Rheological behavior mensuration instrument for system of supercutical fluid - polymer

A technology of supercritical fluid and rheological properties, applied in the direction of DC flow characteristic measurement, etc., can solve the problems that cannot be used to measure the rheology of polymer-supercritical fluid system, cannot be directly introduced into supercritical fluid system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

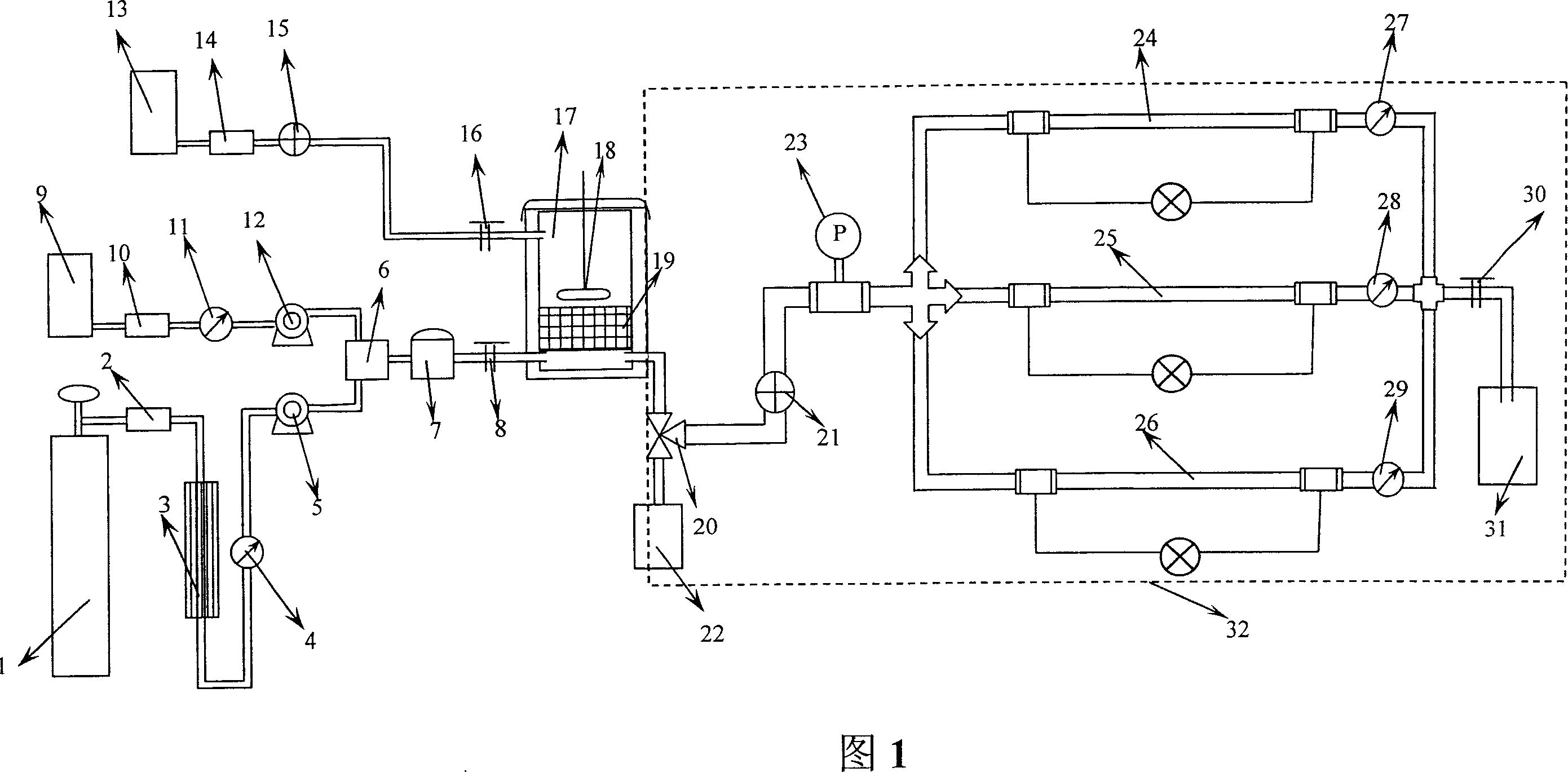

[0059]The supercritical fluid-polymer system rheological property tester of the present invention will be described in detail below with reference to FIG. 1 .

[0060] The polymer-supercritical fluid mixing device may include, for example, four parts: a supercritical fluid generating device, an auxiliary agent delivery device, a liquid polymer delivery device, and a mixing device.

[0061] In one embodiment of the present invention, the supercritical fluid generating device is composed of a storage 1, an optional first filter 2, a condenser 3, an optional first flow meter 4, and a first metering conveyor 5 composed of. The outlet of the reservoir 1 is connected to the inlet of the first filter 2 . The outlet of the first filter 2 is connected with the inlet of the condenser 3 . The condenser 3 can be, for example, a tube-and-tube heat exchanger. The fluid flows inside the tubes, and the coolant flows outside the tubes to cool the fluid in the tubes. The outlet of the conden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com