Patents

Literature

376results about How to "Reduce quality risk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

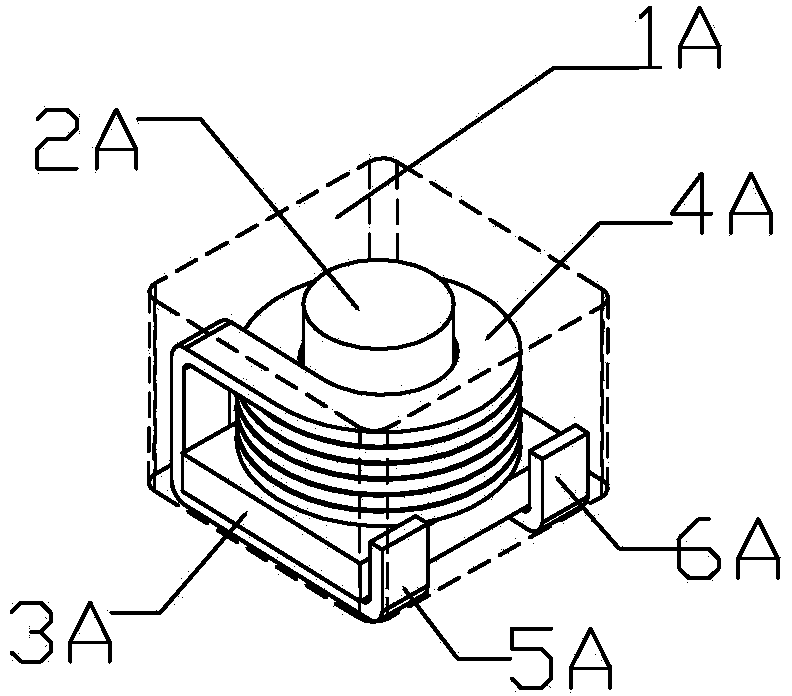

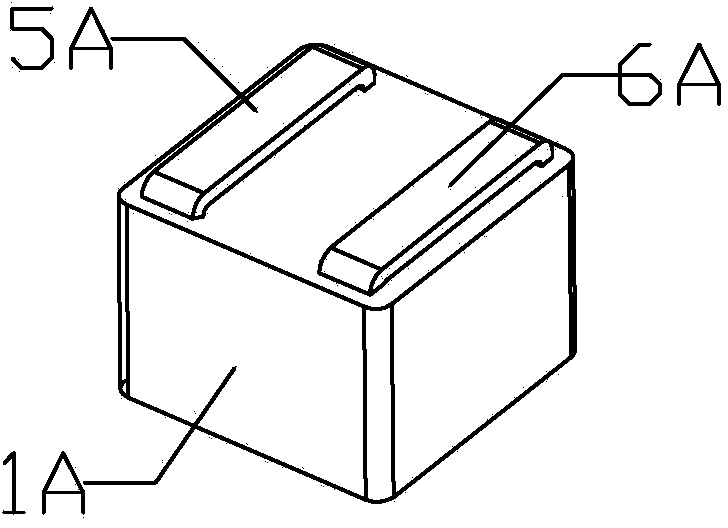

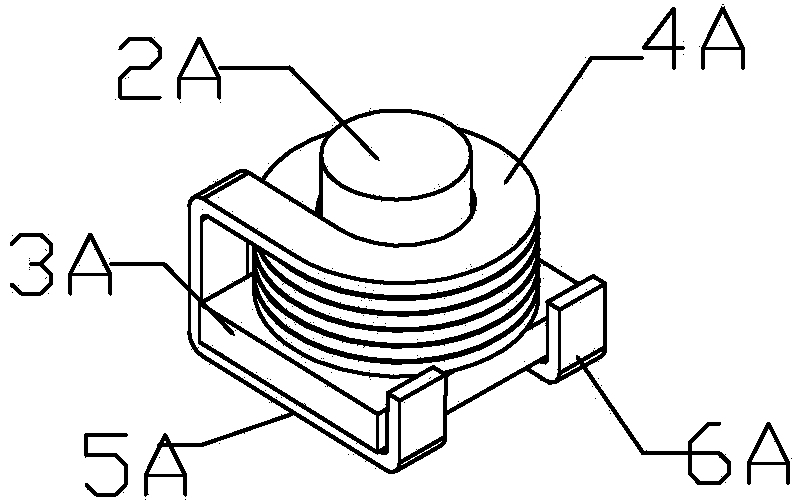

Novel inductor and manufacturing method thereof

InactiveCN103915236AImprove firm performanceReduction of post-processing proceduresVolume/mass flow measurementTransformers/inductances coils/windings/connectionsEngineeringInductor

The invention discloses a novel inductor. The novel inductor is characterized by comprising an inset inner core, an electrode and an outer wrapping layer, the inset inner core comprises an enameled coil and a mandrel, and the inset inner core and the electrode are buried in the center of the outer wrapping layer. The novel inductor has the advantages that manufacturability and performance are improved.

Owner:深圳市科达嘉电子有限公司

Bamboo carbon fiber underwear fabric and manufacture method thereof

InactiveCN101532204AFully reflect the decomposition of odorFully reflect the functionWeft knittingYarnFiberTextile technology

The invention relates to a bamboo carbon fiber underwear fabric and a manufacture method thereof, belonging to the technical field of textiles. The bamboo carbon fiber underwear fabric consists of a lining layer and an external layer, and is characterized in that the lining layer consists of bamboo carbon fibers and cotton fibers according to the weight ratio of 15-30:70-85; the external layer consists of cotton fibers, Newdal fibers and polyurethane elastic fibers according to the weight ratio of 43-54:40-54:3-6. The manufacture method comprises that: the bamboo carbon fibers and the cotton fibers, the cotton fibers and the Newdal fibers are respectively spun into Sirospun blended yarns; the Sirospun blended yarns are interwoven with polyurethane elastic fibers to form a knitted underwear fabric; and the knitted underwear fabric forms a final finished product, namely the bamboo carbon fiber underwear fabric through dyeing, drying, sanding and shaping treatment. The fabric and the manufacture method have the advantages that the bamboo carbon fiber underwear fabric not only has good skin-friendly property, low pilling tendency and comfortable elasticity, and has functions of good odor decomposition, smell elimination and the like.

Owner:SHANGHAI PLANDOO TEXTILE TECH DEV

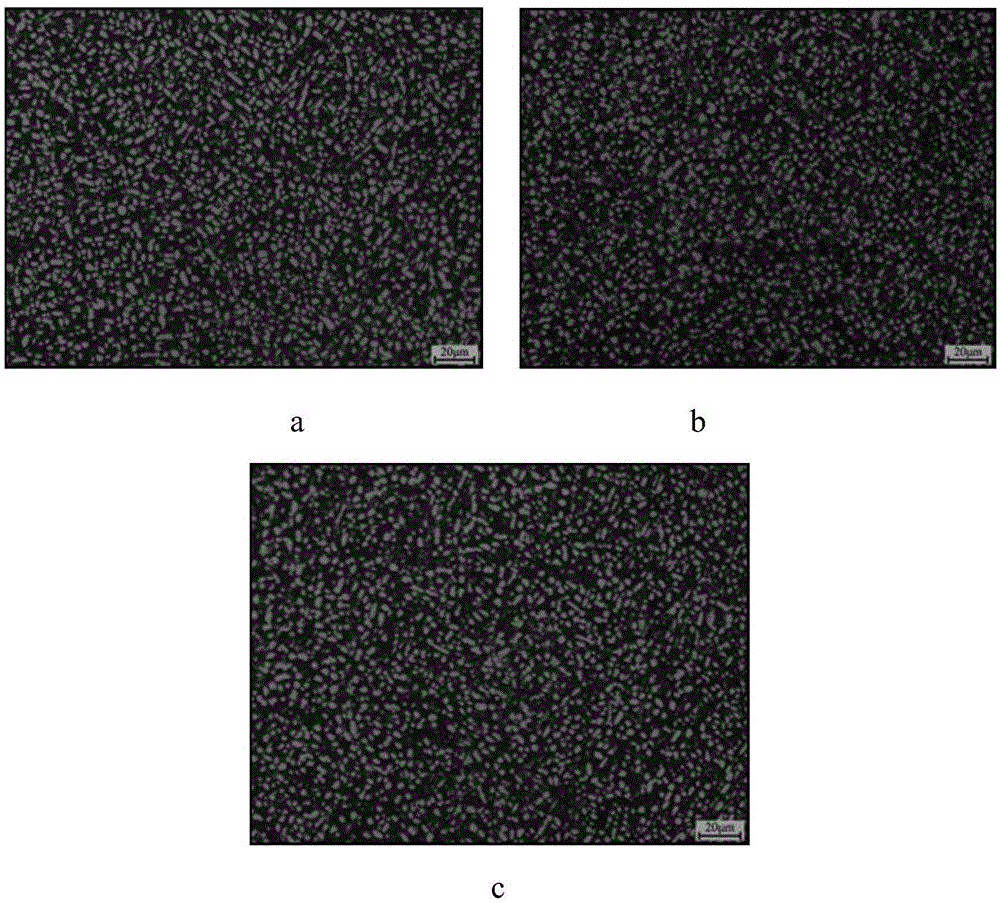

Forging method for improving microstructure uniformity of TC18 titanium alloy bars

The invention discloses a forging method for improving the microstructure uniformity of TC18 titanium alloy bars. The method comprises the following steps: heating TC18 titanium alloy ingots, carrying out upsetting and rolling forging once, and pressing down the forged ingots in a downward pressing process to crush an original cast microstructure; and carrying out upsetting and rolling forging on the obtained forging stock at a temperature being greater than a beta phase transition point 2-3 times, carrying out upsetting and rolling forging on the obtained forging stock at a temperature being smaller than the beta phase transition point 2-4 times to prepare a 16-surface object, and carrying out precise forging on the 16-surface object at a temperature of Tbeta-50DEG C once to finally produce TC18 titanium alloy bars with the diameter of 160-260mm. The method improves the microstructure uniformity of the TC18 titanium alloy bars and effectively reduces the deformation microstructure risk through adopting a less upsetting and rolling + high control precision precise forging technology on the premise of guaranteeing the refinement and fragmentation of the microstructure; and the method reduces the production cost and the quality risk and shortens the production period of the bars through reducing the forging frequency and adopting continuous melting, and is suitable for large-scale batch production of the TC18 titanium alloy bars.

Owner:西部超导材料科技股份有限公司

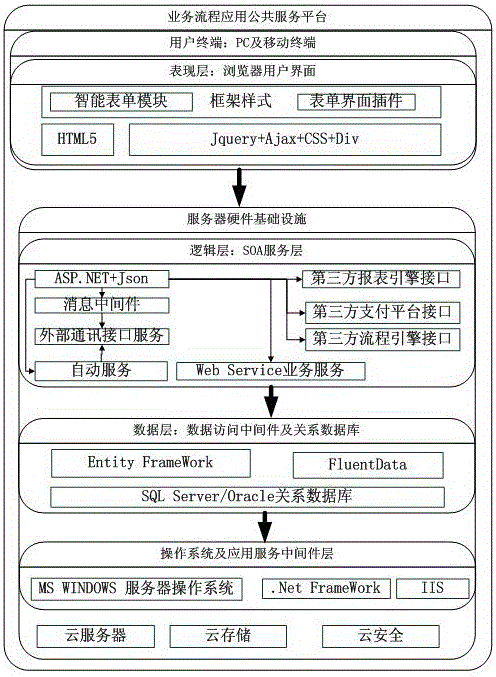

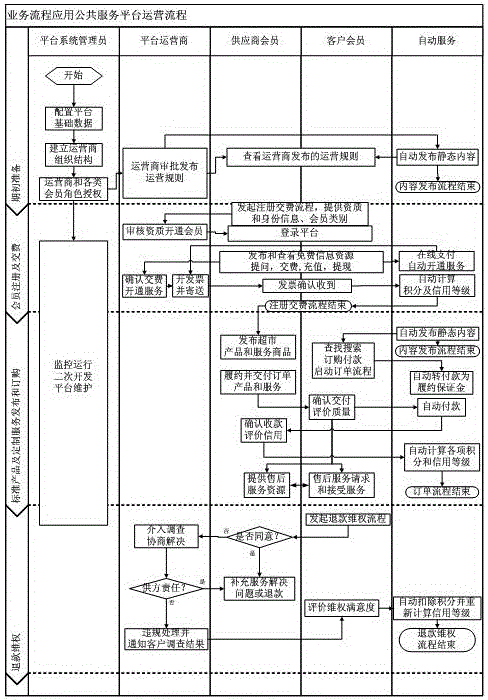

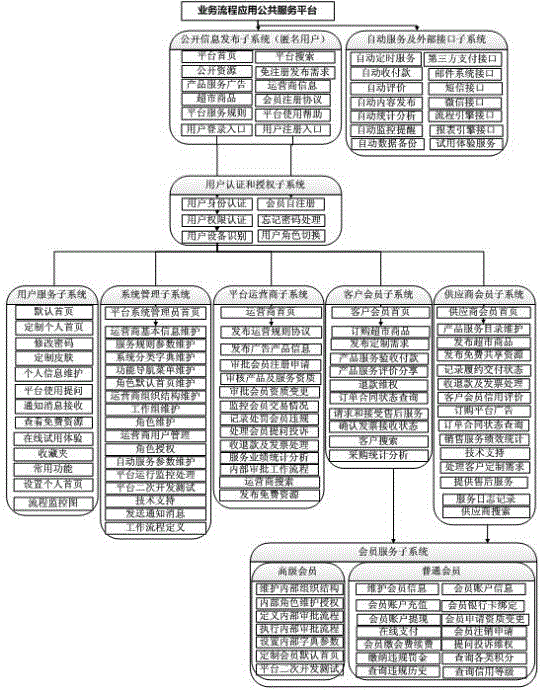

Public service platform and usage method thereof

InactiveCN106169987AGuaranteed safety and reliabilityGuaranteed uninterrupted service capabilityTransmissionService flowOrder processing

The present invention relates to a platform and a usage method thereof, concretely to a public service platform and a usage method thereof. The platform comprises a terminal and a cloud server; the terminal includes a PC terminal and a mobile terminal, wherein the PC terminal and the mobile terminal form a presentation layer; the cloud server includes a logic layer and a data layer; and the data layer, the logic layer and the representation layer form the whole framework of the public service platform, and the whole framework of the public service platform includes two processes of content publishing and order processing. The present invention provides a product display and selling mode similar to a traditional supermarket, and divide a large-scale application business flow management software implementation process with long period, high cost and big risk into a gradually advanced iterative implementation process with short period, low cost and small risk; and moreover, through providing a service platform, the normalized flow correlation product selling, the standardized requirement customization service, standardized order processing and the pre-sales and after-sales service flows, the problem of the traditional offline implementation service of the BPM industrial field is solved, and the cost and risk of supplying to both parties are reduced.

Owner:山东达创网络科技股份有限公司

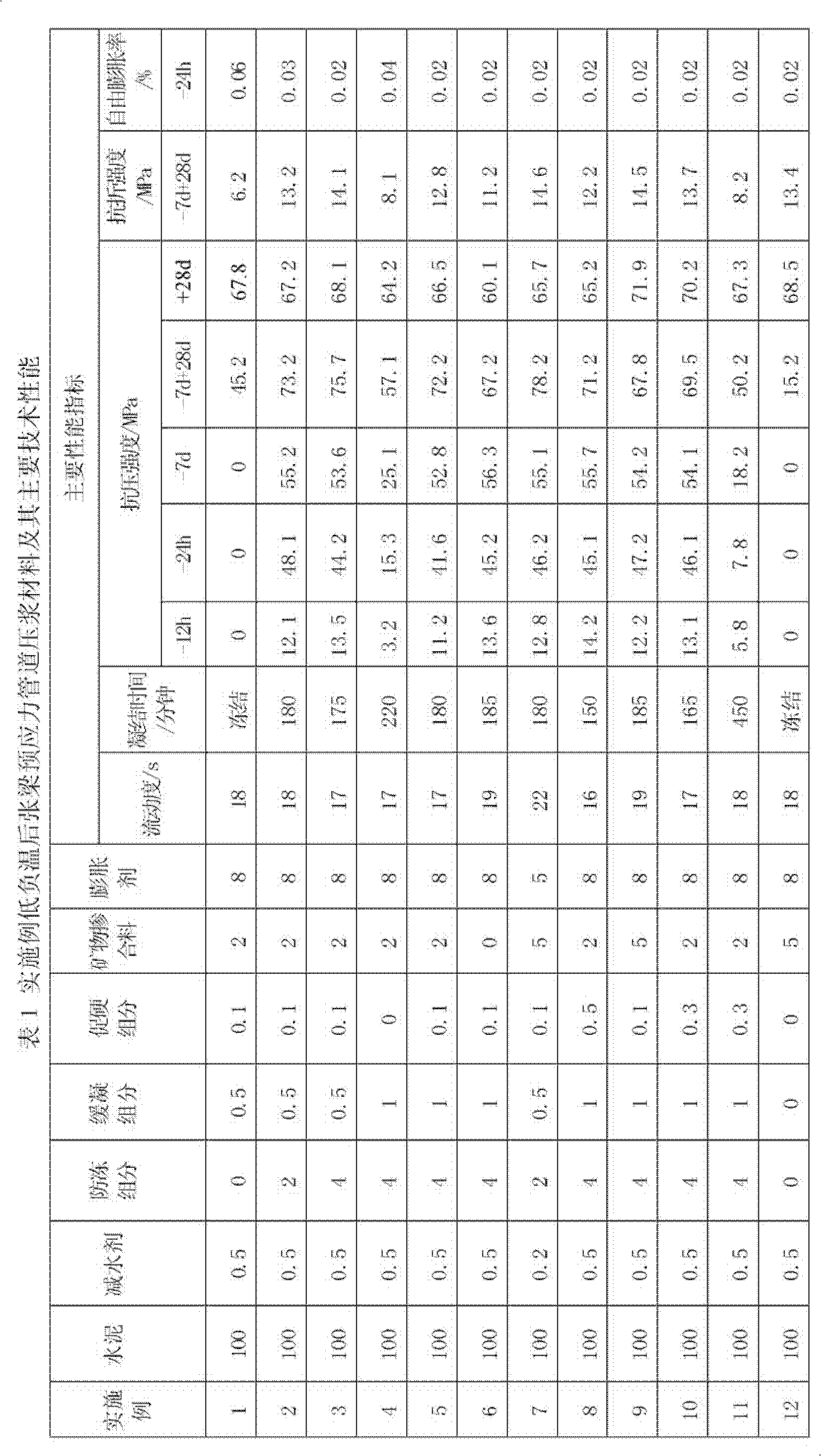

A low negative temperature post-tensioned beam prestressed pipeline grouting material

The invention belongs to the technical field of building materials, and in particular relates to a low negative temperature post-tensioned beam prestress pipeline mudjacking material. The material disclosed by the invention is prepared from cement, a poly-carboxylate water reducer, an anti-freezing component, a retardant component, a harness promoting component, mineral admixtures and an expanding agent through mixing and stirring; the material can be used for the construction of pipe mudjacking of a post-tensioned prestressing T beam and a continuous beam in the construction condition not lower than minus 10 DEG C; and the effect of the material is more obvious in the environment condition of shifts between positive and negative temperatures day and night. The strength of hardened mortarcan develop continuously in the conditions of low temperature and negative temperature, the maintenance time can be shortened greatly, the construction efficiency can be improved, and large energy consumption required by low and negative temperature construction can be reduced.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

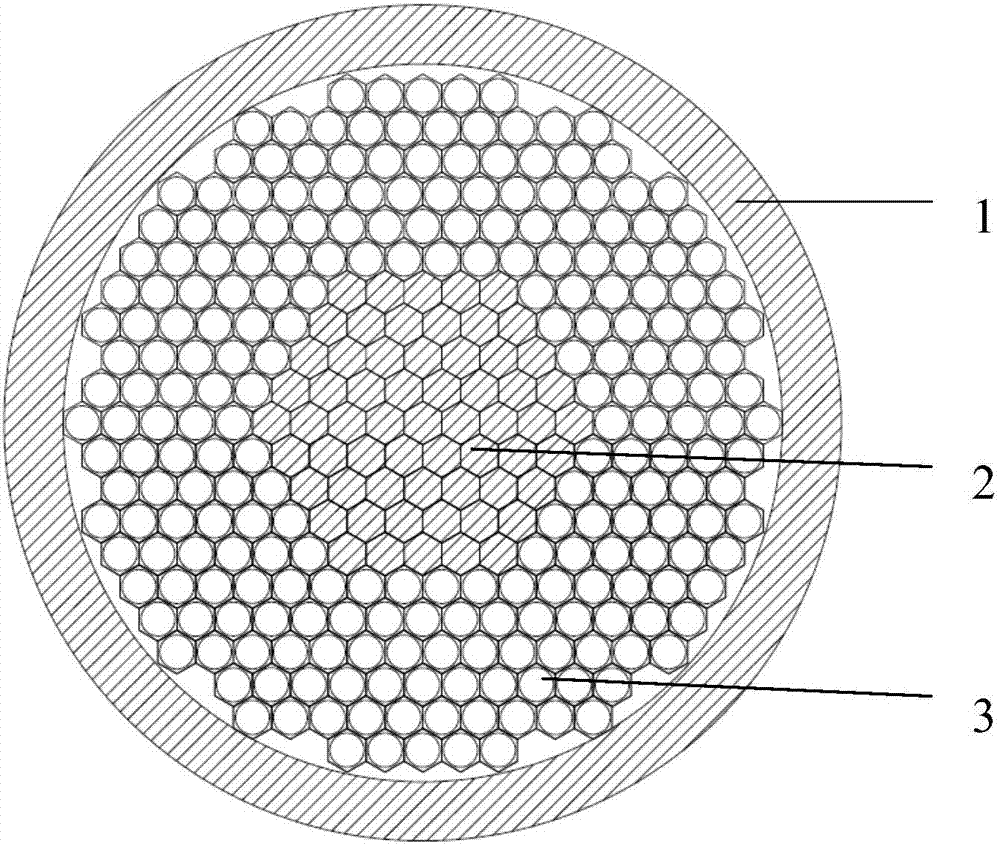

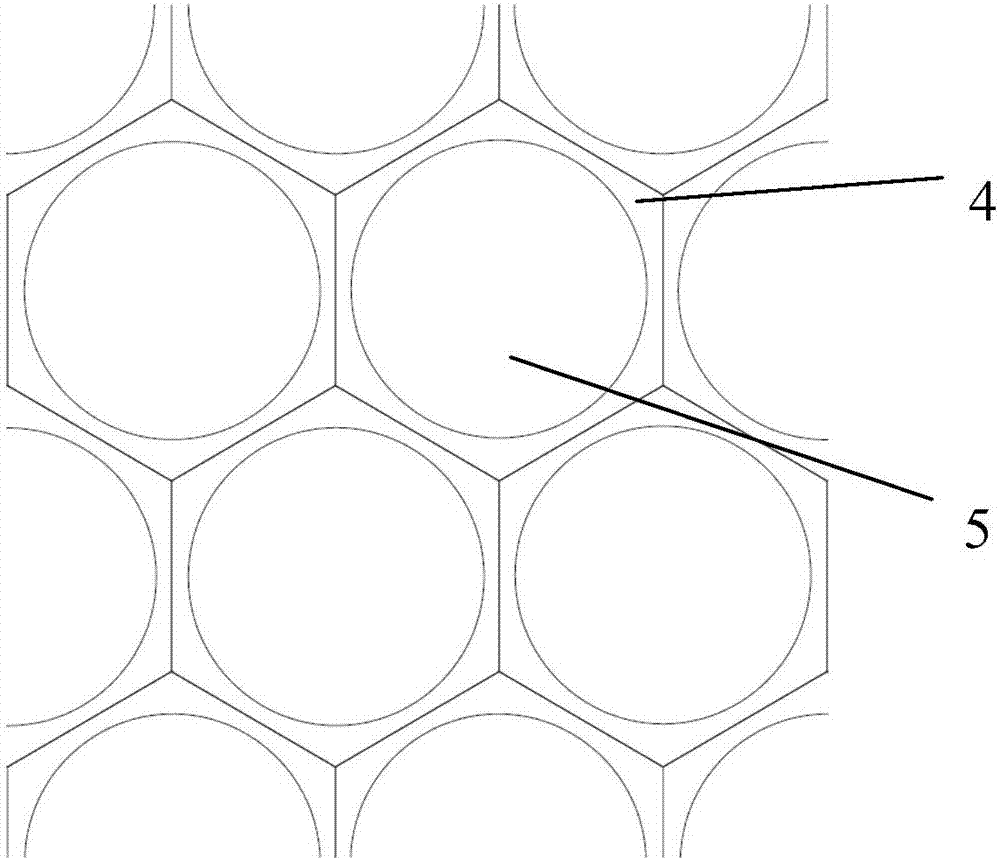

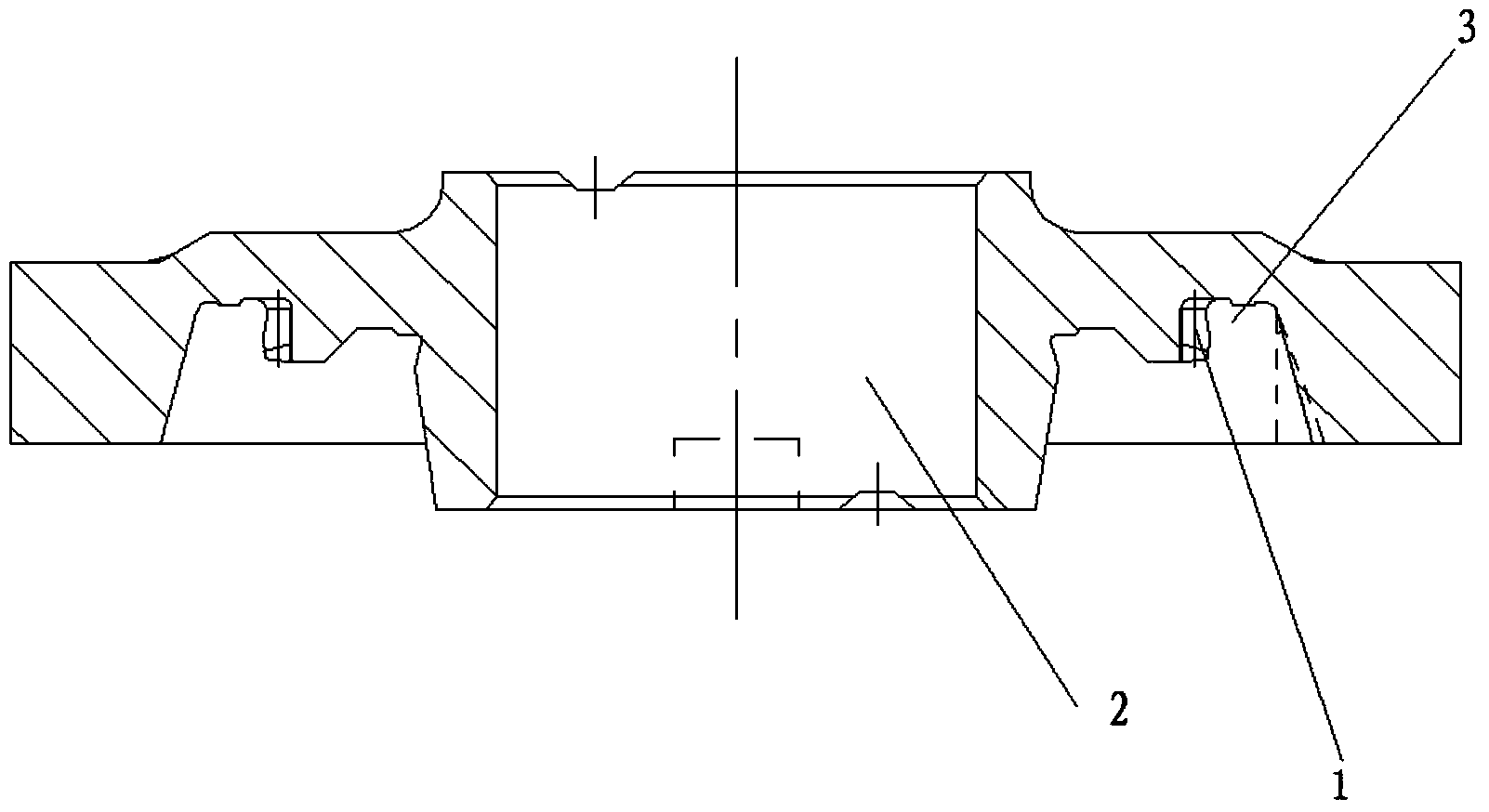

Preparation method for copper-niobium composite rod for Nb3Sn superconducting wire with high critical current density

ActiveCN107170526AReduce processing stepsImprove efficiencySuperconductors/hyperconductorsApparatus for heat treatmentThermal insulationNiobium

The invention discloses a preparation method for a copper-niobium composite rod for an Nb3Sn superconducting wire with high critical current density. The method comprises the following steps of firstly, processing an oxygen-free copper rod into an outer hexagonal inner-circle thin-wall copper pipe; secondly, placing an Nb rod into the hexagonal copper pipe, placing the hexagonal copper pipe into an oxygen-free copper sheath, placing the oxygen-free copper rod at the central zone of the oxygen-free copper sheath and sealing to obtain a CuNb composite sheath; and lastly, carrying out heating, thermal insulation and extrusion on the CuNb composite sheath to obtain the CuNb composite rod. According to the method, the Nb rod with the fine initial grain size is placed into the hexagonal thin-wall copper pipe to carry out assembly, welding and extrusion to obtain the CuNb composite rod, so that the processing of a CuNb single rod is removed, and the problems of line breakage and core breakage after stretch in the subsequent processing process of the superconducting wire, which are caused by uneven texture after extrusion due to the coarse initial grain size of an Nb ingot, are solved, the efficiency is improved and the quality risk of the processing process is reduced.

Owner:西安聚能超导线材科技有限公司

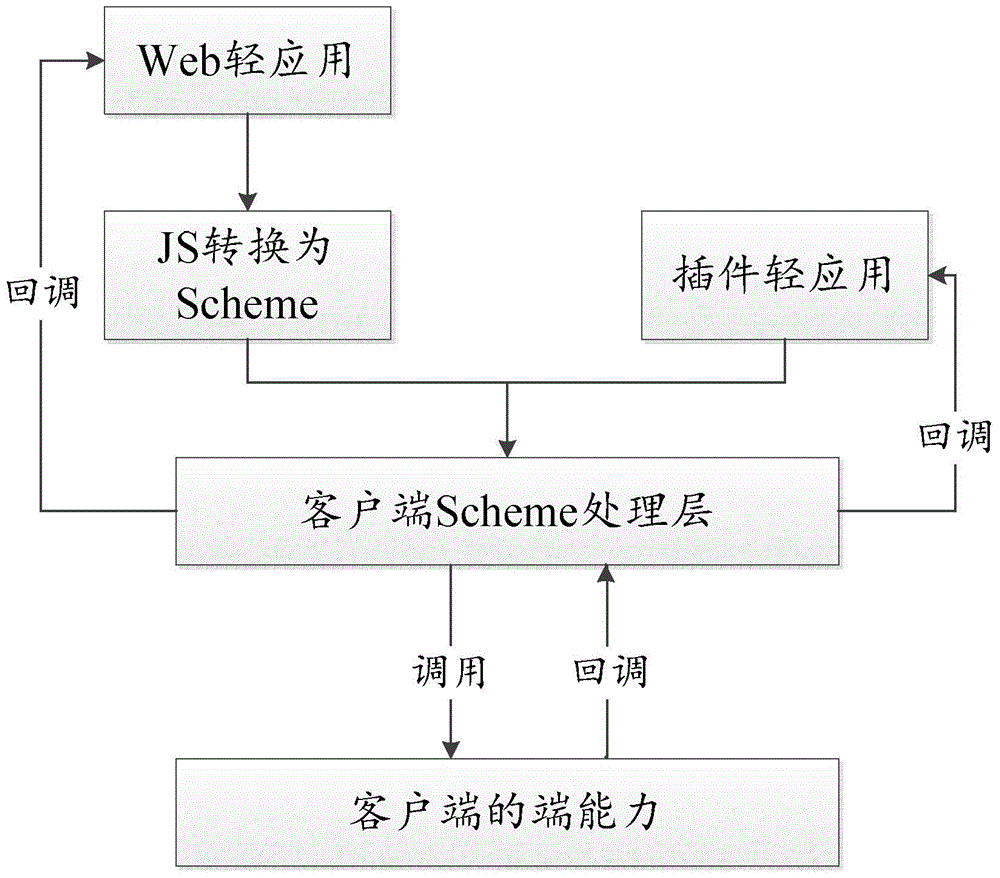

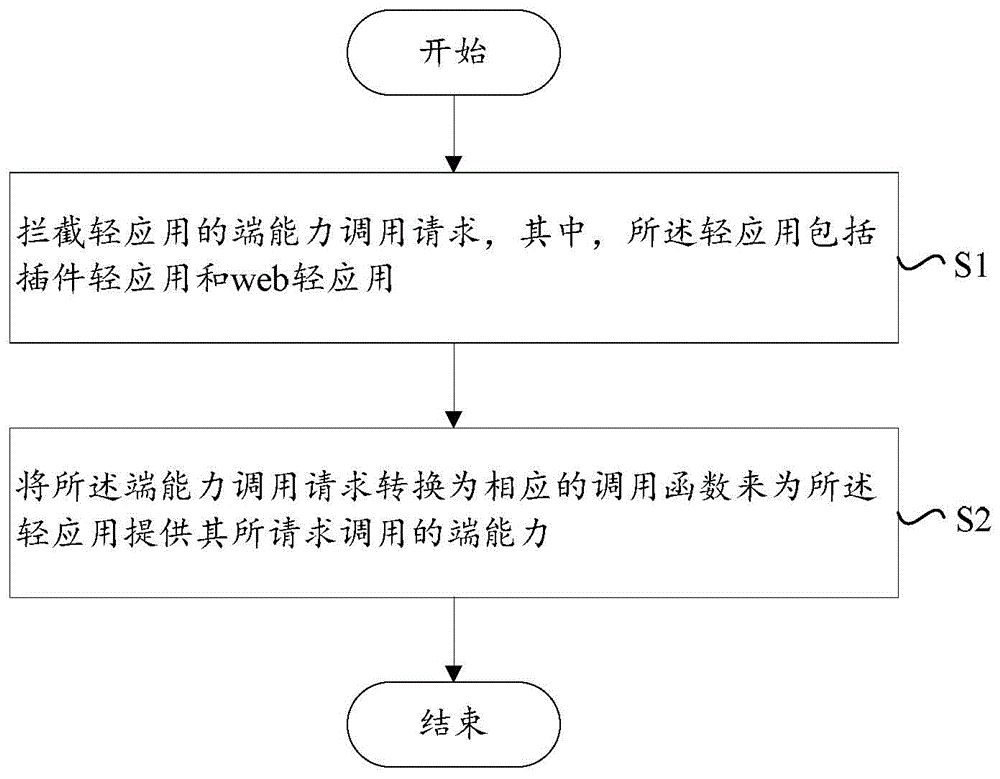

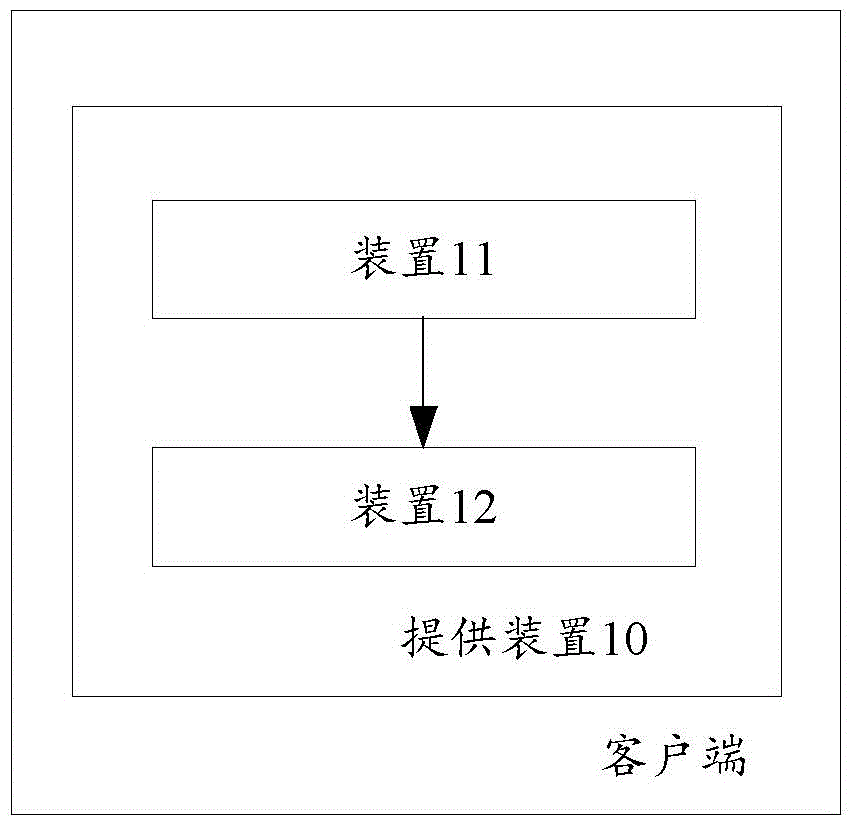

Method and apparatus for providing end capabilities of client for light application

ActiveCN104883384AReduce development costsLower access costsProgram loading/initiatingTransmissionOperating systemDistributed computing

The invention aims to provide a method and apparatus for providing end capabilities of a client for a loaded light application at a client. According to the invention, call requests of loaded light applications for end capabilities of a client is intercepted by the client in a unified way, and the call requests for the end capabilities are transformed into corresponding call functions for providing the requested end capabilities for the light applications. The light applications which can be loaded at the client comprise plug-in light applications and web light applications. On the one hand, unified standards can be formed for the access of light applications at the client, so that the client can become a platform of the light applications; and on the other hand, the access cost of different plug-in light applications can be reduced, the development cost of the client can therefore be reduced, and quality risks brought by the joint development of the client and a product are also reduced.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

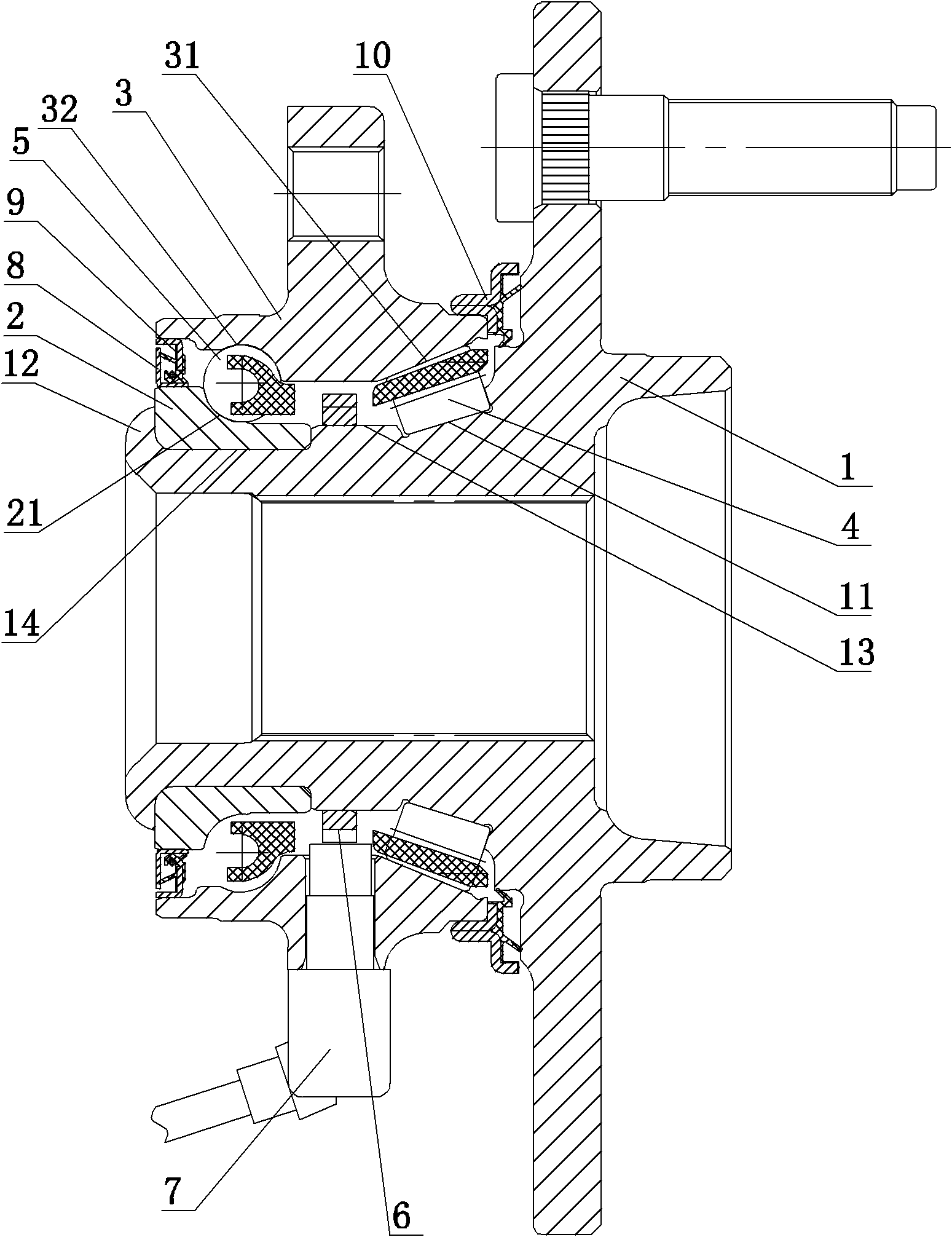

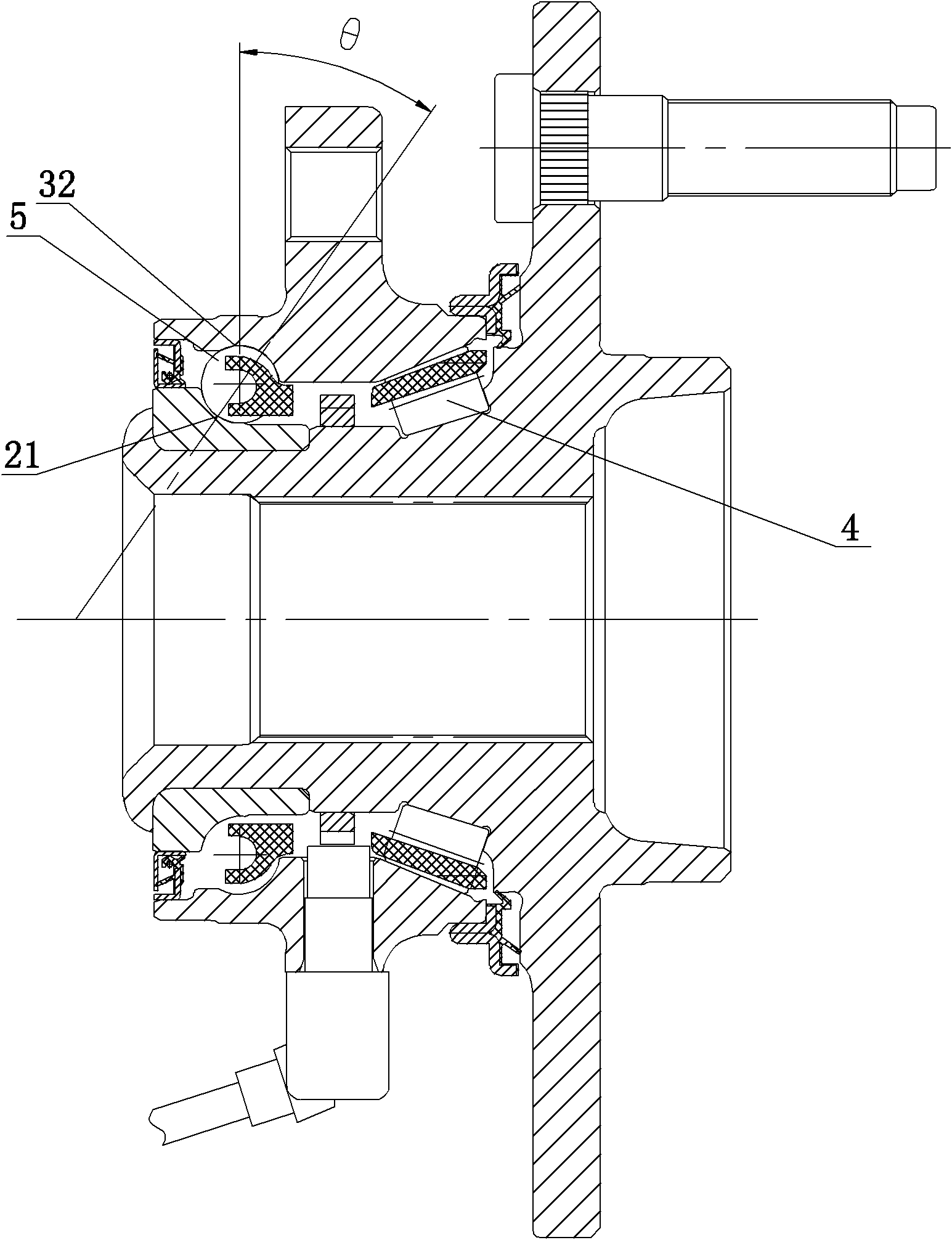

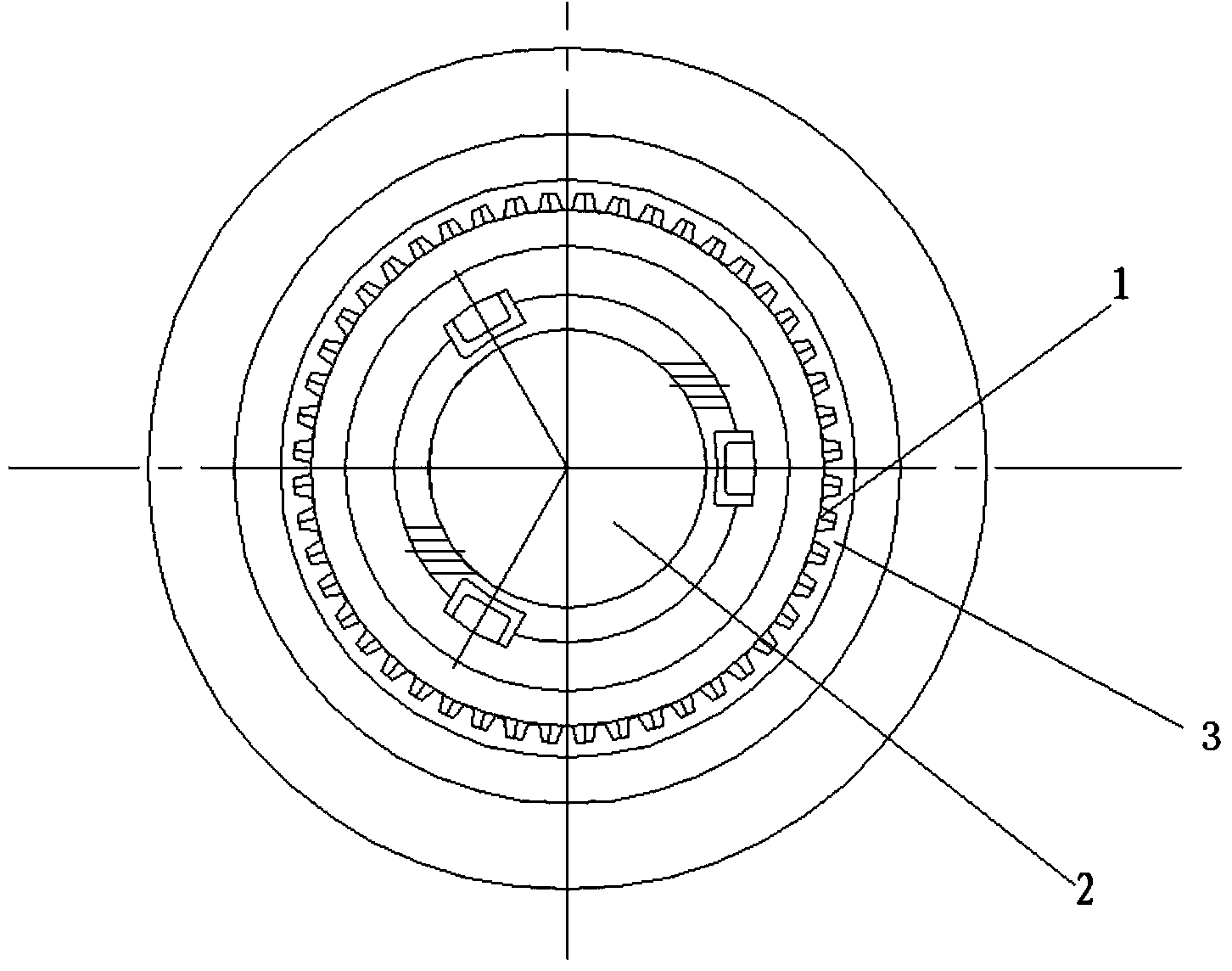

Composite type automobile hub bearing unit

ActiveCN102141080AReduce frictional torqueImprove reliabilityBearing assemblyHubsBall bearingNeck parts

The invention discloses a composite type automobile hub bearing unit which comprises a flange large inner ring, a small inner ring and an outer ring, wherein the end part of the flange large inner ring is provided with a turned edge; the neck part of the flange large inner ring is provided with a step; the small inner ring is fixed on a shaft neck between the turned edge and the step by the turned edge; the step on the neck part of the flange large inner ring is provided with a conical outer roller path; the small inner ring is provided with a spherical outer channel; the inner side of the outer ring is provided with a conical inner roller path and a spherical inner channel; a tapered roller is arranged between the conical outer roller path and the conical inner roller path; and a ball roller is arranged between the spherical outer channel and the spherical inner channel. In the technical scheme of the invention, a bearing with greater stress at the inner side is designed into a tapered roller type, a bearing with smaller stress at the outer side is designed into an angular-contact ball bearing structure, so that the hub bearing unit hardly has early failure, simultaneously the quality risk brought about by the complex manufacturing can be reduced, and the reliability of a unit assembly can be improved better.

Owner:ZHEJIANG ZHAOFENG MECHANICAL & ELECTRONICS CO LTD

Self-adhesive rubber polymer water-proof caulking compound and preparation method thereof

InactiveCN104130469AReduces the risk of scale errors creating quality issuesReduce quality riskPolymer scienceAntioxidant

The invention relates to a self-adhesive rubber polymer water-proof caulking compound and a preparation method thereof. The self-adhesive rubber polymer water-proof caulking compound is prepared from the following components in parts by weight: 10-25 parts of vacuum side cut 3 oil, 10-20 parts of a tackifying resin, 10-25 parts of thermoplastic styrene butadiene rubber, 20-40 parts of BR rubber, 10-20 parts of a softening agent, 0.1-1 part of an anti-aging agent, 0.2-1 part of a flame retardant and 0.2-1 part of an antioxidant. The preparation method comprises the following steps: adding the vacuum side cut 3 oil and the tackifying resin into a mixer, heating the mixture, and stirring the heated mixture till the mixture is dissolved completely; adding the thermoplastic styrene butadiene rubber, and uniformly stirring the mixture by rotating at a high speed; fully grinding the mixture, putting the ground mixture into the mixer, adding the BR rubber, and continuing to stir the mixture at a high speed for certain minutes; adding the softening agent, and stirring the mixture at a high speed for certain minutes; and adding the anti-aging agent, the flame retardant and the antioxidant, stirring the mixture uniformly, and cooling the mixture for molding. The self-adhesive rubber polymer water-proof caulking compound has the beneficial effects that the risk of quality problems caused by proportional errors in a dual field can be lowered to the maximum extent, the subsequent problems of cracking, glue failure, unevenness and the like occurring after construction are solved, and the occurrence of fire disasters in the processes of production, transportation and construction can be effectively prevented.

Owner:中联天盛建材集团有限公司

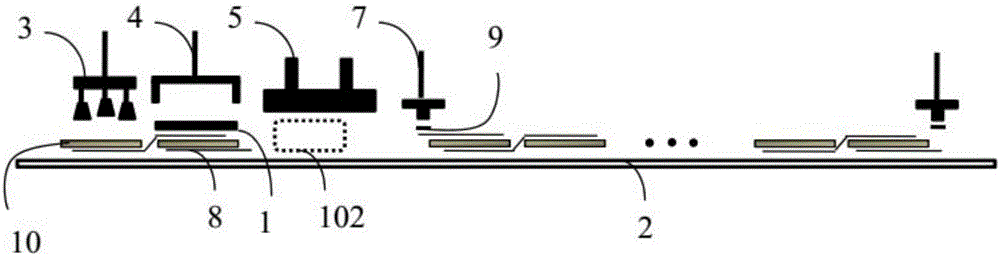

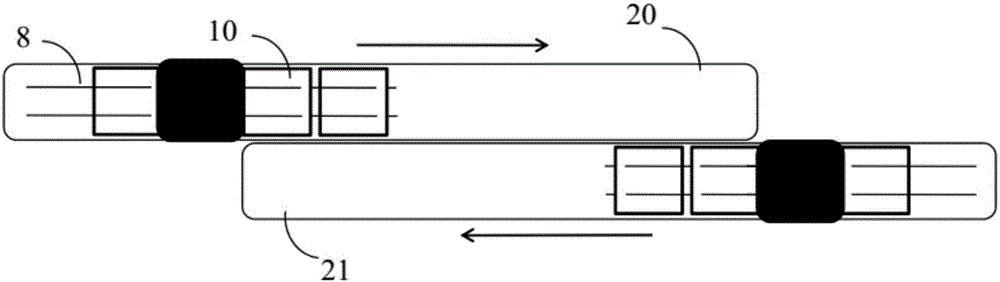

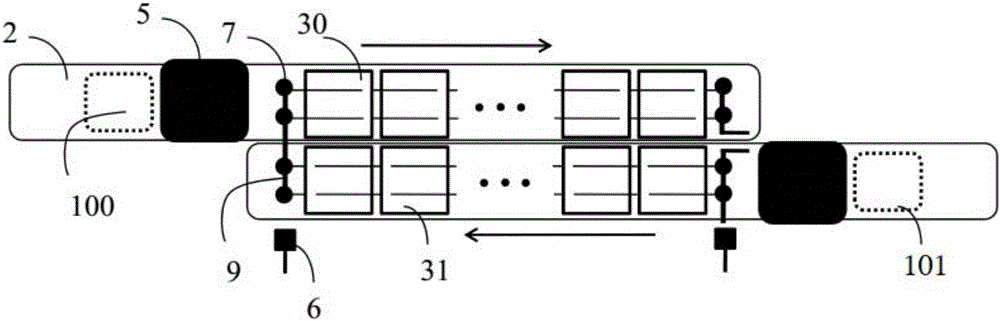

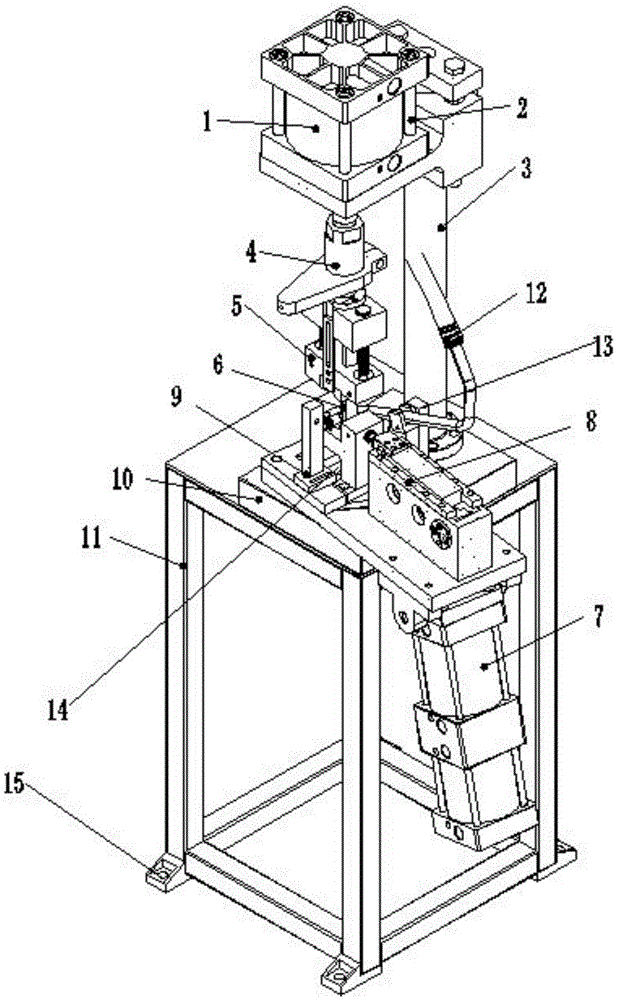

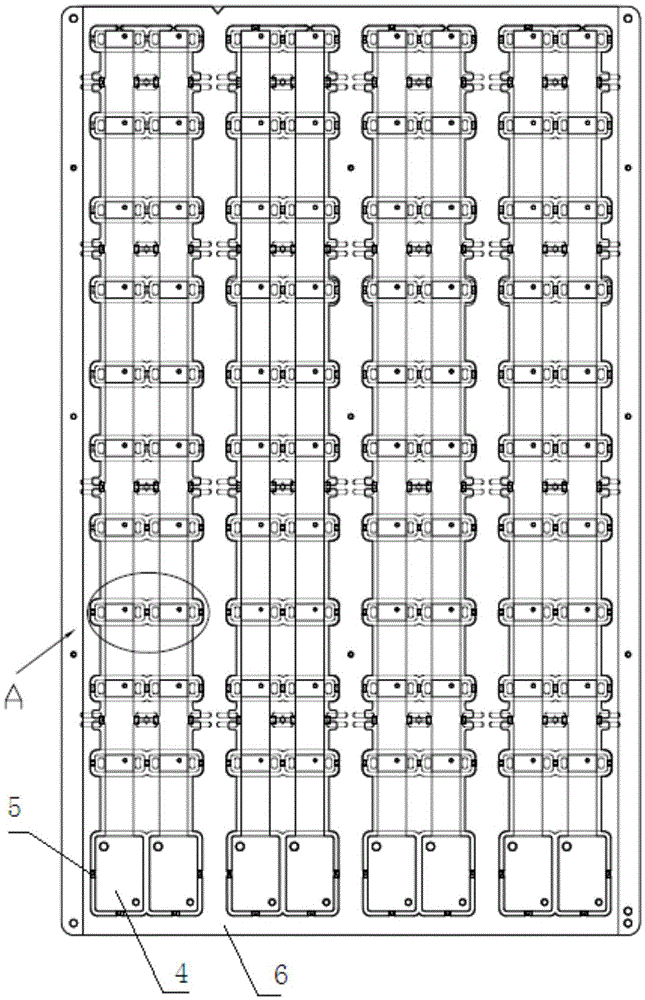

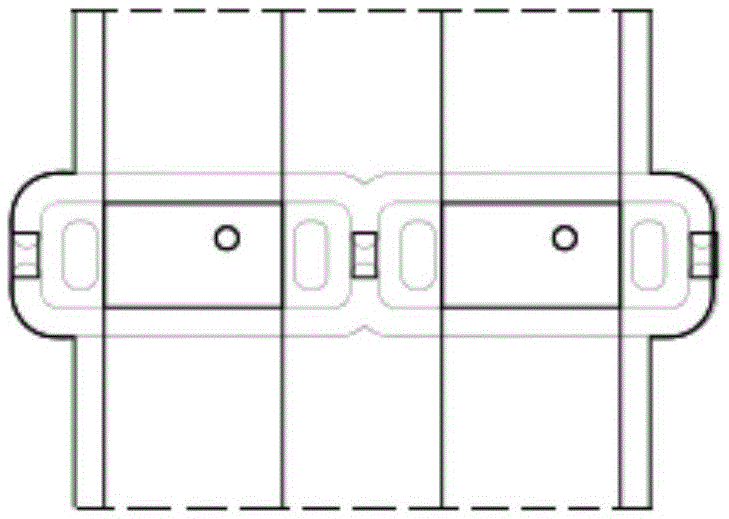

Series welding device for solar photovoltaic cells and series welding method

InactiveCN106229381ASave human effortIncrease productivityFinal product manufactureSemiconductor/solid-state device manufacturingInterconnectionConveyor belt

The invention discloses a series welding device for solar photovoltaic cells and a series welding method, belongs to the technical field of photovoltaic module manufacturing equipment and solves a problem of low production efficiency of the existing series welding device. The series welding device for the solar photovoltaic cells, which is provided by the invention, comprises a conveyor belt, a cell tong, a welding base module, an interconnection strip welding table and a confluence strap welding table which are arranged on the conveyor belt, and a confluence strap tong which is arranged on one side of the conveyor belt, wherein the welding base module comprises a welding base used for clamping a to-be-welded interconnection strip and a welding base tong which is arranged on the welding base, and the welding base tong is used for placing the to-be-welded interconnection strip into a default zone of the conveyor belt; the cell tong is used for placing to-be-welded cells into the default zone of the conveyor belt; and the interconnection strip welding table is used for welding the to-be-welded interconnection strip and to-be-welded cells. According to the series welding device disclosed by the invention, the production efficiency is greatly improved. The invention also provides a series welding method based on the series welding device.

Owner:ALTUSVIA ENERGY TAICANG

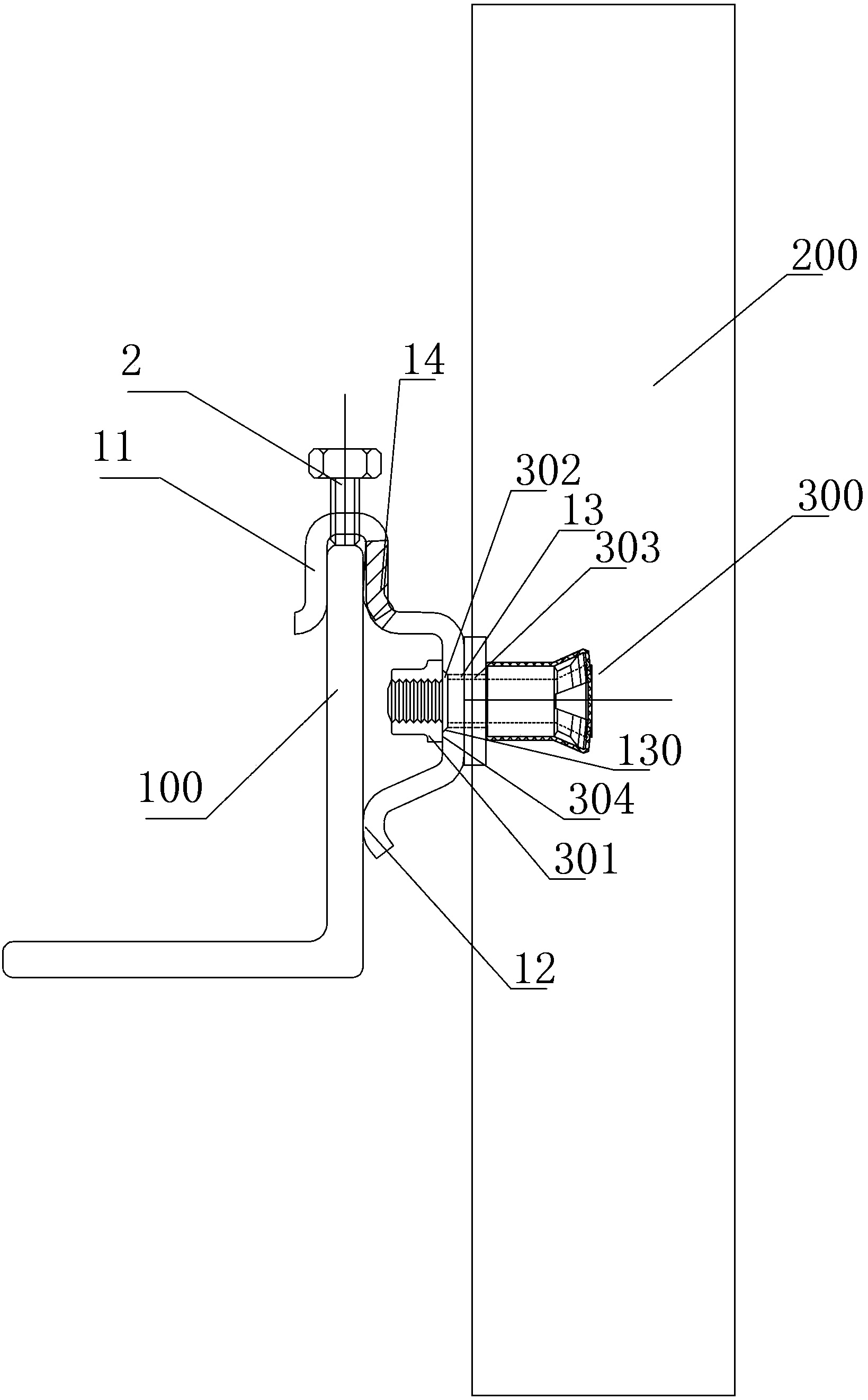

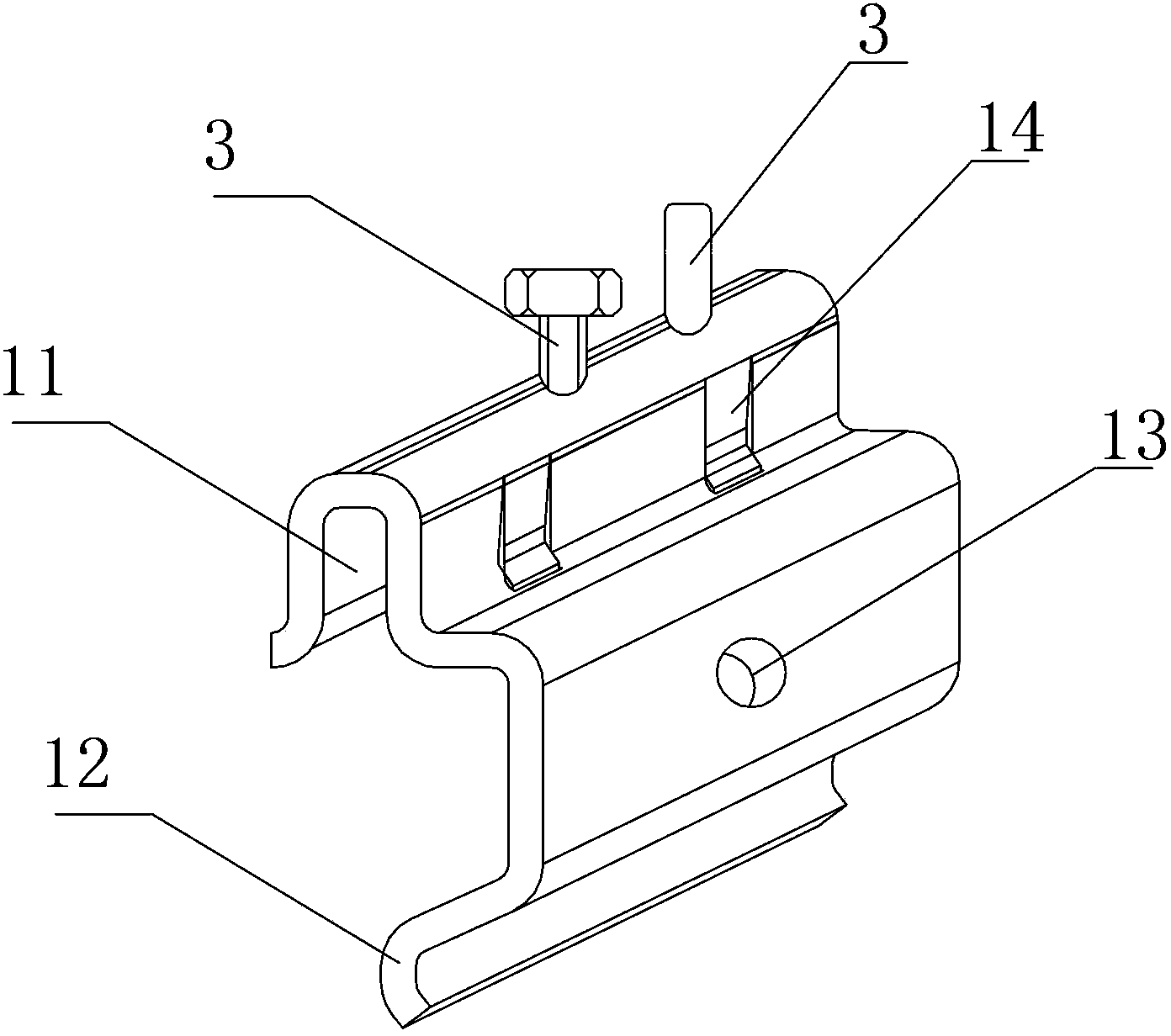

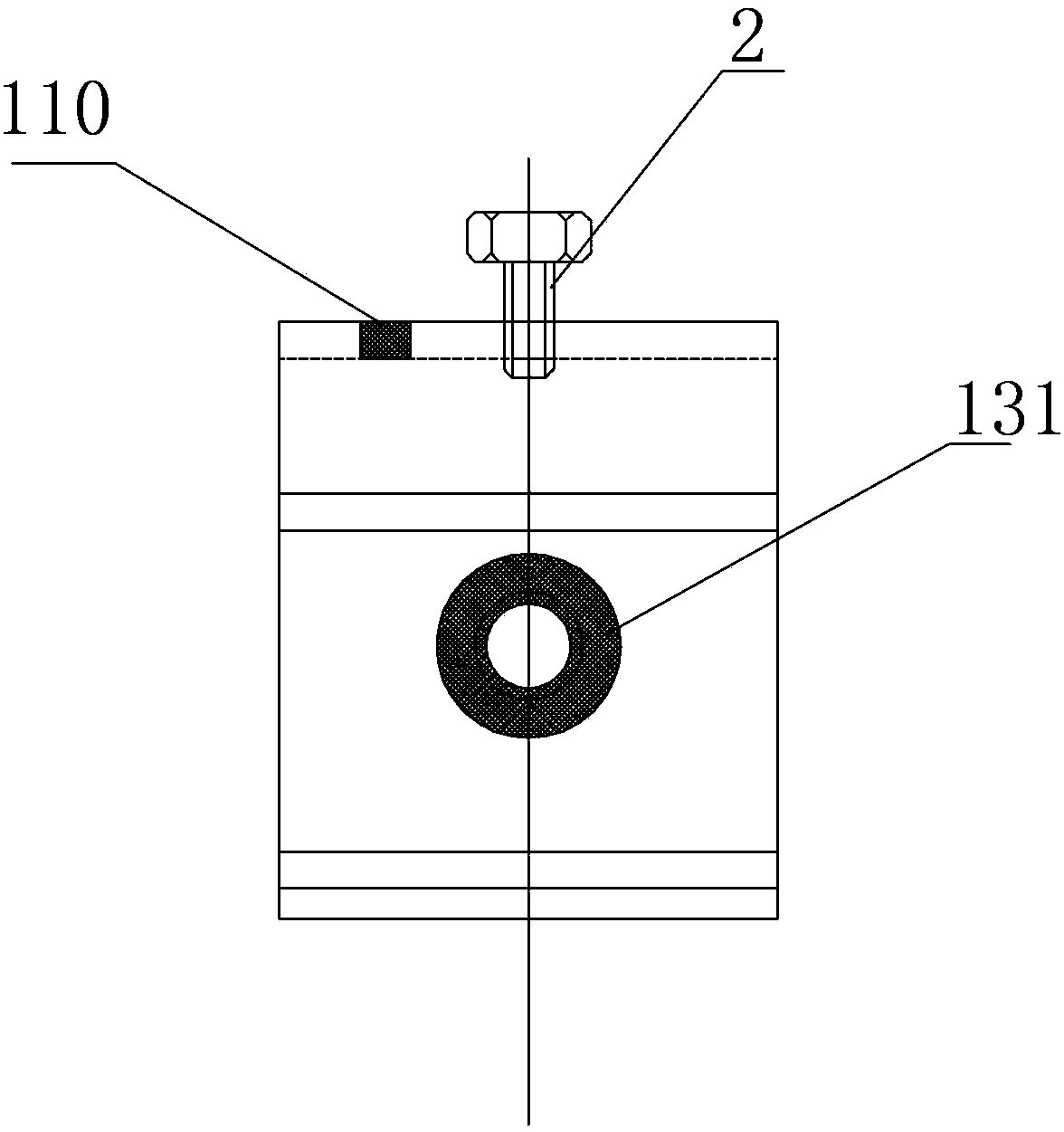

Curtain wall hook member

The invention provides a curtain wall hook member. A hook is arranged on the upper portion of a main body of the curtain wall hook member, an abutting portion or an abutting component is arranged on the lower portion of the main body, a connecting hole is formed in the middle of the main body, an elastic portion is formed in a metal plate by means of punching and bending and is positioned on the upper portion of the main body, or a hole for mounting an elastic component is formed in the metal plate and is positioned on the upper portion of the main body, the elastic component is mounted in the hole, and the elastic portion and the elastic component are used for compensating for dimensional clearance between a hook member carrying component and the hook of the hook member. The curtain wall hook member has the advantages that the elastic portion, the abutting portion and the hook are combined with one another, so that the hook member can be firmly hooked on the hook member carrying component, is simple in structure, and further has a height adjusting function and a transverse thermal expansion displacement prevention function, and a mutual embedding rotation and displacement prevention positioning function can be realized when the curtain wall hook member is connected with a fastener, so that the fastener and the hook member can be permanently prevented from being loosened without secondary welding, curtain wall mounting quality risks are greatly reduced, and the curtain wall mounting cost is lowered.

Owner:斯泰科技(杭州)有限公司

Polyurethane for CMP polishing pad and preparation method of polyurethane

The invention belongs to the technical field of polyurethane application, and particularly relates to polyurethane for a CMP polishing pad and a preparation method of the polyurethane. The polyurethane for the CMP polishing pad comprises a polyurethane prepolymer component A and a curing agent component B. The component A is composed of polymeric polyol A, diisocyanate and an anti-hydrolysis agent, and the component B is composed of an amine chain extender, polymeric polyol B, a hollow filler, a plasticizer and a catalyst. The structures of prepolymer molecules are arranged more regularly, andthe forming speed is high; the stability is good; the quality risk is reduced; the high-content prepolymer component does not crystallize at room temperature, has low initial viscosity, and has higher proportion when being mixed with the curing agent component, the uniform mixing is easier, consistency of hardness and uniformity after slicing of the prepared product is guaranteed, the breakage rate of electronic elements in the later polishing process is greatly reduced, and on the basis of micro-foaming, the hollow filler is added, so that the product has longer service life and storage lifeand good mechanical performance.

Owner:SHANDONG INOV POLYURETHANE

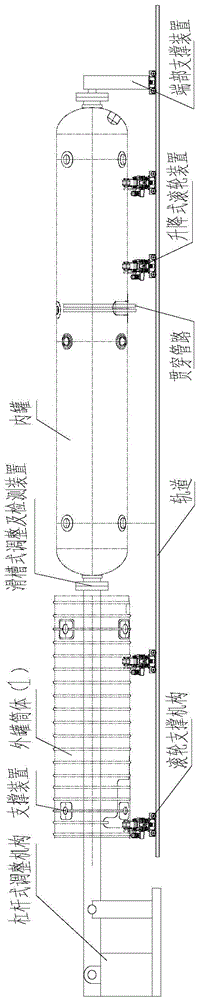

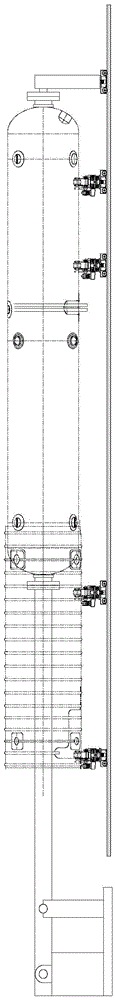

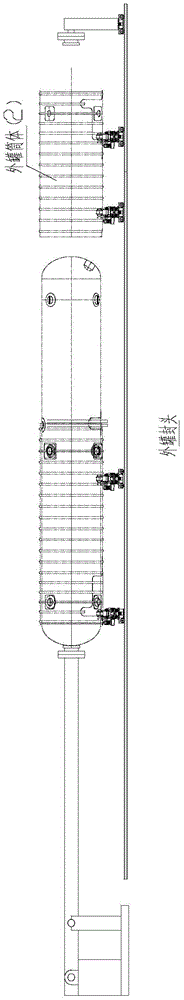

Tank sleeving technological method of railway tank car of double-layer structure

ActiveCN105458609AReduce quality riskAvoid defective productsWelding/cutting auxillary devicesAuxillary welding devicesManufacturing efficiencyProcess control

The invention relates to a tank sleeving technological method of a railway tank car of a double-layer structure. The technological method includes the steps that firstly, one side of an inner tank body and one side of an outer-tank barrel matched with the inner tank body are assembled, wherein one side of the inner tank body and one side of an outer tank body are adjusted by supporting and positioning one side of the outer-tank barrel, and the sleeved outer-tank barrel and the inner tank body are supported and fixed; secondly, the other side of the inner tank body and the other side of the outer-tank barrel matched with the inner tank body are assembled, wherein the other side of the outer-tank barrel and the other side of the inner tank body are adjusted to move relatively, and the sleeved outer-tank barrel and the inner tank body are supported and fixed; thirdly, the two sides of the completely-sleeved outer-tank barrel are overall adjusted, and a circular seam at a combined portion is welded; and finally, end sockets on the two sides are assembled and welded. According to the tank sleeving technological method, quality risks are reduced, all the technical indexes can be more easily guaranteed, and defective products are avoided; the influences of human factors on the quality are eliminated to the maximum degree, and process control is more easily controlled; and the influence of auxiliary time on the production takt is reduced, and the product manufacturing efficiency is improved.

Owner:CRRC YANGTZE CO LTD

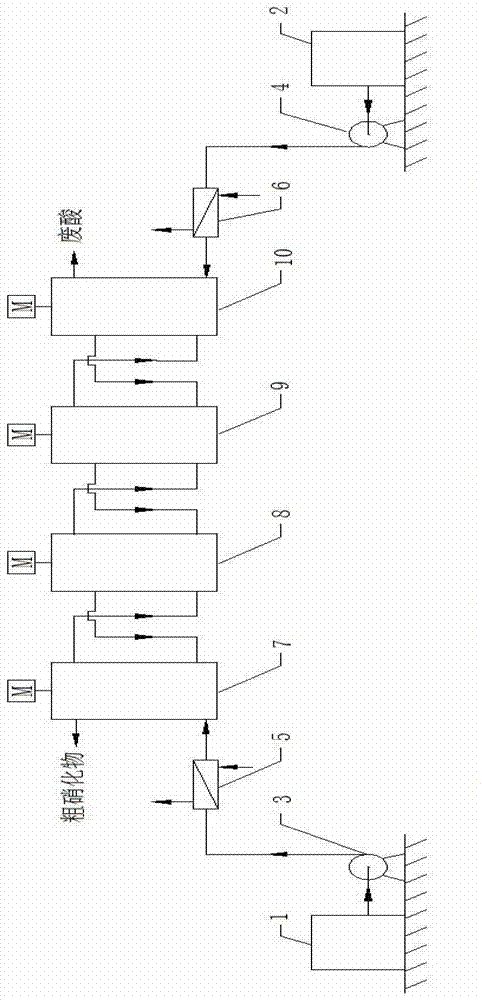

Safe production method of nitro-compound

ActiveCN103044261AHigh yieldLow costNitric acid ester preparationNitro compound preparationNitro compoundAutomatic control

The invention provides a production method of nitro-compound. The production method comprises the steps of: continuously feeding a mixed acid solution from a heavy-phase inlet of a first centrifugal extraction separation device of a nitration separation system disclosed by the invention, and continuously feeding a raw material to be nitrified from a light-phase inlet of a final centrifugal extraction separation device at the same time, wherein the reaction temperature inside each centrifugal extraction separation device is controlled at 10-160 DEG C, and the rotating speed of each centrifugal extraction separation device is controlled at 800-2000 r / min; after multi-stage continuous nitration reaction, discharging final coarse nitride from a light-phase outlet of the first centrifugal extraction separation device, and discharging final waste acid from a heavy-phase outlet of the final centrifugal extraction separation device; and carrying out common alkali washing and water washing on the coarse nitride, and distilling the coarse nitride to obtain the refined nitro-compound product. According to the method disclosed by the invention, the nitration reaction is continuously carried out; the device is compact, easy to achieve automatic control, large in operation elasticity, and high in production efficiency; and as the reaction product and the waste acid are separated from each other at the same time inside the same reactor, the contact time of the reaction product and the waste acid is greatly shortened, side reaction is effectively avoided, energy consumption and material consumption are greatly reduced, and the security of the nitration reaction process is fundamentally ensured.

Owner:徐德良 +1

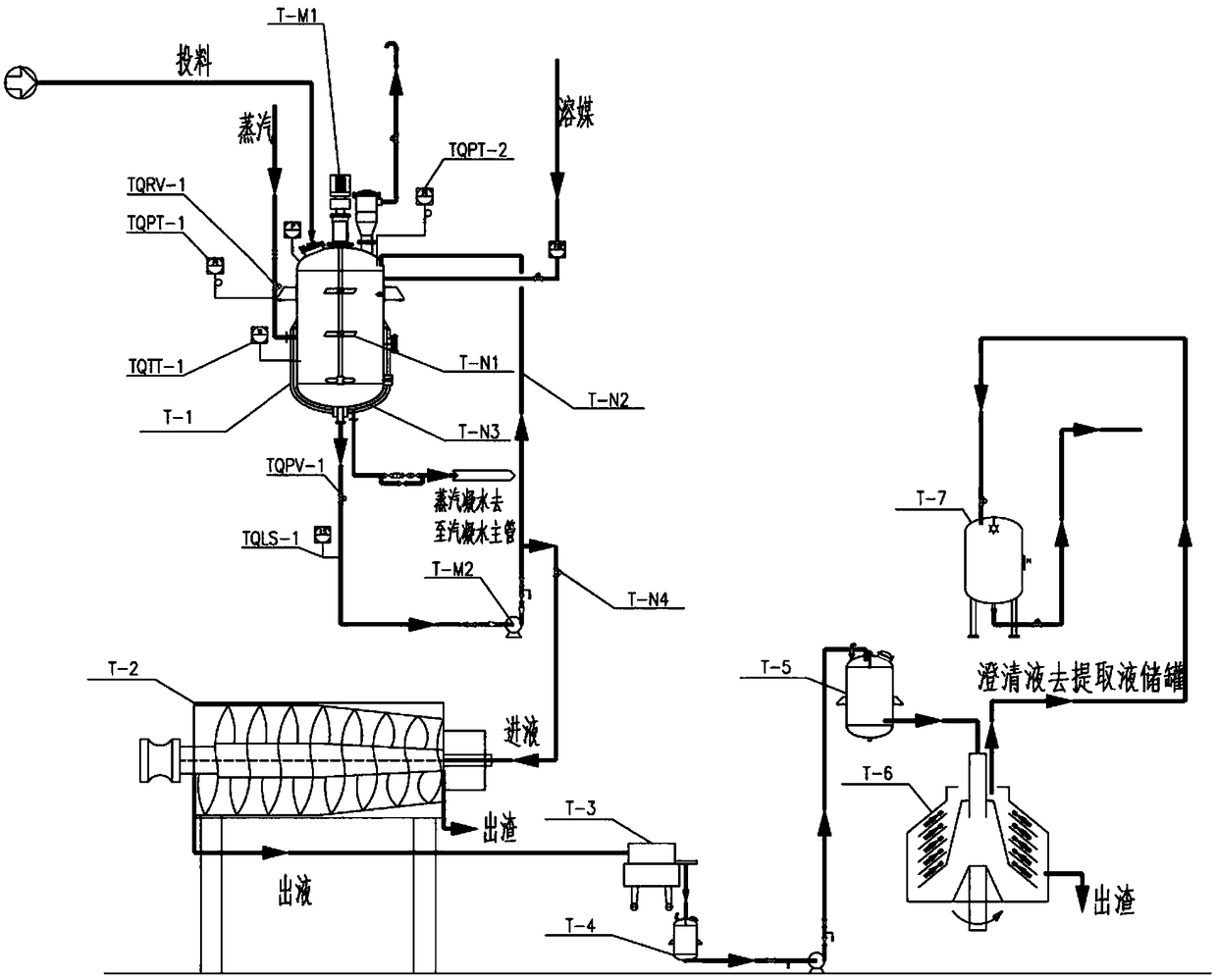

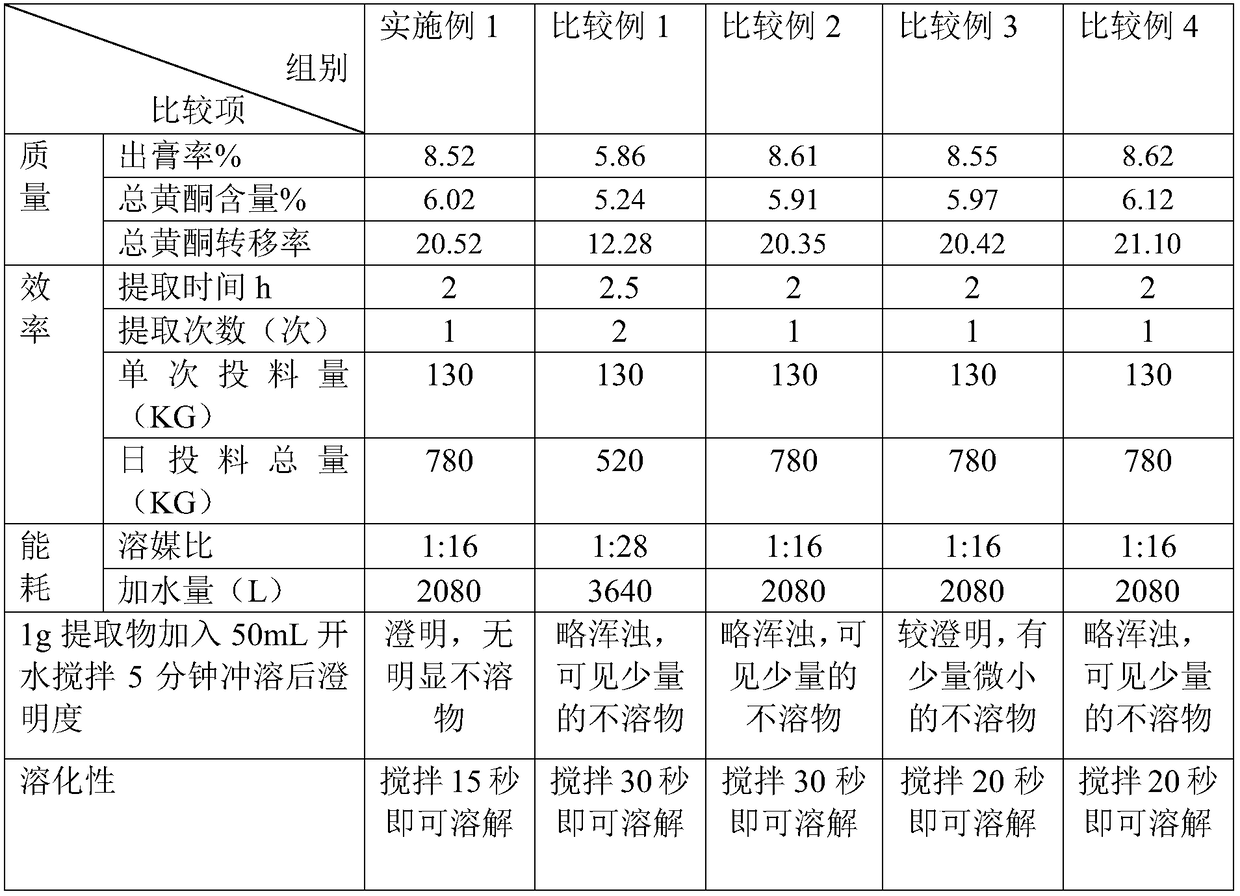

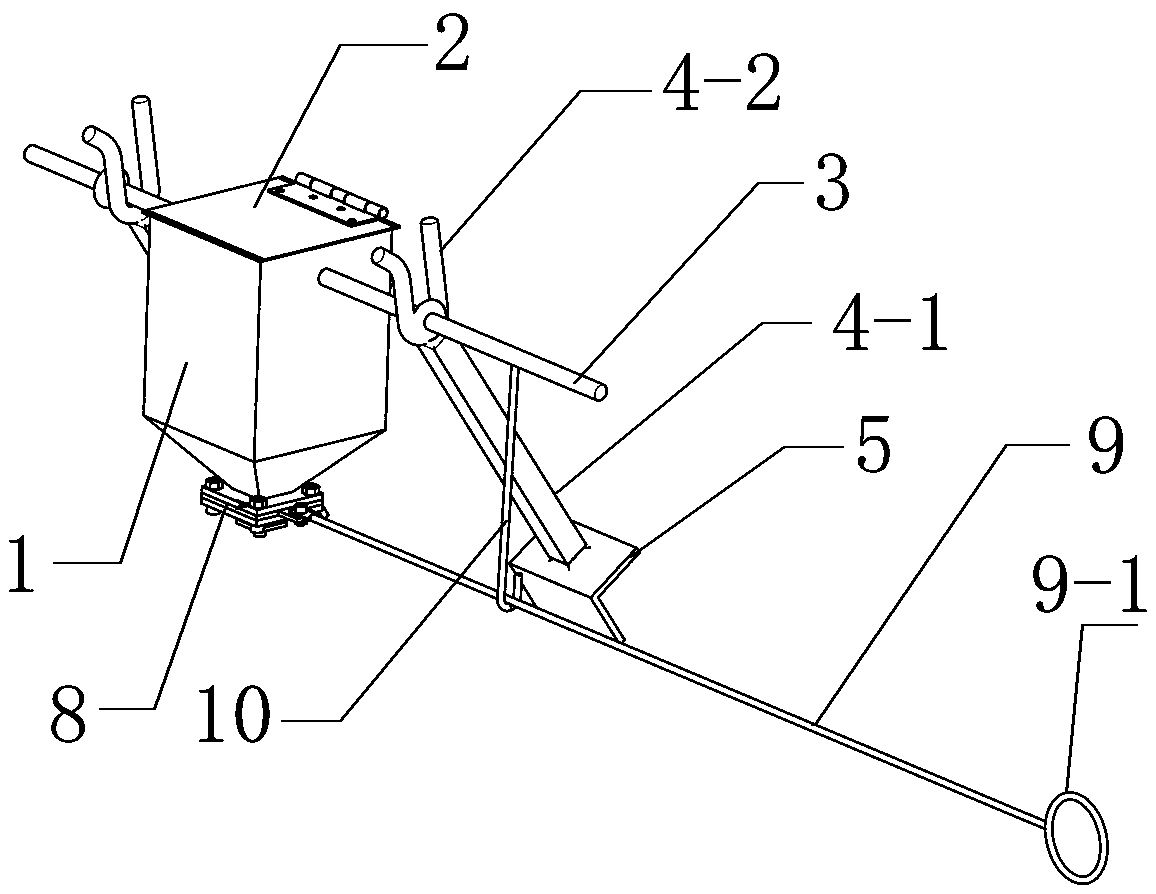

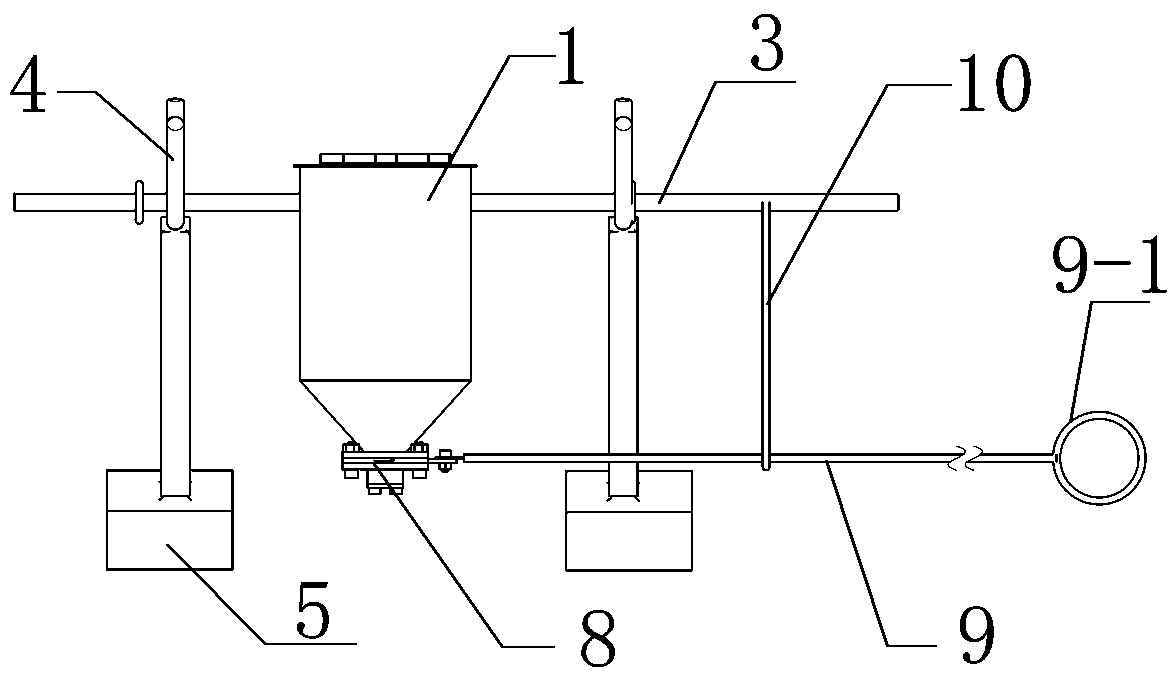

Traditional Chinese medicine automatic extraction and separation device and extraction and separation method and application thereof

PendingCN109126191ADissolves quicklySolve easy blockageSolid solvent extractionFiltration circuitsFiltrationSeparation method

The invention relates to a traditional Chinese medicine automatic extraction and separation device and an extraction and separation method and an application thereof. The traditional Chinese medicineautomatic extraction and separation device is characterized in that the extraction and separation device comprises a dynamic extraction tank and a combined solid-liquid separation module; after extraction, extraction solution and dregs in the dynamic extraction tank are introduced into the combined solid-liquid separation module for solid-liquid separation; the combined solid-liquid separation module comprises three solid-liquid separation devices. The traditional Chinese medicine automatic extraction and separation device has the advantages of improving the adaptability of traditional Chinesemedicine extraction and the filtration efficiency of traditional Chinese medicine extracts, strengthening separation, and reducing production cost and consumption.

Owner:JIANGYIN TIANJIANG PHARMA

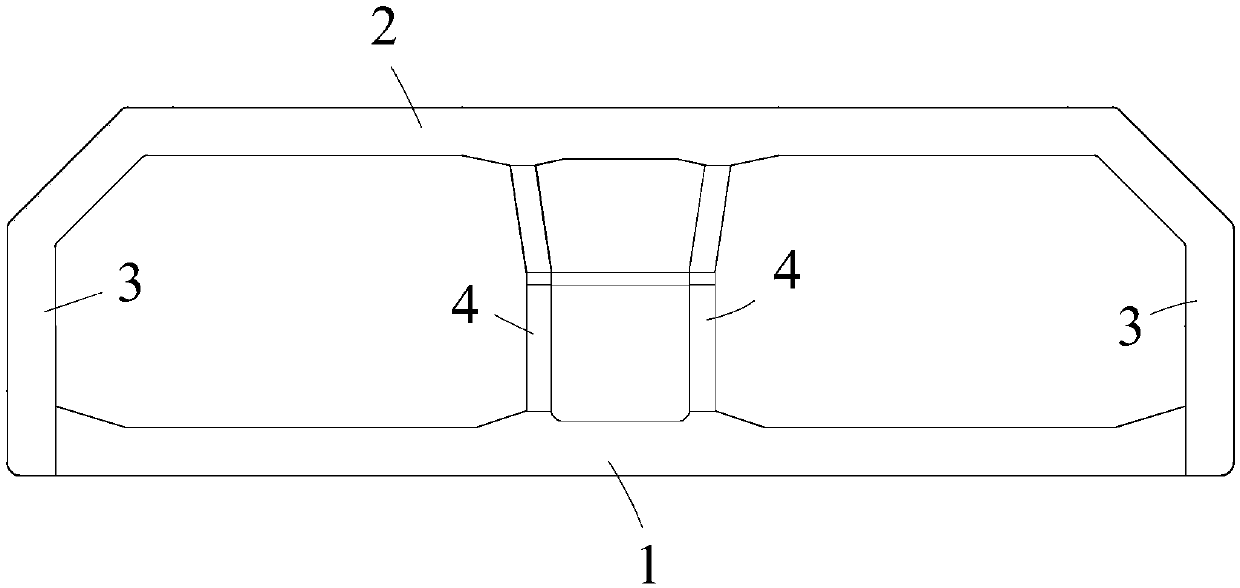

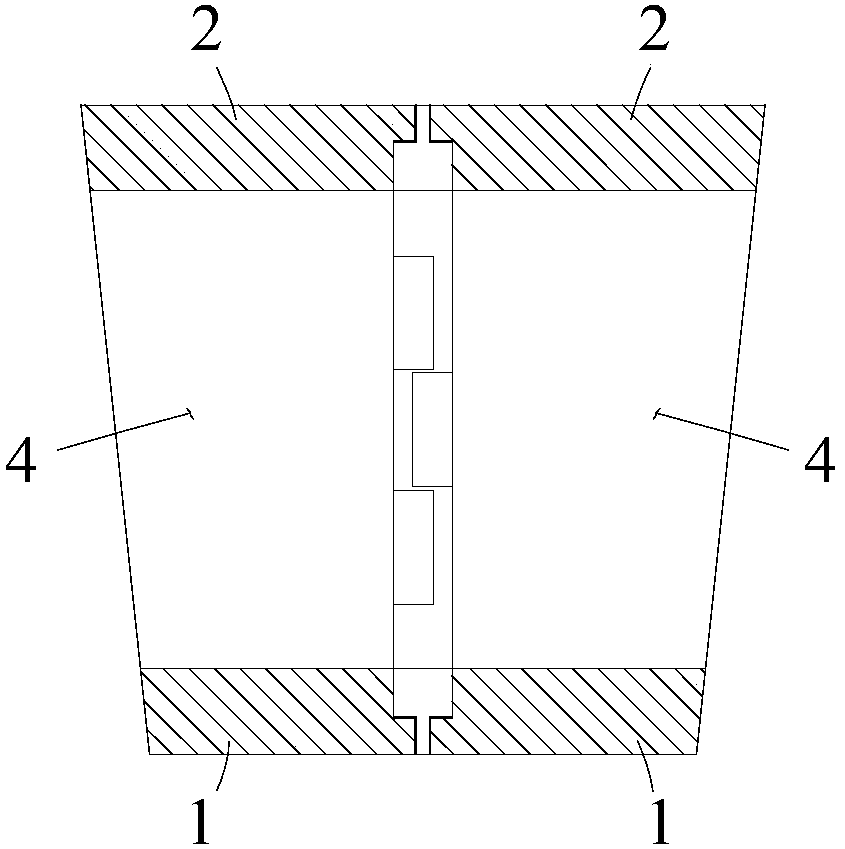

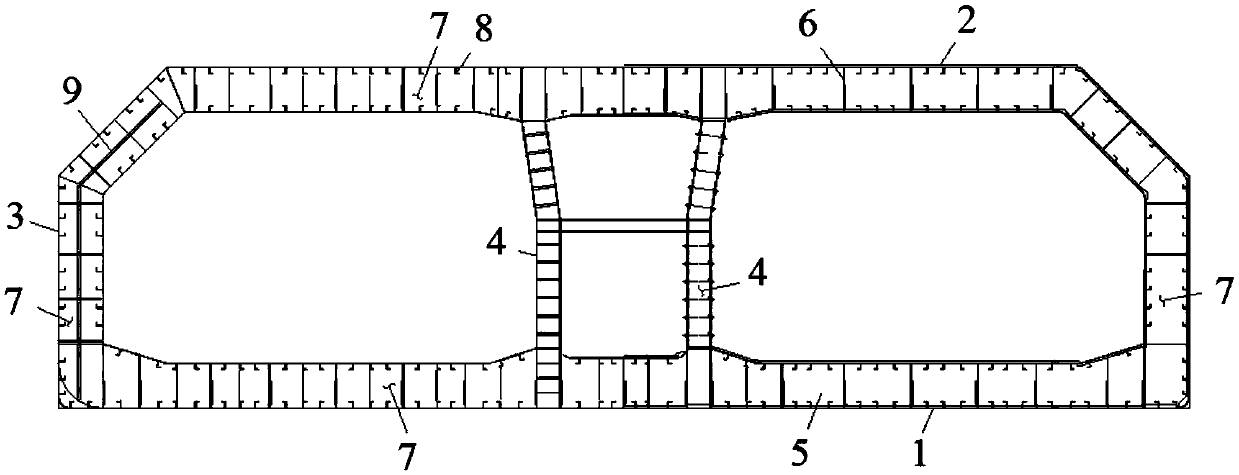

Sandwich sinking pipe connector and production method thereof

ActiveCN107620321AGuaranteed stiffnessGuaranteed StrengthArtificial islandsUnderwater structuresUltimate tensile strengthSeabed

The invention discloses a sandwich sinking pipe connector and a production method thereof. The sinking pipe connector comprises an annular steel structure shell composed of a bottom plate, a top plateand side walls connected between the bottom plate and the top plate, the shell is internally provided with a plurality of longitudinal partition plates and transverse partition plates, and all the transverse partition plates and longitudinal partition plates partition the shell into a plurality of mutually-independent compartment units. Each compartment unit is further internally provided with aplurality of stiffening plates and filled with concrete. According to the sandwich sinking pipe connector, in the adopted steel structure shell, the stiffening plates can be in rigid connection with the compartment units in longitudinal and transverse directions, and when each compartment unit is cast again, it is ensured that a shell body and the filled concrete deform jointly, so that the situation that slippage occurs between the bottom plate and the concrete interface, the top plate and the concrete interface as well as the side walls and the concrete interface is prevented, and thus the rigidity and the strength of the sinking pipe connector are ensured so as to adapt to the seabed sinking pipe requirement; and forming is achieved at a time, subsequent maintenance can be omitted, theusing requirement for 120-year durability can be met, and stability is good.

Owner:CCCC HIGHWAY CONSULTANTS

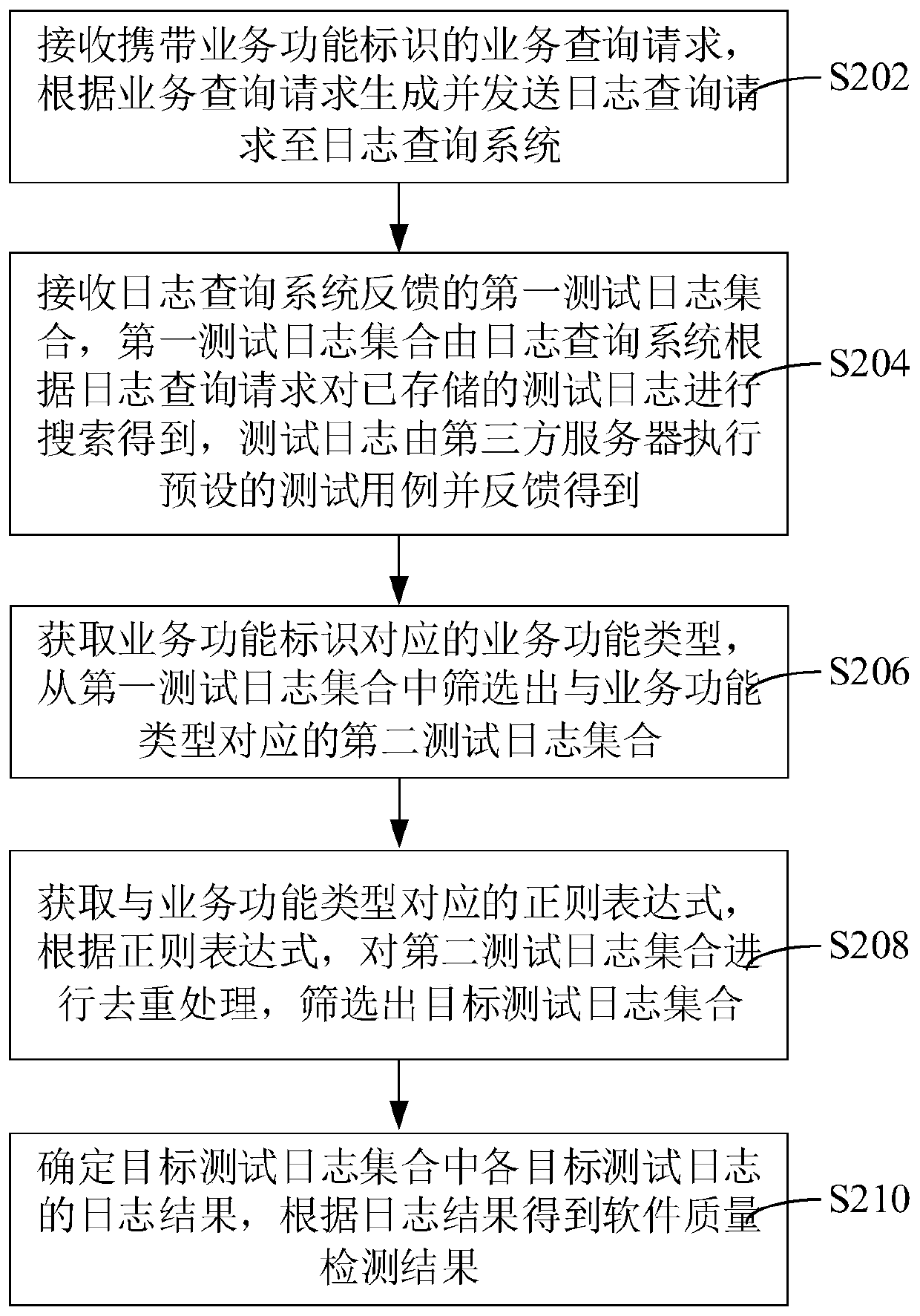

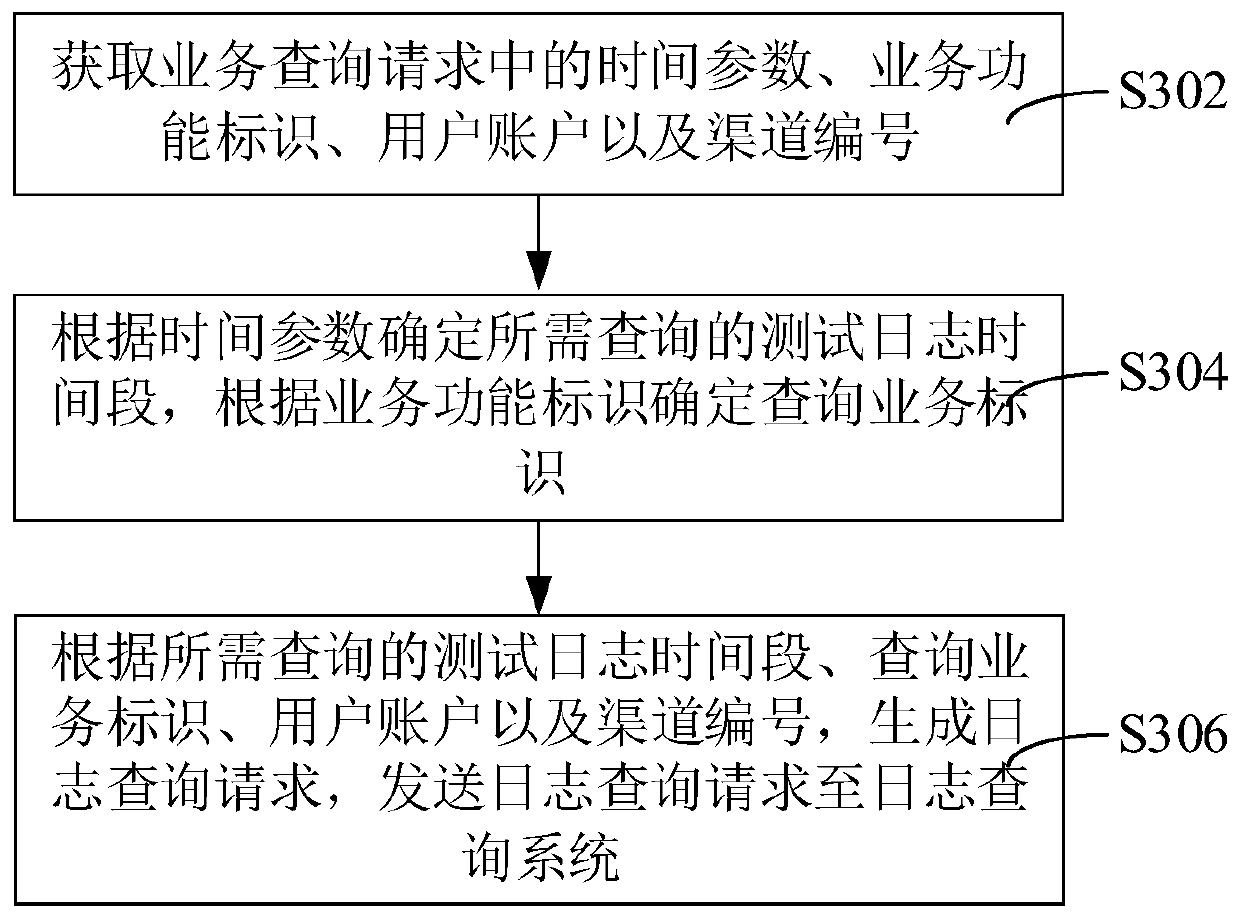

Software quality detection method and device, computer equipment and storage medium

PendingCN110727567ARealize qualityReduce quality riskHardware monitoringProcessingRegular expression

The invention relates to the technical field of software monitoring, and provides a software quality detection method and device, computer equipment and a storage medium. The software quality detection method comprises the following steps: receiving a service query request carrying a service function identifier, generating and sending a log query request to a log query system according to the service query request, receiving a first test log set fed back by the log query system, obtaining a service function type corresponding to the service function identifier, screening out a second test logset corresponding to the service function type from the first test log set, and obtaining a regular expression corresponding to the service function type, performing duplicate removal processing on the second test log set according to the regular expression, screening out a target test log set, determining a log result of each target test log in the target test log set, and obtaining a software quality detection result according to the log result. By adopting the software quality detection method, the quality of new version software can be understood, and the quality risk is reduced.

Owner:PING AN SECURITIES CO LTD

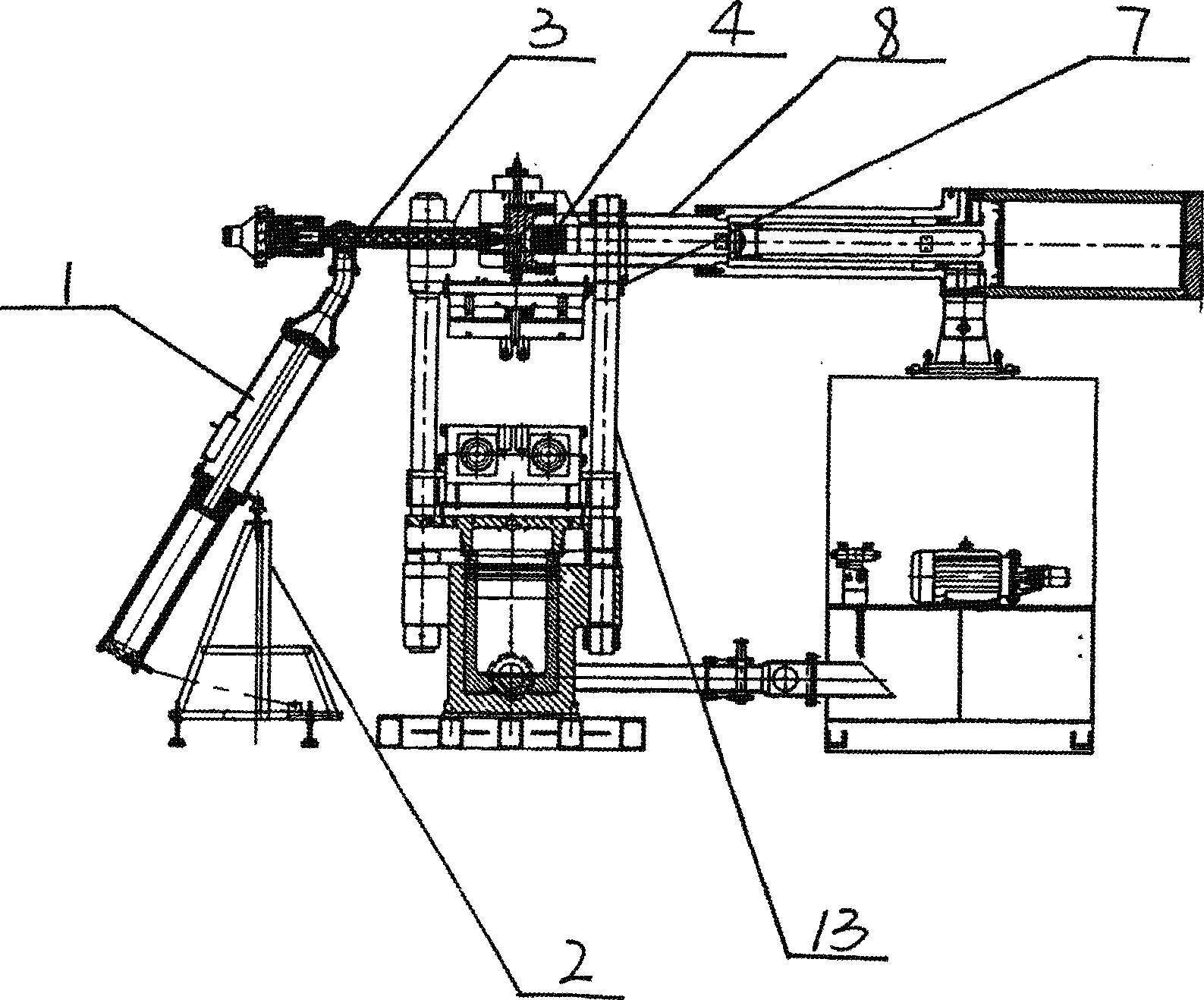

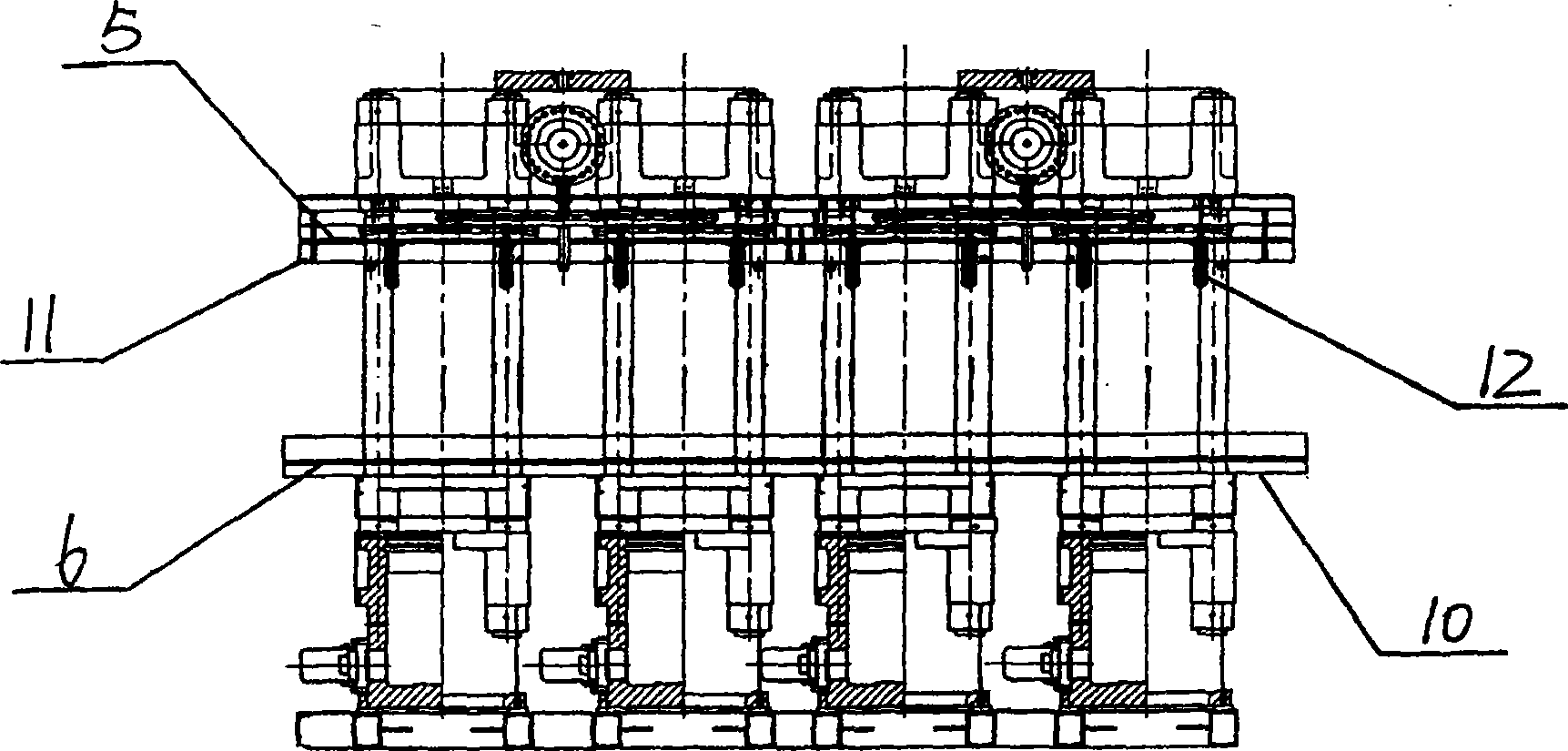

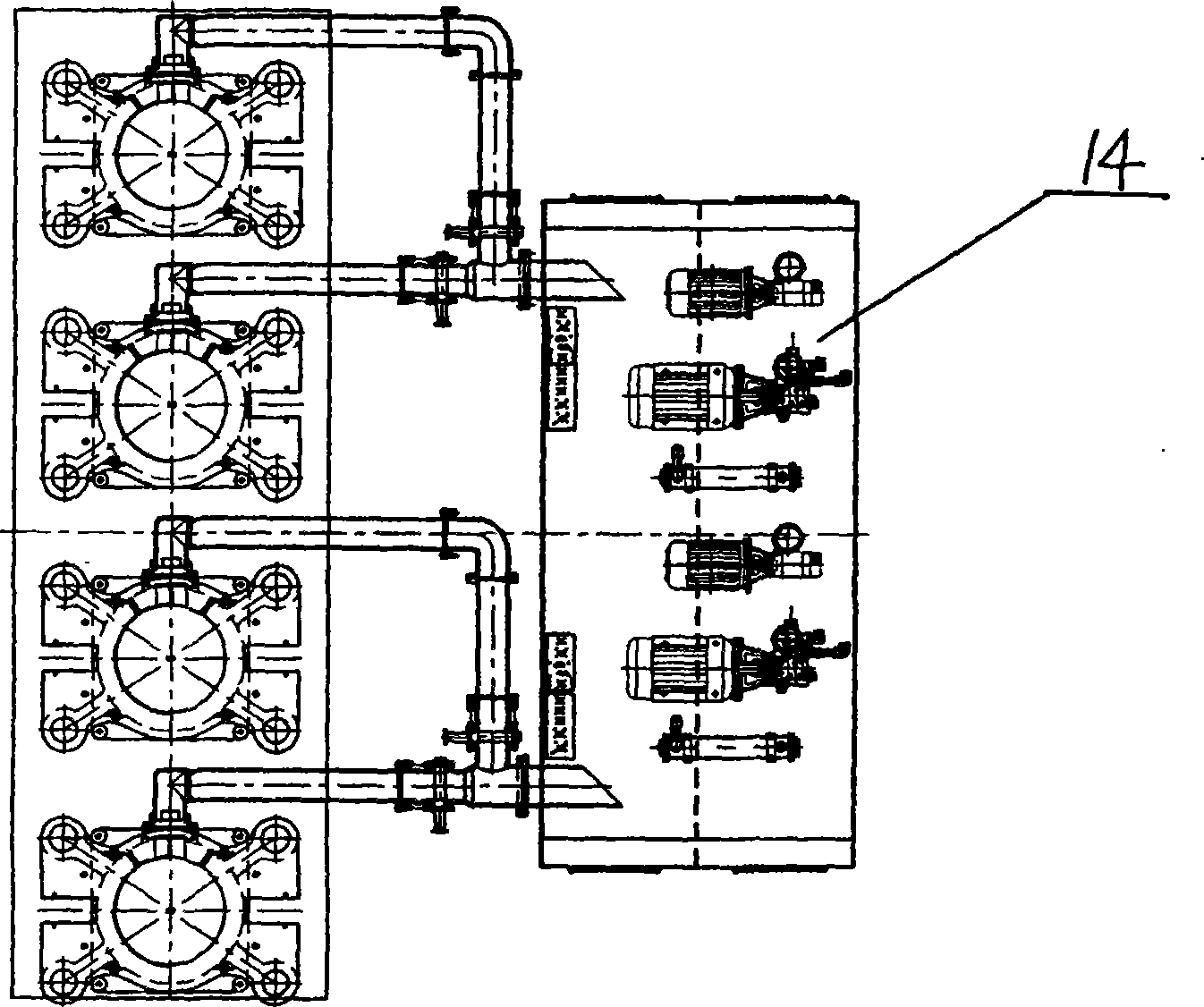

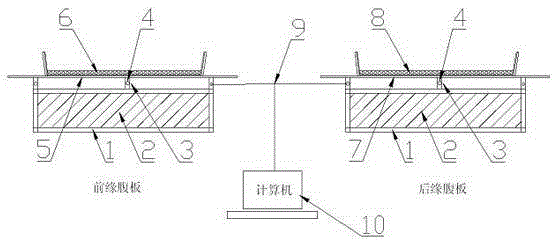

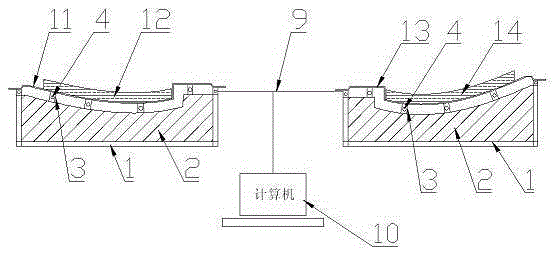

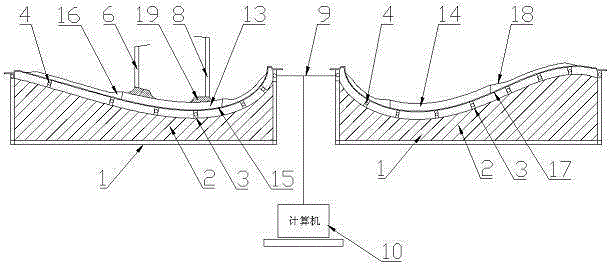

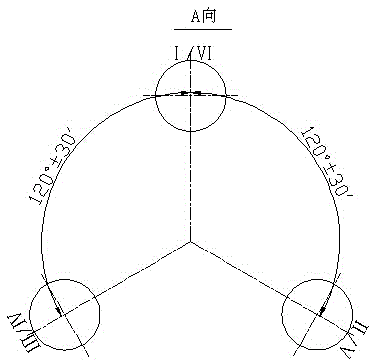

Double module injection molding technique of extra-high voltage combined insulator

InactiveCN101386199AIncreased stressorsReduce intermediate linksCoatingsComposite insulatorsAlternating current

The invention discloses a process for forming an extra-high voltage composite insulator with the voltage class of 1000kV alternating current and minus 800 to 800kV direct current by two-mould injection. In the process, a mandrel is arranged in a mould and is injected with glue stock through preheating the mandrel and the mould, and the extra-high voltage composite insulator is finished at a specific temperature condition. The manufacture process can reduce intermediate links in the process, and improve the manufacture efficiency, mainly because forming equipment of the extra-high voltage composite insulator is used in the process. The equipment is divided into an upper mould and a lower mould, wherein the upper mould and the lower mould are respectively clad by a platen heater; lengths of the moulds and the platen heaters are over 5.5 meters; and the upper mould and the lower mould are respectively connected with two groups of hydro-cylinders as power source; therefore, the uniform and stable effect of injection moulding of the extra-high voltage composite insulator can be ensured through lengthening the moulds and using the two groups of hydro-cylinders as pressure source. Furthermore, the process makes uses of a hydraulic mode for forming, thus not only reducing the risk of quality problem of the product possibly formed by reconnection of sectional production, but also reducing the working procedures.

Owner:JIANGSU CHANGGONG ELECTRIC POWER EQUIP

Novel air conditioner pipeline perforating device

InactiveCN105618858AAvoid processShorten production hoursLarge fixed membersPunchingDrilling machines

The invention discloses a novel air conditioner pipeline perforating device which comprises a cutting assembly, a punching assembly, a support assembly and a perforating tool, wherein the cutting assembly comprises a clamping cylinder, a cylinder seat, a support shaft, a connecting shaft sleeve, a clamping seat and a tool bit assembly; the clamping cylinder is fixed on the support shaft by the cylinder seat and connects the clamping seat with the tool bit assembly by the connecting shaft sleeve; the other end of the support shaft is fixed with the support assembly for connection; the punching assembly comprises a top punching cylinder and a punching device; the punching device is fixed on the support assembly; and a blade on the tool bit assembly and a tool bit at the front end of the punching device both align with the pipeline perforating tool. The novel air conditioner pipeline perforating device avoids the procedures of chamfering and blowing-out of aluminium skimmings, caused by use of conventional drilling machines for perforating, and production hours are saved and quality risk is reduced.

Owner:HEFEI JIANGHUAI AUTOMOBILE PIPE

Wind-power blade preparation method capable of controlling mass distribution

ActiveCN105383074ASingle point counterweight avoid or reduceSingle point counterweight reductionDomestic articlesElectricityMolar mass distribution

The invention belongs to the technical field of nonmetallic composite material machining and forming and mainly relates to a wind-power blade preparation method capable of controlling mass distribution. The wind-power blade preparation method capable of controlling the mass distribution comprises the steps of preparation of a blade upper shell, preparation of a blade lower shell, preparation of a front edge web, preparation of a rear edge web, preparation of a girder and blade die assembly and adhesion forming. Control over the weight and mass distribution is conducted in the processes of the preparation of the blade upper shell, preparation of the blade lower shell, preparation of the front edge web, preparation of the rear edge web, preparation of the girder and blade die assembly and adhesion, and thus control over the mass distribution of the wind-power blade is achieved. The final mass distribution of the blade can be controlled within a certain range, later-stage single-point balance weight of the blade is avoided or reduced, and the quality and security risks of the single-point balance weight are reduced.

Owner:LUOYANG SUNRUI WIND TURBINE BLADE

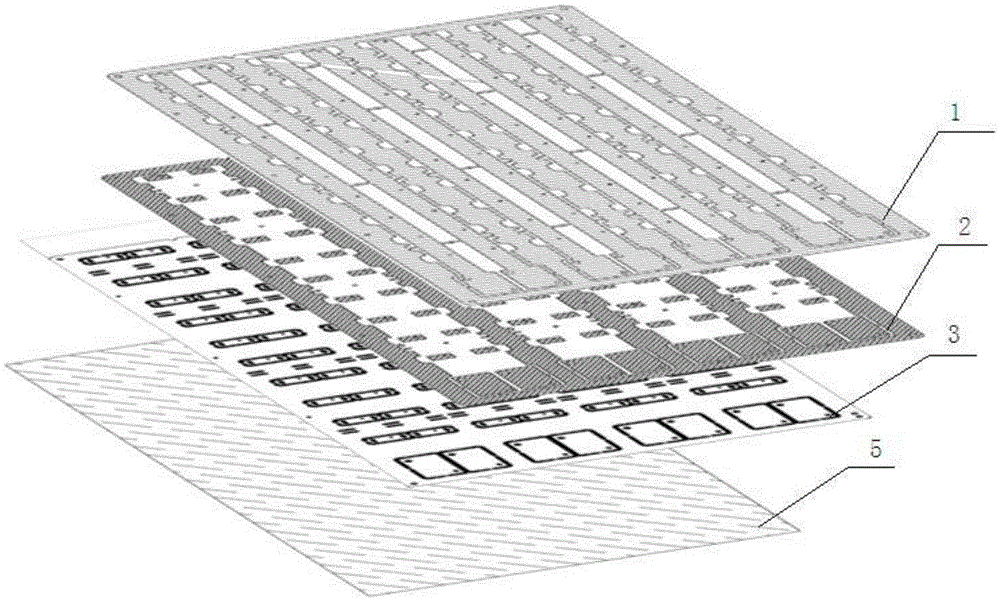

One-piece aluminum flexible circuit board with support layer switching function and preparation technology

ActiveCN105578728AHigh temperature resistantStable supportCircuit bendability/stretchabilityPrinted circuit aspectsFlexible circuitsAdhesive

The invention relates to the technical field of flexible circuit boards, in particular to a one-piece aluminum flexible circuit board with a support layer switching function and a preparation technology. The one-piece aluminum flexible circuit board comprises a one-piece flexible circuit board, a thermosetting adhesive, a one-piece aluminum reinforcing body and a supporting film, wherein the one-piece flexible circuit board consists of a plurality of flexible circuit board bodies and a frame; the flexible circuit board bodies are positioned inside the frame; gaps are formed between the flexible circuit board bodies and the frame; the bottom of the one-piece flexible circuit board and the top of the one-piece aluminum reinforcing body are bonded by using the thermosetting adhesive; and the bottom of the one-piece aluminum reinforcing body is adhered with the supporting film. Compared with the prior art, the one-piece aluminum flexible circuit board structure with the support layer switching function is designed, the flexible circuit board bodies are taken out from the supporting film when the structure is used, the supporting film has the advantages of high supporting degree, low viscidity for a non-cohesive gel and high temperature resistance, the surface packaging assembly accuracy of the product is met, and the product size stability and the consistency of product size accuracy are guaranteed.

Owner:SHANGHAI WLCP ELECTRICAL & TECH

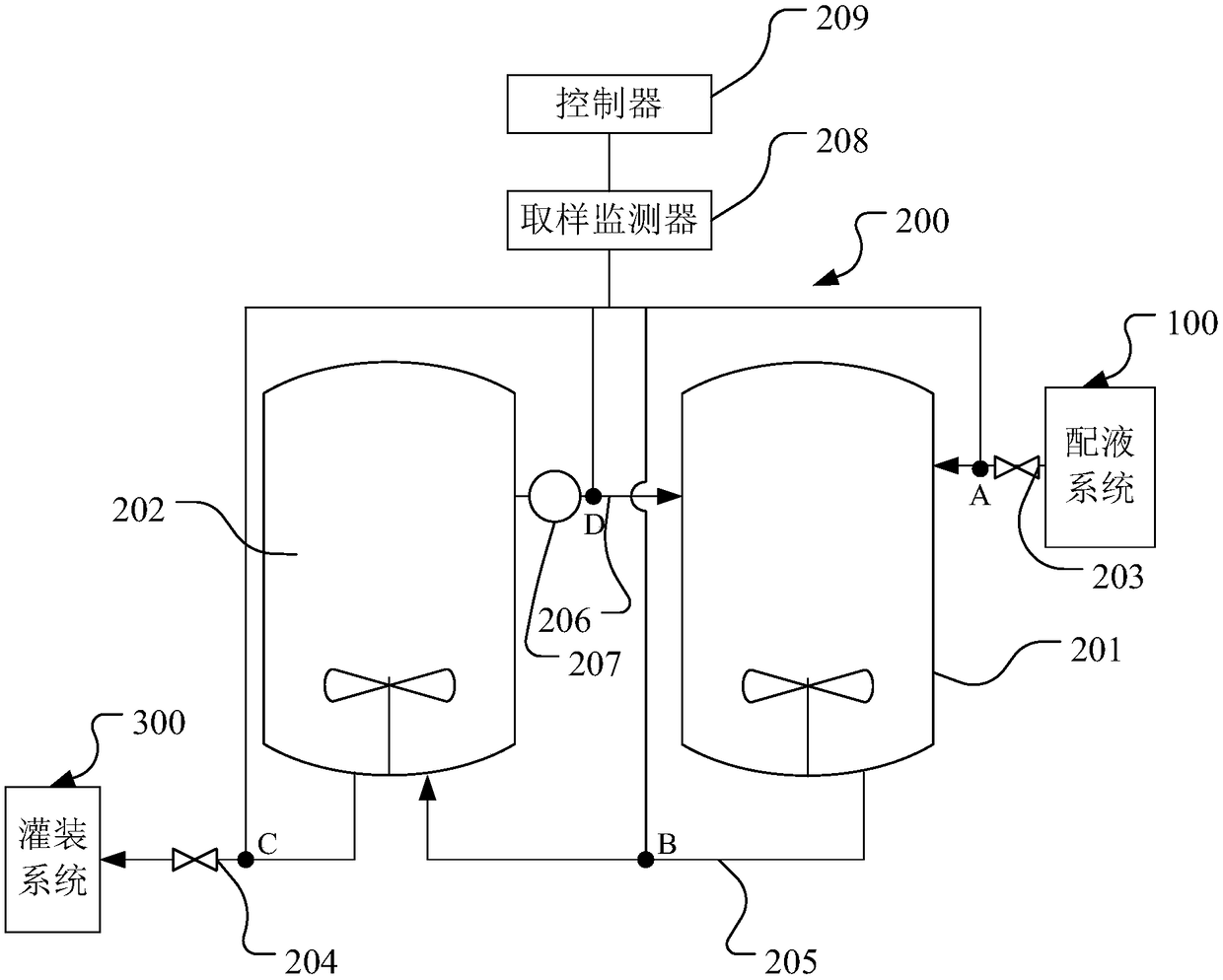

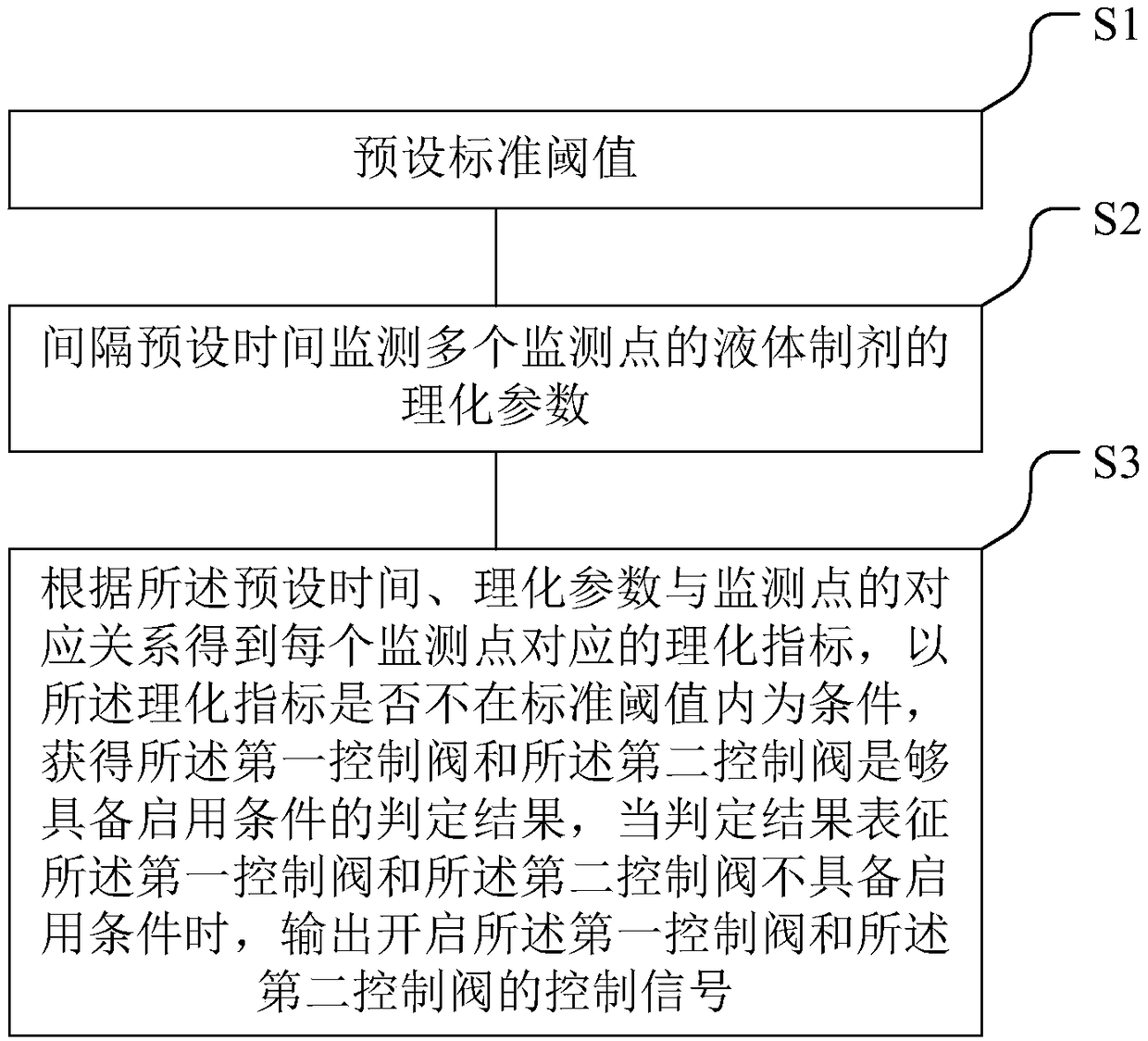

Device and method for continuously mixing liquid preparations

InactiveCN108786633AIncrease profitEnsure uniformity of outputTransportation and packagingMixing methodsEngineeringControl valves

The invention discloses a device and a method for continuously mixing liquid preparations. The device for continuously mixing the liquid preparations can realize the simultaneous and continuous implementation of feeding, mixing and discharging under the control effect of a first control valve and a second control valve, and monitors the physical and chemical parameters of multiple monitoring points at predetermined time intervals under the action of a sampling monitor, thus enabling the liquid preparations to meet the requirements, and further guaranteeing the uniformity of discharge. Since the device for continuously mixing the liquid preparations can realize continuous production, so that the production batches can be divided according to time periods. Compared with the prior art, the production efficiency can be increased by using the device occupying a smaller area, so that the utilization rate of a plant is increased.

Owner:无限极(营口)有限公司

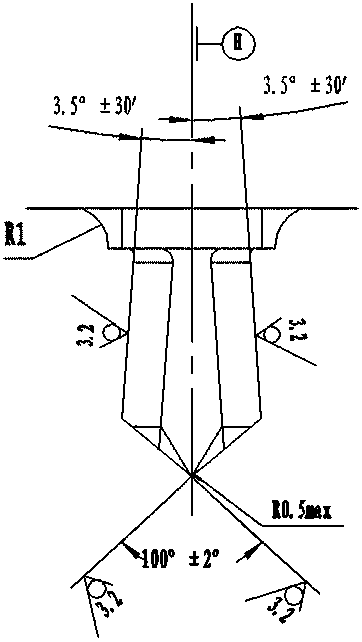

Production method for second gears of automatic automotive transmissions

InactiveCN103753159AMass productionStable productionGearing elementsAutomatic transmissionAutomotive transmission

The invention provides a production method for second gears of automatic automotive transmissions. According to the production method, pre-forging blanks are subjected to cold extrusion after being produced by isothermal forging. The production method is characterized in that the inclination of the inner walls of modified grooves of the pre-forging blanks is 2-4 degrees larger than that of finish-forging blanks. Products produced by the production method are high in accuracy and low oxidizing, good internal structure of metal is realized, crystal grains are fine, and poor textures such as coarse crystals and mixed crystals are avoided; equipment as needed is low in tonnage and small in forming fore, filling of tooth profile is easy, unit pressure borne by molds is remarkably reduced, and service life of the molds are quite long; product hardness reaches HB130-150, and metal structure reaches the second level; the tooth profile is fully filled and does not deform during heat treatment after cold extrusion forming.

Owner:CHONGQING CHUANGJING WARM FORGING FORMING

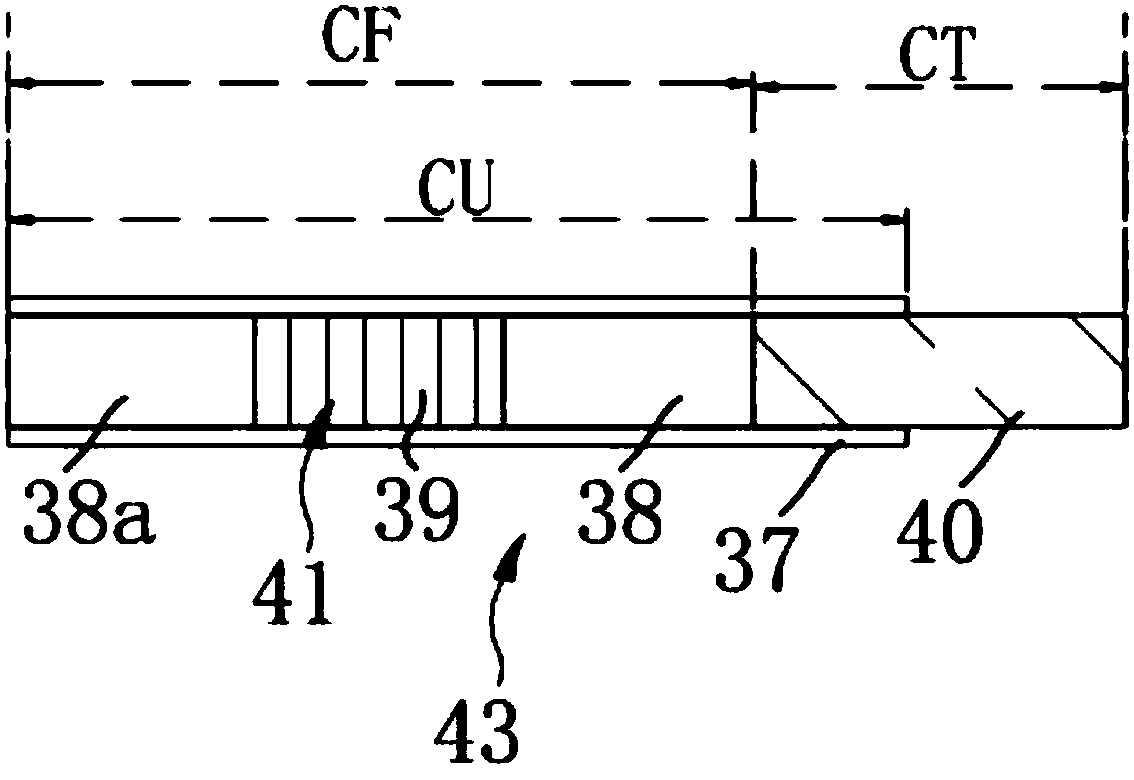

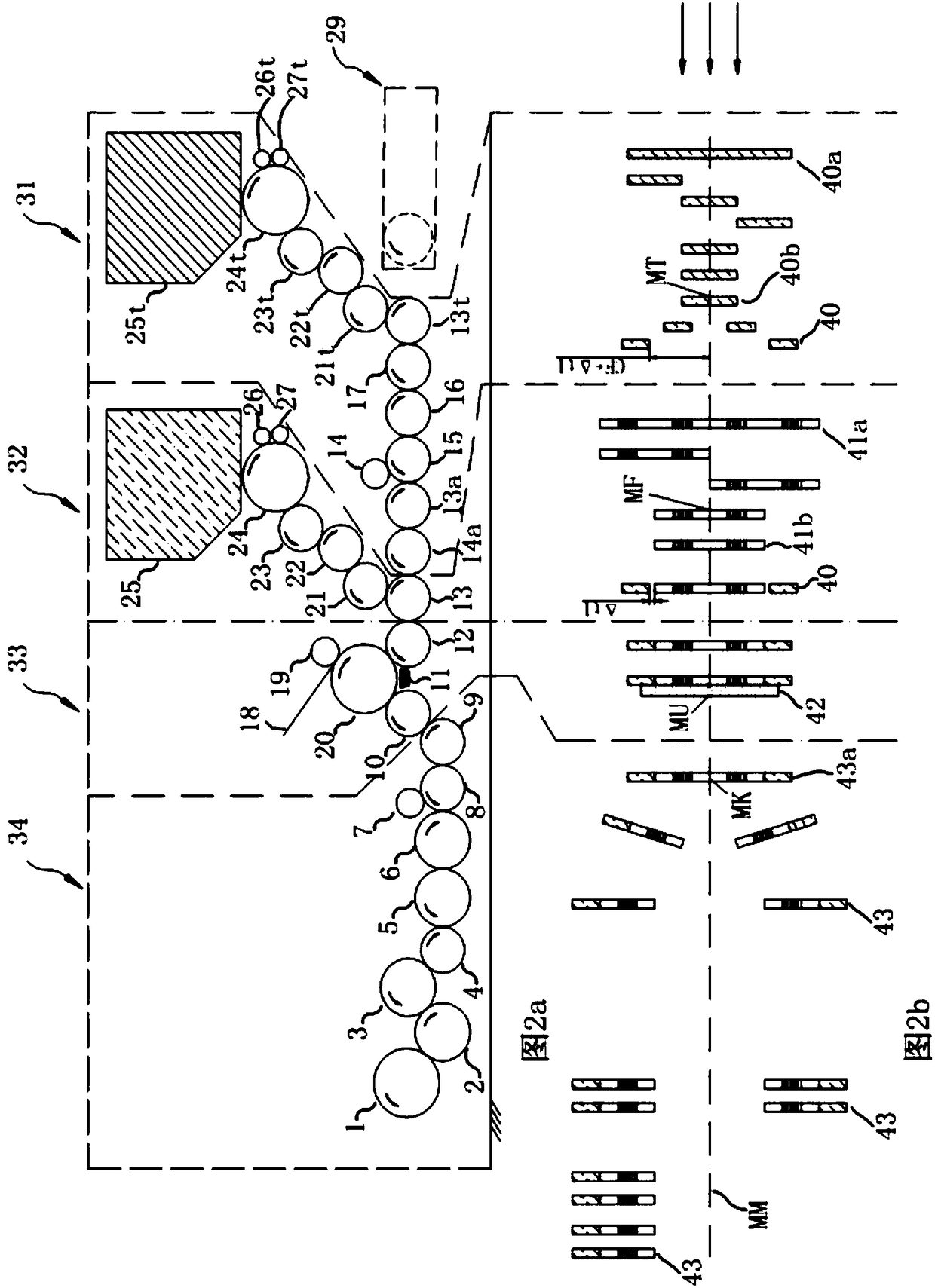

Nontraditional cut tobacco type cigarette production equipment

PendingCN108142989AAvoid quality risksIncrease production rateCigarette manufactureComposite filterPaper sheet

The invention discloses nontraditional cut tobacco type cigarette production equipment, which comprises multiple drum wheels, wherein a nontraditional cut tobacco stick section and a composite filtertip section are delivered to a wrapping region through the drum wheels, tipping paper is supplied along a dual-wide tipping paper centrosymmetric surface MU to wrap and form the nontraditional cut tobacco stick section and the composite filter tip section, and the distance between each of the dual-wide tipping paper centrosymmetric surface MU, a double-length composite filter tip section centrosymmetric surface MF and a double cigarette final cutter centrosymmetric surface MK and a center surface MM of the machine is 0. According to the equipment, the distance between each of the dual-wide tipping paper centrosymmetric surface MU, the double-length composite filter tip section centrosymmetric surface MF and the double cigarette final cutter centrosymmetric surface MK and the center surfaceMM of the machine is ensured to be 0, so that the problems of substandard cigarette appearance quality and scrap consumption caused by such a requirement that the tipping paper is aligned with a filter tip on one side during high-speed operation of the equipment are solved, the aim of controlling the quality and the aesthetics of cigarettes is fulfilled, and in addition, the production efficiencyis improved.

Owner:HONGTA TOBACCO GRP

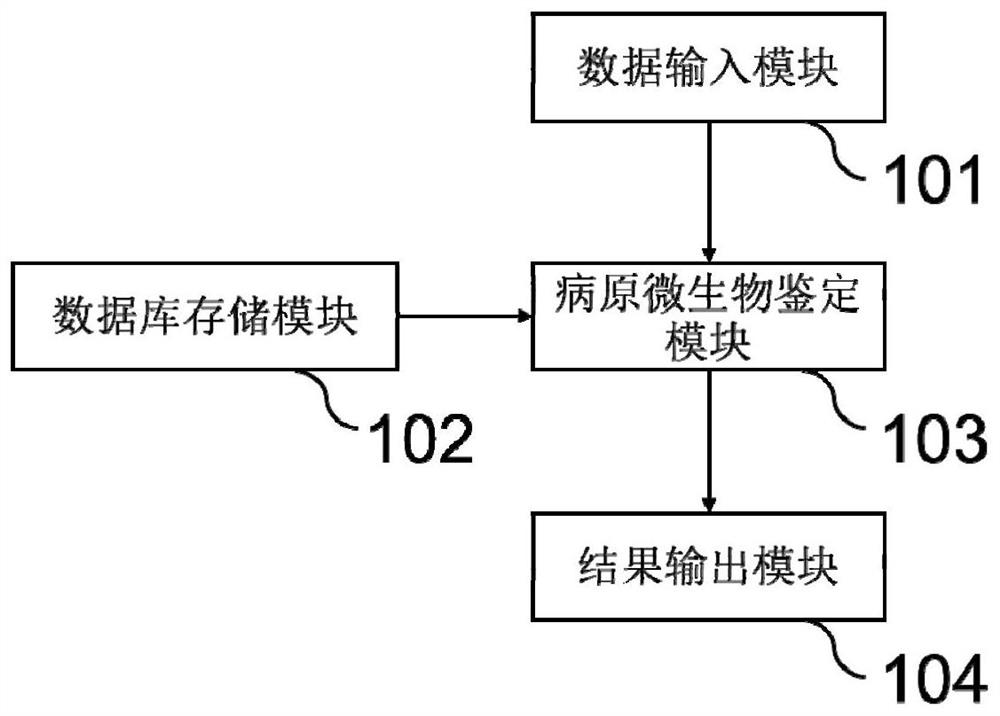

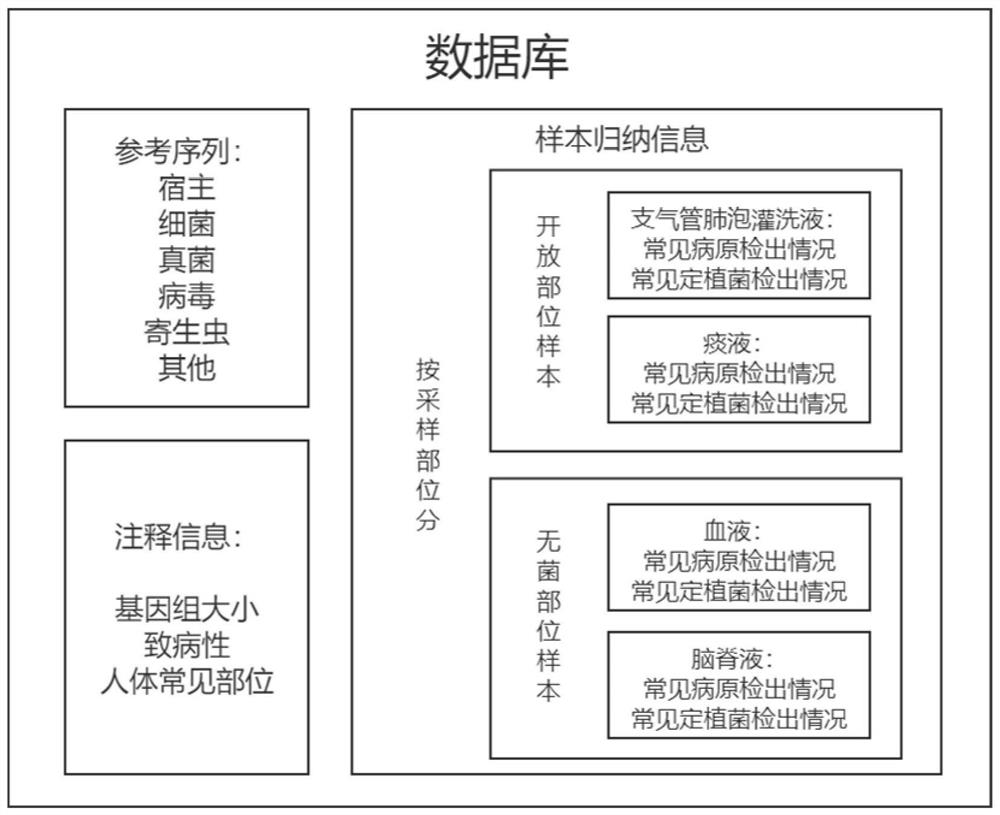

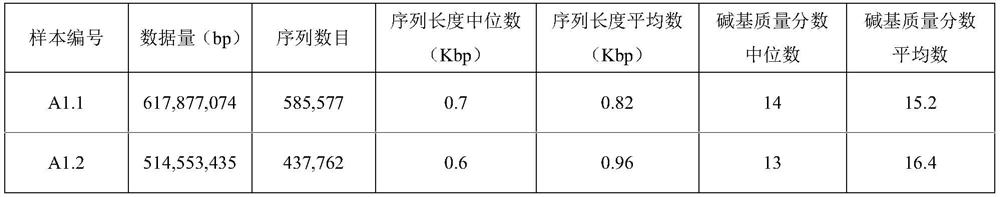

Pathogenic microorganism detection system and method based on nanopore sequencing

The invention discloses a pathogenic microorganism detection system and method based on nanopore sequencing, and belongs to the technical field of microorganism detection. The pathogenic microorganism detection system comprises: a data input module; a database storage module; a pathogenic microorganism identification module; and a result output module. By utilizing the system and the method provided by the invention, pathogens such as bacteria, fungi, viruses, parasites and the like in a sample can be rapidly analyzed. The system and method hav the characteristics of long sequencing reading length, rapid and accurate sequence reading and the like, and can meet the clinical infection POCT detection requirements. Meanwhile, due to the characteristic of long length, the toxicity and drug-resistant genes corresponding to the pathogens can be analyzed through sequencing data, and clinical infection diagnosis and treatment can be effectively assisted.

Owner:美格医学检验所(广州)有限公司

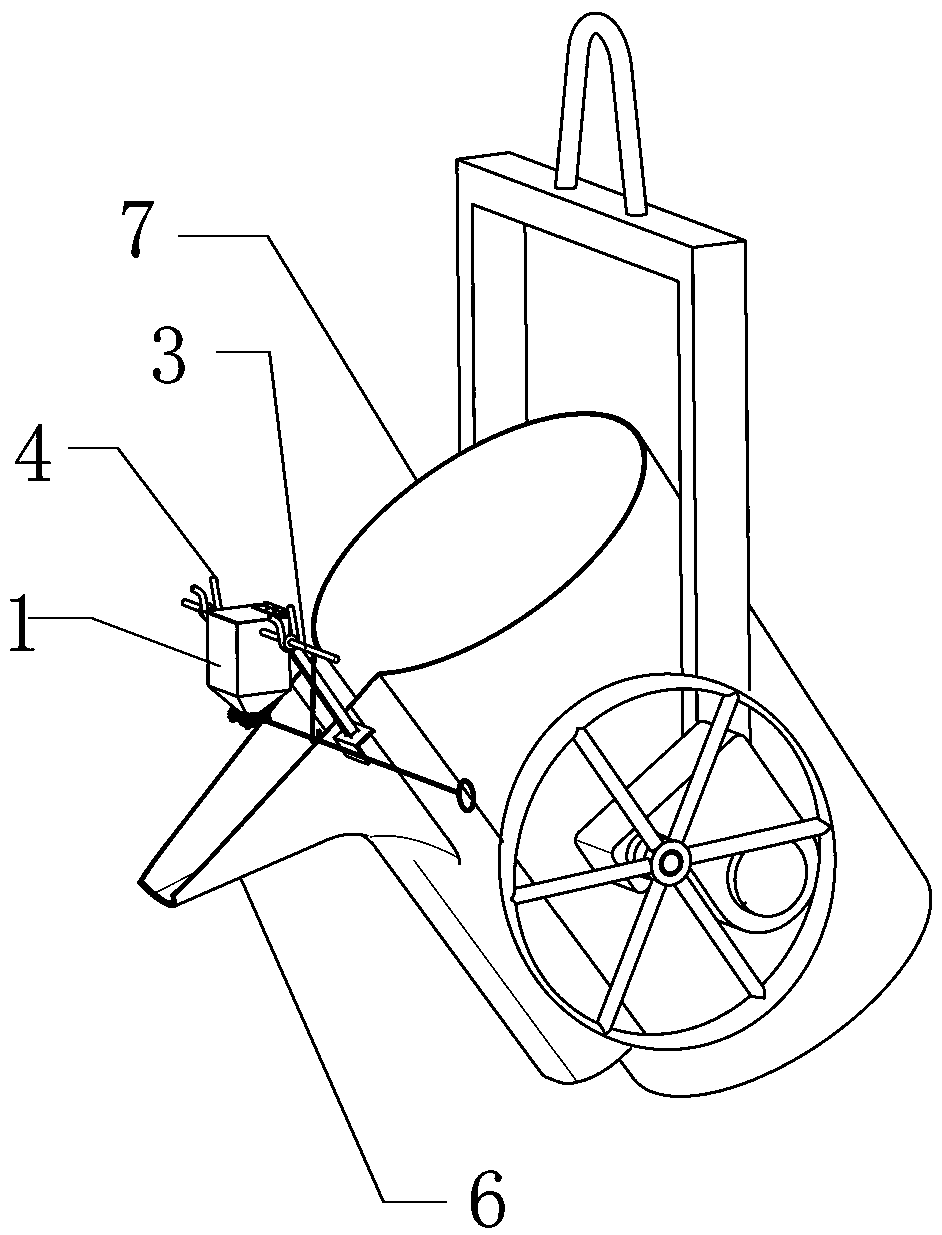

Metal-stream inoculation device for casting

The invention discloses a metal-stream inoculation device for casting. The metal-stream inoculation device for casting comprises a nucleating agent bin, wherein the outer side of the nucleating agentbin is symmetrically fixed with two rotary shafts which reversely extend; the nucleating agent bin is rotatably connected onto two detachable brackets through the two rotary shafts; the two detachablebrackets are separately fixed to the two sides of a ladle mouth through support bases; the support bases are fixedly arranged on the ladle mouth, and the nucleating agent bin is positioned above theladle mouth; the bottom of the nucleating agent bin is equipped with a downward opening part which is positioned above the ladle mouth of a casting ladle, and a gate valve is connected on the openingpart; a detachable discharge spout is connected below the gate valve; and the gate valve controls opening and closing of the gate valve through a pushing-pulling rod. The metal-stream inoculation device for casting overcomes the problems in the prior art, has characteristics of being safe and high in practicability, reducing labor intensity, being low in cost and reducing quality risk, can guarantee consistency and stability of a casting material, increases the yield, and is convenient for maintenance.

Owner:十堰众柴发动机部件制造有限公司

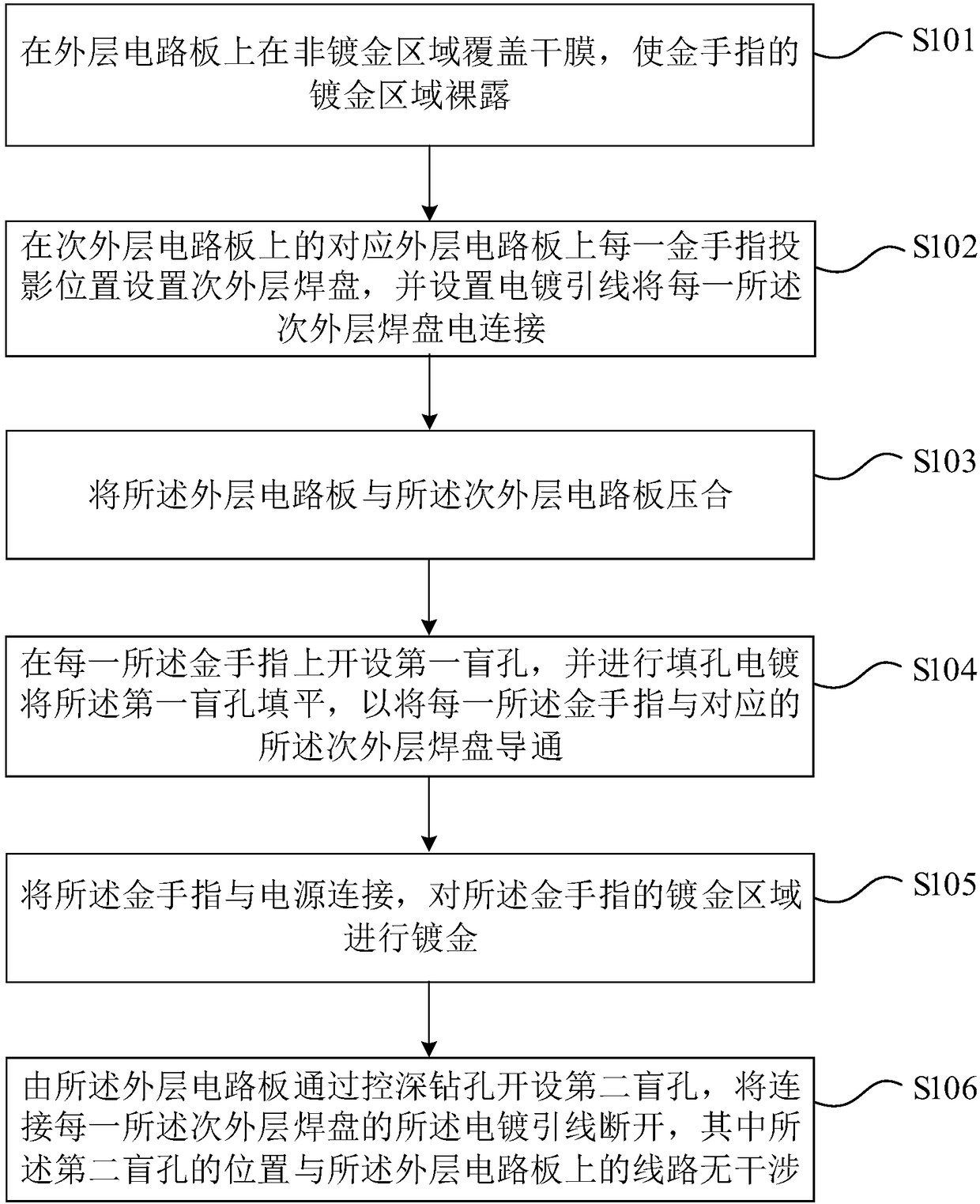

Gold plating method for gold fingers and gold finger circuit board

InactiveCN108882558AReduced chance of scratchesLow costElectrical connection printed elementsConductive pattern reinforcementEngineeringCopper

The invention provides a gold plating method for gold fingers and a gold finger circuit board. According to the gold plating method, a secondary outer pad is arranged corresponding to a projection position of each gold finger on an outer circuit board on a secondary outer circuit board; each secondary outer pad is electrically connected by adopting an electroplated lead; first blind holes are formed in each gold finger and are filled up through hole-filling electroplating, thereby conducting each gold finger and the corresponding secondary outer pad; the gold fingers are connected with a powersupply for carrying out gold plating; and the electroplated lead connected with each secondary outer pad is finally disconnected through depth-controlled drilling, so that each gold finger is broken,thereby achieving production of the gold fingers free of the electroplated lead on the surfaces. A gold-plated lead is arranged on the secondary outer circuit board and the electroplated lead is notdesigned on the surface of the outer circuit board, so that the scratch probability of the gold fingers in the production process is reduced, the quality of a product is improved, the material cost isreduced, gold permeating on a copper surface is avoided, the dependence on manual repair in the production process is reduced and the defect caused by the electroplated lead on the outer circuit board in the prior art is avoided.

Owner:PEKING UNIV FOUNDER GRP CO LTD +1

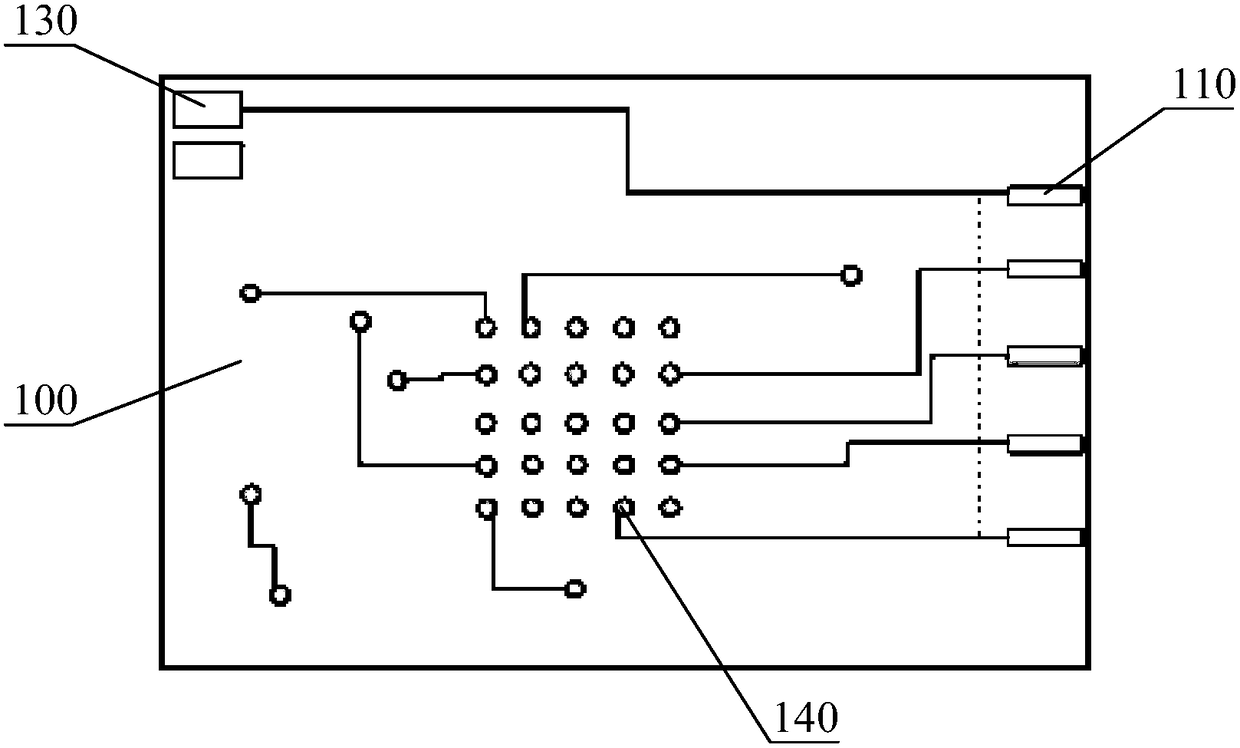

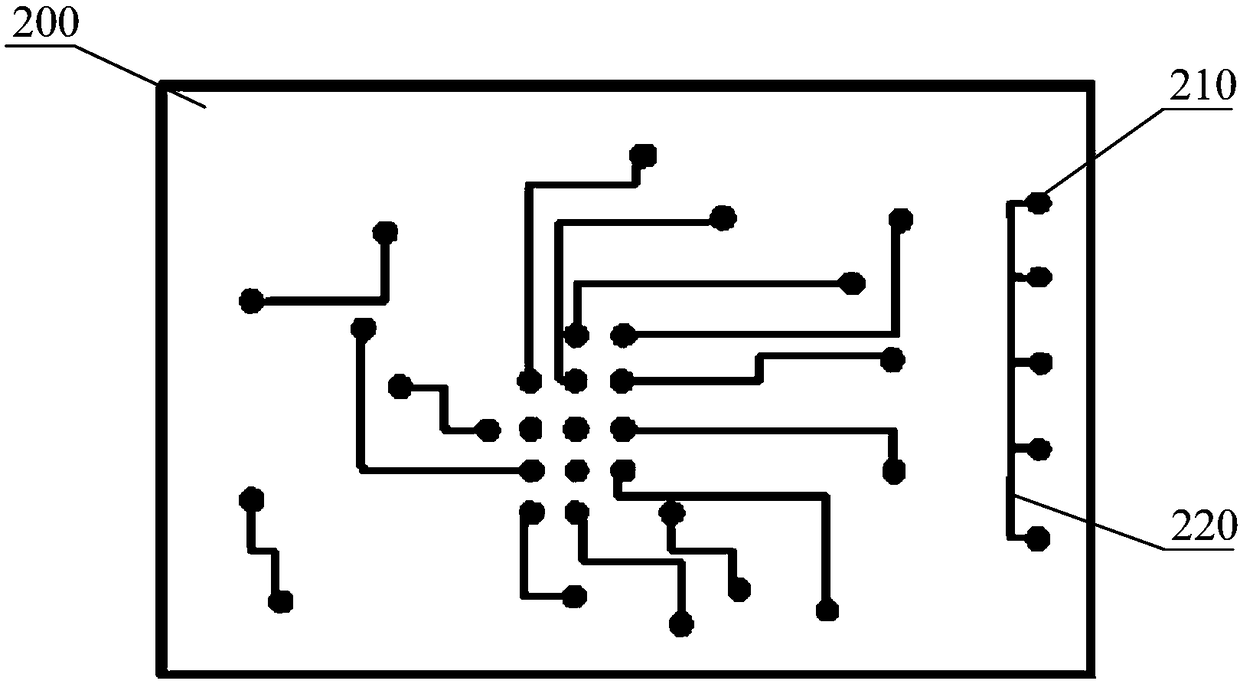

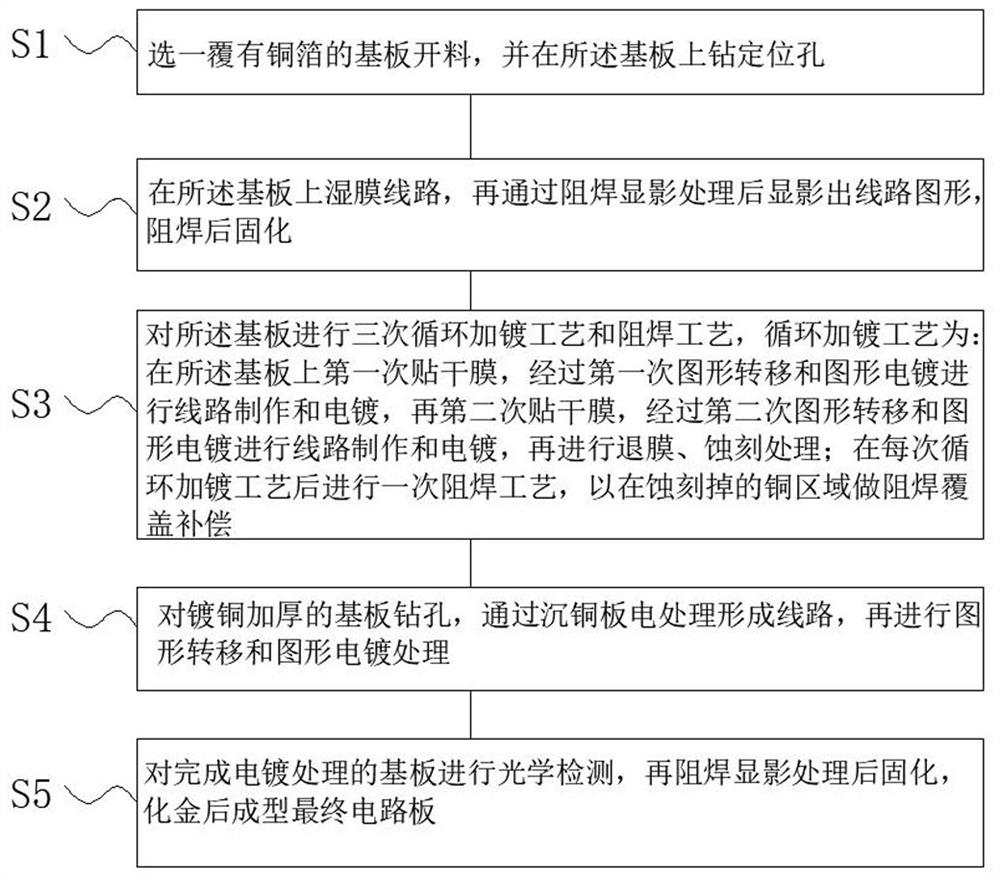

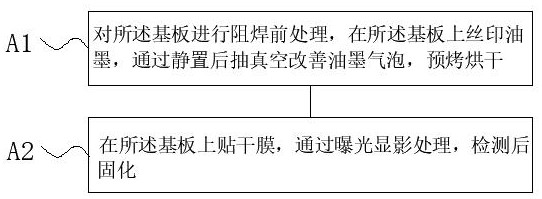

Copper plating thickening process for printed circuit board

ActiveCN112638051AImprove rough edgesAvoid the problem of uneven copper platingConductive material chemical/electrolytical removalMetallurgyPrinted circuit board

The invention belongs to the technical field of circuit board processing and relates to a copper plating thickening process for printed circuit board. By adopting a novel cyclic plating process flow, the problem of uneven copper plating is avoided while copper plating thickening is completed, a processing method for improving uneven copper plating, incomplete etching and excessive ink lateral erosion is obtained by combining process optimization and process parameter adjustment, the production process capability is improved, the production efficiency is improved, the quality risk is reduced, and the production cost is reduced. With the method adopted, the problem that copper plating above 9 oz is difficult to thicken can be effectively solved, the abnormities of uneven copper plating, copper plating hole blockage and the like during thick copper electroplating can be avoided; and circuit burrs can be improved through multiple times of etching, and it is guaranteed that incomplete etching and excessive burrs caused by excessive copper thickness are avoided during circuit manufacturing, and therefore, the problems of ink bubbles, excessive ink lateral erosion and the like caused by overlarge copper thickness and overlarge circuit burrs during solder resist printing are effectively solved, and the product quality is greatly improved.

Owner:惠州市大亚湾科翔科技电路板有限公司

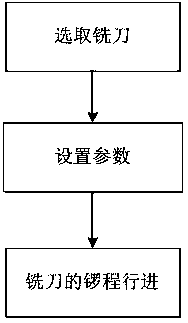

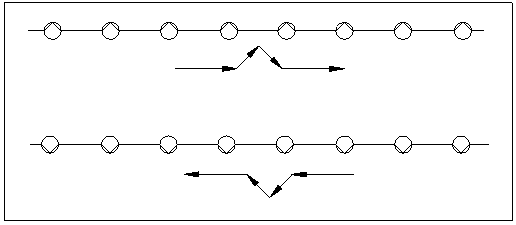

High TG panel PCB non-metallization half-hole CNC machining method

InactiveCN108237253AAvoid it happening againReduce the link of manual deburringMilling equipment detailsPolygonal lineMilling cutter

The invention relates to a high TG panel PCB non-metallization half-hole CNC machining method. The high TG panel PCB non-metallization half-hole CNC machining method comprises the following steps thatfirstly, a milling cutter is selected, and the milling cutter with the cutter diameter being 1.5 mm is selected; secondly, parameters are set, the rotation speed of the milling cutter is 34 krpm, thecutter advancing speed is 2.6 m / min, the cutter lowering speed is 0.6 m / min, the cutter retreating speed is 3m / min, and the PCB stack number is set to be 4pnl / stack; and thirdly, milling cutter routing path advancing is conducted, the parameters in the second step are set in forming equipment, and the feed procedure is conducted on multiple half holes in a PCB in a folded line feed manner according to the machining parameters. When CNC machining is conducted on the PCB through the method, particularly for the non-metallization half holes, burr generation can be prevented, the manual deburringlink is reduced, the machining efficiency is greatly improved, cost is reduced, and the quality risk is reduced; and the traditional milling cutter routing path advancing manner is changed, and a good promoting function is achieved for industry development.

Owner:惠州联创宏科技有限公司

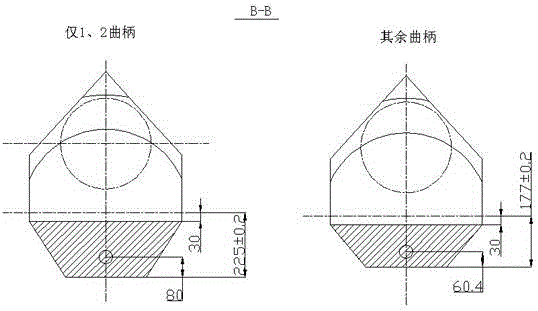

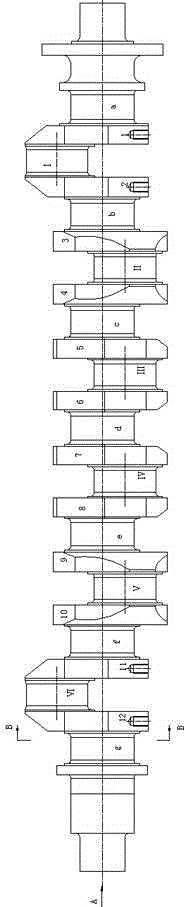

Unbalanced crankshaft balanced grinding method

ActiveCN104440433ASolve technical problems of grinding qualityGuaranteed grinding qualityRevolution surface grinding machinesFree stateEngineering

The invention discloses an unbalanced crankshaft balanced grinding method and belongs to the technical field of crankshaft machining. The unbalanced crankshaft balanced grinding method comprises the steps that 1. the whole structure of a crankshaft is analyzed; 2. the difference of the same portions on the crankshaft is found and marked; 3. whether non-uniform-speed rotating can be caused by the difference of the same portions is analyzed; 4. the unbalance amounts in various directions of the different portions are obtained by computing through moment; 5. the positions and the weights of needed balance weights in various directions of the different portions are determined; 6. corresponding balance weights are designed and manufactured and are connected to the corresponding positions of the crankshaft; and 7. the crankshaft rotates at constant speed, and grinding machining is carried out. According to the unbalanced crankshaft balanced grinding method, the technical problem that unbalanced crankshafts cannot rotate at constant speed under a free state so that the grinding quality on a crankshaft main neck cannot be guaranteed is mainly solved.

Owner:CRRC ZIYANG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com