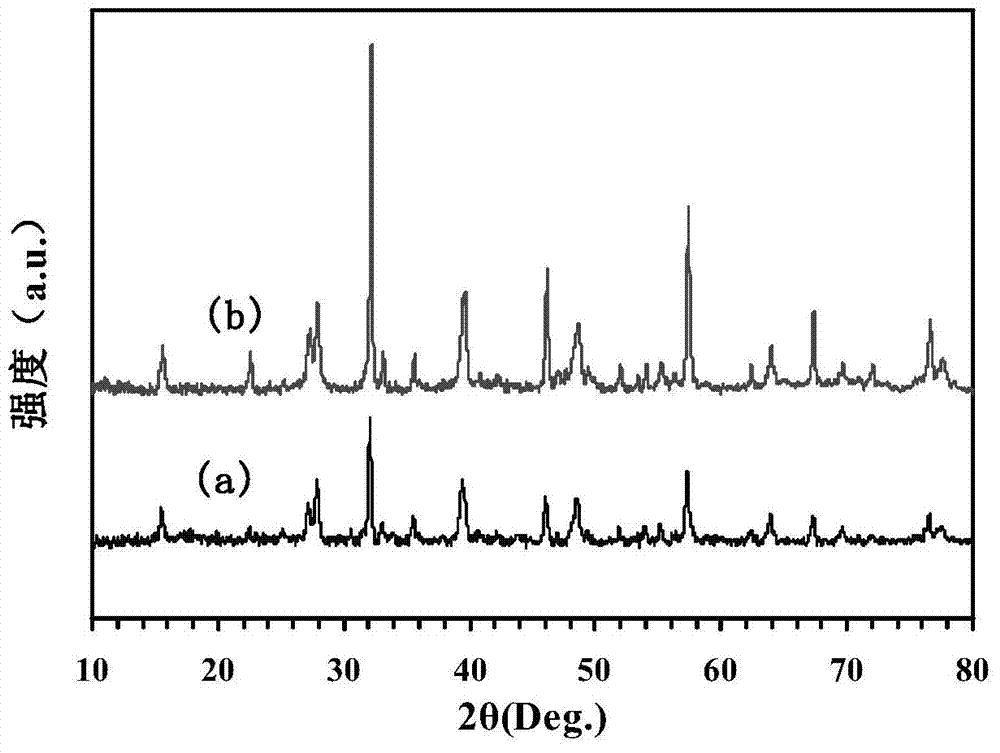

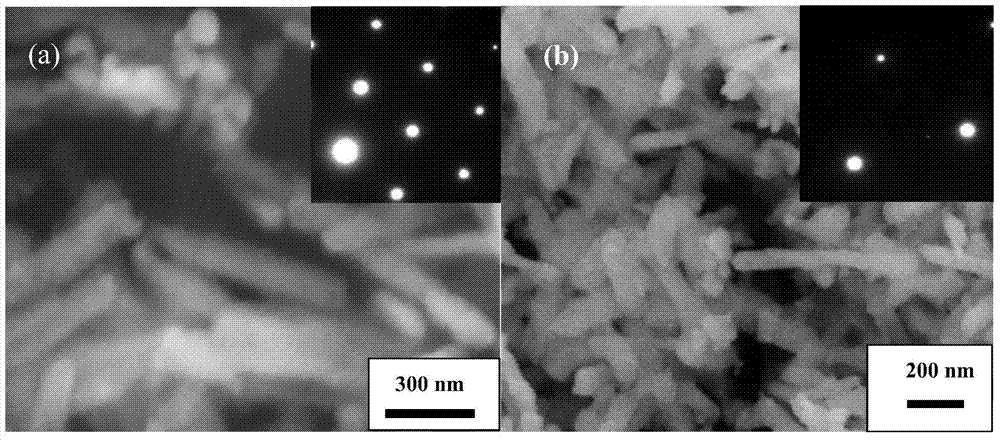

One-dimensional single crystal LaFeO3 nanorods and preparation thereof

A nanorod and single crystal technology, applied in the field of hydrothermal synthesis, to achieve the effects of controllable specific surface area, cheap raw materials, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: Template Fe 2 o 3 The preparation of nanorods, that is, under stirring conditions, 2.02g Fe(NO 3 ) 3 9H 2 O and 1.2g NaOH were dissolved in 10ml deionized water respectively, and then the NaOH solution was added dropwise to the Fe(NO 3 ) 3 In the solution, a brown-yellow precipitate appeared, and then stirred for 30 minutes. The above solution was transferred to a 50ml stainless steel autoclave lined with polytetrafluoroethylene (the volume filling degree was 80%), and placed in a constant temperature box for treatment at 200 ° C. 12h, let it cool down to room temperature naturally after taking it out. Filter the product obtained after the treatment, wash with deionized water and absolute ethanol three times each, dry at 100°C for 12h, raise it to 350°C at a rate of 1°C / min in a muffle furnace and keep the temperature at 350°C for 4h , get Fe 2 o 3 Nano stave.

[0016] One-dimensional single crystal LaFeO 3 Preparation of nanorods: under stirring co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com