Production method for second gears of automatic automotive transmissions

A technology of automatic transmission and gear teeth, which is applied to components with teeth, mechanical equipment, belts/chains/gears, etc. It can solve the problems of reducing the smoothness and flexibility of shifting, reducing the interchangeability of gears, and high parts scrap rates. Achieve the effect of reducing production cost and quality risk, stable size and low scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing second-gear teeth of an advanced automatic transmission for automobiles, comprising the following steps:

[0032] (1) According to the process design requirements, the raw material (20CrMoH) is cut into material sections, the surface is ground by centerless grinding, the crack is inspected by flaw detection, and then the lubricant is sprayed and dried. The selected raw material is 20CrMoH. After blanking according to the process design requirements, firstly grind the surface and then check whether there are cracks with flaw detection equipment. If there are any, it will be judged as unqualified; The agent is graphite or organic polymer lubricant, which acts as a lubricant.

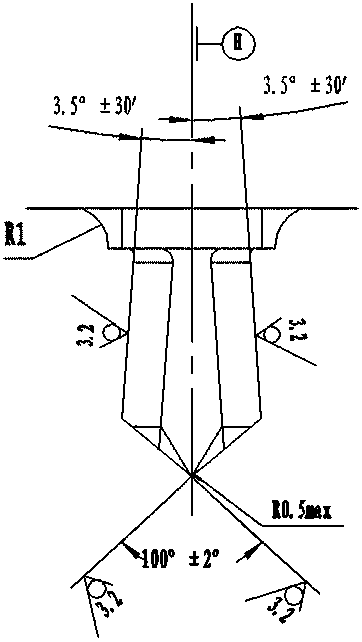

[0033] (2) Heat the blank to 810°C~850°C in an intermediate frequency induction heating furnace of nitrogen or inert gas, and warm forge it on a press to form a pre-forged billet with a tooth shape. The slope of the forging die blank is 2 to 4° larger (such as figure 2 The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com