Concrete workability rapid recovery system

A rapid recovery and workability technology, applied in the field of civil engineering, can solve the problems of difficult construction and poor workability of concrete, and achieve the effect of improving workability, improving quality and reducing quality risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

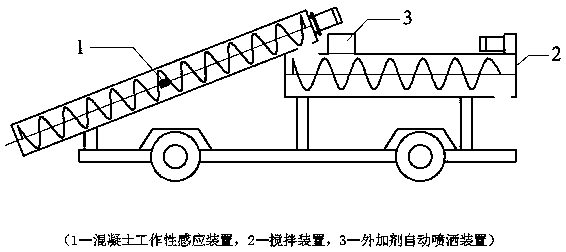

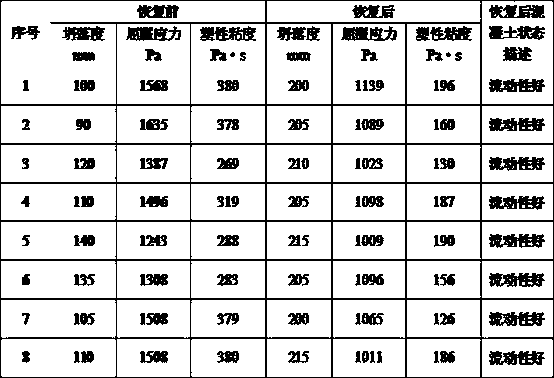

[0014] In order to better illustrate the features of the present invention, the content of the invention will be described below in conjunction with specific examples, but the content of the present invention is not limited to the content of the examples. figure 1 It is a schematic diagram of the rapid recovery system of concrete workability in the present invention. The rapid recovery system of concrete workability is composed of a workability induction device 1, a stirring device 2 and an automatic admixture spraying device 3, and the automatic admixture spraying device 3 is set on the stirring device 2 above. The above devices are all connected to the controller. When the concrete enters the workability sensing device 1, the sensor judges the workability of the concrete by testing the rheological characteristic parameters of the concrete, and transmits the data to the controller. The controller sends instructions to the stirring device 2 and the admixture automatic spraying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield stress | aaaaa | aaaaa |

| Plastic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com