One-piece aluminum flexible circuit board with support layer switching function and preparation technology

A technology of flexible circuit board and preparation process, which is applied in the direction of laminated printed circuit board, printed circuit manufacturing, printed circuit, etc., can solve the problems of inconsistent product assembly accuracy, easy electrostatic breakdown and crushing of components, and solve the problem of static electricity. Breakdown and crushing, reduced quality risk, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described now in conjunction with accompanying drawing.

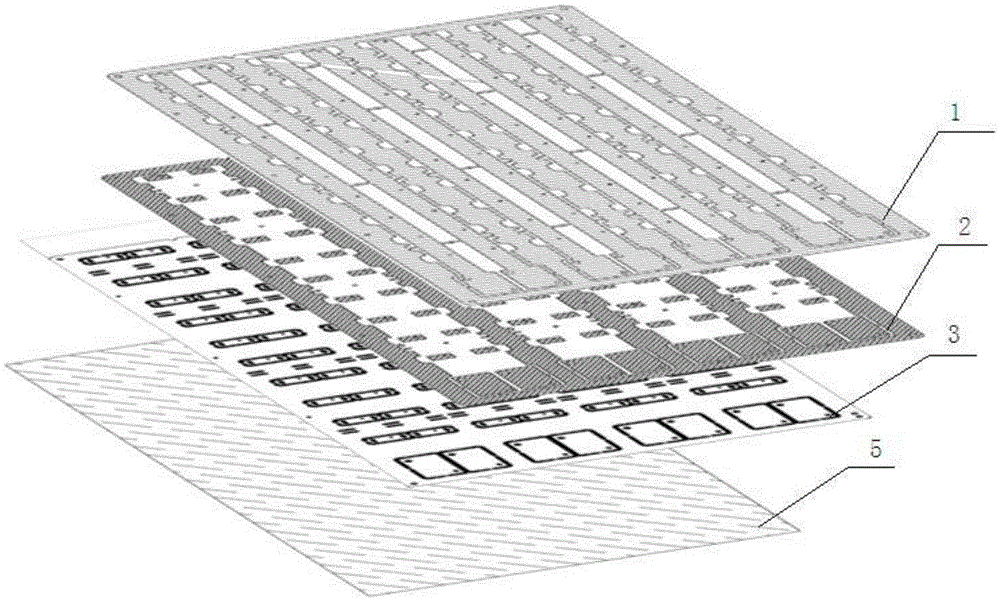

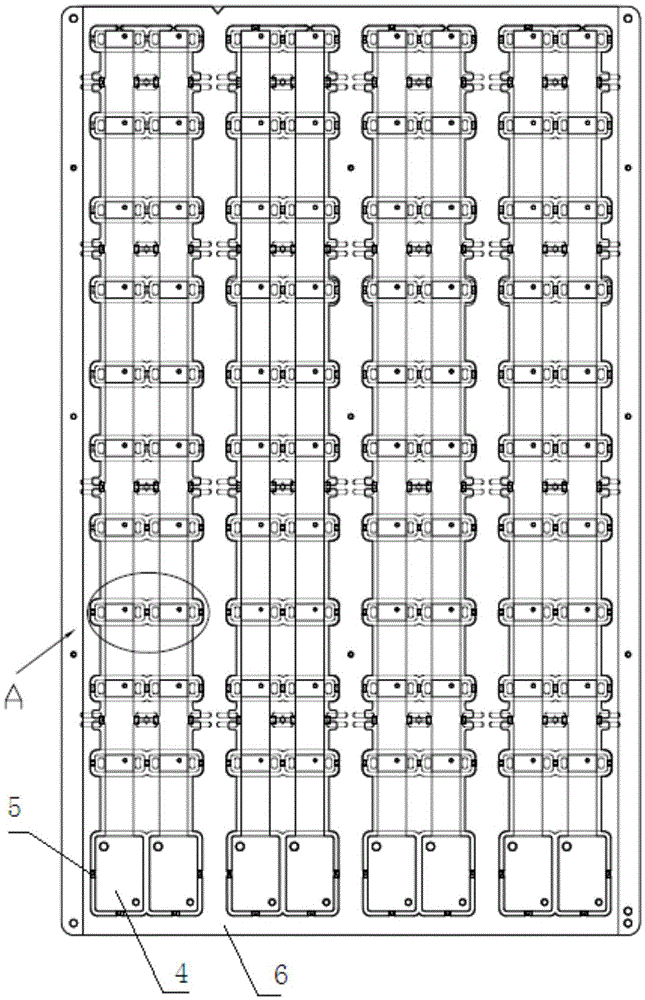

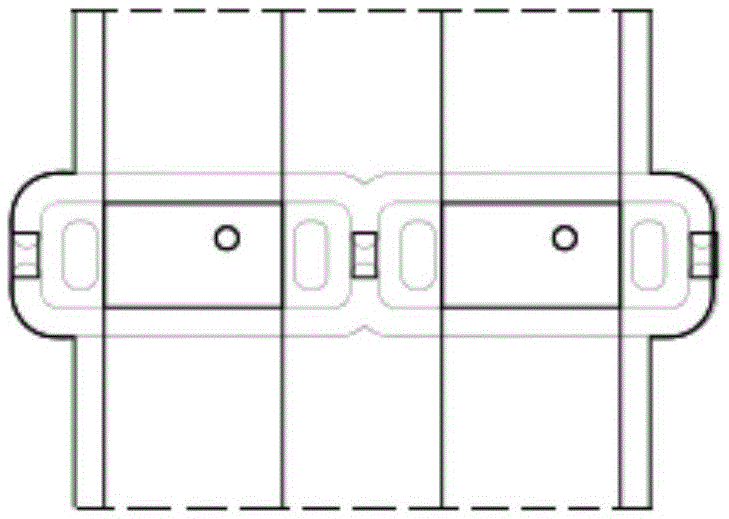

[0020] see Figure 1-3 , The present invention is a whole-board aluminum flexible circuit board with a load-bearing layer transfer function, including a whole-board flexible circuit board, a thermosetting adhesive, a whole-board aluminum reinforcement and a load-bearing film. The whole flexible circuit board 1 is composed of several flexible circuit board bodies 4 and frame 6, several flexible circuit board bodies 4 are located in the frame 6, there is a gap between the flexible circuit board body 4 and the frame 6, the whole flexible circuit board The bottom of 1 is bonded to the top of the entire aluminum reinforcement 3 with thermosetting adhesive 2 , and the bottom of the entire aluminum reinforcement 3 is attached with a carrier film 5 .

[0021] A preparation process of a full-board aluminum flexible circuit board with a load-bearing layer transfer function, which is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com