A low negative temperature post-tensioned beam prestressed pipeline grouting material

A prestressed pipe and negative temperature technology is applied in the field of post-tensioned beam prestressed pipe grouting material at low negative temperature and post-tensioned beam prestressed pipe grouting material, which can solve the problems of high energy consumption and difficulty in ensuring construction quality, etc. Achieve the effect of improving construction efficiency, reducing a lot of energy consumption and quality risks, and achieving obvious results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

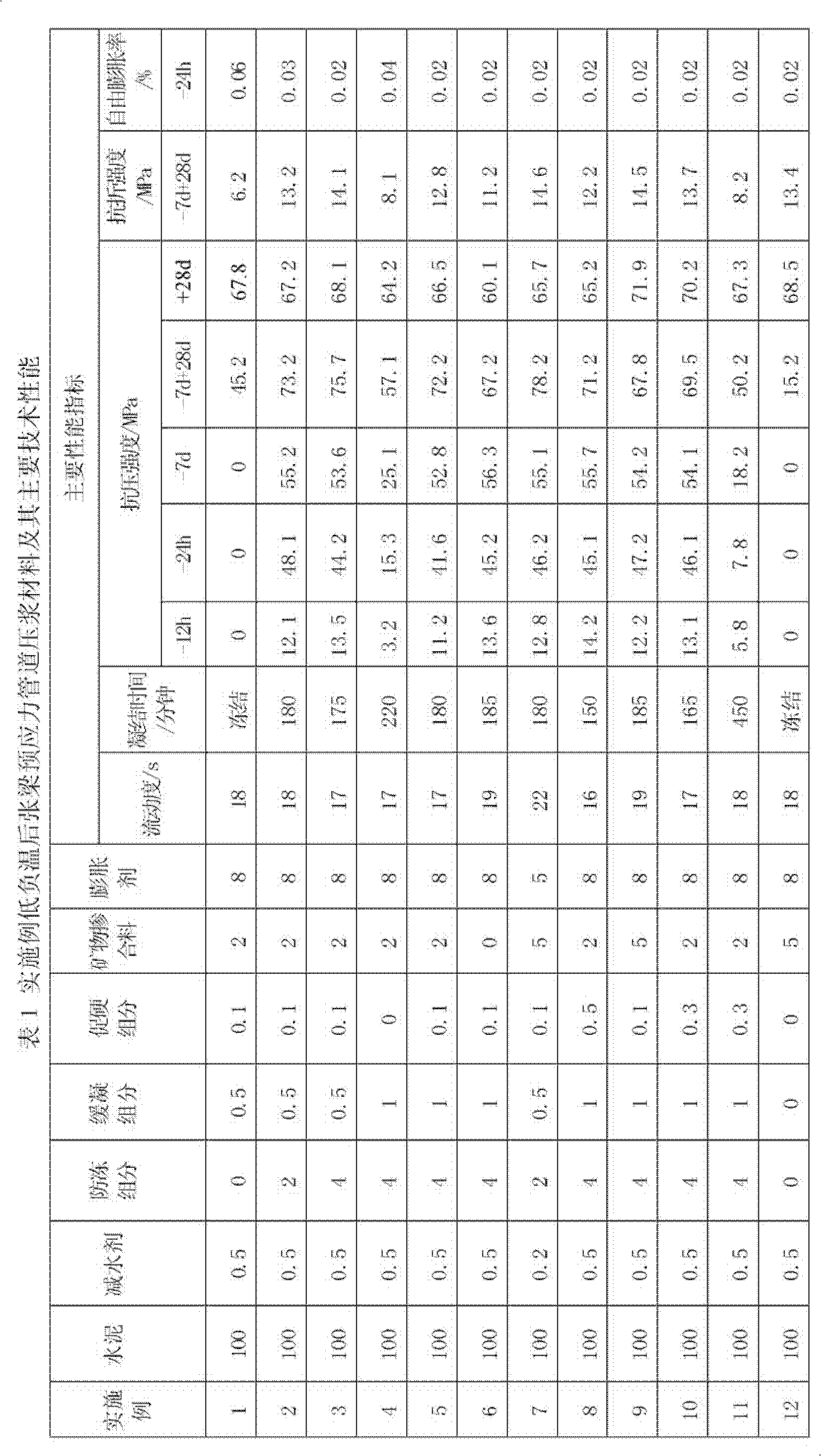

Examples

Embodiment 11

[0042] The aluminum-calcium-silicon weight ratio of the cement used in Example 11 is 1:2.5:0.3, and the other ingredients are the same as in Examples 1-10.

Embodiment 12

[0043] The cement used in embodiment 12 is P.O42.5 ordinary portland cement, and other ingredients are identical to embodiment 1-10.

[0044] As can be seen from the test results, the early strength of Example 4 without adding the hardening component is far lower than the performance of the embodiment with the hardening component added; and the cement does not meet the aluminum-calcium-silicon ratio of the present invention The setting time of the mortar of 11 is prolonged, and the strength is low; the mineral admixture increases from 0 to 5 parts by weight, and the long-term strength of the mortar increases; strength. The prior art grouting material for normal temperature in Example 12 cannot solidify and harden at low temperatures, and appears in a frozen state.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com