Patents

Literature

49results about How to "Controllable specific surface area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-purity trimanganese tetroxide and preparation method thereof

The invention relates to an oxide of manganese, and in particular discloses high-purity trimanganese tetroxide and a preparation method thereof, wherein the Mn content in the high-purity trimanganese tetroxide is larger than 71.5 percent, and the S content is smaller than 0.03 percent. The preparation method thereof comprises the following steps of: 1. firstly dissolving high-purity manganese sulfate into water to obtain a manganese sulfate solution, then neutralizing the manganese sulfate solution with ammonia water, using the pH value of a neutralization system reaching 9.0-10.0 as the end point of a neutralization reaction, filtering, and rinsing to obtain a manganese hydroxide suspension; 2. introducing air into the manganese hydroxide suspension prepared in the step 1 at the temperature of 45-85 DEG C for oxidation, and filtering, rinsing and drying to obtain the high-purity trimanganese tetroxide after the manganese hydroxide in an oxidation system is completely converted into trimanganese tetroxide. The high-purity trimanganese tetroxide has the advantages of lower impurity content, good quality, controllable specific surface area, low preparation cost and the like.

Owner:GUIZHOU DALONG HUICHENG NEW MATERIAL CO LTD

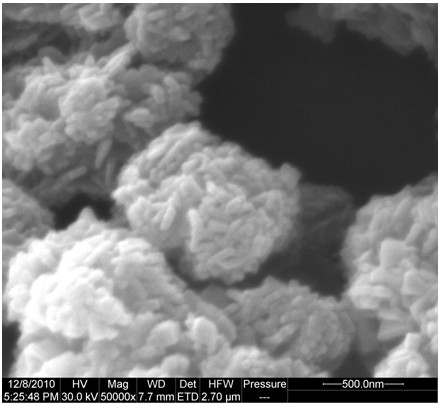

Method for preparing Nano silicon dioxide

A process for preparing nano-SiO2 includes such steps as adding water-soluble polymer and / or water-soluble organic C1-C8 alcohol to the solution alkali-metal silicate, stirring adding weak organic acid as catalyst, hydrolyzing reaction to obtain the hydrosol, washing, filter, and natural drying or supercritical extracting. The obtained amorphous nano-SiO2 has high purity and dispersity and large specific surface area.

Owner:BEIJING UNIV OF CHEM TECH +1

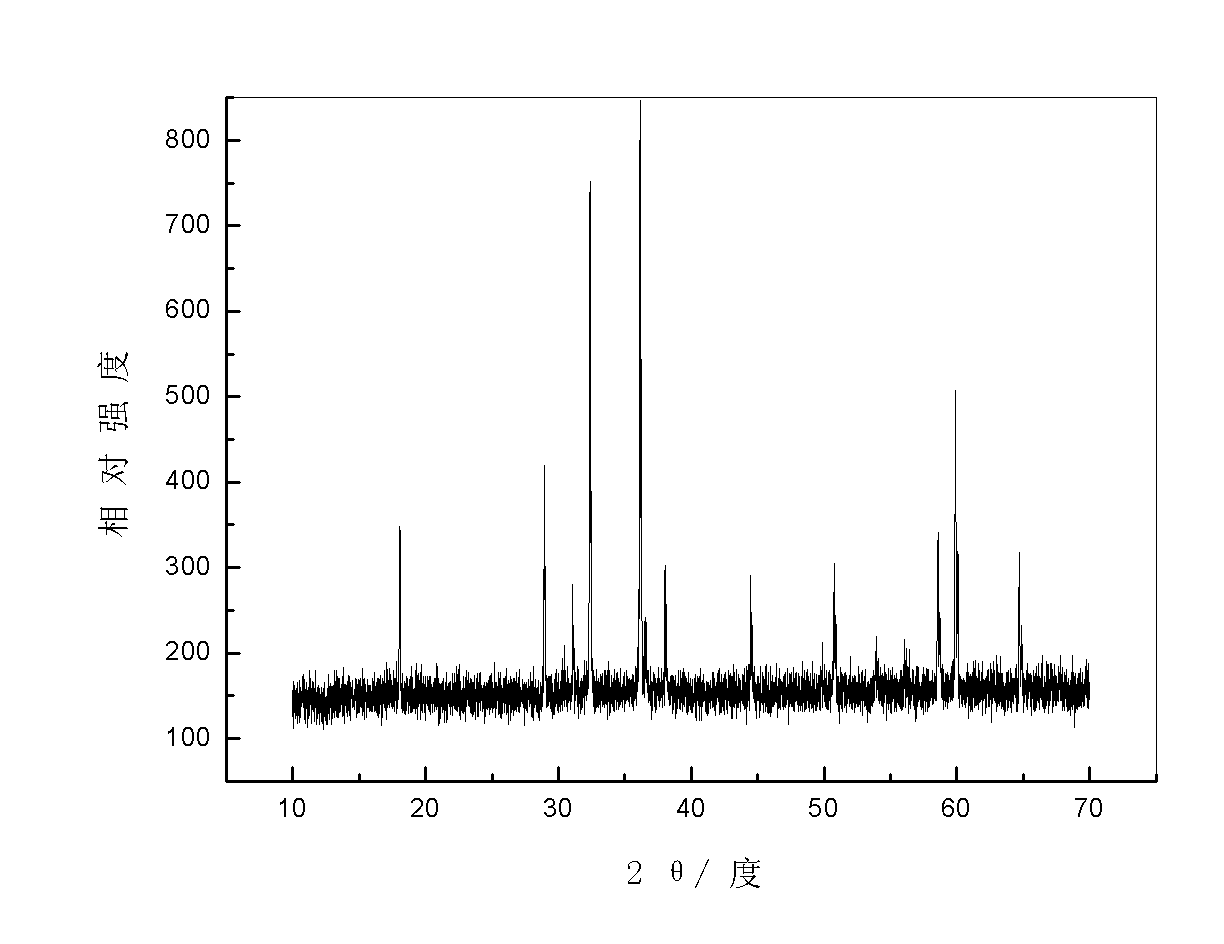

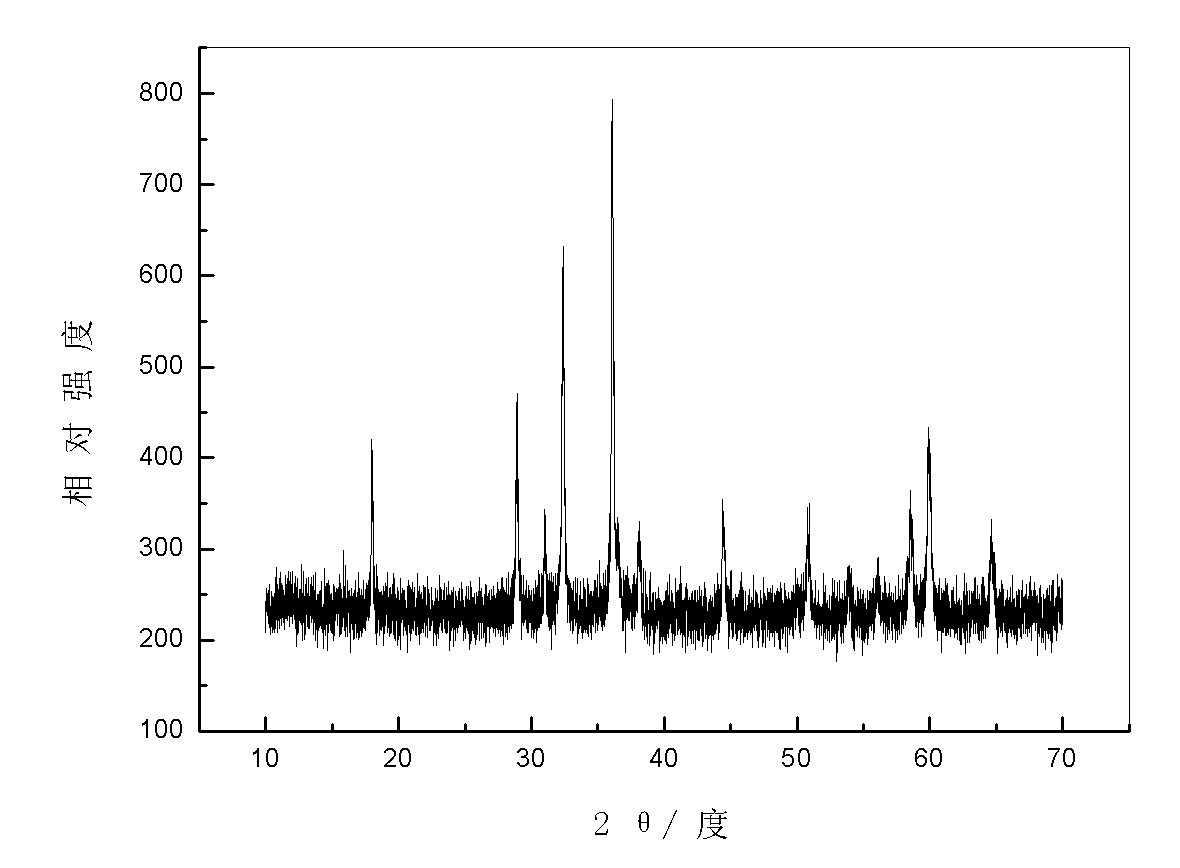

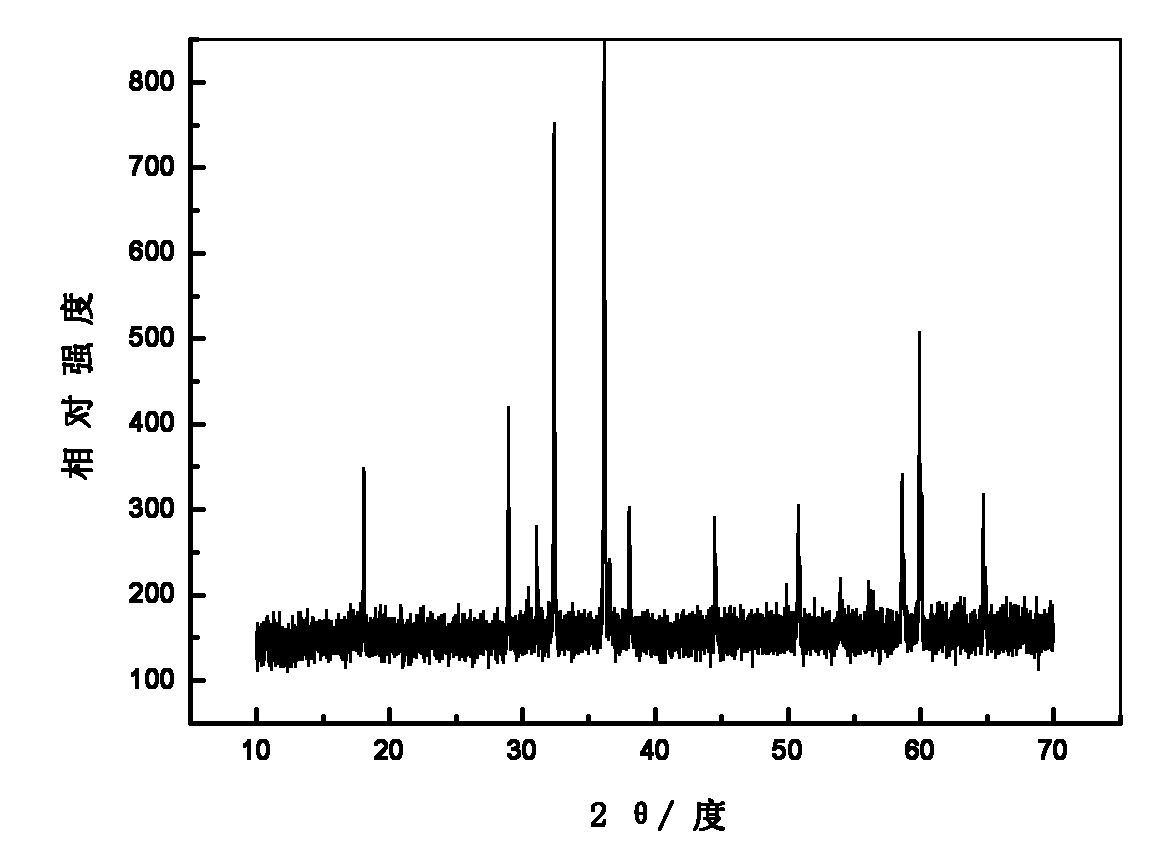

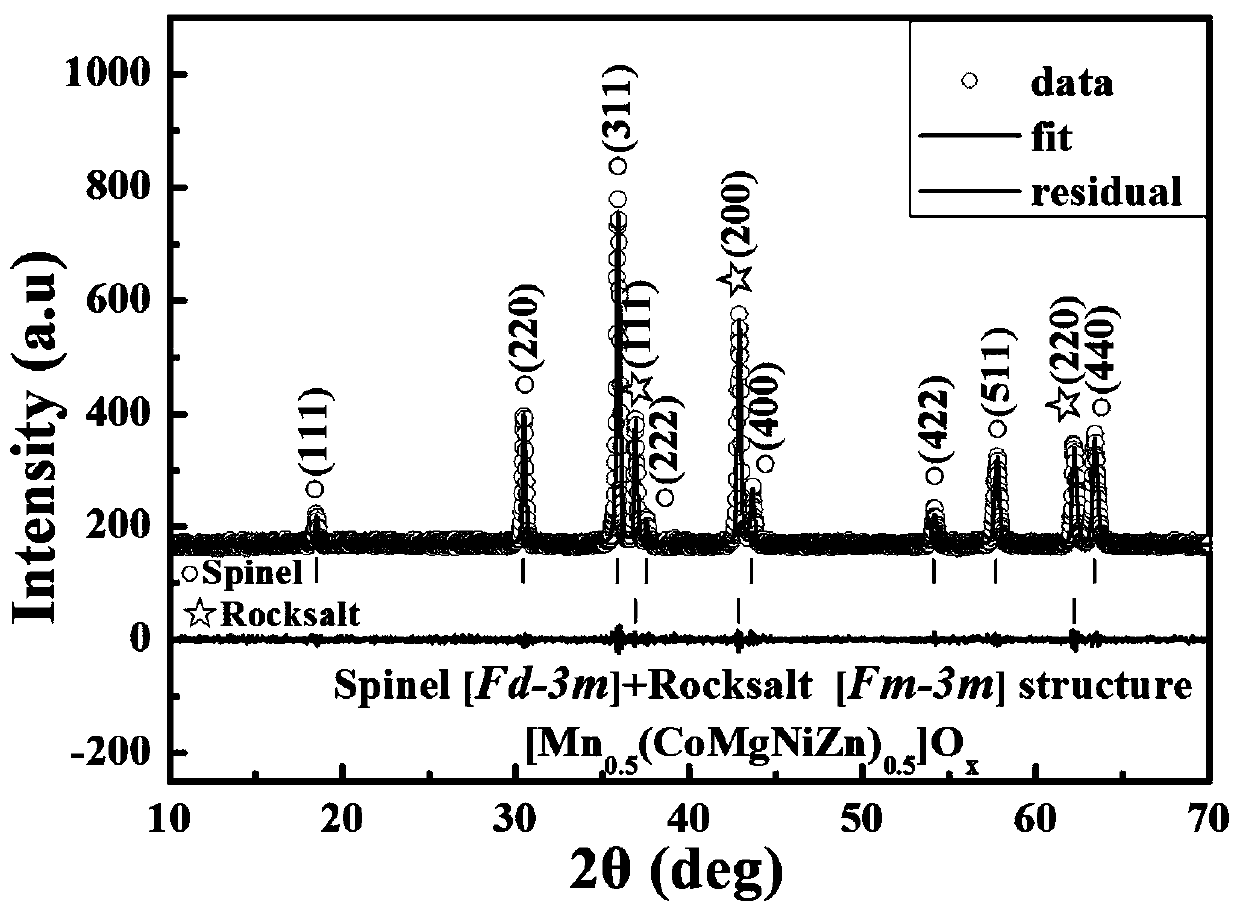

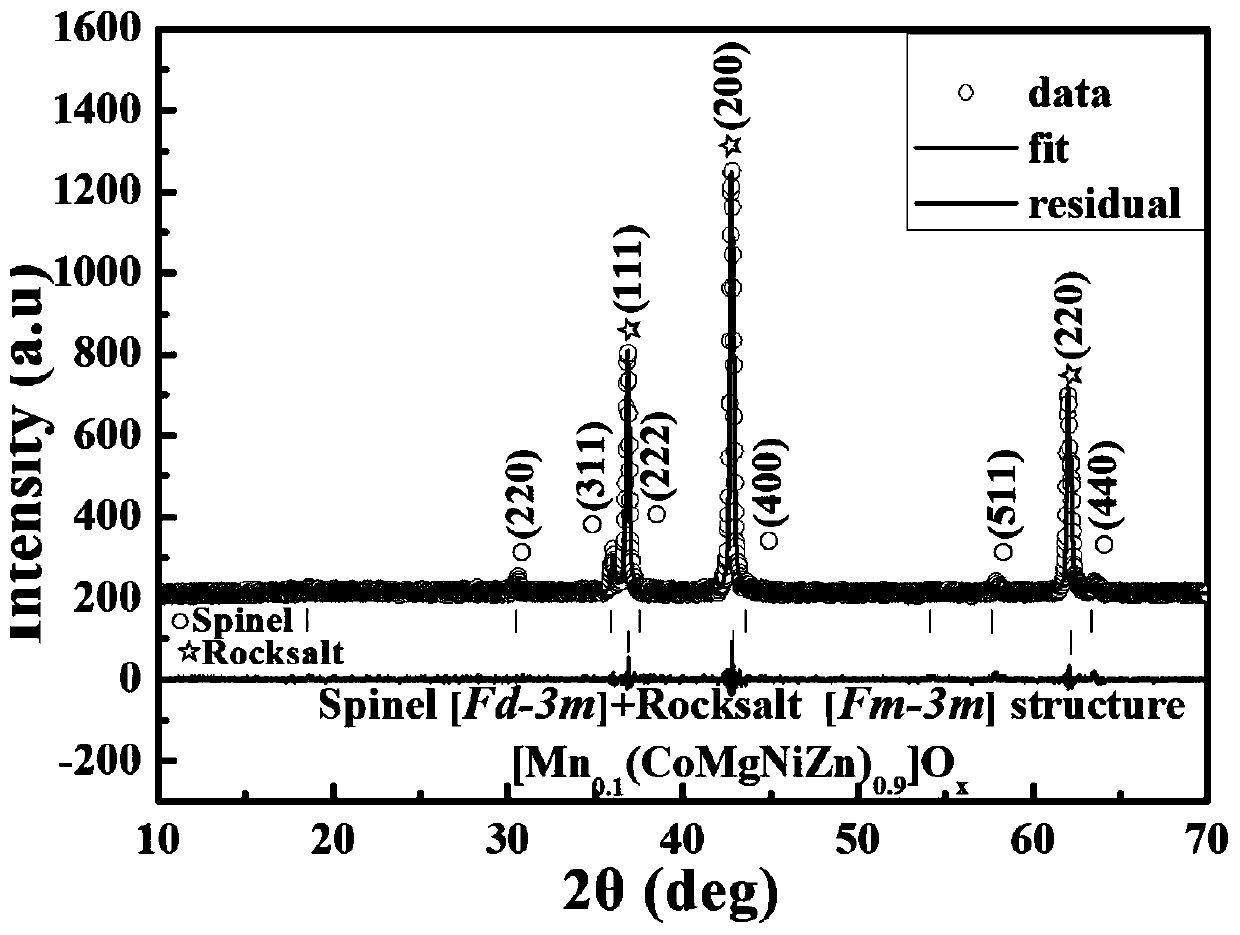

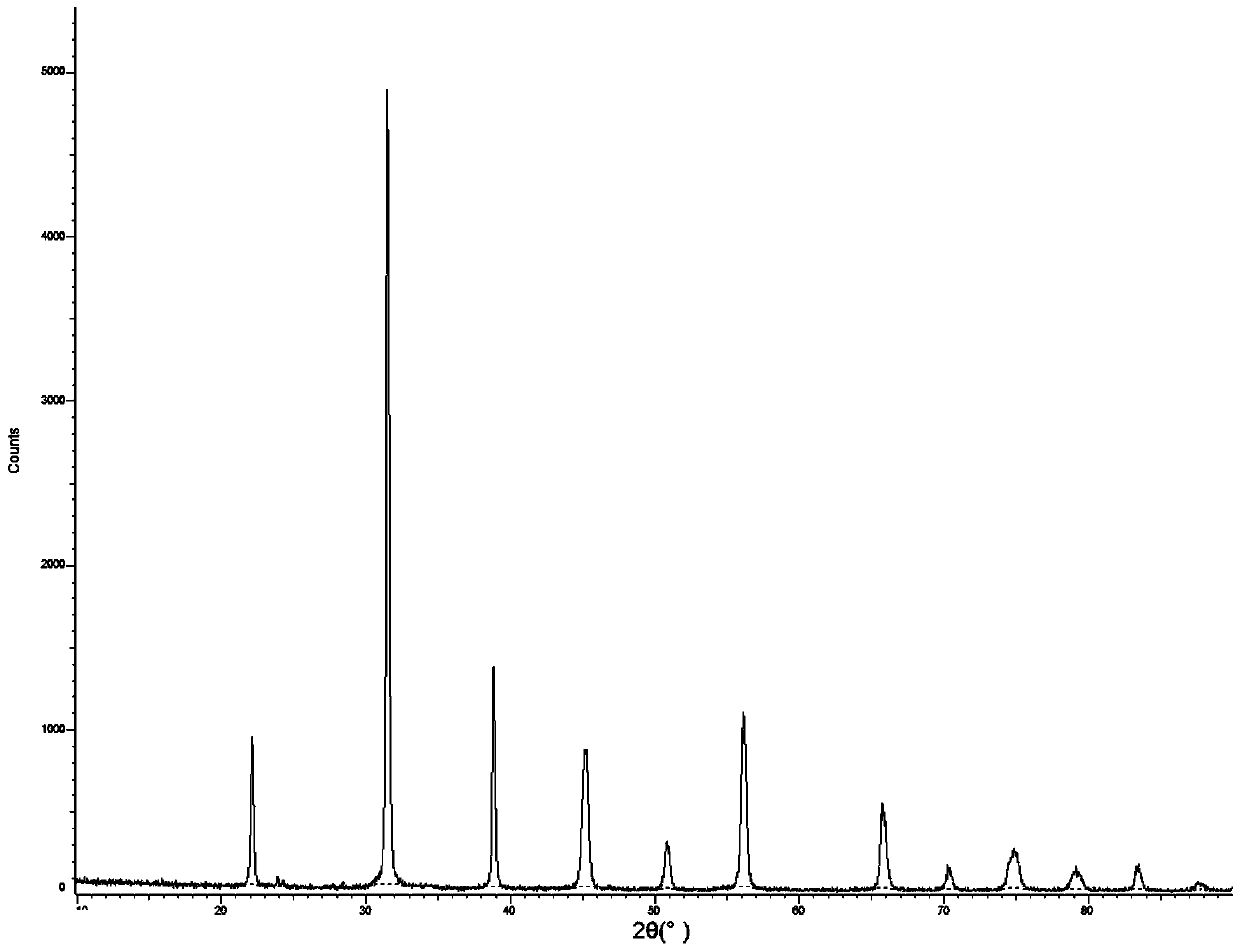

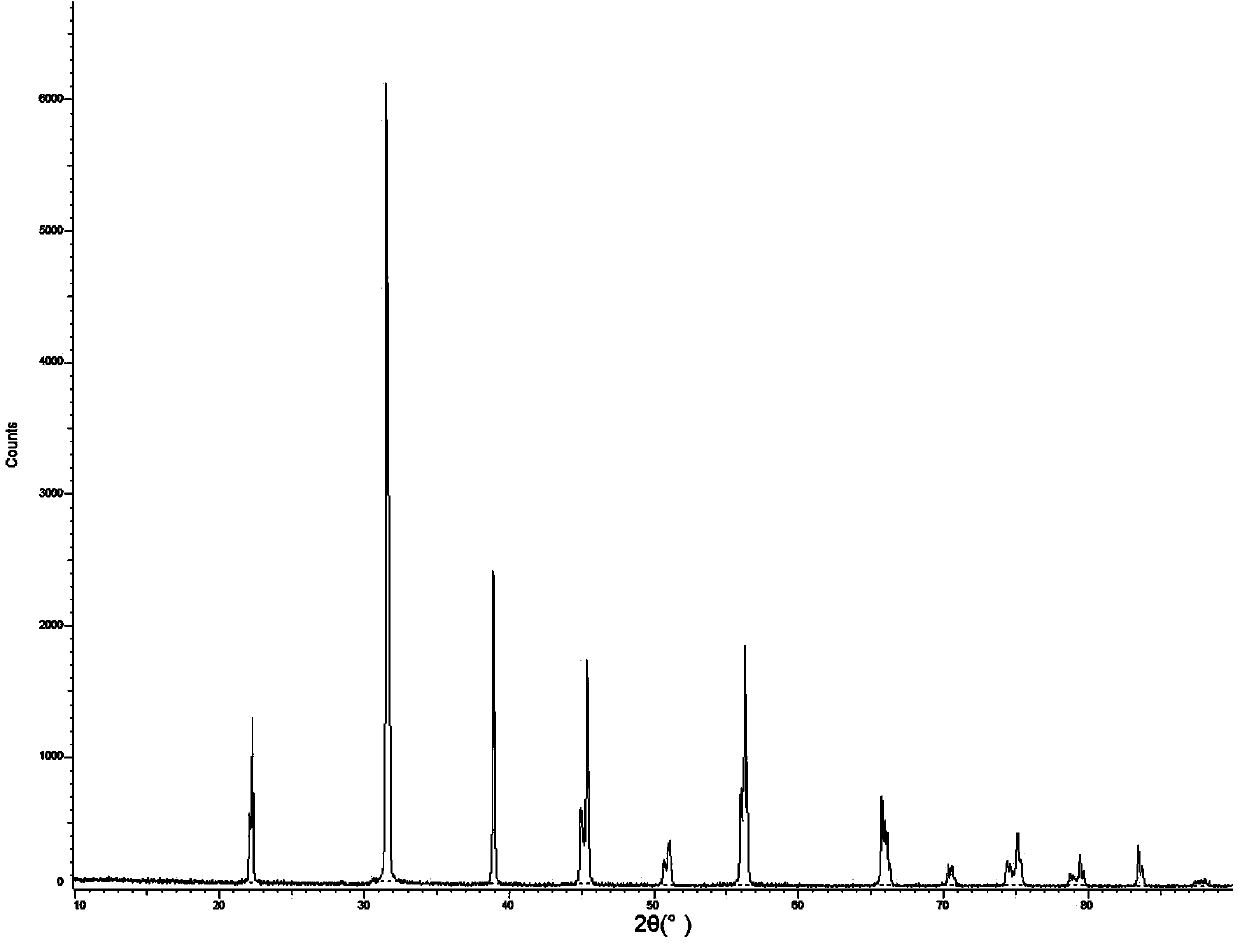

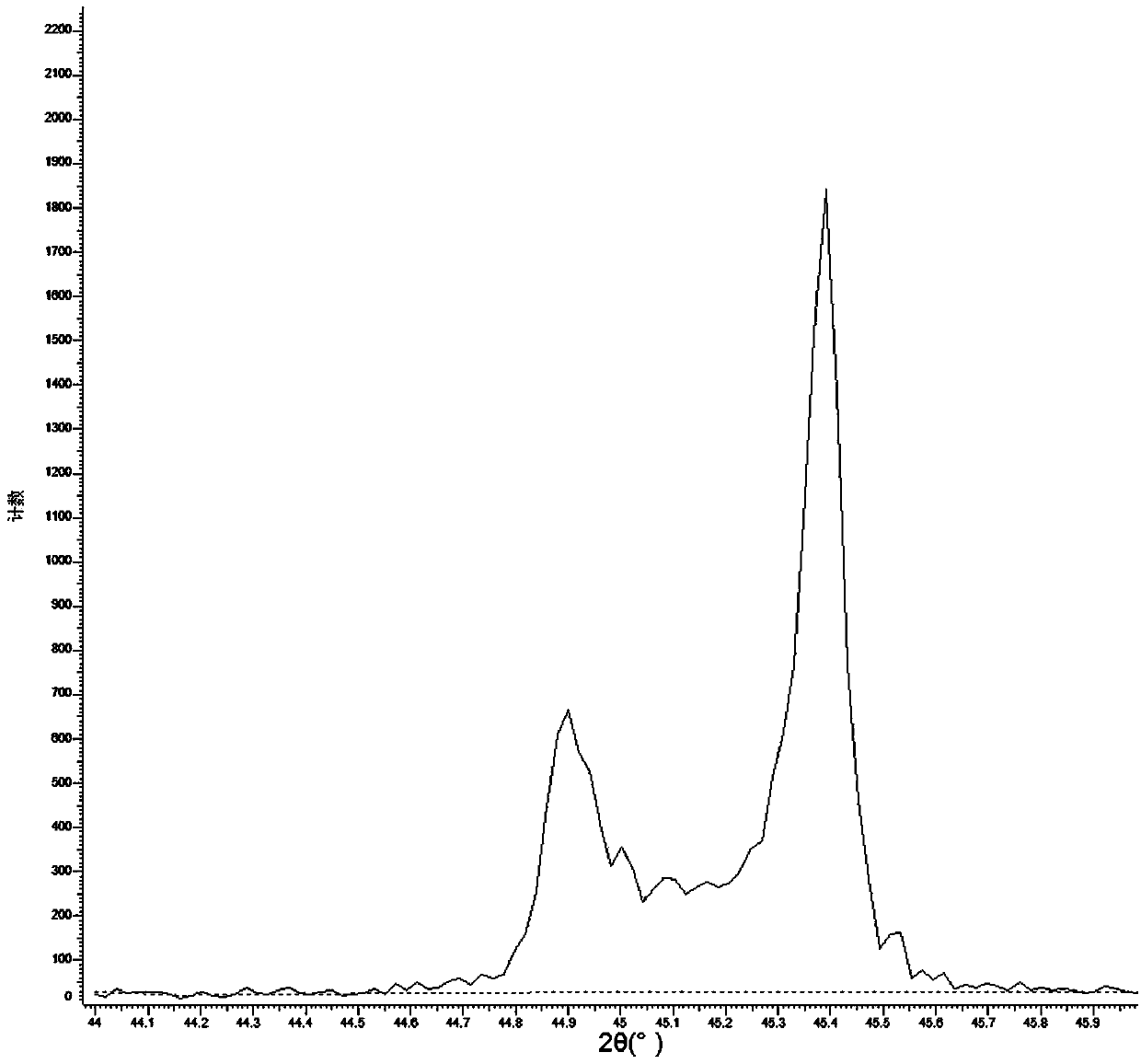

Eutectic high-entropy oxide powder material and preparation method thereof

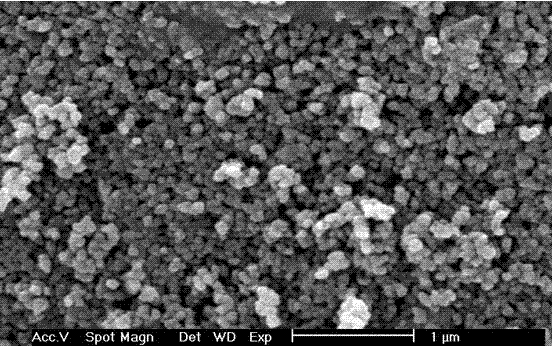

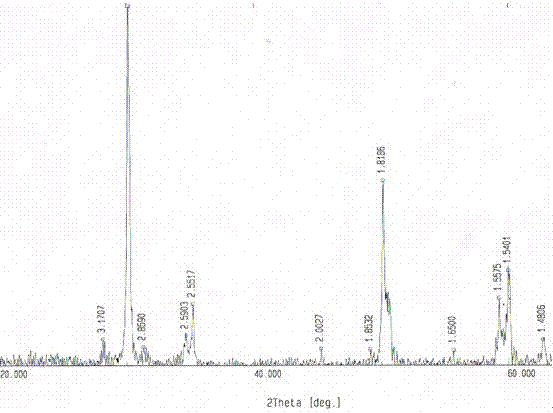

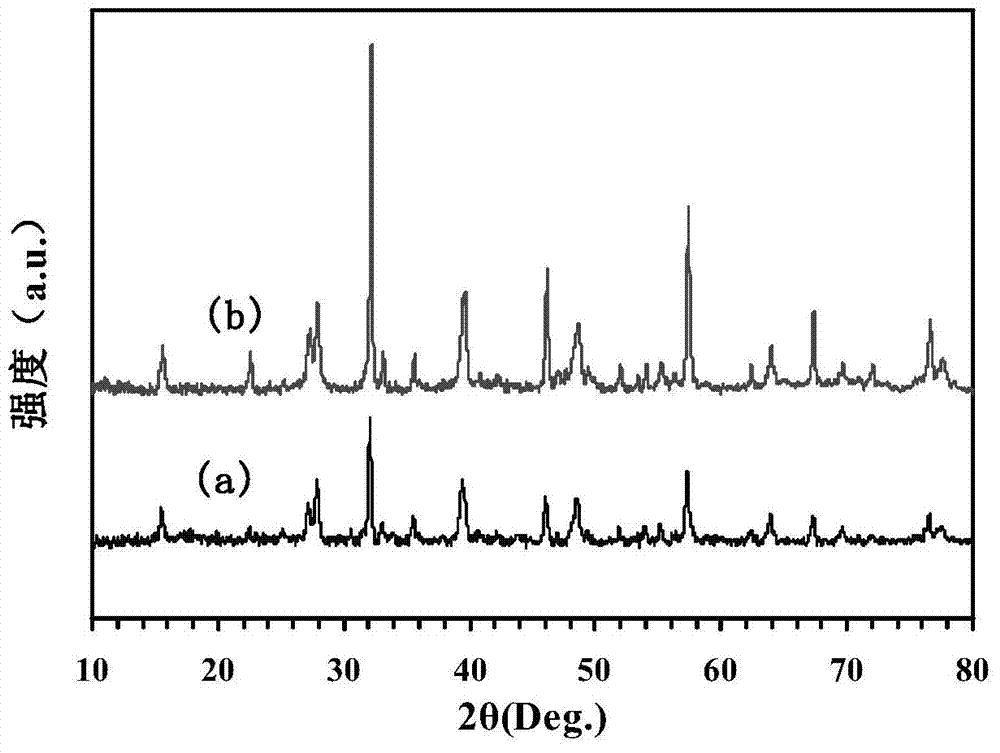

ActiveCN110526706AUniform product composition and microstructureControllable specific surface areaHigh entropy alloysMolecular level

The invention provides an eutectic high-entropy oxide powder material and a preparation method thereof, and belongs to the technical field of high-entropy oxide powder materials. The molecular formulaof the eutectic high-entropy oxide is Mn<x>(CoMgNiZn)<1-x>O (the value of x is 0.1-0.7). The proportion of a rock salt phase and a spinel phase in the eutectic high-entropy oxide is adjusted by changing the proportion of metal cations, so that certain physical and chemical properties are customized, and certain special use requirements are met. Meanwhile, the eutectic high-entropy alloy powder material is prepared by adopting a solution combustion synthesis method with simple reaction process, and liquid-phase material blending is adopted in the preparation process, so that the raw materialsare uniformly mixed at a molecular level, the uniformity of final product composition and microstructures is ensured, and the specific surface area and grain size of the prepared eutectic high-entropyoxide powder material are controllable.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for fabricating porous TiO2 thin film by utilizing nano-crystalline TiO2 hydrosol

ActiveCN101585552AShape is easy to controlHigh degree of crystallizationTitanium dioxideDispersityPhotodetector

The invention relates to a method for a fabricating porous TiO2 thin film by utilizing nano-crystalline TiO2 hydrosol, belonging to the technical field of fabrication process of inorganic metal oxide porous thin film. The fabricating steps of the method are as follows: (1), preparation of nano-crystalline TiO2 hydrosol: titanium salt used as raw material is complexed with ammonia water, extraction filtered, washed, and dissolved in different solvents, and then H2O2 is added thereinto to dissolve colloid to obtain different crystallization results; the sol is transferred to a high-pressure reaction kettle, crystallized for 8-15 hours at temperature of between 100 and 200 DEG C, and extraction filtered and ultrasonic dispersed in water to obtain nano-crystalline TiO2 hydrosol; (2), fabrication of the porous TiO2 thin film: the porous thin film is obtained by directly coating the hydrosol onto a matrix at low temperature. The TiO2 hydrosol prepared by the invention has high crystallization degree, good dispersity, and controllable sol shape; surface of the porous thin film is flat and even with good adhesion. The porous TiO2 thin film can be applied to fields of photocatalysis, photodetector and solar battery and the like.

Owner:SHANGHAI UNIV

Method for preparing iron phosphate with micro/nano structure

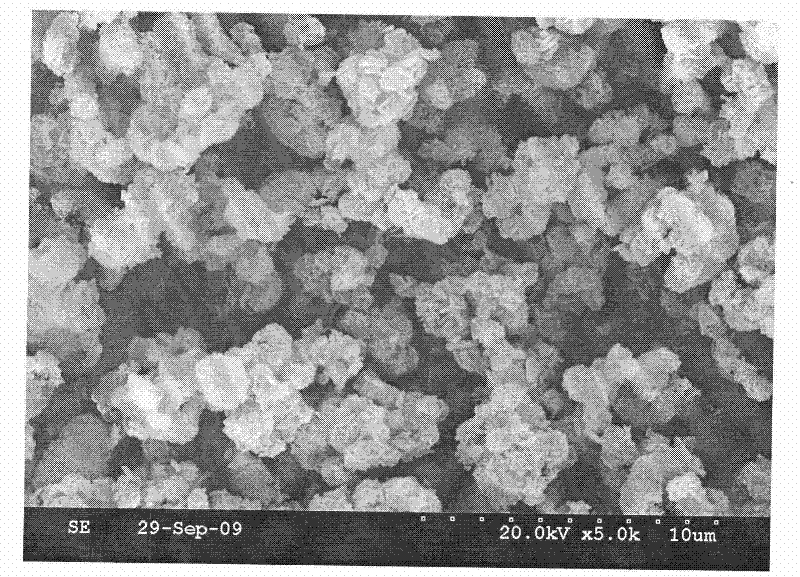

The invention discloses a method for preparing iron phosphate with a micro / nano structure. The method comprises the following steps of: guiding solution of ferrous sulfate, phosphoric acid and an oxidant into a reaction container respectively; performing oxidation reaction for 2 to 5 hours and then adding a water-soluble nonionic surfactant in an amount which is 10 to 0.05 weight percent of the total amount of the ferrous sulfate and the phosphoric acid; heating to the temperature of between 50 and 100 DEG C; performing turbulent circulation for 20 to 60 minutes, then adding 5 to 20 weight percent of solution of sodium hydroxide and controlling pH of a reaction system to be 2.0 to 4.5 on line; after alkali is added, continuously performing the turbulent circulation for 20 to 60 minutes, standing and aging for 120 to 600 minutes and separating; and washing a product with pure water until the pH is 5 to 7, drying the product and performing heat treatment on the surface of the product. By the method, a near-spherical iron phosphate nanocluster with high fluidity and dispersibility and controllable specific surface area is prepared; the size of the primary particles is less than 100nm; the size of cluster particles is regulated and controlled within a range of between 200nm and 2 microns; and the product can be used for preparing lithium iron phosphate serving as a positive material of a lithium ion battery and used in the fields such as food additives, biomedicine and the like.

Owner:河南省净寰新能源科技有限公司

Process for producing controllable micropore polyester fiber fabric

InactiveCN101956275AControllable specific surface areaGood moisture managementWoven fabricsYarnPolyesterYarn

The invention discloses a process for producing a controllable micropore polyester fiber fabric. The process comprises a weaving process and a dyeing and finishing process, wherein warps are warped, drawn in, dented, subjected to a sizing process and woven into a gray fabric together with wefts; a blended yarn comprises the following raw materials in percentage by weight: 65 percent of micropore polyester fiber and 35 percent of raw cotton fiber or 65 percent of micropore polyester fiber and 35 percent of viscose fiber; a sizing agent adopted in the sizing process comprises polyvinyl acetate (PVA)-1799, PVA-205M and polyacrylic ester; a texture structure adopts a plain texture; and the ratio of the warp to the weft is 2:2 in the aspect of yarn arrangement. A product produced by the process has the advantages of keeping the original quick drying and stiffness and smoothness of polyester, reducing the rigidity of the polyester fiber, enhancing flexibility, eliminating polar light of the polyester, achieving sense of touch closer to the texture of natural fibers and fundamentally improving the wet permeability, ventilation property, fuzz resistance and pilling resistance of fibers.

Owner:ZHEJIANG ZHONGFANG XINTIANLONG TEXTILE SCI & TECH

Preparation method of polyvinyl alcohol/ZIF-8 porous composite material

InactiveCN109847723ALarge specific surface areaNo blockingOther chemical processesFreeze-dryingPVA - Polyvinyl alcohol

The invention relates to a preparation method of a polyvinyl alcohol / ZIF-8 porous composite material, and belongs to the field of porous materials. Polyvinyl alcohol is used as a polymer material andis compounded with ZIF-8, and the polyvinyl alcohol / ZIF-8 porous composite material is prepared by adopting an ice template method and a freeze-drying technology. The preparation process is simple andis short in time and the ZIF-8 is uniformly dispersed. In the polyvinyl alcohol / ZIF-8 porous composite material prepared by an ice template method, ZIF-8 particles are adhered to a polyvinyl alcoholporous material skeleton with a macroporous structure; as the polyvinyl alcohol porous material has an open pore structure, the inherent pore structure of ZIF-8 particles cannot be blocked, and therefore the porous composite material with the large specific surface area can be prepared. ZIF-8 nano-particles with different specific surface areas can be prepared by changing the preparation method ofthe ZIF-8 nano-particles; meanwhile, the specific surface area of the porous composite material can be controlled by changing the mass ratio of the ZIF-8 particles to the polyvinyl alcohol.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

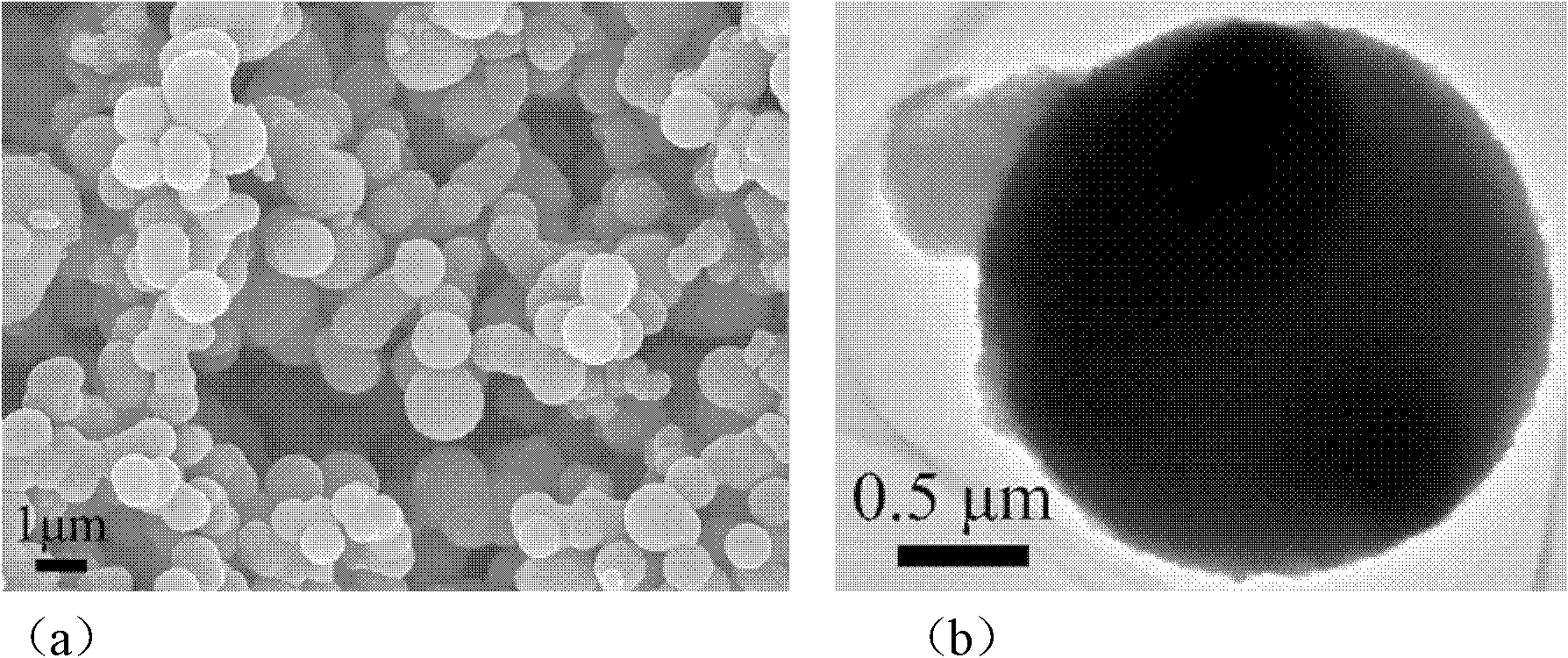

Self-template method for preparing hollow carbon spheres

InactiveCN107673323ARich sourcesEasy to mass manufactureCarbon preparation/purificationOrganic solventPolyphosphazene

The invention provides a self-template method for preparing hollow carbon spheres. The method comprises the steps as follows: phosphonitrilic chloride trimer and a comonomer are dispersed in an organic solvent, then an acid-binding agent is added, the mixture reacts under the ultrasonic assistance condition for 2-6 h, after the reaction ends, centrifugation and washing are performed, and solid polyphosphazene microspheres are obtained; the polyphosphazene microspheres are transferred to a carbonization furnace and calcined at the high temperature under the shielding of inert gas, and the hollow carbon spheres are obtained. The hollow carbon spheres with good monodispersity, uniform particle size and controllable wall thickness and particle size are prepared quickly with the self-template method. No additional templates are required in the whole preparation process, and the preparation method is simple and environmentally friendly and facilitates mass production.

Owner:ZHONGYUAN ENGINEERING COLLEGE

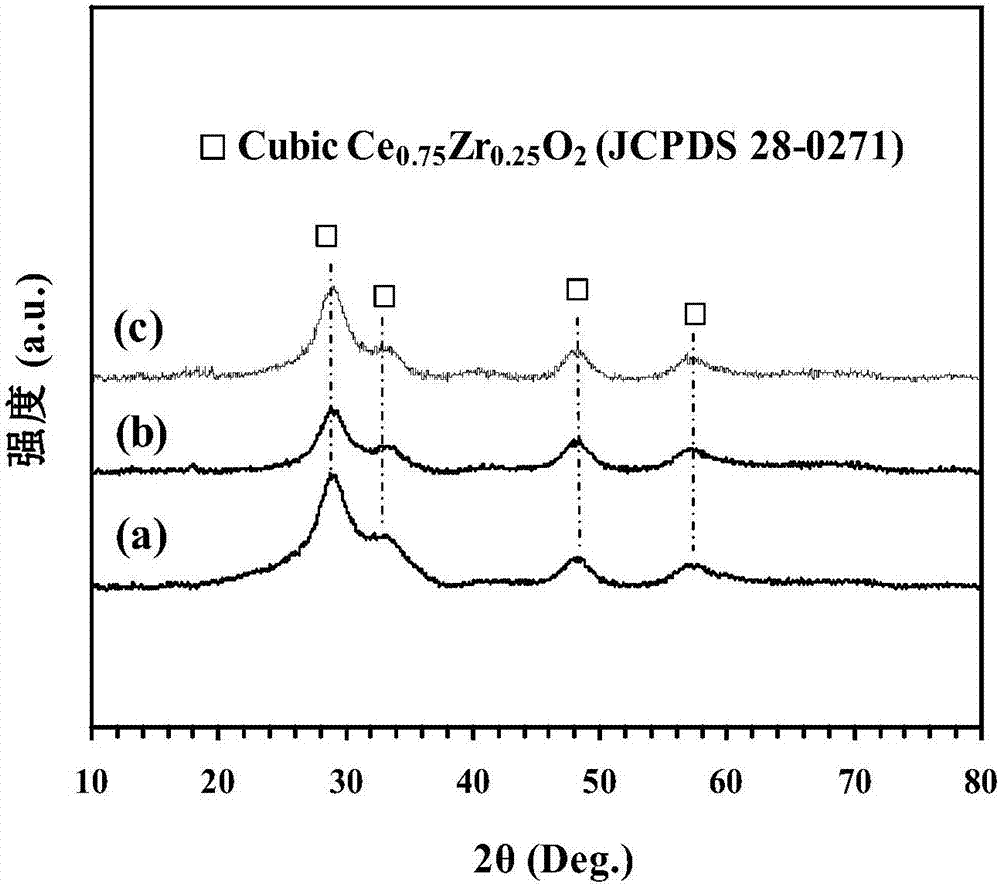

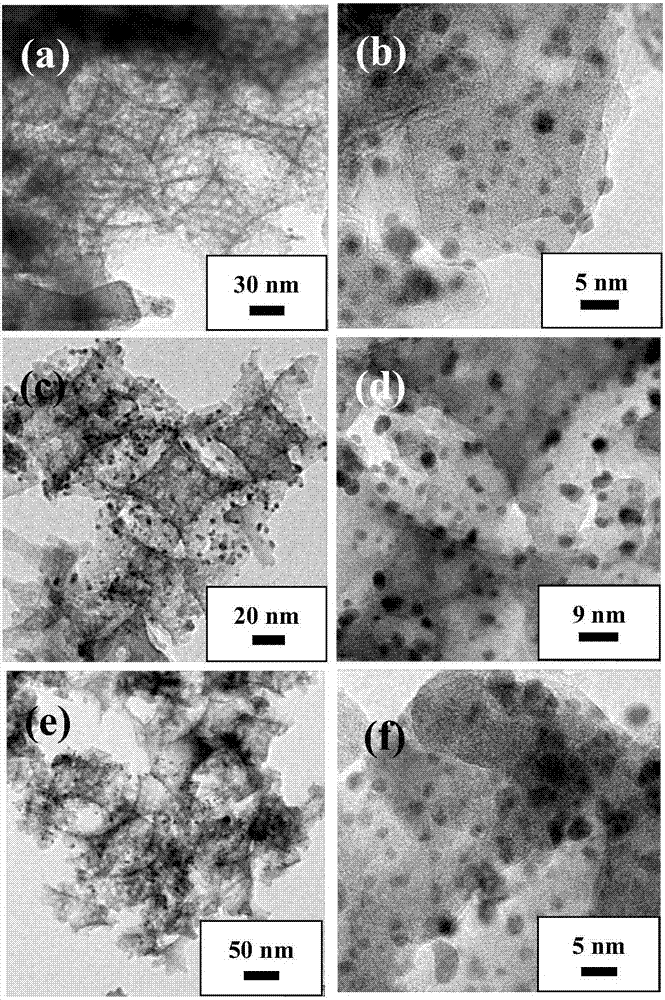

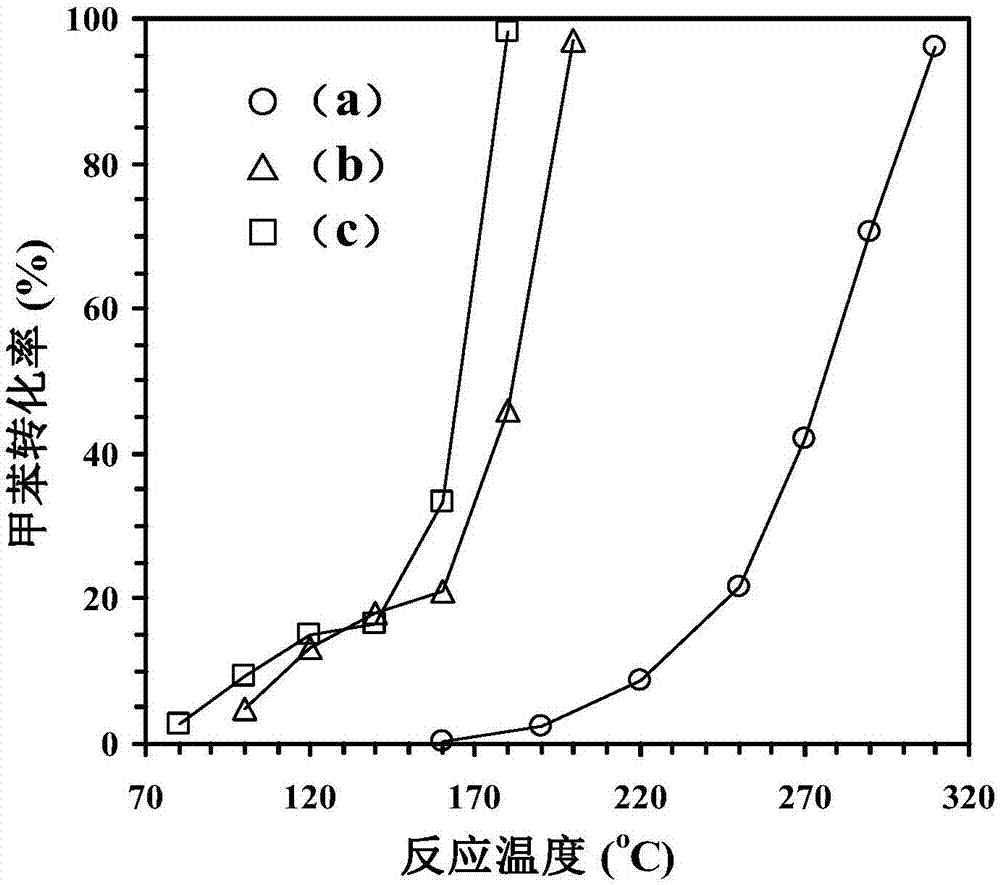

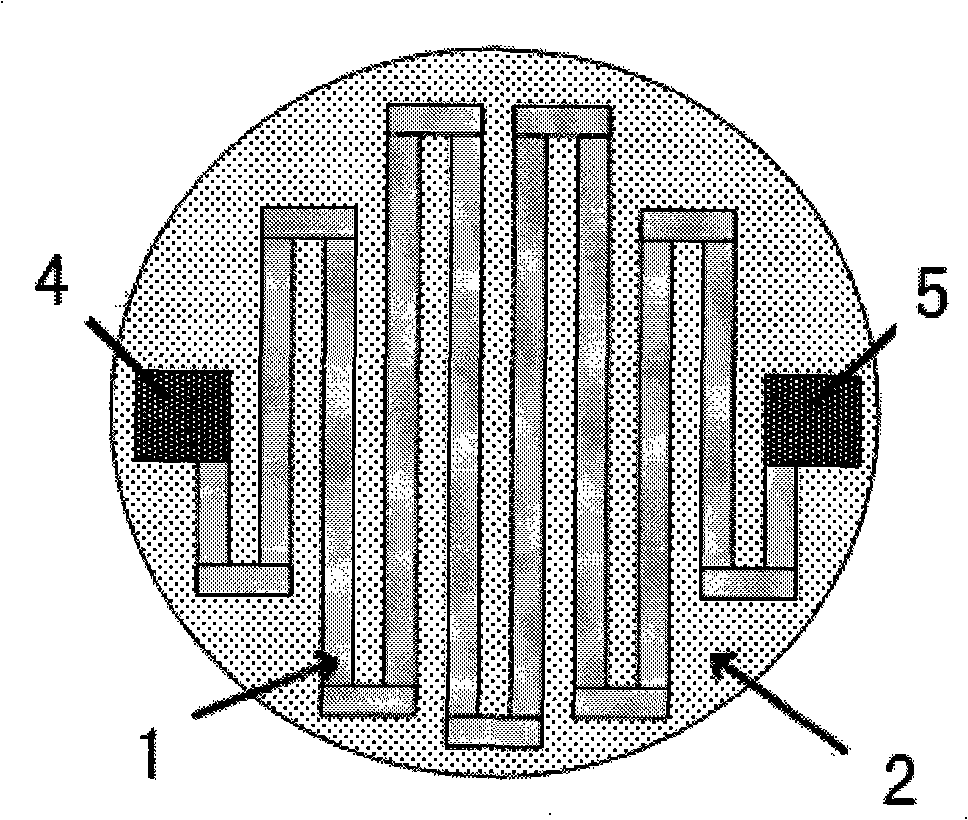

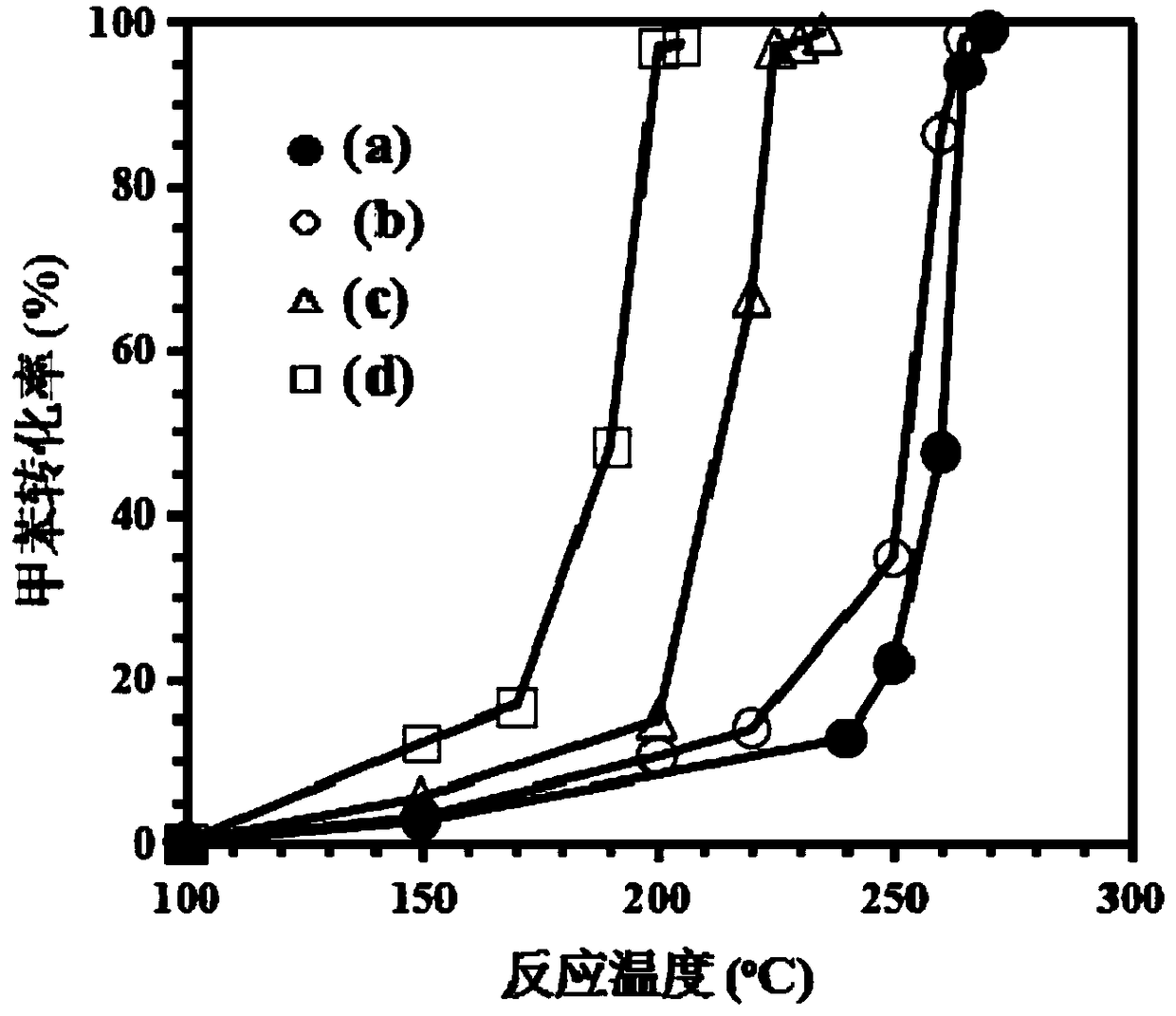

Three-dimensionally ordered macroporous-mesoporous structure cerium-zirconium-aluminum composite oxide supported metal catalyst and preparation method thereof

InactiveCN107159205AShape is easy to controlControllable specific surface areaGas treatmentHeterogenous catalyst chemical elementsNano catalystCatalytic oxidation

The invention discloses a three-dimensionally ordered macroporous-mesoporous structure cerium-zirconium-aluminum composite oxide supported metal catalyst and a preparation method thereof; the three-dimensionally ordered macroporous-mesoporous structure cerium-zirconium-aluminum composite oxide supported metal catalyst comprises a Ce0.75Zr0.25O2-Al2O3 composite oxide support of three-dimensionally ordered macroporous-mesoporous structure, metal M nanoparticles are supported on the pore walls of the support, and noble metal M is one or any of Au, Pt and AuPt2. The three-dimensionally ordered macroporous-mesoporous structure cerium-zirconium-aluminum composite oxide supported metal catalyst is a multilevel-pore nano catalyst, having high activity, good stability, good anti-poisoning property and low price. The three-dimensionally ordered macroporous-mesoporous structure cerium-zirconium-aluminum composite oxide supported metal catalyst is applicable to catalytic oxidation of multi-component VOCs (volatile organic compounds).

Owner:YULIN NORMAL UNIVERSITY

Lead carbon compound material as well as preparation method and application thereof

InactiveCN105990578AAchieve homogeneous mixingControllable specific surface areaElectrode manufacturing processesCarbideSaline solutions

The invention discloses a lead carbon compound material as well as a preparation method and application thereof. The preparation method comprises the following steps of: adding alginic acid or alginate into a lead saline solution, thereby preparing lead alginate; carbonizing the lead alginate in a carbide furnace at a high temperature, thereby preparing a lead carbon compound material with a three-dimensional cellular structure and specific area of 1-3000m<3> / g; uniformly mixing lead with carbon, wherein the total content of lead and carbon is not less than 70% and the mass ratio of lead to carbon is (0.6-1.5):1. The lead carbon compound material can be used for further preparing anode and cathode materials of a lead carbon battery.

Owner:厦门百美特生物材料科技有限公司

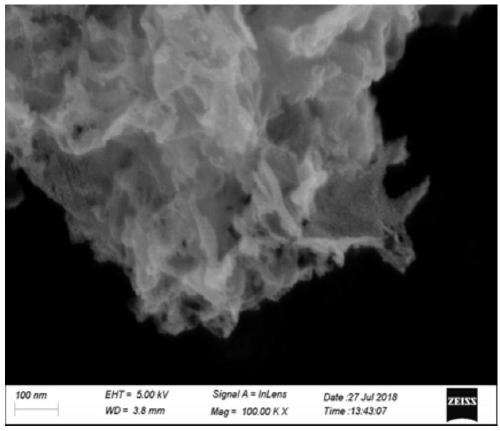

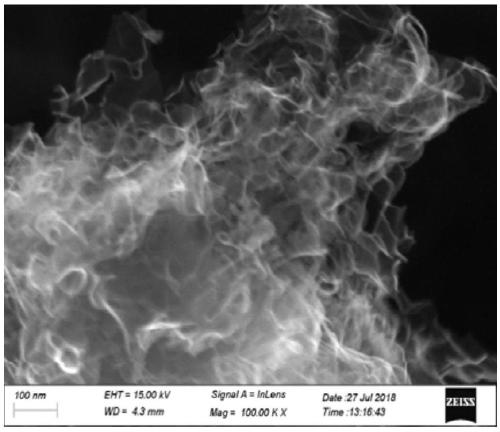

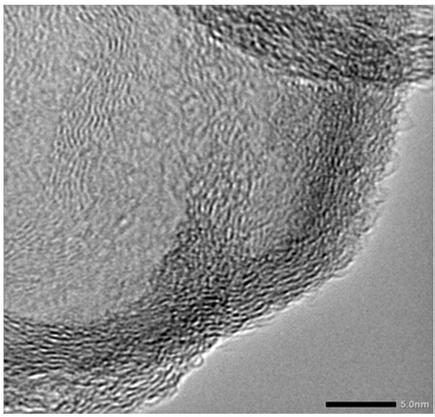

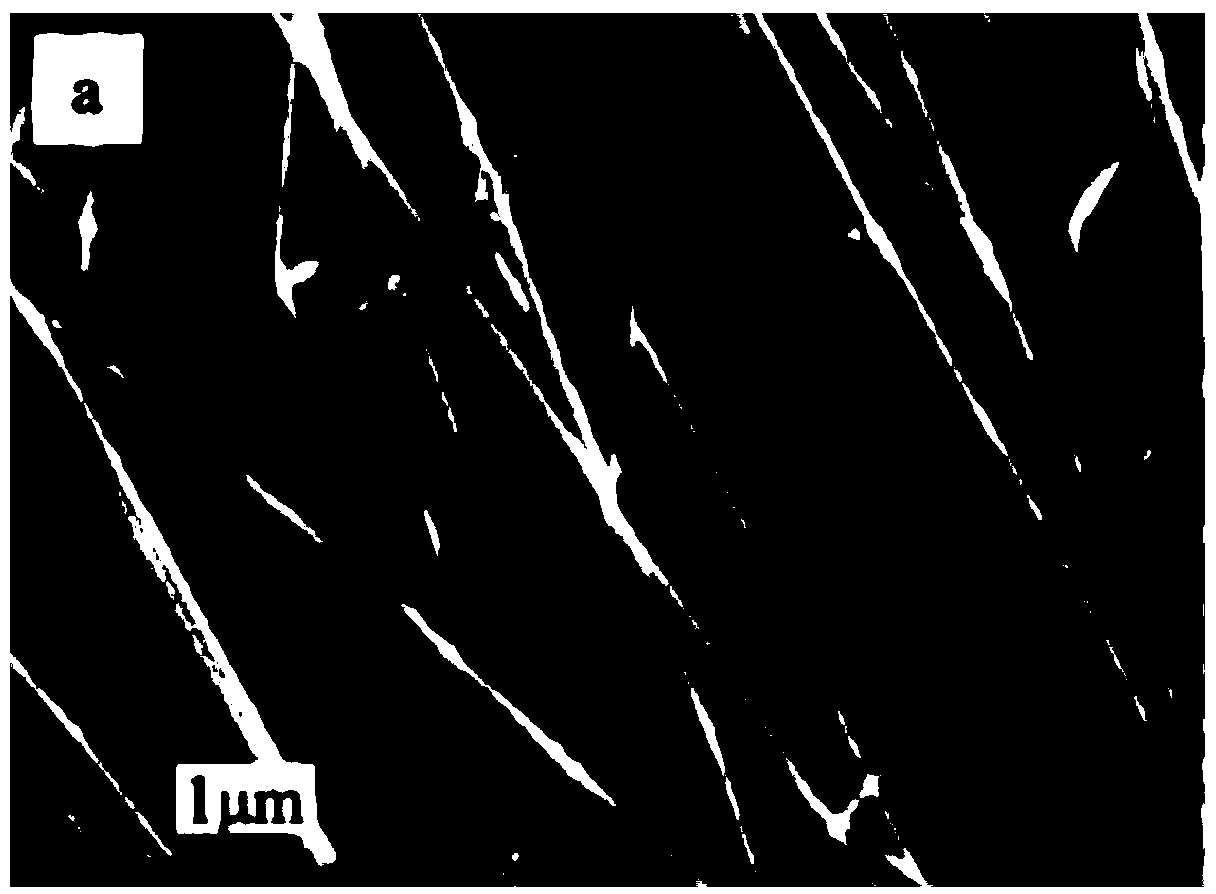

Method for controllably preparing three-dimensional nanometer porous graphene powder by chemical vapor deposition method

ActiveCN109264706AEliminate soft and hard agglomerationsImprove fluidization stateGraphenePorous grapheneGas phase

The invention discloses a method for controllably preparing a three-dimensional nanometer porous graphene powder by a chemical vapor deposition method. The method comprises the following steps of treating a solid catalyst by salt, and activating at high temperature; coating the surface of the solid powder, subjected to high-temperature activating, with a polymer, leading the solid powder, coated with the polymer, into a carbon source at high temperature, performing the chemical vapor deposition, and growing graphene; pickling, filtering, and drying, so as to obtain the three-dimensional nanometer porous graphene powder. The method has the advantages that the common core problem of particle agglomeration of a solid catalyst in a large-scale preparation process of graphene powder by the chemical vapor deposition method is solved by the surface coating of the catalyst; by adjusting the amount of the carbon source, the particle size of the solid catalyst and the amount of salt, the high-quality three-dimensional nanometer porous graphene powder can be controllably prepared; the technology process is simplified, the higher requirement preparation conditions on equipment is decreased, and the large-scale controllable preparation of the three-dimensional nanometer porous graphene powder is easy to implement.

Owner:陕西兴汉澜墨科技有限公司

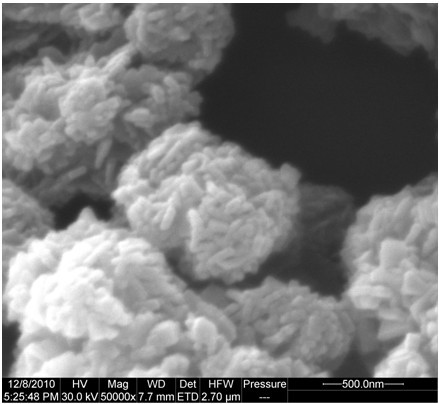

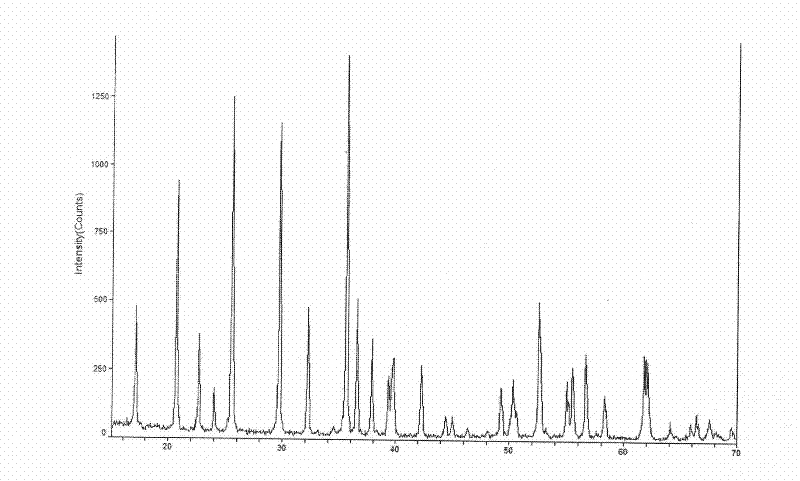

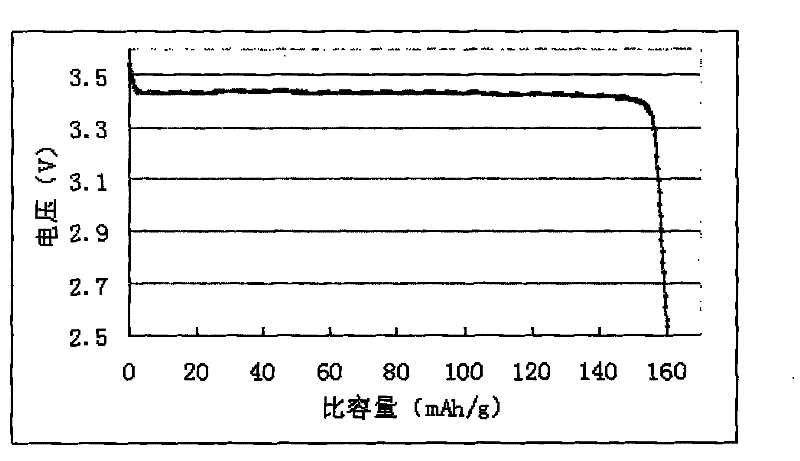

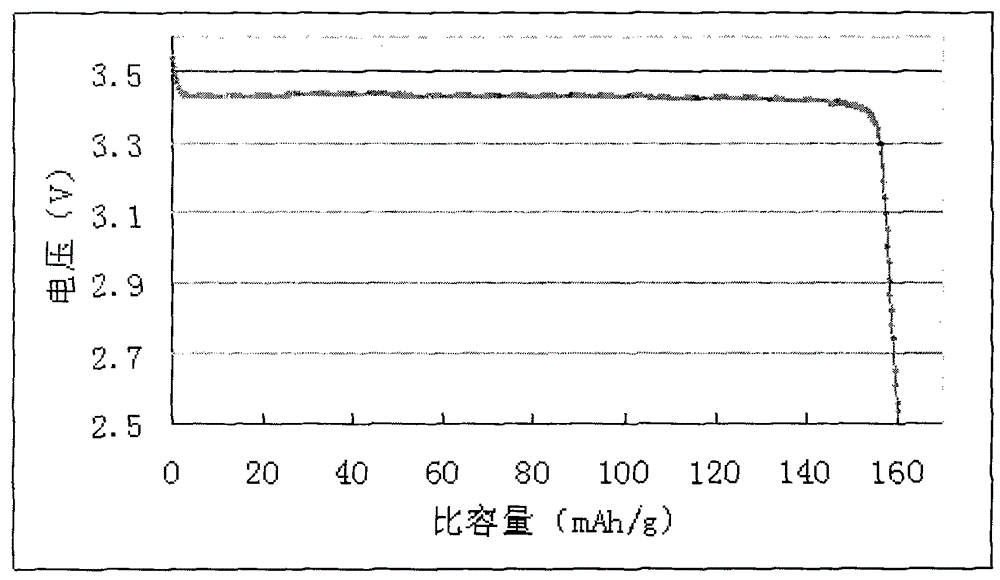

Preparation method of spherical lithium iron phosphate cathode material

A preparation method of a spherical lithium iron phosphate cathode material. The method comprises steps of: 1) preparing lithium source, divalent ferric salt, phosphor salt compound and doped metallic element in a molar ratio of 0.95-1.05:1:1:0.005-0.05 into a solution; adding the solution, reducing agent and precipitating agent into a reaction kettle with an overflow mouth through a metering pump; preparing a spherical lithium iron phosphate precursor through reaction condition control; 2) cladding a layer of nano metal oxide or metallic carbide with excellent conductivity on a surface of the spherical lithium iron phosphate precursor by using polymer as an adjuvant; 3) placing the spherical lithium iron phosphate cladded with metal oxide or metallic carbide in an atmosphere protection furnace, introducing inert atmosphere, insulating for 6-24 h at 500-900 DEG C, cooling naturally to a room temperature to obtain the spherical lithium iron phosphate cladded with metal oxide or metallic carbide conductive film. The lithium iron phosphate material prepared by the method has advantages of uniform chemical components and easily controlled product morphology. Especially, the cladding of metal oxide or metallic carbide enhances conductivity between lithium iron phosphate particles and tap density of the material.

Owner:HENAN KELONG NEW ENERGY CO LTD

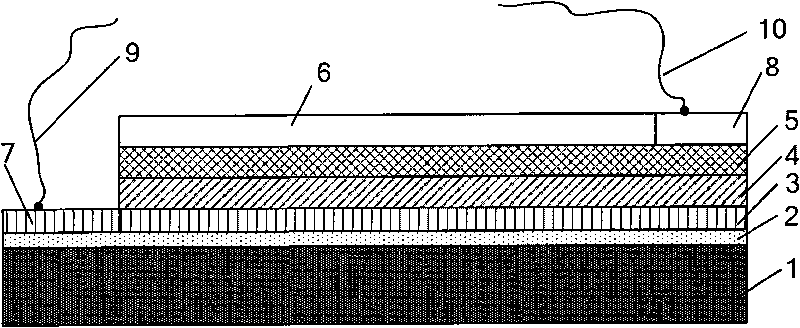

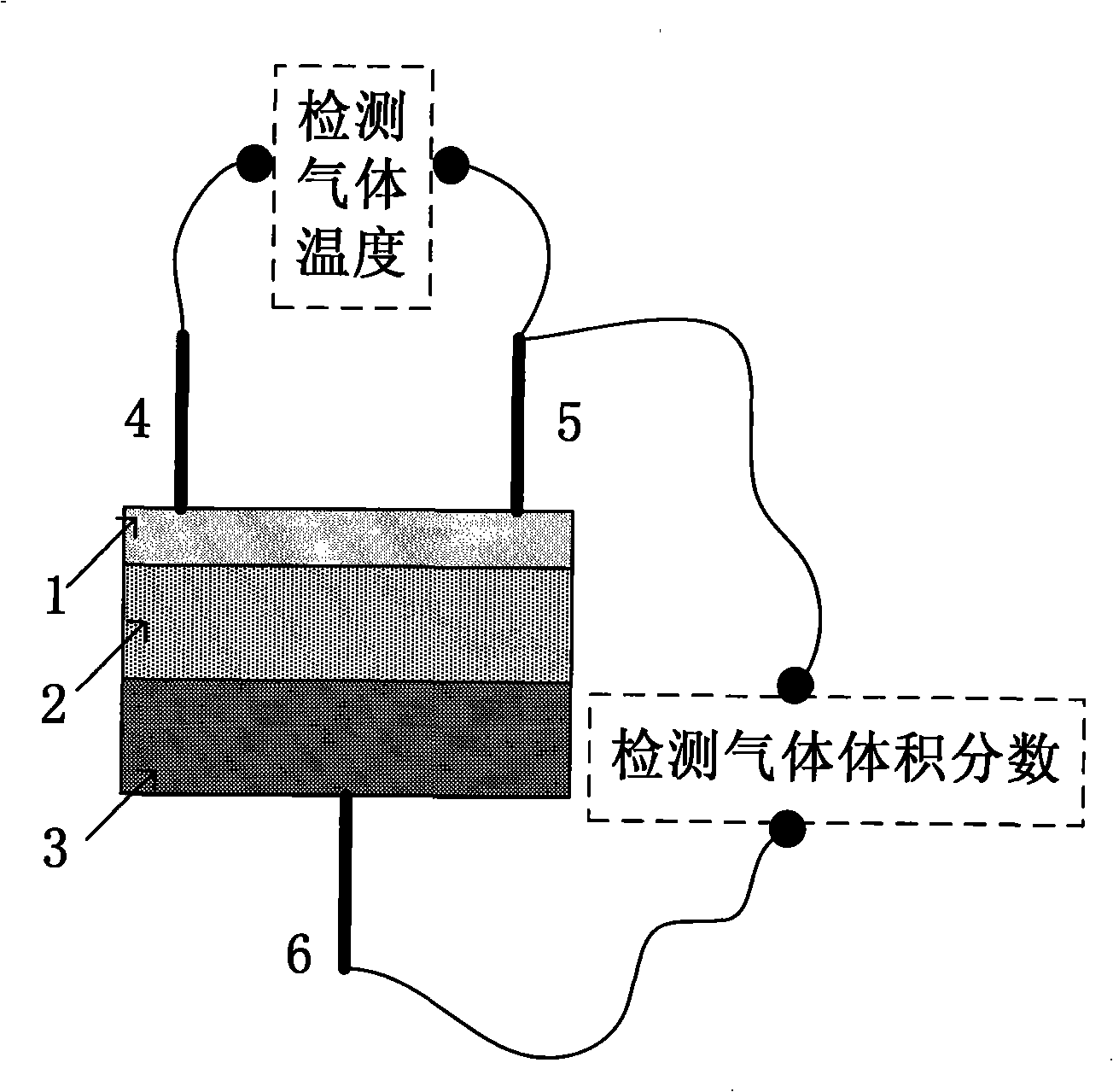

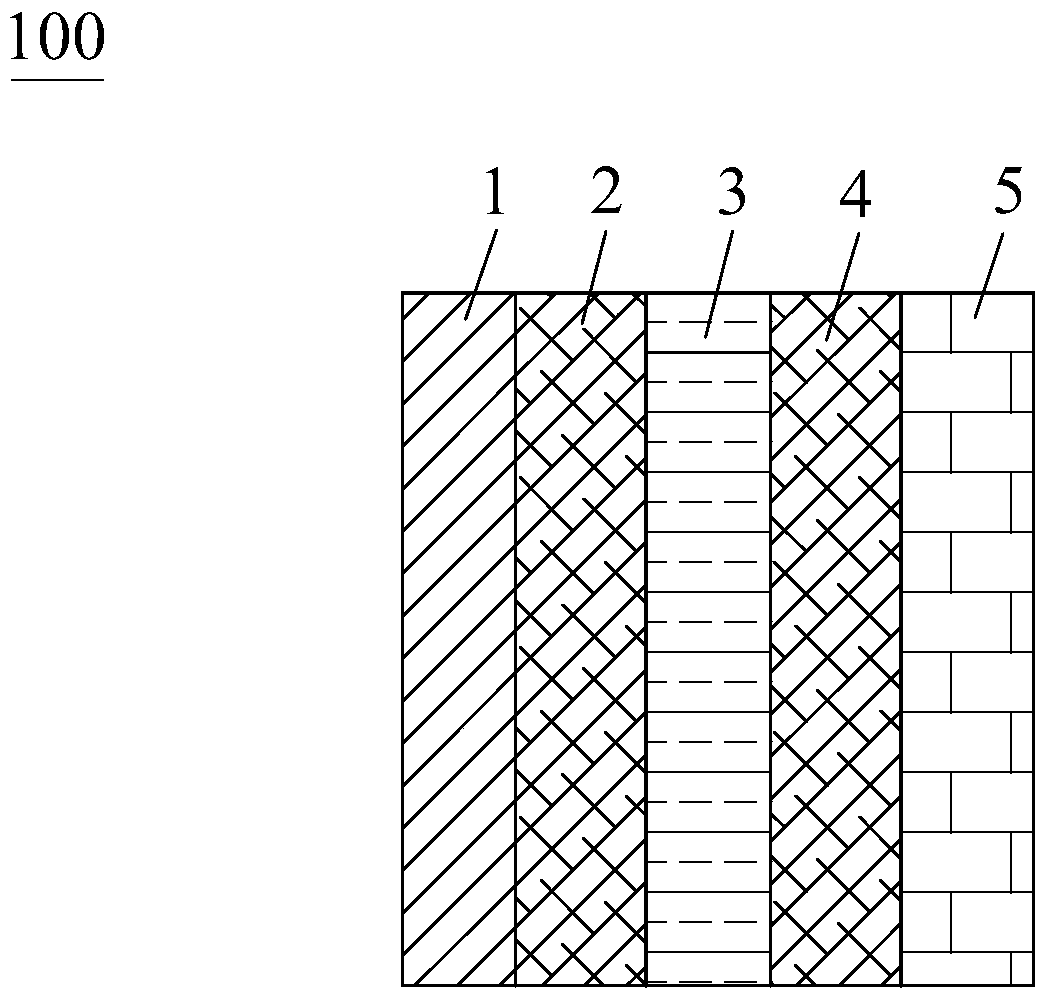

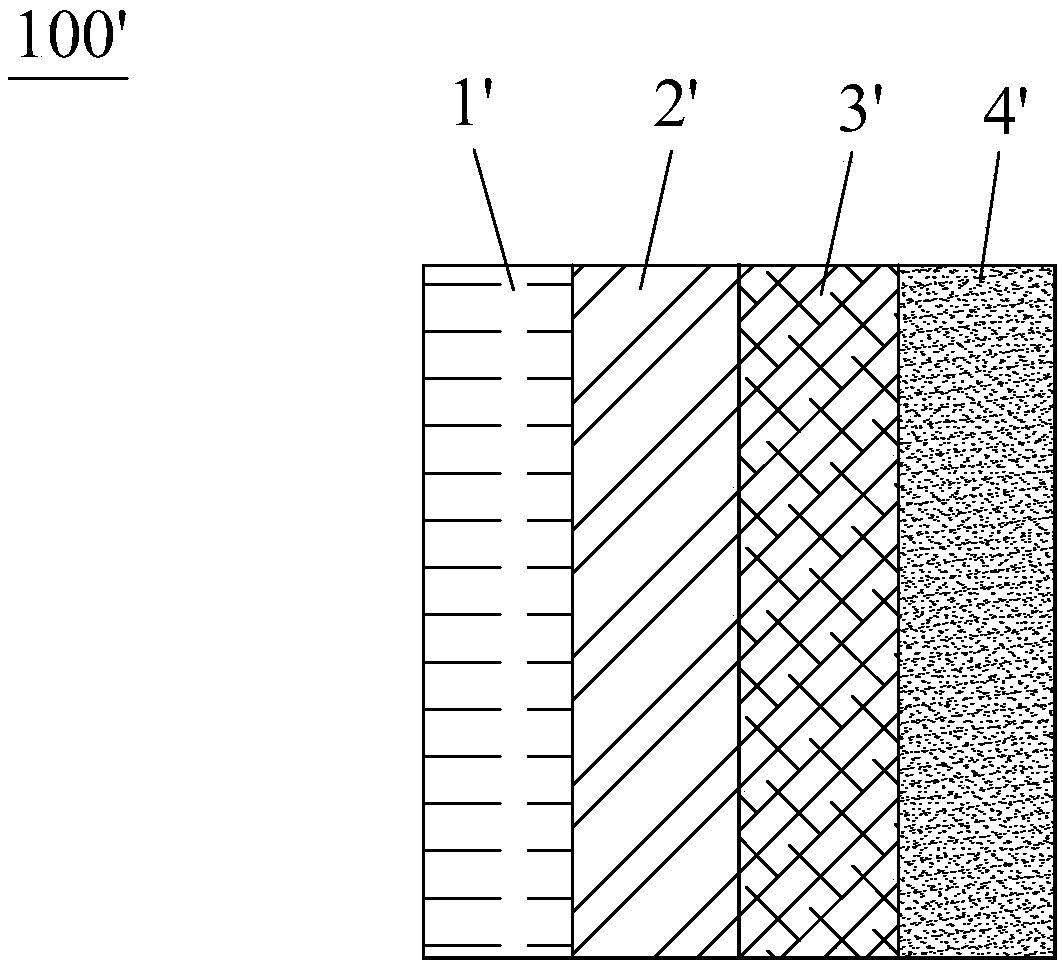

Solid electrolyte SO2 gas sensor and manufacturing method thereof

InactiveCN101726526AEnhanced interface bindingHigh sensitivityTelevision system detailsImpedence networksPhysical chemistryThin membrane

The invention relates to the field of SO2 gas sensors and discloses a solid electrolyte SO2 gas sensor and a manufacturing method thereof. The solid electrolyte SO2 gas sensor comprises a silicon substrate, and a SiO2 insulated layer, a conductive film, a Sn / SnF2 thin film, a LaF3 solid electrolyte thin film and a Pt net which are arranged on the silicon substrate in sequence. The conductive film is connected with a first lead; and the Pt net is connected with a second lead. In the technical scheme, the conductive film is an Al film; and the manufacturing method adopts an MEMS (Micro Electromechanical System) technology and has simple process and convenient realization.

Owner:XI AN JIAOTONG UNIV

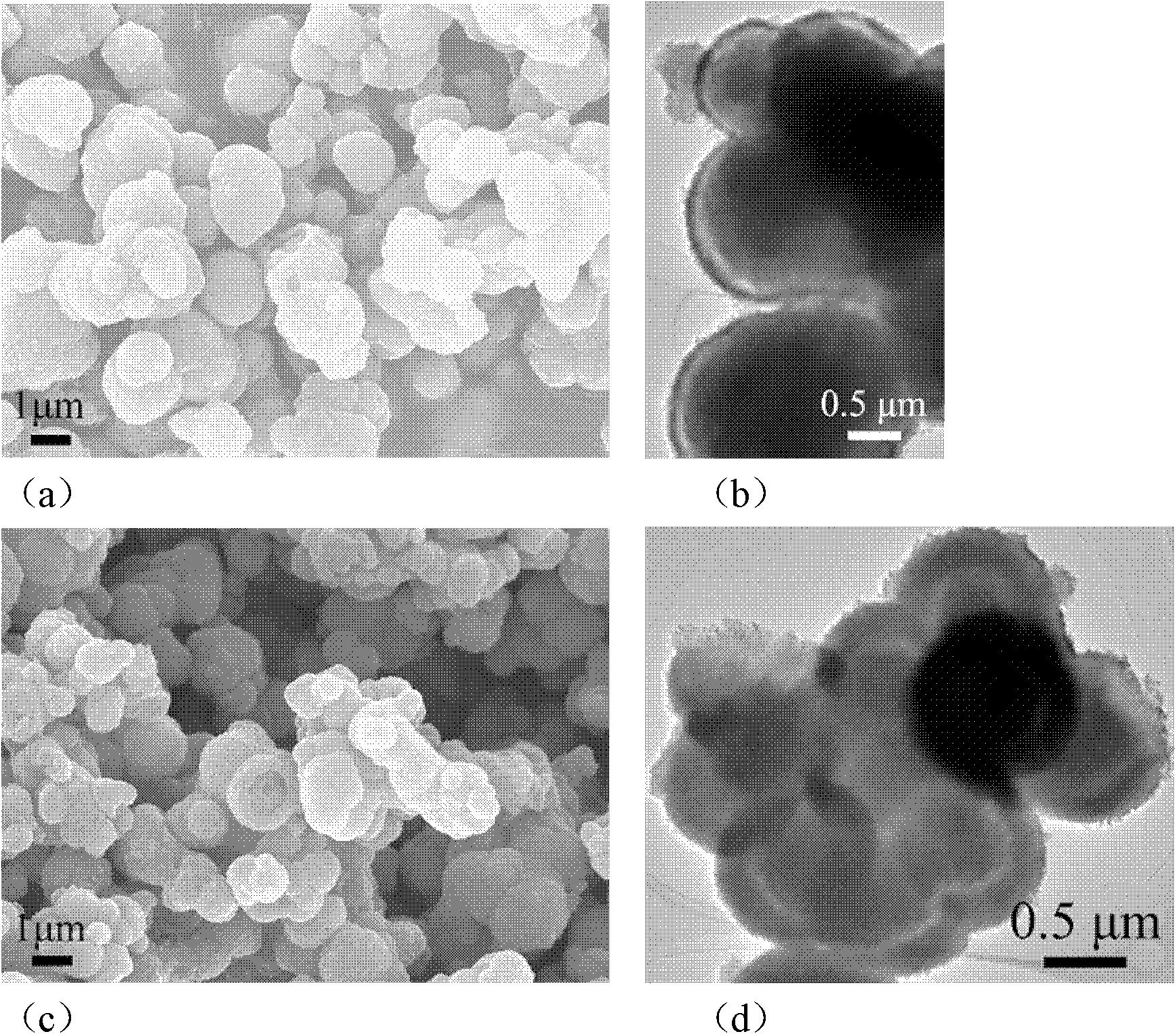

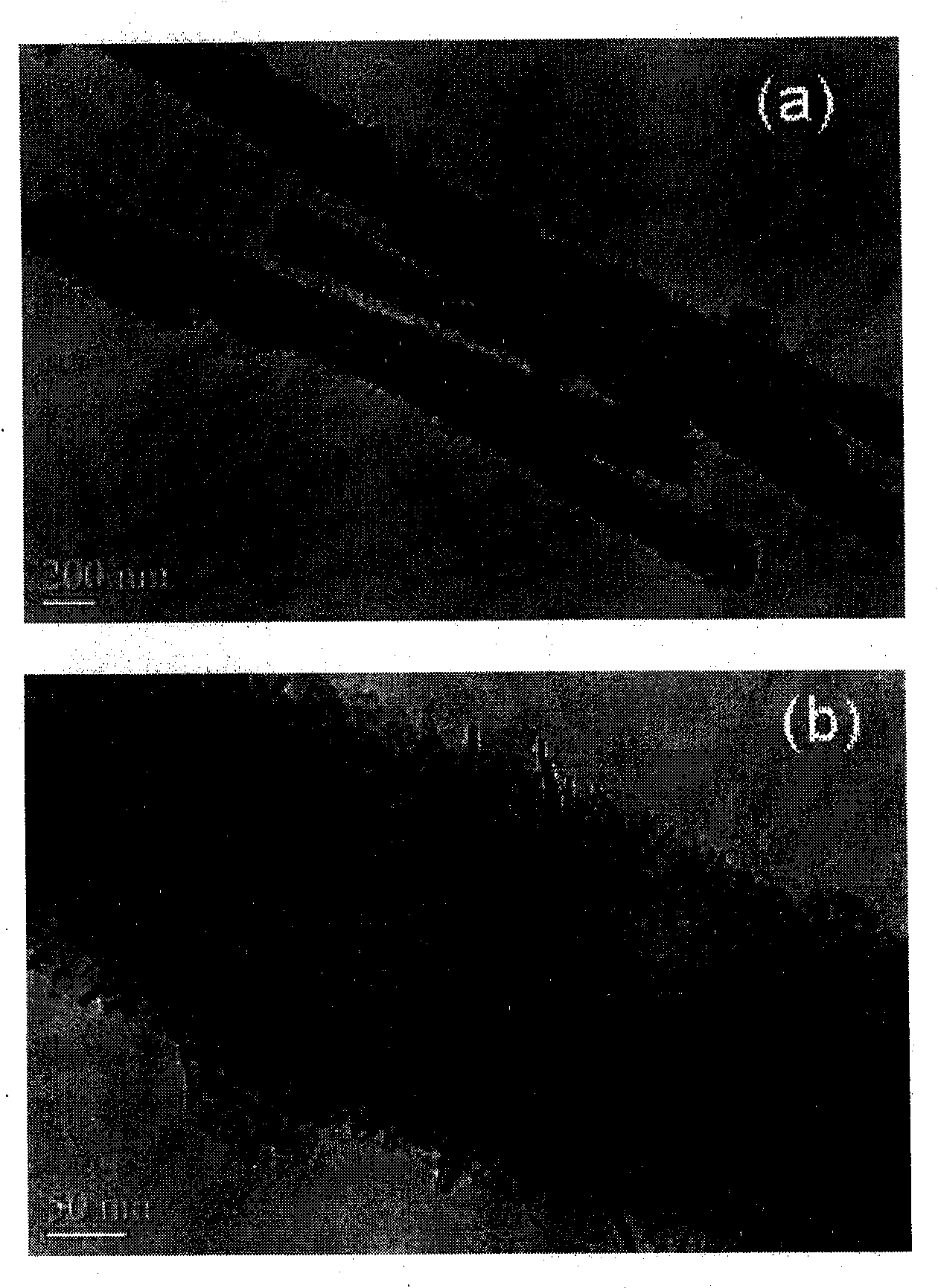

Method for preparing anatase porous TiO2 spheres, core-shell structure and hollow spheres

InactiveCN102730753AReduce riskEasy to operatePhysical/chemical process catalystsTitanium dioxideSolid sphereTitanium

The invention belongs to the photocatalytic material field, concretely relates to a method for preparing anatase porous TiO2 spheres, a core-shell structure and hollow spheres. The method comprises the following steps: dissolving titanium salt in water, then adding a HNO3 solution and carrying out a constant temperature reaction in a reaction vessel to obtain sediments; washing by deionized water until pH value presents neutrality, and drying to obtain the TiO2 powder. The invention is characterized in that TiO2 is replaced HF for taking as a corrosive agent, the method is a fluorine-free preparation process, the TiO2 with solid spheres, the core-shell structure and hollow spheres can be prepared by controlling reaction conditions, thereby the dangerousness of the preparation process can be substantially reduced, the maneuverability is enhanced, so that the method is suitable for requirements of large-scale production and industrial application, and possesses good application prospect.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation method of one-dimensional mesoporous Co nanowire array

InactiveCN101629320ASimple materialEasy to operatePolycrystalline material growthElectroforming processesNano structuringMesoporous silica

The invention discloses a preparation method of a one-dimensional mesoporous Co nanowire array, which comprising the following steps: preparing a precursor solution at room temperature by mixing 0.5-0.7g of PEP-POO-PEP (P123) which is an addition polymer of polypropylene glycol and ethylene oxide, 0.9-3g of tetraethyl orthosilicate and 0.4g of 38 wt% muriatic acid together; in an AAO (anodised aluminium) template, synthesizing SBA (mesoporous silica) nanofibers, wherein the mesoporous canals of the SBA (mesoporous silica) nanofibers are parallel to AAO canals; preparing electrodeposit liquid in the ratio of 2-4g of Co(CH3COO)2 : 1-3g of H3BO3; taking an aluminium base AAO-SBA composite mesoporous template as a working electrode and taking graphite as an auxiliary electrode, and controlling electrode density between 0.5-1.5 mA / cm2 and electrodepositing for 1.0-1.5h to obtain a Co nanowire with the width of about 200nm, wherein the Co nanowire consists of 4-6mn mesoporous Co nano rods. The invention adopts a simple electrochemical method to generate Co nano structures in AAO-SBA composite mesopores for the first time; and the growth direction of the crystals of the nano structures is controlled by the mesoporous canals. The invention has simple equipment, can be operated easily and is suitable to the industrial production.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Preparation method of ultra-fine particle of submicron barium titanate powder

The invention relates to a preparation method of ultra-fine particle of submicron barium titanate powder. The preparation method comprises the following steps of preparing a nano titanium source; removing chlorine ions in the titanium source; preparing a collosol; preparing cubic phase barium titanate sizing agent in a reaction kettle; washing the cubic phase barium titanate sizing agent; preparing tetragonal phase barium titanate powder aggregating preliminarily, and preparing tetragonal phase barium titanate powder. The preparation method has the advantage that the tetragonal phase barium titanate particle synthesized in the method is uniform, is complete, has the dispersibility of 1.01-1.2, is controllable in average particle size and specific surface area, has the tetragonal phase crystallization rate greater than or equal to 1.010, and is highly pure. The preparation method overcomes the defects of existing industrial production process, improves the yield of base powder of MLCC products, and improves the production efficiency.

Owner:安徽凯盛应用材料有限公司 +2

Gas sensor and temperature compensation method based on Pt reaction electrode

InactiveCN101526494AImprove binding performanceHigh sensitivityThermometers using electric/magnetic elementsMaterial analysis by electric/magnetic meansChemistryGas volume fraction

The invention discloses a solid electrolyte gas sensor and a temperature compensation method based on a Pt reaction electrode. The sensor comprises a Pt reaction electrode and a solid electrolyte wafer, wherein one end face of the solid electrolyte wafer is connected with a reference electrode with a third lead. The sensor is characterized in that the Pt reaction electrode is prepared on the other end face of the solid electrolyte wafer by adopting an MEMS process, the Pt reaction electrode adopts a band structure, two ends of the Pt reaction electrode are respectively arranged on opposite edges of the end faces of the solid electrolyte wafer, which pass through the diameter direction, and are respectively connected with a first lead and a second lead; and the band electrode is tortuously distributed along the plane of the end faces of the solid electrolyte wafer. A resistor signal converting circuit is connected between the first lead and the second lead and converts the resistance value change of the Pt reaction electrode caused by the temperature change into electrical signals to be input a signal processing circuit, and electromotive force signals obtained by primary detection through the signal processing circuit and reflecting the gas volume percent are compensated so that the influence of the temperature change to the sensor property is eliminated.

Owner:XI AN JIAOTONG UNIV +1

Preparation method of macroporous weak-base anion exchange resin special for gold extraction

PendingCN113042113AHigh mechanical strengthControllable mechanical strengthAnion exchangersProcess efficiency improvementPolymer scienceDivinylbenzene

The invention discloses a preparation method of macroporous weak-base anion exchange resin special for gold extraction. According to the invention, a crosslinked styrene-divinylbenzene microsphere matrix obtained by regulating and controlling a preparation process of crosslinked styrene-divinylbenzene microspheres has the advantages of high mechanical strength, controllable specific surface area, adjustable aperture and the like; the weak-base anion exchange resin special for gold extraction, synthesized on the basis of the crosslinked styrene-divinylbenzene microsphere matrix also has a controllable pore structure and pore size distribution, and can realize selective adsorption with the gold element; and the total exchange capacity of the resin is 2.0-4.5 mmol / g, the gold element exchange capacity is 30-240 mg per g of dry resin, wear resistance is good, and the problems of low exchange capacity, poor mechanical strength and the like of traditional special gold extraction ion exchange resin are solved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

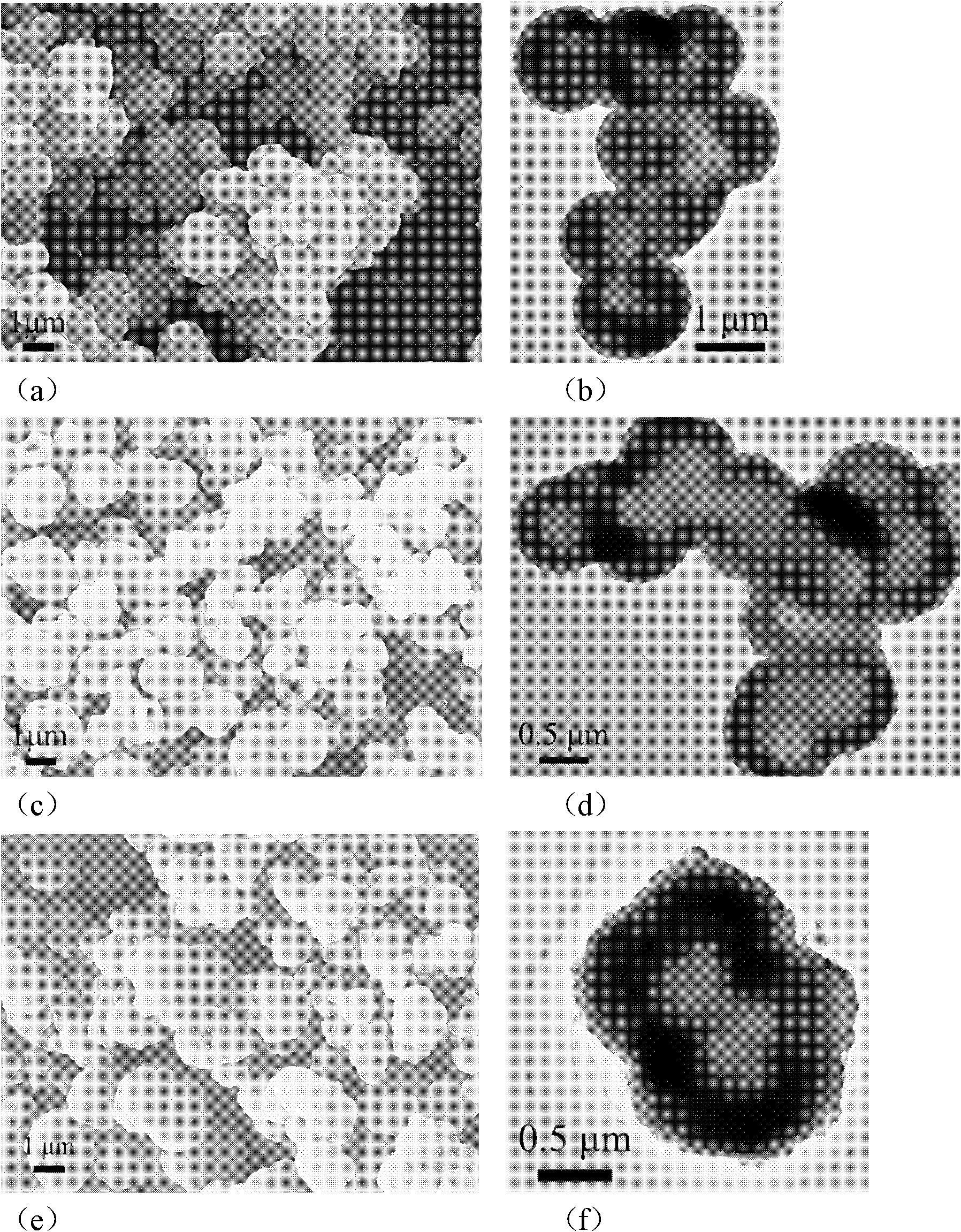

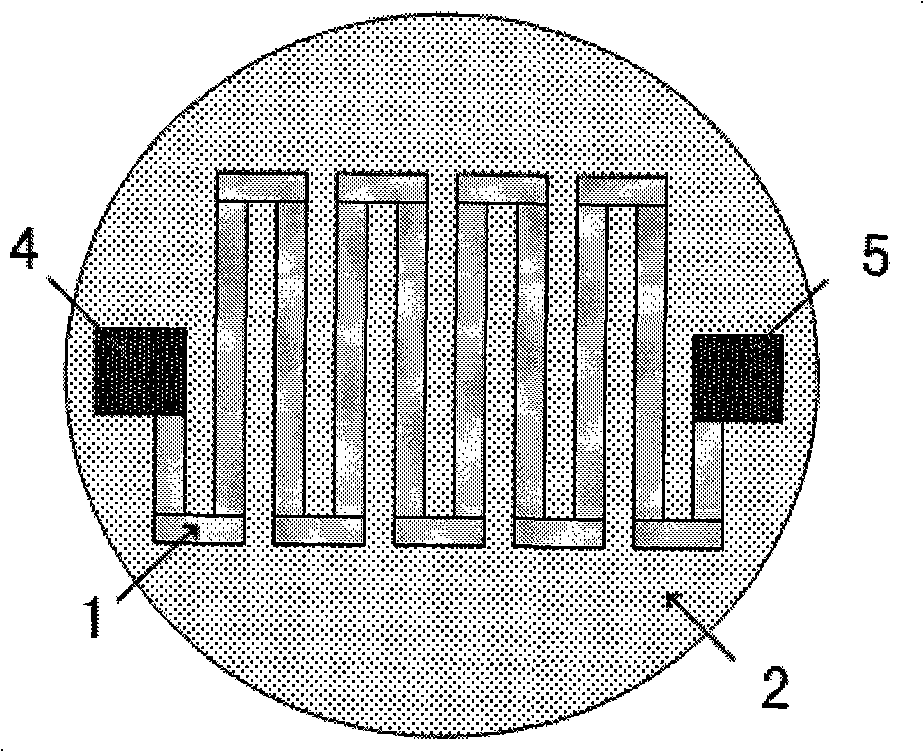

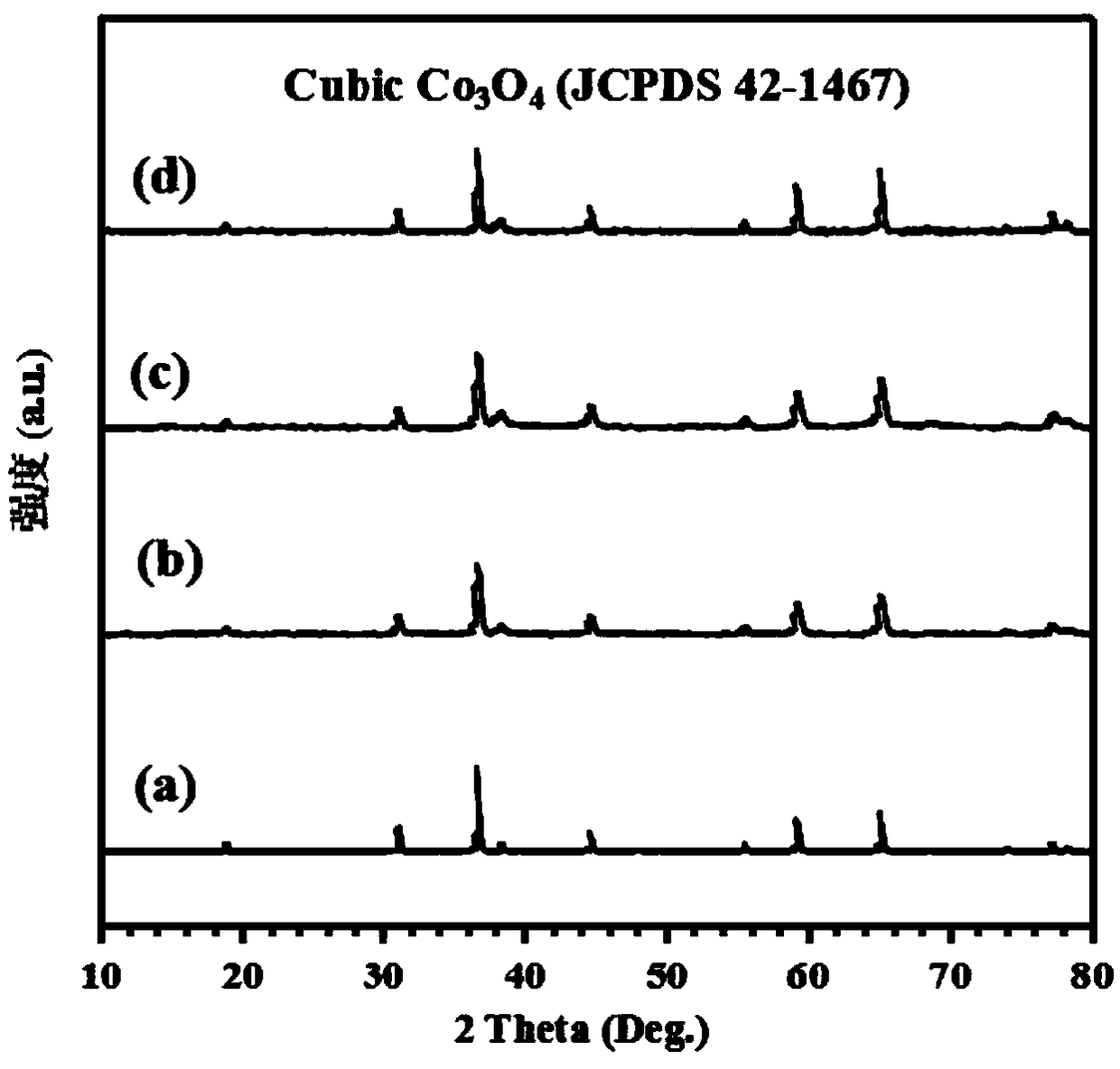

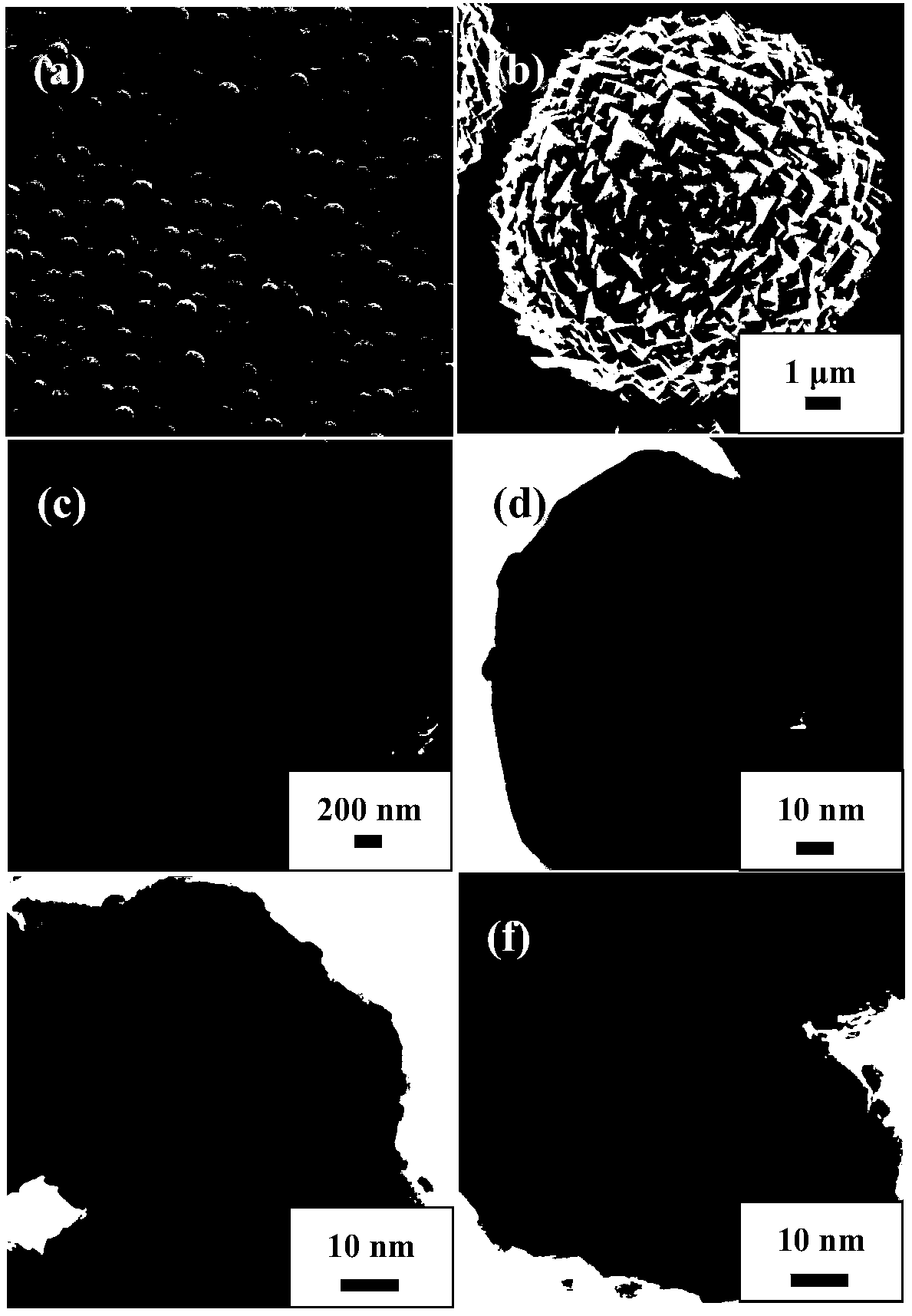

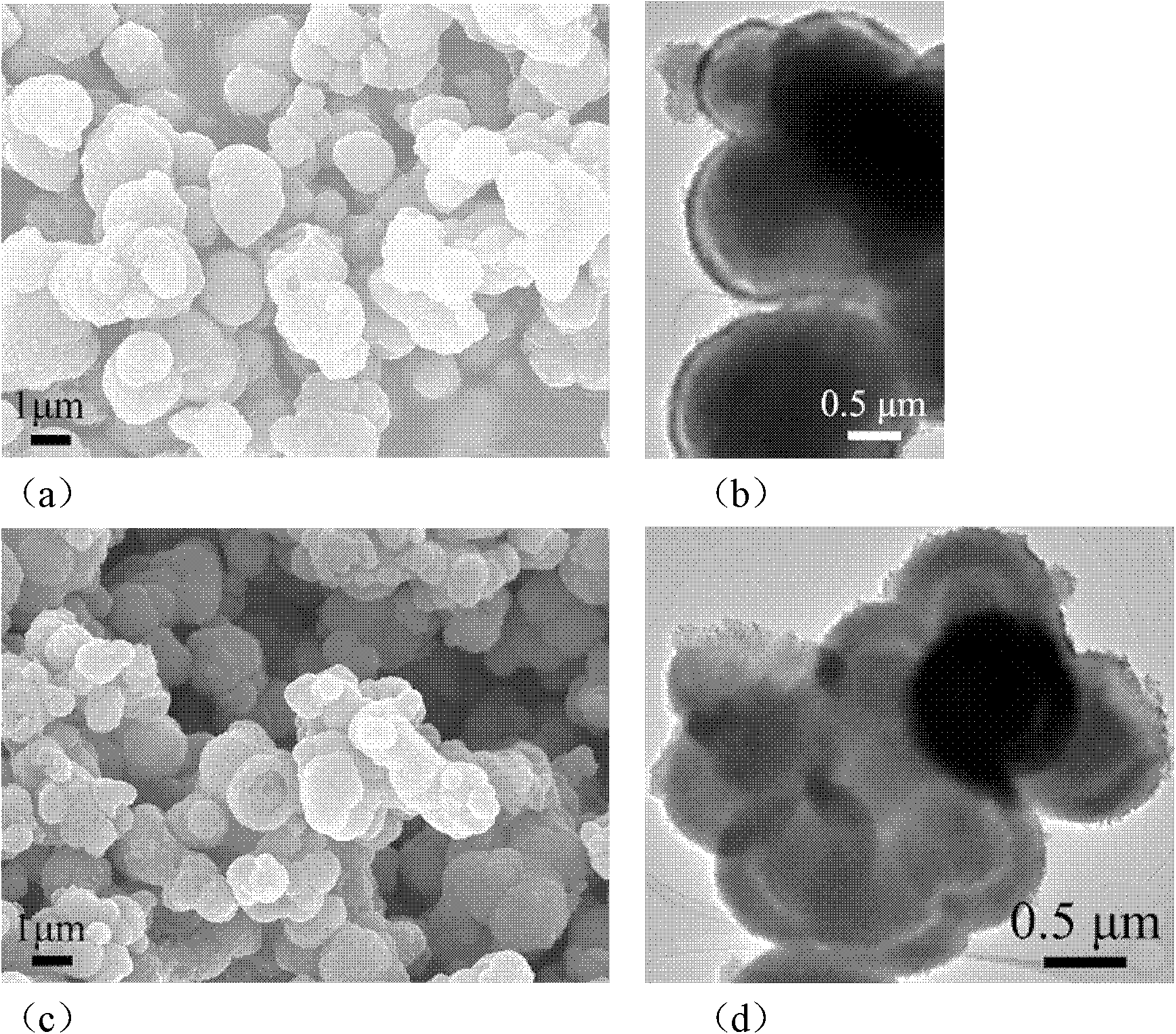

Porous Co3O4 monodisperse microsphere-loaded Au-Pd alloy nanocatalyst and preparation method thereof

InactiveCN108212175AShape is easy to controlControllable specific surface areaGas treatmentDispersed particle separationNano catalystMicrosphere

The invention discloses a porous Co3O4 monodisperse microsphere-loaded Au-Pd alloy nanocatalyst and a preparation method thereof. The porous Co3O4 monodisperse microsphere-loaded Au-Pd alloy nanocatalyst comprises a Co3O4 carrier with a monodisperse microsphere-like morphology having porous cubic agglomeration, and the pore wall of the carrier is loaded with Au-Pd alloy. The porous Co3O4 monodisperse microsphere-loaded Au-Pd alloy nanocatalyst capable of effectively removing volatile organic compounds is a porous nanocatalyst and has better low-temperature catalytic activity, water resistanceand heat resistance.

Owner:YULIN NORMAL UNIVERSITY

Method for preparing air electrode

InactiveCN109411768AImprove breathabilityImprove electrochemical performanceCell electrodesEngineeringElectrochemistry

The invention provides a method for preparing an air electrode. The method comprises the steps: (1) forming a first diffusion layer and a second diffusion layer at the two sides of a current collector; (2) preparing a spinning solution from a catalyst and a macromolecular solution; (3) spraying the spinning solution to the first diffusion layer, so as to obtain a catalyzing layer; (4) placing a waterproof air-permeable film on the second diffusion layer, and carrying out rolling, thereby obtaining the air electrode. According to the method for preparing the air electrode, provided by the invention, the prepared air electrode is high in electric conductivity, good in air permeability and high in catalysis performance, so that a phenomenon of polarization of air batteries can be decelerated,and electrochemical properties of the batteries are improved.

Owner:蔚蓝(广东)新能源科技有限公司

Preparation method of compound zirconium oxide

ActiveCN102503415AGood particle mixing uniformityControl feed flow rateAqueous dropletMixed materials

The invention relates to a preparation method of compound zirconium oxide. The method comprises the following steps that: A, ammonia water is dripped into zirconium oxychloride solution for reaction, and zirconium hydroxide water sol is generated after the reaction completion; B, deionized water is used for washing the zirconium hydroxide water sol, and zirconium hydroxide colloid is obtained after press filtering; C, the zirconium hydroxide colloid is dried, and then, powdery zirconium hydroxide is obtained through powdery processing; D, yttrium oxide and auxiliary materials (one kind of materials or several kinds of materials from aluminum oxide, magnesium oxide and calcium oxide) are added into the powdery zirconium oxide to be mixed (through ball mill or stirring tank mixing), and after the mixing completion, the mixed materials are roasted for 2 to 3 hours at 950 to 1050 DEG C, and compound zirconium oxide powder is obtained. The method has the advantages that the scaled production method of high-performance compound zirconium oxide materials is obtained, the produced compound zirconium oxide materials have good uniformity, the specific surface area of products is controllable, and the crystal phase structure is controllable.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

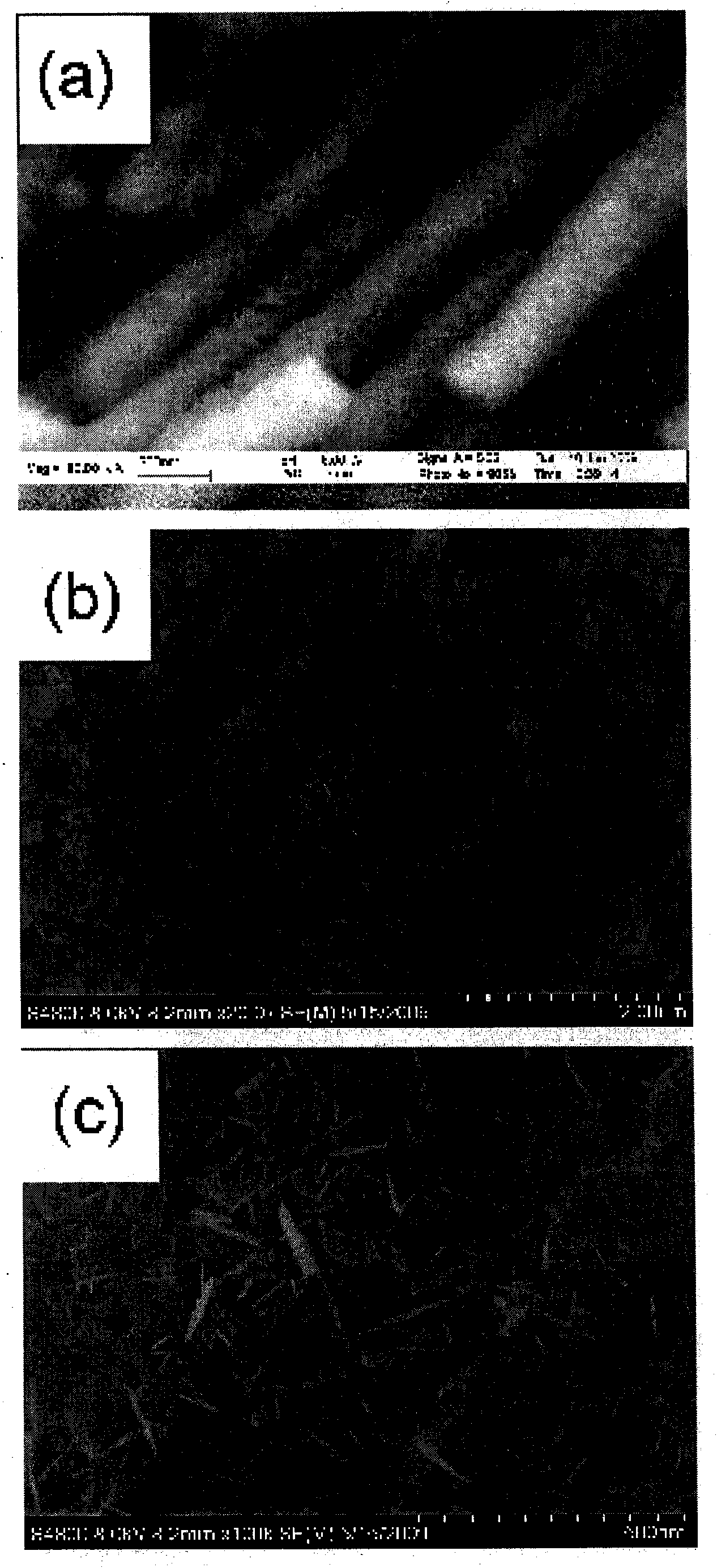

One-dimensional single crystal LaFeO3 nanorods and preparation thereof

InactiveCN103498189ARaw materials are cheap and easy to getEasy to makeMaterial nanotechnologyPolycrystalline material growthAir atmosphereFiltration

The invention relates to one-dimensional single crystal LaFeO3 nanorods and preparation thereof, belonging to the technical field of LaFeO3 nanocrystals. The preparation method comprises the following steps: preparing Fe2O3 nanorods by a hydrothermal synthesis process, dissolving lanthanum nitrate hexahydrate in deionized water, adding the Fe2O3 nanorods under stirring conditions to obtain a template, dropwisely adding a 10% KOH solution under stirring conditions until the pH value of the solution is 10 or so, carrying out ultrasonic treatment for 10-15 minutes, transferring into a teflon-lined autogenous pressure kettle until the volume degree of filling is 80%, carrying out constant-temperature treatment at 180 DEG C for 12 hours, carrying out vacuum filtration,, washing with deionized water three times, washing with anhydrous ethanol three times, drying at 80 DEG C for 12 hours, heating from room temperature to 650-750 DEG C in a muffle furnace in an air atmosphere at the rate of 1 DEG C / minute, and keeping the temperature for 4 hours to obtain the one-dimensional single crystal LaFeO3 nanorods. The raw materials are cheap and accessible; the preparation process is simple; and the product shape is controllable.

Owner:BEIJING UNIV OF TECH

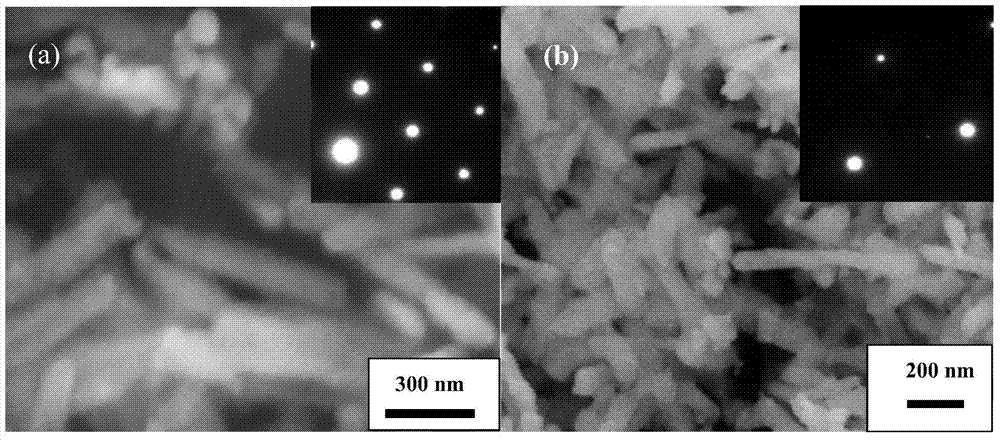

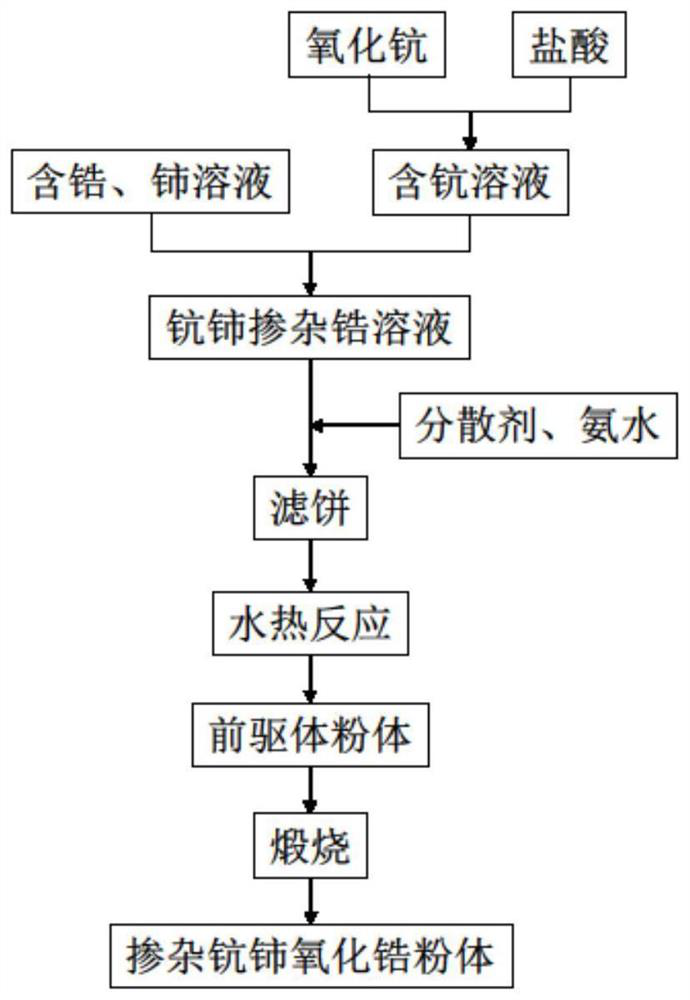

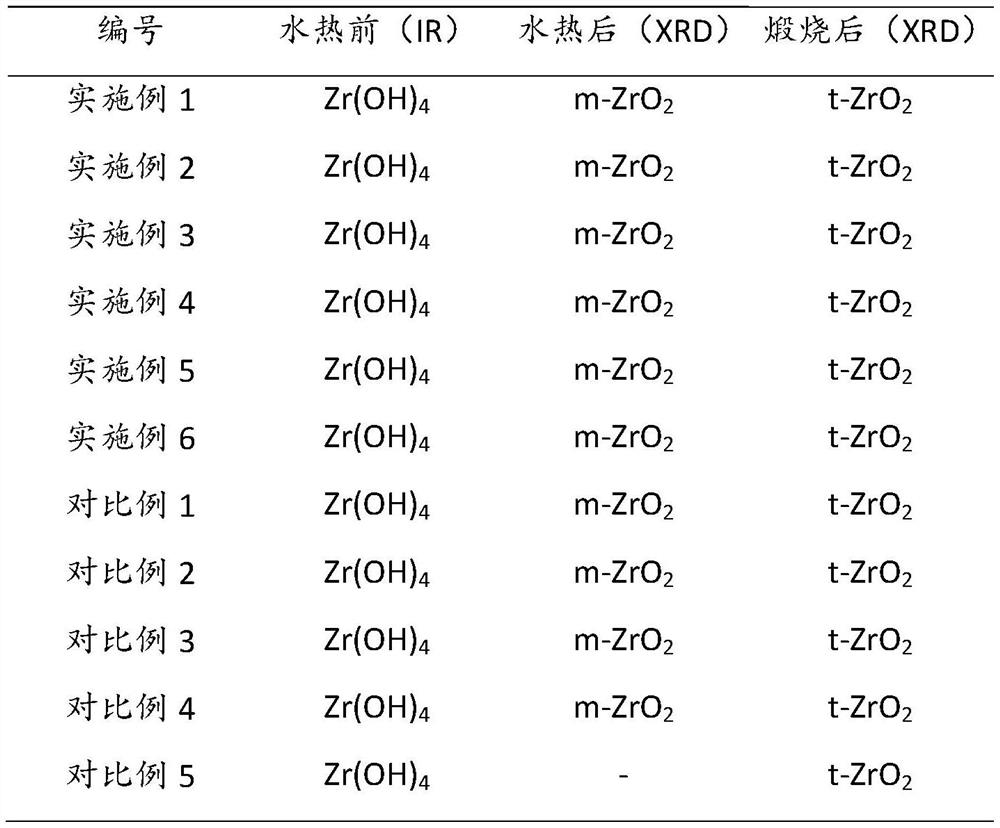

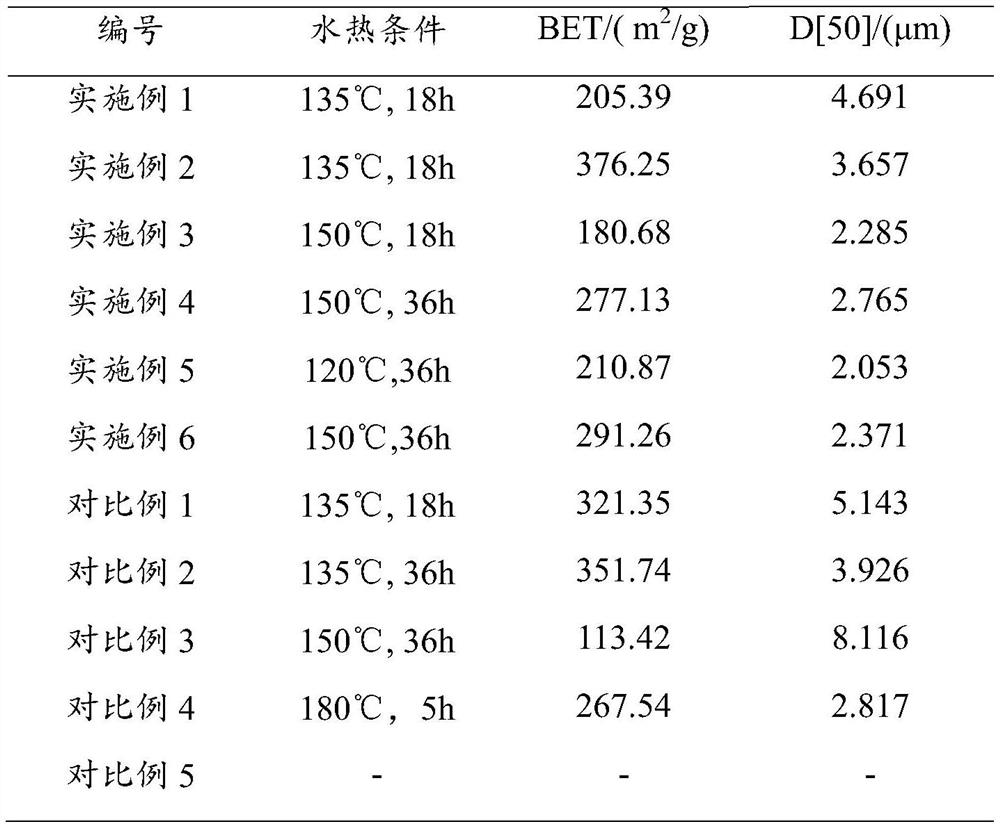

Scandium-and-cerium-doped zirconium oxide ultrafine powder and preparation method thereof

InactiveCN112573570ALarge specific surface areaImprove stabilityZirconium oxidesPhysical chemistryCerium

The invention discloses scandium-and-cerium-doped zirconium oxide ultrafine powder and a preparation method thereof. According to the invention, CTAB is used as a dispersing agent to prepare scandium-and-cerium-doped zirconium oxide ultrafine powder. The preparation method comprises the following steps: firstly, converting a Zr(OH)4 precipitate into monoclinic zirconium oxide by adopting a hydrothermal method to obtain a tetragonal zirconium oxide precursor with enough nucleation core particles; and then conducting calcining to enable tetragonal zirconium oxide crystals to grow into proper particles, thereby preparing the scandium-and-cerium-doped zirconium oxide ultrafine powder with uniform particle size, small particle size and high specific surface area. The preparation method is simple in process and easy for large-scale industrial production.

Owner:FIRST RARE MATERIALS CO LTD

Preparation method of spherical lithium iron phosphate cathode material

A preparation method of a spherical lithium iron phosphate cathode material. The method comprises steps of: 1) preparing lithium source, divalent ferric salt, phosphor salt compound and doped metallic element in a molar ratio of 0.95-1.05:1:1:0.005-0.05 into a solution; adding the solution, reducing agent and precipitating agent into a reaction kettle with an overflow mouth through a metering pump; preparing a spherical lithium iron phosphate precursor through reaction condition control; 2) cladding a layer of nano metal oxide or metallic carbide with excellent conductivity on a surface of the spherical lithium iron phosphate precursor by using polymer as an adjuvant; 3) placing the spherical lithium iron phosphate cladded with metal oxide or metallic carbide in an atmosphere protection furnace, introducing inert atmosphere, insulating for 6-24 h at 500-900 DEG C, cooling naturally to a room temperature to obtain the spherical lithium iron phosphate cladded with metal oxide or metallic carbide conductive film. The lithium iron phosphate material prepared by the method has advantages of uniform chemical components and easily controlled product morphology. Especially, the cladding of metal oxide or metallic carbide enhances conductivity between lithium iron phosphate particles and tap density of the material.

Owner:HENAN KELONG NEW ENERGY CO LTD

Preparation method of magnesium hydroxide powder

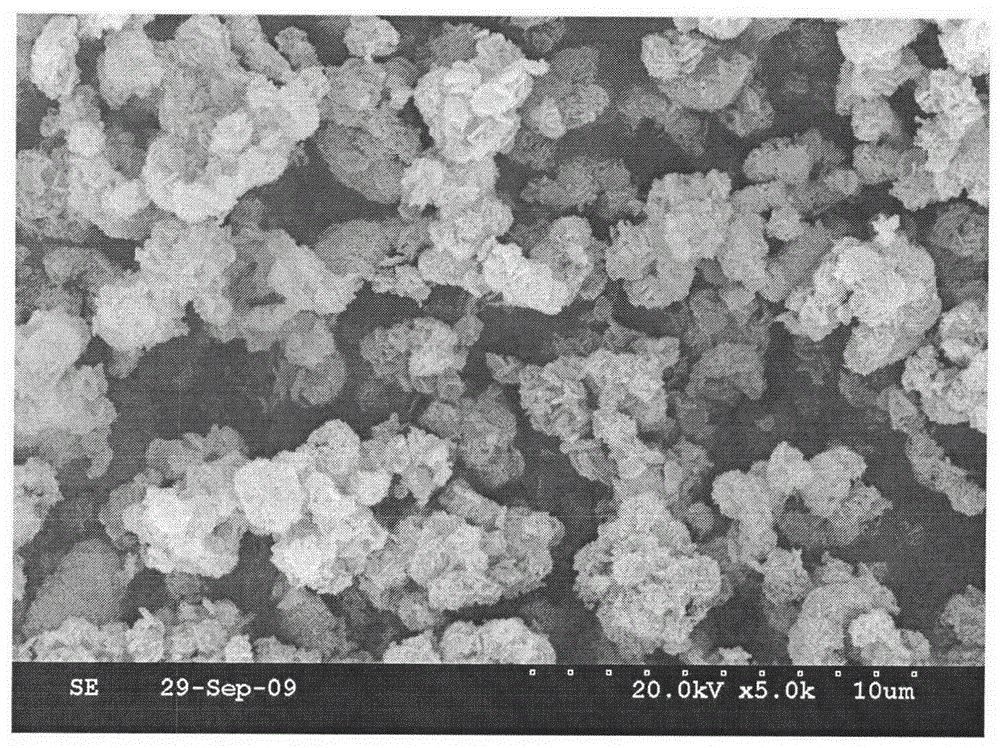

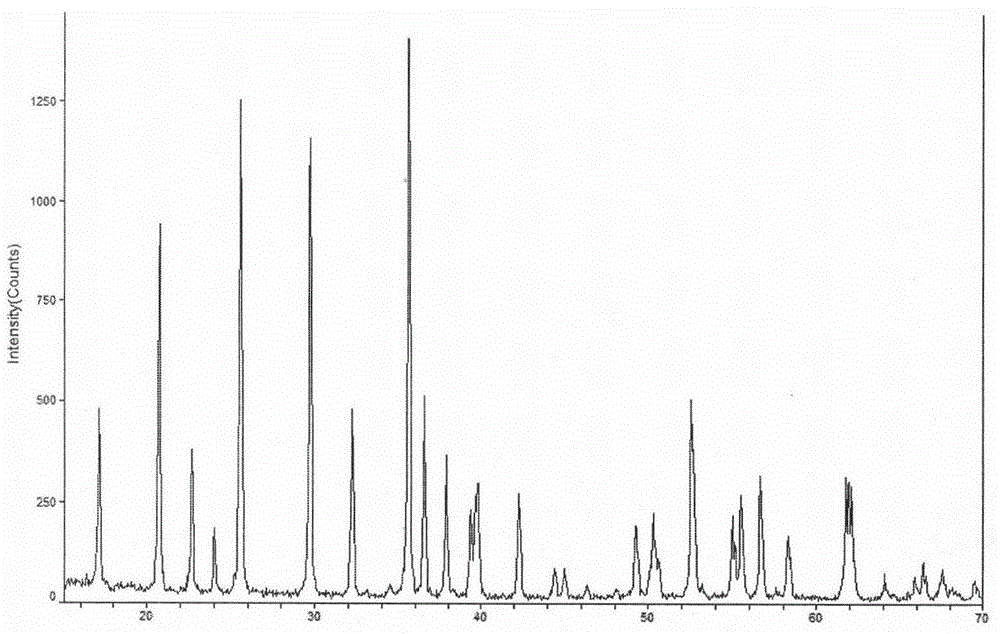

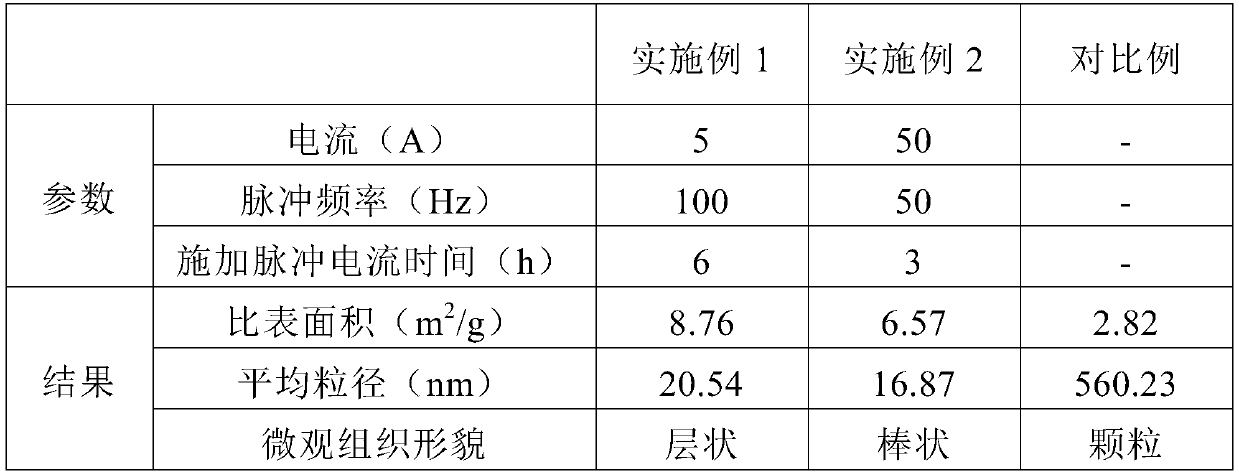

InactiveCN109761252ASimple stepsLow costNanotechnologyMagnesium hydroxidePulse frequencyMicrostructure

The invention provides a preparation method of magnesium hydroxide powder. The method comprises the following step: pulse current is applied in a reaction system when light calcined magnesia is utilized to prepare the magnesium hydroxide powder via hydration reaction. The magnitude of the pulse current applied in the reaction system is 5-1,000 A, and the used pulse frequency is 50-2,000 Hz. By adjusting the magnitude of the pulse current and the pulse frequency, the specific surface area, average particle size and microstructure and morphology of the magnesium hydroxide are controlled by the invention. Compared with the prior art, the preparation method provided by the invention has the following advantages: the process is simple, the cost is low, and the specific surface area, average particle size and microstructure and morphology of the magnesium hydroxide are easy to control.

Owner:ZHONGMIN CHIYUAN IND

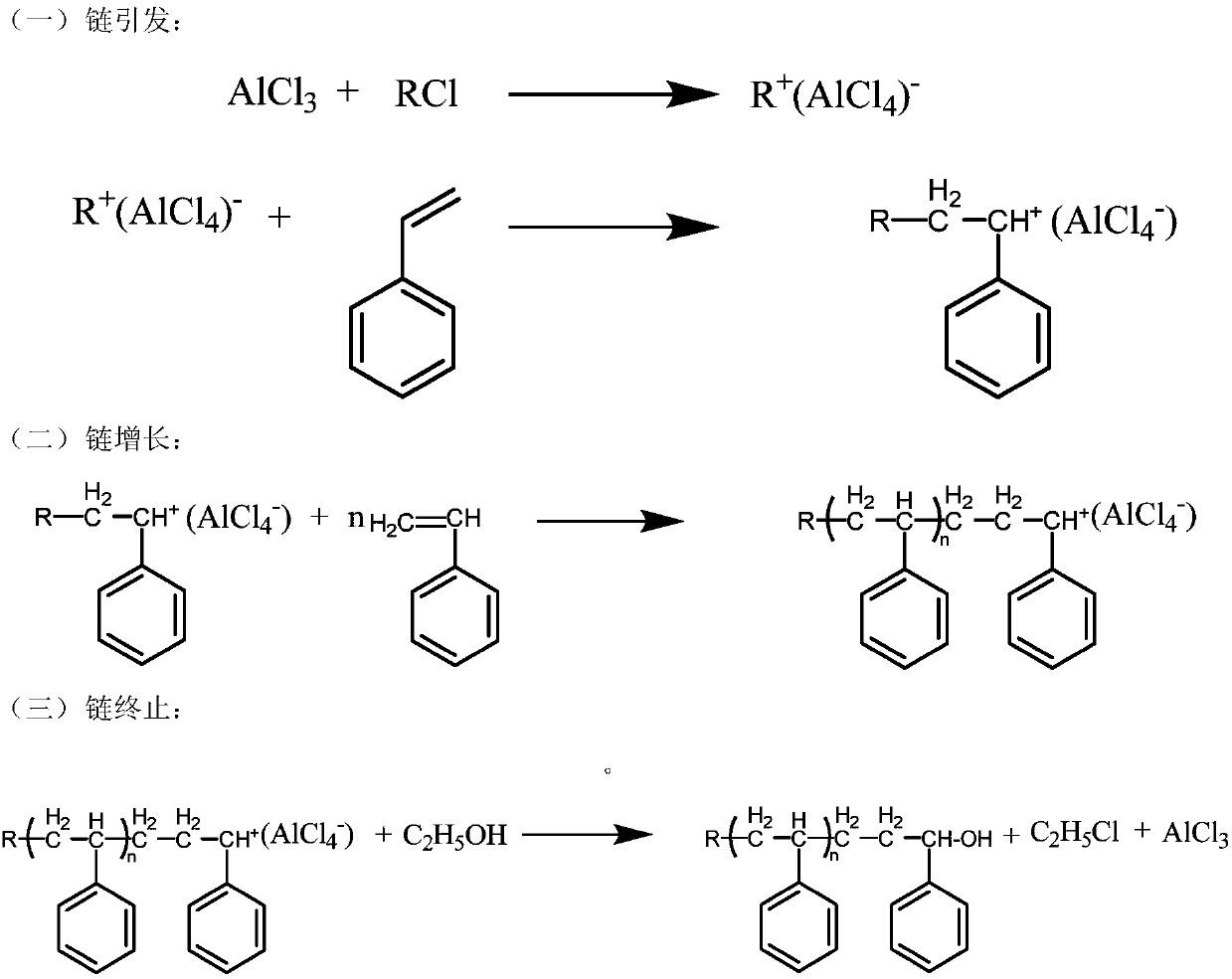

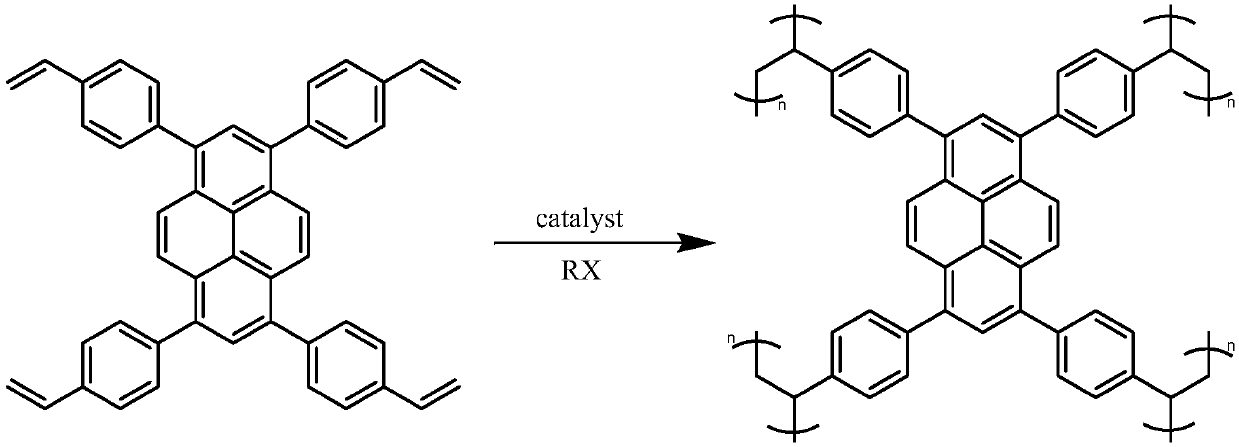

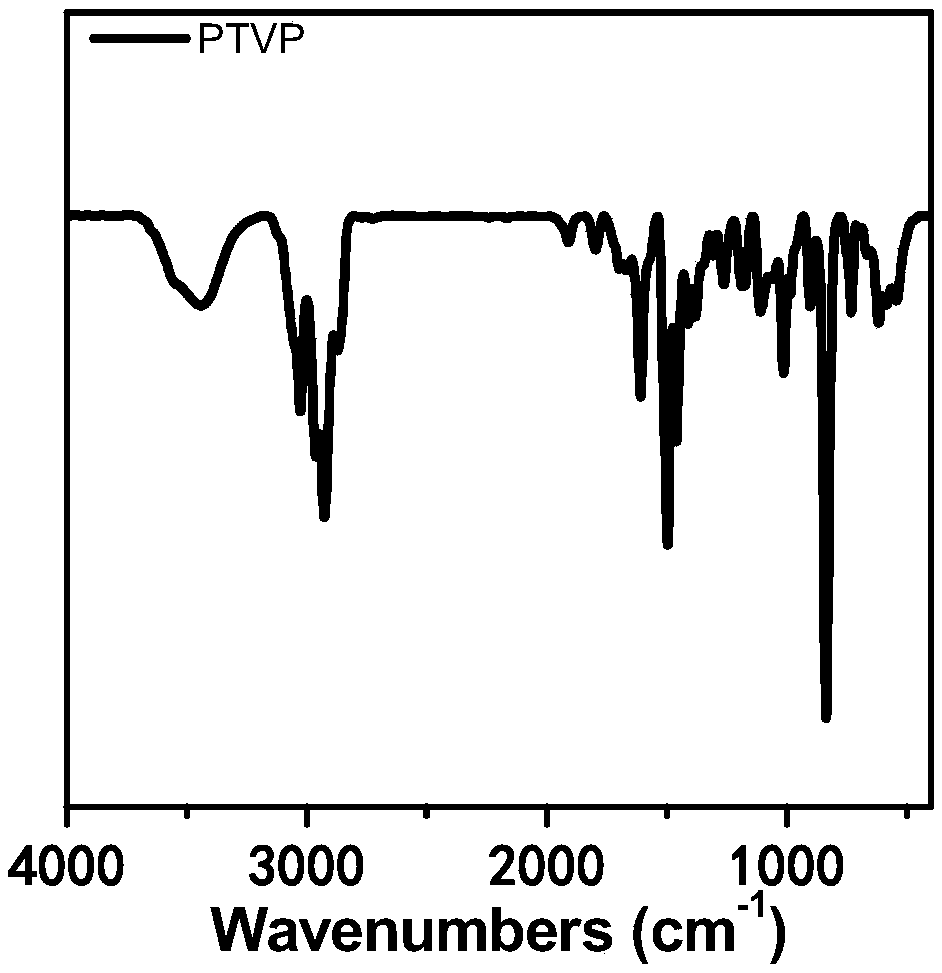

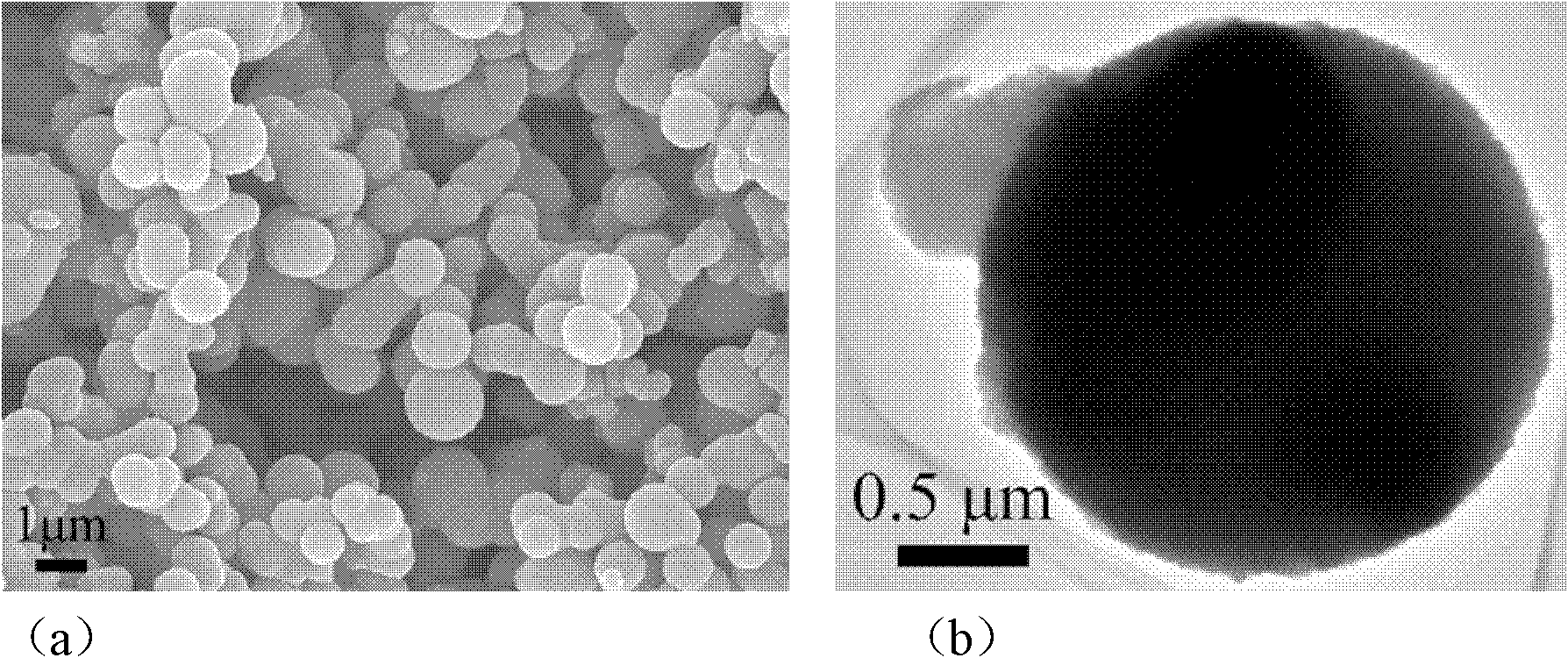

Method for preparation of organic porous material based on cationic polymerization reaction

ActiveCN109970893AFast preparationMany choicesDispersed particle separationMaterials preparationOrganic solvent

Belonging to the technical field of new materials, the invention more specifically relates to a method for rapid preparation of an organic porous material based on cationic polymerization. The methodincludes: taking a binary or multi-element styryl aromatic ring compound dispersed in an organic solvent as the raw material, carrying out cationic polymerization reaction under the catalysis of a catalyst, and then performing separation and purification to obtain an organic porous polymer. The invention fully combines the characteristics and preparation requirements of organic porous materials, redesigns the preparation method specifically for organic porous materials, and selects and optimizes key preparation process raw materials and technological parameters, thus obtaining the organic porous material preparation method with the characteristics of mild conditions, fast reaction speed, convenient operation and high production efficiency accordingly.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method of petroleum-degrading microbial agent

InactiveCN109880756AMany poresLarge apertureBacteriaContaminated soil reclamationCelluloseMicrobial agent

The invention relates to a preparation method of a petroleum-degrading microbial agent and belongs to the technical field of petroleum pollution remediation. According to the method, grapefruit peel and activated carbon are subjected to pyrolysis treatment to serve as a microbial agent carrier, a large amount of cellulose is contained in a white flocculent layer in the grapefruit peel, the grapefruit peel also has the characteristics of multiple pores and a large pore diameter and has a compact structure, the network structure is not obvious, oil products are adsorbed to a certain extent, thethree-dimensional network structure of the pyrolyzed grapefruit peel is more obvious, large and small pores are communicated in a staggered manner, and rapid oil absorption is facilitated, and the pore diameter is obviously increased compared with that before pyrolysis, so that the improvement of oil absorption is facilitated; due to the fact that an artificial carrier has the advantages of controllable specific surface area, pore size distribution, good mass transfer performance and the like, the artificial carrier can be better matched with specific microbes and complex pollutants so as to obtain better immobilization effect and repair performance; biochar has strong petroleum adsorption capacity, achieves the enrichment and degradation integration of pollutants and is beneficial to theimprovement of the soil remediation effect.

Owner:陈傲

Method for preparing anatase porous TiO2 spheres, core-shell structure and hollow spheres

InactiveCN102730753BReduce riskEasy to operatePhysical/chemical process catalystsTitanium dioxidePhoto catalyticPhysical chemistry

The invention belongs to the field of photocatalytic materials, specifically a method for preparing anatase porous TiO2 core-shell structure and hollow spheres, specifically dissolving titanium salt in water, adding HNO3 solution, and reacting at a constant temperature in a reactor to obtain a precipitate ; Wash with deionized water until the pH is neutral, and dry to obtain TiO2 powder; through the present invention, HNO3 is used instead of HF as a corrosive agent, which is a fluorine-free preparation process, and solid spheres, core-shell structures and hollow spheres can be prepared by controlling the reaction conditions TiO2 greatly reduces the risk of the preparation process and improves the operability, making the method suitable for large-scale production and industrial application, and has a good application prospect.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

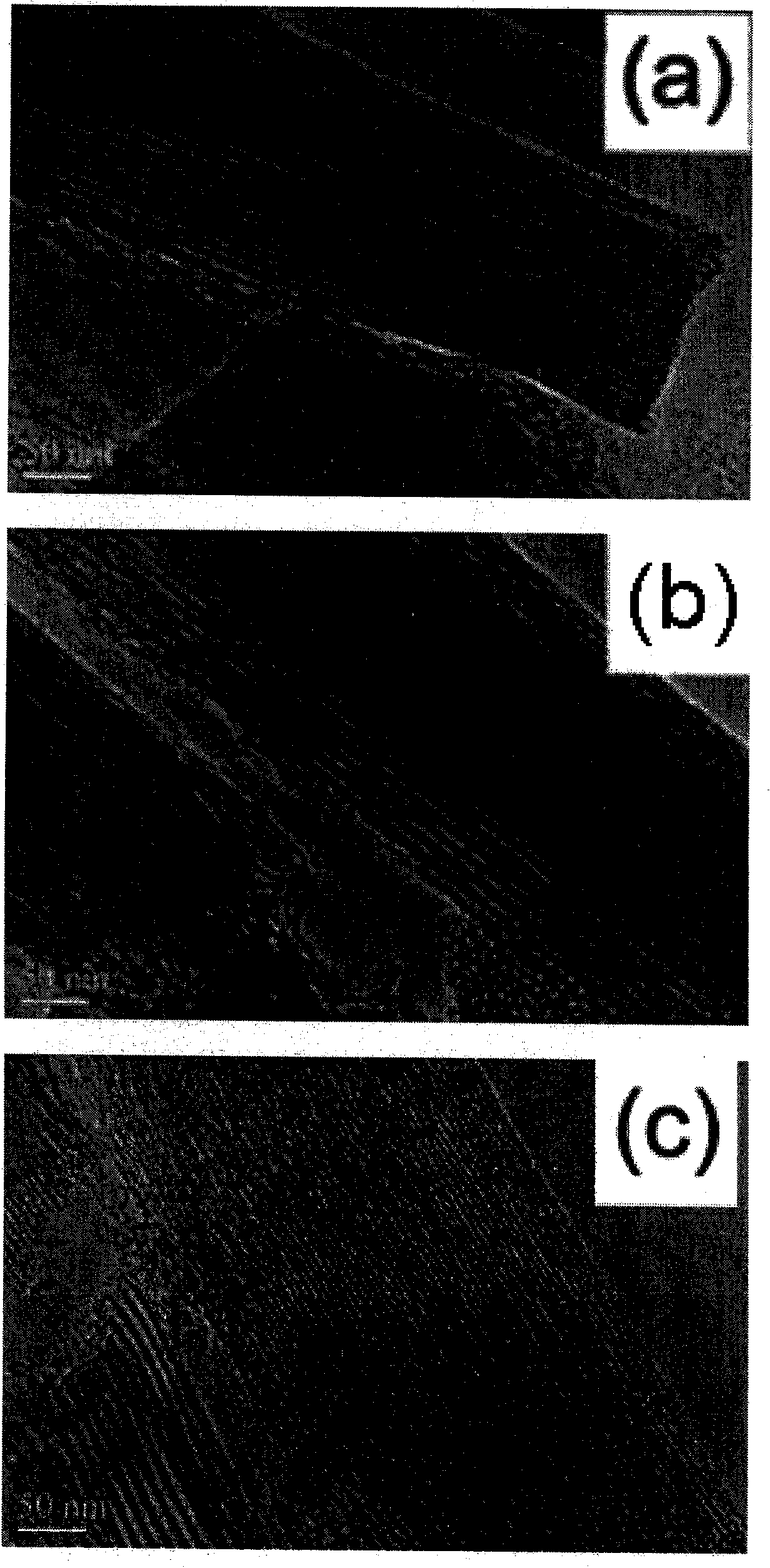

Method for improving activity of carbon fiber felt for vanadium battery

ActiveCN114068959AHigh activityImprove performanceCell electrodesRegenerative fuel cellsFiberCarbon fibers

The invention discloses a method for improving the activity of a carbon fiber felt for a vanadium battery, and belongs to the technical field of vanadium batteries. The method comprises the following steps: putting the carbon fiber felt into a sulfuric acid solution for ultrasonic treatment; immersing the upper end and the lower end which account for 1 / 4-1 / 3 of the total thickness of the felt into pyrrole-acetone liquid for modification; respectively putting the upper end and the lower end of the modified carbon fiber felt into nickel powder liquid and hydrogen peroxide for ultrasonic treatment, adjusting the height, and respectively carrying out ultrasonic treatment on the upper end and the lower end accounting for 1 / 3-3 / 4 of the thickness of the treated part; and carrying out calcining in nitrogen and acetylene, and finally soaking in mixed acid to obtain the electrode for the vanadium battery. Carbon nanotubes are introduced into the upper and lower ends of the carbon fiber felt by using a vapor deposition method, so that the pore diameters of the carbon fibers at the upper and lower ends are changed, the purposes of improving the activity of the carbon fiber felt and improving the performance of the vanadium battery are achieved, and the problem that the performance of the vanadium battery is influenced by non-uniform pore diameters of the carbon fiber felt due to physical extrusion stress during vanadium battery assembly is solved.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

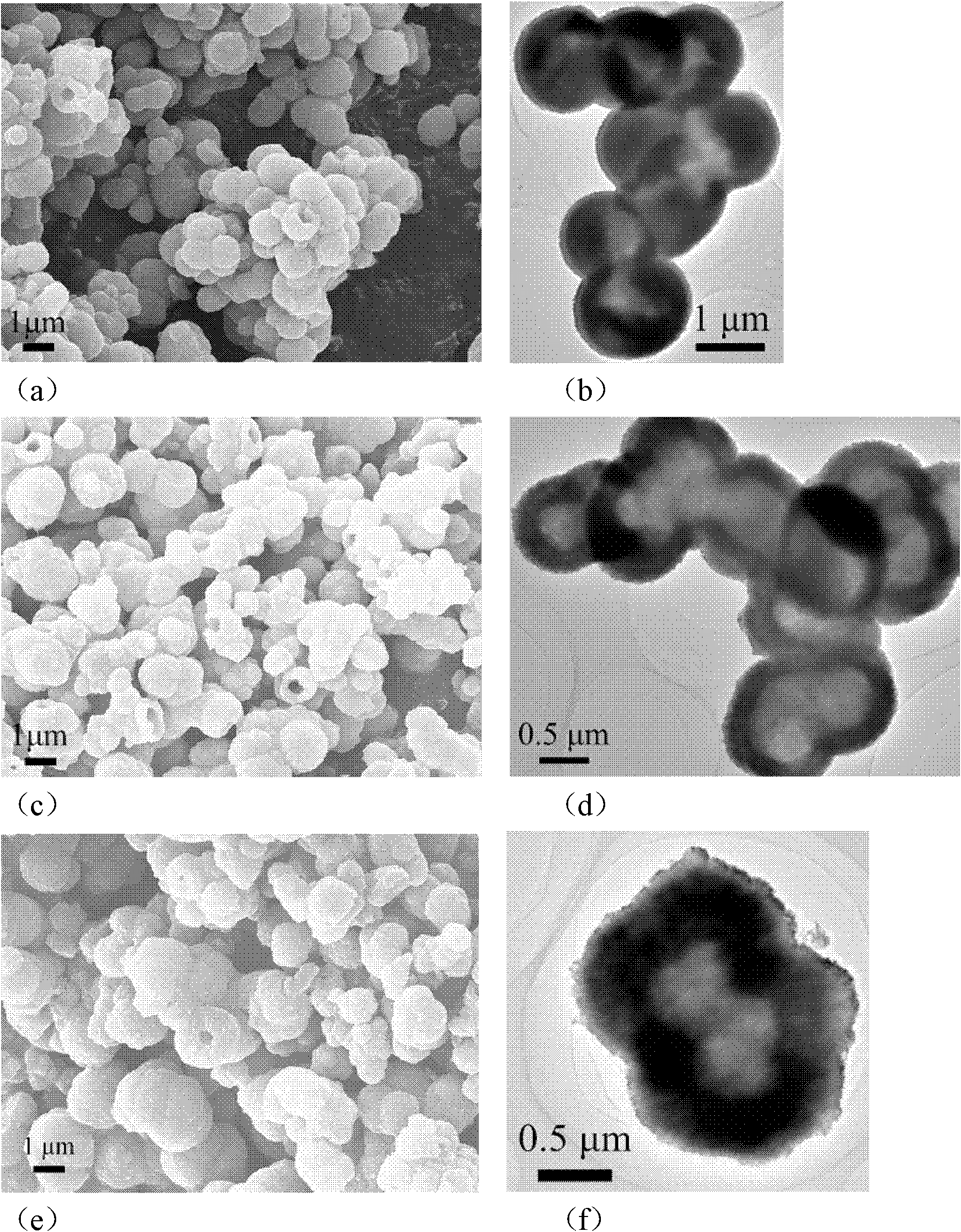

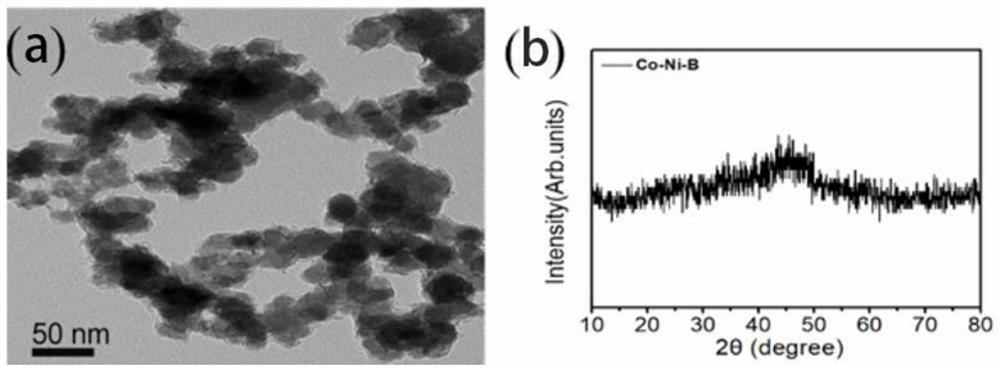

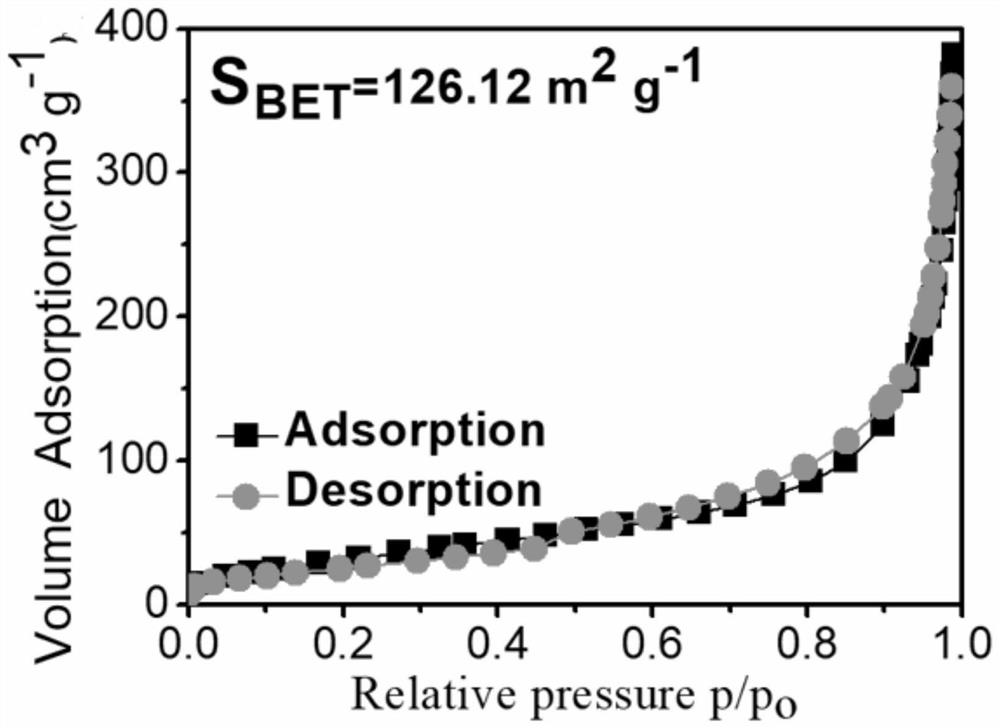

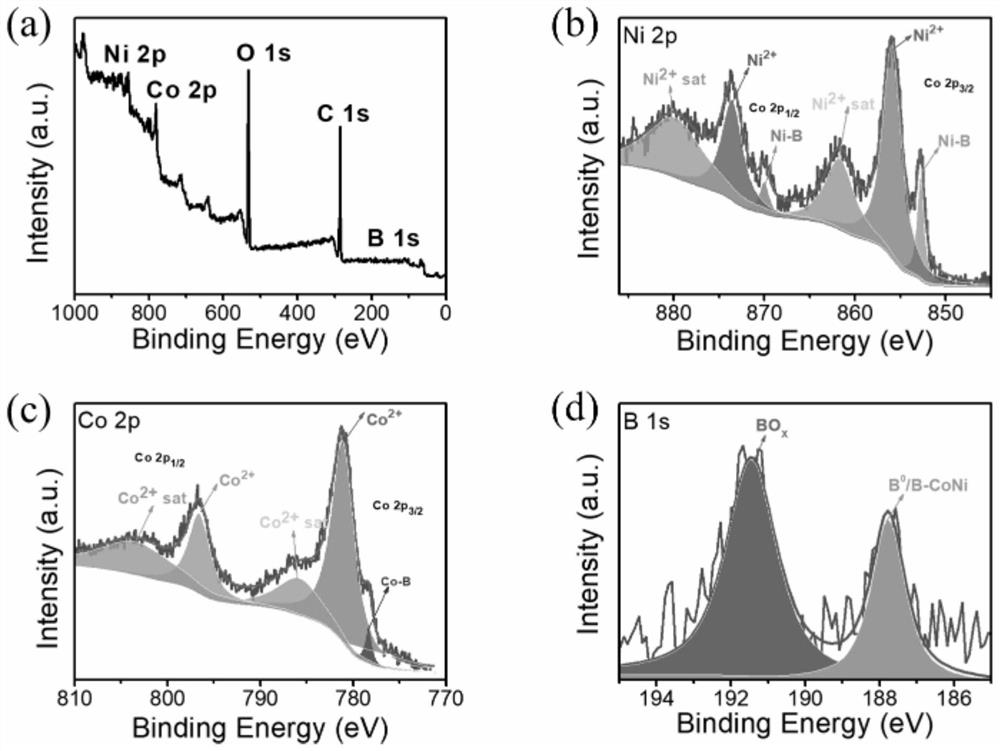

A kind of composite bimetallic boride alkaline aqueous electrolyte system battery cathode material and preparation method thereof

ActiveCN109850912BIncrease the areaImprove featuresMaterial nanotechnologyCell electrodesElectrical batteryAqueous electrolyte

The invention belongs to the field of batteries, and in particular relates to an alkaline aqueous electrolyte system battery cathode material of a composite bimetallic boride and a preparation method thereof. The material is amorphous nano-spherical particles, wherein nickel-cobalt element and boron element form double metal boride Co-Ni-B. The above-mentioned composite bimetallic boride alkaline aqueous electrolyte system battery positive electrode material can be used as an alkaline aqueous electrolyte system battery positive electrode. It is divided into electrodes, which are then used as positive electrodes. It has excellent charge-discharge performance, cycle performance and rate performance.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com