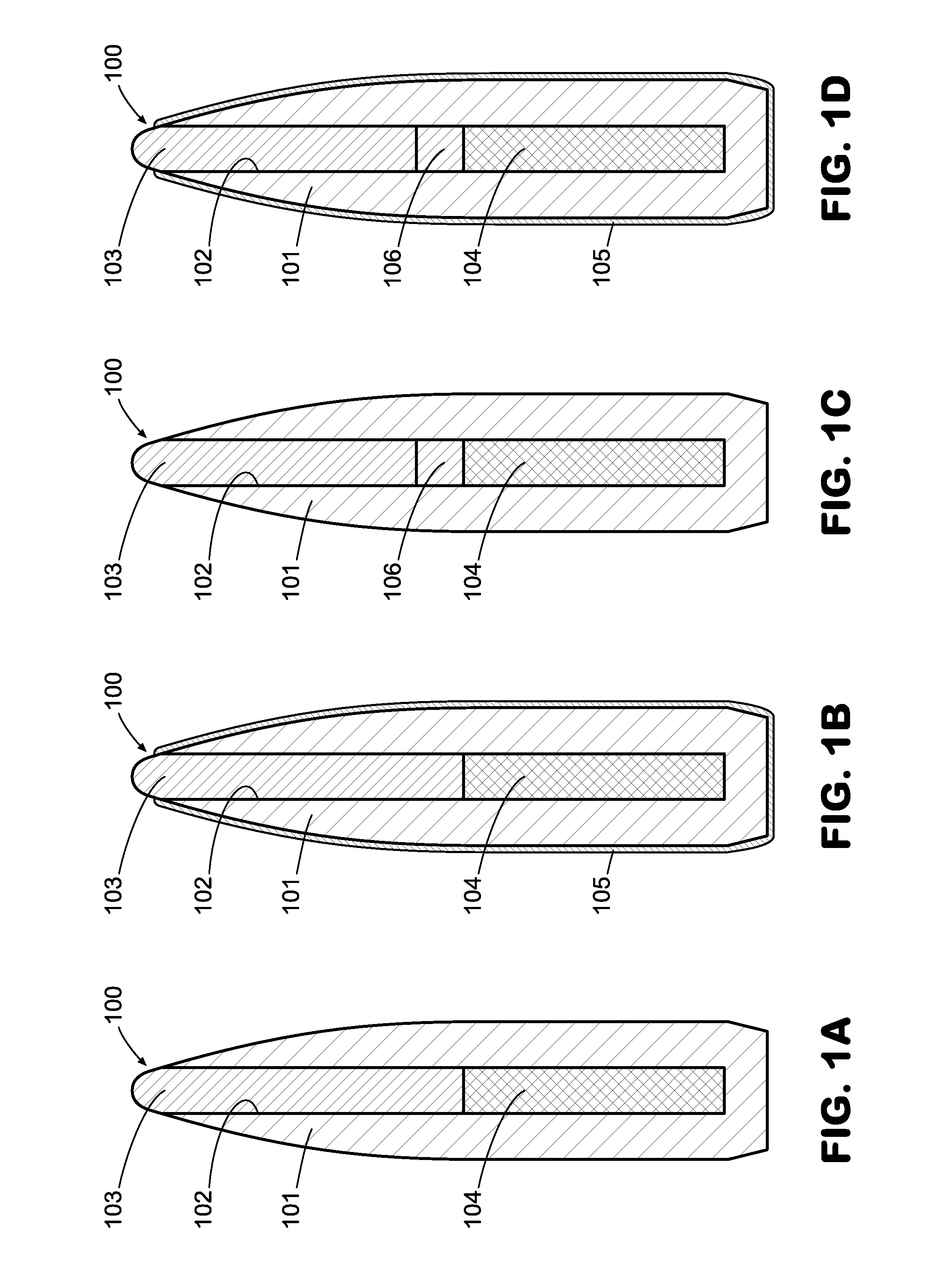

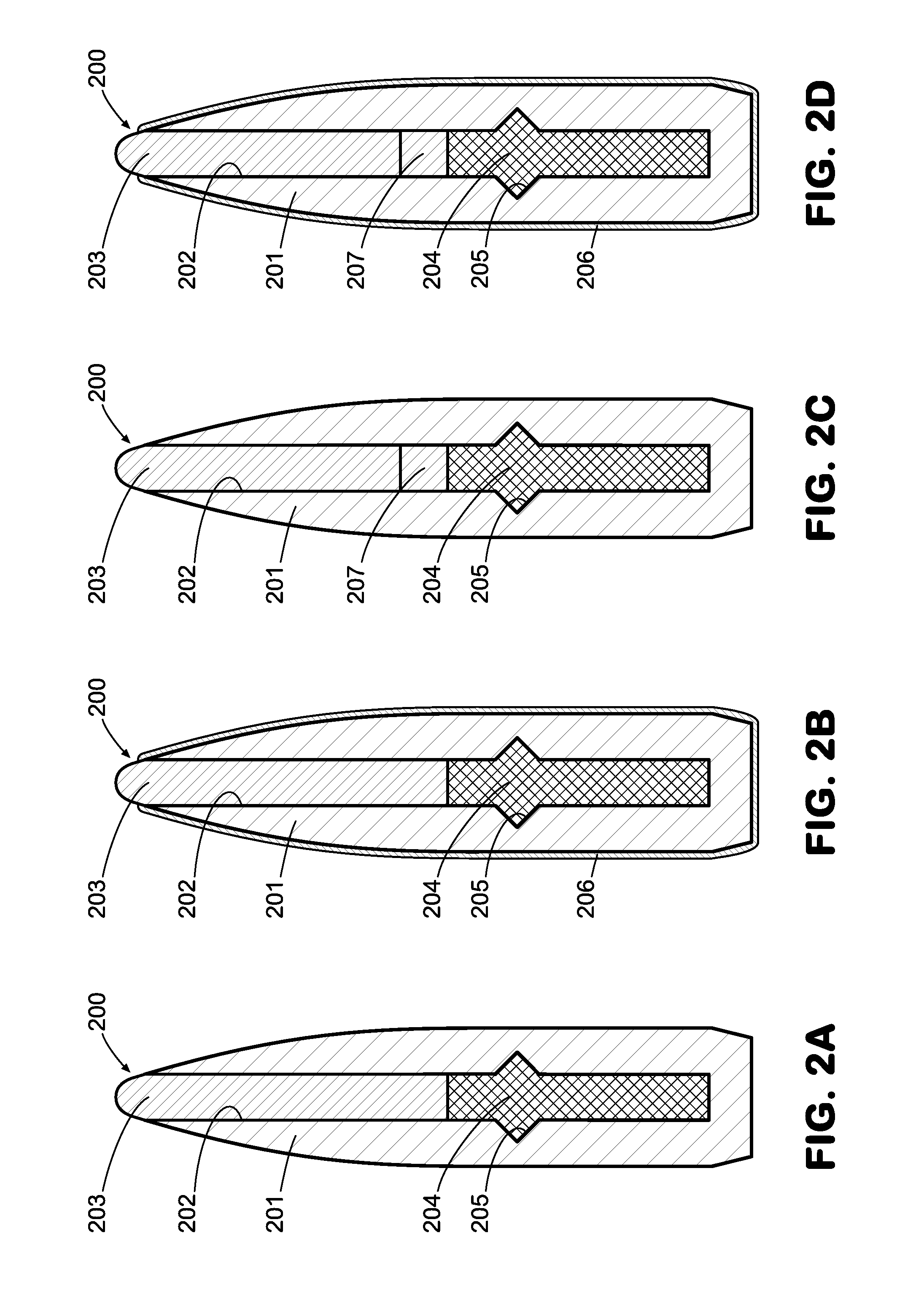

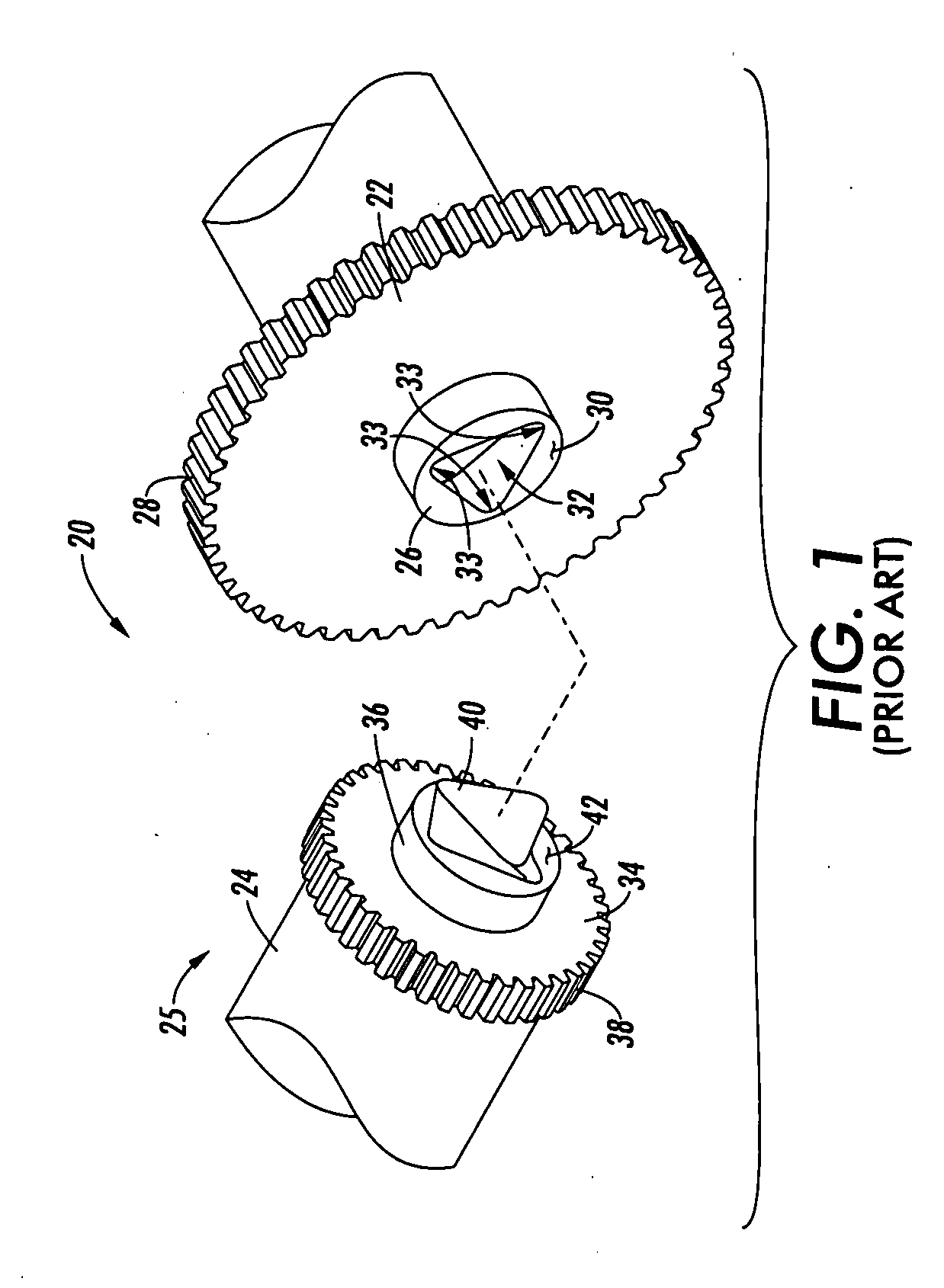

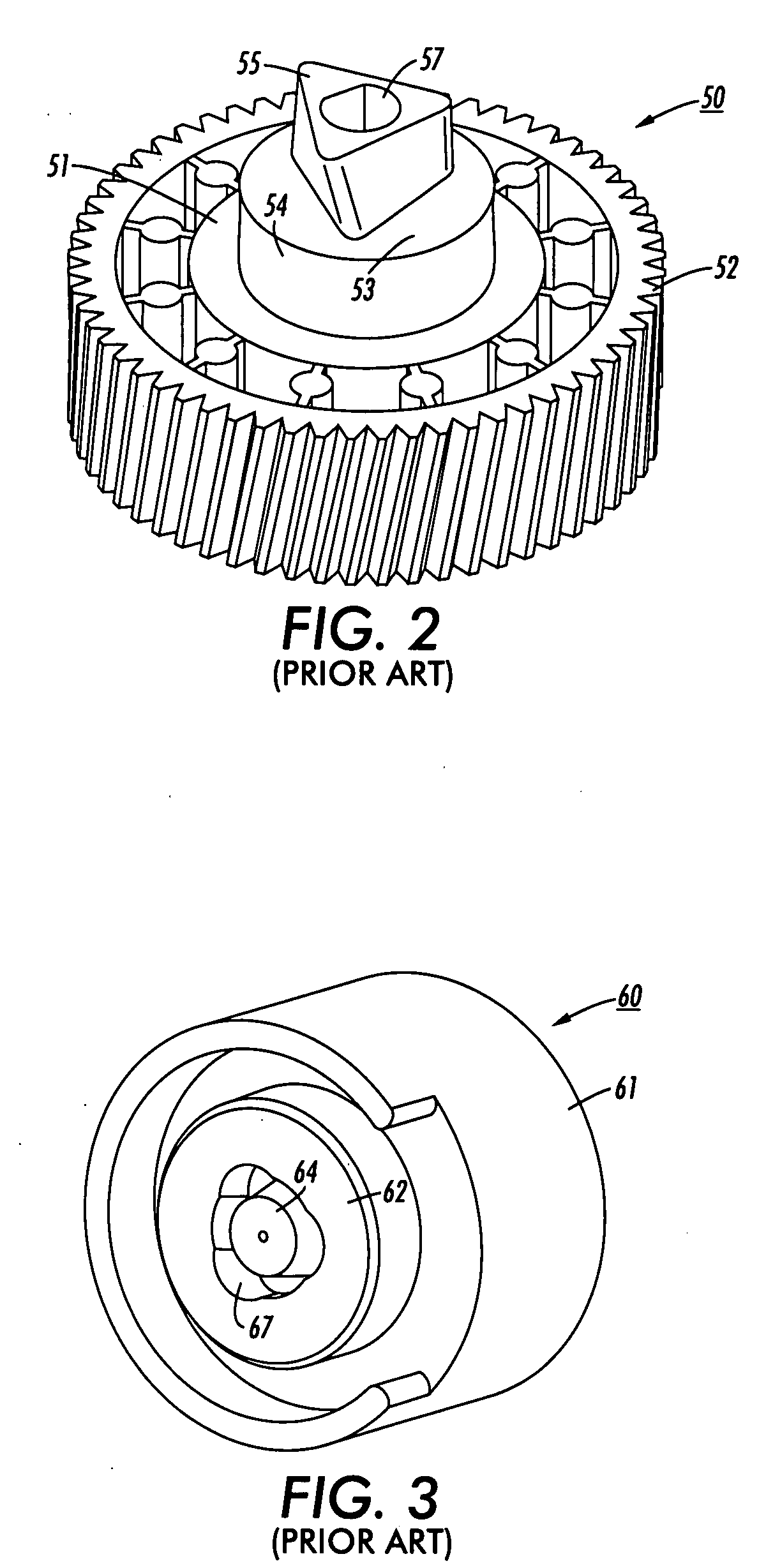

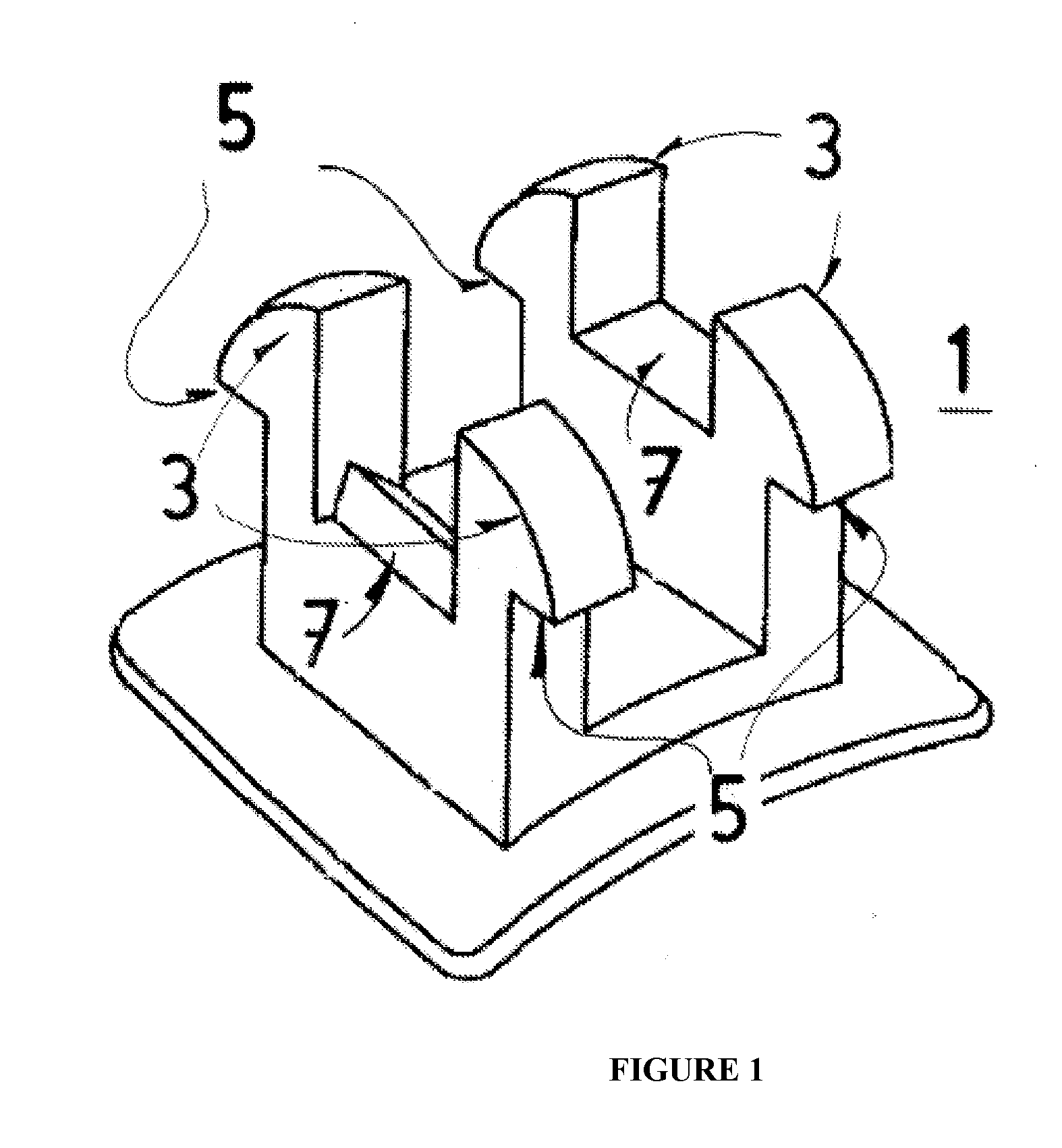

Non-newtonian projectile

ActiveUS7966937B1Pressure be exertAmmunition projectilesTraining ammunitionEngineeringNon-Newtonian fluid

A projectile is provided comprising a body with a channel that contains a non-Newtonian fluid. In various embodiments a plunger is located in the channel, wherein the plunger transmits a force to the non-Newtonian fluid upon interacting with a target, causing the non-Newtonian fluid to exert a pressure in the channel, and wherein the viscosity of the non-Newtonian fluid changes upon interacting with the target. By way of non-limiting example, the non-Newtonian fluid of embodiments of the present invention can comprise a shear-thickening fluid that increases its viscosity with at least the rate of shear upon interacting with the target.

Owner:JACKSON JASON STEWART

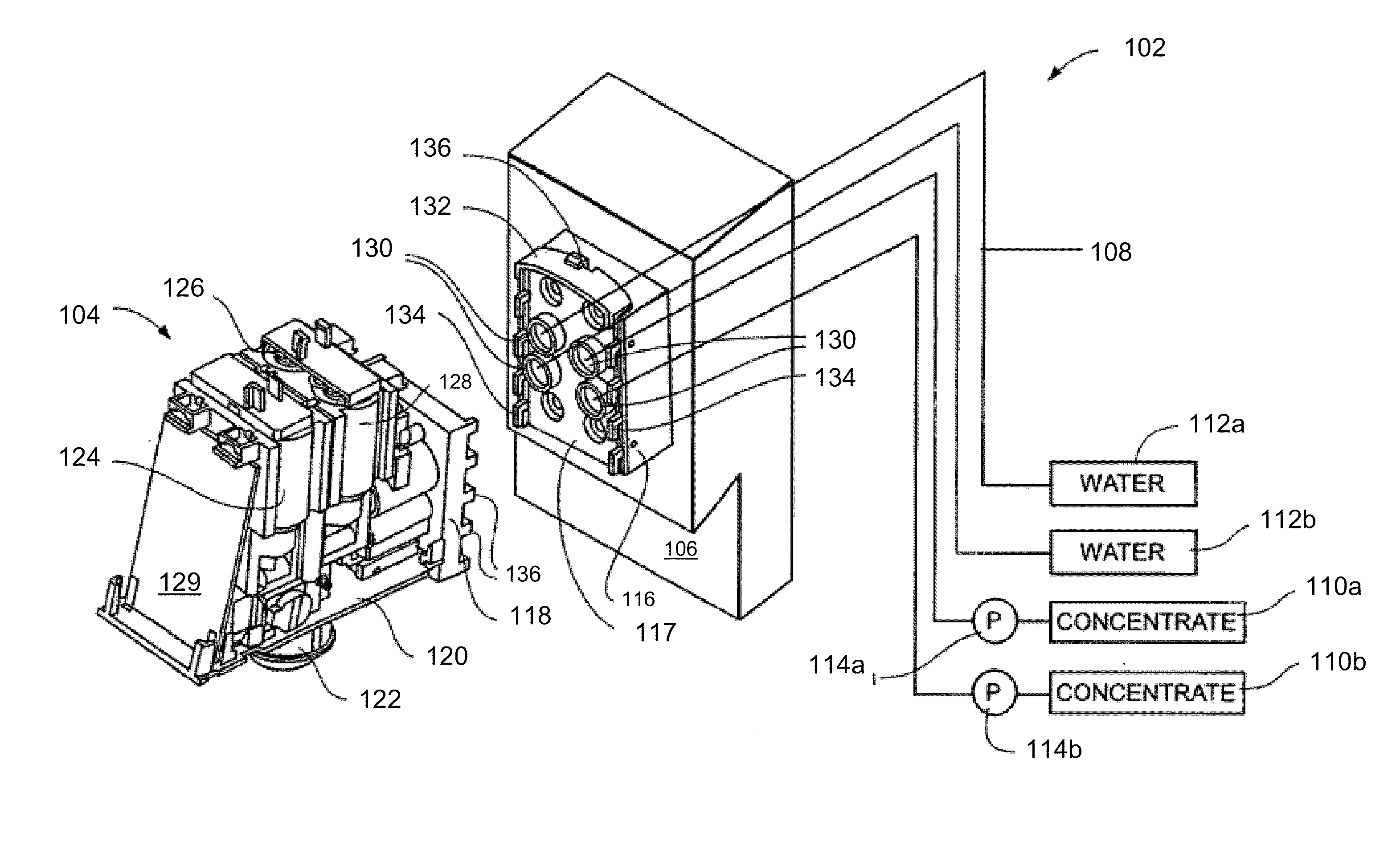

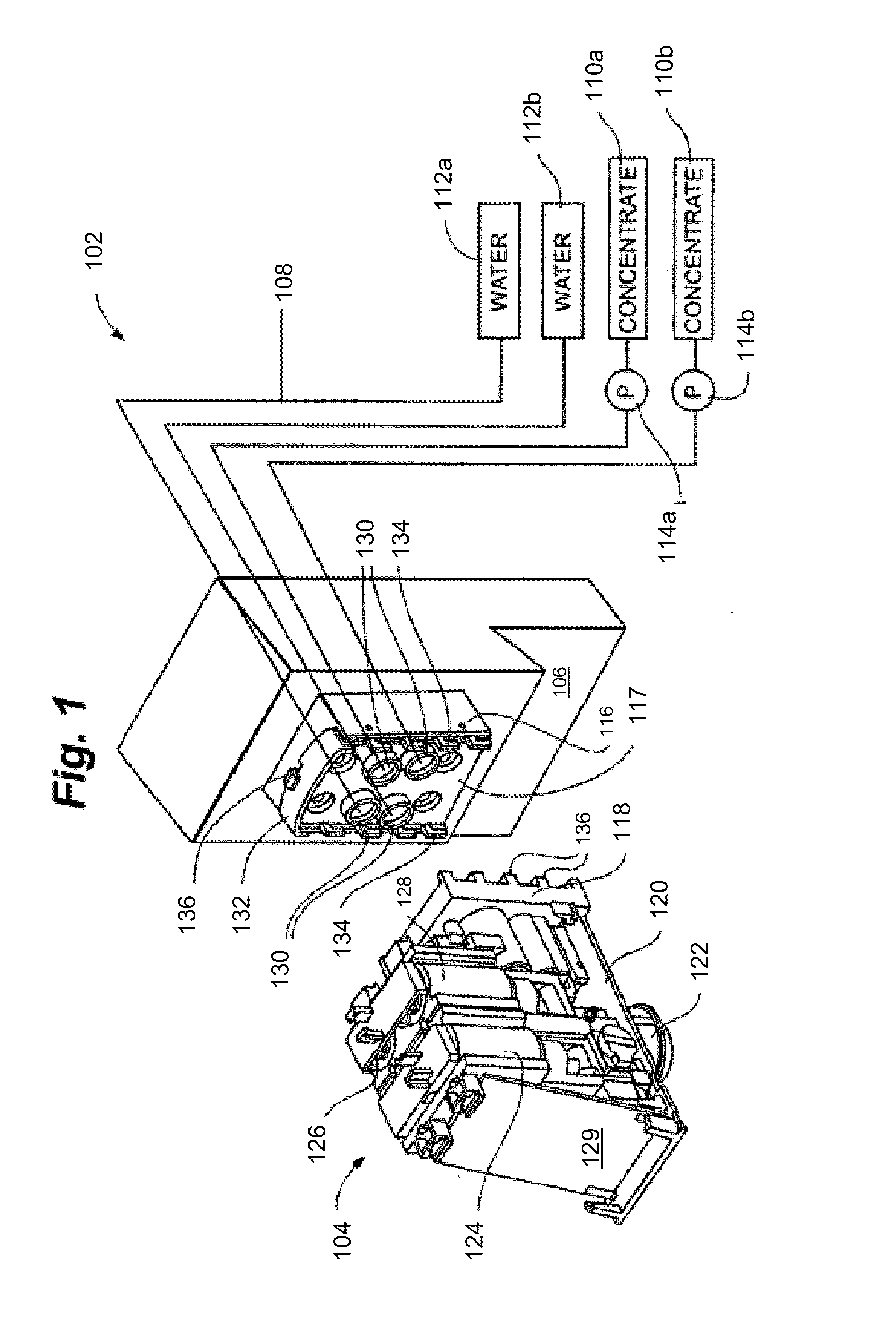

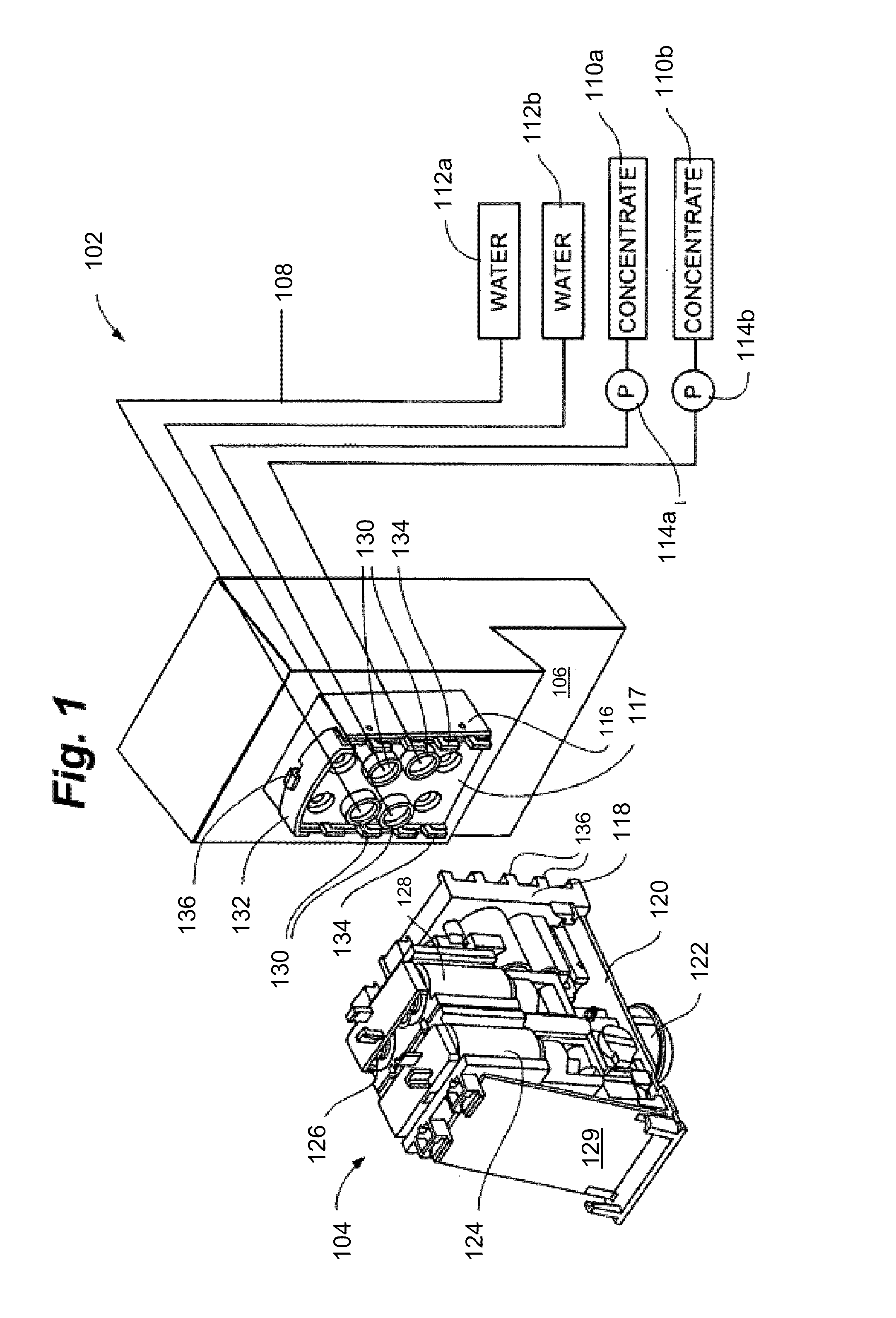

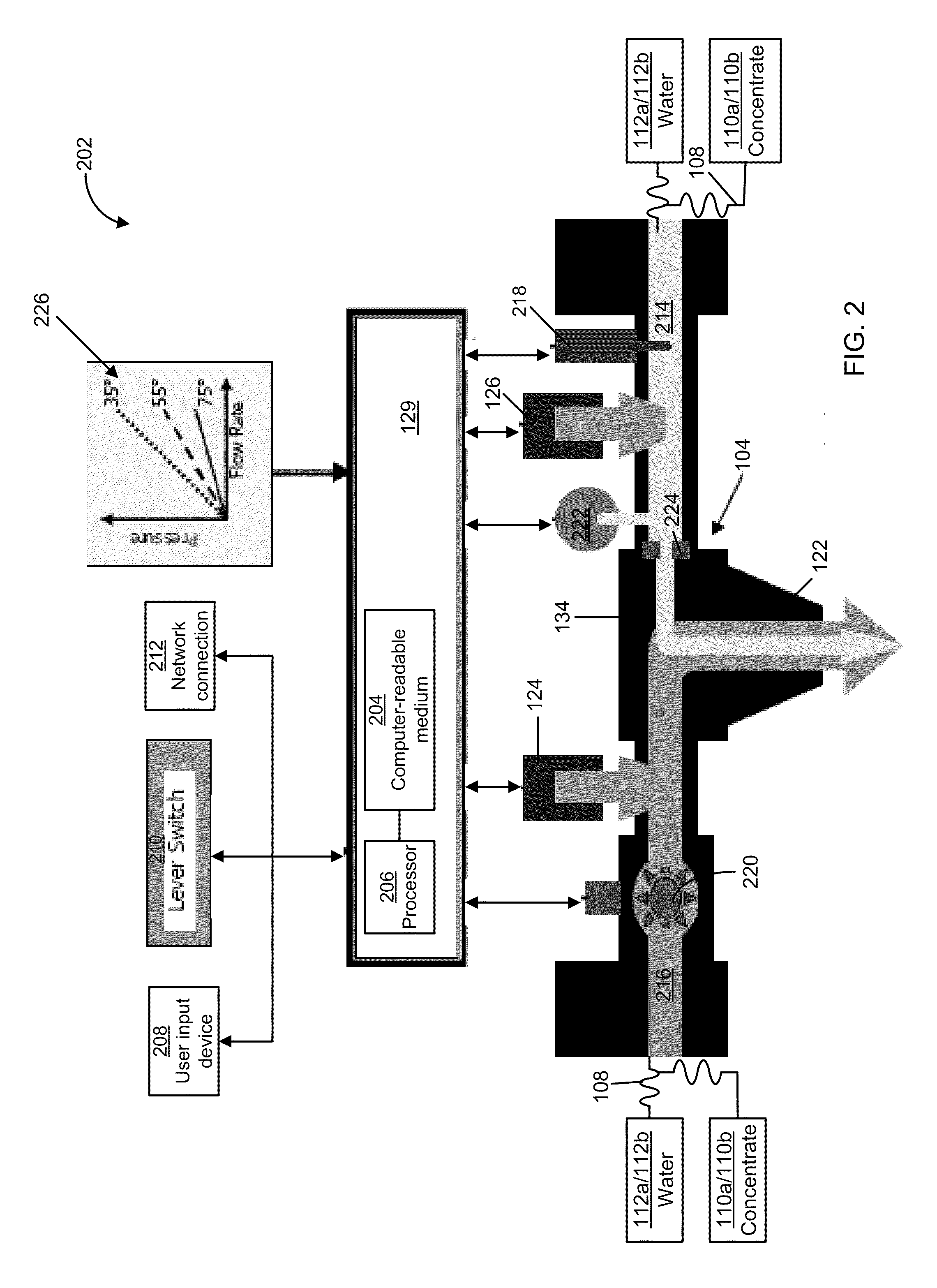

Beverage dispensing device

ActiveUS20110125334A1Beverage vesselsLiquid transferring devicesAdditive ingredientBiomedical engineering

Owner:PEPSICO INC

Body limb movement limiter

InactiveUS7789844B1Move fastConvenient design and constructionRestraining devicesNon-surgical orthopedic devicesThighHand arm

A body limb movement limiter restrains the movement of a person's arm so as to protect the person's shoulder or restrains the movement of a person's lower leg with respect to the upper leg so as to protect the person's knee. The device uses a housing having a reel disposed therein with a tether attached thereto and a shear thickening non-Newtonian fluid disposed within the housing so that the fluid acts on the reel during a payout procedure of the tether. The housing is attached to a strap secured about the torso of the person while the free end of the tether is secured about the person's arm. Alternately, a pair of arms are pivotally secured to each other within a housing having the non-Newtonian fluid therein for limiting movement of one arm with respect to the other.

Owner:ALLEN SUSAN DAVIS

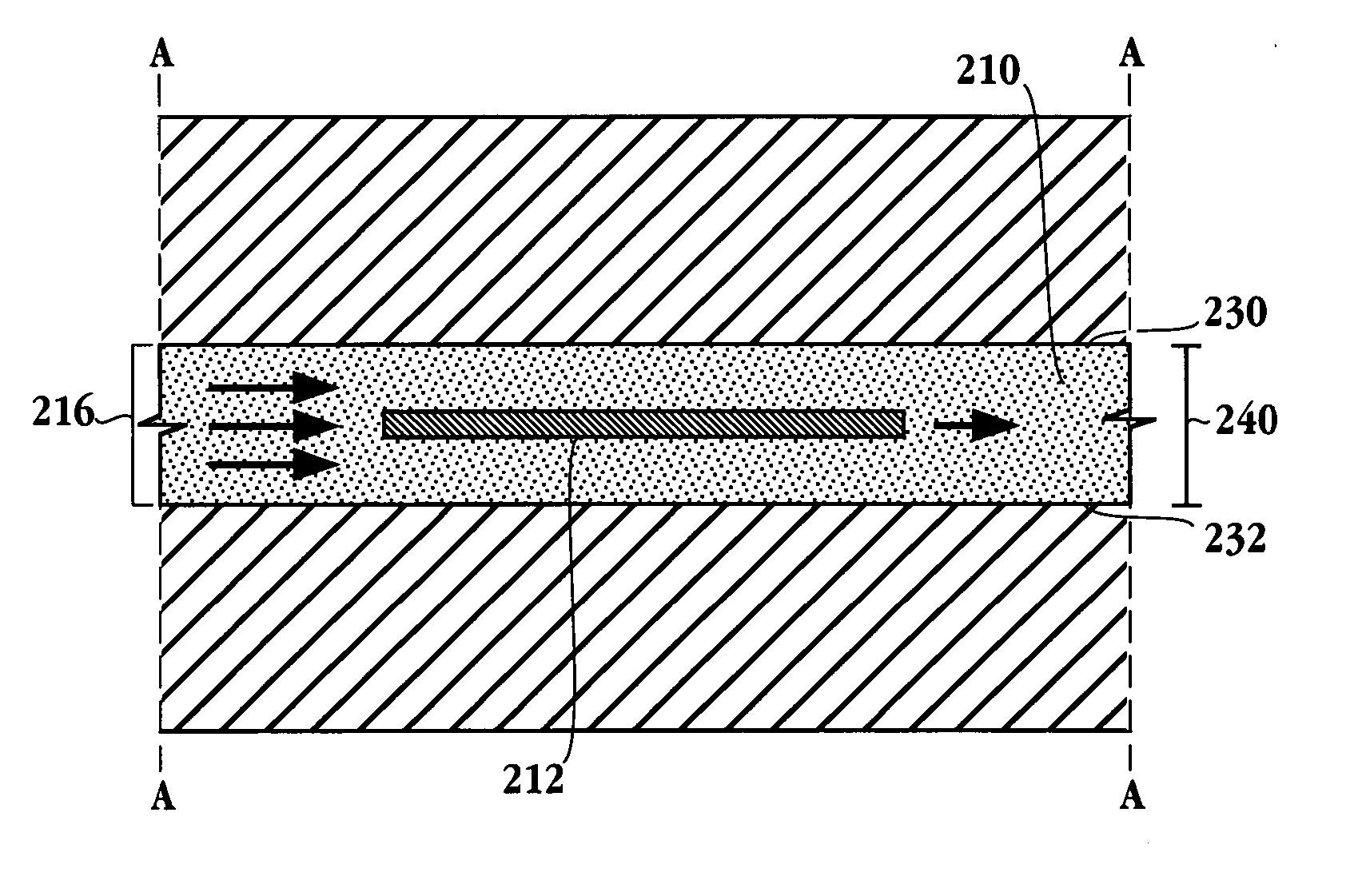

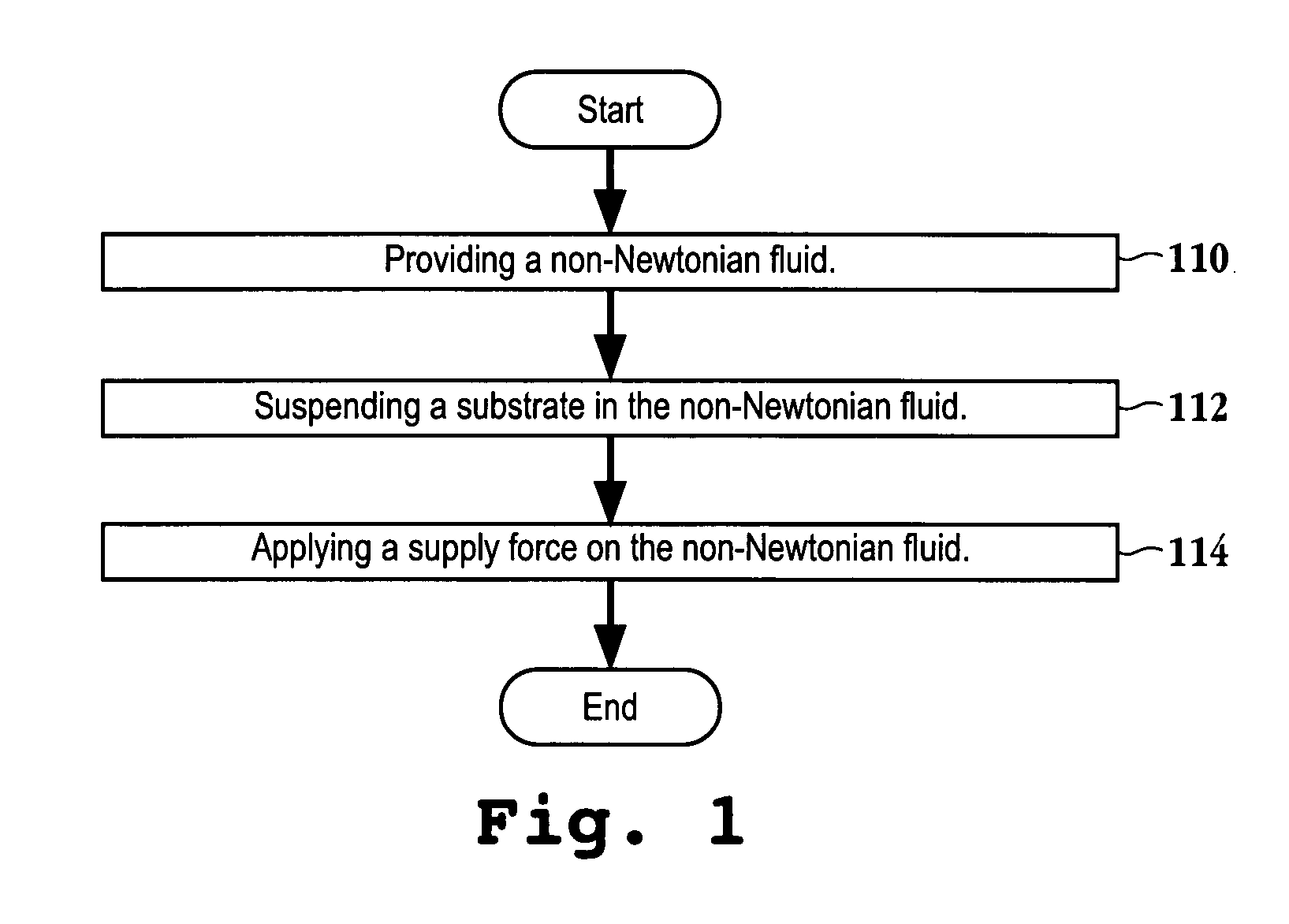

Method and apparatus for transporting a substrate using non-Newtonian fluid

InactiveUS20060285930A1Semiconductor/solid-state device manufacturingNon-mechanical conveyorsEngineeringMechanical engineering

A method for transporting a substrate is provided. In this method, a non-Newtonian fluid is provided and the substrate is suspended in the non-Newtonian fluid. The non-Newtonian fluid is capable of supporting the substrate. Thereafter, a supply force is applied on the non-Newtonian fluid to cause the non-Newtonian fluid to flow, whereby the flow is capable of moving the substrate along a direction of the flow. Apparatuses and systems for transporting the substrate using the non-Newtonian fluid also are described.

Owner:LAM RES CORP

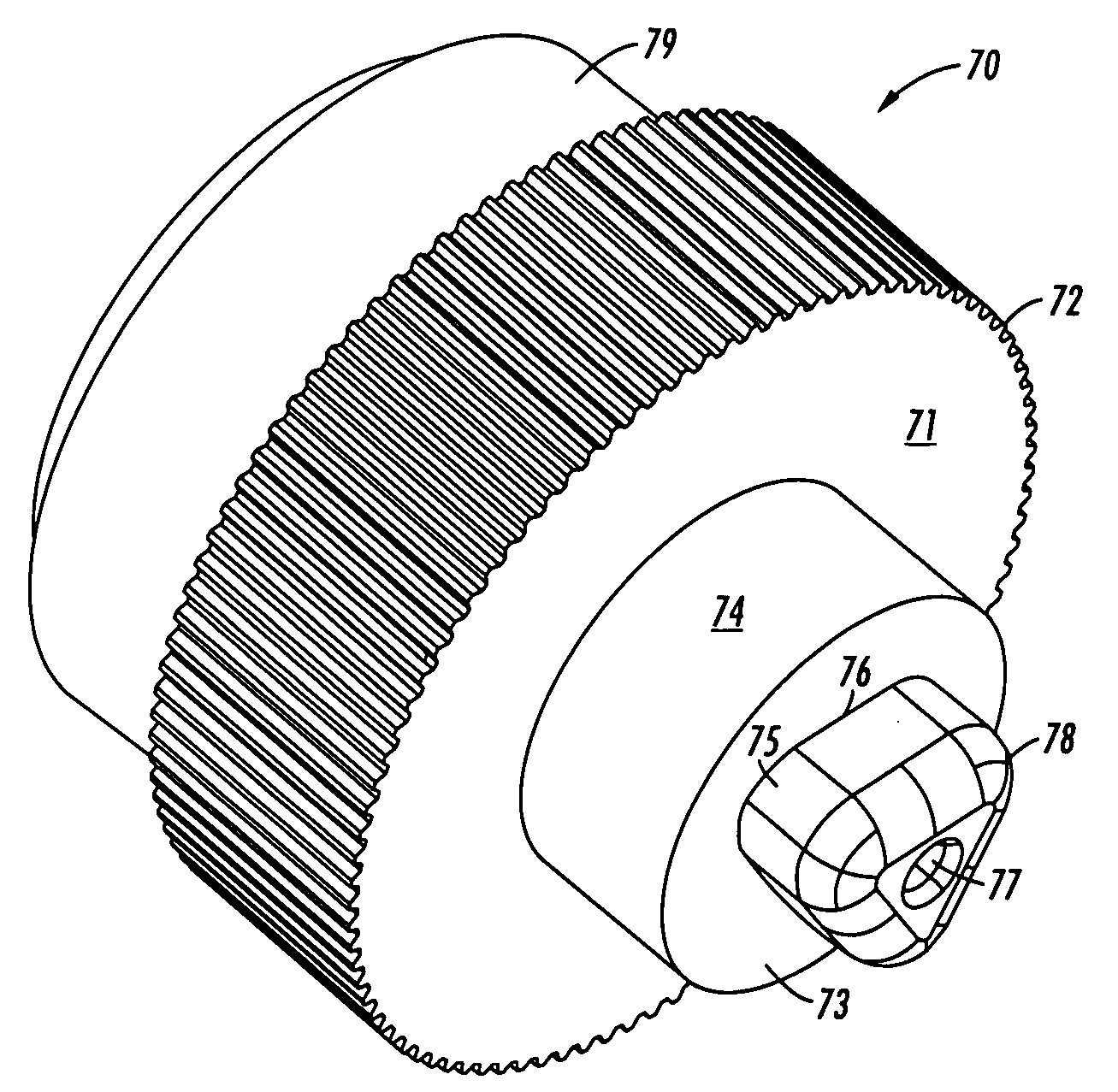

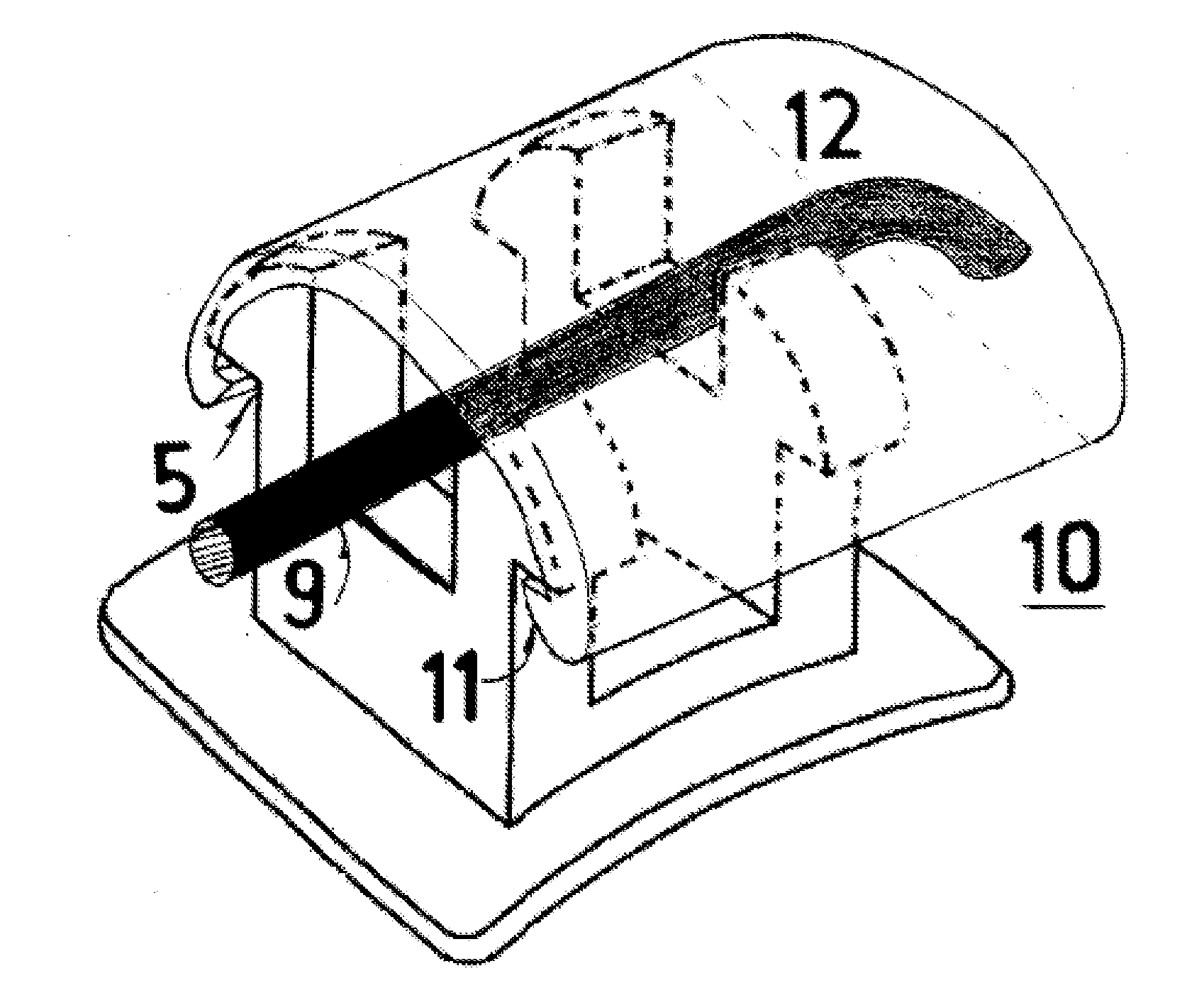

Coupling mechanism for material supply module

A coupling mechanism includes a driven coupling for mating with a driving coupling. The driven coupling includes a cylinder flange, a concentric shaft that extends axially outwardly from the flange, and a cylindrical driven coupling member that extends axially outwardly from the concentric shaft. The driven coupling member comprises a flexible membrane that encases non-rigid fill material, such as, e.g., a flowable granular material or a non-Newtonian fluid. The driven coupling member has a non-twisted, triangular cross-section, and is configured such that, when it is operationally engaged with the driving coupling, the non-rigid material substantially solidifies, thereby providing a substantially non-flexible structure for the membrane. The driven coupling may be connected to, for example, a photoreceptor drum of a material supply module, and the driving coupling may be connected to a reprographic device.

Owner:XEROX CORP

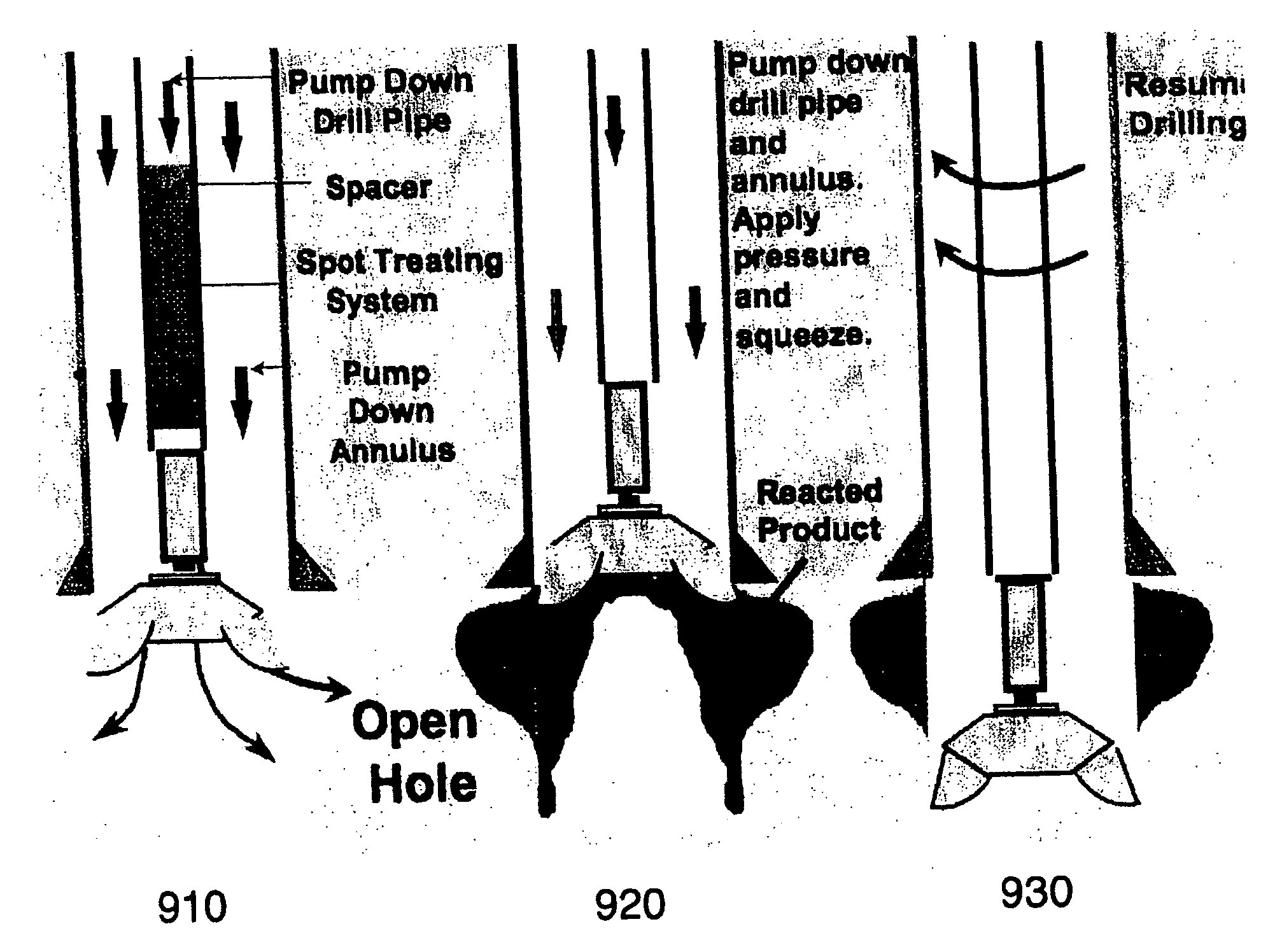

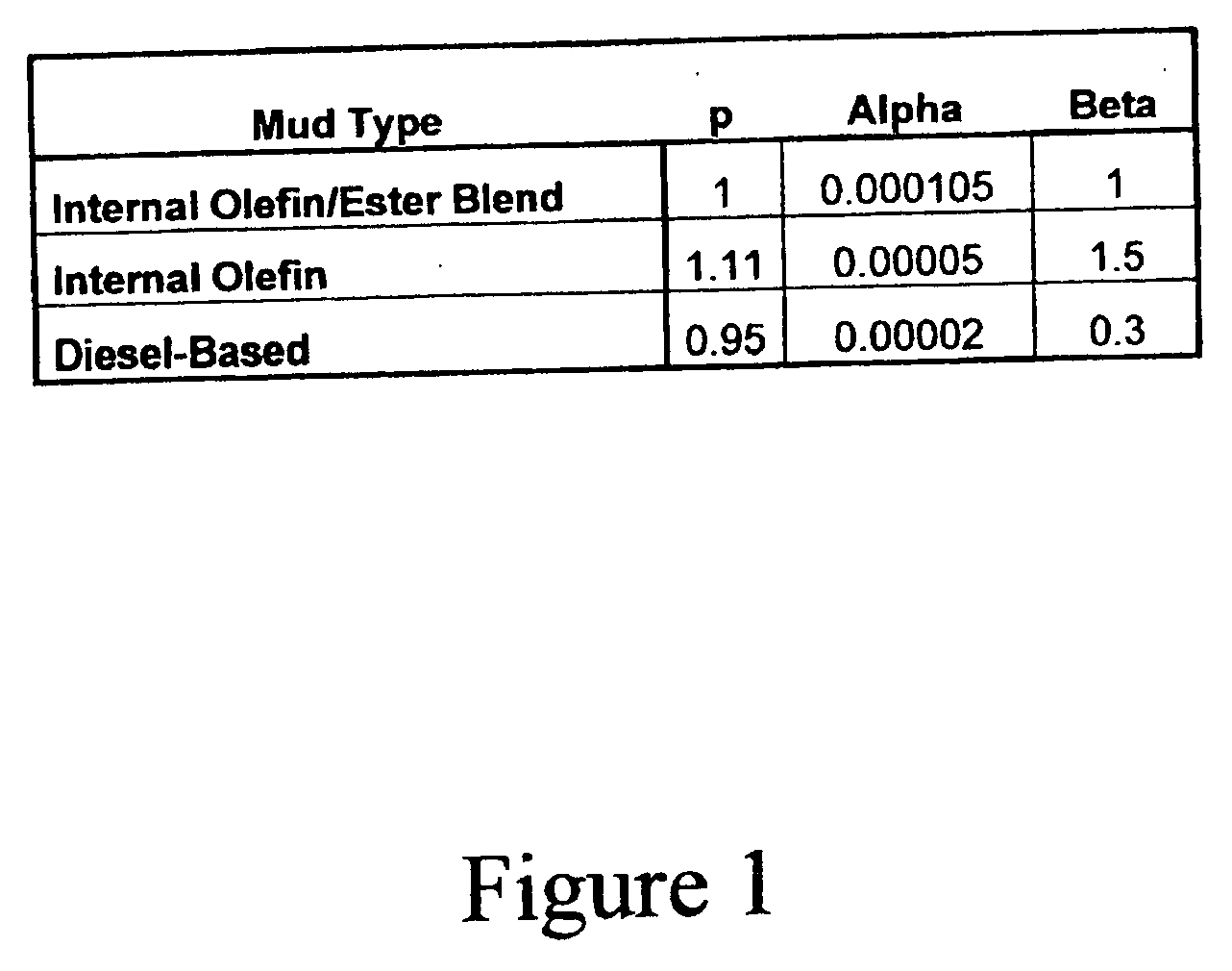

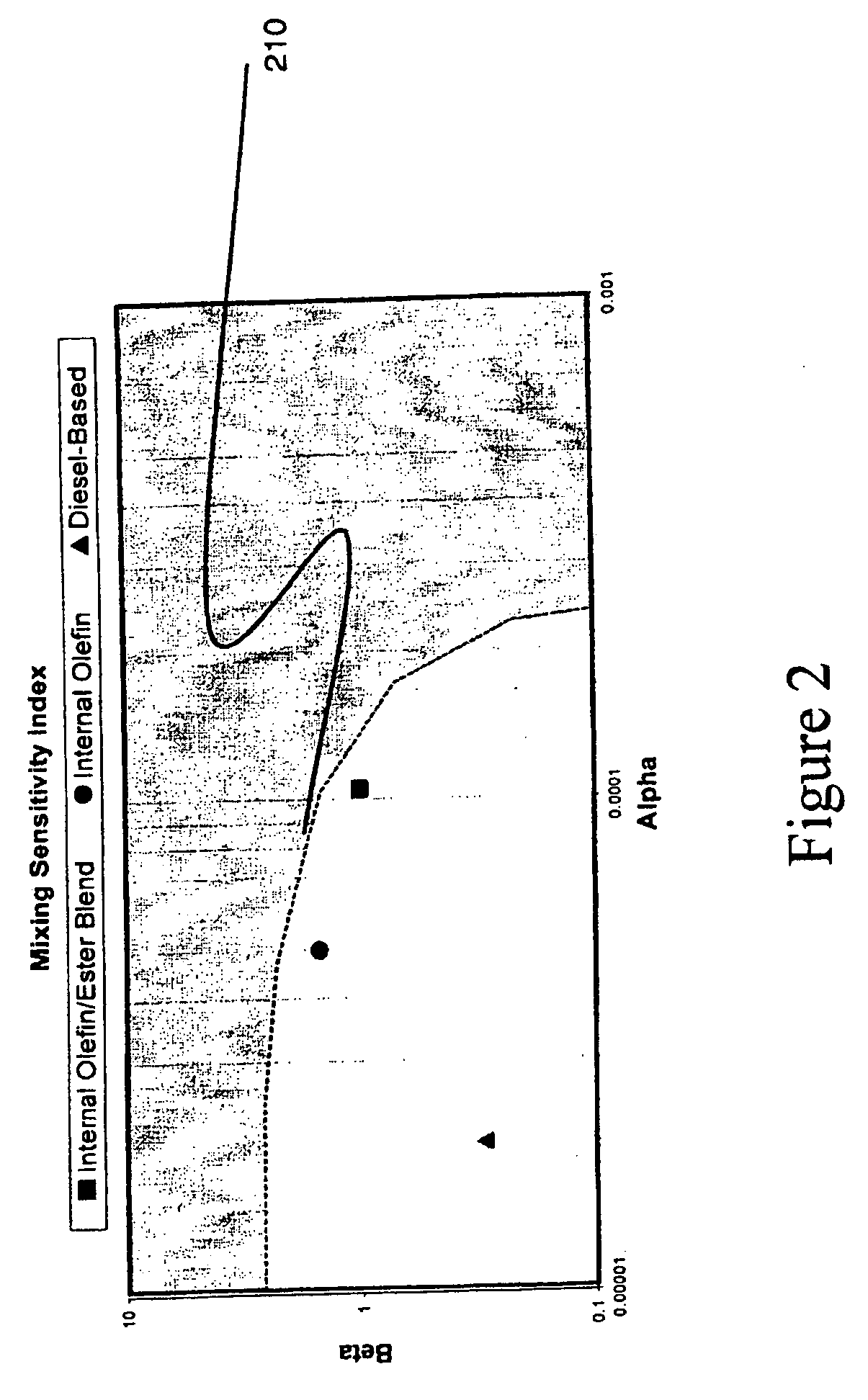

Mixing energy analysis of high-yielding non-newtonian fluids for severe lost circulation prevention

ActiveUS20070007006A1Minimize formation damageAvoid lostElectric/magnetic detection for well-loggingDrilling rodsCompound (substance)Engineering

Owner:HALLIBURTON ENERGY SERVICES INC

Non-newtonian projectile

A projectile is provided comprising a body with a channel that contains a non-Newtonian fluid. In various embodiments a plunger is located in the channel, wherein the plunger transmits a force to the non-Newtonian fluid upon interacting with a target, causing the non-Newtonian fluid to exert a pressure in the channel, and wherein the viscosity of the non-Newtonian fluid changes upon interacting with the target. By way of non-limiting example, the non-Newtonian fluid of embodiments of the present invention can comprise a shear-thickening fluid that increases its viscosity with at least the rate of shear upon interacting with the target.

Owner:JACKSON JASON STEWART

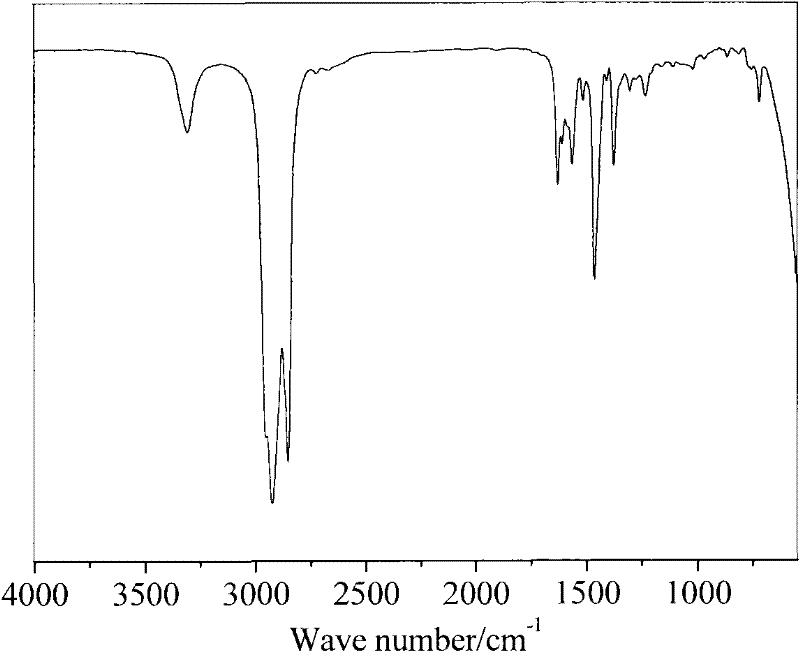

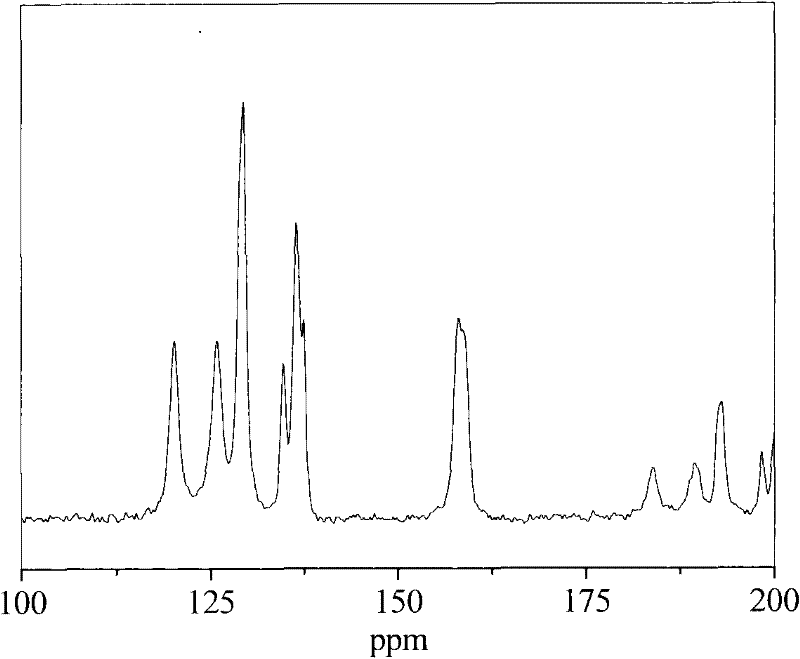

Rheological behavior mensuration instrument for system of supercutical fluid - polymer

A rheological performance analyzer of supercritical fluid-polymer system consists of polymer-supercritical fluid mixing unit and rheological performance analysis unit. It is featured as adding supercritical fluid unit based on thin tube rheological instrument for making it be able to be used to carry out analysis on rheological performance of polymer-supercritical fluid system.

Owner:ZHONGBEI UNIV

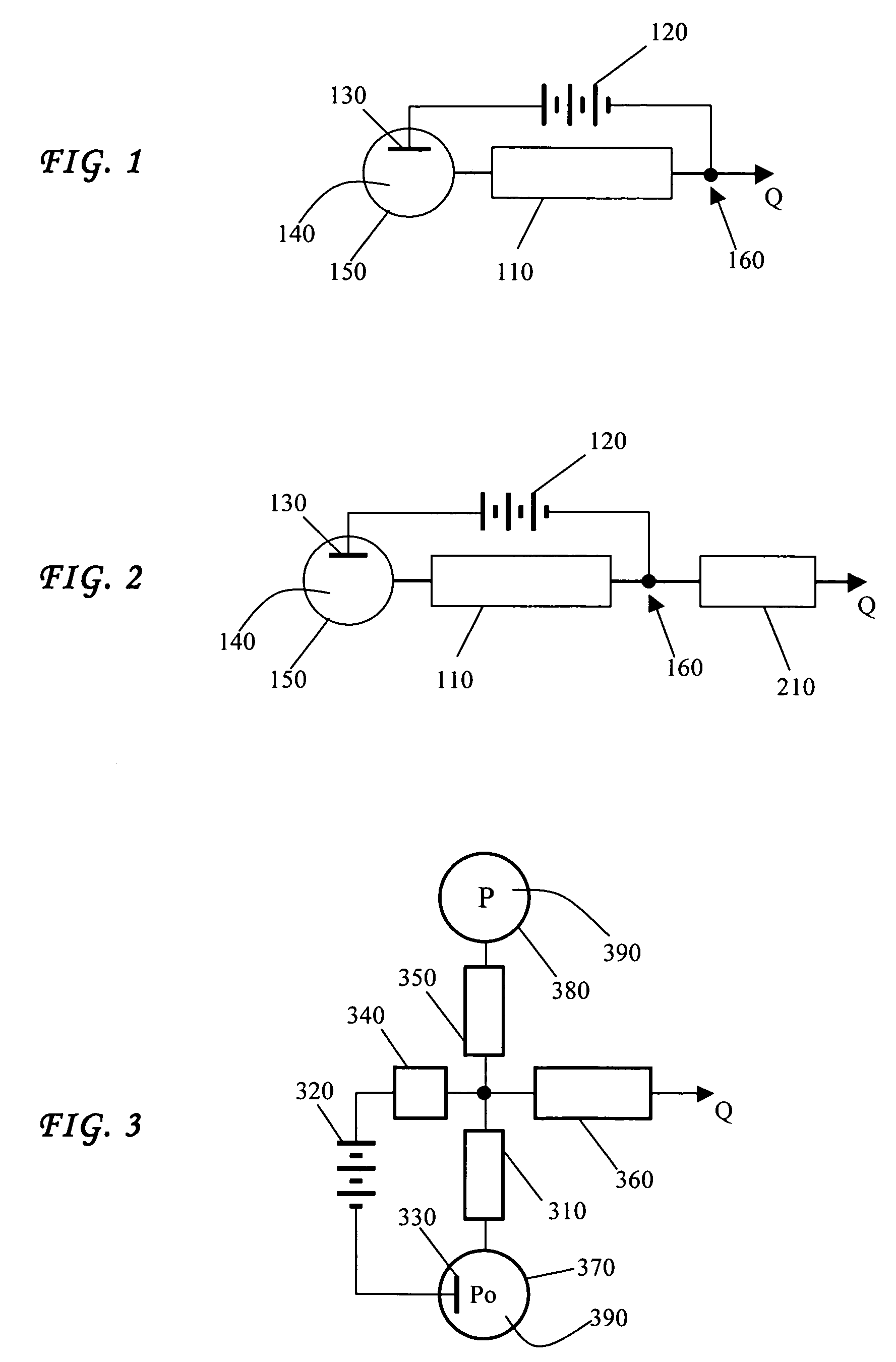

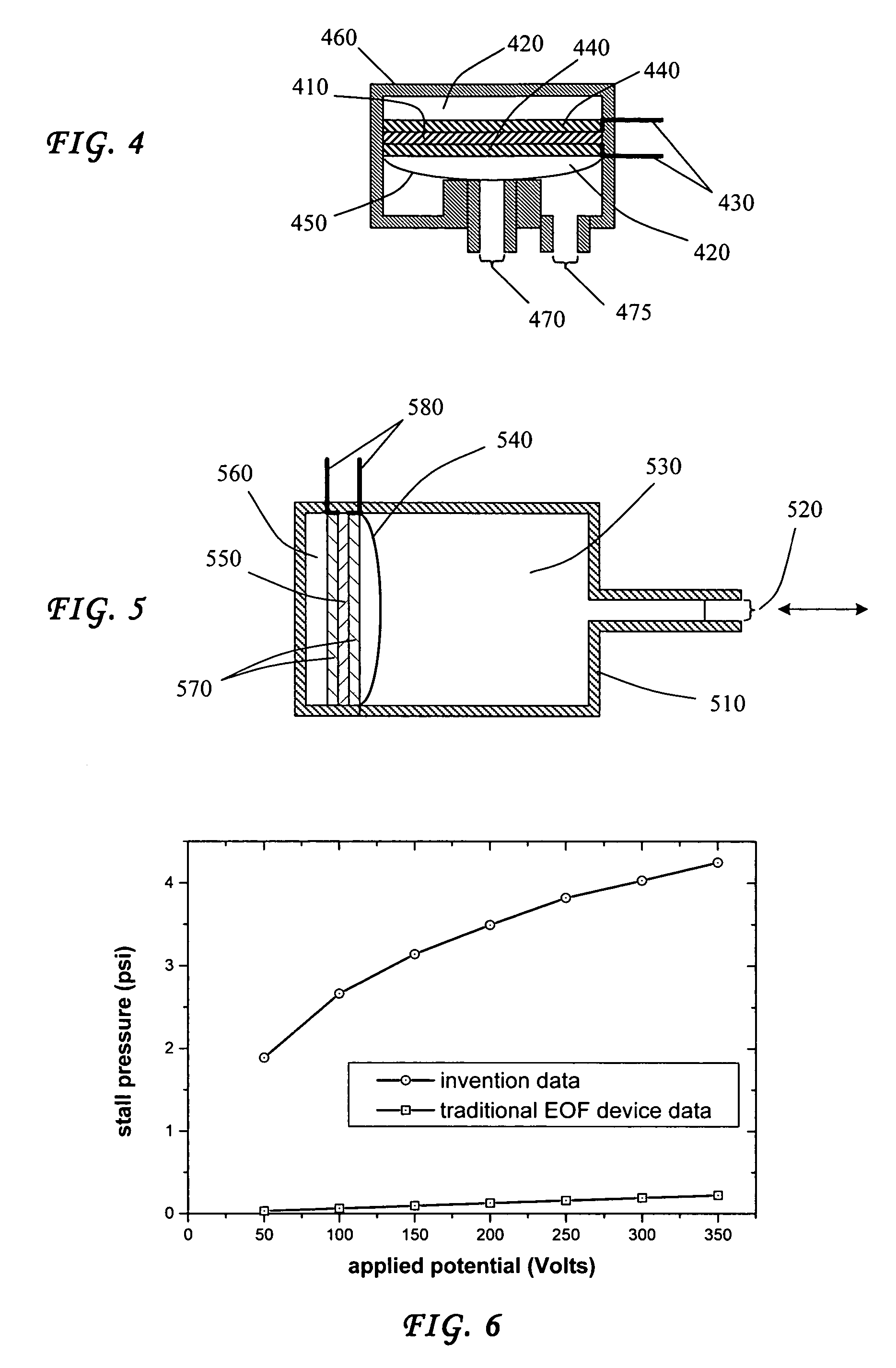

Electrokinetic device employing a non-newtonian liquid

InactiveUS7429317B2Improve execution performanceOvercome limitationsSludge treatmentEngine diaphragmsDiaphragm valveEngineering

A non-Newtonian fluid is used in an electrokinetic device to produce electroosmotic flow therethrough. The nonlinear viscosity of the non-Newtonian fluid allows the electrokinetic device to behave differently under different operating conditions, such as externally applied pressures and electric potentials. Electrokinetic devices can be used with a non-Newtonian fluid in a number of applications, including but not limited to electrokinetic pumps, flow controllers, diaphragm valves, and displacement systems.

Owner:TELEFLEX LIFE SCI PTE LTD

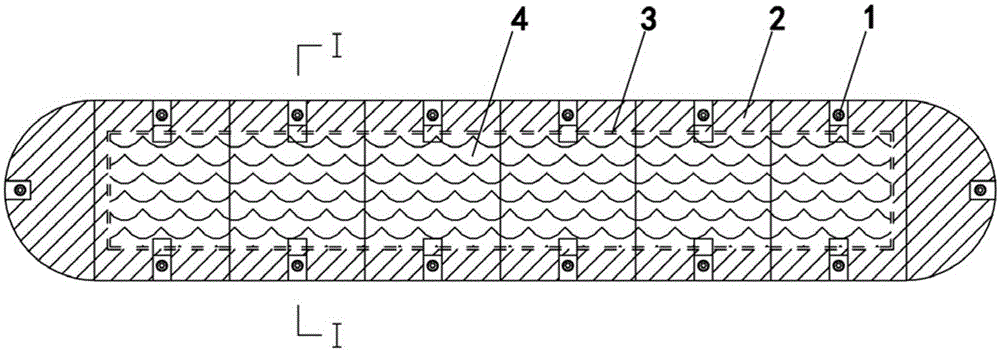

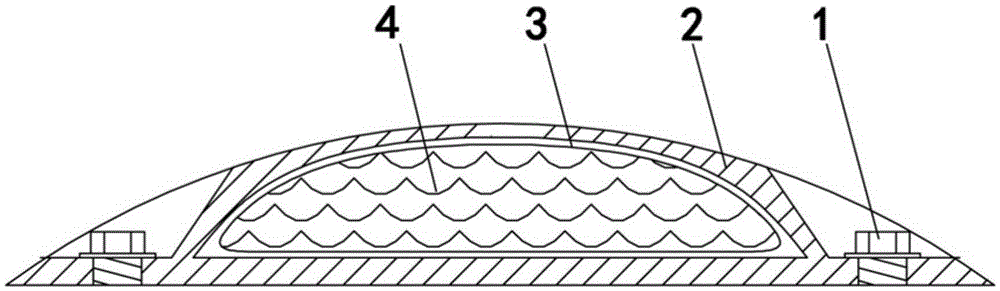

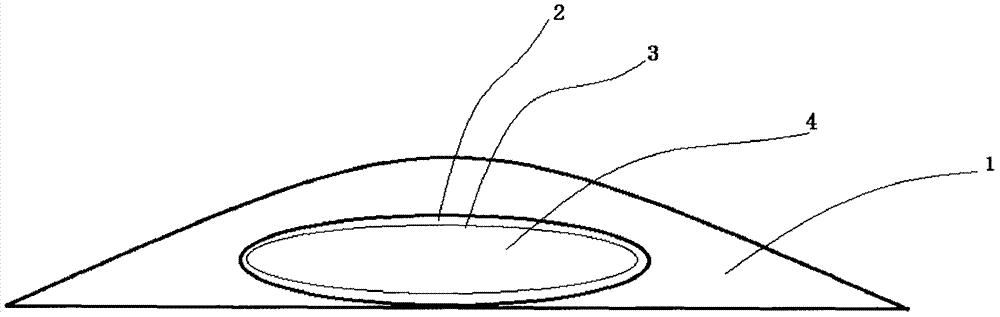

Settleable deceleration strip based on non-Newtonian fluid

InactiveCN105401537APass smoothlyReduce lossTraffic signalsRoad signsStructure of the EarthDual action

The invention relates to the technical field of traffic speed limitation and in particular relates to a settleable deceleration strip based on a non-Newtonian fluid. The settleable deceleration strip based on the non-Newtonian fluid comprises a deceleration strip; a non-Newtonian fluid filler is arranged at an inner layer of the deceleration strip; a soft rubber bag is arranged on an outer layer of the non-Newtonian fluid filler; a hard rubber protective cover is arranged on an outer layer of the soft rubber bag; the hard rubber protective cover is fixed on the floor through a plurality of fixing bolts. The settleable deceleration strip based on the non-Newtonian fluid has dual functions of limiting speeds of vehicles and protecting vehicles; besides, the settleable deceleration strip may settle when vehicles pass through the settleable deceleration strip at low speeds, such that the vehicles can smoothly pass through the settleable deceleration strip; as a result, the comfort of driving is enhanced and the wear of vehicles is reduced; besides, the settleable deceleration strip is simple in structure, ingenious in design and high in practicability.

Owner:WUHAN UNIV OF TECH

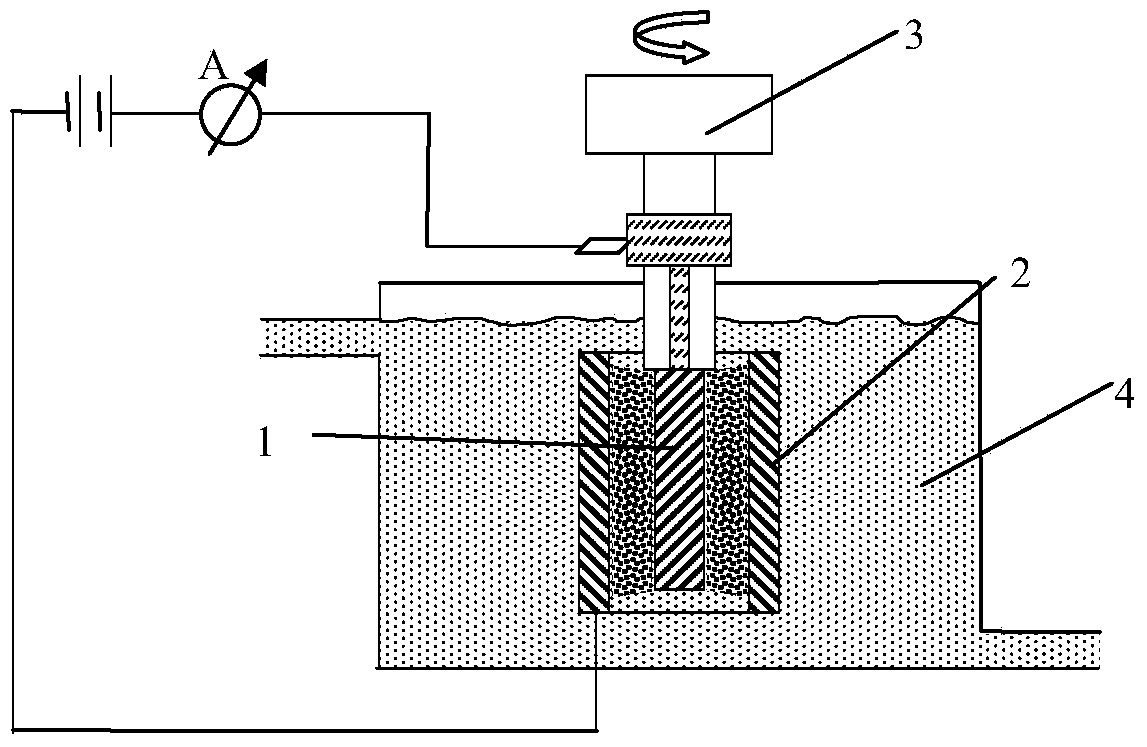

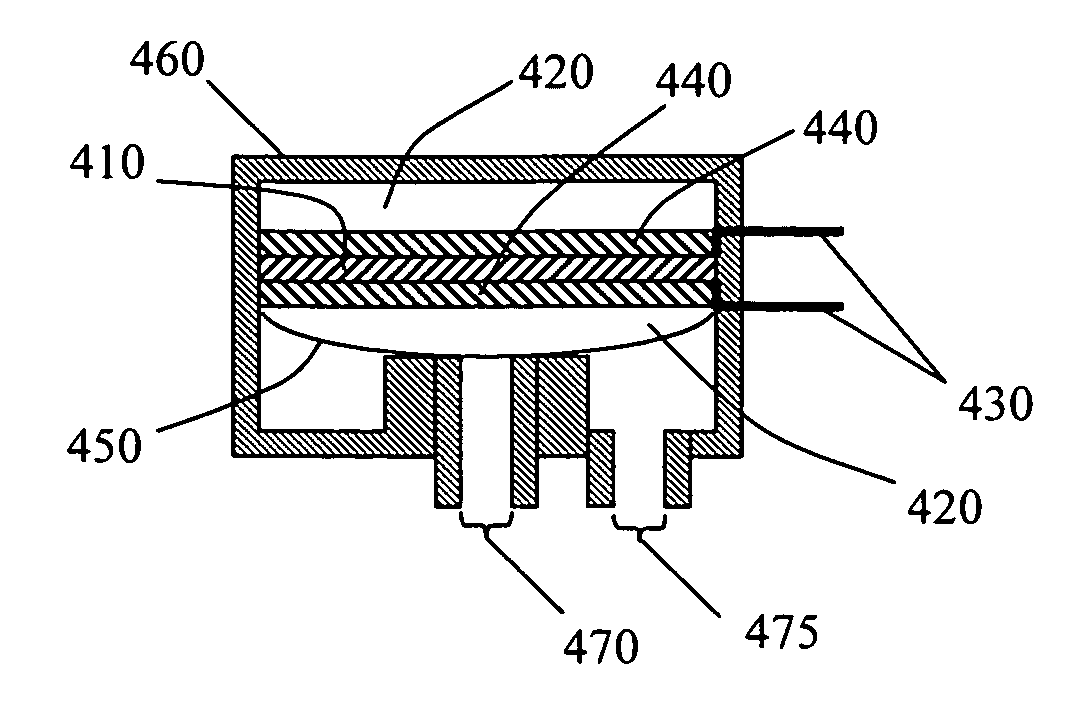

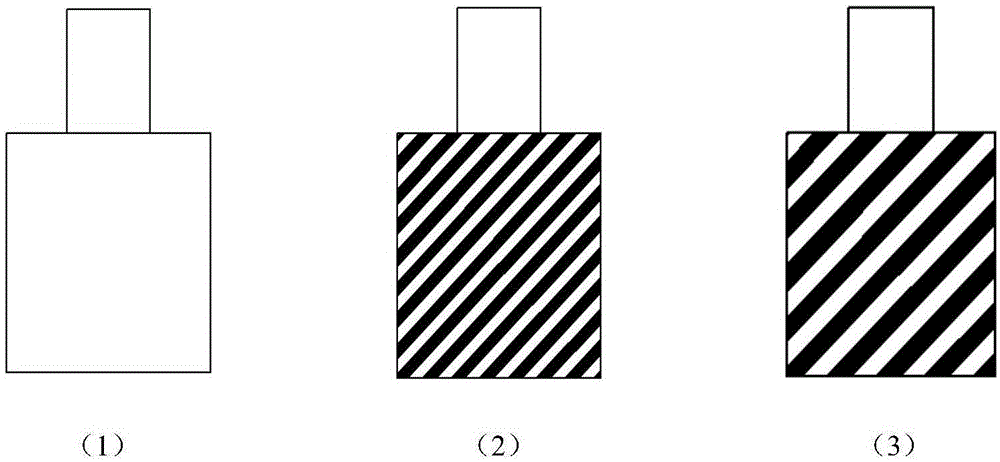

Inner hole wall polishing device based on non-Newtonian fluid shear thickening mechanism

InactiveCN105033833AImprove efficiencyHigh quality processingPolishing machinesGrinding work supportsEngineeringNon-Newtonian fluid

The invention provides an inner hole wall polishing device based on a non-Newtonian fluid shear thickening mechanism. The inner hole wall polishing device comprises a polishing pool, a polishing solution circulation system, a polishing tool and a workpiece clamp. A polishing solution is arranged in the polishing pool and is formed by adding abrasive particles or micro powder in non-Newtonian fluid having a shear thickening effect. The polishing tool is arranged in the polishing pool and a machining gap is kept between the polishing tool and an inner hole wall of a workpiece to be machined. The workpiece clamp is arranged below the polishing tool, and the polishing tool, the workpiece clamp and the workpiece to be machined are located below the liquid level of the polishing pool. The workpiece clamp is connected with a workpiece drive mechanism, and the polishing tool is connected with a polishing tool drive mechanism. A circulation inlet of the polishing solution circulation system is communicated with an outlet in the bottom of the polishing pool. A circulation outlet of the polishing solution circulation system is communicated with an inlet in the upper portion of the polishing pool. The inner hole wall polishing device based on the non-Newtonian fluid shear thickening mechanism is high in polishing efficiency, good in quality, low in cost, and simple in structure.

Owner:ZHEJIANG UNIV OF TECH

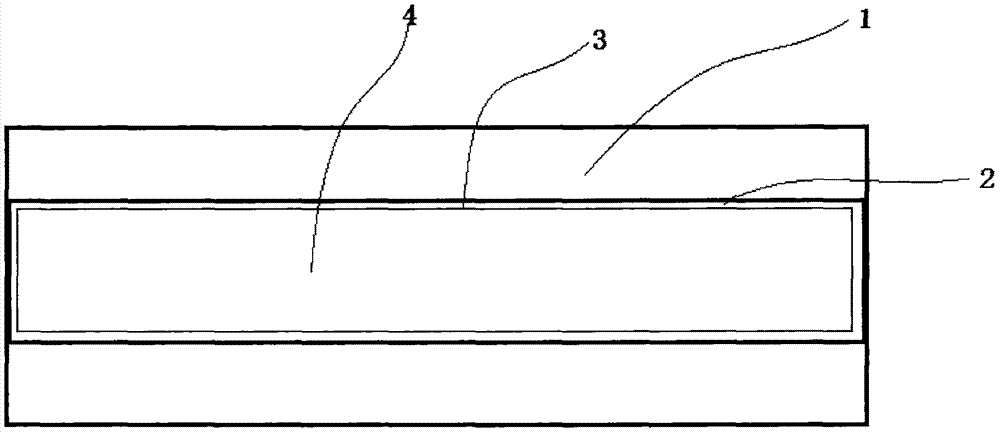

Eccentric auto-rotating large-caliber shape-preserving polishing device by means of atmospheric pressure application

InactiveCN103286659AAvoid fit instabilityQuality improvementOptical surface grinding machinesEngineeringPiston

The invention discloses an eccentric auto-rotating large-caliber shape-preserving polishing device by means of atmospheric pressure application in the field of super-precision optic surface finishing. The eccentric auto-rotating large-caliber shape-preserving polishing device comprises a motor, a rotary joint, a sleeve, a spindle, a piston, a ball head, a polishing plate, a retainer ring, non-Newtonian fluid and a shape-preserving film. The polishing plate is of an eccentric auto-rotating structure and can generate Gaussian-like removal function with central peak. Air enters the air cylinder at the tail end of the spindle to push the piston to apply certain pressure on the polishing plate after passing the rotary joint and the hollow spindle, the non-Newtonian fluid can guarantee close fit of polyurethane and aspheric surface according to real-time deformation of the surface shape of a current contact area in the process of aspheric surface finishing, and stable removal function can be generated. The eccentric auto-rotating large-caliber shape-preserving polishing device is applicable to super-precision surface finishing of large-caliber aspheric-surface optic components.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Brace cap

InactiveUS20110136071A1Precise positioningMore stiffnessArch wiresBracketsDocking stationEngineering

Vibrating dental devices and accessories are provided, including a unique snap fit dental plate and vibrator connection; risers for adjusting the thickness of a dental plate; a pointer or wand that can be clamped onto a dental plate to reach even severely misaligned teeth; a cushioned dental plate having a non-Newtonian fluid therein that allows conformation of the cushion to the dentition, but hardens on use to allow the transmission of vibration to the teeth. Accessories such as carrying cases and docking stations are also provided.

Owner:ADVANCED ORTHODONTICS & EDUCATION ASSOC LLC

Non-Newtonian fluid deceleration strip device

InactiveCN107419673AImprove the forceSmall overall deformationTraffic signalsRoad signsLower limitEngineering

The object of the present invention is to design a non-Newtonian fluid speed bump device, which is composed of a speed bump rubber shell, a cavity, an elastic rubber bladder, and a non-Newtonian fluid. There is a cavity in the rubber shell of the speed bump, an elastic rubber bag is arranged in the cavity, and a non-Newtonian fluid is arranged in the elastic rubber bag. The cross section of the rubber shell of the speed bump is arc-shaped. When the car passes by at high speed, the rubber shell of the speed bump is quickly stressed, and the elastic rubber bag in the cavity is quickly stressed, and the elastic rubber bag quickly transmits the force to the non-Newtonian fluid. The non-Newtonian fluid is not deformed much, and the rubber shell of the speed bump is not deformed much. play a blocking role. When there are low-speed vehicles such as bicycles or cars passing by at low speed, the rubber shell of the speed bump is relatively slow in force, and the elastic rubber bag in the cavity is relatively slow in force, and the elastic rubber bag transmits the force to the non-Newtonian fluid, and the non-Newtonian fluid deforms Larger, the lower limit of the deformation of the top of the rubber shell of the speed bump, the resistance of the vehicle passing through is small, and the vehicle can pass more smoothly.

Owner:武凌川

Establishment method for free surface flow model in moving particle semi-implicit algorithm

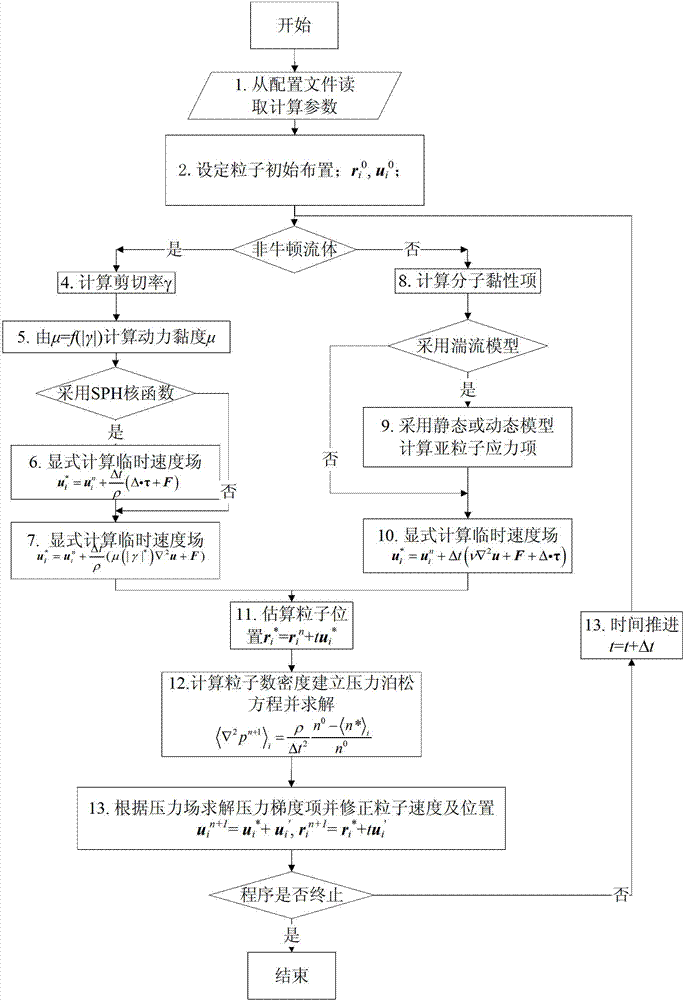

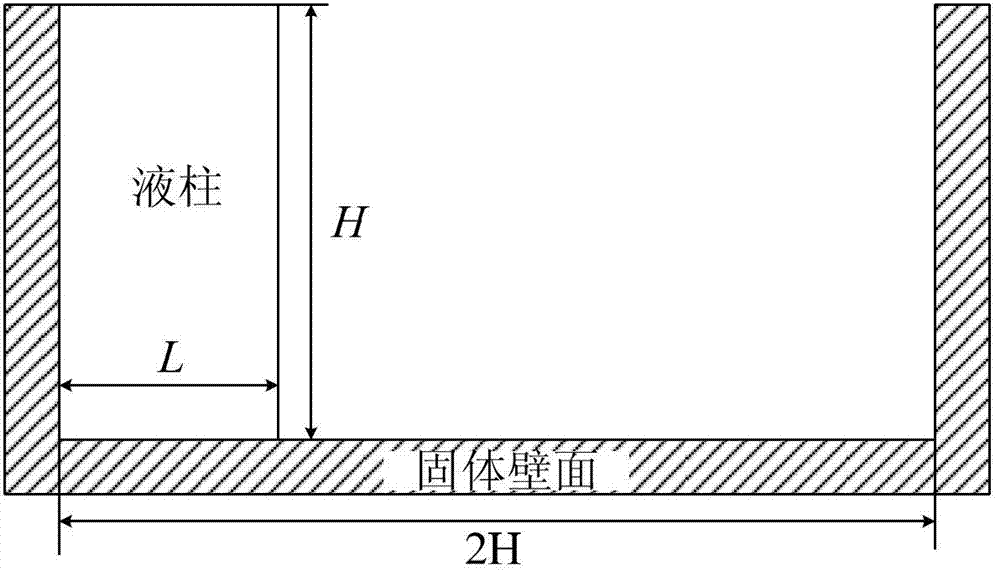

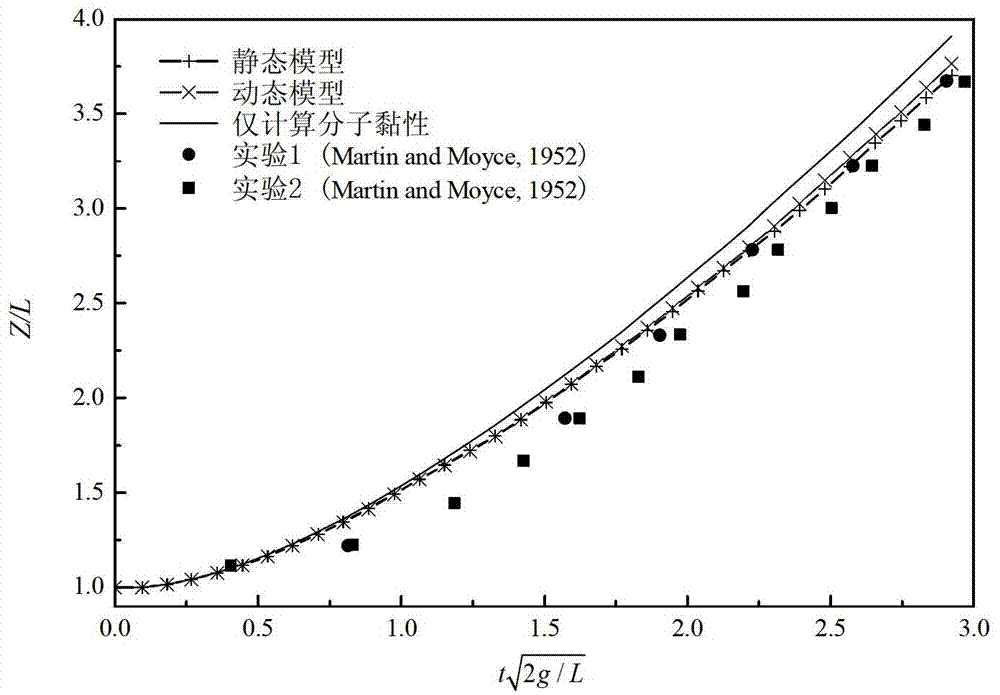

The invention provides an establishment method for a free surface flow model in a moving particle semi-implicit algorithm, comprising the following steps of: introducing a turbulence model which comprises a static Smagorinsky model and a dynamic Smagorinsky model in the form of Lagrange; treating a non-Newtonian fluid having a constitutive equation like mu = f(the absolute value ofgamma) by adopting a variable-viscosity Newtonian fluid model; and introducing a cubic spline kernel function, discretizing the shear stress of the non-Newtonian fluid by adopting the divergence discretization scheme of a smooth particle fluid dynamic method, and treating the free surface flow of the non-Newtonian fluid. According to the method provided by the invention, the sub-particle stress model of turbulence can be considered, and the method provided by the invention can be used for calculation for the non-Newtonian fluid.

Owner:江苏金洋造船有限公司

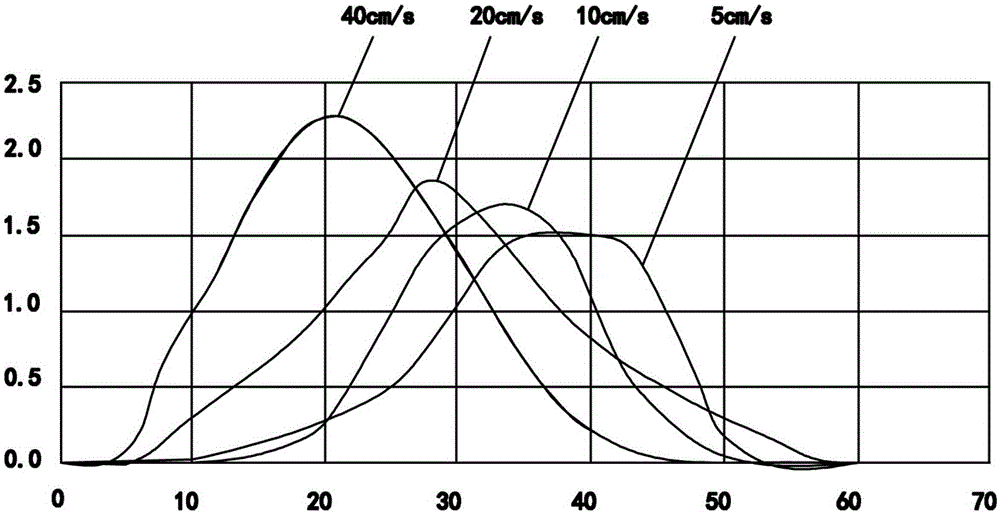

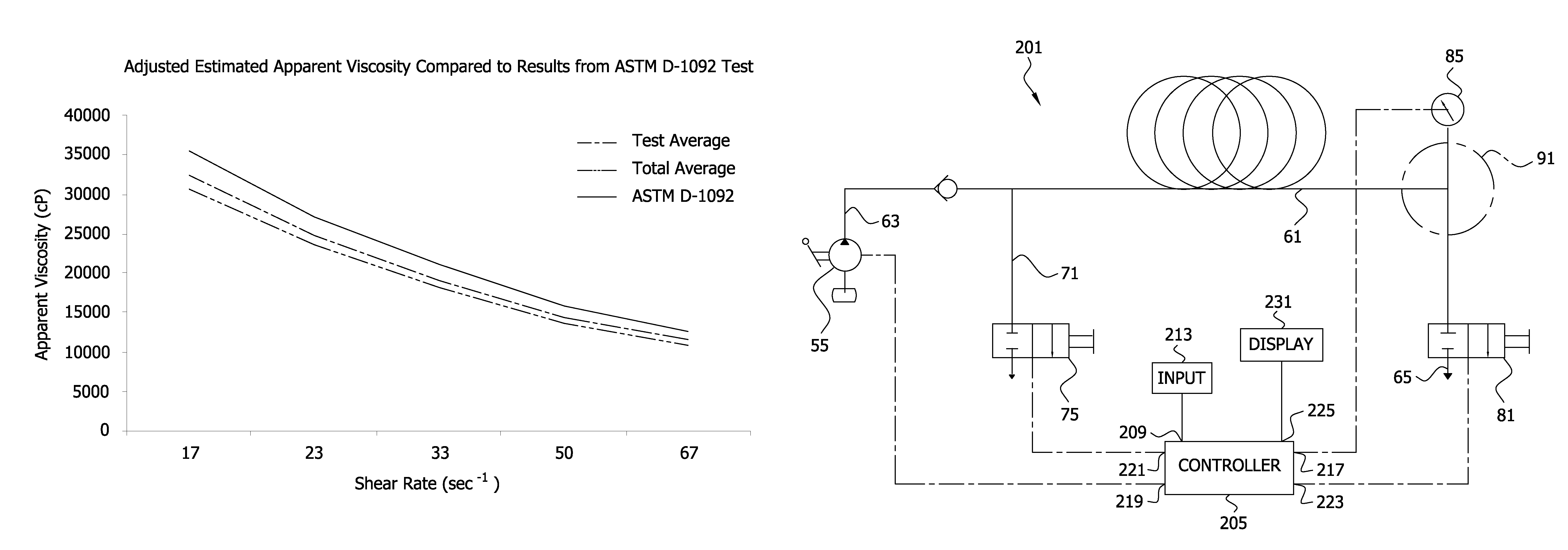

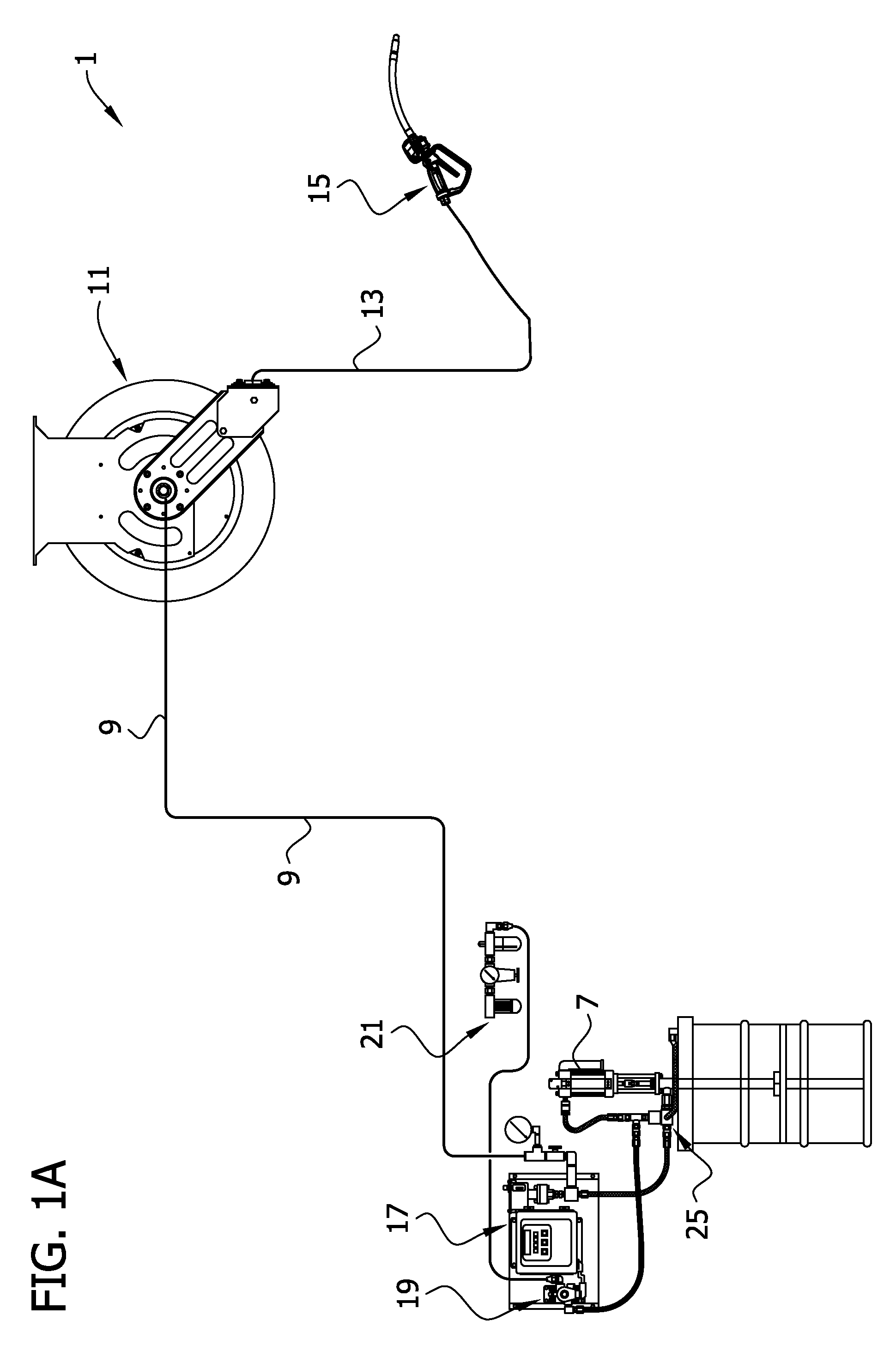

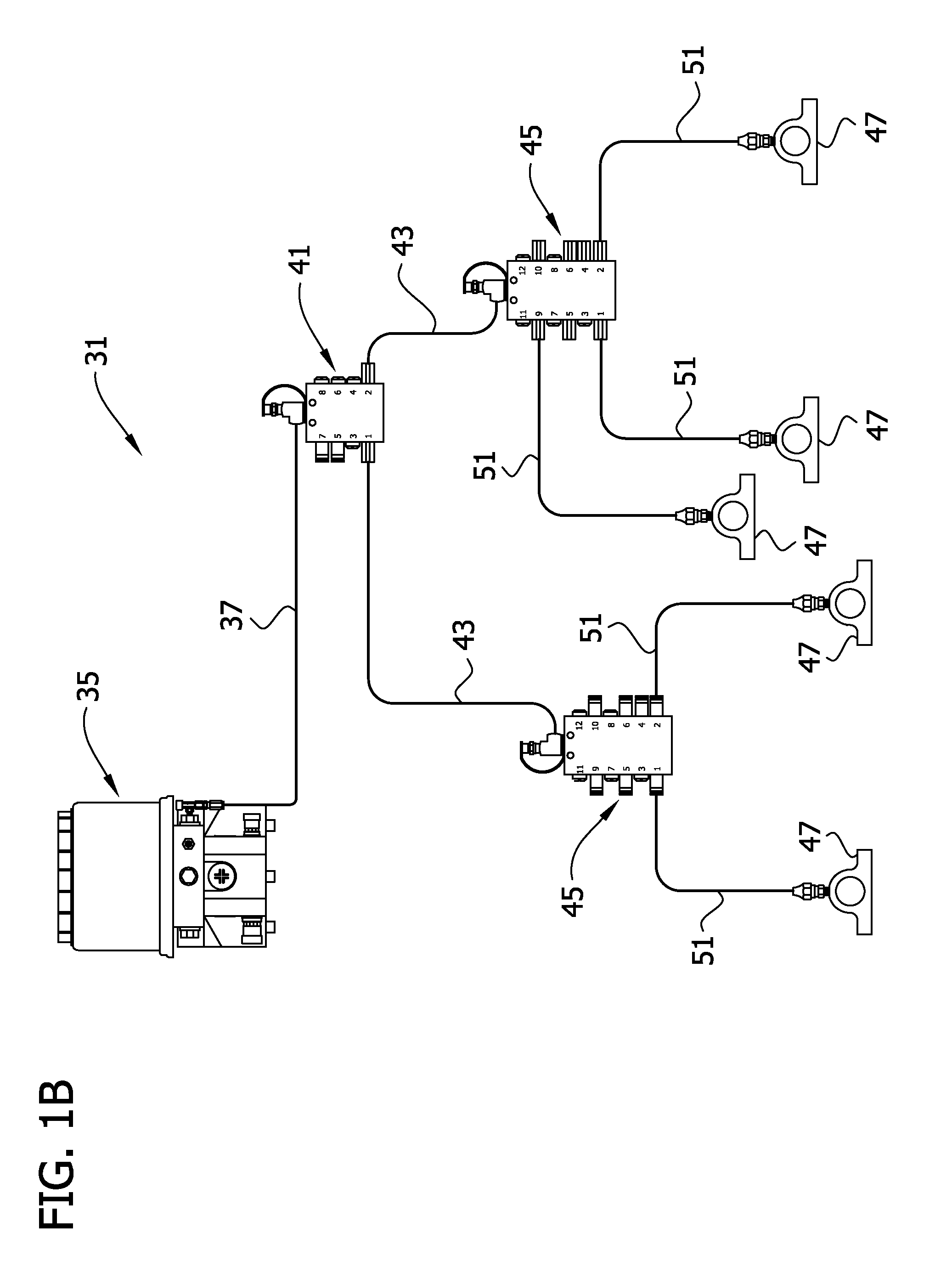

System and method for estimating apparent viscosity of a non-newtonian fluid

ActiveUS7980118B2Material analysis by optical meansFlow properties on non-Newtonian fluidsApparent viscosityNon-Newtonian fluid

Method and apparatus for estimating an apparent viscosity of a non-Newtonian fluid. The results may be used for selecting equipment for pumping systems.

Owner:LINCOLN INDUSTRIES CORP

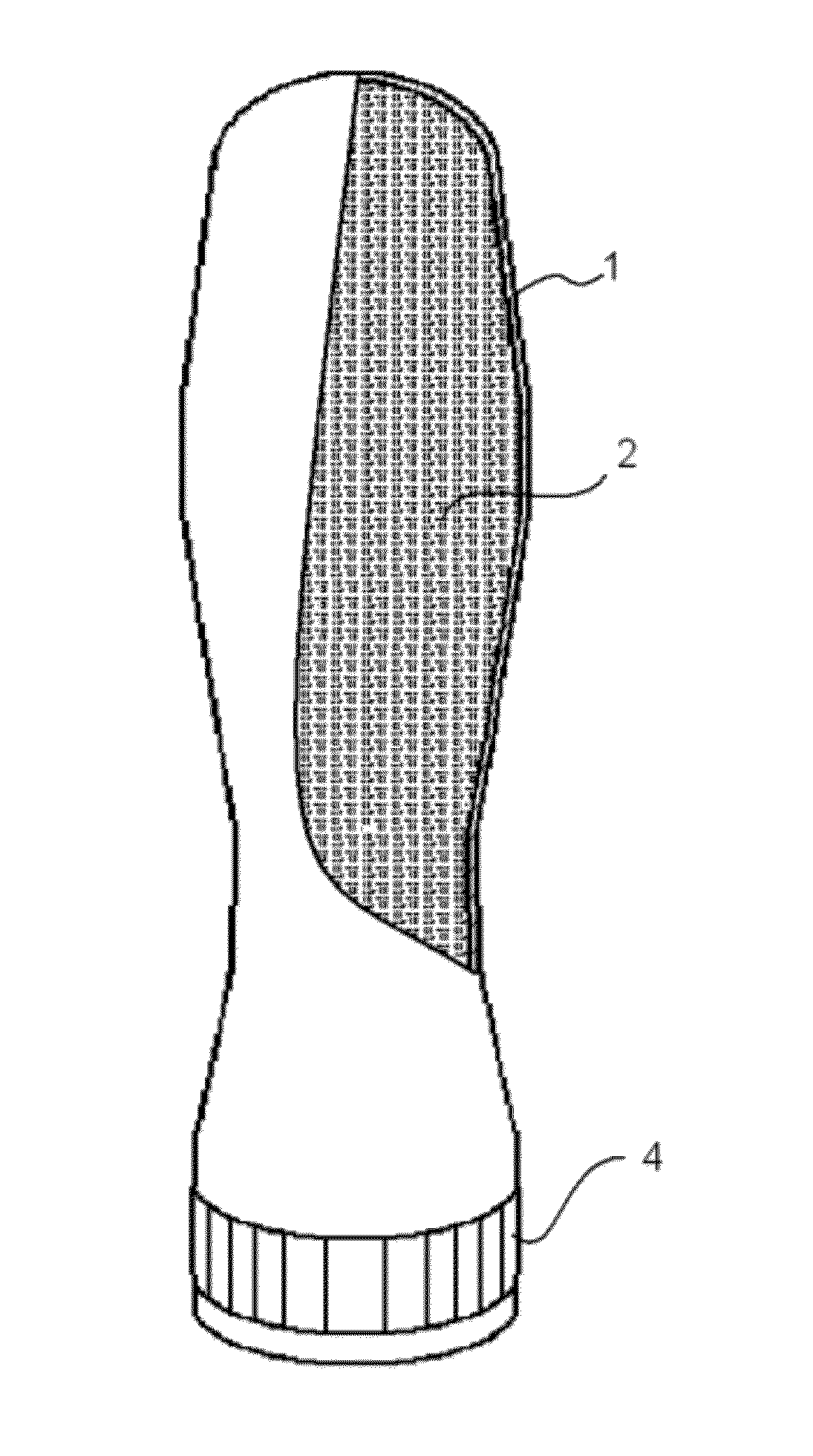

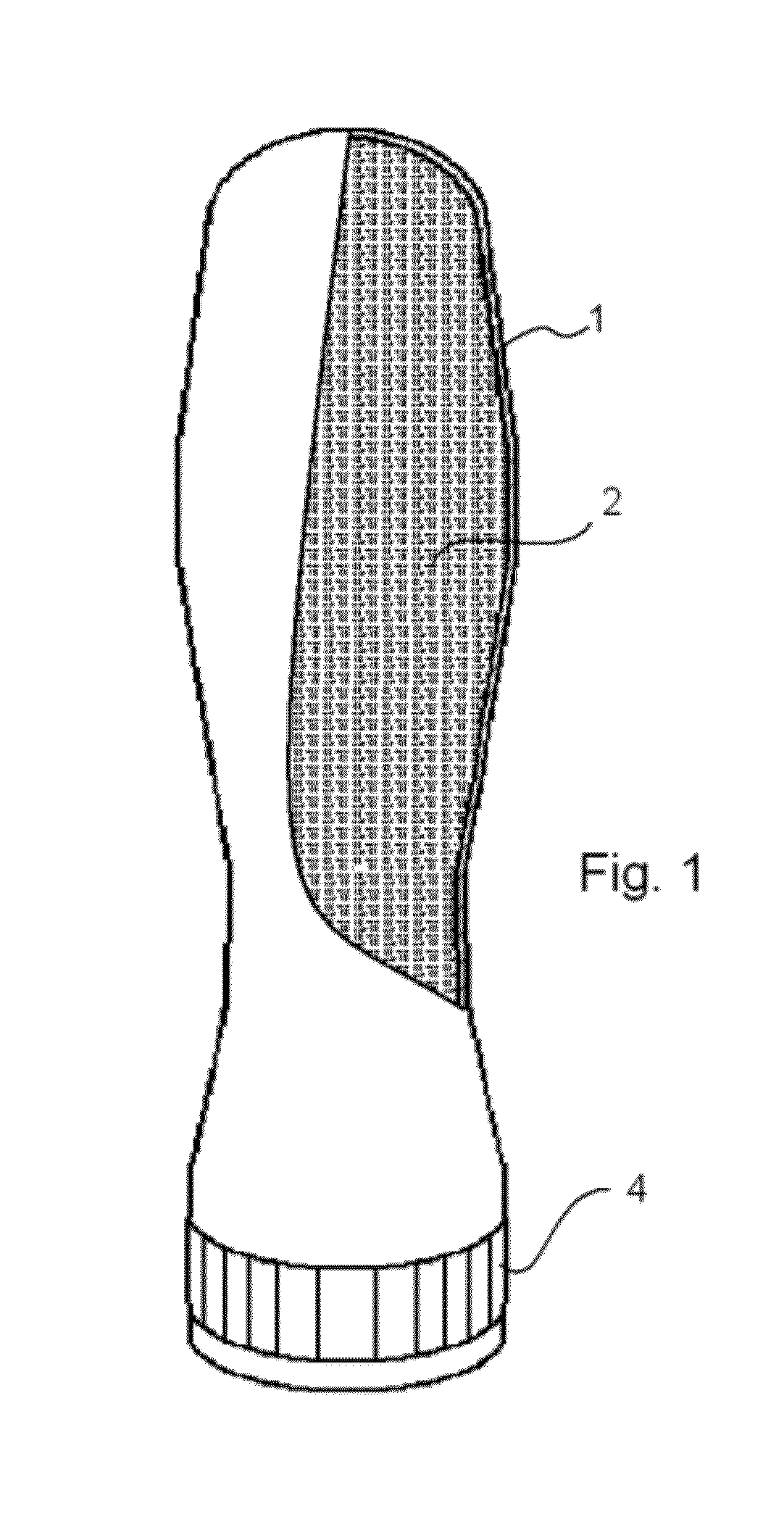

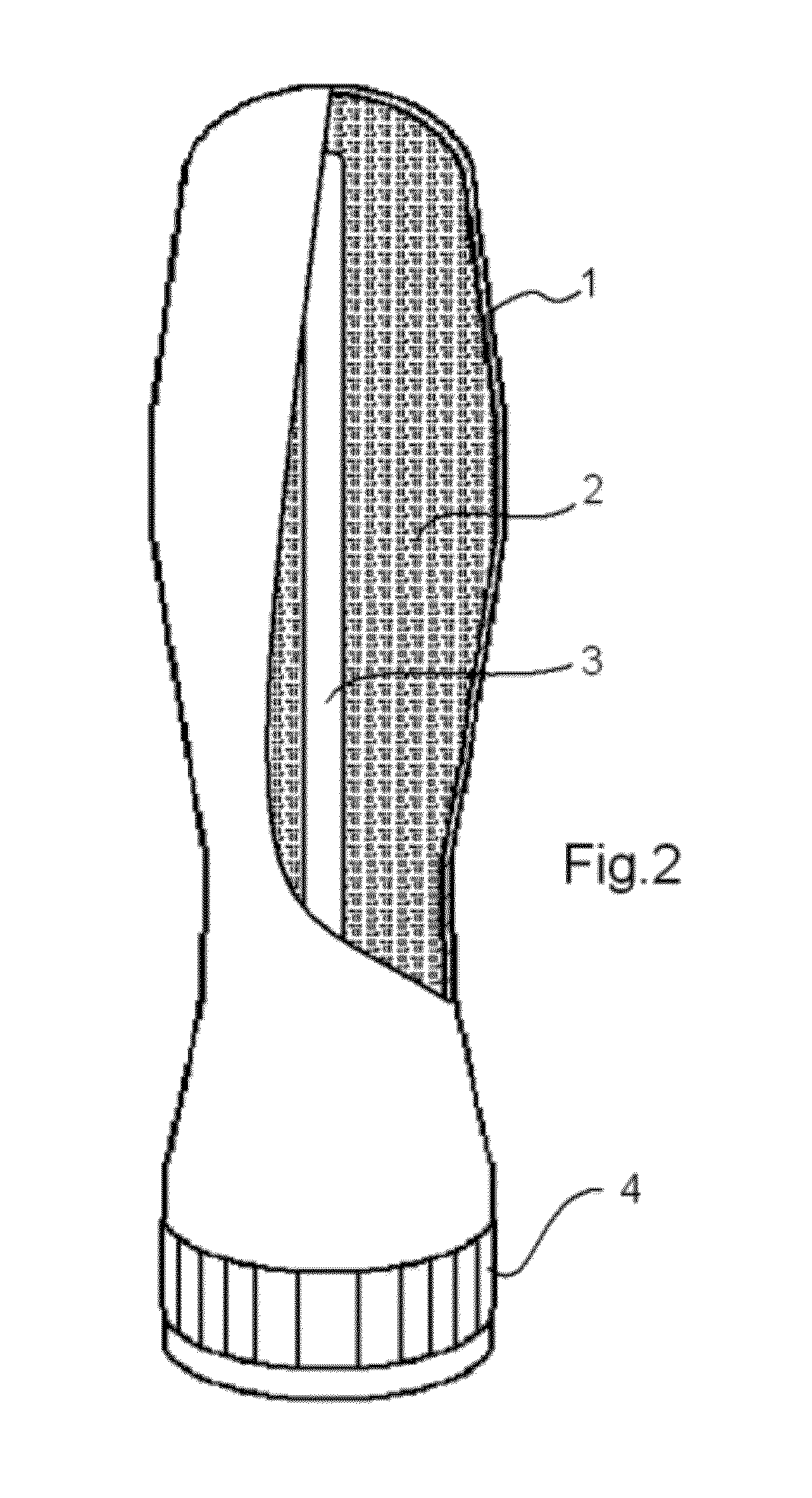

Dildo for sexual stimulation

The object of the invention relates to a dildo for sexual stimulation, comprising a tubular body (1) with a hollow structure made of a smooth material, such as silicone or rubber, having a shape and size similar to a penis, filled with a non-Newtonian fluid (2), the viscosity of which increases as the tension gradient applied thereto increases.

Owner:INNOVACIONES SOSTENIBLES DEL SUR S L U

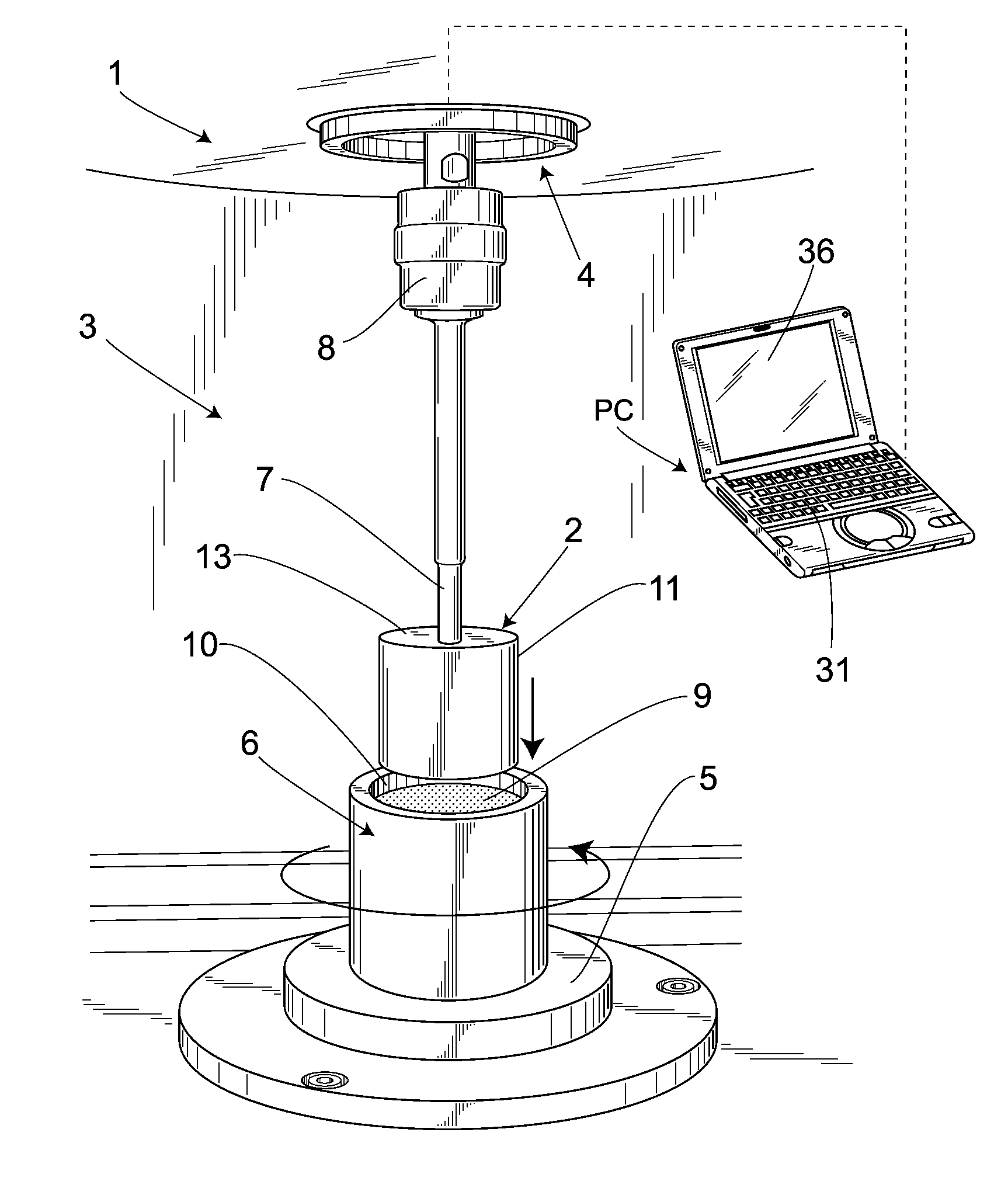

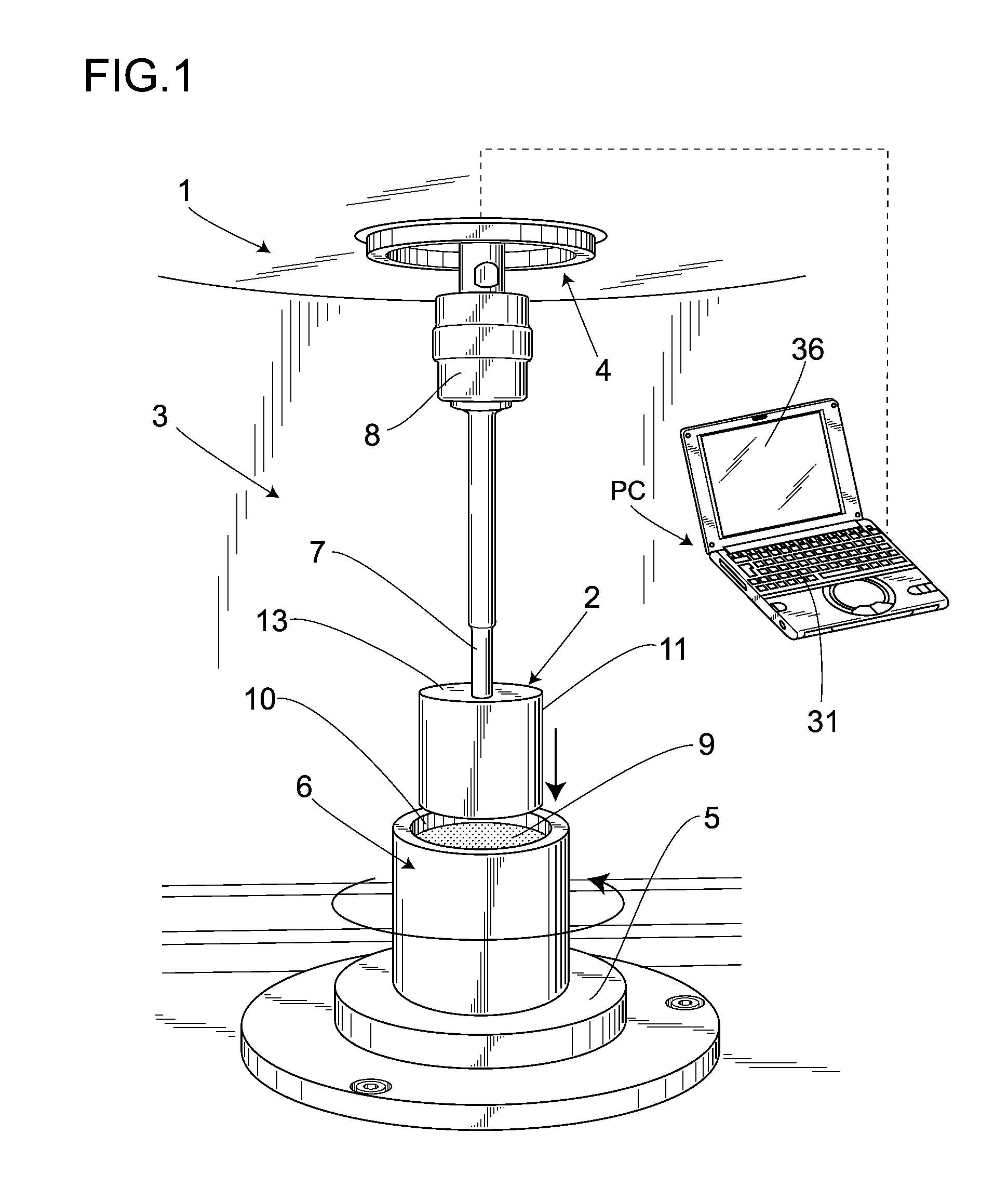

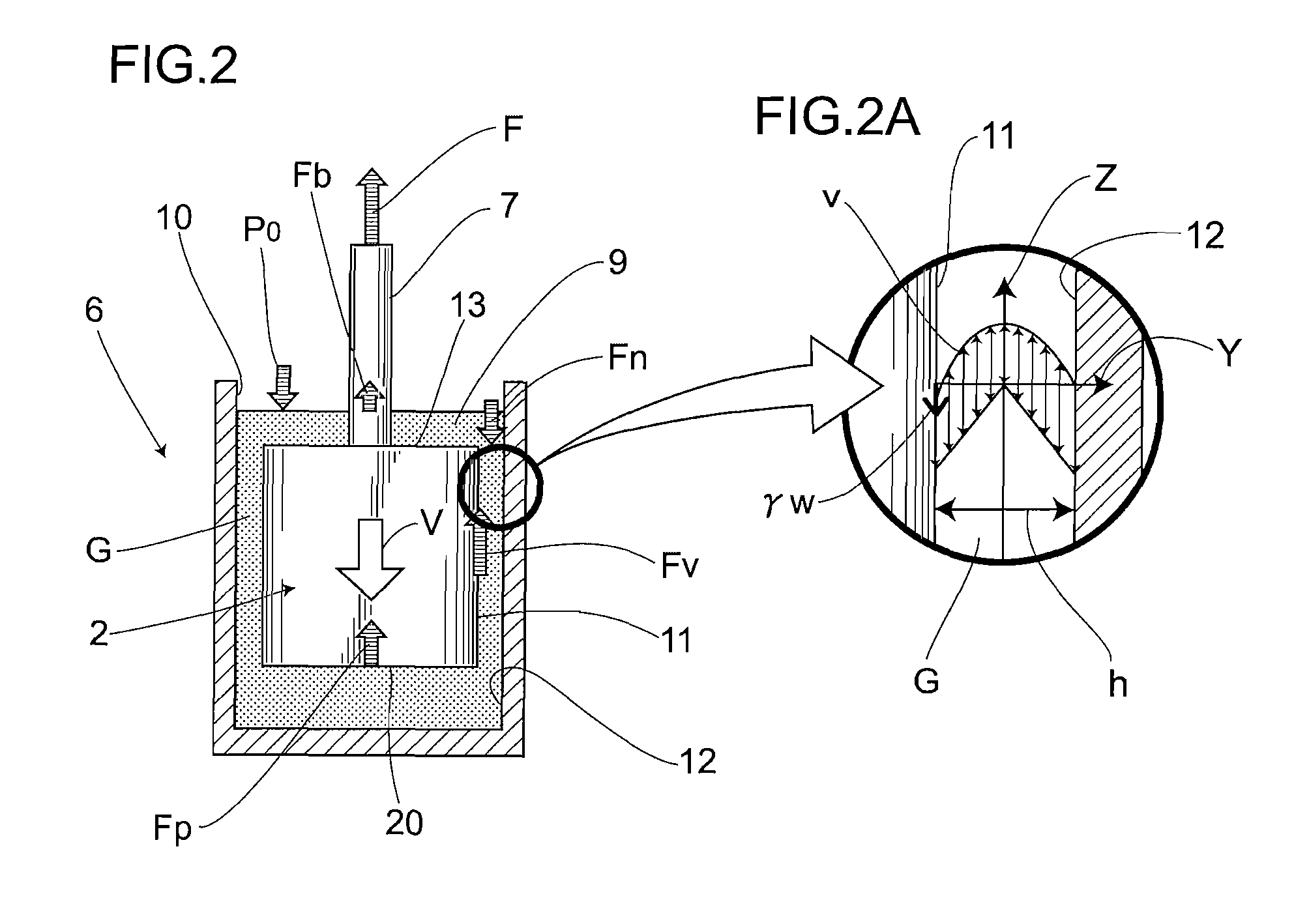

Fluid analysis method and fluid analysis device

InactiveUS20100274504A1Easy to analyzeFluid pressure measurement by mechanical elementsMachines/enginesEngineeringAnalysis method

There is provided a fluid analysis method and its device which are capable of easily analyzing a normal stress difference of a low-viscosity fluid in addition to that of a high-viscosity fluid. A shearing fluidity is applied to a non-Newtonian fluid within a lateral-side gap by pushing a cylindrical bob into a container. At that time, reactive force applied to the cylindrical bob is measured. Then, by practicing an arithmetic process in a given form using the reactive force and each of conditions input by a user, the normal stress difference of the low-viscosity non-Newtonian fluid which is hard to form in a solid state can be certainly determined. Thus, with respect to the low-viscosity non-Newtonian fluid in addition to the high-viscosity non-Newtonian fluid, the normal stress difference can be easily analyzed.

Owner:NAT UNIV CORP NAGAOKA UNIV TECH

Ultra-precision flexible chemical mechanical polishing device and method for micro bearing core element

ActiveCN111216031AUltra-Precise Damage MachiningImprove surface qualityEdge grinding machinesPolishing machinesPolishingEngineering

The invention discloses an ultra-precision flexible chemical mechanical polishing device and method for a micro bearing core element. The core element comprises an inner ferrule, a retainer, a rollingbody and an outer ferrule. The polishing device comprises an element rotation module, an outer ferrule steering module, an element clamping module, a polishing liquid pool rotation module and a support. The element clamping module provides an inner ferrule clamp, a retainer clamp, a rolling body clamp and an outer ferrule clamp in a targeted manner. The polishing method comprises the steps of installing and debugging the polishing device, preparing flexible chemical mechanical polishing liquid, setting polishing process parameters, measuring the surface quality and conducting feedback. The flexible chemical mechanical polishing liquid comprises non-Newtonian fluid, 0.01-40 wt% of grinding particles, 0-10 wt% of an oxidizing agent, 0-10 wt% of a metal complexing agent, 0-5 wt% of a metal corrosion inhibitor and the balance water, and the pH value is 2.0 to 10.0. According to the ultra-precision flexible chemical mechanical polishing device and method, by optimizing the synergistic effect of the chemical reaction and the mechanical force of the force rheological effect, ultra-precision low-damage machining and complex curved surface shape-preserving machining of the surface of the core element can be achieved, and the device and method are green and environment-friendly.

Owner:SOUTHWEST JIAOTONG UNIV +1

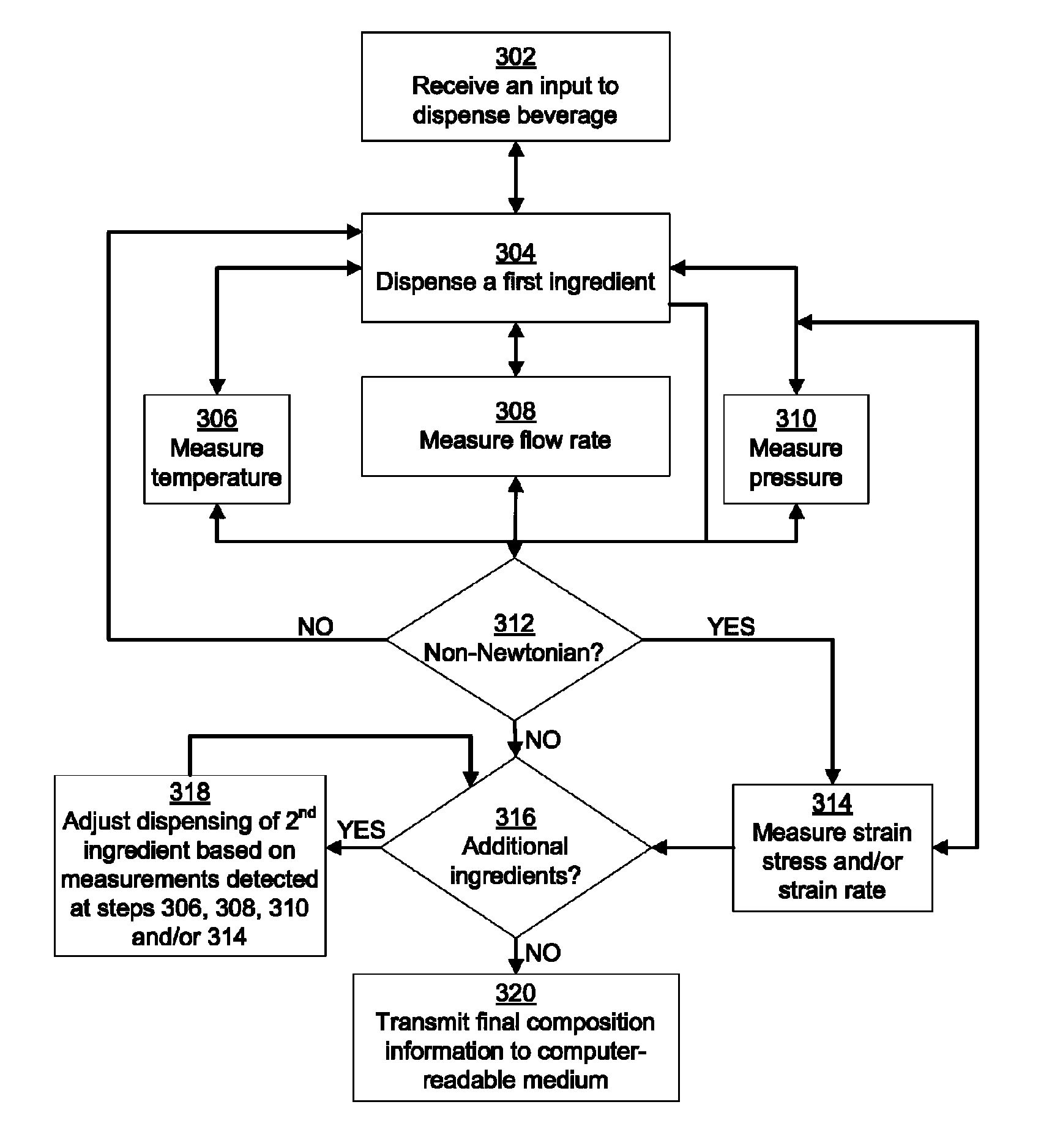

Beverage dispensing device

ActiveUS8335592B2Beverage vesselsLiquid transferring devicesAdditive ingredientBiomedical engineering

Systems and methods for dispensing beverages are provided. Aspects relate to obtaining measurements regarding dispensing an ingredient (including the dispensing conditions of the ingredient) and determining whether to adjust dispensing conditions of at least one other ingredient. In one embodiment, at least one ingredient of a recipe is not dispensed based upon a dispensing measurement. The adjustment of one or more ingredients may comprise the use of adjustable orifices, which do not require separate measurements of ingredients before dispensing, but rather may measure ingredients' parameters (including dispensing conditions) as they are dispensed. Certain embodiments relate to devices and methods that may determine if an ingredient is a non-Newtonian fluid, and if so, may be configured to conduct measurements on such fluids, including, for example, the strain stress and strain rate as the fluid passes within a conduit.

Owner:PEPSICO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com