Patents

Literature

328results about How to "Improve anti-pilling performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing method for low-elastic non-ironing knitted face fabric

InactiveCN101200852AShrunkGood color retentionWeft knittingBiochemical fibre treatmentAmmoniaComputer science

The present invention discloses a processing method of a low-elasticity, wrinkle-free knitted fabric, which includes steps: greige cloth weaving, boiling and bleaching, bio-enzyme washing, dyeing, softening, dehydration, scutching, drying, shaping and preshrinking. The present invention is characterized in that the processing steps of pre-relaxation and ammonia mercerization are added before boiling and bleaching, so that the whole processing steps are changed as greige cloth weaving, pre-relaxation, ammonia mercerization, boiling and bleaching, bio-enzyme washing, dyeing, softening, dehydration, scutching, drying, shaping and preshrinking; the pre-relaxation processing is to add refining agent of 0.5 to 1.5g / L, the processing temperature is between 90 and 130 DEG C, and the processing period is twenty to sixty minutes; in the step of ammonia mercerization, the pre-relaxed fabric receives the processing of ammonia mercerization in an ammonia mercerizing machine at the speed of 15 to 50m / min. The present invention ensures that the cotton and the blended elastic knitted fabric can have soft, smooth handfeel and high washing resistance and shape-keeping property.

Owner:浙江盛泰服装集团股份有限公司

Woven or knit fabric and process for producing the same

InactiveUS20050202741A1Increases interlacement degreeTextureWeft knittingProtective fabricsPolyesterYarn

A woven or knit fabric comprising air-jet interlacing spun yarns comprising polyester fibers of low titanium oxide content; a woven or knit fabric comprising air-jet interlacing spun yarns comprising polyester staple fibers obtained by graft polymerization of a hydrophilic compound; a woven or knit fabric comprising air-jet interlacing spun yarns comprising side by side crimped staple fibers; a woven or knit fabric comprising air-jet interlacing spun yarns comprising low-shrinkage staple fibers and copolymerized polyester staple fibers; and a process for producing these. A woven or knit fabric of polyester staple fibers that is bulky, excelling in moisture retention, lightweightness, water absorptivity, quick dryability, etc. and exhibits excellent anti-pilling properties can be obtained.

Owner:TOYOBO CO LTD

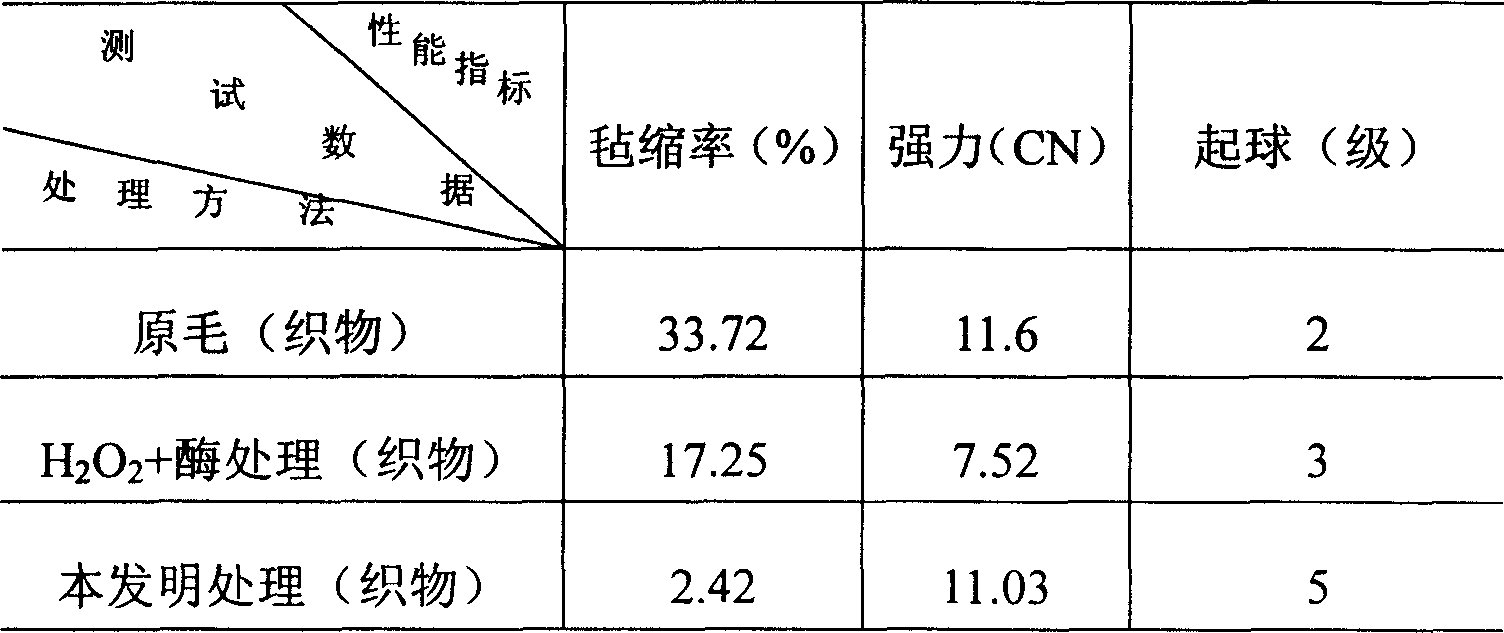

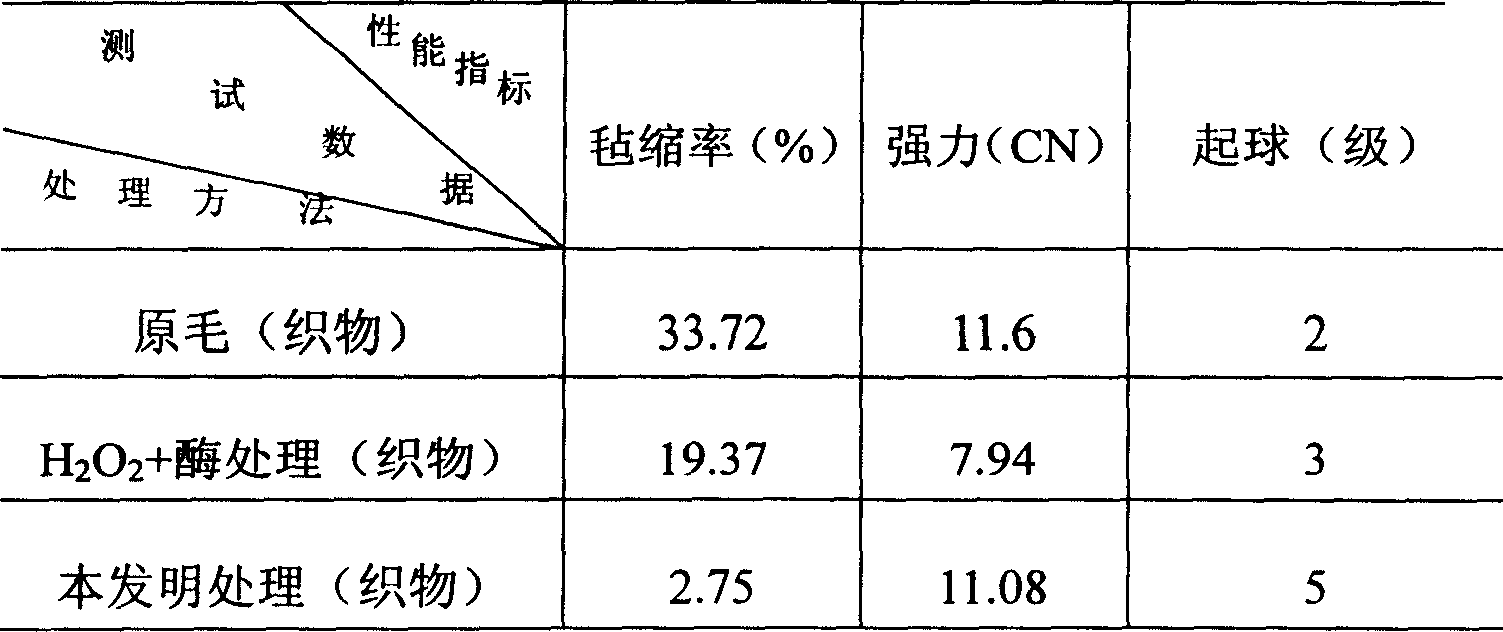

Ecological anti-felting finishing method for wools

InactiveCN101725045AImproves felting resistanceNo residueAnimal fibresHazardous substanceEngineering

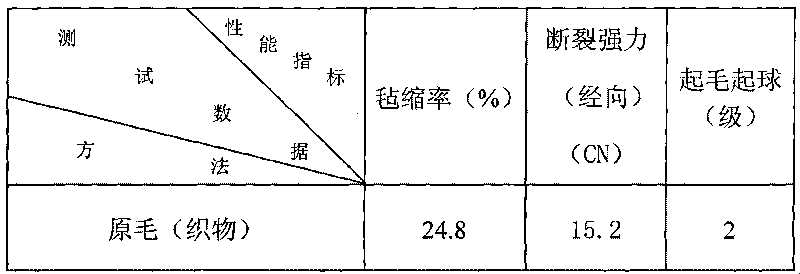

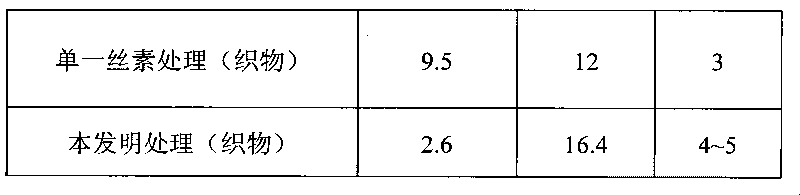

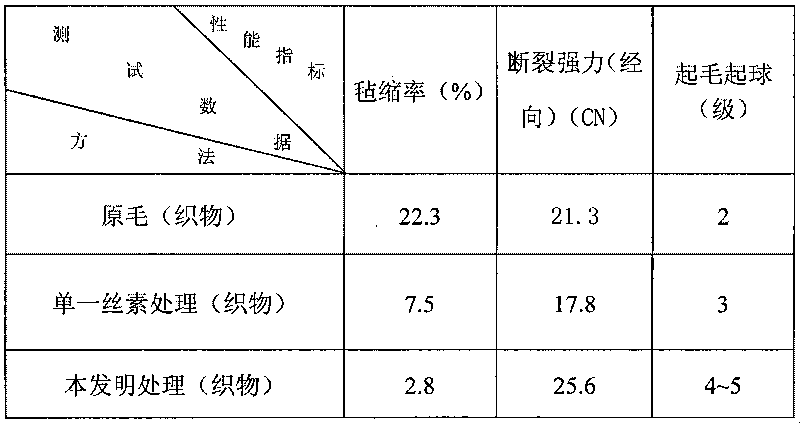

The invention discloses an ecological anti-felting finishing method for wools. The pretreatment adopts hydrogen peroxide pretreatment; and by padding the wools into mixed finishing solution of fibroin finishing agent SP1 and chitosan with certain concentration, the anti-felting rate of the treated wool fabrics is less than 3 percent, the strength is increased by about 6 percent, the whiteness is changed little, the air permeability of the wool fabrics is superior to that of the primary fabrics, the elongation at break is reduced, the water absorption is increased, the handfeel is soft, the anti-pilling property of the wool fibers is improved by 2 to 3 levels, and the wool fabrics can fully meet the requirement of machine wash. The method comprehensively adopts the environment-friendly finishing agent to perform anti-felting finishing for the wools, has no residues of harmful substances, does not cause environment pollution, simplifies the treatment process, shortens the process flow, has shorter period, and improves the feasibility of industrialized operation.

Owner:SHAANXI UNIV OF SCI & TECH

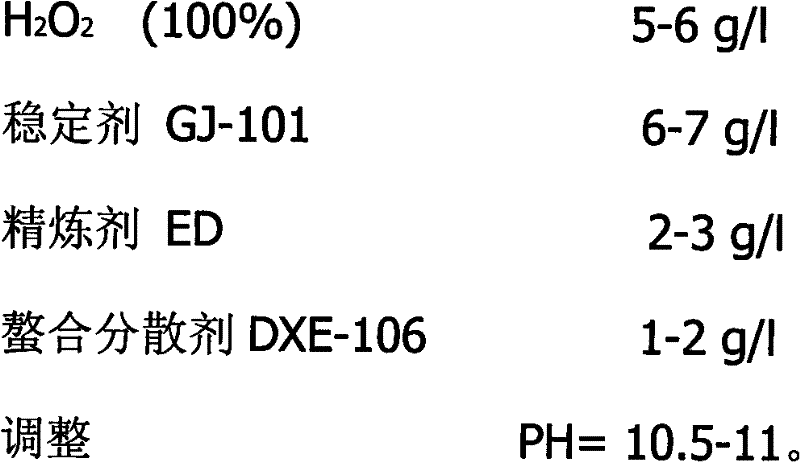

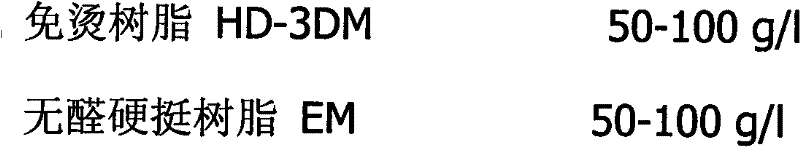

New anti-fluffing and anti-pilling technology for polyester-cotton fabric under special standards

ActiveCN102561040AImprove refining effectReduce slipMercerising of indefinite length fabricsFibre treatmentPolyesterEngineering

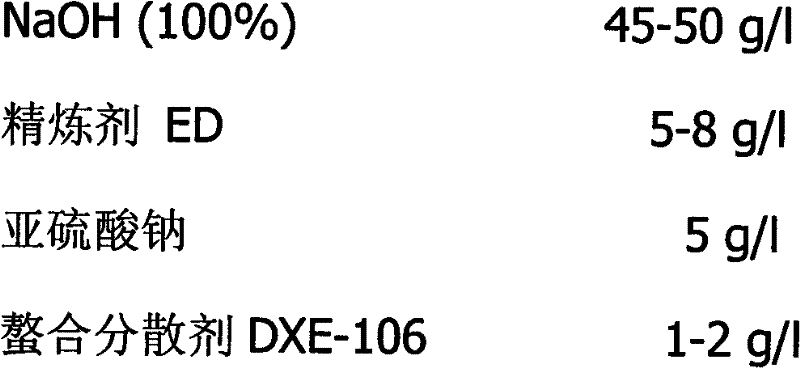

The invention relates to the technical field of dyeing and finishing production of polyester-cotton anti-fluffing and anti-pilling fabrics. A new anti-fluffing and anti-pilling technology for a polyester-cotton fabric under special standards comprises the following steps of: (1) grey cloth seam turning, (2) primary singeing, (3) flat bleaching, (4) secondary singeing, (5) sizing, (6) mercerizing, (7) dyeing (dispersion / reduction), (8) finishing with a compound solution of ironing-free resin and an anti-fluffing and anti-pilling agent, (9) baking, (10) tentering, (11) pre-shrinking, (12) inspection, and (13) formation of a finished product. The product prepared by the technology meets the special quality requirement of customers for washing for 5 times, 30 minutes in each time, in hot water at 92 DEG C, the anti-fluffing and anti-pilling quality index of the fabric is detected, and the anti-fluffing and anti-pilling quality index of the product for clothes reaches the export standard, namely level 3-4.

Owner:辽宁宏润源印染有限公司

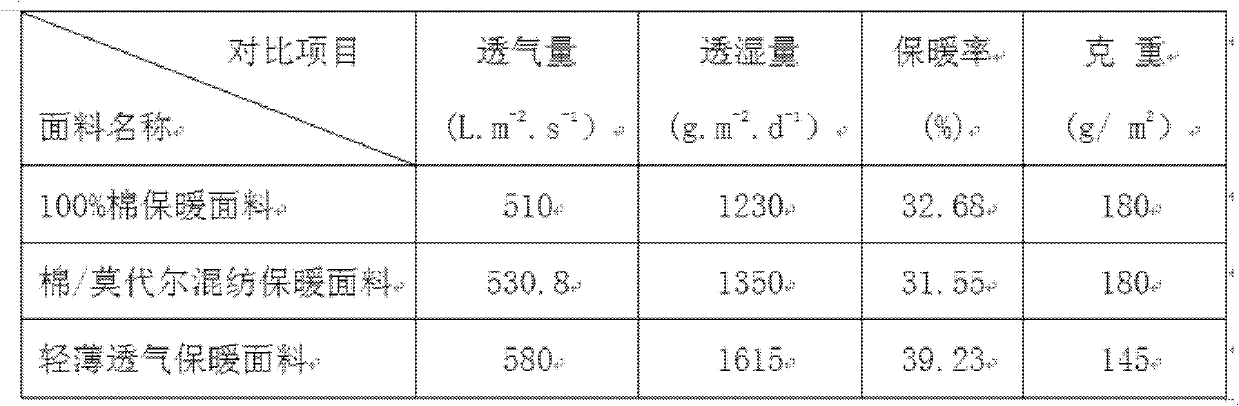

Thin breathable warm fabric and manufacture method thereof

InactiveCN102605523AHigh standardFullnessWeft knittingLiquid/gas/vapor treatment of propelled fabricsYarnMoisture absorption

The invention relates to a thin breathable warm fabric, comprising a surface fabric and an inner layer fabric, wherein the inner layer fabric is a moisture absorption and heating layer; the surface fabric is a warm breathable and moisture-leading layer; the moisture absorption and heating layer is formed by blending 30-60% of moisture absorption and heating EKS fibers and 40-70% of ordinary acrylic fibers; the warm breathable and moisture-leading layer is formed by blending 15-40% of bulk acrylic fibers, 20-60% of superfine acrylic fibers and 0-65% of modal fibers. The invention further relates to a manufacture method of thin breathable warm fabrics, comprising the steps of preparing yarns, weaving, sanding, dyeing, finishing softly and shaping; and the thin breathable warm fabric provided by the invention has the advantages of high wearing comfort, good thin and breathable performance as well as good anti-dropping, anti-static and warmth retention performances.

Owner:SHENZHEN HUIJIE GROUP

Bamboo carbon fiber underwear fabric and manufacture method thereof

InactiveCN101532204AFully reflect the decomposition of odorFully reflect the functionWeft knittingYarnFiberTextile technology

The invention relates to a bamboo carbon fiber underwear fabric and a manufacture method thereof, belonging to the technical field of textiles. The bamboo carbon fiber underwear fabric consists of a lining layer and an external layer, and is characterized in that the lining layer consists of bamboo carbon fibers and cotton fibers according to the weight ratio of 15-30:70-85; the external layer consists of cotton fibers, Newdal fibers and polyurethane elastic fibers according to the weight ratio of 43-54:40-54:3-6. The manufacture method comprises that: the bamboo carbon fibers and the cotton fibers, the cotton fibers and the Newdal fibers are respectively spun into Sirospun blended yarns; the Sirospun blended yarns are interwoven with polyurethane elastic fibers to form a knitted underwear fabric; and the knitted underwear fabric forms a final finished product, namely the bamboo carbon fiber underwear fabric through dyeing, drying, sanding and shaping treatment. The fabric and the manufacture method have the advantages that the bamboo carbon fiber underwear fabric not only has good skin-friendly property, low pilling tendency and comfortable elasticity, and has functions of good odor decomposition, smell elimination and the like.

Owner:SHANGHAI PLANDOO TEXTILE TECH DEV

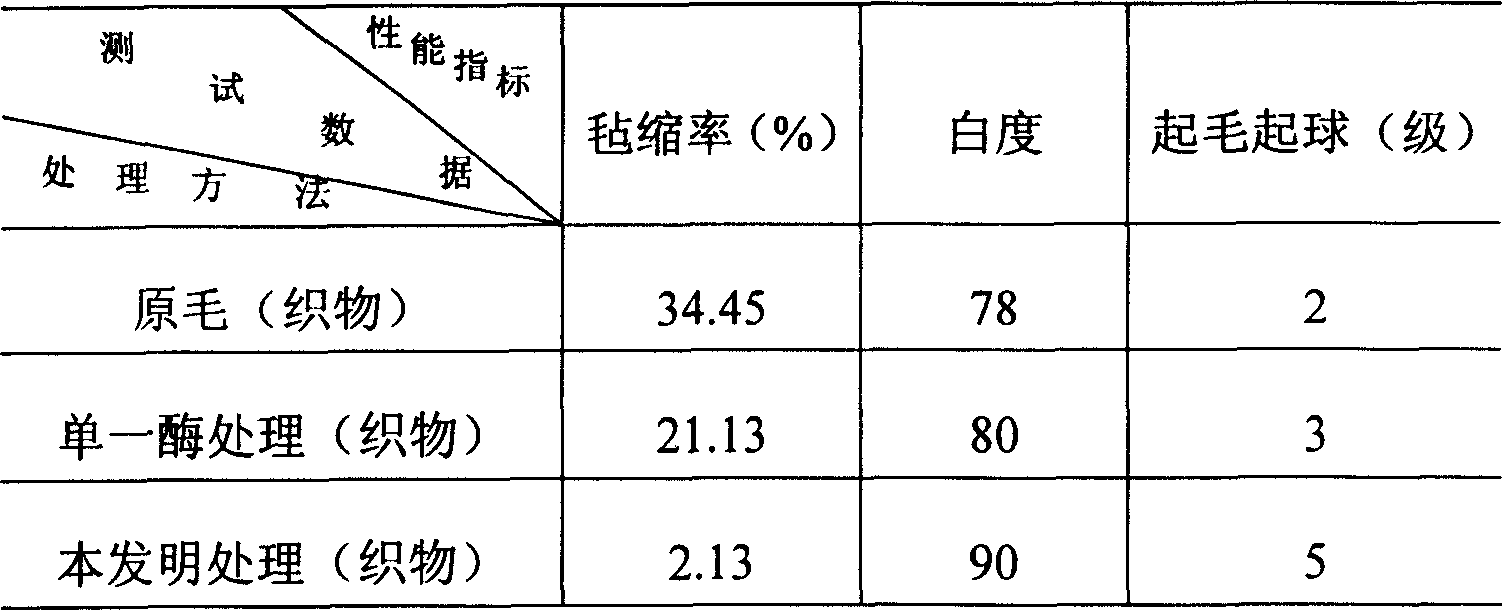

Finishing method for preventing felting and shrinking of wood fabric

InactiveCN1693575AQuality is not affectedAvoid damageBiochemical fibre treatmentHazardous substanceNeutral proteinase

The invention is a wool anti-felting finishing method, and its character: the preprocessing adopts chitosan water solution for soaking and adopts neutral proteinase and neutral fatty to make enzyme degradation treatment, thus making the felting ratio of the processed wool fabric less than 3%, and strong damage within 5% and raising balling resistance of wool fiber by 2-3 grades, and also the whiteness, able to completely meet the machine washing requirement. The invention simplifies the processing course and shortens the process flow and has a shorter cycle so as to strengthen the feasibility in industrialized operation and has no residual harmful matters and can not cause environmental pollution.

Owner:ENZYME ENG INST SHAANXI PROVINCE ACAD OF SCI

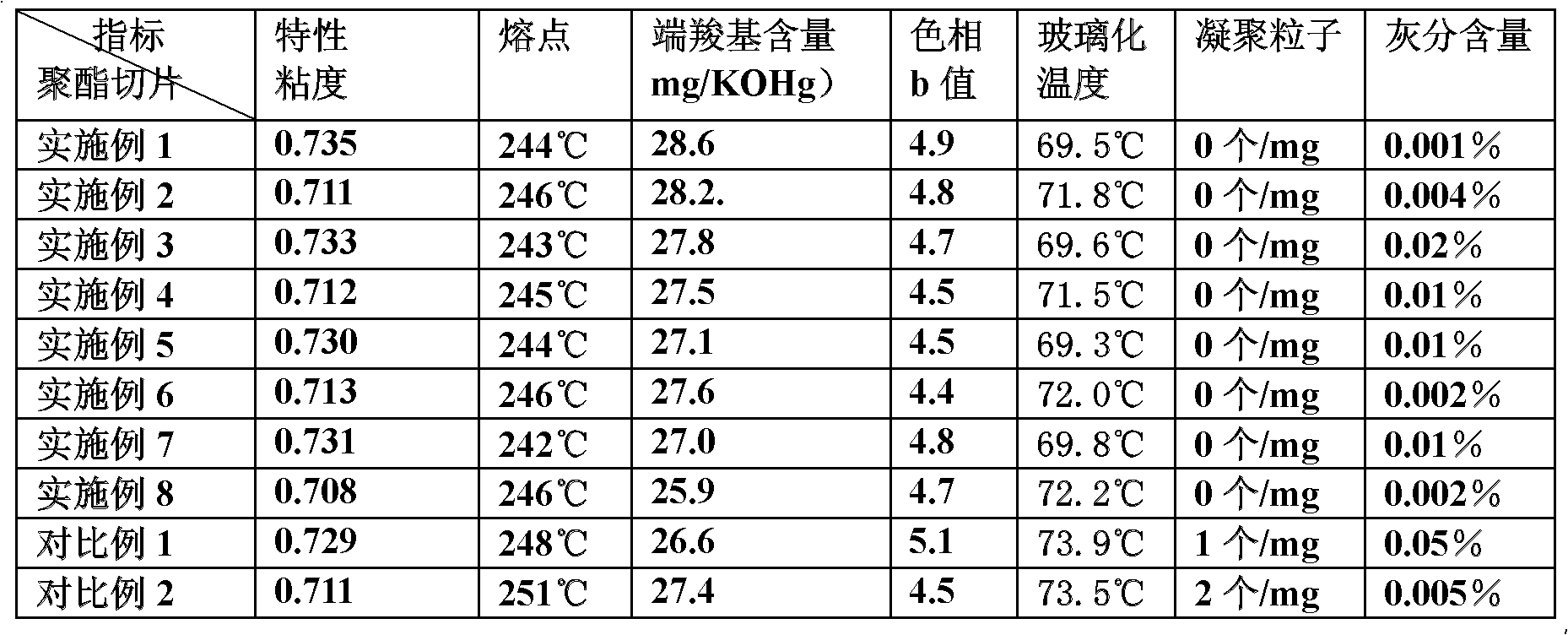

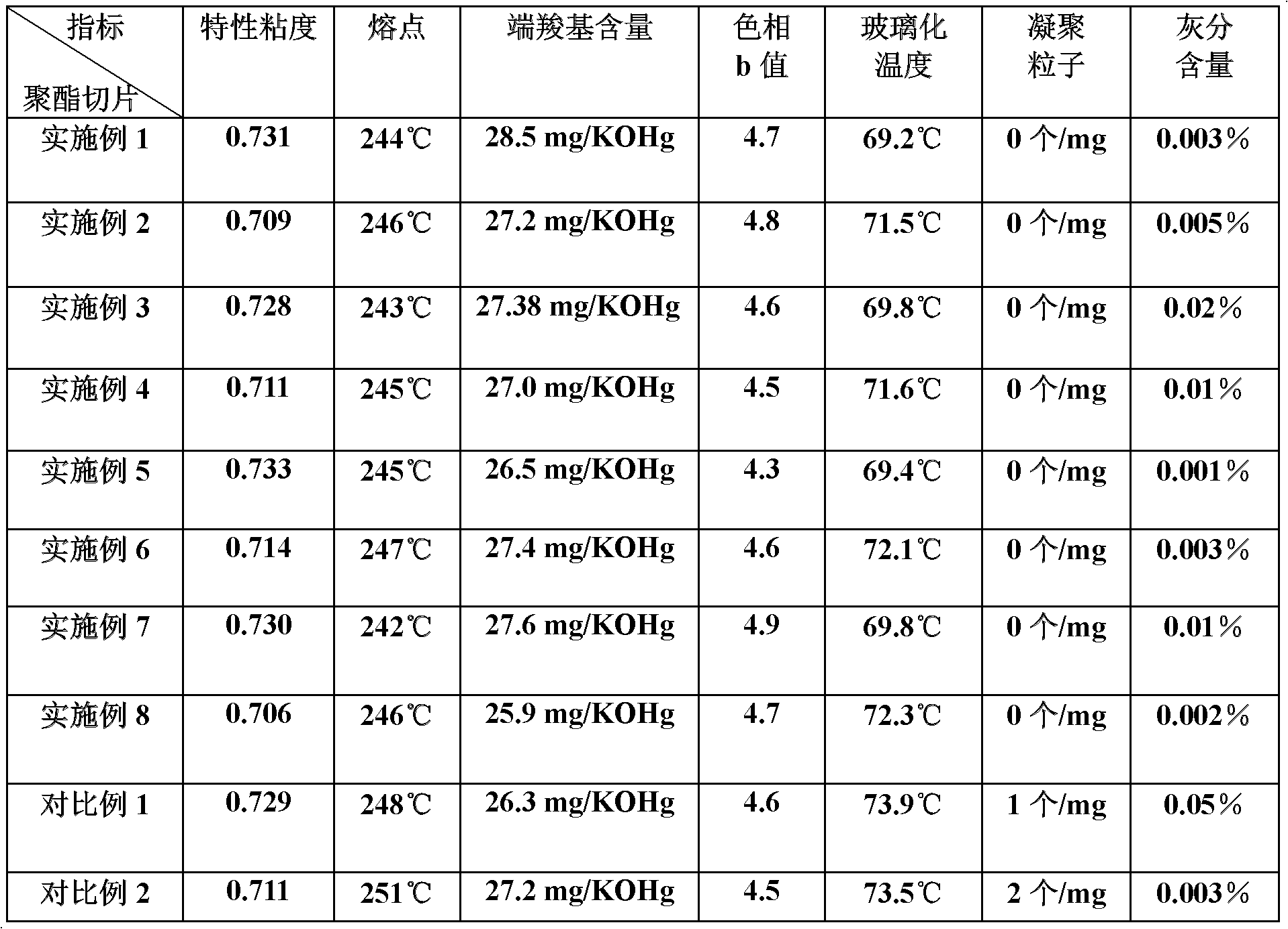

High-shrinkage cation normal-pressure easy-to-dye polyester chip and preparation method thereof

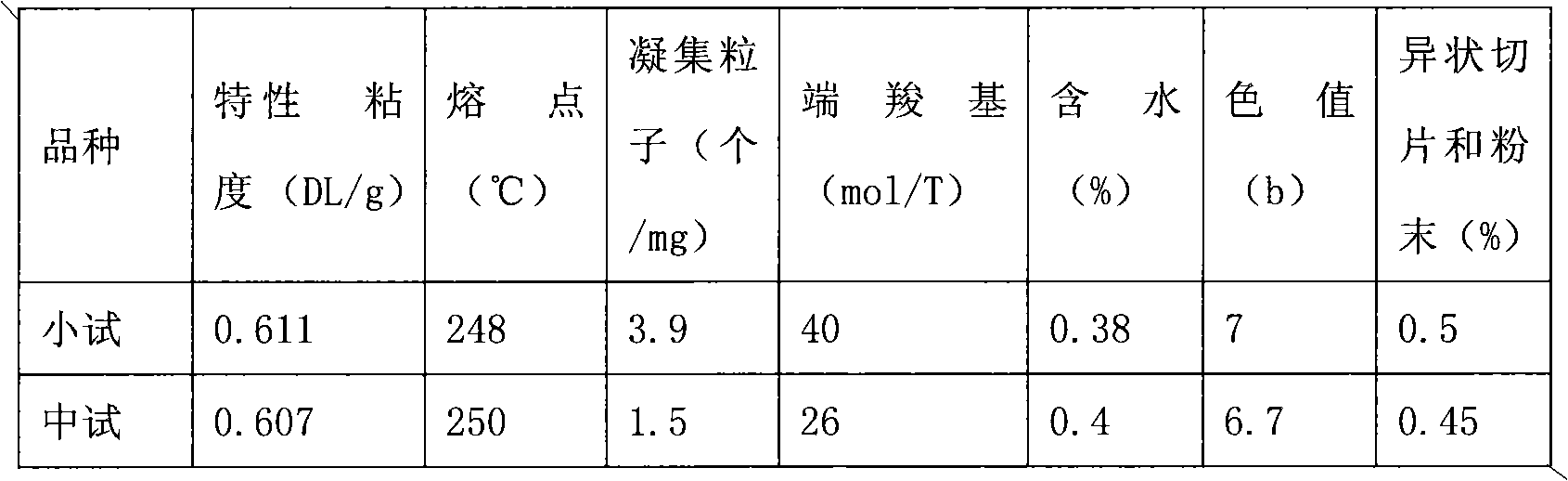

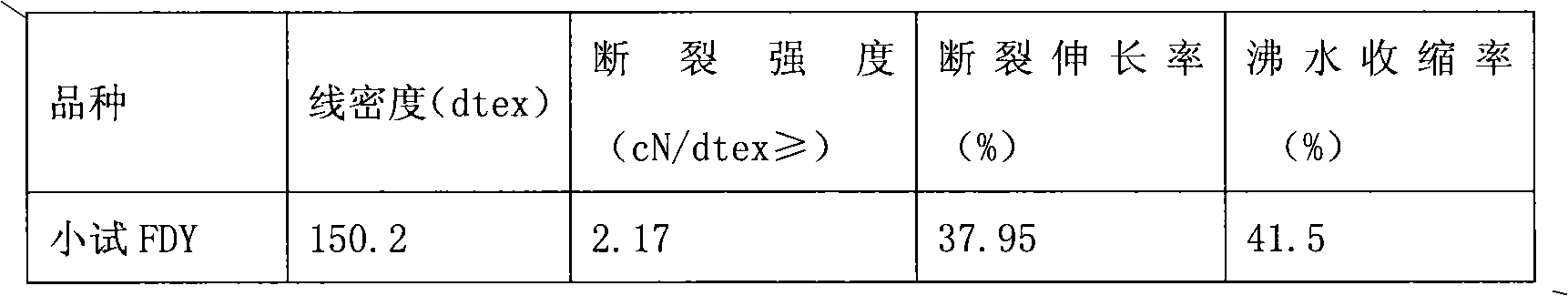

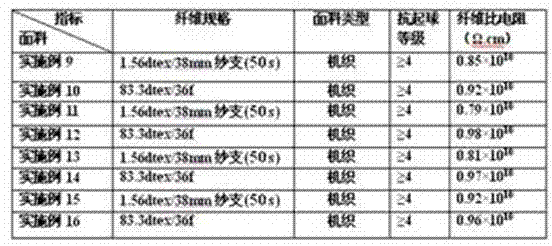

The invention discloses a high-shrinkage cation normal-pressure easy-to-dye polyester chip and a preparation method thereof. The high-shrinkage cation normal-pressure easy-to-dye polyester chip comprises the following components: 66-68 percent of purified terephthalic acid, 23-21 percent of glycol, 3.2-5.5 percent of isophthalic acid digylcol ester-5-sodium sulfonate, 2.1-3.3 percent of polyethylene glycol, 0.5-0.7 percent of isophthalic acid, 3.1-4 percent of hexanedioic acid, 0.012-0.036 percent of antimony acetate and 0.005-0.055 percent of antioxidant. The high-shrinkage cation normal-pressure easy-to-dye polyester chip is subjected to an esterification reaction at the pressure of 0.25-0.3MPa and the temperature of 250-260DEG C and a polycondensation reaction at the temperature of 230-270DEG C and at the vacuum degree of 0.08-0.098MPa and temperature preservation after the temperature reaches 272-278DEG C. The high-shrinkage cation normal-pressure easy-to-dye polyester chip has the advantages of high dyeing rate and dye suction rate at normal temperature and normal pressure, bright color, favorable performances of high shrinkage and resisting pilling, spinnability, drafting property and favorable physical property and post treatment performance of fibers.

Owner:PETROCHINA CO LTD

Method for treating anti-lousiness-pilling for cashmere fabric

InactiveCN1508352AGood anti-pillingImprove anti-pilling performancePhysical treatmentWastewaterEngineering

The invention relates to a processing method to resist the fluffing and pilling of pashm textile. It places the pashm textile in low-temperature plasm processing cavity, then pumps the pressure in the processing cavity to lower than or equal to 10Pa, inputs non-polymeric gas to adjust the pressure in the processing cavity to 10-20Pa and exerts voltage on electrodes to make low-temperature plasm processing for 10-600s under 10-200W power to obtain excellent finished product. It can further make softened finish, shrinkproof finish or other functional finishes on the processed pashm textile.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Bamboo charcoal fiber blended color yarn and its production method

ActiveCN1804166AColorfulMeet individual requirementsYarnMonocomponent polyesters artificial filamentYarnEngineering

The bamboo charcoal fiber mixed-color spinning yarn comprises two or more fibers with different color special with 55-100% bamboo charcoal terylene fiber. This invention keeps the effect of bamboo charcoal fiber of deodorizing, bacterial inhibition, moisture absorption, antistatic and far IR, dyes the bamboo charcoal fiber to provide product with variable color, and meets individual request.

Owner:ZHEJIANG HUAFU COLOR TEXTILE

Cation viscose vortex spun woven fabric and preparation method thereof

The invention relates to a preparation method of a cation viscose vortex spun woven fabric, which comprises the following steps of: drawing polyester fibers with cations, and viscose fibers in a ratio on a drawing frame to obtain cation viscose drawn slivers; spinning cation viscose vortex spun single yarns at a certain vehicle speed, warping, warp-rebeaming, and sizing to obtain the cation viscose vortex spun single yarns serving as the warp beams of the cation viscose vortex spun woven fabric; weaving the cation viscose vortex spun single yarns serving as warp yarns and other raw materials serving as weft yarns into a whole according to different tissue requirements by using a single-warp beam weaving machine; and performing secondary light desizing and secondary dyeing, and drying to obtain the dyed cation viscose vortex spun woven fabric. The cation viscose vortex spun woven fabric prepared by the method is suitable for a clothing fabric, and has a bright and clean surface, soft handfeel, high pilling resistance, washing fastness and hygroscopicity, and higher face quality and lower cost compared with the common polyester viscose fabric, energy consumed in the process of double-twisting into plied yarns is saved, various index requirements of the fabric are improved while the cost is reduced, and the method is suitable for processing and weaving fabrics on a large scale.

Owner:HANGZHOU AOHUA TEXTILE

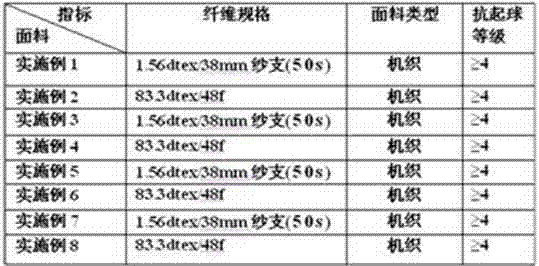

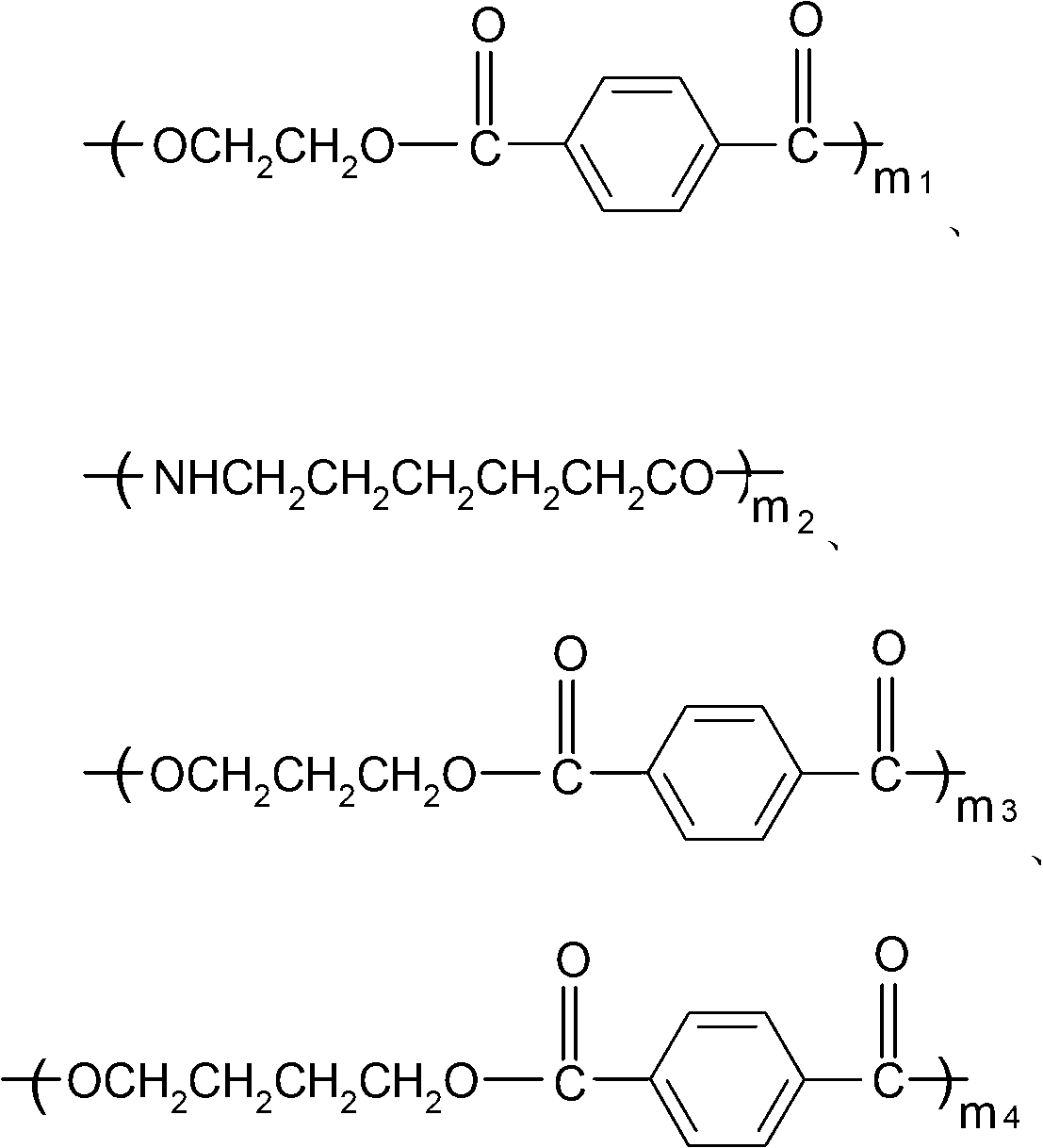

Preparation method for anti-pilling, anti-ageing and normal-pressure cation dyeable polyester chips

InactiveCN102391487AAvoid stickingAvoid self-polymerizationMonocomponent polyesters artificial filamentPolyesterTrans esterification

The invention relates to a preparation method for anti-pilling, anti-ageing and normal-pressure cation dyeable polyester chips. The preparation method comprises procedures of primary esterification, transesterification, secondary esterification and polymerization, wherein three monomers are added in the transesterification procedure; a hindered amine light stabilizer, a hindered phenol antioxidant and hydroxyl silicon oil are added after the secondary esterification and before prepolymerization; and the polyester slices are precrystallized and dried before the spinning procedure. A fabric prepared from fibers spun by the polyester chips has a high anti-pilling property and high light fastness; the polyester fibers can be dyed with various bright colors due to the normal-pressure cation dyeable property; the unified requirement of high-grade spring and summer clothing at present on functionality and color is met; and the polyester fibers and wool can be dyed in the same bath and a good clothing effect of the fibers blended with the wool is achieved. The polyester fibers spun by the polyester chips are important supplement for the cation dyeable polyester fiber market at present and have wide market prospect.

Owner:WUJIANG GANGYANG CHEM FIBER +1

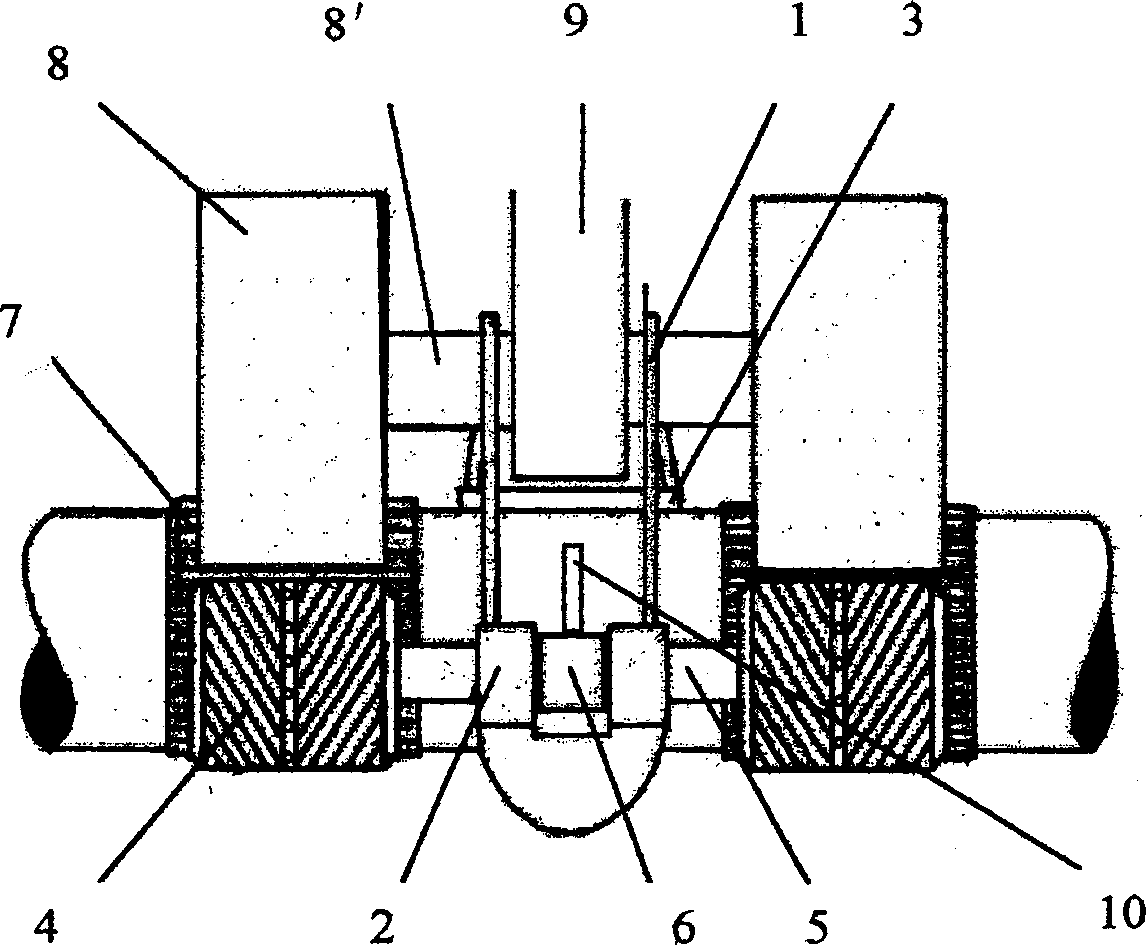

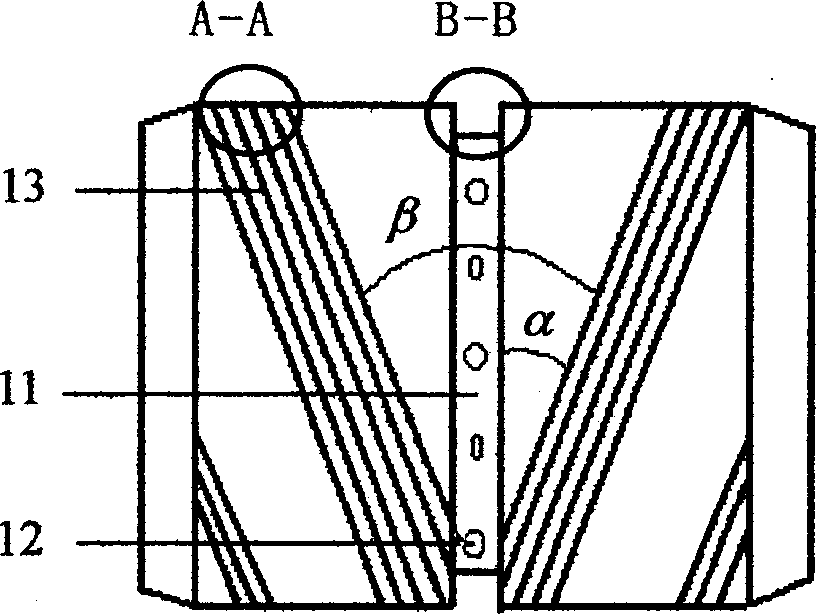

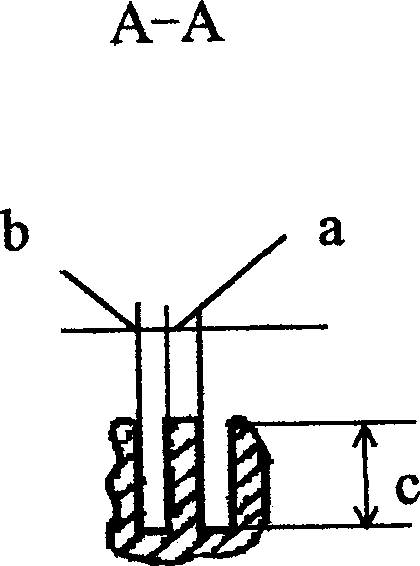

Fiber strand aggregating device for air slide

InactiveCN1388279AHigh glossImprove wear resistanceDrafting machinesContinuous wound-up machinesEngineeringHigh intensity

The present invention is fiber strand aggregating device for air slide, and its novel design is its aggregating roller with new splitting guide flute and porous aggregating flute. It is installed between the front jaw and the spinning section in the drawing area of spinnin frame, and the air slide fiber strand aggregating device and the front roller form one fiber jaw. By means of the additional aggregating air flows, one flow field for fiber inside the guide flute and the aggregating flute is provided. By means of splitting and guide of the guide flute and the aggregating flute and the aggregation of fiber strand in the aggregating flute, the fiber strand is twisted closely in the aggregating flute. The yarn of the present invention has improved axial parallel degree, decreased hairy feather amount outside the yarn and raised yarn strength.

Owner:DONGHUA UNIV

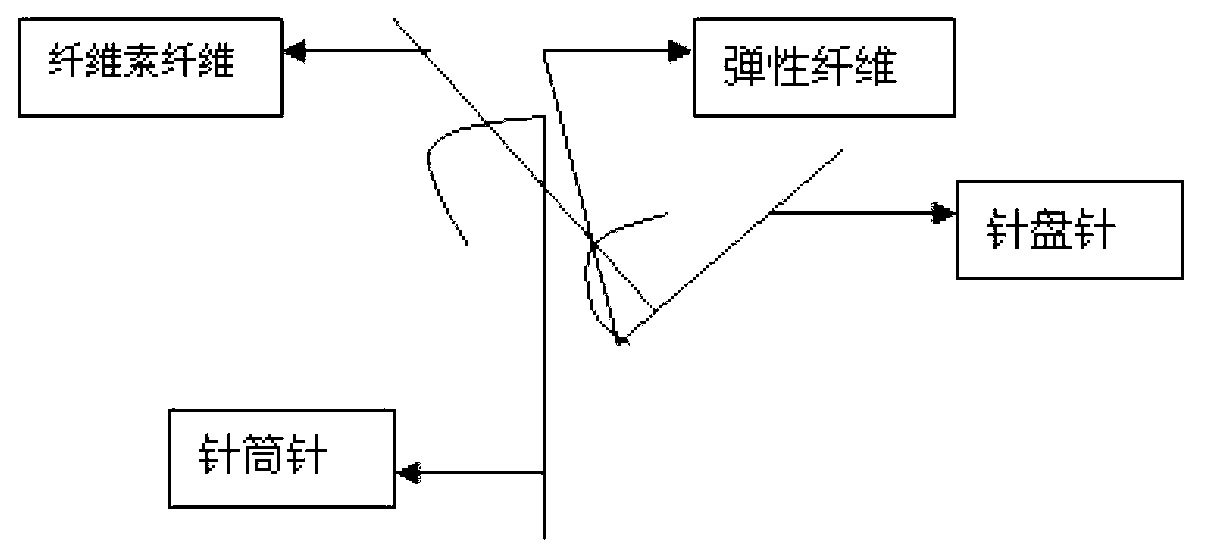

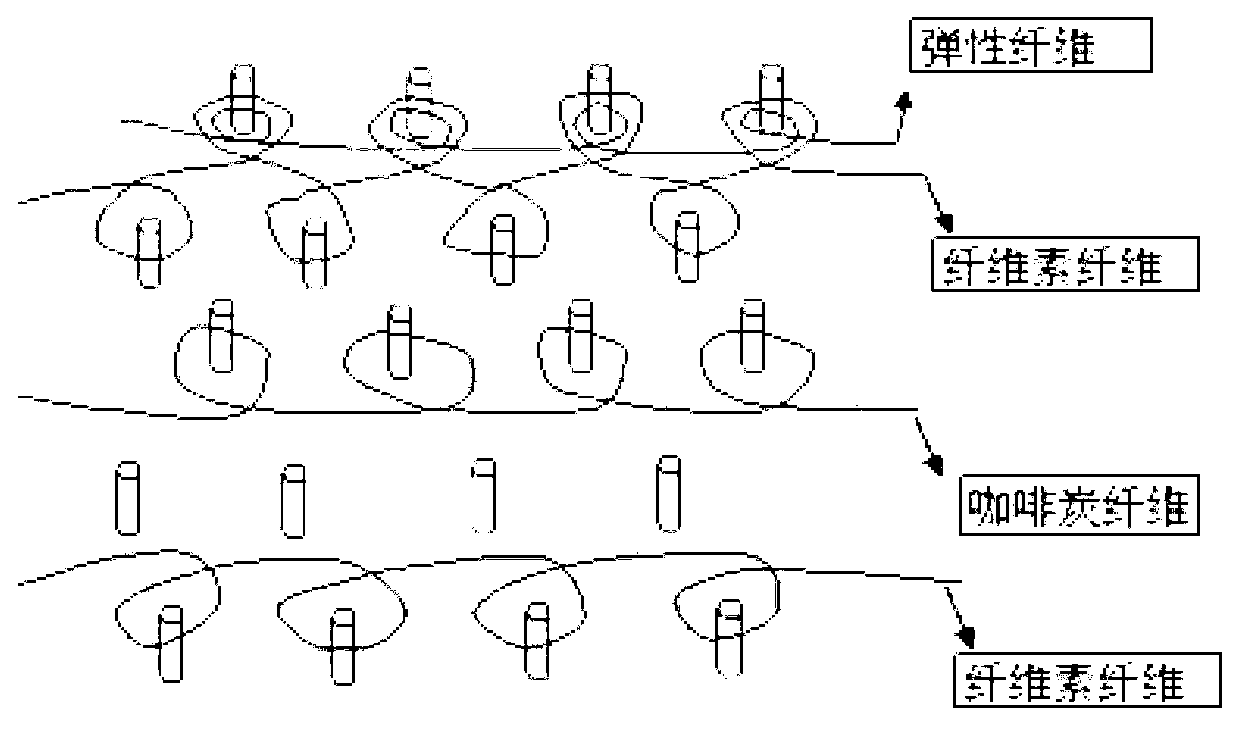

Multifunctional knitted underwear shell fabric and preparation method thereof

ActiveCN103251138AFunction increaseThe preparation process is scientific and environmentally friendlyWeft knittingBiochemical fibre treatmentCarbon fibersCellulose fiber

The invention relates to multifunctional knitted underwear shell fabric and a preparation method thereof. The shell fabric comprises an inner layer structure and an outer layer structure. An outer layer comprises cellulosic fibers and elastic fibers, an inner layer comprises coffee carbon fibers and cellulosic fiber blended yarns, and the weight ratio of the coffee carbon fibers to the cellulosic fiber blended yarns is 35-40: 60-65. The preparation method comprises the following steps of structure designing, weaving by adopting a weft knitting double-face multi-needle channel rib needle machine, fabric presetting, pre-processing, dyeing, post-processing, fixation, washing and drying. The multifunctional knitted underwear shell fabric is obtained through the method. The multifunctional knitted underwear shell fabric has the advantages that preparing processes are scientific and environment-friendly, cost is saved and effects are durable. The multifunctional knitted underwear shell fabric has good water sucking performance and a function of infrared, is anti-bacteria, deodorizing, environment-friendly, moisture-absorbing, anti-pilling and good in elastic recovering property, and can be dried fast and can heat. In addition, the multifunctional knitted underwear shell fabric solves the technical problem that the color systems of coffee carbon fiber products are few, the coffee carbon fiber products are made to be colorful, and the multifunctional knitted underwear shell fabric has good application prospect.

Owner:NINGBO DAQIAN TEXTILE

No-fluff wool fabric of fiber with surface nano structure and its prepn

InactiveCN1548643ALarge specific surface areaImprove cohesionUltrasonic/sonic fibre treatmentWastewaterLow temperature plasma

The present invention belongs to the field of functional fabric, and is especially no-fluff wool fabric of fiber with surface nano structure and its preparation. After wool fabric is set inside low temperature plasma processing cavity, the pressure inside the cavity is first pumped to not higher than 10 Pa and then regulated with introduced non-polymerizing gas to 10-170 Pa and the wool fabric is discharged for low temperature plasma processing at power of 10-300 w for 1-60 min, so as to form nano level embossed structure in the surface of wool fiber, to produce hydrophilic radical in the surface of wool fiber for fast escape of water and to obtain wool fiber with excellent fluff resisting performance. The wool fabric through the low temperature plasma processing may be further finished via softening, etc.

Owner:中科纳米技术工程中心有限公司

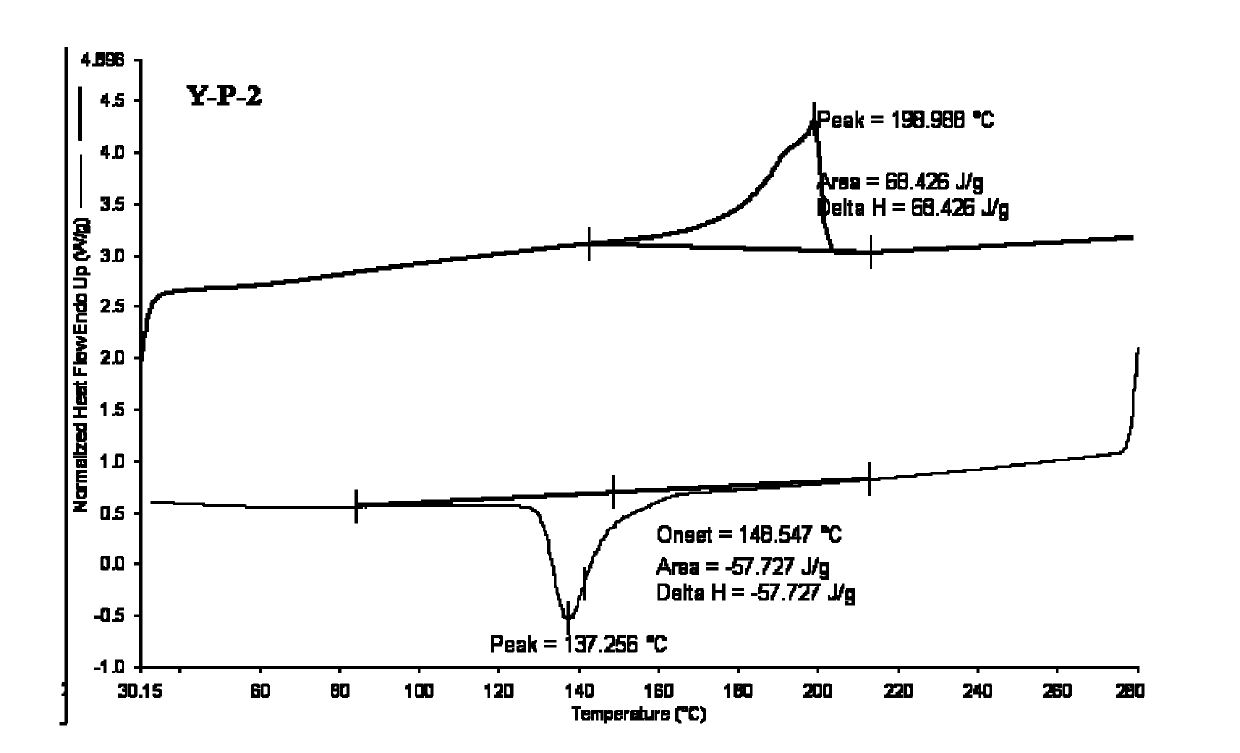

Method for preparing high-comfortable composite functional polyester fiber

ActiveCN102409429AReduce harmImproves UV resistanceElectroconductive/antistatic filament manufactureMonocomponent polyesters artificial filamentSolventAntistatic agent

The invention relates to a method for preparing a high-comfortable composite functional polyester fiber, comprising the steps of: first esterification reaction section, secondary esterification reaction section, polymerization reaction process and spinning process, wherein aliphatic dicarboxylic acid and / or non-centrosymmetrically aromatic dicarboxylic acid is led into the first esterification reaction section to serve as a third monomer; flexible polyethylene glycol is led into the secondary esterification reaction section to serve as a fourth monomer; after finishing the esterification reactions, hindered amine light stabilizer and hindered phenolic antioxidant which are respectively prepared by taking acetic acid and ethylene glycol as solvents and hydroxyl silicone oil are added; after finishing pre-polymerization and before final polymerization of the polymerization reaction process, ultraviolet light absorber and antistatic agent are added; and before finishing the spinning process, polyester slices are performed pre-crystallization and drying; fibers with odd-shaped cross sections of three-leaf, cross, five-leaf and the like are prepared by melt spinning. The obtained polyester fiber is anti-ultraviolet light, antistatic, anti-pilling and has wet-absorbing quick-drying performance; and the fabric has high comfort.

Owner:JIANGSU ZHONGLU TECH DEV +1

One-bath four-step process printing and dyeing method for multi-component fiber fabric

InactiveCN103114460AImprove color fastness to rubbingImprove anti-pilling performanceSynthetic fibresDyeing processFiberEngineering

The invention relates to a printing and dyeing method and particularly relates to a one-bath four-step process printing and dyeing method for multi-component fiber fabric. The method is performed according to the following steps: selecting, performing pretreatment process step, performing unhairing process step, performing printing process step, performing first-step fixing, performing second-step fixing, performing third-step fixing, performing fourth-step fixing, performing trimming process step and inspecting. According to the one-bath four-step process printing and dyeing method for the multi-component fiber fabric, the flame retardance is excellent, the printing color and luster are full and deeply moist, the hand feeling is good in elasticity, the color fastness is good, and the high-strength wear resistance is further realized.

Owner:浙江汇丽印染整理有限公司

Polyester-polyamide copolymer fiber and manufacturing method thereof

ActiveCN101942708BSimplify the dyeing processImprove anti-pilling performanceArtificial filament physical treatmentMonocomponent synthetic polymer artificial filamentDisperse dyeBreaking strength

Owner:CHINESE TEXTILE ACAD

Superfine porous dacron irregular-shaped draw textured yarn (DTY) production process

The invention discloses a superfine porous dacron irregular-shaped draw textured yarn (DTY) production process which includes polyester pre-oriented yarn (POY) protofilament, a pre-network, a first yarn feeding roller, a first texturing heater, a cooling plate, a false twister, a second yarn feeding roller, a second auxiliary roller, a second heat box, a third yarn feeding roller, an oil applying rod and DTY winding molding. The second yarn feeding roller speed is 660m / min-700m / min, and drawing multiple of the second yarn feeding roller is 1.610-1.650. Deforming temperature of the first texturing heater is 183 DEG C-188 DEG C, and sizing temperature of the second heat box is 170 DEG C-180 DEG C. A friction disc of the false twister is 1-4-1 disc combination, and D / Y ratio is 1.55-1.63. Sizing overfeeding rate is 4.25-4.90, winding overfeeding rate is 5.00-5.35, and overfeeding rate of the second auxiliary roller is 3.00-3.50. Flannel fabric produced through the process has the performance of rigidity, glittering, fluffiness, pilling resistance, staining resistance and the like.

Owner:JIANGSU DELI CHEM FIBER CO LTD

Preparation method for polyester fibers with anti-static, anti-pilling and normal-pressure cation dyeable compound functions

InactiveCN102391486AAvoid self-polymerizationEasy-to-stain function guaranteeMonocomponent polyesters artificial filamentPolyesterFiber

The invention relates to a preparation method for polyester fibers with anti-static, anti-pilling and normal-pressure cationic dyeable compound functions. The preparation method comprises procedures of primary esterification, transesterification, secondary esterification and polymerization, wherein three monomers are added in the transesterification procedure; a hindered amine light stabilizer, a hindered phenol antioxidant and hydroxyl silicon oil are added after the secondary esterification and before prepolymerization; and an antistatic agent is added after the prepolymerization and before final polymerization. Fabric spun by the polyester fibers has high anti-static and anti-pilling properties; the polyester fibers can be dyed with various bright colors due to the normal-pressure cation dyeable property; the unified requirement of high-grade spring and summer clothing at present on functionality and color is met; and the fibers and wool can be dyed in the same bath and a good clothing effect of the fibers blended with the wool is achieved. The polyester fibers are important supplement for the cation dyeable polyester fiber market at present and have wide market prospect.

Owner:WUJIANG GANGYANG CHEM FIBER +1

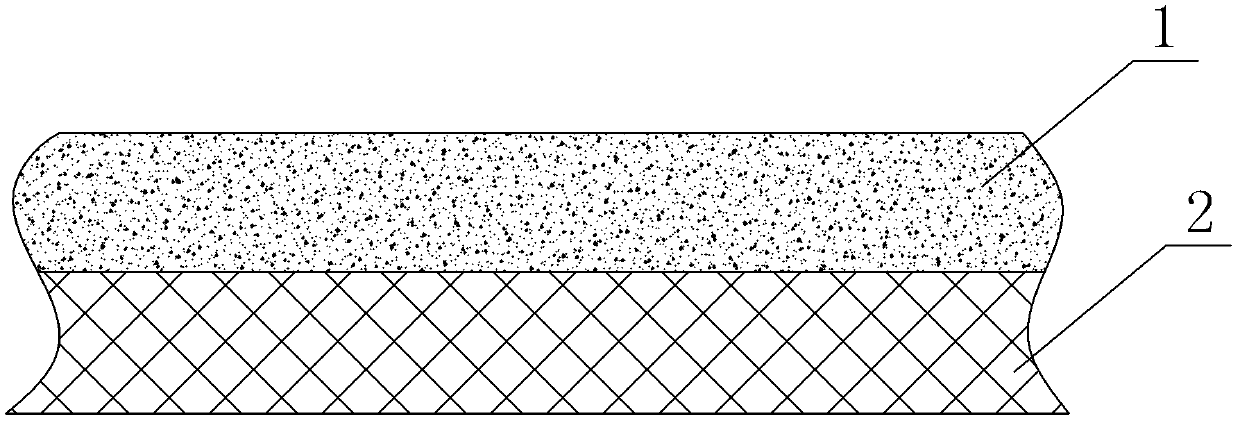

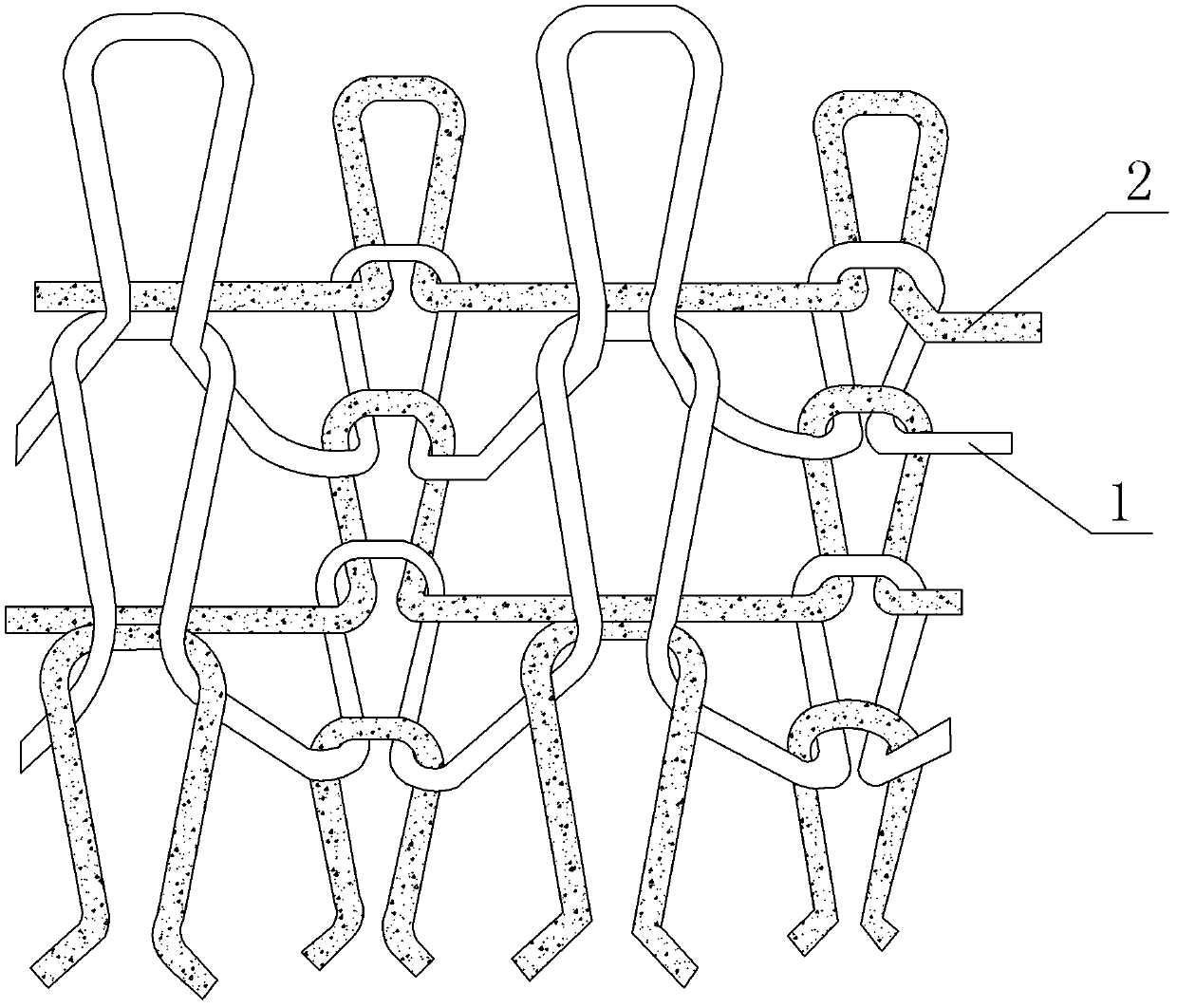

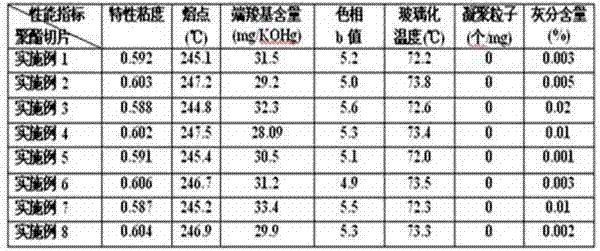

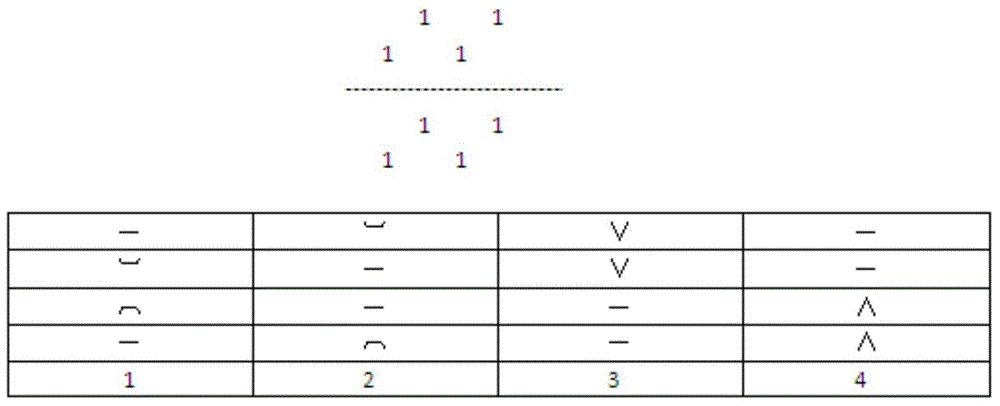

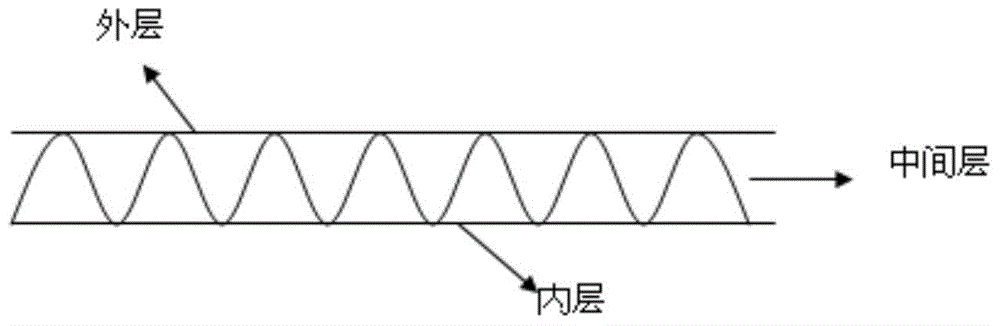

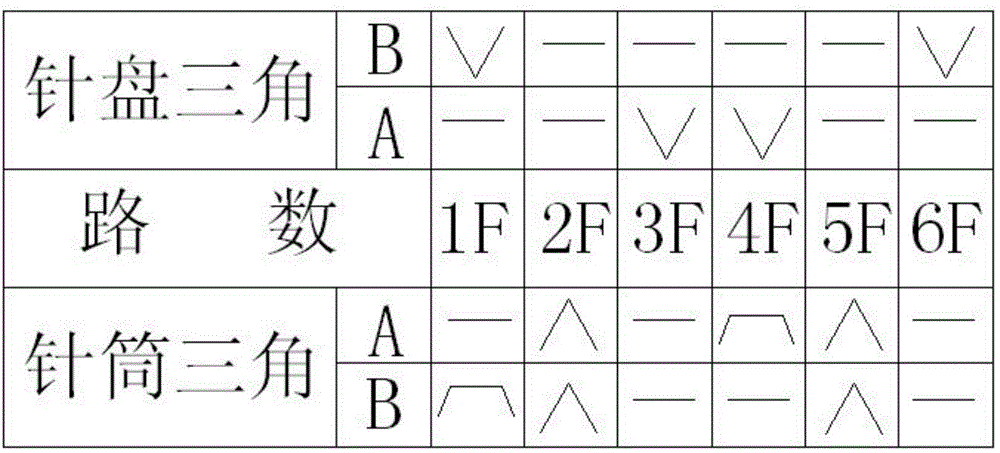

Three-dimensional warm-keeping knitted fabric and preparation method thereof

InactiveCN104088066AGood three-dimensional structureImprove anti-pilling performanceWeft knittingYarnExtensibility

The invention relates to a three-dimensional warm-keeping knitted fabric and a preparation method thereof. The inner layer and the surface layer of the fabric are formed by weaving one or two of synthetic fiber filaments and staple fiber yarns and are in sleeved-connection through the synthetic fiber filaments to form a middle layer. The preparation method comprises the steps that the fabric is formed by a double-face circular knitting machine; the middle layer of the fabric is connected with the inner layer structure and the outer layer structure of the fabric by a needle disk and needle barrel crossing doubling stitch or needle disk and needle barrel complete doubling stitch processing technology; the outer layer of the fabric is processed by a needle barrel complete circling technology, and the inner layer of the fabric is processed by a needle disk complete circling technology. The inner layer of the three-dimensional warm-keeping knitted fabric is lower in extensibility and is higher in heat resistance the good three-dimensional structure of the fabric is kept, so that the fabric is good in warm-keeping effect and high in balling resistance; the preparation technology is simple and low in cost and has a good application prospect.

Owner:NINGBO DAQIAN TEXTILE

Production method for viscose cotton vortex textile

InactiveCN103088579ARaise the indicator requirementsReduce energy consumptionSucessive textile treatmentsYarnYarnCotton fibre

The invention relates to a production method for a viscose cotton vortex textile. The method usually comprises the following steps of: drawing cotton fibers with cations and viscose fibers on a drawing frame according to a proportion to obtain viscose cotton drawn slivers, spinning single viscose cotton vortex spun yarns according to certain speed, performing warping, warp rebeaming and sizing to obtain single viscose cotton vortex spun yarns which are weaved with textile warp beams by a cationic viscose vortex spinning machine, integrally weaving the single viscose cotton vortex spun yarns serving as warps and other raw materials serving as wefts by using single-warp beam weaving machines according to different organizational requirements, and performing secondary light desizing, secondary dyeing and drying to obtain a dyed viscose cotton vortex textile. Vortex spinning is high in production efficiency and unique in yarn forming structure, and has the characteristics moisture absorption and high drying speed; by a proper proportion, a final finished product has a soft and rigid handfeel; and by proper speed, the degree of tightness of the yarns is proper, and cloth is smooth.

Owner:NINGBO SHUANGDUN TEXTILE CANVAS IND

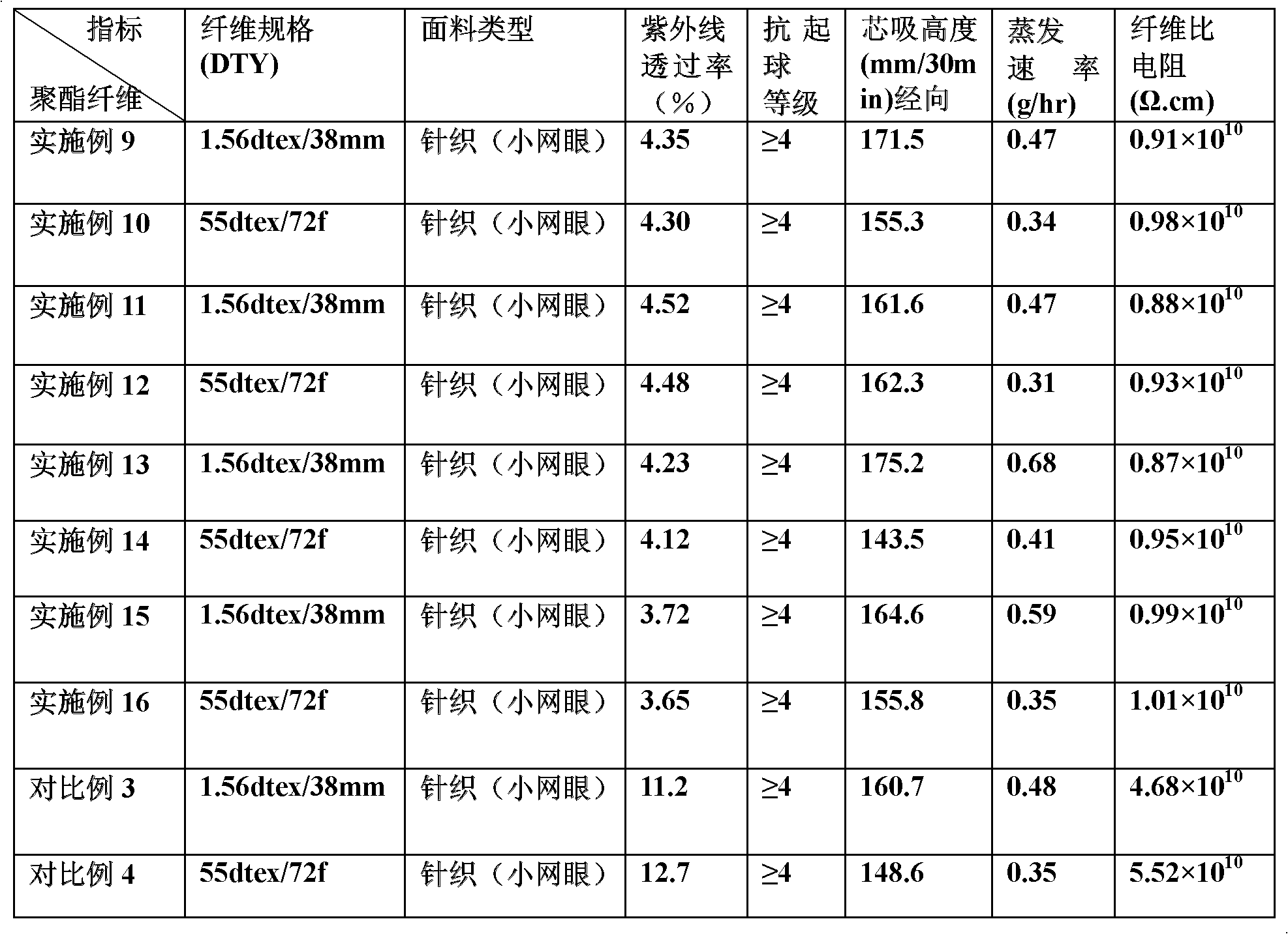

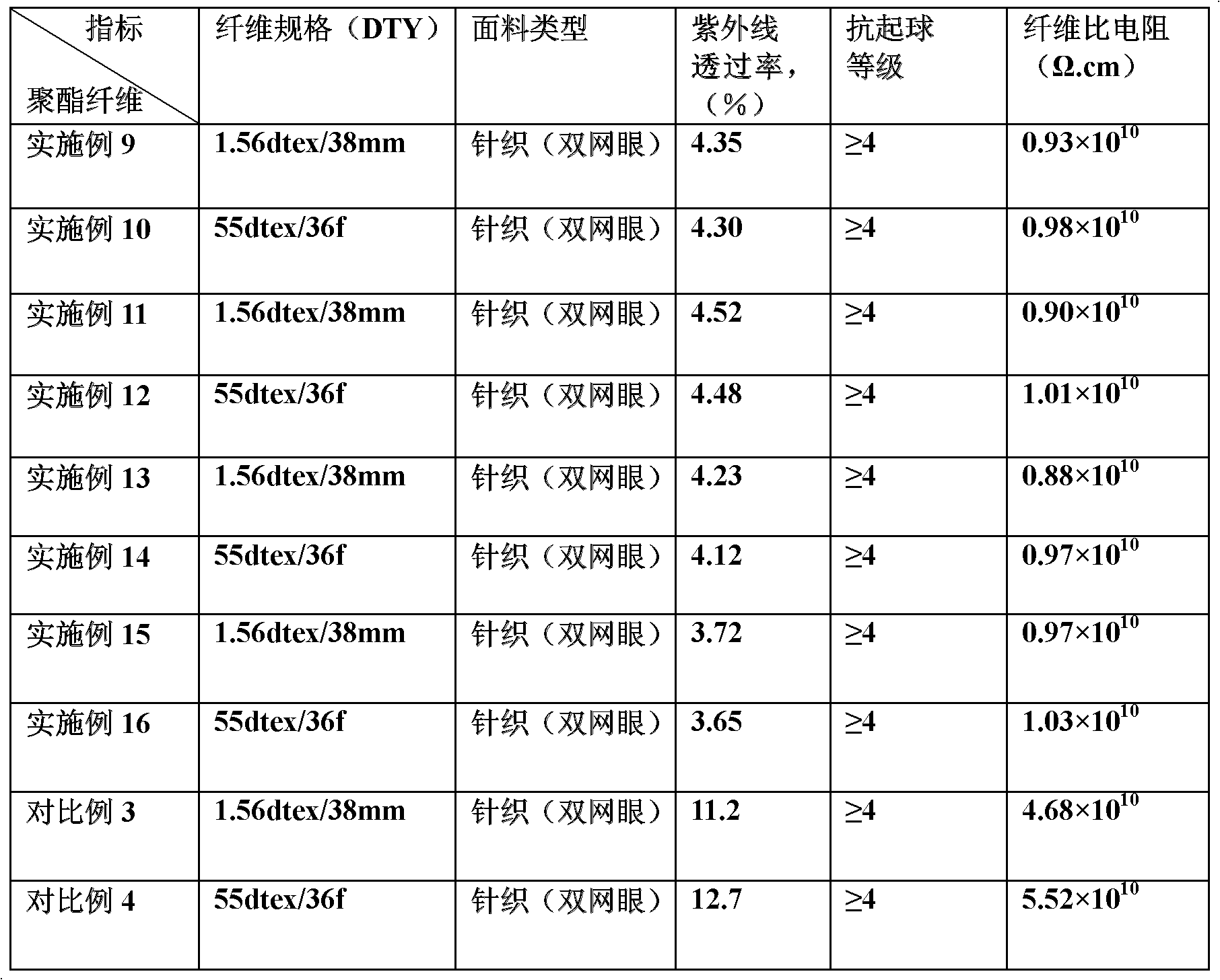

Preparation method for polyester fiber with composite ultraviolet, static electricity and pilling resisting functions

ActiveCN102409427AReduce harmImproves UV resistanceElectroconductive/antistatic filament manufactureArtificial filament heat treatmentSolventTransmittance

The invention relates to a preparation method for a polyester fiber with a composite ultraviolet, static electricity and pilling resisting function. The preparation method comprises an esterification reaction procedure, a polymerization reaction procedure and a spinning procedure. The esterification reaction procedure comprises a primary esterification reaction stage and a secondary esterification reaction stage, flexible polyethylene glycol is introduced as a third monomer in the secondary esterification reaction stage, and after esterification is finished, a hindered amine light stabilizer,a hindered phenol anti-oxidant and hydroxyl silicone oil are added, wherein the hindered amine light stabilizer and the hindered phenol anti-oxidant are prepared by taking an acetic acid and ethyleneglycol as solvents. In the polymerization reaction procedure, after prepolymerization and before final polymerization, an ultraviolet absorbent and an antistatic agent are added. Before the spinning procedure, polyester is sliced for pre-crystallization and drying. The polyester fiber obtained by the method has the outstanding ultraviolet, static electricity and pilling resisting functions, and after being woven into knitted machine-made fabrics, is tested to have related technical indexes comprising the ultraviolet light transmittance of less than or equal to 5.0%, the pilling resistance of more than or equal to level 4 and the fiber volume specific resistance of less than or equal to 10*10<10> ohm.cm.

Owner:JIANGSU ZHONGLU TECH DEV +1

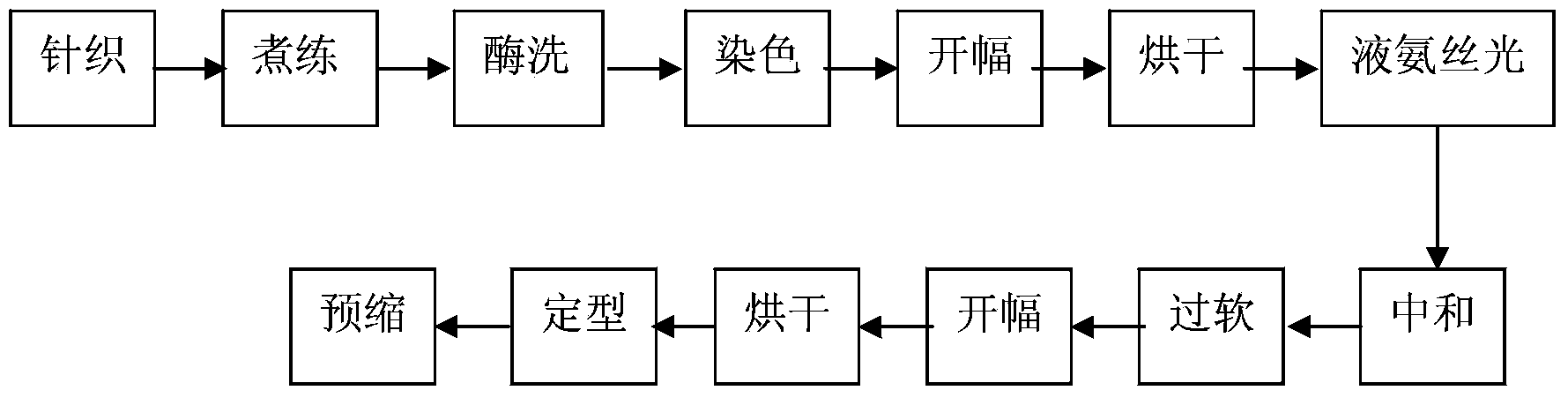

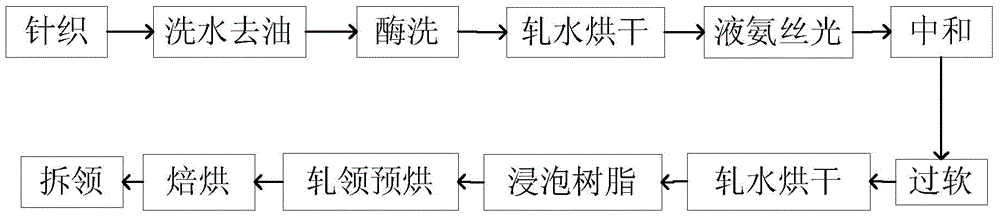

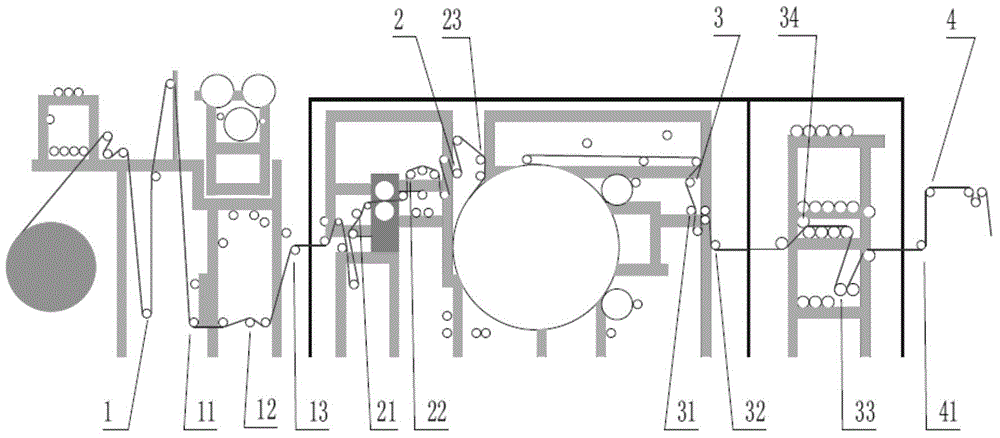

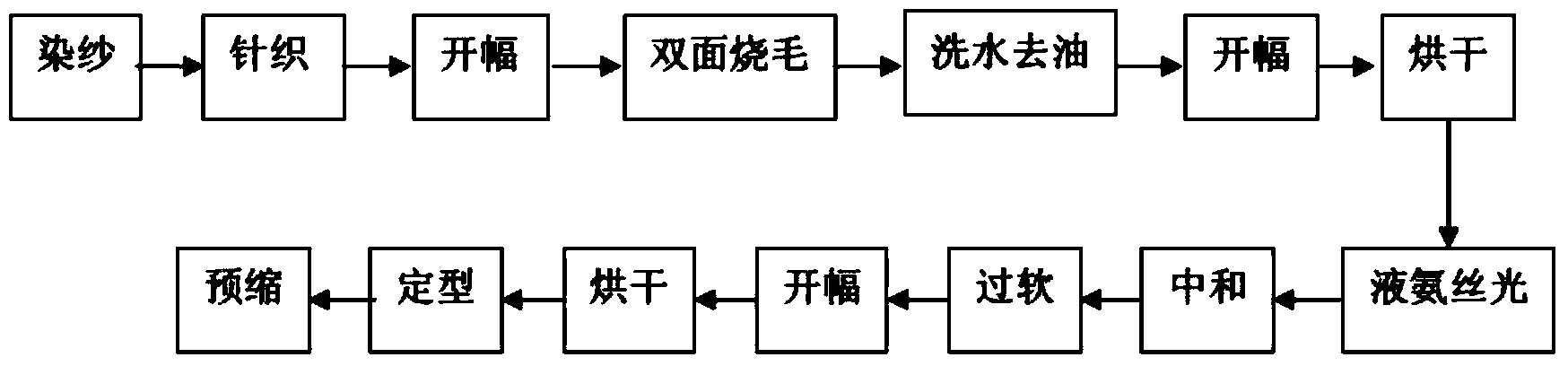

Production method of washable piece-dyed knitted fabric

ActiveCN104264447AImproved dimensional stability and wash resistanceEliminate internal stressMercerising of indefinite length fabricsBiochemical fibre treatmentLiquid ammoniaYarn

The invention provides a production method of washable piece-dyed knitted fabric. The production method comprises steps as follows: undyed yarn is knitted into gray fabric, the gray fabric is sequentially subjected to boiling-off, enzyme wash, dyeing, scotching, drying, liquid ammonia mercerization, neutralization, softening, scotching, drying, setting and preshinking, and the washable piece-dyed knitted fabric is obtained. The production method adopts steps of boiling-off, enzyme wash, dyeing and liquid ammonia mercerization sequentially, the liquid ammonia mercerization effect and the liquid ammonia recycling are facilitated, and resin treatment is combined, so that an obtained knitted product has better dimensional stability, and more durable hand feeling and color are kept; and the fabric has high flatness, touches comfortable and is soft, elastic and better in strength. By means of the production method, various properties of the knitted product are improved, the additional value and the technological content of the knitted product are increased, and recyclable liquid ammonia used for treatment is environment-friendly.

Owner:GUANGDONG ESQUEL TEXTILES

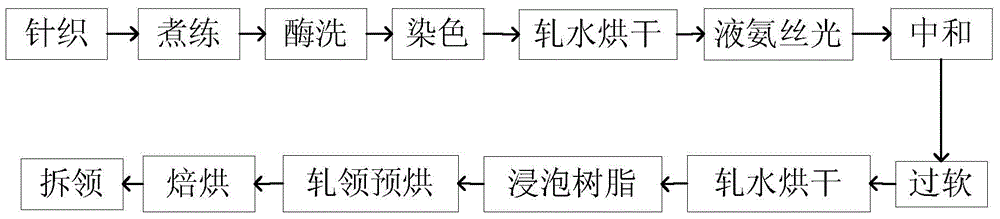

Manufacturing method of washable non-curling knitting collars and cuffs

ActiveCN104358054AGood dimensional stabilityImprove washabilitySucessive textile treatmentsWeft knittingYarnEngineering

The invention provides a manufacturing method of washable non-curling knitting collars and cuffs. The knitting collars and cuffs comprise piece dyeing knitting collars and cuffs and yarn dyeing knitting collars and cuffs; for the piece dyeing knitting collars and cuffs, the method comprises the following steps of knitting, boiling off, enzyme washing, dyeing, squeezing and drying, mercerizing by liquid ammonia, neutralizing, softening, squeezing and drying, soaking in resin, collar rolling and pre-drying, baking, and collar removal; for the yarn dyeing knitting collars and cuffs, the method comprises the following steps of knitting, water washing and oil removal, enzyme washing, squeezing and drying, mercerizing by liquid ammonia, neutralizing, softening, squeezing and drying, soaking in resin, collar rolling and pre-drying, baking, and collar removal. The knitting collars and cuffs manufactured by the method have the advantages that the hand feel is soft after mercerizing by the liquid ammonia, the rebounding property, strength, size stability and washability are obvious improved, the deformation and curling of the collars and the cuffs are avoided after 20 times of water washing, and the good rebounding property is realized; the color change and the fuzzing and pilling resistance respectively reach more than level 4.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Nanometer far infrared ceramic fiber woven fabric and production method of nanometer far infrared ceramic fiber woven fabric

ActiveCN104593931AImprove heat insulation and flame retardant effectImprove wear resistanceConjugated cellulose/protein artificial filamentsWoven fabricsMethacrylateEpoxy

The invention discloses nanometer far infrared ceramic fiber woven fabric. The nanometer far infrared ceramic fiber woven fabric is formed by warp yarns and weft yarns in a woven mode through an air jet loom, and is characterized in that raw materials of the warp yarns and raw materials of the weft yarns comprise, by weight, 27 parts to 33 parts of syndiotactic polypropylene, 10 parts to 14 parts of linear low-density polyethylene, 8 parts to 10 parts of polyurethane films, 16 parts to 22 parts of epoxy resin, 0.4 part to 0.7 part of zinc nitrate, 0.6 part to 0.9 part of magnesium hydrate, 1 part to 3 parts of water glass, 20 parts to 25 parts of nylon yarns, 23 parts to 26 parts of colored cotton fibers, 18 parts to 23 parts of nanometer far infrared ceramic fibers, 21 parts to 24 parts of cellulose acetate fibers, 7 parts to 10 parts of isobutyl methacrylate, 5 parts to 9 parts of peach gum, 1 part to 3 parts of radix bupleuri, 2 parts to 5 parts of fossil fragments, 80 parts to 90 parts of 1-butyl-3-methylimidazolium acetate, 90 parts to 100 parts of 1-allyl-3-methylimidazolium chlorine salt, a proper amount of water and 4 parts to 8 parts of assistants. By means of the nanometer far infrared ceramic fiber woven fabric, the spinnability of plant fibers and the spinning quality are improved, the warmth keeping performance, the wearing resistance, the pilling resistance and the washing resistance of the woven fabric are further improved, and the market prospects are good.

Owner:JIXI YUANDAO AGRI IND TECH

Production method of washable yarn-dyed knitted fabric

InactiveCN104264412AImprove responseImprove hydrophilicityMercerising of indefinite length fabricsFibre treatmentYarnAdditional values

The invention provides a production method of washable yarn-dyed knitted fabric. The production method comprises steps as follows: yarn is sequentially subjected to yarn dyeing, knitting, scotching, double-side singeing, washing for oil removal, scotching, drying, liquid ammonia mercerization, neutralization, softening, scotching, drying, setting and preshinking, and the washable yarn-dyed knitted fabric is obtained. The production method adopts steps of singeing, washing for oil removal and liquid ammonia mercerization sequentially, the liquid ammonia mercerization effect and the liquid ammonia recycling are facilitated, and resin treatment is combined, so that an obtained knitted product has better dimensional stability, and more durable hand feeling and color are kept; and the fabric has high flatness, touches comfortable and is soft, elastic and better in strength. By means of the production method, various properties of the knitted product are improved, the additional value and the technological content of the knitted product are increased, and recyclable liquid ammonia used for treatment is environment-friendly.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Process for producing controllable micropore polyester fiber fabric

InactiveCN101956275AControllable specific surface areaGood moisture managementWoven fabricsYarnPolyesterYarn

The invention discloses a process for producing a controllable micropore polyester fiber fabric. The process comprises a weaving process and a dyeing and finishing process, wherein warps are warped, drawn in, dented, subjected to a sizing process and woven into a gray fabric together with wefts; a blended yarn comprises the following raw materials in percentage by weight: 65 percent of micropore polyester fiber and 35 percent of raw cotton fiber or 65 percent of micropore polyester fiber and 35 percent of viscose fiber; a sizing agent adopted in the sizing process comprises polyvinyl acetate (PVA)-1799, PVA-205M and polyacrylic ester; a texture structure adopts a plain texture; and the ratio of the warp to the weft is 2:2 in the aspect of yarn arrangement. A product produced by the process has the advantages of keeping the original quick drying and stiffness and smoothness of polyester, reducing the rigidity of the polyester fiber, enhancing flexibility, eliminating polar light of the polyester, achieving sense of touch closer to the texture of natural fibers and fundamentally improving the wet permeability, ventilation property, fuzz resistance and pilling resistance of fibers.

Owner:ZHEJIANG ZHONGFANG XINTIANLONG TEXTILE SCI & TECH

Imitation super-soft velvet double-sided weft knitting thermal fabric

The invention relates to an imitation super-soft velvet double-sided weft knitting thermal fabric, comprising a front surface layer and a suede layer. The front surface layer is formed by weaving veils, linking yarns, and spandex filaments. The suede layer is formed by weaving inner yarns and linking yarns. The front surface layer and the suede layer are in six-path circulating braided structure. The fabric is low in manufacturing cost, fin and smooth in the suede, smooth and beautiful in a front cloth cover, good in snag resistance and pilling resistance, soft and comfortable in hand feel, moderate in elasticity, and good in heat retention property.

Owner:JIANGSU NEW XUEZHU INT FASHION

Alpace wool-cashmere yarn blend spinning method

Cashmere and Peru alpaca wool at the Andes are prepared according to the weight ratio of 1:(1.2-2.5) and opened, three assistants of wool-mixing oil, anti-static agent and water after fully mixed are added, then tightly covered for 8-12 hours, opened and mixed through the wool-mixing machine and finally spinned through carding machine and spinning machine. The single yarn is of 300-500 twist / m, the double yarn is of 150-300 twist / m. Advantages: reduced cashmere use-quantity and production cost, improved the piling-resisting property and raised strength and warm-keep properties.

Owner:江苏汇丰羊绒有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com